Page 1

Repair Manuals for other

Briggs & Stratton Engines:

273521 Twin Cylinder OHV Air-Cooled Engines

271172 Twin Cylinder L-Head Air-Cooled Engines

270962 Single Cylinder L-Head Air-Cooled Engines

276535 Two-Cycle Snow Engines

CE8069 Out of Production Engines (1919-1981)

Briggs & Stratton

Single Cylinder OHV

Air-Cooled Engines

Quality Starts With A

Master Service Technician

www.ThePowerPortal.com (Dealers)

BRIGGSandSTRATTON.COM (Consumers)

SINGLE CYLINDER OHV AIR-COOLED ENGINES

Part No. 276781-8/09

BRIGGS&STRATTON

CORPORATION

POST OFFICE BOX 702

MILWAUKEE, WI 53201 USA

©2009 Briggs & Stratton Corporation

8/09

Page 2

FORWARD

This manual was written to assist engine technicians and service personnel with the repair and

maintenance procedures for Briggs & Stratton engines. It assumes that persons using this manual have

been properly trained in and are familiar with the servicing procedures for these products, including the

proper use of required tools and safety equipment and the application of appropriate safety practices.

Persons untrained or unfamiliar with these procedures or products should not attempt to perform such

work.

Proper maintenance and repair is important to safe, reliable operation of all engines and engine-driven

systems. The troubleshooting, testing, maintenance, and repair procedures described in this manual are

appropriate for the Briggs & Stratton engines described herein. Alternative methods or procedures may

pose risk to personal safety and the safety and/or reliability of the engine and are not endorsed or

recommended by Briggs & Stratton.

All information, illustrations, and specifications contained in this manual were based on the data available

at the time of publication. Briggs & Stratton Corporation reserves the right to change, alter, or otherwise

improve the product or the product manuals at any time without prior notice.

Briggs & Stratton offers two complementary publications to enhance understanding of engine technology,

maintenance, and repair. (Neither publication, however, is a substitution for a recognized training program

for engine technicians.)

• For consumers, Small Engine Care & Repair (p/n 274041) provides a comprehensive overview of how

small air-cooled engines work, basic troubleshooting, and step-by-step maintenance procedures.

• For engine technicians and consumers alike, an in-depth study of engine theory and operation can be

found in the textbook Small Engines (p/n CE8020).

Both publications can be purchased at BRIGGSandSTRATTON.COM or through a local Authorized Briggs

& Stratton Service Dealer.

Copyright © 2009 Briggs & Stratton Corporation

All rights reserved.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying or recording by any information storage and retrieval system, without

prior written permission from Briggs & Stratton Corporation.

Page 3

This Engine Repair Manual includes the following

Engine Models:

• MODEL 110000 HORIZONTAL SERIES

• MODEL 120000 HORIZONTAL SERIES

• MODEL 150000 HORIZONTAL SERIES

• MODEL 200000 HORIZONTAL SERIES

• MODEL 210000 HORIZONTAL SERIES

• MODELS 97700 & 99700 VERTICAL SERIES

• MODEL 110000 VERTICAL SERIES

• MODEL 120000 VERTICAL SERIES

• MODEL 210000 VERTICAL SERIES

6

• MODEL 280000 VERTICAL SERIES

• MODEL 310000 VERTICAL SERIES

• MODEL 330000 VERTICAL SERIES

Page 4

SECTION 1 - Safety, Maintenance and Adjustments

SECTION 2 - Troubleshooting

SECTION 3 - Exhaust Systems

SECTION 4 - Fuel Systems and Carburetion

SECTION 5 - Governor Systems

SECTION 6 - Cylinder Heads and Valves

SECTION 7 - Starters

SECTION 8 - Lubrication Systems

SECTION 9 - Cylinders, Covers and Sumps

1

2

3

4

5

6

7

8

9

SECTION 10 - Crankshafts, Camshafts, Balancing Systems, and Gear Reductions

SECTION 11 - Pistons, Rings and Connecting Rods

SECTION 12 - Engine Specifications

10

11

12

Page 5

THISPROPER SERVICE AND REPAIR IS IMPORTANT

TO THE SAFE, ECONOMICAL AND RELIABLE

Page 6

SECTION 1 - SAFETY, MAINTENANCE, AND ADJUSTMENTS

ENGINE SAFETY- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

BRIGGS & STRATTON NUMERICAL IDENTIFICATION SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - - - 7

ENGINE MAINTENANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

FUEL AND OIL RECOMMENDATIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

MAINTENANCE CHART - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

FLYWHEEL BRAKE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

COMBUSTION CHAMBER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

AIR FILTER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

SNOW HOOD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

OIL AND OIL FILTER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

SPARK PLUG - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

COOLING SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

ENGINE ADJUSTMENTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

ADJUST REMOTE CONTROLS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

GOVERNOR ADJUSTMENTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

ADJUST VALVE CLEARANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

1

1

3

Page 7

ENGINE SAFETY

1

1

This repair manual contains safety information

that is designed to:

• Make you aware of hazards associated

with engines.

• Inform you of the risk of injury associated

with those hazards.

• Tell you how to avoid or reduce the risk of

injury.

Signal Words in Safety Messages

The safety alert symbol ( ) is used to identify

safety information about hazards that can result

in personal injury.

A signal word (

is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to

represent the type of hazard.

DANGER, WARNING, or CAUTION)

DANGER indicates a hazard which, if not

avoided, will result in death or serious

injury.

WARNING indicates a hazard which, if

not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if

not avoided, could result in minor or

moderate injury.

NOTICE indicates a situation that could

result in damage to the product.

and cause leakage, flow restrictions, or

other failures.

• Check fuel lines and fittings frequently for

cracks or leaks and replace if necessary.

WAR NING

Before attempting to service this equipment,

read and understand this manual and the

operating instructions of the engine and the

equipment it powers.

Failure to follow instructions could result in

property damage, serious injury (including

paralysis) or even death.

Hazard Symbols and Meanings

Prior to work, read and understand the section(s)

of this manual that pertain to the job. Follow all

safety warnings.

• Wear suitable eye protection.

• When servicing engines or equipment,

prevent accidental starting by

disconnecting spark plug wire from the

spark plug(s) and disconnect negative

battery cable.

• Periodically clean engine. Keep governor

parts free of dirt, grass, and other debris

which can affect engine speed and

cooling.

• Always use fresh gasoline. Stale fuel can

cause gum deposits in the carburetor

4

Page 8

WARNING

WAR NING

Briggs & Stratton does not approve or authorize the use of these engines on 3-wheel All

Terrain Vehicles (ATV’s), motor bikes, fun/recreational go-karts, aircraft products, or vehicles intended for use in competitive events.

Use of these engines in such applications

could result in property damage, serious injury

(including paralysis), or even death.

WARNING

The engine exhaust from this product contains

chemicals known the State of California to

cause cancer, birth defects, and other reproductive harm.

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe

burns or death.

When adding fuel:

• Turn engine OFF and let engine cool for at least 2 minutes

before removing the fuel cap.

• Fill fuel tank outdoors or in a well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of the gasoline, do not fill above the bottom of the fuel tank neck.

• Keep gasoline away from sparks, open flames, pilot lights,

heat and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks

or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before starting engine.

When starting engine:

• Make sure spark plug, muffler, fuel cap, and air cleaner are

in place.

• Do not crank engine with spark plug removed.

• If fuel spills, wait until it evaporates before starting engine.

• If engine floods, set choke (if equipped) to OPEN/RUN position. Place throttle (if equipped) in FAST and crank until

engine starts.

When operating equipment:

• Do not tip engine or equipment at an angle which would

cause fuel to spill.

• Do not choke carburetor to stop engine.

• Never start or run the engine with the air cleaner assembly

(if equipped) or the air filter (if equipped) removed.

When changing oil:

• If you drain the oil from the top oil fill tube, the fuel tank must

be empty or fuel can leak out and result in a fire or explosion.

When transporting equipment:

• Transport with fuel tank empty or with fuel shut-off valve set

to OFF.

When storing gasoline or equipment with fuel in the tank:

• Store away from furnaces, stoves, water heaters, or other

appliances that have a pilot light or other ignition source

because they can ignite gasoline vapors.

Running engines produce heat. Engine

parts, especially mufflers, become

extremely hot.

Severe thermal burns can occur on

contact.

Combustible debris, such as leaves,

grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder fins, and radiator

to cool before touching.

• Remove accumulated debris from muffler area

and cylinder fins.

• It is a violation of California Public Resource

Code, Section 4442, to use or operate the

engine on any forest-covered, brush-covered,

or grass-covered land unless the exhaust system is equipped with a spark arrester, as

defined in Section 4442, maintained in effective

working order. Other States and Federal jurisdictions may have similar laws. Contact the

original equipment manufacturer, retailer, or

dealer to obtain a spark arrester designed for

the exhaust system installed on this engine.

WAR NING

Unintentional sparking can result in fire

or electrical shock.

Unintentional start-up can result in

entanglement, traumatic amputation, or

severe lacerations.

Before performing adjustments or repairs:

• Disconnect spark plug wire and keep it away

from spark plug.

• Disconnect the negative (-) battery terminal.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

WAR NING

Engines give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

nausea, fainting, or death.

• Start and run engine outdoors.

• Do not start or run engine in an enclosed area,

even if doors and windows are open.

1

1

5

Page 9

WARNING

WAR NING

1

1

Starting engine creates sparking.

Sparking can ignite nearby flammable

gases.

Explosion and fire could result.

• If there is a natural or LP gas leak in the area,

do not start engine.

• Do not use pressurized starting fluids because

vapors are flammable.

WARNING

Rotating parts can contact or entangle

hands, feet, hair, clothing, or accessories.

Traumatic amputation or severe lacerations can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings, or items that could become entangled in the equipment.

WARNING

Charging batteries produce hydrogen

gas. Do not store or charge a battery

near an open flame or device that utilizes a pilot light or can create a spark.

Rapid retraction of starter cord (kickback) will pull hand and arm toward

engine faster than you can let go.

Broken bones, fractures, bruises, or

sprains could result.

• When starting engine, pull the starter cord

slowly until resistance is felt and then pull rapidly to avoid kickback.

• Remove all external equipment/engine loads

before starting engine.

• Direct-coupled equipment components, such

as but not limited to blades, impellers, pulleys,

and sprockets, must be securely attached.

WAR NING

Prolonged or repeated contact with used

motor oil could cause injury.

• Used motor oil has been shown to cause skin

cancer in certain laboratory animals.

• Thoroughly wash exposed areas with soap and

water.

WARNING

Kerosene and its vapors are extremely

flammable and should be handled with the

same precautions as gasoline.

WARNING

Damaged, worn, or loose fuel components can leak fuel. Explosion or fire

could result.

• All fuel components should be in good condition and properly maintained.

• Repairs should only be made with factory

approved parts.

• Repair work should be done by a qualified

technician.

• Flexible supply lines should be checked regularly to make sure they are in good condition.

6

Page 10

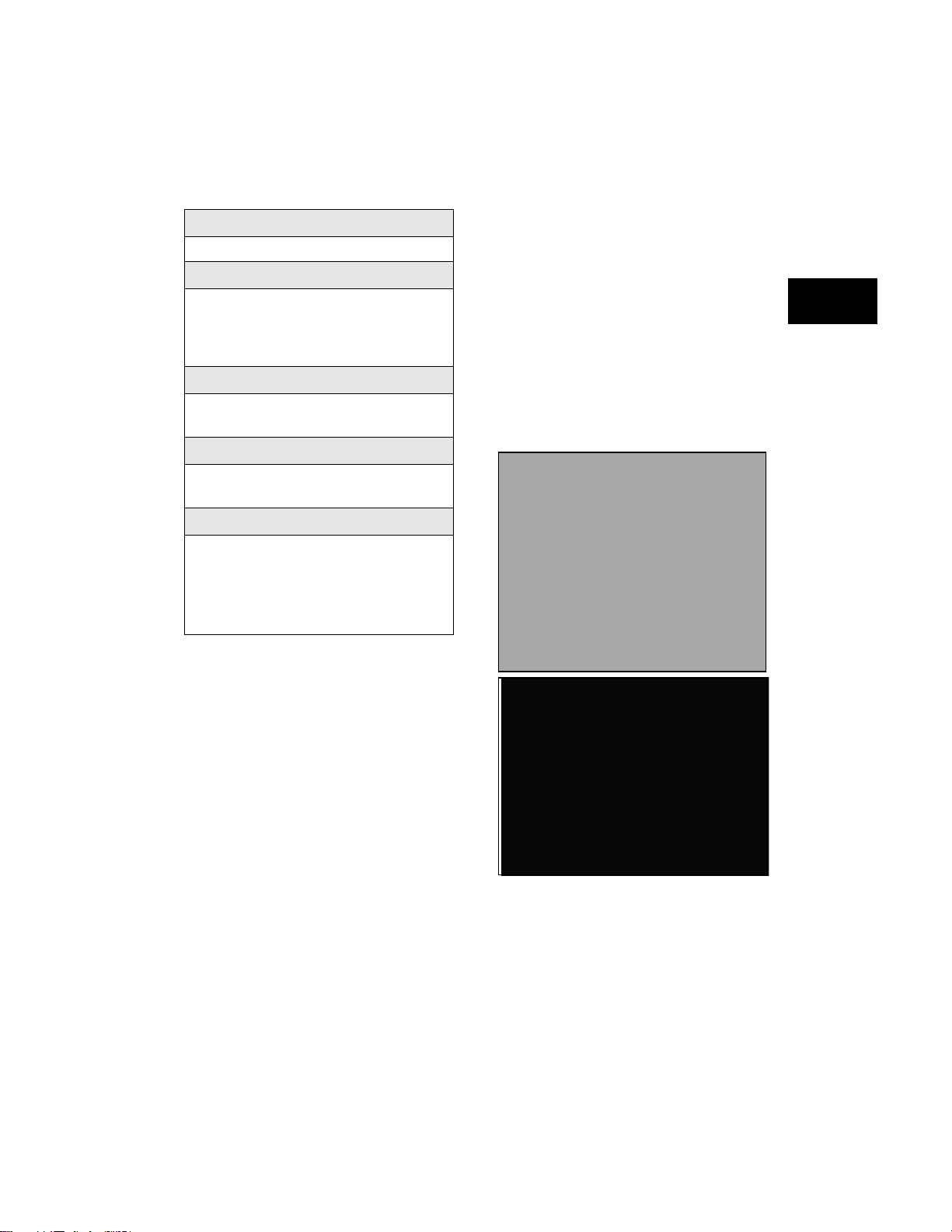

B RI GG S & ST RA TT ON

NUMERICAL IDENTIFICATION SYSTEM

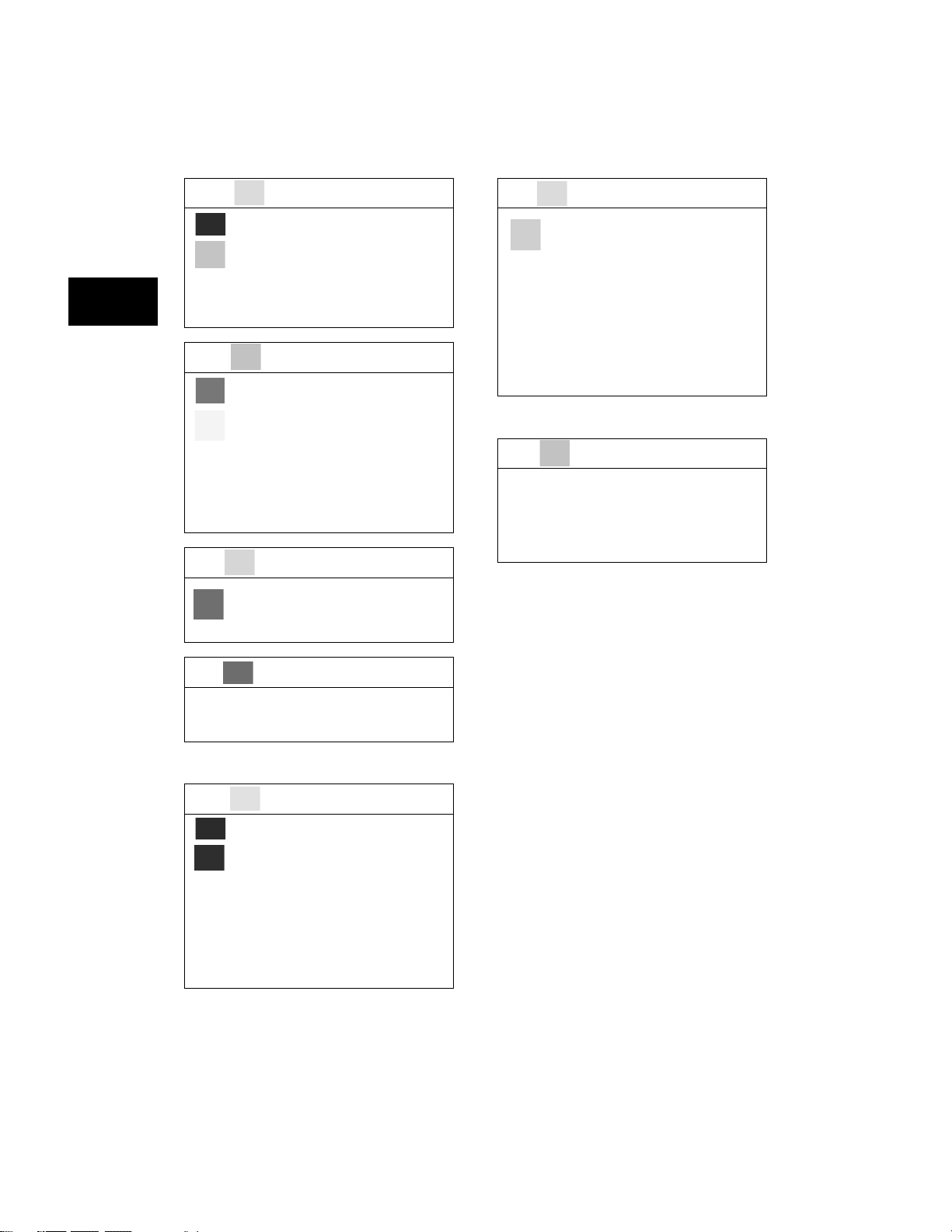

This chart explains the unique Briggs & Stratton numerical model designation system. It is possible to determine most of the

important mechanical features of the engine by merely knowing the model number. Here is how it works:

A. The first one or two digits indicate the approximate CUBIC INCH DISPLACEMENT.

B. The first digit after the displacement indicates the BASIC DESIGN SERIES, relating to

cylinder construction, ignition, general configuration, etc.

C. The second digit after the displacement indicates ORIENTATION OF CRANKSHAFT.

D. The third digit after the displacement indicates TYPE OF BEARINGS, and whether or

not the engine is equipped with REDUCTION GEAR or AUXILIARY DRIVE.

E. The last digit indicates the TYPE OF STARTER.

YOUR KEY TO THE WORLD’S FINEST ENGINES

BRIGGS & STRATTON MODEL NUMBERING SYSTEM

FIRST DIGIT

AFTER DISPLACEMENT

A B C D E

CUBIC INCH

DISPLACEMENT

2

5

6

8

9

10

11

12

13

15

16

18

19

20

21

22

23

24

25

28

29

30

31

32

35

38

40

42

43

44

46

47

49

52

54

58

61

EXAMPLE - To identify Model 303447:

30 3 4 4 7

30 Cubic Inch Design Series 3 Horizontal Shaft Ball Bearing

TYPE 1234–01, The type number identifies the engines mechanical parts, color of paint, decals, governed speed, and Original Equipment

Manufacturer.

CODE

01061201, The code is the manufacturing date and is read as follows:

YEAR MONTH DAY ASSEMBLY LINE AND MANUFACTURING PLANT

01 06 12 01

BASIC

DESIGN SERIES

0

1

2

3

4

5

6

7

8

9

A to Z

SECOND DIGIT

AFTER DISPLACEMENT

CRANKSHAFT

ORIENTATION

0 to 4 - Horizontal Shaft

5 to 9 - Vertical Shaft

A to G - Horizontal Shaft

H to Z - Vertical Shaft

THIRD DIGIT

AFTER DISPLACEMENT

PTO BEARING,

REDUCTION GEAR,

AUXILIARY DRIVE,

LUBRICATION

0 - Plain Bearing/DU

Non–Flange Mount

1 - Plain Bearing

Flange Mounting

2 - Sleeve Bearing

Flange Mounting

Splash Lube

3 - Ball Bearing

Flange Mounting

Splash Lube

4 - Ball Bearing

Flange Mounting

Pressure

Lubrication

5 - Plain Bearing

Gear Reduction

(6 to 1) CCW

Rotation

Flange Mounting

6 - Ball Bearing

Gear Reduction

(2 to 1) CCW

Rotation

7 - Plain Bearing

Pressure

Lubrication

8 - Plain Bearing

Auxiliary Drive

(PTO)

Perpendicular to

Crankshaft

9 - Plain Bearing

Auxiliary Drive

Parallel to

Crankshaft

A - Plain Bearing

Pressure

Lubrication

Without Oil Filter

Flange Mounting

Pressure Lubrication

FOURTH DIGIT

AFTER DISPLACEMENT

TYPE OF STARTER

0 - Without Starter

1 - Rope Starter

2 - Rewind Starter

3 - Electric Starter

Only

110 or 230 Volt

Gear Drive

4 - Electric Starter/

110 or 230 Volt

Gear Drive with

Alternator

5 - Electric Starter

Only

12 or 24 Volt

Gear Drive

6 - Alternator Only

7 - Electric Starter

12 or 24 Volt

Gear Drive with

Alternator

8 - Vertical Pull

Starter or

Side Pull Starter

9 - Mechanical

Starter

A - Electric Starter

12 or 24 Volt

Gear Drive with

Alternator and

Inverter

Electric Starter

12 or 24 Volt Gear Drive

with Alternator

1

1

Revised 12/08

7

Page 11

ENGINE MAINTENANCE

1

1

Fuel and Oil Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane / 87 AKI

(90 RON).

• Gasoline with up to 10% ethanol

(gasahol) or up to 15% MTBE (methyl

tertiary butyl ether) is acceptable.

• NOTICE: Do not use unapproved

gasoline, such as E85. Do not mix oil in

gasoline or modify the engine to run on

alternate fuels. This will damage the

engine components and void the

engine warranty.

To protect the fuel system from gum formation,

mix a fuel stabilizer into the fuel. All fuel is not the

same. If starting or performance problems occur,

change fuel providers or change brands. This

engine is certified to operate on gasoline. The

emissions control system for this engine is EM

(Engine Modifications).

High Altitude

At altitudes over 5,000 feet (1524 meters), a

minimum 85 octane / 85 AKI (89 RON) gasoline

is acceptable. To remain emissions compliant,

high altitude adjustment is required. Operation

without this adjustment will cause decreased

performance, increased fuel consumption, and

increased emissions.

Operation of the engine at altitudes below 2,500

feet (762 meters) with the high altitude kit is not

recommended.

Oil must meet these requirements:

• Briggs & Stratton Warranty Certified oils

are recommended for best performance.

• Other high-quality detergent oils are

acceptable if classified for service SF,

SG, SH, SJ or higher.

• Do not use special additives.

Outdoor temperatures determine the proper oil

viscosity for the engine. Use the chart (Figure 1)

to select the best viscosity for the outdoor

temperature range expected.

Figure 1

Fresh Start

Some engines are equipped with a Fresh Start

fuel cap. The Fresh Start fuel cap is designed to

hold a cartridge (sold separately) that contains

fuel stabilizer.

8

® Fuel Cap

®

Page 12

Maintenance Chart

Flywheel Brake

First 5 Hours

• Change oil

Every 8 Hours or Daily

• Check engine oil level

• Clean area around muffler and

controls

• Clean finger guard

Every 25 Hours or Annually

• Clean air filter*

• Clean pre-cleaner*

Every 50 Hours or Annually

• Change engine oil

• Check muffler and spark arrester

Annually

• Replace air filter

• Replace pre-cleaner

• Replace spark plug

• Replace fuel filter

• Clean air cooling system*

* In dusty conditions or when airborne debris is

present, clean more often.

Model Series 97700, 99700, 110000, 120000

Vertical Shaft

The flywheel brake is part of the safety control

system required for some applications. While

running at FAST speed position, the flywheel

brake MUST stop the engine within three

seconds, when the operator releases the

equipment safety control.

Test Brake Torque

1. Disconnect spark plug wire.

2. Unscrew and/or pry off static guard

(A, Figure 2).

3. Unscrew and remove fuel tank (B).

1

1

Figure 2

4. Remove dipstick and oil fill tube

(A, Figure 3).

5. Unscrew and remove blower housing/

rewind assembly (B).

9

Page 13

1

1

Figure 3

6. Using a torque wrench and socket to fit the

flywheel nut, turn flywheel clockwise with

brake engaged. While turning at a steady

rate, torque reading should be 26 lb.-in.

(3 Nm) or higher.

7. If reading is low, check thickness of brake

pad. Replace brake assembly if thickness

is less than 0.09” (2.28mm).

8. If brake pad thickness is acceptable,

adjust control cable to position pad closer

to flywheel when safety control is in RUN

position.

9. Replace brake assembly if correct

adjustment cannot be made.

Inspect Brake and Switches

1. Disconnect spring from brake anchor

(A, Figure 4).

2. Disconnect stop switch wire from stop

switch (B). If engine is equipped with an

electric starter, disconnect both wires from

the starter interlock switch (C).

3. Remove two screws (D) from brake

bracket and remove bracket.

Figure 4

4. Inspect brake pad on brake lever. Replace

brake assembly if thickness is less than

0.09” (2.28mm).

5. Test stop switch as described in Section 2.

6. Test electric starter interlock switch as

described in Section 2.

Assemble Flywheel Brake

1. Install brake assembly on cylinder and

torque mounting screws to values listed in

Section 12 - Engine Specifications.

2. Install stop switch wire and bend end of

wire 90°. Install wires on interlock switch, if

equipped.

3. Install brake spring.

4. Actuate brake system to ensure proper

movement, then test brake torque as

previously described.

5. Install blower housing/rewind assembly,

install dipstick tube and dipstick, and

install fuel tank and static guard. Torque

all screws to values listed in Section 12 Engine Specifications.

10

Page 14

Combustion Chamber

Remove combustion chamber deposits every

500 hours or whenever the cylinder head is

removed.

With the piston at Top Dead Center (TDC),

scrape deposits from top of piston and upper

bore with a plastic scraper.

Remove the loosened deposits from around the

top ring land area using compressed air or a

shop vacuum and a soft bristle brush.

NOTICE: Use care to prevent debris from

entering push rod or oil return cavities in cylinder.

Do not damage bore, top of piston, cylinder

head, or cylinder head gasket surfaces.

It is not necessary to remove the discoloration

marks on the piston, valves, and/or cylinder

head. These marks are normal and will not affect

engine operation.

Air Filter

A correctly serviced air filter protects internal

engine parts from airborne dirt and dust. Poor

filter maintenance will allow dirt and dust to be

drawn into the engine, causing wear to the intake

system and contamination of the oil. Dirt in the oil

forms an abrasive mixture which wears down

moving parts.

NOTE: Snow engines do not have an air cleaner

assembly. Please refer to Snow Hood

Maintenance for disassembly procedures

2. Gently tap air filter cartridge on a hard

surface to loosen debris. Replace

cartridge if very dirty.

3. Wash foam filters and pre-cleaners in

warm, soapy water, then rinse and allow

to air dry. Saturate foam filters in clean

engine oil, then squeeze out access oil.

DO NOT OIL PRE-CLEANERS.

4. Drain and clean oil bath reservoirs, then

re-fill with clean engine oil.

5. Reassemble the air cleaner system.

Figures 5 through 16 illustrate the various air

cleaner systems found on Briggs & Stratton

single-cylinder OHV engines.

Figure 5

1

1

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe

burns or death.

• Never start or run the engine with the air

cleaner assembly or the air filter removed.

NOTE: Do not use pressurized air or solvents to

clean the filter. Pressurized air can damage the

filter and solvents will dissolve the filter.

1. Disassemble air cleaner system.

11

Figure 6

Page 15

1

1

Figure 7

Figure 8

Figure 10

Figure 11

Figure 9

12

Figure 12

Page 16

1

Figure 13

Figure 14

Snow Hood

NOTE: Snow engines do not have an air cleaner

assembly. Instead, a 1-piece or 2-piece snow

hood is installed to protect the carburetor area,

retain heat to resist carburetor icing, and provide

a mounting surface for engine controls.

Remove

1. Remove choke knob (A, Figure 15 and

Figure 16).

2. Remove fasteners and hood (B).

3. Disconnect stop switch wire (C) and

primer hose (D).

Figure 15

Figure 16

Inspection

1. Check hood for cracks or worn mounting

holes. Replace if necessary.

2. Check primer hose for brittleness or leaks

and check stop switch and wire for

damage. Replace parts as necessary.

Install

1. Connect stop switch wire (C, Figure 15)

and primer hose (D).

2. Install hood and fasteners (B).

3. Install choke knob (A) with tab under knob

fitting into slot of hood. Actuate the choke

knob to check for proper movement.

1

13

Page 17

Oil and Oil Filter

Spark Plug

1

1

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe

burns or death.

• If you drain the oil from the top oil fill tube, the

fuel tank must be empty or fuel can leak out

and result in a fire or explosion.

• To empty the fuel tank, run the engine until it

stops from lack of fuel.

Change oil after the first 5 hours of operation.

After that, change oil after every 50 hours of

operation. Change oil more often if engine is

operated in dirty or dusty conditions, under

heavy loads, or in high ambient temperatures.

1. Remove oil drain plug from side or bottom

of engine and drain oil while the engine is

still warm.

2. Install drain plug.

3. Remove oil filter, if equipped.

• Clean surface of filter mounting adapter.

• Apply light coat of clean engine oil to new

filter gasket.

4. Screw new filter on by hand until gasket

contacts filter mounting adapter. Then

tighten an additional 1/2 to 3/4 turn.

5. Fill crankcase with the correct amount of

new oil.

6. Start engine and run at idle for a minute or

so.

7. Shut engine off and wait for oil to settle

back into the cylinder.

8. Check dipstick. If necessary, add more oil

slowly to bring level to FULL mark on

dipstick.

Spark plugs should be replaced every year.

NOTICE

Spark plugs have different thread “reach”

and heat ranges. When changing a spark

plug, use only the specified replacement,

otherwise engine damage could occur.

NOTE: In some areas, local law requires using

resistor spark plugs to suppress radio frequency

interference.

1. Disconnect spark plug wire.

2. Remove and inspect spark plug for wear

and damage. Replace spark plug if

electrodes are burned away, or the

porcelain is cracked.

3. Do not blast clean spark plugs. Clean by

scraping or wire brushing, and then

washing in a commercial solvent.

4. Using a wire gage, check and set the gap

(A, Figure 15) per Section 12 Specifications.

Figure 17

NOTICE

Do not overfill. Overfilling can cause seals

to fail, smoke from the exhaust, or

overheating due to oil foaming.

9. Replace oil fill cap and dipstick.

10. Start and run engine. Check for oil leaks.

14

5. Re-install spark plug and torque to values

listed in Section 12 - Specifications.

6. Connect spark plug wire.

Page 18

Cooling System

WARNING

Running engines produce heat.

Severe burns can occur on contact.

• Allow muffler, engine cylinder fins, and radiator

to cool before touching.

• Remove accumulated combustibles from muffler area and cylinder area.

Dirt or debris can restrict air flow and cause the

engine to overheat, resulting in poor

performance and reduced engine life. Continued

operation with a clogged cooling system can

cause severe overheating and possible engine

damage. Clean these areas yearly or more often

when dust or airborne debris is present (Figures

18, 19, 20).

NOTICE: Do not use water to clean the engine.

Water could contaminate the fuel system. Use a

brush or dry cloth to clean the engine.

1

1

Figure 19 - Rotating Screen

Figure 20 - Ducting & Cylinder Fins

Figure 18 - Static Screen

15

Page 19

1

1

ENGINE ADJUSTMENTS

Remote Control Wire Travel

The remote control wire should measure 2.125”

(54 mm) when extended outside the casing

(Figure 21). After installation, the travel of the

remote control wire must be at least 1.375” (35

mm) to properly actuate the choke (on Choke-AMatic® systems) and the ignition stop switch (if

equipped).

Figure 21

Remote Controls

Horizontal Models 110000, 120000, 150000

1. Loosen casing clamp screw

(A, Figure 22).

2. Move throttle lever to fast position.

3. Move casing in direction of arrow until

slack is removed.

4. Tighten casing clamp screw.

Figure 22

Vertical Models 97700, 99700

1. Loosen casing clamp screw (A, Figure 23)

on intake elbow assembly.

16

Figure 23

2. Move equipment speed control lever (B) to

FAST position.

3. Move control wire and casing at governor

bracket to align hole (C) in carburetor

control lever with hole in carburetor control

bracket.

4. Tighten casing screw.

Page 20

Vertical Models 110000, 120000 with Primer

Carburetors

1. Loosen casing clamp screw

(A, Figure 24, Figure 25).

2. Move throttle lever to fast position.

3. Move casing in direction of arrow until

slack is removed.

4. Tighten casing clamp screw.

1

Figure 24

Figure 25

Vertical Models Series 110000, 120000 with

Choke-A-Matic® Carburetors

1. Loosen casing clamp screw

(A, Figure 26).

2. Move throttle lever to fast position.

3. Move casing in direction of arrow until

casing stops moving and choke lever (B)

moves to full choke position.

Figure 26

4. Tighten casing clamp screw.

Horizontal and Vertical Models 200000,

210000, 280000, 310000, 330000

1. L oosen casing cl amp screw

(C, Figure 27).

2. Set throttle control to FAST position.

3. Move governor control rack (D) until holes

are aligned (B) between control lever (A)

and the control bracket.

4. Tighten casing clamp screw.

Figure 27

1

17

Page 21

1

1

Governor Adjustments

A complete governor system adjustment

includes a static adjustment, engine warm-up,

idle and/or governed idle adjustment, and top noload adjustment. Be sure to complete all steps.

Static Adjustment

1. Loosen screw holding governor lever to

governor crank (A, Figure 28) or

(C, Figure 29).

2. Rotate throttle linkage from idle position to

wide open throttle. Note direction of

rotation of the governor arm attached to

the throttle linkage.

3. While holding linkage at wide open

throttle, use the appropriate tool to rotate

the governor shaft (B, Figure 29) until it

stops in the direction noted in Step 2.

4. Tighten screw holding governor lever to

governor crank per Section 12 - Engine

Specifications.

5. Before starting engine, manually actuate

throttle linkage to check for binding.

Top No Load Adjustment Vertical Models

97700, 99700

1. Place throttle (A, Figure 30 and 31) in

FAST position and insert a 1/8” (3.2 mm)

rod (B) through holes in carburetor control

bracket and lever.

Figure 30

Figure 28

Figure 29

18

Figure 31

2. Start engine and measure RPM using

Tachometer #19200 or #19389. Adjust

Top No Load RPM by turning screw (C).

3. Remove 1/8” (3.2 mm) rod.

NOTE: Correct Top No Load RPM for each

model-type-trim can be found in the engine

replacement data on Briggs & Stratton websites.

Page 22

Top No Load Adjustment Vertical Models

110000, 120000, 150000 with Primer

Carburetors

1. Start engine and run until it reaches

operating temperature.

2. Place throttle in FAST position.

3. Using Tachometer #19200 or #19389, and

Tang Bender #19229 or #19352, bend

Top No Load spring tang to obtain correct

Top No Load RPM (Figure 32).

NOTE: Correct Top No Load RPM for each

model-type-trim can be found in the engine

replacement data on Briggs & Stratton websites.

Figure 32

3. Hold throttle lever against idle speed

screw and, using Tachometer #19200 or

#19389, adjust to 1500 RPM. Release

throttle lever.

4. Using Tang Bender #19229 or 19352 bend

governed idle spring tang to obtain 1750

RPM (Figure 34).

5. Remove 1/8” rod.

Figure 34

6. Move throttle lever to FAST position. Hole

in lever will line up with hole in governor

control bracket (Figure 35). Insert a 1/8”

rod through holes to lock lever in this

position.

1

1

Idle and Top No Load Adjustment Vertical

Models 110000, 120000, 150000 with ChokeA-Matic® Carburetors

1. Start engine and run until it reaches

operating temperature.

2. Place throttle in SLOW position. Hole in

lever will line up with hole in governor

control bracket (Figure 33). Insert a 1/8”

rod through holes to lock lever in this

position.

Figure 35

7. Using Tang Bender, bend Top No Load

spring tang to obtain correct Top No Load

RPM.

NOTE: Correct Top No Load RPM for each

model-type-trim can be found in the engine

replacement data on Briggs & Stratton websites.

Figure 33

19

Page 23

1

1

Idle and Top No Load Adjustment Horizontal

and Vertical Models 200000, 210000

1. Start engine and run until it reaches

operating temperature.

2. Place throttle in SLOW position.

3. Hold throttle lever against idle speed

screw, and, using Tachometer #19200 or

#19389, adjust screw to obtain 1300 RPM.

Release throttle lever.

4. Using Tang Bender #19229 or #19352,

bend governed idle spring tang to obtain

1750 RPM (Figure 36).

Figure 36

5. Place throttle in FAST position.

6. Adjust screw to obtain correct Top No

Load RPM (Figure 37).

Idle and Top No Load Adjustment Vertical

Models 280000, 310000, 330000

All carburetor mixture adjustments should be

made before adjusting governor speeds.

1. Start engine and run until it reaches

operating temperature.

2. Place control lever in idle position.

3. Hold throttle in closed position with finger,

adjusting idle speed screw to 1200 RPM.

4. Release throttle.

5. Set control to 1750 RPM and bend tang

(A, Figure 38) until it contacts remote

control slide (B).

6. Using Tang Bender #19229 or 19352,

bend spring tang to obtain the correct Top

No Load RPM.

NOTE: Correct Top No Load RPM for each

model-type-trim can be found in the engine

replacement data on Briggs & Stratton websites.

Figure 37

NOTE: Correct Top No Load RPM for each

model-type-trim can be found in the engine

replacement data on Briggs & Stratton websites.

20

Figure 38

Initial Adjustment (All Models)

1. Install idle speed screws and spring.

Install idle mixture screw and spring.

2. Turn idle mixture screw in until it just

bottoms.

3. Then back out screw 1-1/4” turn. This will

permit the engine to start.

Final Adjustment (All Models)

1. Install complete air cleaner before starting

engine. Start and run engine for five

minutes at 1/2 throttle to bring engine up

to operating temperature.

Page 24

2. Move equipment speed control to idle

position.

3. Turn idle screw to obtain 1750 RPM

minimum.

4. Then turn idle mixture screw clockwise

slowly until engine begins to slow.

5. Then turn screw opposite direction until

engine just begins to slow.

6. Then turn screw back to midpoint (Figure

39).

Figure 39

7. Install limiter cap (if equipped) on idle

mixture screw (Figure 40).

Adjust Valve Clearance

All Models - Except Vertical Models 110000,

120000 Early Production

NOTE: Check valve clearance while the engine

is cold.

1. Turn crankshaft counterclockwise until

piston is at top dead center on the

compression stroke. This prevents the

compression release from holding the

valves open.

2. Insert a narrow screwdriver or rod into the

spark plug hole as a gauge, then slowly

turn crankshaft counterclockwise until the

piston has moved down the bore by 1/4”

(6mm).

3. Using a feeler gauge (A, Figure 41), adjust

rocker nut to obtain the clearance as listed

in Section 12 - Engine Specifications.

4. Hold rocker nut and tighten the rocker ball

setscrew (B) to the torque valve shown in

Section 12 - Engine Specifications.

5. Check clearance again and re-adjust, if

necessary.

6. Repeat for other valve.

NOTE: On some models, the nut and setscrew

are positioned above the push rod ends.

1

1

Figure 41

Figure 40

8. Move equipment speed control from idle to

high speed position.

9. Engine should accelerate smoothly. If it

doesn’t, open idle mixture screw 1/8 turn

open.

21

Page 25

1

1

Vertical Models 110000, 120000 Early

Production

1. Using a feeler gauge (A, Figure 42) adjust

the locking hex nut (B) to obtain the

correct clearance as listed in Section 12 Engine Specifications.

2. Repeat for other valve.

Figure 42

- OR -

1. Loosen jam nut (A, Figure 43) at base of

rocker arm stud. Then, using a feeler

gauge (B), turn rocker arm screw (C) to

obtain the correct clearance as listed in

Section 12 - Engine Specifications.

2. Hold the screw and tighten the jam nut to

value shown in Section 12 - Engine

Specifications.

3. Check clearance again and re-adjust, if

necessary.

Figure 43

22

Page 26

SECTION 2 - TROUBLESHOOTING

SYSTEMS CHECK- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

CHECK IGNITION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

CHECK CARBURETION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

CHECK COMPRESSION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

ELECTRICAL SYSTEMS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

EQUIPMENT USED FOR TESTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

ALTERNATOR SYSTEM DIAGNOSIS- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

ALTERNATOR IDENTIFICATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

FLYWHEEL IDENTIFICATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

TESTING ALTERNATOR OUTPUT- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

.5-AMP DC ONLY ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

3-AMP DC ONLY ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

14-VOLT AC ONLY ALTERNATOR- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

DUAL CIRCUIT ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

TRI-CIRCUIT ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

5 & 9 AMP DC REGULATED ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

10 & 16 AMP DC REGULATED ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

20 AMP DC REGULATED ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

ELECTRIC STARTERS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

SYSTEM 3® AND SYSTEM 4®- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

12 VOLT DC STARTER MOTOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

2

2

120 VOLT AC STARTER MOTOR- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

BATTERIES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

BATTERY AND CABLE RECOMMENDATIONS- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

BATTERY INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

CHARGING BATTERY- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

TESTING BATTERY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 48

EQUIPMENT AFFECTING ENGINE OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

23

Page 27

2

OIL GARD SYSTEMS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

ENGINE WILL NOT START - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

ENGINE STARTS AND RUNS WITH LOW OIL - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

2

24

Page 28

SYSTEMS CHECK

Most complaints concerning engine operation

can be classified as one or a combination of the

following:

• Will not start

• Hard starting

• Lack of power

• Runs rough

• Vibration

• Overheating

• High oil consumption

The source of most of these symptoms can be

determined by performing a systems check in the

following order:

1. Ignition

2. Carburetion

3. Compression

This check-up can usually be done in a matter of

minutes. It is the quickest and surest method of

determining the cause of failure.

NOTE: What appears to be an engine

malfunction may be a fault of the powered

equipment rather than the engine. If the

equipment is suspect, see Equipment Affecting

Engine Operation.

2

2

Figure 1

Engine Running

If engine runs but misses during operation, a

quick check to determine whether the ignition is

at fault can be made by installing Ignition Tester

#19368 between the spark plug lead and spark

plug (Figure 2). If spark is good but engine

misses, install a new spark plug.

1) Check Ignition

Engine Stopped

With spark plug installed, attach Ignition Tester

#19368 to spark plug lead and ground the other

end of the tester (Figure 1). Pull the starter rope

or activate the electric starter (if equipped). If

spark jumps the tester gap, you may assume the

ignition system is functioning satisfactorily.

25

Figure 2

If spark does not occur, look for:

• Improperly operating interlock system

• Shorted equipment or engine stop switch

wire

• Incorrect armature air gap

• Armature failure

Page 29

2

2) Check Carburetion

Before making a carburetion check, be sure the

fuel tank has an ample supply of fresh, clean

gasoline.

Be sure the shutoff valve, if equipped, is open

and fuel flows freely through the fuel line. If fuel

fails to flow or is slow, check for plugged fuel cap

vent, fuel line restriction or plugged fuel filter.

Be sure throttle and choke controls are properly

adjusted.

If engine cranks but will not start, remove and

2

inspect the spark plug.

If plug is wet, look for:

• Over choking

• Excessively rich fuel mixture

• Water in fuel

• Float needle valve stuck open

• Plugged air cleaner

• Fouled spark plug

If plug is dry, look for:

• Leaking carburetor or intake manifold

gaskets

• Gummy or dirty carburetor, fuel filter, fuel

lines or fuel tank

• Float needle valve stuck closed

• Inoperative fuel pump (if equipped)

• Inoperative fuel shut off solenoid (if

equipped)

A simple check to determine if the fuel is getting

to the combustion chamber through the

carburetor is to remove the spark plug and pour

a small quantity of gasoline through the spark

plug hole. Replace the plug. If the engine fires a

few times and then stops, look for the same

conditions as for a dry plug.

Solenoid Plunger Test

NOTE: The solenoid requires a minimum of 9

Volts DC to function.

1. Remove the fuel shut off solenoid from the

carburetor.

2. Place a jumper wire on either terminal of a

9 Volt battery and on one of the pins of the

solenoid connector.

3. Place another jumper wire on the other pin

in the solenoid connector and on the other

terminal on the battery (Figure 3).

Figure 3

• Plunger should retract freely, or with very

light fingertip pressure.

• When battery connection is removed,

plunger should extend.

• Replace solenoid if plunger sticks or

does not move.

Solenoid Wiring Test

1. Set multimeter to DC Volts position.

2. With key switch OFF, disconnect solenoid

wiring connector (A, Figure 4).

3. Attach meter test leads (B) to pins inside

wiring connector.

Testing Fuel Shut Off Solenoid

The fuel shut off solenoid is controlled by the

equipment ignition switch. With the switch OFF,

the solenoid plunger closes, stopping the fuel

flow at the fixed main jet. With the switch in the

ON and START positions, the solenoid plunger

opens, allowing normal fuel flow. If operating

properly, the solenoid will click when the switch

is turned ON and OFF.

If solenoid does not click, the problem could be

the equipment wiring, engine wiring or the

solenoid. To determine which is the problem,

perform the following tests in the order shown.

26

Figure 4

Page 30

4. Turn key switch ON. Meter should display

battery voltage.

If meter does not display battery voltage, the

problem is with the solenoid wiring, equipment

wire harness, or the keyswitch. Repair or replace

as required.

3) Check Compression

Use Leakdown Tester #19545 to check the

sealing capabilities of the compression

components.

Follow the instructions provided with the tester to

perform the leakdown test.

NOTE: Any air leaks at the connections or

fittings of the tester will affect the accuracy of the

test.

Listen for air leaking from the cylinder head

gasket, carburetor, exhaust system, and the

crankcase breather tube.

• Air flowing between the cylinder and

cylinder head indicates that the cylinder

head gasket is leaking.

• Air flowing from the carburetor indicates

air is leaking past the intake valve and

seat.

• Air flowing from the exhaust system

indicates air is leaking past the exhaust

valve and seat.

• Air flowing from the crankcase breather

tube or high oil fill dipstick tube indicates

air is leaking past the piston rings.

Possible Causes for Poor Compression:

• Loose cylinder head bolts

• Blown head gasket

• Burned valves, valve seats and/or loose

valve seats

• Insufficient tappet clearance

• Warped cylinder head

• Warped valve stems

• Worn bore and/or rings

• Broken connecting rod

2

2

27

Page 31

2

Equipment Used for Testing

Digital Multimeter

A digital multimeter is recommended for all

electrical testing of Briggs & Stratton engines.

The meter can be used to read volts, ohms,

amperes, and to test diodes.

The Fluke® Digital Multimeter #19464 and the

UNI-T® Digital Multimeter #19581 are available

2

from your Briggs & Stratton source of supply.

NOTICE: The digital multimeters are equipped

with fuses to prevent damage to the meter if the

input limits are exceeded. Check the fuses if the

meter displays a reading of 0.00 when testing

DC Volts output.

Refer to the Fluke® Operator’s Manual for this

procedure. Replacement fuses #19449 for Series

II meters or #19571 for Series III meters are

available from your Briggs & Stratton source of

supply.

The UNI-T® Operator’s Manual lists the fuse

replacement procedure and type of replacement

fuses required.

DC Shunt

The Fluke® meter will withstand DC input of 1020 amps for up to 30 seconds.

The UNI-T® meter will withstand DC input of 10

amps for up to 10 seconds.

When checking DC output on 10 and 16 amp

regulated systems, the DC Shunt #19468

(Figure 5) is required to avoid blowing a fuse in

either of the meters.

ELECTRICAL SYSTEMS

Figure 6

Starter Motor Test Fixture

A starter motor test fixture may be made from

1/4” (6mm) steel stock (Figure 7).

1. Extra hole for mounting starter brackets

(A).

2. Drill two 3/8” (10mm) holes for starter

mounting bracket (B).

3. Drill two holes for mounting Tachometer

#19200. Drill and tap the holes for 1/4-20

NC screws (C).

Figure 5

Tachometer

Tachometers #19200 (A) or #19389 (B, Figure 6)

are available from your Briggs & Stratton source

of supply.

28

Figure 7

Other Equipment

A growler or armature tester (checks armature

for continuity, shorts, and opens) is available

from an Automobile Diagnostic Service supplier.

Also, a known good 12 Volt battery is required

when testing starting systems or alternators.

Page 32

Alternator System Diagnosis

Complaint Possible Causes

Battery Not

Charging

• Engine RPM too low.

• Inline fuse “blown” (if equipped)

• Defective or damaged battery (shortened battery cells)

• Loose, pinched, or corroded battery ground leads or charge

• Open, shorted, or grounded wires between output

• Defective diode (open or shorted)

• Diode installed incorrectly (reversed)

• Defective or improperly grounded regulator-rectifier

• Excessive current draw from accessories

• Weak or damaged alternator magnets

leads

connector and battery

2

2

Battery

Overcharged

Headlamps Not

Working

Electric Clutch

Not Working

(Tri-Circuit

Alternator)

• Severe battery vibration (missing or broken tie-down

straps)

• Battery rate of charge not matched to alternator output

• Damaged battery (shorted battery cells)

• Defective regulator

• 1-Ohm resistor shorted or grounded (Tri-Circuit system

only)

• Inline fuse “blown” (if equipped)

• Defective headlamps

• Loose or corroded wires

• Open, shorted, or grounded wires between output

connector and electric clutch

• Light switch defective

• Defective diode Tri-Circuit system (open or shorted – white

output lead side).

• Weak or damaged alternator magnets

• Inline fuse “blown” (if equipped)

• Loose or corroded wires

• Open, shorted or grounded wires between output

connector and electric clutch.

• Defective diode (open or shorted – red output lead side)

• Defective electric clutch switch

• Open, shorted, or grounded clutch circuit

• Weak or damaged alternator magnets

29

Page 33

2

Alternator

Type

Stator

Output

Wire(s)

Color

Connector

Color

Al

ternator Output

(at 3600 RPM *)

* Unless Noted

Figure

#

DC Only Black White .5 Amp DC + Output at 2800

RPM

8

AC Only Black White 14 Volts AC (Lights)

Unregulated

9

DC Only Red Red 2-4 Amps + DC (Cha rging)

Unregulated

10

Dual

Circuit

Red

Black

White 2-4 Amps + DC (Charging)

Unregulated

14 Volts AC (Lights)

Unregulated

11

Tri-Circuit Black Green 5 Amps + DC (Charging)

5 Amps – DC (Lights)

12

Regulated

5 Amp

Black Green *1-5 Amps + DC (Charging)

Regulated

13

Regulated

9 Amp

Black Green *1-9 Amps + DC (Charging)

Regulated

13

Alternator Identification

The alternator systems installed on Briggs & Stratton OHV Engines can easily be identified by the color of

the stator output wires and the connector.

2

*Alternator output is determined by the size of the flywheel alternator magnets.

30

Page 34

1. 0.5 Amp DC Only (Figure 8)

• Unregulated

• Output at 2800 RPM

• .5 Amps DC for charging battery

• One black lead (A) from stator

• White connector (B) output lead

Figure 8

2. 14 Volt AC Only (Figure 9)

• 14 Volts AC for lighting circuit

• One black lead from stator (A)

• White connector (B) output lead

• Unregulated

2

2

Figure 10

4. Dual Circuit (Figure 11)

• 3 Amps DC unregulated for charging

battery, red lead from stator (A)

• 14 Volts AC for lighting circuit, black lead

from stator (B)

• Diode encased at connector

• White connector (E) with two pin terminals

• White lead (D), AC current for lights

• Red lead (C), DC current for charging circuit

Figure 9

3. 3 Amp DC Only (Figure 10)

• 3 Amps DC unregulated for charging battery

• One red lead (A) from stator

• Diode encased at connector

• Red connector (B) output lead

31

Figure 11

5. Tri-Circuit (Figure 12)

• Stator assembly (A)

• Black lead from stator (B)

• Connector (C)

• Two diodes encased in wiring harness (D)

• WHITE lead - 5 Amps DC (-) to lights (E)

• RED lead - 5 Amps DC (+) to battery, clutch

(F)

Page 35

2

2

Figure 12

6. 5/9 Amp DC (Figure 13)

• 5 or 9 Amp DC based on size of flywheel

magnet

• 5 - 9 Amps DC regulated for charging

battery

• One black lead from stator (A)

• Green connector (B)

• Yellow lead (C) to regulator-rectifier (F)

• One lead (D) from regulator-rectifier with

red connector (E)

• One red lead (B) from regulator-rectifier

to red connector output lead (A)

• 10 and 16 Amp systems use the same

stator, color coding and regulator-rectifier

• Alternator output is determined by the

flywheel alternator magnet size

Figure 14

8. 20 Amp DC (Figure 15)

• 20 Amps DC regulated for charging

battery

• Two yellow leads from stator (A)

• Red output lead from connector (B)

• Connector (C)

• Two yellow AC input leads (D)

• Regulator Rectifier (E)

• Red output lead from regulator-rectifier

(F)

Figure 13

7. 10/16 Amp DC (Figure 14)

• 10 or 16 Amps DC regulated for charging

battery

• Two black leads (C) from stator

• Yellow connector (D) with two pin

terminals

• Two yellow leads (E) to regulator-rectifier

(F)

32

Figure 15

Page 36

Flywheel Identification

OHV single cylinder flywheels have a single ring

of magnets which provide the magnetic field for

the various alternator systems, except Model

Series 97700, 99700, 121600, 126000 which use

the magneto magnet. There are two sizes of

flywheel magnets. The size of the magnet

determines alternator output.

The following table identifies the magnet size to

be used with a specific alternator system.

NOTICE: Do not use large-magnet flywheels

with AC-only, DC-only, or Dual Circuit

Alternators.

• Small Magnet - Approx. 28/32” x 21/32”

(22mm x 17mm).

• Large Magnet - Approx. 1-3/32” x 29/32”

(28mm x 23mm).

Testing Alternator Output

The following alternator test procedures were

developed using the Fluke® Digital Multimeter.

When performing alternator tests with the

UNI-T® Digital Multimeter, refer to the operating

manual supplied with that meter for the proper

procedure.

All test values will be the same regardless the

meter used.

NOTE: Before testing alternator output, use an

accurate tachometer to temporarily adjust the

engine speed to the RPM specified in the test

instructions.

1. Insert RED test lead into 10 Amp

receptacle in meter.

2. Insert BLACK test lead into COM

receptacle in meter.

3. Rotate selector to DC Amps position.

4. Attach RED test c lip to output terminal

(A, Figure 16).

5. Attach BLACK test clip to charging lead

(B) that was disconnected at the

connector.

2

2

Figure 16

6. With engine running at 2800 RPM, output

should be no less than .5 Amp DC.

7. If low or no output, check stator air gap.

8. If stator air gap is within specification and

there is low or no output, replace stator.

When testing alternators, perform the tests in the

following sequence:

1. Test alternator output.

2. Test diode(s) or regulator-rectifier (if

equipped).

3-Amp DC Only Alternator

The DC alternator provides DC current for

charging a 12 Volt battery. Current from the

alternator is unregulated and is rated at 3 Amps.

The output rises from 2 Amps at 2400 RPM to 3

Amps at 3600 RPM.

.5 Amp DC Only Alternator

The .5 Amp, DC alternator is designed to operate

as an integral part of the engine and is separate

from the starting and ignition system. It is

intended to provide DC charging current for a 12

Volt battery. Contact battery or equipment

manufacturer for battery information.

Test Alternator Output

Disconnect charging lead to battery at connector.

33

Test Alternator Output

1. Insert RED test lead (A, Figure 17) into 10

Amp receptacle in meter.

2. Insert BLACK test lead (B) into COM

receptacle in meter.

3. Rotate selector to DC Amps position.

4. Attach RED test lead clip to DC output

terminal connector (C).

Page 37

2

5. Attach BLACK test lead clip to positive (+)

battery terminal.

NOTE: Negative (-) battery terminal must be

grounded.

2

Figure 18

Figure 17

6. With engine running at 3600 RPM, output

should be between 2 to 4 Amps DC.

• Output will vary with battery voltage. If

battery voltage is at its maximum, output

will be approximately 2 Amps.

7. If no or low output is found, test diode.

Test Diode

In the Diode Test position, the meter will display

forward voltage drop across the diode(s). If

voltage drop is less than 0.7 volts, meter will

“Beep” once as well as display voltage drop. A

continuous tone indicates continuity (shorted

diode). An incomplete circuit (open diode) will be

displayed as “OL.”

1. Insert RED test lead (A, Figure 18) into

the V Ω receptacle and set the rotary

switch to Diode position.

2. Insert BLACK test lead (B) into the COM

receptacle in the meter.

3. Attach RED test lead clip to (C) and Black

test lead clip to point (D). (It may be

necessary to pierce wire with a pin as

shown.)

• If meter “Beeps” once, diode is OK.

• If meter makes a continuous tone, diode

is defective (shorted).

• If meter displays “OL,” proceed to Step 4.

4. Reverse test leads.

• If meter “Beeps” once, diode is installed

backwards.

• If meter still displays “OL,” diode is

defective (open).

5. If diode tests OK, replace stator.

NOTE: Service replacement diode harnesses

are available. Use Rosin Core solder when

installing new harness. Use shrink tubing or tape

for all connections. Do not use crimp connectors.

14-Volt AC Alternator

The AC alternator provides current for headlights

only. Current for the lights is available when the

engine is running. To check, use 12 Volt lights

with a total rating of 60-100 watts. Alternator

output varies with engine speed. With lights rated

at 70 watts, the voltage rises from 8 Volts @

2400 RPM to 12 Volts @ 3600 RPM. The lights

should become brighter as the engine speed

increases.

34

Page 38

Test Alternator Output

1. Insert RED test lead (A, Figure 19) into

the V Ω receptacle in the meter.

2. Insert BLACK test lead (B) into COM

receptacle.

3. Rotate selector to AC Volts position.

4. Attach RED test lead clip to AC output

terminal (C).

5. Attach BLACK test lead clip to engine

ground.

Figure 19

Test Alternator Output-AC

1. Insert RED test lead (A, Figure 20) into

the V Ω receptacle in the meter.

2. Insert BLACK test lead (B) into COM

receptacle.

3. Rotate selector to AC Volts position.

4. Attach RED test lead clip to AC output pin

(C).

5. Attach BLACK test lead clip to engine

ground.

2

2

6. With engine running at 3600 RPM, AC

output should be no less than 14 Volts.

• If NO or LOW output is found, replace the

stator.

Dual Circuit Alternator

Dual Circuit alternators use a polarized plug with

two pins. One pin provides DC current for

charging the battery, the second pin is an

independent AC circuit for headlights.

Current for lights is available when the engine is

running. The output varies, so brightness of the

lights changes with engine speed. 12 Volt lights

with a total rating of 60 to 100 watts may be

used. With lights rated at 70 watts, the voltage

rises from 8 Volts @ 2400 RPM to 12 Volts at

3600 RPM. Since the battery is not used for the

lights, the lights are available even if the battery

is disconnected or removed.

Current for the DC side of the alternator is

unregulated and is rated at 3 Amps. The output

rises from 2 Amps @ 2400 RPM to 3 Amps @

3600 RPM.

Figure 20

6. With engine running at 3600 RPM, AC

output should be no less than 14 Volts.

• If NO or LOW output is found, replace the

stator.

Test Alternator Output-DC

NOTE: The battery MUST be in good condition

to perform this test.

1. Insert RED test lead into 10 Amp

receptacle in meter.

2. Insert BLACK test lead into COM

receptacle in meter.

3. Rotate selector to DC Amps position.

4. Attach RED test lead clip (A, Figure 21) to

DC output pin (F) in connector (D).

NOTE: The raised rib on the connector or the

RED wire indicates the DC output pin side. The

AC pin is not used for the test.

5. Attach BLACK test lead clip (B) to the

positive (+) battery terminal.

35

Page 39

2

2

Figure 21

6. With the engine running at 3600 RPM,

output should be between 2 - 4 Amps DC.

NOTE: The output will vary with the battery

voltage. At maximum battery voltage the output

will be approximately 2 Amps.

7. If NO or LOW output is found, test diode.

Test Diode

In the Diode Test position, the meter will display

forward voltage drop across the diode(s). If

voltage drop is less than 0.7 volts, meter will

“Beep” once as well as display voltage drop. A

continuous tone indicates continuity (shorted

diode). An incomplete circuit (open diode) will be

displayed as “OL.”

1. Insert RED test lead (A, Figure 22) into

the V Ω receptacle and set the rotary

switch to Diode position.

2. Insert BLACK test lead (B) into the COM

receptacle in the meter.

3. Attach RED test lead clip to point (C) and

Black test lead clip to point (D). (It may be

necessary to pierce wire with a pin as

shown.)

Figure 22

• If meter “Beeps” once, diode is OK.

• If meter makes a continuous tone, diode

is defective (shorted).

• If meter displays “OL,” proceed to Step 4.

4. Reverse test leads.

• If meter “Beeps” once, diode is installed

backwards.

• If meter still displays “OL,” diode is

defective (open).

5. If diode tests OK, replace stator.

NOTE: Service replacement diode harnesses

are available. Use Rosin Core solder when

installing new harness. Use shrink tubing or tape

for all connections. Do not use crimp connectors.

Tri-Circuit Alternator

The tri-circuit alternator provides alternating

current (AC) through a single output lead and

connector to a wiring harness containing two

diodes.

One diode rectifies the AC current to 5 Amps

negative (-) DC for lights. The second diode

rectifies the AC current to 5 Amps positive (+)

DC for battery charging and external loads, such

as an electric clutch.

NOTE: Some original equipment manufacturers

(OEMs) supply diodes as an integral part of the

equipment wiring harness. Some OEMs use a 1

Ohm-20 Watt resistor placed in series with (+)

DC charging lead, limiting the charging current to

approximately 3 Amps when the clutch is not

engaged. When the clutch is engaged, the

36

Page 40

resistor is bypassed allowing full output to the

battery and clutch.

The battery is not used for the lights, so lights are

available even if the battery is disconnected or

removed. Current for the lights is available when

the engine is running. The output varies, so the

brightness of the lights changes with engine

speed.

Test Alternator Output

1. Insert RED test lead (A, Figure 23) into

the V Ω receptacle in the meter.

2. Insert BLACK test lead (B) into COM

receptacle.

3. Rotate selector to AC Volts position.

4. Attach RED test lead clip to AC output

terminal (C).

5. Attach BLACK test lead clip to engine

ground.

“Beep” once as well as display voltage drop. A

continuous tone indicates continuity (shorted

diode). An incomplete circuit (open diode) will be

displayed as “OL.”

Charging Circuit Test (RED Wire)

1. Insert RED test lead (A, Figure 24) into

the V Ω receptacle and set the rotary

switch to Diode position.

2. Insert BLACK test lead (B) into the COM

receptacle in the meter.

3. Attach BLACK test lead clip to (C) of the

RED wire (D). (It may be necessary to

pierce wire with a pin as shown.)

4. Insert RED test lead (A) into harness

connector.

2

2

Figure 24

Figure 23

6. With engine running at 3600 RPM, AC

output should be no less than 28 Volts.

• If NO or LOW output is found, replace the

stator.

• If alternator output is good, test the

diodes in the wiring harness.

Test Diode

One diode is for the charging circuit, the other

diode is for the lighting circuit.

In the Diode Test position, the meter will display

forward voltage drop across the diode(s). If

voltage drop is less than 0.7 volts, meter will

37

• If meter “Beeps” once, diode is OK.

• If meter makes a continuous tone, diode

is defective (shorted).

• If meter displays “OL,” proceed to Step 4.

5. Reverse test leads.

• If meter “Beeps” once, diode is installed

backwards.

• If meter still displays “OL,” diode is

defective (open).

6. If diode tests OK, replace stator.

Lighting Circuit Test (WHITE Wire)

1. Insert RED test lead (A, Figure 25) into

the V Ω receptacle and set the rotary

switch to Diode position.

Page 41

2

2

2. Insert BLACK test lead (B) into the COM

receptacle in the meter.

3. Attach RED test lead clip to (D) of the

WHITE wire (C). (It may be necessary to

pierce wire with a pin as shown.)

4. Insert BLACK test lead (B) into harness

connector.

Figure 25

• If meter “Beeps” once, diode is OK.

• If meter makes a continuous tone, diode

is defective (shorted).

• If meter displays “OL,” proceed to Step 4.

5. Reverse test leads.

• If meter “Beeps” once, diode is installed

backwards.

• If meter still displays “OL,” diode is

defective (open).

6. If diode tests OK, replace stator.

Test Alternator Output

1. Temporarily disconnect stator wire

harness from the regulator-rectifier.

2. Insert RED test lead (A, Figure 26) into the

V Ω receptacle in the meter.

3. Insert BLACK test lead (B) into COM

receptacle.

4. Rotate selector to AC Volts position.

5. Attach RED test lead clip to GREEN

output terminal (C).

6. Attach BLACK test lead clip to engine

ground.

Figure 26

7. With engine running at 3600 RPM, AC

output should be no less than:

• 28 Volts AC - 5 Amp System

• 40 Volts AC - 9 Amp System

8. If NO or LOW output is found, replace the

stator.

5 & 9 Amp DC Regulated Alternator

The 5 & 9 Amp regulated alternator systems

provide AC current through a single lead into the

regulator-rectifier. The regulator-rectifier

converts the AC current to DC and regulates

current to the battery. The charging rate will vary

with engine RPM and temperature.

Alternator output is determined by the flywheel

alternator magnet size. The stator and regulatorrectifier are the same for the 5 & 9 Amp

regulated system and the Tri-Circuit System.

38

Test Regulator-Rectifier

NOTE: The regulator-rectifier will not function

unless it is grounded to engine. Make sure the

regulator-rectifier is securely mounted to the

engine. When testing regulator-rectifier

amperage output, a 12 Volt battery with a

minimum charge of 5 Volts is required. There will

be no output if battery voltage is below 5 Volts.

NOTICE: Connect test leads BEFORE starting

the engine. Be sure connections are secure. If a

test lead vibrates loose while engine is running,

the regulator-rectifier may be damaged.

Page 42

1. Connect stator wire harness to regulatorrectifier.

2. Insert RED test lead into 10 Amp

receptacle in meter.

3. Insert BLACK test lead into COM

receptacle in meter.

4. Rotate selector to DC Amps position.

5. Attach RED test lead clip (A, Figure 27) to

RED DC output terminal on regulatorrectifier.

6. Attach BLACK test lead clip (B) to positive

(+) battery terminal.

Figure 27

7. Run the engine at 3600 RPM. The output

should be:

• 3-5 Amps - 5 Amp System

• 3-9 Amps - 9 Amp System

NOTE: The amperage produced depends on the

battery voltage. If the battery is below 11 Volts,

the output reading would be 5 or 9 Amps,

depending upon the alternator system being

tested. The amperage will be less at maximum

battery voltage.

8. If NO or LOW output is found, be sure that

the regulator-rectifier is grounded properly

and all connections are clean and secure.

If there is still NO or LOW output, replace

the regulator-rectifier.

10 & 16 Amp DC Regulated Alternator

The 10 & 16 Amp regulated alternator system

provides AC current through two YELLOW

output leads to the regulator-rectifier. The