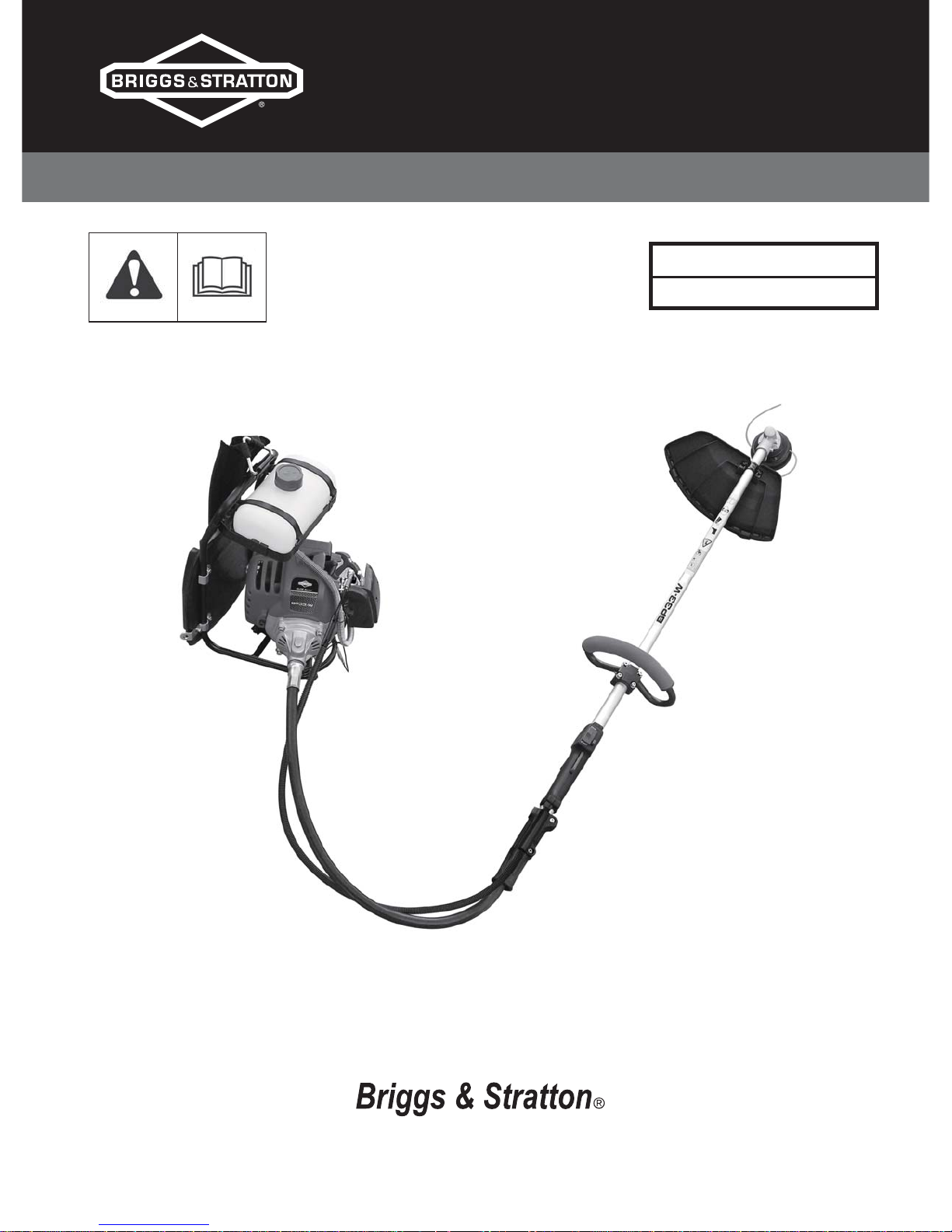

Page 1

MODEL

BP33-W / BP43-W

BRUSH CUTTER OPERATOR’ S MANUAL

©2010.

Briggs & Stratton Power Products Group, LLC.

All Rights Reserved.

Page 2

2

Trimmer / Brushcutter

Model Number

Revision

Serial Number

Date Purchased

Thank You for purchasing this quality-built Briggs & Stratton Trimmer/Brushcutter. We’re

pleased that you placed your confi dence in our brand. When operated and maintained according to the instructions in this manual, your Briggs & Stratton Trimmer/Brushcutter will provide

dependable service.

This manual contains safety information to make you aware of the hazards and risks associated

with the machine and how to avoid them. This machine is intended for trimming and brushcutting

and is not intended for any other purpose. It is important that you read and understand these

instructions thoroughly before attempting to start or operate this equipment. Save these original

instructions for future reference.

The trimmer/brushcutter requires fi nal assembly before use. Refer to the Assembly section of

this manual for instructions on fi nal assembly procedures. Follow the instructions completely.

Where to Find Us For quality support and service for your Briggs & Stratton

Trimmer/Brushcutter. Contact your local distributor. To obtain an Illustrated Parts List for your

product, please visit our website, BRIGGSandSTRATTON.com.

Page 3

3

TABLE OF CONTENTS

4

9

11

11

11

12

13

13

14

14

14

16

16

17

17

17

18

18

18

19

19

20

20

21

22

22

22

23

23

25

26

OPERATOR SAFETY

FEA TURES AND CONTROLS

ASSEMBLY

Install Trimmer Head to the Cutting Head

Install Trimmer Head Guard

Install Trimmer Head Line

Install Brushcutter Blade to the Cutting Head

Install Handle

OPERATION

Fuel Recommendations

How to Add Fuel

Starting the Engine

Stopping the Engine

Operating Position

Using Nylon Trimmer Line

Using Brushcutter Blade

Blade Thrust

Trimming and Edging

Operating on Slopes

MAINTENANCE

Maintenance Schedule

Spark Plug Maintenance

Air Filter Maintenance

Cutting Attachment Maintenance

STORAGE

Protect Fuel System

Clean the Unit

Storage Safety

TROUBLESHOOTING

WARRANTY

SPECIFICATIONS

Page 4

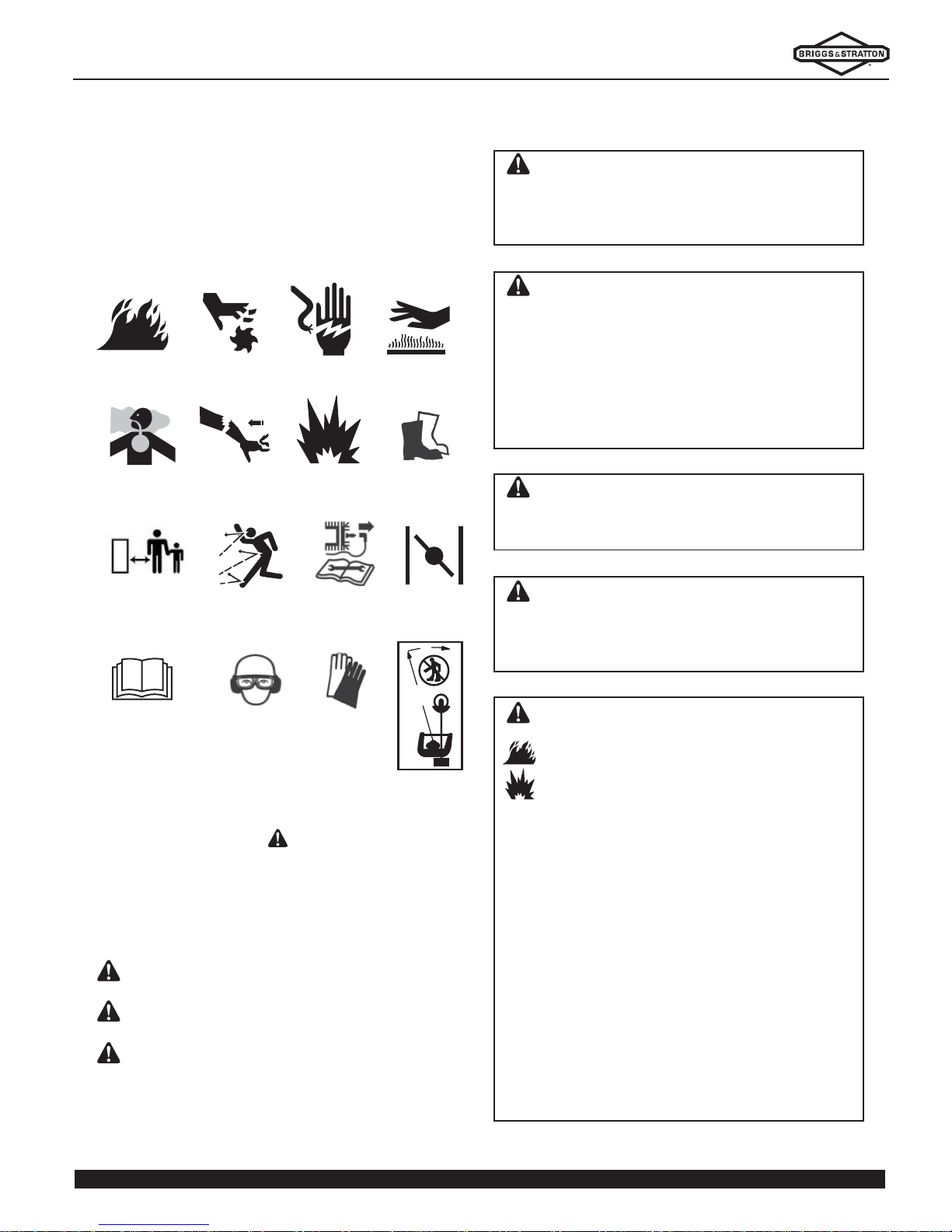

4

FIRE

MOVING PARTS SHOCK

SAFETY

GOGGLES,

& EAR

PROTECTION

TOXIC FUMES KICKBACK EXPLOSION

HOT SURFACE

READ MANUAL

STURDY

FOOTWEAR

CHOKE

Safety Symbols and Meanings

OPERATOR SAFETY

THROWN

OBJECTS

SAFE DISTANCE

SAFETY

GLOVES

REMOVE

SPARK PLUG

360

15 meters (50 feet)

SAFE

DISTANCE

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during the

initial set-up, the operation, and the maintenance of the

equipment.

The safety alert symbol is used to identify safety

information about hazards that can result in personal

injury. A signal word (DANGER, WARNING, or CAUTION) is used with the alert symbol to indicate the likelihood and the potential severity of injury. In addition, a

hazard symbol may be used to represent the type of

hazard.

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE indicates a situation that could result in

damage to the product.

WARNING Read understand and follow all the

instructions on the trimmer and in this manual

before operating the unit. Failure to observe the

safety instructions in this manual will result in death

or serious injury.

WARNING The engine exhaust from this product contains chemicals known to the State of California to cause cancer , birth defects, or other reproductive harm.

WARNING Certain components in this product

and its related accessories contain chemicals

known to the State of California to cause cancer,

birth defects, or other reproductive harm. Wash

hands after handling.

WARNING Gasoline and its vapors are extremely

fl ammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

• Fill fuel tank outdoors or in well-ventilated area.

• Check fuel lines, tank, cap, and fittings frequently

for cracks or leaks. Replace if necessary.

When Starting Engine

• Ensure that spark plug, muffler, and air cleaner (if

equipped) are in place and secured.

• Do not crank engine with spark plug removed.

When Operating Equipment

• Never start or run the engine with the air cleaner

assembly or the air filter removed.

When Transporting Equipment

• Transport with the fuel tank empty.

When Storing Fuel or Equipment With Fuel in Tank

• Store away from furnaces, stoves, water heaters

or other appliances that have pilot lights or other

ignition sources because they can ignite fuel vapors.

WARNING This cutting machine is capable of

amputating hands and feet and throwing objects

that can cause injury and damage! Failure to comply

with the following SAFETY instructions could result

in death or serious injury to the operator or bystanders. The operator must understand these instructions. The operator must be of sound mind and body

and must not be under the infl uence of any

substance that might impair vision, dexterity or judgment.

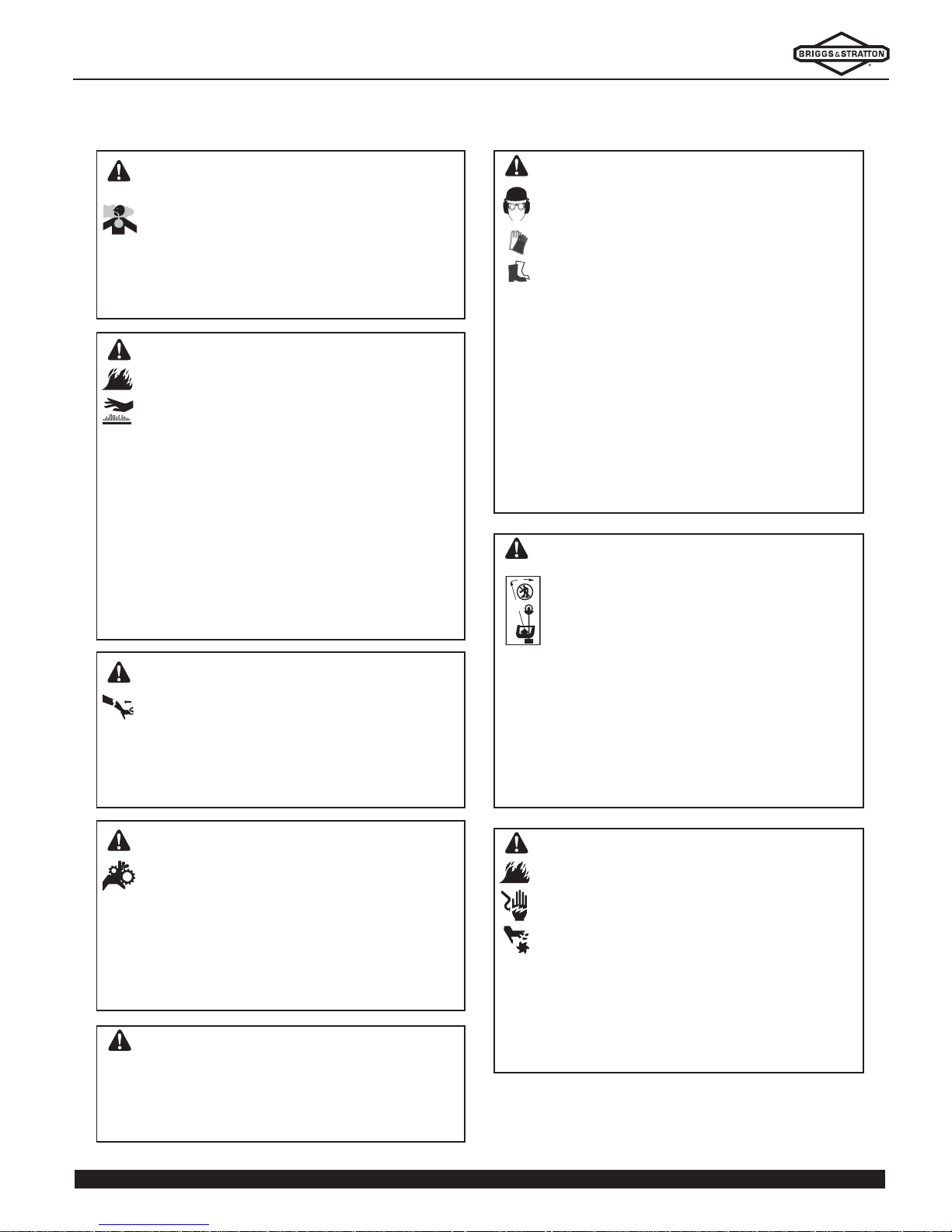

Page 5

5

360

15 meters (50 feet)

OPERATOR SAFETY

WARNING Thrown debris could cause eye

injuries. Noise levels could cause hearing

damage. Nylon trimming line and blades can

cut through clothes and skin.

• NEVER operate unit without protective guards in

place.

• DO NOT wear loose clothing, jewelry or anything

that could be caught in the starter or other rotating

parts.

• Keep hands and feet away from rotating parts.

• Wear safety goggles that meet ANSI standards

whenever you use the trimmer.

• Wear hearing protectors.

• Wear protective clothing to reduce the risk and severity

of injury. Wear trimmer harness, gloves, a longsleeved shirt, long pants, and sturdy boots with

nonslip soles.

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

• Operate equipment ONLY outdoors.

• Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or

other openings.

WARNING Exhaust heat/gases could ignite

combustibles or structures resulting in death,

serious injury or property damage. Contact with

the muffl er area could cause burns resulting in

serious injury.

• DO NOT touch hot parts.

• Allow equipment to cool before touching.

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any

forest-covered, brush-covered, or grass-covered

land unless the exhaust system is equipped with a

spark arrester, as defined in Section 4442, maintained in effective working order. Other states or

jurisdictions may have similar laws. Contact the

original equipment manufacturer, retailer, or

dealer to obtain a spark arrester designed for the

exhaust system installed on the engine.

WARNING Rapid retraction of starter cord

(kickback) will pull hand and arm toward engine

faster than you can let go. Broken bones,

fractures, bruises, or sprains could result.

• When starting engine, pull the starter cord slowly

until resistance is felt and then pull rapidly to avoid

kickback.

• Blade or trimmer head must be securely attached.

WARNING Improperly maintaining the trimmer,

or failure to correct a problem before operation, can

cause a malfunction in which you can be seriously

hurt or killed. Always follow the inspection and maintenance recommendations and schedules in this

manual.

WARNING Moving parts could crush and

cut. Starter and other rotating parts could

entangle hands, hair, clothing, or accessories

resulting in serious injury.

• NEVER operate unit without protective guards in place.

• DO NOT wear loose clothing, jewelry or anything

that could be caught in the starter or other rotating

parts.

• Tie up long hair.

• Keep hands and feet away from rotating parts.

WARNING Objects thrown by the trimmer

can cause serious injury.

• Clear the area to be cut before each use. Remove

all objects such as broken glass, nails, wires, or

string, which could be thrown or become

entangled in the cutting attachment.

• Clear the area of children, bystanders, and pets.

• Keep all children, bystanders outside of a 50 ft (15 m)

radius.

• Bystanders should be encouraged to wear eye

protection.

WARNING

Unintentional sparking can resul t in fire or electric

shock.

Unintentionalstart-up can result in entanglement,

traumatic amputation, or laceration.

Fire hazard.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away

from the spark plug.

• Use only correct tools.

• Replacement parts must be of the same design and

installed in the same position as the original parts.

Page 6

6

OPERATOR SAFETY

Trimmer Safety

• Read, understand, and follow instructions and warnings

in this manual and on the machine, engine and

attachments.

• Know the controls and the proper use of the machine

before starting.

• The equipment should only be used in good weather

conditions and with clear visibility.

• To prevent injury to others, keep people at least 50

feet (15 meters) away from the working area during

operation.

• DO NOT touch the cutting head or blade in motion.

• Keep fi rm footing and balance. Do not over-reach.

Keep cutting attachment below waist level. Keep all

parts of your body away from the rotating cutting

attachment and hot surfaces.

• NEVER use the unit without the blade guard securely

in place.

• Do not strike objects that may cause harm or damage

to the unit.

• Always wear eye protection and protective clothing.

Always wear the safety glasses provided with the

unit. Protect yourself when operating unit by wearing

safety glasses, a dust mask, long pants, ear protection, and substantial footwear.

• Clear the working area. Objects thrown by the trimmer

can cause serious injury. Before operating the

trimmer, carefully inspect the area and remove any

broken glass, pieces of wire, and other loose objects.

• The cutting attachment may be spinning during

carburetor adjustments. Wear protective equipment

and observe all safety instructions. For units

equipped with a clutch, be sure the cutting attachment stops turning when the engine idles. When the

unit is turned off, make sure the attachment has

stopped before the unit is set down.

• A coasting blade can cause injury while it continues

to spin after the engine is stopped or throttle trigger is

released. Maintain proper control until the blade has

completely stopped rotating.

Protection for Children, Bystander, and Pets

Tragic accidents can occur if the operator is not alert to

the presence of children, bystanders, and pets. Children

are often attracted to the machine and the trimming

activity. Never assume that children will remain where

you last saw them.

• Keep children out of the trimming area and under the

watchful care of a responsible adult.

• Clear the area to be cut before each use. Remove all

objects such as broken glass, nails, wires, or string,

which could be thrown or become entangled in the

cutting attachment.

• Clear the area of children, bystanders, and pets.

• Keep all children, bystanders outside of a 50 ft (15 m)

radius.

• Bystanders should be encouraged to wear eye protection.

• Do not allow children or others to use the equipment

or attachments. They can be seriously injured.

• Allow only responsible persons who understand these

instructions to operate this equipment.

• Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

Safe Handling of Gasoline

To avoid personal injury or property damage, use

extreme care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

• Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

• Use only an approved fuel container.

• DO NOT fi ll fuel containers inside a vehicle or on a truck

or trailer with a plastic liner. Always place the containers on the ground away from the vehicle before fi lling.

• Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times until fueling is complete. DO NOT use a nozzle lock-open device.

• DO NOT refuel the machine indoors.

• DO NOT remove fuel cap or add fuel with the engine

running. Allow the engine to cool before refueling.

• Remove gas-powered equipment from the vehicle or

trailer and refuel it on the ground. If this is not

possible, then refuel equipment using a portable

container, rather than a gasoline dispenser nozzle.

• Never overfi ll a fuel tank. Replace fuel cap and tighten

securely.

• DO NOT store the machine or fuel container inside

where there is an open fl ame, spark or pilot light such

as on a water heater or other appliance.

• If fuel is spilled on clothing, change clothing immediately.

Page 7

7

OPERATOR SAFETY

Maintenance Safety

• Keep engine free of grass, leaves or excess grease

to reduce fi re hazard and engine overheating.

• When draining fuel tank, drain fuel into an approved

container outdoors and away from open fl ame.

• Always provide adequate ventilation when running

engine. Exhaust gases contain carbon monoxide, an

odorless and deadly poison.

• Service engine and make adjustments only when engine

is stopped. Remove spark plug wire from spark plug

and secure wire away from spark plug.

• DO NOT change engine governor speed settings or

overspeed engine.

• DO NOT test for spark with spark plug removed.

Transporting and Storage Safety

• DO NOT store equipment or fuel container inside where

fumes may reach an open fl ame, spark or pilot light

such as in a water heater, furnace, clothes dr yer or

other gas appliance. Allow engine to cool before

storing equipment in an enclosure. Store fuel

container out of the reach of children in a well ventilated, unoccupied building.

• Do not stand the unit unsecured or unattended in the

vertical position. Do not store in the vertical position.

• Hand carry the unit in the horizontal position with the

engine stopped and the muffl er away from your body.

Ensure the blade is well clear of people and property.

• Allow the engine to cool before transporting or storing

the unit.

• Empty the fuel tank after each use and before storing

the unit.

Page 8

8

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Please read them carefully. These labels are considered

permanent parts of your trimmer/brush cutter. If a label comes off or becomes hard to read, contact your authorized

dealer for a replacement.

Page 9

9

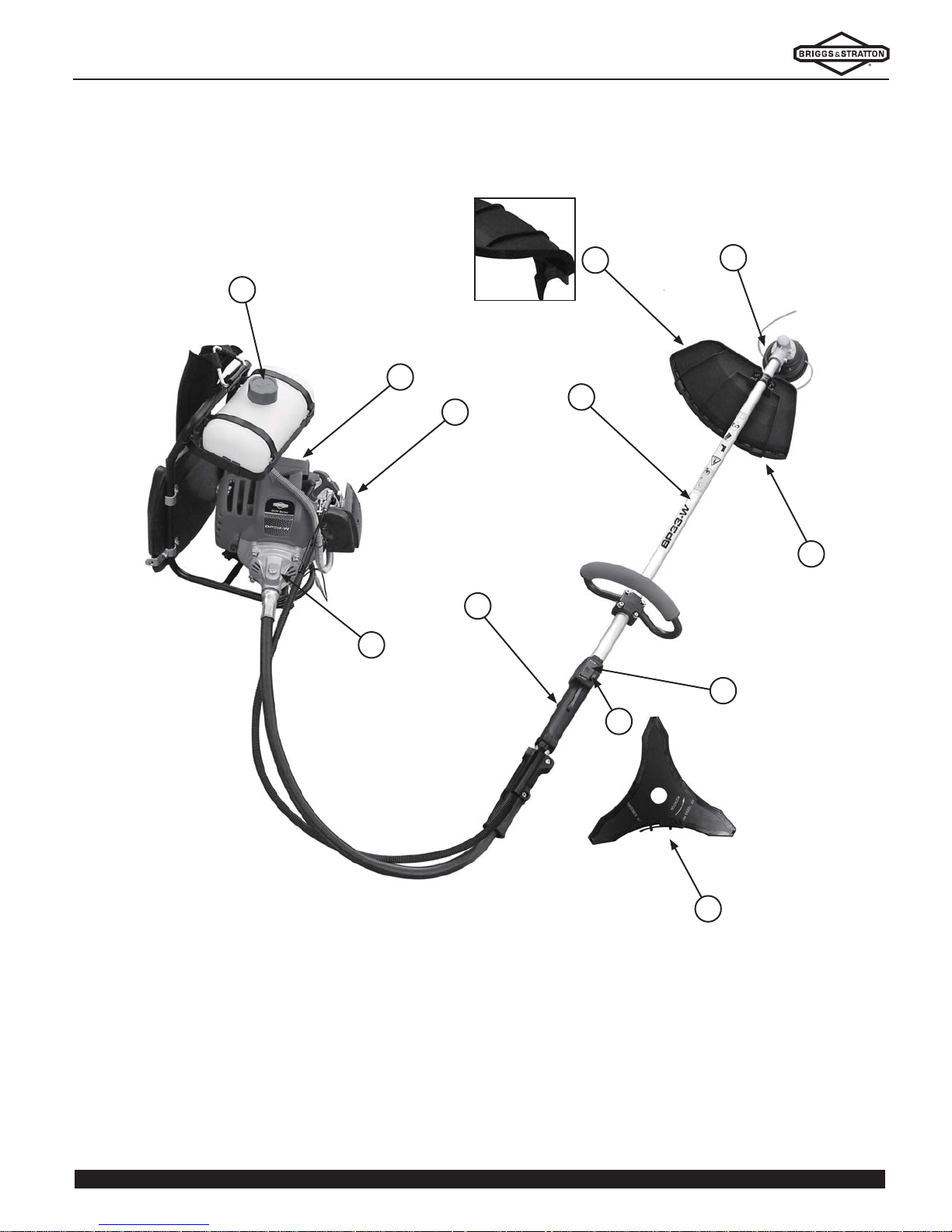

NOTICE: The figures and illustrations in this manual are provided for reference only and may differ from your specific

model.

A. Engine

B. Fuel Cap

C. Air Filter

D. Clutch

E. Blade Guard

F. Line Limiter

G. Spool Head

H. Straight Shaft

I. Throttle Control Switch

J. Ignition Switch

K. Brushcutter Blade

L. Half throttle control switch

A

B

D

F

E

H

I

K

J

FEA TURES AND CONTROLS

C

G

L

Page 10

10

FEA TURES AND CONTROLS

Choke Lever

The choke lever (Figure 1) opens and closes the choke

valve. The CLOSED position enriches the fuel mixture

for starting a cold engine. The OPEN position provides

the correct fuel mixture for operation after starting, and

for restarting a warm engine.

Ignition Switch

The ignition switch (A, Figure 2) controls the ignition

system. The ignition switch must be in the Start position

for the engine to start and run. Moving the ignition

switch to the STOP position stops the engine.

Throttle Control Switch

The throttle control switch (A, Figure 3) controls engine

speed. Pulling the throttle trigger toward the control

handle grip increases engine speed. Releasing the

throttle trigger reduces engine speed.

Priming Bulb

Pressing the priming bulb (Figure 4) pumps fuel from

the fuel tank to the carburetor. This procedure is necessary for starting the engine. Prime the clear fuel bulb at

the bottom of the carburetor until it becomes hard and

full of fuel.

Figure 1

Figure 4

Figure 2

A

Figure 3

A

Page 11

11

ASSEMBLY

WARNING

Unintentional sparking can result in fire or

electric shock.

Unintentional start-up can result in entanglement,

traumatic amputation, or laceration.

Fire hazard.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away

from the spark plug.

• Use only correct tools.

• Replacement parts must be the same and installed

in the same position as the original parts.

• STOP engine.

• Avoid serious burns. Allow all parts to cool before

working on machine.

Figure 5

A

E

Install Trimmer Head to the Cutting Head

1. Align the hole on the cutting head (A, Figure 5) to the

notch (B) on the spline pad (C).

2. Use Allen Wrench (D) to hold spline pad in position.

3. While holding Allen wrench in place, install the

trimmer head (E) by turning in a counterclockwise

direction.

NOTE: Ensure that the spline pad is placed in the

correct position when installing. The shoulder

side must face the cutting head.

Install Trimmer Head Guard

1. Remove the two screws (A, Figure 6) from guard.

2. Position guard and saddle (B) at hole in straight

shaft.

3. Install the two screws through the saddle and into the

guard.

4. Remove third screw (C) from the tool set bag, and

install into the drive shaft.

NOTE: The third screw (C) is shorter than the two

screws (A) installed in guard.

Figure 6

D

A

B

C

C

B

Page 12

12

ASSEMBLY

Figure 7

Figure 8

Figure 9

Figure 10

Install Trimmer Head Line

1. Press in the tabs (A, Figure 7) on the side of the

trimmer head base to remove the cover of the

trimmer head and the spool (B).

2. Cut two of each 1.5 meter length of 2.4 mm trimming

line. Thread the cut lines through the eyelets of the

two ears at the same direction (C, Figure 8).

3. Evenly wind both lines around the spool in the direction

of the arrow on the spool cover (Figure 9).

4. Lock the line at the side of trimmer base spacing holes

(D, Figure 10).

5. Fit the ends of each line through the eyelets (Figure 11)

in the trimmer head base.

6. Place the spool in the base and press until the tabs

lock in place (Figure 12).

A

B

C

Figure 11

D

Figure 12

Figure 13

Page 13

13

Figure 14

H

F

J

E

A

G

ASSEMBLY

Install Brushcutter Blade to the Cutting Head

1. Align the hole on the cutting head (A, Figure 14) to

the notch (B) on the spline pad (C).

2. Use Allen Wrench (D) to hold spline pad in position.

3. While holding Allen wrench in place, install the blade

(E), clamp cup (F), protective cup (G), lock washer

(H) and locknut (J).

NOTE: Ensure that the spline pad is placed in the correct

position when installing. The shoulder side

must face the cutting head.

Install Handle

1. Untight the four screws to loose the handle base.

2. Place the handle base as shown (Figure 15) and

tight the screws.

3. The handle should be placed into a position that is

comfortable and that allows for proper trimming

operation practices.

Install Transmission Shaft

1. Connect two shafts together as showed, tighten the

screw M5x30. (Figure 16)

2. Shaft connect with clutch: Pull up the pin insert shaft

to the clutch end, then release the pin. (Figure 17)

Throttle Cable Installation (Figure 18)

1. Open the sleeve, connect cable 1 & cable 2 together.

2. Close the sleeve.

Figure 15

D

Pin

Shaft

Clutch

WARNING: Please check the pin on the right

position.

Figure 16 Figure 17

Figure 18

Cable 1

Cable 2

Sleeve

C

B

Page 14

14

OPERATION

Figure 19

C

A

B

Fuel Recommendations

Mix Fuel and Oil

Use the provided bottle and mix gasoline and a high

quality 2-cycle oil with a 25:1 gasoline-to-oil ratio.

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline

• A minimum of 87 octane/87 AKI (91 RON).

• Gasoline with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether) is acceptable.

To protect the fuel system from gum formation, mix a

fuel stabilizer into the gasoline. See Storage. All fuel is

not the same. If starting or performance problems

occur, change the fuel providers or change brands.

CAUTION Do not use unapproved gasoline,

such as E85. Do not modify the engine to run on

alternate fuels. This will damage the engine components and void the engine warranty.

WARNING Gasoline and its vapors are

extremely flammable and explosive. Fire or

explosion can cause severe burns or death.

When Adding Fuel

• Turn engine off and let engine cool at least 2 minutes

before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of

gasoline, do not fill above the bottom of the fuel

tank neck.

• Keep gasoline away from sparks, open flames,

pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently

for cracks or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before starting

engine.

How to Add Fuel

1. Clean area around fuel cap. Remove cap.

2. Slowly add fuel and oil mixture (A, Figure 19) to the

fuel tank (B). Do not fill above the bottom of the fuel

tank neck (C).

3. Install fuel cap and let any spilled fuel evaporate

before starting engine.

Page 15

15

360

15

meters (

50

feet)

Figure 20

OPERATION

WARNING Objects thrown by the trimmer can

cause serious injury.

• Clear the area to be cut before each use. Remove

all objects such as broken glass, nails, wires, or

string, which could be thrown or become

entangled in the cutting attachment.

• Clear the area of children, bystanders, and pets.

• Keep all children, bystanders outside of a 50 ft (15

m) radius.

• Bystanders should be encouraged to wear eye

protection.

Inspect Working Area

Objects thrown by the trimmer can cause serious

injury. Before operating the trimmer, carefully inspect

the area and remove all objects that could be thrown

by, or entangled in, the cutting attachment, such as

rocks, broken glass, nails, wire, or other loose objects.

Keep all children and other bystanders at least 50 feet

(15 meters) away from where the trimmer is being

operated.

If anyone approaches while operating the trimmer,

release the throttle and stop the engine.

Inspect Cutting Attachments

Look for signs of damage to the cutting attachment.

Replace any cutting attachment and parts that are worn

out, bent, cracked, chipped, or damaged in any way.

If using the trimmer blade, be sure it is sharp. A dull

blade is more likely to snag and thrust.

Ensure the cutting attachment is installed correctly.

Ensure that the blade guard is securely installed and in

good condition.

Balancing the Trimmer on the Shoulder Harness

Hang the trimmer on the harness hook to check how it

balances.

Adjust the shoulder harness and the harness hanger on

the frame so that the handlebars in a comfortable operating position, and the trimmer hangs with its cutting

attachment a few inches above the ground (Figure 20).

Page 16

16

OPERATION

Starting the Engine

WARNING Gasoline and its vapors are

extremely flammable and explosive.

Fire or explosion can cause severe burns or

death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air

cleaner (if equipped) are in place and secured.

• Do not crank the engine with the spark plug

removed.

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache, fatigue, dizziness, vomiting, confusion,

seizures, nausea, fainting or death.

• Operate equipment ONLY outdoors.

• Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or

other openings.

WARNING Exhaust heat/gases could ignite

combustibles or structures resulting in death,

serious injury or property damage. Contact

with the muffler area could cause burns resulting in serious injury.

• DO NOT touch hot parts.

• Allow equipment to cool before touching.

• Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or

other openings.

• Replacement parts must be the same and installed

in the same position as the original parts.

WARNING Rapid retraction of starter cord

(kickback) will pull hand and arm toward

engine faster than you can let go. Broken

bones, fractures, bruises, or sprains could

result.

• When starting engine, pull the starter cord slowly

until resistance is felt and then pull rapidly to avoid

kickback.

• Direct-coupled equipment components, such as

but not limited to blades, impellers, pulleys, and

sprockets, must be securely attached.

1. Place the machine on a hard, level surface.

2. Slide the stop/start switch (located on the hand grip)

to the Start position.

3. Place the choke lever in the closed (Up) position (A,

Figure 21).

NOTE: Do Not close the choke when starting a warm

engine.

4. Hold the machine firmly and pull the starter cord

slowly until resistance is felt. Then pull rapidly until

the engine starts.

5. After the engine has warmed up, move the choke

lever to the open (Down) position.

Stopping the Engine

1. Release throttle lever.

2. Set Stop Switch to the OFF position.

Figure 21

A

Page 17

17

Attachmen DO NOT TrimYou MAY Tri

Trimmer / Nylon

Head

• Grass

• Lawn Edges

• Borders

• Pasture

• Shrubs

• Trees

Brushcutter Blade

• Grass

• Pasture

• Ferns, Weeds,

Light Growth

• Lawn Edges

• Shrubs

• Trees

WARNING A worn, damaged, or cracked blade

can break, and pieces of the damaged blade can

become dangerous projectiles. A dull blade is more

likely to snag and thrust (kickback). Inspect the

blade regularly, and do not operate the trimmer with

a dull, damaged, or worn blade.

Figure 22

OPERATION

Trimmer Operation

Operating Position

Hold the trimmer firmly with both hands, with your

fingers and thumbs encircling the handles (Figure 22).

This will help keep the trimmer under control at all

times.

• Keep fi rm footing and balance.

• Do not overreach.

• Keep the cutting attachment below waist level.

• Keep all parts of your body away from the rotating

cutting attachment and hot surfaces.

Using a Nylon Trimmer-Line Head

Refer to the chart on this page for appropriate linecutting applications.

Line must be released with the trimmer-line head

spinning rapidly.

1. Hold the rotating cutting head horizontal to the

ground.

2. With the engine running at full speed, tap the

cutting-line head on hard, bare ground. Do not tap

the cutting-line head on pavement or concrete.

3. Each tap releases about two inches of line.

4. The blade on the deflector trims surplus line to correct

length. Avoid tapping the head more than once.

NOTE: Line feed will only operate if both lines still have

a minimum length of 1” (2.5 cm).

Using Brushcutter Blade

Refer to the chart on this page for appropriate blade

applications.

The blade supplied with the trimmer has a protective

cover surrounding the edge of the blade. For your

safety, and to protect the blade, the cover should be

installed whenever the trimmer is not in use or when

installing the blade.

Be sure to remove the blade cover before starting the

engine, or the blade cover may fly off at high speed.

Thrown Debris

The trimmer/brushcutter will throw debris in the direction of blade movement at the point of contact.

The cutting line head or blade rotate counterclockwise,

as viewed from the operator’s position.

• Tilting the cutting head to the right will throw debris

away from you.

• Tilting the cutting head to the left will throw debris

towards you.

• If the cutting head is held parallel to the ground,

debris will scatter in all directions, and there will be

greater friction which will wear out the cutting line or

blade sooner.

Page 18

18

Figure 23

OPERATION

Blade Thrust (Kickback)

WARNING Blade thrust (kickback) is the

sudden, forceful, and uncontrolled movement of a

blade-equipped trimmer that may occur if the blade

binds in the cut of if the blade strikes a solid object.

Blade thrust (kickback) throws the trimmer in the direction opposite blade rotation at the point of contact, and

the jolt received by the operator can result in further

loss of control (Figure 23).

• Replace or resharpen dull blades. Dull blades are more

likely to bind in the cut and cause blade thrust.

• Watch for hidden obstacles, such as rocks, stumps,

roots, etc., that could cause the blade to kickback if

struck. Blade thrust is more likely to occur in areas

where it is diffi cult to see what is being cut.

• Accelerate the engine to maximum speed before

starting the cut, and saw through with uniform pressure.

Trimming and Edging

• Use a nylon line for cutting against a hard surface.

• Work from an angle where debris that strikes the hard

surface will fl y away from you.

• Avoid contact with wires, wire fences, metal rods, etc.

Overlapping a wire will cause the nylon line to wrap

around the wire and break off.

Operating on Slopes

• Start on the low side of a slope, and work upward.

• Avoid steep slopes that would require holding the

cutting head above waist level.

• Avoid slippery slopes that might cause you to lose

your balance.

Page 19

19

MAINTENANCE

First 5 Hours

• Inspect equipment for damage

Every 8 Hours or Daily

• Clean debris from cutting head and engine

• Clean and inspect air filter*

Every 50 Hours or Annually *

•

Inspect cutting head assembly for damage or missing parts

• Replace engine air filter*

• Replace spark plug

•

Inspect muffler and spark arrester for debris and damage

• Clean cooling system*

•

Clean and inspect brushcutter blade or trimmer line

* Service more often under dirty or dusty conditions

To help you properly care for your trimmer, the following pages include a maintenance schedule, routine

inspection procedures, and simple maintenance procedures using basic hand tools.

Other service tasks that are more difficult or that

require special tools are best handled by your authorized service technician.

WARNING Improperly maintaining the trimmer,

or failure to correct a problem before operation, can

cause a malfunction in which you can be seriously

hurt or killed. Always follow the inspection and maintenance recommendations and schedules in this

manual.

WARNING Failure to properly follow

maintenance instructions and precautions can

cause you to be seriously hurt or killed and will void

the warranty. Always follow the procedures and

precautions in the manual.

WARNING

Unintentional sparking can result in fire or

electric shock.

Unintentional start-up can result in entangle-

ment, traumatic amputation, or laceration.

Fire hazard.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away

from the spark plug.

• Use only correct tools.

• Replacement parts must be the same and installed

in the same position as the original parts.

• STOP engine.

• Avoid serious burns. Allow all parts to cool before

working on machine.

Maintenance Schedule

Follow the hourly or calendar intervals, whichever

occurs first. More frequent service is required when

operating in adverse conditions noted below.

Page 20

20

WARNING Gasoline and its vapors are

extremely flammable and explosive.

Fire or explosion can cause severe burns or

death.

• Never start or run the engine with the air

cleaner assembly or the air filter removed.

Figure 25

Figure 24

B

0.7 mm

MAINTENANCE

Spark Plug Maintenance

Changing the spark plug will help the engine to start

easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug (A, Figure 24).

3. Check the gap with wire feeler gauge (B) and reset

to recommended gap if necessary (see Specifications).

4. Replace spark plug if electrodes are pitted or burned,

or the porcelain is cracked.

5. Install spark plug and tighten to 180 lb. in. (20 Nm).

Air Filter Maintenance

NOTICE: Do not use pressurized air or solvents to clean

the filter. Pressurized air can damage the filter and

solvents will dissolve the filter.

1. Remove air cleaner cover (A, Figure 25) and the filter

element (B).

2. Wash foam element in liquid detergent and water to

remove dirt.

3. Wrap foam element in a clean cloth and squeeze dry.

4. Saturate foam element with clean engine oil. Squeeze

to remove excess oil.

5. Reassemble air cleaner.

NOTICE: Make sure the air filter element and cover are

fitted correctly. Warranty coverage will be void if engine

is damaged due to incorrect installation of filter.

A

A

B

Page 21

21

MAINTENANCE

Spark Plug Maintenance

Inspect Trimmer Line Head

Ensure the nylon line is only sticking out of the metal

grommets on the side of the cutting head. If the line

has come off the spool, proceed to Installing Trimmer

Line in the Assembly Section to replace the trimmer

line.

Examine the entire head area, including the debris

shield, and clear or clean it free from dirt, debris, loose

string, wire, or any other foreign material.

Inspect Brushcutter Blade

WARNING A worn, damaged, or cracked

blade can break, and pieces of the damaged blade

can become dangerous projectiles. A dull blade is

more likely to snag and thrust (kickback). Inspect the

blade regularly, and do not operate the trimmer with

a dull, damaged, or worn blade.

Before each use, check the blade for wear and damage,

and check the tightness of the securing nut. Examine the

entire head area, including the debris shield, and clear or

clean it free from dirt, debris, loose string, wire, or any

other foreign material.

Any blade that is worn out, bent, cracked, chipped, or

damaged in any other way, must be replaced.

Page 22

22

Protect Fuel System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel

system or on essential carburetor parts. To keep fuel

fresh, use a quality fuel stabilizer.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throughout

the fuel system. The engine and fuel can then be stored

up to 3 months.

If gasoline in the engine has not been treated with a fuel

stabilizer , it must be drained into an approved container.

The use of a fuel stabilizer in the storage container is

recommended to maintain freshness.

Clean the Unit

Wipe clean the handle, cutter head, guard, and engine

parts with a damp cloth. To avoid fuel contamination or

equipment damage, Do Not apply water or other liquids

directly to the unit.

Storage Safety

Allow the engine to cool before storage. Store the equipment in a clean, dry environment to avoid excessive

dust, dirt, or moisture. Secure the unit to prevent tipping

or falling during storage.

Store the fuel container out of the reach of children in a

well-ventilated, unoccupied building.

Do not store equipment or fuel container inside where

fumes may reach an open flame, spark, or pilot light

such as in a water heater, furnace, clothes dryer , or other

gas appliance.

STORAGE

WARNING Gasoline and its vapors are

extremely fl ammable and explosive.

Fire or explosion can cause severe burns or

death.

When Storing Fuel or Equipment with Fuel in Tank

•

Store away from furnaces, stoves, water heaters

or other appliances that have pilot lights or other

ignition sources because they can ignite fuel

vapors.

Page 23

23

REMEDY

LOOK FORPROBLEM

Engine will not start

Electrode is wet or foule Clean or replace the spark plug

Cracked insulator Replace spark plug

STOP SWITCH in OFF position

Turn switch to ON position

Incorrect spark plug gap Adjust gap to value listed in Specifications

Engine flooded Crank engine with choke open to clear excess fuel

Use of incorrect or stale fuel Drain and replace with correct fuel/oil mixture

No fuel in tank Refuel

Insufficient Power

Clogged air filter Clean air filter

Machine is overworked Operate properly - do not overload

Debris build-up on cutting head

Remove debris from cutting head

Engine overheating Remove debris from engine

Use of incorrect or stale fuel Drain and replace with correct fuel/oil mixture

Engine Stops during

Operation

Switch is bumped Place switch in ON position

Fuel tank empty Refuel

Engine is Difficult to

Stop

Stop wire disconnected from

switch

Attach stop wire to switch

Unit Main Body

Loose cutting head Tighten cutting head securely

Broken clutch spring, bent

main shaft

See authorized dealer

Worn shaft bearings See authorized dealer

Loose gearhead See authorized dealer

Blade bent or damaged Replace blade

TROUBLESHOOTING

Page 24

24

NOTES

Page 25

25

BRIGGS & STRATTON POWER PRODUCTS GROUP, L.L.C. OWNER WARRANTY POLICY

LIMITED WARRANTY

ABOUT YOUR WARRANTY

WARRANTY PERIOD

CONSUMER USE - 180 DAYS

COMMERCIAL USE - 90 DAYS

WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part (s) of the equipment that is defective in material or workmanship or both. This warranty is effective for the time periods and

subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer using

our dealer locator at www.BriggsandStratton.com or www.Murray.com.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a

particular purpose, are limited to one year from purchase or to the extent permitted by law. Liability for incidental

or consequential damages are excluded to the extent exclusion is permitted by law.

Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or

countries do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other

rights which vary from state to state or country to country.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated above. “Consumer use” means personal residential household use by a retail

consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental

purposes. Once equipment has experienced commercial use, it shall thereafter be considered as commercial use

for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL

PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OF

THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate.

This warranty only covers defects in materials or workmanship. It does not cover damage caused by improper use

or abuse, improper maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using

the product in a way not described in the Operator’s Manual or using the product after it has been damaged will void

your warranty. Warranty is not allowed if the serial number on the product has been removed or the product has

been altered or modified in any way, or if the product has evidence of abuse such as impact damage, or

water/chemical corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules

provided in the Operator’s Manual, and serviced or repaired using genuine Briggs & Stratton parts. Damage caused

by lack of maintenance or use of non-original parts is not covered by warranty.

Normal Wear - Like all mechanical devices, your unit is subject to wear even when properly maintained. This

warranty does not cover repairs when normal use has exhausted the life of a part or the equipment. Maintenance

and wear items such as filters, belts, cutting blades, and brake pads (engine brake pads are covered) are not

covered by warranty due to wear characteristics alone, unless the cause is due to defects in material or workmanship.

Stale Fuel - In order to function correctly, this product requires fresh fuel that conforms to the criteria specified in

the Operator’s Manual. Damage caused by stale fuel (carburetor leaks, clogged fuel tubes, sticking valves, etc) is

not covered by warranty.

Page 26

26

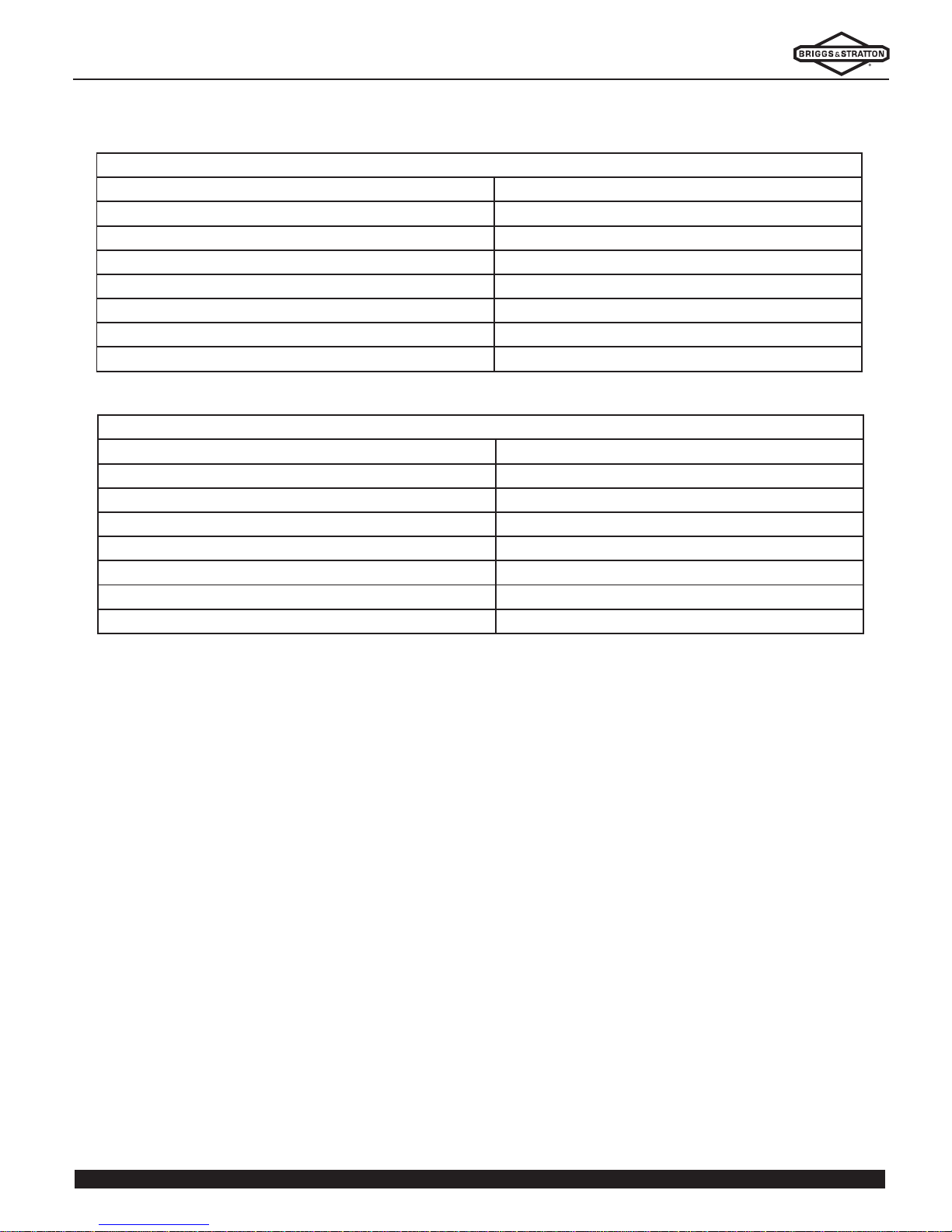

Model # 866032 (BP33-W)

Engine Displacement (cc)

Width of Cut (nylon)

Diameter of Nylon String

Width of Cut (blade)

Fuel Tank Capacity

Weight

paG gulP krapS

euqroT gulP krapS

32.6

30 cm

2.4 mm

41 cm

0.9 L

9.6 kg

).ni 30.0 - 20.0( mm 67.0 - 15.0

).ni .bl 081( mN 02

42.7

30 cm

2.4 mm

41 cm

0.9 L

10 kg

).ni

30.0 - 20.0( mm 67.0 - 15.0

).ni .bl 081( mN 02

Model # 866033 (BP43-W)

Engine Displacement (cc)

Width of Cut (nylon)

Diameter of Nylon String

Width of Cut (blade)

Fuel Tank Capacity

Weight

paG gulP krapS

euqroT gulP krapS

SPECIFICATIONS

Page 27

27

Loading...

Loading...