Briggs & Stratton 950 Series Advance Product Service Information

Not for Reproduction

ADVANCE PRODUCT SERVICE INFORMATION

APSI NO: 101

DATE: AUGUST 2014

SUBJECT: 950 SERIES™ UTILITY ENGINE

MODELS: 130G00 OHV HORIZONTAL SHAFT

This APSI provides basic servicing information in advance of the repair manual under development. Systems

testing, troubleshooting, and component removal and installation procedures are common with most other

single-cylinder horizontal-shaft OHV engines. See the Illustrated Parts List for service part numbers. The

specifications, part numbers, and procedures provided here are preliminary and subject to change.

B

A

MODEL IDENTIFICATION LOCATION

The Model-Type-Trim and Code numbers (A) are printed or etched into the edge of the cylinder base below

the fuel tank. The bar code serial number label (B) is attached to the side of the fuel tank.

Copyright © Briggs & Stratton Corporation Page 1 of 13

All language translations of this document are

derived from the original English source file.

Not for Reproduction

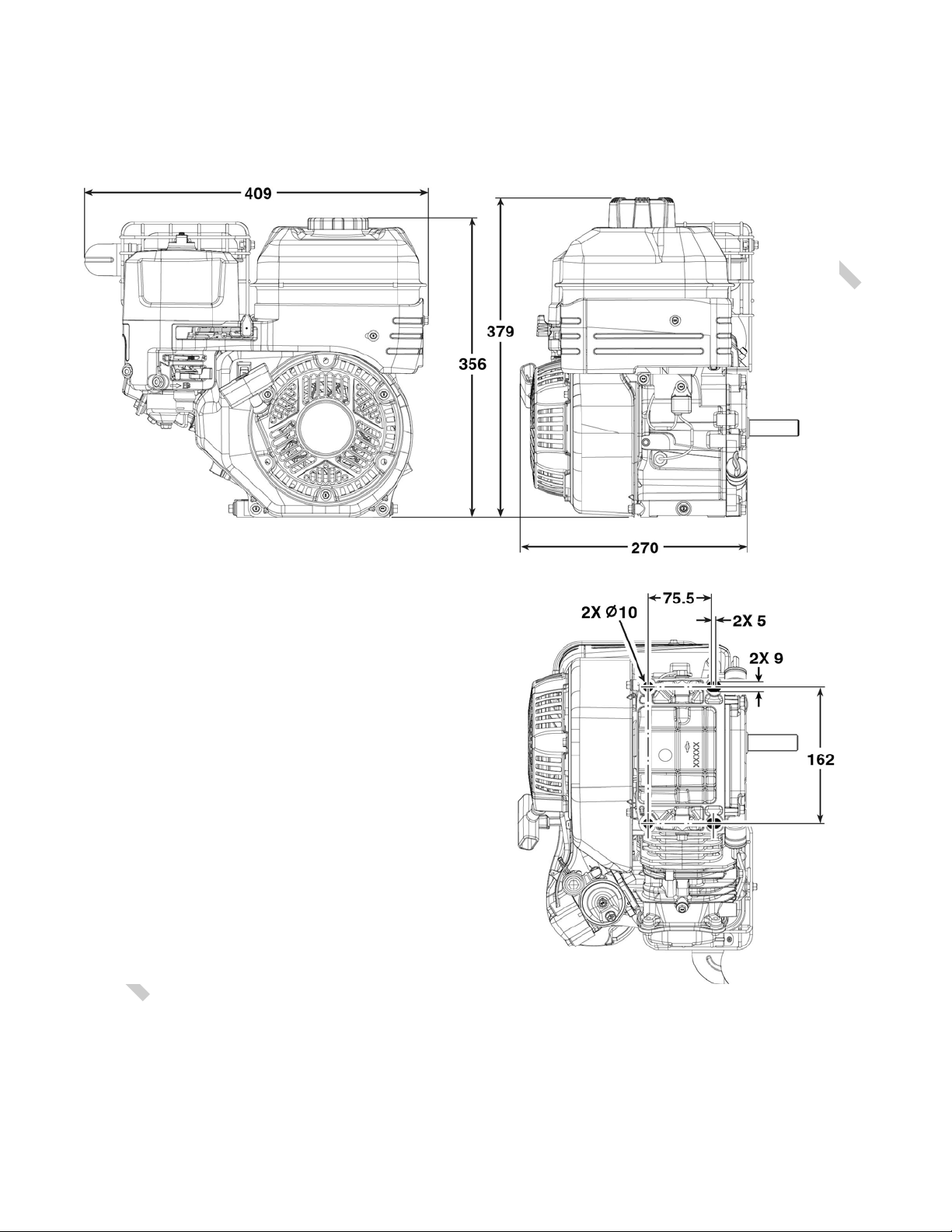

OVERALL ENGINE DIMENSIONS (Millimeters)

Page 2 of 13

Not for Reproduction

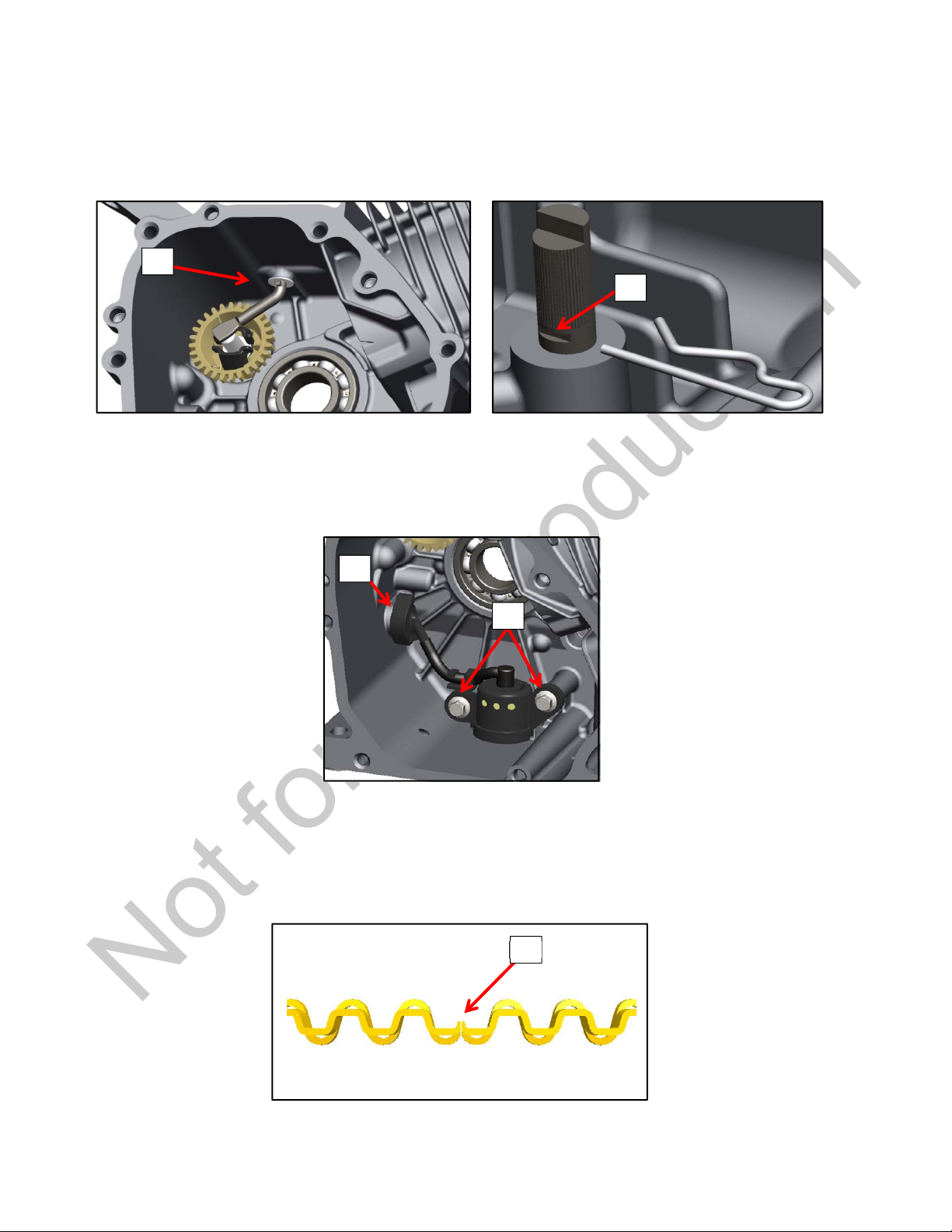

GOVERNOR SHAFT INSTALLATION

There is a washer (A) that must be fitted to the governor shaft before installation into the cylinder. Secure the

governor shaft from the outside with the retaining clip. The straight leg of the clip fits into the groove (B) of

the governor shaft.

A

B

OPTIONAL LOW-OIL SENSOR INSTALLATION

The low-oil sensor installs inside the cylinder with two screws (C). Tighten the screws to 60 lb-in (6.8 Nm).

Next, route the sensor harness (D) through the opening in the cylinder. Secure the harness from the outside

with the hex nut and tighten to 40 lb-in (4.5 Nm). Also see Low-Oil Module Installation.

D

PISTON ASSEMBLY

When installing the oil ring expander, ensure that the ends at the expander gap (E) point up toward the piston

crown. The lettering on the center and top piston rings must also face up toward the crown. When installi ng

the piston assembly into the bore, the notch in the piston (F) and the oil dipper on the connecting rod (G) will

face down toward the push rods.

C

E

Page 3 of 13

Not for Reproduction

F

G

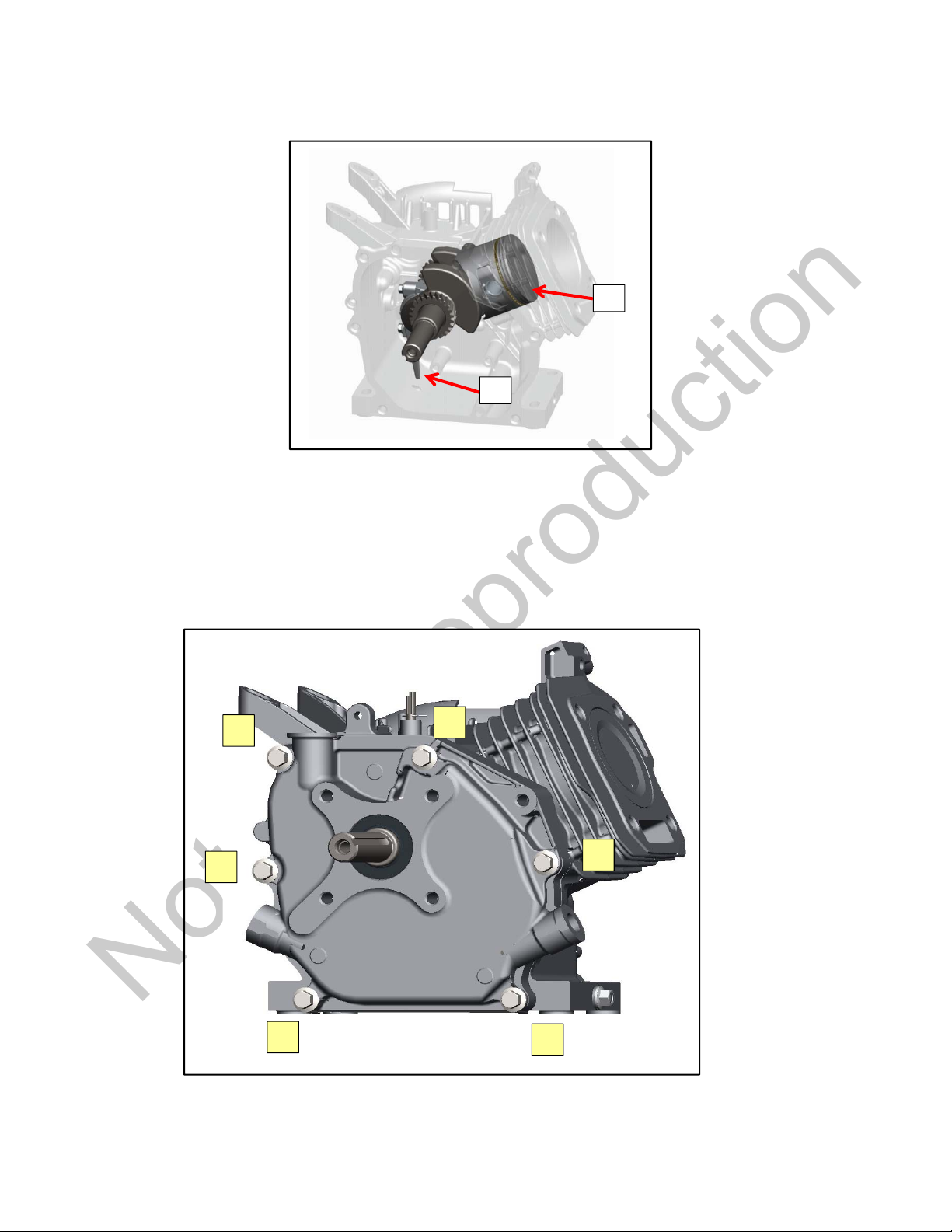

CRANKCASE COVER INSTALLATION

1) Make sure the mating surfaces on the cover and the cylinder are clean and dry.

2) Install the new gasket over the dowel pins, then carefully install the cover over the crankshaft and

press into place.

3) Start the cover screws by hand and then step-torque in the sequence shown below to 220 lb-in (24.9

Nm).

4

2

6

1

5

3

Page 4 of 13

Loading...

Loading...