Briggs & Stratton 276535, 84000 Series Repair Manual

2-Cycle Snow Engine

2-CYCLE SNOW ENGINE

REPAIR MANUAL

MANUAL NUMBER: 276535

0

2-Cycle Snow Engine

SAFETY INFORMATION

The Briggs & Stratton engine is made of the finest

material in a state-of-the-art manufacturing facility.

Please understand that Briggs & Stratton sells engines

to original equipment manufacturers. It also sells to

others in the distribution chain who may sell to the

ultimate consumer, an equipment manufact urer, anot her

distributor or a dealer. As a result, Briggs & Stratton does

not necessarily know the application on which the engin e

will be placed. For that reason, carefully read and

understand the operating instructions of the equipment

before you repair or operate.

You should also understand that there are equipment

applications for which Briggs & Stratton does not

approve the use of its engines. Briggs & Stratton e ngines

are not to be used on vehicles with less than 4 wheels.

This includes motor bikes, aircraft products and all

terrain vehicles. Moreover, Briggs & Stratton does not

approve of its engines being used in competitive events.

FOR THAT REASON, BRIGGS & STRATTON

ENGINES ARE NOT AUTHORIZED FOR ANY OF

THESE APPLICATIONS. Failure to follow this warning

could result in death, serious injury (including paralysis)

or property damage.

• Prior to work, read and understand the section(s) of

this manual that pertain to the job. Follow all safety

warnings.

• Wear suitable eye protection.

• Prevent accidental starting by removing spark plug

wire from spark plug when servicing engine or

equipment. Disconnect negative battery terminal if

equipped with electric starting system.

• Periodically clean engine . K eep go v ernor parts free

of dirt, grass and other debris which can affect

engine speed.

• Always use fresh gasoline. Stale fuel can gum

carburetor and cause leakage.

• Check fuel lines and fittings frequently for cracks or

leaks and replace if necessary.

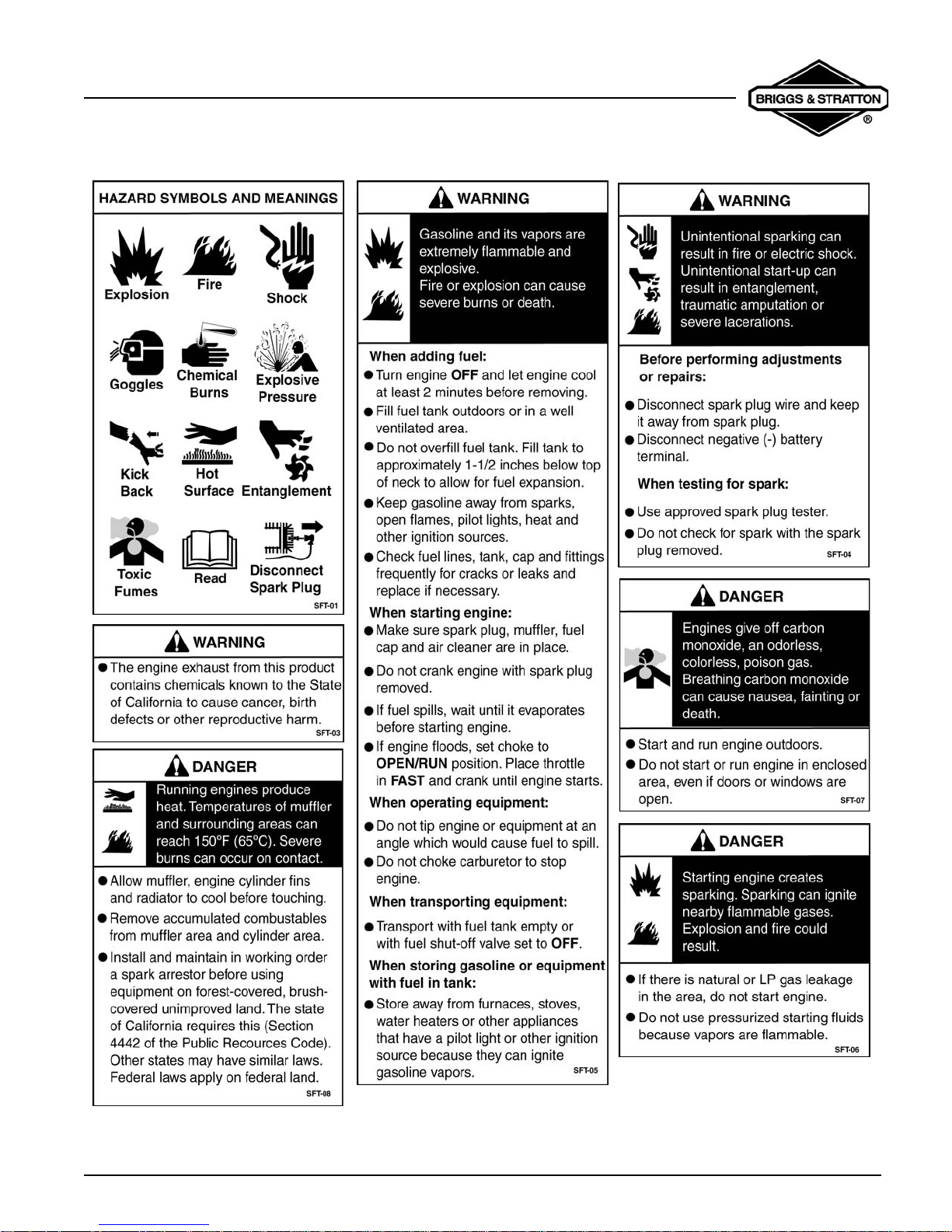

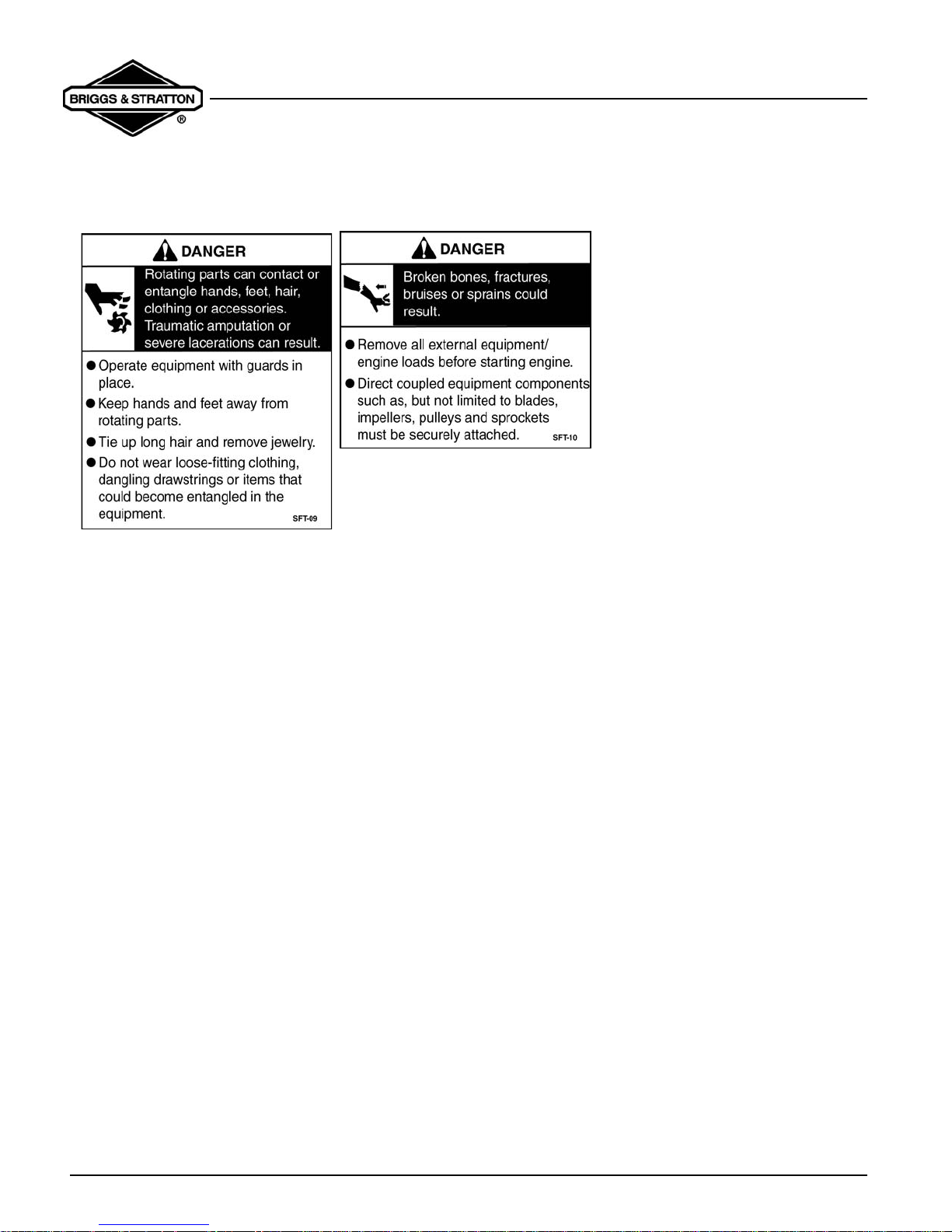

IN THE INTEREST OF SAFETY

The safety alert symbol ( ) is used to identify safety

information about hazards that can result in personal

injury.

A signal word (

with the alert symbol to indicate the likelihood and the

potential severity of injury. In addition, a hazard symbol

may be used to represent the type of hazard.

DANGER indicates a hazard which, if not

avoided,

WARNING indicates a hazard which, if not

avoided,

CAUTION indicates a hazard which, if not

avoided, might result in minor or moderate injury.

CAUTION: When this signal word is used without the

alert symbol, it indicates a situation that could result in

damage to the engine.

DANGER, WARNING, or CAUTION) is used

will result in death or serious injury.

could result in death or serious injury.

i

2-Cycle Snow Engine

ii

2-Cycle Snow Engine

iii

2-Cycle Snow Engine

Table of Contents

2-CYCLE SNOW ENGINE

REPAIR MANUAL .....................................0

SAFETY INFORMATION ...........................i

In The Interest Of Safety ...............................i

SECTION 1

GENERAL INFORMATION .......................1

TWO-CYCLE ENGINE THEORY .................1

IGNITION COIL OPERATION ......................2

REWIND STARTER .....................................3

ELECTRIC START (OPTIONAL) .................3

RECOMMENDED MAINTENANCE

SCHEDULE ..................................................3

25 Hours ............................... ... ... .... ... ..............3

50 Hours ............................... ... ... .... ... ..............3

REPLACE SPARK PLUG .............................4

CLEANING THE EXHAUST SYSTEM .........4

SECTION 2

TROUBLESHOOTING ..............................5

GENERAL TROUBLESHOOTING

INFORMATION ............................................5

Systematic Check ............................................5

Check Ignition ................ .... ... ........................... 5

Engine Misfires ................................................ 5

Check Carburetion .......................................... . 6

Check Compression ....................................... . 6

EQUIPMENT AFFECTING ENGINE

OPERATION ................................................6

Hard Starting, Kickback, or Will Not Start ........ 7

Vibration ............................. ............................. .7

Power Loss .................... .... ... ........................... 7

STARTER MOTOR FAILS TO TURN .........7

Power not reaching product. ............................ 7

Starter switch malfunction. ............................... 7

Engine has seized. ..........................................7

Starter motor has failed. ..................................7

SECTION 3

ENGINE DISASSEMBLY ..........................9

REMOVE SHROUD .....................................9

REMOVE CARBURETOR ............................9

REMOVE FLYWHEEL ................................10

REMOVE OPTIONAL 120V STARTER ......10

REMOVE MUFFLER ..................................10

REMOVE IGNITION MODULE ...................11

ENGINE DISASSEMBLY ...........................11

SECTION 4

ENGINE OVERHAUL ..............................13

ENGINE INSPECTION & REPAIR .............13

Flywheel and Key ............................. .... ..........13

Bearings .........................................................13

Crankcase ......................................................13

Check Cylinder Bore .. ... ... .... ... ... .................... 1 3

Piston And Rings .................. ... ... ... ... ..............14

Piston Pin (Wrist Pin) And Connecting Rod .....4

CARBURETOR DISASSEMBLY ................15

CARBURETOR CLEANING &

INSPECTION ..............................................17

CARBURETOR ASSEMBLY ......................17

REWIND STARTER Replacement .............20

Rope Replacement .. ... ... ... .... ... .......................20

(OPTIONAL) ELECTRIC STARTER

REPLACEMENT .........................................20

SECTION 5

ENGINE ASSEMBLY ..............................21

ASSEMBLE PISTON AND

CONNECTING ROD ..................................21

INSTALL PISTON RINGS ..........................21

Engine Model 84130 & 84230 ........................21

Engine Model 84330 .....................................21

iv

INSTALL PISTON AND

CONNECTING ROD ..................................22

INSTALL CONNECTING ROD BEARINGS 23

INSTALL CRANKSHAFT AND

CONNECTING ROD ..................................23

INSTALL OIL SEALS ..................................24

INSTALL CRANKCASE COVER ................25

INSTALL CYLINDER HEAD .......................25

INSTALL IGNITION COIL AND

FLYWHEEL ................................................25

INSTALL AIR VANE AND GOVERNOR .....26

INSTALL INTAKE MANIFOLD AND

CARBURETOR ..........................................27

CHECK GOVERNOR OPERATION ...........27

INSTALL MUFFLER ...................................28

INSTALL BLOWER HOUSING ...................28

2-Cycle Snow Engine

Table of Contents

SECTION 6

FINAL ADJUSTMENTS &

SPECIFICATIONS ..................................29

GOVERNOR ADJUSTMENTS ...................29

SPECIFICATIONS ......................................30

COMMON SPECIFICATIONS ....................30

STANDARD AND REJECT DIMENSIONS 31

v

2-Cycle Snow Engine

Section 1 - General Information

SECTION 1

GENERAL INFORMATION

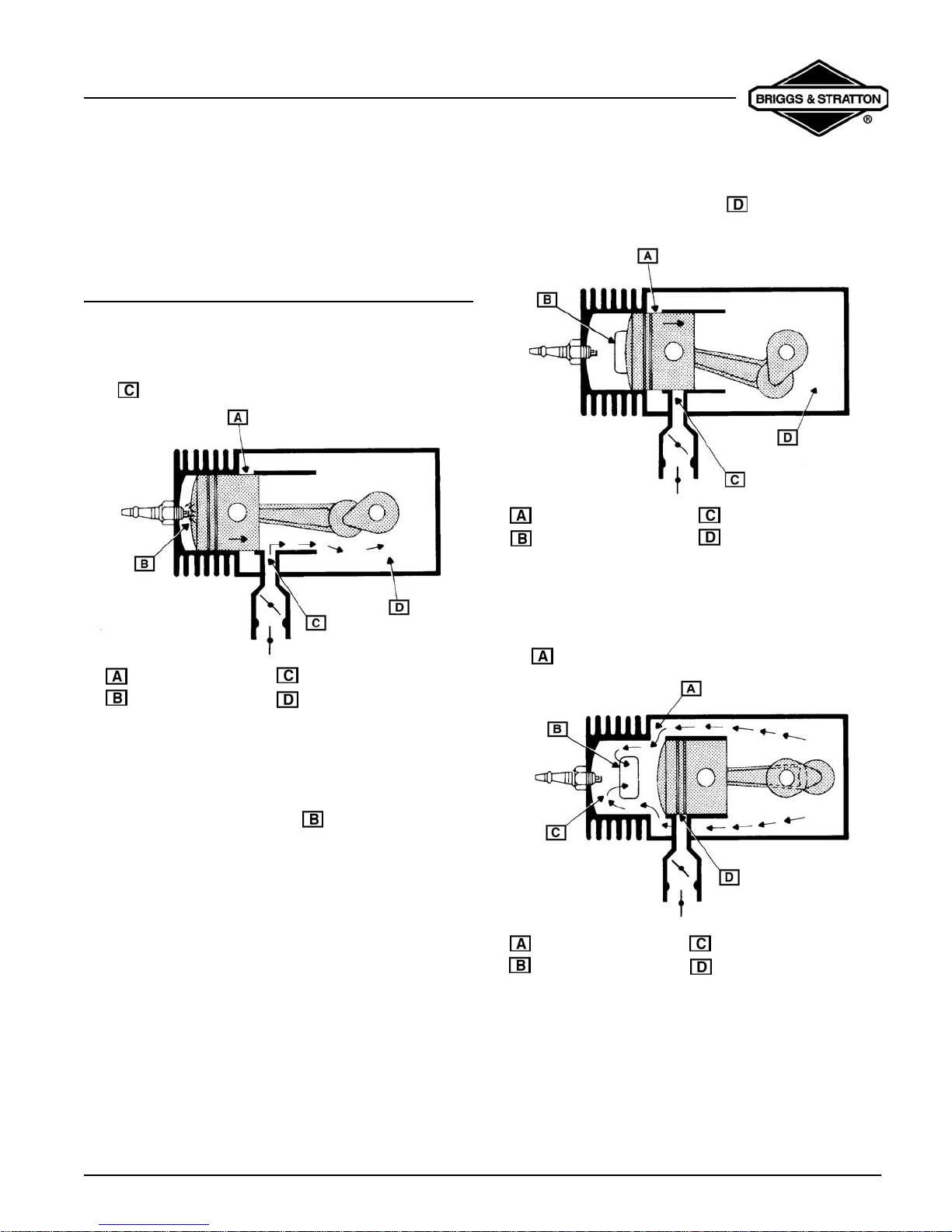

TWO-CYCLE ENGINE THEORY

In a piston-ported engine, the fuel mixture enters the

crankcase through a port that comes directly from the

carburetor (commonly referred to as a “third port”), See

item figure 1.

Intake Ports Closed

Ignition

Third Port Open

Partial Vacuum

compresses the fuel mixture (Item Figure 2) that is on

the bottom side of the piston in the crankcase.

Intake Ports Closed

Exhaust Port Opening

Third Port Closed

Pressure Building Up

Fig. 2

Near the bottom of its travel, the piston uncovers the

pressure transfer port and allows this compressed fuel/

air mixture to expand into the combustion chamber

(Item Figure 3).

Fig. 1

At about 28° before top-dead-center (BTDC), the spark

plug ignites and forces the piston away from the spark

plug. As the piston moves away from the spark plug, it

exposes the exhaust port (Item Figure 2) and the

expanding exhaust gases escape. As the piston

continues to move away from the spark plug, it

Intake Ports Open

Exhaust Port Open

Fresh Fuel Change

Third Port Closed

Fig. 3

Now the piston begins its travel in the opposite direction

and first closes off the transfer po rt and then the exh aust

Page 1

2-Cycle Snow Engine

Section 1 - General Information

port. As it continues, it compresses the fuel mixture in

the combustion chamber (Item Figure 4).

Intake Ports Closed

Compression

Third Port Closed

Partial Vacuum

Fig. 4

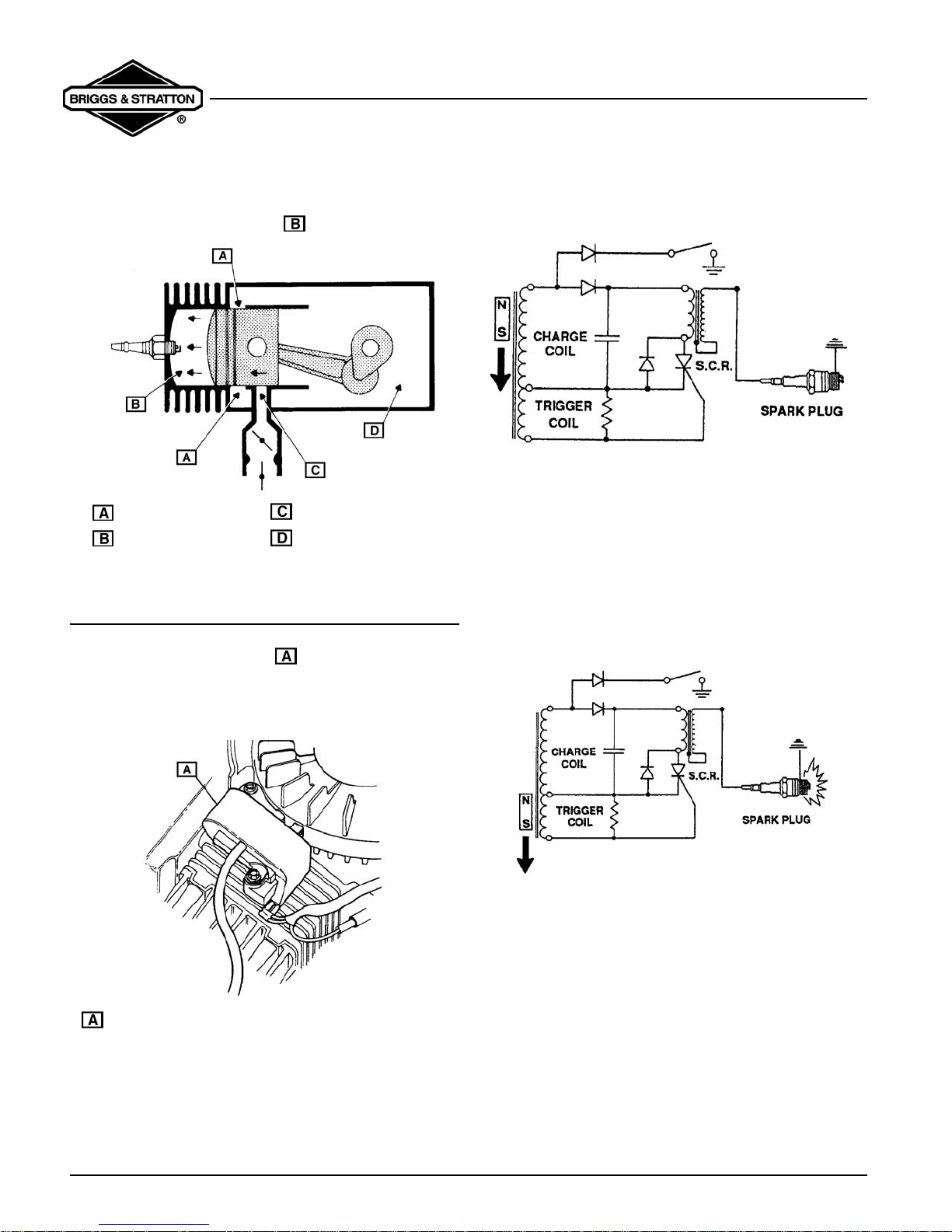

IGNITION COIL OPERATION

The ignition coil system (Item Figure 5) is

breakerless and contains electronic components that

replace mechanical points and related accessories (such

as a breaker cam, spark advance assembly, etc.).

voltage is converted by a rectifier into a DC signal, which

is then stored in a capacitor (Figure 6).

Fig. 6

When the silicone-controlled rectifier (SCR) is triggered,

up to 200 volts DC, stored in the capacitor, travels to the

spark coil. Here it is stepped up to as much as 25,000

volts and is discharged across the electrodes of the

spark plug (Figure 7).

Ignition timing (when the SCR is triggered) is determined

by the flywheel magnet and the keyways in the flywheel

and crankshaft. Damage to any of these parts will affect

the ignition timing.

Ignition Coil Module

Fig. 5

As the flywheel magnet passes the ignition coil module,

an AC voltage is induced into the charge coil. This AC

Page 2

Fig. 7

2-Cycle Snow Engine

Section 1 - General Information

At slower speeds, the flywheel magnet induces a smaller

charge in the trigger coil. This action triggers the (SCR),

enabling easier starting in a “retarded firing position”

-about 5° before top dead center (BTDC). See f igure 8.

Pole Shoe

Flywheel Rotation

Crankshaft at 5° BTDC

Magnet

Starting Leg

Charging Leg

Pole Shoe

Fig. 8

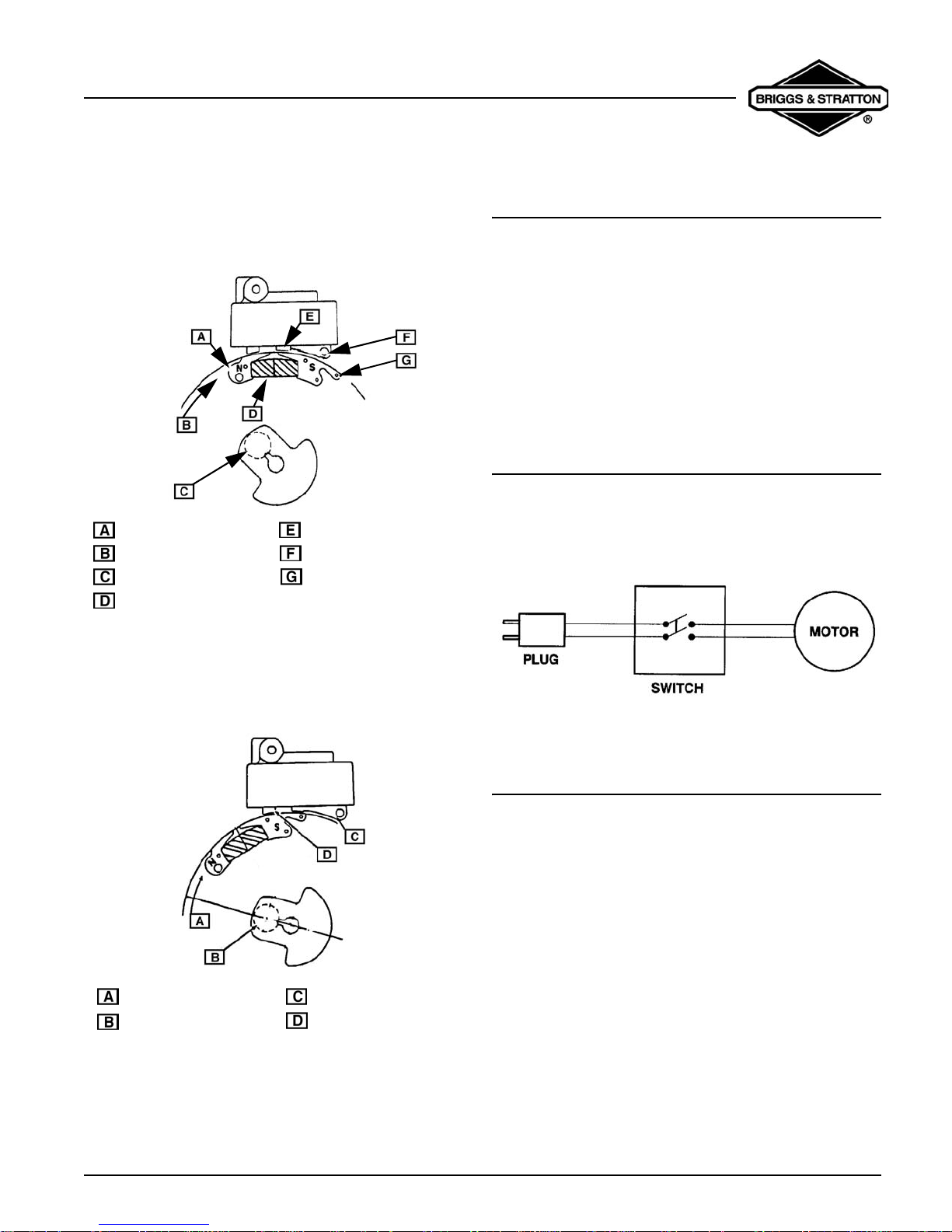

REWIND STARTER

The rewind starter operates through a retainer/friction

disc and two engagement dogs that extend from the

center of the rewind starter and engage the inside of the

starter hub on the flywheel. The engagement dogs

contact the starter hub when the rewind rope is pulled.

When the engine starts, the starter cup exceeds the

speed of the recoil starter causing the ramps on the

inside of the cup to contact the back side of the starter

dogs, pushing them inward. When the starter rope is

relaxed, spring tension retracts the dogs .

ELECTRIC START (OPTIONAL)

The electric start models use a 120VDC starting system.

When the starter is supplied with voltage, the helical

shaft spins to force the pinion gear out on the shaft and

engage the ring gear (Figure 10).

At faster speeds (about 800 RPM), the fl ywheel magnets

induce a large enough charge in the trigger coil to t rigger

the SCR in the “advanced firing position,” -about 28°

BTDC (Figure 9).

Flywheel Rotation

Crankshaft at 25° BTDC

Charging Leg

Running Leg 25°

Advanced

Fig. 9

Fig.10

RECOMMENDED MAINTENANCE

SCHEDULE

25 Hours

• Clean/replace or re-gap spark plu g

50 Hours

• Clean exhaust ports

• Check for fuel leakage

Page 3

2-Cycle Snow Engine

Section 1 - General Information

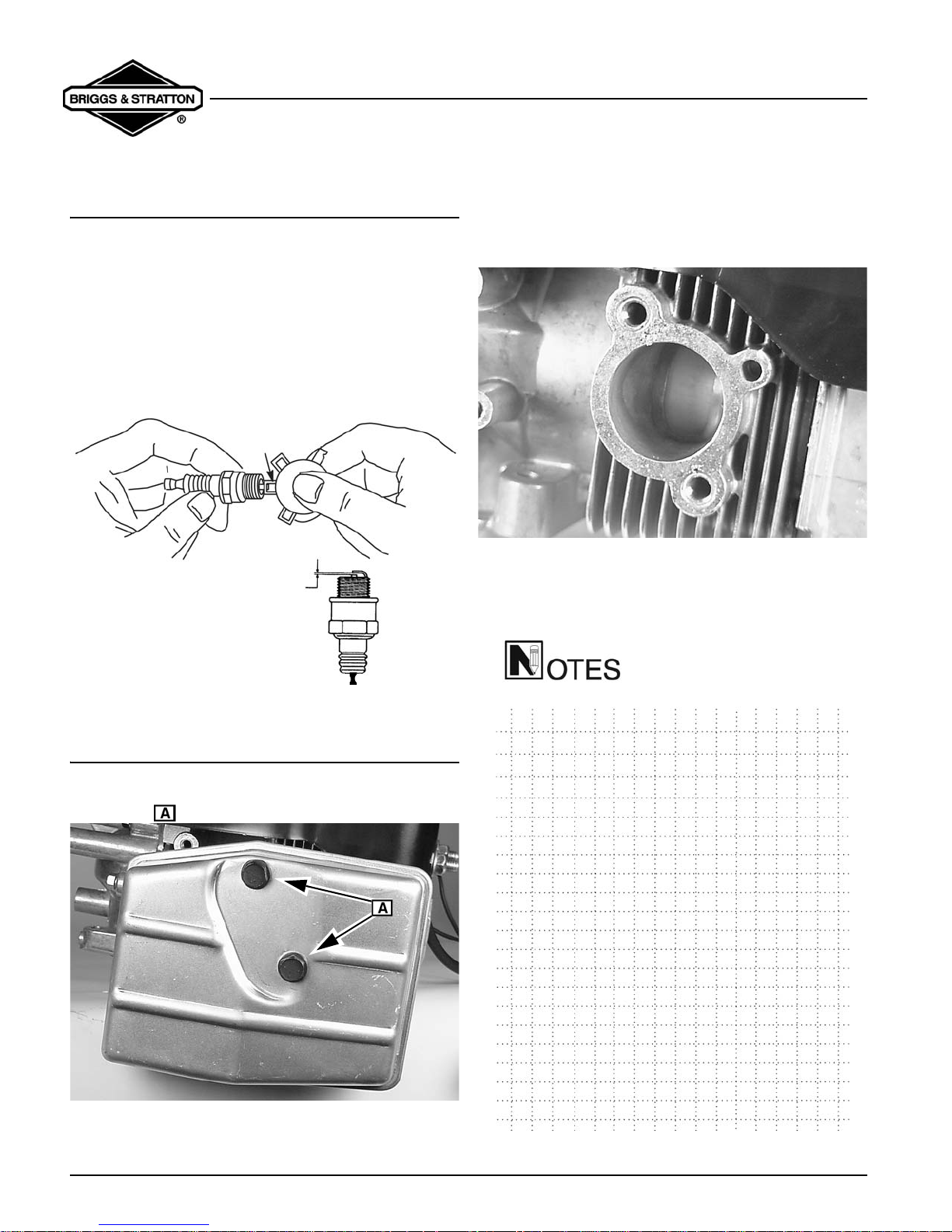

REPLACE SPARK PLUG

Replace spark plug every year. Replace spark plug if

electrode is burned away or if the porcelain is cracked. A

spark plug that is dirty, pitted, carbon covered or has

worn electrodes may cause hard starting and/or poor

operation. Clean plug with a wire brush. Do not sand

blast. Use

gap (Figure 11) at

plug to

NGK BPMR 4A or equivalent. Set spark plug

.028-.032 in. (.71-.81mm). Torque spark

150-200 lb-in. (17-23 Nm).

.28-.032 in.

(.71 - .81mm)

2. Inspect exhaust port (Figure 13). If cleaning is

necessary, rotate piston to cover exhaust port,

and scrape carbon from exhaust port area. Use

wood only to clean this area.

BST01-83

Fig. 13

3. Install the muffler and torque the bolts to 80 lb-in.

(9Nm)

.

Fig. 11

CLEANING THE EXHAUST SYSTEM

1. Remove the muffler (Figure 12) by removi ng the

bolts shown. Clean as needed.

BST01-82

Fig. 12

Page 4

2-Cycle Snow Engine

Section 2 - Troubleshooting

SECTION 2

TROUBLESHOOTING

GENERAL TROUBLESHOOTING

INFORMATION

Most complaints concerning engine operation can be

classified as one or a combination of the following:

• Will not start

• Hard starting

• Lack of power

• Runs rough

• Vibration

NOTE: What appears to be an engine

malfunction may be a fault of the powered

equipment rather than the engine. If equip ment is

suspect, see Equipment Affecting Engine

Operation.

Systematic Check

If the engine is hard starting or will not start and the

cause of malfunction is not readily apparent, perform a

systematic check in the following order:

• Ignition

• Carburetion

• Compression

This check-up, performed in a systematic manner, can

usually be done in a matter of minutes. It is the quickest

and surest method of determining the cause of failure.

observed at the tester gap, you may assume the ignition

system is functioning satisfactorily.

Fig. 14

NOTE: Engines equipped with capacitive

discharge ignition system will still display spark

at tester with a partially or fully sheared flywheel

key. A partially sheared flywheel key will affect

ignition timing and engine performanc e.

Check Ignition

With stop switch in

installed, attach a

lead and ground the other end of the tester as shown in

figure 14. Operate the starter. If a strong , steady spar k is

ON/RUN position and spark plug

#19368 ignition tester to the spark plug

If spark does not occur look for:

• Shorted stop switch

• Shorted ground wire

• Incorrect armature air gap

• Armature failure

Engine Misfires

If engine runs but misses during operatio n, a quick check

to determine if ignition is or is not at fault can be made by

installing Tool

and spark plug (Figure 15). A spark miss will be obvious

#19368 tester between the spark plug lead

Page 5

2-Cycle Snow Engine

Section 2 - Troubleshooting

when the engine is running. If the spark looks good in the

tester but the engine misses, try a new spark plug.

WE NEED TO FIND A TESTER!

Fig. 15

NOTE: A leak at the cylinder crankcase

mounting surfaces or oil seals can create a lean

fuel mixture resulting in low power or a miss.

Check for leakage at these areas.

Check Carburetion

Before checking carburetion, be sure the fuel tank has

an ample supply of fresh, clean gasoline. Make sure

throttle and choke controls are properly adjusted.

If engine cranks but will not start, remove and inspect the

spark plug.

If plug is wet, look for:

• Over choking

• Water in fuel

• Float needle valve stuck open

• Fouled spark plug

If plug is dry, look for:

• Leaking carburetor mounting gaskets.

• Gummy or dirty carburetor, fuel filter, fuel lines or

fuel tank

• Float needle valve stuck shut

• Plugged fuel cap vent

A simple check to determine if the fuel is getting to the

combustion chamber through the carburetor is to remove

the spark plug and pour a small quantity of fuel

(1 teaspoon or 5 mil.) through the spark plug hole.

Replace the plug. If the engine fire s a few times and t hen

stops, look for the same conditions as for a dry plug.

Check Compression

Connect spark plug wire to long terminal of tester, Tool

#19368 and ground tester to engine with alligator clip.

To check compression, remove the spark plug and install

compression tester (Figure 16).

Fig. 16

Crank the engine using the rewind starter. Continue

cranking until meter reading stabilizes. The meter

reading should be approximately

compression is below

• Loose cylinder head bolts

• Blown head gasket

• Worn bore and/or rings

• Broken connecting rod

80 PSI (5.5 bar), look for:

115 PSI. (7.9 bar). If

EQUIPMENT AFFECTING ENGINE

OPERATION

Frequently, what appears to be a problem with engine

operation, such as hard starting, vibration, etc., can be

caused by the equipment being powered rather than the

engine itself. Since many varied types of equipment are

powered by Briggs & Stratton engines, it is not possible

to list all of the various conditions that may exist. Listed

are the most common effects of equipment problems,

and what to look for as the most common cause.

Page 6

Loading...

Loading...