Briggs & Stratton 30469 User Manual

Portable Generator

Operator’s Manual

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

MILWAUKEE, WISCONSIN, U.S.A.

Manual No. 315363GS Revision -

This generator is rated in accordance with CSA (Canadian Standards

Association) standard C22.2 No. 100-04 (motors and generators).

Not for

Reproduction

2 BRIGGSandSTRATTON.COM

Copyright © 2011. Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, USA. All rights reserved.

BRIGGS & STRATTON POWER PRODUCTS is a registered

trademark of Briggs & Stratton Corporation

Milwaukee, WI, USA

Thank you for purchasing this quality-built Briggs & Stratton® generator. We are pleased that you’ve placed your confidence

in the Briggs & Stratton brand. When operated and maintained according to the instructions in this manual, your Briggs &

Stratton generator will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with generator products and

how to avoid them. This generator is designed and intended only for supplying electrical power for operating compatible

electrical lighting, appliances, tools and motor loads, and is not intended for any other purpose. It is important that you read

and understand these instructions thoroughly before attempting to start or operate this equipment. Save this original manual

for future reference.

This generator requires final assembly before use. Refer to the Assembly section of this manual for instructions on final

assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your generator. Consult your Yellow Pages. There

are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also contact

Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Generator

Model Number

Revision

Serial Number

Engine

Model Number

Type Number

Code Number

Date Purchased

Not for

Reproduction

3

Table of Contents

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpack Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Shipment Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install Wheel Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Add Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Add Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting to a Building’s Electrical System. . . . . . . . . . . . . . . . . . . . . . . . 9

Generator Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cord Sets and Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting Electrical Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stopping the Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Don’t Overload Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Generator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fuel Valve Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

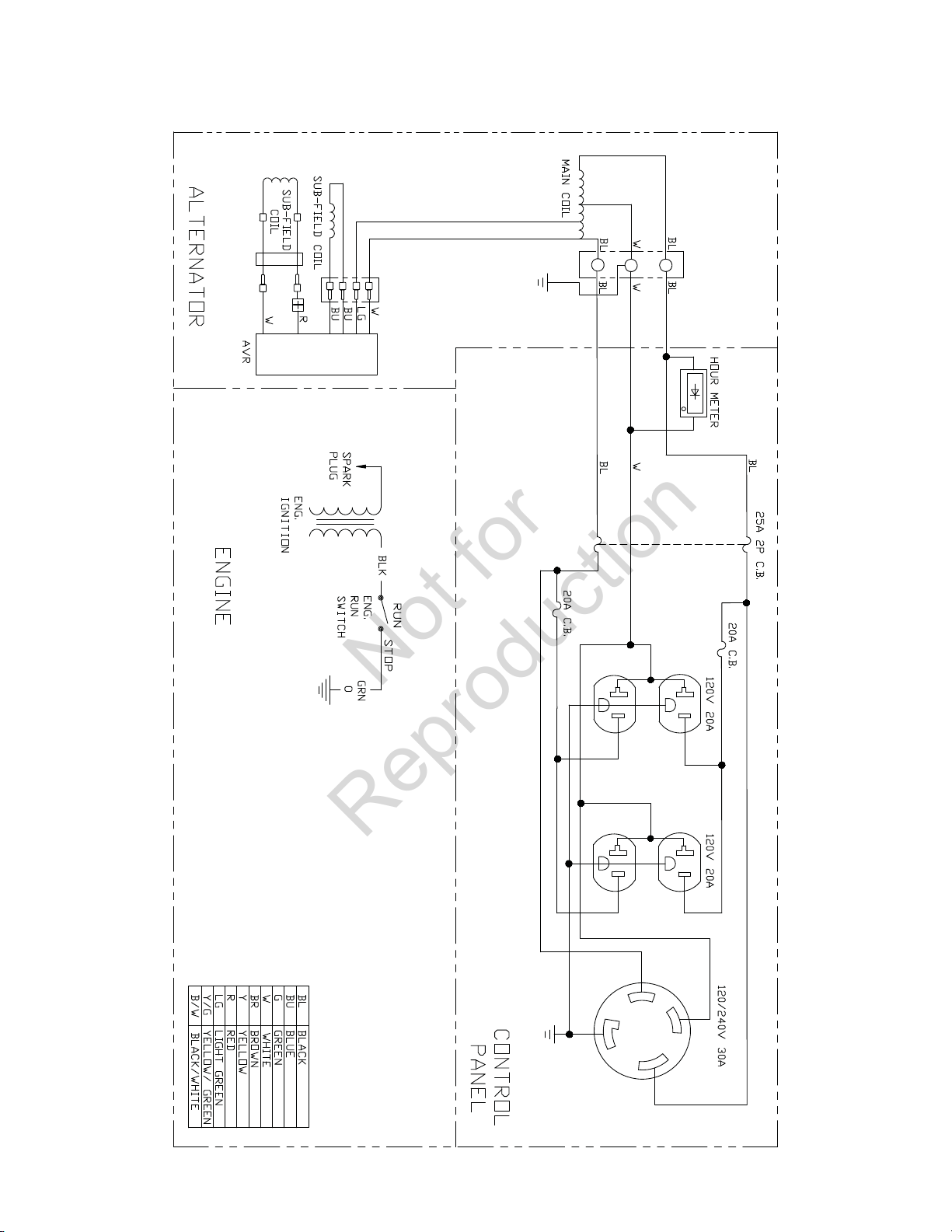

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Emissions Control System Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Generator Owner Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Product Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Common Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Not for

Reproduction

Operator Safety

Equipment Description

Read this manual carefully and become familiar

with your generator. Know its applications, its

limitations and any hazards involved.

The generator is an engine–driven, revolving field, alternating

current (AC) generator. It was designed to supply electrical

power for operating compatible electrical lighting,

appliances, tools and motor loads. The generator’s revolving

field is driven at about 3,600 rpm by a single-cylinder

engine.

NOTICE

Exceeding generators wattage/amperage capacity

could damage generator and/or electrical devices connected

to it.

• DO NOT exceed the generator’s wattage/amperage capacity. See

Don’t Overload Generator in the Operation section.

Every effort has been made to ensure that the information in

this manual is both accurate and current. However, the

manufacturer reserves the right to change, alter or otherwise

improve the generator and this documentation at any time

without prior notice.

The Emission Control System for this generator is warranted

for standards set by the Environmental Protection Agency

and the California Air Resources Board.

Important Safety Information

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and the tags and decals affixed to the unit are,

therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safe for you and others. You must also make sure that the

procedure, work method or operating technique that you

choose does not render the generator unsafe.

Safety Symbols and Meanings

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a

degree or level of hazard seriousness. A safety symbol may

be used to represent the type of hazard. The signal word

NOTICE is used to address practices not related to personal

injury.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE address practices not related to personal injury.

4 BRIGGSandSTRATTON.COM

Fire

Explosion

Toxic Fumes

Hot Surface

Moving Parts

Electrical Shock

Kickback

Flying Objects

Operator’s Manual

Not for

Reproduction

5

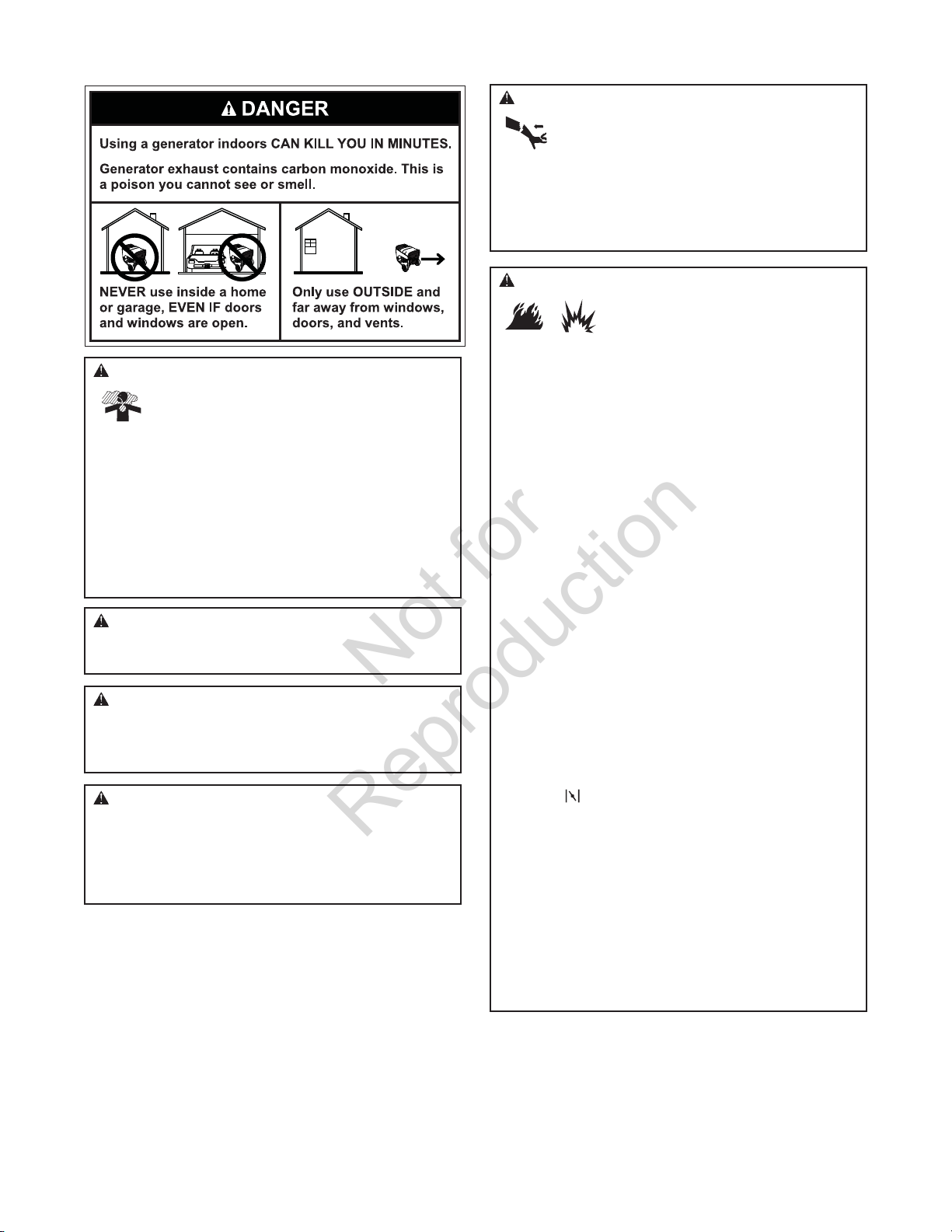

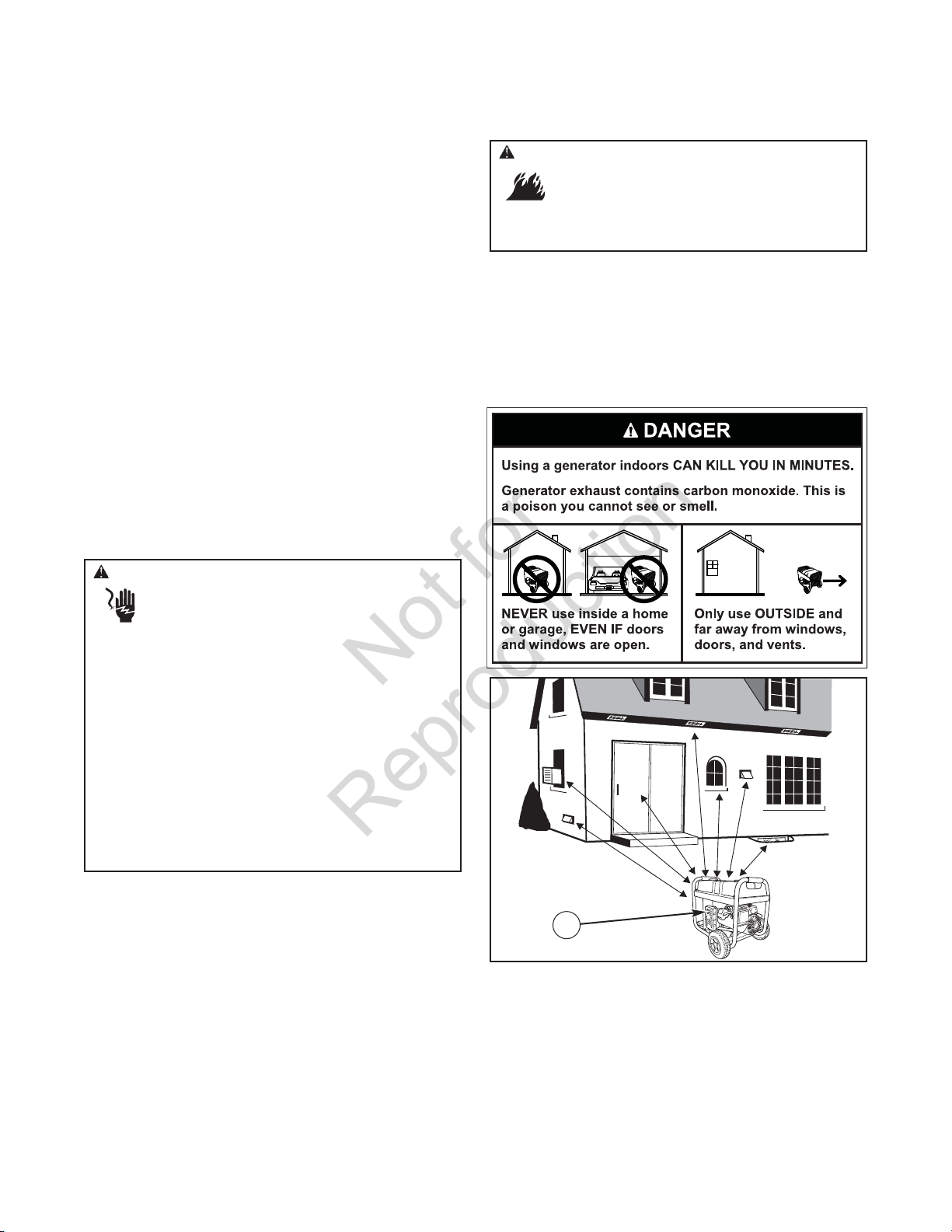

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

• Operate this product ONLY outdoors.

• Install a battery operated carbon monoxide alarm near the

bedrooms.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes, or other openings.

• DO NOT operate this product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure,

even if windows and doors are open.

WARNING The engine exhaust from this product

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

WARNING Certain components in this product and

related accessories contain chemicals known to the State

of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

WARNING

• This generator does not meet U. S. Coast Guard Regulation

33CFR-183 and should not be used on marine applications.

• Failure to use the appropriate U. S. Coast Guard approved

generator could result in death or serious injury and/or property

damage.

WARNING Fuel and its vapors are extremely

flammable and explosive which could

cause burns, fire or explosion resulting

in death, serious injury and/or property

damage.

WHEN ADDING OR DRAINING FUEL

• Turn generator engine OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• Check fuel lines, tank, cap and fittings frequently for cracks or

leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap, and air cleaner are in

place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT operate this product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure.

• DO NOT tip engine or equipment at angle which causes fuel to

spill.

• DO NOT stop engine by moving choke control to “Choke”

position

().

WHEN TRANSPORTING, MOVING OR REPAIRING EQUIPMENT

• Transport/move/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• DO NOT tip engine or equipment at angle which causes fuel to

spill.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers, or other appliances that have pilot light or other ignition

source because they could ignite fuel vapors.

WARNING Starter cord kickback (rapid retraction) will

pull hand and arm toward engine faster than you

can let go which could cause broken bones,

fractures, bruises, or sprains resulting in

serious injury.

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• NEVER start or stop engine with electrical devices plugged in

and turned on.

Not for

Reproduction

NOTICE

Exceeding generators wattage/amperage capacity

could damage generator and/or electrical devices connected

to it.

• DO NOT exceed the generator’s wattage/amperage capacity. See

Don’t Overload Generator in the Operation section.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator before

stopping generator.

NOTICE

Improper treatment of generator could damage it

and shorten its life.

• Use generator only for intended uses.

• If you have questions about intended use, ask dealer or contact

local service center.

• Operate generator only on level surfaces.

• DO NOT expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• DO NOT insert any objects through cooling slots.

• If connected devices overheat, turn them off and disconnect them

from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

6 BRIGGSandSTRATTON.COM

WARNING

Generator voltage could cause electrical

shock or burn resulting in death or serious

injury.

• Use approved transfer equipment to prevent backfeed by

isolating generator from electric utility workers.

• When using generator for backup power, notify utility company.

• Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing in

water, while barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or

service generator.

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of

generator including overhead.

• It is a violation of California Public Resource Code, Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may have similar laws.

Contact the original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must be the same and installed in the same

position as the original parts.

WARNING Unintentional sparking could cause fire or

electric shock resulting in death or

serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

WARNING Starter and other rotating parts could

entangle hands, hair, clothing, or accessories

resulting in serious injury.

• NEVER operate generator without protective housing or covers.

• DO NOT wear loose clothing, jewelry or anything that could be

caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

CAUTION Excessively high operating speeds could

result in minor injury and/or generator damage.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other parts to

increase engine speed. Generator supplies correct rated

frequency and voltage when running at governed speed.

• DO NOT modify generator in any way.

Not for

Reproduction

Assembly

Your generator requires some assembly and is ready for use

after it has been properly serviced with the recommended oil

and fuel.

If you have any problems with the assembly of your generator,

please call the generator helpline at 1-800-743-4115. If calling

for assistance, please have the model, revision, and serial

number from the identification label available. See Generator

Controls and Features for identification label location.

Unpack Generator

1. Set the carton on a rigid, flat surface.

2. Remove everything from carton except generator.

3. Open carton completely by cutting each corner from

top to bottom.

4. Leave generator on carton to install wheel kit.

Shipment Contents

The generator is supplied with:

• Engine oil bottle

• Operator’s manual

• Wheel kit

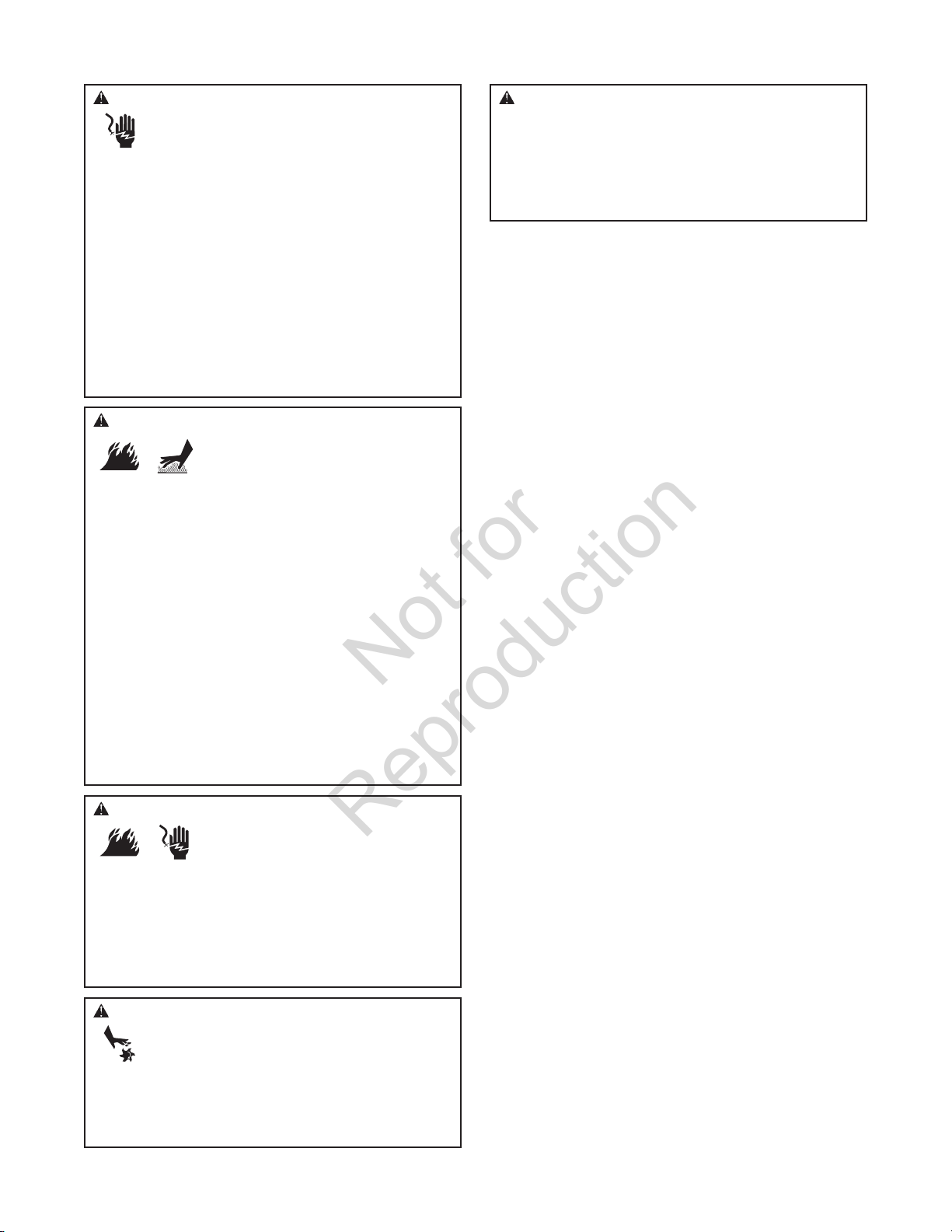

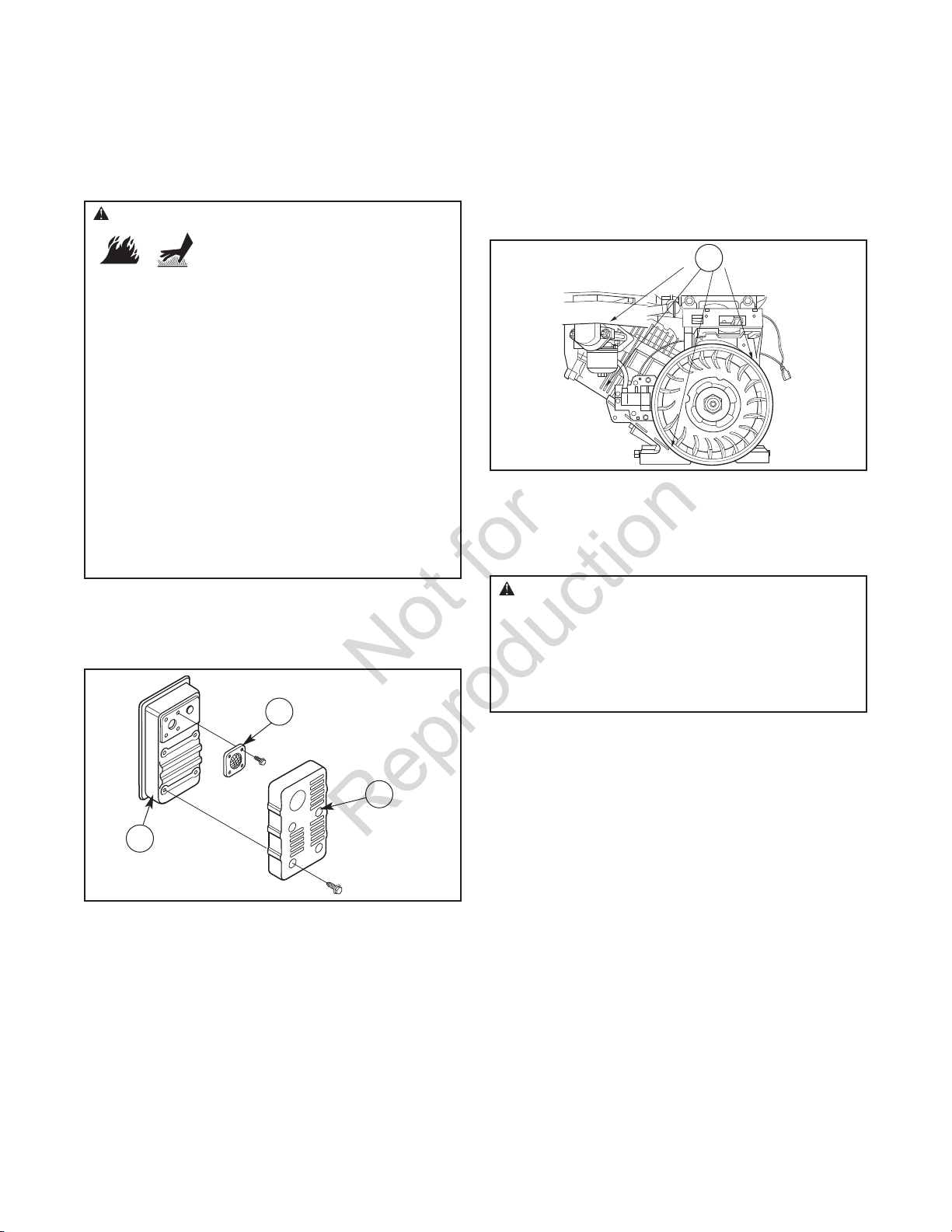

Install Wheel Kit

NOTICE Wheel kit is not intended for over-the-road use.

You will need the following tools to install these

components:

• 13 mm and 18 mm wrench

• Socket wrench with 10 mm and 18 mm sockets

Install the wheel kit as follows:

1. Tip generator so that engine side is down.

2. Slide axle stud (A) through mounting bracket with

threaded end facing out.

3. Insert retaining pin (B) through hole on axle stud.

4. Slide a wheel (C) over axle stud.

NOTICE Be sure to install wheel with raised hub inboard.

5. Attach wheel to axle stud with a washer (D), lock

washer (E) and nut (F). Tighten with a 18 mm socket

wrench and 18 mm wrench.

6. Place hub cap (G) into center of wheel and push until it

snaps into place.

7. Repeat steps 2 through 6 to secure second wheel.

8. Line up holes in support leg (H) with holes in generator

frame.

9. Attach support leg using 4 capscrews (J) and 4 hex

nuts (K). Tighten with a 10 mm socket wrench and

13 mm wrench.

10. Return generator to normal operating position (resting

on wheels).

7

B

G

C

D

A

E

F

K

J

H

Not for

Reproduction

Add Engine Oil

1. Place generator on a flat, level surface.

2. Clean area around oil fill and remove yellow oil fill cap.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE

Improper treatment of generator could damage it

and shorten its life.

• DO NOT attempt to crank or start the engine before it has been

properly serviced with the recommended oil. This could result in

an engine failure.

4. Replace oil fill cap and fully tighten.

Add Fuel

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). For high

altitude use, see High Altitude.

• Gasoline with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether) is acceptable.

NOTICE Avoid generator damage.

Failure to follow Operator’s Manual for fuel

recommendations voids warranty.

• DO NOT use unapproved gasoline such as E85.

• DO NOT mix oil in gasoline.

• DO NOT modify engine to run on alternate fuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizer when adding fuel. See Storage. All fuel is not the

same. If you experience starting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operate on gasoline. The

emission control system for this engine is EM (Engine

Modifications).

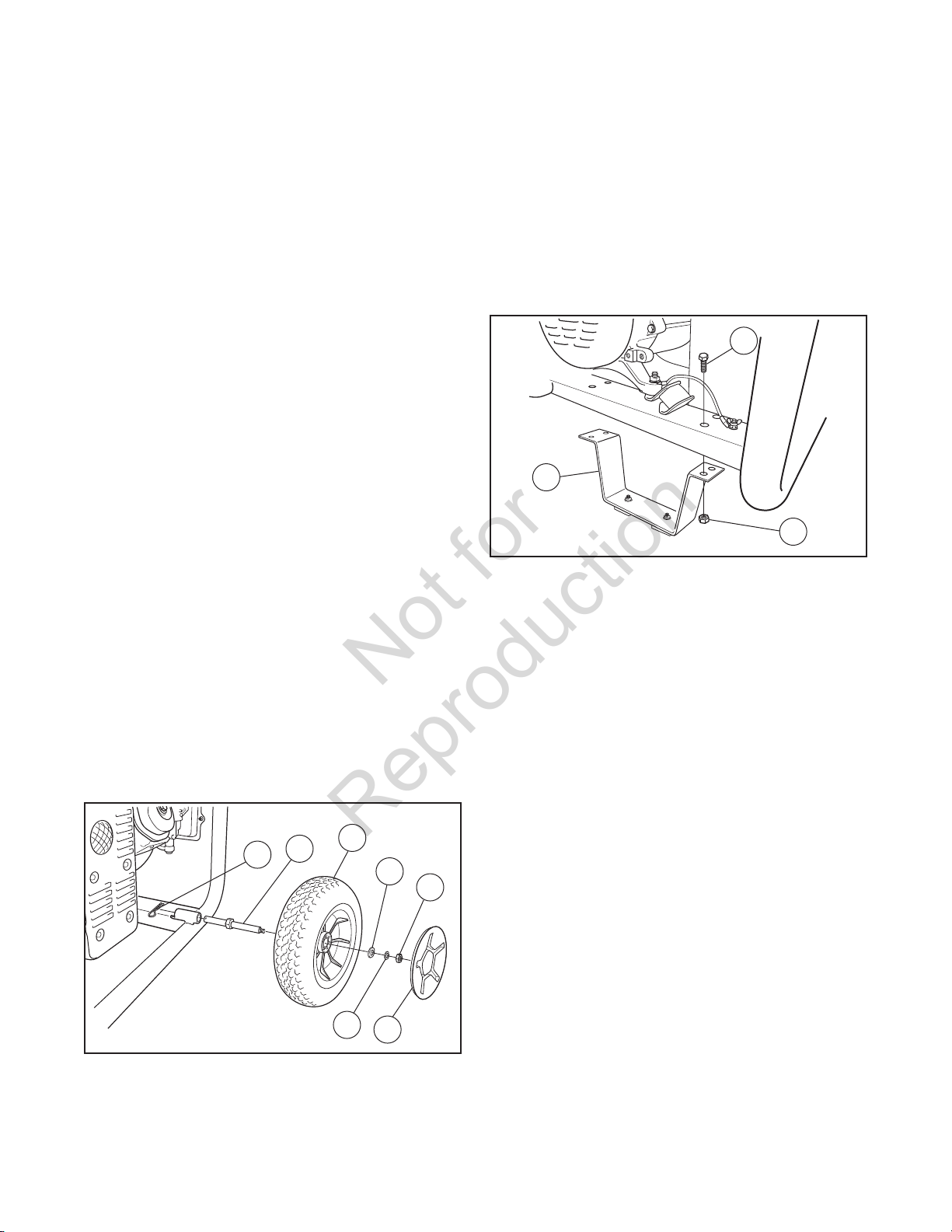

1. Clean area around fuel fill cap, remove cap.

2. Slowly add unleaded gasoline (A) to fuel tank (B). Be

careful not to fill above the baffle (C). This allows

adequate space for fuel expansion as shown.

3. Install fuel cap and let any spilled fuel evaporate before

starting engine.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane / 85 AKI (89 RON) gasoline is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause

decreased performance, increased fuel consumption, and

increased emissions. See an authorized dealer for high

altitude adjustment information. Operation of the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

8 BRIGGSandSTRATTON.COM

WARNING Fuel and its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death,

serious injury and/or property damage.

WHEN ADDING FUEL

• Turn generator engine OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• Check fuel lines, tank, cap and fittings frequently for cracks or

leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

FUEL

TANK

C

B

A

Not for

Reproduction

System Ground

The generator has a system ground that connects the

generator frame components to the ground terminals on the

AC output receptacles. The system ground is connected to

the AC neutral wire (the neutral is bonded to the generator

frame).

Special Requirements

There may be Federal or State Occupational Safety and

Health Administration (OSHA) regulations, local codes, or

ordinances that apply to the intended use of the generator.

Please consult a qualified electrician, electrical inspector, or

the local agency having jurisdiction:

• In some areas, generators are required to be registered

with local utility companies.

• If the generator is used at a construction site, there

may be additional regulations which must be observed.

Connecting to a Building’s Electrical System

Connections for standby power to a building’s electrical

system must be made by a qualified electrician. The

connection must isolate the generator power from utility

power or other alternative power sources and must comply

with all applicable laws and electrical codes.

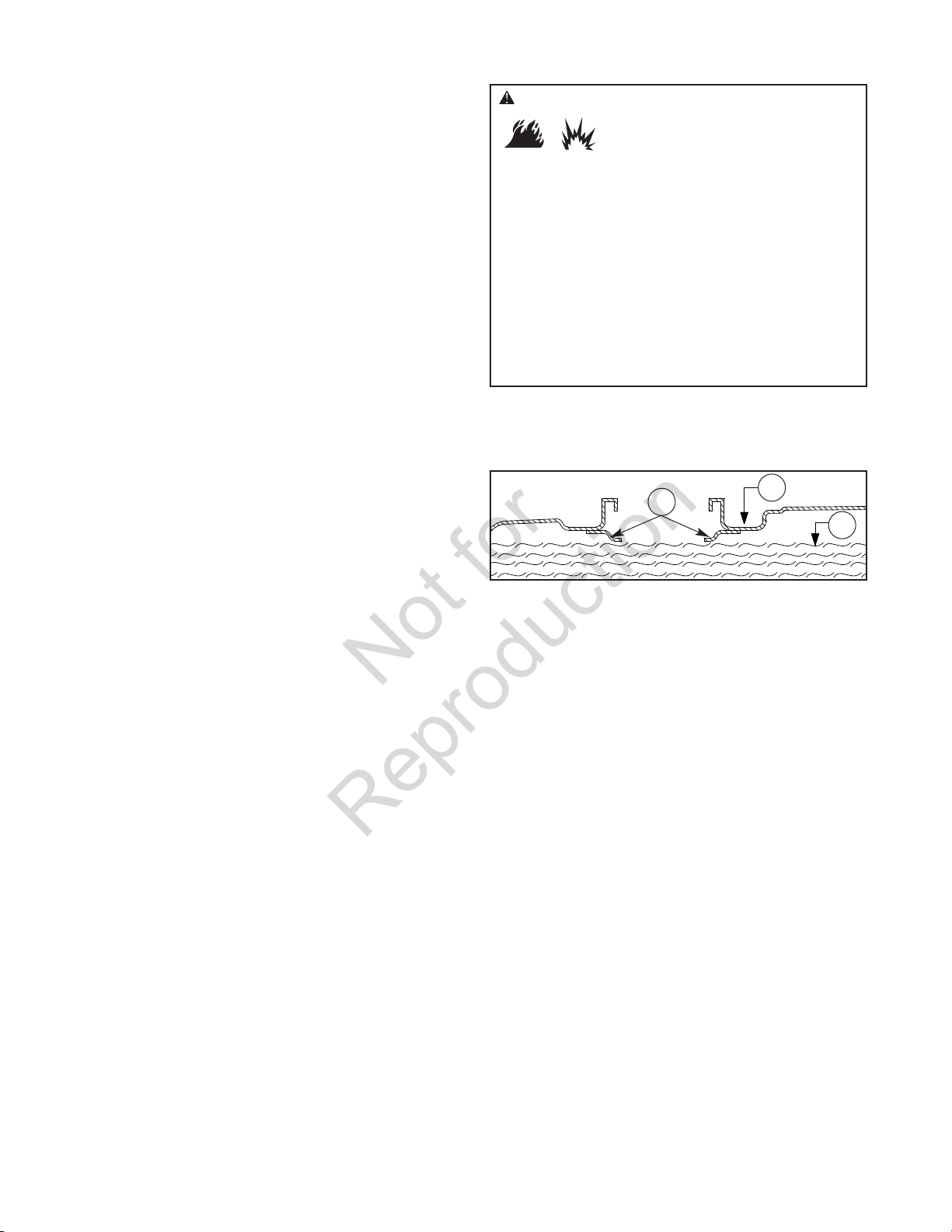

Generator Location

Clearances and Air Movement

Place generator outdoors in an area that will not accumulate

deadly exhaust gas. DO NOT place generator where exhaust

gas (A) could accumulate and enter inside or be drawn into

a potentially occupied building. Ensure exhaust gas is kept

away from any windows, doors, ventilation intakes, or other

openings that can allow exhaust gas to collect in a confined

area. Prevailing winds and air currents should be taken into

consideration when positioning generator.

A

9

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel tank

causing a fire, resulting in death, serious injury

and/or property damage.

• Keep at least 5 ft. (1.5 m) clearance on all sides of generator

including overhead.

WARNING

Generator voltage could cause electrical

shock or burn resulting in death or serious

injury.

• Use approved transfer equipment to prevent backfeed by

isolating generator from electric utility workers.

• When using generator for backup power, notify utility company.

• Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing in

water, while barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or

service generator.

Not for

Reproduction

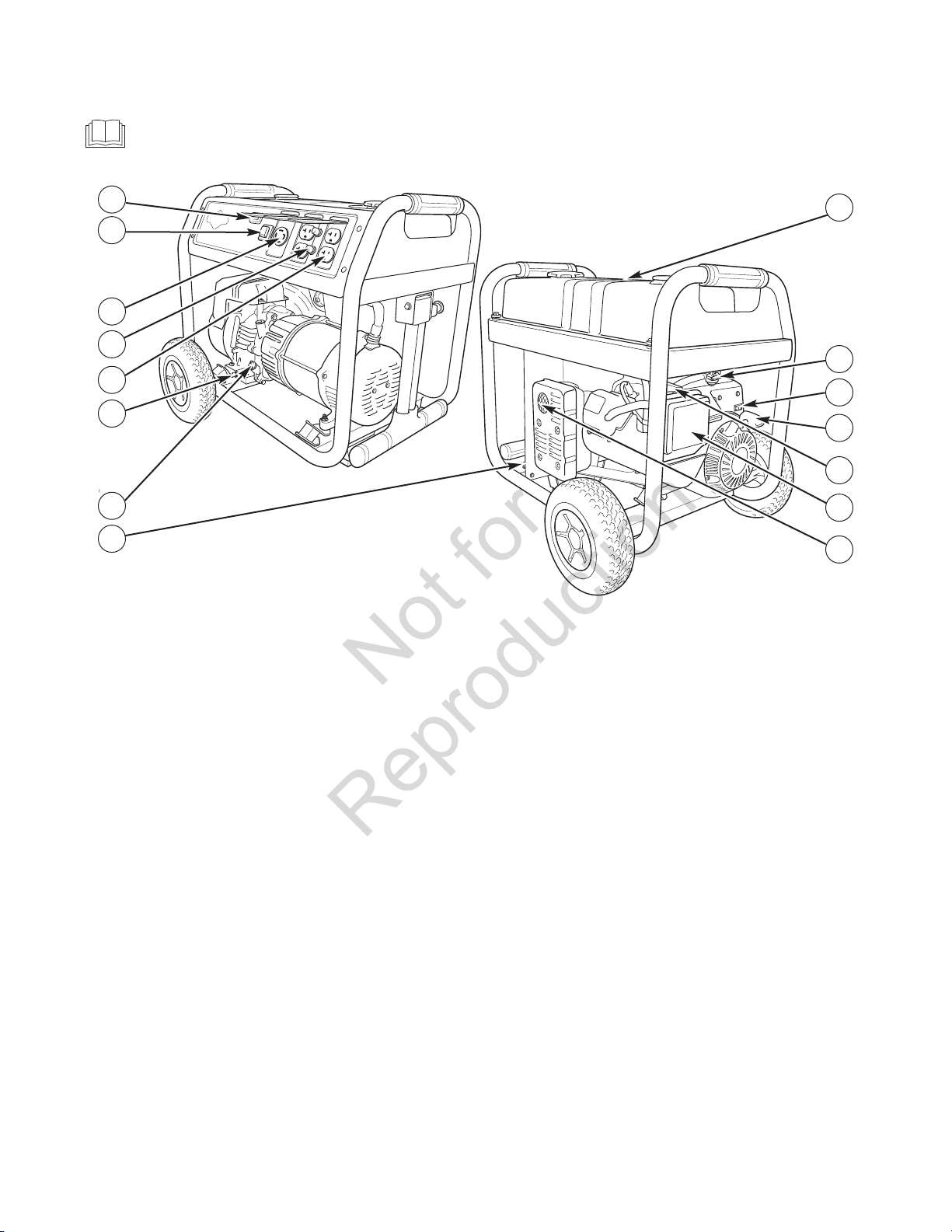

Features and Controls

Read this Operator’s Manual and safety rules before operating your generator.

Compare the illustrations with your generator, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

10 BRIGGSandSTRATTON.COM

A - Hour Meter — Displays and records how many hours

your generator has run (up to 9,999.9).

B - Rocker Switch Circuit Breaker — The 120/240 Volt AC,

30A locking receptacle is provided with a 2 pole rocker

switch circuit breaker to protect the generator against

electrical overload.

C - 120/240 Volt AC, 30 Amp Locking Receptacle — May

be used to supply electrical power for the operation of

120 and/or 240 Volt AC, 30 Amp, single phase, 60 Hz

electrical, lighting, appliance, tool and motor loads.

D - Circuit Breakers (AC) — The 120 Volt AC, 20A duplex

receptacles are provided with "push to reset" circuit

breakers to protect the generator against electrical

overload.

E - 120 Volt AC, 20 Amp, Duplex Receptacle — May be

used to supply electrical power for the operation of

120 Volt AC, 20 Amp, single phase, 60 Hz electrical,

lighting, appliance, tool and motor loads.

F - Oil Drain Plug — Drain engine oil here.

G - Oil Fill Cap — Check and add engine oil here.

H - Grounding Fastener — Consult your local agency having

jurisdiction for grounding requirements in your area.

J - Spark Arrester Muffler — Exhaust muffler lowers engine

noise and is equipped with a spark arrester screen.

K - Air Cleaner — Protects engine by filtering dust and

debris out of intake air.

L - Choke Lever — Used when starting a cold engine.

M - Recoil Starter — Used to start the engine manually.

N - Engine Rocker Switch — Set this switch to ON or I

before using recoil starter. Set switch to OFF or O to

switch off engine.

P - Fuel Valve — Used to turn fuel supply on and off to

engine.

R - Fuel Tank — Capacity of five (5) U.S. gallons (18.9 l) for

5,000 and 5,500 Watt generator. Capacity of seven (7)

U.S. gallons (26.5 l) for 6000 Watt generator.

Items Not Shown:

Engine Identification — Provides model, type and code of

engine. Please have these readily available if calling for

assistance.

Identification Label — Provides model and serial number of

generator. Please have these readily available if calling for

assistance.

A

R

J

B

C

D

E

G

H

M

P

L

N

K

F

Not for

Reproduction

Cord Sets and Receptacles

Use only high quality, well-insulated, grounded extension

cords with the generator’s receptacles. Inspect extension

cords before each use.

Check the ratings of all extension cords before you use

them. Extension cord sets used should be rated for AC loads

20 Amps or greater. Check operator’s manuals of devices to

be powered for the manufacturer’s recommendations.

Keep extension cords as short as possible to minimize

voltage drop.

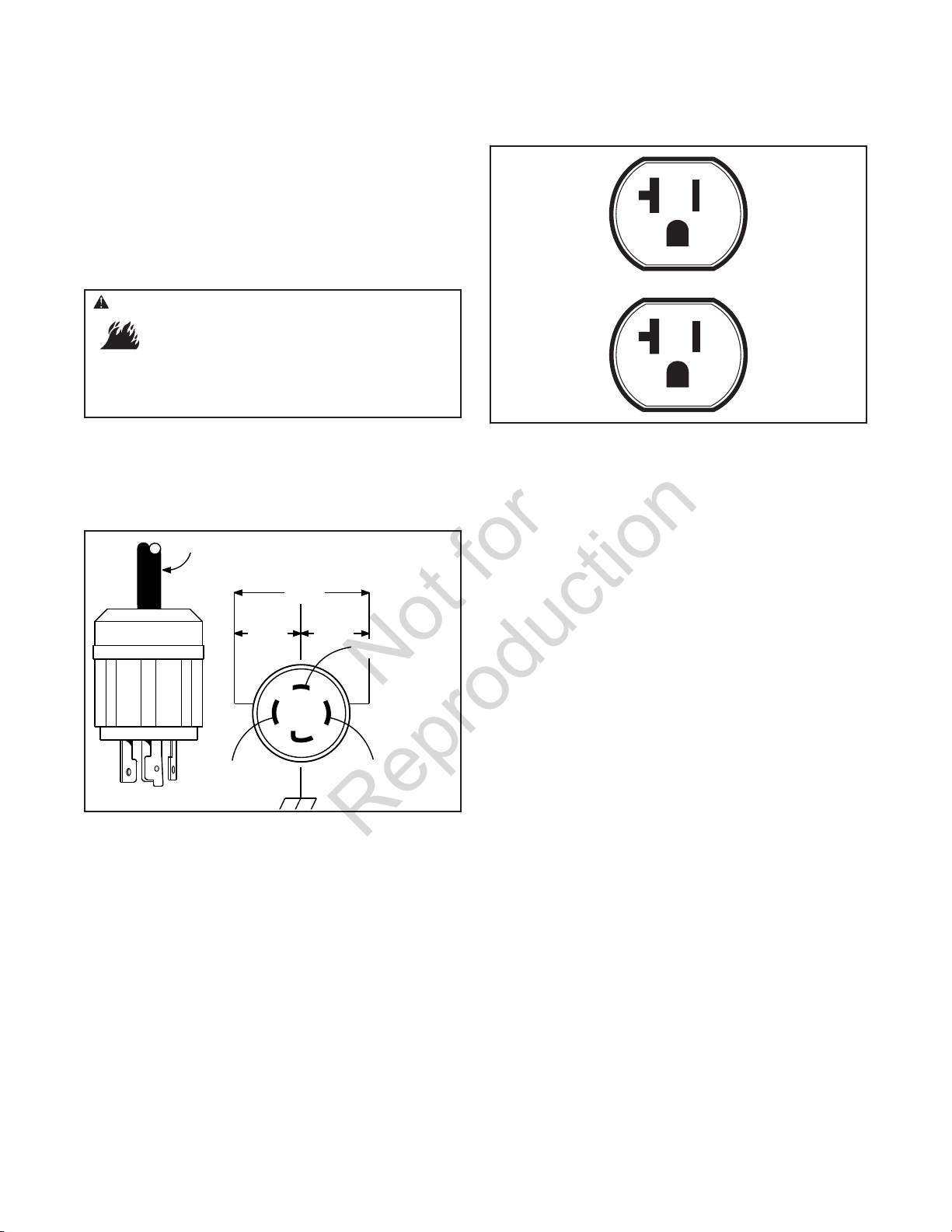

120/240 Volt AC, 30 Amp, Locking Receptacle

Use a NEMA L14-30 plug with this receptacle. Connect a

4-wire cord set rated for 250 Volt AC loads at 30 Amps (or

greater). You can use the same 4-wire cord if you plan to run

a 120 Volt load.

This receptacle powers 120/240 Volt AC, 60 Hz, single phase

loads requiring up to 6,000 watts of power (6.0 kW) at

25 Amps for 240 Volts or two independent 120 Volt loads at

25 Amps each. The outlet is protected by a 2 pole rocker

switch circuit breaker.

NOTICE

Receptacles may be marked with rating value

greater than generator output capacity.

• NEVER attempt to power a device requiring more amperage than

generator or receptacle can supply.

• DO NOT overload the generator. See Don’t Overload Generator.

120 Volt AC, 20 Amp, Duplex Receptacles

The duplex receptacles are protected against overload by

push–to–reset circuit breakers.

Use each receptacle to operate 120 Volt AC, single-phase,

60 Hz electrical loads requiring up to 2,400 watts (2.4 kW) at

20 Amps of current. Use cord sets that are rated for 125 Volt

AC loads at 20 Amps (or greater).

11

4-Wire Cord Set

240V

120V

120V

NEMA L14-30

W (Neutral)

X (Hot)

Y (Hot)

Ground (Green)

WARNING Damaged or overloaded electrical cords

could overheat, arc, and burn resulting in death,

serious injury, and/or property damage.

• ONLY use cords rated for your loads.

• Follow all safeties on electrical cords.

• Inspect cord sets before each use.

Not for

Reproduction

Operation

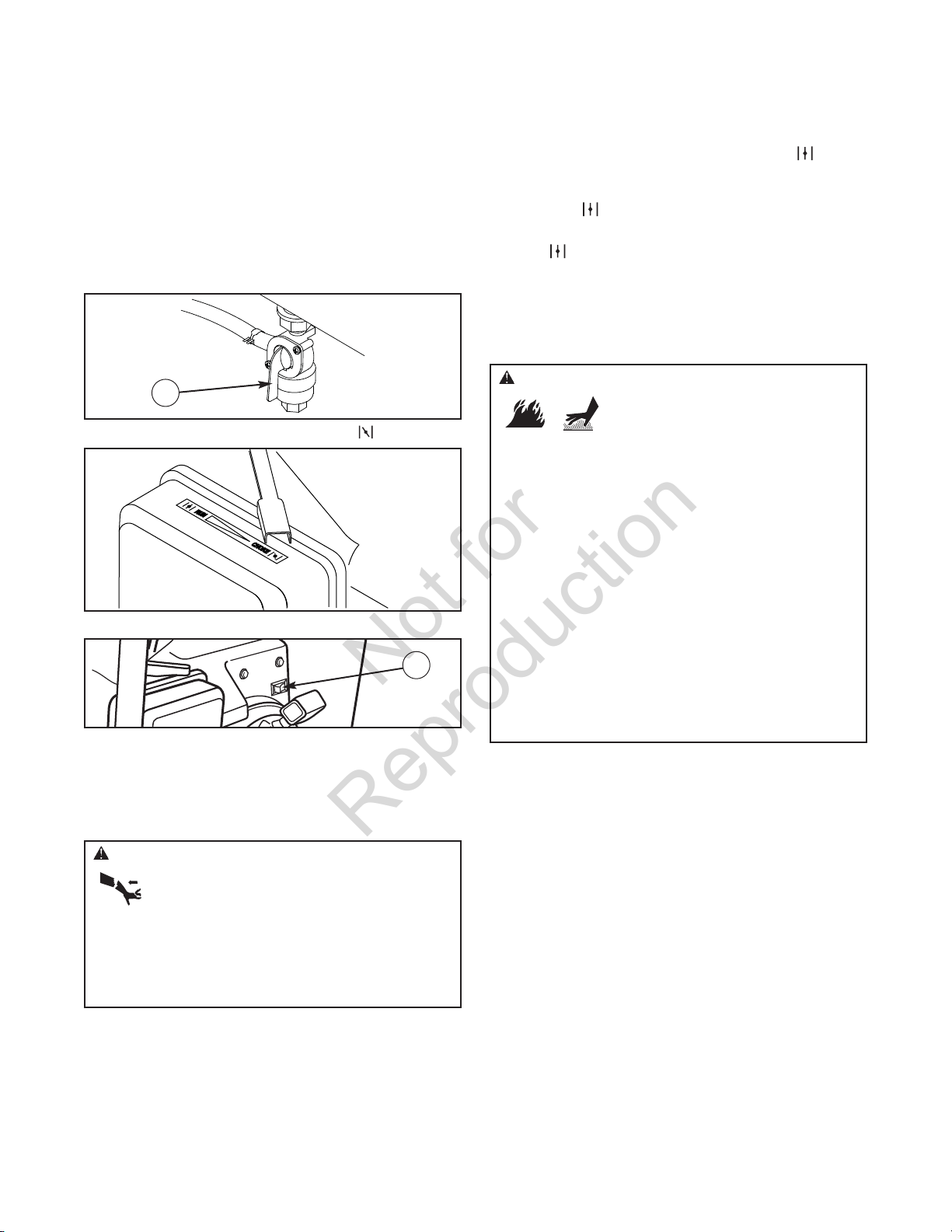

Starting the Engine

Disconnect all electrical loads from the generator. Use the

following start instructions:

1. Make sure unit is on a level surface.

NOTICE Failure to start and operate the unit on a level

surface will cause the unit not to start or shut down during

operation.

2. Turn the fuel valve (A) to the “On” position.

3. Push choke lever to “Choke” position ( ).

4. Push engine rocker switch (B) to ON or I position.

5. Grasp recoil handle and pull slowly until slight

resistance is felt. Then pull rapidly one time only to

start engine.

• If engine starts, proceed to step 7.

• If engine fails to start, proceed to step 6.

6. Move choke lever to “Half” choke position, and pull

recoil handle twice.

• If engine fails to start, repeat steps 5 thru 7.

7. Slowly move choke lever to “Run” position ( ). If

engine falters, move choke lever to “Half” choke

position until engine runs smoothly, and then to “Run”

position ( ).

NOTICE If engine floods, place choke lever in “Run”

position ( ) and crank until engine starts.

NOTICE If engine starts after 3 pulls but fails to run, or if

unit shuts down during operation, make sure unit is on a

level surface and check for proper oil level in crankcase. This

unit may be equipped with a low oil protection device. If so,

oil must be at proper level for engine to start.

B

12 BRIGGSandSTRATTON.COM

A

WARNING Starter cord kickback (rapid retraction) will

pull hand and arm toward engine faster than you

can let go which could cause broken bones,

fractures, bruises, or sprains resulting in

serious injury.

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• NEVER start or stop engine with electrical devices plugged in

and turned on.

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of

generator including overhead.

• It is a violation of California Public Resource Code, Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may have similar laws.

Contact the original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must be the same and installed in the same

position as the original parts.

Not for

Reproduction

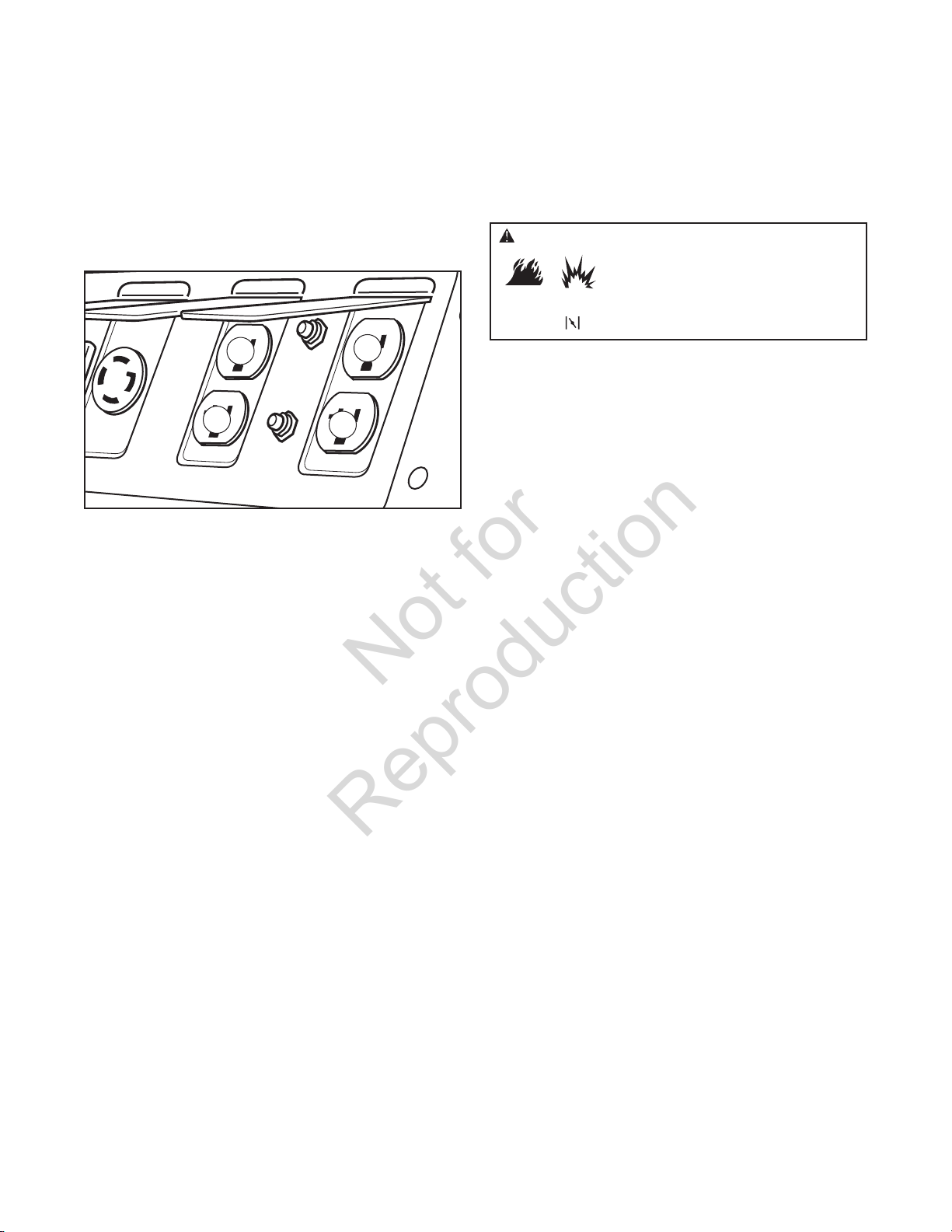

Connecting Electrical Loads

1. Let engine stabilize and warm up for a few minutes

after starting.

2. Ensure circuit breaker on control panel is in “On”

position.

3. Plug in and turn on the desired 120 and/or 240 Volt

AC, single phase, 60 Hz electrical loads.

NOTICE When plugging into the 120 Volt receptacles, plug

items to be powered in sequence as shown below.

NOTICE

• DO NOT connect 240 Volt loads to the 120 Volt duplex

receptacles.

• DO NOT connect 3-phase loads to the generator.

• DO NOT connect 50 Hz loads to the generator.

• DO NOT OVERLOAD THE GENERATOR. See Don’t

Overload Generator.

NOTICE

Exceeding generators wattage/amperage capacity

could damage generator and/or electrical devices connected

to it.

• DO NOT exceed the generator’s wattage/amperage capacity. See

Don’t Overload Generator in the Operation section.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator before

stopping generator.

Stopping the Engine

1. Turn OFF and unplug all electrical loads from generator

panel receptacles. NEVER start or stop engine with

electrical devices plugged in and turned ON.

2. Let engine run at no-load for several minutes to

stabilize internal temperatures of engine and generator.

3. Push engine rocker switch to OFF or O position.

4. Move fuel valve to “Off” position.

13

1

4

3

2

WARNING Fuel and its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death,

serious injury and/or property damage.

• DO NOT stop engine by moving choke control to “Choke”

position

().

Not for

Reproduction

14 BRIGGSandSTRATTON.COM

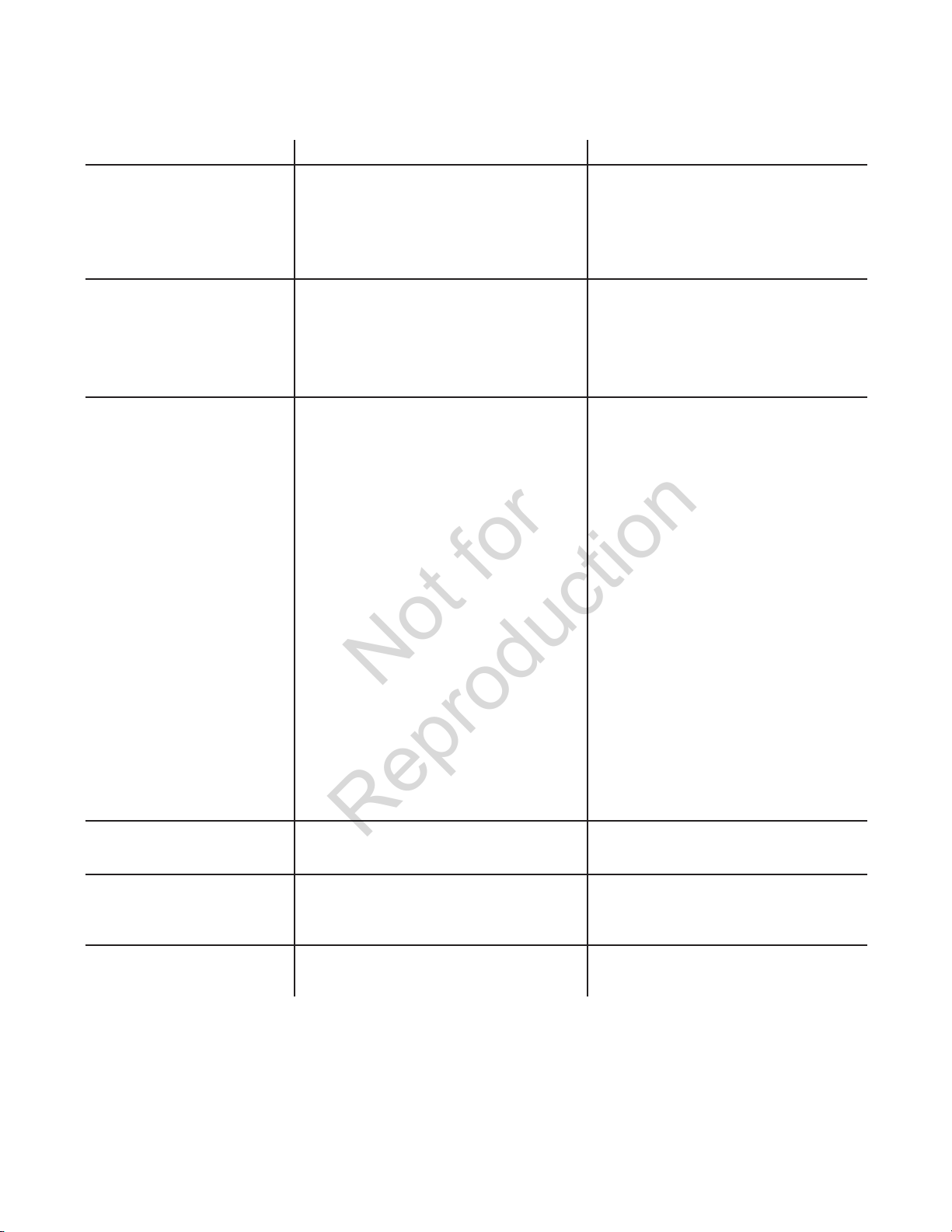

Don’t Overload Generator

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items. This is

the amount of power your generator must produce to

keep your items running. See the table on the right.

3. Estimate how many surge (starting) watts you will need.

Surge wattage is the short burst of power needed to

start electric motor-driven tools or appliances such as a

circular saw or refrigerator. Because not all motors start

at the same time, total surge watts can be estimated by

adding only the item(s) with the highest additional surge

watts to the total rated watts from step 2.

Example:

Total Rated (Running) Watts = 3275

Highest Additional Surge Watts = 2350

Total Generator Output Required = 5625

Power Management

To prolong the life of your generator and attached devices, it

is important to take care when adding electrical loads to your

generator. There should be nothing connected to the

generator outlets before starting its engine. The correct and

safe way to manage generator power is to sequentially add

loads as follows:

1. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly).

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

NEVER add more loads than the generator capacity. Take

special care to consider surge loads in generator capacity, as

described above.

* Wattages listed are approximate only. Check tool or

appliance for actual wattage.

Tool or Appliance

Running (Rated)

Watts

Additional Starting

(Surge) Watts

Water Well Pump 1200 2100

Refrigerator 700 2200

Furnace Fan 800 2350

Television 500 —

Light (75 Watts) 75 —

3275 Total

Running Watts

2350 Highest

Starting Watts

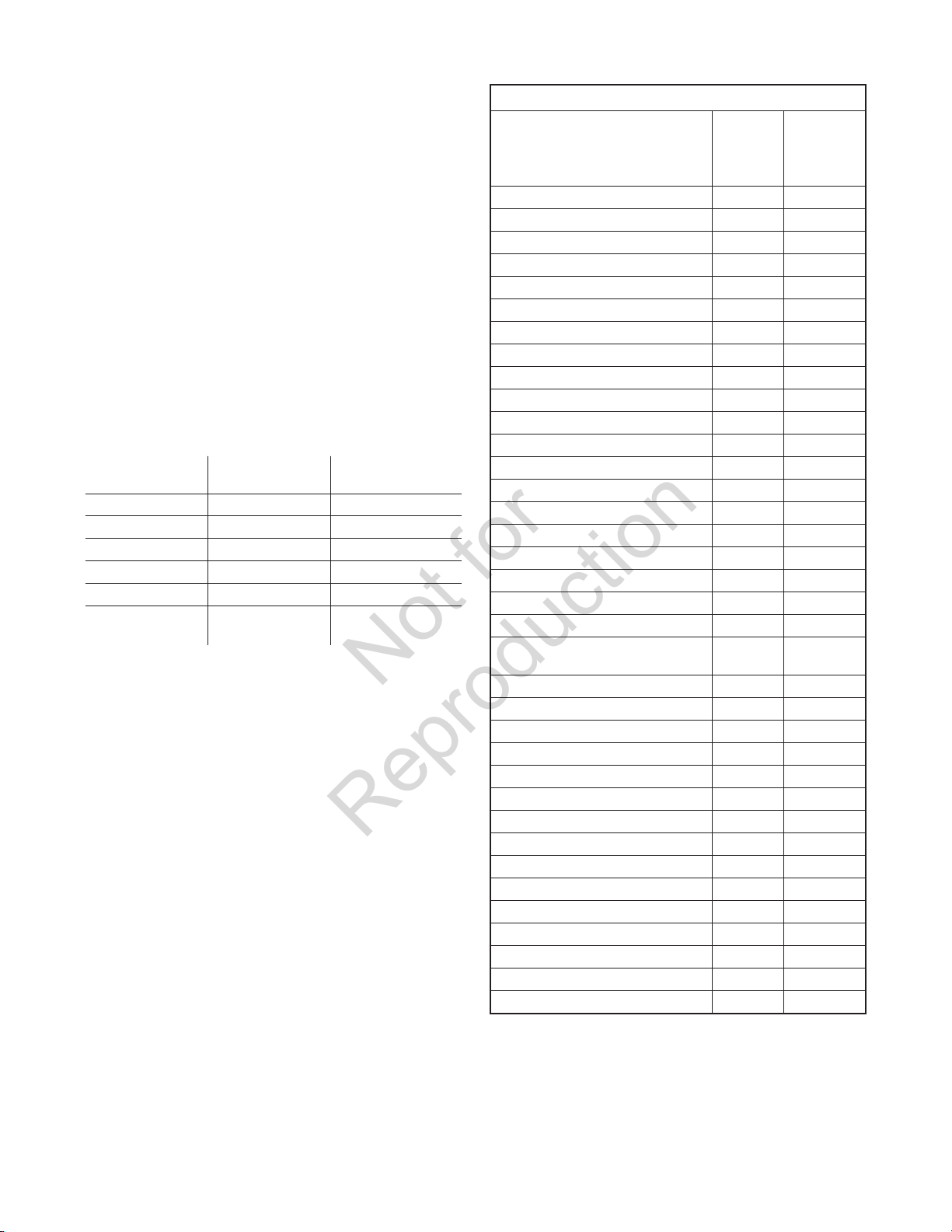

Wattage Reference Guide

Tool or Appliance

Running*

(Rated)

Watts

Additional

Starting

(Surge)

Watts

Essentials

Light Bulb - 75 watt 75 —

Furnace Fan Blower - 1/2 HP 800 2350

Sump Pump - 1/3 HP 800 1300

Refrigerator/Freezer 700 2200

Water Well Pump - 1/2 HP 1000 2100

Heating/Cooling

Window AC - 10,000 BTU 1200 3600

Humidifier - 13 Gal 175 —

Central AC - 24,000 BTU 3800 11400

Kitchen

Microwave Oven - 1000 Watt 1000 —

Coffee Maker 1000 —

Electric Stove - 8” Element 2100 —

Toaster 850 —

Family Room

DVD/CD Player 100 —

VCR 100 —

Stereo Receiver 450 —

Color Television - 27 in 500 —

Personal Computer w/17 in

monitor

800 —

Other

Security System 500 —

AM/FM Clock Radio 100 —

Garage Door Opener - 1/2 HP 875 2350

Electric Water Heater 4700 11700

DIY/Job Site

Quartz Halogen Work Light 1000 —

Airless Sprayer - 1/3 HP 600 1200

Reciprocating Saw 960 —

Electric Drill - 1/2 HP, 5.4 Amps 600 900

Circular Saw - 7-1/4 in 1400 2300

Miter Saw - 10 in 1800 1800

Table Planer - 6 in 1800 1800

Table Saw/Radial Arm Saw - 10 in 2000 2000

Air Compressor - 1 HP 1600 4500

Not for

Reproduction

15

Maintenance

Maintenance Schedule

Follow the hourly or calendar intervals, whichever occurs

first. More frequent service is required when operating in

adverse conditions noted below.

1

Service more often under dirty or dusty conditions.

General Recommendations

Regular maintenance will improve the performance and

extend the life of the generator. See any authorized dealer for

service.

The generator’s warranty does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, the operator must maintain the

generator as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your generator.

All service and adjustments should be made at least once

each season. Follow the requirements in the Maintenance

Schedule chart above.

NOTICE Once a year you should clean or replace the spark

plug and replace the air filter. New spark plugs and clean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

Emissions Control

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by any

non-road engine repair establishment or individual.

However, to obtain ”no charge” emissions control service,

the work must be performed by a factory authorized dealer.

See the Emissions Warranty.

Generator Maintenance

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive dust,

dirt, moisture, or any corrosive vapors. Cooling air slots in

the generator must not become clogged with snow, leaves,

or any other foreign material.

NOTICE DO NOT use water or other liquids to clean

generator. Liquids can enter engine fuel system, causing

poor performance and/or failure to occur. In addition, if

liquid enters generator through cooling air slots, some of the

liquid will be retained in voids and cracks of the rotor and

stator winding insulation. Liquid and dirt buildup on the

generator internal windings will eventually decrease the

insulation resistance of these windings.

Cleaning

Daily or before use, look around and underneath the

generator for signs of oil or fuel leaks. Clean accumulated

debris from inside and outside the generator. Keep the

linkage, spring and other engine controls clean. Keep the

area around and behind the muffler free from any

combustible debris. Inspect cooling air slots and openings

on generator. These openings must be kept clean and

unobstructed.

Engine parts should be kept clean to reduce the risk of

overheating and ignition of accumulated debris:

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE

Improper treatment of generator could damage it

and shorten its life.

• DO NOT expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• DO NOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen caked on dirt or oil.

• Use a vacuum cleaner to pick up loose dirt and debris.

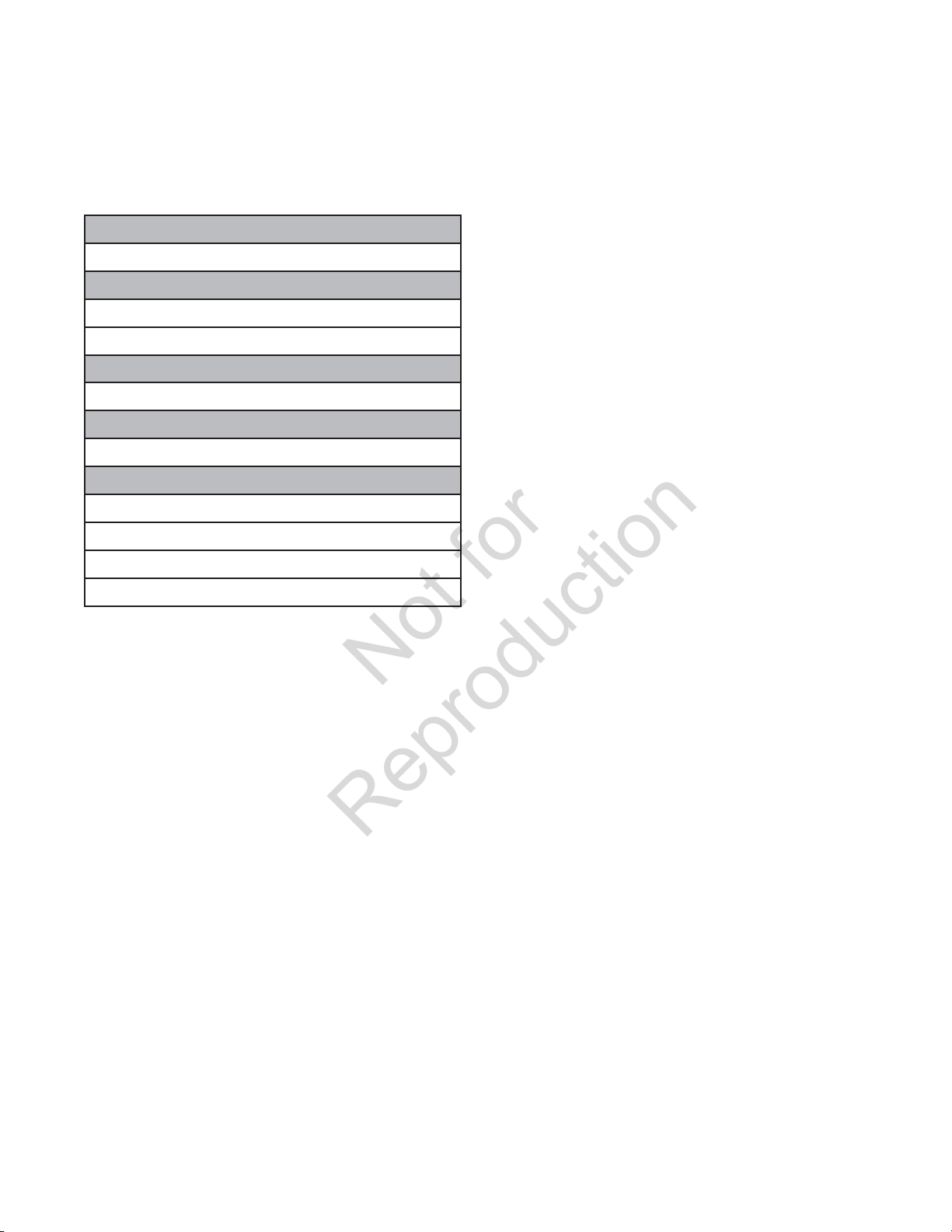

First 5 Hours

• Change engine oil

Every 8 Hours or Daily

• Clean debris

• Check engine oil level

Every 25 Hours or Yearly

• Service engine air cleaner

1

Every 50 Hours or Yearly

• Change engine oil

1

Every 100 Hours or Yearly

• Service fuel valve

• Service spark plug

• Inspect muffler and spark arrester

• Clean cooling system

1

Not for

Reproduction

16 BRIGGSandSTRATTON.COM

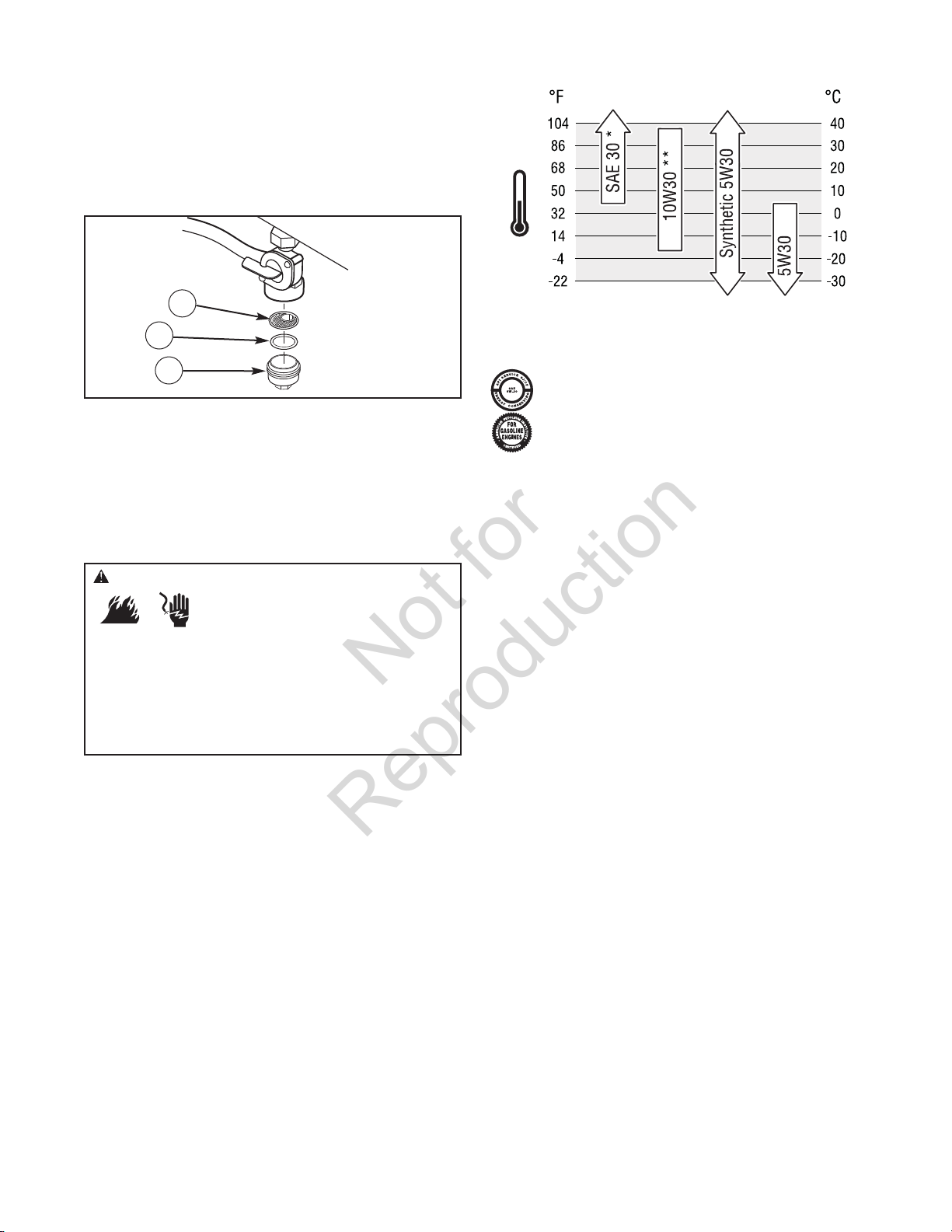

Fuel Valve Maintenance

The fuel valve is equipped with a fuel sediment cup, screen,

and o-ring that need to be cleaned.

1. Move fuel valve to “Off” position.

2. Remove sediment cup (A) from fuel valve. Remove

o-ring (B) and screen (C) from fuel valve.

3. Wash sediment cup, o-ring, and screen in a

nonflammable solvent. Dry them thoroughly.

4. Place screen and o-ring into fuel valve. Install sediment

cup and tighten securely.

5. Move fuel valve to “On” position, and check for leaks.

Replace fuel valve if there is any leakage.

Engine Maintenance

Oil

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF, SG,

SH, SJ or higher. DO NOT use special additives.

Outdoor temperatures determine the proper oil viscosity for

the engine. Use the chart to select the best viscosity for the

outdoor temperature range expected.

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W30 may cause increased oil

consumption. Check oil level more frequently.

NOTICE Synthetic oil meeting ILSAC GF-2, API

certification mark and API service symbol with

“SJ/CF ENERGY CONSERVING” or higher, is an

acceptable oil at all temperatures. Use of synthetic

oil does not alter required oil change intervals.

Checking Oil Level

Oil level should be checked prior to each use or at least

every 8 hours of operation. Keep oil level maintained.

1. Make sure generator is on a level surface.

2. Clean area around oil fill and remove oil fill cap.

3. Verify oil is at the point of overflowing at oil fill

opening.

4. Replace and tighten oil fill cap.

Adding Engine Oil

1. Make sure generator is on a level surface.

2. Check oil level as described in Checking Oil Level.

3. If needed, slowly pour oil into oil fill opening to the

point of overflowing at oil fill.

4. Replace and tighten oil fill cap.

A

B

C

WARNING Unintentional sparking could cause fire or

electric shock resulting in death or

serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Not for

Reproduction

17

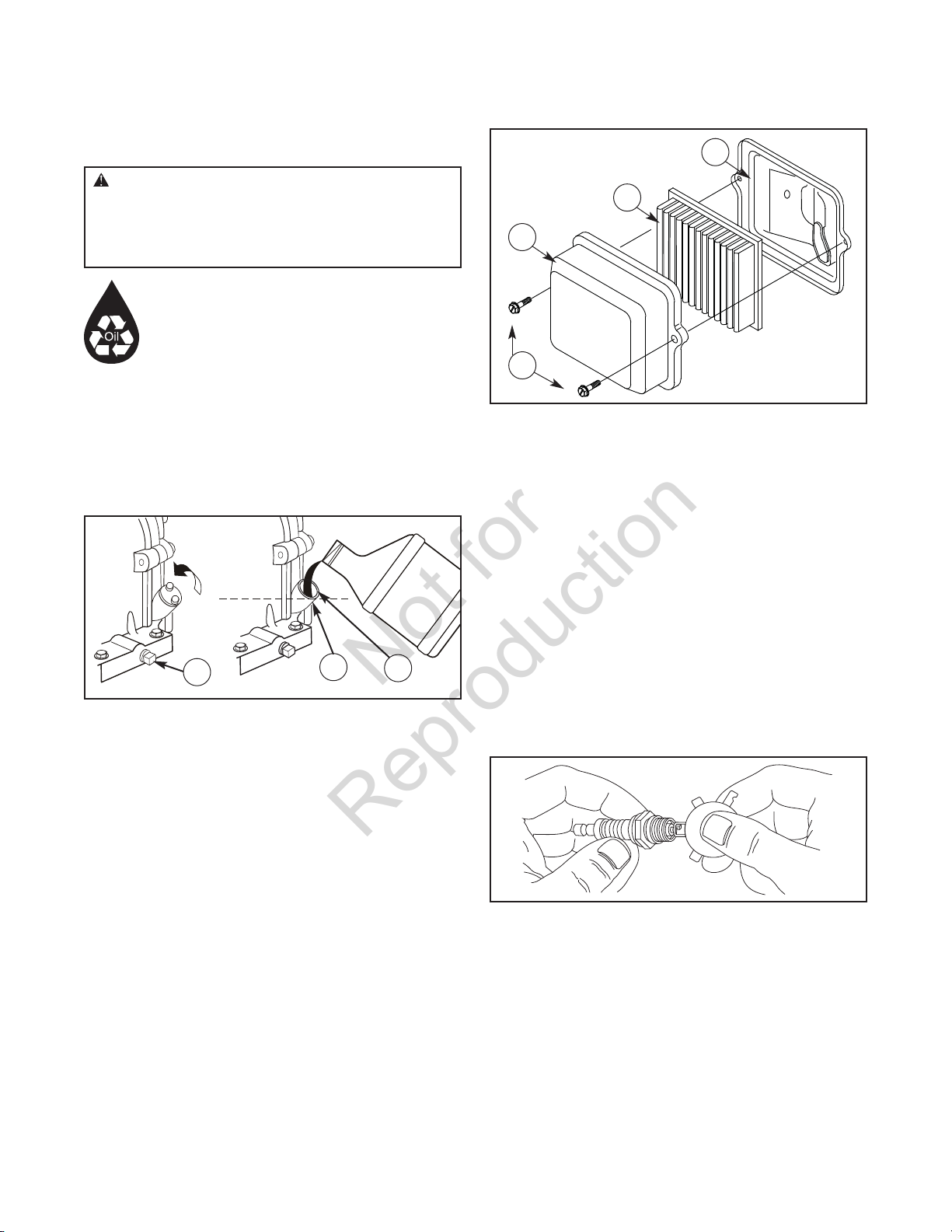

Changing Engine Oil

If you are using your generator under extremely dirty or

dusty conditions, or in extremely hot weather, change the oil

more often.

KEEP OUT OF REACH OF CHILDREN. DON’T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

Change the oil while the engine is still warm from

running, as follows:

1. Make sure unit is on a level surface.

2. Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

3. Clean area around oil drain plug (A). The oil drain plug

is located at base of engine, opposite carburetor.

4. Remove oil drain plug and drain oil completely into a

suitable container.

5. Reinstall oil drain plug and tighten securely. Remove oil

fill cap.

6. Slowly pour oil (about 28 oz.) into oil fill opening (B) to

the point of overflowing (C) at oil fill cap. DO NOT

overfill.

7. Reinstall oil fill cap. Finger tighten cap securely.

8. Wipe up any spilled oil.

Service Air Cleaner

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner. Clean or replace more

often if operating under dusty or dirty conditions.

To service the air cleaner, follow these steps:

1. Loosen screws (D) and remove air cleaner cover (E).

2. Carefully remove cartridge (F) from base (G).

3. Install clean (or new) air cleaner assembly inside cover.

Dispose of old filter properly.

4. Assemble air cleaner cover onto base and tighten

screws.

Service Spark Plug

Changing the spark plug will help your engine to start easier

and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use the recommended

replacement spark plug. See Specifications.

3. Check electrode gap with wire feeler gauge and reset

spark plug gap to recommended gap if necessary (see

Specifications).

5. Install spark plug and tighten firmly.

A

B

C

D

E

F

G

CAUTION Avoid prolonged or repeated skin contact

with used motor oil.

• Used motor oil has been shown to cause skin cancer in certain

laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Not for

Reproduction

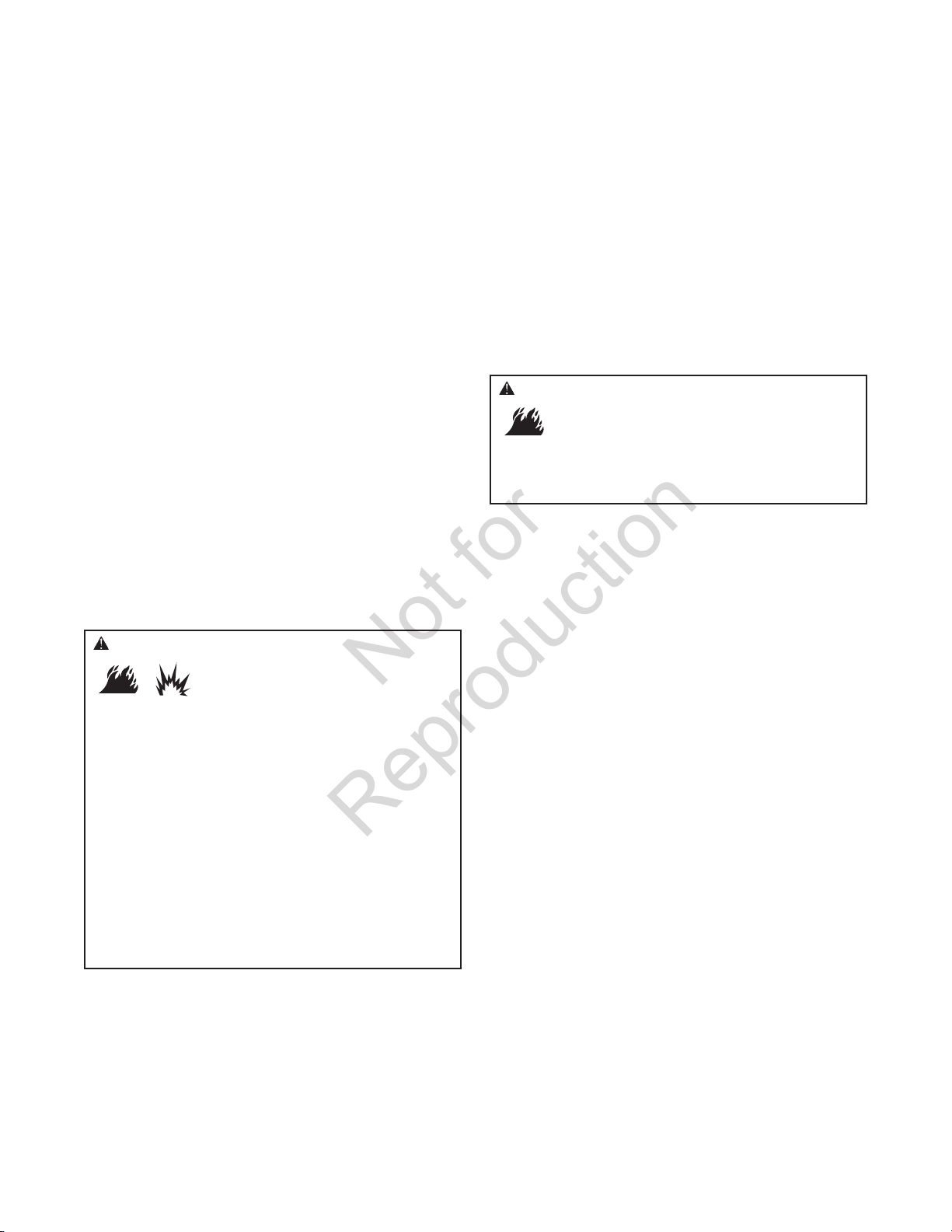

Inspect Muffler and Spark Arrester

Inspect the muffler for cracks, corrosion, or other damage.

Remove the spark arrester, if equipped, and inspect for

damage or carbon blockage. If replacement parts are

required, make sure to use only original equipment

replacement parts.

Clean and inspect the spark arrester as follows:

1. To remove muffler heat shield (A) from muffler (B),

remove four screws that connect guard to muffler

bracket.

2. Remove four screws that attach spark arrester screen (C).

3. Inspect screen and obtain a replacement if torn,

perforated or otherwise damaged. DO NOT use a

defective screen. If screen is not damaged, clean it with

commercial solvent.

4. Reattach screen and muffler guard.

Clean Cooling System

Over time debris may accumulate in cylinder cooling fins and

cannot be observed without partial engine disassembly. For

this reason, we recommend you have a Briggs & Stratton

authorized dealer clean the cooling system (D) per

recommended intervals (see Maintenance Schedule in the

Maintenance section). Equally important is to keep top of

engine free from debris. Also see Cleaning.

Carburetor Adjustment

The carburetor on this engine is low emission. It is equipped

with a non-adjustable idle mixture valve. Top speed has been

set at the factory. If adjustment is required, see a Briggs &

Stratton authorized dealer.

CAUTION Excessively high operating speeds could

result in minor injury and/or generator damage.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other parts to

increase engine speed. Generator supplies correct rated

frequency and voltage when running at governed speed.

• DO NOT modify generator in any way.

18 BRIGGSandSTRATTON.COM

A

B

C

D

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (1.5 m) of clearance on all sides of

generator including overhead.

• It is a violation of California Public Resource Code, Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may have similar laws.

Contact the original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must be the same and installed in the same

position as the original parts.

Not for

Reproduction

19

Storage

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot be

done and you must store the unit for more than 30 days, use

the following guidelines to prepare it for storage.

Generator Storage

• Clean the generator as outlined in Cleaning in the

Maintenance section.

• Check that cooling air slots and openings on generator

are open and unobstructed.

Long Term Storage Instructions

Fuel can become stale when stored over 30 days. Stale fuel

causes acid and gum deposits to form in the fuel system or

on essential carburetor parts. To keep fuel fresh, use Briggs

& Stratton FRESH START® fuel stabilizer, available as a

liquid additive or a drip concentrate cartridge.

There is no need to drain gasoline from the engine if a fuel

stabilizer is added according to instructions. Run the engine

for 2 minutes to circulate the stabilizer throughout the fuel

system. The engine and fuel can then be stored up to

24 months.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container. Run

the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to

maintain freshness.

Change Oil

While engine is still warm, drain oil from crankcase. Refill

with recommended grade. See Changing Engine Oil in Engine

Maintenance.

Other Storage Tips

1. DO NOT store fuel from one season to another unless it

has been treated as described in Long Term Storage

Instructions.

2. Replace fuel can if it starts to rust. Contaminated fuel

will cause engine problems.

3. If possible, store unit indoors and cover it to give

protection from dust and dirt.

4. Cover unit with a suitable protective cover that does not

retain moisture.

5. Store generator in clean, dry area.

WARNING Fuel and its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death,

serious injury and/or property damage.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes dryers

or other appliances that have pilot light or other ignition source

because they could ignite fuel vapors.

WHEN DRAINING FUEL

• Turn generator engine OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

• Drain fuel tank outdoors.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• Check fuel lines, tank, cap and fittings frequently for cracks or

leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

WARNING Storage covers could cause a fire

resulting in death, serious injury and/or property

damage.

• DO NOT place a storage cover over a hot generator.

• Let equipment cool for a sufficient time before placing the

cover on the equipment.

Not for

Reproduction

20 BRIGGSandSTRATTON.COM

Reserved

Not for

Reproduction

21

Troubleshooting

Problem Cause Correction

Engine is running, but no AC

output is available.

1. One of the circuit breakers is open.

2. Fault in generator.

3. Poor connection or defective cord set.

4. Connected device is bad.

1. Reset circuit breaker.

2. Contact authorized service facility.

3. Check and repair.

4. Connect another device that is in good

condition.

Engine runs good at no-load

but "bogs down" when loads

are connected.

1. Short circuit in a connected load.

2. Engine speed is too slow.

3. Generator is overloaded.

4. Shorted generator circuit.

5. Clogged or dirty fuel filter.

1. Disconnect shorted electrical load.

2. Contact authorized service facility.

3. See Don't Overload Generator.

4. Contact authorized service facility.

5. Clean or replace fuel filter.

Engine will not start; or starts

and runs rough.

1. Engine rocker switch set to “Off”

position.

2. Fuel Valve is in “Off” position.

3. Low oil level.

4. Dirty air cleaner.

5. Clogged or dirty fuel filter.

6. Out of fuel.

7. Stale fuel.

8. Spark plug wire not connected to spark

plug.

9. Bad spark plug.

10. Water in fuel.

11. Flooded.

12. Excessively rich fuel mixture.

13. Intake valve stuck open or closed.

14. Engine has lost compression.

1. Set engine rocker switch to

“On”position.

2. Turn fuel valve to “On” position.

3. Fill crankcase to proper level or place

generator on level surface.

4. Clean or replace air cleaner.

5. Clogged or dirty fuel filter.

6. Fill fuel tank.

7. Drain fuel tank and carburetor; fill with

fresh fuel.

8. Connect wire to spark plug.

9. Replace spark plug.

10. Drain gas tank and carburetor; fill with

fresh fuel.

11. Wait 5 minutes and re-crank engine.

12. Contact authorized service facility.

13. Contact authorized service facility.

14. Contact authorized service facility.

Engine shuts down when

running.

1. Out of fuel.

2. Clogged or dirty fuel filter.

1. Fill fuel tank.

2. Clean or replace fuel filter.

Engine lacks power.

1. Load is too high.

2. Dirty air filter.

3. Clogged or dirty fuel filter.

1. See Don't Overload Generator.

2. Replace air filter.

3. Clean or replace fuel filter.

Engine "hunts" or falters.

1. Carburetor is running too rich or too lean.

2. Clogged or dirty fuel filter.

1. Contact authorized service facility.

2. Clean or replace fuel filter.

Not for

Reproduction

Schematic

22 BRIGGSandSTRATTON.COM

Not for

Reproduction

23

Reserved

Not for

Reproduction

Loading...

Loading...