Page 1

Models / Modelos

030319

030320

Operator’s Manual

Manual del Operario

Questions? Help is just a moment away!

Preguntas? La ayuda es justa un momento lejos!

Call: Generator Helpline

Llame: Línea Directa del Generador

1-800-743-4115 M-F 8-5 CT

web: www.briggsandstratton.com

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

Manual No. 199399GS

Revision - (04/05/2006)

4000 WATT

5000 STARTING WATTS

Before using this product, read this manual and follow all

Safety Rules and Operating Instructions.

WARNING

Antes de utilizar el producto, lea este manual y siga todas las

Reglas de Seguridad e Instrucciones de Uso.

ADVERTENCIA

Page 2

2

SAFETY RULES

TABLE OF CONTENTS

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Features and Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 & 22

Emissions Control Warranties. . . . . . . . . . . . . . . . . . . 20-21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-44

EQUIPMENT

DESCRIPTION

Read this manual carefully and become

familiar with your generator. Know its

applications, its limitations and any hazards

involved.

The generators are an engine–driven, revolving field,

alternating current (AC) generator. It was designed to

supply electrical power for operating compatible electrical

lighting, appliances, tools and motor loads.The generator’s

revolving field is driven at about 3,600 rpm by a singlecylinder engine.

CAUTION! DO NOT exceed the generator’s

wattage/amperage capacity. See “Don’t Overload

Generator”.

Every effort has been made to ensure that information in

this manual is accurate and current. However, we reserve

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

The Emission Control System for this generator is

warranted for standards set by the Environmental

Protection Agency and the California Air Resources Board.

SAFETY RULES

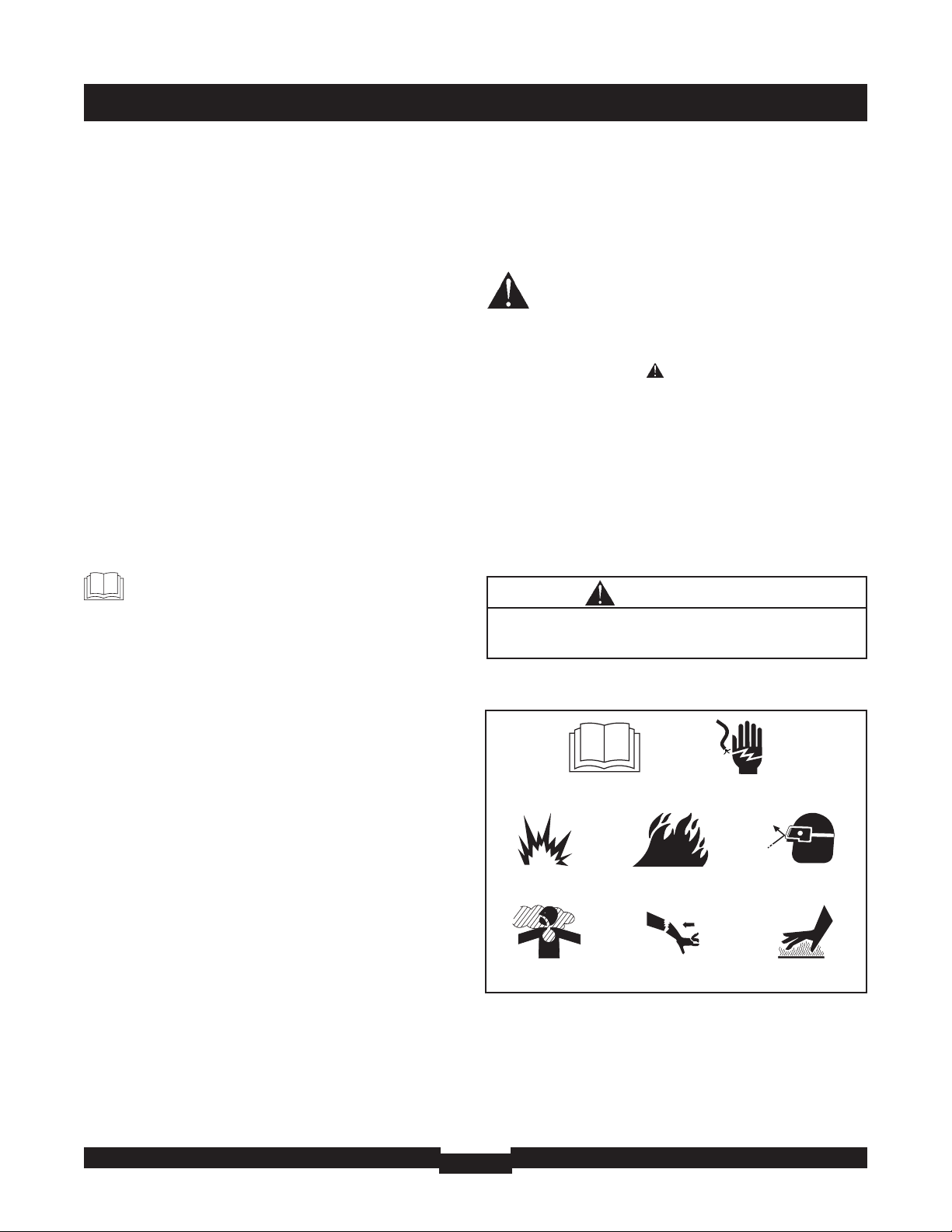

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

Hazard Symbols and Meanings

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

Copyright © 2006 Briggs & Stratton Power Products

Group, LLC. All rights reserved. No part of this material

may be reproduced or transmitted in any form by any

means without the express written permission of Briggs &

Stratton Power Products Group, LLC.

SAVE THESE INSTRUCTIONS

Fire

Explosion

Toxic Fumes

Hot Surface

Electrical Shock

Kickback

Operator’s Manual

Flying Objects

Page 3

3

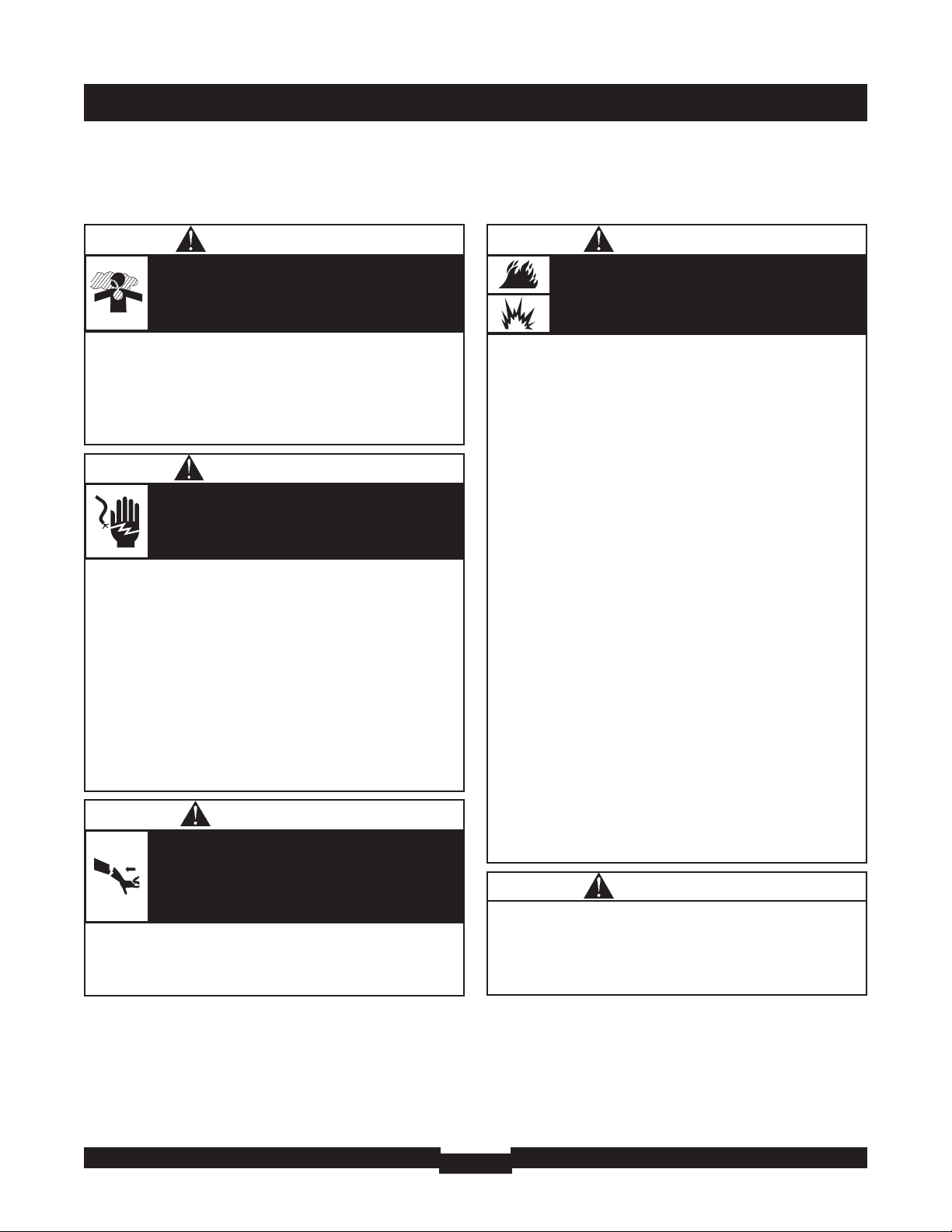

SAFETY RULES

• This generator does not meet U. S. Coast Guard Regulation

33CFR-183 and should not be used on marine applications.

• Failure to use the appropriate U. S. Coast Guard approved

generator could result in death or serious injury and/or

property damage.

WARNING

• When using generator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

• Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing

in water, while barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or

service generator.

Generator produces powerful voltage.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

WARNING

• Operate generator ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

• DO NOT operate generator inside any building or enclosure

(even if doors or windows are open),including the generator

compartment of a recreational vehicle (RV).

Running generator gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea,

fainting or death.

WARNING

WHEN ADDING OR DRAINING FUEL

• Turn generator OFF and let it cool at least 2 minutes before

removing fuel cap.Loosen cap slowly to relieve pressure in

tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank.Allow space for fuel expansion.

• Wait for spilled fuel to evaporate before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap and air cleaner are in place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which causes fuel

to spill.

• This generator is not for use in mobile equipment or marine

applications.

WHEN TRANSPORTING OR REPAIRING

EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• NEVER start or stop engine with electrical devices plugged in

and turned on.

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains could

result.

WARNING

Page 4

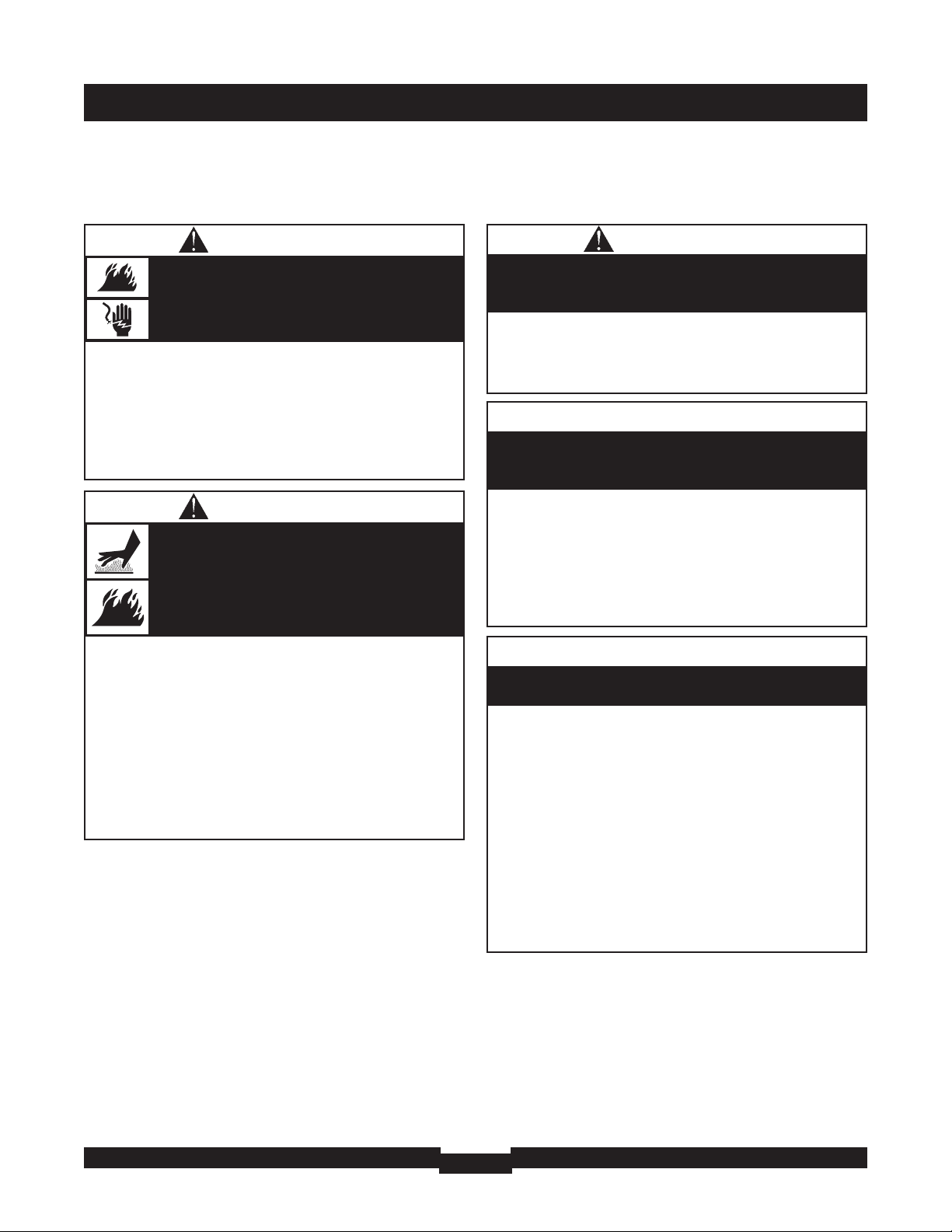

SAFETY RULES

4

• DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

speed.

• DO NOT modify generator in any way.

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

CAUTION

• See “Don’t Overload Generator”.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator

before stopping generator.

Exceeding generators wattage/amperage capacity can

damage generator and/or electrical devices connected

to it.

CAUTION

• Use generator only for intended uses.

• If you have questions about intended use, ask dealer or call

1-800-743-4115.

• Operate generator only on level surfaces.

• DO NOT expose generator to excessive moisture, dust, dirt,

or corrosive vapors.

• DO NOT insert any objects through cooling slots.

• If connected devices overheat, turn them off and disconnect

them from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

Improper treatment of generator can damage it and

shorten its life.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

GENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Unintentional sparking can result in fire or

electric shock.

WARNING

• DO NOT touch hot surfaces and avoid hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of generator

including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Page 5

FEATURES AND CONTROLS

5

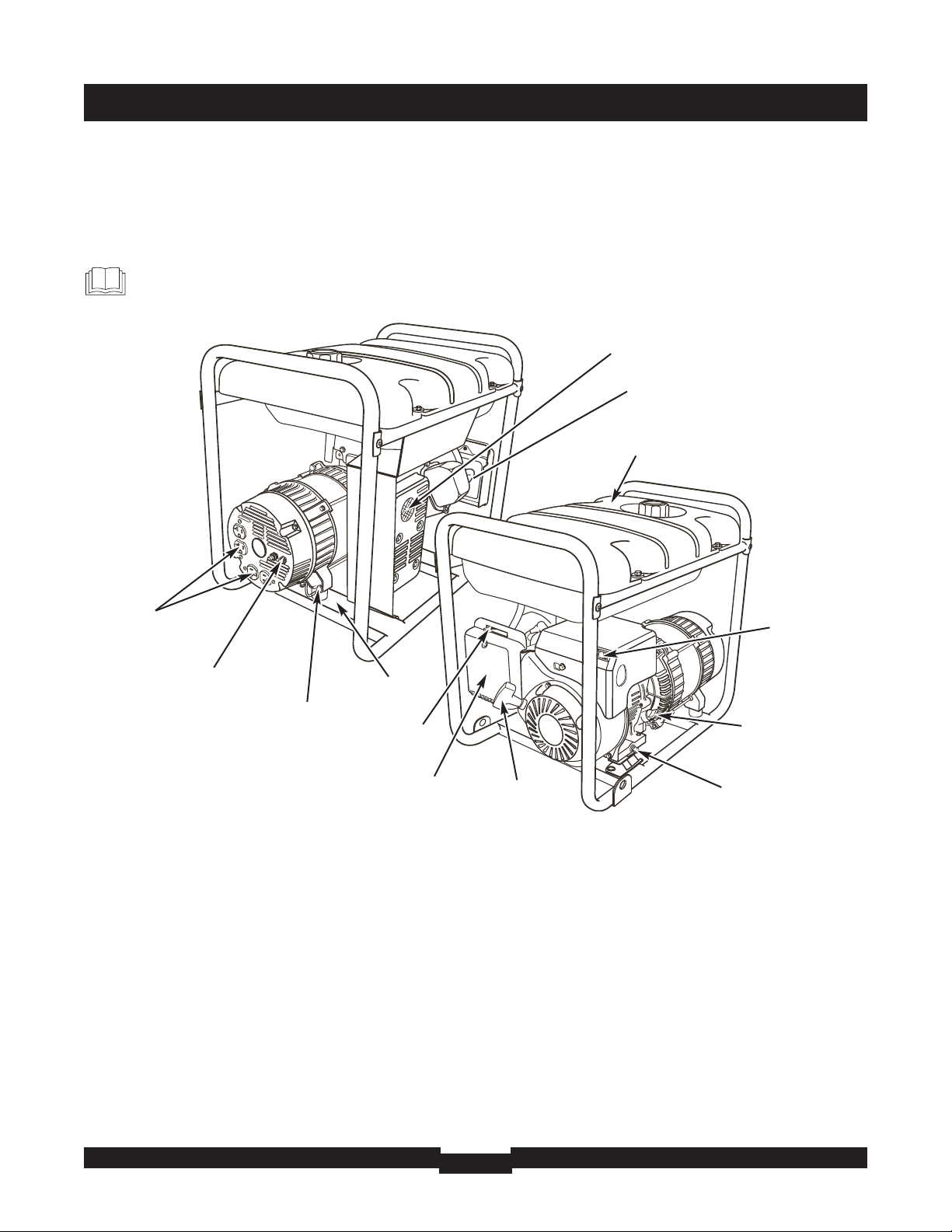

KNOW YOUR GENERATOR

Read this operator’s manual and safety rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

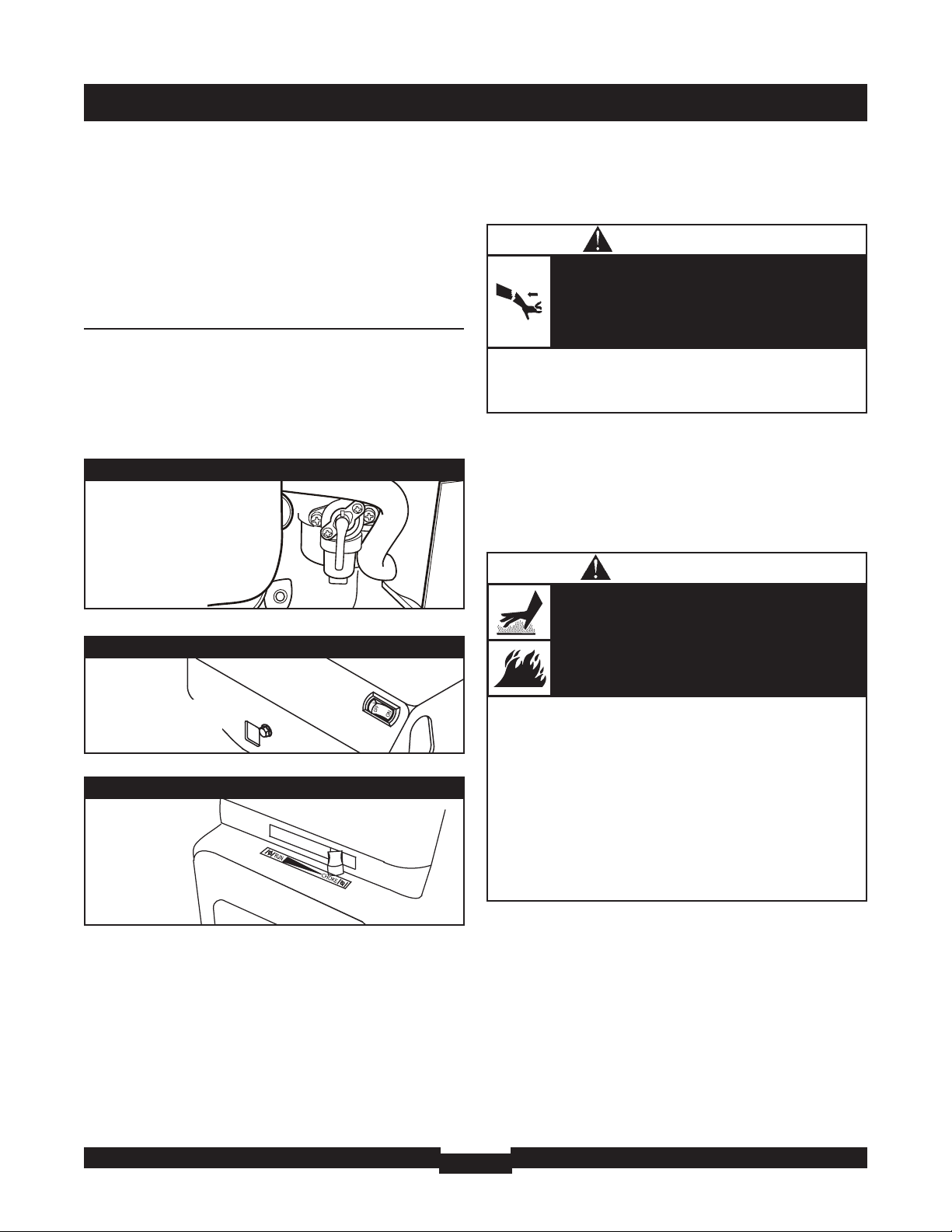

Choke Lever

120 Volt AC, 20 Amp

Duplex Receptacles

On/Off Switch

Spark Arrester Muffler

Grounding Fastener

Air Cleaner

Fuel Tank

Oil Fill Cap/Dipstick

Data Tag

Circuit Breakers (AC)

120 Volt AC, 20 Amp Duplex Receptacles — May be

used to supply electrical power for the operation of

120 Volt AC, 20 Amp, single phase, 60 Hz electrical lighting,

appliance, tool and motor loads.

Air Cleaner — Protects engine by filtering dust and

debris out of intake air.

Choke Lever — Used when starting a cold engine.

Circuit Breakers (AC) — Push to reset circuit breakers

are provided to protect the generator against electrical

overload.

Data Tag – Provides model, revision and serial number of

generator. Please have these readily available if calling for

assistance.

Fuel Tank — Capacity of four (4) U.S. gallons.

Fuel Valve — Used to turn fuel supply on and off to engine.

Grounding Fastener — Consult your local agency having

jurisdiction for grounding requirements in your area.

Oil Drain Plug — Remove to drain engine oil.

Oil Fill Cap/Dipstick — Check and add oil to engine

here.

Recoil Starter — Used to start the engine manually.

On/Off Switch — Set this switch to "On" before starting

engine. Set switch to "Off" to switch off engine.

Spark Arrester Muffler — Exhaust muffler lowers engine

noise and is equipped with a spark arrester screen.

Recoil Starter

Fuel Valve

Oil Drain Plug

Page 6

ASSEMBLY

6

ASSEMBLY

Your generator requires some assembly and is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, please call the generator helpline at

1-800-743-4115. If calling for assistance, please have the

model, revision,and serial number from the data tag available.

See “Know Your Generator” for data tag location.

Unpacking the Generator

1. Set the carton on a rigid flat surface.

2. Open carton completely by cutting each corner from

top to bottom.

3. Cut ties holding accessory kit and axle to generator

and remove everything from carton.

4. Leave generator on carton to install wheel kit.

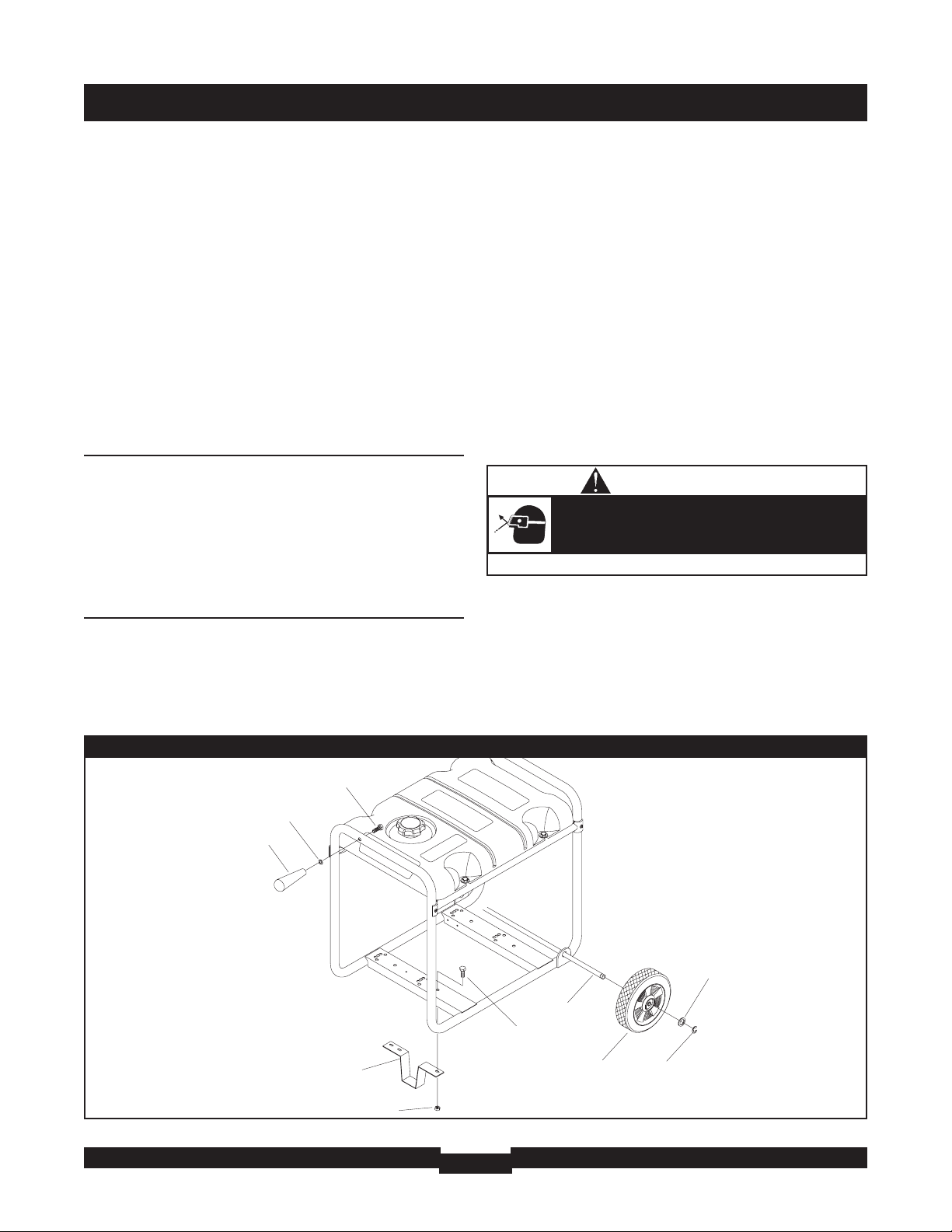

Install Wheel Kit

NOTE:Wheel kit is not intended for over-the-road use.

You will need the following tools to install these

components:

• 13mm wrench

• Socket wrench with a 13mm socket

• 9/16” wrench

• Pliers

• Safety glasses

Refer to Figure 1 and install the wheel kit as follows:

1. Tip generator so that engine end is up.

2. Slide axle through both mounting brackets.

3. Place a wheel on each side with raised hub inboard.

4. Place a washer on axle and then place an e-ring in axle

groove.

5. Install e-ring with pliers, squeezing from top of e-ring

to bottom of axle.

6. Repeat step 4 and 5 to secure second wheel.

7. Tip generator so that engine side is down.

8. Line up holes in support leg with holes in generator

frame.

9. Attach support leg using 2 capscrews (M8 x 16 mm)

and 2 hex nuts.Tighten with a 13mm socket wrench

and 13mm wrench.

Capscrew

Handle

Support Leg

E-Ring

Wheel

Washer

Axle

Lock Washer

Figure 1 — Install Wheel Kit

Capscrew

Nut

• Always wear eye protection when installing/removing e-rings.

E-rings can cause eye injury.

E-rings can spring back and become airborne

when installing or removing.

CAUTION

Page 7

7

ASSEMBLY

10. Return generator to normal operating position (resting

on wheels and support leg).

11. Attach handle using a long (M8 x 45mm) cap screw

and lock washer.Tighten with a 9/16” wrench.

BEFORE STARTING THE

ENGINE

Add Engine Oil

CAUTION! Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

1. Place generator on a flat, level surface.

2. Clean area around oil fill and remove yellow oil fill cap.

NOTE: See the section “Oil” on page 14 to review oil

recommendations.Verify provided oil bottle is correct

viscosity for current ambient temperature.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

4. Replace oil fill cap and fully tighten.

Add Fuel

All fuel is not the same. If a starting or performance

problem is encountered immediately after new fuel has

been used, try another service station or change brands.

NOTE:This engine is certified to operate on gasoline.

Exhaust Emissions Control System: EM (Engine Modifications).

Type of Fuel

1. Always use clean, fresh, UNLEADED gasoline with a

minimum of 87 octane/87 AKI (91 RON). DO NOT

mix oil with fuel. DO NOT modify the engine fuel

system or carburetor to run on alternative fuels.

NOTE: Fuel with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether), is acceptable.

IMPORTANT: Use of any fuel other than those approved

above will void warranty. Some areas require that fuel

pumps be marked if the fuel contains alcohols or ethers. If

you are not sure if your fuel contains alcohol or ethers that

are different than those approved above, then check with

the service station operator.

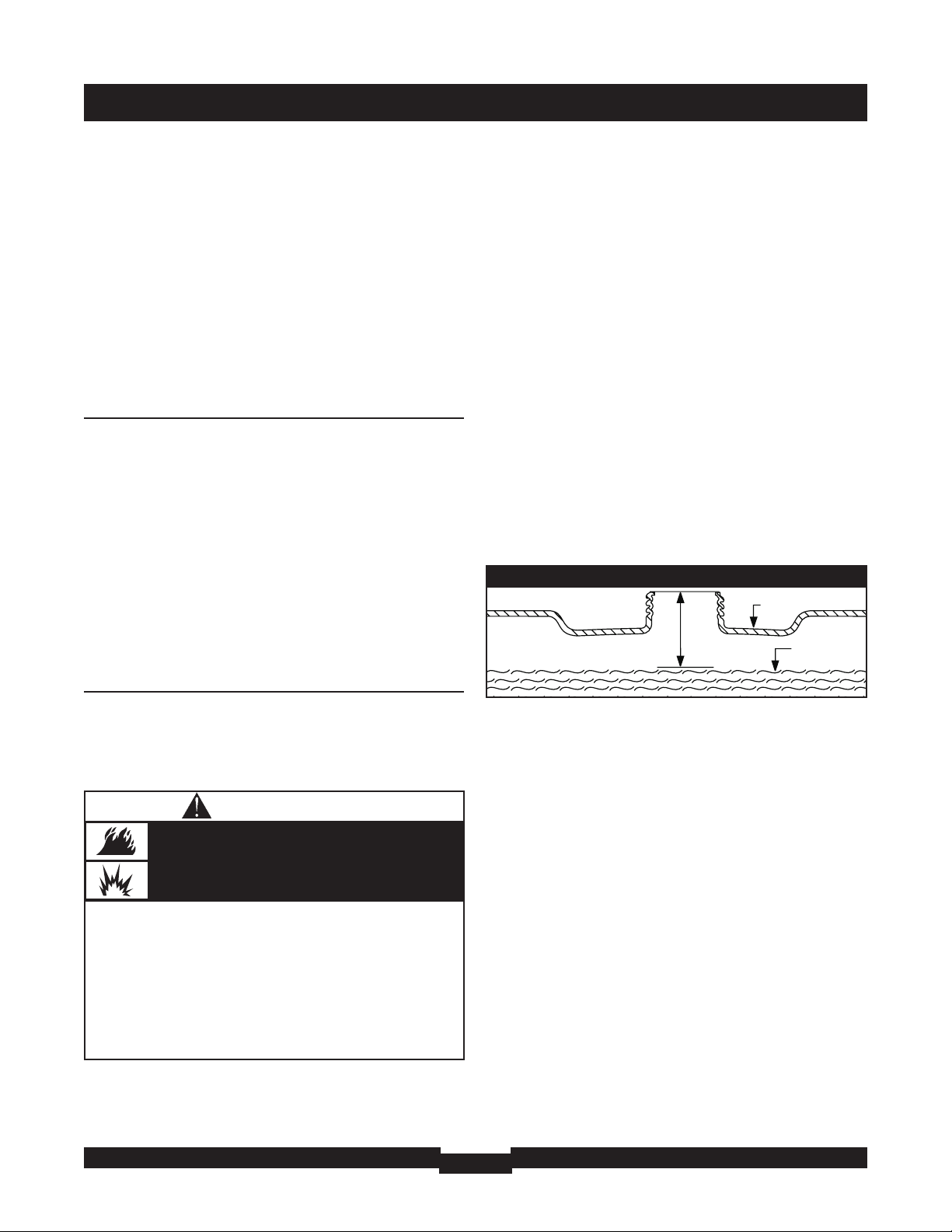

2. Clean area around fuel fill cap, remove cap.

3. Slowly add unleaded gasoline to fuel tank. Be careful

not to overfill.Allow about 1.5" of tank space for fuel

expansion, as shown in Figure 2.

4. Install fuel cap and let any spilled fuel evaporate before

starting engine.

To avoid engine performance issues, the fuel system should

be treated with a fuel preserver or emptied before storage

of 30 days or longer.To protect the fuel system from gum

formation, use Briggs & Stratton FRESH START™ fuel

stabilizer plus, or FRESH START™ continuous fuel

preserver (concentrated liquid cartridge), or FRESH

START™ preservative & stabilizer (granular). If fuel

preserver is not used, drain the fuel tank, start the engine

and let it run until the fuel lines and carburetor are empty.

Use fresh fuel next season. See “Storage” on page 17 for

additional information.

NEVER use engine or carburetor cleaner products in the

fuel tank as permanent damage may occur.

High-altitude use

Operation at high altitude (over 5,000 feet), may require a

high-altitude carburetor jet kit to improve performance and

decrease fuel consumption. See your local authorized Briggs

& Stratton dealer for more information.

WHEN ADDING FUEL

• Turn generator OFF and let it cool at least 2 minutes before

removing fuel cap.Loosen cap slowly to relieve pressure in tank.

• Fill fuel tank outdoors.

• DO NOT overfill tank.Allow space for fuel expansion.

• Wait for spilled fuel to evaporate before starting engine.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

Fuel

Tank

1.5” Air Space

Figure 2 - Fuel Expansion

Page 8

OPERATION

8

USING THE GENERATOR

System Ground

The generator has a system ground that connects the

generator frame components to the ground terminals on

the AC output receptacles.The system ground is connected

to the AC neutral wire (see “Equipment Description”,

earlier in this manual).

Special Requirements

There may be Federal or State Occupational Safety and

Health Administration (OSHA) regulations, local codes, or

ordinances that apply to the intended use of the generator.

Please consult a qualified electrician, electrical inspector, or

the local agency having jurisdiction.

• In some areas, generators are required to be registered

with local utility companies.

• If the generator is used at a construction site, there may

be additional regulations which must be observed.

Connecting to a Building’s Electrical

System

Connections for standby power to a building’s electrical

system must be made by a qualified electrician.The

connection must isolate the generator power from utility

power, and must comply with all applicable laws and

electrical codes.

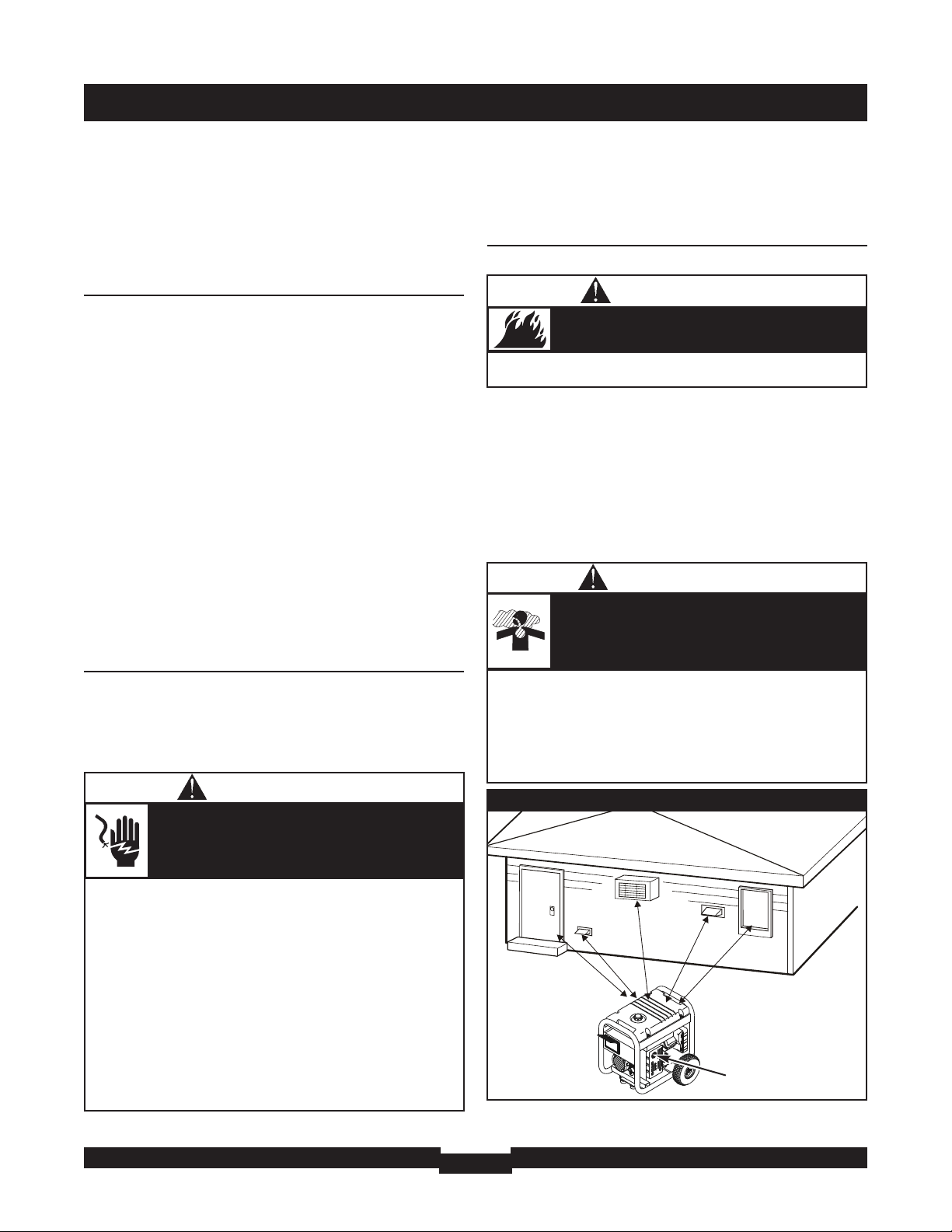

Generator Location

Generator Clearance

Place generator in a well ventilated area, which will allow

for removal of deadly exhaust gas. DO NOT place

generator where exhaust gas could accumulate and enter

inside or be drawn into a potentially occupied building.

Ensure exhaust gas is kept away from any windows,doors,

ventilation intakes or other openings that can allow exhaust

gas to collect in a confined area (Figure 3). Prevailing winds

and air currents should be taken into consideration when

positioning generator.

• When using generator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

• Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT operate generator in the rain or wet weather.

• DO NOT handle generator or electrical cords while standing

in water, while barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or

service generator.

Generator produces powerful voltage.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

WARNING

Figure 3 — Generator Clearance

Exhaust Port

Typical Generator Shown

• Operate generator ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

• DO NOT operate generator inside any building or enclosure

(even if doors or windows are open),including the generator

compartment of a recreational vehicle (RV).

Running generator gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea,

fainting or death.

WARNING

• Keep at least 5 ft. (152 cm) clearance on all sides of generator

including overhead.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Page 9

9

OPERATION

OPERATING THE

GENERATOR

Starting the Engine

Disconnect all electrical loads from the generator. Use the

following start instructions:

1. Make sure unit is on a level surface.

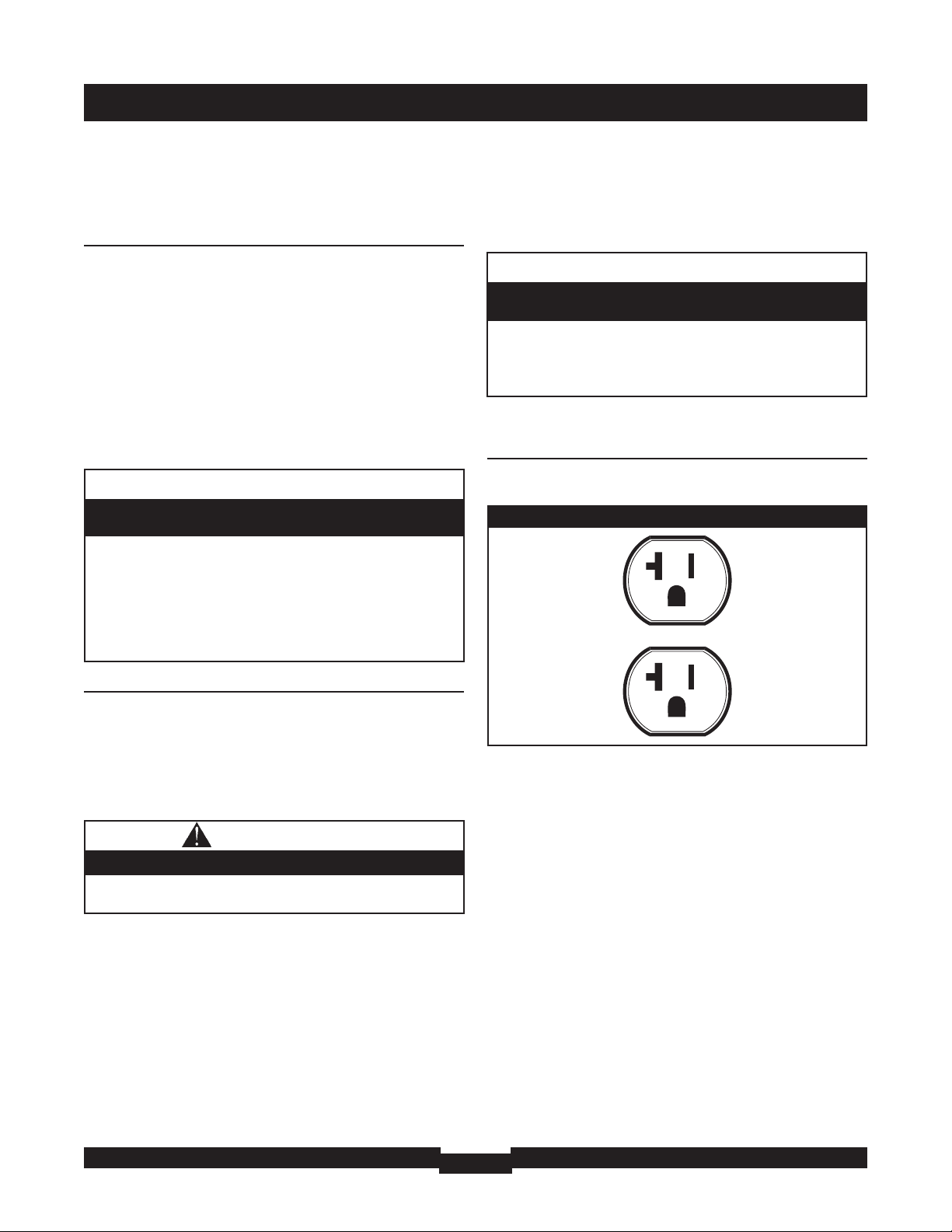

2. Turn white fuel valve to “On” position (Figure 4).The

fuel valve handle will be vertical (pointing toward the

ground).

3. Set on/off switch to “On” position (Figure 5).

4. Place choke lever in “Choke” position (Figure 6).

5. Grasp recoil handle and pull slowly until slight

resistance is felt.Then pull handle rapidly to overcome

compression, prevent kickback and start engine.

IMPORTANT: If excessive fuel is present in the air/fuel

mixture causing a “flooded” condition, move choke lever to

“Run” position and pull handle repeatedly until engine starts.

6. Move choke lever to “Run” position a short distance at

a time over several seconds in warm weather or

minutes in cold weather. Let engine run smoothly before

each change. Operate with choke in “Run” position.

• DO NOT touch hot surfaces and avoid hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of generator

including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Figure 5 — On/Off Switch

Switch is shown in

“On” position

Figure 6 — Choke Lever

Choke Lever

shown in

“Choke”

position

Figure 4 — Fuel Valve

Fuel Valve is shown in

“On” position

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• NEVER start or stop engine with electrical devices plugged in

and turned on.

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains could

result.

WARNING

Page 10

OPERATION

10

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Plug in and turn on the desired 120 Volt AC, single phase,

60 Hz electrical loads.

• DO NOT connect 240 Volt loads to the 120 Volt duplex

receptacles.

• DO NOT connect 3–phase loads to the generator.

• DO NOT connect 50 Hz loads to the generator.

• DO NOT OVERLOAD THE GENERATOR. See

“Don’t Overload Generator”.

Stopping the Engine

1. Turn OFF and unplug all electrical loads from generator

panel receptacles. NEVER start or stop engine with

electrical devices plugged in and turned ON.

2. Let engine run at no-load for several minutes to

stabilize internal temperatures of engine and generator.

3. Move on/off switch to “Off” position.

4. Move fuel valve to “Off” position.

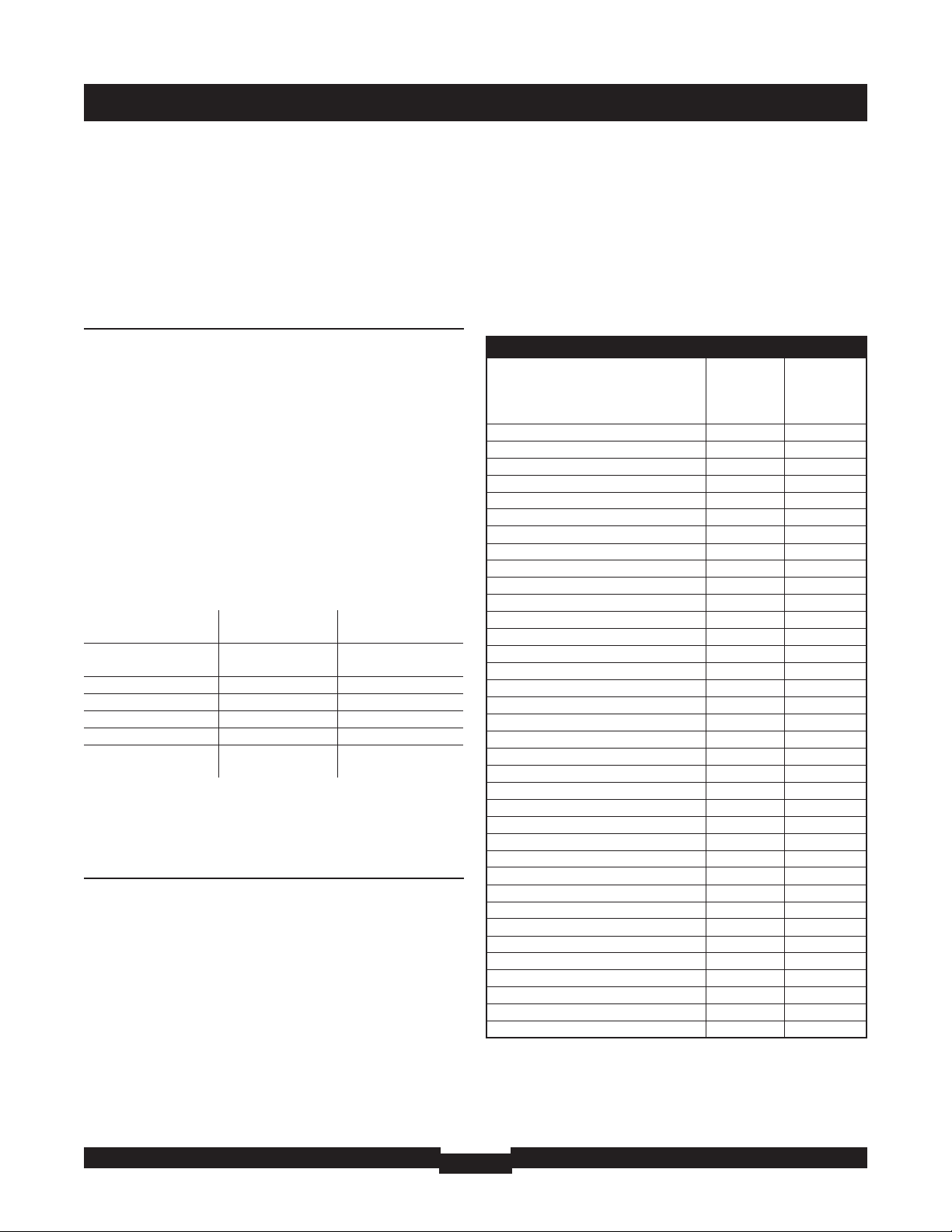

RECEPTACLES

120 Volt AC, 20 Amp, Duplex

Receptacles

Each duplex receptacle (Figure 7) is protected against

overload by a push–to–reset circuit breaker.

Use each receptacle to operate 120 Volt AC, single–phase,

60 Hz electrical loads requiring up to 2,400 watts (2.4 kW)

at 20 Amps of current. Use cord sets that are rated for

125 Volt AC loads at 20 Amps (or greater).

• NEVER attempt to power a device requiring more amperage

than generator or receptacle can supply.

• DO NOT overload the generator.See “Don’t Overload

Generator”.

Receptacles may be marked with rating value greater

than generator output capacity.

CAUTION

Figure 7 — 120 Volt, 20 Amp Duplex Receptacles

• DO NOT stop engine by moving choke lever to “Choke”

position.

Backfire, fire or engine damage could occur.

CAUTION

• See “Don’t Overload Generator”.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator

before stopping generator.

Exceeding generator’s wattage/amperage capacity can

damage generator and/or electrical devices connected to it.

CAUTION

Page 11

OPERATION

11

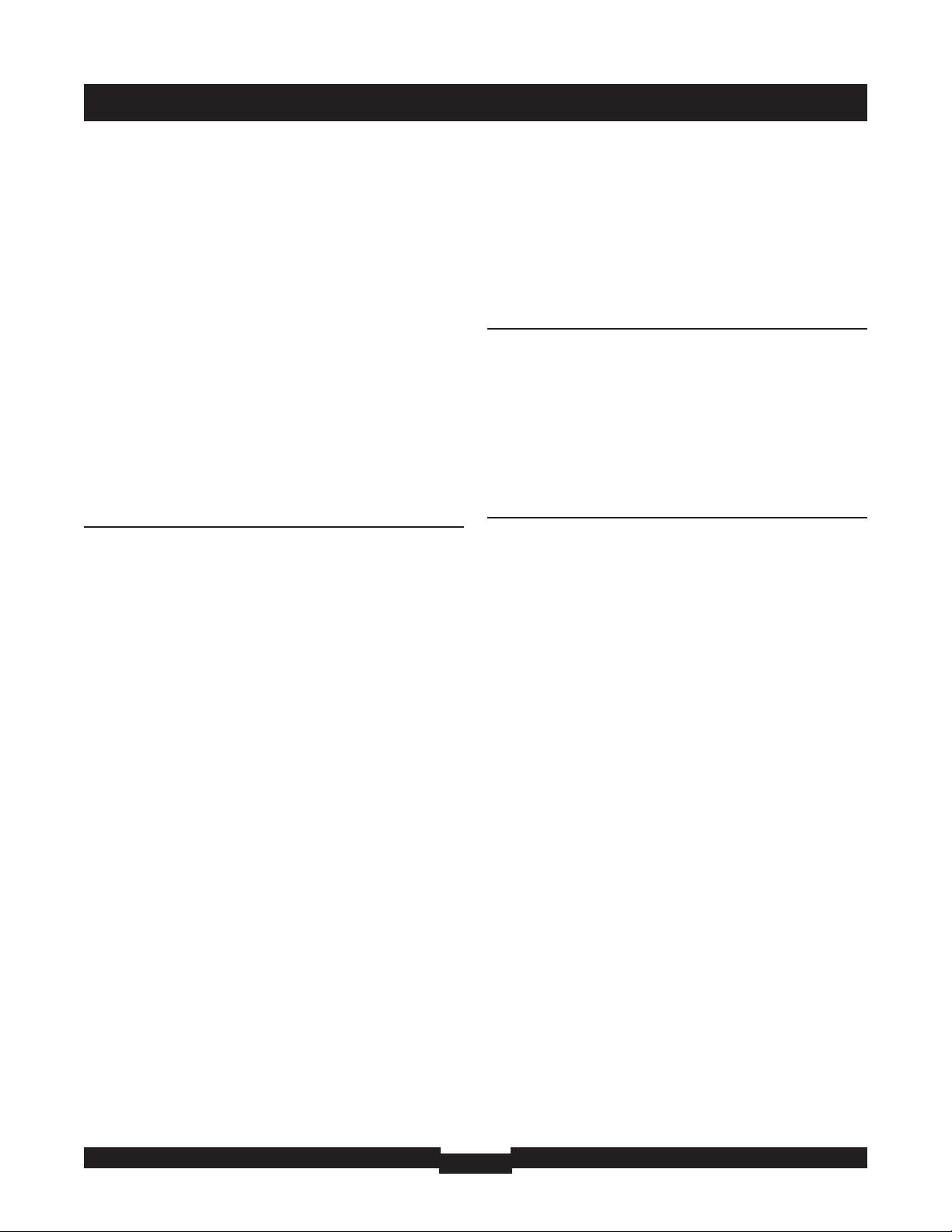

DON'T OVERLOAD

GENERATOR

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items.This is

the amount of power your generator must produce to

keep your items running. See Figure 8.

3. Estimate how many surge (starting) watts you will

need. Surge wattage is the short burst of power

needed to start electric motor-driven tools or

appliances such as a circular saw or refrigerator.

Because not all motors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Example:

Total Rated (Running) Watts = 3075

Highest Additional Surge Watts = 1800

Total Generator Output Required = 4875

Power Management

To prolong the life of your generator and attached devices,

it is important to take care when adding electrical loads to

your generator.There should be nothing connected to the

generator outlets before starting it's engine.The correct

and safe way to manage generator power is to sequentially

add loads as follows:

1. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

NEVER add more loads than the generator capacity.Take

special care to consider surge loads in generator capacity,

as described above.

*Wattages listed are approximate only. Check tool or

appliance for actual wattage.

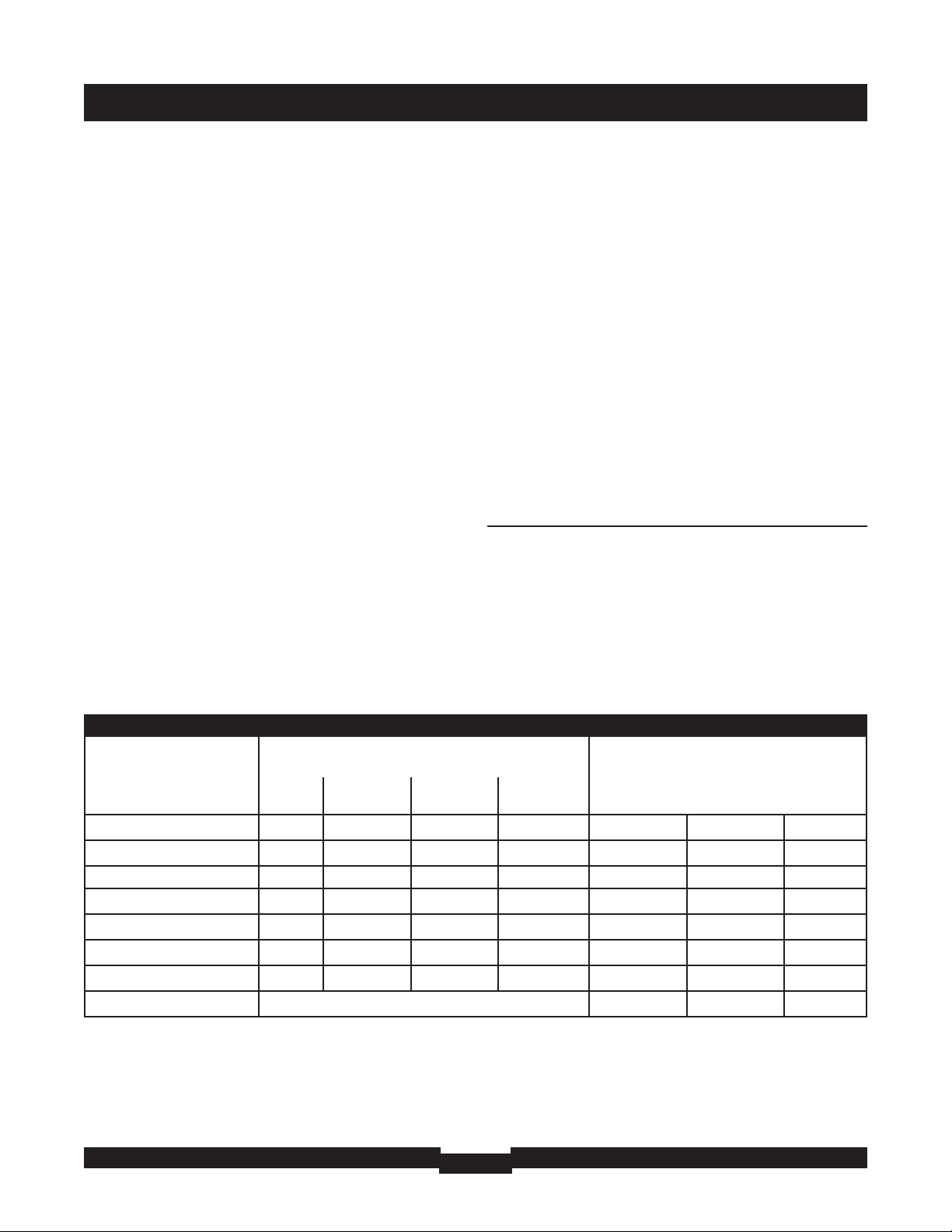

Tool or Appliance

Rated (Running)

Watts

Additional Surge

(Starting) Watts

Window Air

Conditioner

1200 1800

Refrigerator 800 1600

Deep Freezer 500 500

Television 500 Light (75 Watts) 75 -

3075 Total

Running Watts

1800 Highest

Surge Watts

Tool or Appliance

Rated*

(Running)

Watts

Additional

Surge

(Starting)

Watts

Essentials

Light Bulb - 75 watt

75

-

Deep Freezer

500

500

Sump Pump

800

1200

Refrigerator/Freezer - 18 Cu. Ft.

800

1600

Water Well Pump - 1/3 HP

1000

2000

Heating/Cooling

Window AC - 10,000 BTU

1200

1800

Window Fan

300

600

Furnace Fan Blower - 1/2 HP

800

1300

Kitchen

Microwave Oven - 1000 Watt

1000

-

Coffee Maker

1500

-

Electric Stove - Single Element

1500

-

Hot Plate

2500

-

Family Room

DVD/CD Player

100

-

VCR

100

-

Stereo Receiver

450

-

Color Television - 27”

500

-

Personal Computer w/17” monitor

800

-

Other

Security System

180

-

AM/FM Clock Radio

300

-

Garage Door Opener - 1/2 HP

480

520

Electric Water Heater - 40 Gallon

4000

-

DIY/Job Site

Quartz Halogen Work Light

1000

-

Airless Sprayer - 1/3 HP

600

1200

Reciprocating Saw

960

960

Electric Drill - 1/2 HP

1000

1000

Circular Saw - 7 1/4”

1500

1500

Miter Saw - 10”

1800

1800

Table Planer - 6”

1800

1800

Table Saw/Radial Arm Saw - 10”

2000

2000

Air Compressor - 1-1/2 HP

2500

2500

Figure 8 - Wattage Reference Chart

Page 12

SPECIFICATIONS

12

ENGINE TECHNICAL

INFORMATION

This is a single cylinder, overhead valve(OHV), air cooled

engine. It is a low emissions engine.

In the State of California, Model Series 120000 engines are

certified by the California Air Resources Board to meet

emissions standards for 125 hours. Such certification does

not grant the purchaser, owner or operator of this engine

any additional warranties with respect to the performance

or operational life of this engine.The engine is warranted

solely according to the product and emissions warranties

stated elsewhere in this manual.

Power Ratings

* The power ratings for an individual engine model are

initially developed by starting with SAE (Society of

Automotive Engineers) code J1940 (Small Engine Power &

Torque Rating Procedure) (Revision 2002-05). Given both

the wide array of products on which our engines are

placed, and the variety of environmental issues applicable to

operating the equipment, it may be that the engine you

have purchased will not develop the rated horsepower

when used in a piece of power equipment (actual “on-site”

power).This difference is due to a variety of factors

including, but not limited to, the following: differences in

altitude, temperature, barometric pressure, humidity, fuel,

engine lubrication, maximum governed engine speed,

individual engine to engine variability, design of the

particular piece of power equipment, the manner in which

the engine is operated, engine run-in to reduce friction and

clean out of combustion chambers, adjustments to the

valves and carburetor, and other factors.The power ratings

may also be adjusted based on comparisons to other

similar engines utilized in similar applications, and will

therefore not necessarily match the values derived using

the foregoing codes.

PRODUCT

SPECIFICATIONS

Generator Specifications

Starting Wattage . . . . . . . . . . . . . . . . . . . . . . . .5,000 Watts

Wattage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,000 Watts

Rated AC Load Current:

At 120 Volts . . . . . . . . . . . . . . . . . . . . . . . . . . .33.3 Amps

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–phase

Rated Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . .60 Hertz

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . .140 lbs.

Engine Specifications

Gross* Horsepower . . . . . . . . . . . . . . . . . 6.5 at 3600 rpm

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.69 in. (68mm)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.20 in. (56mm)

Displacement . . . . . . . . . . . . . . . . . . . . . . 12.57 in. (206 cc)

Spark Plug

Type: . . . . . . . . . . . . Champion RC12YC or Equivalent

Set Gap To: . . . . . . . . . . . . . . . . . . . 0.030inch (0.76mm)

Armature Air Gap: . . . . . . . . . . . . . . . . . . . . 0.010-0.014 in.

(0.25-0.36mm)

Valve clearance with valve springs installed and piston 1/4 in.

(6 mm) past top dead center (check when engine is cold).

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004-0.006 in.

(0.10-0.15 mm)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.009-0.011 in.

(0.23-0.28 mm)

Fuel Capacity . . . . . . . . . . . . . . . . . . . . . . . . . 4 U.S. gallons

Oil Capacity . . . . . . . . . . . . . . . . . . . .20 Ounces (.6 Liters)

NOTE:For practical operation, the generator load should

not exceed 85% of rated wattage. Engine gross horsepower

will decrease 3-1/2% for each 1,000 feet (300 meters) above

sea level and 1% for each 10° F (5.6° C) above 77° F

(25° C). It should operate satisfactorily at an angle up to 15°.

Page 13

13

MAINTENANCE

FILL IN DATES AS YOU

COMPLETE REGULAR SERVICE

SERVICE DATES

SERVICE DATES

MAINTENANCE TASK

Before

Each Use

Every 25

Hours or Yearly

Every 50

Hours or Yearly

Every 100

Hours or Yearly

Check oil level

X

Clean debris

X

Service air cleaner

X²

Change engine oil

X¹

Service spark plug

X

Service spark arrester

X

Clean cooling system

X²

Prepare for storage If unit is to remain idle for longer than 30 days.

Figure 9 – Maintenance Schedule

GENERAL

RECOMMENDATIONS

Regular maintenance will improve the performance and

extend the life of the generator. See any authorized dealer

for service.

The generator’s warranty does not cover items that have

been subjected to operator abuse or negligence.To receive

full value from the warranty, the operator must maintain

generator as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your generator.

All service and adjustments should be made at least once

each season. Follow the requirements in the “Maintenance

Schedule” chart below in Figure 9.

NOTE: Once a year you should clean or replace the spark

plug and replace the air filter.A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer.

GENERATOR

MAINTENANCE

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors. Cooling air

slots in the generator must not become clogged with snow,

leaves, or any other foreign material.

Check the cleanliness of the generator frequently and clean

when dust, dirt, oil, moisture or other foreign substances

are visible on its exterior surface.

NOTE:DO NOT use water or other liquids to clean

generator. Liquids can enter the engine fuel system causing

poor performance and / or failure to occur. In addition, if

liquids enters the generator through cooling air slots, some

of the liquid will be retained in voids and cracks of the rotor

and stator winding insulation. Liquid and dirt buildup on the

generator internal windings will eventually decrease the

insulation resistance of these windings.

Generator Cleaning

Daily or before use, clean accumulated debris from

generator. Keep linkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Generator parts should be kept clean to reduce the risk of

overheating and ignition of accumulated debris.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

¹ Change oil after the first (5) operating hours and every 50 hours or every year,whichever occurs first, thereafter.

Change sooner when operating under dirty or dusty conditions.

² Replace more often under dirty or dusty conditions.

Page 14

MAINTENANCE

14

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on the

generator.These openings must be kept clean and

unobstructed.

ENGINE MAINTENANCE

Oil

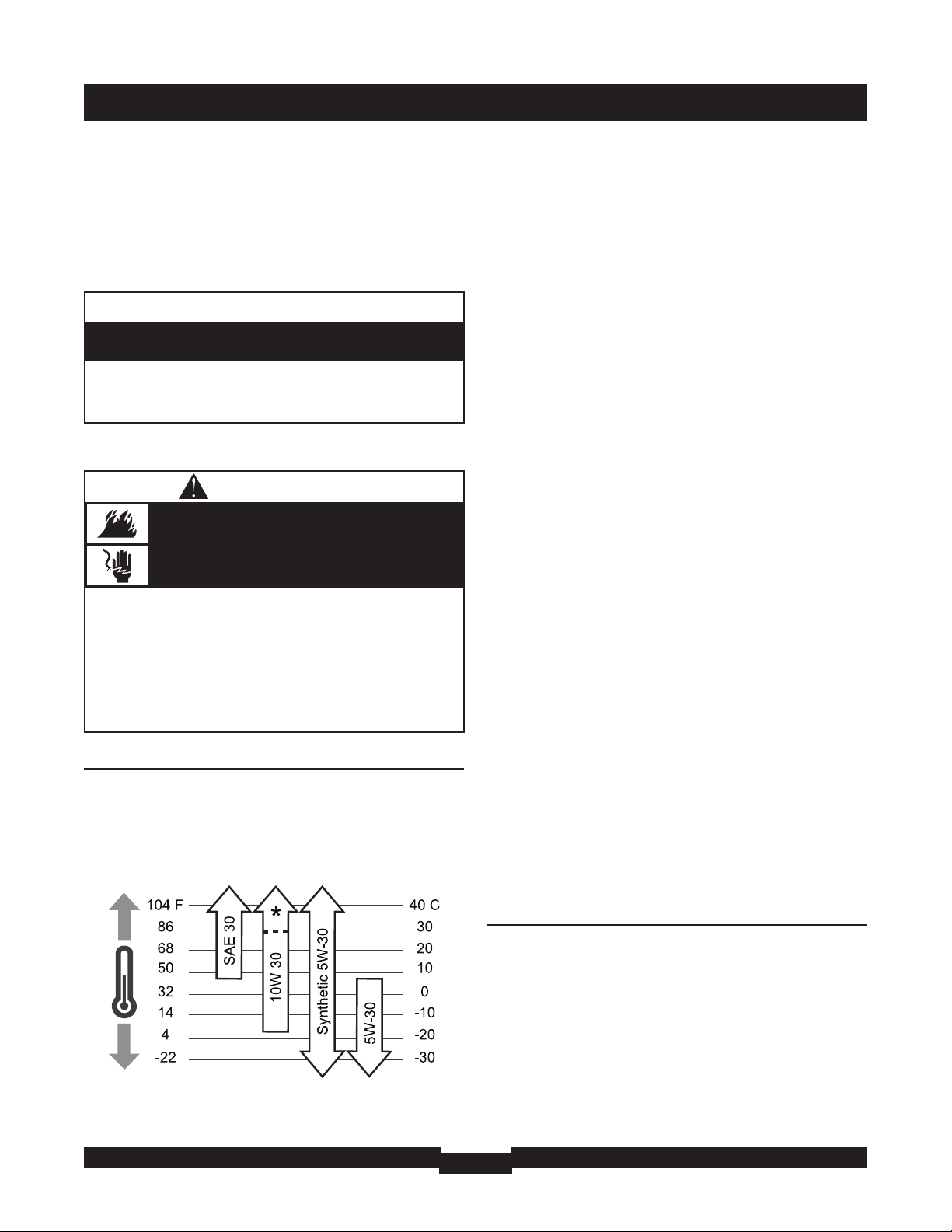

Oil Recommendations

NOTE:When adding oil to the engine crankcase, use only

high quality detergent oil classified “For Service SF, SG, SH,

SJ” or higher. DO NOT use special additives.

1. Choose a viscosity according to the following table:

NOTE: Synthetic oil meeting ILSAC GF-2,API certification

mark and API service symbol with “SJ/CF ENERGY

CONSERVING” or higher, is an acceptable oil at all

temperatures. Use of synthetic oil does not alter required

oil change intervals.

SAE 30: 40 °F and higher (5 °C and higher) is good for all

purpose use above 40°F, use below 40°F will cause hard

starting.

10W-30: 0 to 100 °F (-18 to 38 °C) is better for varying

temperature conditions.This grade of oil improves cold

weather starting, but may increase oil consumption at

80°F(27°C) or higher.

*Check oil level frequently at higher temperatures.

Synthetic 5W-30: -20 to 120 °F (-30 to 40 °C) provides

the best protection at all temperatures as well as improved

starting with less oil consumption.

5W-30: 40 °F and below (5 °C and below) is recommended

for winter use, and works best in cold conditions.

Checking Oil Level

Oil level should be checked prior to each use or at least

every 5 hours of operation. Keep oil level maintained.

1. Make sure generator is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean cloth.

Replace and tighten dipstick. Remove and and check oil

level.

3. Verify oil is at “Full” mark on dipstick. Replace and

tighten dipstick.

Adding Engine Oil

1. Make sure generator is on a level surface.

2. Check oil level as described in “Checking Oil Level”.

3. If needed, slowly pour oil into oil fill opening to the

“Full” mark on dipstick. DO NOT overfill.

4. Replace and tighten dipstick.

Servicing Air Cleaner

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner.

Replace the air cleaner every 25 hours of operation or

once each year, whichever comes first. Replace more often

if operating under dirty or dusty conditions.

• DO NOT expose generator to excessive moisture, dust, dirt,

or corrosive vapors.

• DO NOT insert any objects through cooling slots.

Improper treatment of generator can damage it and

shorten its life.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

GENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Unintentional sparking can result in fire or

electric shock.

WARNING

Page 15

MAINTENANCE

15

To service the air cleaner, follow these steps:

1. Loosen screw and tilt cover down (Figure 10).

2. Carefully remove cartridge assembly.

3. To clean cartridge, gently tap pleated paper side on a

flat surface.

4. Reinstall clean or new cartridge inside cover.

5. Insert cover’s tabs into slots in bottom of base.

6. Tilt cover up and tighten screw securely to base.

Changing Engine Oil

Change the oil after the first 5 hours of operation. Change

oil every 50 hours thereafter. If you are using your

generator under extremely dirty or dusty conditions, or in

extremely hot weather, change the oil more often.

KEEP OUT OF REACH OF CHILDREN. DON'T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

Change the oil while the engine is still warm from running,

as follows:

1. Make sure unit is on a level surface.

2. Disconnect the spark plug wire from the spark plug

and place the wire where it cannot contact spark plug.

3. Clean area around oil drain plug.The oil drain plug is

located at base of engine, opposite carburetor.

4. Remove oil drain plug and drain oil completely into a

suitable container.

5. Reinstall oil drain plug and tighten securely. Remove oil

cap/dipstick.

6. Slowly pour recommended oil (about 20 oz.) into oil

fill opening. Pause to permit oil to settle. Fill to “Full”

mark on dipstick.

7. Wipe dipstick clean each time oil level is checked.DO

NOT overfill.

8. Reinstall oil cap/dipstick.Tighten cap securely.

9. Wipe up any spilled oil.

Servicing Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first.This will help your

engine to start easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Check electrode gap with wire feeler gauge and set

spark plug gap to 0.030 inch (0.76mm) if necessary

(Figure 11).

4. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use a recommended replacement

plug.

5. Install spark plug and tighten firmly.

Servicing Spark Arrester

The engine exhaust muffler has a spark arrester screen.

Inspect and clean the screen every 100 hours of operation

or once each year, whichever comes first.

If you use your generator on any forest-covered, brushcovered, or grass-covered unimproved land, it must have a

spark arrester.The spark arrester must be maintained in

good condition by the owner/operator.

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Avoid prolonged or repeated skin contact with used

motor oil.

CAUTION

Figure 11 — Service Spark Plug

Figure 10 - Air Cleaner

Page 16

MAINTENANCE

16

Clean and inspect the spark arrester as follows:

1. To remove muffler heat shield from muffler, remove

four screws that connect guard to muffler bracket

(Figure 12).

2. Remove four screws that attach spark arrester screen.

3. Inspect screen and replace if torn, perforated or

otherwise damaged. DO NOT use a defective screen. If

screen is not damaged, clean it with commercial

solvent.

4. Reattach screen and muffler guard.

Clean Cooling System

Over time debris may accumulate in cylinder cooling fins

and cannot be observed without partial engine disassembly.

For this reason, we recommend you have a authorized

service dealer clean the cooling system (Figure 13) per

recommended intervals (see “Maintenance Schedule” on

page 13). Equally important is to keep top of engine free

from debris. See “Generator Cleaning”.

Carburetor Adjustment

The carburetor on this engine is low emission. It is

equipped with a non-adjustable idle mixture valve and

governed idle, if equipped. Governed idle and top speed

have been set at the factory. If adjustment is required, see a

authorized service dealer.

Muffler

Spark Arrester

Screen

Heat Shield

• DO NOT touch hot surfaces and avoid hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of generator

including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Figure 12 — Service Spark Arrester

• DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

speed.

• DO NOT modify generator in any way.

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

CAUTION

Figure 13 — Air Cooling System

Clean

Page 17

STORAGE

17

STORAGE

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot be

done and you must store the unit for more than 30 days, use

the following information as a guide to prepare it for storage.

Long Term Storage Instructions

It is important to prevent gum deposits from forming in

essential fuel system parts, such as the carburetor, fuel filter,

fuel hose or tank during storage.Also, experience indicates

that alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leads to separation

and formation of acids during storage.Acidic fuel can

damage the fuel system of an engine while in storage.

Protect Fuel System

Fuel Stabilizer:

Follow these instructions if storing fuel more than 30 days.

To protect the fuel system from gum formation, use Briggs

& Stratton FRESH START™ fuel stabilizer plus, or FRESH

START™ continuous fuel preserver (concentrated liquid

cartridge), or FRESH START™ preservative & stabilizer

(granular).

If fuel stabilizer is used, you do not need to drain fuel prior

to storage. If the FRESH START™ continuous fuel

preserver (concentrated liquid cartridge) is used, there is

no need to drain fuel prior to storage as long as the

cartridge contains stabilizer for the storage season.

• Run engine outdoors for several minutes to be sure

treated fuel has replaced untreated fuel in carburetor.

If fuel preserver is not used, then always remove all fuel

from tank and run engine until it stops from lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase. Refill

with recommended grade.

Oil Cylinder Bore

• Remove spark plug and pour about 1/2 ounce (15 ml) of

clean engine oil into the cylinder.

• Install spark plug and pull recoil starter handle slowly to

distribute oil.

Generator

1. Clean generator as outlined in “Generator Cleaning”.

2. Check that cooling air slots and openings on generator

are open and unobstructed.

Other Storage Tips

1. DO NOT store fuel from one season to another unless

it has been treated as described in “Protect Fuel System”.

2. Replace fuel can if it starts to rust. Contaminated fuel

will cause engine problems.

3. If possible, store unit indoors and cover it to give

protection from dust and dirt. BE SURE TO EMPTY

FUEL TANK.

4. Cover unit with a suitable protective cover that does

not retain moisture.

5. Store generator in clean, dry area.

• DO NOT place a storage cover over a hot generator.

• Let equipment cool for a sufficient time before placing the

cover on the equipment.

Storage covers can be flammable.

WARNING

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

WHEN DRAINING FUEL

• Turn generator OFF and let it cool at least 2 minutes before

removing fuel cap.Loosen cap slowly to relieve pressure in tank.

• Drain fuel tank outdoors.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• NEVER crank engine with spark plug removed.

Unintentional sparking can result in fire or

electric shock.

WARNING

Page 18

TROUBLESHOOTING

18

TROUBLESHOOTING

Problem Cause Correction

Engine is running, but no

AC output is available.

1. One of the circuit breakers is open.

2. Fault in generator.

3. Poor connection or defective cord set.

4. Connected device is bad.

1. Reset circuit breaker.

2. Contact authorized service facility.

3. Check and repair.

4. Connect another device that is in

good condition.

Engine runs good at noload but "bogs down" when

loads are connected.

1. Short circuit in a connected load.

2. Engine speed is too slow.

3. Generator is overloaded.

4. Shorted generator circuit.

1. Disconnect shorted electrical load.

2. Contact authorized service facility.

3. See "Don't Overload Generator".

4. Contact authorized service facility.

Engine will not start; or

starts and runs rough.

1. Engine switch set to "Off".

2. Fuel Valve is in "Off" position.

3. Dirty air cleaner.

4. Out of fuel.

5. Stale fuel.

6. Spark plug wire not connected to spark

plug.

7. Bad spark plug.

8. Water in fuel.

9. Flooded.

10. Excessively rich fuel mixture.

11. Intake valve stuck open or closed.

12. Engine has lost compression.

1. Set switch to "On".

2. Turn fuel valve to "Open" position.

3. Clean or replace air cleaner.

4. Fill fuel tank.

5. Drain fuel tank and carburetor; fill

with fresh fuel.

6. Connect wire to spark plug.

7. Replace spark plug.

8. Drain fuel tank and carburetor; fill

with fresh fuel.

9. Wait 5 minutes and re-crank engine.

10. Contact authorized service facility.

11. Contact authorized service facility.

12. Contact authorized service facility.

Engine shuts down when

running.

Out of fuel. Fill fuel tank.

Engine lacks power.

1. Load is too high.

2. Dirty air filter.

1. See "Don't Overload Generator".

2. Replace air filter.

Engine "hunts" or falters. Carburetor is running too rich or too lean. Contact authorized service facility.

Page 19

NOTES

19

NOTES

Page 20

EMISSIONS CONTROL SYSTEM WARRANTY

Briggs & Stratton Corporation (B&S), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emissions Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

California, United States and Canada Emissions Control

Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and B&S are

pleased to explain the Emissions Control System Warranty on your

small off–road engine (SORE). In California, new small off–road engines

model year 2006 and later must be designed, built and equipped to

meet the State’s stringent anti–smog standards. Elsewhere in the

United States, new non–road,spark–ignition engines certified for model

year 1997 and later must meet similar standards set forth by the U.S.

EPA. B&S must warrant the emissions control system on your engine

for the periods of time listed below, provided there has been no abuse,

neglect or improper maintenance of your small off–road engine.

Your emissions control system includes parts such as the carburetor, air

cleaner, ignition system, fuel line, muffler and catalytic converter.Also

included may be connectors and other emissions related assemblies.

Where a warrantable condition exists, B&S will repair your small

off–road engine at no cost to you including diagnosis, parts and labor.

Briggs & Stratton Emissions Control Defects Warranty

Coverage

Small off–road engines are warranted relative to emissions control

parts defects for a period of two years, subject to provisions set forth

below.If any covered part on your engine is defective, the part will be

repaired or replaced by B&S.

Owner’s Warranty Responsibilities

As the small off–road engine owner, you are responsible for the

performance of the required maintenance listed in your Operating and

Maintenance Instructions. B&S recommends that you retain all your

receipts covering maintenance on your small off–road engine, but B&S

cannot deny warranty solely for the lack of receipts or for your failure

to ensure the performance of all scheduled maintenance.

As the small off–road engine owner, you should however be aware that

B&S may deny you warranty coverage if your small off–road engine or

a part has failed due to abuse, neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your small off–road engine to an

Authorized B&S Service Dealer as soon as a problem exists.The

undisputed warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service Representative at

1–414–259–5262.

The emissions warranty is a defects warranty. Defects are judged on

normal engine performance.The warranty is not related to an in–use

emissions test.

Briggs & Stratton Emissions Control Defects Warranty

Provisions

The following are specific provisions relative to your Emissions Control

Defects Warranty Coverage. It is in addition to the B&S engine

warranty for non–regulated engines found in the Owner’s Manual.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed

below (the emissions control systems parts) to the extent these

parts were present on the engine purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

• Fuel line, fuel line fittings, clamps

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position,time sensitive valves and

switches

• Connectors and assemblies

2. Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser

that the Warranted Parts shall be free from defects in materials

and workmanship which caused the failure of the Warranted Parts

for a period of two years from the date the engine is delivered to

a retail purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be performed

at no charge to the owner, including diagnostic labor which leads

to the determination that a Warranted Part is defective, if the

diagnostic work is performed at an Authorized B&S Service

Dealer. For emissions warranty service contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow Pages”

under “Engines, Gasoline,” “Gasoline Engines,” “Lawn Mowers,” or

similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions of

the B&S Engine Warranty Policy.Warranty coverage shall be

excluded for failures of Warranted Parts which are not original

B&S parts or because of abuse, neglect or improper maintenance

as set forth in the B&S Engine Warranty Policy. B&S is not liable to

cover failures of Warranted Parts caused by the use of add–on,

non–original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as

required maintenance or which is scheduled only for regular

inspection to the effect of “repair or replace as necessary” shall

be warranted as to defects for the warranty period.Any

Warranted Part which is scheduled for replacement as required

maintenance shall be warranted as to defects only for the period

of time up to the first scheduled replacement for that part.Any

replacement part that is equivalent in performance and durability

may be used in the performance of any maintenance or repairs.

The owner is responsible for the performance of all required

maintenance, as defined in the B&S Owner’s Manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine

components caused by the failure of any Warranted Part still

under warranty.

Page 21

Emissions Durability Period and Air

Index Information On Your Engine

Emissions Label

Engines that are certified to meet the California Air Resources

Board (CARB) Tier 2 Emission Standards must display

information regarding the Emissions Durability Period and Air

Index.The engine manufacturer makes this information available

to the consumer on emission labels.

The Emissions Durability Period describes the number of

hours of actual running time for which the engine is certified to

be emissions compliant, assuming proper maintenance in

accordance with the Operating & Maintenance Instructions.The

following categories are used:

Moderate: Engine is certified to be emission compliant for

125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for

250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for

500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to

25 hours per year.Therefore, the Emissions Durability

Period of an engine with an intermediate rating would

equate to 10 to 12 years.

The Air Index is a calculated number describing the relative

level of emissions for a specific engine family.The lower the Air

Index, the cleaner the engine.This information is displayed in

graphical form on the emisions label.

Emissions Compliance Period On

Engine Emissions Compliance Label

After July 1, 2000 certain Briggs & Stratton engines will be

certified to meet the United States Environmental Protection

Agency (USEPA) Phase 2 emission standards. For phase 2 certified

engines, the Emissions Compliance Period referred to on the

Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal

emission requirements. For engines less than 225 cc displacement,

Category C = 125 hours, B = 250 hours and A = 500 hours. For

engines of 225 cc or more, Category C = 250 hours, B = 500

hours and A = 1000 hours.

This engine has an intermediate rating with and Air Index of 2.

The EPA Emissions compliance period is Category B.The

diplacement of these engines is 206 cc.

Below is a generic representation of the emission label typically

found on a certified engine.

Page 22

NOTES

22

NOTES

Page 23

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC PORTABLE GENERATOR OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the portable generator that is

defective in material or workmanship or both. Transportation charges on product submitted for repair or replacement under this

warranty must be borne by purchaser. This warranty is effective for the time periods and subject to the conditions stated below.

For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at www.briggspowerproducts.com.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT

PERMITTED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or

countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from state to state or country to country.

2 years*

1 year

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail end user, and continues for the period of time stated above.

“Consumer Use" means personal residential household use by a retail consumer. “Commercial Use" means all other uses, including

use for commercial, income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter be

considered as commercial use for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE

YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME

WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE

THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty

repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For

example, warranty service would not apply if equipment damage occurred because of misuse, lack of routine maintenance,

shipping, handling, warehousing or improper installation. Similarly, the warranty is void if the manufacturing date or the serial number

on the portable generator has been removed or the equipment has been altered or modified. During the warranty period, the

Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal

use and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This

warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or

unauthorized installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper

maintenance, repair or storage so as, in our judgment, to adversely affect its performance and reliability. This warranty also does

not cover normal maintenance such as air filters, adjustments, fuel system cleaning and obstruction (due to chemical, dirt,

carbon, lime, and so forth).

• Other Exclusions: This warranty excludes wear items such as o-rings, filters, etc., or malfunctions resulting from accidents,

abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration. Accessory parts such as generator

adapter cord sets and storage covers are excluded from the product warranty. This warranty excludes used, reconditioned, and

demonstration equipment, equipment used for prime power in place of utility power, equipment used in life support applications,

and failures due to acts of God and other force majeure events beyond the manufacturers control.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

Effective February 1, 2006 replaces all undated Warranties and all Warranties dated before February 1, 2006

198189E, Rev 0. 02/01/2006

*Second year parts only

WARRANTY PERIOD

Page 24

REGLAS DE SEGURIDAD

24

TABLA DE CONTENIDOS

Reglas De Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

Conozca Su Generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29

Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-34

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-39

Almacenamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Diagnosticos De Averías. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Garantía de Control de Emisiones. . . . . . . . . . . . . . . . . . . . . 42-43

Garantia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DESCRIPCIÓN DEL EQUIPO

Lea este manual de manera cuidadosa y

familiarícese con su generador. Conozca sus

usos, sus limitaciones y cualquier peligro

relacionado con el mismo.

Este generador funciona en base a un motor, de campo eléctrico

giratorio y de corriente alterna (AC). Fue diseñado con la

finalidad de proveer energía eléctrica para luces eléctricas,

aparatos, herramientas compatibles y cargas de motor. El campo

giratorio del generador funciona a una velocidad de 3,6000 rpm

usando un motor con un solo cilindro.

¡PRECAUCIÓN! NO sobrepase la capacidad de vataje y

amperaje del generador. Revise "No Sobrecargue Generador".

Se ha hecho cada esfuerzo posible para asegurarse que la

información que aparece en este manual es exacta y se encuentra

actualizada. Sin embargo,nosotros se reserva el derecho a

cambiar, alterar o de otra manera mejorar, el producto y este

documento en cualquier momento, sin previo aviso.

El Sistema de Control de Emisiones para este generador está

garantizado para juegos estándares por la Agencia de Protección

Ambiental y el Consejo de recursos de aire de California.

REGLAS DE SEGURIDAD

Éste es el símbolo de alerta de seguridad. Sirve

para advertir al usuario de un posible riesgo para

su integridad física. Siga todos los mensajes de

seguridad que figuren después de este símbolo

para evitar lesiones o incluso la muerte.

El símbolo de alerta de seguridad ( ) es usado con una palabra

(PELIGRO,ADVERTENCIA, PRECAUCIÓN), un mensaje por

escrito o una ilustración, para alertarlo acerca de cualquier

situación de peligro que pueda existir. PELIGRO indica un riesgo

el cual, si no se evita, causará la muerte o una herida grave.

ADVERTENCIA indica un riesgo el cual, si no se evita, puede

causar la muerte o una herida grave. PRECAUCIÓN indica un

riesgo, el cual, si no se evita, puede causar heridas menores o

moderadas. PRECAUCIÓN, cuando se usa sin el símbolo de

alerta, indica una situación que podría resultar en el daño del

equipo. Siga los mensajes de seguridad para evitar o reducir los

riesgos de heridas e inclusive la muerte.

Símbolos de Peligro y Significados

El escape del motor de este producto contiene

elementos químicos reconocidos en el Estado de

California por producir cáncer, defectos de nacimiento u

otros daños de tipo reproductivo.

ADVERTENCIA

CONSERVE ESTAS INSTRUCCIONES

Fuego

Explosión

Gases Tóxicos

Superficie Caliente

Descarga Eléctrica

Retroceso

Manual del Operario

Objets volant

Page 25

REGLAS DE SEGURIDAD

25

• Cuando use un generador como poder de energía auxiliar, notifique a

la compañía de utilidades. Use el equipo de transferencia aprobado

para aislar el generador de otra utilidad eléctrica.

• Use un interruptor para la falla del circuito de tierra (GFCI) en

cualquier área bastante húmeda o que sea altamente conductiva, tales

como terrazas de metal o trabajo hecho con acero.

• NO toque los alambres pelados o receptáculos.

• NO use un generador con cables eléctricos que estén malgastados,

rotos, pelados o dañados de cualquier forma.

• NO opere el generador bajo la lluvia.

• NO maneje el generador o cables eléctricos mientras esté parado en

agua, descalzo o cuando las manos y los pies estén mojados.

• NO permita que personas descalificadas o niños operen o sirvan al

generador.

Los generadores producen un voltaje muy poderoso.

Si no aísla el generador de utilidades de energía,

puede hacer que los trabajadores de electricidad

sufran heridas graves e inclusive la muerte, debido a

la retroalimentación de la energía eléctrica.

ADVERTENCIA

• Este generador no cumple la norma 33CFR-183 del cuerpo de

guardacostas de EE.UU. y no debe utilizarse en aplicaciones marinas.

• El uso de un generador no homologado por cuerpo de guardacostas

de EE.UU. puede provocar lesiones y daños materiales.

ADVERTENCIA

CUANDO AÑADA COMBUSTIBLE O VACÍE EL

DEPÓSITO

• Apague el generador (posición OFF) y déjelo enfriar al menos por

2 minutos antes de remover la tapa de la combustible.Afloje la tapa

lentamente para dejar que la presión salga del tanque.

• Llene o vacíe el depósito de combustible a la intemperie.

• NO llene demasiado el tanque. Permita al menos espacio para la

expansión del combustible.

• Si se ha derramado combustible, espere a que se evapore antes de

arrancar el motor.

• Mantenga la combustible alejada de chispas, llamas abiertas, pilotos,

calor y otras fuentes de ignición.

• NO encienda un cigarrillo o fume.

CUANDO PONGA EN FUNCIONAMIENTO EL

EQUIPO

• Compruebe que la bujía, el silenciador, el tapón del depósito de

combustible y el filtro de aire están instalados.

• NO arranque el motor sin la bujía instalada.

CUANDO OPERE EL EQUIPO

• NO incline el motor o el equipo, de tal manera que la combustible se

pueda derramar.

• Este generador no es apto para el uso en equipos móviles ni en

aplicaciones marinas.

CUANDO TRANSPORTE O REPARE EL EQUIPO

• Transporte o repare el equipo con el tanque de combustible vacío, o

con la válvula para apagar el combustible, apagada (posición OFF).

• Desconecte el cable de la bujía.

CUANDO ALMACENE O GUARDE EL EQUIPO CON

COMBUSTIBLE EN EL TANQUE

• Almacene alejado de calderas, estufas, calentadores de agua, secadoras

de ropa u otros aparatos electrodomésticos que posean pilotos u

otras fuentes de ignición, porque ellos pueden encender los vapores

de la combustible.

La combustible y sus vapores son extremadamente

inflamables y explosivos.

El fuego o una explosión pueden causar quemaduras

severas e inclusive la muerte.

ADVERTENCIA

• Cuando arranque el motor,tire lentamente del cable hasta sentir una

resistencia y, a continuación,tire rápidamente de él para evitar su

retroceso.

• NUNCA arranque o pare el motor cuando haya aparatos eléctricos

conectados y en funcionamiento.

El rápido repliegue del cable del arrancador

(retroceso) impedirá que el usuario suelte el cable a

tiempo y tirará de su mano y brazo hacia el motor.

Como resultado, podrían producirse fracturas,

contusiones o esguinces.

ADVERTENCIA

• Opere el generador SOLAMENTE al aire libre.

• Asegúrese de que los gases de escape no puedan entrar por ventanas,

puertas, tomas de aire de ventilación u otras aberturas en un espacio

cerrado en el que puedan acumularse.

• NO opere el generador dentro de un edificio o lugar cerrado (aunque

haya puertas o ventanas abiertas), incluyendo el compartimiento del

generador en un vehículo recreativo o RV.

Al generador funcionar, se produce monóxido de

carbono, un gas inodoro y venenoso.

El respirar el monóxido de carbono, producirá

náusea, desmayo o la muerte.

ADVERTENCIA

Page 26

REGLAS DE SEGURIDAD

26

• NO cambie ninguna velocidad determinada. El generador suministra

una frecuencia y un voltaje calificado cuando funciona a una velocidad

determinada.

• NO modifique al generador en ninguna forma.

Las velocidades de operación en exceso, aumentan los

riesgos de heridas y daños al generador.

Las velocidades bajan en exceso,imponen una carga muy pesada.

PRECAUCIÓN

• Vea "No sobrecargue generador".

• Encienda su generador y deje que el motor se estabilice antes de

conectar las cargas eléctricas.

• Conecte las cargas eléctricas en la posición de apagado (OFF), luego

encienda (ON) para su operación.

• Apague (OFF) las cargas eléctricas y desconéctelas del generador

antes de parar el generador.

El sobrepasar la capacidad del amperaje y vataje del

generador, puede dañar al generador y los aparatos eléctricos

conectados al mismo.

PRECAUCIÓN

• Use el generador solamente con la finalidad para el cual fue diseñado.

• Si usted tiene alguna pregunta acerca de las finalidades de uso del

generador, pregúntele a su concesionario o llamada a 1-800-743-4115.

• Opere el generador solamente en superficies niveladas.

• NO exponga al generador a una humedad excesiva, polvo, suciedad o

vapores corrosivos.

• NO inserte cualquier objeto a través de las ranuras de enfriamiento.

• Si los aparatos conectados se sobrecalientan, apáguelos y

desconéctelos del generador.

• Apague el generador si:

-Se pierde la salida eléctrica;

-El equipo produce chispas, humo o emite llamas;

-La unidad vibra de una manera excesiva.

El tratamiento inadecuado del generador puede dañarlo y

acortar su vida productiva.

PRECAUCIÓN

CUANDO AJUSTE O HAGA REPARACIONES A SU

GENERADOR

• Siempre desconecte el alambre de la bujía y colóquelo donde no

pueda entrar en contacto con la bujía.

CUANDO PRUEBE LA BUJÍA DEL MOTOR

• Utilice un comprobador de bujías homologado.

• NO comprueba la chispa sin la bujía instalada.