Page 1

Owner’s Manual / Manual del Propietario / Manuel de l'Utilisateur

Questions? Help is just a moment away!

Preguntas? La ayuda es justa un momento lejos!

Vous avez des questions? Vous n'avez pas besoin d'aller loin pour trouver de l'aide!

Call: Pressure Washer Helpline / Llame: Línea Directa del Lavador a Presión /

Appelez: Ligne d'Assistance pour les Pulvérisateur - 1-800-270-1408 M-F 8-5 CT

Model No. 1694-1,2 (1900 PSI Pressure Washer) Manual No. 192464GS Revision 4 (12/18/2003)

1900PSI

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

Page 2

Generac Portable Products 1900 PSI Pressure Washer

2

TABLE OF CONTENTS

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Know Your Pressure Washer. . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

EQUIPMENT

DESCRIPTION

Read this manual carefully and become familiar

with your pressure washer. Know its

applications, its limitations and any hazards

involved.

Every effort has been made to ensure that information in

this manual is accurate and current. However, we reserve

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

SAFETY RULES

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

Hazard Symbols and Meanings

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark arrester,

it must be maintained in effective working order.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects,or other reproductive harm.

WARNING

Fire

Explosion

Toxic Fumes

Hot Surface

Moving Parts

Electrical Shock

Slippery Surface

Fall

Kickback

Flying Objects

Fluid Injection

Page 3

Generac Portable Products 1900 PSI Pressure Washer

3

• Keep water spray away from electric wiring or fatal electric

shock may result.

Spray contact with electrical wiring can result in

electrocution.

WARNING

• Operate pressure washer ONLY outdoors.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled.

• Read all instructions with mask so you are certain the mask will

provide the necessary protection against inhaling harmful vapors.

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting or poisoning.

Breathing carbon monoxide will cause nausea,

fainting or death.

DANGER

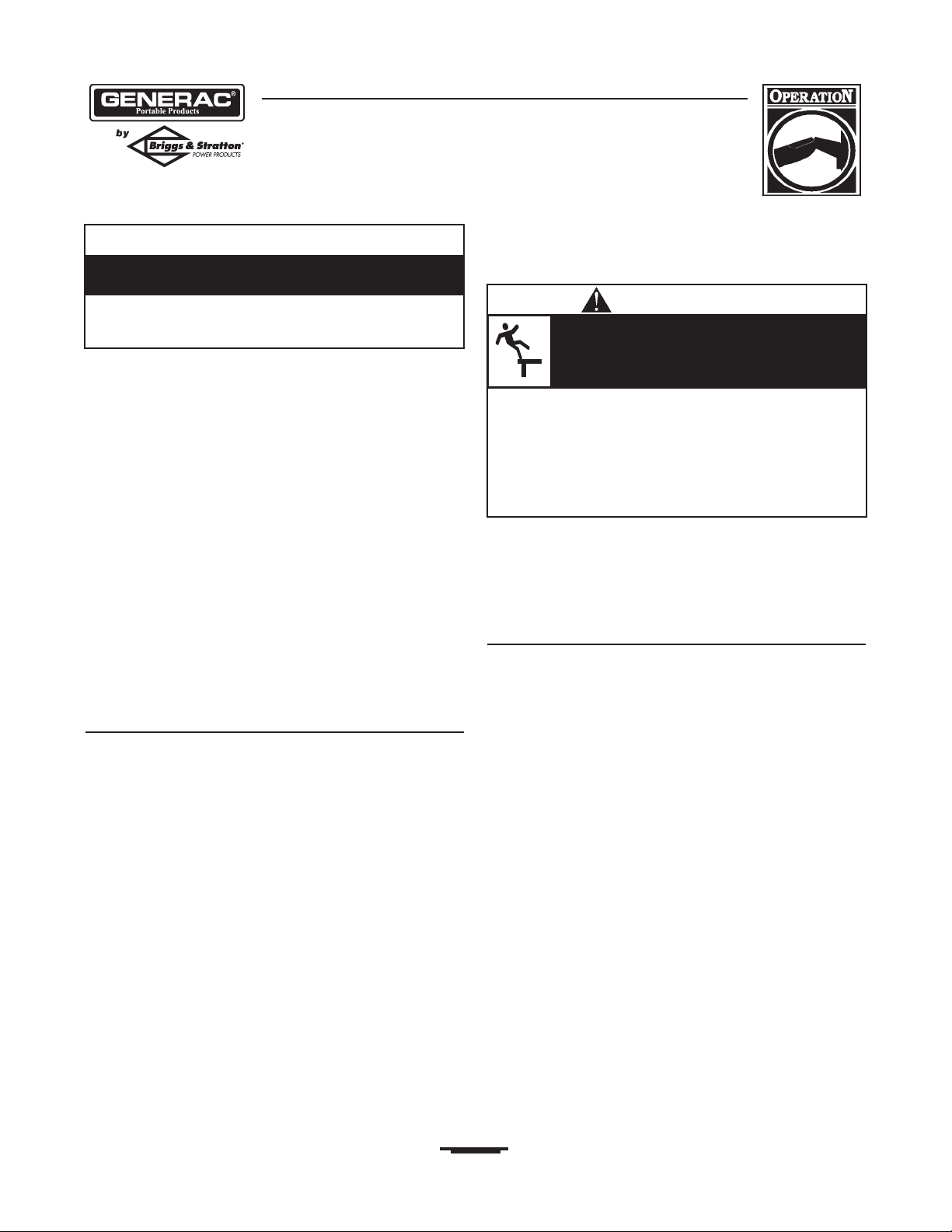

• Keep spray nozzle between 8 to 24 inches away from cleaning

surface.

• Operate this unit on a stable surface.

• The cleaning area should have adequate slopes and drainage to

reduce the possibility of a fall due to slippery surfaces.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding or any other relatively unstable location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

Use of pressure washer can create puddles and

slippery surfaces.

High pressure spray could cause you to fall if

you are too close to the cleaning surface.

WARNING

WHEN ADDING FUEL

• Turn pressure washer OFF and let it cool at least 2 minutes

before removing gas cap.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which causes fuel

to spill.

• DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• NEVER aim spray gun at people, animals or plants.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury and

possible amputation.

WARNING

Page 4

Generac Portable Products 1900 PSI Pressure Washer

4

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

Excessively high or low operating speeds increase risk

of injury and damage to pressure washer.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect spark plug wire from spark plug and place wire

where it cannot contact spark plug.

Unintentional sparking can result in fire or

electric shock.

WARNING

• DO NOT point spray gun at glass when in jet spray mode.

• NEVER aim spray gun at plants.

High pressure spray may damage fragile items including

glass.

CAUTION

• DO NOT wear loose clothing, jewelry or anything that may

be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

Starter and other rotating parts can entangle

hands, hair, clothing,or accessories.

WARNING

• Always wear eye protection when using this equipment or in

vicinity of where equipment is in use.

High pressure spray can cause paint chips or

other particles to become airborne.

WARNING

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger lock or

trigger guard in place and in working order.

• Always be certain spray gun,nozzles and accessories are

correctly attached.

A pressure washer produces a high pressure spray

which increases risk of injury and damage to unit.

CAUTION

• If you have questions about intended use, ask dealer or

contact Briggs & Stratton Power Products.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by–pass any safety device on this machine.

• Before starting pressure washer in cold weather, check all

parts of the equipment to be sure ice has not formed there.

• NEVER move machine by pulling on high pressure hose. Use

handle provided on unit.

• Check fuel system for leaks or signs of deterioration, such as

chafed or spongy hose, loose or missing clamps,or damaged

tank or cap. Correct all defects before operating pressure

washer.

• This equipment is designed to be used with Briggs & Stratton

Power Products authorized parts ONLY. If equipment is used

with parts that DO NOT comply with minimum specifications,

user assumes all risks and liabilities.

Improper treatment of pressure washer can damage it

and shorten its life.

CAUTION

• DO NOT touch hot surfaces.

• Stay clear of exhaust gases.

• Allow equipment to cool before touching.

Running engines produce heat and hot exhaust

gases.Temperature of muffler and nearby areas

can reach or exceed 150°F (65°C).

Fire or severe burns can occur.

WARNING

Page 5

Generac Portable Products 1900 PSI Pressure Washer

5

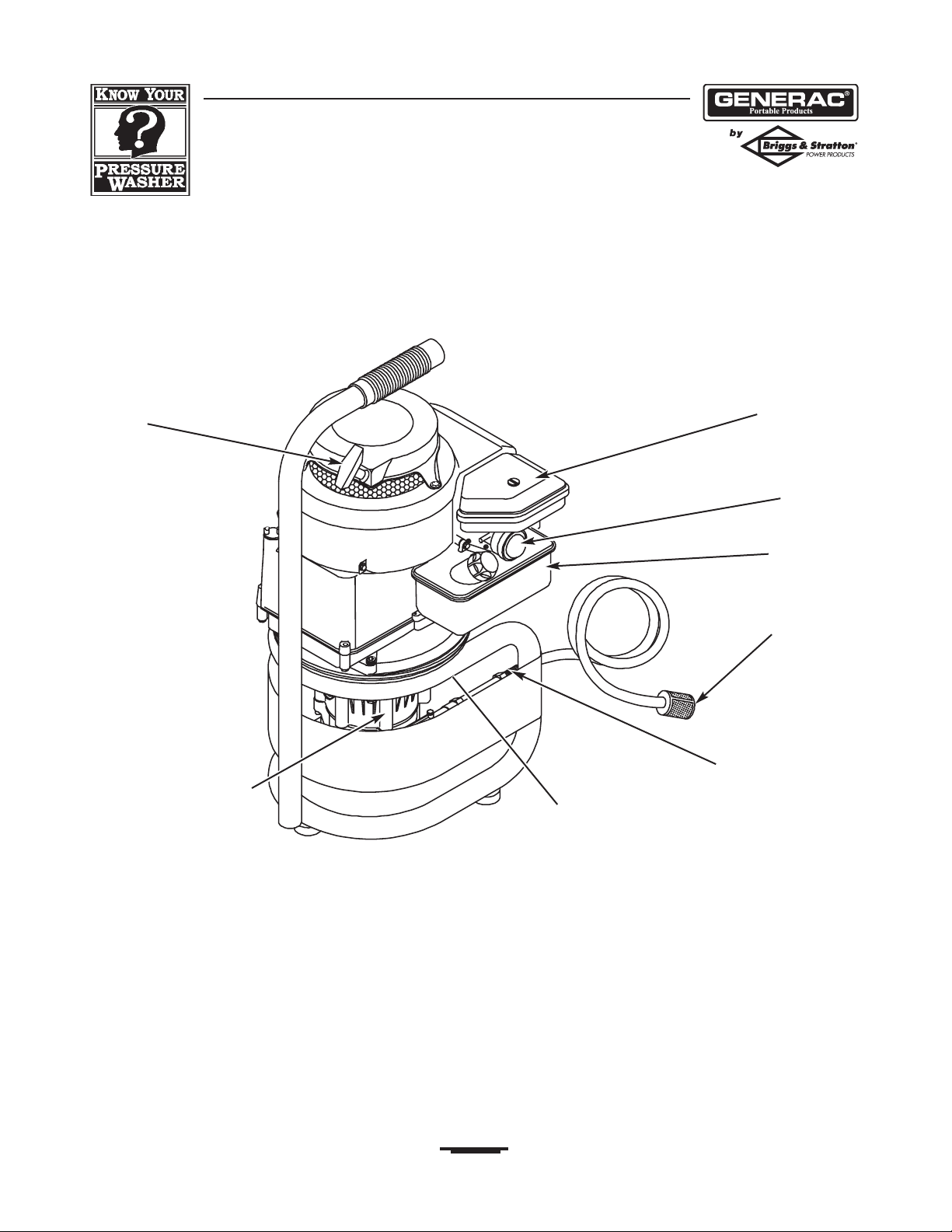

KNOW YOUR PRESSURE WASHER

Read this owner’s manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

Air Cleaner — Dry type filter element limits the amount

of dirt and dust that gets in the engine.

Automatic Cool Down System — Cycles water

through pump when water reaches 125°-155°F. Warm

water will discharge from pump onto ground.This

system prevents internal pump damage.

Chemical Injection Siphon/Filter — Use to siphon

detergent or other pressure washer chemicals into the low

pressure stream.

Fuel Tank — Fill tank with regular unleaded gasoline.

High Pressure Outlet — Connection for high pressure

hose.

Primer Bulb — Prepares a cold engine for starting.

Pump — Develops high water pressure.

Recoil Starter — Used for starting the engine manually.

Water Inlet — Connection for garden hose.

Air Cleaner

Primer Bulb

Fuel Tank

Water Inlet

Pump equipped with

Automatic Cool Down

System

Recoil Starter

High Pressure Outlet

Chemical Injection

Siphon/Filter

Page 6

Generac Portable Products 1900 PSI Pressure Washer

6

ASSEMBLY

IMPORTANT: Read entire owner’s manual before you

attempt to assemble or operate your new pressure washer.

Remove Pressure Washer From

Carton

• Remove the parts bag, accessories, and inserts included

with pressure washer.

• Slice two corners at the end of carton from top to

bottom so the panel can be folded down flat.

• Remove pressure washer from carton.

Carton Contents

Items in the carton include:

• Main Unit

• Goggles

• High Pressure Hose

• Spray Gun

• Nozzle Extension

• Oil Bottle

• Parts Bag (which includes the following):

• Maintenance Kit

• Owner’s Manual

• Engine Manual

• Owner’s Registration Card

If any of the above parts are missing or damaged, call the

pressure washer helpline at 1–800–270–1408.

PREPARING PRESSURE

WASHER FOR USE

To prepare your pressure washer for operation,you

will need to perform these tasks:

1. Fill out and send in registration card.

2. Add oil to engine crankcase.

3. Add fuel to fuel tank.

4. Connect high pressure hose to spray gun and pump.

5. Connect water supply to pump.

6. Attach nozzle extension to spray gun.

Add Engine Oil and Fuel

• Place pressure washer on a level surface.

• Refer to engine owner’s manual and follow oil and fuel

recommendations and instructions.

NOTE: Check oil often during engine break–in. Refer to

engine owner’s manual for recommendations.

CAUTION

• Refer to engine manual for oil and fuel fill information.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Any attempt to crank or start the engine before it has

been properly filled with the recommended oil will result

in equipment failure.

Page 7

Generac Portable Products 1900 PSI Pressure Washer

7

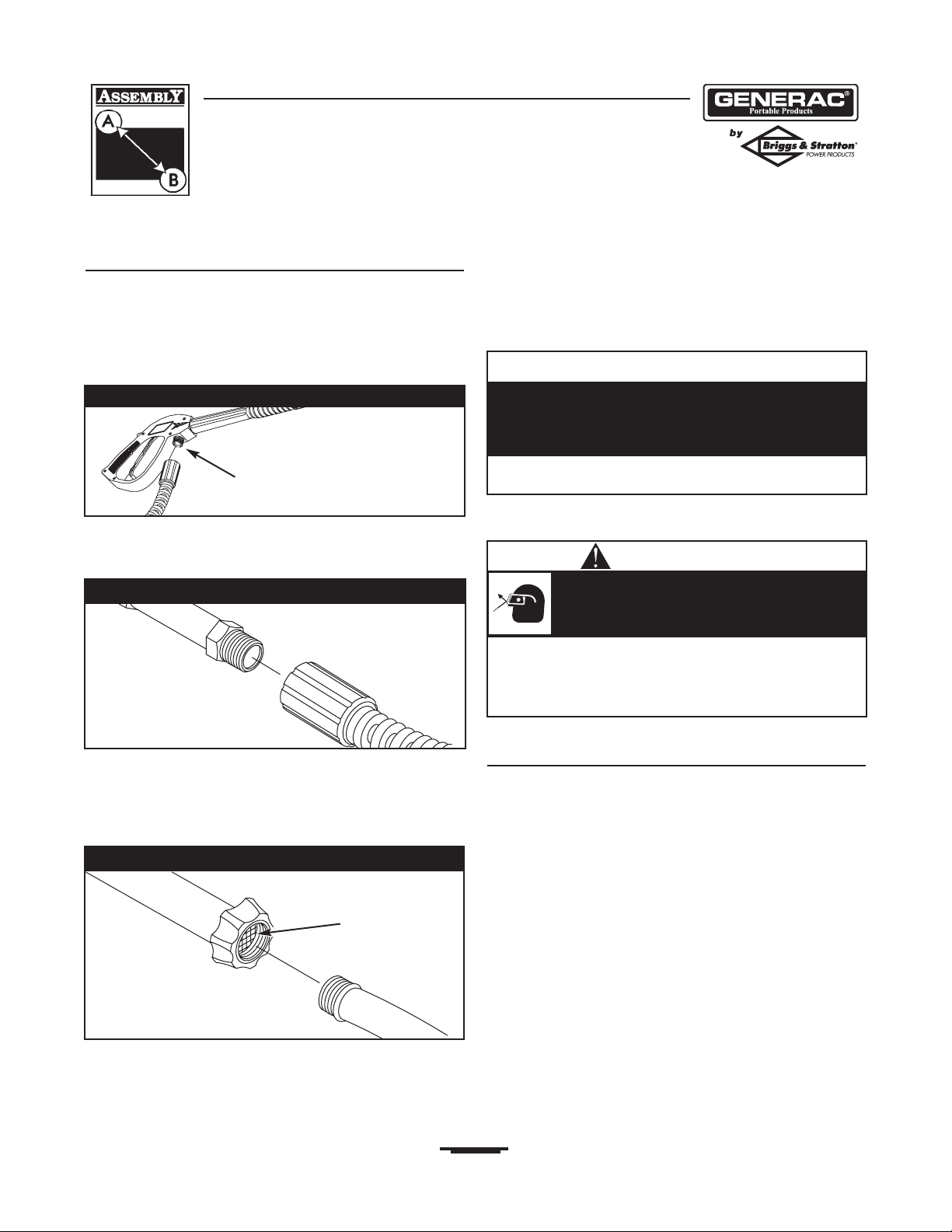

Connect Hose and Water Supply to

Pump

IMPORTANT: To avoid pump damage, you must assemble

the nozzle extension to the spray gun and attach all hoses

before you start the engine.

1. Uncoil high pressure hose and attach one end of hose to

base of spray gun (Figure 1).Tighten by hand.

2. Attach other end of high pressure hose to high pressure

outlet on pump (Figure 2).Tighten by hand.

3. Before connecting garden hose to water inlet, inspect

inlet screen (Figure 3). Clean screen if it contains debris

or replace if damaged. DO NOT RUN PRESSURE

WASHER IF SCREEN IS DAMAGED.

4. Run water through garden hose for 30 seconds to clean

out any debris.

IMPORTANT: DO NOT siphon standing water for water

supply. Use ONLY cold water (less than 100°F).

5. Connect garden hose (not to exceed 50 feet in length)

to water inlet.Tighten by hand (Figure 3).

6. Turn ON water and squeeze trigger on gun to purge

pump system of air and impurities.

Checklist Before Starting Engine

Review the unit’s assembly to ensure you have performed

all of the following.

1. Check that oil has been added to proper level in

engine crankcase.

2. Add proper gasoline to fuel tank.

3. Check for properly tightened hose connections (high

pressure and water supply) and there are no kinks,

cuts, or damage to e high pressure hose.

4. Provide a proper water supply at an adequate flow.

5. Be sure to read "Safety Rules" and "How To Use

Pressure Washer" before using pressure washer.

Connect high

pressure hose here

Figure 1 — Connect High Pressure Hose to Spray Gun

Figure 2 — Connect High Pressure Hose to Pump

Inspect inlet

screen, DO NOT

use if damaged;

clean if dirty.

Figure 3 — Connect the Garden Hose to Water Inlet

• Always wear eye protection when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate eye protection.

High pressure spray can cause paint chips or

other particles to become airborne.

WARNING

CAUTION

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

There MUST be at least ten feet of unrestricted garden

hose between the pressure washer inlet and any flow

shut off device, such as a ‘Y’ shut-off connector or other

convenience-type water shut-off valve.

Page 8

Generac Portable Products 1900 PSI Pressure Washer

8

HOW TO USE PRESSURE

WASHER

If you have any problems operating your pressure washer,

please call the pressure washer helpline at

1-800-270-1408.

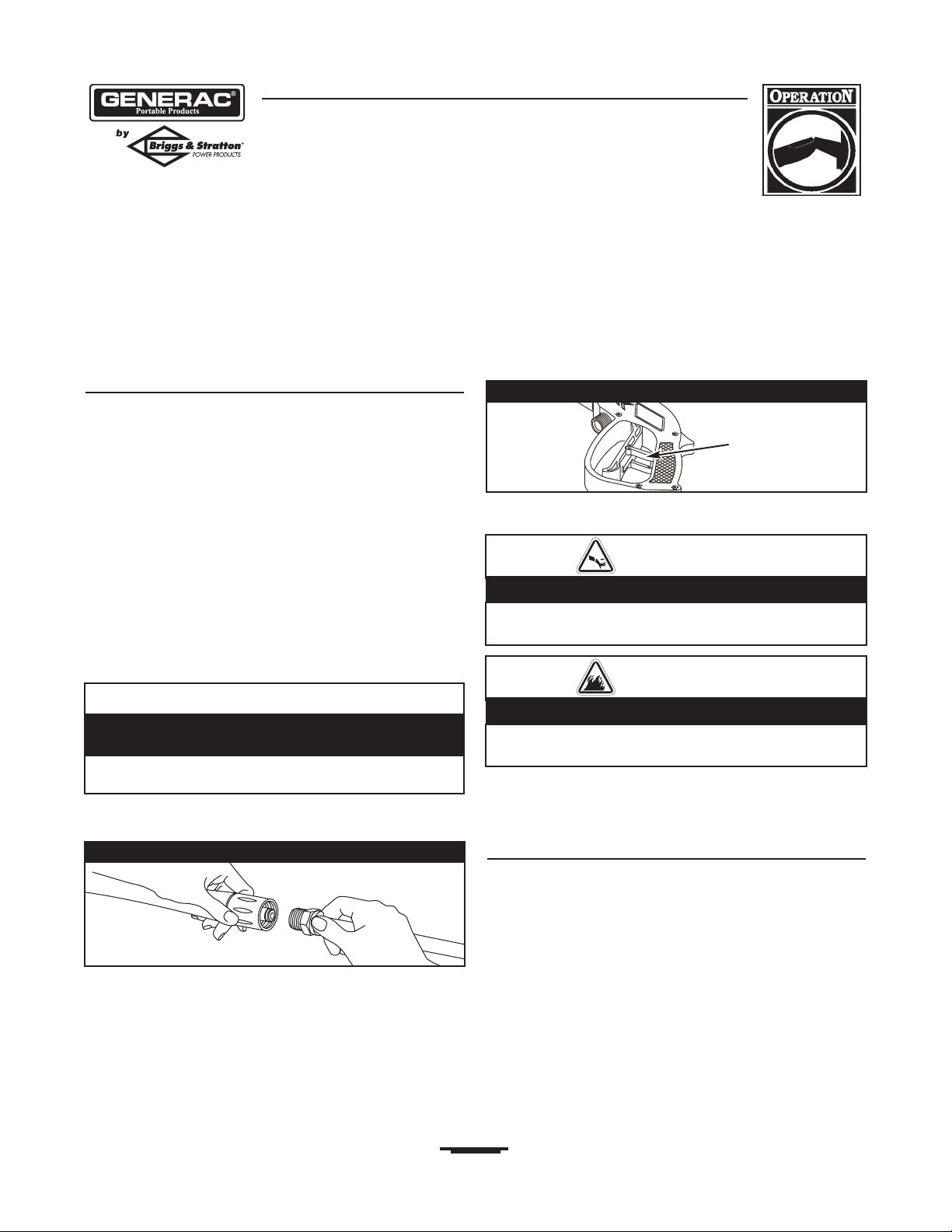

How To Start Pressure Washer

To start your pressure washer for the first time, follow

these instructions step-by-step.This starting information

also applies if you have let the pressure washer sit idle for

at least a day.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

3.0 gallons per minute and no less than 20 PSI at

pressure washer end of garden hose.

2. Check that high pressure hose is tightly connected to

spray gun and to pump. See “Preparing Pressure

Washer for Use” for illustrations.

3. Make sure unit is in level position.

4. Connect garden hose to water inlet on pressure

washer pump. Turn ON the water.

5. Attach adjustable nozzle extension to spray gun

(Figure 4).Tighten by hand.

6. Position nozzle in low pressure mode (see “How To

Use Adjustable Nozzle”) and squeeze trigger on spray

gun to relieve air pressure caused by turning ON

water.Water will flow out of spray gun in thin stream.

Continue to hold trigger until steady stream of water

occurs and no air remains in system.This will make it

easier to pull start the engine. Release trigger.

7. Engage safety latch to spray gun trigger (Figure 5).

8. Start engine according to instructions given in engine

owner’s manual.

NOTE:Always keep the throttle lever in the “Fast”

position when operating the pressure washer.

How To Stop Pressure Washer

• Turn engine off according to instructions given in the

engine owner’s manual.

• Squeeze trigger on the spray gun to relieve

pressure in the hose.

NOTE:A small amount of water will squirt out when

pressure is released.

Figure 4 — Connect Nozzle Extension to Spray Gun

Safety Latch

Figure 5 — Spray Gun with Safety Latch Engaged

CAUTION

• Always use handle to lift equipment.

• NEVER pull on hoses to move equipment.

Avoid fire from equipment tip over.

CAUTION

• Squeeze trigger on spray gun each time recoil starter is

pulled and engine fails to start.

Avoid injury from kickback.

CAUTION

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

DO NOT run the pump without the water supply

connected and turned on.

Page 9

Generac Portable Products 1900 PSI Pressure Washer

9

How To Use Adjustable Nozzle

You now should know how to START your pressure

washer and how to STOP it.The information in this

section will tell you how to adjust the spray pattern and to

apply detergent or other cleaning chemicals.

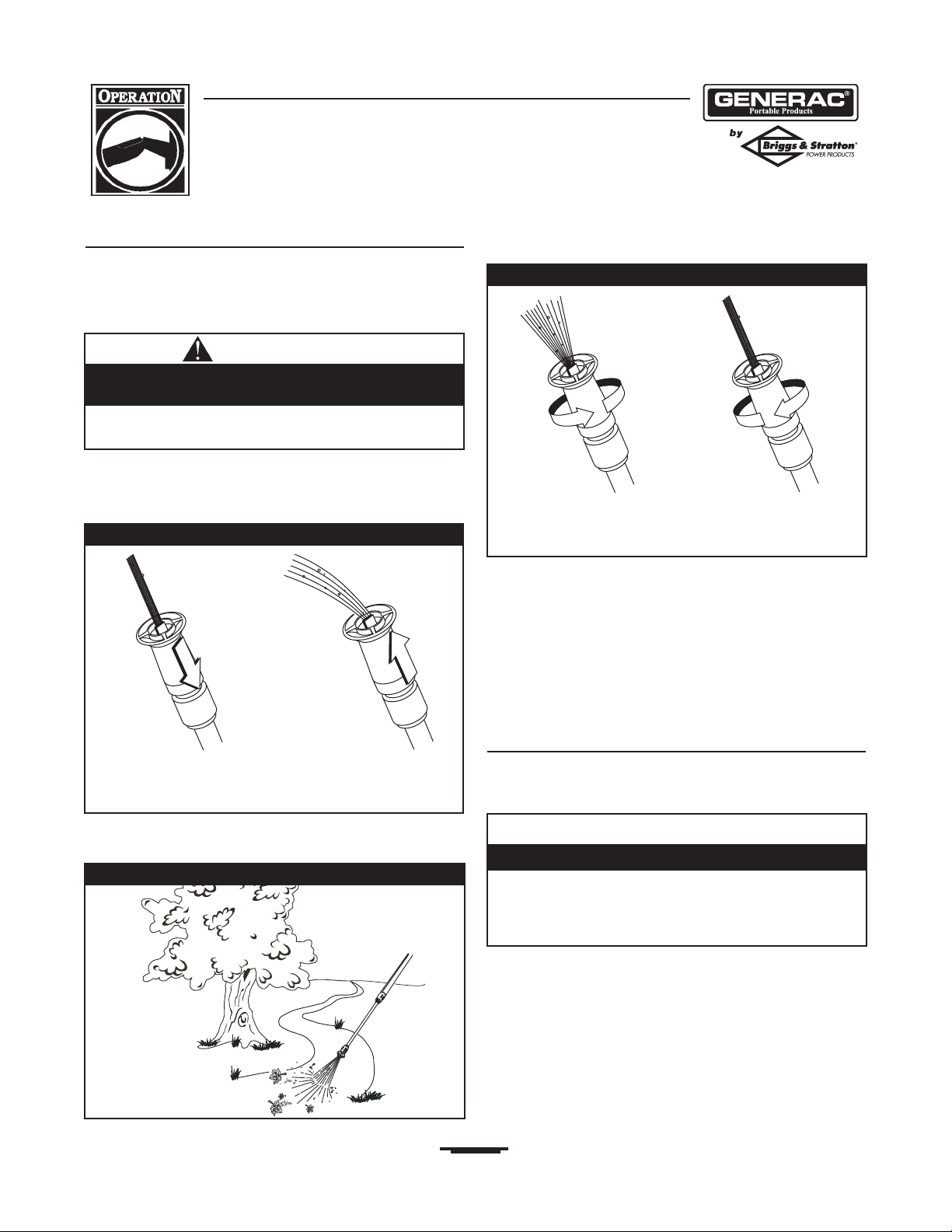

1. Slide nozzle forward to adjust spray to low pressure

mode (Figure 6). Slide nozzle backward to achieve high

pressure.

2. Point nozzle towards a firm surface and press trigger

to test spray pattern (Figure 7).

3. Twisting nozzle adjusts spray pattern from a narrow

pattern to a fan pattern (Figure 8).

4. For most effective cleaning, keep spray nozzle between

8 to 24 inches away from cleaning surface.

5. If spray nozzle is held too close to surface, especially

using high pressure mode, damage to surface may

occur.

6. DO NOT get closer than 6 inches when cleaning tires.

Applying Detergent With Adjustable

Nozzle

IMPORTANT: Use soaps designed specifically for

pressure washers. Household detergents could damage

the pump.

To apply detergent, follow these steps:

1. Review adjustable nozzle use.

2. Prepare detergent solution as required by job.

3. Place filter end of chemical injection hose into detergent

container.

Slide nozzle backward

for High Pressure

Mode

Slide nozzle forward for low

pressure mode and

detergent application

Figure 6 — Adjusting Nozzle for Pressure

Figure 7 — Testing the Spray Pattern

Figure 8 — Adjusting the Nozzle for Spray Pattern

Rotate nozzle

counterclockwise for fan

spray pattern

Rotate nozzle clockwise

for narrow spray pattern

CAUTION

• Starting the engine without all the hoses connected and

without the water turned ON will damage the pump.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

You must attach all hoses before you start the engine.

• NEVER adjust spray pattern when spraying.

• NEVER put hands in front of nozzle to adjust spray pattern.

A pressure washer produces a high pressure spray

which increases risk of injury and damage to unit.

CAUTION

Page 10

Generac Portable Products 1900 PSI Pressure Washer

10

4. Slide adjustable nozzle forward to low pressure mode.

Detergent cannot be applied with nozzle in high pressure

position.

5. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray gun

and pump; start engine.

6. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward, using

long, even, overlapping strokes.

7. Allow detergent to "soak in" for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. DO NOT allow detergent to dry on

(prevents streaking).

IMPORTANT: You must flush the chemical injection

system after each use by placing the filter into a bucket of

clean water, then run the pressure washer in low pressure

for 1-2 minutes.

Pressure Washer Rinsing

For Rinsing:

1. Slide nozzle backward to high pressure, press trigger and

wait for detergent to clear.

NOTE:You can also stop detergent from flowing by simply

removing chemical injection hose from bottle.

2. Keep spray gun a safe distance from surface.

3. Apply high pressure spray to a small area, then check

surface for damage. If no damage is found, it is okay to

continue cleaning.

4. Start at top of area to be rinsed, working down with

same overlapping strokes as used for washing and

applying detergent.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures

above 125°F.The system engages to cool the pump by

discharging the warm water onto the ground.

• Keep spray nozzle between 8 to 24 inches away from cleaning

surface.

• Operate this unit on a stable surface.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding or any other relatively unstable location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

High pressure spray could cause you to fall if

you are too close to the cleaning surface.

WARNING

CAUTION

• When inserting the filter into a detergent solution bottle,

route the tube so as to keep it from inadvertently contacting

the hot muffler.

Keep the chemical injection tube from coming in contact

with the hot muffler.

Page 11

Generac Portable Products 1900 PSI Pressure Washer

11

SPECIFICATIONS

Outlet Pressure . . . . . 1900 psi

Flow Rate . . . . . . . . . . 2.0 gallons per minute (gpm)

Detergent . . . . . . . . . . Use detergent approved for

pressure washers

Water Supply . . . . . . Not to Exceed 100°F

Temperature

Automatic Cool . . . . Will cycle when water

Down System reaches 125°-155°F

Shipping Weight . . . .46 lbs.

GENERAL MAINTENANCE

RECOMMENDATIONS

The pressure washer warranty does not cover items that

have been subjected to operator abuse or negligence.To

receive full value from the warranty, the operator must

maintain the pressure washer as instructed in this manual.

• Some adjustments will need to be made periodically to

properly maintain your pressure washer.

• All maintenance in this manual and the engine owner’s

manual should be made at least once each season.

• Once a year you should check the spray gun and

adjustable nozzle extension assembly for wear.Also clean

or replace the spark plug and clean or replace the engine

air filter. Please refer to engine owner’s manual for more

details.

Before Each Use

1. Check engine oil level.

2. Check water inlet screen for damage.

3. Check in-line filter for damage.

4. Check high pressure hose for leaks.

5. Check chemical injection hose and filter for damage.

6. Check spray gun and adjustable nozzle extension

assembly for leaks.

7. Rinse out garden hose to flush out debris.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine the screen on the water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect the hose each time before using

it. Check for cuts, leaks, abrasions or bulging of cover,

damage or movement of couplings. If any of these

conditions exist, replace the hose immediately.

Check Chemical Injection Hose

Examine the filter on the detergent tube and clean if

clogged.The tube should fit tightly on the barbed fitting.

Examine the tube for leaks or tears. Replace the filter or

tube if either is damaged.

Check Gun and Adjustable Nozzle

Extension

Examine the hose connection to the spray gun and make

sure it is secure.Test the trigger by pressing it and making

sure it “springs back” into place when you release it. Put

the safety latch in the ON position and test the trigger.You

should not be able to press the trigger.

Purge Pump of Air and

Contaminants

To remove air from the pump, follow these steps:

1. Set up pressure washer as described in “Preparing

Pressure Washer For Use”. Connect water supply and

turn water on.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST exceed maximum pressure

rating of unit.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury and

possible amputation.

WARNING

Page 12

Generac Portable Products 1900 PSI Pressure Washer

12

2. Pull spray gun trigger and hold.

3. When water stream is steady and constant, engage safety

latch.

To remove contaminants from the pump, follow

these steps:

1. Set up pressure washer as described in “Preparing

Pressure Washer For Use”. Connect water supply and

turn water on.

2. Remove nozzle extension from spray gun.

3. Start engine according to instructions in engine owner’s

manual.

4. Squeeze spray gun trigger and hold.

5. When water stream is steady and constant, engage safety

latch and reattach nozzle extension.

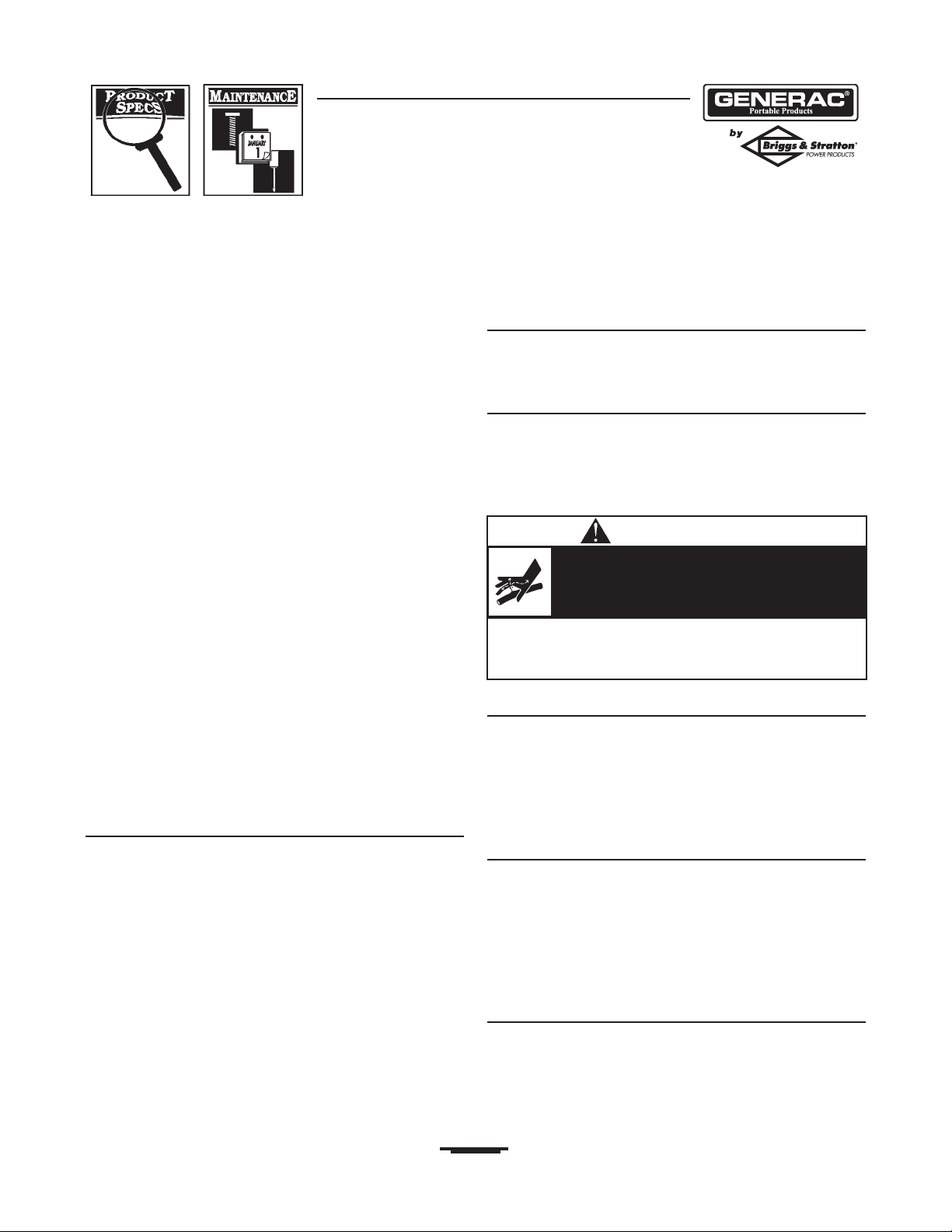

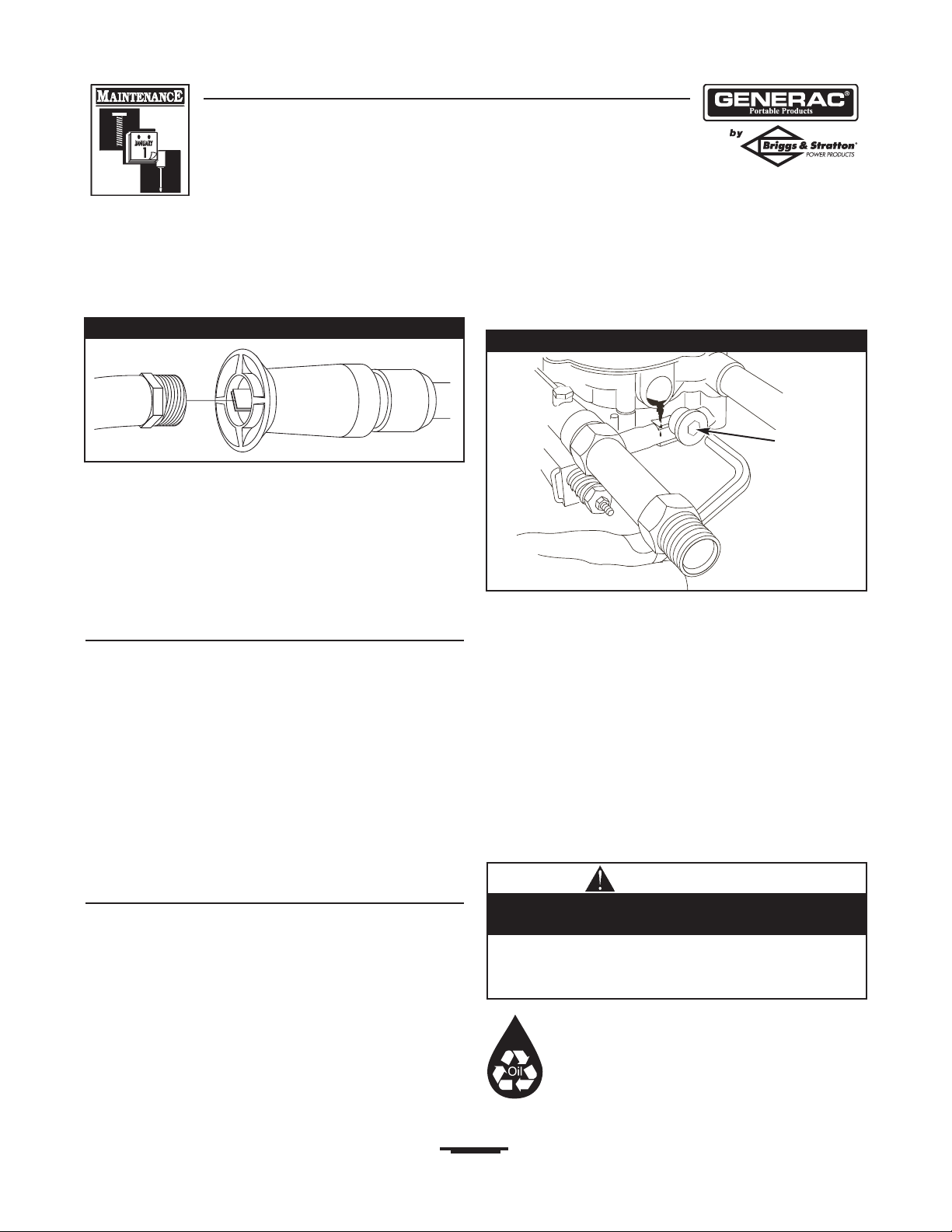

Check In-Line Filter

Refer to Figure 9 and service the in-line filter if it becomes

clogged, as follows:

1. Detach spray gun and nozzle extension from high

pressure hose. Detach nozzle extension from spray gun

and remove o-ring and screen from nozzle extension.

Flush screen, spray gun, and adjustable nozzle extension

with clean water to clear debris.

2. If screen is damaged, o-ring kit contains a replacement

in-line filter screen and o-ring. If undamaged, reuse

screen.

3. Place in-line filter screen into threaded end of nozzle

extension. Direction does not matter. Push screen in

with eraser end of pencil until it rests flat at bottom of

opening.Take care to not bend screen.

4. Place o-ring into threaded end of nozzle extension. Push

o-ring snugly against in-line filter screen.

5. Assemble nozzle extension to spray gun,as described

earlier in this manual.

Cleaning Chemical Injection Hose

If you used the chemical injection hose, you must flush it

with clean water before stopping the engine.

1. Place chemical injection hose in a bucket full of clean

water.

2. Slide adjustable nozzle forward to low pressure

position. Flush for 1-2 minutes.

3. Shut off engine.

IMPORTANT: Simply shutting OFF engine will not

release pressure in the system. When the engine has

shut down, squeeze the trigger on the spray gun to

relieve the pressure in the hose.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.The

principal cause of excessive pump pressure is a orifice

clogged or restricted with foreign materials, such as dirt,

etc.To correct the problem, immediately clean the orifice

using the tools included with your pressure washer and

follow these instructions:

1. Shut off engine and turn off water supply.

2. Detach nozzle extension from spray gun.Twist nozzle

clockwise to stream position. Using 2mm (5/64) allen

wrench, remove orifice from end of nozzle extension

(Figure 10).

3. Remove in-line filter from other end of nozzle extension.

4. Use wire (or small paper clip) to free any foreign

material clogging or restricting orifice (Figure 10).

Nozzle Extension

Filter Screen

O-ring

Figure 9 — Clean In-Line Filter

Orifice

Figure 10 — Removing and Cleaning Orifice

Page 13

Generac Portable Products 1900 PSI Pressure Washer

13

5. Using garden hose, remove additional debris by back

flushing water through nozzle extension (Figure 11). Back

flush between 30 to 60 seconds.Turn adjustable nozzle

extension to stream spray and move nozzle from low to

high while flushing.

6. Reinstall orifice and in-line filter into nozzle extension.

Do Not overtighten orifice with allen wrench.

7. Reconnect nozzle extension to spray gun.

8. Reconnect water supply, turn on water, and start engine.

9. Test pressure washer by operating with nozzle in high

and low positions.

O–Ring Maintenance

Through the normal operation of your pressure washer,

o–rings are used to keep the connections of the hoses and

spray gun tight and leak–free.These o-rings may become

worn or damaged.

An O–Ring Maintenance Kit is provided with your pressure

washer which includes replacement o-rings, rubber washer

and water inlet filter. Refer to the instruction sheet

provided in the kit to service your unit’s o-rings. Note that

you will not use all of the parts in the kit.

To remove a worn or damaged o–ring; use a small flathead

screwdriver to get underneath the o-ring and pry it off.

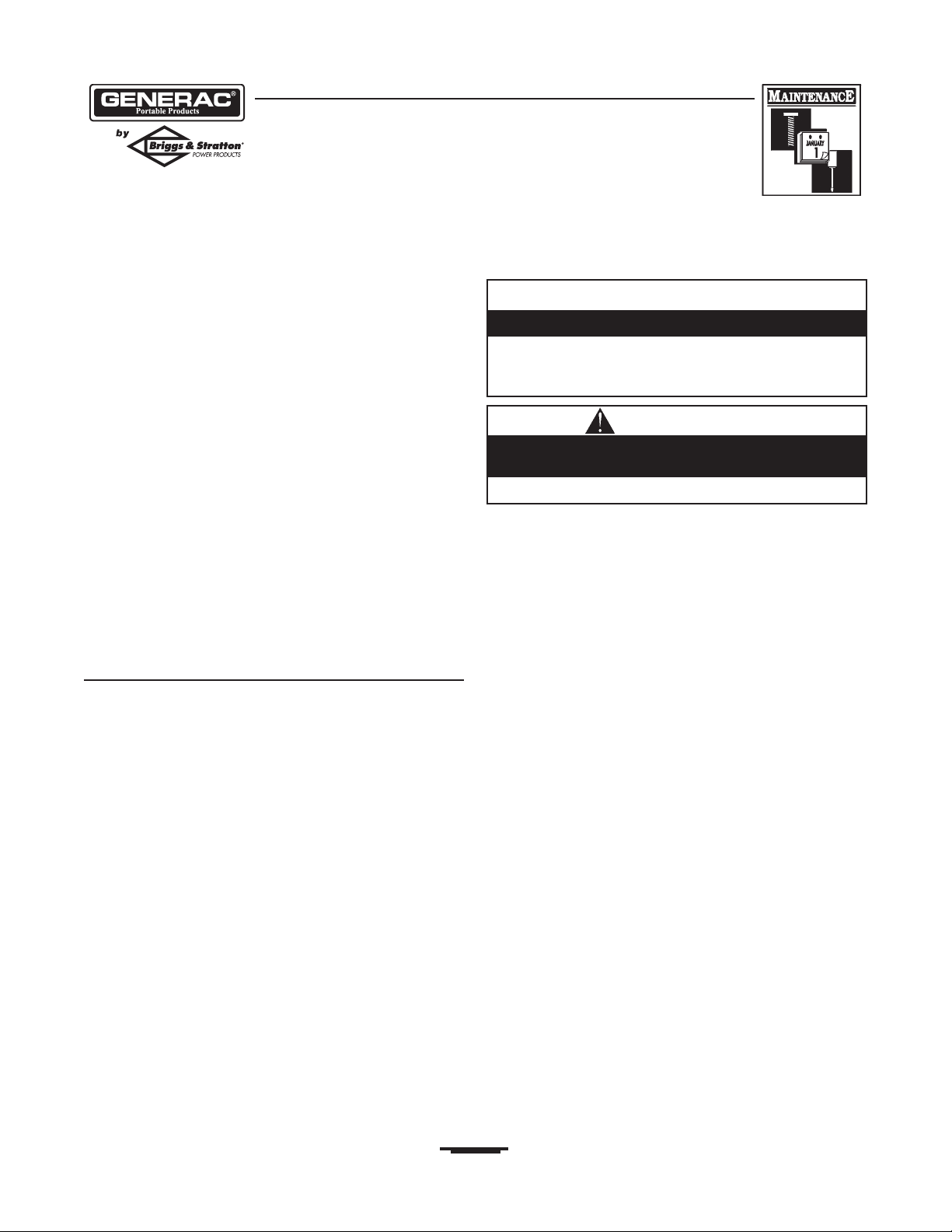

Pump Maintenance

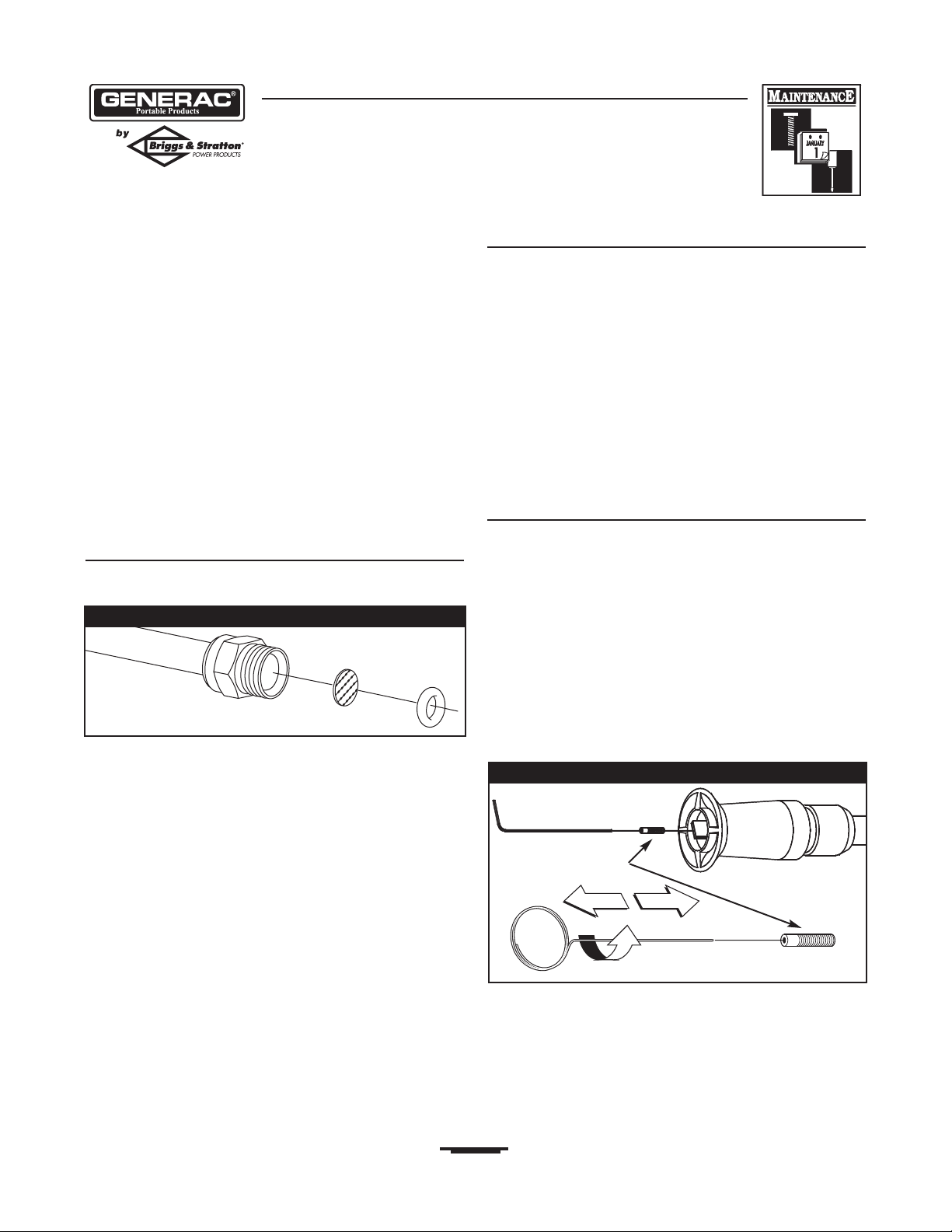

Changing Pump Oil

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE:You must purchase a premeasured bottle of pump

oil, item number 190586GS, by contacting the nearest

authorized service center.

Change pump oil as follows:

1. Drain engine oil and fuel from pressure washer.

2. Use 8mm allen wrench to remove black pump oil cap,

found between high pressure outlet and garden hose

inlet (Figure 12).

3. Tilt pressure washer to drain oil into an approved

container until it drips slowly from the pump.

4. Tilt pressure washer in opposite direction and empty

premeasured pump oil bottle into same opening (a small

funnel may be helpful).

5. Install black pump oil cap and tighten firmly.

6. Set pressure washer in upright position.Add fuel and

engine oil.

ENGINE MAINTENANCE

See the engine owner’s manual for instructions on how to

properly maintain the engine.

CAUTION! KEEP OUT OF REACH OF

CHILDREN. DON'T POLLUTE. CONSERVE

RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

Figure 11 — Backflushing the Nozzle

Oil Cap

Figure 12 - Changing Pump Oil

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Avoid prolonged or repeated skin contact with used

motor oil.

CAUTION

Page 14

14

Generac Portable Products 1900 PSI Pressure Washer

PREPARING THE UNIT

FOR STORAGE

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump parts and

“freeze” pump action. If you do not plan to use the pressure

washer for more than 30 days, follow this procedure:

1. Flush chemical injection hose by placing filter into pail of

clean water while running pressure washer in low

pressure mode (adjustable nozzle in forward position).

Flush for one to two minutes.

2. Shut off engine and let it cool, then remove high pressure

and garden hoses. Disconnect spark plug wire from spark

plug.

3. Empty pump of all pumped liquids by pulling recoil handle

about 6 times.This should remove most of the liquid in

pump.

4. Use PumpSaver to prevent corrosion build up and

freezing of pump.

5. Store unit in a clean, dry area.

Protecting the Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver to treat pump.This

prevents freeze damage and lubricates pistons and seals.

NOTE: PumpSaver is available as an optional accessory. It is

not included with the pressure washer. Contact the nearest

authorized service center to purchase PumpSaver.

To use PumpSaver, make sure the pressure washer is

turned off and disconnected from supply water. Read and

follow all instructions and warnings given on the PumpSaver

container.

NOTE:PumpSaver will drip from pump after treatment

and will stain wood and concrete.

NOTE: If PumpSaver is not available, draw RV antifreeze

(non-alcohol) into the pump by pouring the solution into a

3-foot section of garden hose connected to inlet adapter

and pulling recoil handle twice.

STORING THE ENGINE

See the engine owner’s manual for instructions on how to

properly prepare the engine for storage.

CAUTION

• Failure to do so will permanently damage your pump and

render your unit inoperable.

• Freeze damage is not covered under warranty.

You must protect your unit from freezing temperatures.

• Always wear eye protection when using PumpSaver.

Read and follow all cautions and warnings on the

PumpSaver can label.

CAUTION

Page 15

15

Generac Portable Products 1900 PSI Pressure Washer

TROUBLESHOOTING

Problem

Pump has following problems:

failure to produce pressure,

erratic pressure, chattering, loss

of pressure, low water volume.

Detergent fails to mix with spray.

Engine runs good at no-load but

"bogs" when load is added.

Engine shuts down during

operation.

Cause

1. Nozzle in low pressure mode.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose strainer.

6. Water supply is over 100°F.

7. High pressure hose is blocked or

leaks.

8. Gun leaks.

9. Nozzle is obstructed.

10.Pump is faulty.

1. Detergent siphoning tube is not

submerged.

2. Chemical filter is clogged.

3. Dirty in-line filter.

4. Nozzle is in high pressure mode.

Engine speed is too slow.

Out of gasoline.

Correction

1. Pull nozzle backward for high

pressure mode.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch leak.

5. Check and clean inlet hose

strainer.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace gun.

9. Clean nozzle.

10.Contact Briggs & Stratton Power

Products service facility.

1. Insert detergent siphoning tube

into detergent.

2. Clean or replace filter/detergent

siphoning tube.

3. See "Check In-Line Filter".

4. Push nozzle forward for low

pressure mode.

Move throttle control to FAST

position. If engine still "bogs down",

contact engine manufacturer.

Fill fuel tank.

Page 16

Generac Portable Products 1900 PSI Pressure Washer

16

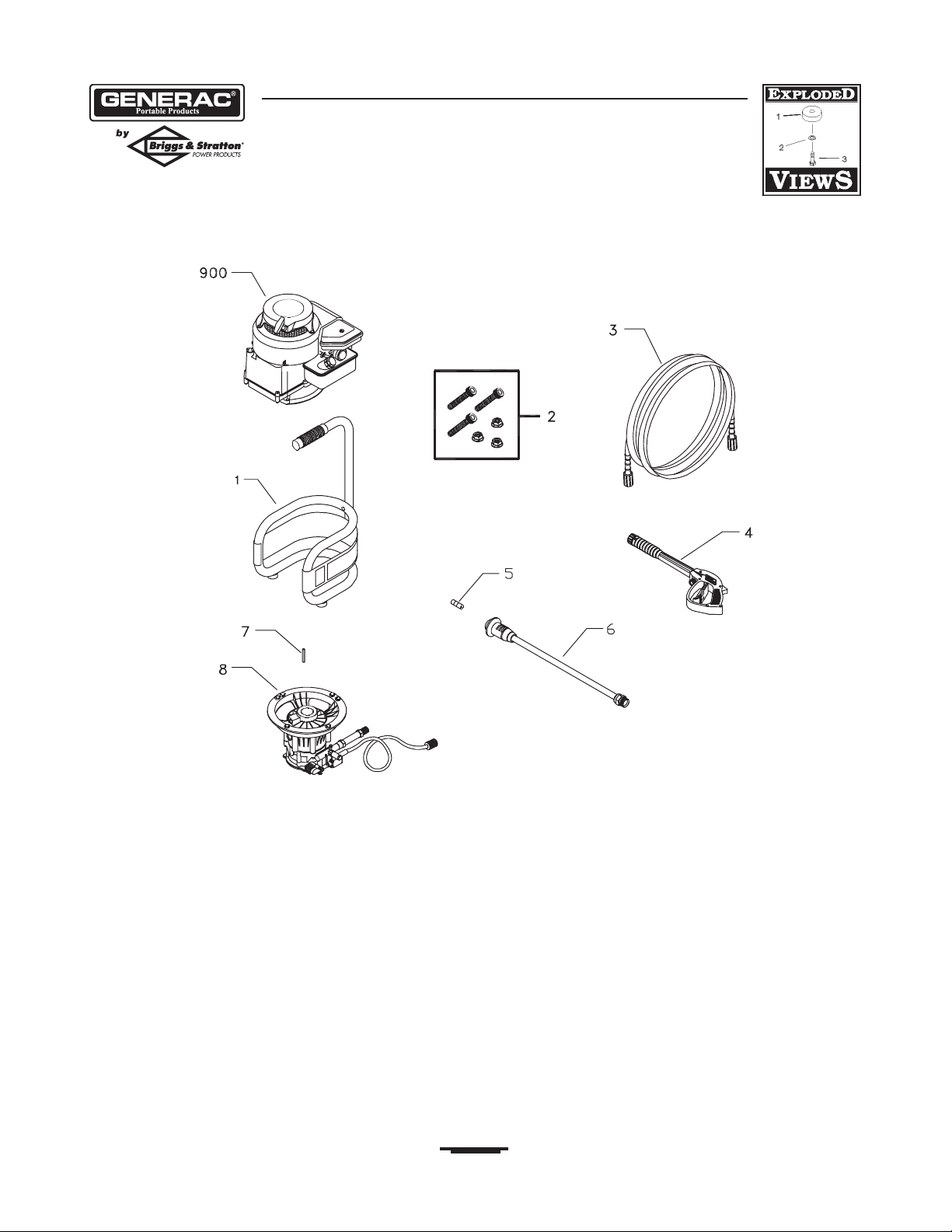

EXPLODED VIEW AND PARTS LIST – MAIN UNIT

Item Part # Description

1 M190259GS BASE

2 192308GS KIT, Pump/Engine Mounting Hardware

3 190249GS HOSE

4 193482GS GUN

5 193609DGS ORIFICE

6 193735DGS WAND,Adjustable Nozzle

7 23139GS KEY

8 194216GS ASSY, Pump (see page 17)

900 NSP ENGINE

Items Not Illustrated

192464GS MANUAL, Owner’s

MS5373 MANUAL, Engine

192674GS KIT, Decal

BB3061BGS BOTTLE, Oil

191922GS KIT, O-RING MAINT & NZZL CLNNG

Page 17

Generac Portable Products 1900 PSI Pressure Washer

17

EXPLODED VIEW AND PARTS LIST – PUMP

Item Part # Description

19 190571GS CAP, Oil

28 190627GS MANIFOLD

29 190575GS O-RING

30 190576GS SCREW

34 190577GS CONNECTION, Chemical Inlet

45 190578GS PIN

46 190629GS VALVE,Seat Plate, Plastic

47 190630GS VALVE,Seat, Plastic

62 190581GS CAP

68 190582GS BALL, SS

69 190584GS O-RING

76 194298GS THERMO RELIEF

Item Part # Description

A NSP ASSY, CASE, PISTON

B 190632GS KIT,WATER INLET,ALUM

C 190634GS KIT, OUTLET,ALUM

E 190591GS KIT,CHECK VALVES

F 190592GS KIT, INLET CHECK

G 190593GS KIT, CHEMICAL INJECTION

H 190628GS KIT, UNLOADER STEM

J 189971GS KIT, CHEMICAL HOSE

K 190636GS KIT, SEAL SET

NOTE: Item letters B - K are service kits and include all

parts shown within the box.

Page 18

Generac Portable Products 1900 PSI Pressure Washer

18

NOTES

Page 19

GENERAC PORTABLE PRODUCTS OWNER EQUIPMENT WARRANTY POLICY

Effective January 1, 2003

WARRANTY PERIOD*

* The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the

period of time stated in the table above. "Consumer use" means personal residential household use by a retail consumer.

"Commercial use" means all other uses, including use for commercial, income producing or rental purposes. Once equipment has

been used commercially, it shall thereafter be considered to be in commercial use for purposes of this warranty.

** The engine and starting batteries are warranted solely by the manufacturers of those products.

WARRANTY REGISTRATION IS NOT NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON POWER

PRODUCTS EQUIPMENT. SAVE YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE

INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED,THE MANUFACTURING DATE OF THE

EQUIPMENT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

About your equipment warranty:

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized service dealer may perform warranty

repairs. Most warranty repairs are handled routinely,but sometimes requests for warranty service may not be appropriate. For

example, warranty service would not apply if equipment damage occurred because of misuse, lack of routine maintenance, shipping,

handling, warehousing or improper installation.Similarly, the warranty is void if the manufacturing date or the serial number on the

equipment has been removed or the equipment has been altered or modified. During the warranty period, the Authorized service

dealer, at its option,will repair or replace any part that, upon examination, is found to be defective under normal use and service.This

warranty will not cover following repairs and equipment:

• Normal Wear: Outdoor power equipment, like all mechanical devices, needs periodic parts, service and replacement to perform

well.This warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or

unauthorized installation or alteration and modification, misuse, negligence, accident, overloading,overspeeding, improper

maintenance, repair or storage so as, in our judgment, to adversely affect its performance and reliability.This warranty also does not

cover normal maintenance such as adjustments, fuel system cleaning and obstruction (due to chemical, dirt, carbon or lime, etc.).

• Other Exclusions: Also excluded from this warranty are wear items such as quick couplers, oil gauges, belts, o-rings, filters,

pump packing, etc., pumps which have been run without water supplied or damage or malfunctions resulting from accidents,

abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration.Accessory parts such as guns,

hoses, wands and nozzles are excluded from the product warranty.Also excluded is used, reconditioned, and demonstration

equipment; equipment used for prime power in place of utility power and equipment used in life support applications.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

LIMITED WARRANTY

"Generac Portable Products is a licensed trademark of Briggs & Stratton Power Products. Briggs & Stratton Power Products will

repair or replace, free of charge, any part, or parts of the equipment** that are defective in material or workmanship or both.

Transportation charges on parts submitted for repair or replacement under this warranty must be borne by purchaser.This

warranty is effective for the time periods and subject to the conditions provided for in this policy. For warranty service, find your

nearest Authorized service dealer by calling 1-800-270-1408.Warranty service may only be performed by a Briggs & Stratton

Power Products Authorized service dealer.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE,ARE LIMITED TO THE TIME PERIOD SPECIFIED, OR TO THE EXTENT PERMITTED

BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER

ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW.Some countries or

states do not allow limitations on how long an implied warranty lasts, and some countries or states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you.This warranty gives

you specific legal rights and you may also have other rights that vary from country to country or state to state.”

PRODUCTS** CONSUMER USE COMMERCIAL USE

Pressure Washer 1 year 90 days

Portable Generator 2 years (2nd year parts only) 1 year

Page 20

Lavadora de Presión 1900 PSI de Generac Portable Products

20

TABLA DE CONTENIDOS

Reglas De Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-22

Conozca Su Generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ensamblaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Funcionamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-28

Especificaciones Del Producto . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-31

Almacenamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Notas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Diagnosticos De Averías. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Piezas De Recambio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Garantia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DESCRIPCIÓN DEL EQUIPO

Lea este manual de manera cuidadosa y

familiarícese con su lavadora a presión. Conozca

sus usos, sus limitaciones y cualquier peligro

relacionado con el mismo.

Se ha hecho cada esfuerzo posible para asegurarse que la

información que aparece en este manual es exacta y se encuentra

actualizada. Sin embargo,nosotros se reserva el derecho a

cambiar, alterar o de otra manera mejorar, el producto y este

documento en cualquier momento, sin previo aviso.

REGLAS DE SEGURIDAD

Éste es el símbolo de alerta de seguridad. Sirve

para advertir al usuario de un posible riesgo para

su integridad física. Siga todos los mensajes de

seguridad que figuren después de este símbolo

para evitar lesiones o incluso la muerte.

El símbolo de alerta de seguridad ( ) es usado con una palabra

(PELIGRO,ADVERTENCIA, PRECAUCIÓN), un mensaje por

escrito o una ilustración, para alertarlo acerca de cualquier

situación de peligro que pueda existir. PELIGRO indica un riesgo

el cual, si no se evita, causará la muerte o una herida grave.

ADVERTENCIA indica un riesgo el cual, si no se evita, puede

causar la muerte o una herida grave. PRECAUCIÓN indica un

riesgo, el cual, si no se evita, puede causar heridas menores o

moderadas. PRECAUCIÓN, cuando se usa sin el símbolo de

alerta, indica una situación que podría resultar en el daño del

equipo. Siga los mensajes de seguridad para evitar o reducir los

riesgos de heridas e inclusive la muerte.

Símbolos de Peligro y Significados

El escape del motor de este producto contiene

elementos químicos reconocidos en el Estado de

California por producir cáncer, defectos de nacimiento u

otros daños de tipo reproductivo.

ADVERTENCIA

En el estado de California es obligatorio, según la ley, el uso de

apagachispas (Sección 4442 del Código de Recursos Públicos de

California). Otros estados pueden tener leyes similares. Las leyes

federales se aplican en tierras federales. Si equipa el silenciador

con un apagachispas, este deberá ser mantenido en buenas

condiciones de trabajo.

Fuego

Explosión

Gases Tóxicos

Superficie Caliente

Partes en Movimiento

Descarga Eléctrica

Superficies Resbalosas

Caer

Contragolpe

Objetos Voladores

Inyección Líquida

Page 21

Lavadora de Presión 1900 PSI de Generac Portable Products

21

• Mantenga el chorro del agua alejado de alambrados eléctricos, de lo

contrario podrían ocurrir descargas eléctricas fatales.

El contacto del rocío con alambrado eléctrico puede

tener como resultado electrocution.

ADVERTENCIA

• Opere el lavadora de presión SOLAMENTE al aire libre.

• Utilice un respirador o máscara siempre que exista la posibilidad de

inhalar vapores.

• Lea todas las instrucciones de la máscara para asegurarse de que le

brindará la protección necesaria contra la inhalación de vapores

nocivos.

Al motor funcionar, se produce monóxido de

carbono, un gas inodoro y venenoso.

El respirar el monóxido de carbono, producirá

náusea, desmayo o la muerte.

PELIGRO

• Mantenga la boquilla de rociado de 8 a 24 pulgadas de la superficie de

limpieza.

• Opere y almacene esta unidad sobre una superficie estable.

• El área de limpieza deberá tener inclinaciones y drenajes adecuados

para disminuir la posibilidad de caídas debido a superficies resbalosas.

• Sea extremadamente cuidadoso si usa la máquina lavadora a presión

desde una escalera, andamio o cualquier superficie relativamente

inestable.

• Sujete la pistola de la hidrolavadora firmemente con ambas manos

cuando utilice el rociado a alta presión. De esta manera evitará

lesiones producidas por el posible golpe de la pistola hacia atrás.

El uso de lavadora de presión puede crear los

charcos y superficies resbalosas.

El rociado de la alta presión podría hacerlo caer si

está muy cerca de la superficie de limpieza.

ADVERTENCIA

CUANDO AÑADA COMBUSTIBLE

• Apague el lavadora de presión (posición OFF) y déjelo enfriar al menos

por 2 minutos antes de remover la tapa de la gasolina.

• Llene el tanque al aire libre.

• NO llene demasiado el tanque. Permita al menos espacio para la

expansión del combustible.

• Mantenga la gasolina alejada de chispas, llamas abiertas, pilotos, calor y

otras fuentes de ignición.

• NO encienda un cigarrillo o fume.

CUANDO OPERE EL EQUIPO

• NO incline el motor o el equipo, de tal manera que la gasolina se

pueda derramar.

• NO rocíe líquidos inflamables.

CUANDO TRANSPORTE O REPARE EL EQUIPO

• Transporte o repare el equipo con el tanque de combustible vacío, o

con la válvula para apagar el combustible, apagada (posición OFF).

CUANDO ALMACENE O GUARDE EL EQUIPO CON

COMBUSTIBLE EN EL TANQUE

• Almacene alejado de calderas, estufas, calentadores de agua, secadoras

de ropa u otros aparatos electrodomésticos que posean pilotos u

otras fuentes de ignición, porque ellos pueden encender los vapores

de la gasolina.

La gasolina y sus vapores son extremadamente

inflamables y explosivos.

El fuego o una explosión pueden causar quemaduras

severas e inclusive la muerte.

ADVERTENCIA

• NUNCA apunte la pistola a la gente, animales o plantas.

• NO permita en ningún momento que NIÑOS operen la máquina

lavadora a presión.

• NUNCA repare la manguera de alta presión. Remplacela.

• Mantenga conectada la manguera a la máquina o a la pistola de

rociado cuando el sistema esté presurizado.

La corriente de agua de alta presión que produce

este equipo pueden perforar la piel y sus tejidos

profundos, ocasionando lesiones serias y posible

amputación.

ADVERTENCIA

Page 22

22

Lavadora de Presión 1900 PSI de Generac Portable Products

• NO juegue con partes que puedan aumentar o disminuir la velocidad

de mando.

• NO opere la máquina lavadora a presión con un valor de presión

superior a su clasificación de presión.

Hacer funcionar el motor a velocidades excesivas aumenta el

riesgo de lesiones personales.

PRECAUCIÓN

• NO apunte la pistola de rociado al vidrio cuando esté en el modo de

rociado a chorro.

• NUNCA apunte la pistola a plantas.

El rociado de alta presión puede dañar elementos frágiles,

incluyendo el vidrio.

PRECAUCIÓN

• NO use ropa suelta, joyas o elementos que puedan quedar atrapados

en el arranque o en otras partes rotatorias.

• Ate para arriba el pelo largo y quite la joyería.

El arrancador y otras piezas que rotan pueden

enredar las manos, el pelo,la ropa, o los accesorios.

ADVERTENCIA

• Siempre use protección para los ojos cuando utilice este equipo o

cuando esté cerca de donde se esté usando el equipo.

El rociado de alta presión puede hacer que partículas

pequeñas de pintura u otras partículas salgan

disparadas y viajen a altas velocidades.

ADVERTENCIA

CUANDO AJUSTE O HAGA REPARACIONES A SU

MÁQUINA LAVADORA DE PRESIÓN

• Siempre desconecte el alambre de la bujía y colóquelo donde no

pueda entrar en contacto con la bujía.

Chispear involuntario puede tener como resultado el

fuego o el golpe eléctrico.

ADVERTENCIA

• NO toque las superficies calientes.

• Manténgase alejado de los gases de escape.

• Permita que el equipo se enfríe antes de tocarlo.

Los motores en funcionamiento producen calor y

gases de escape a altas temperaturas. La temperatura

del silenciador y de las zonas cercanas puede alcanzar

o superar los 65 ºC (150 ºF)

Se pueden producir incendios o quemaduras graves.

ADVERTENCIA

• NO asegure la pistola de rociado en la posición (open = abierto).

• NO abandone la pistola de rociado cuando la máquina esté en

funcionamiento.

• NUNCA utilice una pistola de rociado que no tenga un seguro para

gatillo o protección para gatillo en su lugar y en buenas condiciones.

• Siempre asegúrese de que la pistola de rociado, boquillas y accesorios

estén conectados correctamente.

El lavadora de presión produce un rocío alto de la presión

cuál riesgo de aumentos de la herida y dañe a la unidad.

PRECAUCIÓN

• Si usted tiene alguna pregunta acerca de las finalidades de uso del

generador, pregúntele a su concesionario o contacte a Briggs &

Stratton Power Products.

• NUNCA deberán ser operadas las unidades con partes rotas o

ausentes, o sin la caja o cubiertas de protección.

• NO eluda ningún dispositivo de seguridad de esta máquina.

• Antes de poner en marcha la máquina lavadora a presión en clima

frío, revise todas las partes del equipo y asegúrese de que no se haya

formado hielo sobre ellas.

• NUNCA mueva la máquina halando la manguera de alta presión.

Utilice la manija que viene con la unidad.

• Revise que el sistema de combustible no presente fugas o signos de

deterioro, como mangueras desgastadas o porosas, sujetadores flojos

o ausentes, tapa o tanque dañados.Corrija todos los defectos antes

de operar la máquina lavadora a presión.

• El equipo de alta presión está diseñado para ser utilizado

UNICAMENTE con las partes autorizadas Briggs & Stratton Power

Products. Si utiliza este equipo con partes que no cumplan con las

especificaciones mínimas, el usuario asume todos los riesgos y

responsabilidades.

El tratamiento inadecuado del lavadora de presión puede

dañarlo y acortar su vida productiva.

PRECAUCIÓN

Page 23

23

Lavadora de Presión 1900 PSI de Generac Portable Products

CONOZCA SU MAQUINA LAVADORA DE PRESION

Lea el manual del propietario y las reglas de seguridad antes de poner en marcha su máquina lavadora a presión.

Compare las ilustraciones con su máquina lavadora a presión para familiarizarse con las ubicaciones de los diferentes controles y ajustes.

Guarde este manual para referencias futuras.

Filtro de Aire - El elemento de filtro tipo seco limita la cantidad

de suciedad y polvo que se introduce en el motor.

Automático se Enfría Sistema - Los ciclos regan por bomba

cuando agua alcanza 125º-155ºF. Entibiar agua descargará de

la bomba en el suelo. Este sistema previene el daño

interno de bomba.

Filtro y Tubo para Recolección de Detergente – Usado para

succionar detergente de la botella de químicos a la corriente de

agua de baja presión.

Tanque del Gasolina - Llene el tanque con gasolina regular sin

contenido de plomo en este punto.

Toma de Alta Presión - Conexión para la manguera de alta

presión.

Bombilla más Principal — Usada para arranque de motores

fríos.

Bomba - Desarrolla alta presión de agua.

Arrancador de Retroceso - Usado para arrancar el motor

manualmente.

Entrada de Agua - Conexión para la manguera de jardín.

Filtro de Aire

Bombilla más Principal

Tanque del Gasolina

Entrada de Agua

Bomba equipped with

Automático se Enfría Sistema

Arrancador de Retroceso

Toma de Alta Presión

Filtro y Tubo para

Recolección de Detergente

Page 24

Lavadora de Presión 1900 PSI de Generac Portable Products

24

MONTAJE

IMPORTANTE: Lea totalmente el manual del propietario antes

que intente ensamblar u operar su lavador a presión.

Remueva el Lavador a Presión del

Empaque

• Remueva la bolsa con las piezas, accesorios y las adiciones

incluidas con el lavador de presión.

• Corte dos esquinas en los extremos del cartón desde la parte

superior hasta la parte inferior, de tal manera que el pánel

pueda ser doblado en forma plana.

• Remueva el lavador a presión del la caja.

Contenido de la Caja

Los Artículos que se Encuentran en la Caja Son:

• Unidad principal

• Gafas de seguridad

• Manguera de alta presión

• Pistola rociadora

• Extensión de la lanza

• Botella de aceite para motor

• Bolsa de accesorios (incluye lo siguiente):

• Juego de mantenimiento

• Manual del propietario

• Manual del motor

• Tarjeta de registro del propietario

Si una de las partes que se mencionan arriba se encuentran

dañadas o hacen falta, llame a la línea directa del lavador a presión,

al 1-800-270-1408.

PREPARANDO EL LAVADOR A

PRESIÓN PARA SU USO

A prepara su arandela de la presión para la operación,

usted necesitará a realiza estas tareas:

1. Llene y mande en tarjeta de matrícula.

2. Añada aceite al motor.

3. Añada gasolina al tanque de combustible.

4. Conecte manguera a alta presión a pistola rociadora y a

bomba.

5. Conecte el suministro de agua a bomba.

6. Conecte boquilla la extensión al pistola rociadora.

Agregar Aceite al Motor y Gasolina

• Coloque la lavadora a presión sobre una superficie nivelada.

• Consulte el manual del propietario del motor para añadir al

motor el aceite y el combustible recomendado.

NOTA: Verifique el aceite del motor de manera frecuente cuando

éste se esfuerce demasiado. Consulte el manual del propietario

del motor para conocer cuáles son las recomendaciones al

respecto.

PRECAUCIÓN

• Consulte el manual del propietario del motor para añadir al motor

el aceite y el combustible recomendado

• El daño a la lavadora a presión, resultado de la desatención a

esta precaución, no será cubierto por la garantía.

Cualquier intento para arancar el motor antes de haberle

proporcionado el mantenimiento apropiado con el aceite

recomendado, podría ocasionar la falla del motor.

Page 25

Lavadora de Presión 1900 PSI de Generac Portable Products

25

Conecte Manguera y Suministro de Agua a

Bomba

IMPORTANTE: Usted deberá armar conectar todas las

mangueras antes de darle arranque al motor. La bomba resultará

dañada si arranca el motor sin tener todas las mangueras

conectadas y el suministro agua abierto.

1. Retroceda la manguera a alta presión y conecte a la base de la

pistola rociadora (Figura 13).Apriete con la mano.

2. Conecte el otro extremo de la manguera a alta presión,a la

salida de alta presión de la bomba (Figura 14).Apriete con la

mano.

3. Antes de que conecte la manguera de jardín a la entrada de

agua, inspeccione el colador de la entrada (Figura 15). Limpie

el colador si tiene residuos o solicite su remplazo si está

dañado. NO HAGA FUNCIONAR LA MÁQUINA

LAVADORA A PRESIÓN SI EL COLADOR DE LA ENTRADA

ESTÁ DAÑADO.

4. Haga correr el agua a través de la manguera de su jardín por

30 segundos para limpiar cualquier escombro que se

encuentre en ella. Corte el agua.

IMPORTANTE: Hace no agua de parar de siphon para el

abastecimiento de agua. Use agua SOLO fría (menos que 100°F).

5. Conecte la manguera de jardín (no exceder 50 pies en la

longitud) a la entrada del agua.Apriete con la mano (Figura 15).

6. ABRA el suministo del agua y abra la válvula de suministro

para purgar la sistema de bomba de aire y impureza.

Lista de Revision Previa al Arranque Motor

Revise la unidad para asegurarse que ha llevado a cabo los

siguientes procedimientos:

1. Revise que haya sido depositado aceite y esté al nivel

correcto en la caja del cigüeñal del motor.

2. Deposite la gasolina adecuada en el tanque del combustible.

3. Revise que todas las conexiones de las mangueras (alta

presión y suministro de agua) estén apretadas correctamente

y que no existan dobleces, cortes o daño de la manguera de

alta presión.

4. Proporcione el suministro de agua adecuado.

5. Asegúrese de leer las secciones "Instrucciones de Seguridad"

y "Cómo Usar Su Lavadora A Presión" antes de usar la

máquina lavadora a presión.

Conecte aquí la manguera

a alta presión

Figura 13 — Conecte la Manguera a alta Presión a la Pistola

Rociadora

Figura 14 — Conectar la Manguera de Alta Presión a la Toma

de Agua

Inspeccione la

rejilla de entrada.

NO la use si está

dañada, límpiela si

se encuentra sucia.

Figura 15 — Conectar la Manguera del Jardín a la Entrada de

Agua

PRECAUCIÓN

• El daño a la lavadora a presión, resultado de la desatención a esta

precaución, no será cubierto por la garantía.

DEBE haber por lo menos diez pies de manguera de jardín libre

entre la entrada de agua de la lavadora a presión y cualquier

dispositivo de control de flujo de agua, sea el caso de un

conector 'Y' o de cualquier otro tipo de válvula.

• Siempre use protección para los ojos cuando utilice este equipo o

cuando esté cerca de donde se esté usando el equipo.

• Antes de darle arranque a la máquina lavadora a presión, asegúrese de

usar protección adecuada para los ojos.

El rociado de alta presión puede hacer que partículas

pequeñas de pintura u otras partículas salgan

disparadas y viajen a altas velocidades.

ADVERTENCIA

Page 26

Lavadora de Presión 1900 PSI de Generac Portable Products

26

CÓMO USAR SU MÁQUINA

LAVADORA A PRESIÓN

Si tiene problemas operando su máquina lavadora a presión, por

favor llame a la línea de ayuda para máquinas lavadoras a presión

al 1-800-270-1408.

Cómo Darle Arranque a su Máquina

Lavadora a Presión

Para darle arranque a su máquina lavadora a presión movida a

motor por primera vez, siga estas instrucciones paso a paso. Esta

información acerca del arranque inicial también se aplica cuando vaya

a darle arranque al motor después de haber dejado de la máquina

lavadora a presión fuera de uso por al menos un día.

1. Coloque la máquina lavadora a presión en un área cercana a

una suministro de agua exterior capaz de abastecer agua a un

volumen mayor de 3.0 galones por minuto en no menos que

20 PSI en el fin de arandela de presión de la manga del jardín.

2. Revise que la manguera de alta presión se encuentre

conectada firmemente a la pistola de rociado y a la bomba.Vea

"Preparando El Lavador A Alta Presión Para Su Uso".

3. Asegúrese que la unidad esté nivelada.

4. Conecte la manguera de jardín a la entrada del agua.Aprietela

con la mano. Abra el suministro de agua.

5. Conecte la extensión de la lanza a la pistola rociadora.

Apriétela con las manos (Figura 16).

6. Apriete el gatillo en la pistola rociadora (asegúrese de que la

lanza se encuentra en el modo de baja presión) para

deshacerse de la presión del aire causada al prender el agua. El

agua se descargara de la pistola del spray en un chorro muy

Delgado.Aguante el gatillo hasta que un chorro continuo de

agua aparece. Esto hará que el comienzo del motor se haga

fácilmente. Suelte el gatillo.

7. Coloque el pasador de seguridad al gatillo de la pistola

rociadora (Figura 17).

8. Pour démarrer le moteur, suivez les instructions qui figurent

dans le manuel d'utilisation.

NOTA: Siempre mantenga la control de válvula de admisión en el

“Rápido” (“Fast”) posicione cuándo operar la arandela de la

presión.

Cómo Detener su Máquina Lavadora a

Presión

• Pour éteindre le moteur, suivez les instructions qui figurent

dans le manuel d'utilisation.

• Apriete el gatillo de la pistola de rociado para

eliminar la presión de la manguera.

NOTA: Observará una pequeña cantidad de agua cuando elimine

la presión.

Figura 16 — Conecte la Extensión de la Lanza a la Pistola

Rociadora

El Pasador de la

Seguridad

Figura 17 — La Pistola Rociadora con el Pasador de

Seguridad en su Posición

PRECAUCIÓN

• Apriete el gatillo de la pistola rociadora cada vez que tire del

arrancador de retroceso y que el motor no arranque.

Evite las lesiones que puede causar el retroceso.

PRECAUCIÓN

• Levante siempre el equipo por el asa.

• NUNCA tire de las mangueras para mover el equipo.

Evite los incendios provocados por la caída del equipo.

PRECAUCIÓN

• El daño a la lavadora a presión, resultado de la desatención a esta

precaución, no será cubierto por la garantía.

NO haga funcionar la bomba si no tiene el suministro

conectado y abierto.

Page 27

Lavadora de Presión 1900 PSI de Generac Portable Products

27

Cómo Usar la Boquilla Ajustable

Usted ya debe saber como darle ARRANQUE a su máquina

lavadora a presión y como DETENERLA. La información de esta

sección le dirá como ajustar el patrón de rociado y como aplicar

detergente u otros químicos de limpieza.

1. Usted también puede ajustar el patrón de rociado girando la

boquilla para que esté concentrado en un patrón de chorro

o un patrón expandido en abanico (Figura 18).

2. Apunte la boquilla hacia el suelo, desenganche el cerrojo de

seguridad y apriete el gatillo para probar el patrón de

rociado (Figura 19).

3. El patrón de rociado se ajusta de un patrón angosto a un

patrón en abanico girando la boquilla (Figura 20).

4. Para una limpieza más efectiva, mantenga la boquilla de

rociado de 8 a 24 pulgadas de la superficie de limpieza.

5. Si coloca la boquilla de rociado demasiado cerca podría

dañar la superficie, especialmente cuando esté usando el

modo de alta presión.

6. NO coloque la boquilla a menos de 6 pulgadas cuando esté

limpiando llantas.

Aplicación del Detergente Usando la

Boquilla Ajustable

IMPORTANTE: Utilice químicos diseñados específicamente para

máquinas lavadoras a presión. Los detergentes caseros podrían

dañar la bomba.

Para aplicar el detergente, siga los siguientes pasos:

1. Revise el uso de la boquilla ajustable.

2. Prepare la solución detergente siguiendo las instrucciones del

fabricante.

3. Coloque el pequeño extremo final del filtro del tubo de

inyección del detergente dentro del contenedor del

detergente.

Mueva la boquilla hacia

atrás para obtener el modo

de alta presión.

Mueva la boquilla hacia adelante

para obtener el modo de baja

presión y para la aplicación del

detergente.

Figura 18 — Ajustar la Presión de Aspersión

Figura 19 — Poner a Prueba el Patrón de Aspersión

Figura 20 — Ajustar el Patrón de Aspersión

Gire la boquilla en sentido

contrario a las manecillas del

reloj para un patrón de

rociado en abanico.

Gire la boquilla en sentido de

las manecillas del reloj para

un patrón de rociado a

chorro.

• NUNCA ajuste el patrón de rociado cuando esté rociando.

• NUNCA coloque las manos en frente de la boquilla para ajustar el

patrón de rociado.

El lavadora de presión produce un rocío alto de la presión

cuál riesgo de aumentos de la herida y dañe a la unidad.

PRECAUCIÓN

PRECAUCIÓN

• Arrancar el motor sin tener todas las mangueras conectadas y sin el

suministro de agua ABIERTO (ON) causará el daño de la bomba.

• El daño a la lavadora a presión, resultado de la desatención a esta

precaución, no será cubierto por la garantía.

Usted deberá conectar todas las mangueras antes de darle

arranque al motor.

Page 28

Lavadora de Presión 1900 PSI de Generac Portable Products

28

4. Mueva la boquilla ajustable hacia adelante para obtener el

modo de baja presión. El detergente no puede ser aplicado si

tiene la boquilla en la posición de alta presión.

5. Asegúrese que la manguera de jardín esté conectada a la

entrada del agua. Revise que la manguera de alta presión esté

conectada a la pistola de rociado y a la bomba. Dele arranque

al motor.

6. Aplique el detergente sobre la superficie seca, comenzando en

la parte inferior del área y dirigiéndose hacia arriba, utilizando

movimientos largos, parejos y superpuestos.

7. Permita que el detergente "penetre" de 3 a 5 minutos antes

de enjuagar.Vuelva a aplicarlo cuando sea necesario para evitar

que la superficie se seque. NO permita que el detergente se

seque. Si permite que el detergente se seque, la superficie

podría quedar con manchas.

IMPORTANTE: Usted deberá lavar el sistema de inyección de

químicos después de cada uso colocando el filtro en un balde de

agua limpia y haciendo funcionar la máquina lavadora a presión de

1 a 2 minutos en el modo de baja presión.

Enjuage de la Máquina Lavadora a Presión

Para Enjuage:

1. Deslice la boquilla hacia atrás a la presión alta y apriete el

disparador. Llevará un pocos segundos para el detergente a

claro.

NOTA: También puede detener la circulación del detergente

retirando el tubo de succión del recipiente.

2. Mantenga la pistola de rociado a una distancia segura del área

que planea rociar.

3. Aplique un rociado de alta presión en un área pequeña,

después revise si la superficie presenta daños. Si no encuentra

daños, puede continuar con el trabajo de limpieza.

4. Comience en la parte superior del área que va a enjuagar,

dirigiéndose hacia abajo con los mismos movimientos

superpuestos que utilizó para el limpieza.

Sistema de Enfriamiento Automático

(Alivio Térmico)

El agua que circula dentro de la bomba puede alcanzar

temperaturas entre los 125º-155ºF si hace funcionar el motor de

su máquina lavadora a presión de 3 a 5 minutos sin oprimir el

gatillo de la pistola de rociado. Cuando el agua alcanza dicha

temperatura, el sistema de enfriamiento automático se activa y

enfría la bomba descargando agua caliente en el piso. Este

sistema evita el daño interno de la bomba.

PRECAUCIÓN

• Cuando coloque el filtro en la botella del químico, coloque el tubo

de manera que no entre en contacto accidentalmente con el

silenciador caliente.

Evite que el tubo de inyección de químicos entre en contacto

con el silenciador caliente.

• Mantenga la boquilla de rociado de 8 a 24 pulgadas de la superficie de

limpieza.

• Opere y almacene esta unidad sobre una superficie estable.

• Sea extremadamente cuidadoso si usa la máquina lavadora a presión

desde una escalera, andamio o cualquier superficie relativamente

inestable.

• Sujete la pistola de la hidrolavadora firmemente con ambas manos

cuando utilice el rociado a alta presión. De esta manera evitará

lesiones producidas por el posible golpe de la pistola hacia atrás.

El rociado de la alta presión podría hacerlo caer si

está muy cerca de la superficie de limpieza.

ADVERTENCIA

Page 29

Lavadora de Presión 1900 PSI de Generac Portable Products

29

ESPECIFICACIONES

Presión de Salida . . . . . . 1900 PSI

Promedio de Flujo . . . . 2.0 galones por minuto (gpm)

Detergente . . . . . . . . . . . Use el detergente adecuado para

lavadores a presión

Temperatura del Suministro

de Agua . . . . . . . . . . . . . .Que no pase de 100ºF

Sistema de . . . . . . . . . . .Funcionará cuando el agua alcance de

Enfriamiento . . . . . . . . . .125º-155ºF

Automático

Peso que Embarca . . . . .46 lbs.

RECOMENDACIONES GENERALES

La garantía de la máquina lavadora a presión no cubre los

elementos que han sido sujetos a abuso o negligencia por parte

del operador. Para hacer válida la cobertura total de la garantía, el

operador deberá mantener la lavadora de presión tal y como se

indica en el manual.

• Algunos ajustes tendrán que hacerse periódicamente para

mantener adecuadamente su máquina lavadora a presión.

• Todos los servicios y ajustes deberán hacerse por lo menos

una vez en cada estación.

• Una vez al año, usted deberá limpiar o remplazar la bujía y el

filtro de aire. Una bujía nueva y un filtro de aire limpio

garantizan una mezcla de combustible-aire adecuada y le ayuda

a su motor a funcionar mejor y a tener una vida útil más

prolongada. Por favor, para mayores detalles, consulte el

manual del propietario del motor.

Antes de Cada Uso

1. Revise el nivel de aceite del motor.

2. Revise si existen daños en el colador de la entrada de agua.

3. Revise si existen daños en el filtro en línea.

4. Revise si existen fugas en la manguera de alta presión.

5. Revise si existen daños en los filtros de químicos.

6. Revise si existen fugas en el conjunto de la extensión para

boquillas y pistola.

7. El aclarado fuera manga de jardín para limpiar fuera

escombros.

MANTENIMIENTO DE LA

MAQUINA LAVADORA A

PRESION

Revise y Limpie el Colador de Entrada

Examine el colador de entrada de la manguera de jardín. Límpielo

si está tapado o remplacelo si está roto.

Revise la Manguera de Alta Presión

Las mangueras de alta presión pueden desarrollar fugas debido al

desgaste, dobleces o abuso. Revise la manguera antes de cada uso.

Revise si existen cortes, fugas, abrasiones, levantamiento de la

cubierta, daño o movimiento de los acoplamientos. Si existe

cualquiera de estas condiciones, remplace la manguera

inmediatamente.

Chequee el Tubo de Sifón del Detergente

Examine el filtro en el tubo del detergente y límpielo si se

encuentra sucio. El tubo debería quedar apretado en la pieza.

Examine el tubo para ver si existe cualquier tipo de goteo o está

roto. Reemplace el filtro o el tubo si alguno de ellos se encuentra

dañado.

Revise la Pistola y la Extensión para

Boquillas

Examine la conexión de la manguera a la pistola y cerciorese de

que esté en buen estado. Pruebe el gatillo oprimiéndolo y

asegurándose de que se devuelve a su sitio cuando lo suelte.

Coloque el cerrojo de seguridad y pruebe el gatillo.Usted no

debe ser capaz de oprimir el gatillo. Remplace la pistola

inmediatamente si falla cualquiera de estas pruebas.

Elimine el Aire y los Contaminantes de la

Bomba

Para retirar el aire de la bomba,siga los siguientes pasos:

1. Instale la máquina lavadora a presión como está descrito en

“Preparando El Lavador A Presión Para Su Uso”. Conecte el

abastecimiento de agua y prenda agua.

• NUNCA repare la manguera de alta presión. Remplacela.

• Remplacela con una manguera que cumpla con la capacidad mínima de

presión de su máquina lavadora a presión.

La corriente de agua de alta presión que produce

este equipo pueden perforar la piel y sus tejidos

profundos, ocasionando lesiones serias y posible

amputación.

ADVERTENCIA

Page 30

Lavadora de Presión 1900 PSI de Generac Portable Products

30

2. Estire el disparador en el fusil del rocío y el asidero.

3. Cuándo el agua es constante y constante, compromete el

picaporte de la seguridad.

Para retirar los contaminantes de la bomba, siga los

siguientes pasos:

1. Instale la máquina lavadora a presión como está descrito en

“Preparando El Lavador A Presión Para Su Uso”. Conecte el

abastecimiento de agua y prenda agua.

2. Quite boquilla la extensión del fusil del rocío.

3. Ponga en marcha el motor de acuerdo a las instrucciones de

“Cómo Darle Arranque a su Máquina Lavadora a Presión”.

4. Hale el gatillo de la pistola y manténgalo apretado.

5. Cuando el suministro de agua sea uniforme y constante,

enganche el cerrojo de seguridad y vuelva a ajustar la

extensión para boquillas.

Revise el Filtro en Línea

Consulte la Figura 21 y suministre servicio al filtro en línea si se

tapa siguiendo estos pasos:

1. Retire la pistola y la extensión para boquillas de la manguera

de alta presión. Retire la extensión para boquillas de la

pistola y retire el anillo 'o' y el colador de la extensión para

boquillas. Lave el colador, pistola y extensión para boquillas

con agua limpia para eliminar toda clase de residuos.

2. Si el colador está dañado, encontrará un colador para el filtro

en línea y un anillo 'o' de repuesto en el juego de anillos 'o'.

Si no está dañado, vuelva a usarlo.

3. Coloque el colador del filtro en línea en el extremo con

rosca de la extensión para boquillas. Su dirección no importa.

Coloque el colador ejerciendo presión con el borrador de

un lápiz hasta que se asiente por completo en el fondo de la