Briggs & Stratton 1768-0 Installation Manual

Manual de Instalaci6n y

PEG_JCTS

Briggs& Stratton Power Products Home Generator System

Installation Manual

TABLE OF CONTENTS

TABLEOF CONTENTS ......................... 2

EQUIPMENT DESCRIPTION ..................... 2

CUSTOMER RESPONSIBILITIES................... 2

INSTALLERRESPONSIBILITIES ................... 2

SAFETY RULES................................ 3

INSTALLATION PROCEDURES ................... 4

Unpacking Precautions ....................... 4

Delivery Inspection ......................... 4

Shipment Contents .......................... 4

RequiredTools/Equipment .................... 4

Home Generator System Location .............. 4

Fuel and Electrical Inlet Dimensions ............. S

Lifting the Generator ........................ 5

Access Doors .............................. 6

Automatic PowerTransfer Switch Mounting

Dimensions ......................... 7

THE GASEOUS FUELSYSTEM .................. 7-8

Fuel Consumption .......................... 9

Fuel PipeSizing ............................. 9

ESSENTIALCIRCUIT ISOLATION ................ l0

TRANSFER SWITCH .......................... I I

Generator AC Connection System ............. II

PowerWiring Interconnections ............... 12

Grounding the System ...................... 13

Control Circuit Interconnections .............. 13

Fault Detection System ...................... 13

SystemControl Panel ....................... 13

BEFOREINITIAL ENGINE START-UP.............. 14

EngineOil ................................ 14

Battery Connection ........................ 14

Fuel SupplySystem ......................... 14

INITIAL START-UP(NO LOAD) ................. 15

Electrical Checks .......................... IS

AUTOMATIC OPERATION SEQUENCE ........... 16

CheckingAutomatic Operation ............... 17

SETTING EXERCISETIMER ..................... 17

RECONFIGURING THE FUELSYSTEM ............ 18

EngineAdjustment ......................... 18

POST INSTALLATION INSPECTION .............. 19

REFERENCES ................................ 19

Standards Index ........................... 19

FuelComparison Chart ..................... 20

Sizeof Propane Tank Required atVarious Temperatures

When Kept at Least Half Full .......... 20

INSTALLATION NOTES......................... 21

EQUIPMENT

DESCRIPTION

This system consists of an engine driven AC generator

designedto provide backup electrical power for operating

compatible electrical loads through the supplied automatic

power transfer switch.

This manualcontains installation, startup and adjustment

instructions for Home Generator Systemsthat operates

120and/or 240Volt.singlephase,60Hz devices.The

generator may be operated on LP or natural gasfueI.A

separate owner's manual (part number 191187) contains

specifications,operating and maintenance instructions for

these models.

Everyeffort hasbeen expended to makesure that the

informationinthis manual is both accurate and current

However, the manufacturer reserves the right to change,

alter or otherwise improvethe systemat any time without

prior notice.

_ CAUTION! Do Not tamper with engine

governed speed.High operating speedsare

dangerous and increasethe risk of personal injury

or damageto equipmen_

CUSTOMER

RESPONSIBILITIES

• Read and follow the instructions given in the Owner's

Manual, especially the section regarding selecting essential

circuits.

• Follow a regular schedule in maintaining, caring for and

using your Home Generator System, as specified in the

Owner's Manual.

INSTALLER

RESPONSIBILITIES

• Read and observe the safety rules.

• Read and follow the instructions given in this Installation

and Start-up Manual.

• Employ good workmanship techniques to ensure a long

lasting and trouble-free backup power installation.

w

2

Bri_s & Stratton Power Products Home Generator System

Installation Manual

ComokbyEmo*_JC_,_

SAFETY RULES

The safety alert symbol (_,) is used with a signalword

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety messageto alert you to hazards.DANGER indicates

a hazardwhich, if not avoided,will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

couldresult in death or serious injury. CAUTION

indicatesa hazardwhich, if not avoided,might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage.Follow safety messagesto

avoid or reduce the risk of injury or death.

WARNING

Do not handlegenerator or electrical cordswhile standing in

water, while barefoot, or while hands or feet are wet,

If you mustwork around a unit while it is operating, stand on

an insulateddry surface to reduce shock hazard.

Do not allow unqualified persons or children to operate or

service generator.

In caseof an accident caused by electrical shock, immediately

shut down the source of electrical power. If this is not

possible,attempt to free the victimfrom the live conductor.

Avoid direct contact with the victim, Use a non-

conducting implement, such as a rope or board, to free the

victim from the live conductor. If the victim is unconscious,

apply first aid and get immediate medical help.

Before performing any maintenance on the generator,

disconnect the battery cable indicatedby a NEGATIVE,

NEG or (-) first-When finished, reconnect that cable last.

After your Home Generator System is installed,the generator

maycrank and start without warning anytime there is a

power failure.To prevent possible injury, always set the

AUTO/OFF/MANUAL switch to OFF AND remove the

I5Amp fuse BEFORE working on the equipment.

WARNING

Only c)ualified electricians and gaseous fuel

technicians should attempt installation of this

system, which must strictly comply with applicable

codes, standards and regulations.

WARNING

NOT INTENDED FOR USEAS PRIMARY

POWER IN PLACE OF UTILITY OR IN

LIFE-SUPPORT APPLICATIONS

WARNING

Install the fuel supply system accordingto applicablefuel-gas

codes.

Before placing the Home Generator System intoservice, the

fuel system lines must be properly purged and leak tested.

After the system is installed,you should inspect the fuel

system periodically.

No leakage is permitted.

CAUTION

Adequate, unobstructed flow of cooling and ventilating air is

critical to correct generator operation.

Keep at least 2 feet of clearance on all sides of generator for

adequate ventilation.

Despite the safe design of the Home Generator System,

operating this equipment imprudently, neglecting its

maintenance or being careless can cause possible injury or

death.

Remain alert at all times while working on this equipment.

Never work on the equipment when you are physicallyor

mentally fatigued,

Do not use the generator or any of its parts asa step.

Steppingon the unit cancausestress and break parts,This

may result in dangerous operatingconditionsfrom leaking

exhaust gases,fuel leakage,oil leakage,and soforth.

3

Bri?a_s& Stratten Power Products Home Generator System

Installation Manual

INSTALLATION

PROCEDURES

Unpacking Precautions

The unit is shipped bolted to its mounting pad, ready for

hookup. Use care to avoid damagefrom dropping, bumping,

collision, etc. Store and unpack carton with the proper side

up,asnoted on the shipping carton.

Delivery Inspection

After removing the carton, carefullyinspectthe Home

Generator andAutomatic PowerTransfer Switch

components for any damagethat may haveoccurred during

shipment.

IMPORTANT: If loss or damageis noted at time of

delivery,havethe person(s) making delivery note all damage

on the freight bill and affix his signature under the

consignor's memo of lossor damage.If loss or damage is

noted after delivery, separate the damagedmaterials and

contact the carrier for claim procedures. Missingor

damagedparts are not warranted.

Shipment Contents

The Home Generator System is supplied with:

BackupPower generator

Pre-attached mounting pad

Automatic PowerTransfer switch

One 24" flexible hook-up pipe

Installation and start-up manual (P/N 191186)

Owner's manual(P/N 191187)

Product warranty sheet (P/N 190881)

Installation checklist (P/N 190840)

Three accessdoor keys

Four lifting hole plugs

Oil fill spout

Touch-up paint

One spare 15A fuse

Diagnostic LED kit (diode/plate/decal/pin connectors (2))

Required Tools/Equipment

• Two 48" lengths of I" OD pipe (NOT conduit)

• Hole punches for 16ga steer

• Torque screwdriver, 5 to 50 inch-pound range

Home Generator System Location

TO THE INSTALLER: Consult with the owners

and convey any technical considerations that might

affect their wishes, before applying these general

guidelines.

Generator Clearances

The generator enclosure mustbe a minimum of 3 f_

(92 cm) from combustible material (NFPA 37). Leaveat

least3 ft. (92 cm) all around the enclosure for accessto the

inside of the enclosure (NEC Art. II 0-26a,Art. 110-26b).

The unit's exhaust port must be at least S ft. (152 cm) from

any building opening (window, door, vent etc.), and the

exhaustmust not be able to accumulate in any occupied

area (Figure I).

Exhaust

Exhaustport must be

5 ft (152 cm) minimum

distancefrom building

openings

General Location Guidelines

• Install the unit outdoors ONLY. NO MODIFICATIONS

WILLALLOW INSIDE INSTALLATION!

Place the unit in a prepared location that is fiat and has

provisions for water drainage.

• Instalt the unit where air inlet and outlet openings will

not become obstructed by leaves, grass, snow, etc. If

prevailing winds will cause blowing or drifting, you may

need to construct a windbreak to protect the unit.

• In locations where strong winds blow from one

direction, face the generator air inlet openings into the

prevailing winds, if possible.

/

4

Bri_s & Stra_on Power ProductsHome Generator System

Installation Manual

• Installthe generator as closeaspossibleto the

Automatic PowerTransfer Systemto reduce the length

of wiring and conduit

• Install the generator as close aspossible to the fuel

supply to reducelength of pipes.

_k CAUTION! Lawsor local codes mayregulatethe

distance to the fuel supply.

The Home Generator Systemis shippedalreadyattached

to its mounting pad.Unlessmandatedby localcode,no

concreteslabis required.

If mandatedbylocalcode, detachthe unitfrom itssupplied

base.Construct a concrete slabat least 3 inchesthick and

6 incheslonger and wider than the unit_Attachunit to slab

with I/4" diameter (minimum) masonry anchor bolts long

enough to retain the unit Use the mounting padholes as

anchor bolt Iocators.

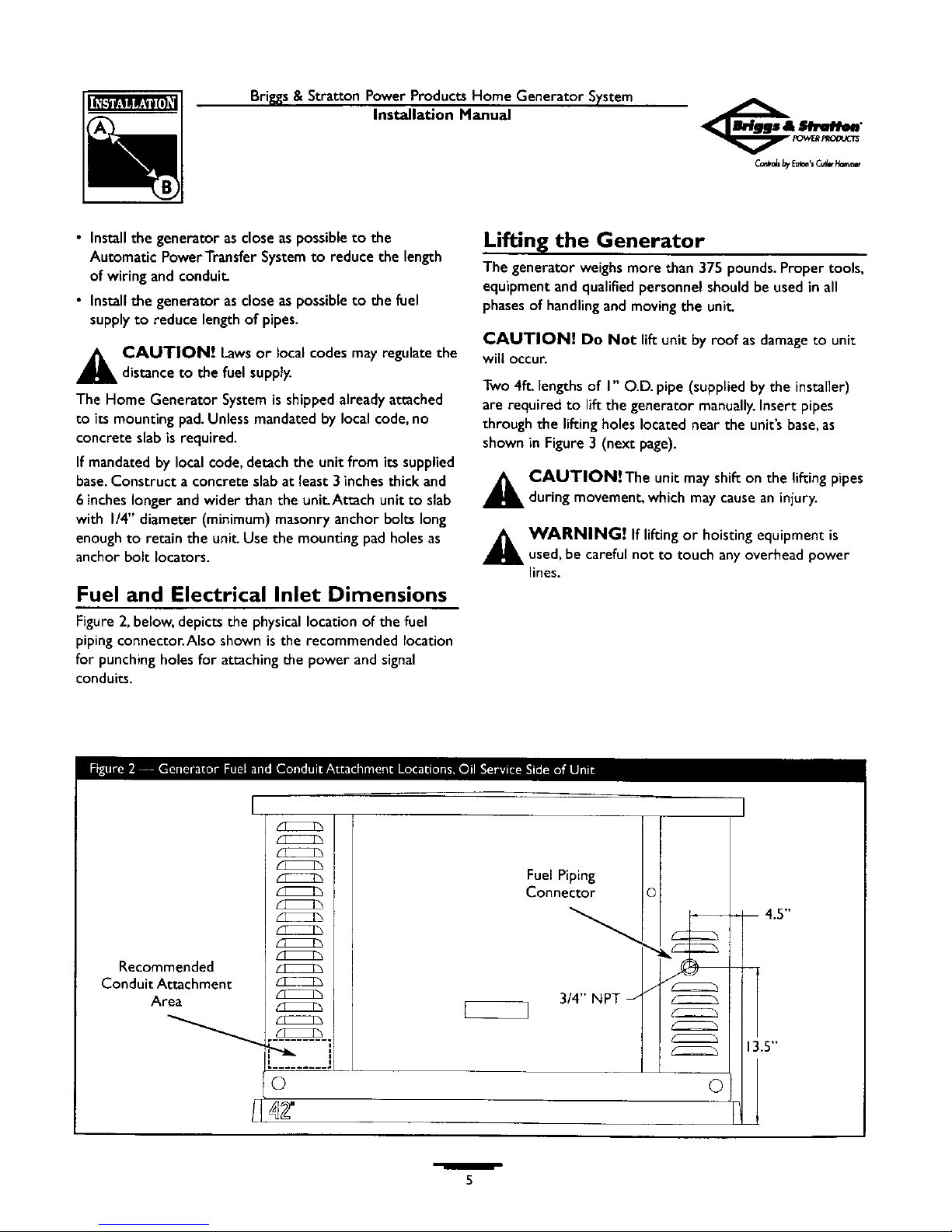

Fuel and Electrical Inlet Dimensions

Figure2, below, depicts the physicallocation of the fuel

piping connector.Also shown is the recommended location

for punching holesfor attaching the power and signal

conduits.

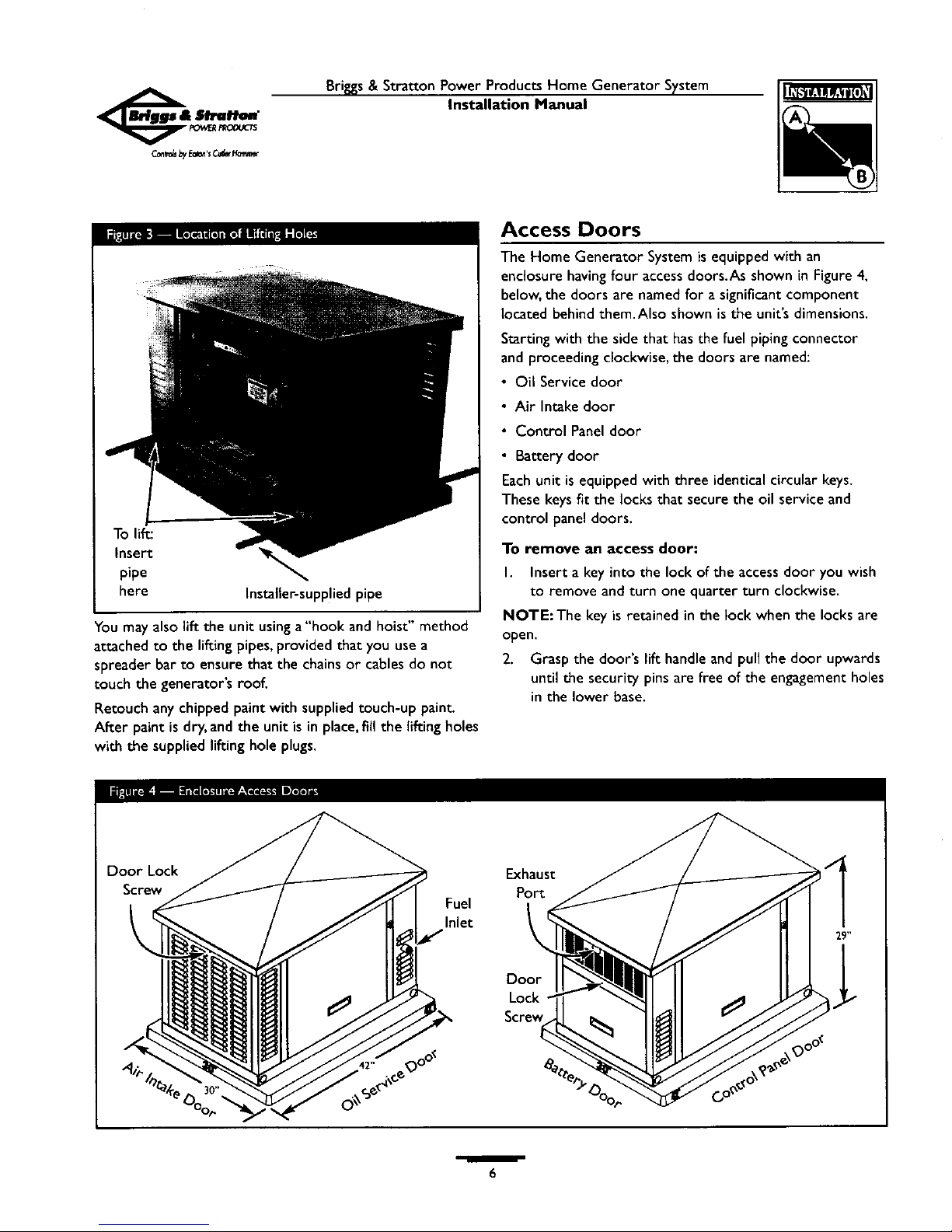

Lifting the Generator

The generator weighsmore than 375 pounds. Proper tools,

equipment and qualified personnel should be used in all

phasesof handlingand moving the unit

CAUTION! Do Not lift unit by roof as damage to unit

will occur.

Two 4E. lengths of I" O.D. pipe (supplied by the installer)

are required to lift the generator manually.Insert pipes

through the lifting holes located near the unit's base,as

shown in Figure 3 (next page).

_ CAUTIONiThe unit may shifton the lifting pipes

during movement, whichmay cause an injury.

_ WARNING! If lifting or hoisting equipment is

used, be careful not to touch any overhead power

lines.

Recommended

Conduit Attachment

Area

I

K_22_

_22222h

lI2222125

(2)

o

3/4" NPT _ I _

©

I

-- 4.5"

13.5"

5

Bri_s&StrattonPowerProductsHomeGeneratorSystem

Installation Manual

To lift:

Insert

pipe

here

Installer-supplied pipe

You may also lift the unit usinga"hook andhoist" method

attached to the lifting pipes,provided that you use a

spreader bar to ensure that the chainsor cables do not

touch the generator's roof.

Retouch any chipped paint with supplied touch-up paint.

After paint is dry, and the unit is in place,fill the lifting holes

with the supplied lifting hole plugs.

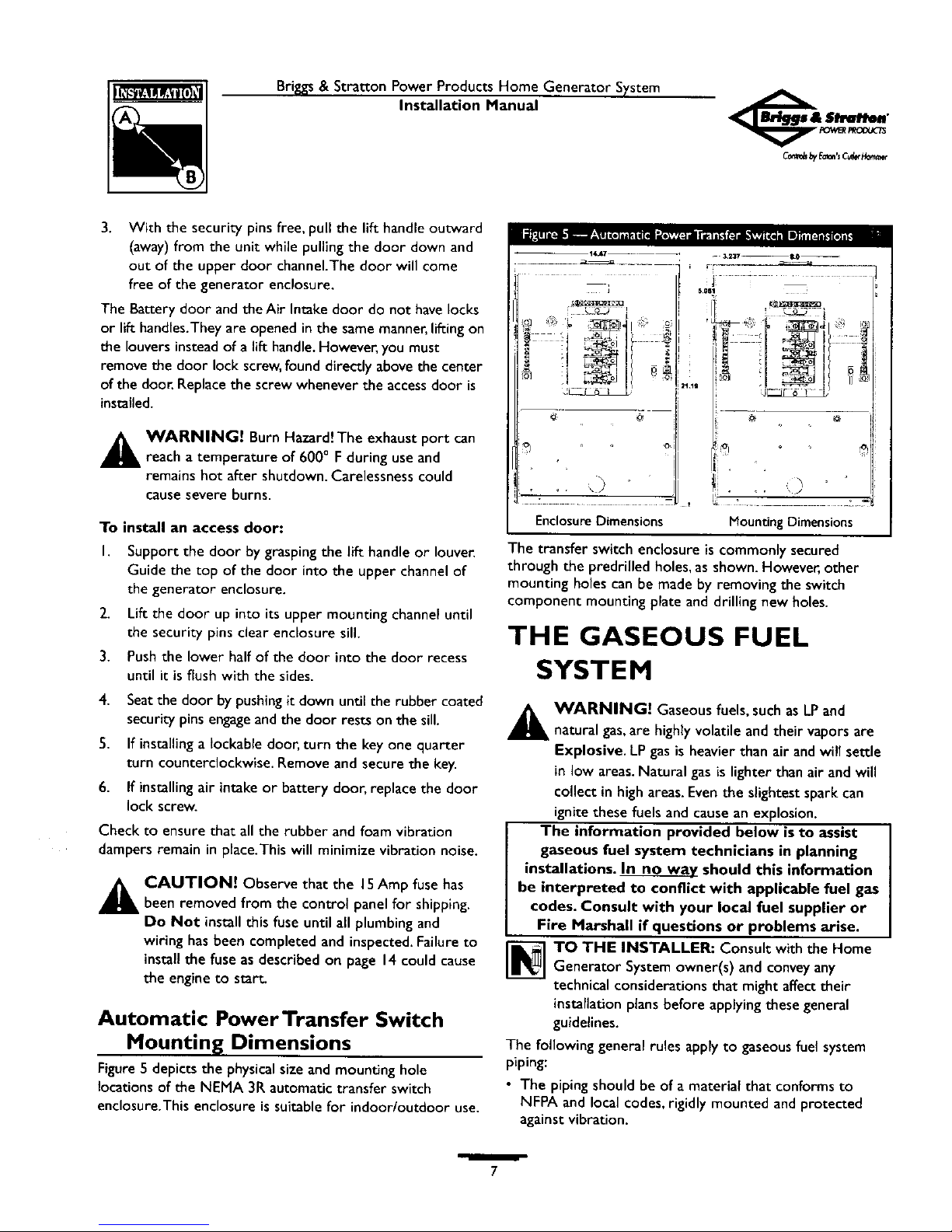

Access Doors

The Home Generator System is equipped with an

enclosure having four access doors.As shown in Figure 4,

below, the doors are named for a significant component

located behind them.Also shown is the unit's dimensions.

Starting with the side that has the fuel piping connector

and proceeding clockwise, the doors are named:

• Oil Service door

• Air Intake door

• Control Panel door

• Battery door

Each unit is equipped with three identical circular keys.

These keys fit the locks that secure the oil service and

control panel doors.

To remove an access door:

I. Insert a key into the lock of the access door you wish

to remove and turn one quarter turn clockwise.

NOTE:The key is retained in the lock when the locks are

open.

2. Grasp the door's lift handle and pull the door upwards

until the security pins are free of the engagement holes

in the lower base.

Door Lock

Screw

Fuel

Inlet

Exhaust

Port

2911

ooo'

Door

Lock

Screw

0oO_

w

6

Briggs& Stratton Power Products Home Generator System

Installation Manual

3. With the security pins free, pull the lift handle outward

(away)from the unit while pulling the door down and

out of the upper door channel.The door will come

free of the generator enclosure.

The Battery door andtheAir Intake door do not havelocks

or lift handles.Theyare opened in the samemanner,lifting on

the louvers instead of a lift handle.However,you must

remove the door lock screw,found directly abovethe center

of the door. Replacethe screw whenever the accessdoor is

installed.

_ WARNING! Burn Hazard!The exhaust port can

reach a temperature of 600° Fduring useand

remains hot after shutdown. Carelessnesscould

causesevere burns.

To install an access door:

I. Support the door by grasping the lift handle or louver.

Guide the top of the door into the upper channel of

the generator enclosure.

2. Lift the door up into its upper mounting channel until

the security pins clear enclosure sill.

3. Push the lower half of the door into the door recess

until it is flush with the sides.

4. Seat the door by pushing it down until the rubber coated

security pins engage and the door rests on the sill.

5. If installing a Iockable door, turn the key one quarter

turn counterclockwise. Remove and secure the key.

6. If installing air intake or battery door, replace the door

lock screw.

Check to ensure that all the rubber and foam vibration

dampers remain in place.This will minimize vibration noise.

_, CAUTION! Observe that the 15Amp fuse has

been removed from the control panel for shipping.

Do Not install this fuse until all plumbing and

wiring has been completed and inspected. Failure to

install the fuse as described on page 14could cause

the engine to start

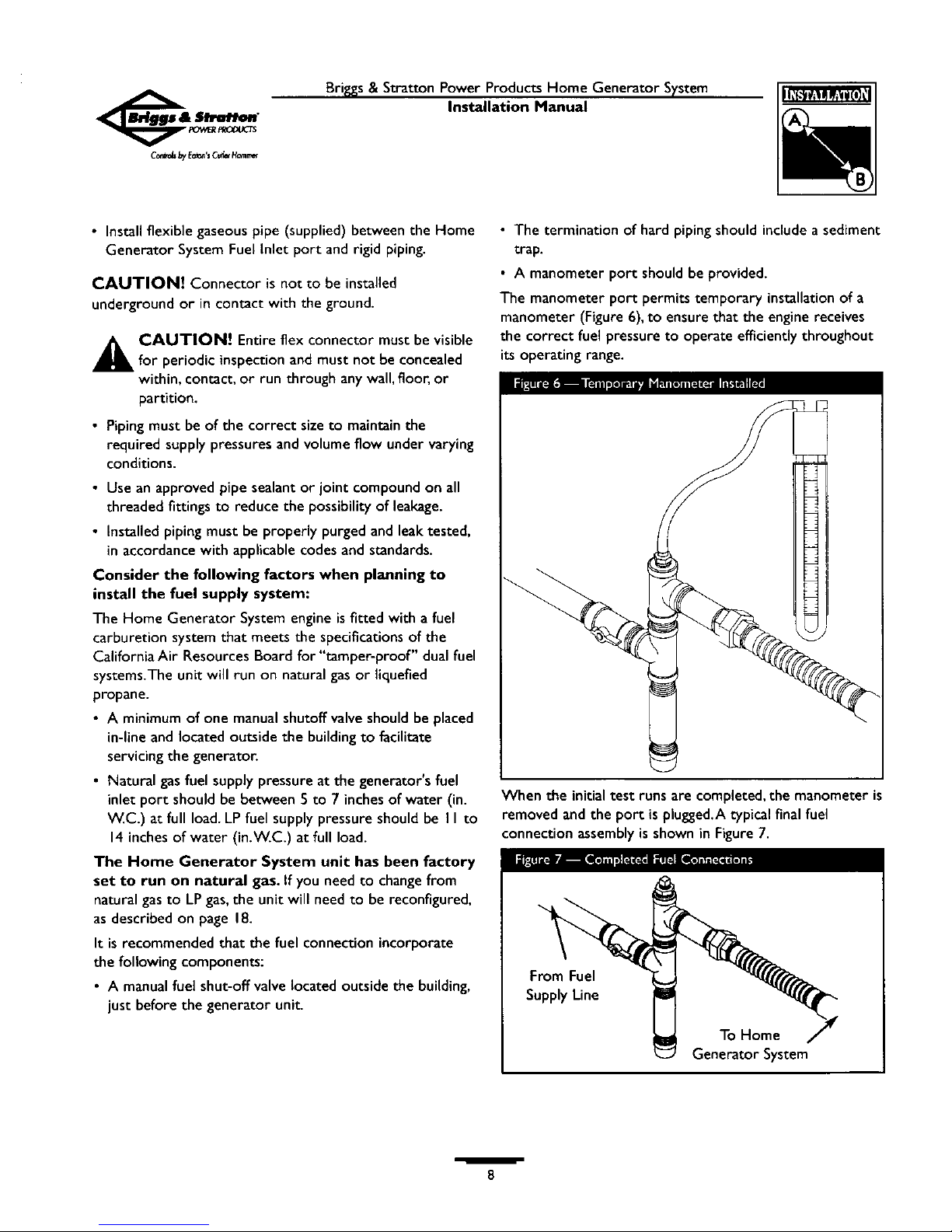

Automatic PowerTransfer Switch

Mounting Dimensions

Figure 5 depicts the physical size and mounting hole

locations of the NEMA 3R automatic transfer switch

enclosure.This enclosure is suitable for indoor/outdoor use.

Enclosure Dimensions Mounting Dimensions

The transfer switch enclosure is commonly secured

through the predrilled holes, as shown. However, other

mounting holes can be made by removing the switch

component mounting plate and drilling new holes.

THE GASEOUS FUEL

SYSTEM

_, WARNING! Gaseous fuels, such asLP and

natural gas,are highlyvolatileand their vaporsare

Explosive. LPgasis heavier than air andwill settle

in low areas.Natural gas islighter than air and will

collect in high areas.Even the slightest spark can

ignite these fuels and causean explosion.

The information provided below isto assist

gaseous fuel system technicians in planning

installations. In no wav should this information

be interpreted to conflict with applicable fuel gas

codes. Consult with your local fuel supplier or

Fire Marshall if questions or problems arise.

TO THE INSTALLER: Consult with the Home

Generator Systemowner(s) and conveyany

technical considerations that might affect their

installationplansbefore applying these general

guidelines.

The following general rules apply to gaseousfuel system

piping:

• The piping should be of a material that conforms to

NFPA and local codes,rigidly mounted and protected

against vibration.

7

Bri_._s& Stratton Power Products Home Generator System

Installation Manual

• Install flexible gaseous pipe (supplied) between the Home

Generator System Fuel Inlet port and rigid piping.

CAUTION! Connector is not to be installed

underground or in contact with the ground.

_k CAUTION! Entire flex connector must be visible

for periodic inspection and must not be concealed

within, contact, or run through any wall, floor, or

partition.

• Piping must be of the correct size to maintain the

required supply pressures and volume flow under varying

conditions.

• Use an approved pipe sealant or joint compound on all

threaded fittings to reduce the possibility of leakage.

• Installed piping must be properly purged and leak tested,

in accordance with applicable codes and standards.

Consider the following factors when planning to

install the fuel supply system:

The Home Generator System engine is fitted with a fuel

carburetion system that meets the specifications of the

California Air Resources Board for "tamper-proof" dual fuel

systems.The unit will run on natural gas or liquefied

propane.

• A minimum of one manual shutoff valve should be placed

in-line and located outside the building to facilitate

servicing the generator.

• Natural gas fuel supply pressure at the generator's fuel

inlet port should be between 5 to 7 inches of water (in.

W.C.) at full load. LP fuel supply pressure should be I I to

14 inches of water (in.W.C.) at full load.

The Home Generator System unit has been factory

set to run on natural gas. If you need to change from

natural gas to LP gas, the unit will need to be reconfigured,

as described on page 18.

It is recommended that the fuel connection incorporate

the following components:

• A manual fuel shut-off valve located outside the building,

just before the generator unit.

• The termination of hard piping should include a sediment

trap.

• A manometer port should be provided.

The manometer port permits temporary installation of a

manometer (Figure 6),to ensure that the engine receives

the correct fuel pressure to operate efficiently throughout

its operating range.

When the initial test runs are completed, the manometer is

removed and the port is plugged.A typical final fuel

connection assembly is shown in Figure 7.

From Fuel

Supply Line

To Home

Generator System

W

8

Brings & Stratton Power Products Home Generator System

Installation Manual

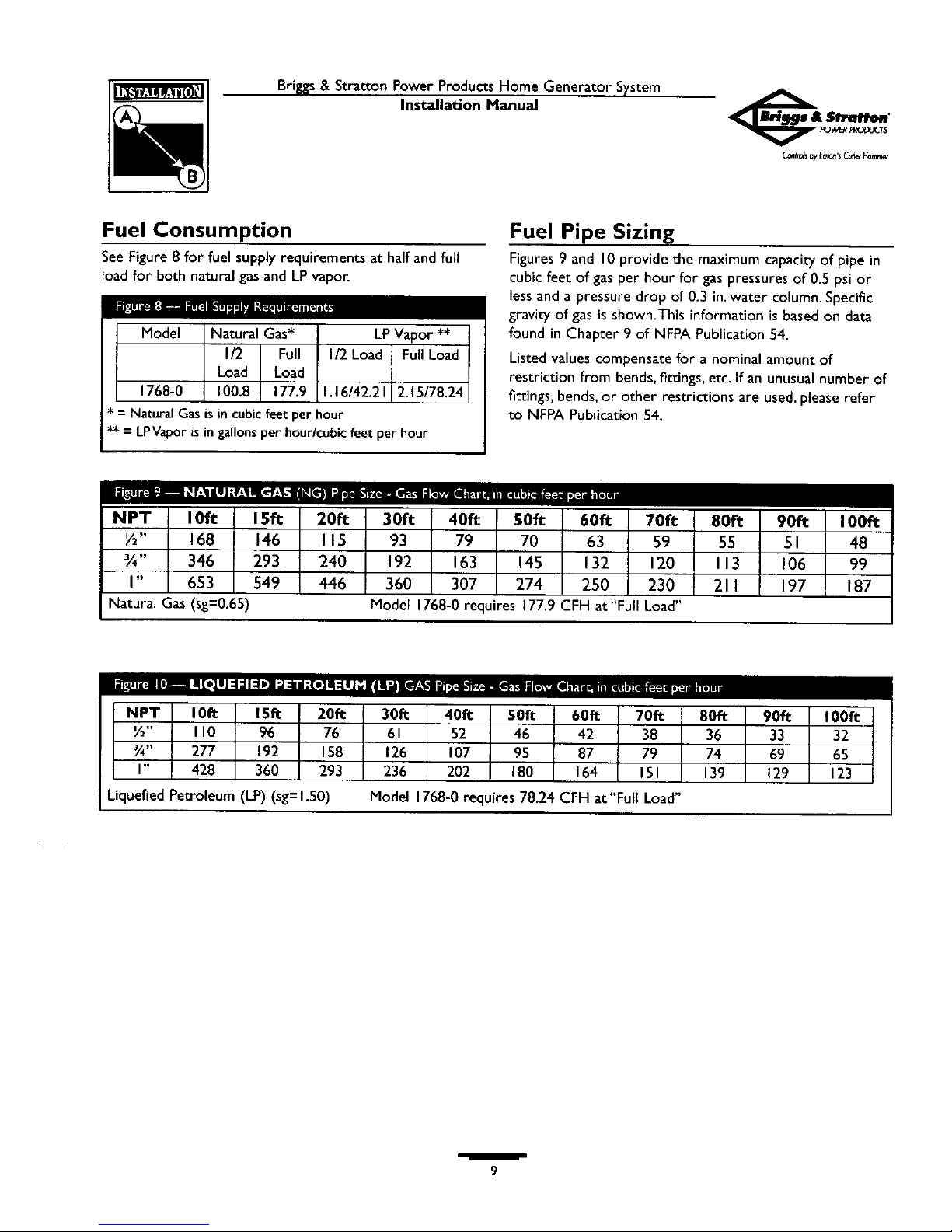

Fuel Consumption

See Figure 8 for fuel supply requirements at half and full

load for both natural gasand LPvapor.

Model Natural Gas* LPVapor *_

I/2 Full I/2 Load Full Load

Load Load

1768-0 100.8 177.9 1.16/42.21 2.15/78.24

* = NaturalGasisincubicfeetper hour

** = LPVaporisin gallonsperhour/cubicfeet per hour

Fuel Pipe Sizing

Figures 9 and 10 provide the maximum capacity of pipe in

cubic feet of gas per hour for gas pressures of 0.5 psi or

less and a pressure drop of 0.3 in. water column. Specific

gravity of gas is shown.This information is based on data

found in Chapter 9 of NFPA Publication 54.

Listed values compensatefor a nominal amount of

restriction from bends,fittings, etc. If an unusual number of

fittings, bends,or other restrictions are used,pleaserefer

to NFPA Publication 54.

10_ 20_

½" 168 146 115

¾" 346 293 240

I" 653 549 446

Natural Gas(sg=0.65)

70_

93 79 70 63 59

192 163 145 132 120

360 307 274 250 230

Model1768-0requires177.9 CFH at"FullLoad"

90_

55 51 48

113 106 99

211 197 187

NPT 10_ 15_ 20_ 30_ 40_ 50_ 60_ 70_ 80_ 90fi 100_

½" II0 96 76 61 52 46 42 38 36 33 32

¾" 277 192 158 126 107 95 87 79 74 69 65

I" 428 360 293 236 202 180 164 151 139 129 123

Liquefied Petroleum (LP) (sg=l.50)

Model 1768-0 requires 78.24 CFH at"Full Load"

/

9

Briggs& Stratton Power Products Home Generator System

Installation Manual

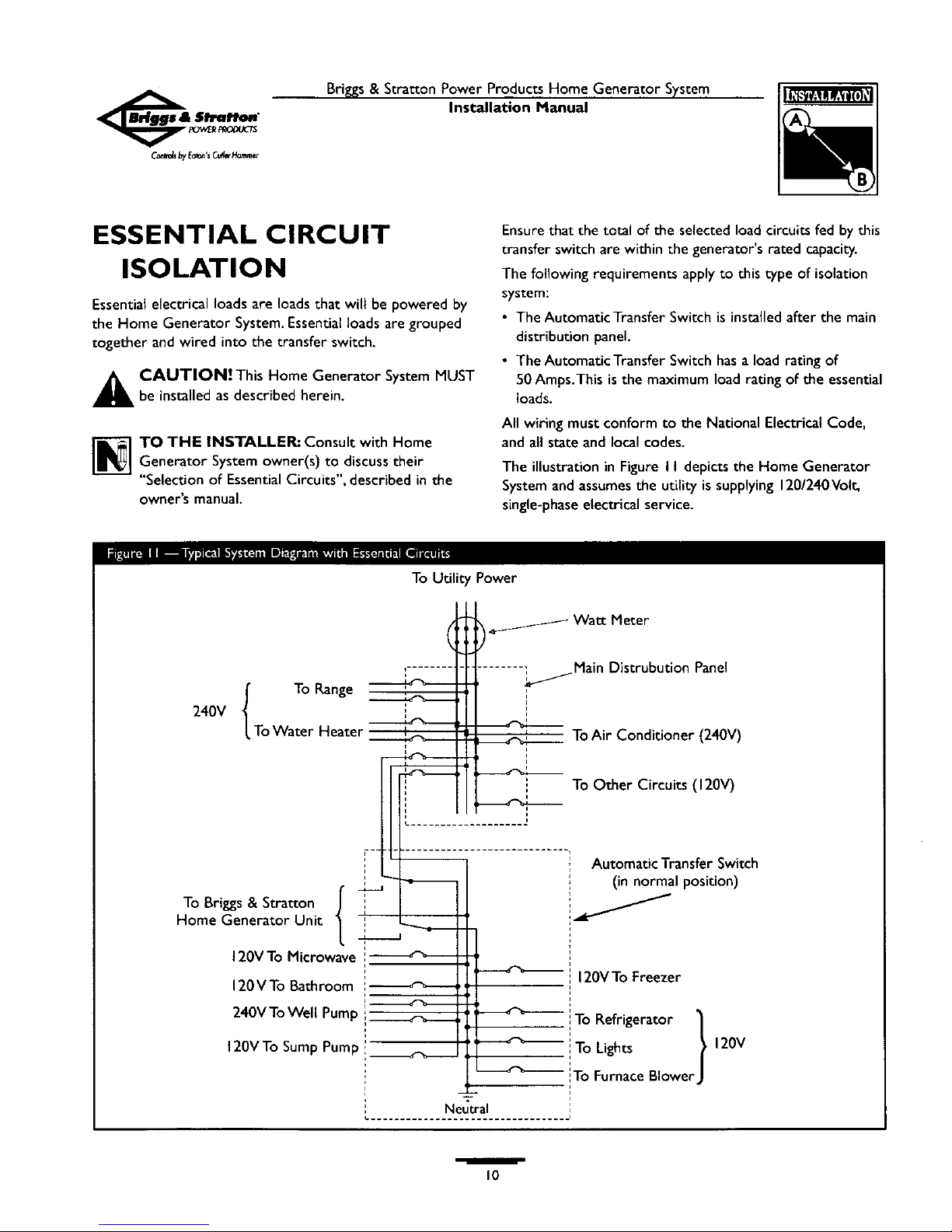

ESSENTIAL CIRCUIT

ISOLATION

Essentialelectrical loads are loadsthat will be powered by

the Home Generator System.Essentialloads are grouped

together and wired into the transfer switch.

_k AUTION! This Home Generator SystemMUSTbe installedasdescribed herein.

TO THE INSTALLER: Consult with Home

Generator System owner(s) to discuss their

"Selection of Essential Circuits", described in the

owner's manual.

Ensure that the total of the selected load circuits fed by this

transfer switch are within the generator's rated capacity.

The following requirements apply to this type of isolation

system:

• The AutomaticTransfer Switch is installed after the main

distribution panel.

• The AutomaticTransfer Switch has a load rating of

50 Amps.This is the maximum load rating of the essential

loads.

All wiringmust conformto the National ElectricalCode,

and all state and local codes.

The illustration in Figure I I depicts the Home Generator

System and assumesthe utility is supplying 120/240Volt,

single-phaseelectrical service.

To Utility Power

240V I To Range

LToWater Heater

To Briggs & Stratton ',

Home Generator Unit i

J

120V To Microwave !

120VTo Bathroom ',----_-_

Watt Meter

.......; Main Distrubution Panel

i

ToAir Conditioner (240V)

To Other Circuits (120V)

I Automatic Transfer Switch

I (in normal position)

_' 120VToFreezer

240VTo Well Pump :_ _ i!To Refrigerator 1

120VTo Sump Pump _______ -- llTo Lights ?

'To Furnace BlowerJ

Neutral

120V

/

10

Briggs& Stratton Power Products Home Generator System

Installation Manual

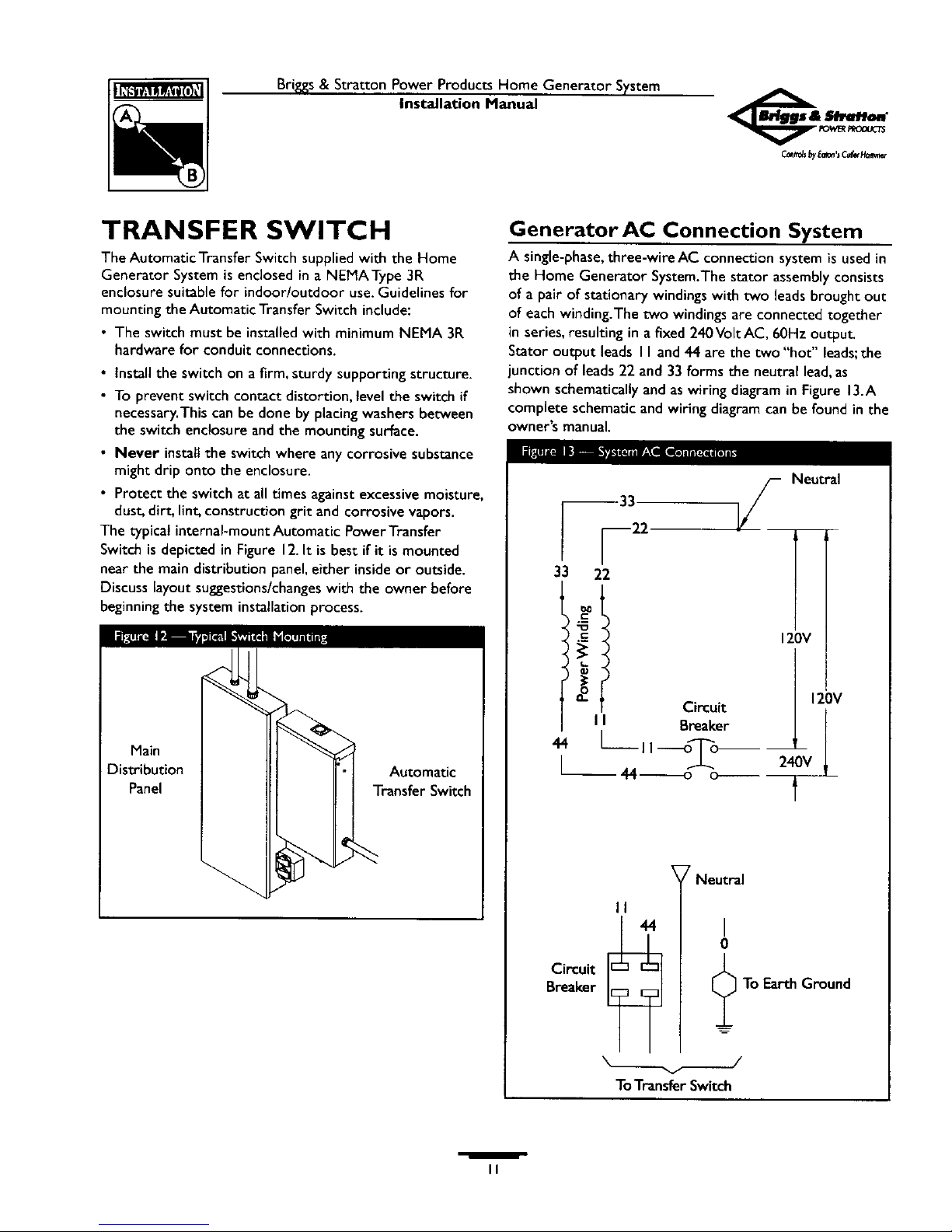

TRANSFER SWITCH

The AutomaticTransfer Switch supplied with the Home

Generator System is enclosed in a NEMAType 3R

enclosure suitable for indoor/outdoor use.Guidelines for

mounting the Automatic Transfer Switch include:

• The switch must be installed with minimum NEMA 3R

hardware for conduit connections.

• Install the switch on a firm, sturdy supporting structure.

• To prevent switch contact distortion, level the switch if

necessary.Thiscan be done by placingwashers between

the switch enclosure and the mounting surface.

• Never install the switch where anycorrosive substance

might drip onto the enclosure.

• Protect the switch at all times againstexcessive moisture,

dust,dirt, lint, construction grit and corrosive vapors.

The typical internal-mount Automatic Power Transfer

Switch is depicted in Figure 12.It is best if it is mounted

near the main distribution panel,either insideor outside.

Discusslayout suggestions/changeswith the owner before

beginningthe system installation process.

Main

Distribution

Panel

Automatic

Generator AC Connection System

A single-phase,three-wire AC connection system is usedin

the Home Generator System.The stator assemblyconsists

of a pair of stationary windings with two leadsbrought out

of each winding.The two windings are connected together

in series,resulting in a fixed 240Volt AC, 60Hz outpu_

Stator output leads I I and 44 are the two "hot" leads;the

junction of leads 22 and 33 forms the neutral lead,as

shown schematically and aswiring diagram in Figure 13.A

complete schematic and wiringdiagram can be found in the

owner'smanual.

33

33 22

o.

Circuit

I I Breaker

1--II ---o+++T"o--

I L o+

Neutral

T

120V

II

44

Circuit I _

Breaker

7 Neutral

I

0

To Earth Ground

ToTransferSwitch

/

II

Briggs& StrattonPower Products Home Generator System

Installation Manual

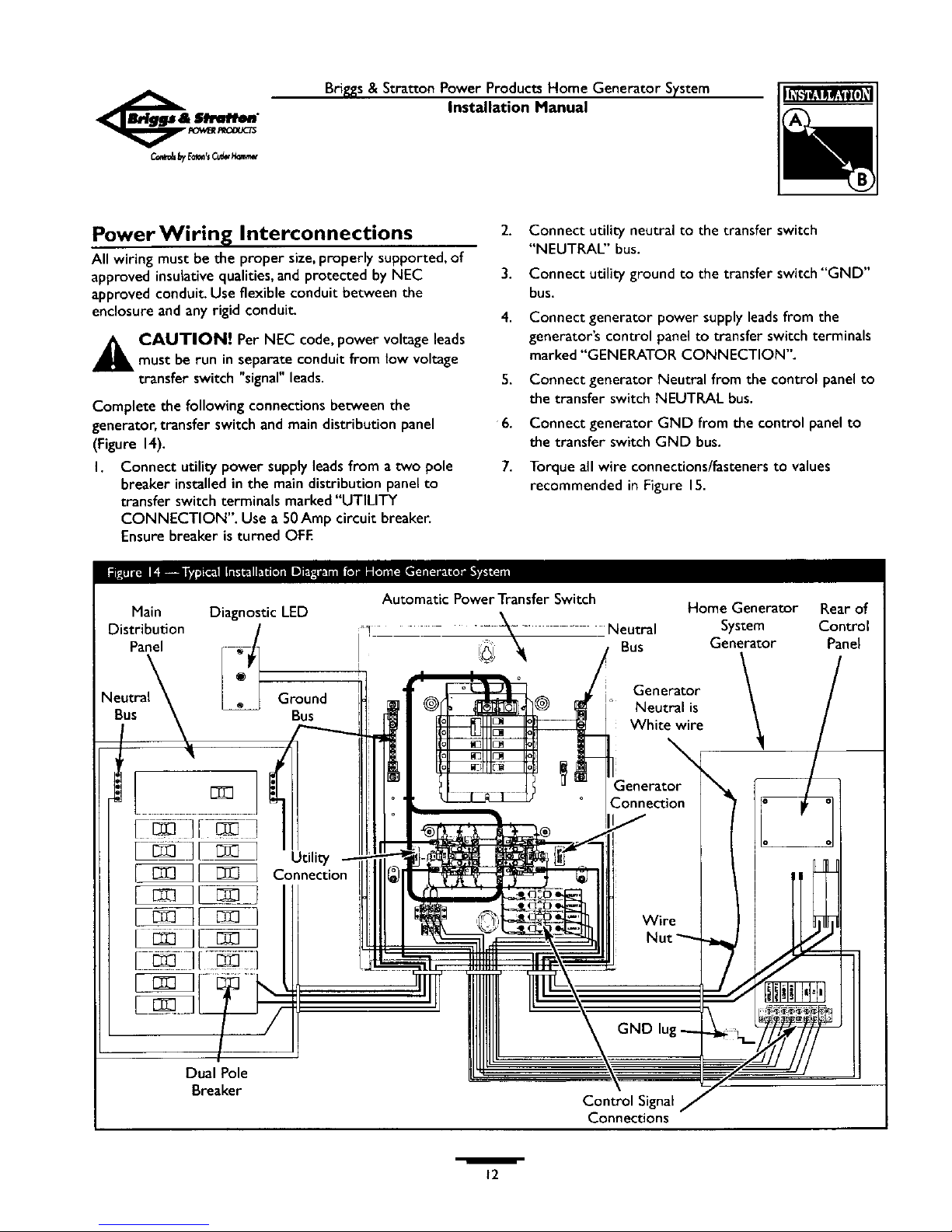

Power Wiring Interconnections

All wiring must be the proper size, properly supported, of

approved insulative qualities,and protected by NEC

approved conduit Use flexible conduit between the

enclosure and any rigid conduit

_ AUTION! Per NEC code, power voltage leads

must be run in separate conduit from Low voltage

transfer switch "signal" leads.

Complete the following connections between the

generator, transfer switch and maindistribution panel

(Figure 14).

I. Connect utility power supply leadsfrom a two pole

breaker installed in the main distribution panel to

transfer switch terminals marked "UTILITY

CONNECTION". Use a 50Amp circuit breaker.

Ensurebreaker is turned OFE

2. Connect utility neutral to the transfer switch

"NEUTRAL" bus.

3. Connect utility ground to the transfer switch"GND"

bus.

4. Connect generator power supply leads from the

generator's control panel to transfer switch terminals

marked "GENERATOR CONNECTION".

5.

6.

7.

Connect generator Neutral from the control panel to

the transfer switch NEUTRAL bus.

Connect generator GND from the control panel to

the transfer switch GND bus.

Torque all wire connections/fasteners to values

recommended in Figure 15.

Main Diagnostic LED

Distribution /

Panel r-_]

Bus

I

Dual Pole

Breaker

Ground

P,us

Utility

Connection

Automatic Power Transfer Switch

"i_j _ NeutralBus

Home Generator Rear of

System Control

Generator Panel

Generator

Neutral is

White wire

Control Signal

Connections

/

12

Briggs&Stratton Power Products Home Generator System

Installation Manual

Grounding the System

Installer-supplied minimum 10AWG strandedcopperwire

isconnected to the generator housingGND lug and routed

through conduit to the Automatic Transfer Switch's GND

bus.Continue the 10AWG wire through conduit to the

main distribution panel ground bus.Torque all wire

connections/fasteners to values recommended in Figure 15.

Generator grounding rod is used ONLY if required

by local code.

_-_llk'] "- • ..-.,-. • .L_&vBIM_

CONNECTIONS:

In Main Distribution Panel:

Refer to panel manufacturerspecs

In Transfer Switch:

UTILITY CONNECTION lugs

GENERATOR CONNECTION lugs

GND Bar and NEUTRAL Bar:

14-10AWG

8AWG

6-4 AWG

Circuit Breakers:

Refer to circuit breaker

manufacturer specs

Control Circuit Interconnections

Control circuit interconnections consist of "Utility" and

"Load" leads, plus leads"15","205", and "206".These seven

signal leads must be routed in conduit that is separate from

the AC power leads. Control lead functions are briefly

described as follows:

• "Utility I" and "Utility 2" deliver utility power to the

generator's circuit board.

• "Load I" and "Load 2" are used to operate the exercise

timer on the generator's circuit board.

• Leads "15","205", and "206" supply control signals to the

Automatic Transfer Switch.

Using installer-supplied minimum 14AWG stranded copper

wire, connect each control circuit terminal in the generator

to its corresponding terminal in the Automatic Transfer

Switch.Torque all wire connections/fasteners to values

recommended in Figure 15.

Torque Value

Minimum Maximum

35 in-rb 45 in-lb

35 in-lb 45 in-lb

20 in-lb

25 in-lb

35 in-lb

Fault Detection System

The righton the control panel is referred to as the

Diagnostic LED. It wilt turn on and off in a series of blinks if

certain problems are detected in the HGS.An extra LED

and mounting plate is supplied so that it can be installed at a

convenient insidelocation.The owner will use it to observe

the status of the HGS.

To install the remote LED panel:

• Apply the supplied decal.

• Pullthe LED through the mountingplatefrom the back

until it snapsin place.

• Usingminimum 18AWG wire, connect the remote LED

to the generator control panel using supplied pin

connectors. Use wire nuts to attach wire to LED leads.

• Attach mounting plate to installer-supplied low voltage

electrical box.

Refer to the section "Fault Detection System" in the

Owner's Manualfor operation.

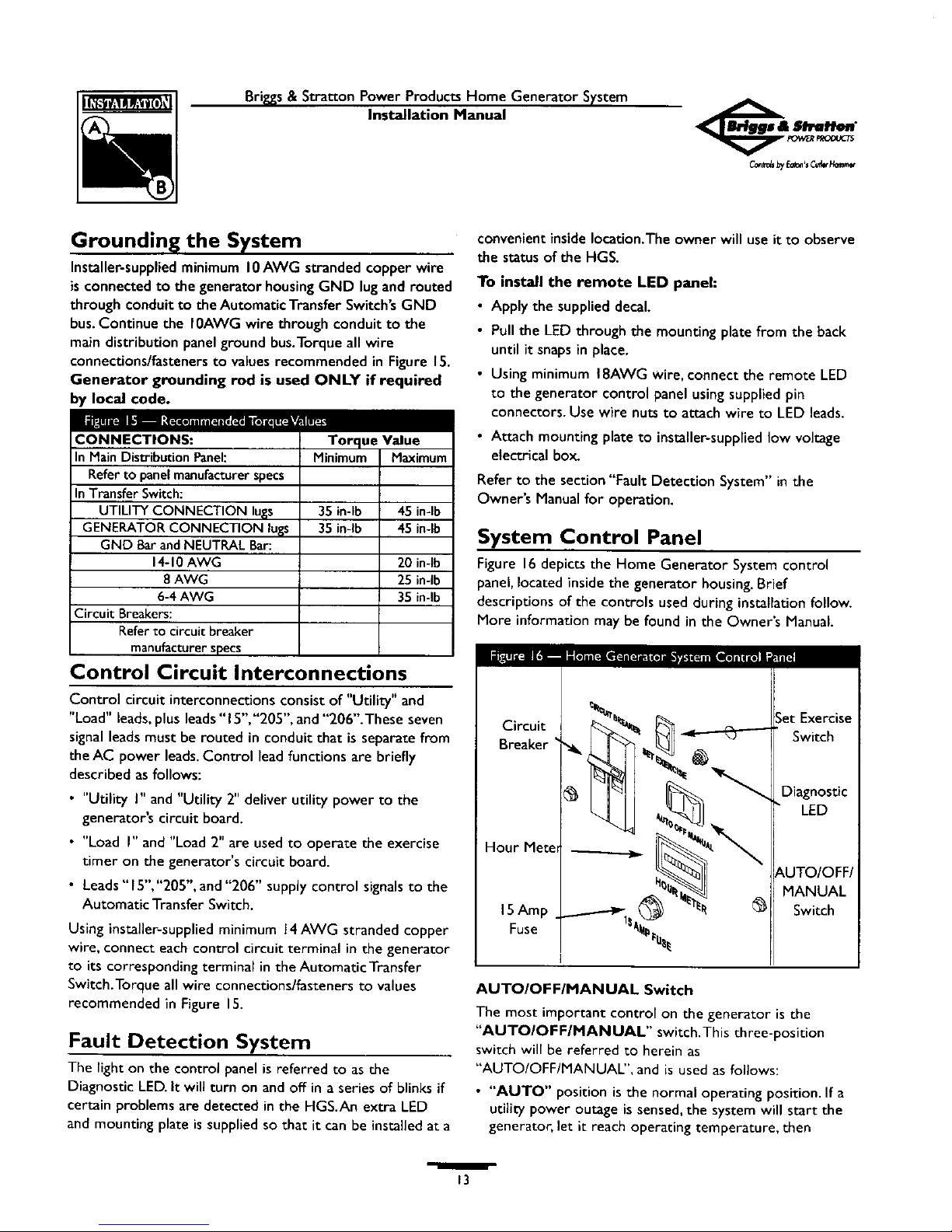

System Control Panel

Figure 16 depicts the Home Generator System control

panel, located inside the generator housing. Brief

descriptions of the controls used during installation follow.

More information may be found in the Owner's Manual

Circuit

Breaker

Hour Met_

15Amp

Fuse

;et Exercise

Switch

Diagnostic

LED

MANUAL

Switch

AUTO/OFF/MANUAL Switch

The most important control on the generator is the

"AUTO/OFF/MANUAL" switch.This three-position

switch will be referred to herein as

"AUTO/OFF/MANUAL", and is used as follows:

• "AUTO" position is the normal operating position. If a

utility power outage is sensed, the system will start the

generator, let it reach operating temperature, then

_3

_by_'sc_w_

Bri_s & Stretton Power Products Home Generator System

Installation Manual

connectgenerator power to the transfer switch.When

utilitypower is restored, the systemreconnectsutility

power to the transfer switch, lets the engine'cool down',

shuts offthe generator,and waits for the next utility

power outage.

• "OFF" position turns off a running generator and takes

the system out of the Automatic operation mode.

• "MANUAL" position starts the engine but does not

disconnect utility power from the transfer switch. It is

usedfor maintenance or diagnostic functions.

I 5 Amp Fuse

The Home Generator System DC control circuit is

protected from overload by a IS Amp fuse mounted on the

generator's control panel (see Figure 16).The fuse is wired

in series with the battery output lead to the control panel.

If the fuse has 'blown' (melted open) or was removed, the

engine cannot crank or start. Replace the fuse using ONLY

an identical BUS AGC 15A fuse. One spare fuse is supplied

with the unit.

BEFORE INITIAL ENGINE

START-UP

Engine Oil

The generator'sengineisshippedfrom the factory full of

oll and should be ready to run. However, check oil level and

ensure that engine is serviced asdescribed in the Engine

Owner's Manual.

CAUTION! Any attempt to crank or start the engine

before it hasbeen properly serviced with the

recommended oil will result in an engine failure that isnot

covered under warranty.

Oil Considerations

Your Home Generator System isequipped with an engine

that has completed the traditional "break-in" process.The

engine should only be filled with synthetic oil (SAE 5W-30,

API SJor later).This permits 'standby' operation in the

widest range of temperature and climate variations.

NOTE: The use of synthetic oil does not alter the

required oil change intervals recommended in the Engine

Owner's Manual.

Battery Connection

The Home Generator Systemissuppliedwith a 12Volt DC

18Amp-Hour battery. It isa sealed,lead-acidrechargeable

battery. It is installedin the unit and the battery cables are

connected at the factory.The unit's 15Amp fuse,which

isolatesthe battery and prevents the unit from starting, has

been removed for shipping.

If it is necessaryto connect the battery, proceed asfollows:

I. Set the generator's"AUTO/OFF/MANUAL" switch to

OFF.

2. Turn OFF the main distribution panel circuit breaker

supplying utility power to the Automatic Power

Transfer System.

_i AUTION!The generator can crank and start

when the battery cable contacts the battery

terminal if the "AUTO/OFF/MANUAL" switch is not

set to its OFF position.

3. Using supplied hardware, connect the red battery lead

to the battery positive terminal (indicated by

POSITIVE, POS, or (+).

4. Repeat step 3 (above) to connect the negative battery

cable.You may need to clip a cable tie to place the

negative wire. Ensure hardware on both positive and

negative battery terminals is secure.

NOTE: With the battery installed and utility power

available to the Automatic Transfer Switch, the battery

receives a trickle charge whenever the engine is not

running.The trickle charge only prevents self-discharge and

cannot be used to recharge a battery that is completely

discharged,

Fuel Supply System

Ensure that all fuel pipe connections are tight, secure and

without leaks.

NOTE: In the absence of local purging and leak test

standards, NFPA No. 54 may be used as a guide. (See

"Standards Index" on page 19).

Ensure that all gas line shutoff valves are OPEN and that

adequate fuel pressure is available whenever automatic

operation is desired.

/

14

Brigss & Stratton Power Products Home Generator System

Installation Manual

INITIAL START-UP (NO LOAD) 4.

Begintesting the system without anyelectrical loads

connected, as follows:

I. Set theAUTO/OFF/MANUAL switch to OFF. S.

2, Set the generator's main circuit breaker to its OFF

(open) position.

3. Install the 15Amp fuse in the control panel. 6.

4, Set the AUTO/OFF/MANUAL switch to MANUAL.

7.

NOTE:When the Home Generator System is started for

the very first time, it will require that air in the gaseousfuel

lines be purged.This may take a few minutes.

5. Use short sorting cycles (I 5 sec.per min.) to reduce

heat in the starter.

6. Repeat process until lines are purged of air and engine

starts.

7. Listen for unusual noises,vibration or other indications

of abnormal operation, Check for oil leaks,evidence of

overheating etc.while the unit runs. 8.

Electrical Checks

With the AUTO/OFF/MANUAL switch set to OFF:

h Turn ON the main distribution panel circuit breaker

that supplies utility power to the Automatic Transfer

Switch.

_1 WARNI NG! The Automatic Transfer Switch is

now electrically "HOT." Contact with "HOT" parts

will result in extremely hazardousand possibly fatal

electrical shock. Proceed with caution,

2.

3.

Use an accurate AC voltmeter to check utility power

voltage across "UTILITY CONNECTION" lugs in the

Automatic Transfer Switch (see Interconnection

Diagram on page 12). Nominal line-to-line voltage

should be 240Volts.

Check utility power between one of the UTILITY

CONNECTION lugs and the neutral lug, then between

the other UTILITY CONNECTION lugs and the

neutral lug. Nominal line-to-neutral voltage should be

120Volts.

When certain that utilityvoltageis asspecified above,

turn OFF the main distribution panel circuit breaker

that supplies utility power to the Automatic Transfer

Switch.

Set the generator'smain circuit breaker to the OFF

position. Initialtests will be conducted at "no-load"

condition.

Set the AUTO/OFF/MANUAL switch to MANUAL.

The engine should crank and start_

Let the enginewarm up for about five minutes to allow

internaltemperatures to stabilize.Then, set the

generator's main circuit breaker to its ON (or closed)

position,

_ WARNING! Proceed with caution. Generator

output voltage is now supplied to the Automatic

Transfer Switch. Contact with "HOT" Automatic

Transfer Switch parts will result in dangerous and

possibly fatal electrical shock.

Connect an accurate AC voltmeter and a frequency

meter to check generator output across

"GENERATOR CONNECTION" lugs in theAutomatic

Transfer Switch (see Interconnection Diagram on

page 12).Voltage should be 239-250 Volts, frequency

should be 62.0 - 62.5 H_

NOTE: If either parameter isoutside these ranges,

perform the EngineAdjustments described on page 18.

9.

Check generator output between one of the

GENERATOR CONNECTION lugs and the neutral

lug,then between the other GENERATOR

CONNECTION lug and the neutral lug.In both cases,

voltage reading should be between 121-126Volts.

I0. Set the generator's main circuit breaker to OFF. Let

the engine run at"no-load" for a few minutes to

stabilize internal engine/generator temperatures.

I h Set the AUTO/OFF/MANUAL switch to OFF. Engine

should stop.

IMPORTANT: Do Not proceed until you are certain

that generator AC voltage and frequency are correct and

within the stated limits.To obtain the proper generator

frequency, see Engine Adjustments on page 18.

/

15

Briggs& Stratton Power Products Home Generator System

Installation Manual

AUTOMATIC OPERATION

SEQUENCE

The generator's control panel housesa logic control circuit

board.This control board constantly monitors utility power

source voltage. Should that voltage drop below a preset

level, control board action will signalthe engine to crank

and stare After the engine starts, the control board signals

the transfer switch to activate and to connect load circuits

to the backup power supply.

When utility source voltage is restored above a preset

voltage level,the control board signalsthe transfer switch

to transfer loads back to the power supply.After retransfer,

the engine is signaled to shut down.

The actual system operation is not adjustable and is

sequenced by sensors and timers on the control board,as

follows:

UtUityVoltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 60 percent of

the nominal supply voltage, the sensor energizes a

6-second timer.The timer is used to 'sense' brown-outs.

• Once the timer has expired, the engine will crank and

start_

Engine Warm-up Time Delay

This mechanism lets the engine warm up for about

I 5 seconds before the load is transferred to the Home

Generator System.

Backup Voltage Sensor

This sensor monitors generator AC output voltage.When

the voltage has reached 50 percent of the nominal rated

voltage, transfer to the backup generator can occur.

UtilityVoltage Pickup Sensor

This sensor monitors utility power supply voltage.When

that voltage is restored above 70 percent of the nominal

source voltage, a retransfer time delay starts timing.

Retransfer Time Delay

• This timer runs for about 6 seconds.

• At the end of a 6-second delay, circuit board action de-

energizes the generator relay in the transfer switch.

• Retransfer to utility power source then occurs.

Engine Cool-down Timer

• When the load is transferred back to the utility power

source, the engine cool-down timer starts timing.

• The timer will run for about one minute, then the

generator will stop.

W

16

Bri_s & Stratton Power Products Home Generator System

Installation Manual

Checking Automatic Operation

To check the systemfor proper automatic operation,

proceed as follows:

I. Check thatAUTO/OFF/MANUAL is set to OFF.

2. Apply utility power to the Automatic Transfer Switch

by turning ON the main distribution panel circuit

breaker.

3. Setthe AUTO/OFF/MANUAL switch to AUTO.The

Automatic Power Systemis now ready for automatic

operation.

4. Turn OFF the main distribution panel circuit breaker

sendingpower to the automatic transfer switch.

The engine will crank and start after sensors havetimed

ou_After starting, the Automatic Power Transfer System

will transfer essential circuit loadsto the generator. Let the

systemgo through its entire automatic operation sequence.

5. With the generator output supplying its loads,turn

ON the main distribution panel circuit breaker that

supplies utility power to the Automatic Power Transfer

Switch.

6. After about 6 seconds, the automatic transfer switch

wilt transfer loads back to the utiJity power.

7. About one minute after re-transfer, the generator will

stop.

This completes the test procedures for the automatic

operation of the Home Generator System.

SETTING EXERCISE TIMER

The Home Generator Systemis equipped with anexercise

timer that will start and exercise the system onceevery

sevendays.During this exercise period, the unit runs for

approximately 12 minutes and then shuts down.Electrical

loadtransfer DOES NOT occur during the exercise cycle

(unless an utility power outage occurs).

A switch on the control panel is labeled"SetExercise" (see

Figure 16).The specificdayand the specific time of daythis

switch ispressed is programmed into the control board

memory.This date and time is then usedto automatically

initiate the system exercise cycle.

To perform the Set Exercise procedure:

I. Choose the dayand time you want your Home

Generator Systemto exercise.

2. On that day and time, set the AUTO/OFF/MANUAL

switch to OFF.

3.

4.

5.

Pressand hold down the "Set Exercise" switch until

the Diagnostic LED turns on (about five seconds).

Pressand hold the switch down until the Diagnostic

LED turns off. Releasethe Set Exerciseswitch.

Set the AUTO/OFF/MANUAL switch to AUTO. "Set

Exercise" iscomplete.

For example, if you press the "Set Exercise" switch on

Sundaymorning at 10:00AM, the unit will run anexercise

cycle the following Sundayat 10:00AM.

NOTE: "Set Exercise"will only work if the unit isin the

Automatic mode and this exact procedure isfollowed.The

exerciser does not need to be re-set if the I5Amp fuse is

removed or changed.The exerciser will need to be re-set if

the 12Volt DC battery is disconnected.

If you want to change the day and time the unit exercises,

simply perform the "Set Exercise" procedure at the exact

weekday and time you want it to take place.

W

17

Briggs& Stratton Power Products Home Generator System

Installation Manual

RECONFIGURING THE

FUEL SYSTEM

The engineof your Home Generator System isfactory

calibrated to run on natural gas (NG). It may also be

operated on liquefied petroleum (LP).There isno additional

hardware/equipment required to switch between either

fuel However, LP fuel inlet pressure must be between

I I and 14incheswater column.

To reconfigure the fuel system for LP use:

• Set the AUTO/OFF/MANUAL switch to OFF.

• Setthe generator's main circuit breaker OFF.

• Remove the 15Amp fuse.

• Activate the fuel transfer solenoid asfollows:

I. Remove the"Oil Service" accesspanel.

2. Join the two-pin electrical connector shown in

Figure 17.

Engine Adjustment

It iscommonly knownthat there are regional variancesin

the combustibilityof natural gas.EachHGS unit isadjusted

at the factory for correct NG operation. If the generator

output voltageor frequency measuredduringinitial

ElectricalCheck (paragraph#8 on page IS) isoutsidethe

listedranges,the combustibilityof the gassupplied at the

installationsitemay be substantially different

To adjust the enginefor this different fuel,proceed as

follows.

I.

2.

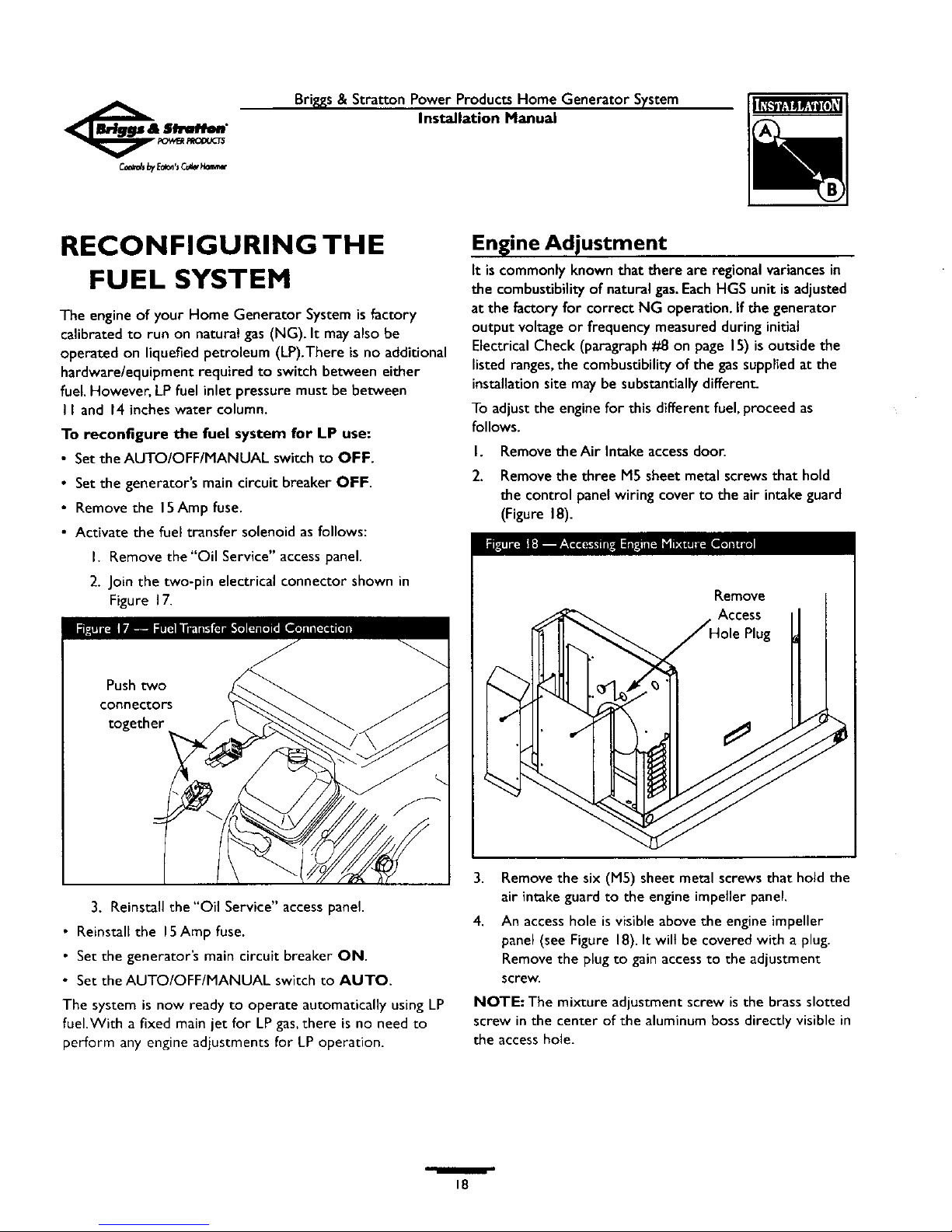

Remove the Air Intake accessdoor.

Remove the three M5 sheet metal screws that hold

the control panel wiring cover to the air intake guard

(Figure 18).

,J

Remove

Access

Plug

3. Reinstall the "Oil Service" access panel

• Reinstall the 15Amp fuse.

• Set the generator's main circuit breaker ON.

• Set the AUTO/OFF/MANUAL switch to AUTO.

The system is now ready to operate automatically using LP

fuel.With a fixed main jet for LP gas, there is no need to

perform any engine adjustments for LP operation.

3,

4.

Removethe six (MS) sheet metal screws that hold the

air intakeguard to the engine impeller panel.

An accesshole isvisible above the engineimpeller

panel (see Figure 18).It wilt be covered with a plug.

Removethe plug to gainaccessto the adjustment

screw.

NOTE: The mixture adjustment screw is the brass slotted

screw in the center of the aluminum boss directly visible in

the access hole.

18

Loading...

Loading...