Page 1

For Models 1461-2 and 1535-1 Manual No. 189141 Revision 2 (12/04/2001)

Visit our Generac website: www.generac-portables.com

NOT INTENDED FOR USE AS PRIMARY POWER IN PLACE OF UTILITY

OR IN LIFE-SUPPORT APPLICATIONS

OWNER’S MANUAL

8000/10000 Watt

Backup Power System

with Automatic Power Transfer Switch

Page 2

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

2

TABLE OF CONTENTS

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . 4

For the Home or Business Owner: . . . . . . . . . . 4

For the Installing Dealer/Contractor: . . . . . . . . . 4

OWNER ORIENTATION . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Decrease at High Altitude or High

Temperature . . . . . . . . . . . . . . . . . . . . 5

Generator Location . . . . . . . . . . . . . . . . . . . . . . . . . 5

Generator Clearances . . . . . . . . . . . . . . . . . . . . . . . 5

Essential Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Essential Circuit Selection . . . . . . . . . . . . . . . . . 7

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Delivery Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shipment Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 8

KNOW YOUR BACKUP GENERATOR . . . . . . . . . . . . . 9

KNOW YOUR SYSTEM CONTROL PANEL . . . . . . . . . 10

Access Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

To remove an access door: . . . . . . . . . . . . . . . 11

To install an access door: . . . . . . . . . . . . . . . . . 11

BEFORE INITIAL START-UP . . . . . . . . . . . . . . . . . . . . . 12

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Oil Considerations . . . . . . . . . . . . . . . . . . . . . 12

Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . 12

Gaseous Fuel System . . . . . . . . . . . . . . . . . . . . . . . 12

The AUTO/OFF/MANUAL Switch . . . . . . . . . . . . . 12

AUTOMATIC OPERATION . . . . . . . . . . . . . . . . . . . . . 13

Checking Automatic Operation . . . . . . . . . . . . . . . 13

Stopping the System . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting Exercise Timer . . . . . . . . . . . . . . . . . . . . . . 13

MANUAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . 14

Transfer to Generator Power . . . . . . . . . . . . . . . . . 14

Transfer Back to Utility Power . . . . . . . . . . . . . . . . 14

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fault Detection System . . . . . . . . . . . . . . . . . . . . . 15

Reset Fault Detection System . . . . . . . . . . . . . 15

No Blinks - ‘Dead’ Unit . . . . . . . . . . . . . . . . . . 15

Low Battery Voltage . . . . . . . . . . . . . . . . . . . . . 15

Low Oil Pressure . . . . . . . . . . . . . . . . . . . . . . . 15

Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine Fail To Start . . . . . . . . . . . . . . . . . . . . . 16

Low Frequency . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine Overspeed . . . . . . . . . . . . . . . . . . . . . . 16

Oil Temperature High . . . . . . . . . . . . . . . . . . . 16

Power During Fault Condition . . . . . . . . . . . . . . . . 16

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . 17

Generator Maintenance . . . . . . . . . . . . . . . . . . . . . 17

To Clean the Generator: . . . . . . . . . . . . . . . . . 17

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 18

Checking Oil Level . . . . . . . . . . . . . . . . . . . . . 18

Changing the Oil and Oil Filter . . . . . . . . . . . . 18

Replace the Spark Plugs . . . . . . . . . . . . . . . . . . 19

Service Air Cleaner . . . . . . . . . . . . . . . . . . . . . 19

Inspect Spark Arrester Screen . . . . . . . . . . . . . 20

Engine Governed Speed . . . . . . . . . . . . . . . . . . 20

Valve Lash . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Carburetor Adjustments . . . . . . . . . . . . . . . . . 20

If You Call the Factory: . . . . . . . . . . . . . . . . . . . . . . 20

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 21

DIAGRAMS, EXPLODED VIEWS, PARTS LISTS. . . . . 22-42

EMISSION CONTROL SYSTEM WARRANTY . . . . . . . 43

POWER SYSTEM WARRANTY . . . . . . . . . . . . . . . . . . . 44

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

Page 3

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

3

SAFETY RULES

• Your Briggs & Stratton Backup Power System produces

dangerous electrical voltages that can cause a fatal

electrical shock.Avoid contact with bare wires, terminals

and connections at all times while the unit is running.

Ensure that all the appropriate covers, guards and

barriers are in place before operating the generator. If

you must work around a unit while it is operating, stand

on an insulated dry surface to reduce shock hazard.

• In case of an accident caused by electrical shock

immediately shut down the source of electrical power. If

this is not possible, attempt to free the victim from the

live conductor.

DANGER! Avoid direct contact with the

victim. Use a non-conducting implement, such as a

rope or board to free the victim from the live

conductor. If the victim is unconscious, apply first aid

and get immediate medical help.

• Your Backup Power System is powered by gaseous fuel.

Liquid Propane (LP) or natural gas is extremely

Explosive! Do Not smoke around the generator.Wipe

up any oil spills immediately. Ensure that no combustible

materials are left in the generator compartment. Keep

the area near the generator clean and free of debris.

• Do Not use the generator or any of its parts as a step.

Stepping on the unit can stress and break parts.This may

result in dangerous operating conditions from leaking

exhaust gases, fuel leakage, oil leakage, etc.

CAUTION! After the installation of your Backup

Power System is complete, the generator may crank

and start without warning any time there is a power

interruption.To prevent possible injury, before

working on the equipment, always set the

AUTO/OFF/MANUAL switch to OFF and remove

the 15 Amp fuse.

• Do Not handle any kind of electrical device while

standing in water.Avoid electrical devices while barefoot

or while hands or feet are wet.

• Remain alert at all times while working on this

equipment. Never work on the equipment when you are

physically or mentally fatigued.

• An adequate, unobstructed flow of cooling and ventilating

air is critical for generator operation. Do Not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operation of

the generator.The Oil Service door and/or the Control

Panel door must be installed whenever the unit is

running.

• Before performing any maintenance on the generator,

remove the 15 Amp fuse AND disconnect the battery

NEGATIVE, NEG, or (-) cable.

• Do Not operate engine if smell of fuel is present or

other explosive conditions exist.

• Do Not tamper with governor springs, links or other

parts to increase engine speed.

• Do Not touch hot muffler, engine cylinder, or engine

exhaust port which can cause burns.

• Do Not start engine with air cleaner or air cleaner

cover removed.

CAUTION! Despite the safe design of the

Backup Power System, operating this equipment

imprudently, neglecting its maintenance or being

careless can cause possible injury or death. Permit

only responsible and capable persons to operate

and/or maintain this equipment.

NOTE:Your generator is equipped with a spark arrester

muffler. The spark arrester must be maintained in effective

working order by the owner/operator. In the State of

California, a spark arrester is required by law (Section 4442

of the California Public Resources Code). Other states may

have similar laws. Federal laws apply on federal lands.

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard.The warnings in

this manual, and the tags and decals affixed to the unit are,

therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safe for you and others.You must also make sure that the

procedure, work method or operating technique that you

choose does not render the generator unsafe.

Only qualified electricians and gaseous fuel

technicians should attempt installation of this

system, which must strictly comply with

applicable codes, standards and regulations.

WARNING!

Page 4

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

4

INTRODUCTION

Congratulations on your purchase of a Briggs & Stratton

Backup Power System (BPS).Your BPS was designed to

provide automatic auxiliary electrical power for the

duration of normal power interruption. It is not intended

for use as primary power in place of utility nor for use in

life-support applications.The generator unit has been

engineered and tested to exacting standards of

performance and reliability and is equipped with a UL®

listed Automatic Power Transfer Switch.

Generac Portable Products has made every effort to

provide for a safe, streamlined and cost-effective

installation. Because each installation is unique, it is

impossible to know of and advise the trade of all

conceivable procedures and methods by which installation

might be achieved. Neither could we know of possible

hazards and/or the results of each method or procedure.

For these reasons,

Only current qualified electrical and

plumbing contractors should attempt

BPS installations.

Installations must strictly comply with

all applicable codes, industry standards

and regulations.

Your Briggs & Stratton Backup Power System is supplied

with this “Owners Manual” and a separate “Installation

Manual” (Generac part number 184957).These are both

important documents and should be retained by the owner

after the installation has been completed.

Installation Assistance

For the Home or Business Owner:

To help you make informed choices and communicate

effectively with your installation contractor(s),

Read and understand the

Owner Orientation Section of this manual

BEFORE

contracting or starting

your BPS installation.

To arrange for proper installation, contact the store at

which you purchased your Briggs & Stratton Backup Power

System, your dealer,or your utility power provider.

The BPS Warranty is VOID unless the system

is installed by certified electrical and

plumbing professionals.

For the Installing Dealer/Contractor:

For most applications, the Installation manual contains all

the information required to properly install and start the

Backup Power System.This Owner’s Manual describes

essential circuit selection, routine operation and owner

maintenance procedures.

If you need more information, call 920-674-3750,

extension 2716, between 8:00 AM and 5:00 PM CT.

The Emission Control System for this generator is

warranted for standards set by the U.S. Environmental

Protection Agency and by the California Air Resources

Board (CARB). For warranty information refer to the back

of this Owner’s manual.

OWNER ORIENTATION

This section provides Backup Power System owners with

the information necessary to achieve the most satisfactory

and cost effective installation possible.

The illustrations are for typical circumstances and are

meant to familiarize you with the installation options

available with your Backup Power System.A thorough

understanding of these options will provide fundamental

control over the cost of your installation, as well as ensure

your final satisfaction and security.

Local codes, appearance, noise levels, fuel types, and

distances are the factors that must be considered when

negotiating with an installation professional. Remember that

as the distance from the existing electrical service and

gaseous fuel supply increases, equal compensations in piping

and wiring materials must be allowed for.This is necessary

to comply with local codes and overcome electrical voltage

drops and gaseous fuel pressure drops.

The factors mentioned above will have a direct

affect on the overall price of your Backup Power

System installation.

Page 5

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

5

NOTE: In some areas you may need to acquire electrical

permits for installing the Backup Power System,building

permits for installing gas lines, and permits for noise

allowances.Your installer should check your local codes

AND obtain the permits before installing the system.

Fuel Factors

An important consideration affecting the entire installation

is the type of fuel used by your Backup Power System.The

system was factory tested and adjusted using natural gas as

a fuel. Liquid propane (LP) may also be used as a fuel (see

the Installation Manual).

Although there are specific factors that are inherent to

each of these fuels, your location and the duration of

possible utility interruptions should guide your selection of

fuel type. For urban installations, Natural Gas (if available)

should be your fuel of choice. For remote installations, a

Liquefied Petroleum (LP) tank might better meet your

needs.

For proper engine function, the following fuel guidelines are

recommended:

• Use clean, dry fuel, free of moisture or any particulate

material. Using fuels outside the following recommended

values may cause performance problems.

In engines set up to run on propane (LP) gas,

commercial grade HD5 propane with a minimum fuel

energy of 2500 BTUs/ft

3

with maximum propylene

content of 5% and butane and heavier gas content of

2.5% and minimum propane content of 90%.

CAUTION!This equipment is equipped with an

automatic safety gas “fuel shut-off” valve. Do Not

operate the equipment if the “fuel shut-off” valve is

missing or inoperative.

Power Decrease at High Altitude or High

Temperature

Air density is less at high altitudes, resulting in less available

engine power. Specifically, engine power will decrease 3.5%

for each 1,000 feet (300 meters) above sea level and 1% for

each 10° F (5.6°C) above 77°F (25°C). Make sure you and

your installer consider these factors when determining

total generator load.

Generator Location

The actual physical location of your backup generator has a

direct affect on:

1. The amount of plumbing required to fuel your

generator.

2. The amount of wiring required to control and connect

your generator.

NOTE: Specific location guidelines are discussed in the

Installation Manual.Acquaint yourself with that information

and confer with your installer. Be sure to ask how your site

might affect installation costs and compliance with local

codes and standards.

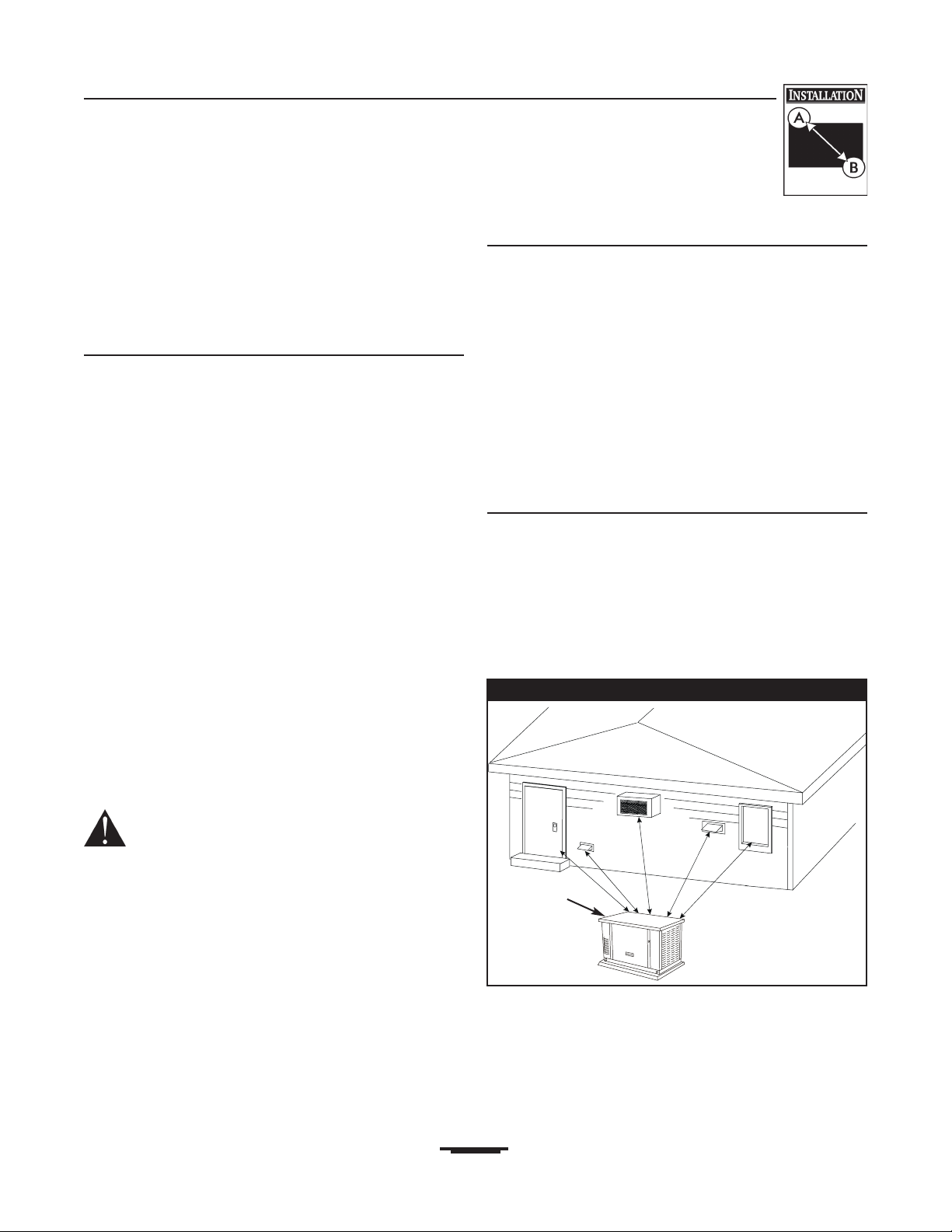

Generator Clearances

The generator enclosure must be a minimum of 3 ft.

(92 cm) from combustible material (NFPA 37). Leave at

least 3 ft. (92 cm) all around the enclosure for access to the

inside of the enclosure (NEC Art. 110-26a, Art. 110-26b).

The unit’s exhaust port must be at least 5 ft. (152 cm) from

any building opening (window, door,vent etc.), and the

exhaust must not be able to accumulate in any occupied

area (Figure 1).

Figure 1 — Backup Power System Clearances

Exhaust port must be

5 ft (152 cm) minimum

distance from building

openings

Exhaust

Port

Page 6

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

6

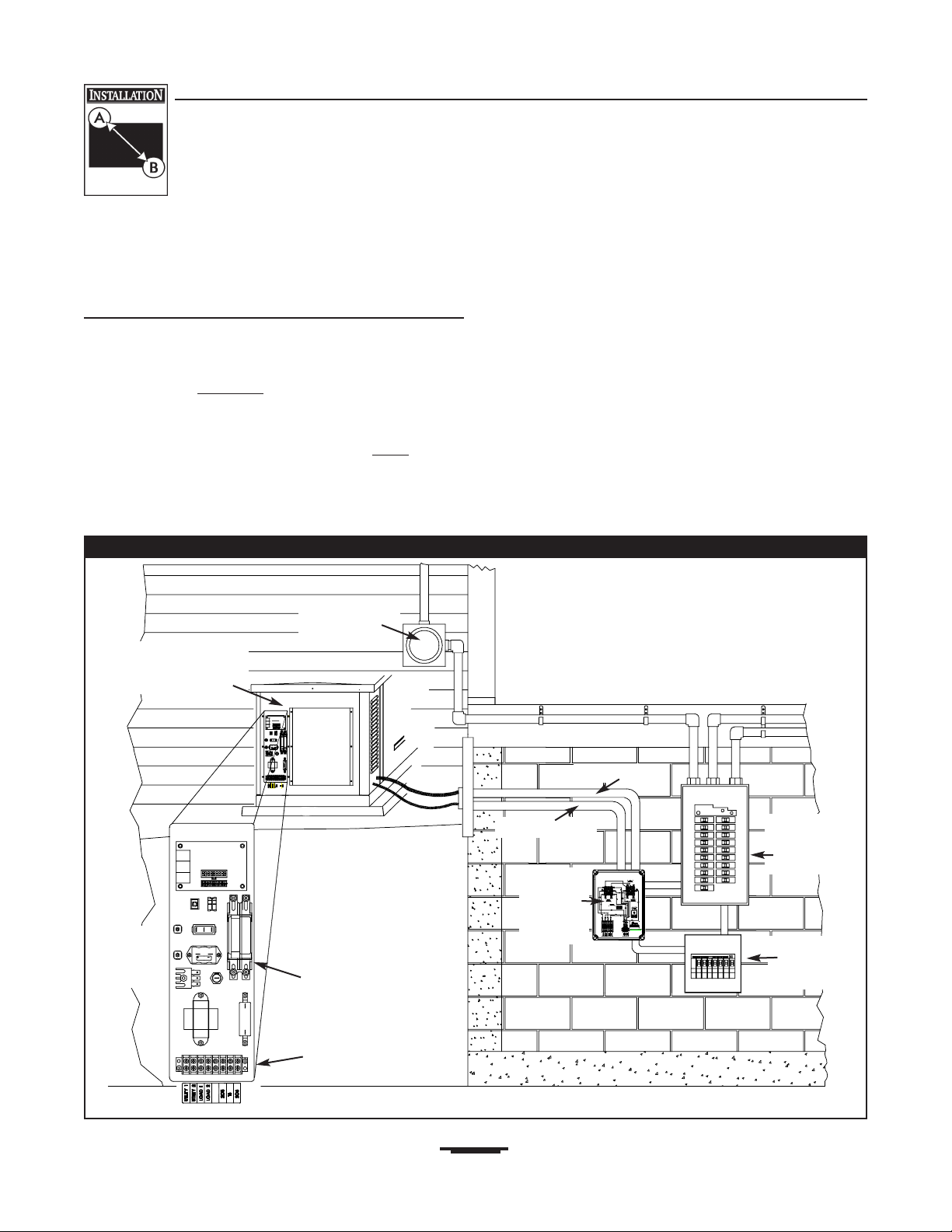

Figure 2 identifies system components and shows typical

installation details.Variations to this illustration are related

to code issues, piping distances and materials.

Essential Circuits

As a Backup Power System owner, it is important that you

clearly identify the circuits in your building that are

"essential" to you. Because the Backup Power System is

equipped with an Automatic Transfer Switch, your selection

of essential circuits will be transferred to the Backup

Power System within 15 seconds (+/- 5 seconds).

It is important that your installer understand which

circuits

you want to include as "Essential Circuits". Depending on

the power consumed by these circuits,most or all of them

can be switched to the Backup Power System for the

duration of normal power interruption.

The essential circuits are gathered in a special circuit

breaker box,referred to as the Essential Circuit “subpanel”, that is connected by conduit to the transfer switch.

This breaker box is provided by the installer because it

allows him to use the brand that is most compatible with

your existing electrical service components.

The wattage reference guide shown in Figure 3 will assist

you with your decision-making process.It provides the

wattage used by many ordinary household devices. Use it

as a guide when selecting your essential circuits. Review

this information with your installer and ask about any

technical considerations that might affect the cost of your

installation.

Power Lead

Connections

NEUTRAL to White wire

GND to chassis

Control Signal

Connections

Automatic

Power

Transfer

Switch

Rear of

Control

Panel

Backup Power

System Generator

Power Leads

Signal Leads

Main

Distribution

Panel

Essential

Circuit

Sub-panel

Utility Power

Meter

Figure 2 — Typical Installation Diagram for Backup Power System

Page 7

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

7

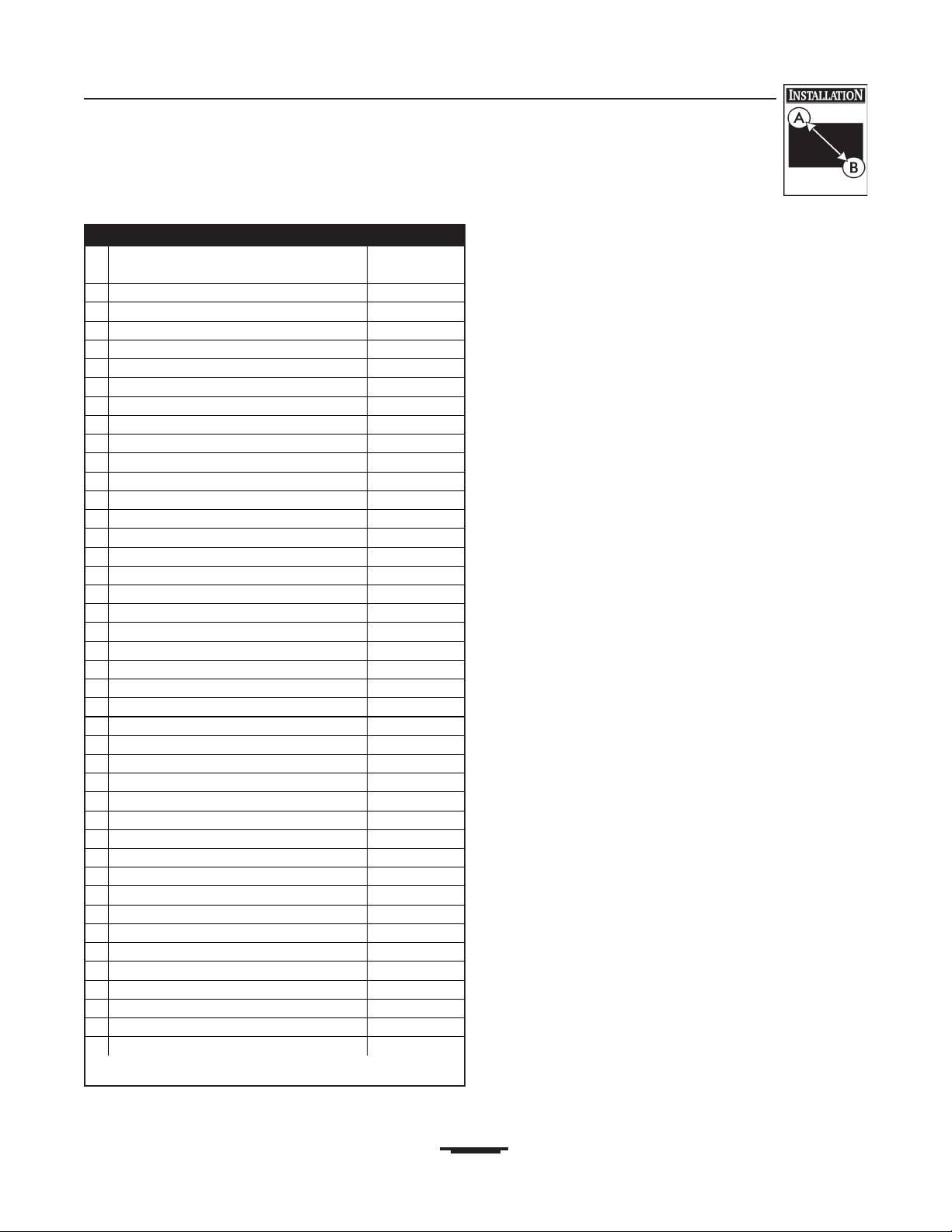

Essential Circuit Selection

When selecting the essential circuits that will be switched

to “Backup Power,” it is important that the sum of the

combined circuit loads does not exceed the

wattage/amperage capacity of the generator. To help you

with your selection of essential circuits, please consider the

following:

Add up the total wattage of all electrical devices to be

connected at one time.This total should NOT be

greater than the generator’s wattage capacity.

The rated wattage of lights can be taken from light bulbs.

The rated wattage of tools, appliances and motors can

usually be found on a data plate or decal affixed to the

device.

If the appliance, tool or motor does not give wattage,

multiply 120 Volts times the ampere rating to determine

watts (Volts x Amps = Watts).

Some electric motors (induction types) require about

three times more watts of power for starting than for

running.This surge lasts for only a few seconds. Be sure

you allow for this high starting wattage when selecting

electrical devices that will be energized by the backup

power system:

Figure the watts required to start the largest motor.

Add that to the total running watts of all other

connected loads.

This Briggs & Stratton Backup Power System

complies with the following “stationary standby

power rating”:

The standby power rating is applicable for supplying

emergency power for the duration of normal power

interruption. No sustained overload capability is available

for this rating.

This rating is applicable to installations served by a

reliable normal utility source.This rating is only applicable

to variable loads with an average load factor of 80% of

the standby rating for a maximum of 500 hours of

operation per year.The standby rating is only applicable

for emergency and standby power where the generator

set serves as the backup to the normal utility source.

Use the “Wattage Reference Guide” provided and mark

those circuits you consider “critical” or “essential”. Make

sure you and your installer consider the system’s altitude

above sea level and the ambient temperature range when

determining total generator load.

Device

Running

Watts

Air Conditioner (12,000 Btu)* 1700

Air Conditioner (24,000 Btu)* 3800

Air Conditioner (40,000 Btu)* 6000

Battery Charger (20 Amp) 500

Circular Saw (6-1/2") 800 to 1000

Clothes Dryer (Electric)* 5750

Clothes Dryer (Gas)* 700

Clothes Washer* 1150

Coffee Maker 1750

Compressor (1 HP)* 2000

Compressor (1/2 HP)* 1400

Compressor (3/4 HP)* 1800

Curling Iron 700

Dehumidifier* 650

Electric Blanket 400

Electric Range (per element) 1500

Electric Skillet 1250

Freezer* 700

Furnace Fan (3/5 HP)* 875

Garage Door Opener* 500 to 750

Hair Dryer 1200

Hand Drill 250 to 1100

Iron 1200

Jet Pump* 800

Light Bulb 100

Microwave Oven 700 to 1000

Milk Cooler* 1100

Oil Burner on Furnace 300

Oil Fired Space Heater (140,000 Btu) 400

Oil Fired Space Heater (30,000 Btu) 150

Oil Fired Space Heater (85,000 Btu) 225

Radio 50 to 200

Refrigerator 700

Slow Cooker 200

Submersible Pump (1 HP)* 2000

Submersible Pump (1/2 HP)* 1500

Submersible Pump (1-1/2 HP)* 2800

Sump Pump* 800 to 1050

Table Saw (10")* 1750 to 2000

Television 200 to 500

Toaster 1000 to 1650

Figure 3 — Wattage Reference Guide

*Allow three (3) times listed watts for starting device

Page 8

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

8

UNPACKING

Refer to the Installation Manual for detailed unpacking

instructions, if desired.

Delivery Inspection

After removing the carton, carefully inspect the Backup

Generator and Automatic Power Transfer Switch

components for any damage that may have occurred during

shipment.

IMPORTANT: If loss or damage is noted at time of

delivery, have the person(s) making delivery note all damage

on the freight bill and affix his signature under the

consignor's memo of loss or damage. If loss or damage is

noted after delivery, separate the damaged materials and

contact the carrier for claim procedures.Missing or

damaged parts are not warranted.

Shipment Contents

The Backup Power System is supplied with:

• Backup Power generator

• Pre-attached mounting pad

• Automatic Power Transfer switch

• One 18” flexible fuel hook-up pipe

• Installation manual

• Owner’s manual

• Installation checklist

• Three access door keys

• Four lifting hole plugs

• Oil fill spout

• Touch-up paint

• One spare 15 Amp fuse

Page 9

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

9

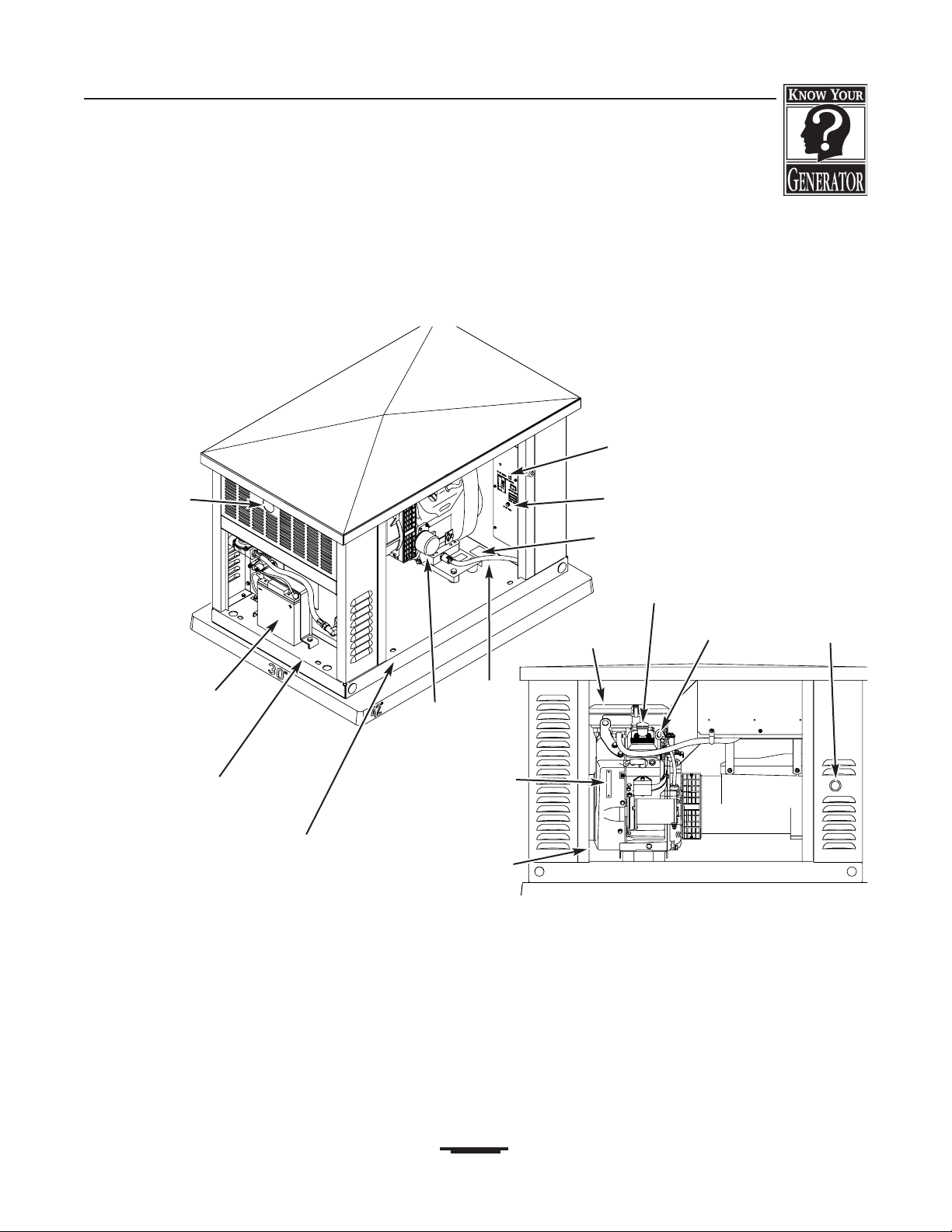

15 Amp Fuse — Protects the DC control circuits.

Air Cleaner — Uses a dry type filter element and foam

precleaner to limit the amount of dirt and dust drawn into

the engine.

Battery — 12 Volt DC, 18 Amp-Hour sealed battery

provides power to start the engine. Battery receives trickle

charge whenever generator is not running.

Control Panel — Used for various test,operation and

maintenance functions. See “KNOW YOUR SYSTEM

CONTROL PANEL” on the next page.

Engine Label — Identifies engine model and type.

Exhaust Port — High-performance muffler lowers engine

noise to comply with most residential codes.

Oil Dip Stick — Used to check the engine oil level.

Oil Drain Hose — Provided to facilitate oil changing.

Oil Fill Cap — Remove to service the engine with

recommended oil.

Oil Filter — Filters engine oil to prolong system life.

Unit Data Decal — Identifies unit by serial number.

KNOW YOUR BACKUP GENERATOR

Read this owner’s manual and safety rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

Air Cleaner

Oil

Filter

Battery Door Opening

Control Panel Door Opening

Unit Data Decal

Oil Service Door Opening

Exhaust

Port

Oil Dip Stick

Fuel Inlet

Control Panel

(see page 10)

Battery

Oil

Drain

Hose

Oil Fill Cap

15 Amp Fuse

Engine Label

Page 10

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

10

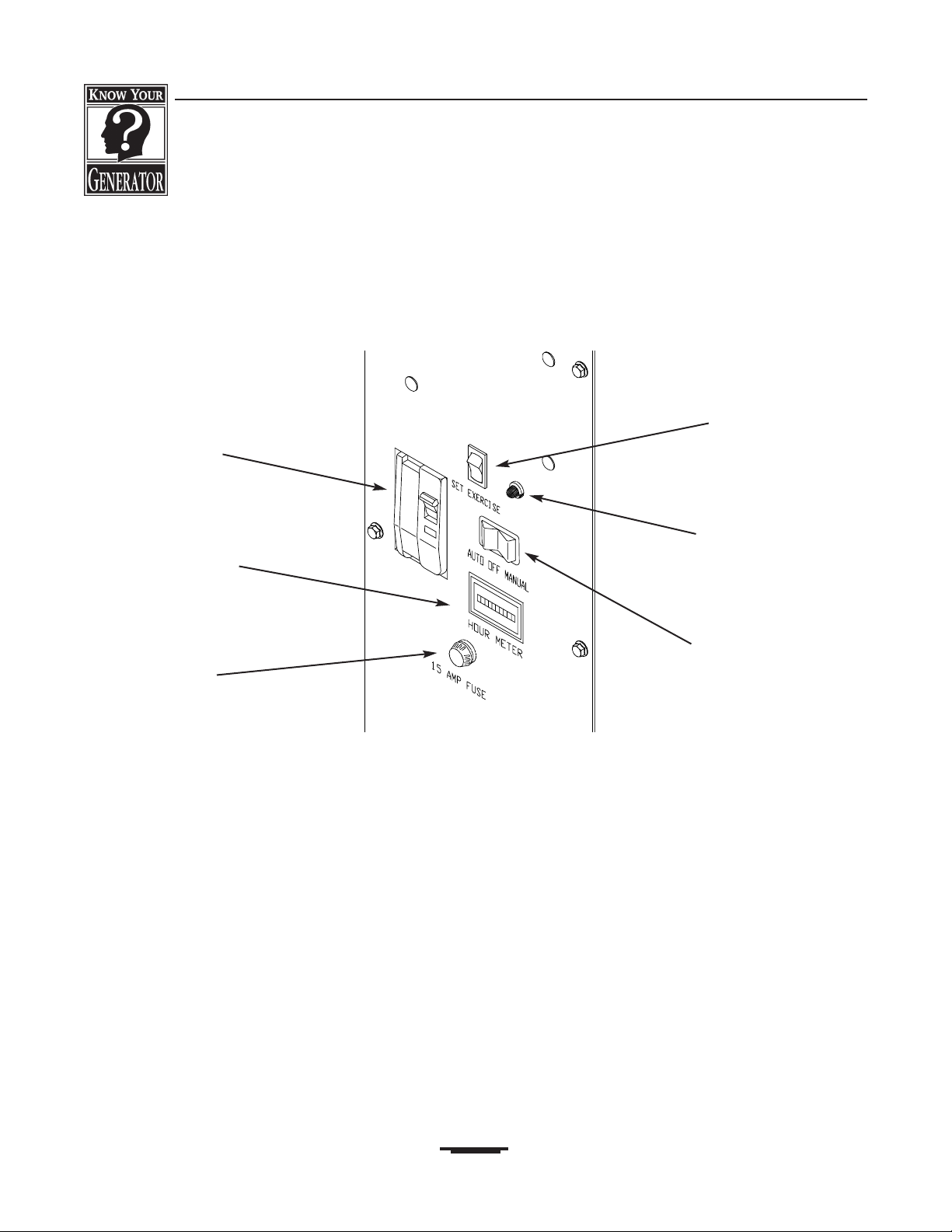

Hour Meter

Circuit

Breaker

Set Exercise

Switch

AUTO/OFF/MANUAL

Switch

Diagnostic

LED

15 Amp

Fuse

15 Amp Fuse — Protects the Backup Power System DC

control circuits. If the fuse has ‘blown’ (melted open) or

was removed, the engine cannot crank or start. Replace the

fuse using only an identical BUS AGC 15A fuse.

AUTO/OFF/MANUAL Switch — This three-position

device is the most important control on the system and is

used as follows:

•“AUTO” position is the normal operating position. If a

utility power outage is sensed, the system will start the

generator, let it reach stable operating speed, then

connect generator power to the sub-panel.When utility

power is restored, the system reconnects utility power

to the sub-panel, lets the engine stabilize internal

temperatures, shuts off the generator,and waits for the

next utility power outage.While waiting, it maintains

battery with trickle charge.

•“OFF” position turns off running generator, takes system

out of Automatic mode and resets any detected faults.

•“MANUAL” position starts the engine but does not

disconnect the sub-panel from utility power. It is used for

maintenance or diagnostic functions.

Circuit Breaker — Protects the system from shorts and

other over-current conditions. Must be ON to supply

power to the Automatic Transfer Switch.

Diagnostic LED — Used for troubleshooting operational

problems with the Backup Power System.All fault

conditions are described in the section “Fault Detection

System”.

Hour Meter — The hour meter records the total number

of hours the generator has been running and is used to

schedule maintenance tasks.

Set Exercise Switch — Used to set the exercise cycle

start time and day-of-the-week. Exercise cycle only occurs

in AUTO mode.

KNOW YOUR SYSTEM CONTROL PANEL

Compare this Control Panel illustration with your generator to familiarize yourself with the location of these important

controls:

Page 11

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

11

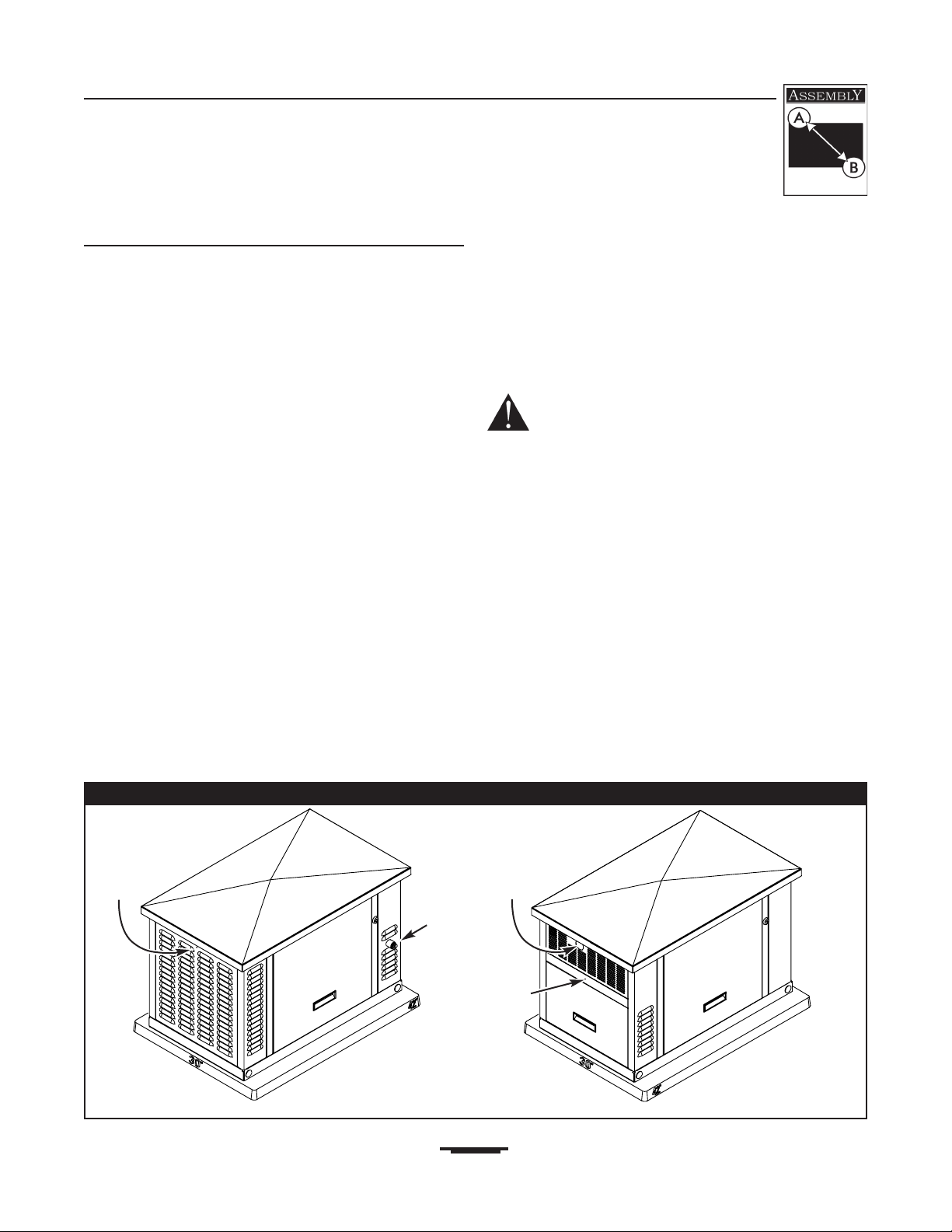

Access Doors

The Backup Power System is equipped with an enclosure

that has four access doors (Figure 4).The doors are named

for a significant component located behind them. Starting

with the side that has the fuel connection and proceeding

clockwise, the doors are named:

• Oil Service door

• Air Intake door

• Control Panel door

• Battery door

Each backup power system is equipped with three identical

keys.These keys fit the locks that secure the oil service and

control panel doors.

CAUTION! Do Not operate the backup generator

unless the Oil Service and/or Control Panel doors are

installed. Failure to do so will cause overheating.

To remove an access door:

1. Insert a key into the lock of the access door you wish

to remove and turn one quarter turn clockwise.

NOTE:The key is retained in the lock when the locks are

open.

2. Grasp the door’s lift handle and pull the door upwards

until the security pins are free of the lower base.

3. With the security pins free, pull the lift handle outward

(away) from the unit while pulling the door down and

out of the upper door channel.The door will come

free of the generator enclosure.

The battery door and the air intake door do not have locks

or lift handles.They are opened by lifting on the louvers

instead of a lift handle. However, you must remove the

door lock screw, found directly above the center of the

door. Replace the screw to secure the access door.

CAUTION!

Burn Hazard! The exhaust port

can reach a temperature of 600° F during use and

remains hot after shutdown. Carelessness could

cause severe burns.

To install an access door:

1. Support the door by grasping the lift handle or louver.

Guide the top of the door into the generator

enclosure.

2. Lift the door up into its upper channel until the

security pins clear the sill of the enclosure.

3. Push the lower half of the door into the door recess

until it is flush with the sides.

4. Seat the door by pushing it down until the rubber

coated security pins engage and the door rests on the

mounting sill.

5. If installing a lockable door, turn the key one quarter

turn counterclockwise. Remove the key.

Oil Service Door

Fuel

Inlet

Exhaust

Port

Air Intake Door

Door Lock

Screw

Door

Lock

Screw

Battery Door

Control Panel Door

Figure 4 — Enclosure Access Doors

Page 12

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

12

BEFORE INITIAL START-UP

Engine Oil

This engine is shipped from the factory filled with the

recommended oil. Before starting the engine, check oil level

and ensure that engine is serviced as described on page 18

in “Checking Oil Level”.

CAUTION! Any attempt to crank or start the

engine before it has been properly serviced with the

recommended oil will result in an engine failure that

is not covered under warranty.

Oil Considerations

Your Backup Power System is equipped with an engine that

has been pre-run at the factory and does not require the

traditional “break-in” procedure.

In order to provide a greater “backup” capability, the

system is filled with synthetic oil (API SJ/CF 5W-30W).This

allows for system operation in the widest range of

temperature and climate conditions.

NOTE:The use of synthetic oil DOES NOT alter the

required oil change intervals described later in the

Maintenance section of this manual.

Battery Connection

The Backup Power System is supplied with a 12Volt DC

18 Amp-Hour sealed rechargeable battery. It is installed in

the unit and the battery cables are connected at the

factory.The unit’s 15 Amp fuse has been removed for

shipping (this prevents the unit from starting).

CAUTION! Do Not install the 15 Amp fuse until

all plumbing and wiring has been completed and

inspected. Failure to install the fuse as described in

the Installation Manual could cause the engine to

start.

NOTE:With the battery installed, utility power supplied to

the Automatic Transfer Switch, and the unit in AUTO mode,

the battery receives a trickle charge while the engine is not

running.The trickle charger cannot be used to recharge a

battery that is completely discharged.

Gaseous Fuel System

• Ensure that all fuel pipe connections are tight, secure and

without leaks.

• Ensure that all shutoff valves are OPEN and that

adequate pressure is available.

If you smell ‘raw’ gaseous fuel (natural or LP) near the unit,

immediately turn off the gas supply to the generator.

Contact your gas utility or the system installer for

assistance in determining the source of the smell.

The AUTO/OFF/MANUAL Switch

This three-position device is referred to herein as

“AUTO/OFF/MANUAL”. It is found on the control panel, as

shown earlier, and is used as follows:

•“AUTO” position is the normal operating position. If a

utility power outage is sensed, the system will start the

generator, let it reach stable operating speed, then

connect generator power to the sub-panel.

When utility power is restored, the system reconnects

utility power to the sub-panel, lets the engine ‘cool

down’, shuts off the generator, and waits for the next

utility power outage.

•“OFF” position turns off a running generator, takes the

system out of Automatic mode and resets faults.The unit

will not exercise, but the ‘Set Exercise’ setting is not lost.

•“MANUAL” position starts the engine but does not

disconnect utility power from the sub-panel. It is used for

maintenance or diagnostic functions.

CAUTION!With the switch set to AUTO, the

engine may crank and start at any time without

warning. Such automatic starting normally occurs

when utility source voltage drops below a preset

level or during the normal exercise cycle.To prevent

possible injury that might be caused by such sudden

starts, always set the AUTO/OFF/MANUAL switch

to OFF and remove the 15 Amp fuse before

working on or around the generator or transfer

switch.

The other controls and devices installed on the control

panel are described on page 10,“Know Your System

Control Panel”.

Page 13

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

13

AUTOMATIC OPERATION

To select automatic transfer operation, do the following:

1. Set the main distribution panel circuit breaker that

sends utility voltage to the transfer switch to ON.

2. Set the AUTO/OFF/MANUAL switch to AUTO.

3. Set the generator’s main circuit breaker to its ON

position.

Checking Automatic Operation

To check the system for proper automatic operation,

proceed as follows:

1. Check that AUTO/OFF/MANUAL is set to OFF.

2. Apply utility power to the Automatic Transfer Switch

by turning ON the main distribution panel circuit

breaker.

3. Set the AUTO/OFF/MANUAL switch to AUTO.The

Automatic Power System is now ready for automatic

operation.

4. Turn OFF the main distribution panel circuit breaker

sending power to the automatic transfer switch.

The engine will crank and start once the utility voltage

drops out and the sensor has timed out.After starting, the

Automatic Power Transfer System will transfer essential

circuit sub-panel loads to the generator. Let the system go

through its entire automatic operation sequence.

5. With the generator output supplying its loads, turn

ON the main distribution panel circuit breaker that

supplies utility power to the Automatic Power Transfer

Switch.

6. After about 6 seconds, the automatic transfer switch

will transfer loads back to the utility power.

7. About one minute after re-transfer, the engine will shut

down.

This completes the test procedures for automatic

operation.The backup power system will now start

automatically when utility power is lost and will supply

power to the essential circuit sub-panel.

Stopping the System

To disable the power transfer system for maintenance:

1. Ensure that the main distribution panel circuit breaker

that sends utility voltage to the transfer switch is ON.

2. Set the AUTO/OFF/MANUAL switch to OFF.

3. Set the generator’s main circuit breaker to its OFF

position.

Setting Exercise Timer

The Backup Power System is equipped with an exercise

timer that will start and exercise the system once every

seven days. During this exercise period, the unit runs for

approximately 12 minutes and then shuts down. Electrical

load transfer DOES NOT occur during the exercise cycle

(unless an utility power outage occurs).

Page 14

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

14

A switch on the control panel is labeled “Set Exercise”

(depicted on page 10).The specific day and the specific time

of day this switch is pressed is programmed into the

control board memory.This date and time is then used to

automatically initiate the system exercise cycle.

To perform the Set Exercise procedure:

1. Choose the day and time you want your backup power

system to exercise.

2. On that da

y and time, set the AUTO/OFF/MANUAL

switch to OFF.

3. Press and hold down the “Set Exercise” switch.The

Diagnostic LED blinks.

4. Hold the switch down until the Diagnostic LED stops

blinking. Release the Set Exercise switch.

5. Set the AUTO/OFF/MANUAL switch to AUTO.“Set

Exercise” is complete.

For example, if you press the “Set Exercise” switch on

Sunday morning at 10:00 AM, the unit will run an exercise

cycle the following Sunday at 10:00 AM.

NOTE:“Set Exercise” will only work if the unit is in the

Automatic mode and this exact procedure is followed.The

exerciser does not need to be re-set if the 15 Amp fuse is

removed or changed.The exerciser will need to be re-set if

the 12 Volt DC battery is disconnected.

If you want to change the day and time the unit exercises,

simply perform the “Set Exercise” procedure at the exact

weekday and time you want it to take place.

SPECIFICATIONS

Generator

Model . . . . . . . . . . . . . . . . . . . . 1461 1535

Rated Maximum Power (LP*). . . 10.0 kW 8.0 kW

Rated Maximum Load Current:

at 240 Volts. . . . . . . . . . . . . . . 41.7 Amps 33.3 Amps

at 120 Volts. . . . . . . . . . . . . . . 83.3 Amps 66.7 Amps

Rated AC Voltage . . . . . . . . . . . . 120/240 Volts

Rated Frequency . . . . . . . . . . . . 60 Hz at 3600 rpm

Phase . . . . . . . . . . . . . . . . . . . . . Single Phase

Power Factor. . . . . . . . . . . . . . . 1.0

NG Fuel Supply Pressure. . . . . 5-14 in W.C. (127-356 mm)

LP Fuel Supply Pressure. . . . . . 11-14 in W.C. (279-

356 mm)

Normal Operating Range . . . . -20°F (-28.8°C) to 104°F

(40°C)

Output Sound Level . . . . . . . . 70 dB(A) at 23 ft. (7 m) at

full load

* Natural gas rating will depend on specific fuel but typical derates

are between 10 to 20% off the LP gas rating.

Engine

Type . . . . . . . . . . . . . . . . . . . . . . Air Cooled, 4 stroke,V-Twin,

Horizontal Shaft, OHV dual

fuel engine

Bore x Stroke . . . . . . . . . . . . . . 2–72 mm x 70 mm

Displacement . . . . . . . . . . . . . . . 570 cc

Spark Plug . . . . . . . . . . . . . . . . . Champion RC12YC

Oil Type . . . . . . . . . . . . . . . . . . . Synthetic SAE 5W30,API

SJ/CF

Oil Capacity (w/filter) . . . . . . . . 48 oz. (1.6 l)

Spark Plug gap . . . . . . . . . . . . . 0.030 in (.76 mm)

Page 15

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

15

MAINTENANCE

Fault Detection System

The generator may have to run for long periods of time

with no operator present. For that reason, the system is

equipped with sensors that automatically shut down the

generator in the event of potentially damaging conditions,

such as low oil pressure, high oil temperature, over speed,

and other conditions.

A light on the control panel called the Diagnostic LED will

turn on and off in a series of blinks.The blink pattern is

repeated with a brief pause between each series.The

number of blinks in the series indicates the detected fault,

as listed on the control panel and below:

Number of LED Flashes Fault Description

1 Low battery voltage

2 Low oil pressure

3 Low voltage

4 Engine fail to start

5 Low frequency

6 Engine overspeed

7 Oil temperature high

Reset Fault Detection System

The operator must reset the fault detection system each

time it activates.To do so, place the AUTO/OFF/MANUAL

switch in the OFF position for 30 seconds or more.

Return the backup power system to service after

correcting the problem by placing the

AUTO/OFF/MANUAL switch in the AUTO position.

A description of each fault and suggested remedies are as

follows:

No Blinks - ‘Dead’ Unit

This condition is caused by a completely dead starting

battery.To remedy the problem, remove the 15 Amp fuse

and disconnect the battery from the generator.Take the

battery to a local battery store for analysis. Replace battery

only with a genuine Generac part number 188443.

Replace the battery in the battery compartment after it has

been fully recharged, connecting the NEGATIVE cable last.

Install the 15 Amp fuse. Reset the Fault Detection system

as described above.

Low Battery Voltage

This fault is indicated by one blink.This condition occurs if

the generator cannot start because the starting battery

output power is below that needed to ‘turn-over’ the

engine. Causes for this problem may be a failed battery or a

failed trickle charger circuit.

To remedy the problem, remove the 15 Amp fuse and

disconnect the battery from the generator.Take the battery

to a local battery store for analysis. Replace battery only

with a genuine Generac part number 188443.

Replace the battery in the battery compartment after it has

been fully recharged, connecting the NEGATIVE cable last.

Install the 15 Amp fuse. Reset the Fault Detection system

as described above. Check battery trickle charge output.

Low Oil Pressure

This fault is indicated by two blinks.The unit is equipped

with an oil pressure switch (Figure 5) using normally closed

contacts that are held open by engine oil pressure during

operation. Should oil pressure drop below the 8 psi range,

switch contacts close and the engine is shut down.

To remedy the low oil pressure condition, fix any obvious

oil leak and/or add the recommended oil to the FULL mark

on the dipstick. Reset the Fault Detection system as

described above.

If low oil pressure condition still exists, engine will start,

then shut down after about 10 seconds and diagnostic LED

will flash. In this case, contact an authorized service facility.

Figure 5 — Low Oil Pressure & High Temp. Switches

High

Temperature

Switch

Oil Drain

Fitting

Oil

Pressure

Switch

Page 16

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

16

Low Voltage

This fault is indicated by three blinks.This condition is

caused by a restriction in the fuel flow, a broken or

disconnected signal lead, a failed alternator winding, the

control panel circuit breaker is open, or overloaded circuits

in the essential circuit sub-panel.

Remedy the problem (you may need to contact your

installer or Generac Technical Services for assistance), then

reset the Fault Detection system, as described above.

Engine Fail To Start

This fault is indicated by four blinks.This feature prevents

the generator from damaging itself if it continually attempts

to start in spite of another problem, such as no fuel supply.

Each time the system is directed to start, the unit will

crank for 15 seconds, pause for 15 seconds, crank for

15 seconds, pause for 15 seconds, and repeat. If the system

does not begin producing electricity after approximately

90 seconds, the unit will stop cranking and the LED will

blink.

The most likely cause of this problem is no fuel supply.

Check the inside and outside fuel shut off valves to ensure

they are fully open. Other causes could be failed spark

plug(s), failed engine ignition, or the engine air filter is

clogged.You may need to contact your installer for

assistance if you can’t remedy these problems.When the

problem is corrected, reset the Fault Detection system as

described above.

Low Frequency

This fault is indicated by 5 blinks.This feature protects

devices connected to the essential circuit sub-panel by

shutting the generator down if its engine runs slower than

the preset limit.

This condition is caused by a failed engine governor or by

excessive loads on the essential circuit sub-panel.To

remedy the problem, you may need to contact your

installer or Generac Technical Services for assistance.When

the problem is corrected, reset the Fault Detection system

as described above.

Engine Overspeed

This fault is indicated by 6 blinks.This feature protects

devices connected to the essential circuit sub-panel by

shutting the generator down if its engine happens to run

faster than the preset limit.The overspeed fault is detected

as follows:

• If the generator output frequency runs at 72 Hz for five

seconds, the generator will shut down.

• If the generator output frequency reaches 75 Hz, the

generator will shut down instantly.

This condition is caused by a failed engine governor.To

remedy the problem, you should contact your installer or

Generac Technical Services for assistance.When the

problem is corrected, reset the Fault Detection system as

described above.

Oil Temperature High

This fault is indicated by seven blinks.The contacts of the

temperature switch (Figure 6) are normally open. If the

engine temperature exceeds approximately 140°C (284°F),

the fault is detected and the engine shuts down.

Common causes for this condition include running the unit

with all access doors removed, obstructed air inlet or

exhaust port, or debris in the engine cylinder cooling fins.

To resolve the problem, remove any accumulated debris

and obstructions and let the engine cool down. Ensure that

the Oil Service door and/or the Control Panel door is

installed whenever the unit is running.When the problem is

corrected, reset the Fault Detection system as described

above.

Power During Fault Condition

Whenever the backup power system is in an uncorrected

fault condition, the automatic transfer switch is reset to

UTILITY POWER.This means that when utility power is

restored, utility power will be applied to the essential

circuit sub-panel loads.The generator is disconnected from

the automatic transfer switch for the duration of any

detected fault condition.

Page 17

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

17

Generator Maintenance

The generator warranty does not cover items that have

been subjected to operator abuse or negligence.To receive

full value from the warranty, the operator must maintain

the system as instructed in this manual.

All adjustments in this section should be made at least

once each season. Follow the requirements in the

“Maintenance Schedule” chart above.

Generator maintenance consists of keeping the unit clean

and dry. Operate the unit in an environment where it will

not be exposed to excessive dust, dirt, moisture or any

corrosive vapors.Cooling air louvers on the enclosure

must not become clogged with snow, leaves, or any other

foreign material.

Check the cleanliness of the unit frequently and clean when

dust, dirt, oil, moisture or other foreign substances are

visible on its exterior surface.

NOTE:Do Not use direct spray from a garden hose to

clean generator.Water can enter the engine and cause

problems. In addition, if water enters the generator through

cooling air slots, some water will be retained in voids and

cracks may develop in the rotor and stator winding

insulation.Water and dirt buildup on the generator internal

windings will eventually decrease the insulation resistance

of these windings.

To Clean the Generator:

CAUTION! Never insert any object or tool

through the air cooling slots, even if the engine is

not running.

• Use a damp cloth to wipe exterior surfaces clean.

• A soft, bristle brush may be used to loosen caked on

dirt, oil, etc.

• A vacuum cleaner may be used to pick up loose dirt and

debris.

• Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspect cooling air slots and openings on

the generator.These openings must be kept clean and

unobstructed.

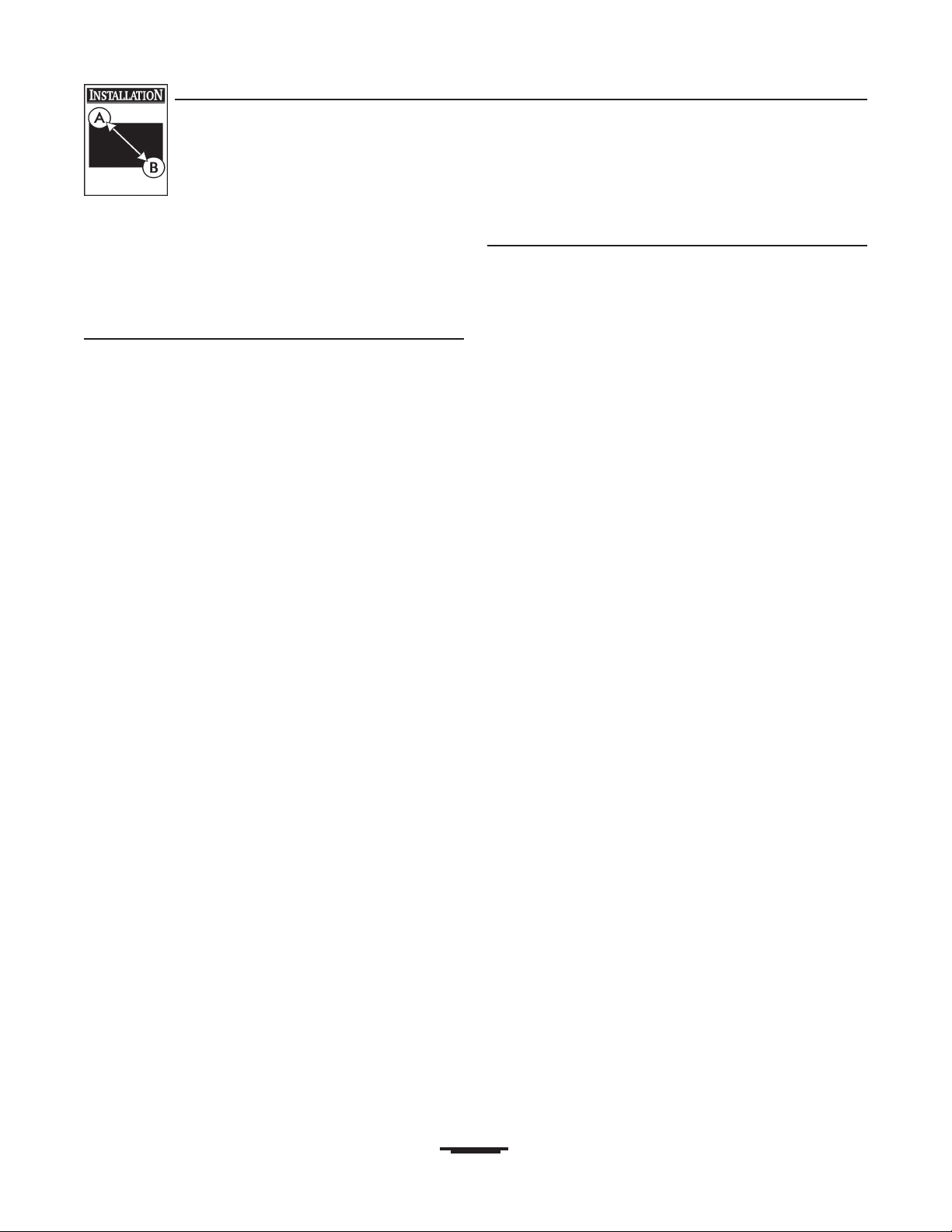

Maintenance Schedule

The following chart is based on normal engine operation. Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in extremely dusty or heavy load conditions.

Maintenance Operation

Every

8 Hours

or Daily

Every

25 Hours or

Every Season

Every 50 Hours

or Every

Season

Every

100 Hours or

Every Season

Yearly

Check and refill engine oil X (Note 1)

Service air cleaner precleaner X (Note 2)

Change engine oil X (Note 1)

Replace air cleaner precleaner X

Inspect (and clean) spark arrester X

Service air cleaner cartridge X (Note 2)

Change oil filter X

Clean cooling fins, screens X

Check and adjust valve lash X

Replace spark plugs X

Note 1 - Change oil every 25 hours when operating under heavy load or in high temperatures.

Note 2 - Clean more often under dusty conditions or when airborne debris is present. Replace air cleaner parts, if very

dirty.

Page 18

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

18

Engine Maintenance

CAUTION!When working on the generator,

always remove the 15 Amp fuse from control panel.

Also disconnect spark plug wires from spark plugs

and keep wires away from spark plugs.This will

prevent accidental start–up.

Check fuel lines and fittings frequently for cracks or leaks.

Replace if necessary.

Checking Oil Level

Before placing the backup generator in service and at the

recommended maintenance interval, check the engine oil

level, as follows:

• Remove Oil Service door. Clean area around oil fill and

dipstick locations.

• Remove dipstick.Wipe with clean cloth.

• Insert dipstick fully. Remove and check oil level.

• If oil level is low, slowly add recommended oil to bring

level to “Full” mark on dipstick (Figure 6).

• A reusable oil spout that fits most oil bottles is supplied

to make it easier to pour oil into the engine (Figure 7).

Changing the Oil and Oil Filter

Oil capacity is approximately 1-1/2 quarts (48 ounces or

1.6 liters) when changing oil and filter. Use only 5W-30 API

Service Grade SJ or greater synthetic oil.

Change the oil after every 50 hours and replace oil

filter every 100 hours. If you are using this engine under

dirty or dusty conditions, or in extremely hot weather,

change the oil more often.

Use the following instructions to change the oil

while the engine is still warm:

1. Unclip and wipe the oil drain hose clean with a rag.

Place the oil drain hose into a suitable container. Grasp

the oil drain fitting (see Figure 5), push it in towards

the engine, rotate it counterclockwise to its stop, then

pull the fitting outwards. Oil should begin to flow out

of the oil drain hose.

2. When the oil is drained, grasp the oil drain fitting and

rotate it clockwise until it locks in place. Position the

oil drain hose into its storage clip.

3. Place a suitable container beneath the oil filter and

remove the filter.

Figure 6 — Oil Dipstick Markings

Figure 7 — Oil Fill Spout on Oil Bottle

Page 19

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

19

4. Coat the o-ring of a new filter with fresh, clean engine

oil.Turn the new filter by hand clockwise until the

gasket contacts the filter adapter, then tighten 1/2 to

3/4 turn more.

5. Fill engine with oil as described above.

6. Install and tighten the oil fill cap.

7. Run the engine for a minute; stop the engine and check

for oil leakage around the oil filter. Recheck oil level.

Replace the Spark Plugs

Replace the plugs every year. Use the recommended

spark plugs gapped for 0.030 in. (0.76 mm).

1. Stop the engine and pull the spark plug wires off of the

spark plugs.

2. Clean around the spark plugs and remove them from

the cylinder head.

3. Clean off carbon deposits on the spark plug electrode

using a wire brush or commercial solvent.Do Not

blast clean.

4. Set the spark plugs’ gap as recommended (Figure 8).

Install the correctly gapped spark plugs into the

cylinder heads.

Service Air Cleaner

The engine’s air cleaner is one of the most important areas

to maintain.The engine will not run properly and will be

damaged if it is run with a dirty air cleaner system.

Use only genuine Briggs & Stratton parts or their

equivalent.The use of replacement parts which are not of

equivalent quality may damage the engine.

Clean the foam precleaner every 25 hours and the

cartridge every 100 hours of operation. Clean or

replace more often in dusty or dirty conditions.

CAUTION! Never run this equipment without the

complete air cleaner system installed on the engine. Failure

to do so will result in premature engine wear and

significantly reduced engine life.

To service the air cleaner components:

1. Unhook clips on both sides of cover and remove cover

(Figure 9).

2. Carefully slide foam precleaner off cartridge.

3. To service precleaner,wash in liquid detergent and

water. Squeeze dry in a clean cloth. Never twist!

Saturate in clean, fresh engine oil. Squeeze in clean,

absorbent cloth to remove all EXCESS oil. Replace if

very dirty or damaged.

4. Remove knob and plate. Carefully remove cartridge to

prevent debris from entering carburetor.

5. To service cartridge, clean by tapping gently on a flat

surface. Do Not oil cartridge. Replace if very dirty or

damaged.

NOTE:Do Not use petroleum solvents, e.g. kerosene,

which will cause the cartridge to deteriorate. Do Not use

pressurized air to clean cartridge. Pressurized air can

damage the cartridge.

Figure 9 — Engine Air Cleaner Components

Cartridge

Precleaner

Plate

Body

Knob

Clips

Figure 8 — Gapping A Spark Plug

Page 20

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

20

4. Reinstall cartridge, plate and knob.

5. Reassemble precleaner on cartridge.

6. Replace cover and attach clips to body.

Inspect Spark Arrester Screen

The engine exhaust muffler has a spark arrester screen.

Inspect the screen every 50 hours of operation or once

each year, whichever comes first..The spark arrester must

be maintained in good condition by the owner/operator.

Inspect the spark arrester as follows:

• Using a powerful flashlight, examine the circular screen

installed in the end of the exhaust port.There should be

no rips or tears in the screen.There should be little or

no accumulated soot on the screen.

• Replace the screen if torn, perforated or otherwise

damaged. Do Not use a defective screen. Consult

Generac Technical Services for assistance in changing the

screen.

• If screen is not damaged, it may be cleaned in place with

a gentle brushing from a wire brush or bottle brush.

Engine Governed Speed

CAUTION!The engine speed was properly adjusted at

the factory and should require no additional adjustment.

Do Not attempt to change engine speed. If you believe the

engine is running too fast or too slow, contact the factory

for assistance. CHANGING THE ENGINE GOVERNED

SPEED WILL VOID THE ENGINE WARRANTY AND WILL

ADVERSELY AFFECT SYSTEM OPERATION.

To assure smooth operation, keep governor linkage, springs

and controls free of debris.

Valve Lash

Valve lash must be checked while engine is cold after every

100 hours of operation.Adjust if necessary.Valve lash is:

Intake and Exhaust. . . . . 0.004 - 0.006 in. (0.10 - 0.15 mm)

Carburetor Adjustments

The engine carburetor is preset at the factory.The

carburetor should not be tampered with because doing so

will void the emission control system warranty. If you

experience problems or your engine is used at an altitude

higher than 5,000 feet, contact your installer or the factory.

If You Call the Factory:

You must have the following information at hand if it is

necessary to contact Generac Technical Services regarding

service or repair of this unit:

1. Obtain the unit Model Number and Serial Number

from the unit data decal. See “Know Your Backup

Generator” diagram for location.

2. Obtain the engine Model/Type/Code numbers from the

engine label. See “Know Your Backup Generator”

diagram for location. Please note that the model

number may vary slightly from that presented herein.

STORAGE

The Briggs & Stratton Backup Power System is designed for

continuous backup operational duty.As such, there is no

need to take any storage precautions. However, if it

becomes necessary to take the system out of service for

an extended period, call Generac Technical Services at

920-674-3750, extension 2716, between 8:00AM and

5:00 PM CT for specific recommendations.

Page 21

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

21

TROUBLESHOOTING

Problem Cause Correction

Engine is running, but no

AC output is available.

1. Generator circuit breaker is open.

2. Fault in generator.

3. Poor wiring connections or defective

transfer switch.

4. Sub-panel circuit breaker open or

defective.

1. Reset circuit breaker.

2. Contact Generac Portable Products

service facility.

3. Check and repair.

4. Reset or replace circuit breaker.

Engine runs good at noload but “bogs down"

when loads are

connected.

1. Short circuit in a connected load.

2. Generator is overloaded.

3. Shorted generator circuit.

1. Disconnect shorted electrical load.

2. See “Essential Circuits” on page 6.

3. Contact Generac Portable Products

service facility.

Engine will not start; or

starts and runs rough.

1. 15 Amp fuse missing or blown.

2. Dirty air cleaner.

3. Out of fuel.

4. Spark plug wire not connected to

spark plug.

5. Bad spark plug.

6. Intake valve stuck open or closed.

7. Engine compression lost.

8. Failed battery.

1. Install (new) 15 Amp fuse.

2. Clean or replace air cleaner.

3. Open fuel valve(s); check propane tank..

4. Connect wire to spark plug.

5. Replace spark plug.

6. Contact Generac Portable Products

service facility.

7. Contact Generac Portable Products

service facility.

8. Replace battery.

Engine shuts down during

operation.

1. Out of fuel.

2. Fault indicator blinking.

1. Check fuel valves, fill propane tank.

2. Count blinks and refer to “Fault

Detection System” on page 15.

Engine lacks power.

1. Dirty air filter.

2. Generator overloaded

1. Replace air filter.

2. See “Essential Circuits” on page 6.

Page 22

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

22

UNIT SCHEMATIC DIAGRAM

Page 23

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

23

UNIT WIRING DIAGRAM

PLG

Page 24

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

24

TRANSFER SWITCH SCHEMATIC DIAGRAM

Page 25

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

25

TRANSFER SWITCH WIRING DIAGRAM

Page 26

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

26

UNIT EXPLODED VIEW

Page 27

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

27

UNIT PARTS LIST

Item Part # Qty. Description

1 NSP 1 ENGINE, B&S, 18 HP

2 22259GS 6 NUT, 5/16" - 18

3 22129GS 16 LOCKWASHER, 5/16" - M8

4 48031JGS 1 CLIP, Hoseband

5 92134GS 1 FILTER, Oil

6 H186285GS 1 PAN, Engine Mounting

7 186071GS 1 VALVE, Oil Drain

8 186430GS 1 HOSE, Oil Drain

9 25017GS 2 HHCS, 3/8" - 16 x 1/2"

10 22237GS 14 LOCKWASHER, 3/8"

11 38353GS 4 MOUNTS,Vibration

12 H185972GS 1 BASE, Mount

13 22531GS 2 HHCS, 5/16" - 18 x 1-3/4"

14 92609GS 2 MOUNTS,Vibration

15 29745GS 2 HHCS, 3/8" - 16 x 1"

16 22241GS 6 NUT, 3/8" - 16

17 51754GS 1 HHCS, M8 - 1.25 x 12

18 187032GS 1 WASHER, 3/8 Ext., Shakeproof

19 H185957GS 1 SUPPORT,Alt.

20 22127GS 5 NUT, 1/4" - 20

21 186152GS 1 HOSE, Gas Regulator to Engine

22 57822GS 2 CLAMP, Hose

23 H185966GS 1 BULKHEAD,Alternator Side

24 186647GS 1 DECAL, Outdoor Use Only

25 H189952GS 1 STRAP, Battery Hold Down

26 B4300GS 2 SWAGE BOLT, 1/4" - 20 x 1/2"

27 42907GS 6 HHCS, M8 1.25 x 16

28 188574GS 1 CABLE, Battery Positive

29 188443GS 1 BATTERY, 33AH

30 22131GS 2 WASHER, Flat 3/8"

31 22145GS 2 WASHER, Flat 5/16 - M8

32 188573GS 1 CABLE, Battery Negative

33 186070GS 4 WASHER, Fiber .26 x .62 x .06

34 39253GS 2 HHCS, M8 x 20

35 186148GS 1 HOSE, Gas - regulator

36 186151GS 1 ELBOW, Brass, 3/4" NPT x 1/2"

Gas

37 22413GS 2 HHCS, 1/4" - 20 x 1"

38 B4774GS 1 REGULATOR, Gas Fuel

39 186150GS 1 ELBOW, Brass 3/8 NPT

40 B4773GS 1 SOLENOID, Gas Fuel

41 H185961GS 1 CORNER,Alt.Air Inlet, Left

42 26850GS 3 WASHER, Ext. M6-1/4"

Shakeproof

43 B4300GS 2 BOLT SWAG, 1/4 - 20

44 B4769GS 1 CONTACTOR, Starter

Item Part # Qty. Description

45 186375GS 1 CLAMP, Hose

46 185955GS 4 STUD, Muffler Mount

47 187049GS 1 PLUG, Dome

48 49813GS 4 NUT, M6 - 1.0

49 22097GS 9 LOCKWASHER, M6 - 1/4"

50 22473GS 4 FLAT WASHER, M6 - 1/4"

51 H186125GS 4 BRACKET, Muffler

52 H186030GS 1 BASE, Muffler Box

53 56893GS 16 CRIMPTITE, 10 - 24 x 1/2"

54 22264GS 2 LOCKWASHER, M4 #8

55 186790BGS 1 WIRE, Ground

56 67897GS 2 MANIFOLD, Gasket

57 185900GS 1 MANIFOLD, Exhaust

58 186062GS 1 GASKET, Manifold, Muffler

59 86307GS 2 HHCS, 5/16" x 3/4" SEMS

60 B4260GS 1 DISK,Air Blocker

61 186242GS 2 PPHMS, #4 - 40 x .019"

62 186205GS 1 SWITCH, Thermodisk Oil Temp.

63 27772GS 2 LOCKWASHER, #4 Int.Tooth

64 186206GS 1 PLATE, Oil Temp Switch

65 B4268GS 1 ALTERNATOR, Sincro

66 22511GS 4 HHCS, 3/8 - 16 x 1-1/4"

67 H186320GS 1 DEFLECTOR, 45° Muffler Box

68 H186038GS 1 BOX, Muffler

69 185894GS 1 MUFFLER, with Brackets

70 22471GS 2 NUT, #8-32

71 185939CGS 1 CABLE, Starter

72 23152GS 2 HHCS, 3/8" - 16 x 3/4"

73 27482GS 1 WASHER, 5/16" Ext. Shakeproof

74 186790CGS 1 WIRE, Ground

75 186649GS 1 DECAL, Oil Drain

76 B4986GS 1 DECAL, Ground, Green

77 186551GS 1 INSULATION, Fuel Hose

78 26915GS 1 NIPPLE, 3/4" NPT

79 69397GS 4 BOLT, Manifold

80 45771GS 8 NUT, M8 - 1.25

81 187277GS 1 SCREEN, Spark Arrestor w/

screws

82 H189951GS 1 TRAY, Battery Support

83 96924GS 2 J-BOLT

84 49820GS 2 NUT, Locking Hex

85 59637GS 1 TAPTITE, 3/8" - 16 x 3/4"

86 96137GS 1 PLUG, 1/8" - 27

87 189295GS 1 FLAT WASHER

88 A6344GS 1 FITTING, Barbed, 90°, 1/8" NPT

89 189294GS 1 E-RING

Page 28

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

28

ENCLOSURE EXPLODED VIEW

Page 29

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

29

ENCLOSURE PARTS LIST

Item Part # Qty. Description

1 186564GS 1 PAD, Fountation Base w/ Holes

2 H185972GS 1 BASE, Mounting

3 186061GS 8 BUSHING, Stem

4 H185971GS 1 DOOR,Alternator Side

5 186049GS 3 HANDLE, Door, Recessed Pull

6 189792GS 5 PPHMS, #10-32 x 5/8"

7 H185962GS 1 CORNER,Alt. Air Inlet Right

8 B4300GS 40 SWAG BOLT, 1/4" - 20

9 H185968GS 1 BAFFLE, Horizontal,Alt. Side

10 H185961GS 1 CORNER,Alt.Air Inlet, Left

11 H185965GS 1 PANEL, Muffler Air Out

12 186582GS 1 BUSHING, Snap 11/16" I.D.

13 H185966GS 1 BULKHEAD,Alternator Side

14 B5053GS 1 KEY, Lock

15 186172GS 2 ASSEMBLY, Lock/Doors

16 H187232GS 2 DOOR, with Insulation

17 H186046GS 2 RAIL, Support Upper Front/Back

18 H187234GS 1 ROOF, with Insulation

19 H185963GS 1 CORNER, Engine Air Inlet Right

20 H186047GS 1 RAIL, Support Upper Engine Side

21 H185969GS 1 DOOR, Engine Air Inlet

22 H185964GS 1 CORNER, Engine, Left Side

23 H187235GS 1 BAFFLE, with Insulation

24 74908GS 12 TAPTITE, M5

25 B4986GS 1 DECAL, Ground

26 186173GS 2 BUSHING, Snap, 1" I.D.

27 H185967GS 1 BULKHEAD, Engine Side

28 186065GS 1 SEAL, Foam Engine Air Inlet

29 B4889GS 1 SEAL, Foam Alternator Air Inlet

30 H186760GS 1 COVER, Control Panel

31 29745GS 4 HHCS, 3/8" - 16 x 1"

32 185976GS 6 PLUG, Hole 1-1/8"

33 22131GS 4 FLATWASHER, 3/8"

34 22237GS 4 LOCKWASHER, 3/8"

35 22241GS 4 NUT, 3/8"

36 187060GS 1 CLAMP, 3/4" Nylon

37 186202GS 6 CLAMP, 1" Nylon

38 186277GS 1 WIRE HARNESS, Engine

39 B5082GS 1 DECAL, Danger High Voltage

40 22097GS 4 LOCKWASHER, M6

41 49813GS 4 NUT, M6 x 1.0

42 186790AGS 1 WIRE, Ground,To Control Panel

43 186345GS 1 LUG, Ground

44 186642GS 1 DECAL, LP/Natural Gas

45 186827GS 1 DECAL,Terminal Strip

46 28739AGS 1 TIE WRAP, 4" Black

47 26850GS 1 WASHER, Ext. M6 - 1/4" Shakeproof

Part Not Illustrated

187008GS 1 KIT, Door Seal

Page 30

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

30

INSULATION SET EXPLODED VIEW

Page 31

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

31

INSULATION SET PARTS LIST

Item Part # Qty. Description

1 H187234GS 1 ROOF, with Insulation

2 186188GS 2 INSULATION, Baffle Alt. Side

3 H186030GS 1 BASE, Muffler Box

4 H185966GS 1 BULKHEAD,Alternator Side

5 186186GS 1 INSULATION, Bulk Head Alt.. End

6 B4772GS 27 CLIPS,Dart

7 H185968GS 1 BAFFLE, Horizontal,Alt. Side

8 H187232GS 2 DOOR, with Insulation

9 189144GS 1 DECAL, Unit

10 H185972GS 1 BASE, Mounting

11 186641GS 1 DECAL, Operation Instructions

12 186646GS 1 DECAL,Warning Engine Can Start

13 H185962GS 1 CORNER,Alt.Air Inlet Right

14 186351GS 1 INSULATION, Muffler Box

15 186189GS 1 INSULATION, Corner, Right Side

16 186190GS 1 INSULATION, Corner, Left Side

17 H185961GS 1 CORNER,Alt.Air Inlet, Left

18 186643GS 1 DECAL, Fuel Inlet

19 H186038GS 1 BOX, Muffler

20 77816GS 1 DECAL, Hot Muffler

21 186352GS 1 INSULATION, Muffler Base

Page 32

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

32

ALTERNATOR EXPLODED VIEW AND PARTS LIST

Item Part # Qty. Description

1 B4906GS 1 SHIELD, Front

2 B4907GS 2 GRID, Front

3 B4908GS 1 BOLT, Shaft Stay

4 B4909GS 4 STAY BOLT, M8 x 30

5 B4910GS 1 ASSEMBLY, Housing

6 B4911GS 1 CAP

7 B4912GS 1 COVER, Blind End

8 B4913GS 1 COVER,Top Black

9 B4914GS 2 CAPACITOR, 25mF 450V

10 B4915GS 1 BEARING, 62052RS C3

11 B4916GS 1 CAPACITOR, Diode + Varistor + EMC

12 B4917GS 1 ROTOR, (Includes Item 13)

13 B4918GS 1 FAN

14 B4919GS 2 SCREW, M6 - 1.0 x 10mm

15 B4920GS 8 SCREW, M5 - 0.8 x 10mm

16 49820GS 1 LOCK NUT, M8 - 1.25

17 188928GS 1 CONNECTOR, 6-Pin Sincro

18 22473GS 6 WASHER, Flat M6

19 49813GS 6 NUT, M6

Page 33

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

33

CONTROL PANEL EXPLODED VIEW AND PARTS LIST

Item Part # Qty. Description

1 187225GS 1 CONTROL PANEL, with Silk

Screen

2 B4776GS 1 TRANSFORMER

3 B4799GS 1 STRIP,Terminal

4 65795GS 1 RECTIFIER, Battery Charge

5 H185967GS 1 BULKHEAD, Engine Side

6 77604GS 1 HOUR METER

7 B5111GS 1 CONTROL BOARD

8 186280GS 1 CIRCUIT BREAKER, 50 Amp,

Model 1461

186280BGS 1 CIRCUIT BREAKER, 40 Amp,

Model 1535

9 B4893GS 2 BRACKET, Resistor

10 B4867GS 1 RESISTOR, 25W, .5 OHM

11 57345GS 2 NEUTRAL, 4 Prong

12 186413GS 4 STANDOFF, Control Board

13 B4300GS 6 BOLT, Swage, 1/4-20

Item Part # Qty. Description

14 87799GS 1 SWITCH, Set Exercise

15 B5133GS 1 DIODE, Light

16 186443GS 1 SWITCH, Auto/Off/Manual

17 32300GS 1 HOLDER, Fuse

18 22676GS 1 FUSE, 15 Amp AGC

19 22264GS 10 LOCKWASHER, M4

20 51715GS 10 NUT, M4 - 0.7

21 22985GS 4 FLATWASHER, M4

22 49226GS 1 LOCKWASHER, M5

23 23897GS 1 FLATWASHER, M5

24 51716GS 1 NUT, M5 - 0.8

25 43182GS 4 LOCKWASHER, M3

26 51714GS 4 NUT, M3 - 0.5

27 187060GS 1 CLAMP, Cable 3/4" I.D.

28 186645GS 1 DECAL, Caution Electrical Shock

29 186648GS 1 DECAL, Control Panel Fault

Description

Page 34

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

34

TRANSFER SWITCH EXPLODED VIEW

Page 35

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

35

TRANSFER SWITCH PARTS LIST

Item Part # Qty. Description

1 B4852GS 1 BOX, Plastic

2 B5079GS 1 DECAL, Utility Load

3 B4852GS 1 INSERT, Box

4 57073GS 1 NEUTRAL BLOCK

5 185890GS 2 RELAY, 900 Series

6 B4858GS 1 FUSE HOLDER, 30 Amp

7 B4857GS 4 FUSE, 2 Amp, 600 Volt

8 75475GS 4 SCREW, M4 x 10

9 75476GS 6 SCREW, M4 x 16

10 43116GS 1 SCREW, M6 x 12

11 B4856GS 1 CONNECTION LUG, Ground

12 91526GS 4 SCREW, M5 x 12

13 49226GS 4 LOCK WASHER, M5

14 23897GS 4 FLAT WASHER, #10

15 B5052GS 1 TERMINAL STRIP

16 22264GS 10 LOCK WASHER, #8

17 51715GS 10 NUT, M4

18 22097GS 1 LOCK WASHER, 1/4

19 49813GS 1 NUT, M6

20 B5084GS 1 DECAL, UL Type

21 B5083GS 1 DECAL, UL Listed

22 B4986GS 1 DECAL, Ground

23 B5107GS 1 DECAL, Generator Connection

24 B5081GS 1 DECAL, Neutral

25 B5106GS 1 DECAL, Utility Connection

26 B5105GS 1 DECAL, Load Connection

27 B5087GS 1 DECAL, Intended Use

28 B5080GS 1 DECAL,Terminal Strip

29 186021GS 1 DECAL, Identification

30 B5086GS 1 DECAL,Warning, Live Circuit

31 B5082GS 1 DECAL, Danger High Voltage

32 B5085GS 1 DECAL,Warning Shock

33 B5088GS 1 DECAL,Auto Sequence

34 B4854GS 6 TERMINAL, 14-6 Awg

35 22241GS 1 NUT, 3/8"-16

36 22237GS 1 LOCK WASHER, 3/8"

Page 36

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

36

ENGINE EXPLODED VIEW

Briggs & Stratton 18 hp Engine, Model 354445 0123-E1

Page 37

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

37

Page 38

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

38

Page 39

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

39

Page 40

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

40

Page 41

Briggs & Stratton Power Products Backup Power System

Owner’s Manual

41

Item Part # Description

1 808702 Cylinder Assembly

2 808534 Kit-Bushing/Seal (Magneto Side)

3 805101* Seal-Oil (Magneto Side)

5 808698 Head-Cylinder (Cylinder #1)

5A 808699 Head-Cylinder (Cylinder #2)

7 690888*§ Gasket-Cylinder Head

8 808984 Breather Assembly

9 807893* Gasket-Breather

10 690751 Screw (Breather Assembly)

10A 806421 Screw (Breather Assembly)

11 808686 Tube-Breather

12 691684* Gasket-Crankcase

13 692059 Screw (Cylinder Head)

15 690946 Plug-Oil Drain

16 692173 Crankshaft

17 690752 Bearing-Ball

18 808847 Cover-Crankcase

20 805049* Seal-Oil (PTO Side)

22 692540 Screw (Crankcase Cover)

23 808768 Flywheel

25 808326 Piston Assembly-Std (Standard)

26 807889 Ring Set (Standard)

27 690683 Lock-Piston Pin

28 807886 Pin- Piston

29 807900 Rod-Connecting (Standard)

32 690698 Screw (Connecting Rod)

33 808687 Valve - Exhaust

34 807680 Valve- Intake

35 692084 Spring-Valve (Intake)

36 692084 Spring-Valve (Exhaust)

39 690745 Deflector-Oil

40 692058 Retainer- Valve

42 807683 Keeper- Valve

45 690977 Tappet- Valve

46 691557 Camshaft

50 692124 Manifold-Intake

51 806457* Gasket-Intake

51A 692035*§ Gasket- Intake

54 690676 Screw (Intake Manifold)

89 690283 Plug-Oil

122 690747 Spacer-Carburetor

125 808692 Carburetor

146 691639 Key-Timing

161 691561 Base-Air Cleaner

163 692081* Gasket-Air Cleaner

188 692056 Screw (Control Bracket)

192 807623 Adjuster-Rocker Arm

206 691244 Nut-Governor Control

208 691549 Rod-Governor Control

209 691506 Spring-Governor

211 692068 Spring-Governor Idle

212 690712 Link-Throttle

222 808454 Bracket-Control

227 690236 Lever-Governor Control

232 692073 Spring-Governor Link

239 690233 Switch-Oil Pressure

262 692083 Screw (Rod Bracket)

273 690681* O-Ring Seal (Oil Pump)

276 691766*§ Washer-Sealing

276A 690704 Washer-Sealing (Governor Crank)

280 691526 Bracket-Rod

287 692062 Screw (Dipstick Tube)

304 690930 Housing-Blower

Item Part # Description

305 692056 Screw (Blower Housing)

305A 692539 Screw (Blower Housing)

308 806546 Cover-Cylinder Head (Cyl. #1)

308A 806547 Cover-Cylinder Head (Cyl. #2)

309 691564 Motor-Starter (Steel Pinion)

310 692033 Bolt (Starter Motor)

311 497605 Brush Set

322 692539 Screw (Cylinder Head Cover)

332 690887 Nut (Flywheel)

333 492341 Armature-Magneto

334 692066 Screw (Magneto Armature)

337 491055 Sparkplug

338 691312* Gasket-Dipstick

358 808784* Gasket Set-Engine

359 691077 Washer (Ground Terminal)

363 19203 Flywheel Puller

365 690711 Screw (Carburetor to Manifold)

373 691612 Nut (Ground Terminal)

377 806066 Key-Woodruff

413 693587 Nut (Starter Motor)

432 691509 Cap-Spring

439 692154* O-Ring Seal (Crankcase Cover)

445 394018 Filter-Air Cleaner Cartridge