Briggs & Stratton 110400, 111400, 120400, 113400, 121400 Operator Owner's Manual

...

Before starting this engine, read and understand

Operator/Owner Manual

this

. Failure to follow instructions

in this manual could result in serious injury or death.

For future reference, write your

For future reference, write your

In the Interest of Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil & Fuel Recommendations 3. . . . . . . . . . . . . . . . . . . . . .

Starting & Stopping 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Briggs & Stratton Corporation

Milwaukee, Wisconsin 53201

www.briggsandstratton.com

engine

engine

Model/T ype/Code here.

Date of Purchase here.

Copyright 1998 by Briggs & Stratton Corporation

Model Type Code

Table of Contents

Maintenance Schedule 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service, Storage & Specifications 9. . . . . . . . . . . . . . . . . .

Emission System Warranty 10. . . . . . . . . . . . . . . . . . . . . . .

About Engine Warranty 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Warranty 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORM NO. 273700-7/98

PRINTED IN U.S.A.

Maintenance, replacement or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual. However, to obtain no charge repairs under the terms and provisions of the

Briggs & Stratton warranty statement, any service or emission control part repair or replacement must be performed by a

factory authorized dealer.

In the Interest of Safety

This safety alert symbol indicates that this message

involves personal safety. Words danger, warning

and caution indicate degree of hazard. Death,

personal injury and/or property damage may occur

unless instructions are followed carefully.

The Briggs & Stratton engine you bought with your equipment is made of the finest material in a state-of-the-art manufacturing

facility . Please understand that Briggs & Stratton sells engines to original equipment manufacturers. It also sells to others in the

distribution chain who may sell to the ultimate consumer, an equipment manufacturer , another distributor or a dealer . As a result,

Briggs & Stratton does not necessarily know the application on which the engine will be placed. For that reason, you should

carefully read and understand the operating instructions of the equipment on which your engine is placed before you operate it.

You should also understand that there are equipment applications for which Briggs & Stratton does not approve the use of its

engines. Briggs & Stratton engines are not to be used on vehicles with less than 4 wheels. They include motor bikes, aircraft

products and All T errain V ehicles. Moreover, Briggs & Stratton does not approve of its engines being used in competitive events .

F0R THA T REASON, BRIGGS & STRATTON ENGINES ARE NOT AUTHORIZED FOR ANY OF THESE APPLICATIONS. Failure to follow this warning could result in death, serious injury (including paralysis) or property damage.

DO NOT run engine in an enclosed area.

(Exhaust gases contain carbon monoxide, an

odorless and deadly poison.)

DO NOT remove fuel tank cap nor fill fuel tank while

engine is hot or running. DO NOT refuel indoors or in

an unventilated area. (Allow engine to cool 2 min utes before refueling.)

DO NOT place hands or feet near moving or rotating parts.

DO NOT store, spill, or use gasoline near an open flame, nor

near an appliance like a stove, furnace, or water heater that

uses a pilot light or can create a spark.

DO NOT refuel indoors or in an unventilated area.

DO NOT operate or tip engine/equipment at such a severe

angle that causes gasoline spillage.

DO NOT operate engine if gasoline is spilled or when smell of

gasoline is present or other explosive conditions exist. (Move

equipment away from spill and avoid any ignition until gasoline

has evaporated.)

DO NOT transport engine with fuel in tank or fuel shut-off

valve open.

DO NOT choke carburetor to stop engine, especially in an enclosed vehicle. (Whenever possible, gradually reduce engine

speed before stopping.)

DO NOT tamper with governor springs, links or other parts to

increase engine speed. (Run engine at speed set for equipment

manufacturer.)

✔ PULL starter cord slowly until resistance is felt. Then pull

cord rapidly to avoid kickback and prevent hand or arm injury.

✔ PREVENT ACCIDENTAL STARTING by removing spark

plug wire from spark plug when servicing engine or equipment. Disconnect negative wire from battery terminal if

equipped with electric starting system.

✔ REMOVE blower housing periodically and clean engine.

Keep cylinder fins and governor parts free of dirt, grass

and other debris which can affect engine speed.

✔ USE fresh gasoline. Stale fuel can gum carburetor and

cause leakage.

✔ CHECK fuel lines and fittings frequently for cracks or

International

Symbols

Safety Alert - Read

Owner’s Manual

DO NOT check for spark with spark plug removed. (Use an

approved tester.)

DO NOT crank engine with spark plug removed. (If engine is

flooded, place throttle in FAST and crank until engine starts.)

DO NOT strike flywheel with a hammer or hard object as this

may cause flywheel to shatter in operation. (T o remove flywheel,

use Briggs & Stratton approved tools only.)

DO NOT operate engine without a muffler . (Inspect periodically

and replace if worn or leaking. If engine is equipped with muffler deflector, inspect periodically and replace if necessary. Replacement parts must be same as on original equipment.)

DO NOT operate engine with an accumulation of grass,

leaves or other combustible material in muffler area.

DO NOT use this engine on any forest covered, brush covered, or grass covered unimproved land unless a spark arrester is installed on muffler . The spark arrester must be maintained in working order by the owner and/or operator. In the

State of California the above is required by law (Section 4442

of the California Public Resources Code). Other states may

have similar laws. Federal laws apply on federal lands.

DO NOT touch hot muffler , cylinder, or fins which can cause

burns.

DO NOT start engine with air cleaner or air cleaner cover re moved (or cover over carburetor air intake, if Sno/Gard engine).

DO NOT attempt to start engine with cutting blade loose or removed. (Blade must be tight, otherwise a kickback may occur.)

✔ Use only Genuine Briggs & Stratton Parts or their

On Off Stop

You are not ready to operate this engine if you

have not read and understood the following

safety items. Read this entire owner’s manual and

the operating instructions of the equipment this

engine powers.

leaks. Replace if necessary.

equivalent. The use of replacement parts which are

not of equivalent quality may damage the engine.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

Fuel

Shutoff

Fuel

Choke

In the USA and Canada, a 24 hour hot line, 1-800-233-3723, has a menu of pre-recorded messages offering you engine maintenance information.

2

Oil & Fuel Recommendations

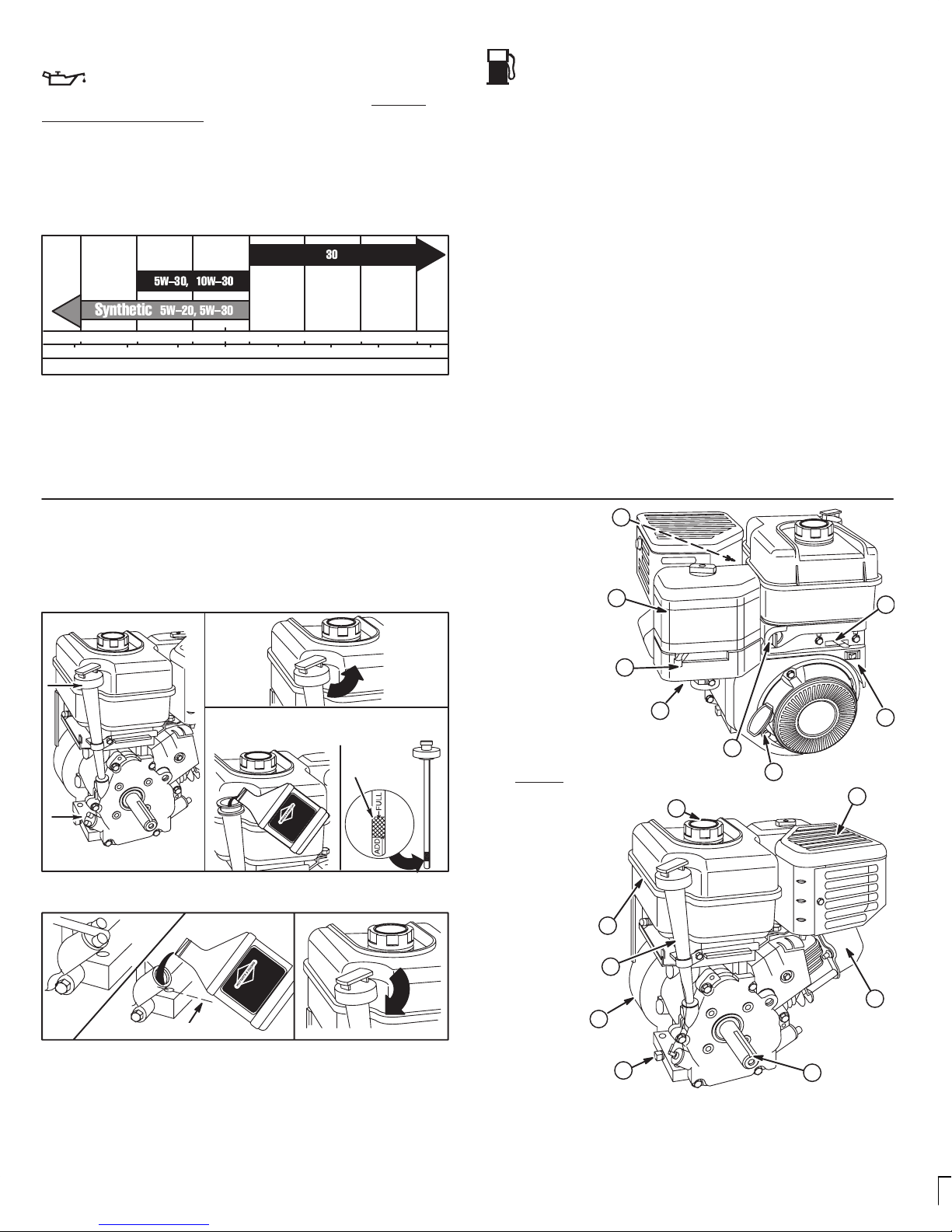

Oil

This engine is shipped from Briggs & Stratton without

Before starting engine

, check oil level as shown below.

Change and add oil according to chart below. Do not over-fill.

Use a high quality detergent oil classified “For Service SF , SG,

SH,” such as Briggs & Stratton “warranty certified” SAE 30 oil,

Part No. 100005. Use no special additives with recommended

oils. Do not mix oil with gasoline.

SAE Viscosity Grades

**

*

20 40 60 80 100

-20 0

°F

°C -30

STAR TING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

* Air cooled engines run hotter than automotive engines. The use of

multi-viscosity oil such as (10W-30, etc.) in ambient temperatures

above 40° F (4°C) will result in higher than normal oil consumption.

If multi-viscosity oil is used, check the oil level more frequently to

prevent any possible engine damage due to lack of lubrication.

** Use of SAE 30 oil below 40° F (4° C) will result in hard starting

and possible engine damage due to inadequate lubrication.

-20 -10 0 10 20 30 40

32

oil.

Fuel

Use clean, fresh, regular unleaded gasoline with a minimum

of 85 octane. Do not mix oil with gasoline. Fresh fuel prevents

gum from forming in fuel system or on essential carburetor

parts. Purchase fuel in quantity that can be used within 30

days. In countries other than the U.S.A., leaded gasoline may

be used if commercially available and unleaded is unavailable.

We recommend the use of Briggs & Stratton Gasoline Additive.

(See your Authorized Briggs & Stratton Service Dealer for

Part No. 5041 or the single-use pouch.) See storage instructions, on page 9.

Note: Some fuels, called oxygenated or reformulated

gasolines, are gasolines blended with alcohols or ethers.

Excessive amounts of these blends can damage the fuel

system or cause performance problems. Do not use gasoline

which contains Methanol. If any undesirable operating

symptoms occur, use gasoline with a lower percentage of

alcohol or ether.

Do not over-fill fuel tank. Allow space for fuel expansion.

Check oil level before starting engine.

Add oil as shown below.

Engine oil capacity is about 20 ounces (5/8 quart or 0.6 liter).

After filling with or changing oil, start and run engine at idle for

30 seconds. Shut engine off. Wait 30 seconds and check oil

level. Add oil, if required, to bring level to Full mark on dipstick.

Remove dipstick. Wipe clean.

T urn dipstick in 1/4 turn to check oil.

FULL

Place engine level.

Clean around oil fill.

Pour oil slowly.

Fill to FULL mark – recheck.

1

2

1. Spark plug wire

2. Air cleaner

3. Choke

3

4. Carburetor

5. Fuel shut-off valve

6. Rope handle

4

7. Stop switch/OIL GARD light

(if equipped)

8. Throttle

9. Engine Model Type Code

xxxxxx xxxx xx xxxxxxxx

10. Muffler

11

11. Fuel fill

12. Fuel tank

13. Oil fill/Dipstick

(if equipped)

14. Blower housing

15. Oil drain plug

16. Crankshaft

12

13

8

7

5

6

10

OIL LEVEL

If equipped with oil filler plug,

remove plug and fill to overflowing.

In the USA and Canada, a 24 hour hot line, 1-800-233-3723, has a menu of pre-recorded messages offering you engine maintenance information.

Tighten oil filler plug

or dipstick

before starting engine.

3

14

15

9

16

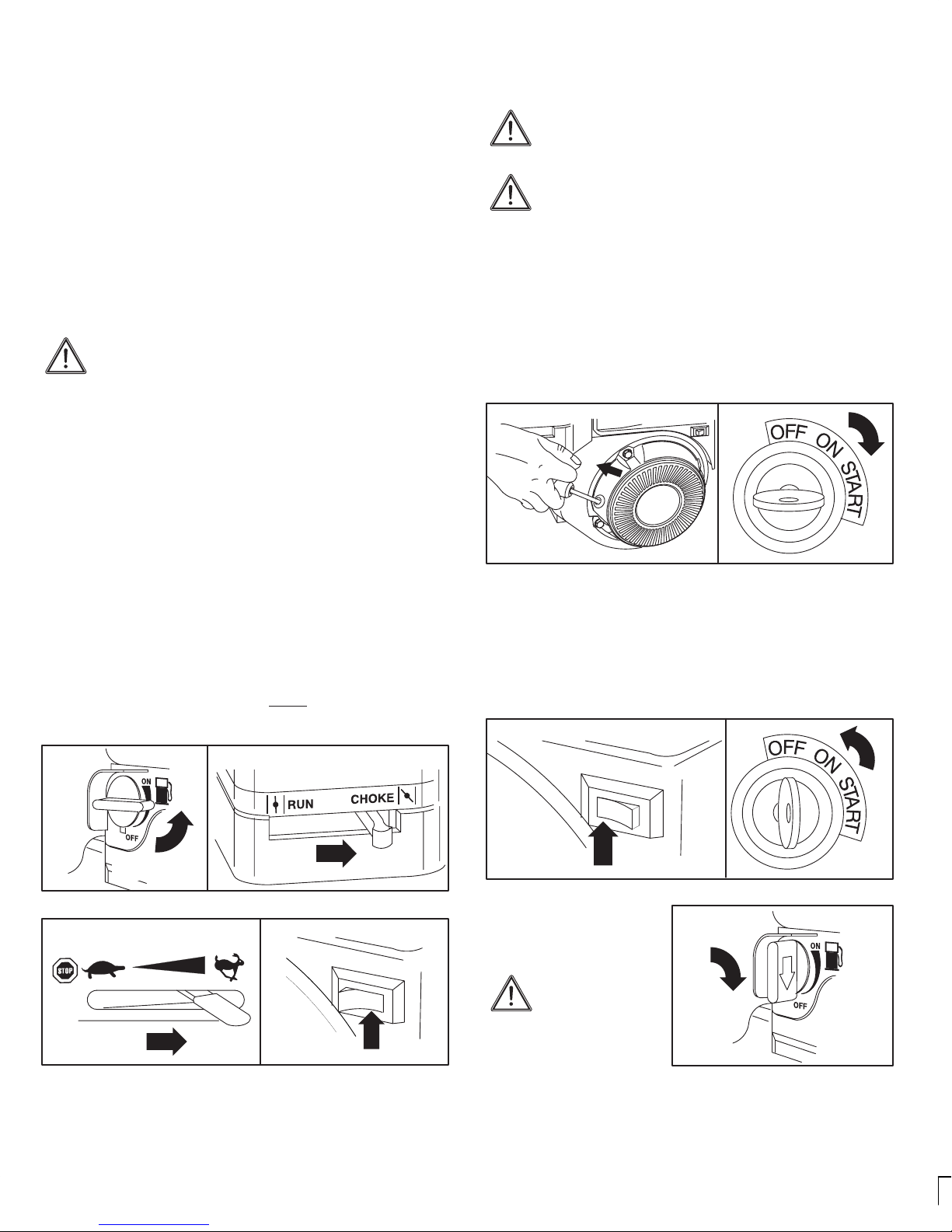

Starting & Stopping

Choke operation/engine warm-up

This engine is a low emissions engine which operates differently from previously built engines. It is designed for maximum performance and life if operated with the choke fully

open (in RUN) and throttle fully open (in FAST). To open the

choke fully requires an engine warm-up period of several

seconds to several minutes, depending on the temperature.

After starting engine, first open the choke (toward RUN) until

the engine just begins to run smoothly . Then open the choke in

small steps, allowing the engine to accept small changes in

speed and load, until the choke is fully open (in RUN).

During engine warm-up, the equipment can be operated.

To obtain best starting results

Start, store and fuel equipment with engine in level position.

Do not use a pressurized starting fluid. Starting fluid is

flammable. Severe engine damage or fire may occur.

A warm engine requires less choking than a cold engine.

Starting in cold weather:

Use the correct oil for the starting temperature expected.

De-clutch all possible external loads.

A warm battery has more starting capacity than a cold battery .

Do not use gasoline left over from summer. Use fresh winter

grade gasoline which has higher volatility to improve starting.

Start engine

Always keep hands and feet clear of mower blade or

other moving parts.

Rewind starter

Grasp rope handle as illustrated and pull slowly until

resistance is felt. Then pull cord rapidly to overcome

compression, prevent kickback and start engine.

Repeat if necessary with choke off and throttle control

in FAST position. Operate engine in FAST position.

Electric starter

, if equipped

Turn key to ST ART. Repeat if necessary with choke off and

throttle control in FAST . Operate engine with choke in RUN and

throttle in FAST position.

Note: If equipment manufacturer has supplied battery, charge it

before trying to start engine, as equipment manufacturer recommends. Use short starting cycles (15 secs. per min.) to prolong

starter life. Extended cranking can damage starter motor.

Before starting engine

Turn fuel shut-off valve 1/4 turn to OPEN position.

Move choke control to CHOKE position.

Move throttle control to FAST position.

Push rocker stop switch to ON position, if equipped.

OIL GARD light in rocker stop switch, if equipped, warns of

low oil level. Light will flicker and engine will not start, or

restart. Oil must be added. Fill to FULL mark on dipstick. Do

not over-fill. OIL GARD, however, will not stop a running

engine if the engine runs low on oil.

OPEN

POSITION

Choke controlsFuel shut-off

Rewind starter

Stop engine

Do not move choke control to CHOKE position to stop engine.

Backfire or engine damage may occur. Move throttle control

to SLOW position, then to STOP, or turn key to OFF, if

equipped. Always remove key from switch when equipment is

not in use or left unattended.

OFF

Typical stop switches

Turn fuel shut-off valve 1/4

turn to CLOSED position.

Typical electric starter

switch

CLOSED

POSITION

ON

Close fuel shut-off valve,

when transporting engine,

to prevent fuel leakage.

In the USA and Canada, a 24 hour hot line, 1-800-233-3723, has a menu of pre-recorded messages offering you engine maintenance information.

Stop switchThrottle control

4

Fuel shut-off valve

Loading...

Loading...