Briggs & Stratton 138400, 086400, 118400, 085400, 235400 User Manual

...

Briggs & Stratton

VANGUARD

™

SINGLE CYLINDER OHV AIR-COOLED ENGINES

1/07

Quality Starts With A

Master Service Technician

272147 - Vanguard Single Cylinder OHV Air-Cooled Engines

272144 - Vanguard Twin Cylinder OHV Air-Cooled Engines

275429 - Vanguard Twin Cylinder OHV Liquid-Cooled Engines

MS-0750 - Vanguard 3-Cylinder OHV Liquid-Cooled Gasoline Engines

MS-1055 - Vanguard 3-Cylinder OHV Liquid-Cooled Diesel Engines

Other Briggs & Stratton

Commercial Power Repair Manuals:

Vanguard Single Cylinder

OHV Air-Cooled Engines

™

POST OFFICE BOX 702

MILWAUKEE, WI 53201 USA

BRIGGSandSTRATTON.COM

©2007 Briggs & Stratton Corporation

BRIGGS&STRATTON

CORPORATION

Part No. 272147-1/07

272147 Vanguard Single Cylinder 4/27/07 1:03 PM Page 1

SECT ION 1- Saf ety, Maintenance & Adjustments

SECT ION 2 -Troubles hooting

SECTION 3 - En gine Disa ssembly

SECTION 4 - Exhaust Systems

SECTION 5 - Fuel Systems & Carburetion

S ECTION 6 - Governor Systems

SECTION 7- Cylinder Heads & Valves

1

2

3

4

5

6

7

SECTION 8 - Starters

SECTION 9 - Lubrication Systems

S ECTION 10 - Cylinders, Covers & Sumps

SECTION 11 - Crankshafts, Camshafts, Balancing Systems &

Gear Reducti ons

SECTION 12 - Pistons, Rings & Connecti ng Rods

SECTION 13 - Final Engine Assem bly

SECTION 14 - Engin e Specifications & Reference Tables

8

9

10

11

12

13

14

FORWARD

This guide has been written and published by Br iggs & Stratton Corporation to aid our dealers' mechanics

and company service personnel when servici ng the products described herein.

It is assumed th at these personnel are familiar with the servicing procedures for these products, or like or

similar products, manufactured by Briggs & Stratton Corporation. It is also assumed that they have been

trained in the r ecommended servicing procedures for these products, which includes the use of mechanics

hand tools and any special tools that might be required.

Proper service and repair is important to th e safe , econo mical and reliable operation of all engines and

engine driven systems. The troubleshooting, testing, service and repair procedures desc ribed in this guide

are effec tive methods of performing such oper ations.

We could not possibly know of and advise the service trade of all conceivable procedures or methods by

which a servi ce might be performed, nor of ever y possible hazards and/or results of each procedure or

method. We have not undertaken any such wide evaluation. Therefore, anyone who uses a procedure or

method not described by the manufactu rer must first satisfy himself that neither his safety, nor the safety of

the product, will be endangered by the service or operating procedure selected.

All information, illustrations, and specifications contained in this guide are based on the latest production

information available at the time of publication . However, Briggs & Stratton Corporation reserves the right

to change, alter, or oth erwise improve the product at any time without prior notice.

Some components or assemblies of the product described in this guide may not be con sidered repairab le.

Disassembly, repair and reassembly of such compo nents may not be included in this guide.

C opyrigh t © 2008 Briggs & Stratton Cor poration

All rig hts reserved.

No part of this material may be reproduced or transmitted, in any form or by any means, electronic or

mechanical, including photocopying, recording or by any information storage and retrieval system, w ithout

prior permission in writ ing from Briggs & Stratto n Corporat ion.

SECTION 1 - SAFETY, MAINTENANCE AND ADJUSTMENTS

ENGINE SAFETY ..... ............................................................................ 5

In Th e Interest Of Safety ........................ ............................. 5

The Safety Alert Symbol............................................................. .......... 5

Additional Precautions..........................................................................8

BRIG GS & STRATTO N NUMERIC AL IDENTIFICATIO N SYSTEM..... 9

ENGINE MAINTENANCE...................................................................10

Fuel and Oil Recommen dations............................... ...................... ..... 10

Changing Oil.......................................................................................11

MAINTENANCE SCHEDULE............................................................. 12

Air Cleaner Service............................................................................. 13

In-Line Fuel Filter Service................................................................... 15

ENGINE ADJUSTMENTS .................................................................. 15

Armature Air Gap Adjustments................................ ...........................15

Carburetor Idle-Mixture Adjustments.................................................. 15

Control Adjustments ...........................................................................16

Cooling System Maintenance............................................................. 18

Flywheel Brake Adjustments (104700)...............................................19

Governor Adjustments........................................................................19

Electro-Magnetic Idle Down Adjustments ...........................................25

Spark Plug Maintenance.....................................................................26

Valve Clearance Adjustments.............................................................26

Combustion Chamber Deposits........................................................ . 27

1

3

1

4

ENGINE SAFETY

engines is such applications could result in

In The Interest Of Safety

This repair manual contains safety information

that is designed to:

• Make you aware of hazards associated

with engines.

• Inform you of the risk of injury associated

with those hazar ds.

• Tell you how to avoi d or reduce the risk

of injury.

The Saf ety Alert Symbol

The safety alert symbol ( ) is used to identify

safety information about hazards that can result

in personal inj ury.

A signal word (DANGER, WARNING, or CAUTION)

is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to

represent the t ype of hazard.

DANGER indicates a hazard which, if

not avoided, will result in death or

serious injury.

1

WARNING

•

Before attempting to service this

equipment, read and understand this

manual and the operating instructions of

the equipment it powers.

Failure to FOLLOW instructions could result in

DEATH, SERIOUS INJURY

paralysis) or pr opert y dam age.

(includi ng

WARNING

Briggs & Stratton does not approve or

authorize th e use of these engines on 3wheel All Terrain Vehicles (ATV’s) ,

motorbikes, fun/recreational vehicles for

use in competitive events. Use of these

property damage, serious injury (including

paralysis), or even death.

WARNING indicates a hazard which, if

not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if

not avoided, might result in minor or

moder ate injury.

CAUTION: When this signal word is used

without the alert symbol, it indica tes a situation

that could result in damage to the engine.

• Prior to work, read and understand the

section(s) of this manual that pertain to

the job. Follow all safety warnings.

• Wear sui table eye protection.

• When servicing engines or equipment,

prevent accidental starti ng by remo ving

the spark plug wire from the spark

plug(s).

• Disconnect ne gative battery terminal if

the application is equipped with an

electric startin g system.

• Periodically clean engine. Keep governor

parts free of dirt, grass and other debris

which can affect engine speed and

cooling.

• Always use fresh gasoline. Stale fuel can

cause gum deposits in the carbure tor

and cause leakage, flow restrictions or

other failure s.

• Check fuel lines and fittings frequently for

cracks or leaks and replace if necessary.

5

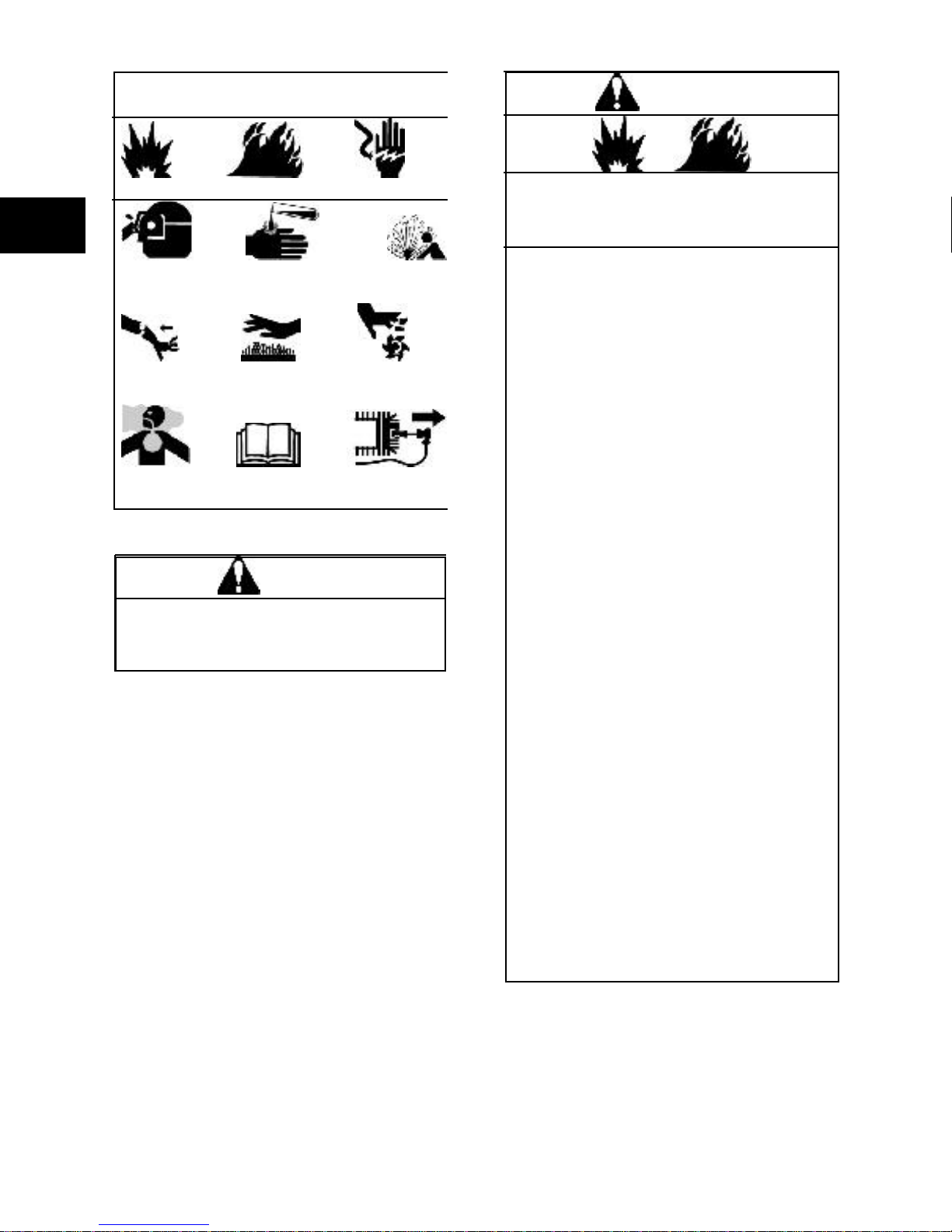

HAZAR D SYMBO LS AND

Toxic Read Disconnect

Fumes Spark Plug

and other reproductive harm.

MEANINGS

WARNING

1

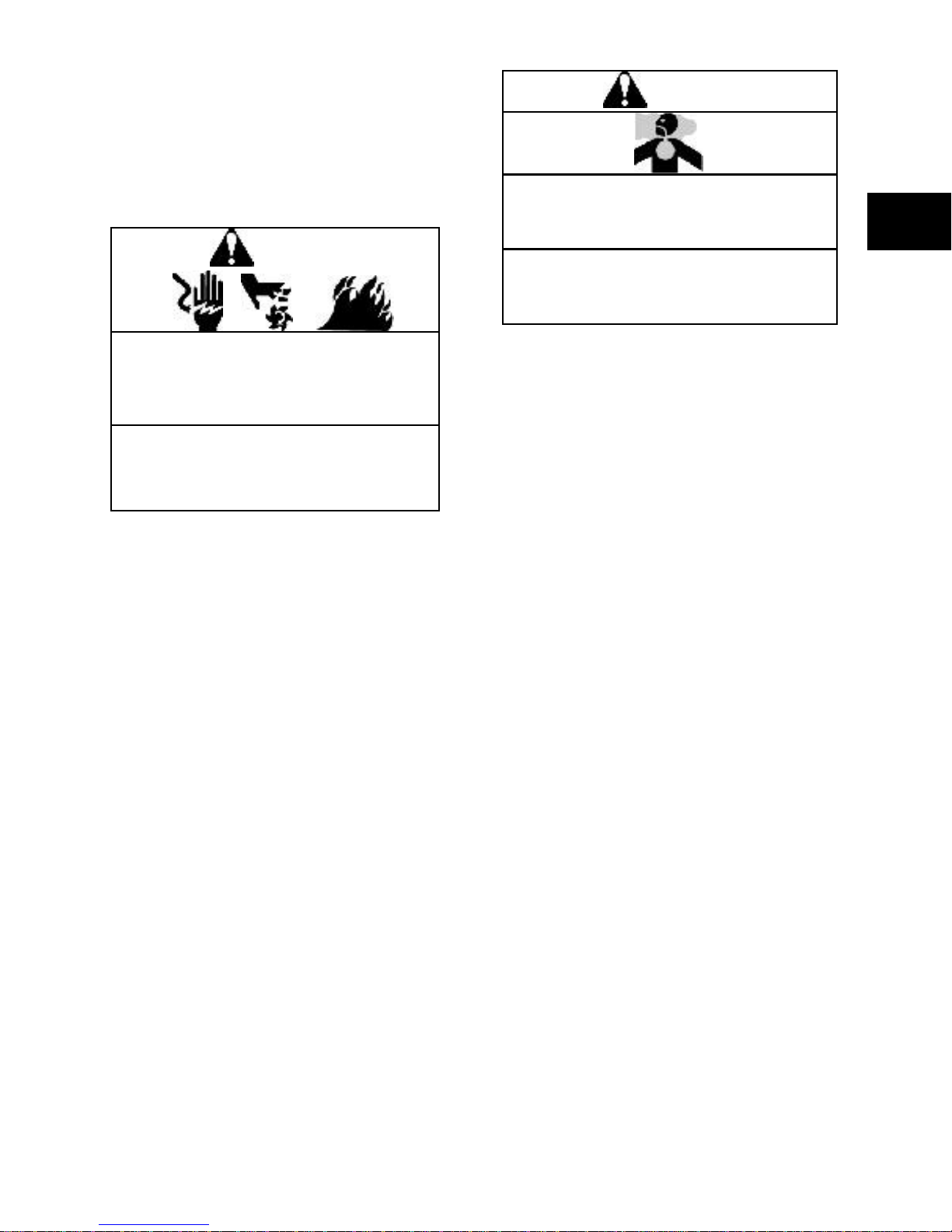

Explosion Fire Shock

Goggles Chemical Explosive

Burns Pressure

Kick Hot Entanglement

Back Surface

W AR NING

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

When adding fuel:

• Turn engine

least 2 minu tes before filling or refillin g.

• Fill fuel tank outdoors or in a wellventilated area.

• Do not overfill fuel tank. Fi ll tank to

approxi mately 1- 1/2 inches below top

of neck to allow for fuel expansion.

• Keep gasoline away from sparks, open

flames, pilot lights, heat and other

ignition sources.

Check fuel lines, tank, cap and fittings

•

frequentl y for cracks or leaks and

replace if necessary.

When starting engine:

• Make sure spark plug , muffler, fuel cap

and air cleaner are in place.

• Do not crank engine with spark plug

removed.

• If fuel spills, wait until it evaporates

befor e star ting engine .

If engine floods, set choke to

•

OPEN/RUN

and crank until engine starts.

FAST

When operating equipment:

Do not tip engine or equipment at an

•

angle which would cause fuel to sp ill.

Do not choke carburetor to stop

•

engine.

When transporting equipment:

• Transpor t with fuel tank empty or with

fuel shut-off valve set to OFF.

When storing gasoline or equipment with

fuel in tank:

and let engine cool at

OFF

position. Place throttle in

• Store away from furnaces, stoves,

water heaters or other appliances that

have a pilot light or other ignition

source because they can ignite

gasolin e vapors .

6

DANGER

Running engines p ro duce heat.

Temperatur e of muffler and surrounding

areas can exceed 150°F (65°C). Severe

burns can occur on contact.

Allow muffler, engine cylinder fins and

•

radiator to cool before touching.

• Remove accumulated combustib les

from m uffler area and cylind er are a.

• Install and maintain in working order a

spark arre stor before using equ ipment

on forest-covered, brush -covered

unimproved land. The state of

California requires this (Section 4442

of the Public Resources Code). Other

states may have similar laws. Federal

laws apply on feder al land.

DANGER

Engin es give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carb on monoxide can cause

nausea, fainting or death.

• Start and run engine out doors.

• Do not start or run engine in an

enclosed area, even if doors and

windows are open.

DANGER

Starting engine creates sparking. Spa rking

can ig nite nearby flammable gases.

Explosion and fire could result.

• If there is a natural or LP gas leakage

in the area, do not start engine.

• Do not use pressurized starting fluids

because vapors are flammable.

1

WARNING

Unintentional sparking can result in fire or

electric shock.

Unintentional start-up can result in

entang lement, t raumatic amputation or

severe lacerations.

Before performing adjustments or repairs:

Disconnec t spark plug wire and keep it

•

away from spark plug.

Disconnec t negative (-) battery

•

termin al.

When test ing for spa rk:

• Use approved spark plug tester.

Do not check for spark with spark plug

•

removed.

DANGER

Rotating parts can contact or entangle

hands, feet, hair, clothing or accessories.

Traumatic amputation or severe lacerations

can result.

• Operate equipment with guards in

place.

• Keep hands and feet away from

rotating parts.

Tie up long hair and remove jewelry.

•

• Do not wear loose-fitting clothin g,

dangling drawstrings or items that

could become entangled in the

equipment.

7

1

WARNING

Charging batteries produces hydrogen gas.

Do not store or charg e and battery near an

open flame or devices that utilize a pilot

light or can create a spark.

WARNING

Kerosene and its vapors are extreme ly

flammable and should be handled with the

same precautions as gasoline.

DANGER

Broken bones, fractures, bruise s or sprai ns

could re sult.

• Remove al l external equipment/engine

loads before starting engine.

• Direct-coupled equipment components

such as, but not limited to blades,

impeller s, pulleys and sprockets must

be securely attached.

WARNING

All f uel components should b e in good

conditio n and proper ly maintained.

• Repairs should only be made with

factory approved parts.

• Repair work should be done by a

qualified technici an.

• Flexible supply lines should be

checked regularly to make sure they

are in good condition.

8

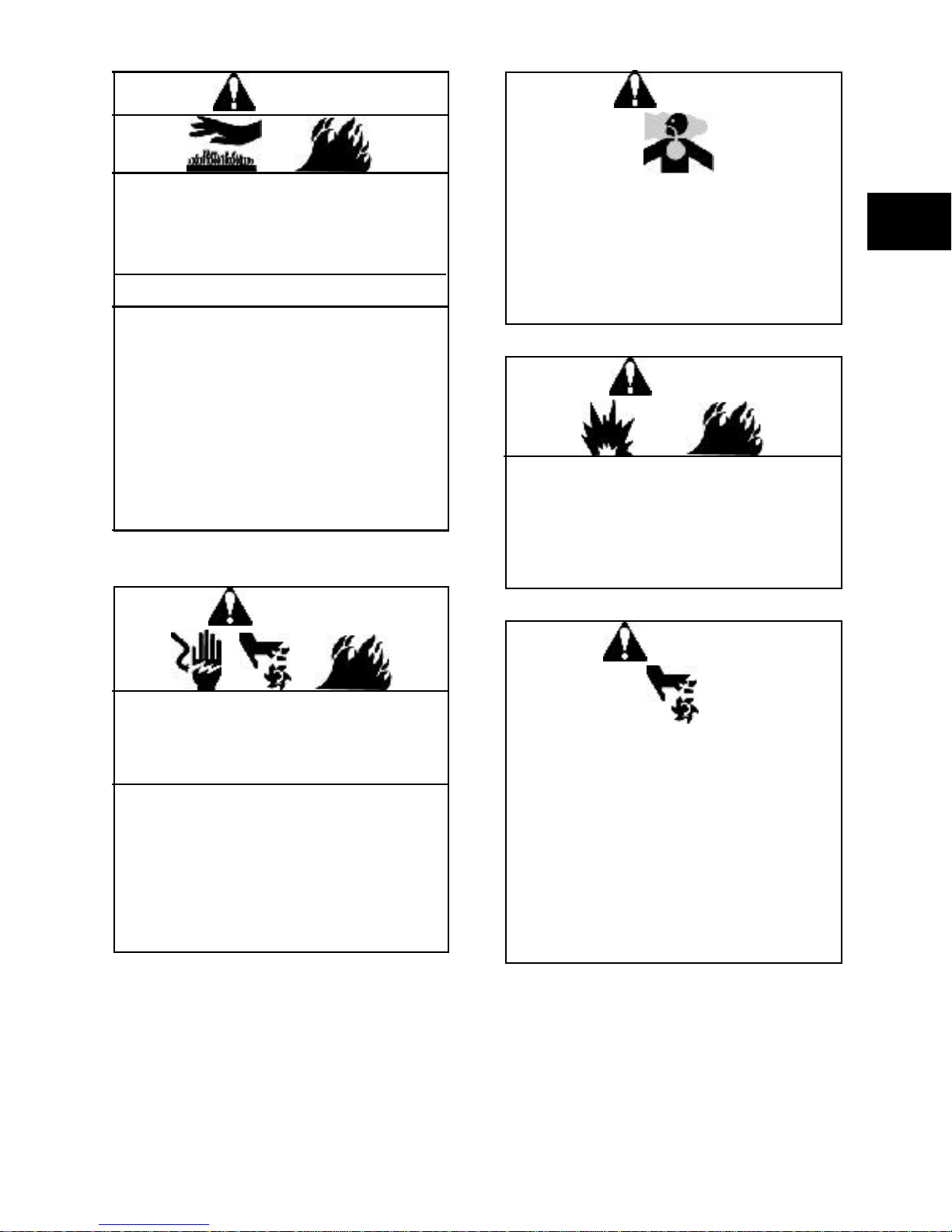

BRIGGS & STRATTON NUMERIC AL

IDEN TIFICATION SYSTEM

1

9

1

ENGI NE MAINTENANCE

Fu el and Oil Recommendations

Fuel

Fuel must meet these requirements:

• Use clean, fresh unleaded gasoline.

• A minimum of 87 octane / 87 AKI (91

RON). For high altitude use, see “High

Altitude” below.

• Gasoline with up to 10% ethanol

(gasohol) or up to 15% MTBE (Methyl

Tertiar y Bu tyl Eith er) is accepta ble.

CAUTION: Do not use unapproved gasoline

such as E85. Do not mix in gasoline or modify

the engine to run on alternate fuels. This will

damage the engine components and void the

engine warranty.

To protect the fuel system from gum formation,

mix a fuel stabilizer into the gasoline see

“Storage” below. All fuel is not the same.

If starting or performance problems occur:

• Change fuel providers or change brands.

High Altitude

At altitudes over 5000 feet (1524 meters), a

minimum of 85 octane / 85 AKI (89 RON)

gasoline is accepta ble. To remain emissions

compli ant, high al titude adjustm ent is r equire d.

Operati on w ithout this adjustment will cause

decreased perform ance, increased fuel

consumption and increased emiss ions.

At altitudes below 2500 feet (762 meters), high

alti tude adju stment i s not recommended.

Storage

Fuel can become stale when stored over 30

days. Stale fuel causes acid and gum deposits to

form in the fuel system and/or on essential

carburetor parts. To keep fuel fresh, use Briggs

& Stratton FRESH START™ (#5041) fuel

stabilizer, availabl e as a liquid additive or a drip

concentrate cartr idge.

There is no need to drain gasoline from the

engine before storage if fuel stabilizer is added

according to instructions. Run the engine for two

minutes to circulate the stabilizer throughout the

system. The engine and fuel can then be stored

for up to 24 mon ths.

If gasoline has not been treated with a fuel

stabilizer prior to storage, it must be drained from

the engine into an approved container. Run the

engine until it stops from lack of fuel. The use of

a fuel stabilizer in the storage container is

recommend ed to maintain freshness.

CAUTION: Some fuel, called “oxygenated” or

“reformulated” gasoline, is gasoline blended with

alcohol or eth er. Excessive amounts of these

blends can damage the fuel system or cause

performance problems. If any undesirable

operating sym ptoms occur, use ga soline with a

lower percentage of alcohol or ether.

Oil

Oil has four purposes:

• It cools

• It cleans

• It seals

• It l ubricates

During normal operation, small particles of metal

from the cylinder w alls, pistons, bearings as well

as normal combustio n deposits will gradually

contaminate the oil. Dust particles from the air

also contaminate the oil. This forms an abrasive

mixture that can cause wear to the internal parts

of the engine if the oi l is not changed regularly.

Fresh oil also assists in cooling. Old oil gradually

becomes thick and loses its cooling ability as

well as its lubricating qualities.

Use a high quality detergent oil classified “For

Service SF, SG, SH, SJ” or higher. Use synthetic

oil such as Briggs & Stratton (#100074) or

equivalen t. If synthetic oil is not available, Briggs

& Stratton non-synthetic 30 weight oil (#100005 or

#100028) is an acceptable substitute. Do not use

special additives with recommended oils.

Do not mix oil with gasoline.

10

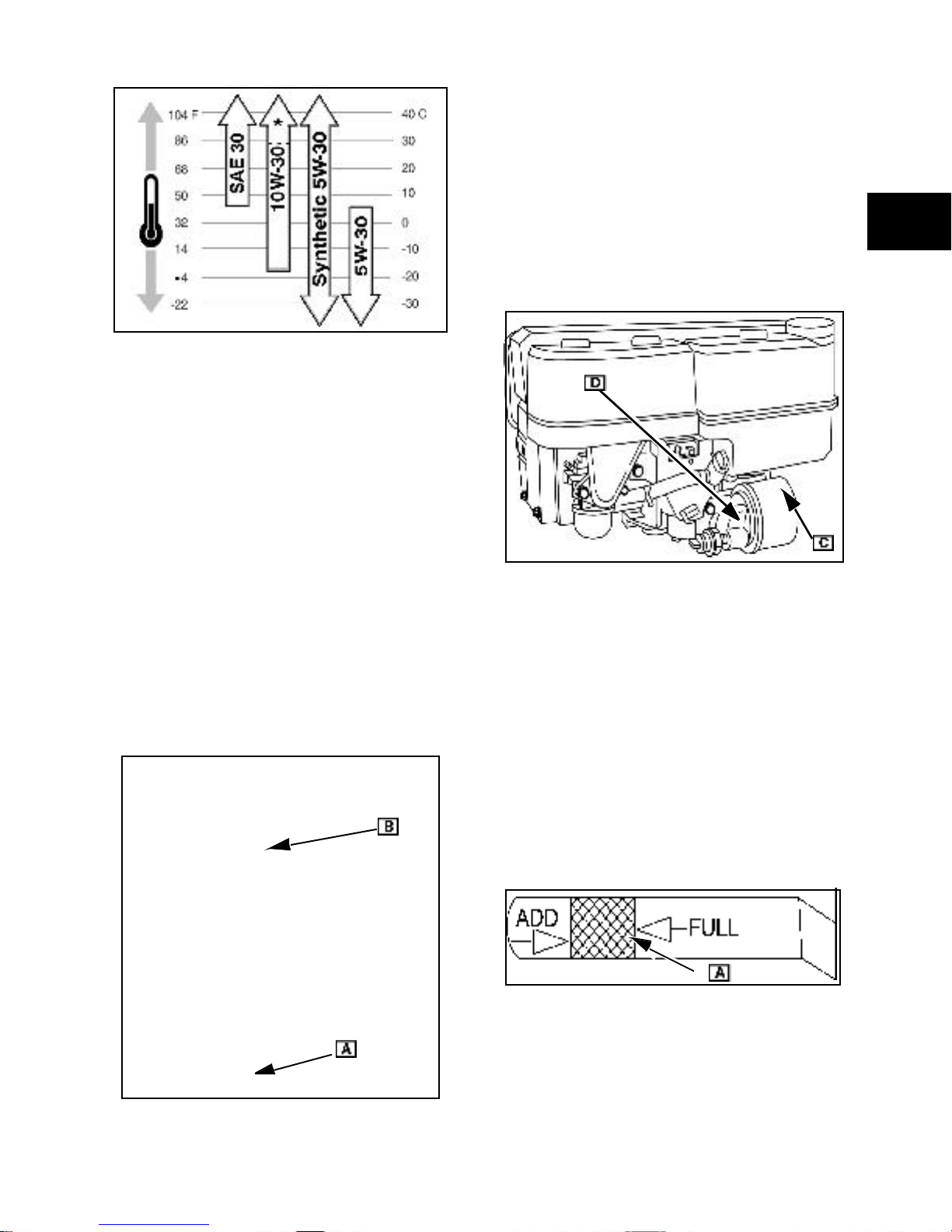

Fig. 1

CAUTION: The use of non-synthetic multi-

viscosity oils (5W-30, 10W-3 0, etc.) in

temperatures above 40°F (4°C) will result in

higher th an nor mal oil consumption. When using

a multi-viscosity oil, check oil level more

frequentl y. SAE 30 oil, i f used below 40°F (4°C),

will result in hard starting and possible engine

bore damage due to inadequate lubrication.

1. Park equipment so engine is level.

2. Remove oil drain plug ([A] Fig. 2).

• Dr ain oil while engine is still warm.

3. Install drain plug. Torq ue to value listed.

SEE SECTION 14- ENGINE SPECIFICATIONS.

4. Remov e oil filter ([ C] Fig. 3), if equipped.

• Clean surface of fi lter mounting adaptor

([D] Fig. 3).

• Apply light coa t of clean engine oil to new

filter gasket.

1

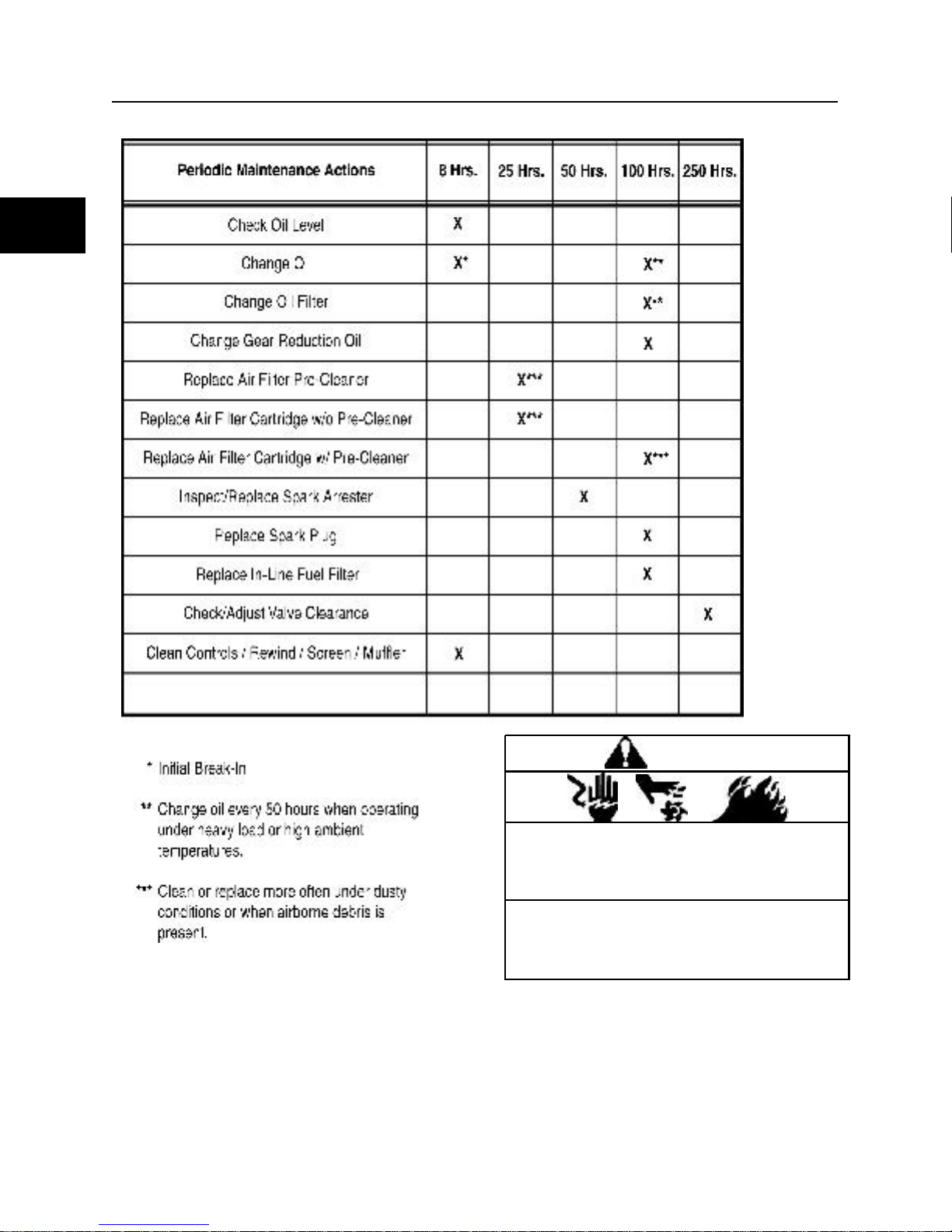

NOTE : The use of synthetic oils does not alter

the oil change intervals.

C hanging Oil

Change oil and filter (if equipped) after the first 58 hours. Thereafter, change oil every 100 hours

of operation.

Change oil mor e ofte n if engi ne is op erated in

dirty or dusty conditions or if engine is operated

under heavy loads and/or in high ambient air

temperatures.

Fig. 3

5. Screw filter on by hand until gasket

contacts oil fi lter mounting adapter. Then

tighten an additional 1/2 to 3/4 turn .

6. Clean area around oil fill cap and tube ([B]

Fig. 2).

7. Fill with the correct amount of new oil.

SEE SECTION 14- ENGINE SPECIFICATIONS.

Start engine and run at idle for a minute or so.

8. Shut engine off and wait for oil to settle

back into the cylinder.

9. Check dipstick. If necessary, add more oil

slowly to bring oil level to FULL mark ([A]

Fig. 4) on di pstick.

Fig. 4

Fig. 2

CAUTION: Do not overfill. Overfilling can cause

seals to fail or overheating due to oil foaming.

10. Replace oil fi ll cap and dipstick.

11. Start and run engine. Check for oil leaks.

11

1

MAINTENA NCE SCHEDULE

12

WARNING

Unintentional sparking can result in fire or

electric shock.

Unintentional start-up can result in

entanglement, traumatic amputation or

severe lacerations.

Before performing adjustments or repairs:

•

Disconnect spark plug(s).

• Disconnect negative (-) battery cable.

• Use only the correct tools.

Air Cl eaner Servic e

CAUTION: Never operate an engine with the air

cleaner assembly or air cleaner cartridge

removed.

A correctly serviced air cleaner protects internal

engine parts from airborne dirt and dust part icles.

If air cleaner instructions are not followed,

particles that should be collected in the air

cleaner will pass int o the engine. These particles

are abrasive and will cause the piston rings and

cylinder bore to wear more quickly. As the rings

and bore wear , th e particles enter the cyli nder

and contaminate the oil. This forms an abrasive

mixture that will erode and damage internal

engine compone nts.

Prevent dirt and dust from entering the engine

through improper sealing.

• Replace worn or damaged air cleaner

gaskets and seals.

• Replace air cl eaner mounting brackets if

bent or damaged.

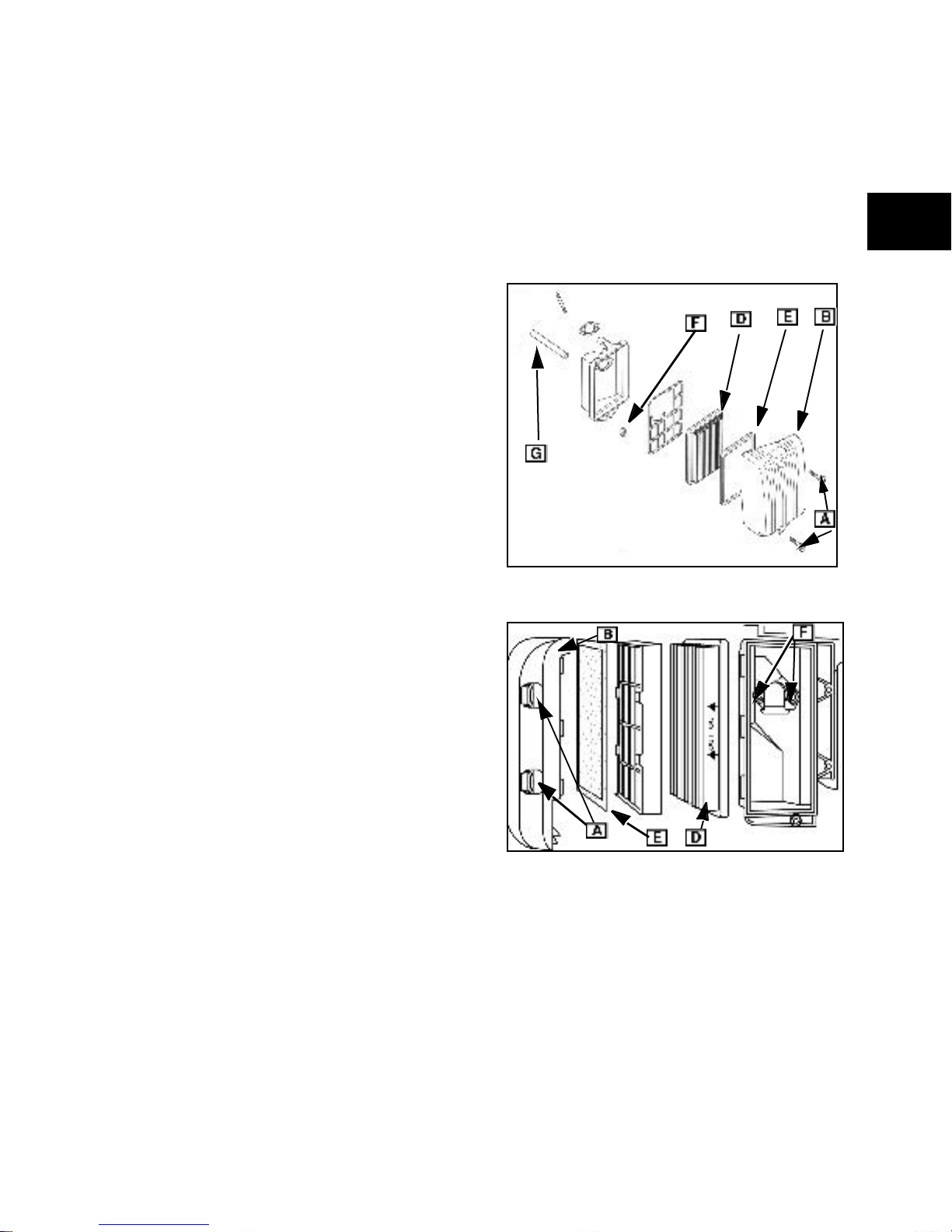

Remove Air Cleaner Assembly

1. Follow steps 1 through 3 listed previously.

2. Remove screws and nuts holding air

cleaner base (F) to carburetor and/or

control bracket.

3. Pull air cleaner base away from

carburetor.

4. Disconnect breather tube (G) from air

cleaner base or rocke r cover.

Fig. 5

1

Cle aning and Replacing Air Filters

Refer to Figures 5-10 that show the air cleaner

for your engine.

1. Loosen screws or knobs (A) holding air

cleaner cover in place and remove cover

(B).

2. Carefully clean debris f rom the base and

cover, then remove air filter element

retaining nut (C) (if equipped).

3. Lift off filter element (D ) with the pre-

cle aner (E) (if so equipped).

4. Wash pre-cleaner in warm soapy water.

5. Rinse and dry thoroughly.

6. Saturate pre-cleaner in fresh clean engine

oil and squeeze out excess. (Do not oil

pre-cleaners labeled DO NOT OIL. )

Replace pre-cleaner if no longer

serviceable.

7. Gently tap filter element on a solid surface

to dislodge debris. Replace filter element

if very dirty or damaged.

8. Reinstall pre-cleaner , element , retai ning

nut(s), cover and screws.

Fig. 6

CAUTION: Do not use pressurized air or

solvents to clean filter elements. Pressurized air

can damage elements and solvents might

dis solve fi lter mesh.

13

1

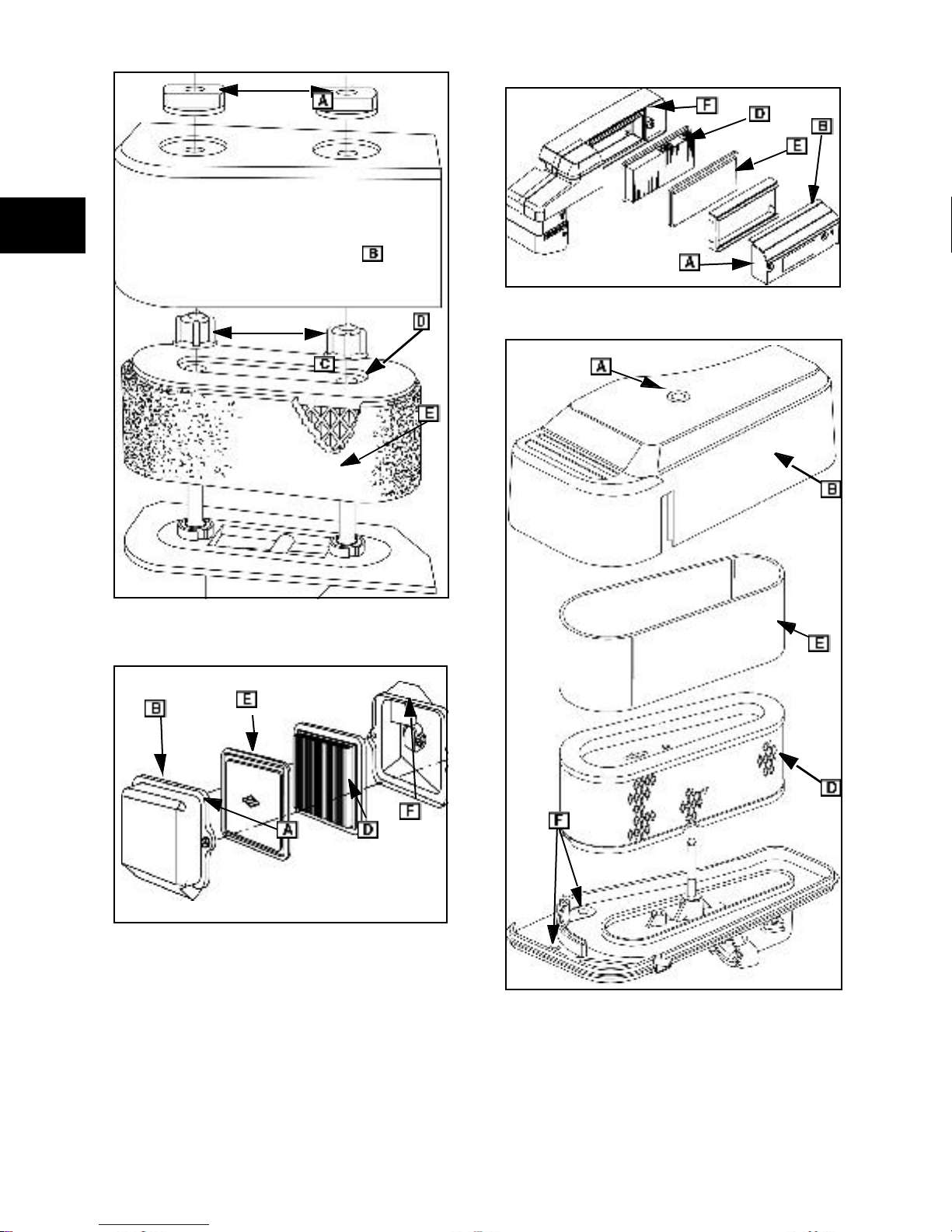

Fig. 9

Fig. 7

Fig. 8

14

Fig. 10

Install Air Cleaner Assembly

1. Connect breather tube to back side of air

cleaner base.

2. Position base (with new gasket) on

carburetor.

NOTE: Use new screws with sealant band or

place non-hardening sealant on mounting

screws.

3. Start screws into carburetor and tighten

securely.

4. Install air clean er element and/or precleaner.

In-Line Fuel Filter Service

Replace in-line fuel filter every year or 100 hours

of operation, whichever occurs first. Replace the

filter if dirt or water are present. Refer to the

correct illustrated parts list (IPL) that applies to

your engine for the correct filter.

ENGINE ADJUSTMENTS

Armatu re Air Gap Adju stments

1. Rotate flywheel until magnets are away

from armatu re.

2. Loosen both armature mounting screws

(A) and pull armature away from flywheel.

3. Snug one screw.

4. Insert the proper thickness gauge ([B] Fig.

11) between armature and flywheel.

SEE SECTION 14- ENGINE SPECIFICATIONS.

5. Turn flywheel. Loos en screws and allow

the magnets to pull armature against

thickness gauge ([B] Fig. 11).

6. Tighten screws to listed values. See on

page 255.

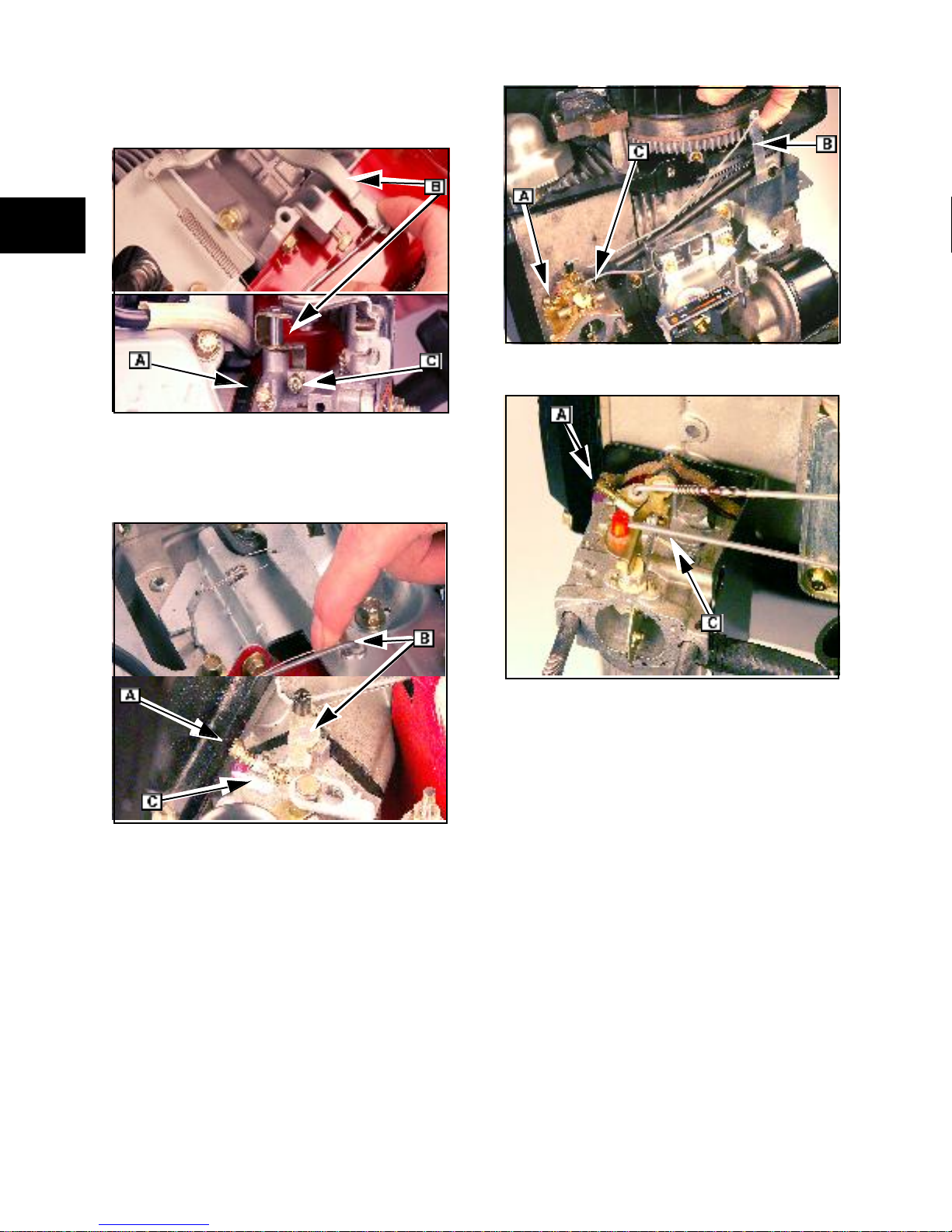

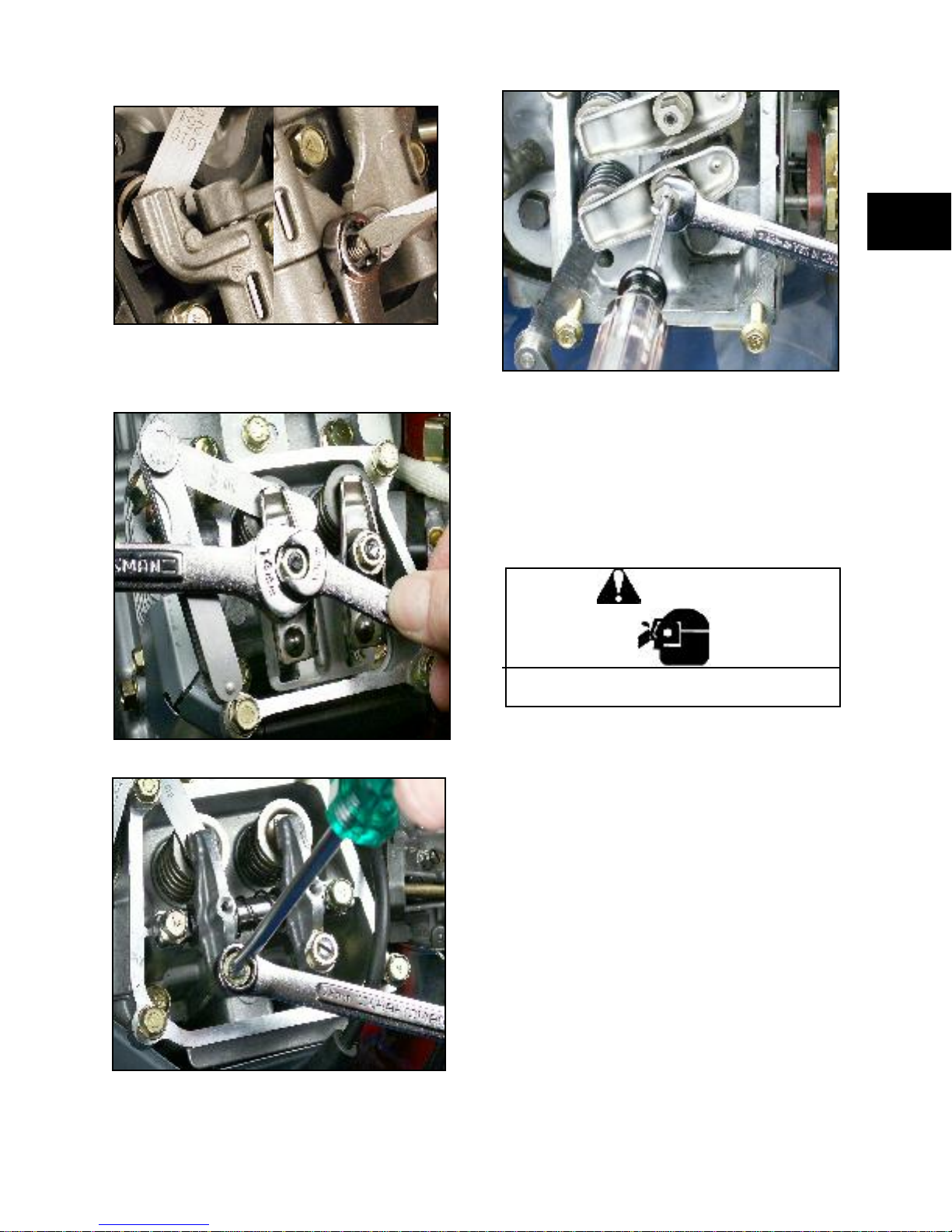

C arburetor Idle-Mixture Adjustments

Initial Mixt ure Adjustmen t

Refer to the figure that shows your engine.

1. Turn the idle mixture screw ( [A] Fig. 12) in

until you feel it just make contact with the

seat.

2. Back the idle mixture screw out 1-1/4

turns.

3. Start the engine and let run at half throttle

for 5 minutes to bring it up to operating

temperature.

1

Fig. 11

Adjusting Idle Mixture RPM

Refer to the figure that shows your engine.

NOTE: Parts removed for clarity.

1. Move throttle to SLOW.

2. While holding the speed control lever (B)

against the idle speed screw, ad just the

idle speed screw (C) to obtain 1750 RPM,

except as noted for the following models:

• Model 104700: 1500 RPM

• Models 161400, 260700, 261700: 1200

RPM

• Models 085400, 086400, 115400,

117400, 118400, 185400: 1300 RPM

3. Turn idle mixture screw ( A) clo ckwise

(CW) until the engine just begi ns to slow.

4. Turn idle mixture screw counterclockwise

(CCW) until the engine just begins to

slow.

15

1

5. Turn idle mixture screw back to midpoint

and release the speed control lever.

6. Install limiter cap (if equipped) using

knockout pin (#19135).

Fig. 14

Fig. 12

NOTE: (138400) Does not have an idle

adjus tment scr ew.

Fig. 13

Fig. 15

7. Move speed control from SLOW to FAST.

If the engine does not accelerate smoothly:

• Adjust idle mixture screw 1/ 8 turn CCW.

8. Check idle RPM and readjust to

specifica tions, i f req uired.

C ontrol Adjustme nts

Throttle Control

(050000, 085400, 086400, 115400, 117400,

118400, 138400, 185400, 235400, 245400,

28Q700)

The throttle controls on these units are

interco nnected with th e gover nor linkage system.

SEE SECTIO N 6- GOVERN OR SYSTEMS.

16

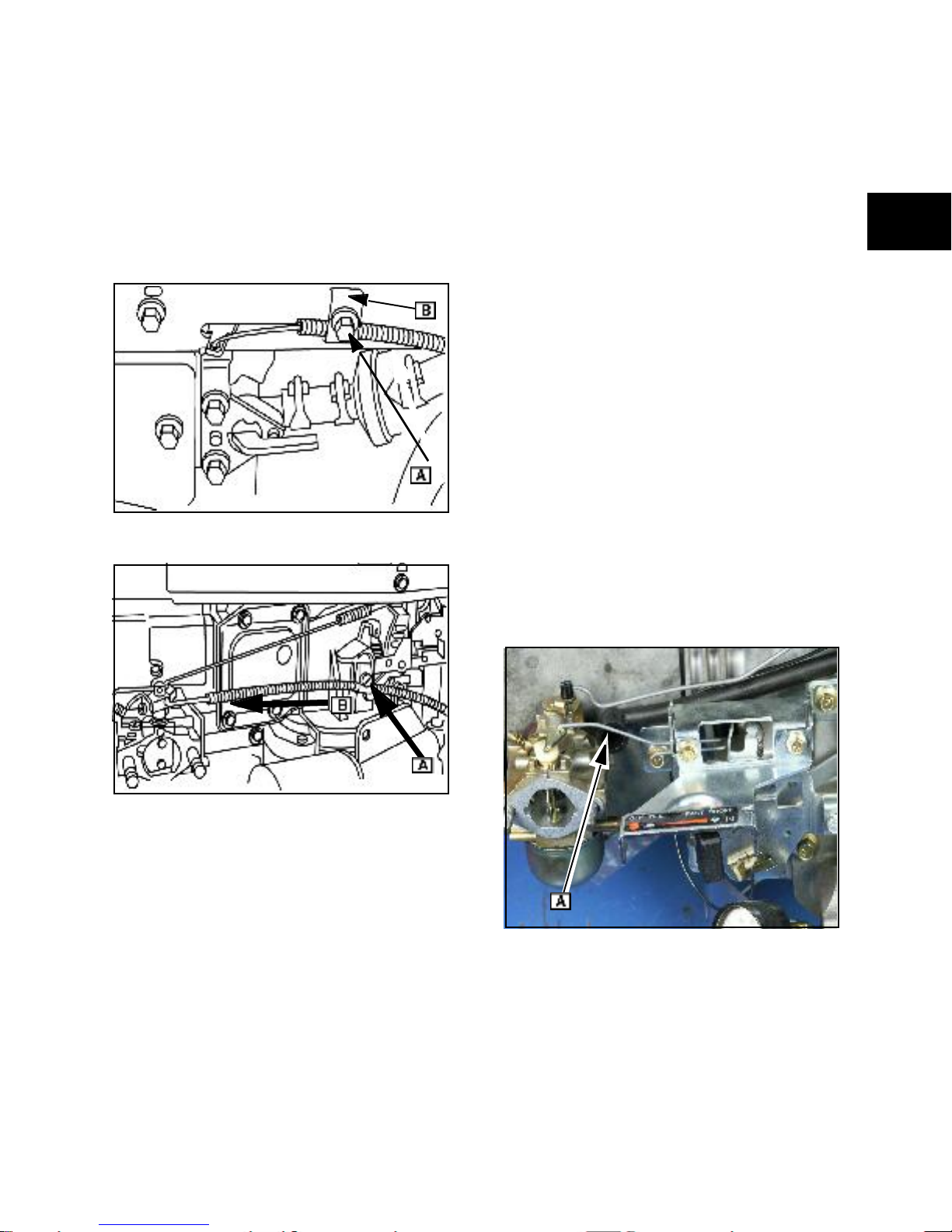

Throttle Control

(161400, 104700, 260700, 261700)

Refer to Figures 16 and 17 that show your

engine.

1. Loosen casing clamp screw (A).

2. Move throttle to FA ST .

3. Move casing in direction of arrow (B) until

casing stops.

4. Tighten casing clamp screw.

Fig. 16

Choke-A-Matic®

(104700, 161400, 2607 00, 261700,

28Q700)

Choke control cables are often provided by the

original equipment manufacturer. Please refer to

the i nformation provided by the OEM when this

general description is not sufficient to adjust the

choke control.

1. Loosen choke control casing clamp screw

on engine control panel or gove rnor

control bracket.

2. Move choke control l ever or kno b to

CHOKE.

3. Move choke control casing in the direction

that completely closes the choke valve.

4. Tighten the casing cl amp screw.

Choke-A-Matic® Adjustments (161400)

Refer to the figure that shows your engine.

1. Move thrott le control to FAST. The end of

the choke link should contact the end of

the choke lever slot. To adjust, expand or

contract loop (A ) in the choke link.

2. Move equipment control lever to CHOKE.

The choke plate must be closed. Readjust

as req uired.

1

Fig. 17

Choke Co ntrol

(050000, 085400, 086400, 115400, 117400,

118400, 138400, 185400, 235400, 245400)

The choke on these models has a separate

manual contr ol.

Ensure that the choke valve is completel y open

or closed when the control is moved through its

range of m otion.

Fig. 18

17

1

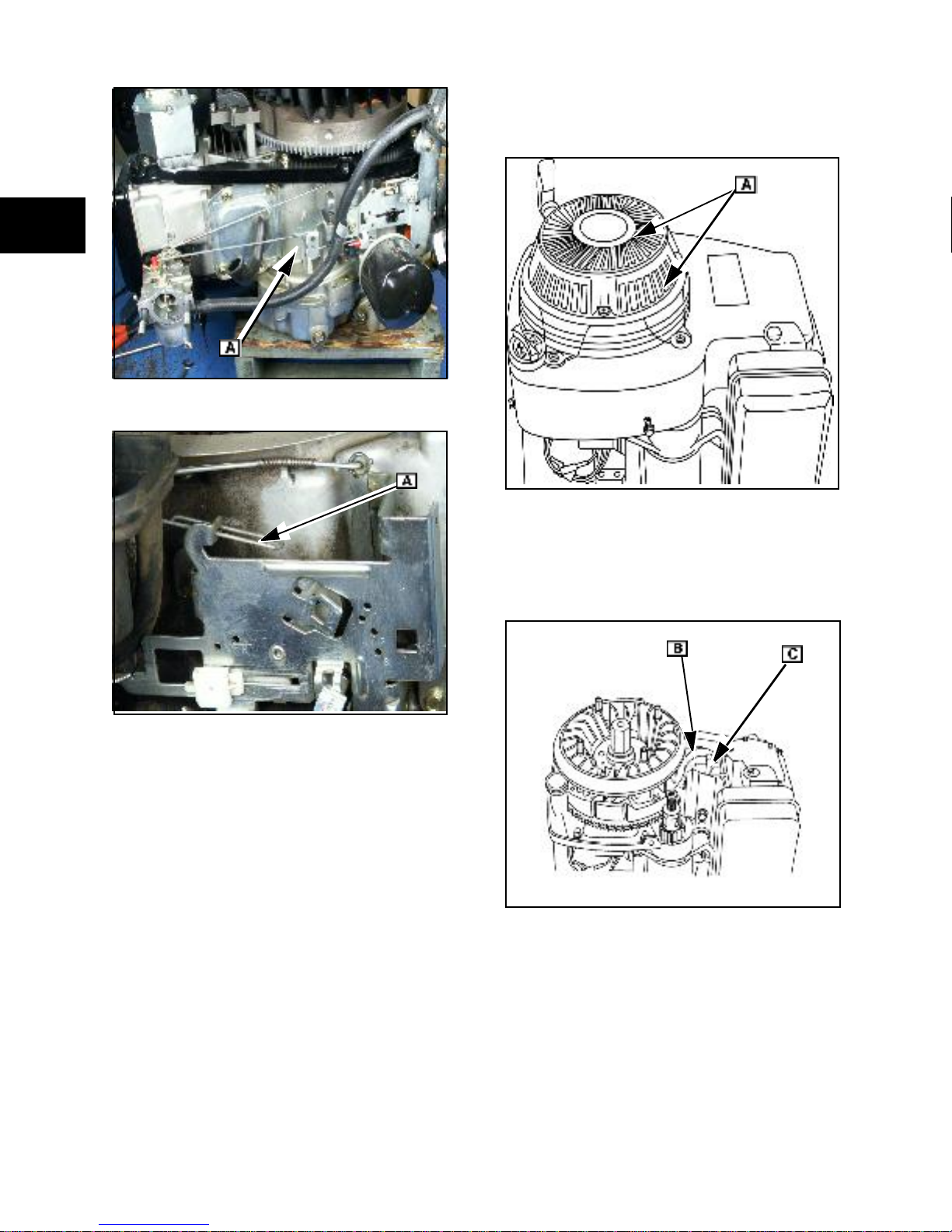

Clean the static screen ([A] Fig. 21)

.

Fig. 19

Fig. 21

Clean the ducting (B) and cylinder fins ([C] Fig.

22), yearly or every 100 hours of operation. Clean

more often when dust or airborne debris is

present.

Fig. 20

C ooling System Maint enance

CAUTION: Keep engine parts clean to reduce

the risk of overheatin g and ignition of

accumulated debris.

Do not use water to clean engine. Water could

contaminate fuel system and short out electrical

systems. Low pressure (5-10 psi.) compressed

air may be used.

Grass partic les, chaff, or dirt can clog the air

cooling system, especially after prolonged

service in very dusty conditions or when cutting

dry grass. Continued operatio n with a clogged

cooling system can cause severe overheating

and possible engine damage.

18

Fig. 22

Fly wheel Brake Adjustments

(104700)

The flywheel brake system is part of a safety

control mechan ism required by some equipment

applications. When the operator releases an

equipment control (bail) with the engine running

at theFAST selection, the flywheel brake must

stop the engine within 3 seconds.

WARNING

DANGER

Engines give off carbon monoxi de, an

odorless, colo rless, poison gas.

Breathing carbon monoxide can cause

nause a, fain ting or d eath.

• Start and run engine outdoors.

• Do not start or run engine in an

enclosed area, even if doors and

windows are open.

1

Unintentional sparking can result in fire or

electric shock.

Unintentional start-up can result in

entang lement, t raumatic amputation or

severe lacerations.

Before performing adjustments or repairs:

Disconnec t spar k plu g(s).

•

• Disconnect negative (-) battery cable.

• Use only the correct tools.

Using torque wrench#19393 and a socket to fit

the flywheel nut, turn the flywheel clockwise

( CW) with the brake engaged. Turning at a

steady rate, the torque reading should be the

listed value. SEE SECTION 14- ENGINE

SP ECIFICA TIONS.

If the reading is low:

• Check the thickness of the brake pad.

• Replace brake lever and pad if the brake

pad thickness is less than0.090 in.

(2.29mm).

If the pad is with in specification:

• Adjust the control cable casing anchor to

posi tion the pad closer to the flywheel

when the safety control is in RUN.

If correct adjustment cannot be made:

• Replace the brake assembly.

Governor Adjustments

CAUTION: C omplete the governor static

adj ustment before starting or r unning engin e.

In correct adjustment could result i n engine overspeedi ng causing engine damage.

NOTE: (161432-0080-01,161430-0199-01,

185430-0099-01, 185430-0140-01, 1854300299-01) These engine models are equipped

with governors supplie d by equipment

m anufacturers. Consult with the OEM for service

procedures on these model/types.

A complete governor system adjustment

includes t he following:

1. A static governor adjustment.

2. Engine warm-up.

3. Idle and/or governed idle adjustment.

4. Top no-load RPM adjustment.

In stall all linkages and springs before performing

static governor adjustments. Refer to the

illustration that matches the governor system on

your engine.

NOTE: (050000, 085400, 086400, 115400,

117400, 118400, 138400, 185400, 235400,

245400) These models have left hand threads

on the governor lever nu t.

Static Governor Adjustment

(050000, 085400, 086400, 115400, 117400,

118400, 138400, 185400, 235400, 245400)

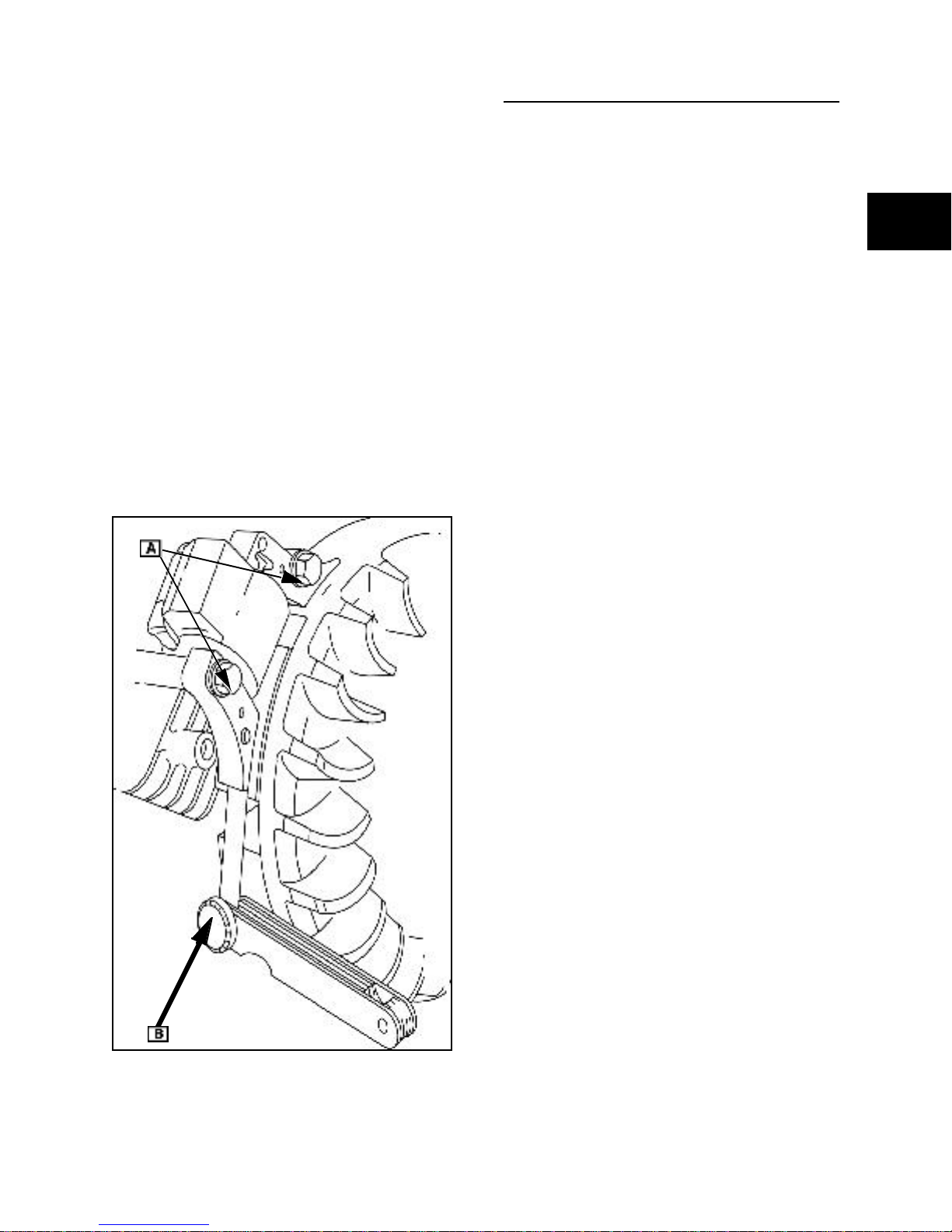

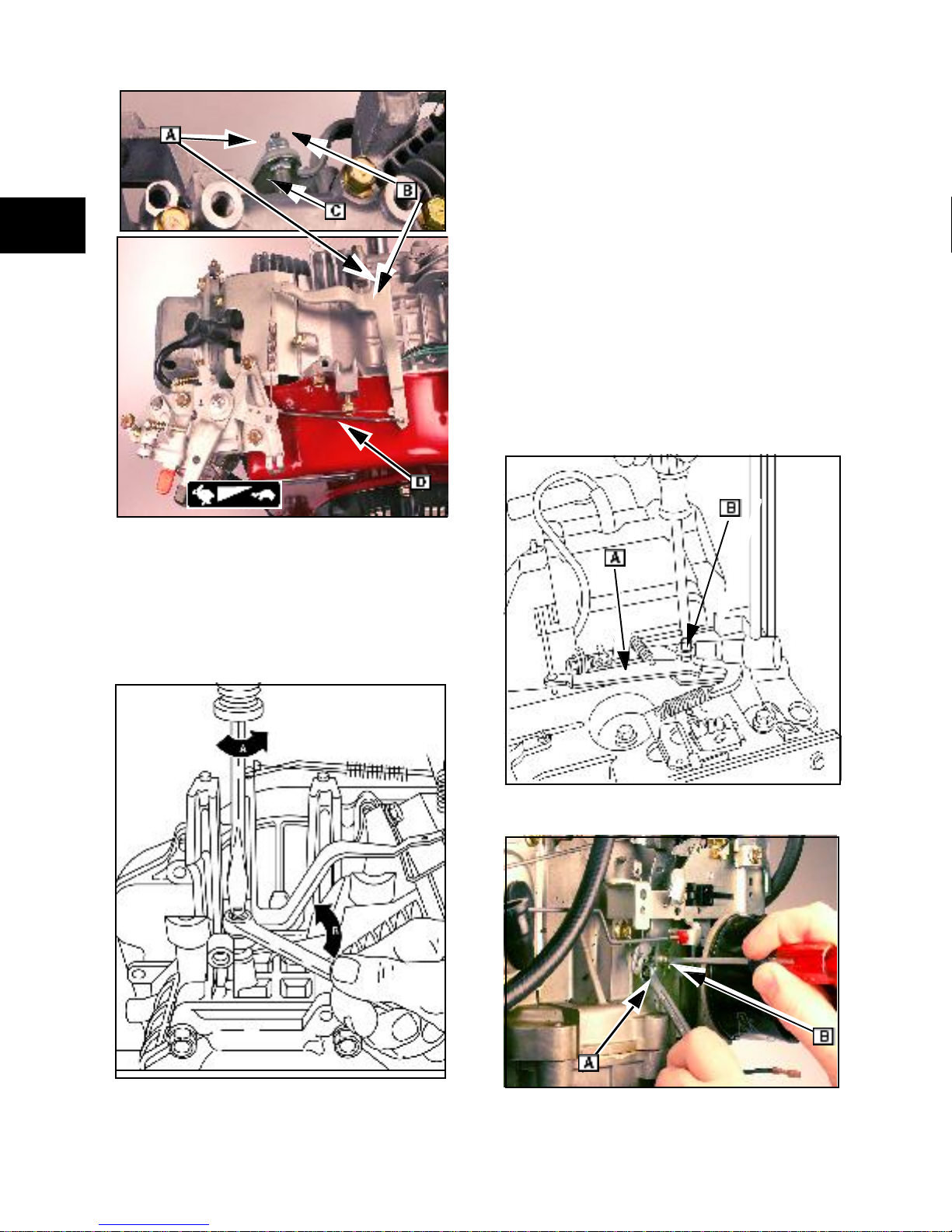

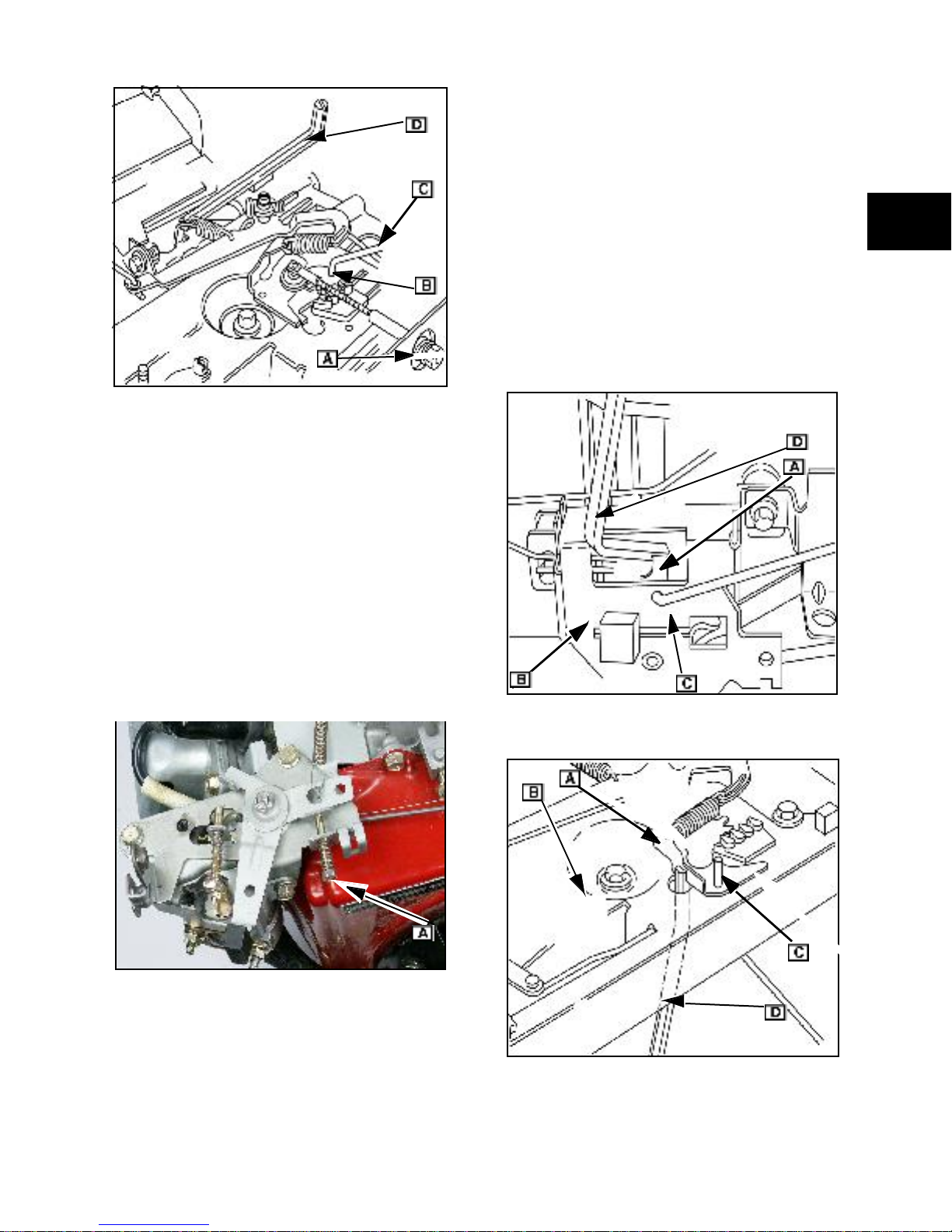

1. Loosen lock nut (A) holding governo r lever

(B) to governor crank ([C] Fig. 23).

2. Rotate thro ttle plate linkage from IDLE to

WOT(Wide Open T hrottle). Note direction

of rotation of the governor lever (B)

attached to the throttle linkage ([D]

Fig.23).

3. Place and hold the throttle plate linkage in

FAST position.

19

1

Static Gover nor Adjustment

(161400, 104700, 260700, 261700, 28Q700)

1. Loosen nut holding governor l ever ([A]

Fig. 25) to governor crank.

2. Rotate thr ottle linkage from idle to wide

open throttle. Note the direction of rotation

of the governor arm attached to the

throttle linkage.

3. Place and hold the throttle in high speed

position.

4. While holding the throttle plate, rotate the

governor shaft ([B] Fig. 25) until it stops in

the direction noted in step 2.

5. While holding the governor shaft, torque

the governor lever nut to listed value.

SEE SECTION 14- ENGINE SPECIFICATIONS.

Fig. 23

4. Rotate the governor shaft in direction

noted in previous step, until it stops.

5. While holding governor crank, torque the

governor lever nut (left hand

thread)(Fig.2.)

Fig. 25

Fig. 24

20

Fig. 26

Fig. 27

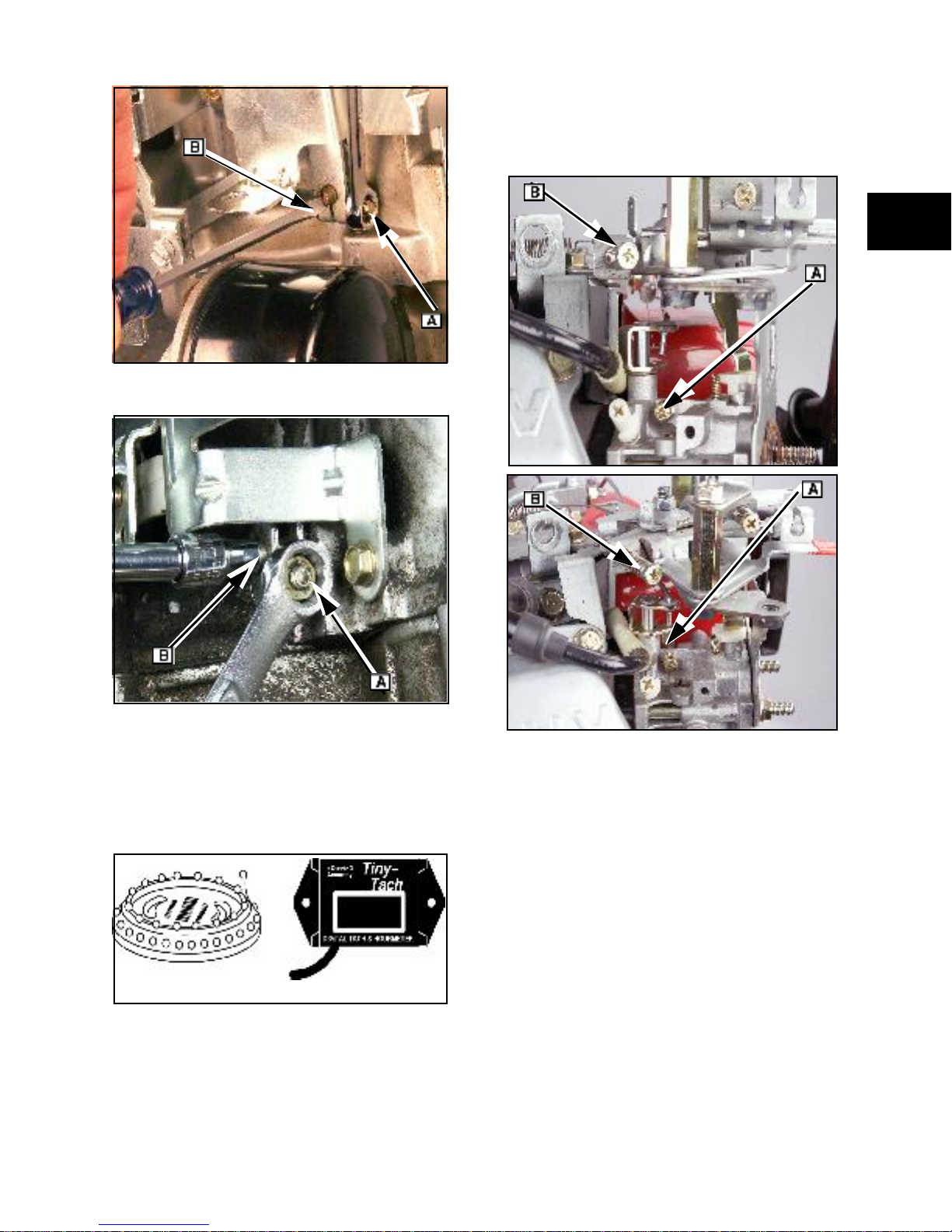

3. With the carburetor idl e speed screw (A),

adjust RPM to 1200 RPM.

4. With gover ned idle screw ([ B] Fig. 30),

adjust RPM to 1400 RPM.

1

Fig. 28

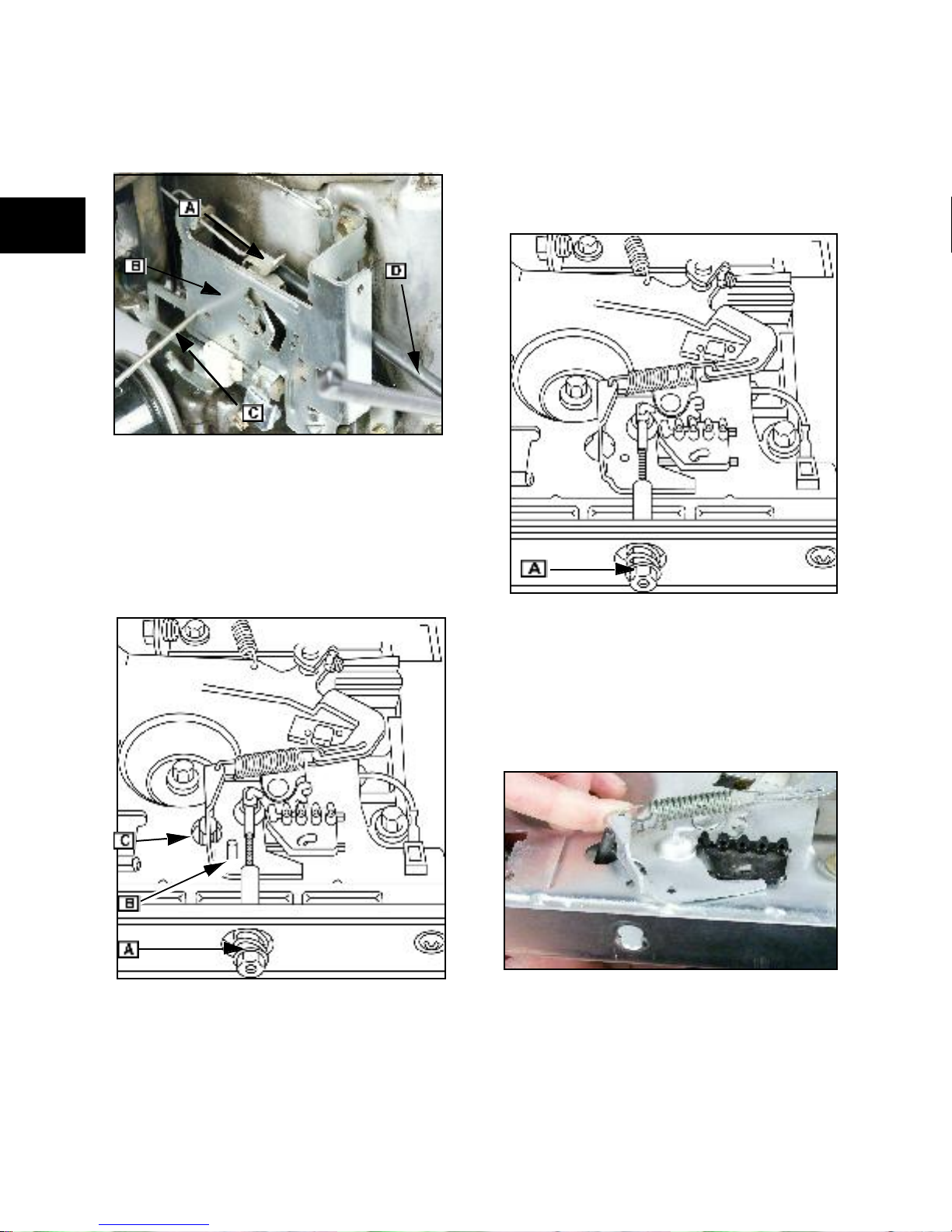

Governed Idle Spe ed Adjustments

(085400, 086400, 115400, 117400, 138400,

185400, 235400, 245400)

Recommended tools:

#19200 #19389

Fig. 29

1. Start and run engine at 1/2 throttle for 5

minutes to bring engine to operating

temperature.

2. Move throttle to SLOW.

Fig. 30

NOTE: (050000, 118400, 28Q700) Do not

have a Governed Idle Speed adjustment.

21

Go verned Idle RPM Adjustments

(161400, 260700, 261700)

5. Remove rod ([C] Fig. 33 through Fig. 35).

1

#19480 or #19229

Fig. 31

Install all linkages and sprin gs and be sure that

all carburetor adjustments have been made

before performing any of the running governor

adjustments. To find the correct top no load RPM

by model-type number, log into

thepowerportal. com//repower.

NOTE: (104700) Does not have a governed

idle adjustment.

Early production versio ns of 260700 and 261700

had governor levers with three spring anchor ing

slots. Position spring in middle slot.

Fig. 33

Fig. 32

Refer to figure that shows your model.

1. Start and run engine at 1/2 throttle for 5

minutes to bring engine to operating

temperature.

2. Move throttle to SLOW.

3. Align holes in the governor control lever

gear (A) and governor contro l plate ([B]

Fig. 33 through Fig. 35) Insert 0.125 in.

(3.2 mm) diameter rod (C).

4. Using tang bender tool (D), bend

governed idle speed tang to obtain 1400

RPM .

22

Fig. 34

Governed Idle RPM, Fixed Speed Adjustable

(161400 - No Generators)

1. Start and run engine at 1/2 throttle for 5

minutes to bring engine to operating

temperature.

2. Turn speed regulator nut (A)

counterclockwise (CCW) to align idle

speed holes (B) in governor control lever

gear with governor control plate.

3. Insert 0.12 5 in. (3.2 mm) diameter rod ([C]

Fig. 35).

Fig. 35

4. Using tang bender tool ([D] Fig. 35), bend

governed idle spring tab to obtain 1400

RPM .

5. Remove rod.

• Some units may have remote throttles

furnished by the OEM.

1. Move throttle to FA ST .

2. Align holes in the governor control lever

gear (A) and governor contro l plate ([B]

Fig. 37 or Fig. 38).

3. Insert 0.12 5 in. (3.2 mm) diameter rod ([C]

Fig. 37 or Fig. 38).

NOTE: (104700) Alignment holes on early

productio n m odels were 0.062 in. (3.2 mm).

4. Using tang bender tool (D), bend spring

tab (or turn adjustment screw) to obtain

proper top no load RPM.

59

1

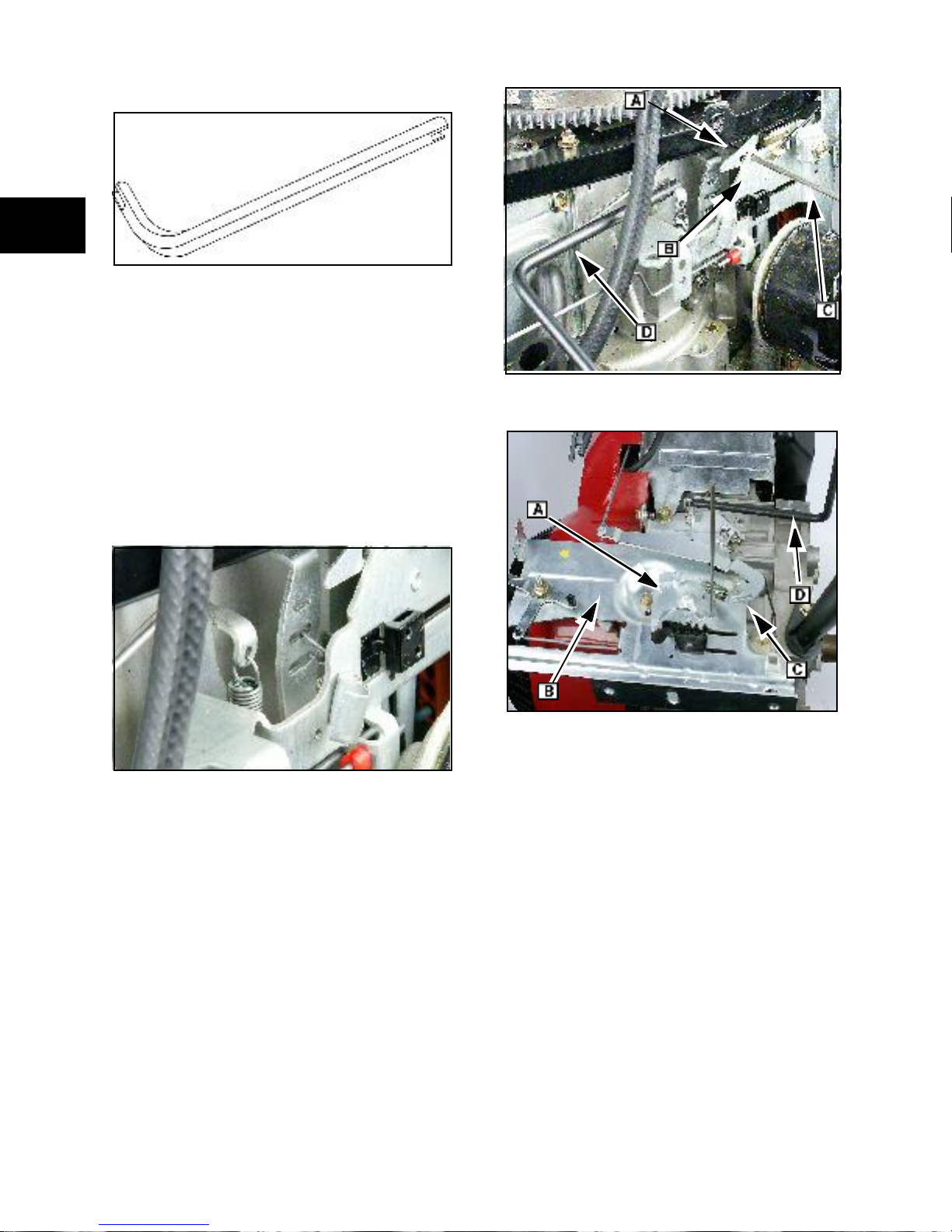

Top No Load RPM Adjus tments

(050000, 085400, 086400, 115400, 117400,

118400, 138400, 185400, 235400, 245400)

1. Start and run engine at 1/2 throttle for 5

minutes to bring engine to operating

temperature.

2. Move throttle to FA ST .

3. Adjust top no load limiting s crew ([ A] Fi g.

36) to obtain proper no load RPM.

Fig. 36

Fig. 37

Top No Load RPM Adjus tments

(104700, 161400, 260700, 261700, 28Q700)

• Refer to the figure that shows your

model.

Fig. 38

5. Remove rod.

23

1

Top No Load RPM, Fixed Speed

Adjustable

(161400 - No Generators)

Fig. 39

1. Turn speed regulator nut (A) clockwise

(CW) to align top no load holes in

governor control lever gear and governo r

control plate.

2. Insert 0.12 5 in. (3.2 mm) diameter rod ([B]

Fig. 40).

Top No Load RPM, Fixed Speed Adjustable

(161400 - Generators)

1. Turn the speed regulator nut ([A] Fig. 41)

until the desired top no load speed is

achieved.

Fig. 41

63

Fig. 40

3. Using tang bender tool ([C] Fig. 40), bend

governor spring tang to obtain proper top

no load R PM.

4. Remove rod.

Pre-Load RPM, Fixed Speed Adjustable

(161400 - Generators)

1. Push in and up on speed regulator nut to

disengage from notch in control panel.

2. Start and run engine at 1/2 throttle for 5

minutes to bring to operating temperature.

Fig. 42

3. Push the governor control all the way to

the end of its travel and hold it there.

4. While holding the governor control, (Fixed

Speed Regul ator rod removed for

24

clarity)use the tang bender ([A ] Fig. 42) to

obtain proper pre-load speed.

5. use the tang bender ([A] Fig. 42) to obtain

proper pre-loa d spee d.

6. As soon as pre-load RPM is set, move

throttle toIDLE.

7. Stop engine.

8. Engage speed regulator nut back into

notch in the control panel.

Top No Load RPM:

• 3150 RPM (50 cycles)

• 3750 RPM (60 cycles)

Pre Load RPM:

• 4000 RPM (50 cycles)

• 4300 RPM (60 cycles)

1

Fig. 43

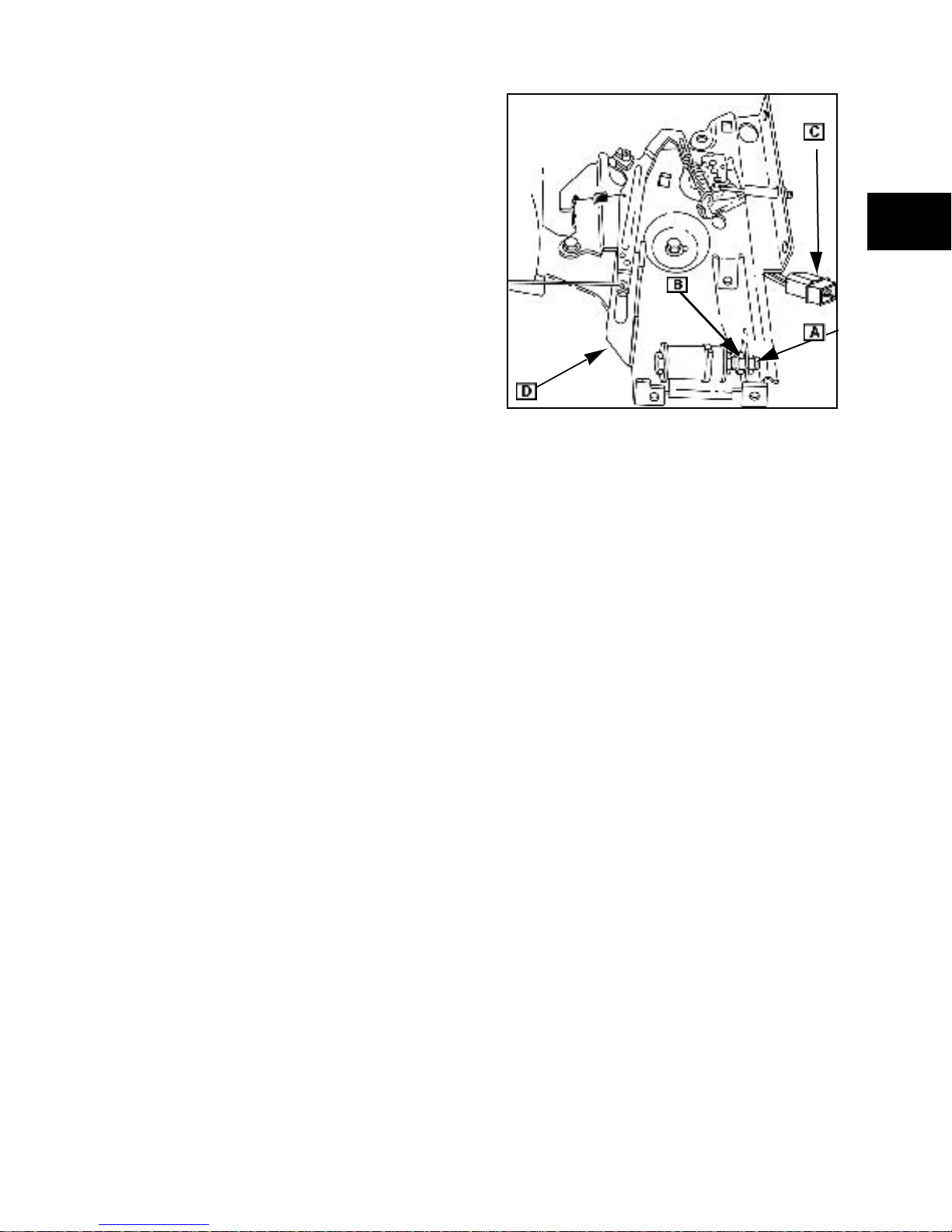

Elec tro-Magnetic Idle Down

A djustments

NOTE: Governed idle speed and top no-load

speed must be properly set before adjusting the

electro-ma gneti c i dle down.

Electro-Magnetic Idle Down (161400)

1. Loosen both adjusting nuts ([A] and [B]

Fig. 43). Then, un screw nut (A) until flush

with end of bolt.

2. Start and run engine at 1/2 throttle for 5

minutes to bring engine up to operating

temperature.

3. With the engine running, apply 12VDC to

connect or (C). Extended governor lever

([D] Fig. 43) will be pulled against head of

idle bolt.

4. Adjust nut (A) to obtain 2300 RPM.

Remove 12VDC from connector.

5. Hold nut (A) and idle down control in

position. Tighten nut ([ B] Fig. 43.)

6. Reapply 12VDC to connector to check

electro-mag netic action and engine RPM.

Readjust as necessary.

Elec tro-Magnetic Idle Down

(115400, 117400, 1184 00, 185400,

235400, 245400, 246400)

1. Loosen both adjusting nuts ([A] and [B]

Fig. 44). Then, un screw nut (A) until flush

with end of bolt.

2. Start and run engine at 1/2 throttle for 5

minutes to bring engine up to operating

temperature.

25

1

3. With the engine running, apply 12VDC to

white conn ector with the blue

wir es([ C]Fig. 44). Extended governor will

be pulled against head of idle down bolt.

([C]Fig. 44).

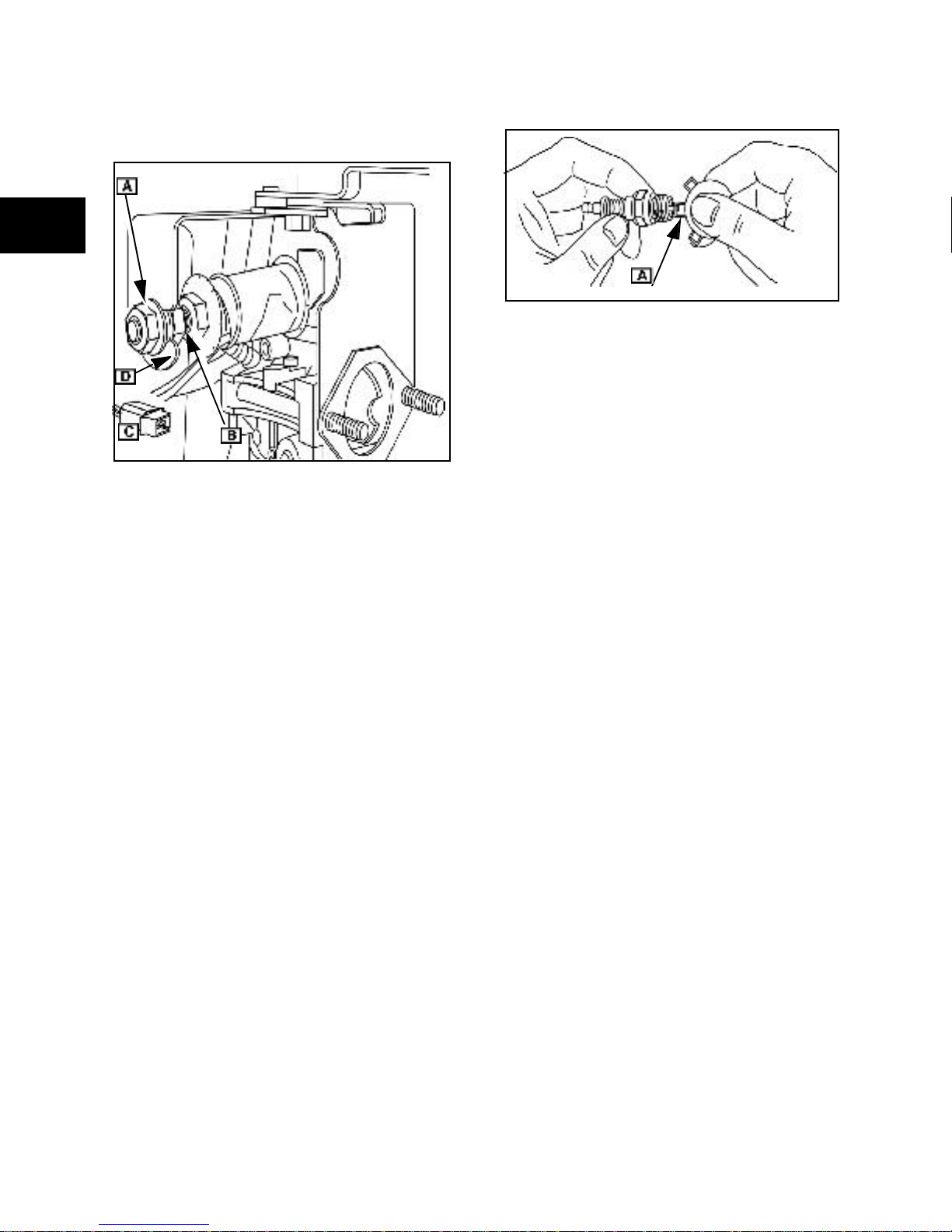

Use a wire gauge ([A] Fig. 45) to set the spark

plug gap.

Set spark plug gap at listed value.

Fig. 45

Torque spark plugs to li sted value.

SEE SECTION 14- ENGINE SPECIFICATIONS.

Valve Clea rance Adjustments

Fig. 44

4. Adjust nut ([A] Fig. 44) to obtain 2100-2500

RPM .

Use the lowest RPM in this range that the

electro -magne t will hold reliably. Remove 12 VDC

from connector.

5. Hold nut and idle down control in this

position and tighten nut ([B] Fig. 44) to

listed val ue.

SEE SECTION 14- ENGINE SPECIFICATIONS.

6. Re-apply 12VDC to connector to check

electro-mag netic action and engine RPM.

Re-adjust, if necessary.

Spar k Plug Maintenance

Replace Spark Plug

Replace spark plug every year. Replace spark

plugs if electrodes are burned away, or the

porcelain is cracked.

NOTE : Local laws may require the use of a

resistor spark plug to suppre ss ignition signals. If

an engine was originally equipped with a resistor

spark plug, replace it with the same type of spark

plug .

Adjust Valve Clearance

Valve clearances should al ways be adjusted on

a cold engine.

1. Remove the valve cover.

2. Rotate the crankshaft in the normal

direction until you get to TDC (Top Dead

Center) of the compression stroke.

3. Insert a narrow indicator (screwdriver or

small rod) into the spark plug hole against

the piston to indicate piston movement.

4. While watching the indicator, rotate

crankshaft clockwise (C W) past TDC until

piston is 0.25 in. (6mm) down from TDC.

This is to prevent the compression

release (if equipped) from affecting

adjustments.

5. Loosen the jamb nut on the rocker arm.

For correct clearance dimensions see page 255.

6. Insert the proper feeler gauge. While

moving it back and forth, carefully tighten

the adjustment screw u ntil a slight amount

of resistance is fe lt on the feeler gauge.

Do not blast-clean spark plugs. Spark plugs

should be cleaned by scraping or hand wire

brushin g and washing in a commercial solvent.

26

7. Tighten the jamb nut without moving the

adjus tment scr ew Fig. 46, 47, 49, 49.

Fig. 46

8. Rotate the crankshaft through a few

revolutions and recheck the clearance.

1

Fig. 49

Combus tion Cha mber De posits

Remove combust ion chamber deposits every

500 hours or whenever cylinder head is

removed.

Fig. 47

WARNING

Wear eye protection when using

compressed air to clean parts.

With the piston at Top Dead Center (TDC),

remove combustion chamber deposits from top

of piston with a plastic scr aper or a scotch pad.

CAUTION: Use care to prevent debris from

entering push rod or oil return cavities in cylinder.

Do not d amage cylinder, top of piston, cylinder

head and cylinder head gask et surfaces.

It is not necessary to remove the discoloration

marks on the piston, valves and/or cylinder head.

These marks are normal and will not affect

engine operatio n.

Remove the loose deposits from around t he top

ring land area using compressed air and a soft

bristle bru sh.

Fig. 48

27

1

28

SEC TION 2 - TROUBLESHOOTING

GENERAL INFORMATION............................................................................31

SYSTEMATIC ENGINE CHECKS.................................. ........... ..................... 31

IGNITION SYSTEM........................................................................................ 32

Spark Test................................................................................................................32

Spark Miss Test........................................................................................................32

CARBURETION ............................................................................................. 32

COMPRESSION ............................................................................................ 33

Compression Test....................................................................................................33

ELECTRICAL TEST EQUIPMENT............................. ....................................35

D igital Multimeters & Settings ........................................... .......................................35

AC Volts. ..................................................................................................................35

DC Volts...................................................................................................................35

D C Amps over 10 Amps...... ......................... ............................................................ 35

Ohms or Continuity ..................................................................................................35

Diode Test................................................................................................................36

AC Amps ..................................................................................................................36

D C Amps under 10 Amps ........................................................................................36

DC Shunt..................................................................................................................36

Tachometers............................................................................................................36

2

ALTERNATOR OUTPUT TESTS...................................................................36

DC Alternator............................................................................................................36

AC Alternator............................................................................................................38

1.2 Amp U nregulated Alternator................... ............................................................3 8

4 Amp Regulated Alte rnator ......................... ............................................................ 39

9 Amp Regulated Alte rnator ......................... ............................................................ 39

10 Amp Regulated Alternator. .................................................................................. 40

10 & 16 Amp Regulated Alte rnator .......................................................................... 41

Dual Circuit Alternator ..............................................................................................43

Tri–Circuit Alternator ................................................................................................44

29

Loading...

Loading...