Briggs & Stratton 074005 Owner’s Manual

r Compressor

rator's I

BRIGGS& STRATTONPOWERPRODUCTSGROUP,LLC

JEFFERSON,WISCONSIN,U.S.A.

Manual No. 206934GS Revision - (03/13/2008)

Thankyonfor purchasingthis quality-built Briggs & Strattonair compressor.We are pleasedthat you've placedyour

confidence inthe BRUTETM brand.When operatedand maintained according to the instructions in this manual,your Briggs &

Stratton air compressor will provide manyyears of dependableservice.

Thismanual containssafety information to makeyou awareof the hazardsand risks associatedwith air compressors and

how to avoid them. This air compressor has beenmanufacturedto provide an adequatevolume of compressed air for

operating avariety of light-duty airtools (hand grinders, nailers, ratchets, or staplers), spraying equipment, andinflators

requiring less than 5.1 CFMair flow for operation, it is important that you readand understandthese instructions thoroughly

before attemptingto start or operatethis equipment. Save these instructionsfor future reference.

Thisair compressorrequires final assembly before use. Referto the Assembly sectionof this manual for instructions on

final assembly procedures. Follow the instructions completely.

Where toFindUs

You neverhaveto look far to find Briggs & Stratton support andservice for your air compressor. Consult your Yellow Pages.

Thereare over 30,000 Briggs & Stratton authorizedservice dealersworldwide who provide quality service. You can also

contact Briggs & Stratton CustomerService by phoneat (BOO)743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Air Compressor

Model Number

Revision

Serial Number

Date Purchased

BRUTETM is atrademark of Bfiggs & Stratton PowerProducts.

Briggs & Stratton PowerProducts Group, LLC

900 North Parkway

Jefferson, WI 53549

Copyright © 2008 Briggs & Stratton Power Products Group,

LLC. All rights reserved. No part of this material may be

reproduced or transmitted in any form by any meanswithout

the expresswritten permission of Briggs & Stratton Power

Products Group, LLC.

2 www.brutepower.com

Table of Contents

OperatorSafety ................................. 4

Equipment Description......................................... 4

Safety Rules................................................. 4

Assembly ..................................... 7

Air Compressor Assembly...................................... 7

Air ToolAssembly ............................................ 9

Featuresand Controls............................ 11

Air Compressor ............................................. 11

Air Tools................................................... 12

Operation .................................... 13

Air Compressor Operating Location.............................. 13

Grounding Instructions ....................................... 13

ExtensionCords............................................. 13

Break-In Procedure .......................................... 13

Starting Your Air Compressor .................................. 14

Compressor Operation........................................ 14

Stopping YourAir Compressor ................................. 14

Air ToolOperation ........................................... 15

3

O

o

Maintenance .................................. 17

GeneralRecommendations .................................... 17

MaintenanceSchedule........................................ 17

Air ToolMaintenance......................................... 17

Air Compressor Maintenance................................... 17

Storage ................................................... 20

Troubleshooting................................ 21

BeforeYou Call ............................................. 21

Air ToolTroubleshooting Chart ................................. 21

Air Compressor Troubleshooting Chart........................... 22

Glossary................................................... 24

Warranty ..................................... 25

Product Specifications............................ 26

Air Compressor ............................................. 26

Air Tools................................................... 26

=o

o

=,,,=

o

€1o

o

o

m.

Espa_ol

Frangais

OperatorSafety

EquipmentDescription

Readthis manualcarefully and becomefamiliar

with yourair compressor.Knowitsapplications, its

limitationsand any hazardsinvolved.

This manualcontains operation and maintenanceinformation

for a single-stageair compressor that produces 5.1 CFMat

40 PSi (2.8 bars) and 4.2 CFIVlat 90 PSi (6.2 bars) using an

120 Volt A.C. electric motor. This high quality system

featuresa direct drive oil lubepump with cast ironsleeve,an

easystart valve, and an air outlet. This unit also featuresa

motor overload protection featurewith manualrestart.

This air compressor has beenmanufactured to provide an

adequatevolume of compressed airfor operating avariety of

light-duty air tools (hand grinders, nailers, ratchets,

staplers), spraying equipment, and inflators requiring less

than 5.1 CFMair flow for operation.Operatethis compressor

ONLYinan ambient temperature rangefrom 32° to 95°F

(0° to 35°0). This compressor is designed for a maximum of

70% duty per hour atfull load.

Everyeffort hasbeen madeto ensurethat informationin this

manual isaccurateand current. However,we reservethe

right to change,alter or otherwise improvethe product and

this document at any time without prior notice.

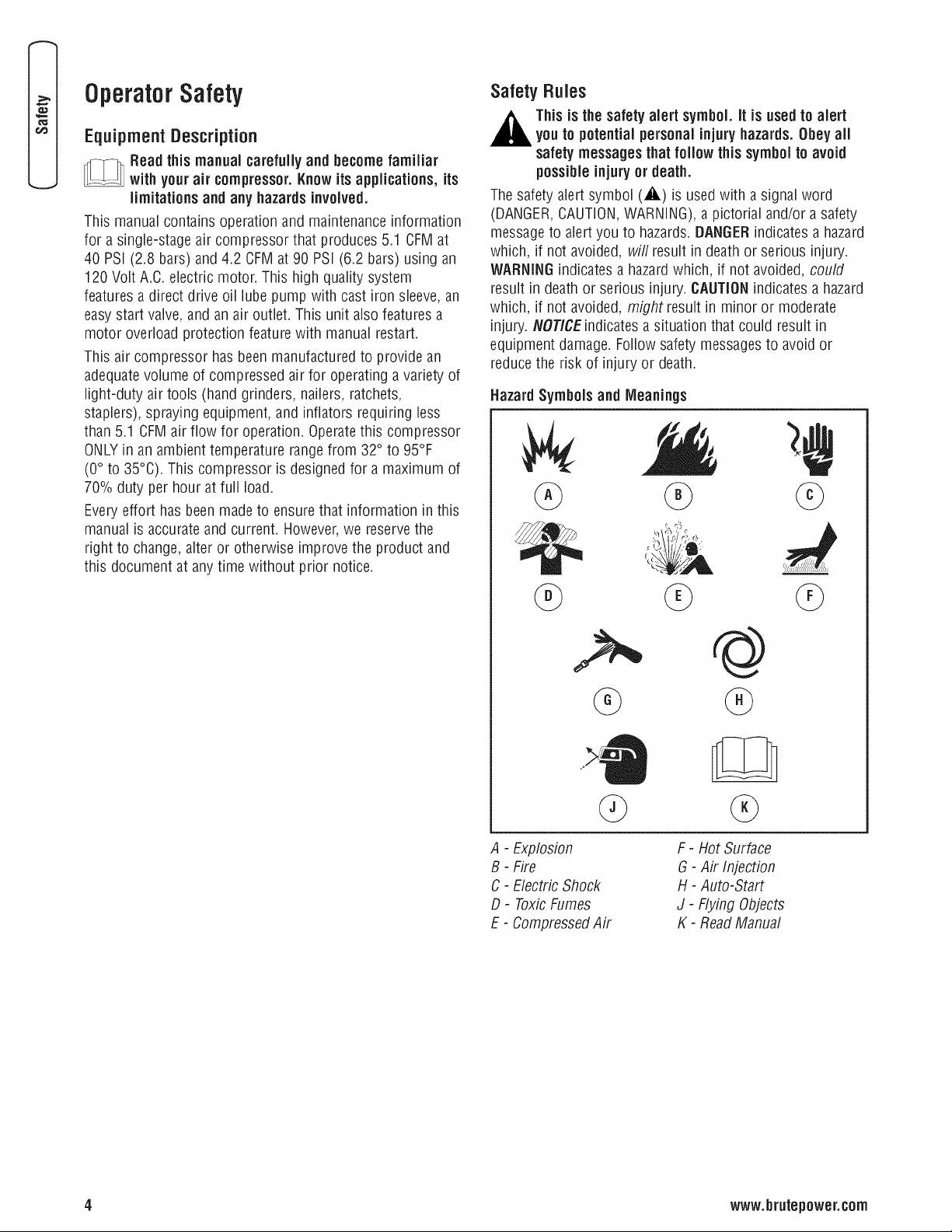

Safety Rules

,_ This isthe safetyalert symbol.It is usedto alert

youto potential personal injuryhazards.Obey all

safety messagesthat follow this symbolto avoid

possibleinjury or death.

Thesafety alert symbol (,_.) isused with a signal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert youto hazards. DANGERindicatesa hazard

which, if not avoided, will result in deathor serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in deathor serious injury. CAUTIONindicates a hazard

which, if not avoided, might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage. Follow safety messagesto avoid or

reducethe risk of injuryor death.

HazardSymbolsand Meanings

A - Explosion

B - Fire

C- Electric Shock

D - ToxicFumes

E - CompressedAir

@

F - HotSurface

G- Air Injection

H - Auto-Start

J - Flying Objects

K - ReadManual

4. www.brutepower.com

WARNING

Failure to read and follow instructions in

_ Operator's Manual result in death,

injury and / or property damage.

• Beforeusing this product, readthis Operator's Manualand

follow all SafetyRulesand OperatingInstructions listed.

• Makethis manualavailable to other users of this equipment.

can

bodily

WARNING

Contact with compressor or its cord can cause

electric shock or burn.

_¢ Improper grounding can result in electricalshock.

Contact with components under protective cover

cancause electric shock or burn.

• DONOT use grounding adapters. Inspect cord beforeeachuse.

• DONOT operatewith protective covers/ guards removedor

damaged.

• DONOToperatein wet conditions. Storeunit indoors.

• Disconnectfrom power source and drain pressurefrom tank

when not in use or beforeservicing.

• DONOTmodify the plug provided. If itdoes not fit the available

outlet, a qualified electrician should install aproper outlet.

• Aqualified electrician MUST makerepairsto the cord set or

plug.

WARNING

Certain componentsinthis productand related

accessories containchemicals known to theState of

California to causecancer,birth defectsor other

reproductiveharm. Wash handsafter handling.

WARNING

Hidden internaltank corrosion can causeviolent

explosion leading to severeinjury and / or

property damage.

Exceedingpressure rating of attachments or

inflatablescan cause severeinjury and / or

property damage.

Tamperingwith or removingASMESafety Valve

cancause explosion leadingto severe injury

and/ or property damage.

DRAINTANKafterevery4 hoursofuseor dailybyopening

drainfitting(s)andtiltingcompressorto emptyaccumulated

water.

e

DONOTmodifyor repairtankinanyway.

e

DONOTadjustpressuregreaterthan maximumratingof

attachmentsor inflatables.

DONOTtamperwithor removeASMESafetyValve.Check

ASMESafetyValvebypullingringbeforeeachuse.ASME

SafetyValvehasbeensetto maximumsaferating.

WARNING

._1_ Spraying flammable or combustible liquids can

• DONOTsprayflammable or combustible liquids while smoking,

• Spray in an open, well ventilatedarea at least20 feet

cause fire or explosion.

Compressor produces sparks during operation,

which canignite flammable or combustible

vapors.

near sparks,open flames, pilot lights, any ignition source, or in

confined areas.

(6.1 meters) awayfrom compressor or other ignition source.

WARNING

Compressedair is not breathableand can cause

bodily injury.

Somepaints or solvents may be harmful if

inhaled or ingested,causing severenausea,

fainting or poisoning.

• DONOTusecompressedairfor breathing.

• AlwaysuseNIOSHrespiratorapprovedfor yourapplication

whenspraying.

• Readall instructionswith respiratorsoyouarecertainitwill

providenecessaryprotectionagainstinhalingharmfulvapors.

WARNING

Operatingair compressor andtubing are HOT

and cancause burns.

• DONOTtouch compressor or tubing.

• Allow compressorto cool before servicing.

WARNING

('_ Compressor can start any time when plugged in.

• STAYCLEAR

• Disconnectfrom power source and drain pressurefrom tank

when not in use or beforeservicing.

NOT/

Serious damage may result if the break-in instructions are

not closely followed.

• Thisprocedure is requiredbeforethe air compressor is put into

serviceandwhen the CheckValve or a compbte compressor

pump has beenrepbced.

Serious damage may result if operating the unit with

i NOTICE

insufficient oil. Check oil level daily or with each use.

, amageto equipment resultingfrom failure to follow thisinstruction will void warranty.

NOT/

Air tools are critical parts of a high-pressure system.

• Disconnectthe tool from the air supply before changingtools or

accessories,when servicing andwhen not in use.

• Do not wear loosefitting clothing and jewelry that may become

caught in moving parts.

• Do not depresstrigger when connecting theair supply.

• Alwaysuse accessoryfittings designed for use with air tools.

• Makesure allair connections are secureand checkair hoses,air

tools, andaccessoriesfor weakor worn condition before each

use.

• Beforeeach use, drain water out of air compressor tank and

condensationfrom air lines.

WARNING

_ Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin

. and / or property damage.

>_ iand can propel objects leading to severe injury

• DONOTdirect air stream at self or others.

• DONOTattempt to repair air hose(s).

• Alwayswear ANSIZ87.1 approvedsafetyglasses with side

shields.

6 www.brutepower.corn

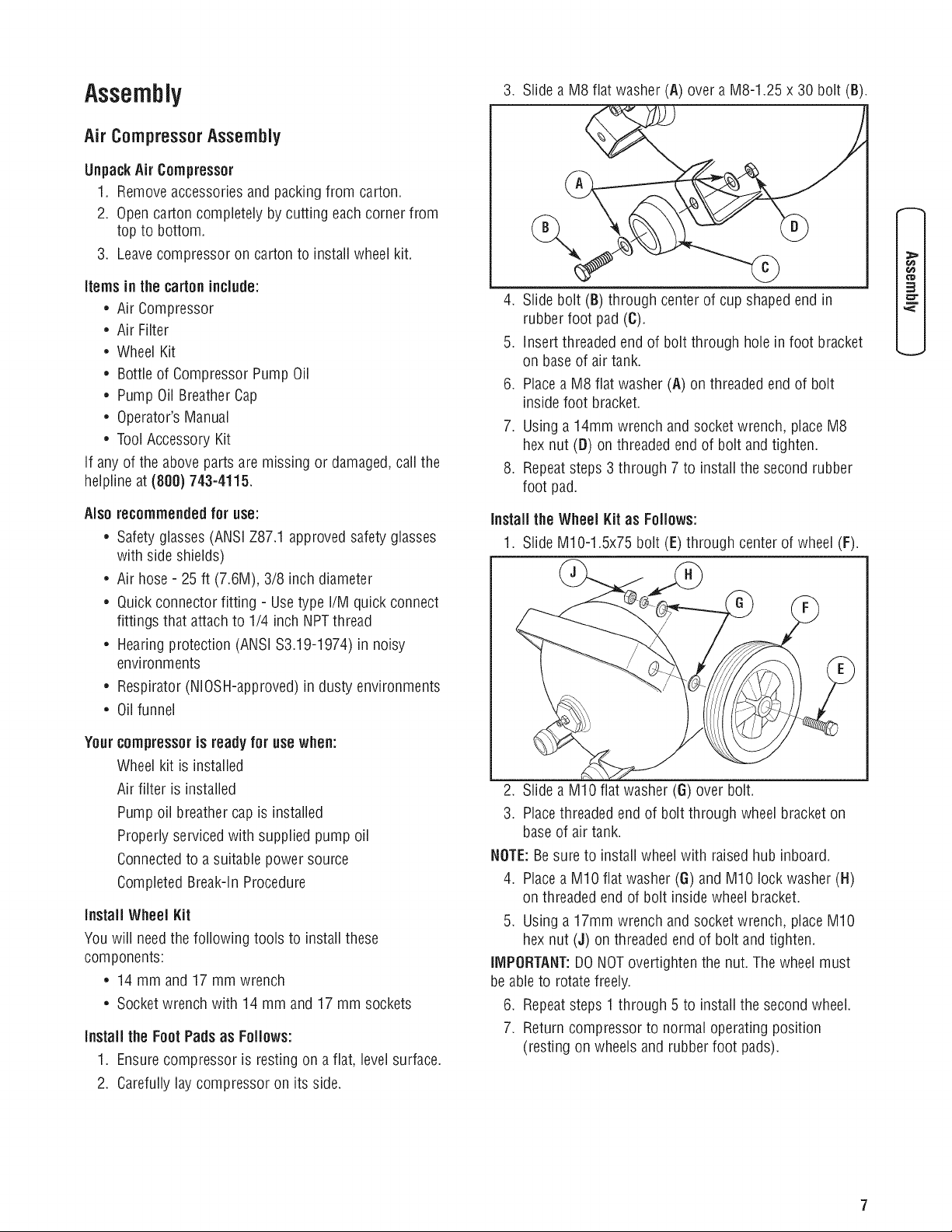

ASSe[[IbJy 3. Slide a M8 flat washer(A) over aM8-1.25 x 30 bolt (B).

Air CompressorAssembly

UnpackAir Compressor

1. Removeaccessoriesand packingfrom carton.

2. Opencarton completely by cutting eachcorner from

top to bottom.

3. Leavecompressor on carton to install wheel kit.

Items in the cartoninclude:

• Air Compressor

• Air Filter

• Wheel Kit

• Bottle of CompressorPump Oil

• PumpOil BreatherCap

• Operator's Manual

• ToolAccessory Kit

If any of the above parts are missing or damaged,call the

helpline at (800) 743-4115.

Also recommended for use:

* Safetyglasses (ANSiZ87.1 approved safety glasses

with side shields)

* Air hose- 25 ft (7.6M), 3/8 inch diameter

* Quick connector fitting - Usetype I/M quick connect

fittings that attachto 1/4 inch NPTthread

* Hearingprotection (ANSi $3.19-1974)in noisy

environments

* Respirator(NlOSH-approved)in dusty environments

* Oil funnel

.

Slide bolt (8) through centerof cup shapedend in

rubber foot pad (C).

5.

insertthreaded endof bolt through hole infoot bracket

on baseof air tank.

6.

Placea M8 fiat washer (A) on threadedend of bolt

insidefoot bracket.

7.

Using a 14mm wrench and socket wrench, placeM8

hex nut (D) on threaded end of bolt and tighten.

8.

Repeatsteps 3through 7 to installthe secondrubber

foot pad.

Install the Wheel Kit as Follows:

1. Slide M10-1.5x75 bolt (E) through centerof wheel (F).

€_

3

Yourcompressor is readyfor use when:

Wheelkit isinstalled

Air filter isinstalled

Pumpoil breathercap is installed

Properlyserviced with supplied pump oil

Connectedto asuitable power source

CompletedBreak-in Procedure

Install Wheel Kit

You will needthe following tools to install these

components:

• 14 mm and 17 mm wrench

• Socketwrench with 14mm and 17 mm sockets

Install the FootPadsas Follows:

1. Ensurecompressor is resting on a flat, levelsurface.

2. Carefullylay compressor on its side.

2. Slide a MIO fiat washer (G) over bolt.

3. Placethreadedend of bolt through wheel bracket on

baseof airtank.

NOTE:Besure to install wheelwith raised hub inboard.

4. Placea MIO fiat washer (G) and MIO lockwasher (H)

on threaded endof bolt insidewheel bracket.

5. Using a 17mm wrench and socket wrench, placeMIO

hex nut (J) on threaded end of bolt and tighten.

IMPORTANT:DONOTovertighten the nut. Thewheel must

be able to rotatefreely.

6. Repeatsteps 1through 5 to installthe secondwheel.

7. Return compressor to normal operating position

(resting on wheelsand rubber foot pads).

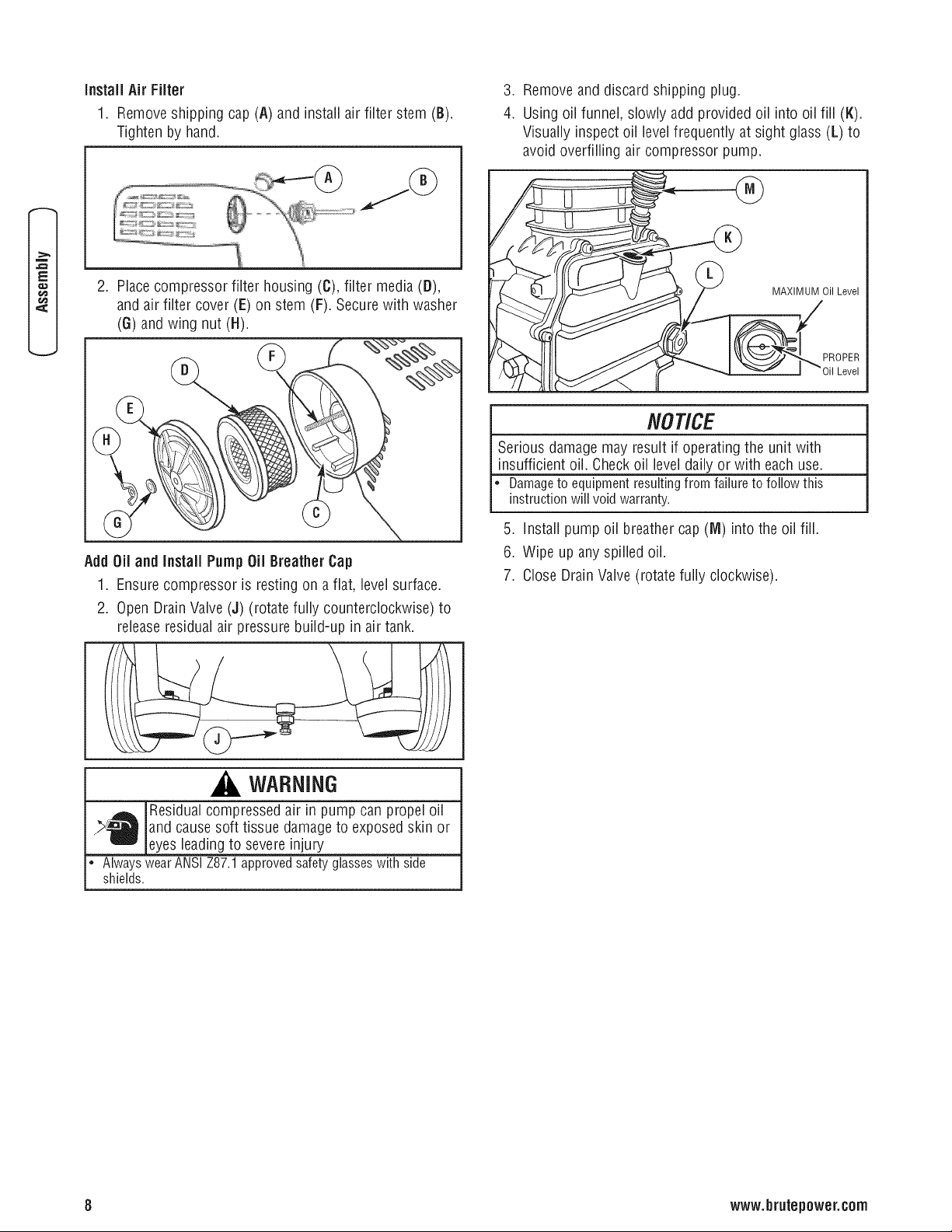

Install Air Filter

1. Removeshipping cap (A) and install air filter stem (B).

Tighten by hand.

.

Removeand discard shipping plug.

4.

Using oil funnel, slowly add provided oil into oil fill (!().

Visually inspectoil levelfrequently at sight glass (L) to

avoid overfilling air compressor pump.

E

€_

2. Placecompressor filter housing (C),filter media (D),

and air filter cover (E) on stem (F). Securewith washer

(G) and wing nut (H).

Add Oil and Install Pump Oil Breather Cap

1. Ensurecompressor is resting on a fiat, levelsurface.

2. Open DrainValve(J) (rotatefully counterclockwise) to

releaseresidual air pressure build-up in air tank.

MAXIMUM Oil Level

Serious damagemay resultif operating the unit with

i NOTICE

insufficient oil. Checkoil leveldaily or with eachuse.

= amagetoequipmentresultingfrom failuretofollowthisinstructionwillvoidwarranty.

5. install pump oil breathercap (IVl)into the oil fill.

6. Wipe up anyspilled oil.

7. Close Drain Valve(rotate fully clockwise).

WARNING

Residualcompressed air in pump can propel oil

>,_ and causesoft tissue damageto exposedskin or

eyesleading to severeinjury

• AlwayswearANSiZ87.1approvedsafetyglasseswithside

shields.

8 www.brutepewer.cem

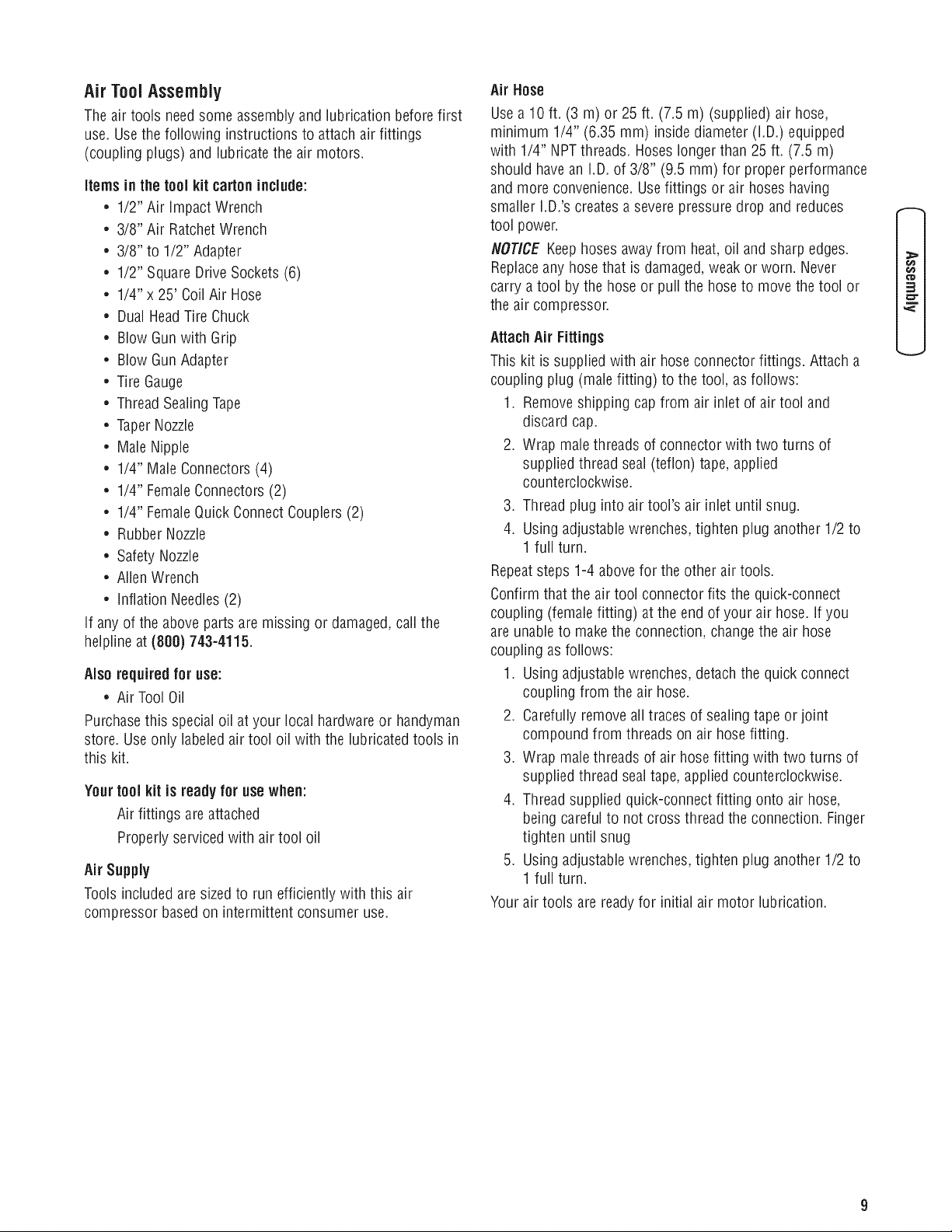

Air ToolAssernbly

Theair tools need some assemblyand lubrication beforefirst

use. Usethe following instructions to attach air fittings

(coupling plugs) andlubricate the air motors.

Items in the tool kit cartoninclude:

• 1/2" Air impact Wrench

• 3/8" Air RatchetWrench

• 3/8" to 1/2" Adapter

• 1/2" Square DriveSockets (6)

• 1/4" x 25' CoilAir Hose

• DualHeadTire Chuck

• BlowGun with Grip

• BlowGun Adapter

• Tire Gauge

• ThreadSealingTape

• TaperNozzle

• Male Nipple

• 1/4" Male Connectors (4)

• 1/4" FemaleConnectors (2)

• 1/4" FemaleQuick ConnectCouplers(2)

• RubberNozzle

• SafetyNozzle

• Alien Wrench

• inflation Needles(2)

If any of the above parts are missing or damaged,call the

helpline at (800) 743-4115.

Also required for use:

• Air ToolOil

Purchasethis special oil at your local hardwareor handyman

store. Useonly labeledairtool oil with the lubricatedtools in

this kit.

Yourtool kit is readyfor usewhen:

Air fittings areattached

Properlyserviced with air tool oil

Air Supply

Tools included aresizedto run efficiently with this air

compressor basedon intermittent consumer use.

Air Hose

Usea 10 ft. (3 m) or 25 ft. (7.5 m) (supplied) air hose,

minimum 1/4" (6.35 mm) inside diameter (i.D.) equipped

with 1/4" NPTthreads. Hoseslonger than 25 ft. (7.5 m)

should have an I.D. of 3/8" (9.5 mm) for properperformance

and more convenience.Usefittings or air hoseshaving

smaller I.D.'screatesa severepressure drop and reduces

tool power.

NOTICE Keephoses away from heat, oil and sharp edges.

Replaceany hosethat is damaged,weak or worn. Never

carry a tool by the hose or pull the hoseto move thetool or

the air compressor.

Attach Air Fittings

This kit is supplied with air hoseconnector fittings. Attach a

coupling plug (malefitting) to the tool, asfollows:

1. Removeshipping cap from air inlet of air tool and

discard cap.

2. Wrap malethreads of connector with two turns of

supplied thread seal(teflon) tape, applied

counterclockwise.

3. Threadplug into air tool's air inlet until snug.

4. Using adjustable wrenches, tighten plug another 1/2 to

1 full turn.

Repeatsteps 1-4 above for the other airtools.

Confirm that the air tool connector fits the quick-connect

coupling (female fitting) atthe end of your air hose.If you

are unable to makethe connection, changethe air hose

coupling as follows:

1. Using adjustable wrenches,detach the quick connect

coupling from the air hose.

2. Carefully removeall traces of sealingtape or joint

compound from threads on air hosefitting.

3. Wrap malethreads of air hosefitting with two turns of

supplied thread sealtape, appliedcounterclockwise.

4. Threadsupplied quick-connect fitting onto air hose,

being careful to not cross thread the connection. Finger

tighten until snug

5. Using adjustable wrenches,tighten plug another 1/2 to

1 full turn.

Your air tools are ready for initial air motor lubrication.

3

E

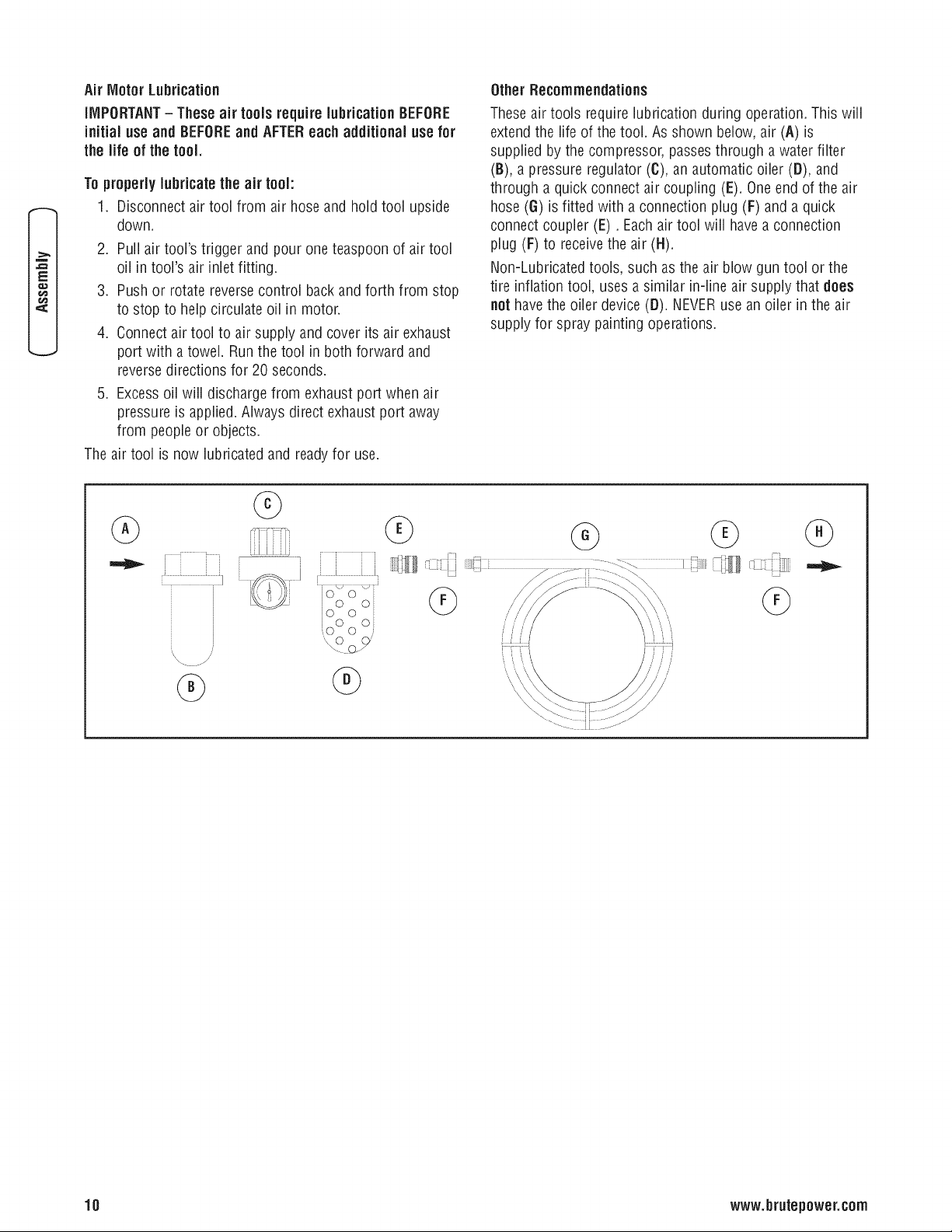

Air Motor Lubrication

iMPORTANT- Theseair toolsrequire lubricationBEFORE

initial use and BEFOREand AFTEReach additionaluse for

the life ofthetool.

Toproperlylubricatethe air tool:

1. Disconnect airtool from air hoseand hold tool upside

down.

2. Pull air tool's trigger and pourone teaspoonof air tool

oil in tool's air inlet fitting.

3. Push or rotate reversecontrol backand forth from stop

to stop to help circulate oil in motor.

4. Connectair tool to air supply and cover its air exhaust

port with a towel. Runthe tool in both forward and

reversedirections for 20 seconds.

5. Excessoil will discharge from exhaustport when air

pressure is applied. Always directexhaust port away

from peopleor objects.

Theair tool is now lubricatedand readyfor use.

Other Recommendations

Theseair tools requirelubrication during operation.This will

extend the life of thetool. As shown below, air (A) is

supplied by the compressor, passesthrough a waterfilter

(B), a pressureregulator (C),an automatic oiler (D), and

through a quick connect air coupling (E). Oneend of the air

hose (G)is fitted with a connection plug (F) and a quick

connect coupler (E). Eachair tool will have a connection

plug (F) to receivethe air (R).

Non-Lubricatedtools, such as the air blow gun tool orthe

tire inflation tool, uses a similar in-line air supply that does

not havethe oiler device (D). NEVERuse an oiler in the air

supply for spray painting operations.

J _ ..... j _i iJ

oOoO

[o° o o

10 www.brutepower.corn

Featuresand Controls

Air Compressor

Readthis Operator's Manual andsafety rulesbeforeoperating yourair compressor.

Comparethe illustrations with your air compressor,to familiarize yourself with the locationsof various controls and

adjustments. Savethis manual for future reference.

/

0

;=1

A- ON- OFFSwitch-- Pull to ONposition to powerair

compressor. Push to OFFposition to remove power.

B - Pressure Control -- Controls air pressure deliveredto

Quick ConnectFitting.

C- QuickConnect Fitting-- Connect air tools here.

D - SafetyValve-- Valveprotects against excessivetank

pressure by 'popping out' atits factory setting, thus

relieving pressure.

E - Tank Pressure Gauge-- Gaugeindicatesair pressure

within air tank.

F - Regulated Pressure Gauge-- indicates air pressureat

quick connectfitting.

G - Brain Valve-- Valveis located near bottom of air tank

and is used to draincondensation.

H - CheckValve-- When unit is operating,check valveis

open, allowing air to enter tank. At "cut-out" pressure,

checkvalve closes, preventingair from flowing back into

pump. Valveis not serviceable by user.

<b

J - Air Compressor Pump-- Pumpcompressesair into tank.

I{ - Overload Protector- if motor is overloaded,protector

shuts motor off. SeeOverload Protection Reset.

L - Oil Fill Location -- Fill pump with oil here.Oillevelsight

glass indicates pump oil level.

M - Air Filter -- Protectsair compressor by filtering dust

and debris out of intake air.

items Not Illustrated:

identificationLabel- The identification labelcontains serial

number, model number,and revision number information.

Pressure Release Valve-- Located on top of tank adjacent

to quick connect fitting, valveautomatically releasesair from

internal compressor components at "cut-out" pressureor

when unit is shut off. Valveis not serviceable by user.

Pressure Switch -- Automatically starts motor when tank

pressure drops below "cut-in" pressure andstops motor

when pressure risesto "cut-out" pressure.

NOTE:See Glossaryfor definitions.

11

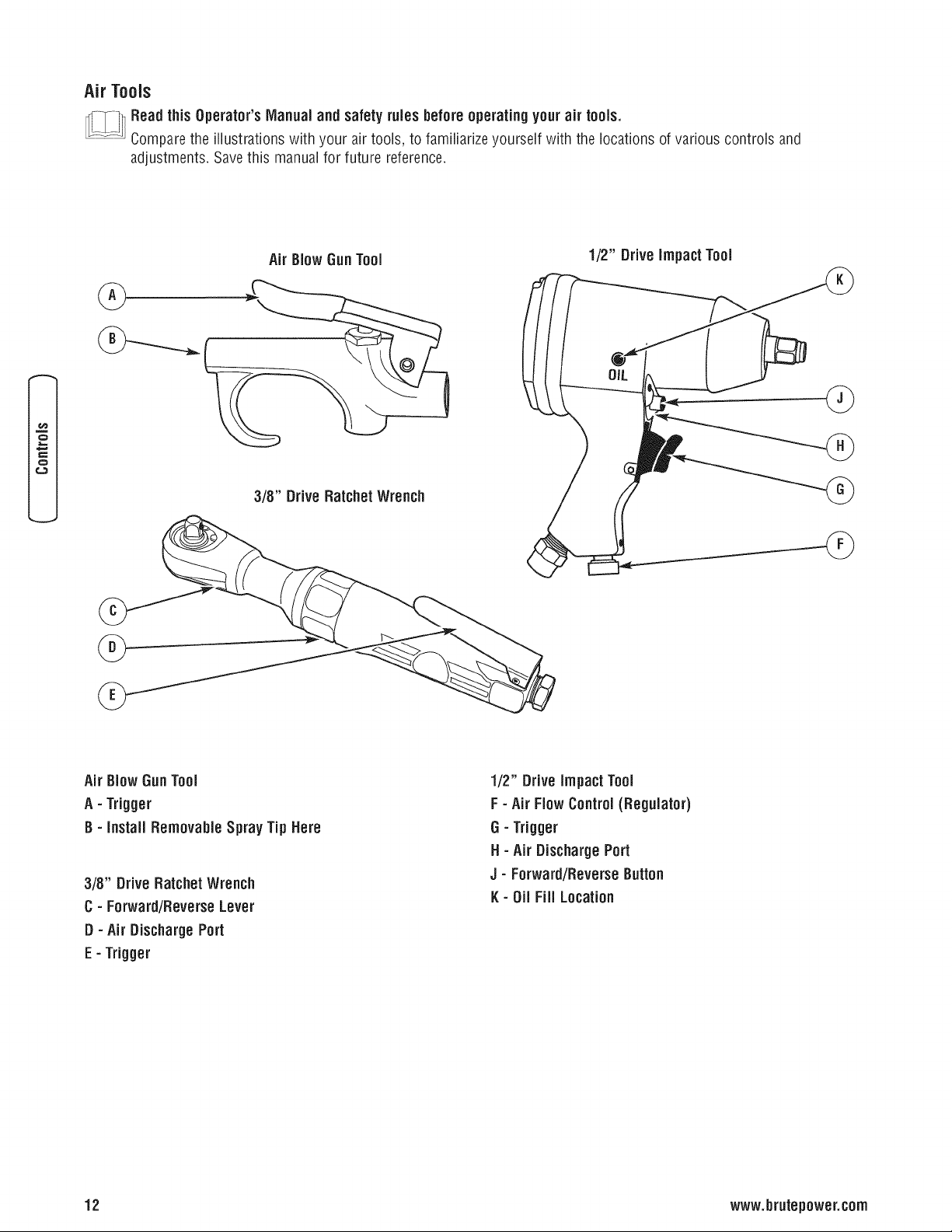

Air Tools

Readthis Operator'sManual andsafety rules beforeoperating yourair tools.

................................Comparethe illustrationswith your air tools, to familiarize yourself with the locations of various controls and

adjustments. Savethis manual for future reference.

AirBlow GunTool

c)

o

1/2" DriveimpactTool

3/8" Drive RatchetWrench

Air Blow GunTool

A - Trigger

B - Install Removable Spray Tip Here

1/2" DriveimpactTool

F - Air Row Control (Regulator)

G - Trigger

H - Air DischargePort

3/8" DriveHatchetWrench

C- Forward/ReverseLever

J - Forward/ReverseButton

K- Oil FiJJLocation

D - Air DischargePort

E - Trigger

12 www.brutepower.com

Operation

Air CompressorOperatingLocation

Locate the air compressor ina clean, dryand well-ventilated

areafor operation. The air compressor should beplacedat

least 12 inches (30 cm) away from walls or other

obstructions that could interferewith airflow.

Theair compressor pump and shroud are designedto allow

for proper cooling. Theventilation openings on the

compressor are necessaryto maintain proper operating

temperature. DONOTplace ragsor containers on or near

these openings. Keepthe air filter clear of obstructions that

could reduce airflow to the air compressor.

Operatethe air compressor with unit located on a flat

surface to ensure that it receivesproper lubrication.

If you haveanyproblems with operationof your air

compressor, call air compressor helpline at (800) 743-4115.

If calling for assistance, pleasehavethe model, revision, and

serial number from the identificationlabel available.

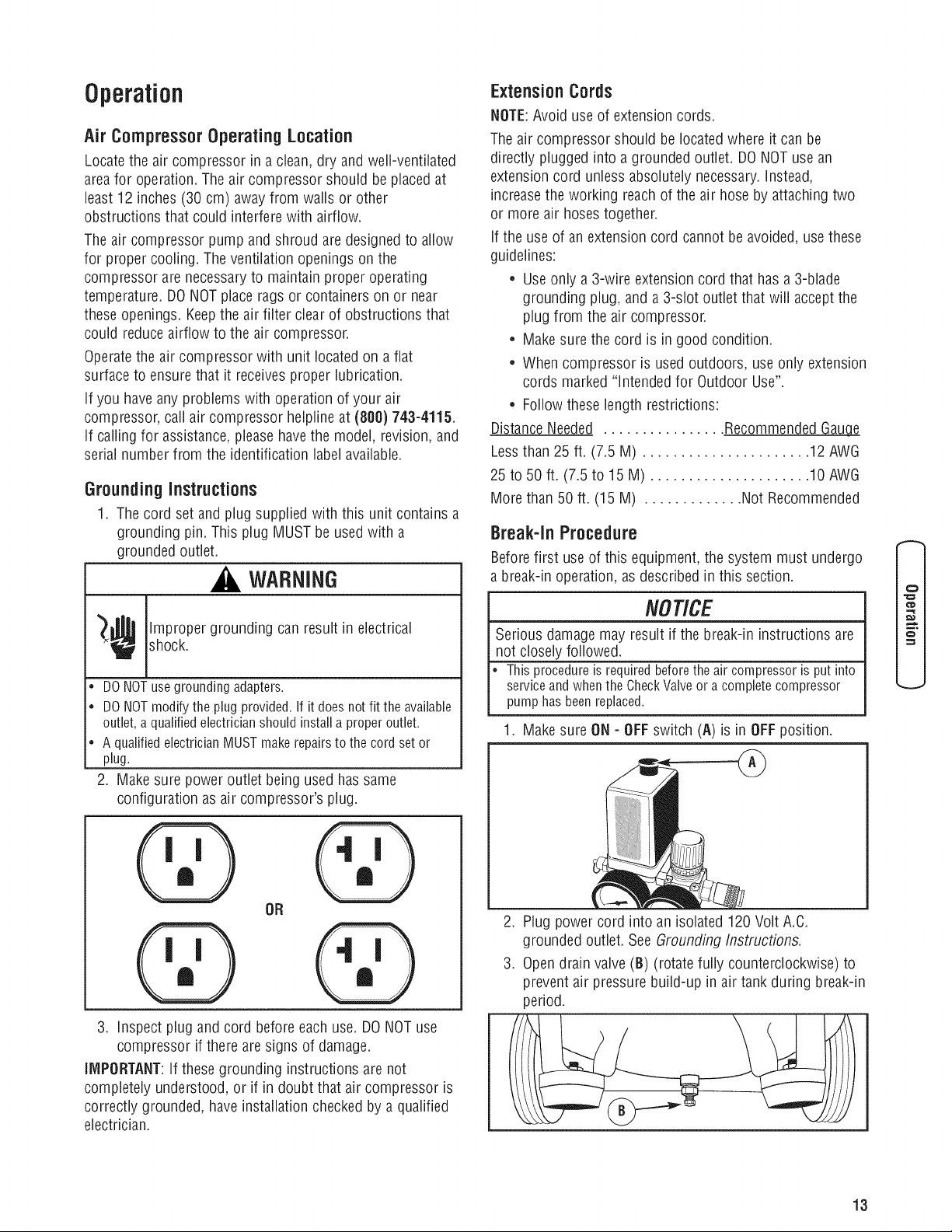

Groundinginstructions

1. Thecord set and plug supplied with this unit contains a

grounding pin. This plug MUST be usedwith a

grounded outlet.

WARNING

_¢ improper grounding can result in electricalshock.

• DONOT use grounding adapters.

• DONOTmodify the plug provided. If itdoes not fit the available

outlet, a qualified electrician should install aproper outlet.

• Aqualified electrician MUST makerepairsto the cord set or

plug.

2. Make sure power outlet being used has same

configuration as air compressor's plug.

ExtensionCords

NOTE:Avoid use of extension cords.

Theair compressor should belocatedwhere it can be

directly plugged into a grounded outlet. DONOTuse an

extensioncord unlessabsolutely necessary.Instead,

increasethe working reachof the air hoseby attaching two

or more air hoses together.

If the use of anextensioncord cannotbe avoided,use these

guidelines:

• Use only a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot outlet that will accept the

plug from the air compressor.

• Make sure the cord is ingoodcondition.

• Whencompressor isused outdoors, useonly extension

cords marked "Intended for Outdoor Use".

• Follow these length restrictions:

DistanceNeeded ................ RecommendedGauee

Lessthan 25 ft. (7.5 M) ...................... 12 AWG

25 to 50 ft. (7.5 to 15 M) ..................... 10 AWG

More than 50 ft. (15 M) ............. Not Recommended

Break-InProcedure

Beforefirst useof this equipment, the system must undergo

a break-in operation, asdescribed in this section.

NOT/CE

Serious damagemay result ifthe break-in instructionsare

not closely followed.

• Thisprocedureis requiredbeforetheair compressorisputinto

serviceandwhentheCheckValveora completecompressor

pumphasbeenreplaced.

1. Make sure ON- OFFswitch (A) is in OFFposition.

o

OR

3. inspect plug and cord beforeeachuse. DONOTuse

compressor if there aresigns of damage.

IMPORTANT:If thesegrounding instructions are not

completely understood, or if in doubt that air compressor is

correctly grounded, have installation checkedby aqualified

electrician.

2. Plug power cord into anisolated 120 Volt A.C.

grounded outlet. See GroundingInstructions.

3. Opendrain valve (B) (rotate fully counterclockwise) to

prevent air pressure build-up in air tank during break-in

period.

13

NOTE:Always drain air tank over awashablesurface or in a

suitable container to preventdamaging or staining surfaces.

4. Pull ON- OFFswitch to ONposition. Compressorwill

start.

5. Runcompressor for 15 minutes. Makesure drain valve

remainsopen.

6. After 15 minutes, close drain valve (rotate fully

clockwise). Air tankwill fill to "cut-out" pressure and

compressor will stop.

NOTE:Checkoil level in compressor after break-in.

Thecompressor has completedthe break-in procedureand

is ready for normal use.

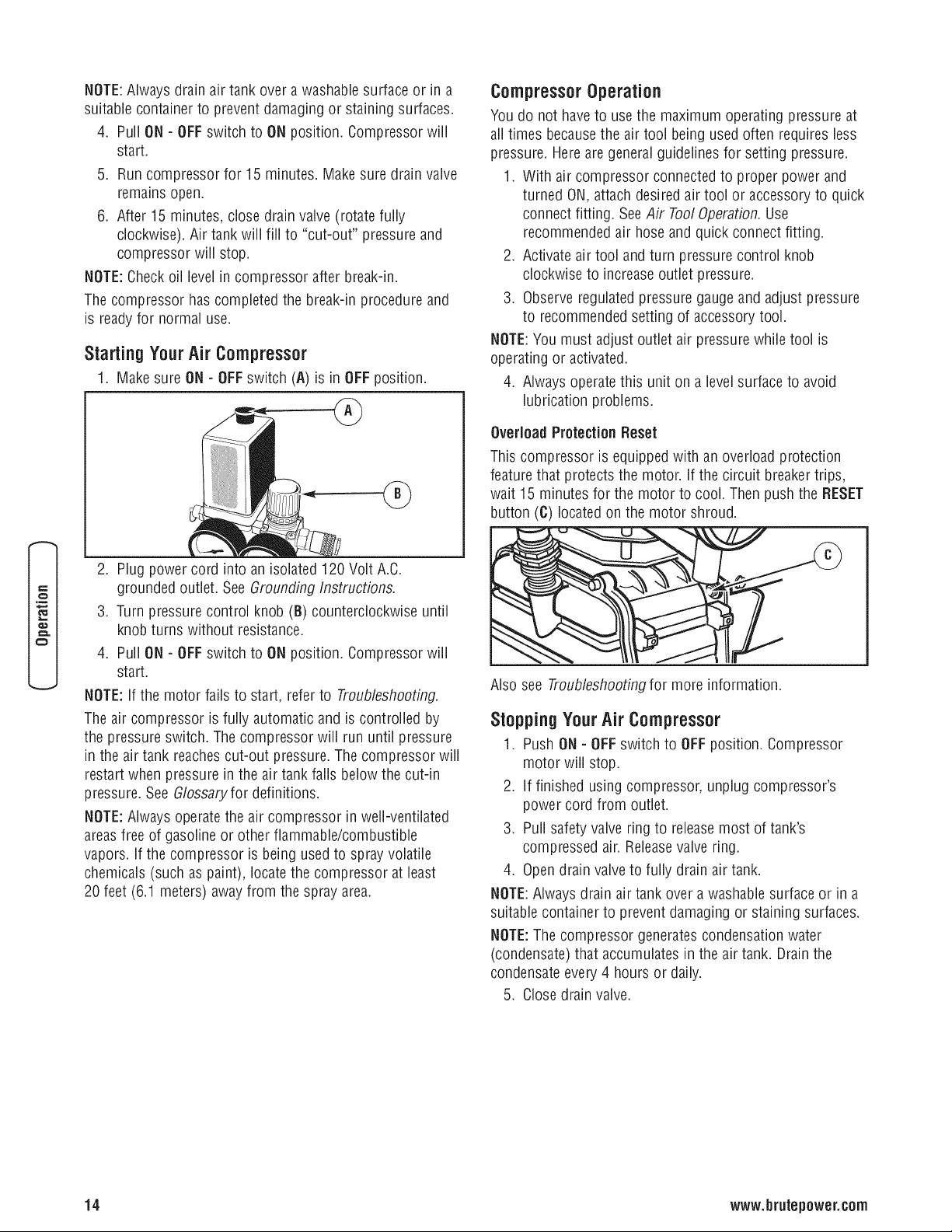

Starting YourAir Compressor

1. Make sure ON=OFFswitch (A) is in OFFposition.

CompressorOperation

You do not haveto use the maximumoperating pressureat

all times becausethe air tool being used often requiresless

pressure. Hereare generalguidelines for setting pressure.

1. With air compressor connectedto proper power and

turned ON,attach desired airtool or accessory to quick

connect fitting. SeeAir ToolOperation.Use

recommendedair hose andquick connectfitting.

2. Activate air tool andturn pressure control knob

clockwise to increaseoutlet pressure.

3. Observe regulated pressure gaugeand adjust pressure

to recommended setting of accessorytool.

NOTE:Youmust adjust outlet air pressurewhile tool is

operating or activated.

4. Alwaysoperate this unit on a level surface to avoid

lubrication problems.

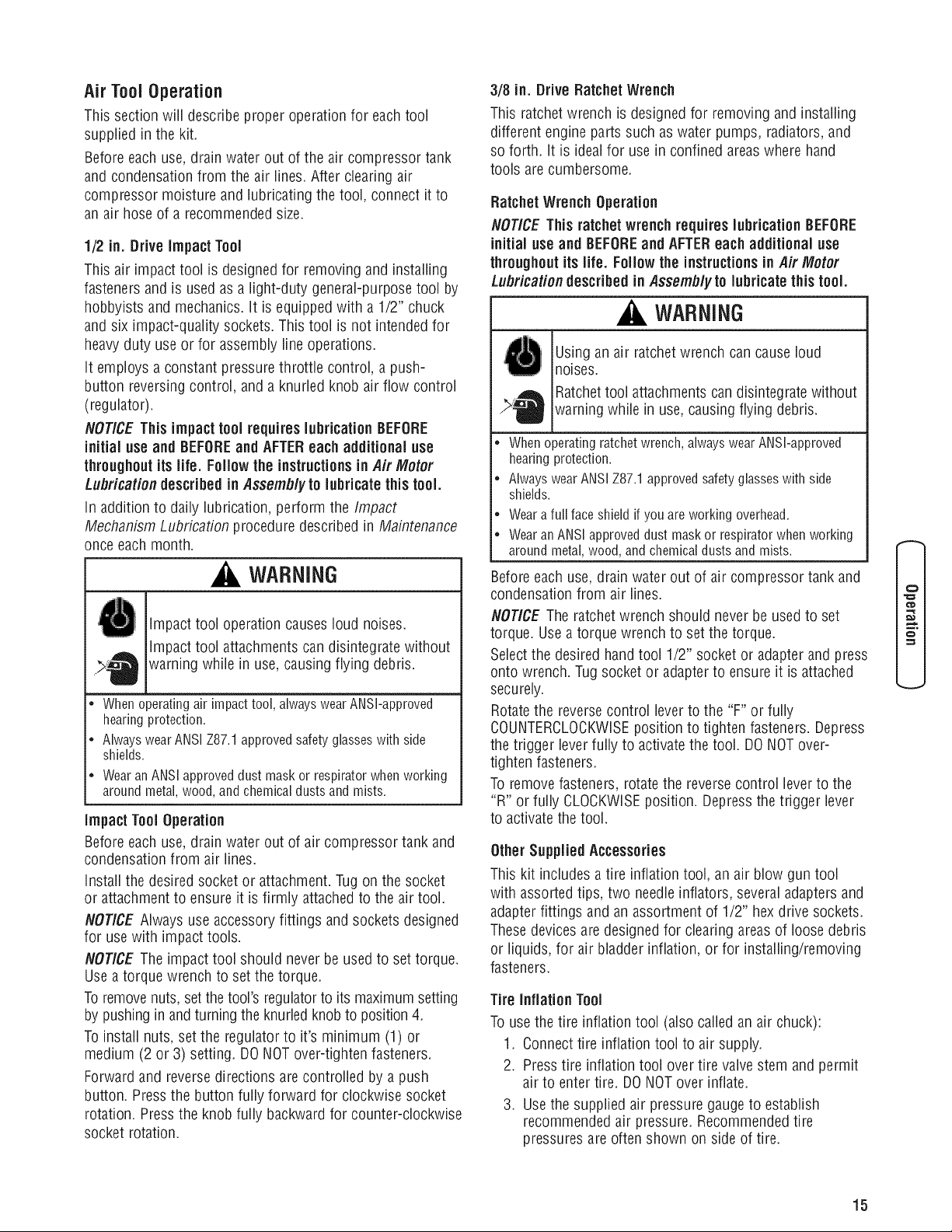

Overload Protection Reset

This compressor is equippedwith an overload protection

feature that protects the motor, if the circuit breakertrips,

wait 15 minutes for the motor to cool. Thenpush the RESET

button (C) locatedon the motor shroud.

2. Plug power cord into an isolated 120Volt A.C.

o

L=

grounded outlet. See GroundingInstructions.

3. Turn pressurecontrol knob (B)counterclockwise until

knob turns without resistance.

4. Pull ON- OFFswitch to ONposition. Compressorwill

start.

NOTE:If the motor failsto start, referto Troubleshooting.

Theair compressor is fully automaticand is controlled by

the pressureswitch. Thecompressor will run until pressure

in the air tank reachescut-out pressure.Thecompressor will

restart when pressure in the air tankfalls below the cut-in

pressure. SeeGlossaryfor definitions.

NOTE:Always operatethe air compressor in weft-ventilated

areasfree of gasolineor other flammable/combustible

vapors. If the compressor is being usedto spray volatile

chemicals (such as paint), locatethe compressor at least

20 feet (6.1 meters) awayfrom the spray area.

Also see Troubleshootingfor more information.

Stopping YourAir Compressor

1. Push ON=OFFswitch to OFFposition. Compressor

motor will stop.

2. If finished using compressor, unplug compressor's

power cord from outlet.

3. Pull safety valve ring to releasemost of tank's

compressed air. Releasevalvering.

4. Opendrain valveto fully drain air tank.

NOTE:Always drain air tank over awashablesurface or in a

suitable container to preventdamaging or staining surfaces.

NOTE:The compressor generatescondensationwater

(condensate)that accumulates in the air tank. Drainthe

condensateevery4 hours or daily.

5. Closedrain valve.

14 www.brutepower.com

Air ToolOperation

This section will describe proper operationfor eachtool

supplied in the kit.

Beforeeach use,drain water out of the air compressor tank

and condensationfrom the air lines. After clearing air

compressor moisture and lubricating the tool, connect it to

an air hose of a recommendedsize.

1/2 in. Drive Impact Tool

This air impact tool is designed for removing and installing

fasteners and is usedas alight-duty general-purposetool by

hobbyists and mechanics.It is equippedwith a1/2" chuck

and six impact-quality sockets. Thistool is not intendedfor

heavyduty useor for assembly lineoperations.

It employs a constant pressure throttle control, a push-

button reversingcontrol, and a knufled knob air flow control

(regulator).

NOTICE This impacttool requires lubrication BEFORE

initial use and BEFOREand AFTEReach additional use

throughoutits life. Followthe instructionsin Air Motor

Lubrication described in Assemblyto lubricate this tool.

In addition to daily lubrication, perform the Impact

Mechanism Lubrication proceduredescribed in Maintenance

once eachmonth.

WARNING

impacttool operation causesloud noises.

impacttool attachments can disintegrate without

->"I_ warning while inuse, causing flying debris.

. Whenoperatingairimpacttooi_alwayswearANSI-approved

hearingprotection.

* AlwayswearANSIZ87.1approvedsafetyglasseswithside

shields.

, WearanANSIapproveddustmaskorrespiratorwhenworking

aroundmetal,wood,andchemicaldustsandmists.

impactTool Operation

Beforeeach use,drain water out of aircompressor tank and

condensationfrom air lines.

Installthe desired socket or attachment. Tugon the socket

or attachmentto ensure it isfirmly attachedto the airtool.

NOTICE Always useaccessoryfittings andsockets designed

for use with impacttools.

NOTICE The impacttool should neverbe usedto set torque.

Use a torque wrench to set the torque.

Toremovenuts, set the tool's regulatorto its maximum setting

by pushingin and turning theknurledknob to position4.

Toinstall nuts, set the regulator to it's minimum (1) or

medium (2 or 3) setting. DONOTover-tighten fasteners.

Forward and reversedirections arecontrolled by apush

button. Pressthe button fully forward for clockwise socket

rotation. Pressthe knob fully backwardfor counter-clockwise

socket rotation.

3/8 in. Drive RatchetWrench

This ratchetwrench is designed for removing andinstalling

different engine parts such aswater pumps, radiators,and

so forth. It is idealfor use in confinedareas where hand

tools are cumbersome.

Ratchet Wrench Operation

NOTICE This ratchet wrench requires lubrication BEFORE

initial use and BEFOREand AFTEReach additional use

throughout its life. Follow the instructions inAir Motor

Lubrication described in Assembly to lubricate this tool.

WARNING

Using an air ratchetwrench cancause loud

noises.

Ratchettool attachmentscan disintegratewithout

warningwhile in use,causingflying debris.

• When operatingratchet wrench, always wear ANSI-approved

hearing protection.

• Alwayswear ANSi Z87.1 approvedsafety glasses with side

shields.

• Weara full faceshield if youareworking overhead.

• Wearan ANSiapproved dust maskor respirator whenworking

around metal, wood, and chemical dustsand mists.

Beforeeach use,drain water out of air compressor tank and

condensationfrom air lines.

NOTICE The ratchetwrench should never be used to set

torque. Use a torque wrenchto set thetorque.

Selectthe desired handtool 1/2" socket or adapter and press

onto wrench. Tug socketor adapter to ensureit is attached

securely.

Rotatethe reversecontrol leverto the "F" or fully

COUNTERCLOCKWISEposition to tighten fasteners. Depress

the trigger leverfully to activatethe tool. DONOTover-

tighten fasteners.

To removefasteners, rotatethe reversecontrol lever to the

"R" orfully CLOCKWISEposition. Depressthe trigger lever

to activatethe tool.

Other Supplied Accessories

This kit includesa tire inflation tool, an air blow gun tool

with assorted tips, two needleinflators, severaladapters and

adapterfittings and an assortment of 1/2" hex drive sockets.

Thesedevicesare designedfor clearing areasof loosedebris

or liquids, for air bladder inflation, or for installing/removing

fasteners.

Tire Inflation Tool

Touse the tire inflation tool (also called an air chuck):

1. Connecttire inflation tool to air supply.

2. Press tire inflation tool overtire valve stem andpermit

air to enter tire. DONOTover inflate.

3. Use the supplied air pressure gaugeto establish

recommendedair pressure. Recommendedtire

pressures areoften shown on side of tire.

i,=1.

o

.,=1

15

AirBlowGun

CAUTION!Never aim air stream at living things. Ensureother

people in the sprayarea arewearing safety goggles anddust

masks, asappropriate.

WARNING

Operatingair blow gun causesflying debris.

,,dm_

--_W Air inflation tools could cause air bladder to

explode,causing flying debris.

• AlwayswearANSIZ87.1approvedsafetyglasseswithside

shields.

• WearanANSIapproveddustmaskorrespiratorwhenworking

aroundmetal,wood,andchemicaldustsandmists.

Touse the air blow gun:

1. Attachthe desired nozzleto the gun finger tight.

2. Connectair blow gun to air supply.

3. Put on ANSiZ87.1 approvedsafety glasses with side

shields. Presstrigger onair blow gun and direct air

stream at debris.

4. Sweepair stream back and forth to blow debris out of

the desired area.

An adapter is supplied to connectthe rubber tip air nozzleto

the air blow gun.

Needle inflator

Touse a needleinflator to inflate a basketballor volleyball,

for example:

1. Connecttire inflation tool to air supply.

2. Lubricate needleinflator with water or other non-

petroleum-based lubricant.

3. Gently and fully insert needleinto air valveon

basketball.

4. Press tire inflation tool over needleinflator and permit

air to enter bladder.DONOTover inflate.

5. Use supplied air pressuregaugeto establish

recommendedair pressure.

1/2" HexDrive Sockets

The1/2" hex drive sockets are designedto be used with the

impact tool.

Touse a 1/2 in. hex drive socketswith the ratchetwrench:

1. Attach 3/8" to 1/2" hex drive adapterto ratchetwrench.

2. Press desired 1/2" hex drive socket into adapteruntil

fully seated.

3. Connect ratchetwrench to air supply.

4. Follow ratchet instructions given earlier.

e.=

o

16 www.brutepower.corn

Loading...

Loading...