Briggs & Stratton 040298, 040298A, 040301, 040315, 040320 Service & Troubleshooting Manual

Home Generator System

Not for

Reproduction

Manual 278994GS Rev. -

SERVICE & TROUBLESHOOTING MANUAL

BRIGGS & STRATTON

HOME GENERATOR SYSTEM - 7kW

FORWARD

Not for

Reproduction

This manual was written to assist technicians and service personnel with the repair and maintenance procedures for

Briggs & Stratton Home Standby Generators. It assumes that persons using this manual have been properly trained in

and are familiar with the servicing procedures for these products, including the proper use of required tools and safety

equipment and the application of appropriate safety practices. Persons untrained or unfamiliar with these procedures or

products should not attempt to perform such work.

Proper maintenance and repair is important to safe, reliable operation of all engines and engine-driven systems. The

troubleshooting, testing, maintenance, and repair procedures described in this manual are appropriate for the Briggs &

Stratton Home Standby Generators described herein. Alternative methods or procedures may pose risk to personal

safety and the safety and/or reliability of the engine and are not endorsed or recommended by Briggs & Stratton.

All information, illustrations, and specifications contained in this manual were based on the data available at the time of

publication. Briggs & Stratton Corporation reserves the right to change, alter, or otherwise improve the product or the

product manuals at any time without prior notice.

Copyright © 2010 Briggs & Stratton Corporation

All rights reserved.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying or recording by any information storage and retrieval system, without prior written permission

from Briggs & Stratton Corporation.

This generator is rated in accordance with UL (Underwriters Laboratories) 2200 (stationary generator assemblies) and

CSA (Canadian Standards Association) standard C22.2 No. 100-04 (motors and generators).

SECTION 1 - Safety, Maintenance and Adjustments

Not for

Reproduction

SECTION 2 - Troubleshooting

SECTION 3 - Unit Disassembly

SECTION 4 - Generator Specifications

1

2

3

4

THISPROPER SERVICE AND REPAIR IS IMPORTANT

Not for

Reproduction

TO THE SAFE, ECONOMICAL AND RELIABLE

MODELS COVERED IN THIS MANUAL

• 040298

• 040298A

• 040301

• 040315

• 040320

SECTION 1 - SAFETY, MAINTENANCE AND ADJUSTMENTS

Not for

Reproduction

Equipment Description

This product is intended for use as an optional residential

generator system which provides an alternate source of

electric power. This product does not qualify for emergency

standby as defined by NFPA 70 (NEC).

Every effort has been made to ensure that the information in

this manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

This repair manual contains safety information that is

designed to:

• Make you aware of hazards associated with

generators.

• Inform you of the risk of injury associated with

those hazards.

• Tell you how to avoid or reduce the risk of injury.

Signal Words in Safety Messages

WARNING Before attempting to service this

equipment, read and understand this manual and the

operating instructions of the generator. Failure to follow

instructions could result in property damage, serious

injury (including paralysis) or even death.

Safety Symbols and Meanings

EXPLOSION FIRE ELECTRICAL

SHOCK

1

1

The safety alert symbol is used to identify safety

information about hazards that can result in personal injury.

A signal word (DANGER, WARNING, or CAUTION) is used

with the alert symbol to indicate the likelihood and the

potential severity of injury. In addition, a hazard symbol may

be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard, which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE address practices not related to personal injury.

TOXIC FUMES ROTATING

PARTS

AUTO START EXPLOSIVE

PRESSURE

LIFT HAZARD READ MANUAL

WARNING Running engines gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting, or death.

• Operate generator ONLY outdoors.

• Install a battery operated carbon monoxide alarm

near the bedroom.

• Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or

other openings.

HOT SURFACE

CHEMICAL

BURN

1

WARNING Battery posts, terminals, and related

Not for

Reproduction

accessories contain lead and lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

1

WARNING The engine exhaust from this product

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

1

WARNING Certain components in this product and

related accessories contain chemicals known to the State

of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

WARNING Storage batteries give off explosive

hydrogen gas during recharging. Slightest spark

will ignite hydrogen and cause explosion. Battery

electrolyte fluid contains acid and is extremely

caustic. Contact with battery contents will cause

severe chemical burns. A battery presents a risk

of electrical shock and high short circuit current.

• DO NOT dispose of a battery in a fire. Recycle the

battery.

• DO NOT allow any open flame, spark, heat, or lit

cigarette during and for several minutes after

charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective gloves, rubber apron, rubber boots,

and rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

WARNING Generators produce hazardous voltage.

Failure to properly ground generator can result in

electrocution. Failure to isolate generator from

utility power can result in death or injury to

electric utility workers due to back feed of

electrical energy.

• When using generator for backup power, notify

utility.

• DO NOT touch bare wires or bare receptacles.

• DO NOT use generator with electrical cords which

are worn, frayed, bare, or otherwise damaged.

• DO NOT handle generator or electrical cords while

standing in water, while barefoot, or while hands and

feet are wet.

• If you must work around a unit while it is operating,

stand on an insulated dry surface to reduce the risk

of a shock hazard.

• DO NOT allow unqualified persons or children to

operate or service generator.

• In case of accident caused by electrical shock,

immediately shut down the source of electrical

power and contact the local authorities. Avoid direct

contact with the victim.

• Despite the safe design of the residential generator,

operating the equipment imprudently, neglecting its

maintenance, or being careless can cause possible

injury or death.

• Remain alert at all times while working on this

equipment. Never work on the equipment when you

are physically or mentally fatigued.

• Before performing any maintenance on the

generator, disconnect the battery cable indicated by

a NEGATIVE, NEG or (-) first. When finished,

reconnect that cable last.

• After the system is installed, the generator may

crank and start without warning any time there is a

power failure. To prevent possible injury, always set

the generator’s system switch to OFF, remove the

service disconnect from the disconnect box, AND

remove the 15 Amp fuse BEFORE working on the

equipment.

2

WARNING Propane and Natural Gas are extremely

Not for

Reproduction

flammable and explosive. Fire or explosion can

cause severe burns or death.

• Install the fuel supply system according to NFPA 37

and other applicable fuel-gas codes.

• Before placing the generator into service, the fuel

system lines must be properly purged and leak

tested.

• After the generator is installed, you should inspect

the fuel system periodically.

• NO leakage is permitted.

• DO NOT operate engine if smell of fuel is present or

other explosive conditions exist.

• DO NOT smoke around the generator. Wipe up any

oil spills immediately. Ensure that no combustible

materials are left in the generator compartment.

Keep the area near the generator clean and free of

debris.

WARNING Contact with the muffler area can result in

serious burns. Exhaust heat/gases can ignite

combustibles or structures causing a fire.

WARNING Starter and other rotating parts can

entangle hands, hair, clothing, or accessories.

• NEVER operate generator without protective

housings, covers, or guards in place.

• DO NOT wear loose clothing, jewelry, or anything

that may be caught in the starter or other rotating

parts.

• Tie up long hair and remove jewelry.

• Before servicing, remove 15 Amp fuse from control

panel and disconnect negative (-) battery cable.

CAUTION Installing the 15 Amp fuse could cause the

engine to start.

• Observe that the 15 Amp fuse has been removed

from the control panel for shipping.

• DO NOT install this fuse until all plumbing and wiring

has been completed and inspected.

1

1

• DO NOT touch hot parts and AVOID hot exhaust

gases.

• Allow equipment to cool before touching.

• DO NOT install the generator closer than 5 feet

(1.5m) from any combustibles or structures with

combustible walls having a fire rating of less than 1

hour.

• Keep at least minimum distances shown in General

Location Guidelines to ensure proper generator

cooling and maintenance clearances.

• Replacement parts must be the same and installed in

the same position as the original parts.

WARNING Hazardous Voltage - Contact with power

lines can cause electric shock or burn. Lifting

Hazard / Heavy Object - Can cause muscle strain

or back injury.

• If lifting or hoisting equipment is used, DO NOT

contact power lines.

• DO NOT lift or move generator without assistance.

• DO NOT lift unit by roof as damage to the generator

will occur.

CAUTION Excessively high operating speeds

increase the risk of injury and damage to the generator.

Excessively low speeds impose a heavy load on the

generator.

• DO NOT tamper with governed speed. Generator

supplies correct rated frequency and voltage when

running at governed speed.

• DO NOT modify generator in any way.

NOTICE: Exceeding generator’s wattage/amperage capacity

can damage generator and/or electrical devices connected to

it.

• See Essential Circuits in operator’s manual.

• Start generator and let engine stabilize before

connecting electrical loads.

NOTICE: Improper treatment of generator can damage and

shorten its life.

• Use generator only for intended uses.

• If you have questions about intended use, contact

your authorized dealer.

• Operate generator only on level surfaces.

• Adequate, unobstructed flow of cooling and

ventilating air is critical to correct generator

operation.

• The access panels/doors must be installed

whenever the unit is running.

3

1

Not for

Reproduction

1

• DO NOT expose generator to excessive moisture,

dust, dirt, lint, or corrosive vapors.

• Remain alert at all times while working on this

equipment. Never work on the equipment when

you are physically or mentally fatigued.

• DO NOT start engine with air cleaner or air

cleaner cover removed.

• DO NOT insert any objects through cooling slots.

• DO NOT use the generator or any of its parts as a

step. Stepping on the unit can cause stress and

break parts. This may result in dangerous

operating conditions from leaking exhaust gases,

fuel leakage, oil leakage, etc.

• If connected devices overheat, turn them off and

disconnect them from generator.

• Shut off generator if electrical output is lost, if

equipment sparks, smokes, or emits flames, or if

unit vibrates excessively.

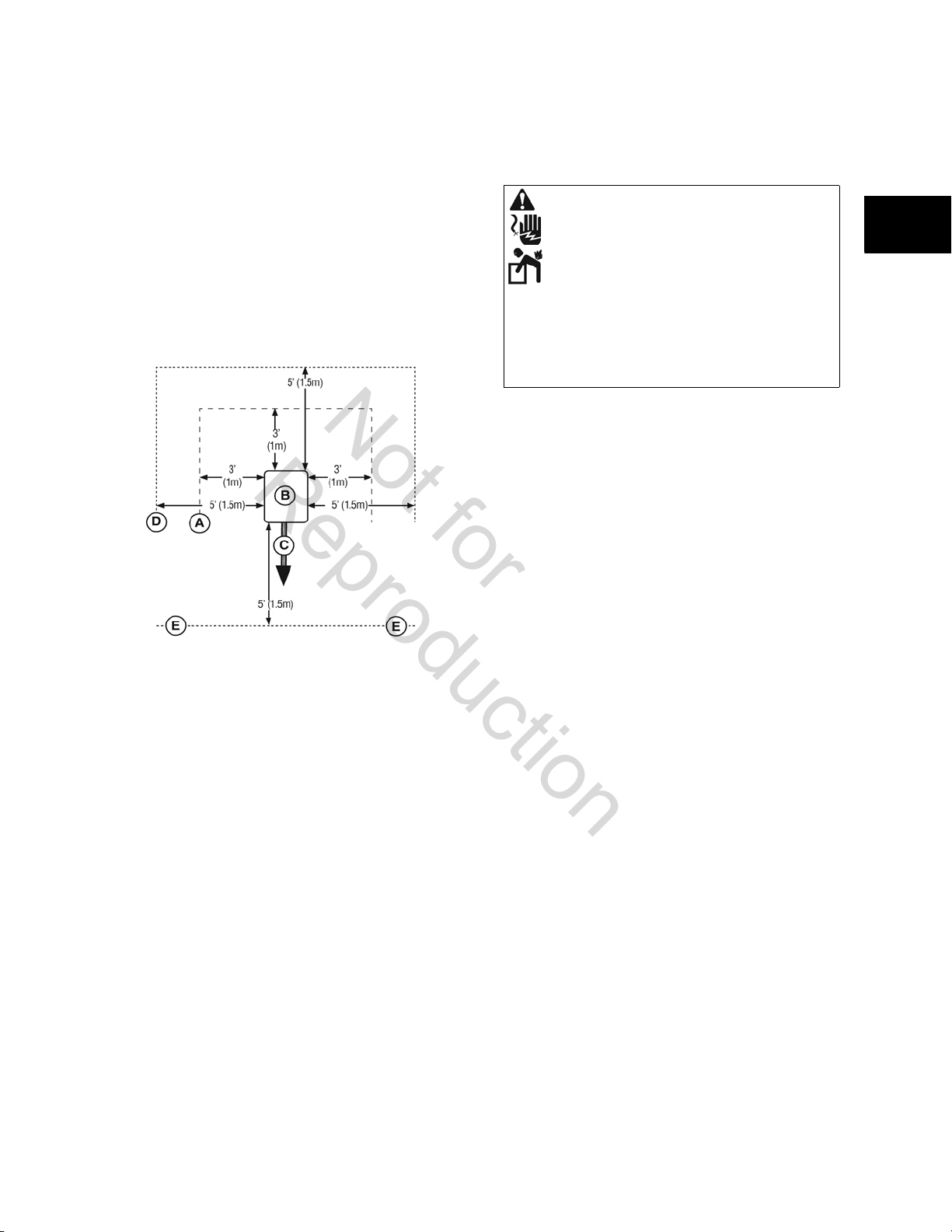

Generator Clearances

Install generator outdoors in an area which will not

accumulate deadly exhaust gas. DO NOT install generator

where exhaust gas could accumulate and enter inside or be

drawn into a potentially occupied building. Ensure exhaust

gas is kept away from any windows, doors, ventilation

intakes, or other openings that can allow exhaust gas to

collect in a confined area.

WARNING Running engines gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting, or death.

• Operate generator ONLY outdoors.

• Install a battery operated carbon monoxide alarm

near the bedroom.

• Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or

other openings.

WARNING Exhaust heat/gases can ignite

combustibles or structures causing a fire.

• DO NOT install the generator closer than 5 feet

(1.5m) from any combustibles or structures with

combustible walls having a fire resistance rating of

less than 1 hour.

General Location Guidelines

• Install the unit outdoors ONLY.

• Place the unit in a prepared location that is flat

and has provisions for water drainage.

• Install the unit in a location where sump pump

discharge, rain gutter down spouts, roof run-off,

landscape irrigation, or water sprinklers will not

flood the unit or spray the enclosure and enter

any air inlet or outlet openings.

• Install the unit where it will not affect or obstruct

any services (including covered, concealed, and

underground), such as telephone, electric, fuel,

irrigation, air conditioning, and so forth.

• Install the unit where air inlet and outlet openings

will not become obstructed by leaves, grass,

snow, etc. If prevailing winds will cause blowing

or drifting, you may need to construct a

windbreak to protect the unit.

• Install the generator as close as possible to the

transfer switch and fuel supply to reduce the

length of wiring, conduit, and piping.

4

NOTICE: Laws or local codes may regulate the distance to the

Not for

Reproduction

fuel supply.

The minimum (MIN) clearances from aerial view of generator

(B) to combustible (D), and non-combustible (A) materials is

shown below.

• These distances are provided to give generator

clearances relative ONLY to combustibles,

generator cooling, and maintenance.

• The minimum distances in the figure are as

shown. All four sides of the generator cannot be

enclosed or restricted, even if the minimum

distances are maintained. DO NOT connect (A)

and/or (D) to (E).

• Do NOT install a roof over the generator, or place

the generator under an existing roof.

• Exhaust (C) must not be allowed to accumulate.

Lifting the Generator

The generator weighs more than 350 pounds (159 kg).

Proper tools, equipment, and qualified personnel should be

used in all phases of handling and moving the generator.

WARNING Hazardous Voltage - Contact with power

lines can cause electric shock or burn. Lifting

Hazard / Heavy Object - Can cause muscle strain

or back injury.

• If lifting or hoisting equipment is used, DO NOT

contact power lines.

• DO NOT lift or move generator without assistance.

• DO NOT lift unit by roof as damage to the generator

will occur.

Lifting pockets are provided at each corner between the base

of the generator and its mounting pad. See Generator

Components for lifting pocket location. Retouch any chipped

paint with supplied touch-up paint.

1

1

A- Non-Combustible material with Fire Resistant Rating of 1

hour or greater.

B- Home Standby Generator

C- Engine Exhaust

D-Combustible Material or Structure with a Fire Resistance

Rating of less than 1 hour.

E- Any structure or material. DO NOT connect (A) and/or (D)

to (E).

5

1

Not for

Reproduction

1

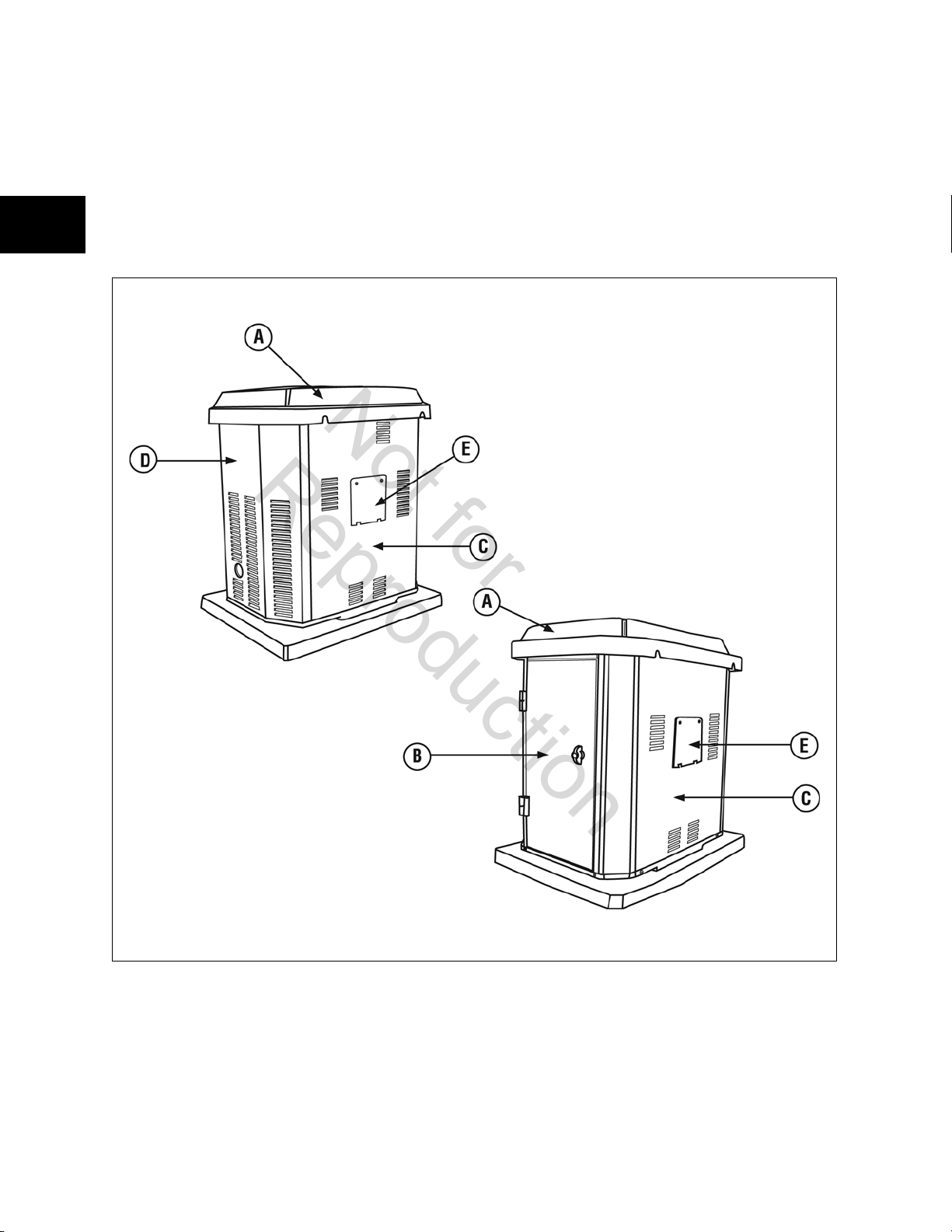

Access To The Generator

The 7kW Home Standby Generator System is equipped with

several access openings and a removable roof (Figure 1).

• Roof (A)

• Access Door (B)

• Side Panel (C)

• Access Panel (D)

• Access Cover for Oil Drain and Oil Filter (E)

Each generator is supplied with a set of identical keys. These

keys fit the locks that secure the access door.

Figure 1

6

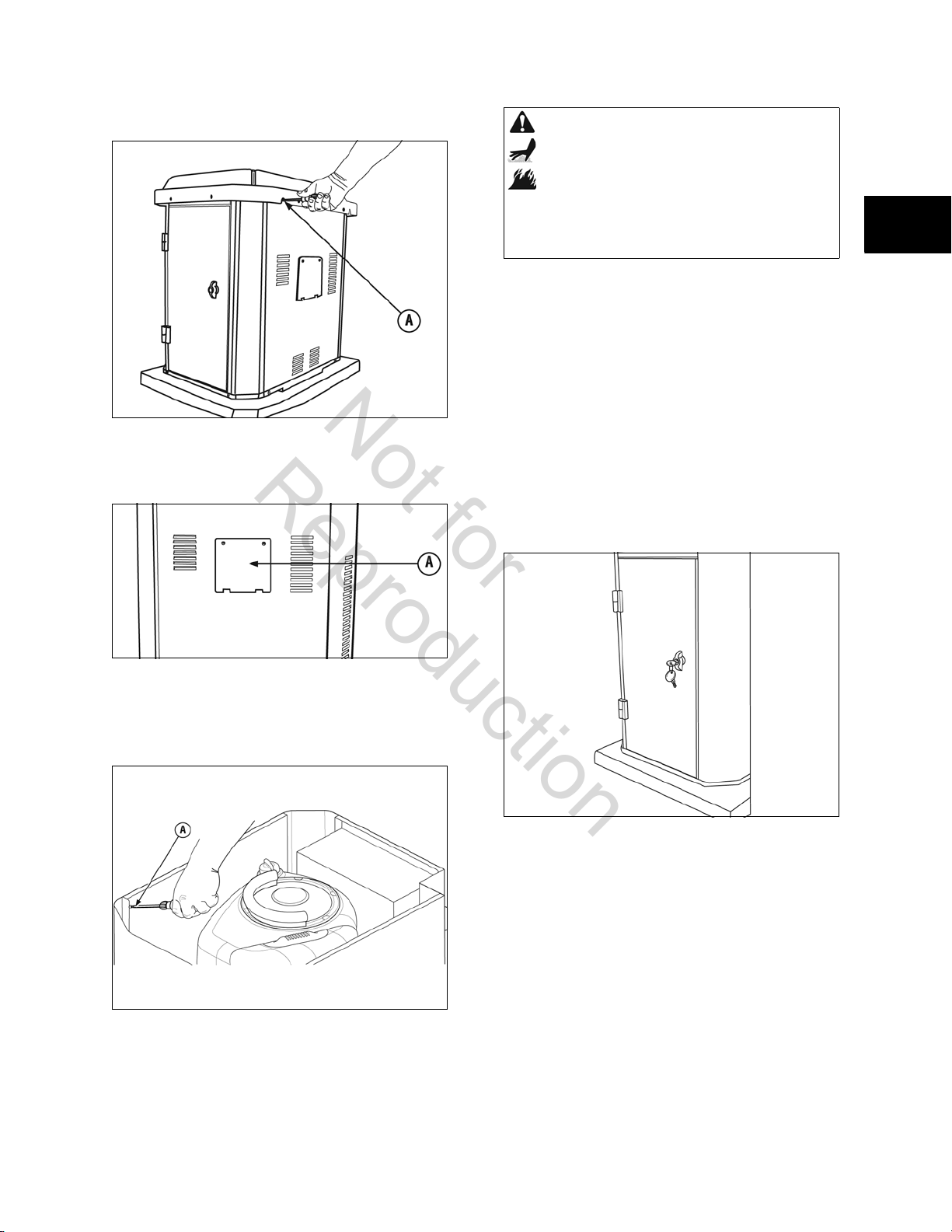

To remove roof:

Not for

Reproduction

Remove the four screws and lift off (A, Figure 2). Reinstall

roof in the reverse order.

WARNING Contact with the muffler area can result in

serious burns. Exhaust heat/gases can ignite

combustibles or structures causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust

gases.

• Allow equipment to cool before touching.

1

Figure 2

To remove access cover:

Remove two screws, tilt cover out, and lift cover off panel (A,

Figure 3). Reinstall cover in the reverse order.

Figure 3

To remove side panels:

1. Remove roof.

2. Remove screws at base of enclosure and along the

side of the control panel (A, Figure 4).

3. Pull panel outward (away) from unit while pulling

panel upward and out of base.

To install side panel:

1. Guide bottom of panel into base.

2. Push panel until flush with sides.

3. Replace panel screw(s).

4. Replace roof and screws.

To open access door:

1. Insert key into lock of access door handle and turn

key one quarter turn clockwise (Figure 5).

1

Figure 4

7

Figure 5

2. Grasp door handle and turn one quarter turn

counterclockwise to open. Remove key.

To close access door:

1. Close door and turn door handle one quarter turn

clockwise.

2. Insert key into lock of door handle and turn key one

quarter turn clockwise. Remove key.

1

Not for

Reproduction

1

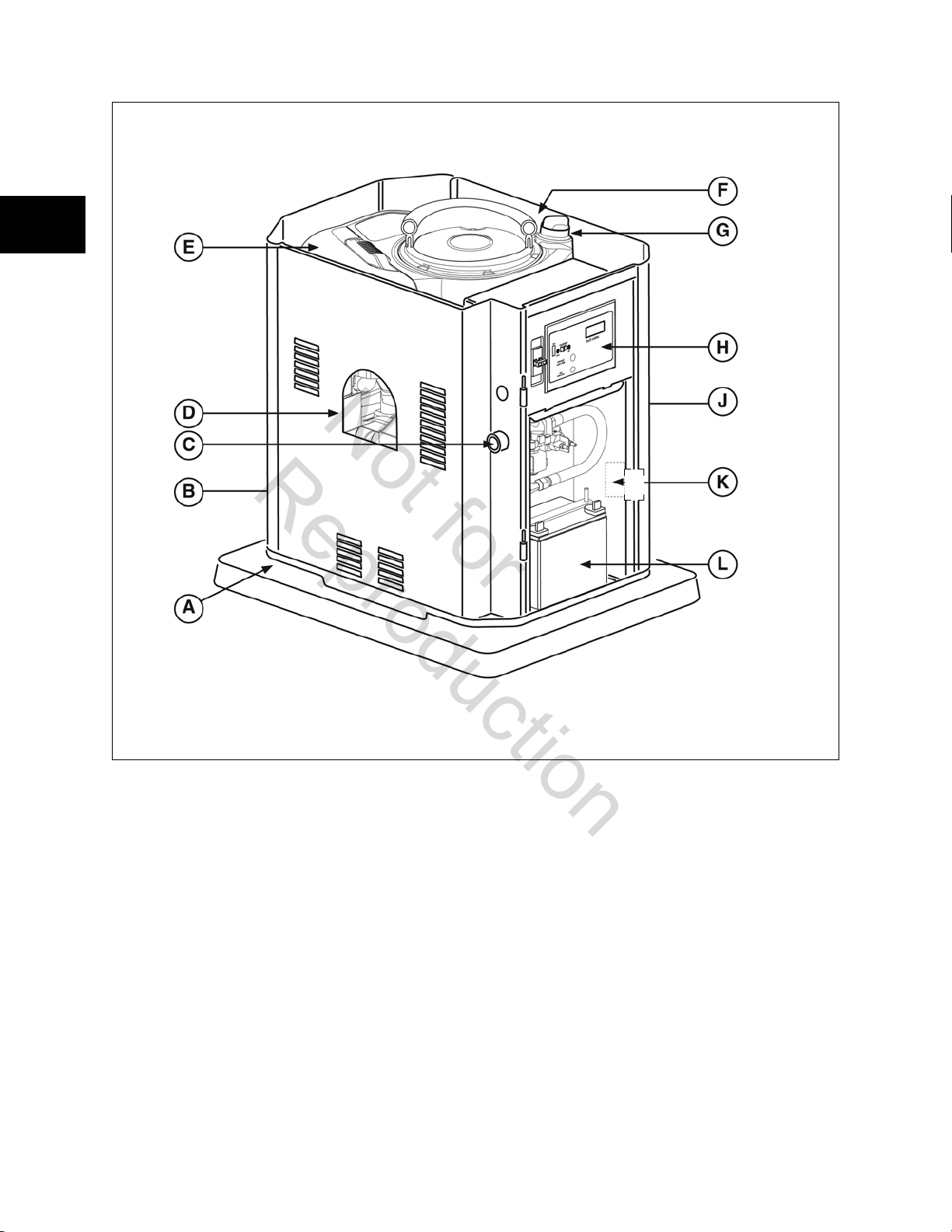

Generator Components

Generator is shown with roof and access doors removed for

clarity.

A - Lifting Pocket — Provided at each corner for lifting

generator.

B - Exhaust Port

engine noise to comply with most residential codes.

C - Fuel Inlet

here.

D - Oil Filter

Filters engine oil to prolong generator life.

E - Air Cleaner

element and foam pre-clean er to protect engine by filtering

dust and debris out of intake air.

8

— High-performance muffler lowers

— Attach appropriate fuel supply to generator

— Located inside access cover on side panel.

— Uses a dry type, UL approved filter

F - Engine Label

numbers.

G - Oil Fill Cap/Dipstick

recommended oil here.

H - Control Panel

maintenance functions. See System Controls.

J - Oil Drain Hose

panel. Provided to facilitate oil changing.

K - Unit Identification Label

serial number.

L - Battery

provides power to start the engine.

— Identifies engine model, type, and code

— Check and fill engine with

— Used for various test, operation, and

— Located inside access cover on side

— Identifies unit by model and

— (Installer-supplied) 12 Volt DC, sealed battery

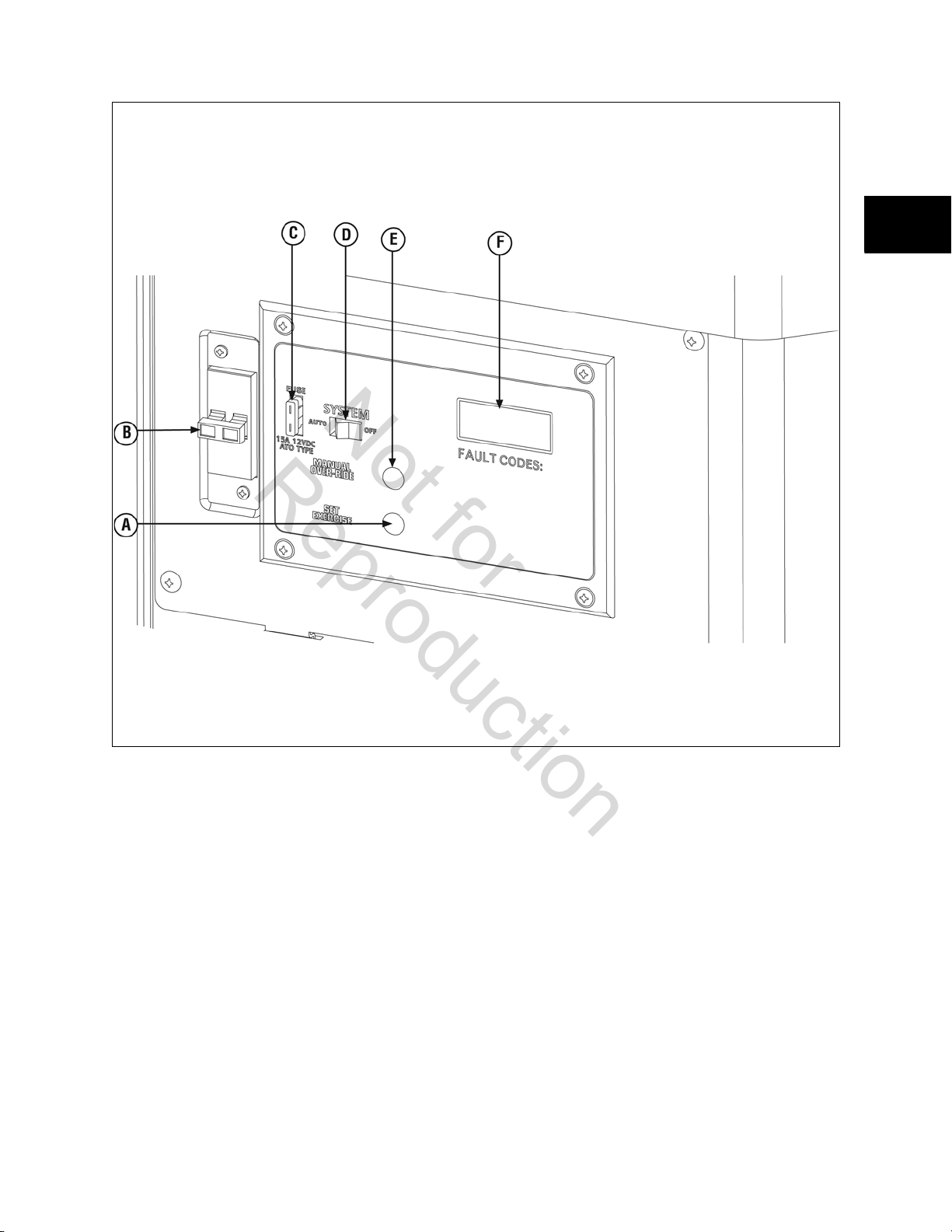

System Controls

Not for

Reproduction

1

1

A - Set Exercise — Used to set the exercise cycle start time

and day-of-the-week. Exercise cycle only occurs in AUTO

mode.

B - Circuit Breaker

and other over-current conditions. Must be ON to supply

power to the automatic transfer switch.

C- 15 Amp Fuse

circuits. If the fuse has ‘blown’ (melted open) or was

removed, the engine cannot crank or start. Replace the fuse

using only an identical ATO 15A fuse.

D - System Switch

important control on the system and is used as follows:

“AUTO” position is the normal operating position. If a utility

power outage is sensed, the system will start the generator.

When utility power is restored, AUTO lets the engine stabilize

internal temperatures, shuts off the generator, and waits for

the next utility power outage.

“OFF” position turns off running generator, prevents unit

from starting, and resets any detected faults.

9

— Protects the generator from shorts

— Protects the generator DC control

— This two-position switch is the most

E - Manual Over-RIde

technician to manually start and stop the generator.

With system switch in the AUTO position, push and hold the

MANUAL OVER-RIDE for six seconds to start the generator.

To turn off the generator, push and hold MANUAL OVERRIDE until engine stops.

F- Digital Display

generator has been running and fault codes. It is used to

schedule maintenance tasks and for troubleshooting

operational problems with the residential generator. A

constant number displayed indicates the total hours of

operation. Fault conditions will flash “FC” followed by a fault

code number.

— This function allows the

— Displays the total number of hours the

1

Not for

Reproduction

1

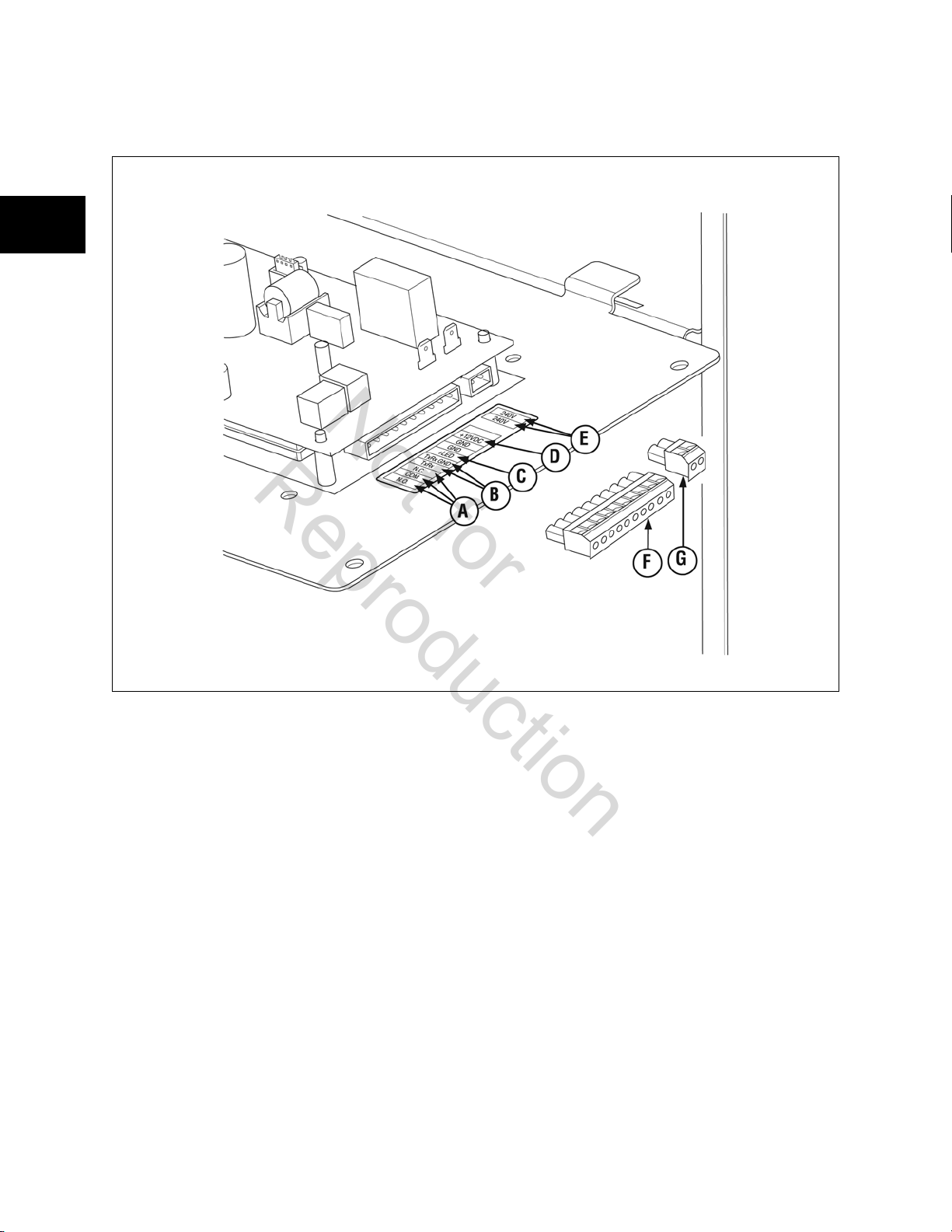

System Connections

Except for the power output and grounding connectors, all signal wire connections are made to removable two- or ten-pin connector

plugs. Compare this illustration with your generator to familiarize yourself wtih the location of these important connections. Count

down to the proper pin location on the control board since visual alignment with the decal can be misleading:

A- Fault Contacts

optional phone dialer or a siren, light, etc. to alert you in case

of a fault. Contacts reverse state (NO goes to NC and vice

versa) upon a fault condition.

B - Transfer Switch Communication

GND to connect to transfer switch control board for

communication interface.

C - Remote LED Output

the remote LED supplied with the generator. The remote LED

will turn on and off in a series of blinks if certain faults are

detected in the generator.

D - +12 Volt DC,.5 Amp Output

Use +12VDC and GND to connect installer-supplied

accessories (siren, light, etc).

E - 240 Volt Utility Connection

utility leads from the transfer switch fuses to the generator.

F - Ten-pin Connector Plug

G - Two-pin Connector Plug

10

— Use NO, COM, and NC to hook up an

— Use TxRx and TxRx

— Use +LED and GND to connect

— Auxiliary power supply.

— Use to connect the 240V

NOTICE:

• For power output connection, use #8 AWG

minimum 300 volt 75°C-90°C copper wire, (ref.

NEC Table 310.16, 100 ft. Use National Electric

Code for correction factors and wire size

calculations).

• For 240 Volt Utility Circuit Connection, use #14

AWG minimum 300 volts 75°C-90°C copper wire.

• For transfer switch communication use #18 AWG

twisted pair conductors, no greater than 200 ft. in

length, 300 volt 75°C-90°C copper wire.

• When connecting to the connector plugs, fasten

only one wire to each connector screw.

• Torque connector plug screws to 7lb.-in.(8 Nm).

Fuel Factors

Not for

Reproduction

An important consideration affecting the performance of the

generator is the type of fuel used. The system was factory

tested and adjusted using either natural gas or liquid propane

(LP). For proper engine function, important NG or LP factors

are:

• Use clean, dry fuel, free of moisture or any

particulate material. Using fuels outside the

following recommended values may cause

performance problems.

• In engines set up to run on propane (LP),

commercial grade HD5 propane with a minimum

fuel energy of 2500 BTUs/ft3 with maximum

propylene content of 5% and butane heavier gas

content of 2.5% and minimum propane content

of 90%.

WARNING Propane and Natural Gas are extremely

flammable and explosive. Fire or explosion can

cause severe burns or death.

• The residential generator is equipped with an

automatic safety fuel shut-off valve.

• DO NOT operate the equipment if the fuel shut-off

valve is missing or inoperative.

Power Decrease at High Altitude or High Temperature

Air density is less at high altitudes, resulting in less available

engine power. Specifically, engine power will decrease 3.5%

for each 1,000 feet (300 meters) above sea level and 1% for

each 10° F (5.6°C) above 77°F (25°C). Generators located in

these conditions must have their transfer switch

programmed appropriately for this power decrease.

Natural Gas LP Vapor

½ Load Full Load ½ Load Full Load

80 C 137 C 33 C 56 C

80,000 B 137,000 B 82,500 B 140,000 B

C = Cubic feet per hour

B = BTU’s per hour

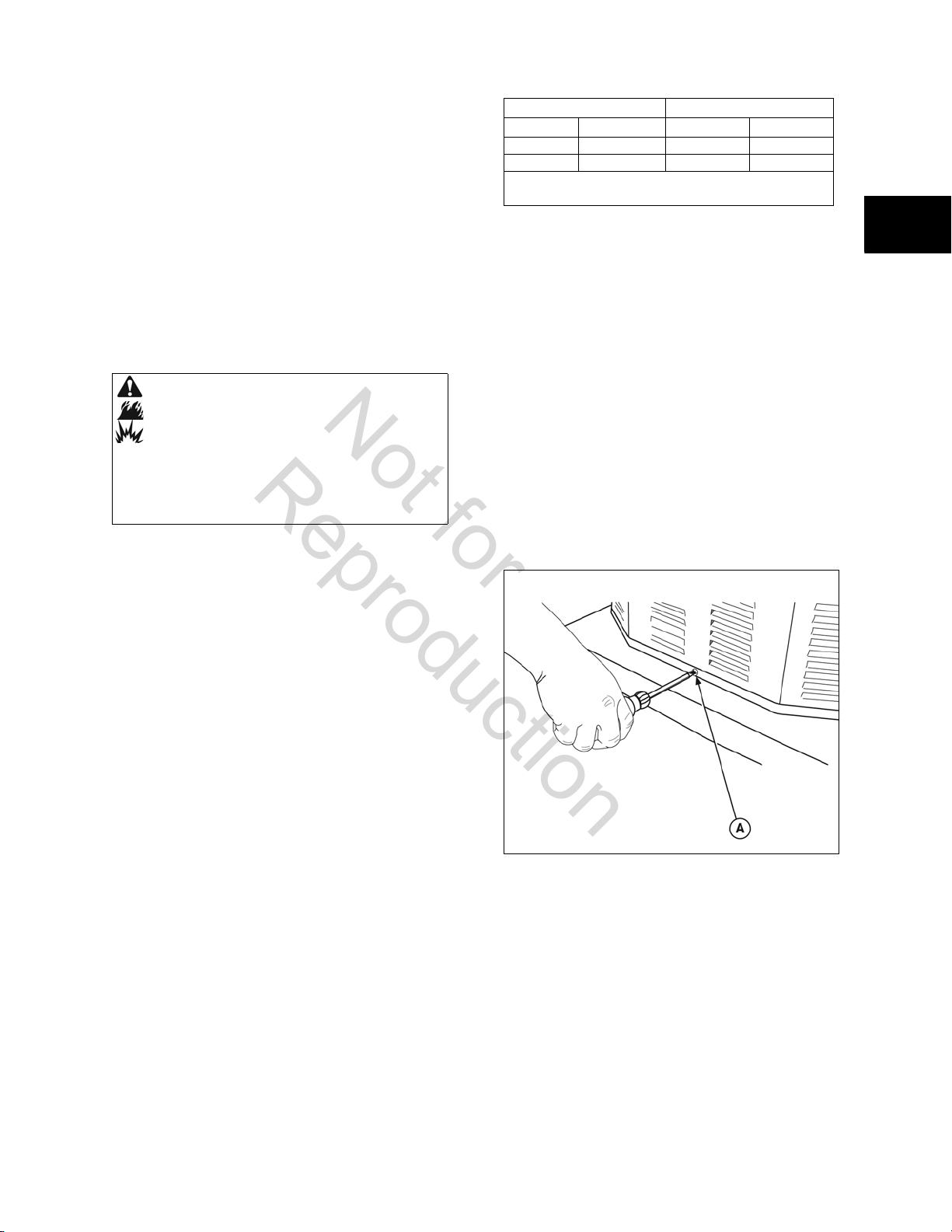

Reconfigure the Fuel System

The engine of your generator is factory calibrated to run on

natural gas (NG). It may also be operated on liquid propane

(LP). There is no additional hardware/equipment required to

switch between either fuel. However, LP fuel inlet pressure

must be between 11 and 14 inches water column at full load

with all gas appliances turned on and operating.

To reconfigure the fuel system for LP use:

1. Set control panel system switch to OFF.

2. Remove 15 Amp fuse.

3. Open oil fill access panel.

4. Remove four screws that secure roof to side panels

and lift off roof.

5. Remove screw at base of enclosure front panel (A,

Figure 6).

1

1

Fuel Consumption

The generator has been factory set to run on natural gas. If

you need to change from natural gas to LP gas, the unit will

need to be reconfigured, as described in Reconfigure the Fuel

System.

The table below provides approximate fuel supply

requirements at half load and full load to ensure effective

generator operation.To check fuel supply pressure, use

#19495, Vacuum Tester.

• Natural gas fuel supply pressure at the generator

fuel inlet port should be between 5 to 7 inches of

water column (in. W.C.) at full load with all gas

appliances turned on and operating.

• LP gas fuel supply pressure should be 11 to 14

inches of water column (in. W.C.) at full load with

all gas appliances turned on and operating.

11

Figure 6

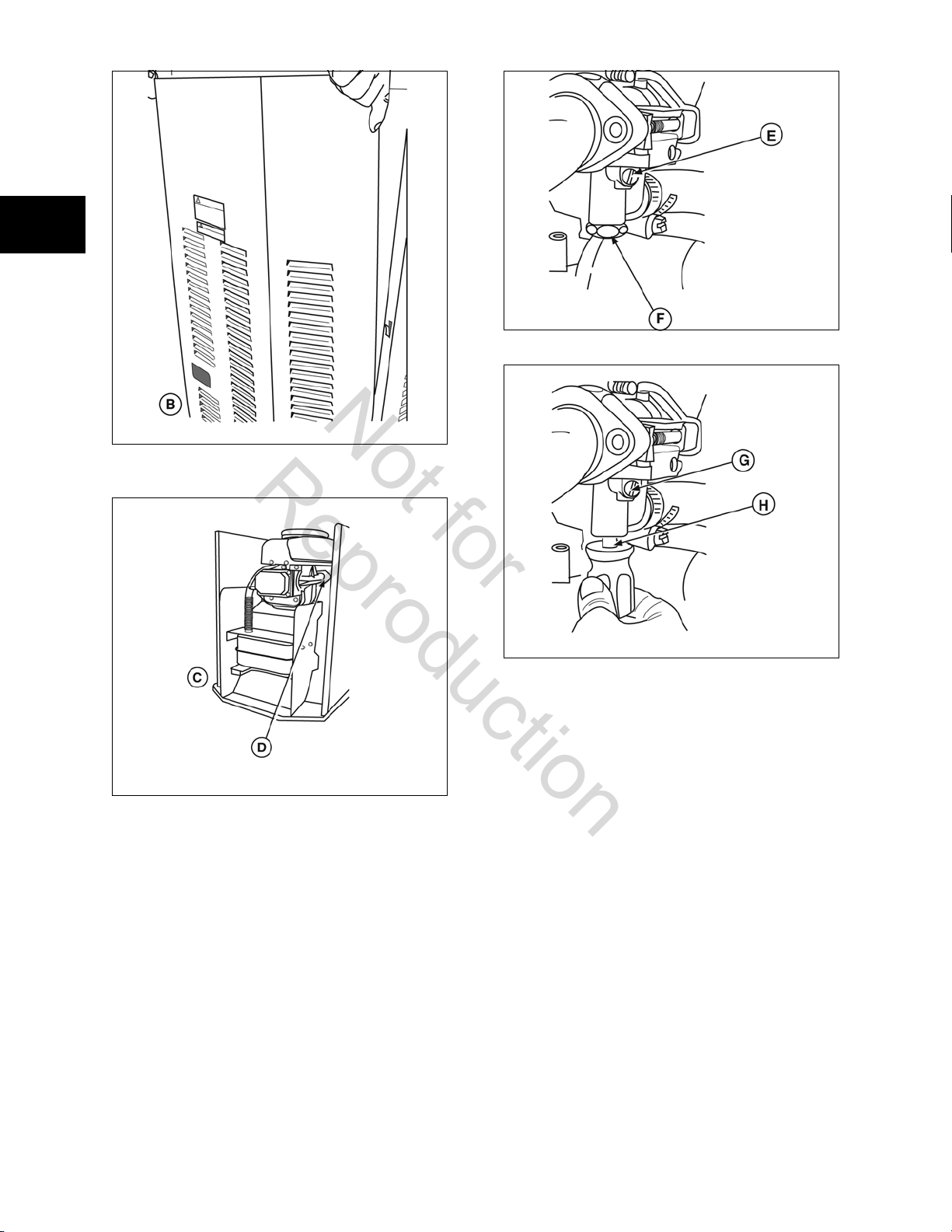

6. Remove two screws at front panel top corners from

inside enclosure.

7. Lift front panel off base (B, Figure 7) and expose

muffler and engine (C,Figure 8).

1

Not for

Reproduction

1

Figure 9

Figure 7

8. Locate the mixer (D).

Figure 10

Figure 8

9. Remove upper brass cover (E, Figure 9) and 3/4” cap

(F).

10. Using a common screwdriver, install supplied plug

into upper chamber (G, Figure 10).

11. Reinstall brass cover (E).

12. Using Insertion Tool #19570, remove existing jet

from lower carburetor inlet (H).

13. Install new jet using Insertion Tool #19570.

14. Replace 3/4” brass cap (F).

15. Reinstall enclosure front panel and roof.

16. Reinstall 15Amp fuse.

17. Set generator circuit breaker to ON position.

The system is now ready to operate automatically using LP

vapor fuel.

12

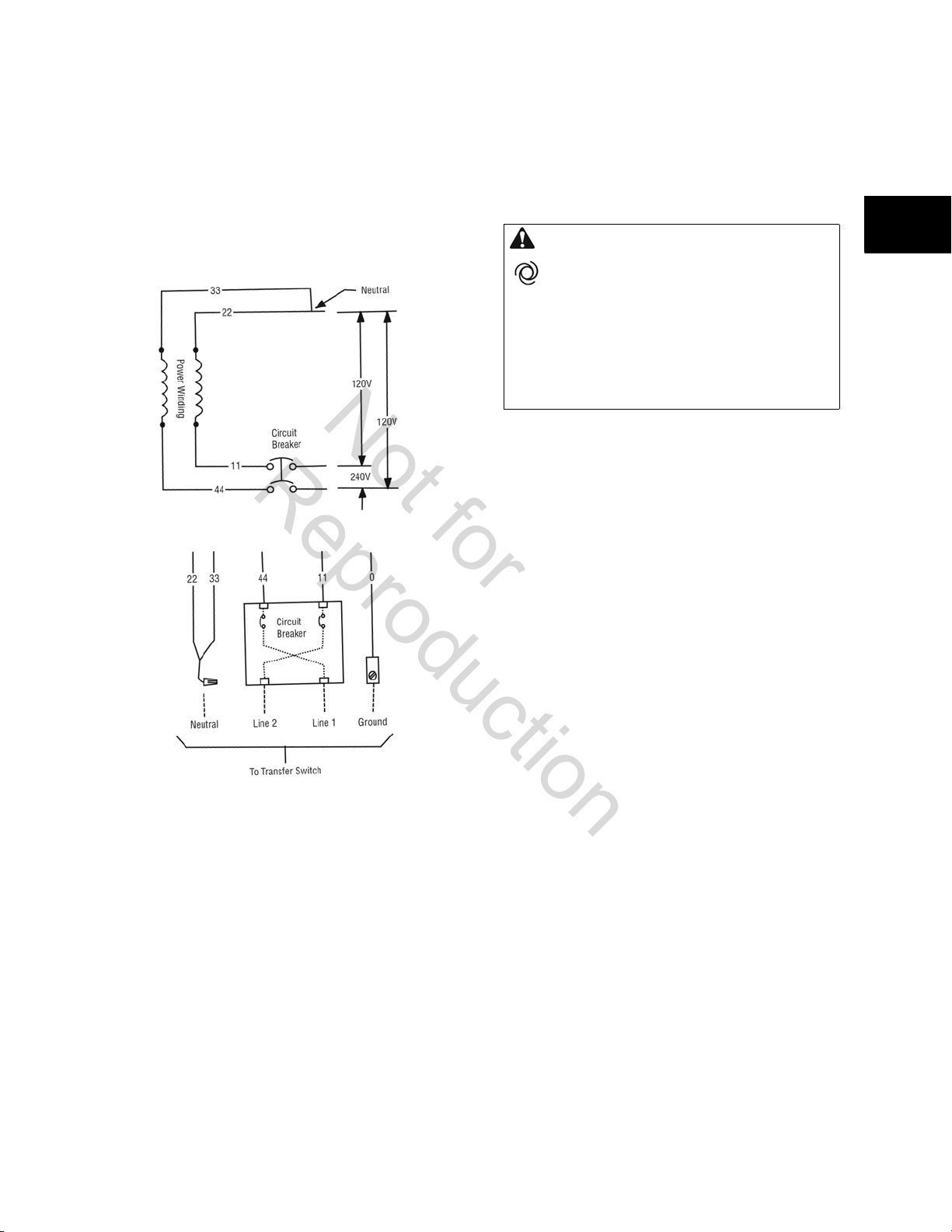

Generator AC Connection System

Not for

Reproduction

A single-phase, three-wire AC connection system is used in

this generator. The stator assembly consists of a pair of

stationary windings with two leads brought out of each

winding. The junction of leads 22 and 33 forms the neutral

lead, as shown schematically and as a wiring diagram. A

complete schematic and wiring diagram can be found in

Section 4 - Generator Specifications.

Automatic Operation

To select automatic operation, proceed as follows:

1. Confirm 15 Amp fuse is installed.

2. Turn on the main distribution panel circuit breaker

that sends utility voltage to the transfer switch.

3. Turn on the generator circuit breaker.

1

CAUTION With the system switch set to AUTO, the

engine may crank and start at any time without

warning.

NOTICE: Neutral is not bonded to ground at generator.

• To prevent possible injury that may be caused by

sudden starts, always set the system switch to OFF if

performing maintenance on the system.

• Remove the 15 Amp fuse before working on or

around the generator or transfer switch.

4. Set the control panel system switch to AUTO.

Checking Automatic Operation

To check the system for proper automatic operation, proceed

as follows:

1. Turn OFF the circuit breaker that sends utility power

to the automatic transfer switch.

NOTICE: When utility voltage is lost and the sensor has timed

out, the engine will crank and start. Let the system go

through its entire automatic operation sequence.

2. With the generator output supplying power, turn ON

the circuit breaker that supplies utility power to the

automatic transfer switch.

3. The automatic transfer switch will transfer loads back

to utility power after a 5 minute minimum run time.

4. The generator will run for an additional one minute

for engine cool down, then shut down.

If utility is restored and generator does not shut down after

10 minutes, set control panel system switch to OFF and

proceed to Section 2 - Troubleshooting.

1

13

Setting Exercise Timer

Not for

Reproduction

The generator is equipped with an exercise timer that will

start and exercise the system once every seven days. During

this exercise period, the unit runs for approximately 20

minutes and then shuts down. Electrical load transfer DOES

NOT occur during the exercise cycle (unless a utility power

outage occurs during the cycle).

A button on the control panel is labeled “Set Exercise” (see

1

System Controls). The day and time at which this button is

pressed is programmed into the control board memory. This

day and time is then used to automatically initiate the system

exercise cycle. The “SET EXERCISE” legend on the control

panel will flash until the set exercise cycle is set.

1

To perform the Set Exercise procedure:

1. Choose the day and time you want the generator to

exercise.

2. On that day and time, press and hold “SET

EXERCISE” for three seconds. “SET EXERCISE” will

flash until the button is held for three seconds, the

“SET EXERCISE” will illuminate for five seconds, and

finally turn off.

For example, if you press “SET EXERCISE” on Sunday

morning at 10:00 AM, the unit will run an exercise cycle every

Sunday at 10:00 AM (+/- 1/2 hour).

“SET EXERCISE” will only work if the unit is in AUTO mode

and this exact procedure is followed. The exerciser will need

to be reset if the 15 Amp fuse is removed or changed, or if

the starting battery is disconnected.

If you want to change the day and time the unit exercises,

simply perform the “Set Exercise” procedure at the new day

and time that you want it to take place.

Generator Maintenance

Before performing any generator maintenance, always

perform the following steps:

1. Set generator’s circuit breaker to its OFF position.

2. Set control panel system switch to OFF.

3. Remove 15 Amp fuse from control panel.

4. Utility voltage is present at generator control panel.

Disconnect utility power before servicing control

panel.

5. Remove roof.

6. After all servicing has been completed, replace fuses

in transfer switch, replace 15 Amp fuse in control

panel, set system switch and circuit breaker ON turn

ON utility power and reset exercise timer. See

Setting Exercise Timer.

For detailed servicing information for the Briggs & Stratton

engine, please refer to the Single Cylinder OHV Repair

Manual (#276781), available from your Briggs & Stratton

source of supply.

Cleaning the Generator

1. Set control panel system switch to OFF.

2. Remove 15 Amp fuse from control panel.

NOTICE: Improper treatment of generator can damage it or

shorten its life.

• DO NOT expose generator to excessive moisture,

dust, dirt, or corrosive vapors.

• DO NOT insert any objects through cooling slots.

3. Use a damp cloth to wipe exterior surfaces clean.

4. Use a soft, bristle brush to loosen caked on dirt, etc.

5. Use a vacuum cleaner to pick up loose dirt and

debris.

6. Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings in

the generator. These openings must be kept clean

and unobstructed.

7. Reinstall 15 Amp fuse in control panel.

8. Set generator’s system switch to AUTO.

9. Reset exercise timer. See Setting Exercise Timer.

14

Cooling Fins

Periodically check to make sure the engine cylinder fins, oil

cooler, screens, and mixer ducting are free of leaves, grass,

mulch, or other debris.

Adjusting the Valve Lash

Not for

Reproduction

The valve lash must be checked every 100 hours of

operation. Measure valve clearance with the engine cold.

To adjust the valve lash, proceed as follows:

1. Turn crankshaft counterclosckwise until piston is at

top dead center on the compression stroke. This

prevents the compression release from holding the

valves open.

2. Insert a narrow screwdriver or rod into the sparkplug

hole as a gauge, then slowly turn crankshaft

counterclockwise until the piston has moved down

the bore by 1/4”.

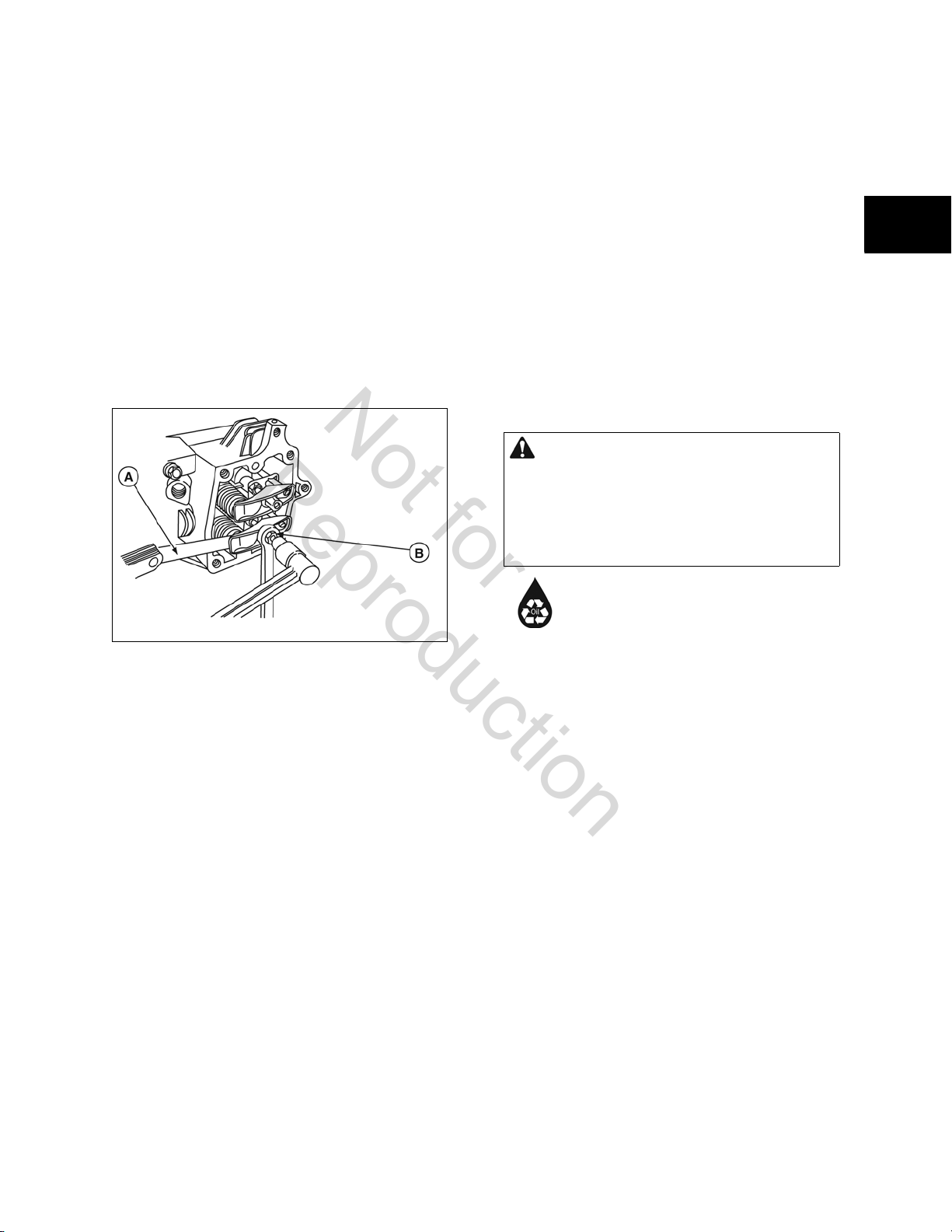

3. Using a feeler gauge (A, Figure 9), adjust the rocker

nut to obtain the correct clearance as listed below:

• Intake - 0.003 - 0.005 in. (0.08 - 0.13 mm)

• Exhaust - 0.005 - 0.007 in. (0.13 - 0.18 mm)

4. Hold rocker nut and tighten the rocker ball setscrew

(B) to 45 lb-in. (5 Nm).

Oil Service

Checking the Oil Level

Check the engine oil level as follows:

1. Remove the roof to the unit to access the oil fill and

dipstick locations.

2. Remove dipstick. Wipe with clean cloth.

3. Insert and rotate dipstick fully to locked position.

Remove and check oil level.

If oil level is low, remove the oil fill cap and slowly add

recommended oil to bring level to the FULL mark on the

dipstick.

Changing the Oil and Oil Filter

Oil capacity is approximately 2-1/2 quarts (80 ounces or 2.3

liters) when changing both the oil and oil filter. Use only 5W-

30 full- synthetic detergent oil rated for service SJ or higher.

This allows for system operation in the widest range of

temperature and climate conditions.

CAUTION Avoid prolonged or repeated contact with

used motor oil.

• Used motor oil has been shown to cause cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and

water.

1

1

Figure 11

5. Check clearance again and readjust, if necessary.

6. Repeat for the other valve.

Replacing the Spark Plugs

Replace the spark plugs every year. Use only the

recommended spark plugs and make sure they are gapped to

0.030 in. (0.76 mm).

1. Stop the engine and disconnect the wires from the

spark plugs.

2. Clean around the spark plugs and remove them from

the cylinder head.

3. Inspect the spark plugs for wear or damage - replace

as necessary. DO NOT blast clean.

4. Set the gap as specified above and install the cleaned

or new spark plugs into the cylinder heads. Torque

to 180 lb-in. (20 Nm).

KEEP OUT OF REACH OF CHILDREN. DON’T

POLLUTE. CONSERVE RESOURCES. TAKE

USED OIL TO COLLECTION CENTERS.

Change oil and oil filter after every 100 hours of operation. If

the unit is run under dirty or dusty conditions or in extremely

hot weather, change the oil more often.

Use the following instructions to change the oil while the

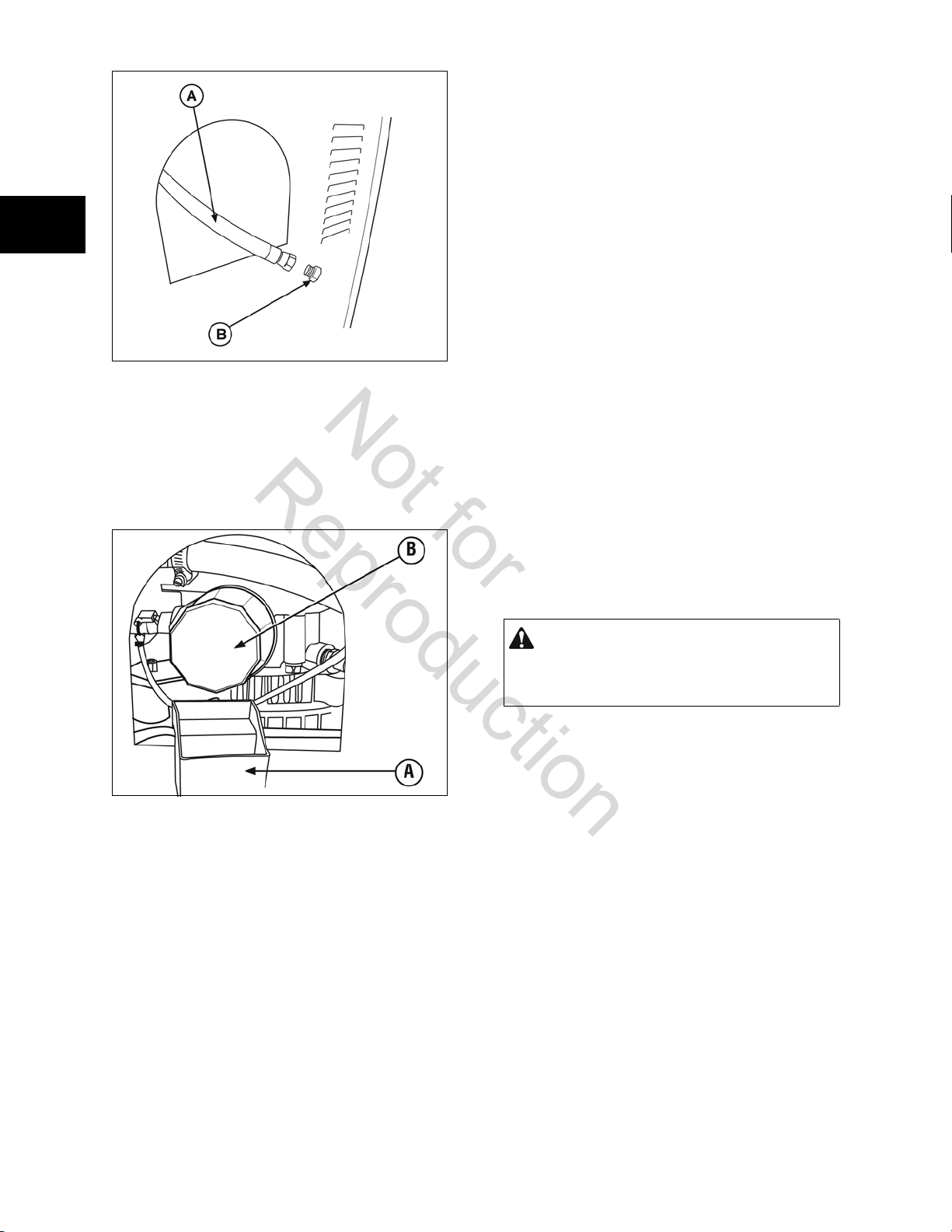

engine is still warm.

1. Set control panel system switch to OFF.

2. Remove the 15 Amp fuse.

3. Gain access to oil drain hose. It is located inside the

access cover on the side panel (Figure 10).

15

Servicing the Air Cleaner

Not for

Reproduction

The engine air cleaner is one of the most important areas to

maintain. Use only genuine Briggs & Stratton parts which

meet UL requirements for a generator. Clean the foam precleaner (if equipped) every 25 hours and the filter cartridge

every 100 hours of operation. Clean or replace more often in

dusty or dirty conditions.

1

1

Figure 12

4. Place oil drain hose (A) into an approved container.

5. Remove fitting (B) from end of drain hose.

6. When oil has drained, reinstall the fitting on the hose.

7. Gain access to the oil filter. It is located inside the

access cover on the side panel.

8. Place the provided oil filter drain tray (A, Figure 11)

beneath the oil filter (B) and remove the filter.

To service the air cleaner:

1. Unsnap and remove the air filter cover.

2. Remove the air filter cartridge and clean by tapping

gently on a flat surface. Replace if very dirty or

damaged.

3. If equipped, remove the foam pre-cleaner from filter

cartridge and wash in soapy water. Rinse thoroughly

and allow to air dry.

4. Remove the foam filter and clean.

5. Reinstall foam filter and clean air filter cartridge.

Make sure that the rubber seals are in contact with

the mounting all around the filter.

6. Engage the two clips of the air filter cover into their

slots and close the air filter cover. Engage the

locking latch of the filter cover and snap shut.

NOTICE: NEVER use petroleum solvents or pressurized air to

clean the air filter cartridge. Solvents will cause the cartridge

to deteriorate; pressurized air will perforate the paper media.

Battery

The installer must supply a valve-regulated, rechargeable 12

volt starting battery. See Battery in the installation manual.

WARNING Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Figure 13

9. Coat the gasket of the new filter with clean engine oil.

Turn the new filter clockwise by hand until the gasket

contacts the filter adapter, then tighten 1/2 to 3/4

turn more.

10. Fill the engine with oil until the level is at the FULL

mark on the dipstick.

11. Install and tighten the oil fill cap.

12. Reinstall the 15 Amp fuse.

13. Start and run the generator using the Manual Over-

Ride button.

14. Run the engine for one minute and check for leaks.

Recheck the oil level.

15. Turn control panel system switch to AUTO and reset

the exercise timer. See Resetting the Exercise TImer.

16. Empty oil filter drain tray.

16

The battery receives a trickle charge from the control board

when:

• The generator is running and,

• When utility power is present and the control

panel system switch is either in the AUTO or OFF

position.

The trickle charge will not recharge a battery that is

completely discharged.

Servicing the Battery

Battery service should be performed or supervised only by

personnel who are knowledgeable of batteries and the

required precautions.

If it is necessary to service the battery, proceed as follows:

1. Set control panel system switch to OFF.

2. Remove 15 Amp fuse from control panel.

3. Service or replace battery as required. See Battery in

section under Final Installation Considerations in the

installation manual for battery specifications.

4. Connect red battery cable to battery positive terminal,

Not for

Reproduction

indicated by POSITIVE, POS, or (+).

5. Connect black battery cable to negative battery

terminal, indicated by NEGATIVE, NEG, or (-).

6. Ensure hardware on both positive and negative

battery terminals is secure.

7. Reinstall 15 Amp fuse in control panel.

8. Set control panel system switch to AUTO.

9. Reset exercise time. See Setting Exercise Timer.

DON’T POLLUTE. CONSERVE RESOURCES.

TAKE USED BATTERY TO RECYCLING

COLLECTION CENTERS.

Charging the Battery

If it is necessary to charge the battery, proceed as follows:

1. Set control panel system switch to OFF.

2. Remove 15 Amp fuse from control panel.

3. Disconnect negative (-) battery cable from negative

(-) battery terminal.

NOTICE: Failure to disconnect negative (-) battery cable will

result in equipment failure.

• DO NOT attempt to jump start the generator.

• Damage to equipment resulting from failure to

follow this instruction will void engine and

generator warranty.

4. Charge battery with battery charger at 2 Amps until

battery is fully charged. DO NOT exceed 13.7 volts

when charging.

7. Reinstall 15 Amp fuse in control panel.

CAUTION With the system switch set to AUTO, the

engine may crank and start at any time without

warning.

• To prevent possible injury that may be caused by

sudden starts, always set the system switch to OFF if

performing maintenance on the system.

• Remove the 15 Amp fuse before working on or

around the generator or transfer switch.

8. Set control panel system switch to AUTO.

9. Reset exercise timer. See Setting the Exercise Timer.

Engine Adjustment

There are regional variances in the composition of natural

gas. Each generator leaves the factory set for NG operation. If

the generator frequency is outside the ranges given below,

the combustibility of the gas at the installation site may be

different from the fuel used at the factory.

• Minimum generator frequency is 57 Hz at full

load.

• Maximum generator frequency is 62.0 - 62.5 Hz

at no-load.

1

1

WARNING Storage batteries give off explosive

hydrogen gas during recharging. Slightest spark

will ignite hydrogen and cause explosion. Battery

electrolyte fluid contains acid and is extremely

caustic. Contact with battery contents will cause

severe chemical burns. A battery presents a risk

of electrical shock and high short circuit current.

• DO NOT dispose of a battery in a fire. Recycle the

battery.

• DO NOT allow any open flame, spark, heat, or lit

cigarette during and for several minutes after

charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective gloves, rubber apron, rubber boots,

and rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

5. Connect negative (-) battery cable to negative (-)

battery terminal.

6. Ensure hardware on both positive (+) and negative

(-) terminals is secure.

To adjust the engine for this difference, proceed as follows:

1. Remove four screws and control panel from the

enclosure to expose the main circuit breaker.

2. Connect an accurate frequency meter to line side of

the main circuit breaker or connect tachometer on

spark plug lead.

3. Ensure that the 15 Amp fuse is installed.

4. Set the main circuit breaker ON.

5. Set the control panel system switch to AUTO.

6. Push MANUAL OVER-RIDE on the control panel.

When the engine starts, allow it to warm up for five

minutes.

17

Loading...

Loading...