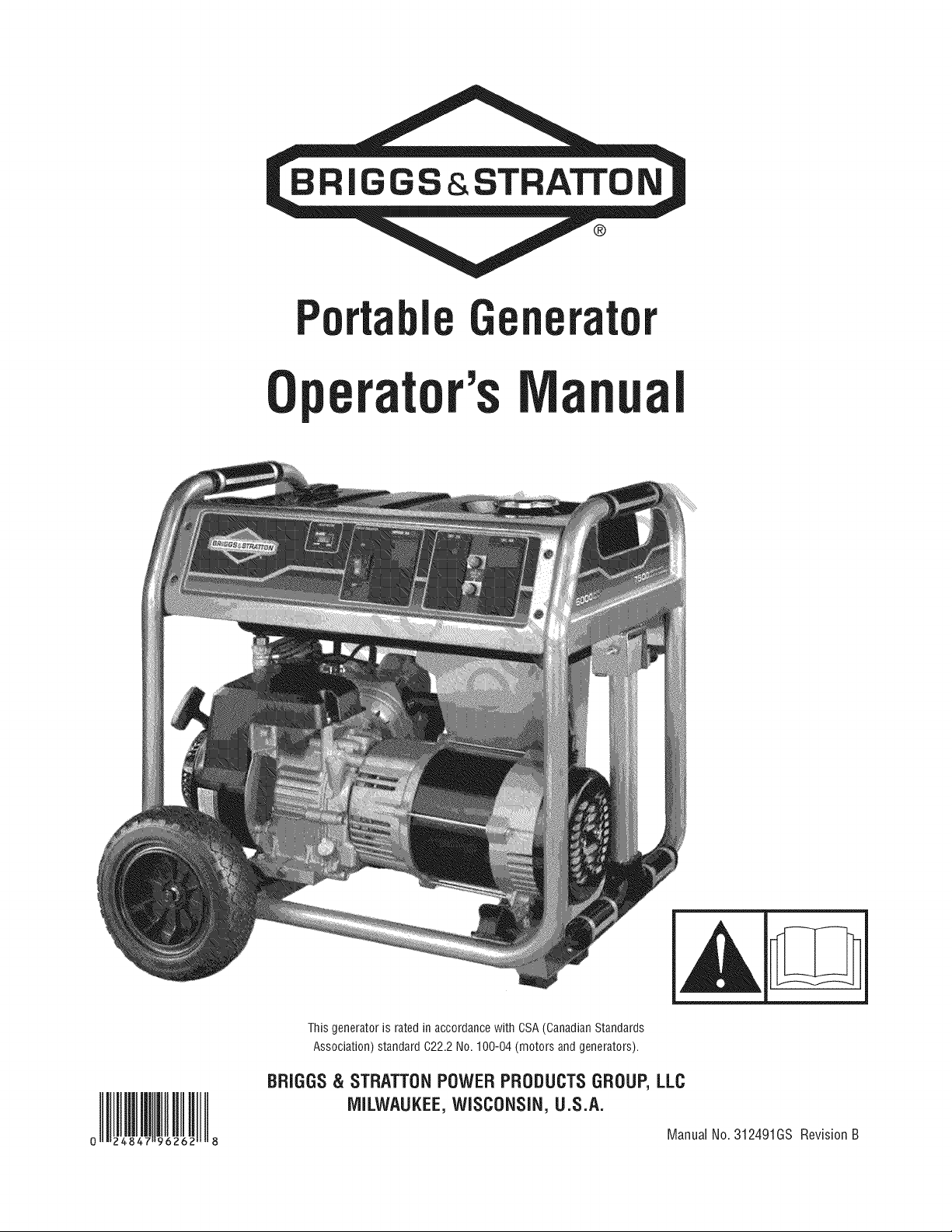

Briggs & Stratton 030467-0 Owner’s Manual

&

®

rator's I

This generator is ratedin accordance with CSA(Canadian Standards

Association) standard C22.2 No. 100-04 (motors and generators).

BRIGGS& STRATTONPOWERPRODUCTSGROUP,LLC

MILWAUKEE,WISCONSIN,U.S.A.

8

Manual No. 312491GS RevisionB

Thankyou for purchasingthis quality-built Briggs & Stratton@generator. We arepleasedthat you've placedyour confidence

in the Briggs & Stratton brand. Whenoperatedand maintainedaccording to the instructions inthis manual,your Briggs &

Stratton generatorwill provide many years of dependableservice.

This manual containssafety information to makeyou awareof the hazardsand risks associatedwith generatorproducts and

how to avoid them. This generator is designed andintendedonly for supplying electrical powerfor operatingcompatible

electrical lighting, appliances,tools andmotor loads, andis not intendedfor any other purpose, it is important that you read

and understand these instructions thoroughly before attemptingto start or operatethis equipment. Save this originalmanual

for future reference.

This generator requires final assemblybeforeuse. Referto the Assembly sectionof this manual for instructions on final

assembly procedures. Followthe instructions completely.

Whereto Find Us

You never haveto look far to find Briggs & Stratton support and servicefor your generator. Consultyour Yellow Pages.There

are over 30,000 Briggs & Stratton authorizedservice dealersworldwide who provide quality service. You canalso contact

Briggs & Stratton CustomerService by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Generator

Model Number

Revision

Serial Number

Engine

Model Number

Type Number

Code Number

Date Purchased

Copyright © 2011. Briggs & Stratton PowerProducts Group, LLC

Milwaukee, WI, USA.All rights reserved.

BRIGGS& STRATTONPOWERPRODUCTSis aregistered

trademark of Briggs & Stratton Corporation

Milwaukee, WI, USA

2 BRIGGSandSTRATTON.COM

Tableof Contents

Operator Safety ................................. 4

Equipment Description......................................... 4

important Safetyinformation.................................... 4

Assembly ..................................... 7

UnpackGenerator ............................................ 7

Shipment Contents ........................................... 7

InstallWheel Kit.............................................. 7

Add Engine Oil............................................... 8

Add Fuel.................................................... 8

System Ground .............................................. 9

Connectingto aBuilding's Electrical System........................ 9

GeneratorLocation ........................................... 9

Featuresand Controls............................ 10

Cord Setsand Receptacles.................................... 11

Operation .................................... 12

Starting the Engine ......................................... ............12

ConnectingElectrical Loads............ ............... 3

Storage ................... . . .. ........................ 19

Troubleshooting ....... 21

Schematic .... :.'. ".;.'. :.'. ".;.'. :.'.'. ;.'. :.'. 22

Warranties...................... 24

Emissions trranty ............................. 24

Generator .................................... 26

Specifications. .!:.. ............................ 28

Product Specifications........................................ 28

Common ServiceParts ....................................... 28

Frangais Espa_ol

(Z}

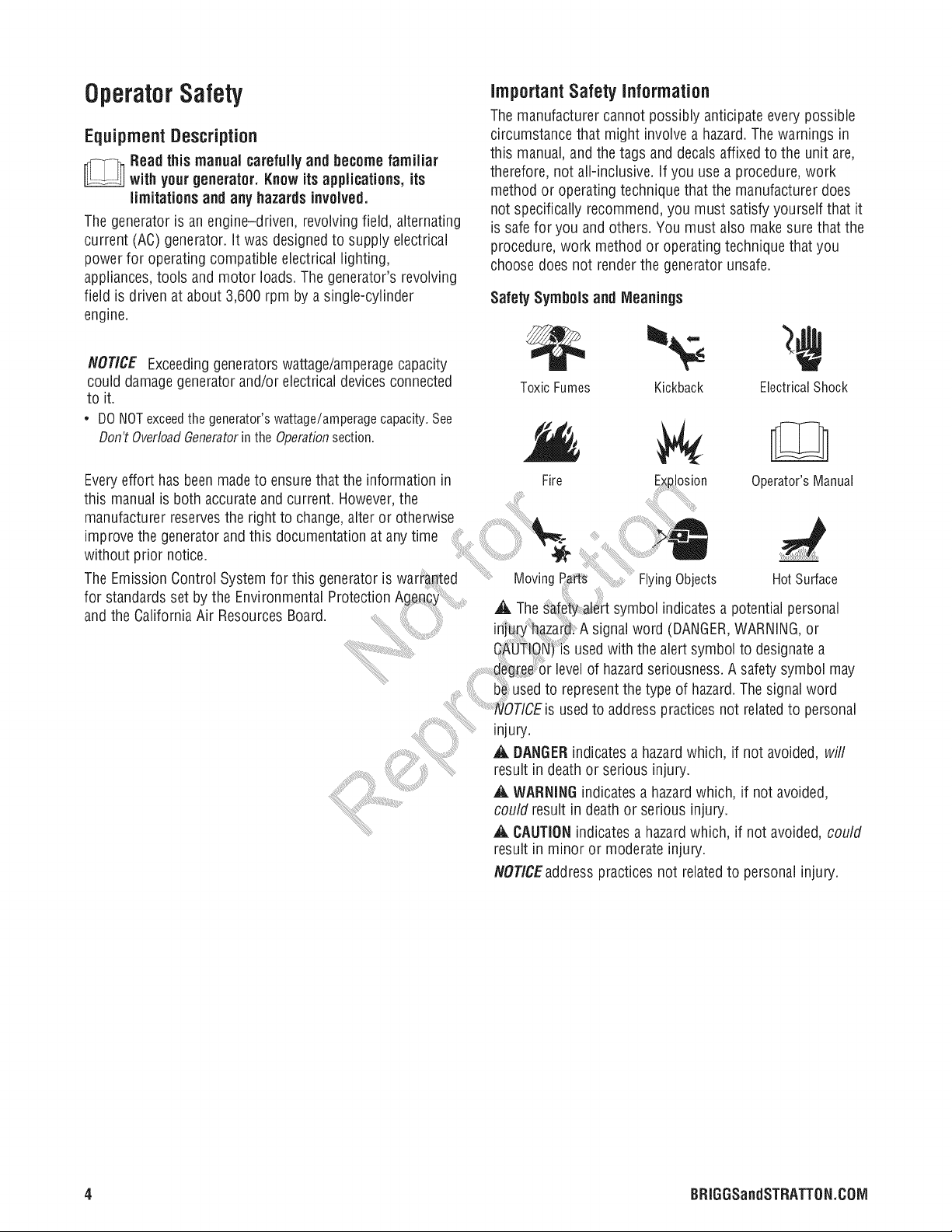

OperatorSafety

EquipmentDescription

Readthis manual carefullyand become familiar

with your generator. Knowitsapplications, its

limitationsand any hazardsinvolved.

Thegenerator is anengine-driven, revolvingfield, alternating

current (AC) generator. It was designedto supply electrical

power for operating compatible electrical lighting,

appliances,tools andmotor loads. Thegenerator's revolving

field is driven at about 3,600 rpm by a single-cylinder

engine.

NOT/CE Exceedinggeneratorswattage/amperagecapacity

could damagegeneratorand/orelectrical devicesconnected

to it.

* DO NOTexceedthe generator's wattage/amperagecapacity. See

Don't OverloadGeneratorin the Operationsection.

Everyeffort hasbeen madeto ensurethat the information in Fire Iosion Operator'sManual

this manualis both accurateand current. However,the

manufacturer reservesthe right to change alter or otherwise .....

improve the generatorand this documentationat anytime .......... ..........

without prior notice.

The EmissionControl System for this generator is warranted ............ MovingRaff_ FlyingObjects HotSurface

for standardsset by the Environmental ProtectionAgency .....

and the California Air ResourcesBoard. ......................_t, The symbol indicatesa potential personal

important Safety information

Themanufacturer cannot possibly anticipateevery possible

circumstance that might involvea hazard.Thewarnings in

this manual, andthe tags and decalsaffixedto the unit are,

therefore, not all-inclusive, if you usea procedure,work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safefor you andothers. You must also makesure that the

procedure, work methodor operating technique that you

choose does not renderthe generator unsafe.

Safety Symbols and Meanings

ToxicFumes Kickback ElectricalShock

A signalword (DANGER,WARNING,or

usedwith the alert symbol to designatea

....... level of hazardseriousness.A safety symbol may

.... usedto representthetype of hazard.Thesignal word

....._OTICE is usedto address practicesnot relatedto personal

injury.

,& BANGERindicatesa hazardwhich, if not avoided, will

result in deathor serious injury.

A WARNINGindicatesa hazardwhich, if not avoided,

could result in death or serious injury.

A, CAUTIONindicates ahazardwhich, if not avoided, could

result in minor or moderateinjury.

NOT/CEaddresspractices not relatedto personal injury.

4 BRIGGSandSTRATTON.COIVl

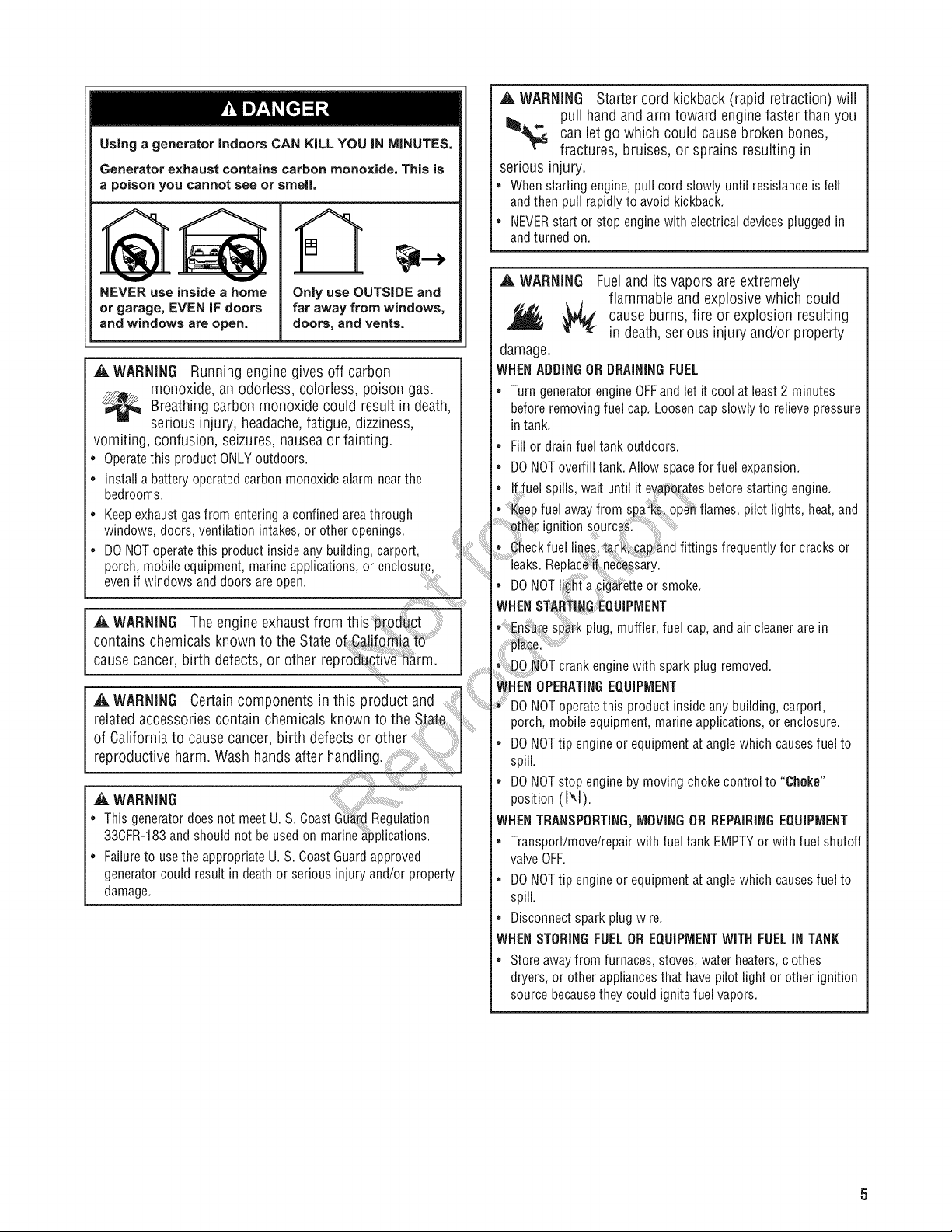

Using a generator indoors CAN KiLL YOU iN MINUTES,

Generator exhaust contains carbon monoxide, This is

a poison you cannot see or smell,

[]

,& WARNING Startercord kickback(rapid retraction) will

pull hand andarm toward engine faster than you

can letgo which could causebroken bones,

fractures, bruises, or sprains resulting in

serious injury.

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpull rapidlytoavoidkickback.

• NEVERstartor stopenginewithelectricaldevicespluggedin

andturnedon.

V

NEVER use inside a home

or garage, EVEN iF doors

and windows are open,

Only use OUTSIDE and

far away from windows,

doors, and vents,

,& WARNING Runningengine givesoff carbon

monoxide, anodorless, colorless, poison gas.

_ Breathingcarbon monoxidecould result in

death,

serious injury, headache,fatigue,dizziness,

vomiting, confusion, seizures,nauseaor fainting.

• Operatethis productONLYoutdoors.

• Installabatteryoperatedcarbonmonoxidealarmnearthe

bedrooms.

• Keep exhaustgas from entering a confined areathrough

windows, doors, ventilation intakes,or other openings.

• DO NOToperatethis product insideany building, carport,

porch, mobile equipment, marine applications, or enclosu[e

evenif windows anddoors are open.

,& WARNING The engine exhaustfrom this p_od_ct

contains chemicalsknown to the Stateo_Gali_oihia_6 .........

causecancer, birth defects, or other reproducti_ _rm.

_ikWARNING Certain componentsin this product and

relatedaccessoriescontain chemicals knownto the

of Californiato causecancer, birth defects

reproductive harm. Wash hands after handling.

A WARNING

• This generatordoes not meet U. S. CoastG_ # Regulation

33CFR-183and should not be usedon marine _pplications.

• Failureto usethe appropriate U.S. CoastGuard approved

generator could result in deathor serious injury and/or property

damage.

,& WARNING Fuel and its vapors are extremely

flammable and explosive which could

cause burns, fire or explosion resulting

in death, serious injury and/or property

damage.

WHENADDING OR DRAiNiNG FUEL

• Turn generator engineOFFand letit cool at least2 minutes

before removingfuel cap. Loosencapslowly to relieve pressure

in tank.

• Fill or drain fuel tank outdoors.

• DONOT overfill tank. Allow spacefor fuel expansion.

i! !uel spills, wait until it e_ape_atesbefore starting engine.

fuel awayfrom spai_ open flames,pilot lights, heat,and

ignition ....

_heckfuel lin#_ fittings frequently for cracks or

ieaks. Replacdii n_e_sary.

• DONOT ii_Nte or smoke.

WHEN

s_Fk, plug,muffler, fuel cap,and air cleanerare in

crank enginewith spark plug removed.

dENOPERATINGEQUIPMENT

NOToperatethis product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure.

• DONOTtip engine or equipment at anglewhich causesfuel to

spill.

• DONOT stop engineby moving chokecontrol to "Choke"

position (1'*,1).

WHEN TRANSPORTING, MOVING OR REPAiRiNGEQUIPMENT

• Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

• DONOTtip engine or equipment at anglewhich causesfuel to

spill.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL INTANK

• Store awayfrom furnaces, stoves,water heaters,clothes

dryers, or otherappliancesthat have pilot light or other ignition

source becausethey could ignitefuel vapors.

A WARNING Generator voltage could cause electrical

_)dh| shock or burn resulting in death or serious

mjury.

• Use approvedtransfer equipment to preventbackfeed by

isolating generatorfrom electric utility workers.

• When usinggenerator for backup power, notify utility company.

• Use aground fault circuit interrupter (GFCI)in any damp or

highly conductive area,such as metal decking or steel work.

• DO NOTtouch barewires or receptacles.

• DO NOTuse generator with electrical cords which areworn,

frayed, bareor otherwise damaged.

• DO NOToperategenerator in the rain orwet weather.

• DO NOThandle generator or electrical cords while standing in

water, while barefoot,or while hands orfeetare wet.

• DO NOTallow unqualified persons or children to operate or

servicegenerator.

_1_WARNING Exhaust heat/gases could ignite

_ ombustibles, structures or damage fuel

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOTtouch hot parts and AVOID hotexhaust gases.

• Allow equipment to cool beforetouching.

• Keepat least5 feet (1.5 m) of clearanceon all sidesof

generator including overhead.

• It is aviolation of California Public Resource Code, S_

4442, to use or operatethe engineon any

brush-covered, or grass-covered land unlessthe e_h_

system is equipped with aspark arrester

4442, maintained in effective working order.

federal jurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or deal!

to obtain a sparkarrester designed for the exhaust

installed on this engine.

• Replacement parts must bethe sameand installed

position as the original parts. ....

tank causing a fire, resulting in death,

- serious injury and/or property damage.

...... __

A, CAUTION Excessively high operating speeds could

result in minor injury and/or generator damage.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Generatorsuppliescorrect rated

frequency and voltage when running at governed speed.

• DO NOTmodify generator inany way.

NOTICE Exceeding generators wattage/amperage capacity

could damage generator and/or electrical devices connected

to it.

• DO NOTexceedthe generator's wattage/amperagecapacity. See

Don't OverloadGeneratorin the Operationsection.

• Start generatorand letengine stabilize beforeconnecting

electrical loads.

• Connectelectrical loads in OFFposition, thenturn ONfor

operation.

• Turn electricalloads OFFand disconnectfrom generatorbefore

stopping generator.

Improper t_i_ of generator couId damageit

;hortenits fife, .............

Usegenerate[_:_[_i:8#jniendeduses.

• If you have_u_st:ioRdaboutintendeduse,askdealerorcontact

localse_i_ cen_#r.

....._pe_:gteg_gratoronlyonlevelsurfaces.

. B_:N_Te_ose generatorto excessivemoisture,dust,dirt, or

;orr_ivevapors.

insertanyobjectsthroughcoofingslots.

devicesoverheat,turn themoff anddisconnectthem

fromgenerator.

• Shutoffgeneratorif:

-electricaloutputis lost;

-equipmentsparks,smokes,oremitsflames;

-unitvibratesexcessively.

AWARNING Unintentional sparking fire or

electric shock resulting iR death or

_.¢ serious injury.

WHENADJUSTINGORMAKINGREPAIRSTOYOURGENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Use approvedspark plug tester.

• DO NOTcheckfor spark with spark plug removed.

A WARNING Starter and other rotating parts could

entangle hands, hair, clothing, or accessoriesresulting in serious injury.

• NEVERoperate generator without protective housing or covers.

• DO NOTwear looseclothing, jewelry or anythingthat could be

caught in the starter or other rotating parts.

• Tie uplong hair and removejewelry.

6 BRIGGSandSTRATTON.COIVl

Assembly

Your generator requiressome assembly and is ready for use

after it hasbeen properly servicedwith the recommendedoil

and fuel.

If you haveany problemswith the assemblyof your generator,

pleasecall the generatorhelplineat 1-800-743-4115. Ifcalling

for assistance,pleasehavethe model,revision,and serial

numberfrom the identificationlabel available.SeeGenerator

Controlsand Featuresfor identificationlabellocation.

UnpackGenerator

1. Setthe carton on arigid, fiat surface.

2. Removeeverything from carton except generator.

3. Opencarton completely by cutting eachcorner from

top to bottom.

4. Leavegenerator on carton to install wheel kit.

Shipment Contents

The generator is suppliedwith:

• Engineoil bottle

• Operator's manual

• Wheelkit

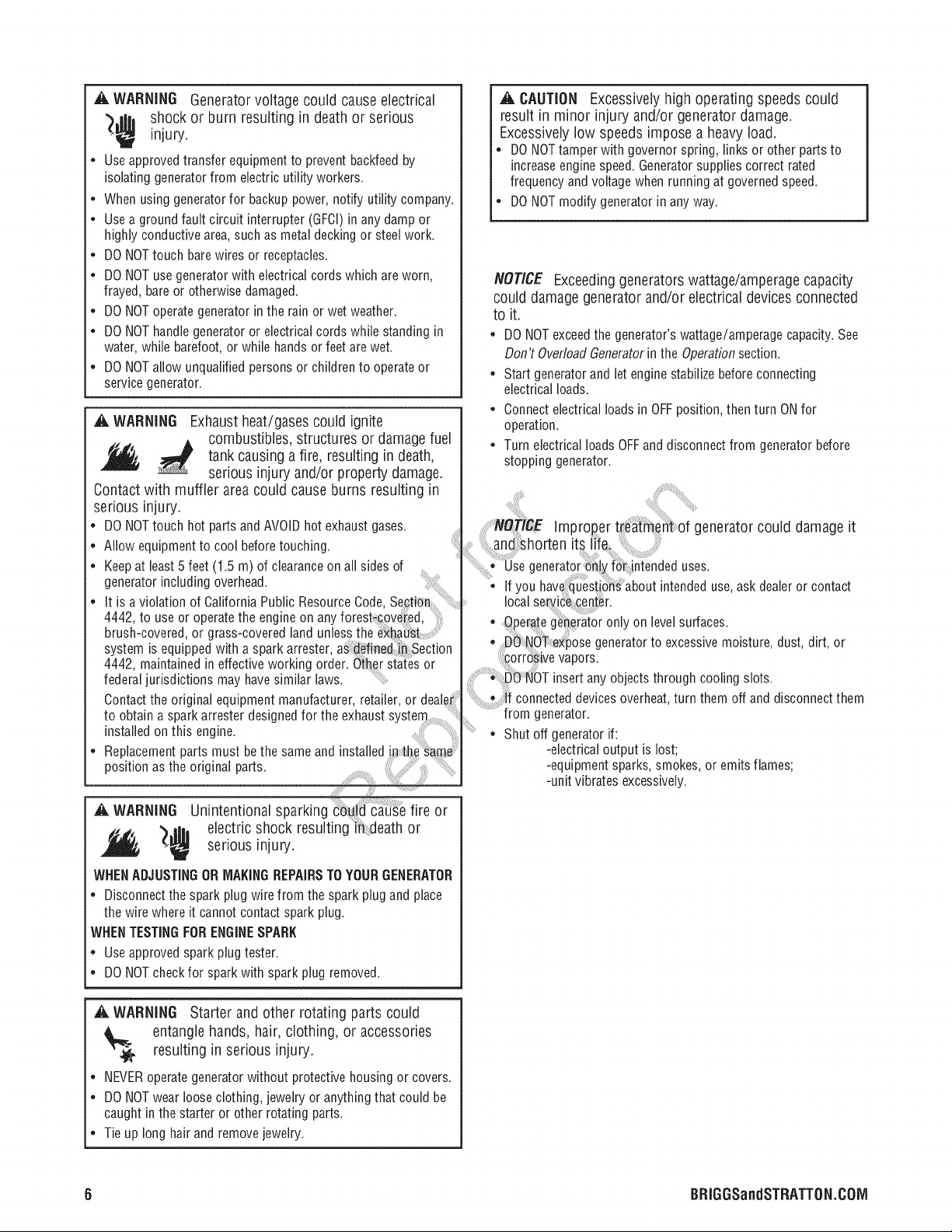

3. insert retaining pin (B) through hole on axlestud.

4. Slidea wheel (C) over axlestud.

NOTICE Besure to install wheelwith raised hub inboard.

5. Attach wheelto axlestud with a washer (D), lock

washer (E) and nut (F). Tightenwith a18 mm socket

wrench and 18 mm wrench.

6. Placehub cap (G) into center of wheel and push until it

snaps into place.

7. Repeatsteps 2 through 6 to secure secondwheel.

8. Line upholes in support leg (H) with holes ingenerator

frame.

.......... 9. Attach SU_Q[t leg using 4 capscrews(,!) and 4 hexInstall Wheel Kit

NOTICE Wheelkit is not intendedfor over-the-road 8_e 13 m_ w[e_bh.

You will needthe following tools to install thes_ .............. to normal operatingposition (resting

components: ..............

• 13 mm and 18mm wrench

• Socketwrench with 10 mm and 18 mm sockets

InstalJthewheelkitas follows:

1. Tip generatorsothat engine side is down. ..................................................

2. Slideaxlestud (A)through mounting .....

threadedend facing out.

nuts (Ki Tigfi_ with a10 mm socket wrench and

Add Engine Oil

1. Placegeneratoron a fiat, level surface.

2. Cleanarea aroundoil fill andremoveyellow oil fill cap.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE improper treatment of generator could damage it

and shorten its life.

• DO NOTattempt to crank or start the enginebeforeit has been

properly servicedwith the recommended oil. This could result in

an enginefailure.

4. Replaceoil fill cap andfully tighten.

AddFuel

Fuel mustmeet these requirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87AKI (91 RON).Forhigh

altitude use, seeHigh Altitude.

• Gasolinewith upto 10% ethanol (gasohol) or up to

15% MTBE(methyl tertiary butyl ether) is acceptable.

NOTICE Avoid generatordamage.

Failureto follow Operator's Manualfor fuel .........

recommendations voidswarranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoil ingasoline. ........

• DONOTmodifyengineto runonalternatefuels. ..............................

A WARNING Fueland its vaporsareextremelyflammable

and explosivewhich could causeburns,

fire or explosionresulting in death,

serious injury and/orproperty damage.

WHENADDINGFUEL

* Turn generatorengineOFFand letit cool at least2 minutes

before removingfuel cap. Loosencapslowly to relieve pressure

in tank.

,. Fillfuel tank outdoors.

* DONOToverfill tank. Allow spacefor fuel expansion.

* iffuel spills, wait until it evaporatesbefore starting engine.

* Keepfuel awayfrom sparks, open flames, pilot lights,heat,and

other ignition sources.

* Checkfuel lines,tank, cap andfittings frequently for cracks or

leaks.Replaceif necessary.

* DONOTlighta cigaretteor smoke.

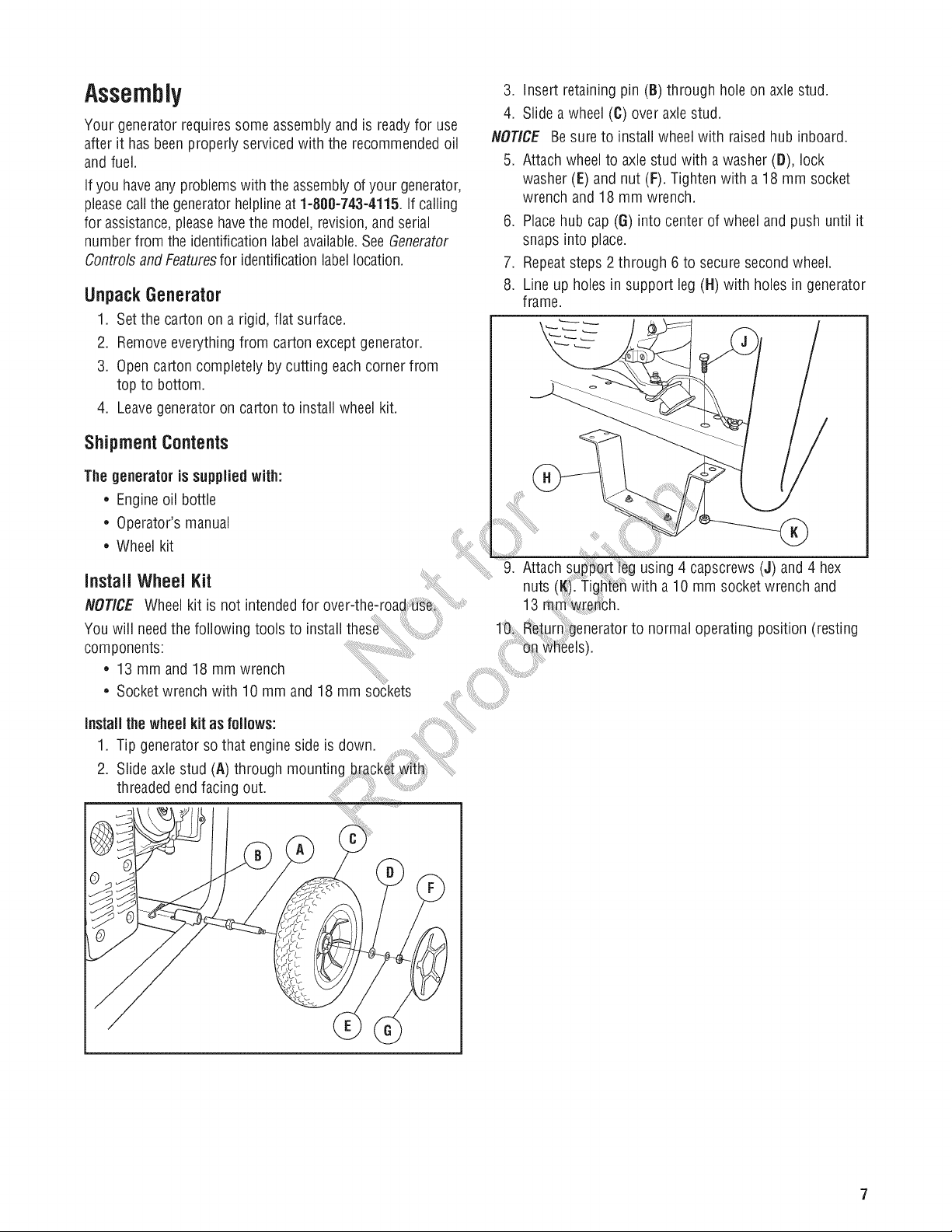

1. Clean area around fuel fill cap, remove cap.

2. Slowly add unleaded fuel to fuel tank. Be careful not to

fill above the red fuel level indicator (A). This allows

adequate space for fuel expansion.

To protect the fuel system from gum formaiie_ _i :::ina fuel

stabilizerwhen addingfuel. SeeStorage.All fu_l:is not the

capand let anyspilled fuel evaporatebefore

engine.

same. if you experiencestarting or performanceproblems :::::_i_h Altitude

after usng fue sw tchto a dfferent fue prov der or chang_ .... At Itit ,4_o_v_r _ ,_,_,_P_t '1_24 m_Pr°' _ minim m

..... , . . . a uu_u _ ,_vvv _ t ,J _j a u

oranas In s eng ne s cer_Ted to operateon paso ..... t n AKi R N lin i t I T

• ..... 85oca e/85 (89 0 )paso e saccepabe, o

emis.s!on..con!rolsystem for this engine is EM ...... remainemissions compliant, high altitude adjustment is

MooTcat ons). ..... required.Operation without this adjustmentwill cause

.... .................. decreasedperformance, increasedfuel consumption, and

....... increasedemissions. Seean authorizeddealerfor high

............ altitude adjustment information. Operation of the engine at

altitudes below 2,500feet (762 meters) with the high altitude

kit is not recommended.

8 BRIGGSandSTRATTON.COM

SystemGround

Thegenerator hasa system ground that connectsthe

generatorframe components to the ground terminals onthe

ACoutput receptacles.Thesystem ground is connectedto

the ACneutral wire (the neutral is bondedto the generator

frame).

Special Requirements

Theremay be Federalor StateOccupationalSafety and

Health Administration (OSHA)regulations, local codes, or

ordinances that applyto the intended useof the generator.

Pleaseconsult a qualified electrician, electrical inspector, or

the local agencyhavingjurisdiction:

+ In someareas,generators are requiredto be registered

with local utility companies.

+ If the generator is used at a construction site, there

may be additional regulations which must beobserved.

Connectingto a Buiiding'sElectricalSystem

Connectionsfor standby powerto a building's electrical

system must be made bya qualified electrician. The

connection must isolate the generator powerfrom utility

power or other alternative power sources and must comply

with all applicable laws andelectrical codes.

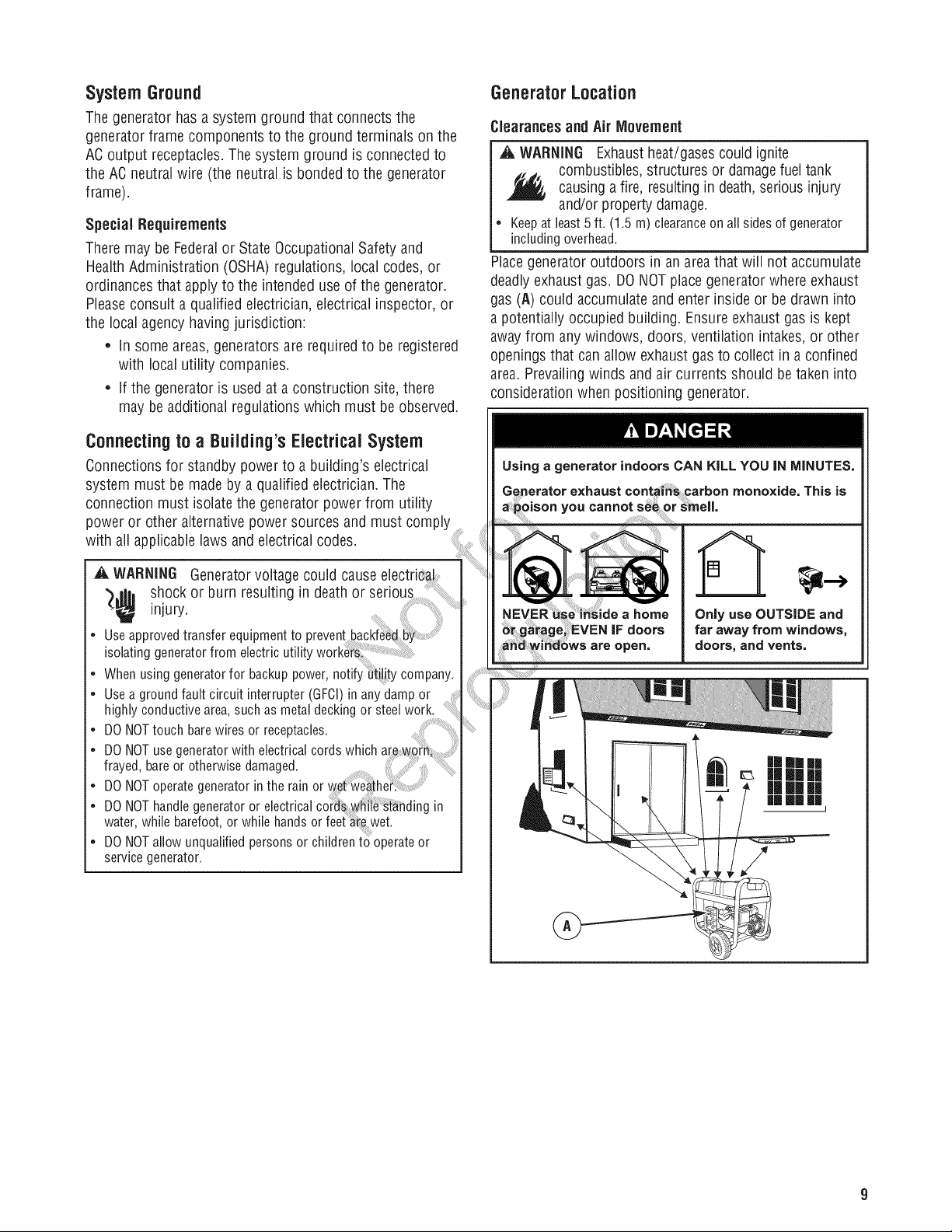

GeneratorLocation

Clearancesand Air Movement

,i_ WARNING Exhaustheat/gases could ignite

combustibles, structures or damagefueltank

causing afire, resultingin death,serious injury

and/or propertydamage.

+ Keepat least5ft. (1.5m)clearanceonall sidesof generator

includingoverhead.

Placegenerator outdoors in anareathat will not accumulate

deadlyexhaust gas.DONOTplace generator where exhaust

gas (A) could accumulateand enterinside or be drawn into

a potentially occupied building. Ensureexhaustgas is kept

awayfrom any windows, doors, ventilation intakes, or other

openingsthat canallow exhaustgasto collect in a confined

area.Prevailingwinds and aircurrents should betaken into

consideration when positioning generator.

Usinga generatorindoorsCAN KILL YOU iN MINUTES,

Generatorexhaustcontai_;_carbon monoxide,This is

youcannot mell.

A WARNING Generatorvoltage could cause

)dill .shockor burn resulting in deathor serious

mjury.

+ Useapprovedtransferequipmentto

isolatinggeneratorfromelectricutility

®

When

usinggeneratorfor backuppower,notify:_i!itYcompany.

+ Useagroundfaultcircuitinterrupter(GFCI)in anydampor

highlyconductivearea,suchasmetaldeckingorsteelwork.

+ DONOTtouchbarewiresor receptacles.

+ DONOTusegeneratorwithelectricalcordswhicha

frayed,bareorotherwisedamaged.

+ DONOToperategeneratorinthe rainor

+ DONOThandlegeneratororelectrical

water,whilebarefoot,or whilehandsorfeet_e wet.

e

DO NOTallow unqualified persons or children to operate or

servicegenerator.

ig in

|

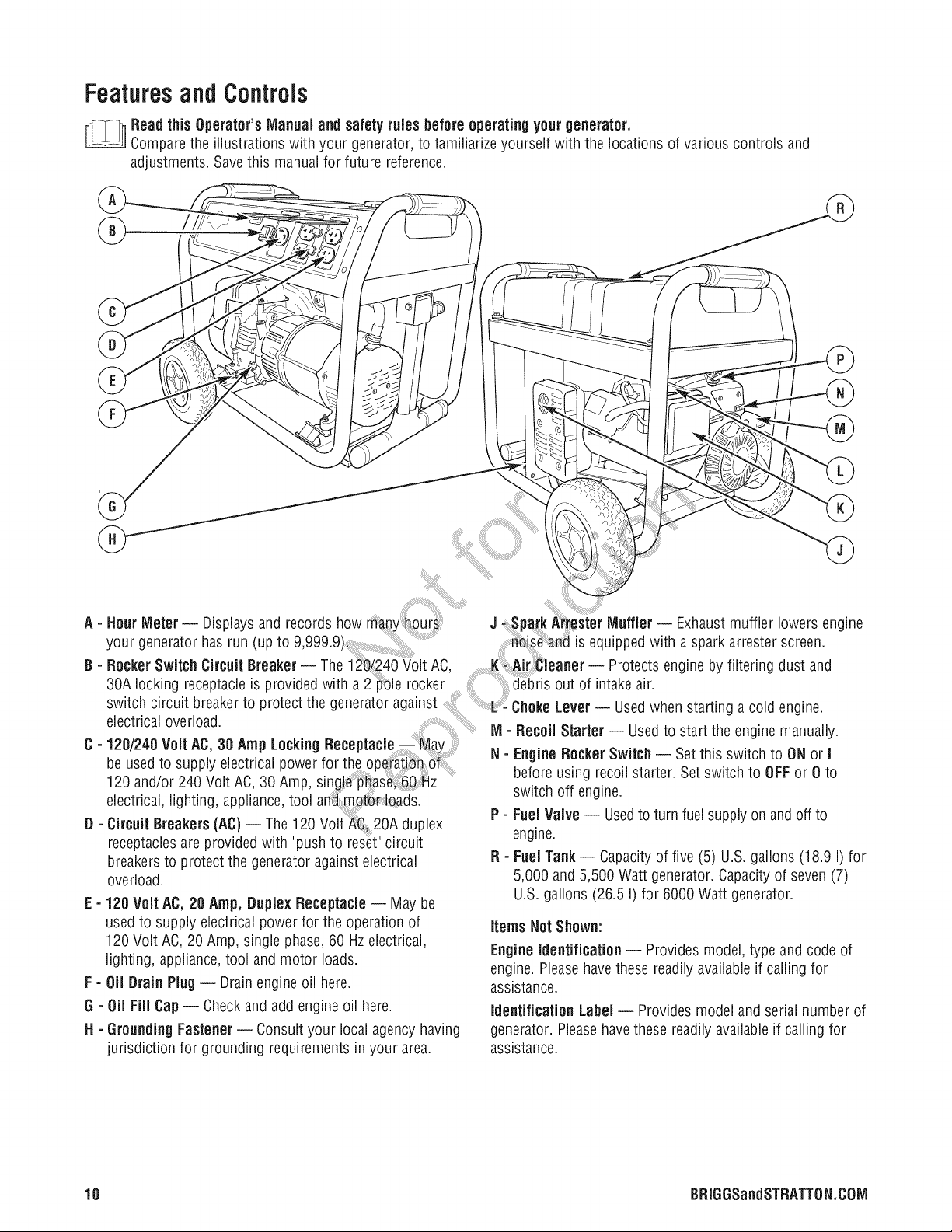

FeaturesandControls

Readthis Operator's Manual and safetyrulesbefore operating your generator.

Comparethe illustrations with your generator,to familiarize yourself with the locations of various controls and

adjustments. Savethis manual for future reference.

A- Hour Meter -- Displays and records how _By :hour_ J _Spa[k A_[ester Muffler -- Exhaustmuffler lowersengine

your generator hasrun (up to 9,999.9) ........ is equippedwith a sparkarrester screen.

B- RockerSwitch Circuit Breaker- The AC ................ -- Protects engine byfiltering dust and

30A locking receptacle is provided with a rocker ................: d_bris out of intake air.

sw tch c rcut breakerto protect the generator aga nst Choke Lever Usedwhen starting acol n in

• .... .................. d e g e.

e ectr ca over cad. M- Recoil Starter -- Usedto start the enginemanually.

C-lb_O/fe4d0tVoe_tuAC[3e0ecAtmcPaLO_;g N-Engine RockerSwitch- Setthis switch to ONor,

_._,^. oar, ,,^,_^,. o,, ^m_ i,_ ..... before us ng reco starter Set sw tchto OFFor 0 to

.... ....... 5WILUII UH _HLJIH_

electrical, hghbng,appl,ance,tool andmg;_erleads.

D- CircuitBreakers(AC)-- The 120 Voli G_20A duplex " . --

receptaclesare providedwith "pushto reset"circuit engine.

breakersto protect the generator against electrical

overload.

E - 120Volt AC,20 Amp, Duplex Receptacle -- May be

usedto supply electrical powerfor the operation of

120 Volt AC,20 Amp,single phase,60 Hz electrical,

lighting, appliance,tool and motor loads.

F - Oil Drain Plug-- Drain engine oil here.

G - Oil Fill Cap-- Checkand add engineoil here.

H - Grounding Fastener -- Consultyour local agencyhaving

jurisdiction for grounding requirements in your area.

PPY P P_

P Fuel Valve Usedto turn fuel supply onandoff to

R - FuelTank-- Capacityof five (5) U.S.gallons (18.9 I) for

5,000 and5,500 Watt generator. Capacityof seven(7)

U.S.gallons (26.5 I) for 6000 Watt generator.

Items Not Shown:

Engineidentification-- Provides model,type and code of

engine. Pleasehavethese readilyavailableif calling for

assistance.

Identification Label-- Provides model and serial number of

generator. Pleasehavethese readily available if calling for

assistance.

10 BRIGGSandSTRATTON.COIVl

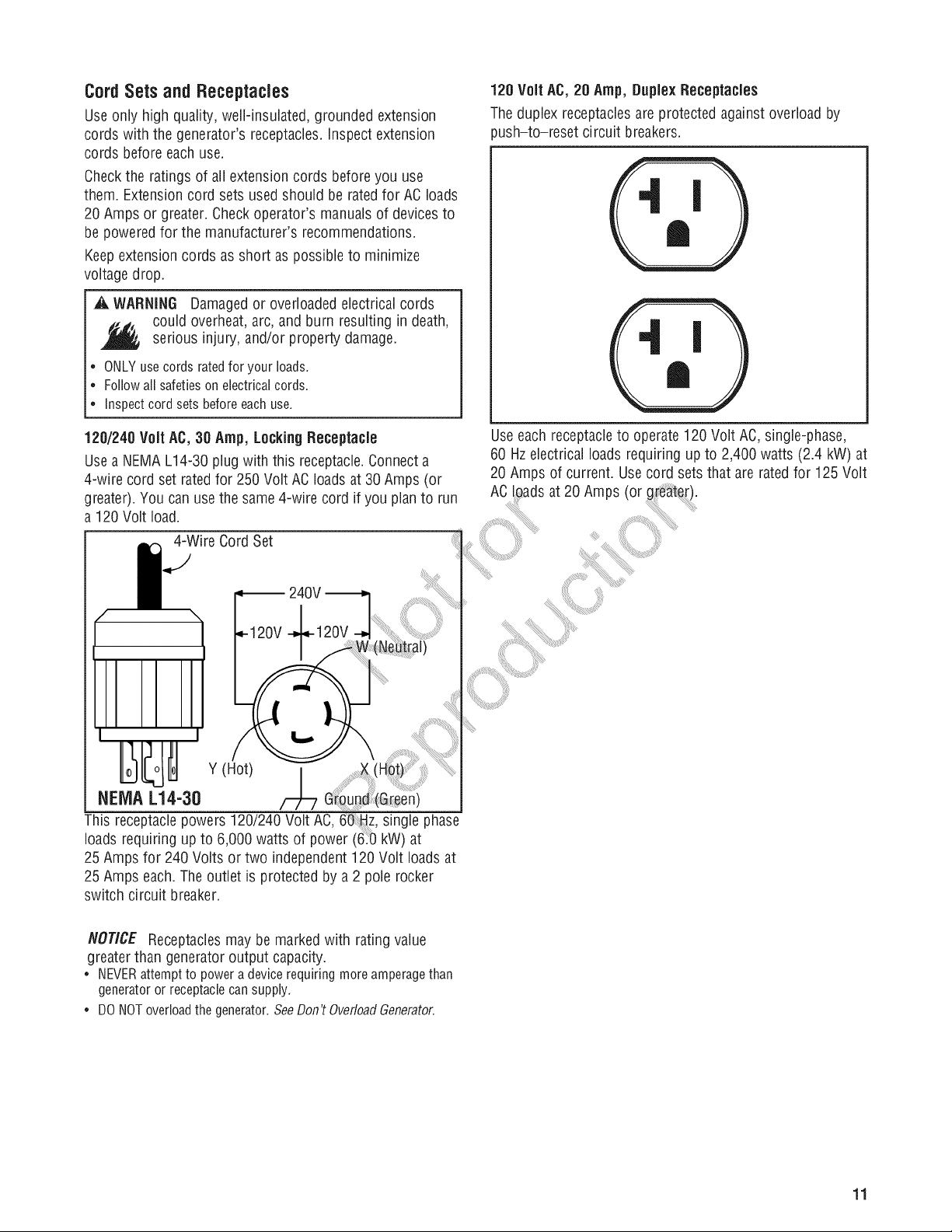

Cord Sets and Receptacles

Use only high quality, well-insulated, grounded extension

cords with the generator's receptacles. Inspect extension

cords before eachuse.

Checkthe ratings of all extension cords beforeyou use

them. Extensioncord sets usedshould beratedfor AC loads

20 Amps or greater. Check operator's manuals ofdevicesto

be powered for the manufacturer's recommendations.

Keepextension cords asshort as possible to minimize

voltage drop.

,& WARNING Damagedor overloaded electrical cords

could overheat,arc, and burn resulting in death,

serious injury, and/or property damage.

* ONLYuse cords ratedfor your loads.

* Follow all safeties onelectricalcords.

* Inspect cord sets before eachuse.

120 Volt AC, 20 Amp, DuplexReceptacles

Theduplex receptaclesare protected against overload by

push-to-reset circuit breakers.

120/240 VoltAC, 30 Amp, LockingReceptacle

Use a NEMAL14-30 plug with this receptacle.Connecta

4-wire cord set ratedfor 250 VoltAC loadsat 30Amps (or

greater). You can usethe same4-wire cord if you planto run

a 120 Volt load.

4-Wire CordSet

Y

(Hot)

/

NEiViAL14o30 7)-z

This receptaclepowers 120/240 Volt AC,6-0-_-Hz,single phase

loads requiring up to 6,000 watts of power (6:0 kW) at

25 Amps for 240 Volts or two independent120Volt loads at

25 Amps each.The outlet is protected bya 2 pole rocker

switch circuit breaker.

Useeachreceptacleto operate 120 Volt AC,single-phase,

60 Hz electricalloads requiring up to 2,400 watts (2.4 kW)at

20 Amps of current. Usecord setsthat are rated for 125 Volt

ACloads at 20Amps (or gre_er).

NOTICE Receptacles may be marked with rating value

greater than generator output capacity.

• NEVERattempt to power adevice requiring moreamperagethan

generator or receptaclecan supply.

• DONOT overloadthe generator.SeeDon't OverloadGenerator.

11

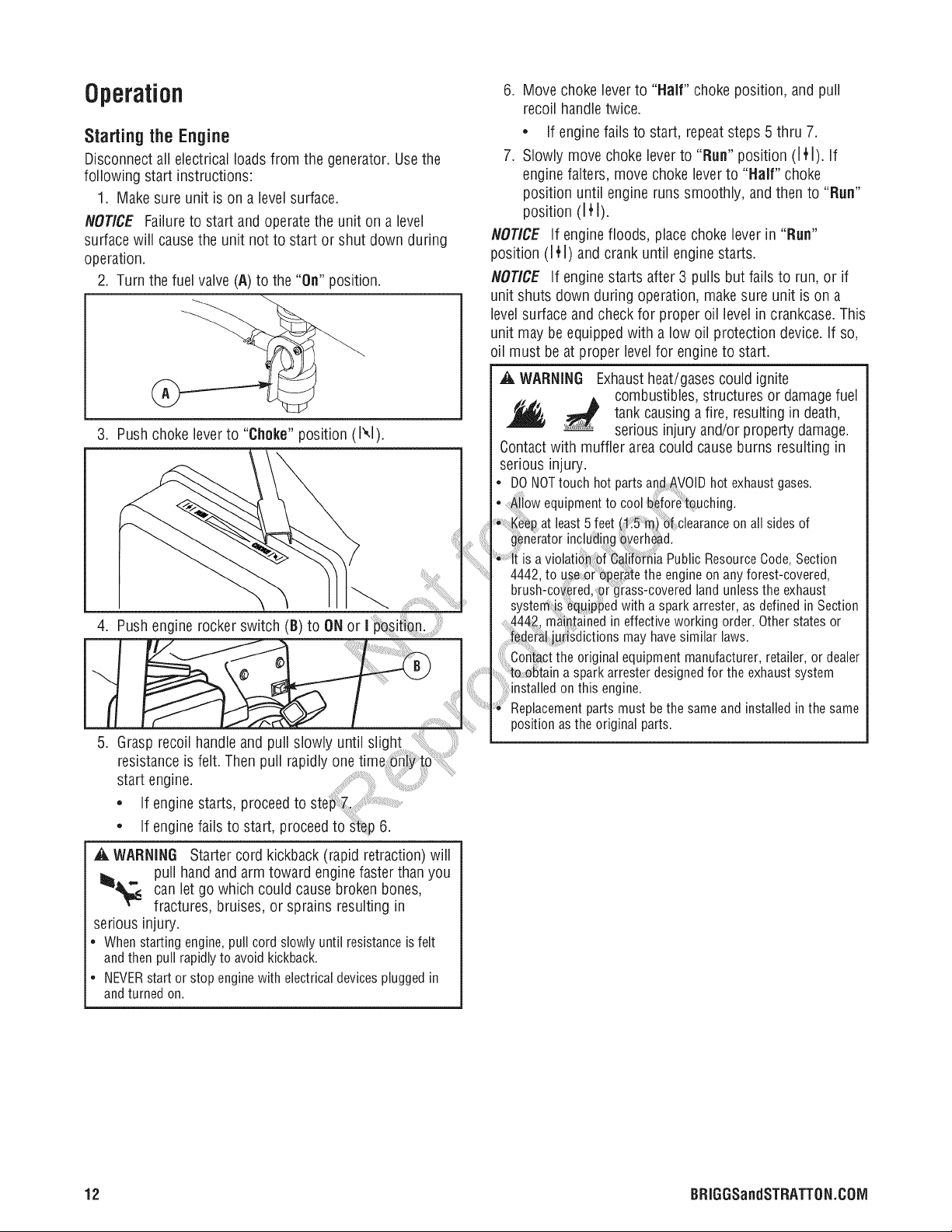

Operation

Startingthe Engine

Disconnect allelectrical loads from the generator. Usethe

following start instructions:

1. Makesure unit is on a levelsurface.

NOTICE Failureto start and operatethe unit ona level

surfacewill causethe unit not to start or shut down during

operation.

2. Turnthe fuel valve(A) to the "On" position.

3. Push chokelever to "Choke" position (l_,l).

4. Push enginerocker switch (B)to ONor I _Osi_ian.

5. Grasp recoil handleand pull slowly until siigh

resistanceis felt. Then pull rapidlyone

start engine.

• If engine starts, proceed to

• If engine failsto start, proceedto _ap 6.

6. Movechoke leverto "Half" choke position, and pull

recoil handletwice.

• Ifengine fails to start, repeat steps 5 thru 7.

7. Slowly movechoke leverto "Run" position (l+l). If

engine falters, movechoke leverto "Half" choke

position until engine runs smoothly, andthen to "Run"

position (I_I).

NOTICE If engine floods, placechoke lever in "Run"

position (1+1)and crank until engine starts.

NOTICE If engine starts after3 pulls but fails to run, or if

unit shuts down during operation, makesure unit is on a

levelsurfaceand check for proper oil level incrankcase.This

unit maybe equippedwith a low oil protection device. If so,

oil must be at proper levelfor engine to start.

A WARNING Exhaustheat/gasescould ignite

combustibles, structures or damagefuel

tank causinga fire, resultingin death,

serious injury and/or property damage.

Contact with muffler area could causeburns resulting in

serious injury.

• DONOTtouchhotpartsandAVOIDhotexhaustgases.

........iow equipmentto coolb_foi__ouching.

atleast5 feet onall sidesof

includin

iia PublicResourceCode,Section

engineonanyforest-covered,

landunlesstheexhaust

,edwithasparkarrester,asdefinedinSection

in effectiveworkingorder.Otherstatesor

mayhavesimilarlaws.

theoriginalequipmentmanufacturer,retailer,or dealer

asparkarresterdesignedfor theexhaustsystem

installed onthis engine.

Replacementpartsmustbethesameandinstalledinthesame

positionasthe originalparts.

A WARNING Starter cord kickback (rapid retraction)will

pull hand andarm toward enginefasterthan you

,_ can letgo which could cause brokenbones,

fractures, bruises, or sprains resulting in

serious injury.

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpullrapidlytoavoidkickback.

• NEVERstartor stopenginewithelectricaldevicespluggedin

andturnedon.

12 BRIGGSandSTRATTON.COIVl

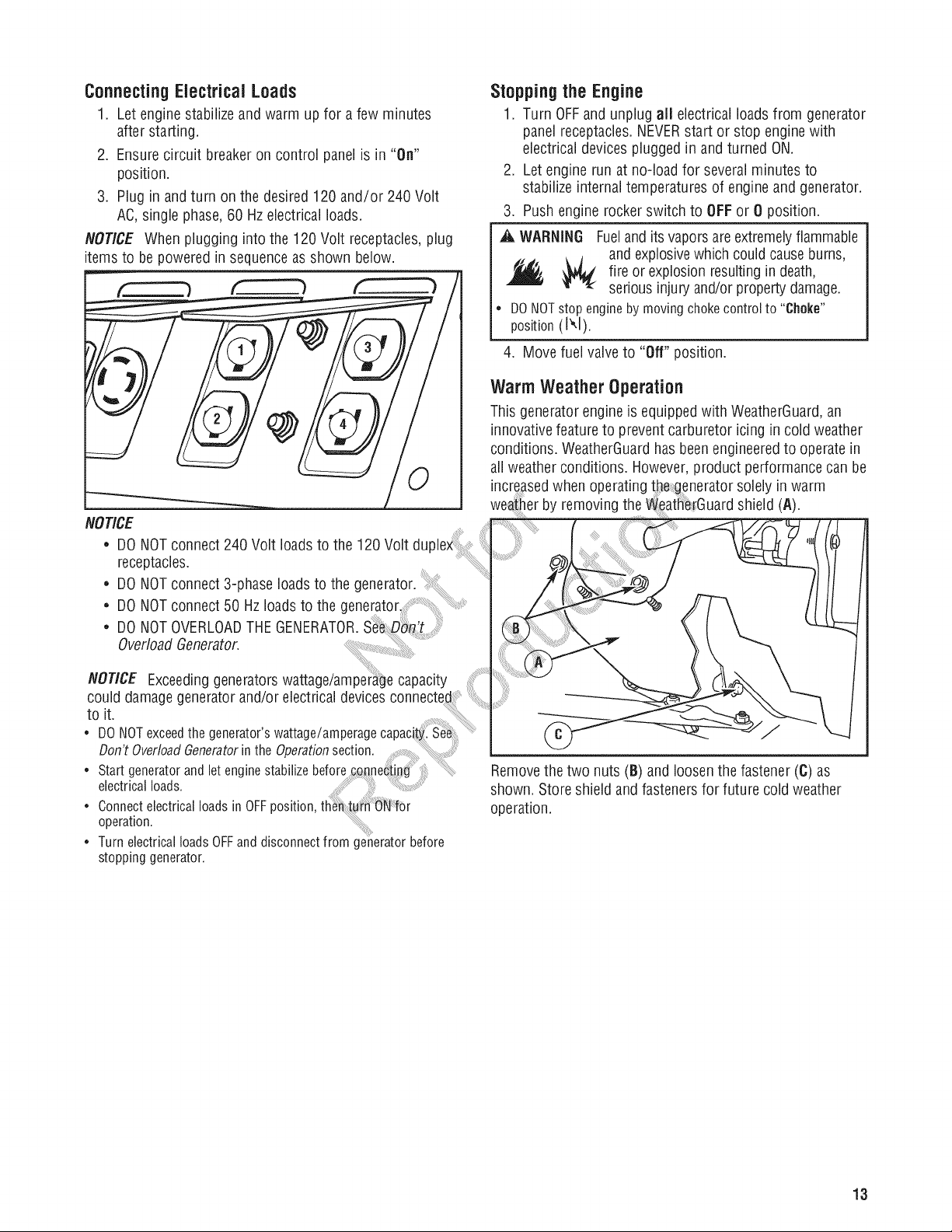

Connecting Electrical Loads

1. Let enginestabilize and warm up for a few minutes

after starting.

2. Ensurecircuit breakeron control panelis in "On"

position.

3. Plug in andturn on the desired 120 and/or 240Volt

AC,single phase,60 Hz electrical loads.

NOTICE When plugging into the 120 Volt receptacles,plug

items to be powered in sequenceasshown below.

o

NOTICE

• DONOTconnect24OVoltloadstothe120Volt ....

receptacles.

• DONOTconnect 3-phaseloads to the generator.

• DONOTconnect 50 Hzloads to the generator:: ..........

DONOTOVERLOADTHEGENERATOR.SeeDQnt ....

OverloadGenerator.

Stopping the Engine

1. Turn OFFandunplug aiI electrical loads from generator

panel receptacles. NEVERstart or stop enginewith

electrical devicesplugged in andturned ON.

2. Let enginerun at no-loadfor several minutes to

stabilize internaltemperatures of engine andgenerator.

3. Push enginerocker switch to OFFor 0 position.

A WARNING Fueland its vaporsareextremelyflammable

and explosivewhich could causeburns,

fire or explosionresulting in death,

serious injury and/orproperty damage.

* DONOTstopenginebymovingchokecontrolto"Choke"

position(IXl).

4. Movefuel valve to "Off" position.

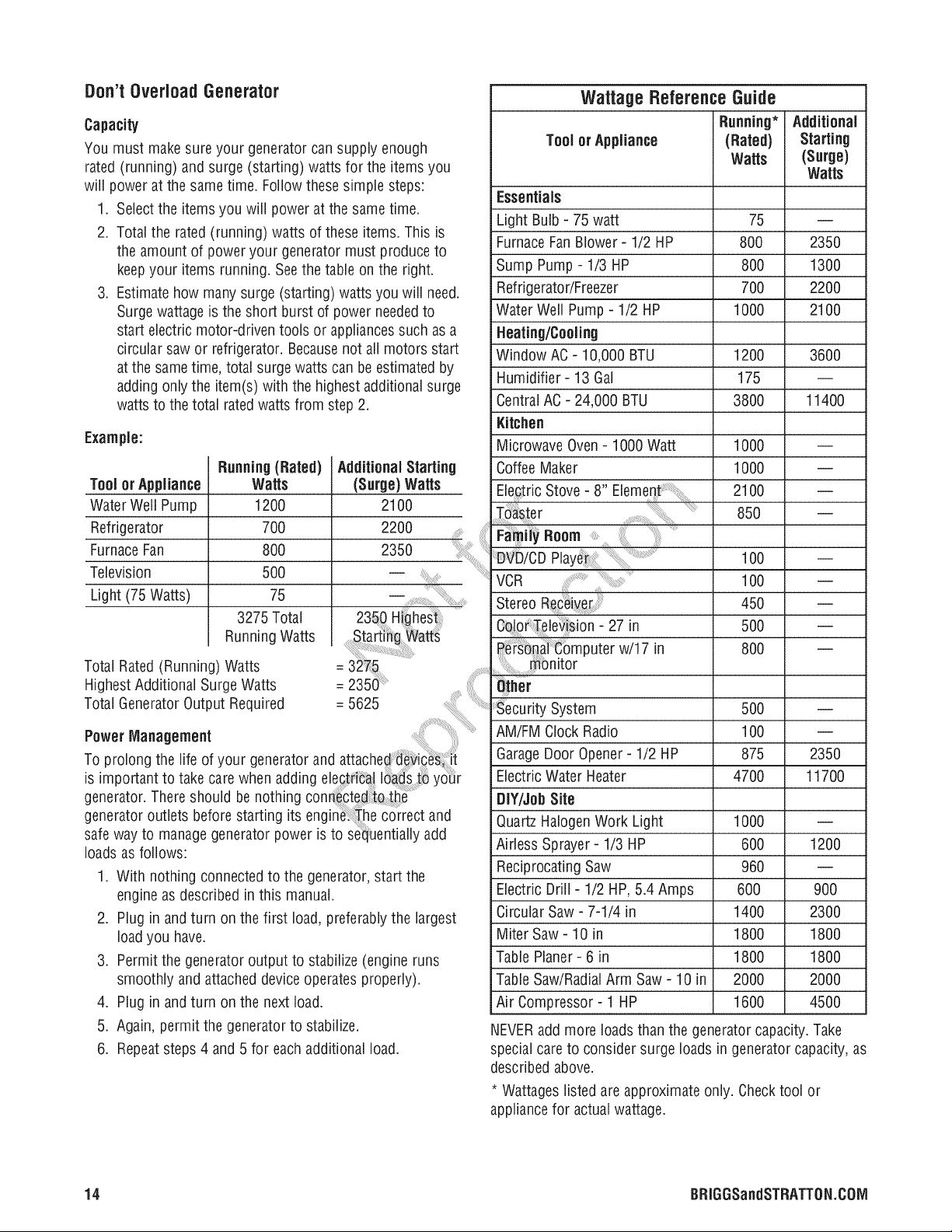

WarmWeatherOperation

This generator engine is equippedwith WeatherGuard,an

innovativefeature to preventcarburetor icing in cold weather

conditions. WeatherGuardhas beenengineeredto operatein

aii weather conditions. However,product performance can be

increasedwhen operatingt)e generator solely in warm

weather by removing the _eat_[Guard shield (A).

NOTICE Exceedinggeneratorswattage/amperagecapacity

could damagegeneratorand/orelectrical devicesconnectc

to it.

• DONOTexceedthegenerator'swattage/amperage

Don'tOverloadGeneratorintheOperationsection.

• Startgeneratorandletenginestabilizebefore

electricalloads.

• ConnectelectricalloadsinOFFposition,

operation. ....

• TurnelectricalloadsOFFanddisconnectfrom generatorbefore

stoppinggenerator.

/

Removethe two nuts(B) and loosenthe fastener(C) as

shown. Store shield andfasteners for future coldweather

operation.

13

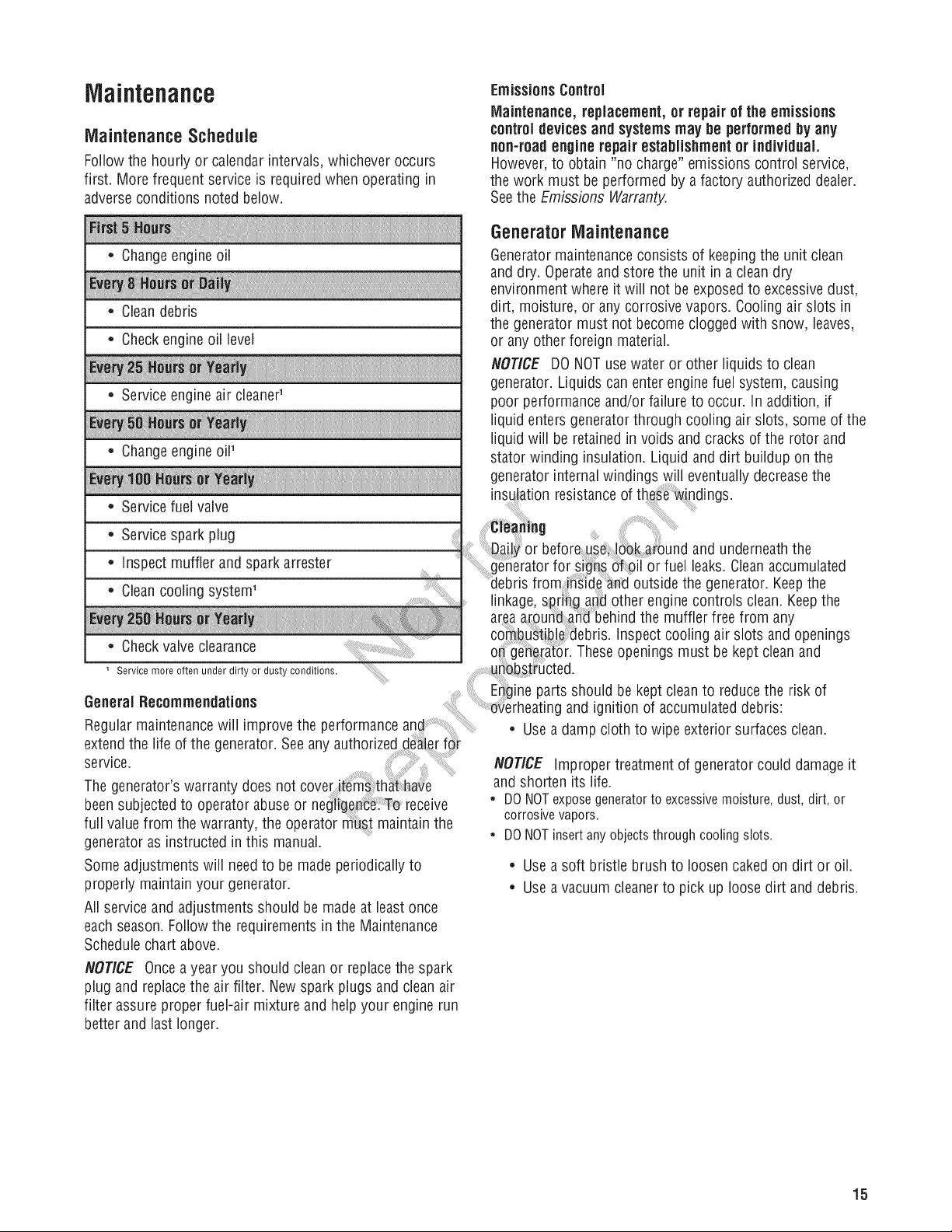

Don't OverloadGenerator

Capacity

You must make sureyour generator cansupply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Followthese simple steps:

1. Selectthe items you will power at the sametime.

2. Totalthe rated(running) watts of these items. This is

the amount of power your generator must produce to

keepyour items running. Seethe table onthe right.

3. Estimatehow many surge (starting) watts you will need.

Surge wattage is the short burst of power neededto

start electric motor-driven tools or appliancessuch as a

circular saw or refrigerator. Becausenotall motors start

atthe sametime, total surgewatts can be estimatedby

adding only the item(s) with the highest additionalsurge

watts to the total ratedwatts from step2.

Example:

Running (Rated)

Tool or Appliance

WaterWell Pump

Refrigerator

FurnaceFan

Television

Light (75Watts)

Watts

1200

700

8O0

5O0

75

3275 Total

Running Watts

Total Rated (Running) Watts

HighestAdditional SurgeWatts

Total Generator Output Required

Power Management

To prolong the lifeof your generatorand

is importantto take carewhen adding eleG$fiea! y6_r

generator. There should be nothing cona_cted&Q$5_........

generator outlets beforestarting itsengine:: he Correctand

safe way to manage generator power isto s_uentially add

loads asfollows:

1. With nothing connected to the generator,start the

engine as described inthis manual.

2. Plug in andturn on the first load, preferablythe largest

load you have.

3. Permitthe generatoroutput to stabilize (engineruns

smoothly and attacheddeviceoperates properly).

4. Plug in andturn on the next load.

5. Again, permitthe generator to stabilize.

6. Repeatsteps 4 and5 for eachadditional load.

Additional Starting

(Surge) Watts

21O0

2200

2350

2350 H:ighesi

Sta_i_g _a_

= 32_5

235

= 5625

WattageReference Guide

75

Additional

Starting

(Surge)

Watts

E

2350

1300

2200

2100

3600

11400

E

E

E

E

Tool or Appliance

Essentials

Light Bulb- 75 watt

FurnaceFanBlower- 1/2 HP

Sump Pump- 1/3 HP

Refrigerator/Freezer

Water Well Pump - 1/2 HP

Heating/Cooling

Window AC- 10,000 BTU

Humidifier- 13 Gal

CentralAC- 24,000 BTU

Kitchen

Microwave Oven- 1000 Watt

CoffeeMaker

Electric Stove- 8" Elemen_ :.....

Running*

(Rated)

Watts

800

800

700

1000

1200

175

3800

1000

1000

21O0

850

Room ..... ......

BvD/CD ........

VCR .....

Stereo

0e 0__ele_iSion- 27 in

w/17 in

100

100

450

500

800

a her

Security System 500 --

AM/FM Clock Radio 100 --

GarageDoor Opener- 1/2 HP 875 2350

ElectricWater Heater 4700 11700

DIY/Jab Site

Quartz HalogenWork Light 1000 =

Airless Sprayer- 1/3 HP 600 1200

Reciprocating Saw 960 --

Electric Drill- 1/2 HP, 5.4Amps 600 900

Circular Saw - 7-1/4 in 1400 2300

Miter Saw- 10 in 1800 1800

Table Planer- 6 in 1800 1800

Table Saw/RadialArm Saw- 10 in 2000 2000

Air Compressor - 1 HP 1600 4500

NEVERadd more loadsthan the generator capacity. Take

special care to consider surge loads in generator capacity,as

described above.

* Wattageslisted are approximate only. Checktool or

appliancefor actualwattage.

E

E

E

E

E

14 BRIGGSandSTRATTON.COIVl

Maintenance

MaintenanceSchedule

Follow the hourly or calendarintervals, whichever occurs

first. More frequent serviceis required when operating in

adverseconditions noted below.

• Changeengine oil

Cleandebris

Checkengineoil level

• Service engineair cleaner1

Changeengine oiP

Servicefuel valve

EmissionsControl

Maintenance, replacement, or repair of the emissions

controldevices and systems may be performed byany

non-road engine repair establishment or individual.

However,to obtain "no charge" emissions control service,

the work must be performed by afactory authorized dealer.

Seethe Emissions Warranty.

GeneratorMaintenance

Generatormaintenanceconsists of keepingthe unit clean

and dry. Operateand storethe unit in a clean dry

environment where it will not beexposedto excessivedust,

dirt, moisture, or any corrosive vapors. Coolingair slots in

the generator must not become cloggedwith snow, leaves,

or any other foreign material.

NOTICE DONOTuse water or other liquids to clean

generator. Liquids canenter engine fuel system, causing

poor performance and/or failure to occur, in addition, if

liquid enters generator through cooling air slots, someof the

liquid will beretainedin voids and cracks of the rotor and

stator winding insulation. Liquid and dirt buildup on the

generator internalwindings will eventuallydecreasethe

insu ation resistanceof the_ _indings.

Service spark plug

Inspect muffler and spark arrester

Cleancooling system1

• Checkvalve clearance

1 Service more often under dirty or dusty conditions.

General Recommendations

Regular maintenancewill improve the performance ant

extendthe life of the generator. Seeany authorized

service.

Thegenerator's warranty doesnot coveEi_m '

been subjected to operator abuseor negiigen_ Te receive

full valuefrom the warranty,the operator _st maintainthe

generator asinstructed inthis manual.

Someadjustments will needto bemade periodically to

properly maintainyour generator.

All serviceand adjustments should bemade at leastonce

eachseason.Follow the requirementsin the Maintenance

Schedulechart above.

NOTICE Onceayear you should clean or replacethe spark

plug and replacethe air filter. Newspark plugs and cleanair

filter assure proper fuel-air mixture and help your engine run

better and last longer.

and underneath the

fil or fuel leaks.Cleanaccumulated

from outsidethe generator. Keepthe

other enginecontrols clean. Keepthe

the muffler free from any

Inspect cooling air slots and openings

_.Theseopenings must be kept cleanand

jine parts should be kept cleanto reducethe risk of

_rheatingand ignition of accumulateddebris:

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE improper treatment of generator could damage it

and shorten its life.

• DO NOTexposegenerator to excessivemoisture, dust, dirt, or

corrosive vapors.

• DONOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen cakedon dirt or oil.

• Use a vacuum cleanerto pick up loose dirt and debris.

15

FuelValve Maintenance

Thefuel valveis equipped with afuel sediment cup, screen,

and o-ring that needto be cleaned.

1. Movefuel valveto "Off" position•

2. Removesediment cup (A) from fuel valve. Remove

o-ring (B) and screen(C)from fuel valve.

oF oC

86 -_ _ _ 30

68 _' _ _ 20

50 _ 10

32 __ _n -- 0

14 __ A-10

-4 I--J_L---- -20

-22 _ -30

* Below40°F(4°C)theuseofSAE30will resultin hardstarting.

** Above 80°F(27°C) the useof 10W30 may cause increasedoil

consumption• Checkoil level more frequently.

o

3. Wash sediment cup, o-ring, and screen in a

nonflammablesolvent. Drythem thoroughly.

4. Place screen and o-ring intofuel valve, installsediment

cup and tightensecurely.

5. Movefuel valveto "On"position, and check for leaks.

Replacefuel valve if there is anyleakage.

EngineMaintenance

,& WARNING Unintentionalsparking could cause

'_.l|ll electric shock resulting in death

£W serious injury......

HENADJUSTI,GoRMAKI,GREPAIRSTo

W

--Disconnectthesparkplugwirefromthe

thewirewhereit cannotcontactsparkplug•

WHENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester•

* DONOTcheckfor sparkwithsparkplugremoved•

Oil

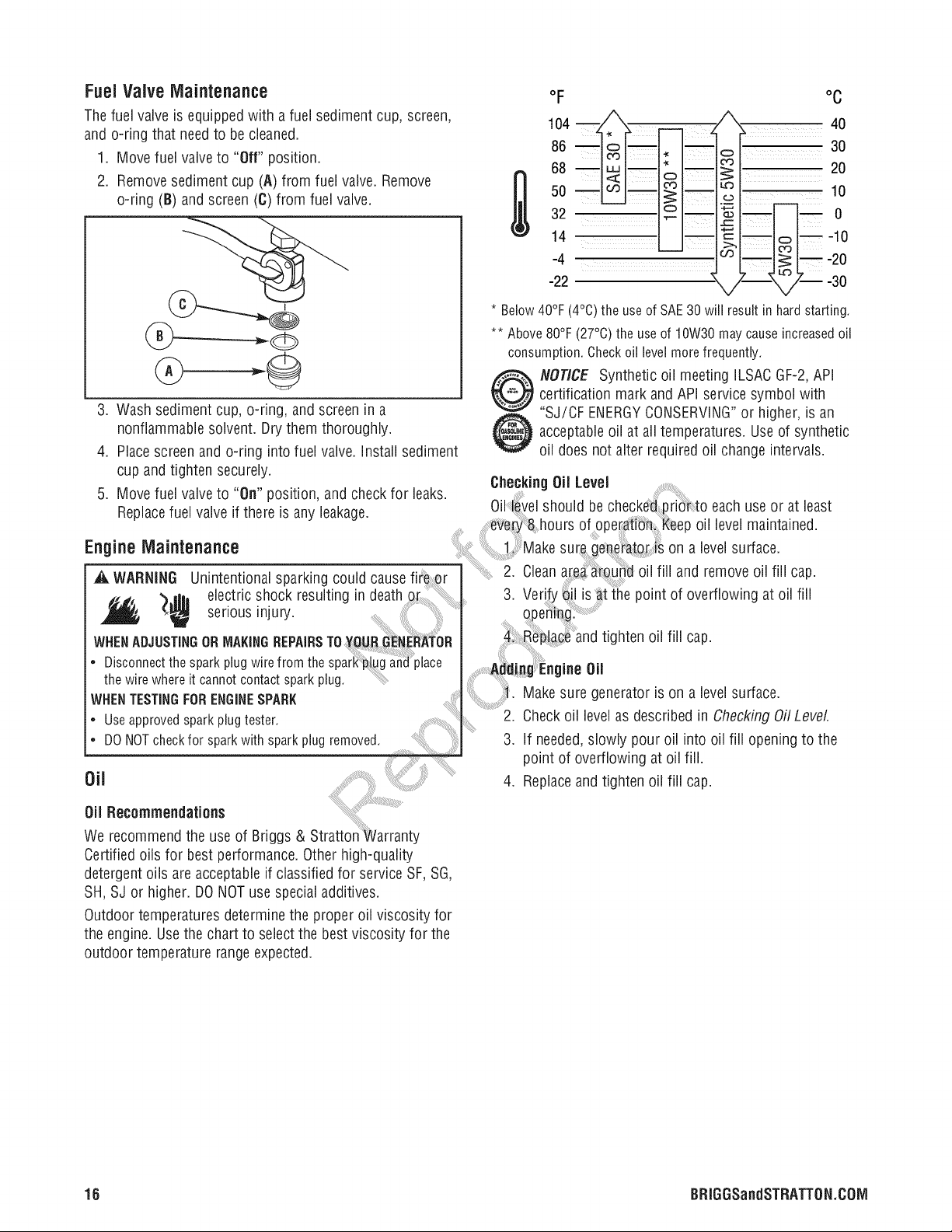

Oil Recommendations

We recommendthe useof Briggs &

Certified oils for best performance•Otherhigh-quality

detergent oils are acceptableif classifiedfor serviceSF, SG,

SH, SJ or higher• DONOTuse specialadditives•

Outdoor temperaturesdetermine theproper oil viscosity for

the engine•Usethe chart to selectthe best viscosity for the

outdoor temperature rangeexpected•

O OTICE Synthetic oil meeting iLSACGF-2,APi

_ cceptable oil at alltemperatures• Useof synthetic

CheckingOil Level

certification markand API service symbol with

"SJ/CF ENERGYCONSERVING"or higher, is an

oil does not alter required oil change intervals•

should be

hours ofope

Make sure

2. Clean

3. Veri

ine Oil

• Make sure generator is on a levelsurface•

Checkoil levelas described in Checking OilLevel

3. If needed,slowly pour oil into oil fill opening to the

point of overflowing at oil fill.

4. Replaceand tighten oil fill cap.

oil fill andremove oil fill cap.

point of overflowing at oil fill

tighten oil fill cap.

each useor at least

oil levelmaintained•

on a levelsurface•

18 BRIGGSandSTRATTON.COIVl

ChangingEngineOil

if you are usingyour generator under extremely dirty or

dusty conditions, or in extremely hot weather,changethe oil

more often.

A CAUTION Avoid prolonged or repeated skin contact

with used motor oil.

• Used motor oil has beenshown to cause skin cancerin certain

laboratory animals.

• Thoroughly wash exposed areaswith soap and water.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOIL TOCOLLECTIONCENTERS.

Changethe oil while the engineis still warm from

running,as follows:

1. Makesure unit is on a levelsurface.

.

Disconnectthe sparkplug wire from the spark plug and

placethe wire where it cannotcontact spark plug.

3.

Cleanarea aroundoil drain plug(A). Theoil drain plug

is locatedat baseof engine,opposite carburetor.

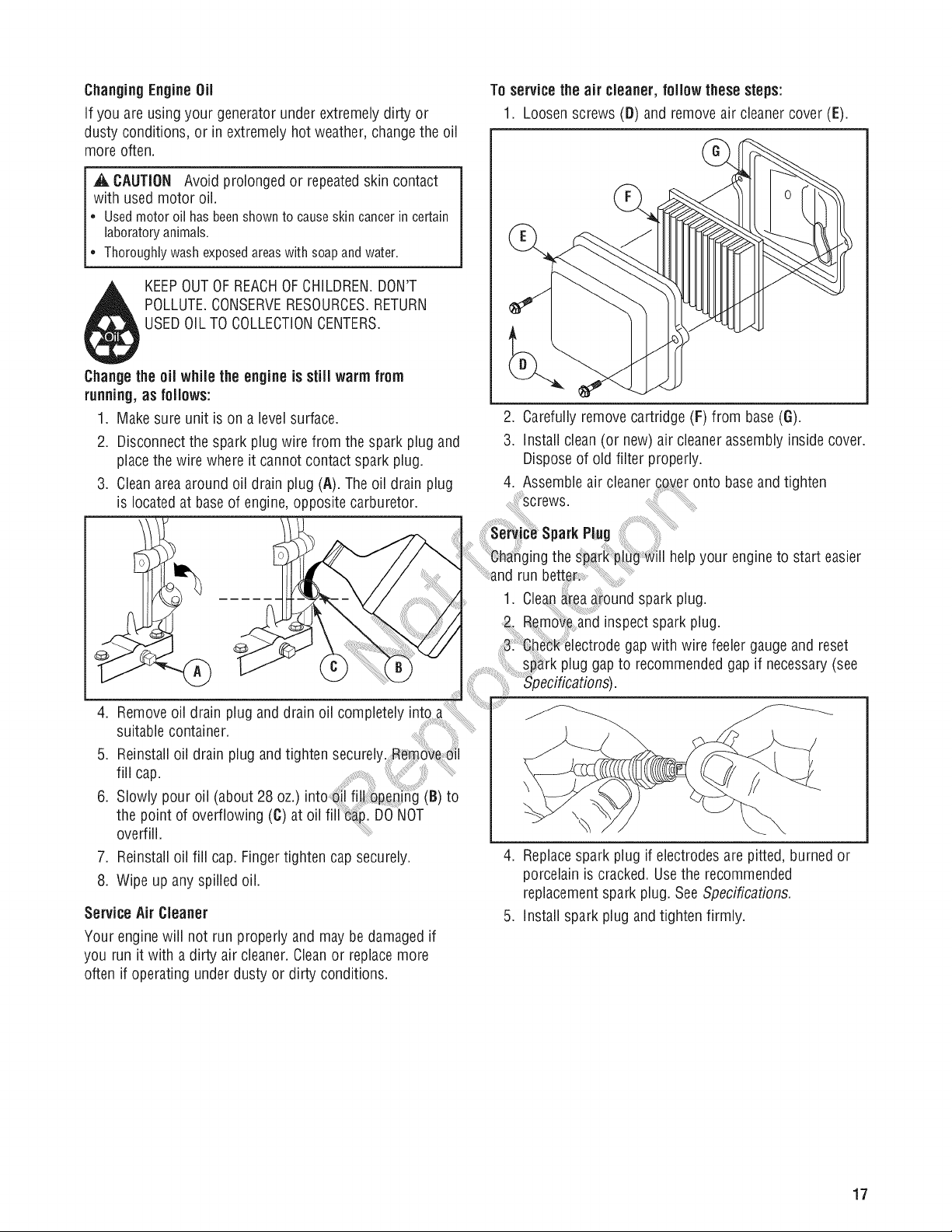

To service the air cleaner, follow thesesteps:

1. Loosen screws(D) and removeair cleanercover (E).

2. Carefully removecartridge (F) from base (G).

3. Install clean(or new)air cleaner assembly inside cover.

Disposeof old filter properly.

4. Assembleair cleaner co_eronto baseand tighten

P ug

4. Removeoil drain plug and drain oil completely

suitable container.

5. Reinstall oil drain plug andtighten securely.

fill cap.

6. Slowly pour oil (about 28 oz.)

the point of overflowing (C) at oil DONOT

overfill.

7. Reinstall oil fill cap. Fingertighten cap securely.

8. Wipe upany spilled oil.

Service Air Cleaner

Your enginewill not run properly and maybe damaged if

you run it with a dirty air cleaner.Cleanor replacemore

often if operating under dusty or dirty conditions.

gingthe helpyourengineto starteasier

run .....

1. Clean_rea aound spark plug.

a. and inspect spark plug.

gapwith wire feeler gauge and reset

plug gap to recommended gap if necessary(see

secifications).

tO

4. Replacespark plug if electrodes are pitted, burned or

porcelain is cracked.Usethe recommended

replacementspark plug. SeeSpecifications.

5. Install spark plug andtighten firmly.

17

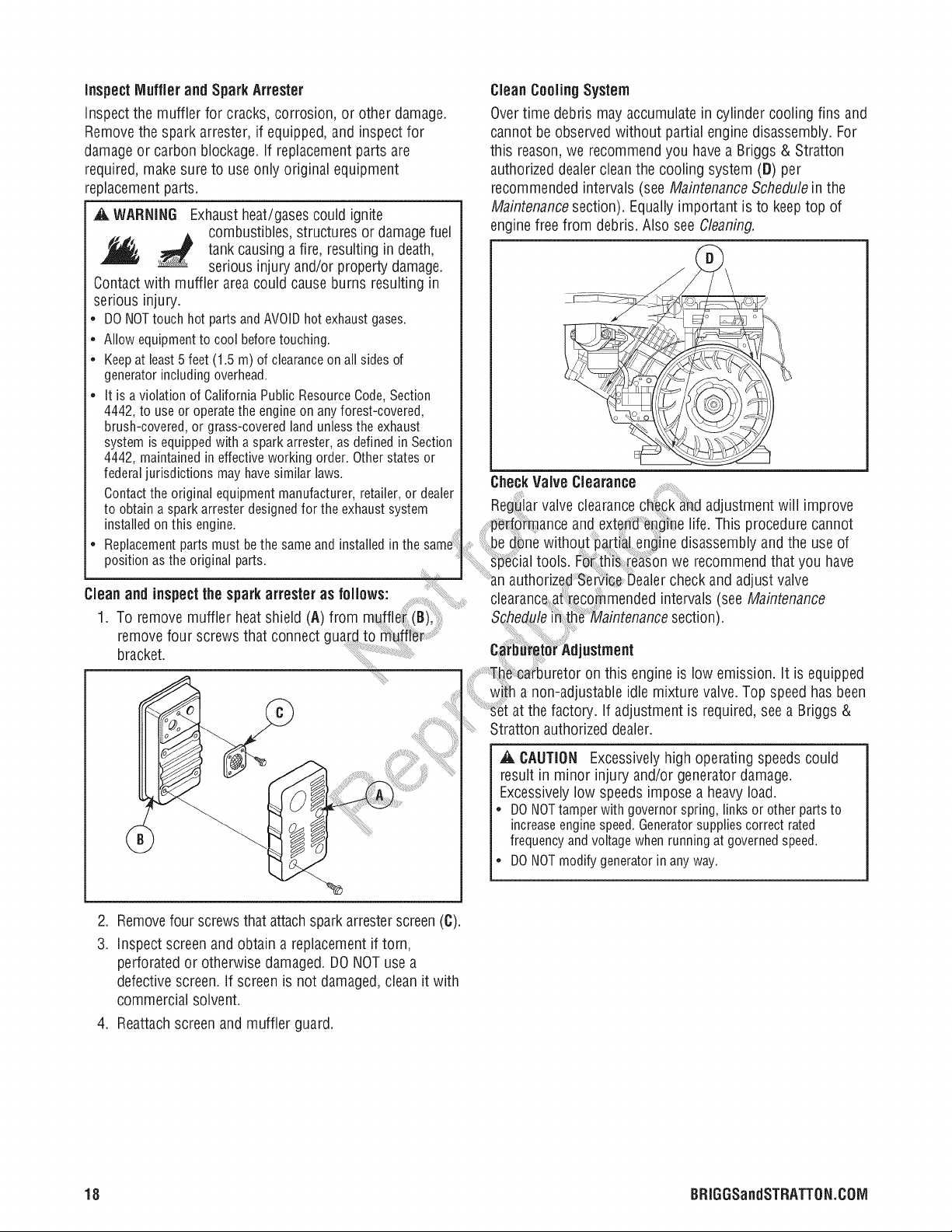

inspectMuffler andSparkArrester

Inspect the muffler for cracks, corrosion, or other damage.

Removethe sparkarrester, if equipped,and inspectfor

damageor carbon blockage, if replacementparts are

required, makesureto useonly original equipment

replacementparts.

_1_WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

• DO NOTtouch hot parts and AVOID hotexhaust gases.

• Allow equipment to cool beforetouching.

• Keepat least5 feet (1.5 m) of clearanceon all sidesof

generator including overhead.

• It is aviolation of California Public Resource Code, Section

4442, to use or operatethe engineon any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with aspark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtaina sparkarresterdesignedfor theexhaustsystem

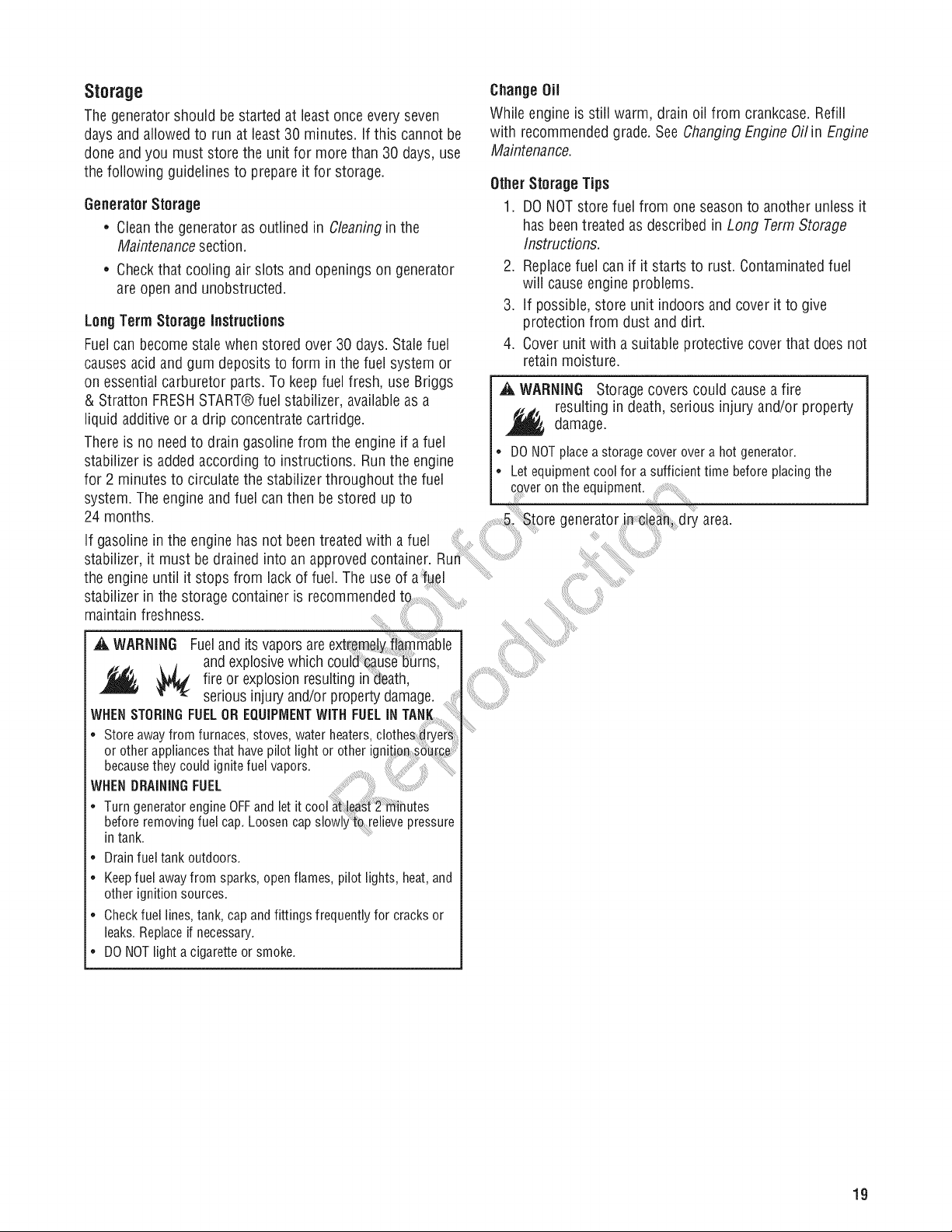

Clean Cooling System

Overtime debris may accumulatein cylinder cooling fins and

cannot be observedwithout partial enginedisassembly. For

this reason,we recommendyou havea Briggs & Stratton

authorized dealercleanthe cooling system (D) per

recommendedintervals (seeMaintenance Schedule in the

Maintenancesection). Equallyimportant is to keeptop of

engine free from debris. Also see Cleaning.

CheckValve Clearance

liar valve clearance

adjustment will improve

installedonthis engine, and extend _n_iBelife. This procedure cannot

• Replacementpartsmustbethesameandinstalledinthe

positionasthe originalparts.

_newithout _a[ti_! engine disassembly and the use of

iiaitools, we recommendthat you have

authorized Se_iGe _ealercheck and adjust valve

Clean andinspectthe sparkarrester as fellows:

1. To removemuffler heat shield (A) from

clearanceat [_co_mended intervals (seeMaintenance

S_hedulei_ _ Maintenancesection).

removefour screws that connect gu_

djust ent

bracket.

....: T_ea_uretor on this engine is low emission. It is equipped

Wh a non-adjustable idle mixture valve.Top speedhas been

.........at the factory, if adjustment is required,seea Briggs &

Stratton authorizeddealer.

,_ CAUTION Excessively high operating speeds could

result in minor injury and/or generator damage.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Generatorsuppliescorrect rated

frequency and voltage when running at governed speed.

• DO NOTmodify generator inany way.

.

Removefour screwsthat attachsparkarresterscreen(C).

3.

Inspect screenand obtain a replacementif torn,

perforated or otherwise damaged.DONOTusea

defective screen. If screenis not damaged,clean it with

commercial solvent.

4. Reattachscreen and muffler guard.

18 BRIGGSandSTRATTON.C01Vl

Storage

Thegenerator should bestarted at least once every seven

days and allowed to run at least 30 minutes, if this cannot be

done and you must store the unit for more than 30 days,use

the following guidelinesto prepareit for storage.

GeneratorStorage

• Cleanthe generator as outlined in Cleaningin the

Maintenancesection.

• Checkthat cooling air slots and openingson generator

are open and unobstructed.

LongTerm Storage Instructions

Fuelcan becomestale when stored over 30 days.Stalefuel

causesacid andgum deposits to form inthe fuel system or

on essentialcarburetor parts. To keepfuel fresh, use Briggs

& Stratton FRESHSTART®fuel stabilizer, availableasa

liquid additive or a drip concentrate cartridge.

Thereis noneedto drain gasoline from the engineif afuel

stabilizer is addedaccording to instructions. Runthe engine

for 2 minutesto circulate the stabilizerthroughout the fuel

system. The engine andfuel canthen be stored upto

24 months.

ChangeOil

While engineis still warm, drain oil from crankcase.Refill

with recommendedgrade.See ChangingEngine Oilin Engine

Maintenance.

Other Storage Tips

1. DONOTstore fuel from one seasonto another unlessit

has beentreatedas described in Long TermStorage

Instructions.

2. Replacefuel can if it starts to rust. Contaminatedfuel

will causeengine problems.

3. if possible, store unit indoors and coverit to give

protection from dust and dirt.

4. Coverunit with a suitableprotective cover that does not

retain moisture.

,i_ WARNING Storage covers could causea fire

resulting in death, seriousinjury and/or property

damage.

• DONOTplaceastoragecoverovera hot generator.

• Letequipmentcoolfor a sufficienttime beforeplacingthe

coverontheequipment. .....

_ _tore

....... generatoria e!e_aidry area.

If gasoline in the engine hasnot beentreated with a fuel

stabilizer, it must be drainedinto an approvedcontainer. Ru ...........

the engineuntil it stops from lack of fuel. The useof ............

stabilizer inthe storage container is

maintain freshness.... ....

A WARNING Fueland itsvapors are

_,_ , , andexplosivewhich coul8 Caus_bSrns,

J[d_ _ fire or explosionresulting indeath,

m.,m, _r "_: seriousinjury and/orproperty damage.

WHENSTORINGFUELOREQUIPMENTWITHFUELIN

Storeawayfromfurnaces,stoves,waterheaters,clothes_iye_

or otherappliancesthathavepilotlightor otherignitio__GU_:::

becausetheycouldignitefuelvapors.

WHENDRAININGFUEL ....

* TurngeneratorengineOFFandJetit _olat:e_i _ _ihutes

beforeremovingfuelcap.Loosencapslowly_Qrelievepressure

intank.

* Drain fuel tank outdoors.

* Keepfuel awayfrom sparks, open flames, pilot lights,heat,and

other ignition sources.

* Checkfuel lines,tank, cap andfittings frequently for cracks or

leaks.Replaceif necessary.

. DO NOTlighta cigarette or smoke.

19

20 BRIGGSandSTRATTON.COM

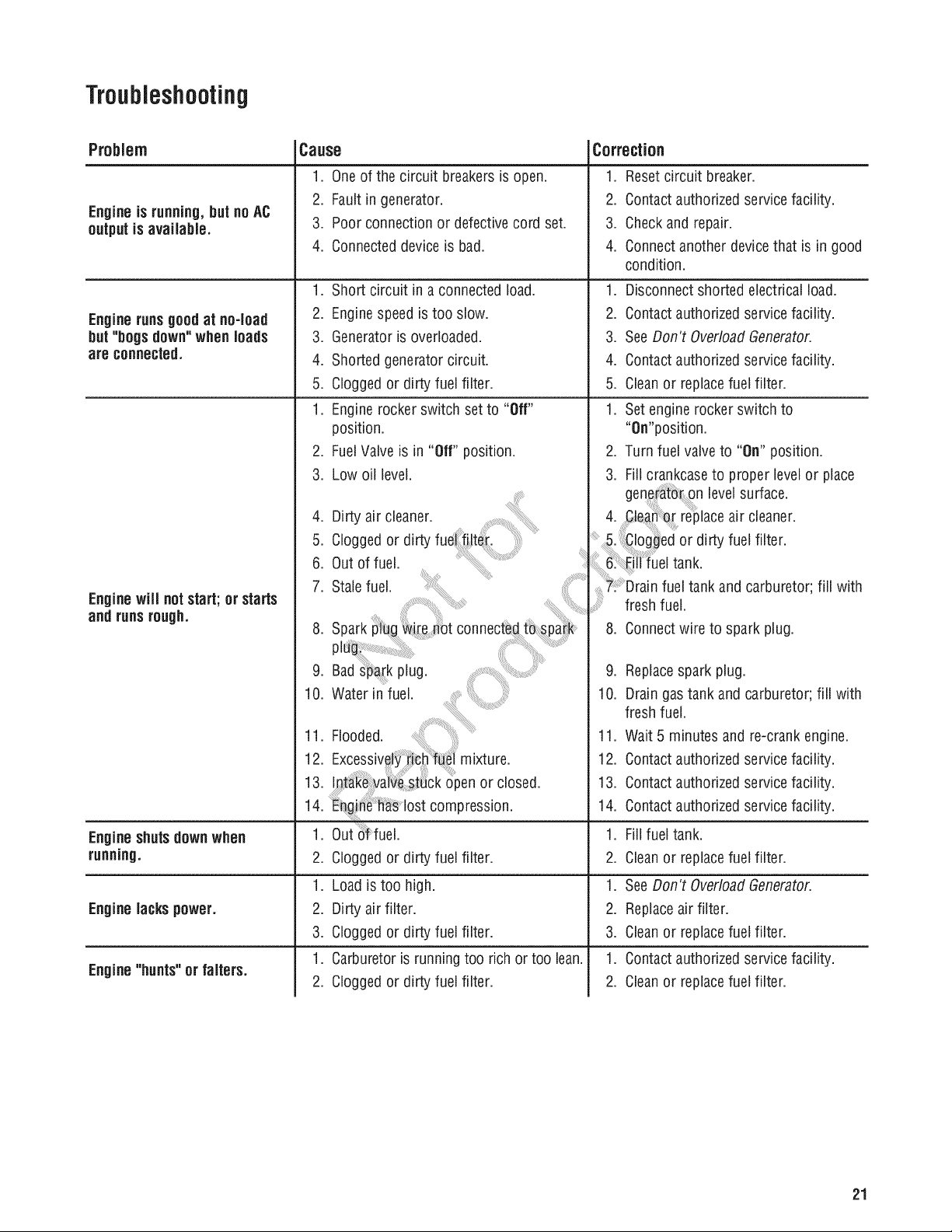

Troubleshooting

Problem

Engineisrunning,hut noAC

output is available.

Enginerunsgood at no-load

but"hogs down"when loads

are connected.

Enginewill notstart;or starts

Cause

1. Oneof the circuit breakers is open.

2. Faultin generator.

3. Poor connection or defectivecord set.

4. Connecteddeviceis bad.

.

Short circuit in a connectedload. 1.

2.

Enginespeed istoo slow. 2.

3.

Generatoris overloaded. 3.

4.

Shorted generator circuit. 4.

5.

Cloggedor dirty fuel filter. 5.

1.

Engine rocker switch setto "Off" 1.

position.

2. FuelValveis in "Off" position.

3. Low oil level.

4. Dirty air cleaner.

5. Cloggedor dirty

6. Out offuel.

7. Stalefuel.

Correction

1. Resetcircuit breaker.

2. Contactauthorized service facility.

3. Checkand repair.

4. Connectanother devicethat is in good

condition.

Disconnectshorted electrical load.

Contactauthorized servicefacility.

SeeDon't OverloadGenerator.

Contactauthorized servicefacility.

Cleanor replacefuel filter.

Setengine rocker switch to

"On'position.

.

Turn fuel valveto "On" position.

3.

Fillcrankcaseto proper levelor place

levelsurface.

replaceair cleaner.

or dirty fuel filter.

tank.

fuel tank and carburetor; fifl with

fresh fuel.

Connectwire to spark plug.

Engineshutsdown when

running.

Enginelackspower.

Engine"hunts" or falters.

11. Flooded.

12. Excessive;l_ic_ _8_imixture.

13. IDt_vaJ _ S_ck _penor closed.

14. _ngifi_ h_slost compression.

1. Out_ fuel.

2. Cloggedor dirty fuel filter.

1. Loadis too high.

2. Dirty air filter.

3. Cloggedor dirty fuel filter.

1. Carburetoris runningtoo rich ortoo lean.

2. Cloggedor dirty fuel filter.

Replacespark plug.

Drain gastank and carburetor; fill with

fresh fuel.

11. Wait5 minutes and re-crank engine.

12. Contactauthorizedservice facility.

13. Contactauthorizedservice facility.

14. Contactauthorizedservice facility.

1. Fillfuel tank.

2. Cleanor replace fuel filter.

1. SeeDon't OverloadGenerator.

2. Replaceair filter.

3. Cleanor replace fuel filter.

1. Contactauthorized servicefacility.

2. Cleanor replace fuel filter.

21

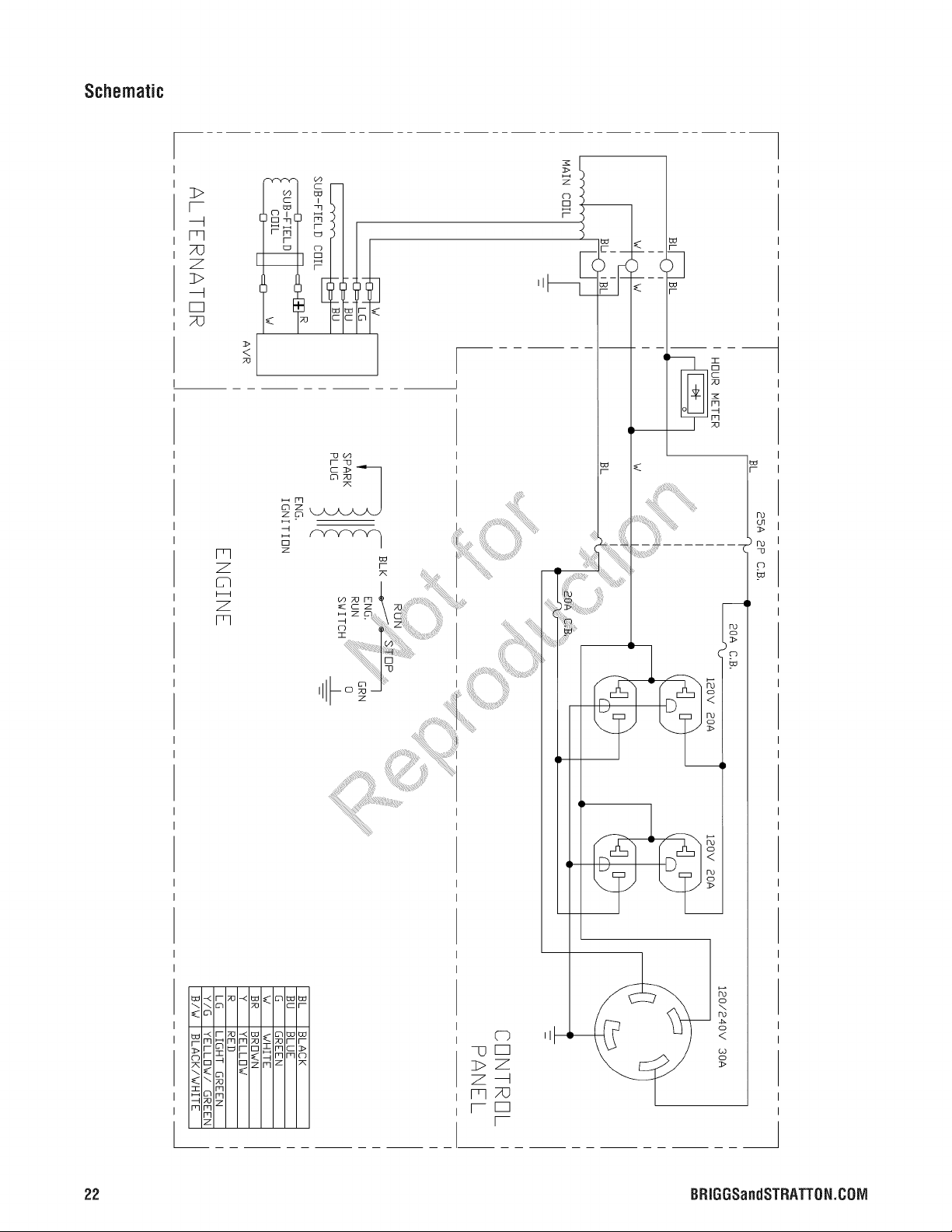

Schematic

]>

i-

n

Z

1>

n

}

n

Z

H

Z

n

L _

C_

8

iI>

8

8

_@-_@_65_

_z

y

22 BRiGGSandSTRATTON.COiVi

Ct

_n

l>Z

z_

Fn

F

<

8

23

Loading...

Loading...