Briggs & Stratton 030439-0, 030439 Owner’s Manual

®

PortableGenerator

Operator'sManual

This generator is rated to be compliant with CSA(CanadianStandards

Association) standard 022.2 No. 100-04 (motors and generators).

BRIGGS & STRATTONPOWER PRODUCTS GROUP, LLC

JEFFERSON, WISCONSIN, U.S.A.

Manual No. 209269GS Revision - (01/15/2009)

Thankyou for purchasing this quality-built Briggs & Stratton generator.We are pleasedthat you've placedyour confidence in

the Briggs & Stratton brand. When operatedand maintained accordingto the instructions in this manual,your Briggs &

Stratton generator will provide manyyears of dependableservice.

Thismanual containssafety information to makeyou awareof the hazardsand risks associatedwith generatorsand how to

avoid them. This generatoris designedand intendedonly for supplying electrical power for operatingcompatible electrical

lighting, appliances,tools andmotor loads,and is not intendedfor any other purpose.It is important that you readand

understand these instructions thoroughly beforeattempting to start or operate this equipment. Savethese instructions for

future reference.

Thisgenerator requiresfinal assemblybefore use. Referto the Assemb/ysection of this manualfor instructions on final

assembly procedures. Followthe instructions completely.

Where to Find Us

You neverhave to look far to find Briggs & Stratton support and service for your generator. Consult your Yellow Pages.There

are over 30,000 Briggs & Stratton authorized service dealersworldwide who providequality service. You canalso contact

Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Generator

Model Number

Revision

Serial Number

Engine

ModelNumber

TypeNumber III

Code Number

DatePurchased

Briggs & Stratton Power ProductsGroup, LLC

900 North Parkway

Jefferson, WI 53549

III

III III III

Copyright © 2009 Briggs & Stratton Power Products Group,

LLC. All rights reserved. No part of this materialmay be

reproducedor transmitted in any form by any meanswithout

the expresswritten permission of Briggs & Stratton Power

Products Group, LLC.

2 BRIGGSandSTRATTON.COM

Tableof Contents

OperatorSafety ................................. 4

Equipment Description......................................... 4

Important SafetyInformation.................................... 4

Assembly ..................................... 7

UnpackGenerator ............................................ 7

Install WheelKit.............................................. 7

Verify EngineOil Level......................................... 8

Add Fuel.................................................... 8

System Ground .............................................. 9

Connectingto a Building's ElectricalSystem........................ 9

GeneratorLocation ........................................... 9

Featuresand Controls............................ 10

Cord Setsand Receptacles .................................... 11

Operation .................................... 12

Starting theEngine .......................................... 12

ConnectingElectrical Loads.................................... 13

Stopping theEngine.......................................... 13

Warm WeatherOperation ..................................... 13

Don't Overload Generator ..................................... 14

Maintenance .................................. 15

MaintenanceSchedule........................................ 15

GeneratorMaintenance ....................................... 15

Engine Maintenance.......................................... 16

Storage ................................................... 19

Troubleshooting ................................ 21

Schematic ................................................. 22

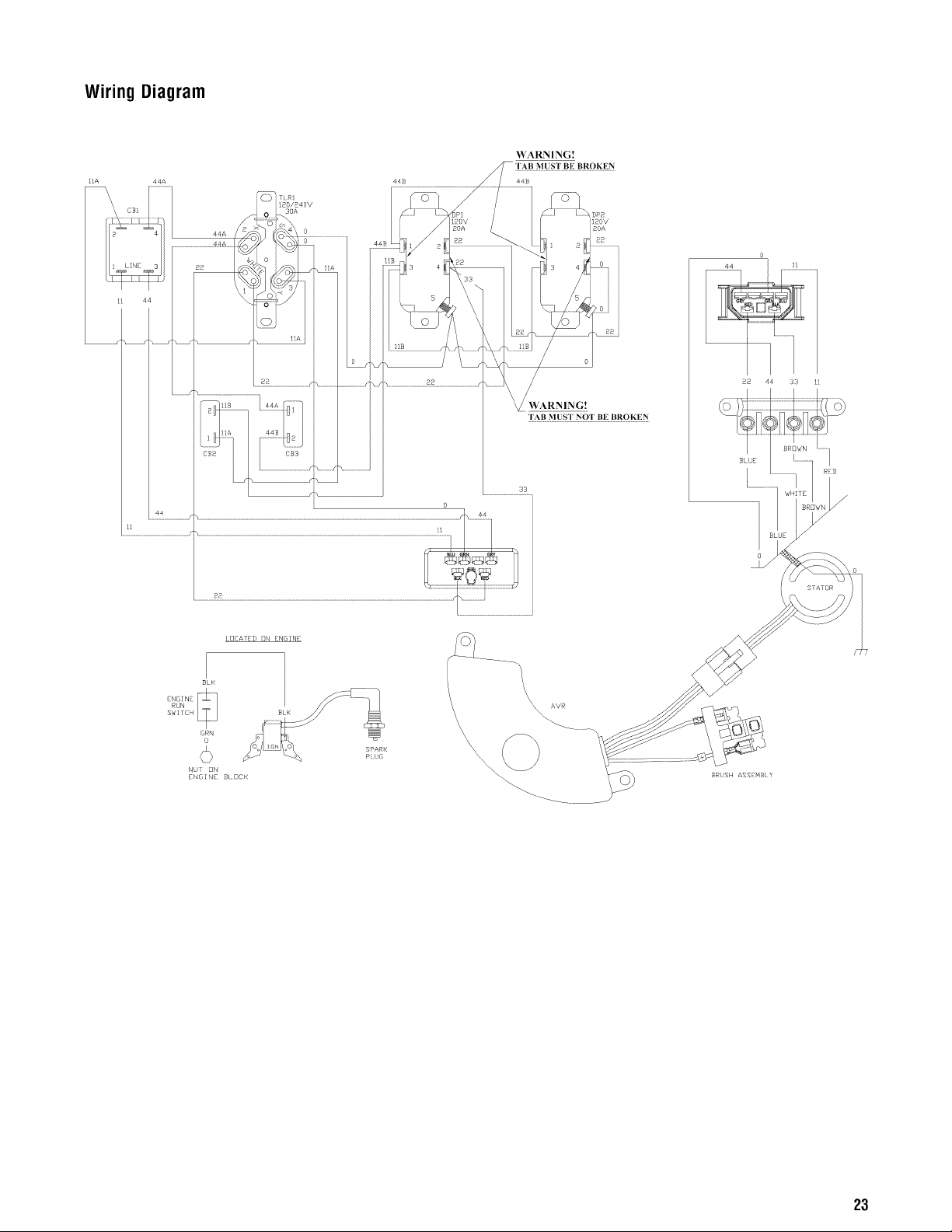

Wiring Diagram ............................................. 23

Warranties .................................... 24

Emissions Control System Warranty ............................. 24

GeneratorOwner Warranty .................................... 26

Specifications ................................. 28

Product Specifications........................................ 28

Common ServiceParts ....................................... 28

Frangais Espa_ol

OperatorSafety

Equipment Description

Readthis manualcarefully and becomefamiliar

with yourgenerator. Knowits applications, its

limitationsand anyhazardsinvolved.

Thegenerator is anengine-driven, revolvingfield, alternating

current (AC)generator. It wasdesignedto supplyelectrical

power for operatingcompatible electricallighting, appliances,

tools and motor loads.Thegenerator's revolving field is

driven atabout 3,600 rpm by a single-cylinder engine.

NOTICP.Exceedinggeneratorswattage/amperagecapacity

can damagegeneratorand/or electricaldevices connectedto

it.

• DONOTexceedthegenerator'swattage/amperagecapacity.See

Don'tOverloadGeneratorintheOperationsection.

Everyeffort has been madeto ensure that the information in

this manual is both accurateand current. However,the

manufacturer reservesthe right to change,alter or otherwise

improve thegenerator and this documentation at anytime

without prior notice.

The EmissionControl System for this generator is warranted

for standards set by the Environmental ProtectionAgency

and the CaliforniaAir ResourcesBoard.

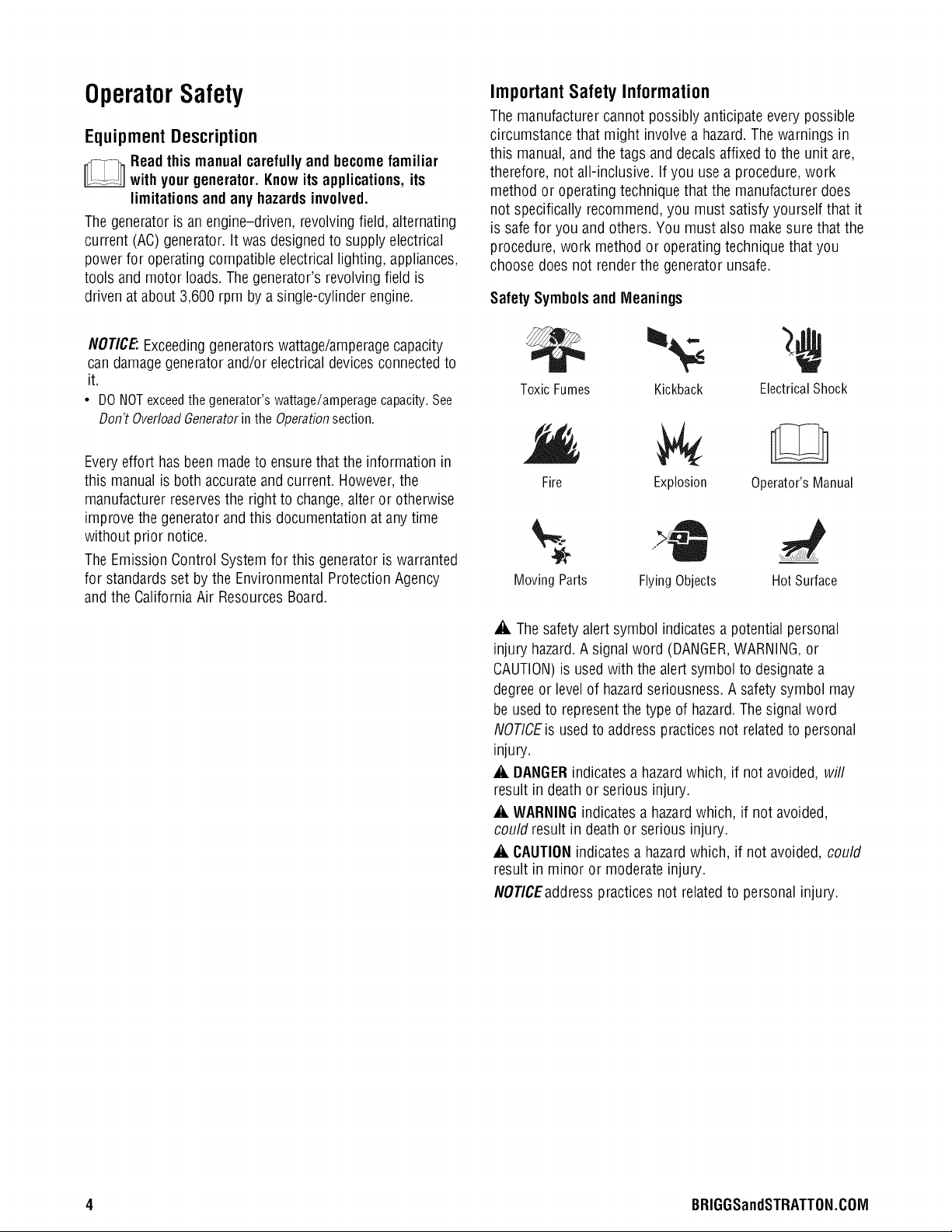

Important Safety Information

Themanufacturer cannot possibly anticipate everypossible

circumstance that might involve a hazard.The warnings in

this manual, and the tags and decalsaffixed to the unit are,

therefore, not all-inclusive. If you usea procedure,work

method or operatingtechnique that the manufacturer does

not specifically recommend,you must satisfy yourself that it

is safefor you andothers. You must also makesure that the

procedure, work method or operating technique that you

choose does not renderthe generator unsafe.

SafetySymbolsand Mleanings

ToxicFumes Kickback ElectricalShock

Fire

MovingParts FlyingObjects Hot Surface

Explosion Operator'sManual

Thesafetyalert symbol indicatesa potential personal

injury hazard.A signal word (DANGER,WARNING,or

CAUTION)is usedwith the alert symbol to designatea

degreeor levelof hazardseriousness.A safety symbol may

be usedto representthe type of hazard.Thesignal word

NOTICEisusedto address practicesnot relatedto personal

injury.

_k DANGERindicatesa hazardwhich, if not avoided, will

result in deathor serious injury.

_k WARNINGindicatesa hazardwhich, if not avoided,

could resultin death or serious injury.

A. CAUTIONindicatesa hazardwhich, if not avoided, could

result in minor or moderateinjury.

NOTICEaddress practices not relatedto personal injury.

4 BRIGGSandSTRATTON.COIVl

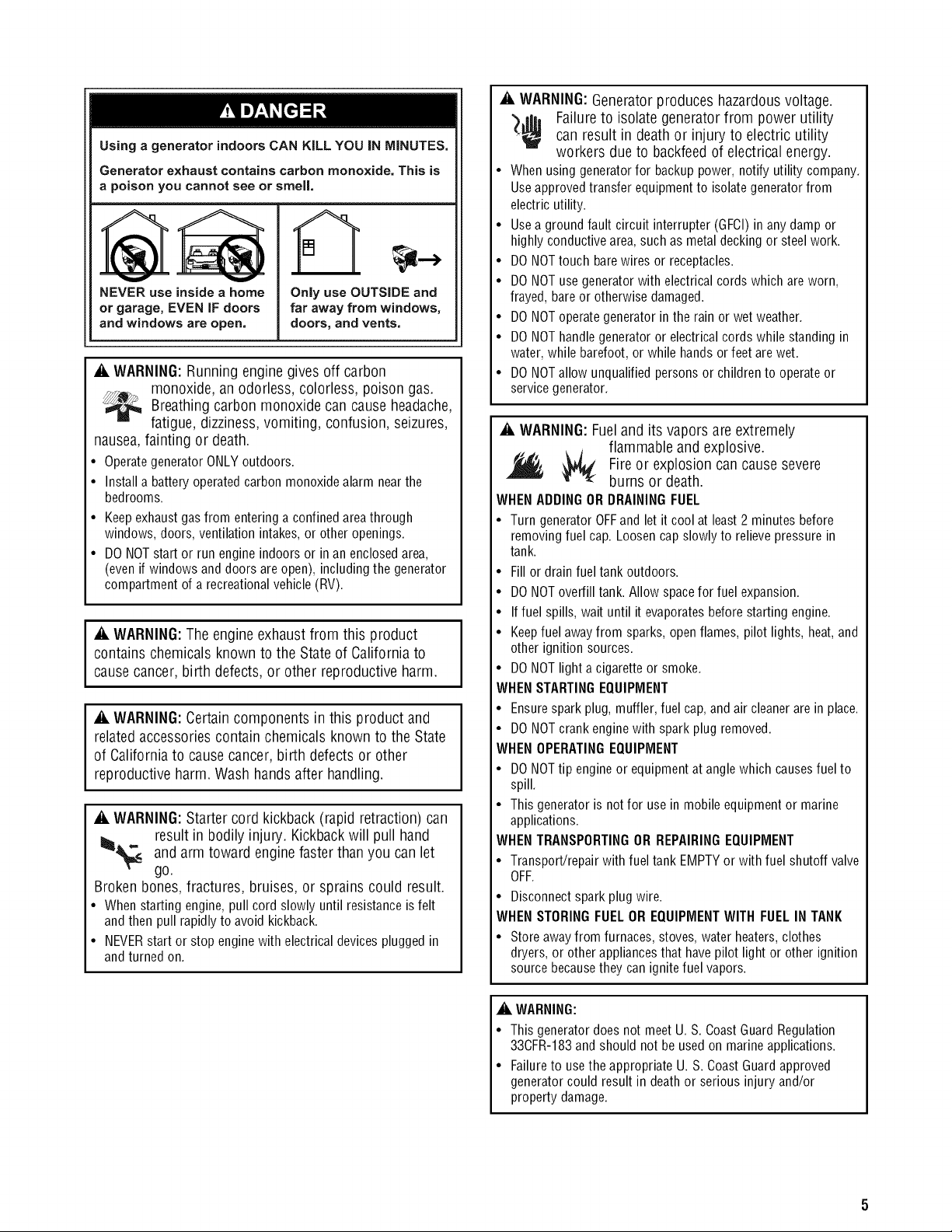

¥:IImT'-I([__ ;.(

Using a generator indoors CAN KiLL YOU iN MINUTES,

Generator exhaust contains carbon monoxide, This is

a poison you cannot see or smeJL

V V

NEVER use inside a home

or garage, EVEN iF doors

and windows are open,

_i, WARNING:Running engine gives off carbon

monoxide, anodorless, colorless, poison gas.

_ Breathing can causeheadache,

carbon monoxide

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

• OperategeneratorONLYoutdoors.

• Installabatteryoperatedcarbonmonoxidealarmnearthe

bedrooms.

Keepexhaustgas from enteringa confined areathrough

windows, doors, ventilation intakes,or other openings.

DO NOTstart or run engine indoors or in an enclosedarea,

(even if windows anddoors are open), including the generator

compartment of arecreationalvehicle (RV).

_i, WARNING:The engine exhaust from this product

contains chemicals knownto the Stateof California to

cause cancer,birth defects, or other reproductive harm.

_i, WARNING:Certaincomponents in this product and

relatedaccessories contain chemicals known to the State

of Californiato cause cancer,birth defects or other

reproductive harm.Wash handsafter handling.

_i, WARNING: Starter cord kickback (rapid retraction) can

result in bodily injury. Kickback will pull hand

_,_< and arm toward engine faster than you can let

go.

Broken bones, fractures, bruises, or sprains could result.

• When starting engine, pull cord slowly until resistanceisfelt

andthen pull rapidlyto avoid kickback.

• NEVERstart or stop engine with electrical devices plugged in

andturned on.

Only use OUTSIDE and

far away from windows,

doors, and vents,

_i, WARNING: Generator produces hazardous voltage.

")Jllll Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

• When using generatorfor backup power, notify utility company.

Useapprovedtransfer equipment to isolate generatorfrom

electric utility.

• Usea ground fault circuit interrupter (GFCI)in any damp or

highly conductive area,such as metal decking or steel work.

• DO NOTtouch barewires or receptacles.

• DO NOTuse generatorwith electrical cordswhich areworn,

frayed,bare or otherwisedamaged.

• DO NOToperate generatorin the rain or wet weather.

• DO NOThandle generatoror electrical cords while standing in

water, while barefoot,or while hands or feet arewet.

• DO NOTallow unqualified personsor children to operateor

servicegenerator.

_i, WARNING:Fueland its vapors are extremely

flammable andexplosive.

Fireor explosion can causesevere

burns or death.

WHENADDINGORDRAININGFUEL

• Turn generatorOFFand let it cool at least2 minutes before

removing fuel cap. Loosen cap slowly to relieve pressure in

tank.

• Fill or drain fueltank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• If fuel spills, wait until it evaporatesbefore starting engine.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat,and

other ignition sources.

• DONOTlight a cigaretteor smoke.

WHENSTARTINGEQUIPMENT

• Ensurespark plug, muffler, fuel cap,andair cleanerarein place.

• DO NOTcrank enginewith sparkplug removed.

WHENOPERATINGEQUIPMENT

• DONOTtip engine or equipment at anglewhich causesfuel to

spill.

• This generator is notfor use inmobile equipment or marine

applications.

WHENTRANSPORTINGOR REPAIRINGEQUIPMENT

• Transport/repairwithfueltankEMPTYorwith fuelshutoffvalve

OFF.

• Disconnectsparkplugwire.

WHENSTORINGFUELOREQUIPMENTWITHFUELIN TANK

• Store away from furnaces, stoves, water heaters,clothes

dryers, or otherappliancesthat havepilot light or other ignition

source becausethey can ignite fuel vapors.

A WARNING:

This generator does notmeet U. S. CoastGuard Regulation

33CFR-183and should not be used on marine applications.

Failureto usethe appropriate U. S. CoastGuardapproved

generator could result in death or serious injury and/or

property damage.

_kWARNING:Contactwithmufflerareacanresultin

seriousburns.

_ Exhaustheat/gasescanignite

_-_ combustibles,structuresordamage

fueltankcausingafire.

• DONOTtouchhotpartsandAVOIDhotexhaustgases.

• Allowequipmenttocoolbeforetouching.

• Keepatleast5feet(152cm)ofclearanceonallsidesof

generatorincludingoverhead.

• ItisaviolationofCaliforniaPublicResourceCode,Section

4442,touseoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredlandunlesstheexhaust

systemisequippedwithasparkarrester,asdefinedinSection

4442,maintainedineffectiveworkingorder.Otherstatesor

federaljurisdictionsmayhavesimilarlaws.

Contacttheoriginalequipmentmanufacturer,retailer,ordealer

toobtainasparkarresterdesignedfortheexhaustsystem

installedonthisengine.

• Replacementpartsmustbethesameandinstalledinthesame

positionastheoriginalparts.

_k WARNING: Unintentional sparking can result in fire or

_i, CAUTION: Excessively high operating speeds increase

risk of injury and damage to generator.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governedspeed. Generatorsupplies

correct ratedfrequency and voltage whenrunning at governed

speed.

• DO NOTmodify generator in any way.

NOTICE:Exceedinggeneratorswattage/amperagecapacity

candamage generatorand/or electrical devicesconnectedto

it.

DONOTexceedthe generator's wattage/amperagecapacity. See

Don't OverloadGeneratorin the Operationsection.

Start generator and letengine stabilize beforeconnecting

electrical loads.

Connectelectrical loadsin OFFposition, thenturn ONfor

operation.

Turn electricalloads OFFand disconnect from generator before

stopping generator.

_ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOURGENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Use approved spark plugtester.

• DO NOTcheck for spark with spark plug removed.

_k WARNING: Starter and other rotating parts can

entangle hands, hair, clothing, or accessories.

• NEVERoperategeneratorwithout protective housing or covers.

• DO NOTwear loose clothing, jewelry or anything that may be

caught in the starter or other rotating parts.

• Tie up long hair and removejewelry.

NOTICE: Improper treatment of generator can damage it

and shorten its life.

• Use generator onlyfor intended uses.

• If you havequestions aboutintended use,ask dealeror contact

local servicecenter.

• Operategenerator only on levelsurfaces.

• DONOTexpose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• DONOTinsert any objects through cooling slots.

• If connected devicesoverheat,turn them off and disconnect them

from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emitsflames;

-unit vibrates excessively.

6 BRIGGSandSTRATTON.COIVI

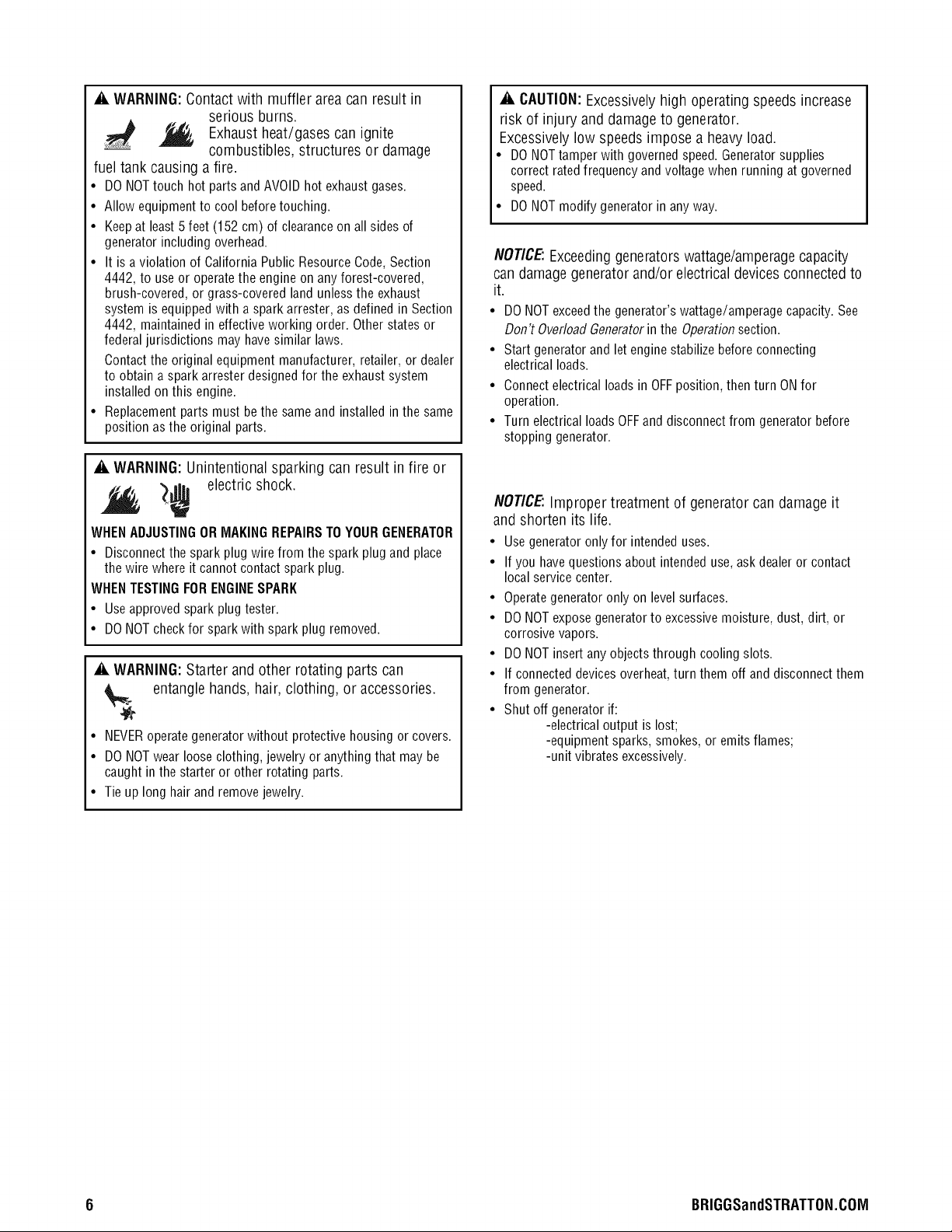

Assembly

Your generator requiressome assembly and is readyfor use

after it has been properly servicedwith the recommended

fuel and oil levelis verified.

If you haveany problemswith theassemblyof your generator,

pleasecall the generatorhelplineat (808)743-4115. If calling

for assistance,pleasehavethe model revision, and serial

number from the identificationlabelavailable.Seegenerator

Featuresand Controlsfor identification labellocation.

UnpackGenerator

1. Set the carton on a rigid, flat surface.

2. Removeeverything from carton except generator.

3. Opencarton completely by cutting eachcorner from

top to bottom.

4. Leavegeneratoron cartonto install wheel kit.

The generatoris suppliedwith:

• Operator's manual

• Wheels(2)

• Axle

• Support leg

• Wheelkit hardware

Install Wheel Kit

NOTE:Wheel kit is not intended for over-the-road use.

You will needthe following tools to install thesecomponents:

• 13 mm wrench

• Socketwrench with a 13 mm socket

• Pliers

• Safetyglasses

Install the wheelkit asfollows:

1. Tip generatorso that engine end is up.

2. Slide axle (A) through holesin generator frame.

3. Slide awasher (C)and then a wheel (B) over axle.

NOTE:Besure to install wheel with raised hub inboard.

4. Place a washer (C) on axleandthen placean e-ring (D)

in axlegroove.

_i, CAUTION:E-rings cancause eyeinjury.

E-rings can spring backand becomeairborne

when installing or removing.

• Always wear eye protection when installing/removing e-rings.

5. Install e-ring with pliers, squeezingfrom top of e-ring

to bottom of axle.

6. Repeatsteps 3 through 5 to securesecond wheel.

7. Return generator to normal operating position (resting

on wheels).

8. Remove handle (N) from generatorframe by pushing in

pins (J) and pulling up on handle.

9. Turn handle around as shown below andattach it to

generatorframe by pushing in pins on generatorframe.

Slide handle down until pins lock into holes on handle.

10. Tip generatorso that engine side is down.

11. Line up holes in support leg (E) with holesin generator

frame.

12. Attach support leg using 2 capscrews(M8 x 20 mm)

(F) and2 hexnuts (G). Tightenwith a 13 mm socket

wrench and 13 mm wrench.

13. Return generator to normal operating position (resting

on wheels and support leg).

NOTE:Turn the handlearound on the generatorframe for

storage purposes ONLY.

VerifyEngineOil Level

Thegenerator engine is shippedfrom the factory filled with

oil (API SJor higher 10W-30). This allows for generator

operation inthe widest rangeof temperatureandclimate

conditions. Beforestarting theengine,check oil leveland

ensurethat engine isserviced asdescribed in Maintenance.

NOTE:SeeOil inthe Maintenancesection to review oil

recomendations.Verify provided oil in engine is the correct

viscosity for current ambienttemperature.

NOTICE..Any attempt to crank or start the enginebefore it

has beenproperly filled with the recommendedoil will

result in equipment failure.

• Referto Maintenancefor oilfill information.

• Damageto equipment resulting from failure to follow this

instruction will void warranty.

Add

Fuel

Fuel

mustmeet these requirements:

Clean,fresh, unleadedgasoline.

A minimum of 87 octane/87 AKI (91 RON).High

altitude use, seeHigh Altitude.

Gasolinewith up to 10% ethanol (gasohol) or upto

15% MTBE (methyl tertiary butyl ether) is acceptable.

NOTICE:.Avoid generator damage.

Failureto follow Operator's Manualfor fuel

recommendationsvoids warranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoilin gasoline.

• DONOTmodifyengineto runonalternatefuels.

To protectthefuel systemfrom gum formation, mixin afuel

stabilizerwhen addingfuel. SeeStorage.All fuel is not the

same.If you experiencestarting or performanceproblemsafter

using fuel,switch to a differentfuel provider or changebrands.

This engineis certifiedto operateon gasoline.Theemission

control systemfor this engineis EM(EngineModifications).

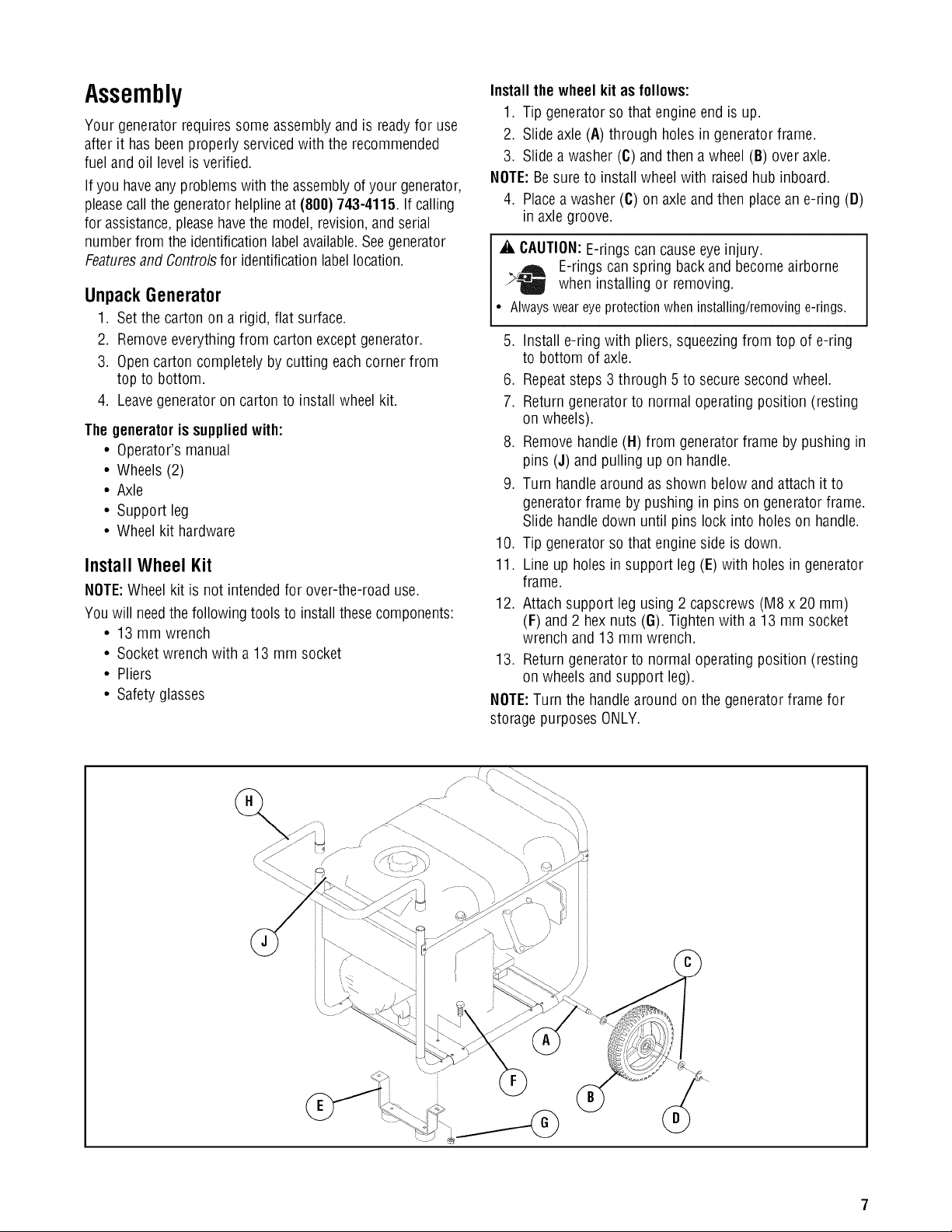

_i, WARNING:Fueland its vapors are extremely

flammable andexplosive.

Fireor explosion can causesevere

burns or death.

WHENADDINGFUEL

• Turn generatorOFFand let it cool at least2 minutes before

removing fuel cap. Loosen cap slowly to relieve pressure in

tank.

• Fill fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• If fuel spills, wait until it evaporatesbefore starting engine.

• Keepfuel awayfrom sparks, open flames, pilot lights, heat,and

other ignition sources.

• DONOTlight a cigaretteor smoke.

1. Cleanareaaround fuel fill cap, remove cap.

2. Slowly add unleadedgasoline (A) to fuel tank (B). Be

careful not to fill abovethe baffle (C). This allows

adequatespacefor fuel expansionas shown.

3. Install fuel cap and let anyspilled fuel evaporatebefore

starting engine.

HighAltitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remain emissions compliant, highaltitude adjustment is

required. Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seean authorizeddealerfor high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

8 BRIGGSandSTRATTON.COIVl

SystemGround

Thegenerator hasa system ground that connects the

generator framecomponents to the ground terminals on the

ACoutput receptacles.Thesystem ground is connectedto

the ACneutral wire (the neutral is bondedto the generator

frame).

Special Requirements

Theremay be Federalor State OccupationalSafetyand

HealthAdministration (OSHA)regulations,local codes, or

ordinances that apply to the intended use of the generator.

Pleaseconsult a qualified electrician, electricalinspector, or

the local agency having jurisdiction:

• In someareas, generatorsare required to be registered

with local utility companies.

• If the generator is usedat a construction site, there

may be additional regulationswhich must beobserved.

Connecting to a Building's Electrical System

Connections for standby power to abuilding's electrical

system must be made bya qualified electrician.The

connection must isolate the generator power from utility

power and must comply with all applicablelaws and

electrical codes.

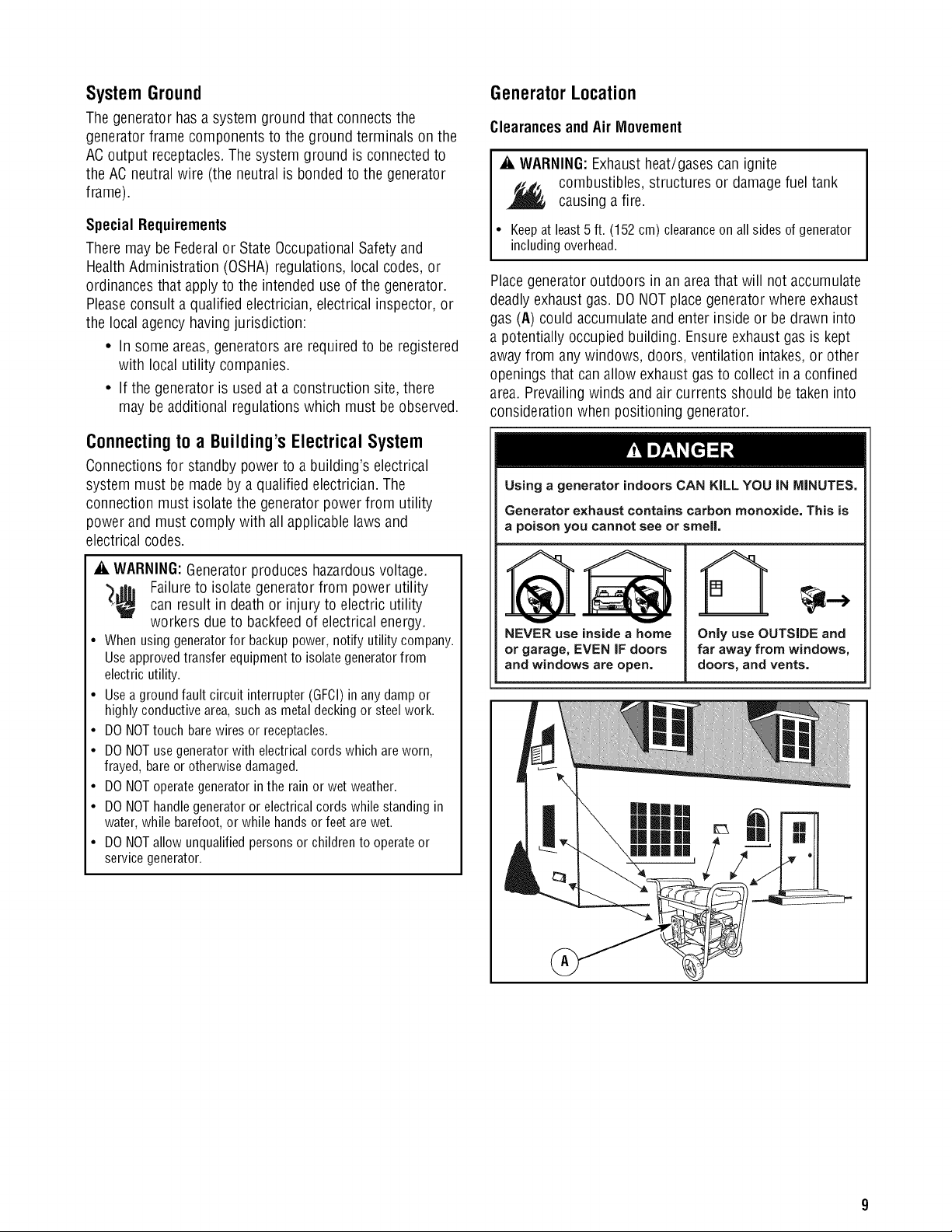

GeneratorLocation

Clearancesand Air Movement

A. WARNING:Exhaustheat/gases can ignite

combustibles, structures or damagefuel tank

causing a fire.

• Keepat least5 ft. (152 cm) clearanceon all sidesof generator

including overhead.

Placegenerator outdoors in an areathat will not accumulate

deadlyexhaust gas. DONOTplacegenerator where exhaust

gas (A) could accumulateand enter inside or be drawn into

a potentially occupiedbuilding. Ensureexhaust gas is kept

awayfrom any windows, doors, ventilation intakes,or other

openings that canallow exhaust gasto collect in a confined

area.Prevailing winds and air currents should betakeninto

consideration when positioning generator.

Using a generator indoors CAN KILL YOU IN MINUTES,

Generator exhaust contains carbon monoxide, This is

a poison you cannot see or smell,

_lLWARNING:Generatorproduces hazardousvoltage.

"),||h Failureto isolate generatorfrom power utility

can result in death or injury to electric utility

workers due to backfeedof electrical energy.

• Whenusinggeneratorfor backuppower,notifyutilitycompany.

Useapprovedtransferequipmentto isolategeneratorfrom

electricutility.

• Useagroundfault circuitinterrupter(GFCI)in anydampor

highlyconductivearea,suchasmetaldeckingor steelwork.

• DONOTtouchbarewiresor receptacles.

• DONOTusegeneratorwithelectricalcordswhichareworn,

frayed,bareor otherwisedamaged.

• DONOToperategeneratorinthe rainorwetweather.

• DONOThandlegeneratoror electricalcordswhilestandingin

water,whilebarefoot,or whilehandsorfeetarewet.

• DONOTallowunqualifiedpersonsor childrento operateor

servicegenerator.

V V

NEVER useinsidea home

or garage, EVENIF doors

and windowsare open,

\

|

Only use OUTSIDE and

far away from windows,

doors, and vents,

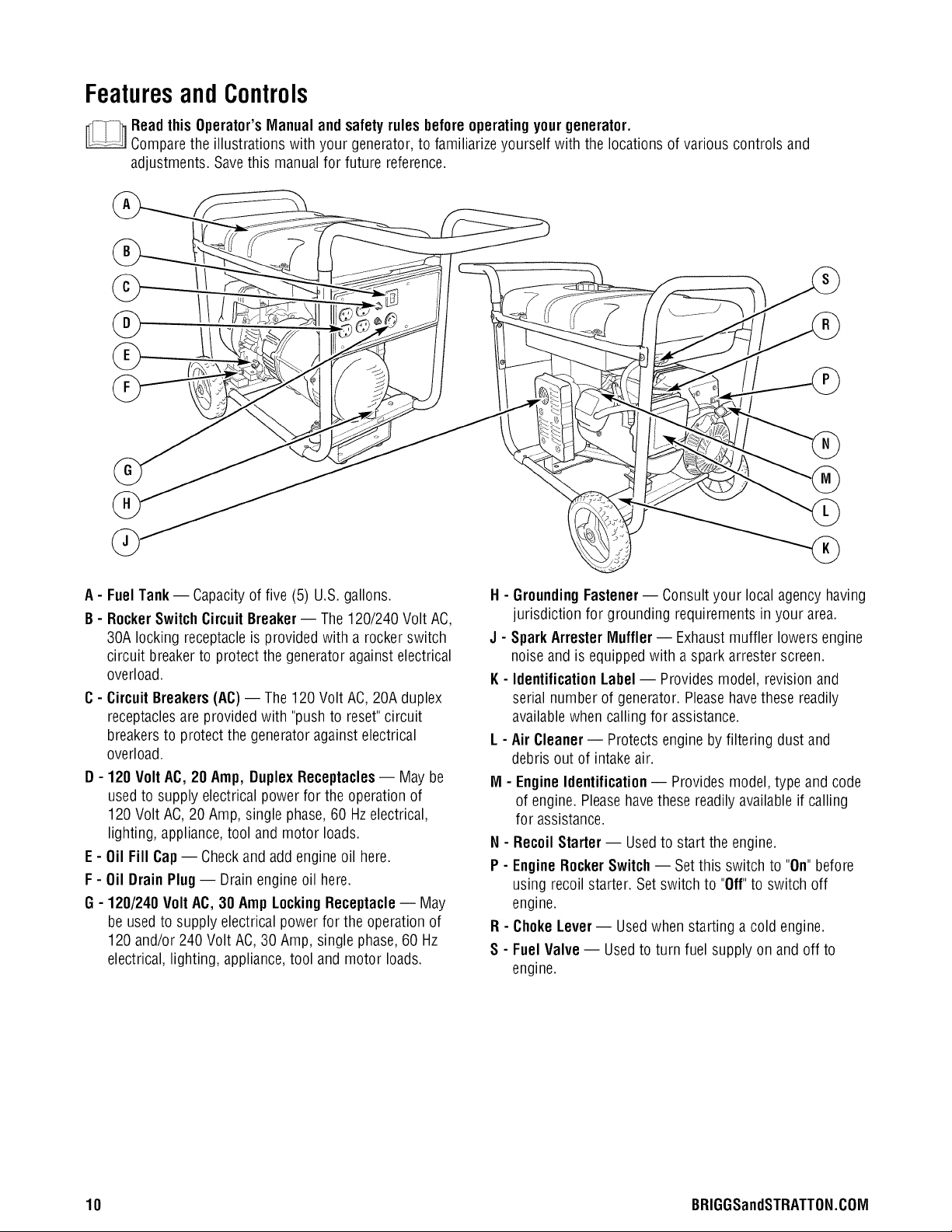

FeaturesandControls

Readthis Operator'sManual and safetyrules beforeoperatingyourgenerator.

Comparethe illustrations with your generator, to familiarize yourself with the locations of various controls and

adjustments. Savethis manual for future reference.

A- FuelTank-- Capacityof five (5) U.S.gallons.

B- RockerSwitchCircuitBreaker-- The120/240 Volt AC,

30A locking receptacleis provided with a rocker switch

circuit breaker to protect the generatoragainst electrical

overload.

C- CircuitBreakers(AC) -- The 120 Volt AC,20A duplex

receptaclesare provided with "pushto reset"circuit

breakersto protect the generatoragainst electrical

overload.

D - 120 VoltAC, 20 Amp, DuplexReceptacles-- May be

usedto supply electrical power for the operation of

120 Volt AC,20 Amp, single phase,60 Hzelectrical,

lighting, appliance, tool andmotor loads.

E- 0il Fill Cap-- Checkand add engine oil here.

F - Oil DrainPlug-- Drainengine oil here.

G - 120/240 VoltAC,30 Amp LockingReceptacle-- May

be usedto supply electrical power for the operation of

120 and/or 240Volt AC, 30 Amp, single phase,60 Hz

electrical, lighting, appliance,tool and motor loads.

H - GroundingFastener-- Consultyour local agencyhaving

jurisdiction for grounding requirements inyour area.

J - SparkArresterMuffler -- Exhaust muffler lowersengine

noiseand is equippedwith a spark arrester screen.

K- Identification Label -- Provides model, revision and

serial number of generator.Pleasehave these readily

availablewhen calling for assistance.

L - Air Cleaner-- Protects engine by filtering dust and

debris out of intakeair.

M - EngineIdentification-- Providesmodel, type and code

of engine. Pleasehavethese readilyavailable if calling

for assistance.

N - Recoil Starter -- Usedto start the engine.

P - EngineRocker Switch-- Setthis switch to "On"before

using recoil starter. Setswitch to "Off"to switch off

engine.

R - ChokeLever- Usedwhen starting a cold engine.

S - Fuel Valve-- Usedto turn fuel supply on and off to

engine.

10 BRIGGSandSTRATTON.COM

CordSetsandReceptacles

Useonly high quality, well-insulated, grounded extension

cords with the generator's 120Volt duplex receptacle.

Inspect extensioncords before each use.

Checkthe ratings of all extensioncords beforeyou use

them. Extensioncord sets usedshould be rated for 125 Volt

ACloads at 20Amps or greaterfor most electrical devices.

Some devices,however, may not requirethis type of

extension cord. Checkthe operator's manualsof those

devicesfor the manufacturer's recommendations.

Keepextension cords asshort as possibleto minimize

voltage drop.

_k WARNING:Overloadedelectricalcords can overheat,

arc, and burn resulting in death, bodily injury,

and/or property damage.

• ONLYusecordsratedforyourloads.

• Followallsafetiesonelectricalcords.

A double pole rocker switch circuit breakeris providedto

protect the locking receptacle.If this circuit breakeris

tripped, all panelreceptaclesare disconnected.

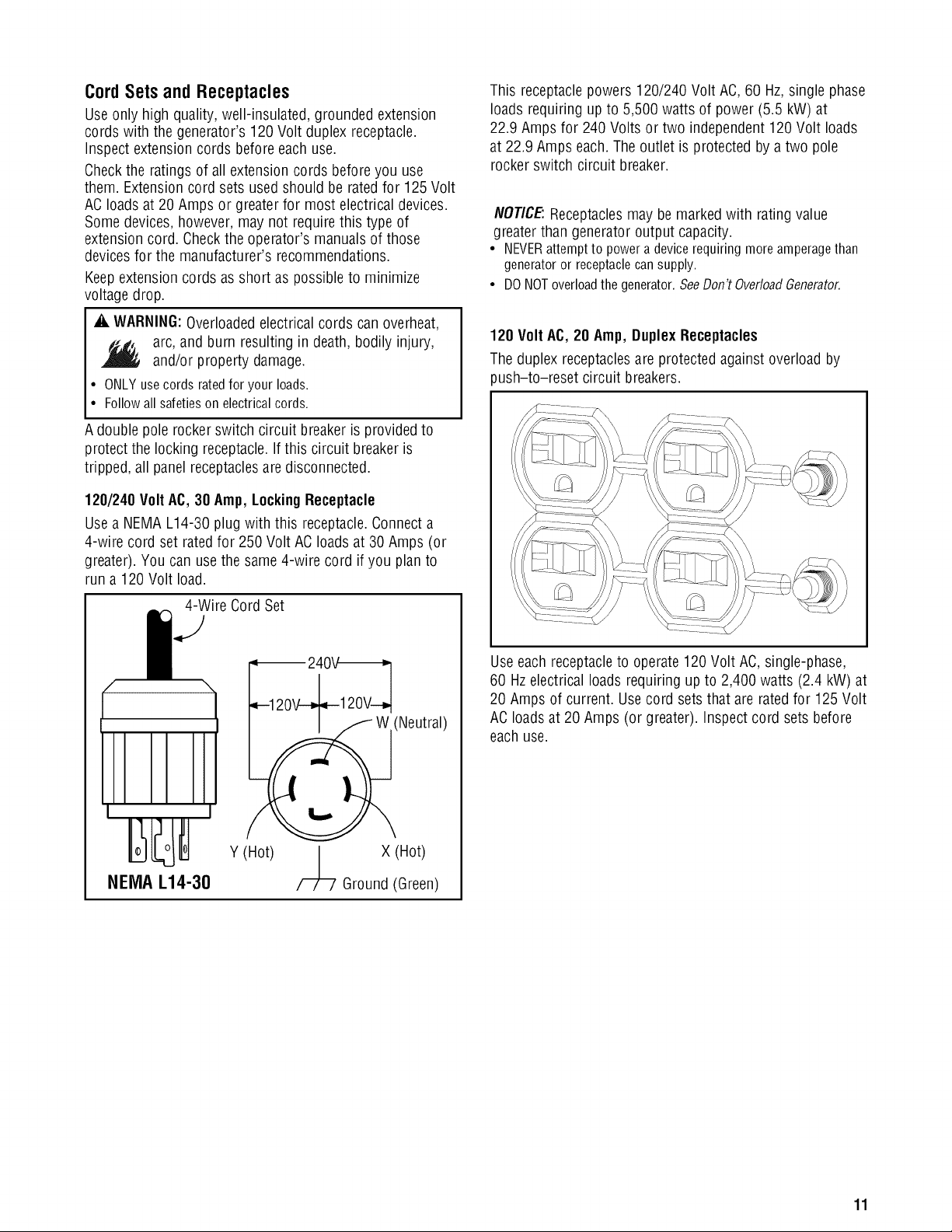

120/240 VoltAC, 30 Amp, LockingReceptacle

Usea NEMA L14-30 plug with this receptacle.Connect a

4-wire cord set ratedfor 250 Volt AC loads at 30Amps (or

greater). You can usethe same4-wire cord if you plan to

run a 120 Volt load.

4-Wire Cord Set

This receptaclepowers 120/240 Volt AC,60 Hz, single phase

loads requiring up to 5,500 watts of power (5.5 kW) at

22.9 Ampsfor 240 Volts or two independent120 Volt loads

at 22.9 Amps each. The outlet is protected bya two pole

rocker switch circuit breaker.

NOTICE: Receptacles may be marked with rating value

greater than generator output capacity.

• NEVERattempt to power adevice requiring more amperagethan

generator or receptaclecansupply.

• DONOToverload the generator.SeeDon't OverloadGenerator.

120 Volt AC, 20 Amp, DuplexReceptacles

Theduplex receptaclesare protected againstoverload by

push-to-reset circuit breakers.

__1i

--\

NEMA L14-30

Y (Hot)

(Neutral)

X (Hot)

Ground (Green)

Use eachreceptacleto operate120 Volt AC, single-phase,

60 Hz electricalloads requiring up to 2,400 watts (2.4 kW) at

20 Amps of current. Usecord setsthat are rated for 125 Volt

ACloads at 20Amps (or greater). Inspect cord sets before

eachuse.

11

Operation

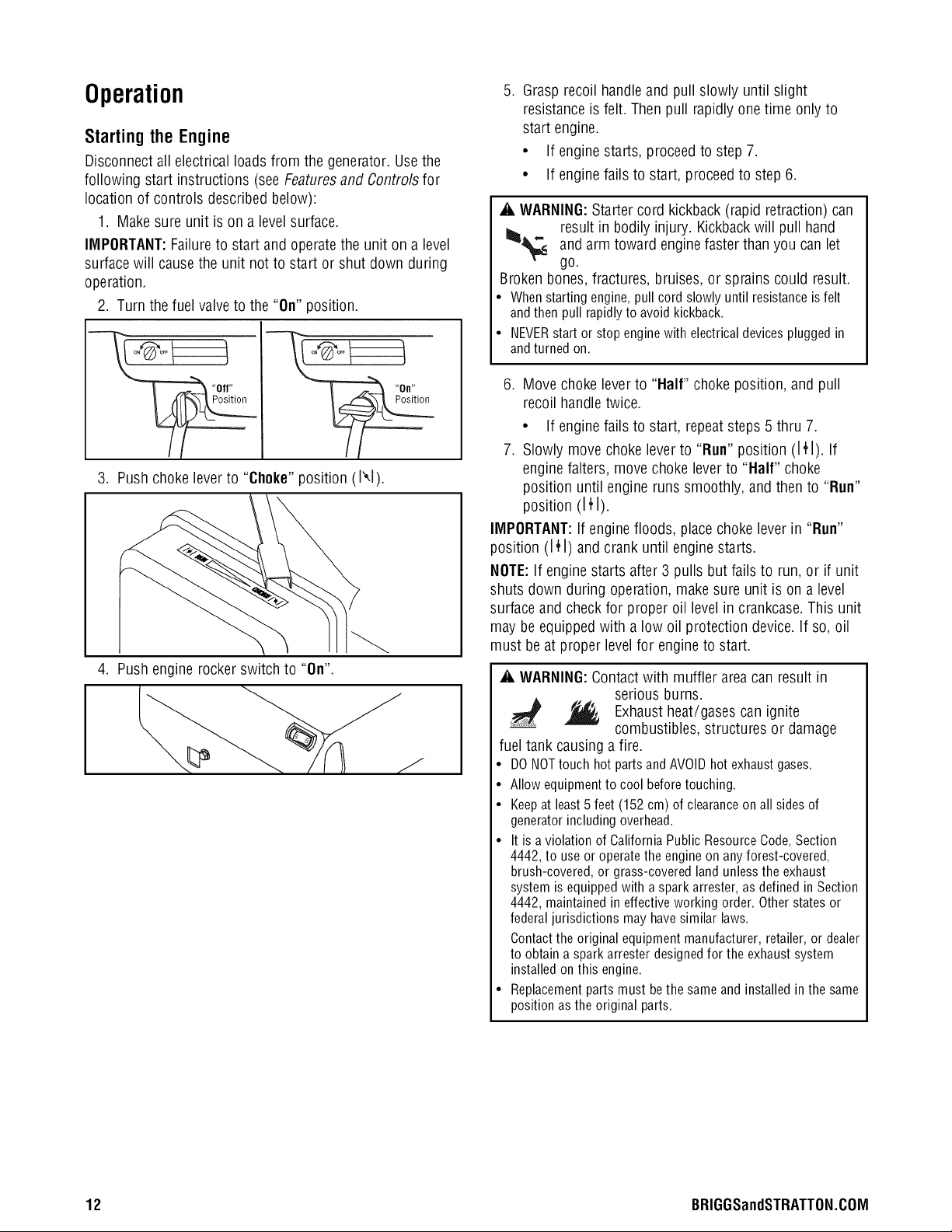

Starting the Engine

Disconnectall electrical loads from the generator. Usethe

following start instructions (seeFeaturesand Controls for

location of controls described below):

1. Make sure unit is on alevel surface.

IMPORTANT:Failureto start and operatethe unit on a level

surfacewill causethe unit not to start or shut down during

operation.

2. Turn thefuel valve to the "On" position.

3. Push choke leverto "Choke" position (l_,l).

,

Grasprecoil handleand pull slowly until slight

resistance is felt. Then pull rapidly onetime only to

start engine.

• If engine starts, proceedto step 7.

• If engine fails to start, proceedto step 6.

_iLWARNING:Starter cord kickback(rapid retraction) can

result in bodily injury. Kickbackwill pull hand

_,_ and arm toward enginefasterthan you can let

T--

gO.

Broken bones,fractures, bruises, or sprains could result.

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpull rapidlyto avoidkickback.

• NEVERstartor stopenginewith electricaldevicespluggedin

andturnedon.

6. Move choke leverto "Half" choke position, and pull

recoil handletwice.

• If engine fails to start, repeatsteps 5 thru 7.

7. Slowly move chokelever to "Run" position (J_I). If

engine falters, move choke lever to "Half" choke

position until engine runs smoothly, andthen to "Run"

position (1+1).

IMPORTANT:If enginefloods, placechoke leverin "Run"

position (J_'J)andcrank until engine starts.

NOTE:If engine starts after3 pulls but fails to run, or if unit

shuts down during operation, makesure unit is on a level

surfaceand check for proper oil level in crankcase.This unit

may be equippedwith a low oil protection device. If so, oil

must be at proper levelfor engine to start.

_iL WARNING: Contact with muffler area can result in

serious burns.

_ Exhaust heat/gases can ignite

fuel tank causing a fire.

• DO NOTtouch hot parts andAVOIDhot exhaustgases.

• Allow equipment to cool beforetouching.

• Keepat least5 feet (152 cm) of clearanceon all sidesof

generator including overhead.

• It is a violation of California Public Resource Code,Section

4442, to use or operatethe engine on anyforest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with a spark arrester, as definedin Section

4442, maintained in effective working order. Other states or

federaljurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain aspark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must bethe same and installed in the same

position as the original parts.

combustibles, structures or damage

12 BRIGGSandSTRATTON.COIVl

Connecting Electrical Loads

1. Let engine stabilizeand warm up for a few minutes

after starting.

2. Ensure circuit breakeron control panel is in "On"

position.

3. Plug in and turn on the desired 120 and/or 240 Volt

AC,single phase,60 Hz electrical loads.

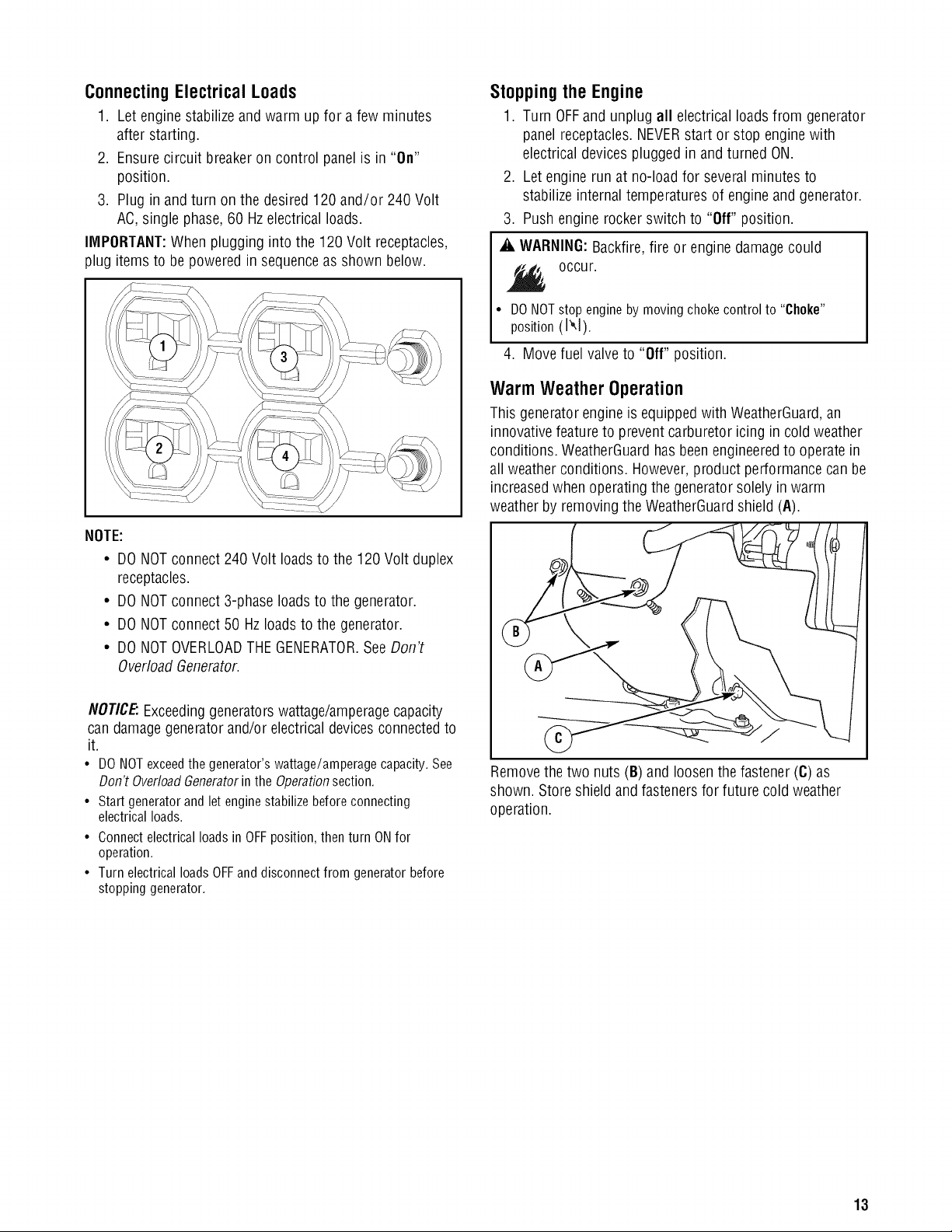

IMPORTANT:When plugging into the 120 Volt receptacles,

plug items to be powered in sequenceas shown below.

NOTE:

• DONOTconnect 240 Volt loads to the 120 Volt duplex

receptacles.

• DONOTconnect 3-phase loadsto the generator.

• DONOTconnect 50 Hz loadsto the generator.

• DONOTOVERLOADTHEGENERATOR.SeeDon't

OverloadGenerator.

Stoppingthe Engine

1. Turn OFFand unplug all electrical loadsfrom generator

panel receptacles.NEVERstart or stop enginewith

electrical devicesplugged in and turned ON.

2. Let engine run at no-loadfor several minutes to

stabilize internaltemperatures of engineand generator.

3. Push engine rocker switch to "Off" position.

_i, WARNING:Backfire,fire or engine damagecould

occur.

• DONOTstopenginebymovingchokecontrolto "Choke"

position(H).

4. Move fuel valve to "Off" position.

Warm Weather Operation

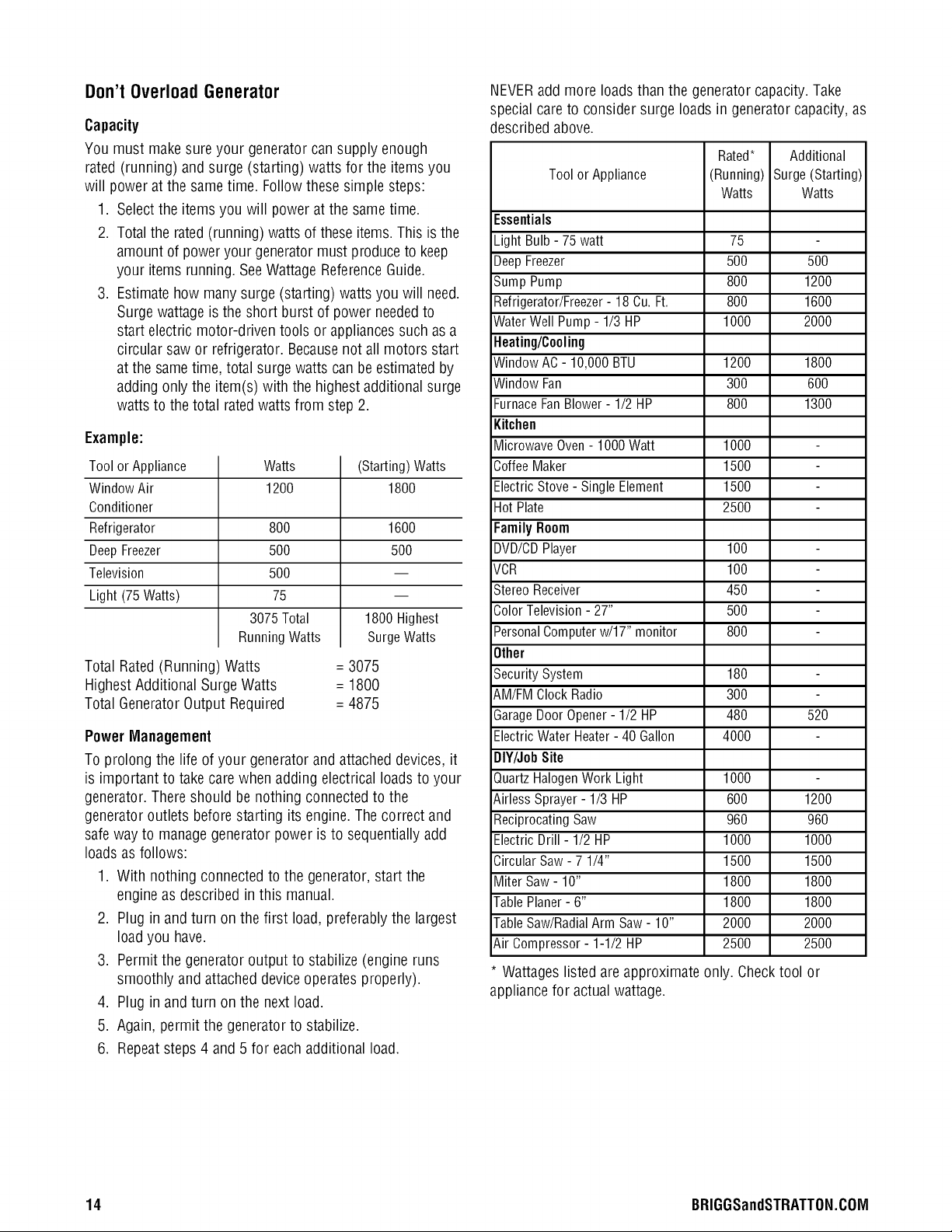

This generatorengineis equippedwith WeatherGuard,an

innovativefeature to preventcarburetor icing in cold weather

conditions. WeatherGuardhas beenengineeredto operatein

all weather conditions. However,product performance canbe

increasedwhen operatingthe generatorsolely in warm

weather by removingthe WeatherGuardshield (A).

NOTICE. Exceeding generators wattage/amperage capacity

can damagegeneratorand/or electrical devices connected to

it.

• DO NOTexceedthe generator's wattage/amperage capacity.See

Don't OverloadGeneratorin the Operationsection.

• Start generator and let engine stabilize before connecting

electrical loads.

• Oonnectelectrical loadsin OFFposition, thenturn ONfor

operation.

• Turn electrical loads OFFand disconnectfrom generator before

stopping generator.

Removethe two nuts (B) and loosen the fastener(C)as

shown. Store shieldand fasteners for future cold weather

operation.

13

Don'tOverload Generator

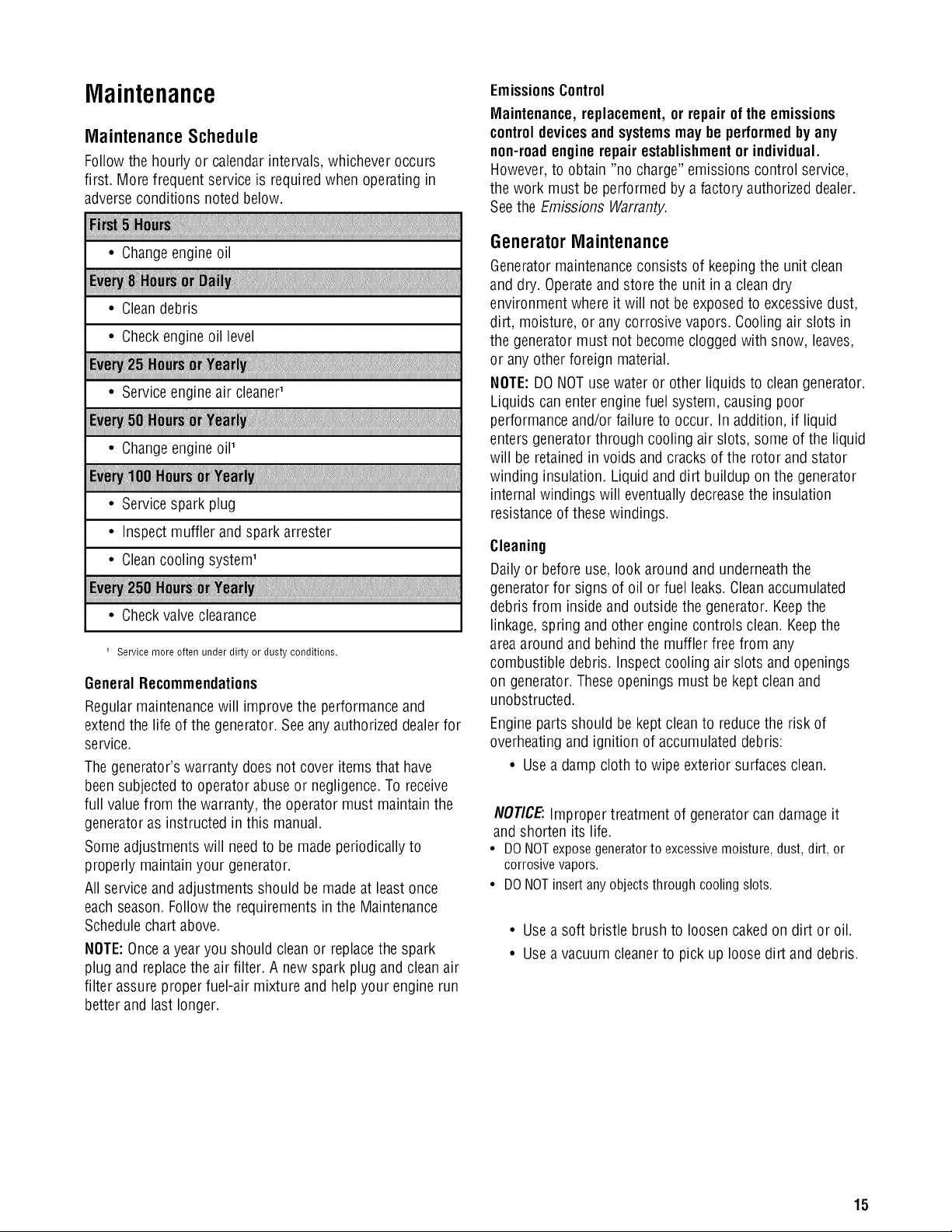

Capacity

You must makesure your generatorcansupply enough

rated(running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

1. Select the items you will powerat the sametime.

2. Totalthe rated(running) watts of theseitems.This is the

amount of poweryour generatormust produceto keep

your items running.SeeWattage ReferenceGuide.

3. Estimate how many surge (starting) wattsyou will need.

Surge wattageis the short burst of power neededto

start electric motor-driven tools orappliancessuch as a

circular saw or refrigerator. Becausenot all motors start

at the sametime, total surge watts can be estimatedby

adding only the item(s) with the highestadditional surge

watts to the total rated watts from step 2.

Example:

Toolor Appliance

WindowAir

Conditioner

Refrigerator

DeepFreezer

Television

Light(75Watts)

Total Rated(Running) Watts

HighestAdditional Surge Watts

Total GeneratorOutput Required

Power Mlanagement

To prolong the life of your generatorandattacheddevices, it

is important to take carewhen adding electrical loadsto your

generator. Thereshould be nothing connectedto the

generator outlets before starting its engine.Thecorrect and

safe way to managegenerator power isto sequentiallyadd

loads as follows:

1. With nothing connectedto the generator, start the

engine as describedin this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generatoroutput to stabilize (engine runs

smoothly and attacheddeviceoperates properly).

4. Plug inand turn on the next load.

5. Again, permit the generatorto stabilize.

6. Repeatsteps 4 and 5 for eachadditional load.

Watts

1200

8OO

5OO

5OO

75

3075Total

RunningWatts

(Starting)Watts

1800

1600

5OO

1800Highest

SurgeW_ts

= 3075

= 1800

= 4875

NEVERadd more loadsthan the generatorcapacity. Take

special careto consider surge loadsin generatorcapacity, as

described above.

Rated* Additional

ToolorAppliance

Essentials

Light Bulb - 75 watt 75

Deep Freezer 500 500

Sump Pump 800 1200

Refrigerator/Freezer- 18 Cu.Ft. 800 1600

WaterWell Pump - 1/3 HP 1000 2000

Heating/Cooling

Window AC- 10,000 BTU 1200 1800

Window Fan 300 600

FurnaceFanBlower - 1/2 HP 800 1300

Kitchen

Microwave Oven- 1000 Watt 1000

CoffeeMaker 1500

Electric Stove - Single Element 1500

Hot Plate 2500

Family Room

DVD/CDPlayer 100

VCR 100

Stereo Receiver 450

Color Television - 27" 500

PersonalComputerw/17" monitor 800

Other

Security System 180

AM/FM Clock Radio 300

GarageDoor Opener- 1/2 HP 480 520

Electric Water Heater- 40 Gallon 4000

DIf/Job Site

Quartz HalogenWork Light 1000

Airless Sprayer - 1/3 HP 600 1200

Reciprocating Saw 960 960

Electric Drill- 1/2 HP 1000 1000

Circular Saw- 7 1/4" 1500 1500

Miter Saw- 10" 1800 1800

Table Planer- 6" 1800 1800

TableSaw/RadialArm Saw- 10" 2000 2000

Air Compressor- 1-1/2 HP 2500 2500

Wattageslisted are approximateonly. Checktool

(Running) Surge (Starting)

Watts Watts

or

appliancefor actual wattage.

14 BRIGGSandSTRATTON.COIVl

Maintenance

MaintenanceSchedule

Follow the hourly or calendar intervals,whichever occurs

first. More frequent serviceis requiredwhen operating in

adverseconditions noted below.

_: _ _iI illillillillillillillillill:ill:ill:ill:ill:ill:ill

• Changeengine oil

• Cleandebris

• Checkengine oil level

_ _ _ Y_rJ_ :ii,i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i :

• Serviceengineair cleaner'

• Changeengine oil'

_ 11_ _ _ :>i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i

• Service spark plug

• Inspect mufflerand spark arrester

• Cleancooling system'

_ _ _ :>i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i?i

• Check valveclearance

' Service more often under dirty or dusty conditions.

GeneralRecommendations

Regularmaintenancewill improve the performanceand

extend the life of the generator.Seeany authorized dealer for

service.

Thegenerator's warranty does not cover items that have

been subjectedto operator abuse or negligence.To receive

full value from the warranty,the operator must maintain the

generatoras instructed in this manual.

Someadjustments will needto be made periodically to

properly maintain your generator.

All serviceand adjustments should bemade at least once

eachseason. Follow the requirements inthe Maintenance

Schedulechart above.

NOTE:Oncea year you should cleanor replacethe spark

plug and replacethe air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

EmissionsControl

Maintenance, replacement,or repair of the emissions

controldevicesandsystemsmay be performedbyany

non-roadengine repair establishmentor individual.

However,to obtain "no charge" emissions control service,

the work must be performed by afactory authorized dealer.

Seethe Emissions Warranty.

GeneratorMaintenance

Generatormaintenanceconsists of keepingthe unit clean

and dry. Operateand storethe unit in a cleandry

environment where it will not beexposedto excessive dust,

dirt, moisture, or any corrosive vapors. Coolingair slots in

the generator must not become clogged with snow, leaves,

or any other foreign material.

NOTE:DO NOTusewater or other liquids to clean generator.

Liquids can enter enginefuel system, causing poor

performanceand/or failure to occur. Inaddition, if liquid

enters generatorthrough cooling air slots, some of the liquid

will be retained in voids and cracks of the rotor and stator

winding insulation. Liquid and dirt buildup on the generator

internal windings will eventuallydecreasethe insulation

resistance of thesewindings.

Cleaning

Daily or before use,look around andunderneath the

generatorfor signs of oil or fuel leaks. Cleanaccumulated

debris from inside and outside the generator. Keepthe

linkage, spring and other engine controls clean. Keepthe

areaaround and behind the muffler free from any

combustible debris. Inspect cooling air slots and openings

on generator. Theseopenings must be kept cleanand

unobstructed.

Engine parts should be kept clean to reducethe risk of

overheating and ignition of accumulateddebris:

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE: Improper treatment of generator can damage it

and shorten its life.

• DONOTexpose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• DONOTinsert any objects through cooling slots.

• Use a soft bristle brush to loosen cakedon dirt or oil.

• Use a vacuum cleanerto pick up loose dirt and debris.

15

EngineMaintenance

_k WARNING:Unintentional sparking can result infire or

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTOYOUR

GENERATOR

• Disconnectthesparkplugwirefromthesparkplugandplace

thewirewhereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

• Useapprovedsparkplugtester.

• DONOTcheckfor sparkwithsparkplugremoved.

Oil

Oil Recommendations

We recommendthe use of Briggs & Stratton Warranty

Certified oils for best performance.Otherhigh-quality

detergent oils are acceptableif classifiedfor service SF, SG,

SH, SJ or higher. DONOTuse specialadditives.

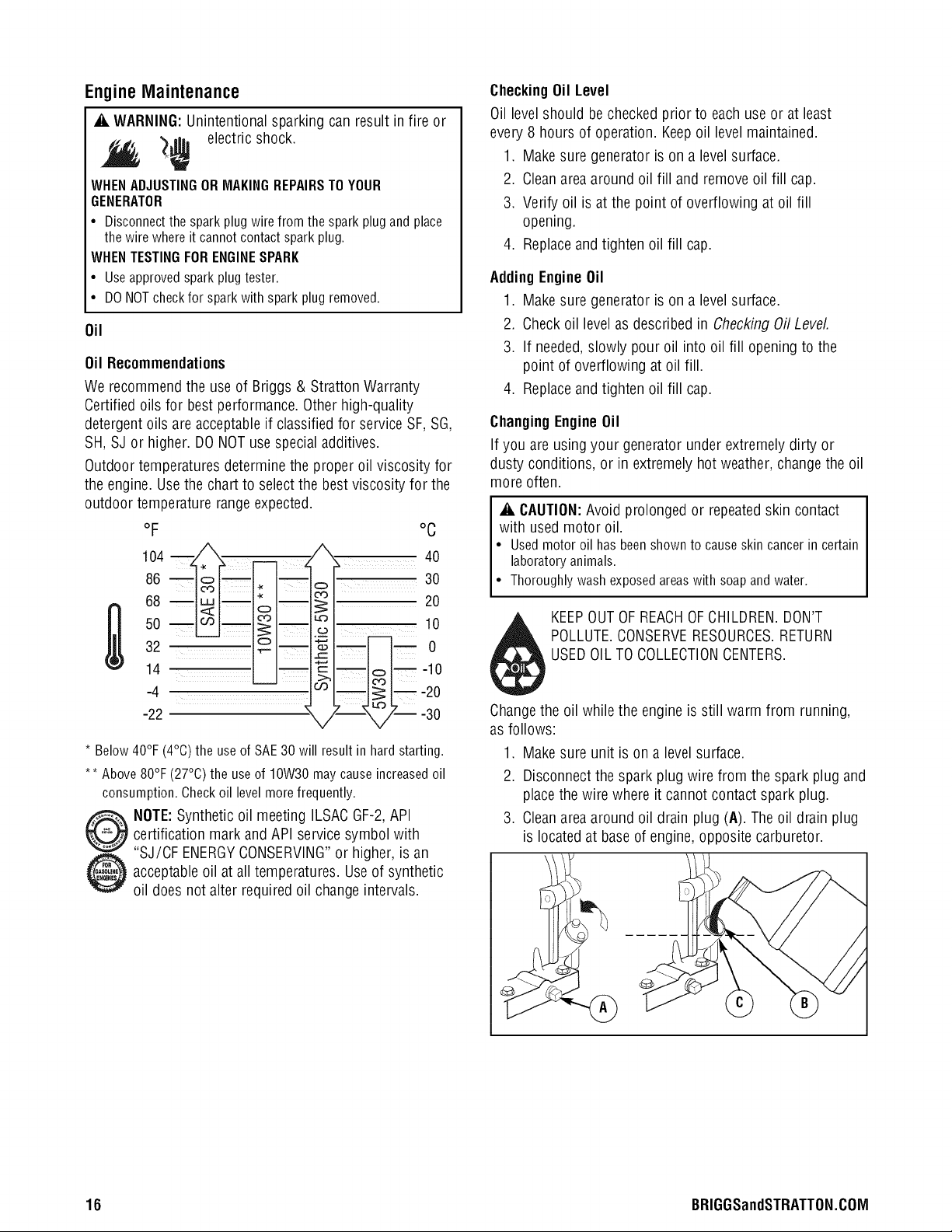

Outdoor temperaturesdetermine the proper oil viscosity for

the engine. Usethe chart to select the bestviscosity for the

outdoor temperature rangeexpected.

oF

104 -- _ u

68

o

32 o

14

-4

-22 _

* Below 40°F (4°C) the use of SAE30 will result in hard starting.

** Above 80°F (27°C) the useof 10W30 maycause increasedoil

consumption. Check oil levelmore frequently.

certification mark andAPI service symbol with

NOTE:Synthetic oil meeting ILSACGF-2,API

"SJ/CF ENERGYCONSERVING"or higher, is an

acceptableoil at all temperatures. Useof synthetic

oil does not alter requiredoil changeintervals.

• 40

>_ 20

__ 30

_n _ 0

--___--- -10

oC

10

-20

-30

CheckingOil Level

Oil levelshould be checked prior to each useor at least

every 8 hours of operation. Keepoil levelmaintained.

1. Make sure generatoris on a levelsurface.

2. Cleanareaaround oil fill and removeoil fill cap.

3. Verify oil is at the point of overflowing at oil fill

opening.

4. Replaceand tighten oil fill cap.

AddingEngineOil

1. Make sure generatoris on a levelsurface.

2. Check oil levelas describedin CheckingOffLevel

3. If needed, slowly pour oil into oil fill opening to the

point of overflowing at oil fill.

4. Replaceand tighten oil fill cap.

ChangingEngineOil

If you are usingyour generator under extremely dirty or

dusty conditions, or in extremely hot weather,changethe oil

more often.

_i, CAUTION: Avoid prolonged or repeated skin contact

with used motor oil.

• Used motor oil has beenshown to cause skin cancer in certain

laboratory animals.

• Thoroughly wash exposedareaswith soap and water.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOIL TOCOLLECTIONCENTERS.

Changethe oil while the engine is still warm from running,

asfollows:

1. Make sure unit is ona level surface.

2. Disconnect the spark plug wire from the spark plug and

placethe wire where it cannotcontact spark plug.

3. Cleanareaaround oil drain plug (A). The oil drain plug

is locatedat baseof engine, opposite carburetor.

16 BRIGGSandSTRATTON.COIVl

4. Removeoil drain plug and drain oil completely into a

suitable container.

5. Reinstall oil drain plug and tighten securely. Remove oil

fill cap.

6. Slowly pour oil (about 28 oz.) into oil fill opening(B) to

the point of overflowing (C) at oil fill cap.DONOT

overfill.

7. Reinstall oil fill cap. Fingertighten cap securely.

8. Wipe up any spilled oil.

Service Air Cleaner

Your enginewill not run properlyand may bedamaged if

you run it with a dirty air cleaner. Replacemore often if

operating under dirty or dusty conditions.

To servicethe air cleaner,follow thesesteps:

1. Loosen screws (D) andremove air cleanercover(E).

Service Spark Plug

Changingthe spark plug will helpyour engine to start easier

and run better.

1. Cleanareaaround spark plug.

2. Remove and inspect spark plug.

3. Check electrodegap with wire feeler gaugeand reset

spark plug gap to recommendedgap if necessary (see

Specifications).

4. Replacespark plug if electrodesare pitted, burned or

porcelain is cracked. Use the recommended

replacementspark plug. SeeSpecifications.

5. Install spark plug and tighten firmly.

InspectMuffler andSpark Arrester

Inspect the muffler for cracks, corrosion, or other damage.

Removethe spark arrester, if equipped,and inspectfor

damageor carbon blockage. If replacementparts are

required, makesure to useonly original equipment

replacementparts.

2. Carefully removecartridge (F) from base (G).

3. Install clean(or new) air cleanerassembly insidecover.

Disposeof old filter properly.

4. Assemble air cleanercoveronto base and tighten

screws.

A. WARNING: Contact with muffler area can result in

serious burns.

_ _ Exhaust heat/gases can ignite

combustibles, structures or damage

fuel tank causing a fire.

• DO NOTtouch hot parts andAVOIDhot exhaustgases.

• Allow equipment to cool beforetouching.

• Keepat least5 feet (152 cm) of clearanceon all sidesof

generator including overhead.

• It is a violation of California Public Resource Code,Section

4442, to use or operatethe engine on anyforest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with a spark arrester, as definedin Section

4442, maintained in effective working order. Other states or

federaljurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain aspark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must bethe same and installed in the same

position as the original parts.

17

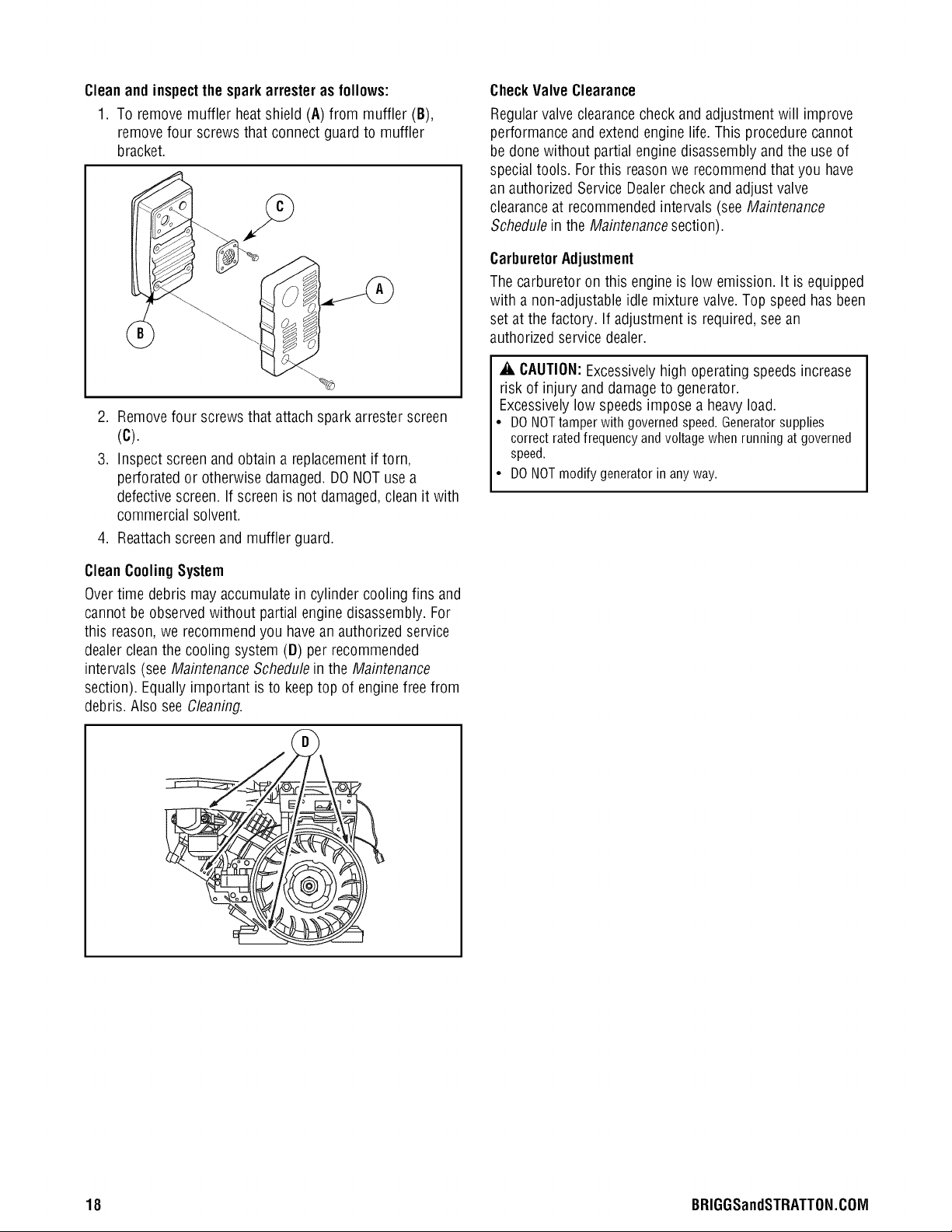

Cleanand inspectthespark arresteras follows:

1. To remove muffler heatshield (A) from muffler (B),

removefour screws that connect guard to muffler

bracket.

2. Removefour screws that attach spark arrester screen

(c).

3. Inspect screenand obtain a replacementif torn,

perforated or otherwise damaged.DONOTuse a

defective screen. Ifscreen is not damaged,clean it with

commercial solvent.

4. Reattachscreen and muffler guard.

CheckValve Clearance

Regularvalve clearancecheck and adjustment will improve

performanceand extend enginelife. This procedure cannot

be done without partial engine disassemblyand the use of

special tools. Forthis reasonwe recommend that you have

an authorized Service Dealercheck andadjustvalve

clearanceat recommendedintervals (see Maintenance

Schedulein the Maintenancesection).

CarburetorAdjustment

Thecarburetor on this engine is low emission. It is equipped

with a non-adjustable idlemixture valve.Top speedhas been

set at the factory. If adjustment is required, seean

authorized servicedealer.

_k CAUTION: Excessively high operating speeds increase

risk of injury and damage to generator.

Excessively low speeds impose a heavy load.

• DO NOTtamper with governedspeed. Generatorsupplies

correct ratedfrequency and voltage whenrunning at governed

speed.

• DO NOTmodify generator in any way.

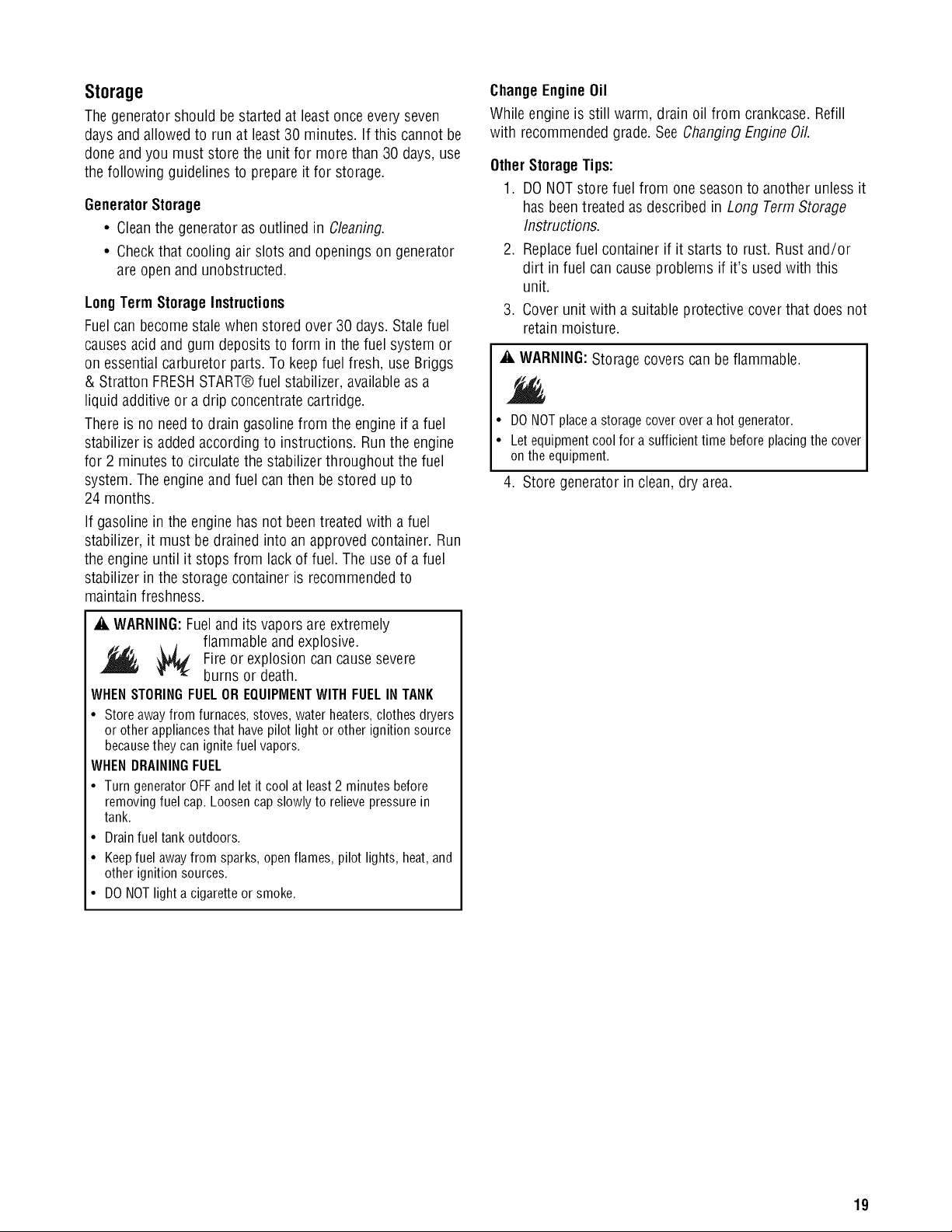

CleanCoolingSystem

Overtime debris may accumulate in cylinder cooling fins and

cannot be observedwithout partial engine disassembly. For

this reason,we recommendyou havean authorized service

dealer cleanthe cooling system (D) per recommended

intervals (see MaintenanceSchedulein the Maintenance

section). Equallyimportant is to keeptop of engine freefrom

debris. Also seeCleaning.

18 BRIGGSandSTRATTON.COIVI

Storage

Thegenerator should bestarted at leastonce every seven

days and allowed to run at least 30 minutes. If this cannot be

done and you must store the unit for more than 30 days,use

the following guidelines to prepareit for storage.

GeneratorStorage

• Cleanthe generator as outlined in Cleaning.

• Checkthat cooling air slots and openings on generator

are open and unobstructed.

LongTerm StorageInstructions

Fuelcan becomestale when stored over 30 days. Stalefuel

causesacid and gum depositsto form in the fuel system or

on essentialcarburetor parts. To keepfuel fresh, useBriggs

& Stratton FRESHSTART® fuel stabilizer,availableas a

liquid additive or a drip concentrate cartridge.

Thereis no needto drain gasolinefrom the engine if a fuel

stabilizer is added according to instructions. Runthe engine

for 2 minutes to circulate the stabilizerthroughout the fuel

system. Theengineand fuel can then be stored up to

24 months.

If gasoline in the engine hasnot beentreated with a fuel

stabilizer, it must be drained into an approved container. Run

the engineuntil it stops from lack of fuel. The useof a fuel

stabilizer in the storage container is recommendedto

maintain freshness.

ChangeEngineOil

While engineis still warm, drain oil from crankcase.Refill

with recommendedgrade. See Changing EngineOil.

OtherStorageTips:

1. DO NOTstore fuel from one seasonto another unless it

has beentreated as described in Long TermStorage

Instructions.

2. Replacefuel container if it starts to rust. Rust and/or

dirt in fuel can causeproblems if it's used with this

unit.

3. Cover unit with a suitable protective cover that does not

retain moisture.

_k WARNING:Storage covers canbe flammable.

• DONOTplacea storagecoveroverahotgenerator.

• Letequipmentcoolfor a sufficienttime beforeplacingthecover

ontheequipment.

4. Store generator inclean, dry area.

_k WARNING:Fueland its vapors are extremely

flammable and explosive.

Fireor explosion can causesevere

burns or death.

WHENSTORINGFUELOREQUIPMENTWITHFUELINTANK

• Store away from furnaces, stoves, water heaters,clothes dryers

or otherappliancesthat havepilot light or other ignition source

becausetheycan ignitefuel vapors.

WHENDRAININGFUEL

• Turn generatorOFFandlet it coolat least2 minutes before

removing fuel cap. Loosen cap slowly to relieve pressure in

tank.

• Drain fuel tank outdoors.

• Keepfuel awayfrom sparks,open flames, pilot lights, heat,and

other ignition sources.

• DO NOTlight a cigarette or smoke.

19

Reserved

20 BRIGGSandSTRATTON.COIVI

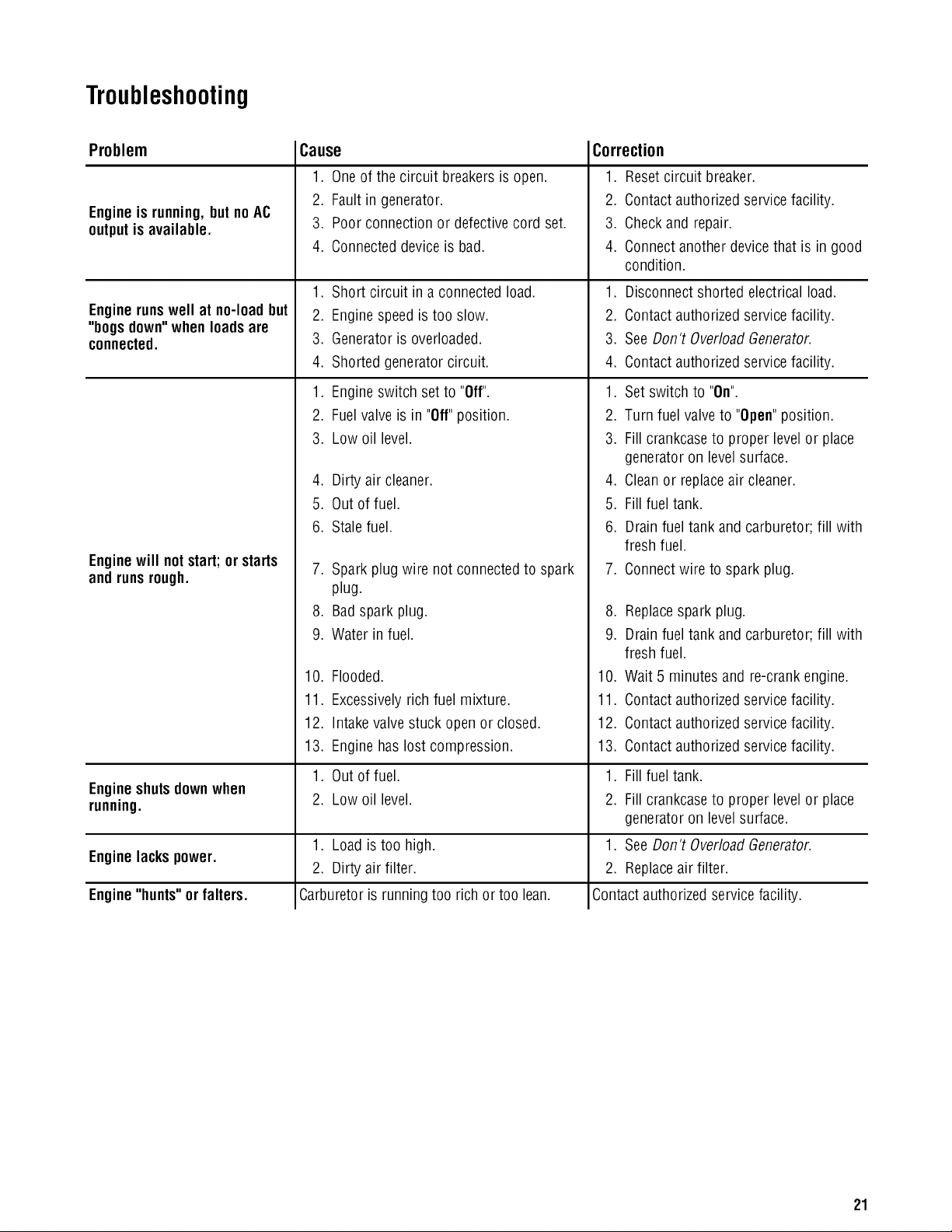

Troubleshooting

Problem Cause

1. Oneof the circuit breakers is open.

Engineis running,butnoAC

outputis available.

Enginerunswell at no-loadbut

"bogs down"whenloads are

connected.

Enginewill notstart; or starts

and runsrough.

2. Fault in generator.

3. Poor connection or defective cord set.

4. Connected deviceis bad.

,

Short circuit in a connectedload. 1.

2.

Engine speedis too slow. 2.

3.

Generatoris overloaded. 3.

4.

Shorted generator circuit. 4.

1.

Engine switch set to "Off". 1.

2.

Fuelvalve is in "Off" position. 2.

3.

Low oil level. 3.

4. Dirty air cleaner.

5. Out of fuel.

6. Stale fuel.

,

Spark plugwire not connectedto spark

plug.

8. Badspark plug.

9. Water in fuel.

10. Flooded.

11.

Excessivelyrich fuel mixture. 11.

12.

Intakevalve stuckopen or closed. 12.

13.

Engine haslost compression. 13.

Correction

1. Resetcircuit breaker.

2. Contactauthorized servicefacility.

3. Checkand repair.

4. Connectanother devicethat is in good

condition.

Disconnectshorted electrical load.

Contactauthorized servicefacility.

SeeDon't OverloadGenerator.

Contactauthorized servicefacility.

Setswitch to "On".

Turn fuel valveto "Open"position.

Fillcrankcaseto proper levelor place

generatoron level surface.

4.

Cleanor replaceair cleaner.

5.

Fillfuel tank.

6.

Drainfuel tank and carburetor; fill with

fresh fuel.

7.

Connectwire to spark plug.

8. Replacespark plug.

9. Drain fuel tank andcarburetor; fill with

fresh fuel.

10. Wait 5 minutes and re-crank engine.

Contactauthorized servicefacility.

Contactauthorized servicefacility.

Contactauthorized servicefacility.

Engineshutsdownwhen

running.

Out of fuel. 1.

2.

Low oil level. 2.

Fillfuel tank.

Fillcrankcaseto proper levelor place

1.

generatoron level surface.

1. Load is too high. 1. SeeDon't OverloadGenerator.

Enginelackspower.

2. Dirty air filter. 2. Replaceair filter.

Engine"hunts" or falters. Carburetoris runningtoo rich ortoo lean. Contactauthorizedservicefacility.

21

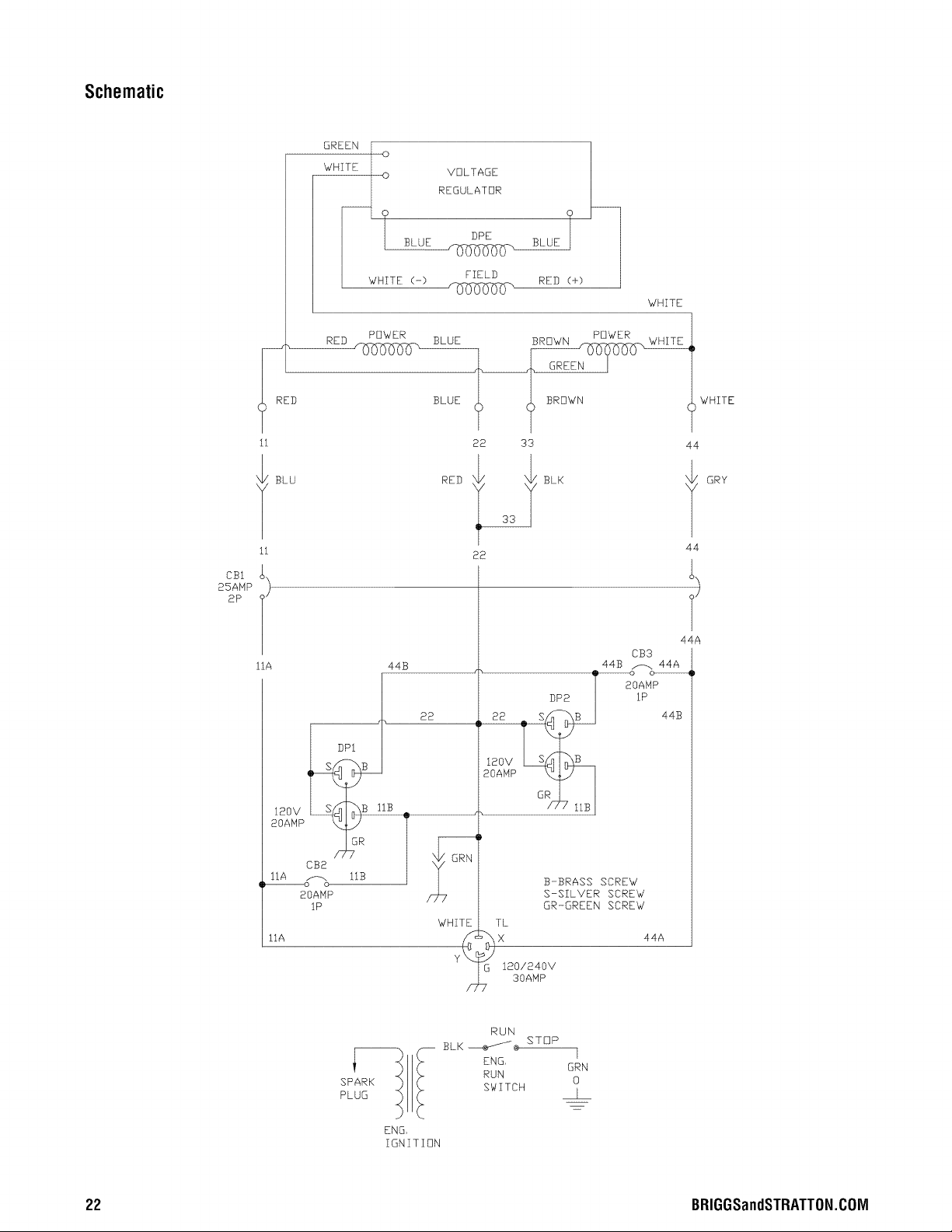

Schematic

CSI

8SAHP

2P

11

_V/BLU

11

WHITE

GREEl o

RED _ BLUE

o

BLUE

WHITE (-)

POWER

BLUE

VOLTAGE

REGULATOR

BLUE I

FIELD

22 33 44

RED _ BLK t

22 44

RE]} (+)

WHITE

BROWN POWER WHITE

WHITE

GRY

llA 44B

120V S q

20AHP

CB2

lIB

20AHP

£P

IIA

__

SPARK

PLUG

22

: 22 . S_ 44B

20AHP

120V S_

WHITE

TL

S

/7

BLK _® STOP

RUN

ENG, GRN

RUN

SWITCH ®

CB3

44B _ 44_A

DP2

S-BRASS SCREW

S-SILVER SCREW

GR-GREEN SCREW

X 44A

120/240V

30AHP

E

0

44A

ENG,

IGNITION

22 BRIGGSandSTRATTON.COIVl

Wiring Diagram

TIRI

44A ........

<2.................................A

WARNING!

TAB MUST BE BROKEN

44B 44_

....... _? ":? ....

5 "33

.............................................................................................._I_._.o:,

33

RUN

S%£ITCH

ENGINE

BLK

0

NUT ON

ENGINE BLOCK

\

\ AVR

\

\

\\\\\\\\\\\\

\

\\

\.

23

Loading...

Loading...