Briggs & Stratton 030319, 030320 Owner’s Manual

BRiGGS & STRATTON

I_!_J_WARNING

Before using this product, read this manual and follow all

Safety Rules and Operating Instructions.

BP,IGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WiSCONSiN, U.S.A.

ADVERTENCIA

Antes de utilizar el producto, lea este manual y siga todas [as

Reglas de Segur[dad e Instrucc[ones de Uso.

Manual No, [99399GS

Revision - (04/05/2006)

SAVE THESE INSTRUCTIONS

TABLE OF CONTENTS

Safety Rules .................................... 2-4

Features and Controls ............................. 5

Assembly ...................................... 6-7

Operation .................................... 8-II

Specifications ................................... 12

Maintenance ................................. 13-16

Storage ........................................ 17

Troubleshooting ................................. [8

Notes .................................... 19 & 22

Emissions Control _¢arranties ................... 20-2 [

_¢arranty ...................................... 23

Espa_o[ ..................................... 24-44

EQUIPMENT

DESCRmPTiON

Read this manual carefully and become

v- familiar with your generator. Know its

applications, its limitations and any hazards

invomved.

The generators are an engine-driven, revolving field,

alternating current (AC) generator. It was designed to

supply electrical power for operating compatible electrical

lighting, appliances, tools and motor loads.The generator's

revolving field is driven at about 3,600 rpm by a single°

cylinder engine.

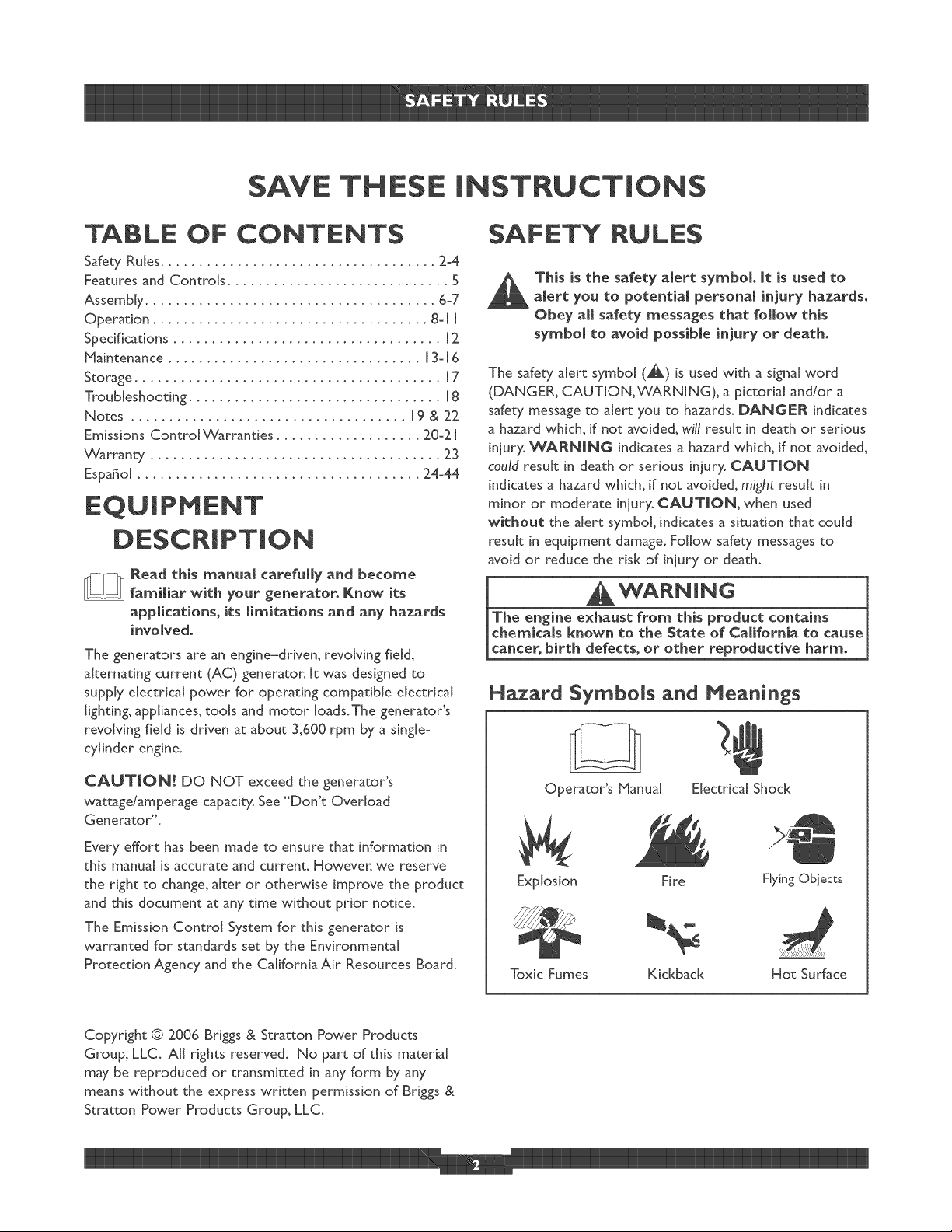

SAFETY RULES

This isthe safety alertsymbol. Itisused to

alertyou to potential personal iniury hazards.

Obey all safety messages that follow this

symbol to avoid possible iniury or death.

The safety alert symbol (_) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

iniury. WARNING indicates a hazard which, if not avoided,

could result in death or serious iniury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate iniury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of iniury or death.

Hazard Symbols and Meanings

CAUTION! DO NOT exceed the generator's

wattage/amperage capacity. See '°Don't Overload

Generator".

Every effort has been made to ensure that information in

this manual is accurate and current. However, we reserve

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

The Emission Control System for this generator is

warranted for standards set by the Environmental

Protection Agency and the California Air Resources Board.

Copyright © 2006 Brigs & Stratton Power Products

Group, LLC. All rights reserved. No part of this material

may be reproduced or transmitted in any form by any

means without the express written permission of Briggs &

Stratton Power Products Group, LLC.

Operator's Nanual Electrical Shock

Explosion Fire FlyingObjects

Toxic Fumes Kickback Hot Surface

WARNING

WARNING

Operate generator ONLY outdoors.

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

. DO NOT operate generator inside any building or enclosure

(even if doors or windows are open), including the generator

compartment of a recreational vehicle (RV).

WARNmNG

, When using generator for backup powea notify utihty

company. Use approved transfer equipment to isolate

generator from electric utility.

Use a ground fault circuit interrupter (GFC[) in any damp or

highly conductive area, such as metal decking or steel work.

DO NOT touch bare wires or receptacles.

DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

DO NOT operate generator in the rain or wet weathe[:

DO NOT handle generator or electrical cords while standing

in watelq while barefoot, or while hands or feet are wet.

DO NOT allow unqualified persons or children to operate or

service generatol:

WARNING

WHEN ADDING OR DRAINING FUEL

Turn generator OFF and let it coo[ at [east 2 minutes before

removing fuel cap. Loosen cap slowly to relieve pressure in

tan[<.

Fill or drain fuel tan[< outdoors.

DO NOT overfill tank°Allow space for fuel expansion.

_%/ait for spilled fuel to evaporate before starting engine.

Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

DO NOT light a cigarette or smoke.

NHEN STARTING EQUIPNENT

Ensure spark plug, muff[era:fuel cap and air cleaner are in place.

DO NOT crank engine with spar[< plug removed.

WHEN OPERATING EQUIPNENT

DO NOT tip engine or equipment at angle which causes fuel

to spill

This generator is not for use in mobile equipment or marine

applications,

NHEN TRANSPORTING OR REPAIRING

EQUIPNENT

IN TANK

Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback°

NEVER start or stop engine with electrical devices plugged in

and turned on.

WARNING

This generator does not meet U. S.Coast Guard Regulation

33CFR-[83 and should not be used on marine applications.

Failure to use the appropriate U. S.Coast Guard approved

generator could result in death or serious injury and/or

property damage.

WARNING

WHEN ADJUSTING OR MAKING REPAIRSTO¥OUR

GENERATOR

Disconnect the spar[< plug wire from the spar[< plug and place

the wire where it cannot contact spark plug.

WNENTESTING FOR ENGINE SPARK

* Use approved spar[< plug testen

DO NOT check for spark with spark plug removed.

CAUTION

DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

spee&

DO NOT modify generator in am/way.

WARNING

DO NOT touch hot surfaces and avoid hot exhaust gases.

Allow equipment to cool before touching.

Keep at [east 5 ft. ([ 52 cm) clearance on at[ sides of generator

including overhea&

Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spar[< arrester, maintained in

effective working ordemqcomplying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spar[< arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

See "Don't Overload Generator".

Start generator and let engine stabilize before connecting

electrical loads.

Connect electrical loads in OFF position, then turn ON for

operation.

Turn electrical loads OFF and disconnect from generator

before stopping generaton

Use generator only for intended uses.

[f you have questions about intended use, as[< dealer or ca[[

[-800-743-4115.

Operate generator only on [eve[ surfaces.

DO NOT expose generator to excessive moisture, dust, dirt,

or corrosive vapors.

DO NOT insert any objects through cooling slots.

If connected devices overheat, turn them off and disconnect

them from generatom:

Shut off generator if:

-e[ectrica[ output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessive[y_

1

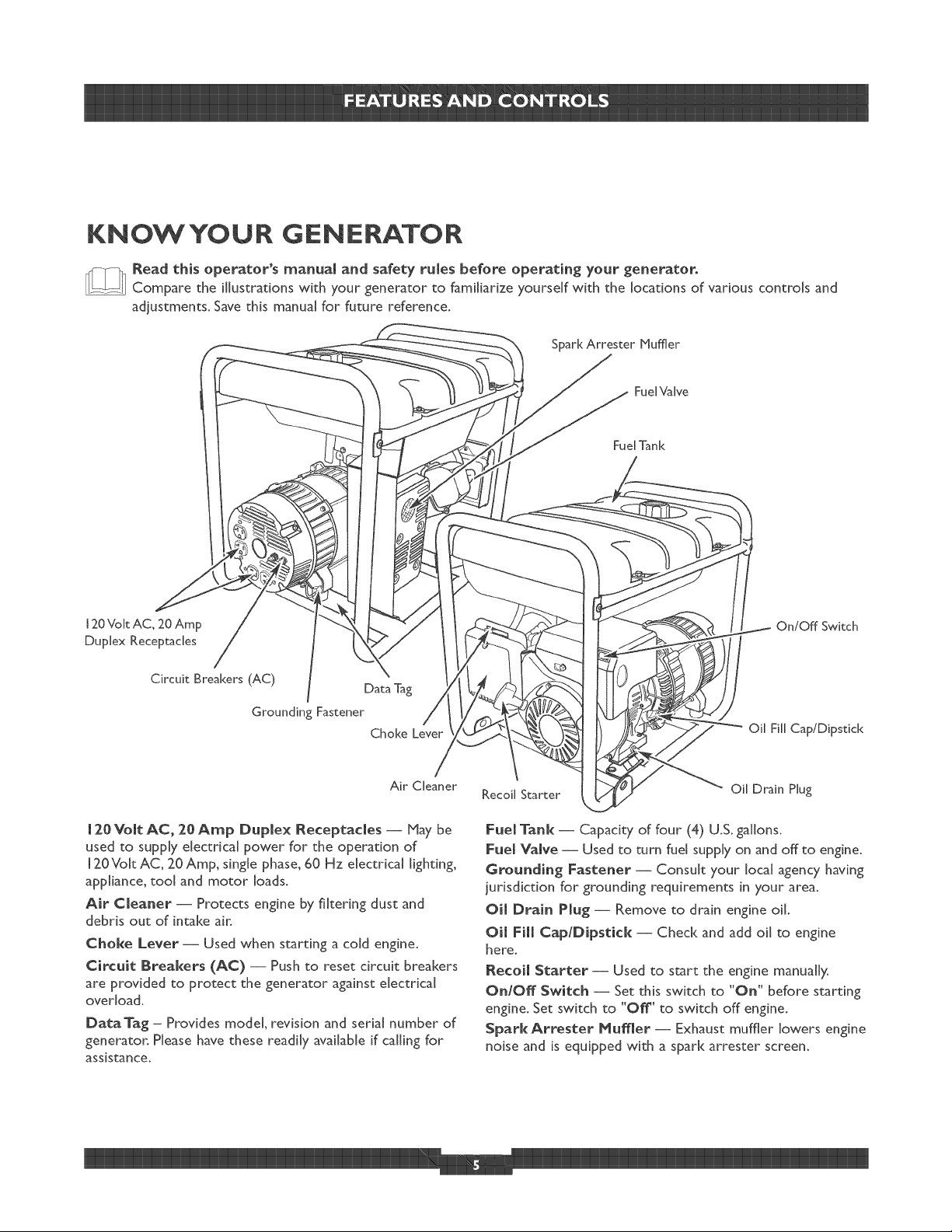

KNOWYOUR GENERATOR

Read this operator's manua[ and safety fumes before operating your generator.

Compare the illustrations with your generator to famiIhrize yourself with the locations of various controls and

adjustments. Save this manual for future reference°

SparkArrester Muffler

Fue[Valve

Fuel Tank

120 Volt AC, 20 Amp

Duplex Receptacles

Circuit Breakers (AC)

Data Tag

Grounding Fastener

Choke Lever

Air Cleaner

[ 20 Volt AC, 20 Amp Duplex Receptacles -- May be

used to supply electrical power for the operation of

[ 20Volt AC, 20 Amp, single phase, 60 Hz electrical lighting,

app[hnce, too[ and motor loads.

Air Cleaner -- Protects engine by fi[terhg dust and

debris out of intake air.

Choke Lever -- Used when starting a cold engine.

Circuit Breakers (AC) -- Push to reset circuit breakers

are provided to protect the generator against electrical

overload.

DataTag - Provides model, revision and serial number of

generator. Please have these readily available if calling for

assistance.

On/Off Switch

Oil Fill Cap/Dipstick

Recoil Starter

Oil Drain Plug

Fuel Tank -- Capacity of four (4) U.& gallons.

Fuel Valve -- Used to turn fuel supply on and off to engine.

Grounding Fastener -- Consult your local agency having

jurisdiction for grounding requirements in your area,

Oim Drain Pmug -- Remove to drain engine oil.

Oil Fill Cap/Dipstick -- Check and add oil to engine

here.

Recoil Starter -- Used to start the engine manually.

On/Off Switch -- Set this switch to "On" before starting

engine. Set switch to "Off' to switch off engine.

Spark Attester Muffler- Exhaust muffler lowers engine

noise and is equipped with a spark arrester screen.

ASSENBL¥

Your generator requires some assembly and is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, please call the generator heIpJine at

[°800°743°4 [ [ 5. If calling for assistance, please have the

model, revision, and serial number from the data tag available.

See "KnowYour Generator" for data tag location.

Unpacking the Generator

1. Set the carton on a rigid flat surface.

2. Open carton completely by cutting each corner from

top to bottom.

3. Cut ties holding accessory kit and axle to generator

and remove everything from carton.

4. Leave generator on carton to install wheel kit.

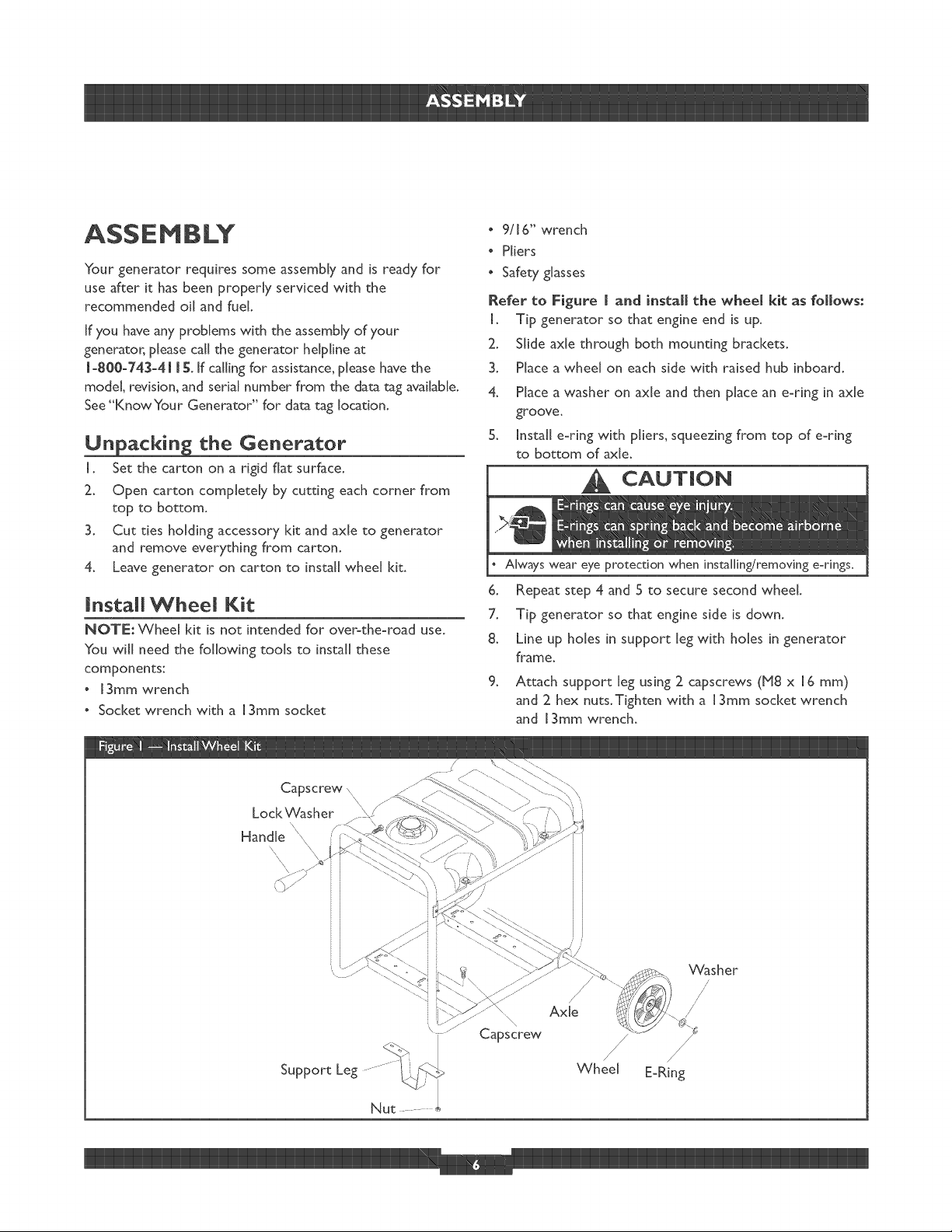

[nstallWheel Kit

NOTE: Wheel kit is not intended for over-the-road use.

You will need the following tools to install these

components:

I3ram wrench

Socket wrench with a I 3mm socket

o 9/16" wrench

o Pliers

o Safety glasses

Refer to Figure ( and install the wheel kit as follows:

I. Tip generator so that engine end is up.

2. Slide axle through both mounting brackets.

3. Place a wheel on each side with raised hub inboard.

4. Place a washer on axle and then place an e-ring in axle

groove.

5. Install e-ring with pliers, squeezing from top of e-ring

to bottom of axle.

CAUTmON

Always wear eye protection when installing/removing e-rings,

6. Repeat step 4 and 5 to secure second wheel.

7. Tip generator so that engine side is down.

8. Line up holes in support leg with holes in generator

frame.

.

Attach support leg using 2 capscrews (b18 x 16 mm)

and 2 hex nuts.Tighten with a 13ram socket wrench

and 13mm wrench.

Capscrew \\

Lock 'v_/asher

Handle _\,

\

\\

_asher

/

/

Capscrew

/ /

Axle /

/

/ /

/ j/

Wheel E-Ring

I0. Returngeneratortonormaloperatingposition(resting

onwheelsandsupportleg).

I I. Attach handle using a long (M8 x 45mm) cap screw

and lock washer.Tighten with a 9/16" wrench.

BEFORE STARTING THE

ENGINE

Add Engine Oil

CAUTION! Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

I. Place generator on a flat, level surface.

2. Clean area around oil fill and remove yellow oil fill cap.

NOTE: See the section °°Oil" on page 14 to review oil

recommendations.Verify provided oil bottle is correct

viscosity for current ambient temperature.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

4. Replace oil fill cap and fully tighten.

Add Fuel

All fuel is not the same. If a starting or performance

problem is encountered immediately after new fuel has

been used, try another service station or change brands.

NOTE: This engine is certified to operate on gasoline.

Exhaust Emissions Control System: EM (Engine Modifications).

WANNING

WNEN ADDING FUEL

Turn generator OFF and let it coo[ at least 2 minutes before

removing fuel cap. Loosen cap slowly to relieve pressure in tan[<.

Fill fuel tank outdoors.

DO NOT overfill tank.Allow space for fuel expansion_

Wait for spilled fuel to evaporate before starting engine.

Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

DO NOT light a cigarette or smoke_

Type of Fuel

I. Always use clean, fresh, UNLEADED gasoline with a

minimum of 87 octane/87 AKI (91 RON). DO NOT

mix oil with fuel. DO NOT modify the engine fuel

system or carburetor to run on alternative fuels.

NOTE: Fuel with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether), is acceptable.

IMPORTANT: Use of any fuel other than those approved

above will void warranty. Some areas require that fuel

pumps be marked if the fuel contains alcohols or ethers. If

you are not sure if your fuel contains alcohol or ethers that

are different than those approved above, then check with

the service station operator.

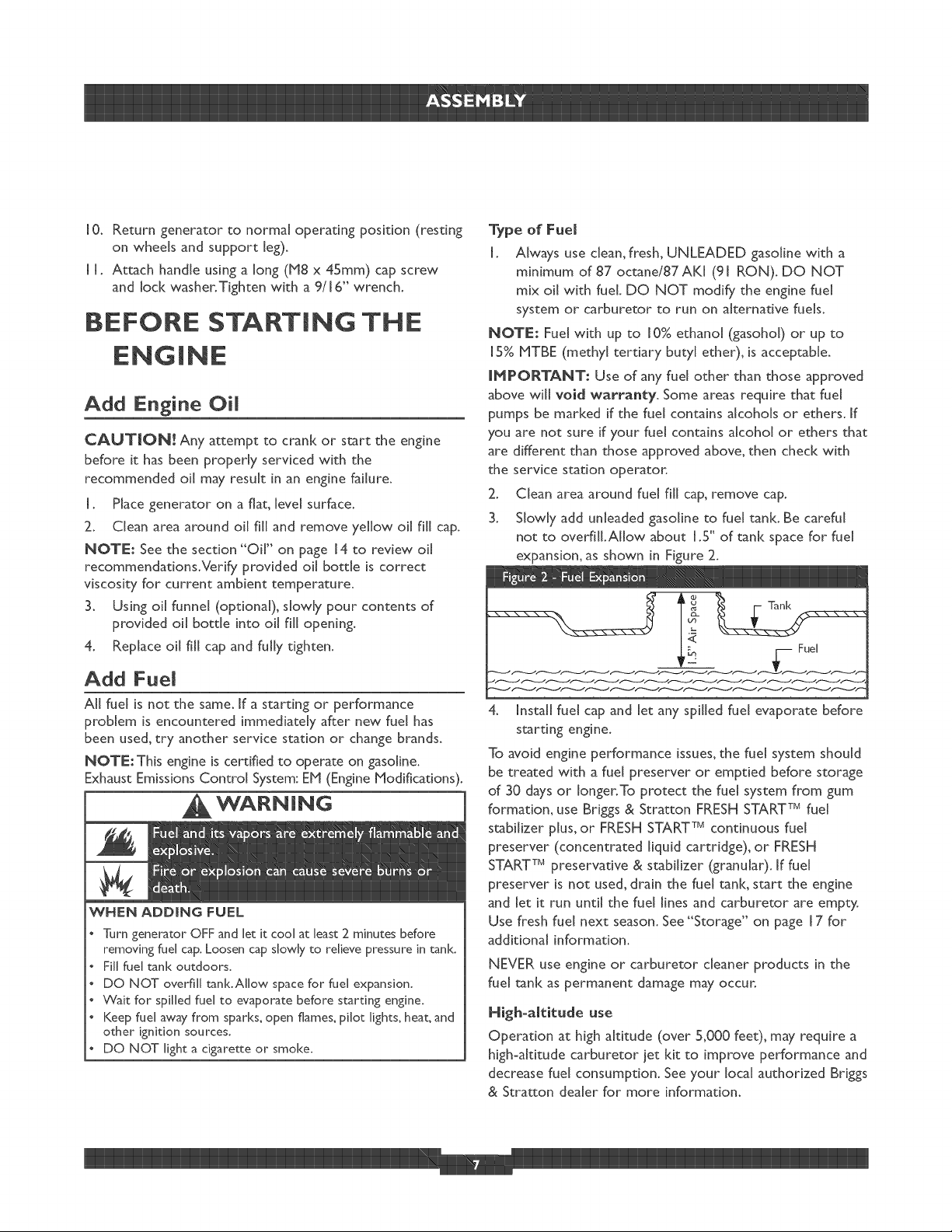

2. Clean area around fuel fill cap, remove cap.

3. Slowly add unleaded gasoline to fuel tank. Be careful

not to overfill.Allow about 1.5" of tank space for fuel

expansion, as shown in Figure 2.

_,_ _ Fuel

4. Install fuel cap and let any spilled fuel evaporate before

starting engine.

To avoid engine performance issues, the fuel system should

be treated with a fuel preserver or emptied before storage

of 30 days or longer.To protect the fuel system from gum

formation, use Briggs & Stratton FRESH START TMfuel

stabilizer plus, or FRESH START TMcontinuous fuel

preserver (concentrated liquid cartridge), or FRESH

START TMpreservative & stabilizer (granular). Iffuel

preserver is not used, drain the fuel tank, start the engine

and let it run until the fuel lines and carburetor are empty.

Use fresh fuel next season. See "Storage" on page 17 for

additional information.

NEVER use engine or carburetor cleaner products in the

fuel tank as permanent damage may occur.

Nigh-altitude use

Operation at high altitude (over 5,000 feet), may require a

high-altitude carburetor iet kit to improve performance and

decrease fuel consumption. See your local authorized Briggs

& Stratton dealer for more information.

1

USING THE GENERATOR

System 6; round

The generator has a system ground that connects the

generator frame components to the ground terminals on

the AC output receptacles.The system ground is connected

to the AC neutral wire (see '°Equipment Description",

earlier in this manual).

Speciam Requirements

There may be Federal or State Occupational Safety and

Health Administration (OSHA) regulations, local codes, or

ordinances that apply to the intended use of the generator.

Please consult a qualified electridan, electrical inspector, or

the local agency having jurisdiction.

o In some areas, generators are required to be registered

with local utility companies.

o If the generator Jsused at a construction site, there may

be additional regulations which must be observed.

Connecting to a Buimding's Electrical

System

Connections for standby power to a building's electrical

system must be made by a qualified electrician.The

connection must isolate the generator power from utility

power, and must comply with all applicable laws and

electrical codes.

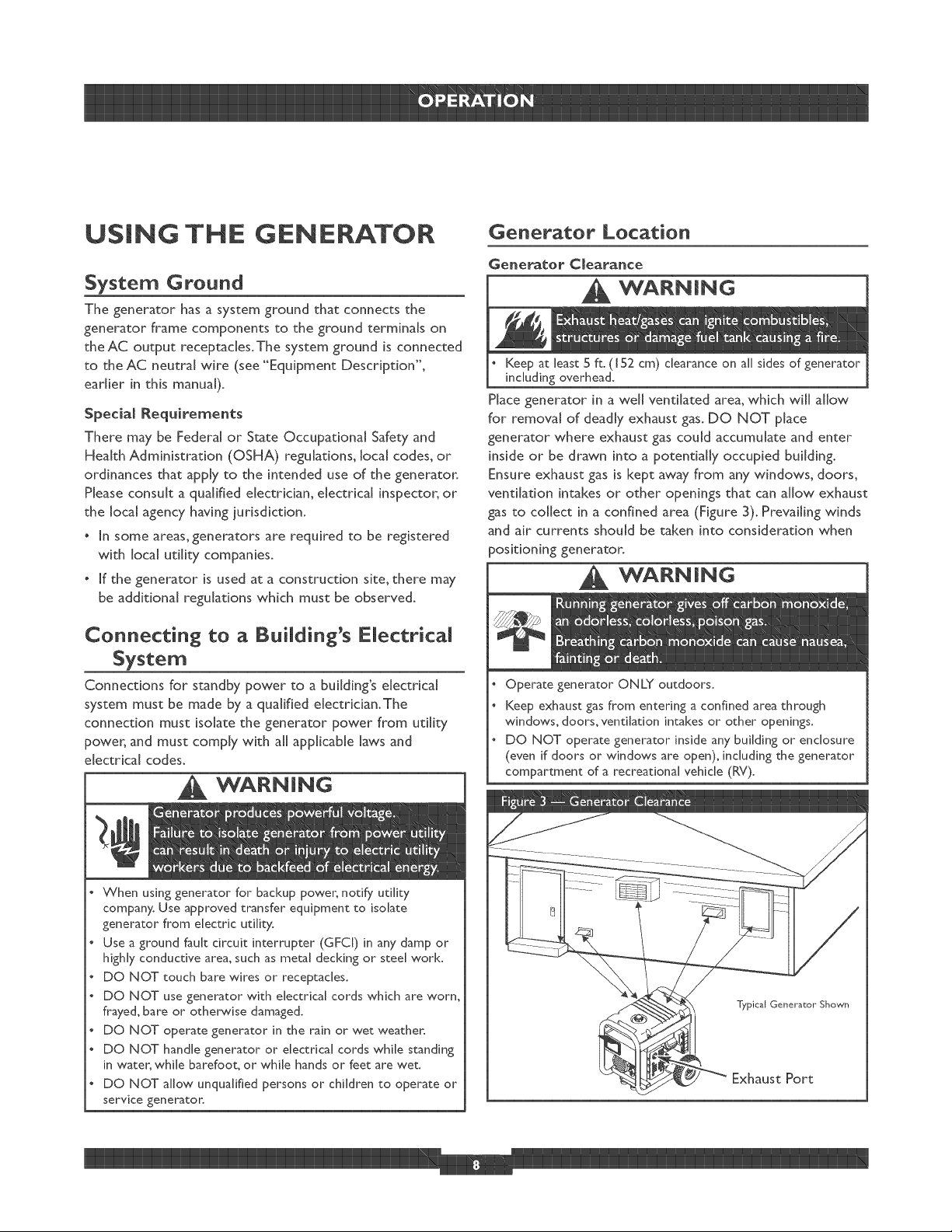

Generator Location

Generator Clearance

WANNmNG

Keep at least 5 ft. (152 cm) clearance on all sidesof generator

including overhead°

Place generator in a well ventilated area, which will allow

for removal of deadly exhaust gas. DO NOT place

generator where exhaust gas could accumulate and enter

inside or be drawn into a potentially occupied building.

Ensure exhaust gas is kept away from any windows, doors,

ventilation intakes or other openings that can allow exhaust

gas to collect Jna confined area (Figure 3). Prevailing winds

and air currents should be taken into consideration when

positioning generator.

WANNmNG

Operate generator ONLY outdoors.

Keep exhaust gasfrom entering aconfined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate generator inside any building or enclosure

(even if doors or windows are open), including the generator

compartment of a recreational vehicle (RV).

service generatol:

Typical Generator Shown

Exhaust Port

OPERATING THE

Starting the Engine

Disconnect all electrical loads from the generator. Use the

following start instructions:

I. Make sure unit is on a level surface.

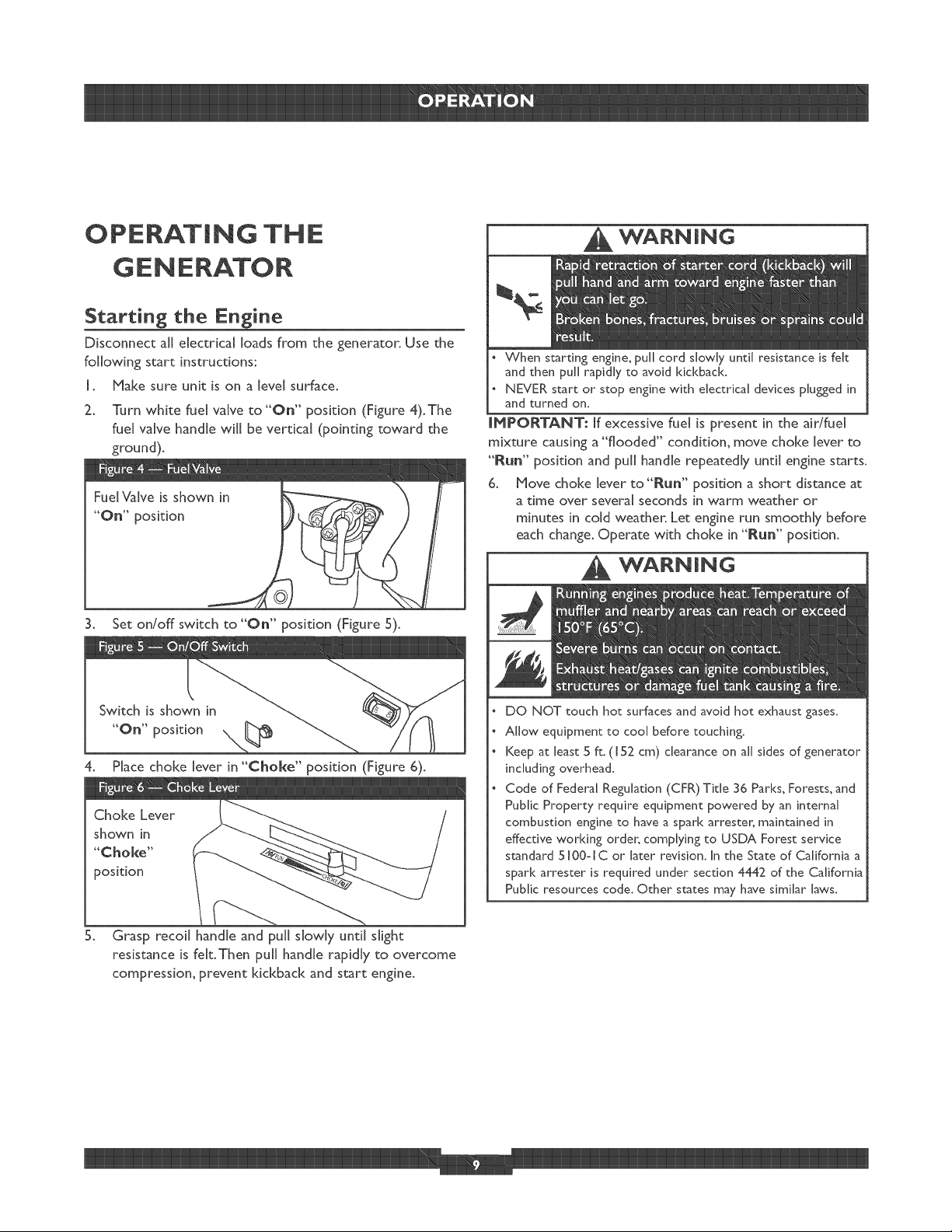

2. Turn white fuel valve to"On" position (Figure 4).The

fuel valve handle will be vertical (pointing toward the

ground).

3. Set on!off switch to"On" position (Figure 5).

WARNmNG

When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kid<bad<.

NEVERstart or stop engine with electrical devices plugged in

and turned on,

IMPORTANT: if excessive fuel is present in the air/fuel

mixture causing a "flooded" condition, move choke [ever to

"Run" position and pull handle repeatedly until engine starts.

B. Move choke lever to"P_un" position a short distance at

a time over several seconds in warm weather or

minutes in cold weather. Let engine run smoothly before

each change. Operate with choke in "[_un" position.

WARNING

5. Grasp recoil handle and pull slowly until slight

resistance is felt.Then pull handle rapidly to overcome

compression, prevent kickback and start engine.

DO NOT touch hot surfaces and avoid hot exhaust gases.

Allow equipment to cool before touching.

Keep at least 5 ft. (152 cm) clearance on all sides of generator

including overhead.

Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spar[< attester, maintained in

effective working order, complying to USDA Forest service

standard 5[00-IC or later revision. In the State of California a

spar[< attester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Connecting Electrical Loads

Let engine stabilize and warm up for a few minutes after

starting.

o Plug in and turn on the desired J2OVokAC, single phase,

60 Hz electrical loads.

o DO NOT connect 240Voff loads to the J20Vok duplex

receptacles.

o DO NOT connect 3-phase loads to the generator.

o DO NOT connect 50 Hz loads to the generator.

o DO NOT OVERLOAD THE GENERATOR° See

"Don't Overload Generator".

See"Don't Overload Generator"°

Start generator and let engine stabilize before connecting

electrical loads.

Connect electrical loads in OFF position, then turn ON for

operation.

Turn electrical loads OFF and disconnect from generator

before stopping generator.

Stopping the Engine

I. Turn OFF and unplug all electrical loads from generator

panel receptacles. NEVER start or stop enghe with

electrical devices plugged in and turned ON.

2. Let engine run at no°load for several minutes to

stabilize internal temperatures of engine and generator.

3. Move on/off switch to "Off" position.

CAUTION

than generator or receptacle can supply.

DO NOT overload the generator, See "Don't Overload

NEVER attempt to power a device requiring more amperage

Generator",

[ 20 Volt AC, 20 Amp, Duple×

Receptacles

Each duplex receptacle (Figure 7) is protected against

overload by a push-to-reset circuit breaker.

Use each receptacle to operate 120Volt AC, single-phase,

60 Hz electrical loads requiring up to 2,400 watts (2.4 k_¢)

at 20Amps of current. Use cord sets that are rated for

125 Volt AC loads at 20 Amps (or greater).

DO NOT stop engine by moving choke [ever to "Choke"

position.

4. Move fuel valve to "Off" position.

DON'T OVERLOAD

C adty

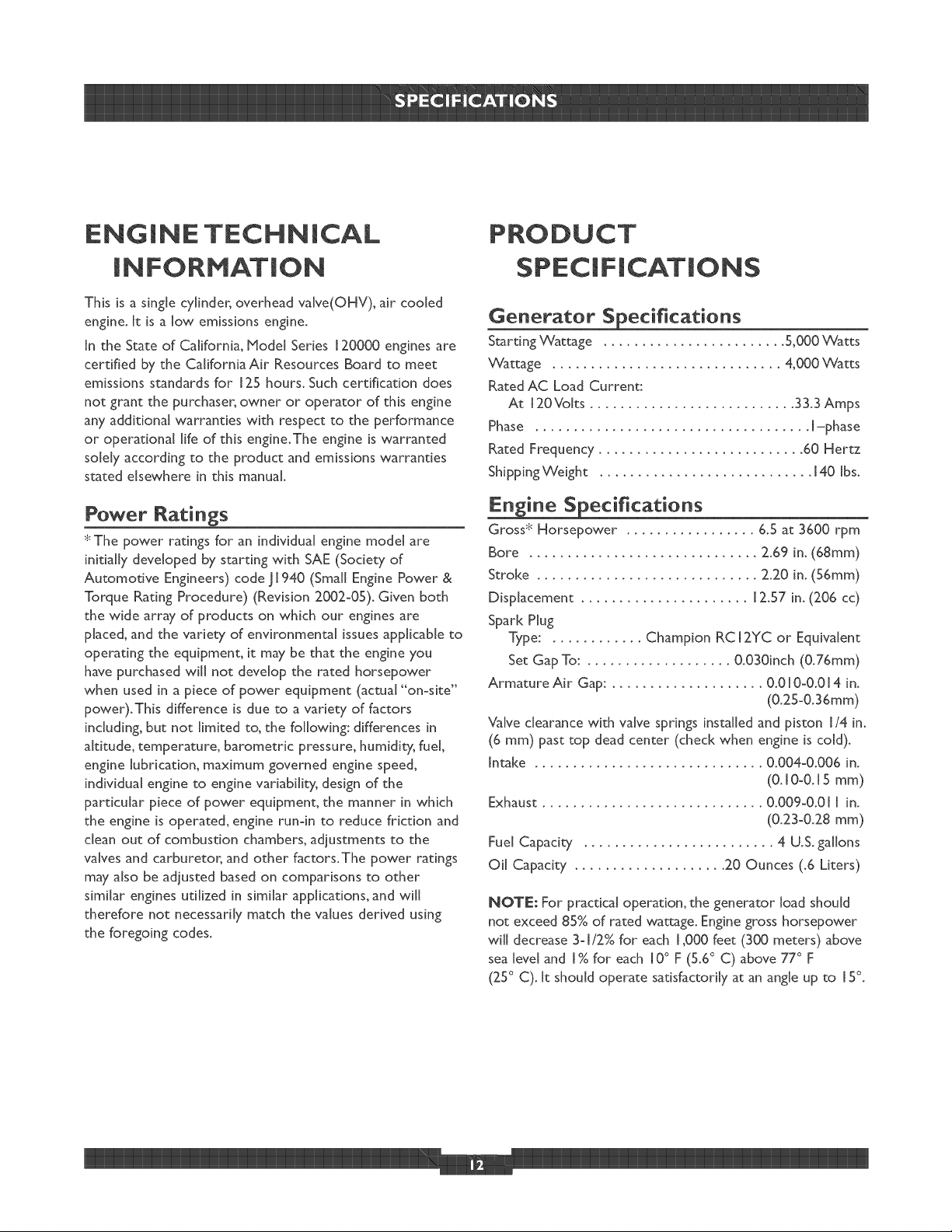

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

I. Select the items you will power at the same time.

2. Total the rated (running) watts of these items.This is

the amount of power your generator must produce to

keep your items running. See Figure 8.

3. Estimate how many surge (starting) watts you will

need. Surge wattage is the short burst of power

needed to start electric motor-driven tools or

appliances such as a circular saw or refrigerator.

Because not aJJmotors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Tool or Appliance

Window Air

Rated (Running)

Watts

1200

Conditioner

Refrigerator

Dee_ Freezer

Television

8OO

5OO

5OO

75

3075 Total

Running Watts

Total Rated (Running)_atts -- 3075

HighestAdditiona[ Surge_atts -- 1800

Total Generator Output Required -- 4875

Power Manasement

To prolong the JJfeof your generator and attached devices,

it is important to take care when adding electrical loads to

your generator.There should be nothing connected to the

generator outlets before starting it's engine.The correct

and safe way to manage generator power is to sequentially

add loads as follows:

I. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

Additional Surge

(Starting) Watts

1800

1600

5OO

1800 Highest

Surge Watts

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

NEVER add more loads than the generator capacity.Take

special care to consider surge loads in generator capacity,

as described above.

Rated*

Tool or Appliance (Running) Surge

Watts (Starting)

Essentiams

Light Bulb - 75 watt 75

Deep Freezer 500 500

Sump Pump 800 1200

Refrigerator/Freezer - 18 Cu. Ft. 800 1600

Water Well Pump - 1/3 HP 1000 2000

Neating/Cooming

Window AC - 10,000 BTU 1200 1800

Window Fan 300 600

Furnace Fan Blower- 1/2 HP 800 1300

Kitchen

Microwave Oven - 1000 Watt 1000

Coffee Maker 1500

Electric Stove - Single Element 1500

Hot Plate 2500

FamiRy Room

DVDiCD Player 100

VCR 100

Stereo Receiver 450

Color Television - 27" 500

Personal Computer w/l 7" monitor 800

Other

Security System J80

AM/FM Clock Radio 300

Garage Door Opener - 1/2 HP 480 520

Electric Water Heater - 40 Gallon 4000

DJYtjob Site

Quartz Halogen Work Light JO00

Airless Sprayer - J/3 HP 600 J200

Reciprocating Saw 960 960

Electric Drill - 1/2 HP i 000 i 000

Circular Saw - 7 1/4" 1500 1500

Miter Saw - J0" J800 J800

TaMe Planer - 6" J800 J800

Table Saw/Radia[ Arm Saw - 10" 2000 2000

Air Compressor - i-i/2 HP 2500 2500

%_Tattages listed are approximate only. Check tool or

appliance for actual wattage.

Additional

VVatts

ENGINE TECHNICAL

PRODUCT

INFORMATION

This is a single cylinder, overhead vaIve(OHV), air cooled

engine. [t is a low emissions engine.

In the State of California, Model Series J20000 engines are

certified by the Ca[ffornh Air Resources Board to meet

emissions standards for 125 hours. Such certification does

not grant the purchaser, owner or operator of this engine

any additional warranties with respect to the performance

or operational life of this engine.The engine is warranted

solely according to the product and emissions warranties

stated elsewhere in this manual

Power Ratings

_The power ratings for an individual engine model are

initially developed by starting with SAE (Society of

Automotive Engineers) code J[ 940 (Small Engine Power &

Torque Rating Procedure) (Revision 2002-05). Given both

the wide array of products on which our engines are

placed, and the variety of environmental issues applicable to

operating the equipment, it may be that the engine you

have purchased will not develop the rated horsepower

when used in a piece of power equipment (actual "on-site"

power).This difference is due to a variety of factors

including, but not limited to, the following: differences in

altitude, temperature, barometric pressure, humidity, fuel,

engine lubrication, maximum governed engine speed,

individual engine to engine variability, design of the

particular piece of power equipment, the manner in which

the engine is operated, engine run-in to reduce friction and

clean out of combustion chambers, adjustments to the

valves and carburetor, and other factors.The power ratings

may also be adiusted based on comparisons to other

similar engines utilized in similar applications, and will

therefore not necessarily match the values derived using

the foregoing codes.

SPECIFICATIONS

Generator Specifications

Starting _attage ........................ 5,000 Watts

_attage .............................. 4,000 _atts

Rated AC Load Current:

At 120Voks ........................... 33.3 Amps

Phase .................................... I-phase

Rated Frequency ........................... 60 Hertz

Shipping Weight ............................ 140 Ibs.

Gross _ Horsepower ................. 6.5 at 3600 rpm

Bore .............................. 2.69 in. (68ram)

Stroke ............................. 2.20 in. (56mm)

Displacement ...................... 12.57 in. (206 cc)

SparkPlug

Type: ............ Champion RCI2YC or Equivalent

Set Gap To: ................... O.030inch (0.76ram)

Armature Air Gap: .................... 0.010-0.014 in.

(0.25-0.36mm)

Valve clearance with valve springs installed and piston I/4 in.

(6 mm) past top dead center (check when engine is cold).

Intake .............................. 0.004-0.006 in.

(0.10-0.1S mm)

Exhaust ............................. 0.009-0.01 I in.

(0.23-0.28 mm)

Fuel Capacity ......................... 4 U.S. gallons

Oil Capacity .................... 20 Ounces (.6 Liters)

NOTE: For practical operation, the generator load should

not exceed 85% of rated wattage. Engine gross horsepower

will decrease 3-1/2% for each I,O00 feet (300 meters) above

sea level and 1% for each 10° F (5.6 ° C) above 77 ° F

(25 ° C). It should operate satisfactorily at an angle up to 15°.

GENERAL

R :COMMENDAT[ONS

ReguJar maintenance will improve the performance and

extend the life of the generator. See any authorized dealer

for service.

The generator's warranty does not cover items that have

been subjected to operator abuse or negligence.To receive

fu[Jvalue from the warranty, the operator must maintain

generator as instructed in this manua[.

Some adjustments wiJl need to be made periodically to

properly maintain your generator.

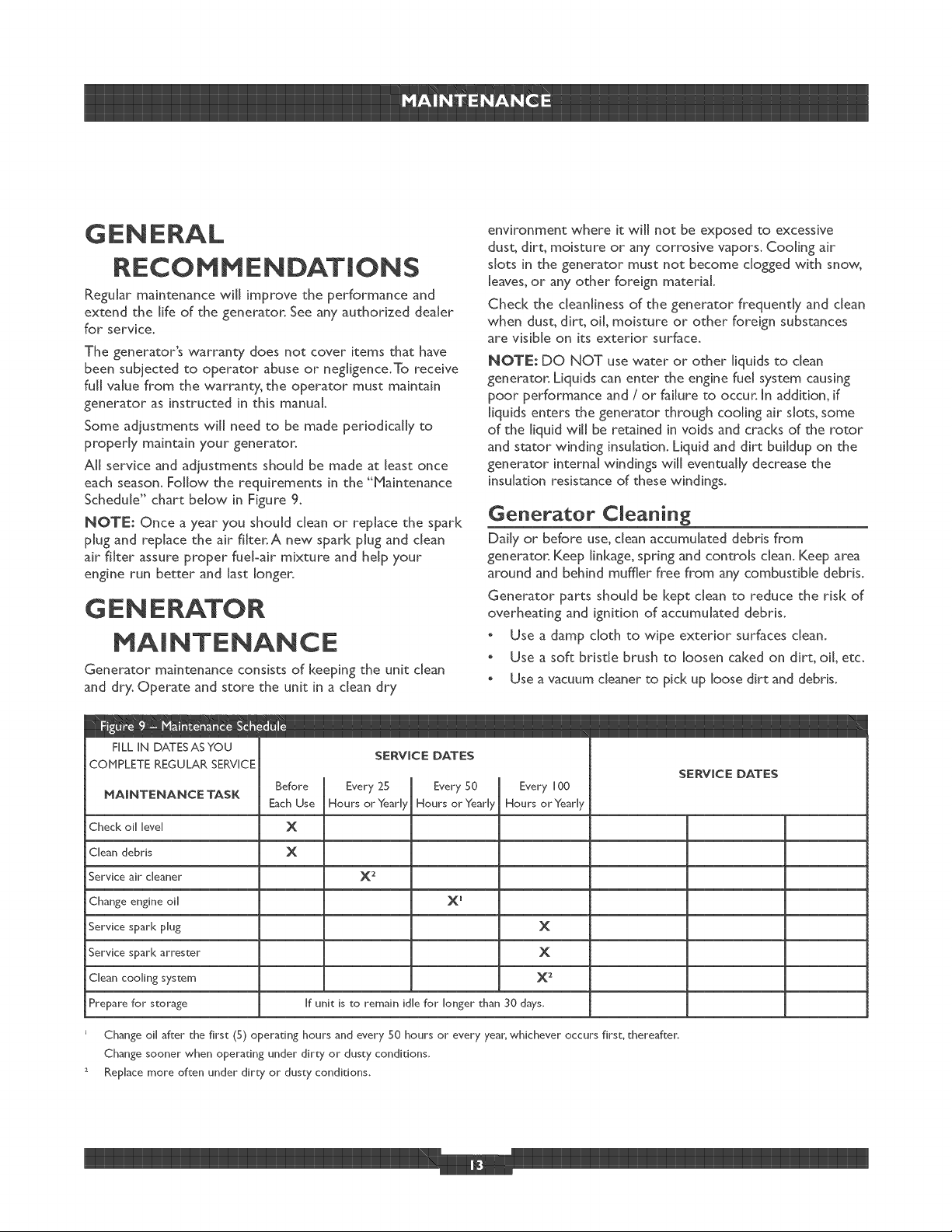

All service and adjustments should be made at [east once

each season. Follow the requirements in the "bqaintenance

Schedule" chart below in Figure 9.

NOTE; Once a year you should clean or replace the spar[4

plug and replace the air fi[ter.A new spar[( plug and dean

air filter assure proper fuebair mixture and help your

engine run better and last longer.

GS:NS:RATOR

MAINTENANCE

Generator maintenance consists of [Keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors. Cooling air

slots in the generator must not become dogged with snow,

[eaves,or any other foreign material

Check the cleanliness of the generator frequently and dean

when dust, dirt, oil, moisture or other foreign substances

are visible on its exterior surface.

NOTE: DO NOT use water or other liquids to dean

generator. Liquids can enter the engine fuel system causing

poor performance and / or failure to occur. [n addition, ff

liquids enters the generator through cooling air slots, some

of the liquid will be retained in voids and cracks of the rotor

and stator winding insulation. Liquid and dirt buildup on the

generator internal windings will eventually decrease the

insulation resistance of these windings.

Generator Cleaning

DaJJyor before use, dean accumulated debris from

generator. Keep linkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Generator parts should be kept dean to reduce the risk of

overheating and ignition of accumulated debris.

o Use a damp cloth to wipe exterior surfaces dean.

o Use a soft brisde brush to loosen caked on dirt, oil etc.

o Use a vacuum cleaner to pick up bose dirt and debris.

FILL IN DATESASYOU

COMPLETE REGULAR SERVICE

MA|NTENANCE TASK

Before Every 25 Every 50 Every 100

SERVICE DATES

EachUse Hours orYearly Hours orYeary HoursorYeady

Check oil level

Clean debris

Service air cleaner

Change engine oil

Service spar[< plug

Service spar[< arrester

Clean cooling system

Prepare for storage

E Change oil after the first (5) operating hours and every 50 hours or every year, whichever occurs first, thereafter,

Change sooner when operating under dirt}" or dust}" conditions,

2 Replace more often under dirt}" or dust}" conditions,

X

X

X2

X _

x

x

x 2

If unit is to remain idle for longer than 30 days,

SERVICE DATES

Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on the

generator.These openings must be kept clean and

unobstructed.

J

DO NOT expose generator to excessive moisture, dust, dirt,

or corrosivevapors.

DO NOT insert any objects through cooling slots.

ENGINE MAINTENANCE

WARN(NG

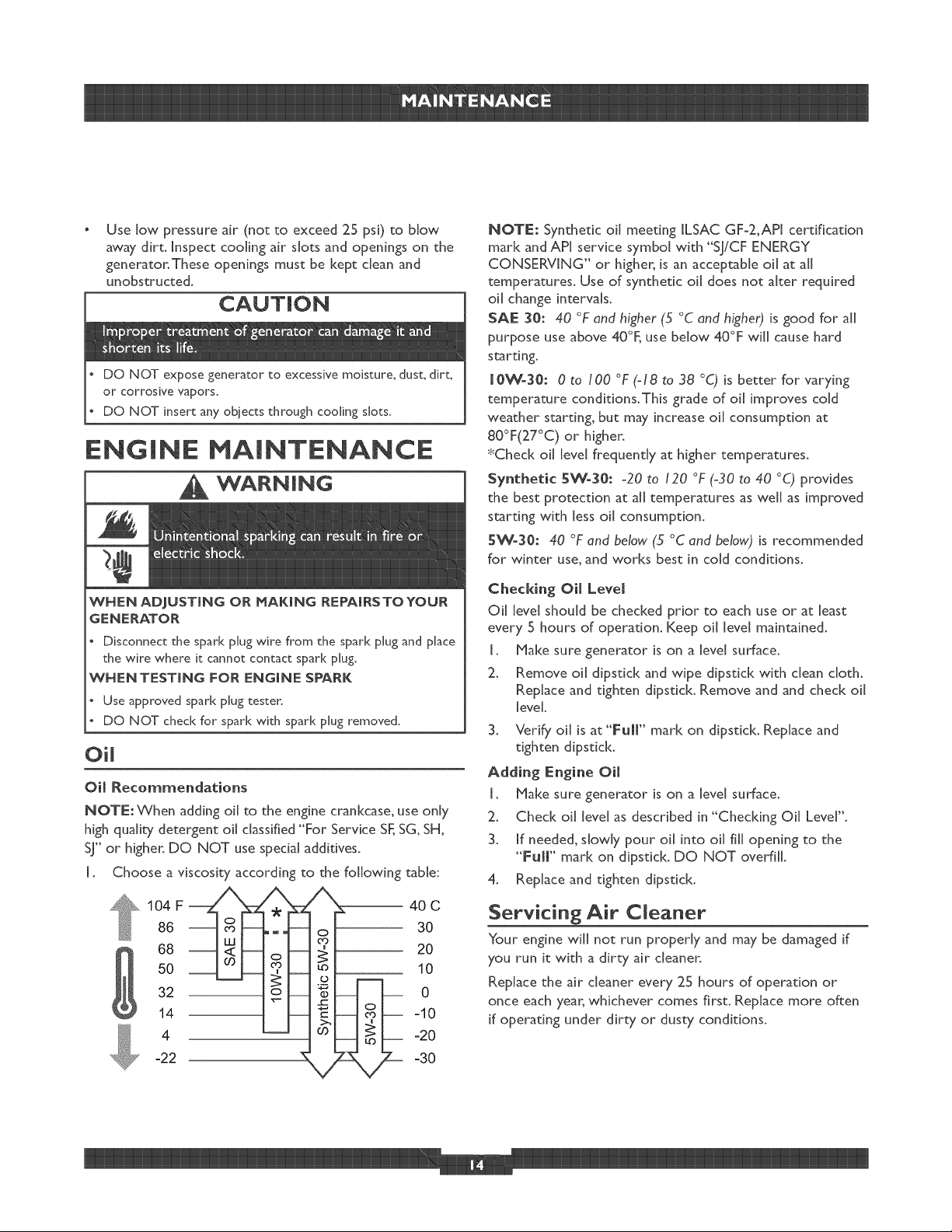

NOTE: Synthetic oil meeting ILSAC GF-2,API certification

mark and API service symbol with "SJiCF ENERGY

CONSERVING" or higher, is an acceptable oil at all

temperatures. Use of synthetic oil does not alter required

oil change intervals.

J

SAE 30:40 °F and higher G °C and higher) is good for all

purpose use above 40°F, use below 40°F will cause hard

starting.

J0Wo30:0 to 100 °F (-18 to 38 °C) is better for varying

temperature conditions.This grade of oil improves cold

weather starting, but may increase oil consumption at

80°F(27°C) or higher.

*Check oil level frequently at higher temperatures.

Synthetic BW-30:-20 to I20 °F (-30 to 40 o© provides

the best protection at all temperatures as well as improved

starting with less oil consumption.

SWo30:40 °F and below (5 °C and below,) is recommended

for winter use, and works best in cold conditions.

WNEN ADJUSTING OR MAKING REPAJRSTOYOUR

GENERATOR

Disconnect the spar[< plug wire from the spar[< plug and place

the wire where it cannot contact spar[< plug.

WNENTESTJNG FOR ENGINE SPARK

Use approved spar[< plug testen

DO NOT check for spark with spark plug removed,

Oil

Oil Recommendations

NOTE: When adding oil to the engine crankcase, use only

high quality detergent oil classified "For Service SF, SG, SH,

SJ" or higher. DO NOT use special additives.

I. Choose a viscosity according to the following table:

104 F

86

68

50

32

14

4

-22

) 30

i

)

40 C

10

0

-10

-20

-30

Checking Oil Level

Oil level should be checked prior to each use or at least

every 5 hours of operation. Keep oil level maintained.

I. Make sure generator is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean cloth.

Replace and tighten dipstick. Remove and and check oil

level.

3. Verify oil is at"Full" marl< on dipstick. Replace and

tighten dipstick.

Adding Engine Oil

I. Make sure generator is on a level surface.

2. Check oil level as described in "Checking Oil Level".

3. If needed, slowly pour oil into oil fill opening to the

°°Full" marl< on dipstid<. DO NOT overfill.

4. Replace and tighten dipstick.

Servicing Air Cleaner

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner.

Replace the air cleaner every 25 hours of operation or

once each year, whichever comes first. Replace more often

if operating under dirty or dusty conditions.

Loading...

Loading...