Briggs & Stratton 020507-00 Owner’s Manual

®

S er

I

This pressure washer is rated in accordance to the PressureWasher Manufacturers Association

(PWMA) standard PW101-2010 (Testing and Rating Performance of Pressure Washers).

8RIGGS & STRATTONPOWER PRODUCTS GROUP, LLC

MILWAUKEE, WiSCONSiN, U.S.A.

IVianualNo.316320 RevA

Thank youfor purchasingthis quality-built Briggs & Stratton@ pressurewasher. We are pleasedthat you've placedyour

confidence inthe Briggs & Stratton brand. When operatedand maintainedaccording to the instructions in this manual, your

Bdggs & Stratton pressurewasher will provide manyyears of dependableservice.

Thismanual contains safety information to makeyou awareof the hazardsand risks associatedwith pressure washersand

how to avoid them. BecauseBriggs & Stratton does not necessarily know allthe applicationsthis pressure washer could be

usedfor, it is important that you readand understandthese instructions thoroughly before attempting to start or operatethis

equipment. Savethese original instructionsfar future reference.

This pressurewasher requires final assembly before use, Referto the Assembly section of this manualfor instructions on

final assembly procedures.Follow the instructions completely.

Where to Find Us

You never haveto look far to find Briggs & Stratton support and service for your pressure washer.Consult your Yellow Pages.

Thereare over 30,000 Briggs & Stratton authorized service dealersworldwide who provide quality service. You canalso

contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Pressul'e Washer

Model Number

Revision

Serial Number

Engine

Model Number

Type Number

Code Number

Date Purchased

Copyright © 2013. Briggs & Stratton PowerProducts Group, LLC

Milwaukee, Wl, USA.All rights reserved.

BRIGGS& STRATTONPOWERPRODUCTSis aregistered

trademark of Briggs & Stratton Corporation

Milwaukee, Wl, USA

2 BRIGGSandSTRATTON.COM

Table of Contents

Operation .................................... 12

PressureWasher Location..................................... 12

How to Stad Your PressureWasher ............................. 12

How to Stop Your PressureWasher ............................. 14

How to Use SprayTips ....................................... 14

Cleaningand Applying Detergent................................ 15

PressureWasher Rinsing ..................................... 16

CleaningDetergent Siphoning Tube.............................. 16

Automatic Cool Down System _ThermalReliefl..................... 16

Maintenance .................................. 17

MaintenanceSchedule........................................ 17

PressureWasher Maintenance ................................ 17

Pump Oil Maintenance........................................ 19

Engine Maintenance.......................................... 19

After EachUse.............................................. 21

Winter Storage.............................................. 22

Long Term Storage .......................................... 22

Treubiesheeting ................................ 23

Warranties .................................... 24

Emissions Control Warranty Statement........................... 24

PressureWasher OwnerWarranty............................... 26

EspaSol

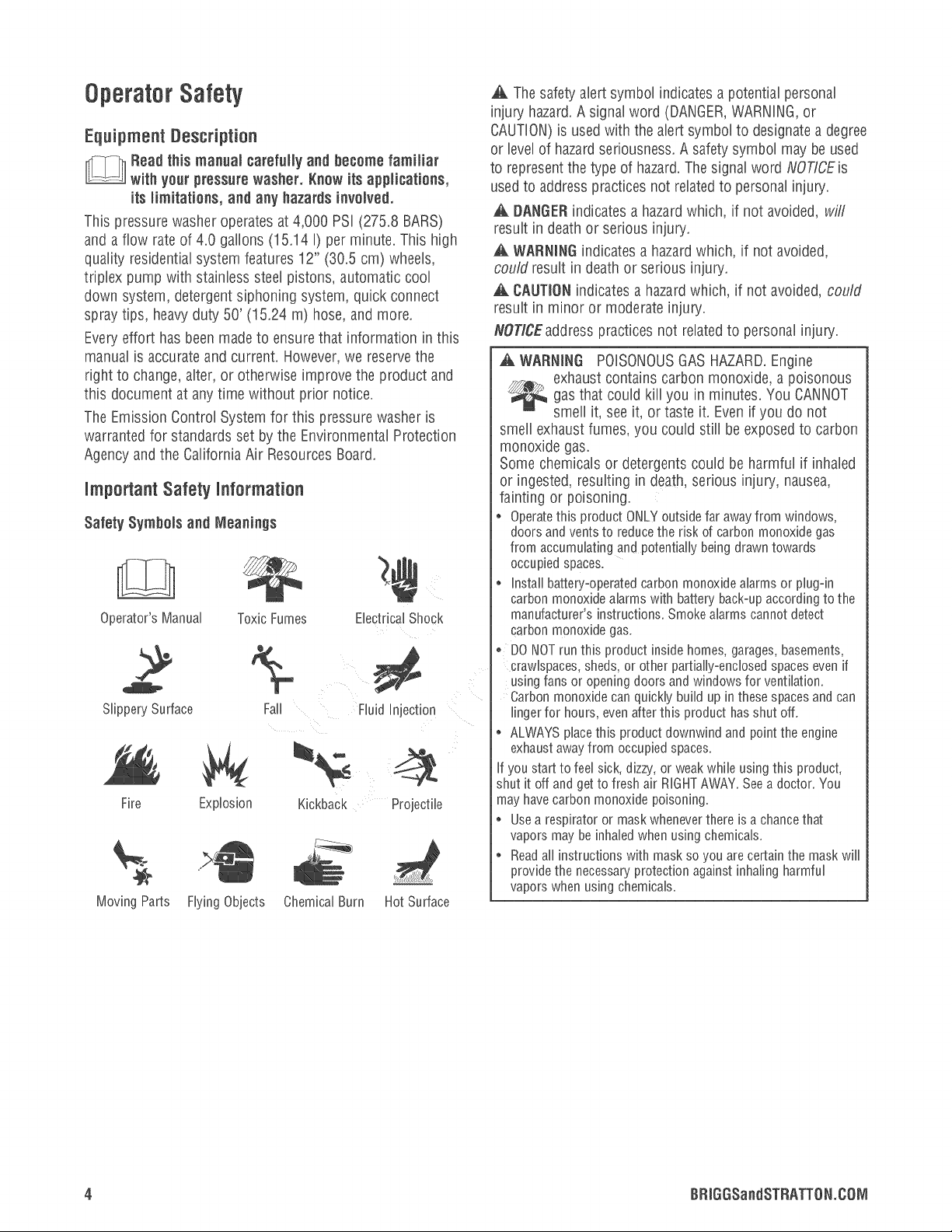

OperatorSafety

Equipment Description

Read this ITlanUal carefuiJy and became familiar

with yourpressurewasher. Know itsappJicatians,

its limitations,and any hazardsinvolved.

This pressurewasher operatesat 4,000 PSi (275.8 BARS)

and a flow rateof 4.0 gallons (15.14 I) per minute. This high

quality residential system features 12" (30.5 cm) wheels,

triplex pump with stainless steel pistons, automatic cool

down system, detergentsiphoning system, quick connect

spray tips, heavy duty 50' (15.24 m) hose,and more.

Everyeffort has been madeto ensurethat information in this

manual is accurate and current. However,we reservethe

right to change,alter, or otherwise improve the product and

this document at any time without prior notice.

The EmissionControl System for this pressure washer is

warranted for standards setby the Environmental Protection

Agency andthe CaliforniaAir ResourcesBoard.

Important Safety Mnformation

SafetySymbolsandMeanings

Operator'sManual ToxicFumes

SlipperySurface Fal

Fire Explosion Kickback Projectile

Moving Parts Flying Objects ChemicalBurn Hot Surface

Electrical Shock

Fluid injection

Thesafetyalert symbol indicatesa potentialpersonal

injury hazard.A signalword (DANGER,WARNING,or

CAUTION)is usedwith the alert symbol to designatea degree

or levelof hazardseriousness.A safetysymbol may be used

to representthe type of hazard.Thesignal word NOTICEis

usedto addresspractices not relatedto personalinjury.

A DANGERindicatesa hazardwhich, if not avoided, vvitt

result in death or serious injury.

A WARNINGindicates a hazardwhich, if not avoided,

could result in death or serious injury.

A CAUTIONindicates a hazardwhich, if not avoided, could

result in minor or moderate injury.

NOTICEaddresspractices not relatedto personal injury.

,a, WARNING POISONOUS GAS HAZARD. Engine

exhaust contains carbon monoxide, a poisonous

gas that could kill you in minutes. You CANNOT

smell it, see it, or taste it. Even if you do not

smell exhaust fumes, you could stiff be exposed to carbon

monoxide gas.

Some chemicals or detergents could be harmful if inhaled

or ingested, resulting in death, serious injury, nausea,

fainting or poisoning.

, Operatethis product ONLYoutside far awayfrom windows,

doors and vents to reducethe risk of carbonmonoxide gas

from accumulating and potentially being drawn towards

occupied spaces.

Install battery=operatedcarbon monoxide alarms or plug=in

carbon monoxidealarms with battery back=upaccording to the

manufacturer's instructions. Smoke alarms cannotdetect

carbon monoxide gas.

o DO NOTrun this product inside homes, garages,basements,

crawlspaces, sheds,or other partially=enclosedspacesevenif

using fans or opening doors and windows for ventilation.

Carbon monoxide can quickly build up in these spacesand can

finger for hours, even after this product has shut off.

, ALVVAYSplacethis product downwind and pointthe engine

exhaustawayfrom occupied spaces.

if you start to feel sick, dizzy, or weak while using this product,

shut it off and get to fresh air RIGHTAWAY.Seea doctor. You

may have carbon monoxide poisoning.

Usea respirator or maskwheneverthere is a chancethat

vapors may be inhaledwhen using chemicals.

Readall instructions with mask so you are certain the mask will

provide the necessaryprotection against inhaling harmful

vapors when using chemicals.

4 BRIGGSandSTRATTON.COM

A WARNENG Theengine exhaust from this product

contains chemicalsknown to the State of Californiato

causecancer, birth defects,or other reproductive harm.

A WARNmNGThis product contains lead and lead

compounds, known to the State of California to cause

birth defectsor other reproductive harm. VVashyour

hands afterhandling t,_isproduct.

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death or

serious injury.

Contact with muffler area could cause burns resulting in

serious injury.

o DO NOTtouch hot parts andAVOID hotexhaust gases.

, Allow equipment to cool beforetouching.

Keepat least5 feet (1.5 m) of clearanceon ail sides of pressure

washer including overhead.

it is aviolation of California Public ResourceCode,Section

4442, to use or operate the engineon anyforest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with aspark attester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may havesimilar aws.

Contactthe original equipment manufacturer, retailer,or dealer

to obtain a sparkattester designed for the exhaust system

installed on this engine.

Replacement parts must be the sameand nstalled inthe same

position as the original parts.

A WARNENG Risk of electrocution.

Contactwith power source could causeelectric

shock or burn resulting in death or seriousinjury.

o NEVERspray near power source.

A WARNING Use of pressure washer could create

puddles and slippery surfaces causing

_ you to fall resulting in death or serious

T- injury.

Kickback from spray gun could cause you to fall resulting

in death or serious injury.

Operatepressurewasher from a stable surface.

o Thecleaning areashould have adequateslopes and drainageto

reducethe possibility of a fall due to slippery surfaces.

Beextremely careful if you must use the pressurewasher from

a ladder,scaffolding, or any other similar location.

o Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

A WARNING Fuel and its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death or

serious injury.

WHENADDING ORDRAININGFUEL

, Turn pressurewasher engineOFFandlet it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

, Fillor drain fuel tank outdoors.

, DONOToverfill tank. Allow spacefor fuel expansion.

, iffuel spills, wait until it evaporates beforestarting engine.

Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

Checkfuel lines, tank, cap and fittings frequently for cracks or

leaks. Replaceif necessary.

DONOTlight a cigarette or smoke.

WHENSTARTINGEQUIPMENT

* Ensurespark plug, muffler,fuel cap,and air cleanerarein place.

* DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPMENT

* DO NOToperatethis product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure.

* DONOTtip engine or equipment at anglewhich causes fuel to

spill.

* DONOTsprayflammabb fiquids.

WHENTRANSPORTING,MOVINGOR REPAiRiNG EQUIPMENT

* Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

* DONOTtip engine or equipment at anglewhich causes fuel to

spill.

Disconnectspark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUEL iN TANK

Store awayfrom furnaces, stoves, water heaters,clothes

dryers, or otherappliancesthat have pilot light or other ignition

source becausethey could ignite fuel vapors.

A WARNING Starter cord kickback (rapid retraction) will

pull hand and arm toward engine faster than you

can let go which could cause broken bones,

fractures, bruises, or sprains resulting in serious

injury.

NEVERpull starter cord without first relieving spray gun

pressure.

When starting engine, pull cord slowly until resistanceis felt

andthen pull rapidly to avoid kickback.

After each starting attempt, where enginefails to run, always

point spray gun in safedirection, press red button and squeeze

spray guntrigger to releasehigh pressure.

Firmly grasp spray gun with both handswhen using high

pressure sprayto avoid injury when spray gun kicks back.

A WARNING ChemicalBurn Hazard.

Chemicals could cause burns resulting in death

or serious injury.

, DO NOTuse caustic liquid with pressure washer.

Use ONLYpressurewasher safe detergents/soaps. Followall

manufacturers instructions.

WARNING The high pressure stream of water that

_, his equipment produces could cut through skin

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

. if cut by fluid, call physicianimmediately. DONOTtreat as a

* DONOTallow CHILDRENto operate pressure washer.

* NEVERrepair high pressure hose. Replaceit.

* NEVERrepair leaking connections with sealant of any kind.

* NEVERconnect highpressure hose to nozzleextension.

* Keephigh pressure hose connectedto pump and spray gun

* ALWAYS point spray gun in safedirection, press red button

* NEVERaimspray gun at people,animals, or plants.

* DO NOTsecure spray gun in open position.

* DO NOTleavespray gun unattendedwhile machineis running.

* NEVERusea spray gun which does not have a trigger lock or

* Always be certain spray gun, nozzlesand accessoriesare

and its underlying tissues, resulting in serious

injury and possible amputation.

simple cut.

Replaceo-ring or seal.

while system is pressurized.

andsqueezespray gun trigger to releasehigh pressure, every

time you stop engine.

trigger guardin placeand in working order.

correctly attached.

A WARNING Unintentional sparking could cause fire or

electric shock resulting n death or

serious injury.

WRENADJUSTINGOR MAKING REPAIRSTOYOURPRESSURE

WASHER

* Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WRENTESTINGFORENgiNESPARK

Use approvedspark plug tester.

° DONOTcheckfor sparkwith spark plugremoved.

A WARNING Starter andother rotating parts could

resulting in serious injury.

entanglehands, hair, clothing, or accessories

, NEVERoperatepressurewasherwithoutprotectivehousingor

covers.

* DONOTwearloosedotNng,jewelryor anythingthat couNbe

caughtin thestarterorotherrotatingparts.

* Tieuplonghairandremovejewdry.

A WARNING Risk of eyeor bodily injury.

Spraycould splash back or propel

objects resulting in serious injury.

,, Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSi Z87.1 when using or in vicinity of

this equipment.

* NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

* Alwayswear protectiveclothing such as a long-sleevedshirt,

long pantsand close4oed shoes.

* NEVERoperatepressure washerwhen barefootor wearing

sandalsor shorts.

A CAUTION Excessively high operating speeds could

result in minor injury.

Excessively low speeds impose a heavy Ioa&

, DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Pressurewasher supplies correct rated

pressure and flow when running at governed speed.

* DO NOTmodify pressure washer inany way.

NOTICE High pressure spray could damage fragile items

including glass.

, DONOTpointspraygunatglasswhenusingred(0°) spraytip.

* NEVERaimspraygunat plants.

NOTICE Improper treatment of pressure washer could

damageit and shorten its life.

if you havequestions about intended use,ask dealeror contact

qualified service center.

° NEVERoperateunits with brokenor missing parts, or without

protective housing or covers.

° DO NOTby-pass any safetydevice on this machine_

* DONOTtamper with governed spee&

DONOToperate pressurewasher above rated pressure_

* DONOTmodify pressurewasher in any way_

* Beforestarting pressure washer in cold weather, check all parts of

the equipment to be sure ice has not formed there_

* NEVERmove machine by pulling on hoses_Usehandleprovided

on uniL

* This equipment is designed to be usedwith Briggs & Stratton

Power Products authorized parts ONLY_if equipment is used with

parts that DONOTcomply with minimum specifications, user

assumesall risks andliabilities_

6 gRIGGSaadSTRATTON.COM

Your pressure washer requires some assembly and is ready

for useafter it has beenproperly serviced with the

recommendedoil and fuel.

if you haveany problemswith the assemblyof your pressure

washer,pleasecallthe pressurewasher helplineat

(888) 743o4115.if calling for assistance,pleasehavethe

model, revision,andserialnumber from the identification label

available.

Unpack Pressure Washer

1. Removethe parts bag,accessories, and inserts

included with pressure washer.

.

Opencarton completely by cutting eachcorner from

top to bottom.

3. Ensureyou have all included items prior to assembly.

items in the carton include:

o Main Unit

o Handle

o High Pressure Hose

o Spray (Sun

o NozzleExtensionwith Quick ConnectFitting

o Oil Pouch (2)

o Parts Bag(which includesthe following/:

o Operator's Manual

o Owner's RegistrationCard

o Bag containing 5 Multi-Colored Spray Tips

o HandleFasteningHardwareKit(which includes/:

o CarriageBolts (2)

o Plastic Knobs (2)

To prepareyour pressure washer fer eperatien, ynu wiii

need te perferm these tasks:

1. Fill out and send in registration card_

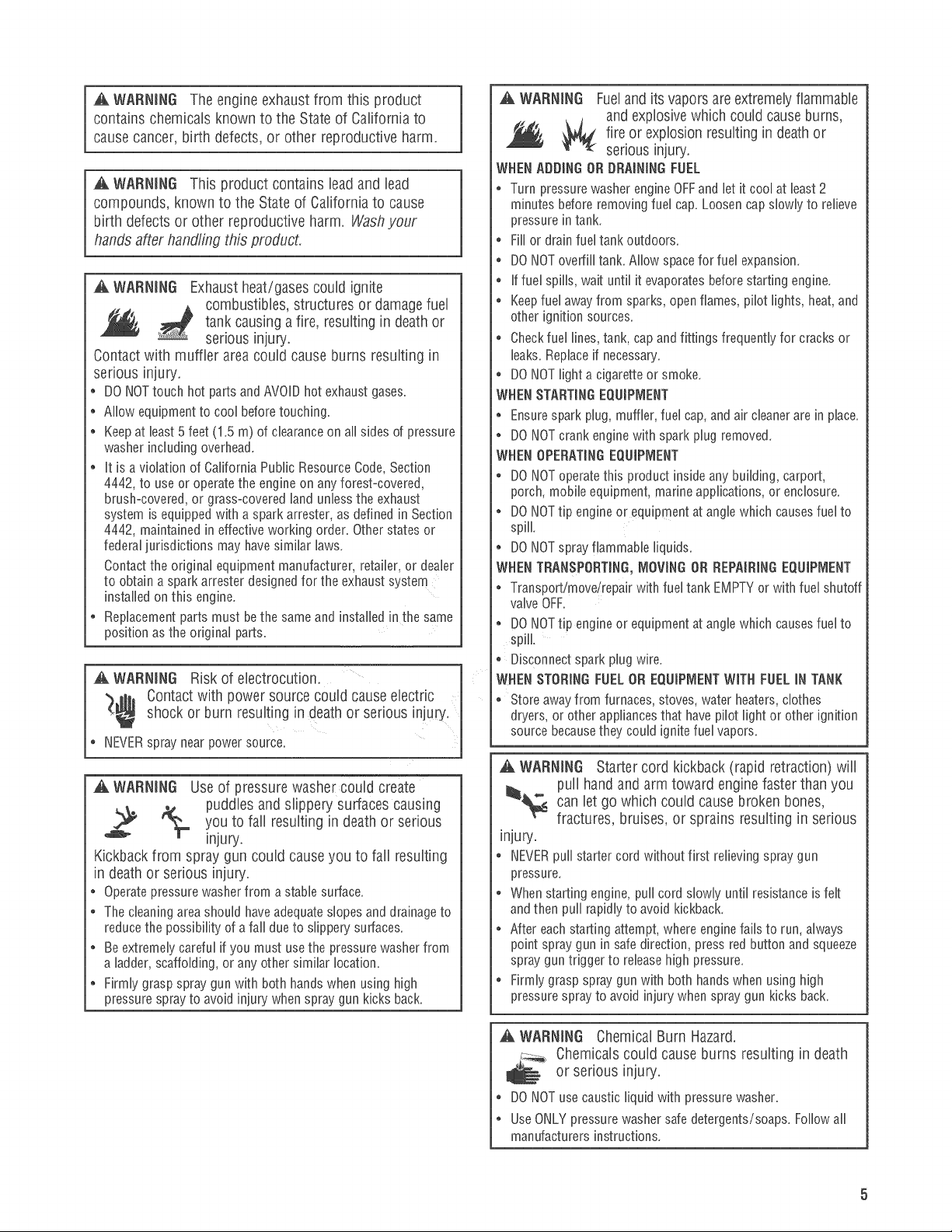

2. Verify oil dipstick (A) has beeninstalled into pump.

3. Attach handleto main uniL

4. Add oil to enginecrankcase.

5. Add fuel to fuel tank.

6. Connecthigh pressure hoseto spray gun and pump.

7. Connectwater supply to pump.

8. Attach nozzleextensionto spray gun.

9. Select/attach quick connect spray tip to nozzle

extension.

Attach Nandie

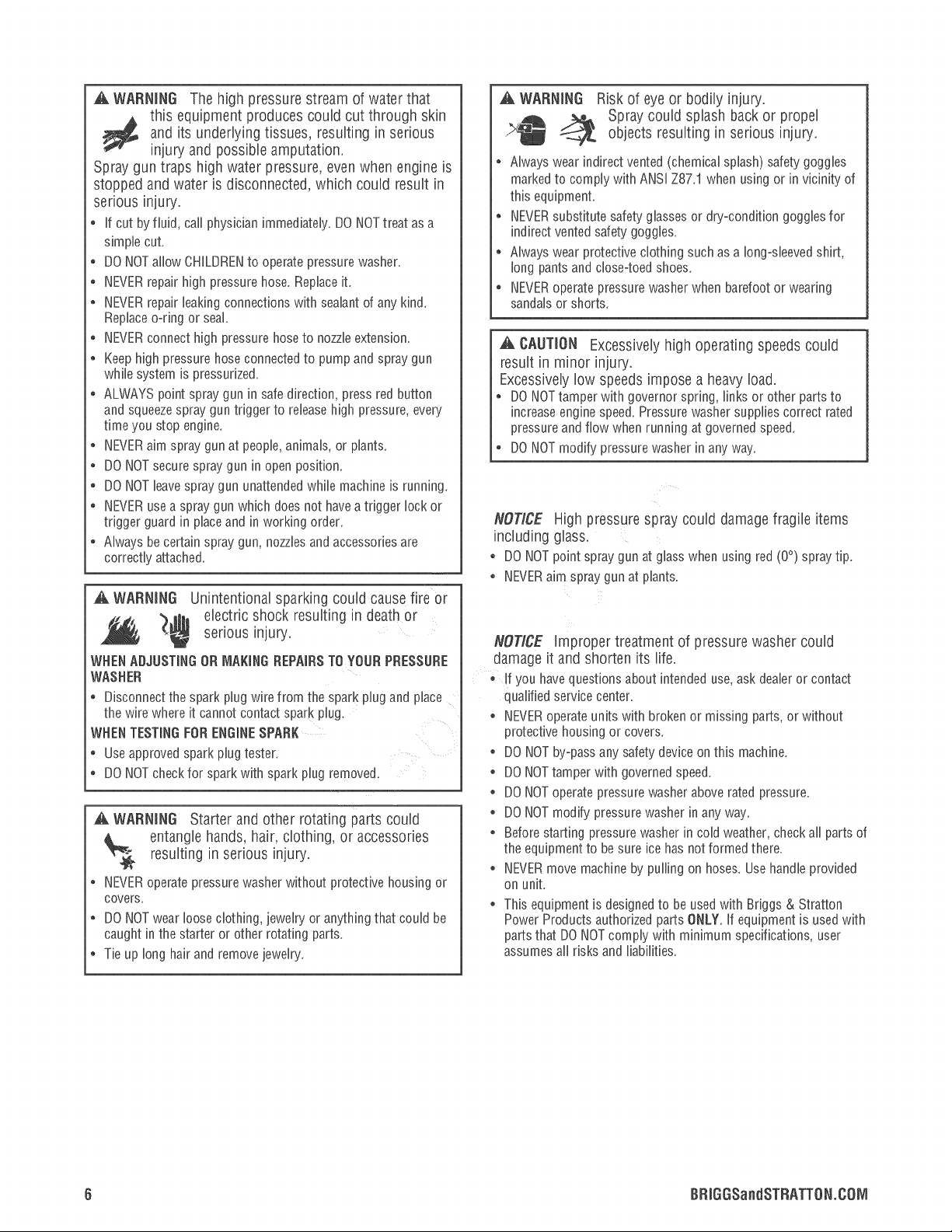

1. Placehandle (B) onto handlesupports (C) connectedto

main unit. Makesure hobs (t}) in handlealign with

hobs (t}) on handle supports.

.

insert handlecarriage bolts (E) through hobs from

inside of unit and attacha plastic knob (F) from outside

of unit.Tighten by hand.

.

insert multi-colored spray tips in spacesprovided in

handle.

Add Engine Oit

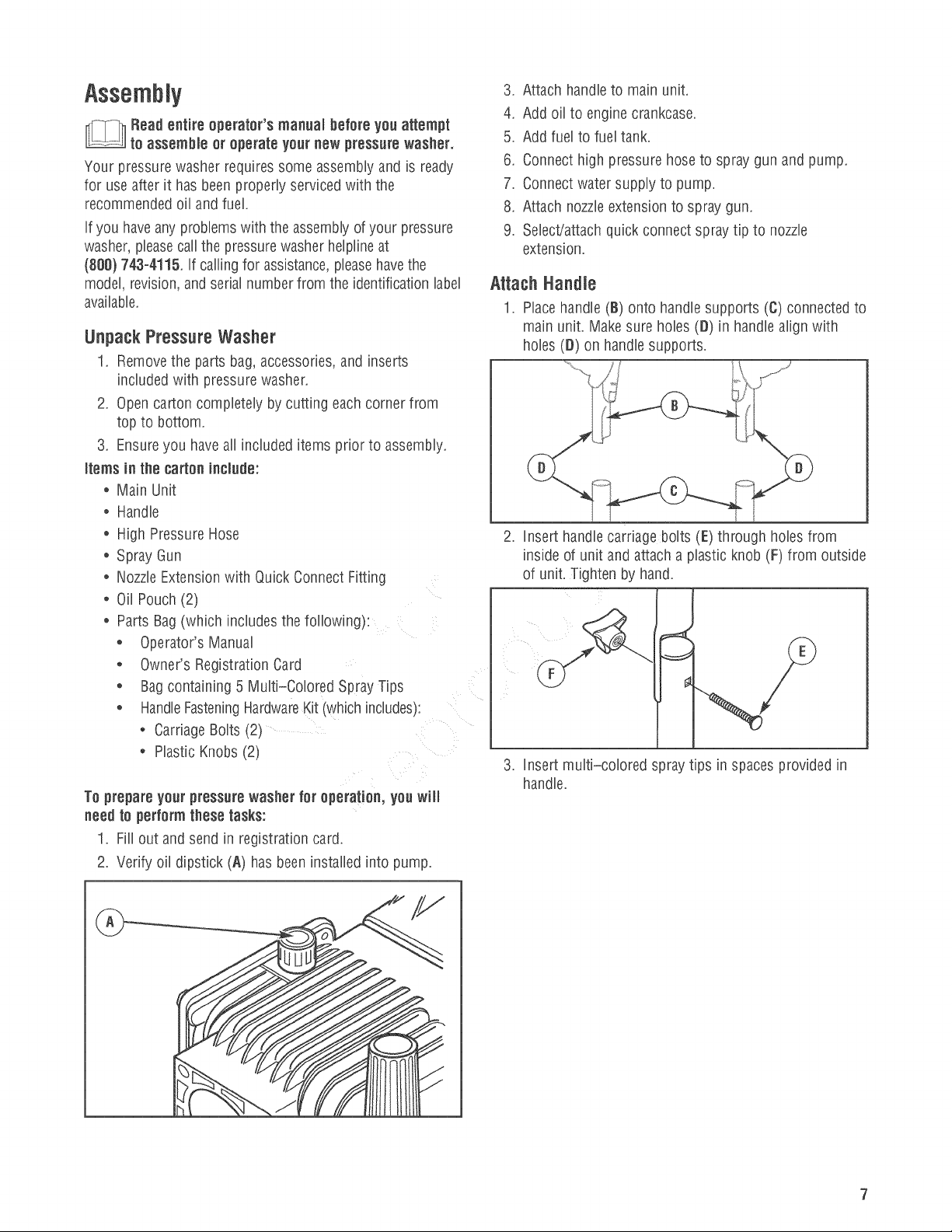

1. Placepressure washeron a fiat, levelsurface.

2. Cleanareaaround oil fill and removeyellow oil fill

cap/dipstick.

3. Hold neck of supplied oil pouch and removecap.

4. Slowly pour contents of oil pouches into oil fill opening.

Checkingoil levelfrequently, fill to FULLmark (A) on

dipstick.

NOTICE Pauseto permit oil to settle. Wipe dipstick clean

eachtime oil level is checked. DONOToverfill.

NOTICE improper treatment of pressure washer could

damage it and shorten its life.

. DO NOTattempt to crank or start the engine beforeit has been

properly servicedwith the recommended oi This could result in

an enginefailure.

WARNING Fueland its vapors areextremelyflammable

andexplosivewhich could causeburns,

fire or explosionresulting in deathor

seriousinjury.

WHENADDINGFUEL

, Turn pressurewasher engineOFFandlet it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

Fill fuel tank outdoors.

* DONOToverfill tank. Allow spacefor fuel expansion.

if fuel spills, wait until it evaporatesbefore starting engine.

Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

Checkfuel fines,tank, cap andfittings frequently for cracks or

leaks. Replaceif necessary.

DONOTlight a cigarette or smoke.

,

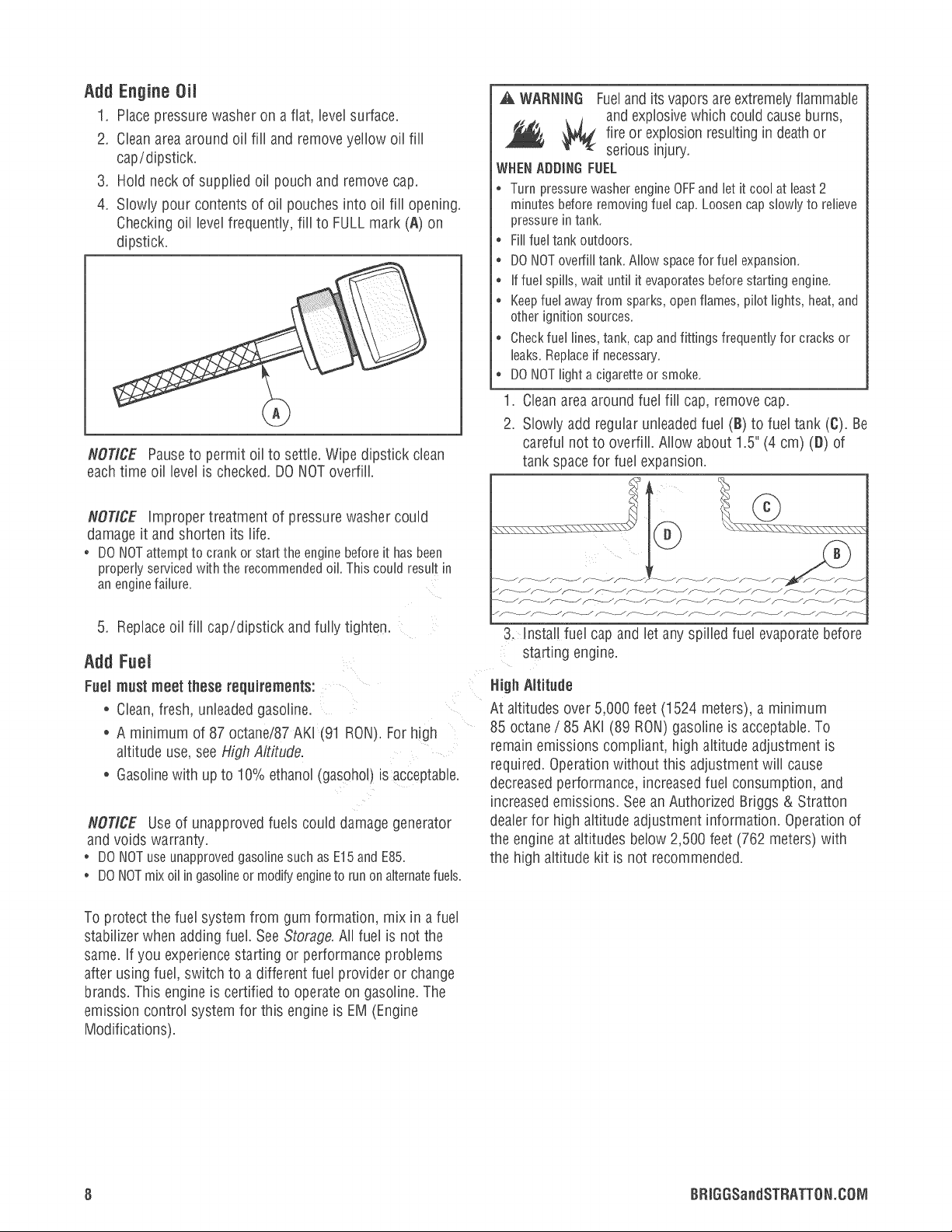

Cleanarea aroundfuel fill cap, remove cap.

2.

Slowly add regular unleadedfuel (B) to fuel tank (C). Be

careful notto overfill. Allow about 1.5" (4 cm) (D) of

tank space for fuel expansion.

5. Replaceoil fill cap/dipstick and fully tighten.

Add Fuel

Fuel must meet these requirements:

, Clean,fresh, unleadedgasoline.

, A minimum of 87 octane/87AKI (91 RONL Forhigh

altitude use, see High Aititude.

, Gasolinewith up to 10% ethanol(gasohol) isacceptable.

NOTICE Use of unapproved fuels could damagegenerator

and voids warranty.

DONOTuseunapprovedgasolinesuchasE15andE85.

DONOTmixoilingasolineormodifyengineto runonalternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizerwhen adding fuel. SeeStorage.All fuel is not the

same. if you experiencestarting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline.The

emission control system for this engine is EM (Engine

Modifications).

3. Install fuel cap and let anyspilled fuel evaporatebefore

starting engine.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remain emissions compliant, high altitude adjustment is

required. Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. SeeanAuthorized Briggs & Stratton

dealerfor high altitude adjustment information. Operation of

the engineat altitudes below 2,500 feet (762 meters) with

the high altitude kit is not recommended.

8 BRIGGSandSTRATTON.COM

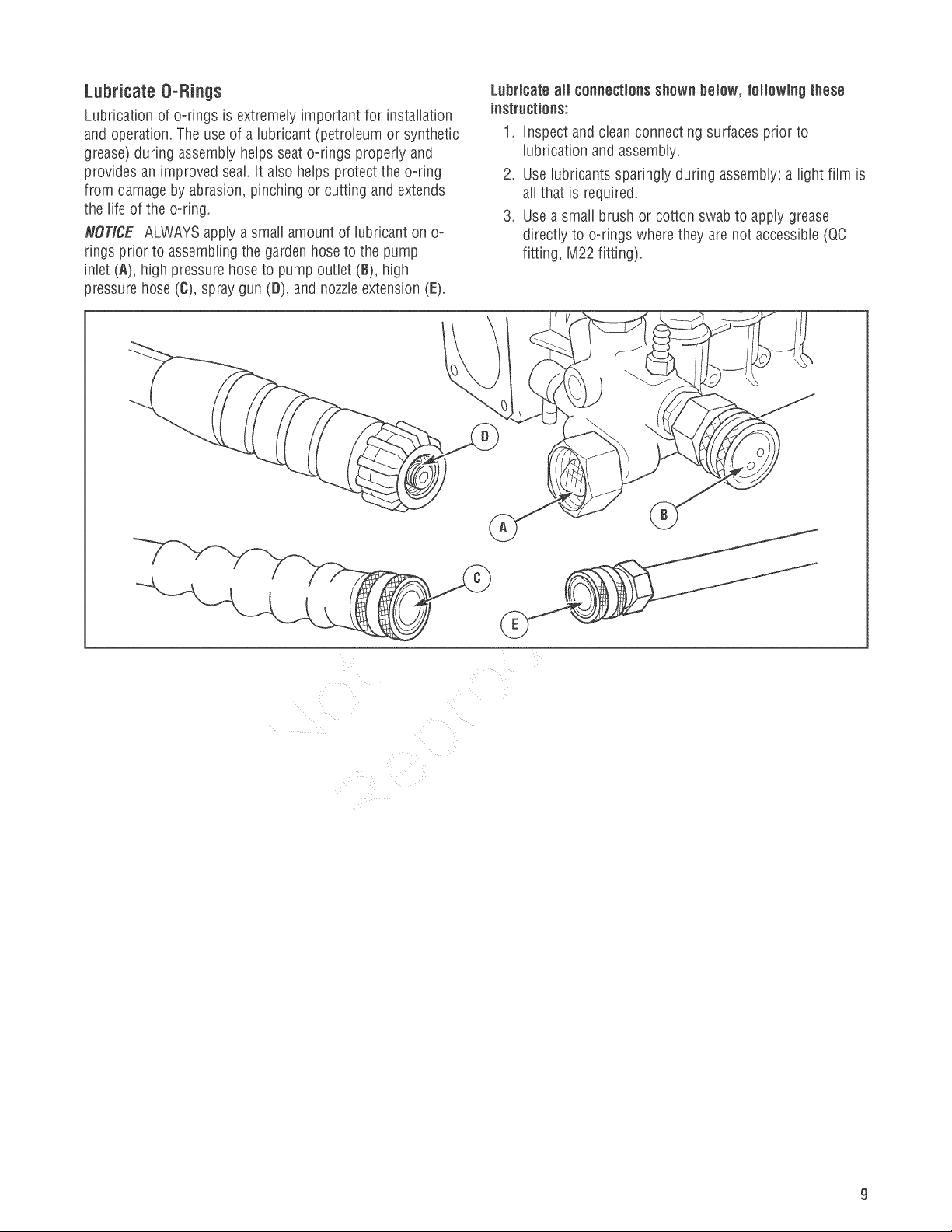

Lubricate OoRings

Lubrication of o-rings is extremelyimportant for installation

and operation. The useof a lubricant (petroleum or synthetic

grease)during assembly helpsseat o-rings properly and

provides an improved seal. it also helps protect the o-ring

from damageby abrasion,pinching or cutting and extends

the life of the o-ring.

HOTICE ALWAYSapplya small amount of lubricant on o-

rings priorto assemblingthe garden hose to the pump

inlet (A), high pressure hoseto pump outlet (B), high

pressure hose(C), spray gun (D), and nozzleextension(E).

Lubricateaii connections shownbelow, following these

instructions:

1. inspect and cleanconnecting surfaces prior to

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light film is

all that is required.

3. Use a small brush or cotton swab to apply grease

directly to oorings wherethey are not accessible(QC

fitting, M22 fitting).

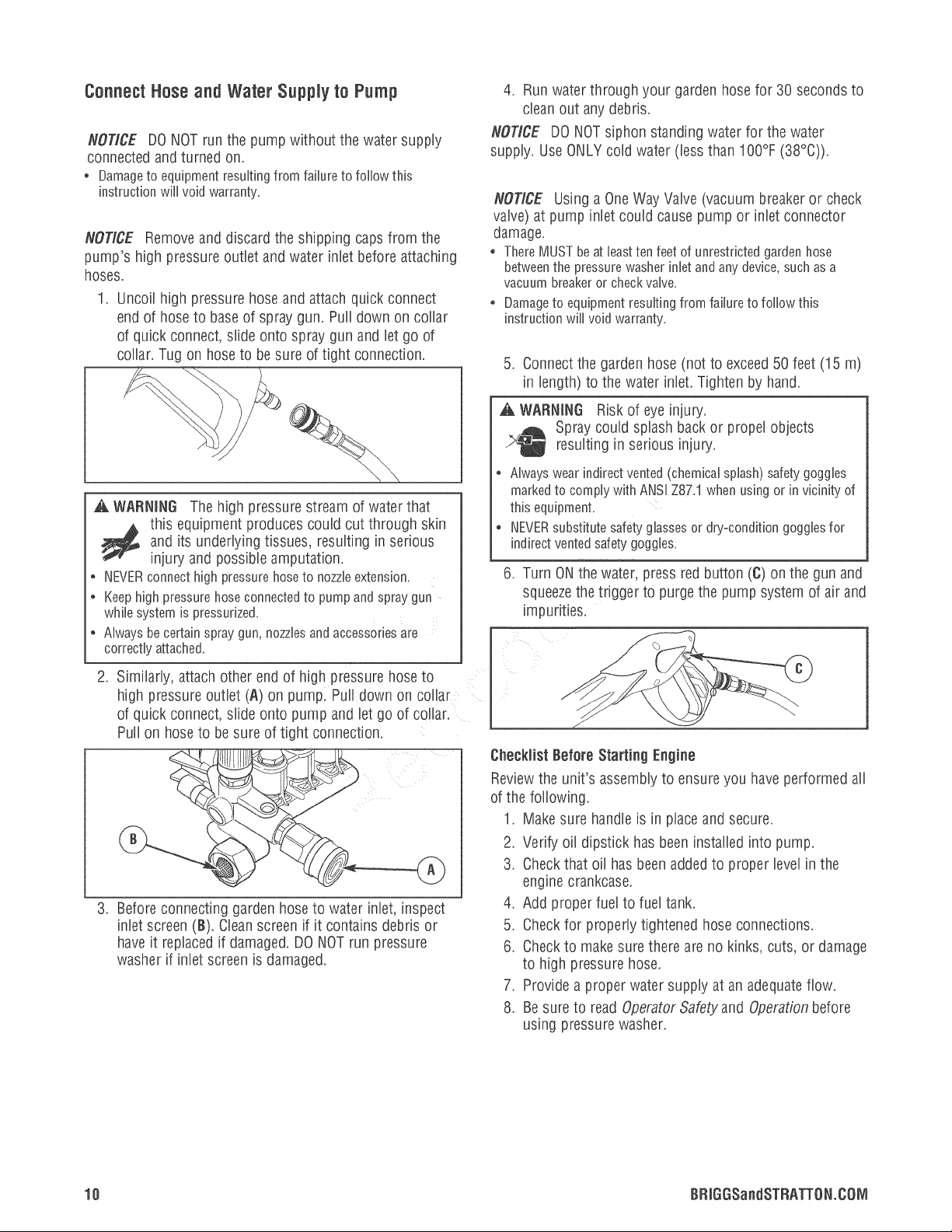

Connect Hose and Water Supply to Pump

NOTICE DO NOTrun the pump without the water supply

connectedand turned on.

, Damagetoequipmentresultingfrom failuretofollowthis

instructionwillvoidwarranty.

NOTICE Remove and discard the shipping caps from the

pump's high pressure outlet and water inlet before attaching

hoses.

1. Uncoil high pressure hoseand attach quick connect

end of hoseto base of spray gun. Pull down on collar

of quickconnect, slide onto spray gun and let go of

collar. Tug on hoseto be sure of tight connection.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

* NEVERconnect highpressure hose to nozzleextension.

Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

,

Similarly, attachother end of high pressure hoseto

high pressure outlet (A) on pump. Pull down on collar

of quickconnect, slide onto pump and let go of collar.

Pull on hose to be sure of tight connection.

,

Beforeconnecting garden hoseto water inlet, inspect

inlet screen(B). Cleanscreen if it contains debris or

haveit replacedif damaged.DONOTrun pressure

washer if inlet screenis damaged.

4. Run water through your garden hosefor 30 secondsto

cleanout anydebris.

NOTICE DO NOTsiphon standing water for the water

supply. UseONLYcold water (less than 100% (38°C)).

NOTICE Using a OneWayValve (vacuum breaker or check

valve) at pump inlet could cause pump or inlet connector

damage.

, ThereMUSTbeatleasttenfeetof unrestrictedgardenhose

betweenthe pressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

* Damageto equipment resulting from failure to follow this

instruction will void warranty.

5. Connectthe garden hose (not to exceed50 feet (15 m)

in length) to the water inlet. Tighten by hand.

WARNING Risk of eyeinjury.

Spray could splash back or propel objects

resulting in serious injury.

* Alwayswear indirect vented (chemical splash) safetygoggles

markedto comply with ANSi Z87.1 when using or in vicinity of

this equipment.

* NEVERsubstitute safety glasses or dry=condition goggles for

indirect vented safety goggles.

6, Turn ONthe water, press red button (C) on the gun and

squeezethetrigger to purgethe pump system of air and

impurities.

Checklist Befere Starting Engine

Reviewthe unit's assemblyto ensureyou haveperformed all

of the following.

1. Make sure handle is in placeandsecure.

2. Verify oil dipstick has beeninstalled into pump.

3. Checkthat oil hasbeen addedto proper level in the

engine crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor properly tightened hoseconnections.

6. Checkto make surethere are no kinks, cuts, or damage

to high pressure hose.

7. Provide aproper water supply at an adequateflow.

8. Be sureto read OperatorSafetyand Operationbefore

using pressurewasher.

10 BRIGGSandSTRATTON.CONI

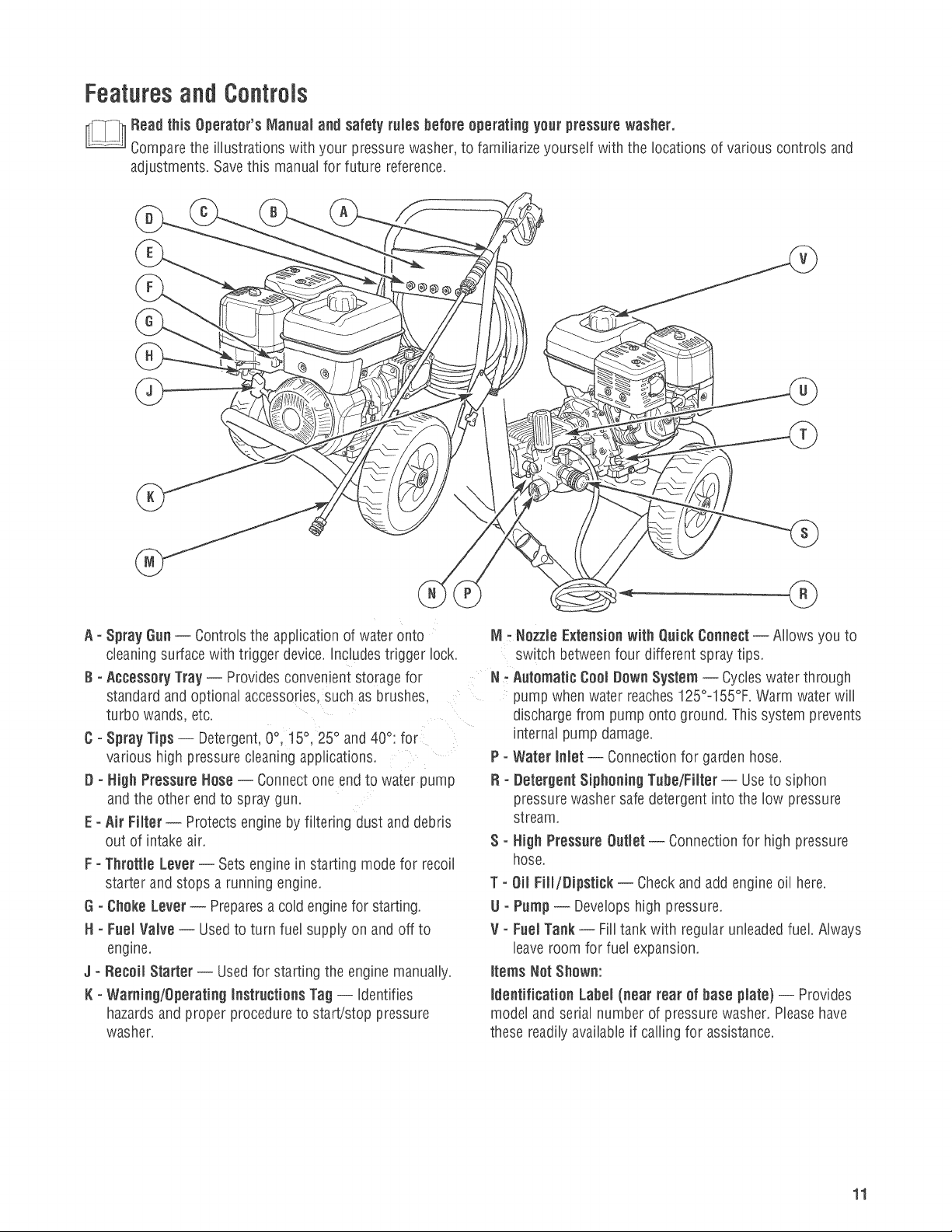

Featuresand Controts

Readthis Operator'sManual and safety rules before operating yourpressurewasher.

Comparethe illustrations with your pressure washer, to familiarizeyourself with the locations of various controls and

adjustments. Savethis manual for future reference.

A ° Spray Gun-- Controls the application of water onto

cleaningsurface with trigger device.Includestrigger lock.

B ° Accessory Tray Provides convenientstorage for

standard and optional accessories, such as brushes

turbo wands, etc.

C° Spray Tips-- Detergent,0°. 15°. 25° and 40°: for

various high pressure cleaning applications.

D ° Nigh PressureNose Connectone endto water pump

and the other end to spray gun.

E °Air Filter Protectsengine by filtering dust and debris

out of intake air.

F °Throttle Lever Sets engine in starting mode for recoil

starter andstops a running engine.

G ° ChokeLever -- Preparesa cold enginefor starting.

H ° Fuel Valve Usedto turn fuel supply on and off to

engine.

S° Recoil Starter Usedfor starting the engine manually.

1(° Warning/Operating instructions Tag identifies

hazardsand proper procedureto staWstop pressure

washer.

iVi- NozzleExtension with Quick Connect Allows you to

switch betweenfour different spray tips,

N =Automatic Coal Dawn System Cycleswater through

pump whenwater reaches125°-155°R Warm water will

dischargefrom pump onto ground, This system prevents

internal pump damage.

P =Water Inlet Connectionfor garden hose.

R =Detergent Siphoning Tube/Niter Useto siphon

pressure washer safe detergent into the low pressure

stream.

S - Nigh Pressure Outlet Connectionfor high pressure

hose.

T - Oil Fill/Dipstick Checkand add engineoil here.

U ° Pump Develops high pressure.

V ° FuelTank Filltank with regular unleadedfuel. Always

leaveroom for fuel expansion.

Hems NatShawn:

identification Label(near rear ef base plate}-- Provides

model and serial number of pressure washer. Pleasehave

these readily availableif calling for assistance.

11

ifyouhaveanyproblemsoperatingyourpressurewasher,

pleasecallthepressurewasherhelplineat(800}743-4115.

Pressure Washer Lecatian

Carben IVlenexidePoisening

WARNING POISONOUS GAS HAZARD. Engine

exhaust contains carbon monoxide, a poisonous

gas that could kill you in minutes. You CANNOT

smell it, see it, or taste it. Even if you do not

smell exhaust fumes, you could still be exposed to carbon

monoxide gas.

, Operatethis product ONLYoutside far awayfrom windows,

doors and vents to reducethe risk of carbon monoxide gas

from accumulating and potentblly beingdrawn towards

occupied spaces,

Install battery-operatedcarbon monoxide abrms or plugqn

carbon monoxide abrms with battery back-up according to the

manufacturer's instructions, Smoke abrms cannot detect

carbon monoxide gas,

, DO NOTrun this product inside homes, garages,basements,

crawbpaces, sheds, or other partially-enclosedspaceseven if

using fans or opening doors and windows for ventilation,

Carbon monoxide canquickly build up in these spacesand can

linger for hours, even after this product has shut off.

ALWAYS placethis product downwind and pointthe engine

exhaustawayfrom occupied spaces,

if you start to feel sick, dizzy, or weak while using this product.

shut it off and getto fresh air RIGHTAWAY See adoctor. You

may havecarbon monoxide poisoning.

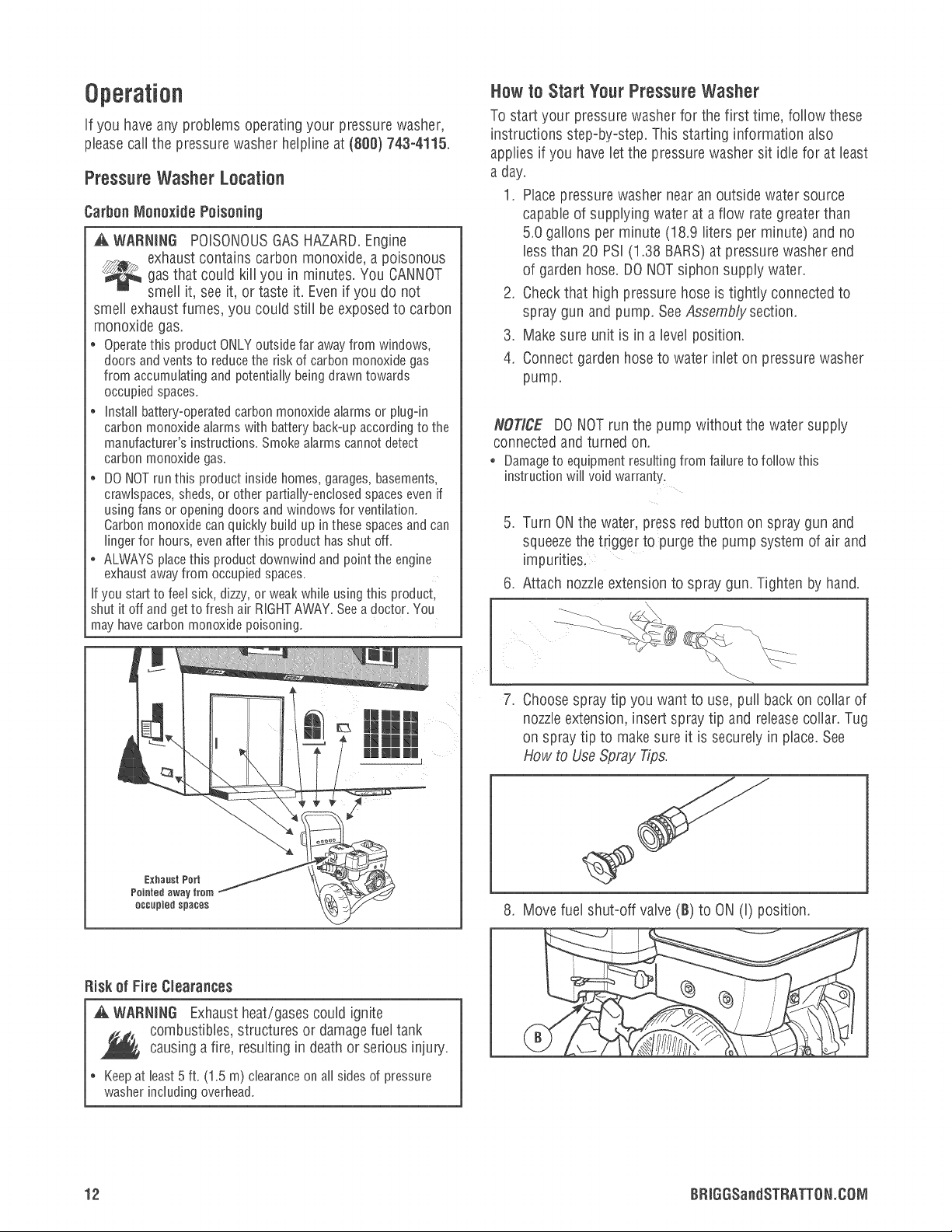

Haw to Start Your Pressure Washer

To start your pressure washer for the first time, follow these

instructions step-by-step. This starting information also

applies if you haveletthe pressure washersit idle for at bast

a day,

1. Placepressure washernear an outside watersource

capableof supplying water at a flow rategreaterthan

5.0 gallons per minute (18.9 liters per minute) and no

less than 20 PSi (1.38 BARS)at pressurewasherend

of gardenhose. DONOTsiphon supplywater.

2. Checkthat high pressure hose is tightly connectedto

spray gun and pump. SeeAssembly section.

3. Make sure unit is in alevel position.

4. Connectgarden hoseto water inlet on pressure washer

pump.

NOTICE DO NOTrun the pump without the water supply

connectedand turned on.

, Damageto equipmentresultingfromfailuretofollowthis

instructionwillvoidwarranty.

5, Turn ONthe water, pressred button on spray gun and

squeezethetrigger to purgethe pump system of air and

impurities.

6. Attach nozzleextensionto spray gun. Tighten by hand.

/

Risk of Fire Ciearanees

A WARNING Exhaustheat/gasescould ignite

combustibles, structuresor damagefuel tank

causing afire, resultingin deathor seriousinjury.

* Keepat least5 ft. (1.5 m) clearanceon all sidesof pressure

washer including overhead.

.

Choosespray tip you want to use, pull back on collar of

nozzleextension, insert spray tip and releasecollar. Tug

on spray tip to makesure it is securely in place. See

How to Use@ray Tips.

.

Move fuel shut-off valve (B) to ON(I) position.

12 BRIGGSandSTRATTON.CONI

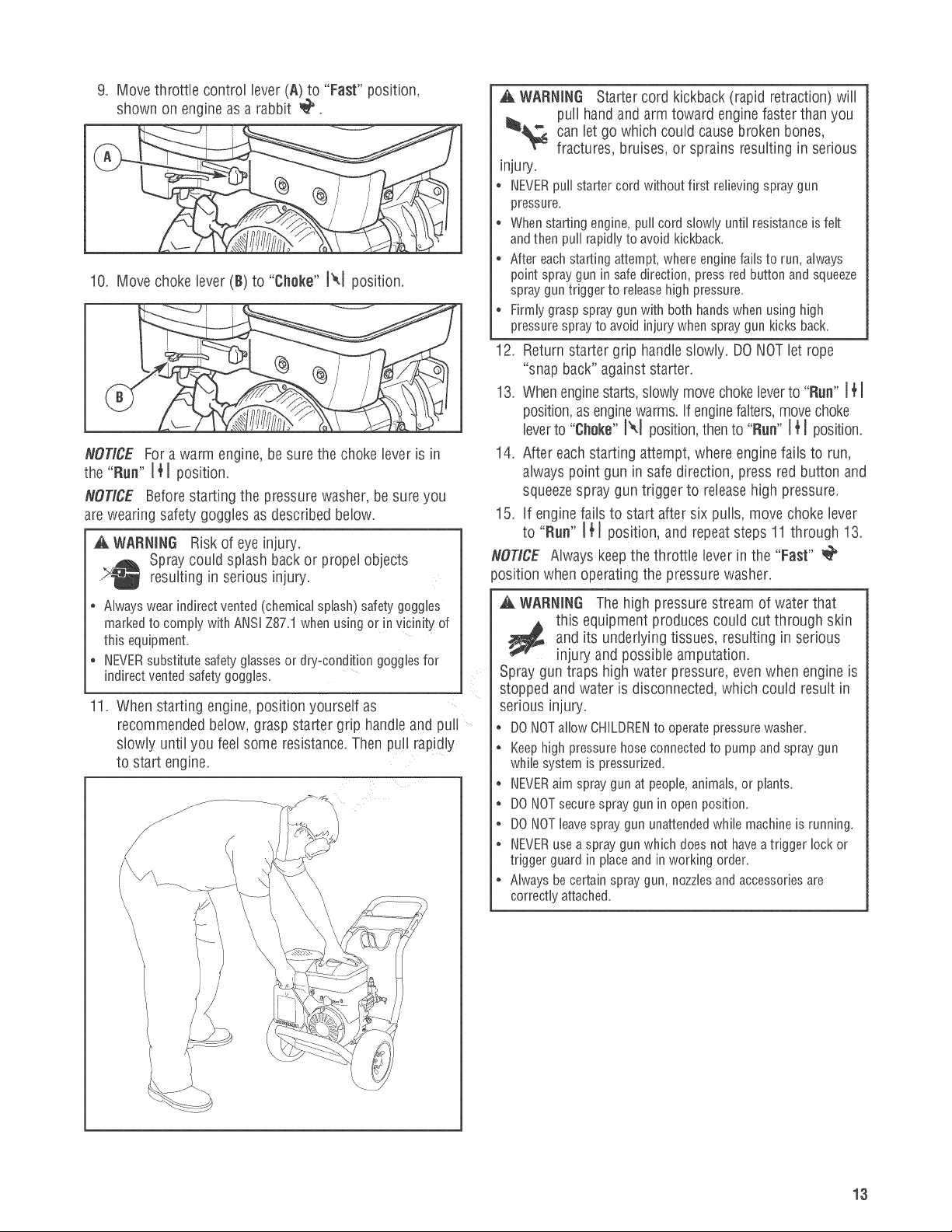

9. Move throttle control lever (A) to "Fast" position,

shown on engineas a rabbit @.

10. Move choke lever (B) to "Cheke" IX1 position.

NOTICE For a warm engine, besure the choke lever is in

the "Run" I JtJposition.

NOTICE Beforestarting the pressurewasher, be sure you

are wearing safety goggles asdescribed below.

WARNING Risk of eyeinjury.

Spraycould splash back or propel objects

resulting in serious injury.

* Always wear indirect vented(chemicalsplash) safety goggles

markedto comply with ANSi Z87A when using or

this equipment.

* NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

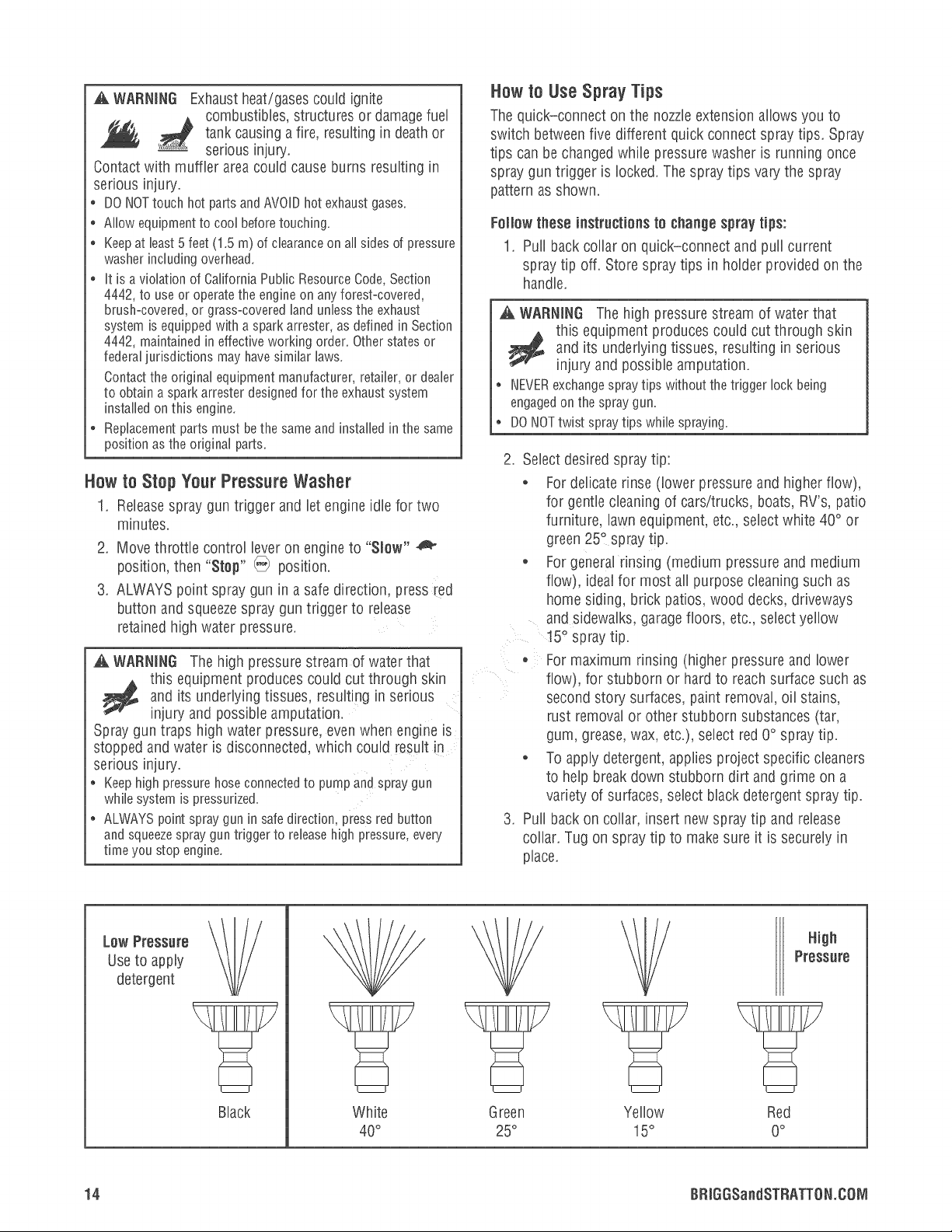

11.

When starting engine, position yourself as

recommended below,grasp starter grip handleand puff

slowly until you feel some resistance. Then pull rapidly

to start engine.

,& WARNING Starter cord kickback (rapid retraction)will

pull hand and arm toward enginefasterthan you

_ can letgo which could causebroken bones,

fractures, bruises, or sprains resulting in serious

injury.

. NEVERpull startercordwithoutfirst relievingspraygun

pressure.

* Whenstartingengine,pullcordslowlyuntil resistanceisfelt

andthenpull rapidlytoavoidkickback.

* Aftereachstartingattempt,whereenginefailsto run,always

pointspraygunin safedirection,pressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

* Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

12. Return starter grip handle slowly. DONOTlet rope

"snap back" against starter.

13. Whenenginestarts, slowlymovechokeleverto "Run" J+I

position,as enginewarms, if enginefalters,movechoke

leverto "Choke" IXI position,thento "Run" IJtJ position.

14. After eachstarting attempt, where engine fails to run,

always point gun in safe direction, press red button and

squeezespray gun trigger to releasehigh pressure.

15. if engine fails to start after six pulls, move choke lever

to "Run" I_tJ position, and repeatsteps 11 through 13.

NOTICE Always keepthe throttle lever in the "Fast" @

position when operating the pressure washer.

_. WARNIN6 The high pressurestream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray guntraps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

. DONOTallowCHILDRENto operatepressurewasher.

* Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* NEVERaimspraygunat people,animals,or plants.

* DONOTsecurespraygunin openposition.

* DONOTleavespraygununattendedwhilemachineis running.

* NEVERuseaspraygunwhichdoesnothaveatriggerlockor

triggerguardinplaceandin workingorder.

* Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

13

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death or

serious injury.

Contact with muffler area could cause burns resulting in

serious injury.

, DO NOTtouch hot parts and AVOID hot exhaust gases.

Allow equipment to cool before touching.

Keepat least5 feet (1.5 m) of clearanceon ail sides of pressure

washer including overhead.

it is aviolation of California PuNic Resource Code, Section

4442, to use or operate the engineon anyforest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equipped with aspark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrester designed for the exhaust system

installed on this engine.

Replacement parts must be the sameand installed in the same

position as the original parts.

New t{) Step Y{)ur Pressure Washer

1. Releasespray gun trigger and let engine idle for two

minutes.

2. Move throttle control lever on engine to "Slaw" 41-

position, then "Step" (_} position.

3. ALWAYSpoint spray gun in a safedirection, pressred

button and squeezespray gun trigger to release

retainedhigh water pressure.

A WARNING The high pressure streamof water that

this equipment produces could cutthrough skin

and its underlying tissues, resulting in serious

injury and possible amputation,

Spraygun traps high water pressure, evenwhen engineus

stopped and water is disconnected, which could result i

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

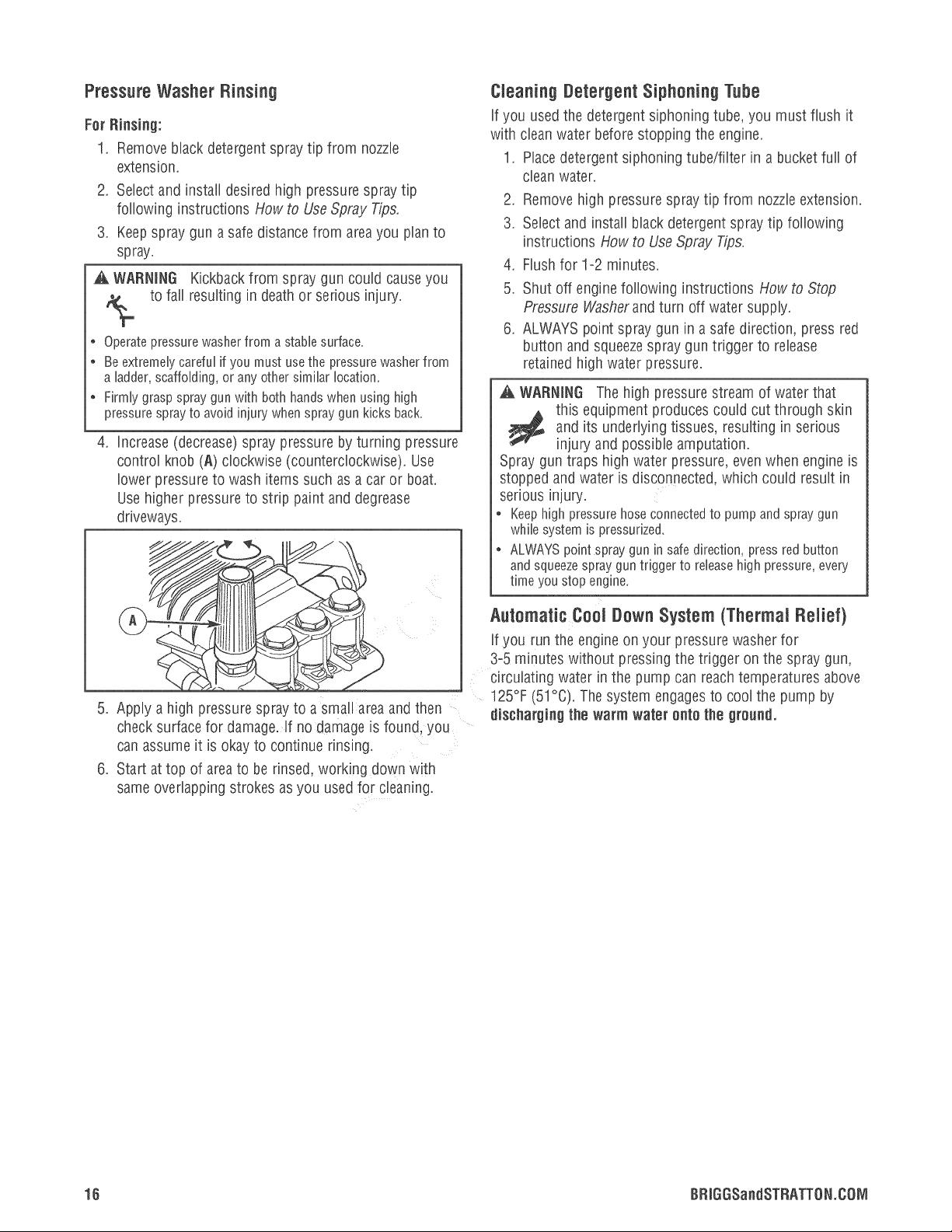

New to Use Spray Tips

Thequick-connect on the nozzleextension allows you to

switch betweenfive different quick connect spray tips. Spray

tips can be changedwhile pressure washer is running once

spray gun trigger is locked.Thespray tips vary the spray

pattern asshown.

Fallow these instructionsto change spray tips:

1. Pull back collar on quick-connect and pull current

spray tip off. Store spraytips in holder provided on the

handle.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

. NEVERexchangespraytipswithoutthetriggerlockbeing

engagedonthe spraygun.

* DONOTtwistspraytipswhilespraying.

2. Select desiredspray tip:

° For delicate rinse (lower pressure and higher flow),

for gentlecleaning of cars/trucks, boats, RV's,patio

furniture, lawn equipment, etc, selectwhite 40° or

green 25° spray tip.

* Forgeneral rinsing (medium pressure and medium

flow), idealfor most all purposecleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garagefloors, etc, selectyellow

15° spray tip.

* For maximum rinsing (higher pressure and lower

flow), for stubborn or hard to reach surface such as

second story surfaces, paint removal, oil stains,

rust removal or other stubborn substances (tar,

gum, grease,wax, etc.), select red0° spraytip.

* To apply detergent,applies project specificcleaners

to helpbreakdown stubborn dirt and grime on a

variety of surfaces, select blackdetergent spray tip.

3. Pull back on collar, insert newspray tip and release

collar. Tug on spray tip to make sure it is securely in

place.

LOwPressure

Useto apply

detergent

Black White

40°

Green Yellow

25° 15°

Red

0o

14 BRIGGSandSTRATTON.CONI

UsageTips

, For most effective cleaning,keepspray tip from 8 to

24 inches (20 to 61 cm) awayfrom cleaning surface.

, if you get spray tip too close, especiallyusing a high

pressure spray tip, you may damagesurface being

cleaned.

, DO NOTget closer than 6 inches (15 cm) when

cleaningtires.

Cleaning and Applying Detergent

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in death

or serious injury.

* DO NOTuse caustic liquid with pressure washer,

* Use ONLYpressurewasher safe detergents/soaps, Follow all

manufacturers instructions,

To apply detergent, fallow these steps:

1, Reviewuse of spray tips.

2. Preparedetergent solution as requiredbyjob.

3. Placesmall filter end of detergent siphoning tube into

detergent container.

NOTICE Make surethe filter is fully submerged in detergent

whib applying detergent.

5. Make sure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray

gun and pump. Turn on water.

NOTICE You must attach all hoses before you start the

engine.

, Starting the engine without all the hoses connected and without

the water turned ONcould damagethe pump,

* Damageto equipment resulting from failure to follow this

instruction will void warranty.

6. Start enginefollowing instructions How to Start Your

Pressure Washer.

7. Apply detergentto a dry surface, starting at lower

portion of areato be washedand work upward, using

long, even,overlapping strokes.

8. Allow detergentto "soakin"for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surfacefrom drying. DO NOTallow detergentto dry on

(prevents streaking).

NOTICE You must flush the detergent siphoning system

after eachuseby placingthe filter into a bucket of clean

water, then run the pressure washer in low pressure for 1-2

minutes.

NOTICE Contact with the hot muffler could damage

detergent siphoning tube.

, When inserting the siphon into adetergent solution bottle, route

the tube so as to keep it from inadvertently contacting the hot

muffler,

4. Make sure black detergent spraytip is installed.

NOTICE Detergent cannot be appliedwith the high pressure

spray tips (White, Green,Yellow or Red).

15

Pressure Washer Rinsing

ForRinsing:

1. Removeblack detergentspray tip from nozzle

extension.

2. Select and install desired high pressure spray tip

following instructions How to UseSpray Tips.

3. Keepspray gun asafe distance from areayou plan to

spray.

WARNING Kickbackfrom spray gun could causeyou

to fall resulting in deathor serious injury.

* Operatepressurewasher from a stable surface.

* Beextremely careful if you must use the pressurewasherfrom

a ladder,scaffolding, or any other similar location.

Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

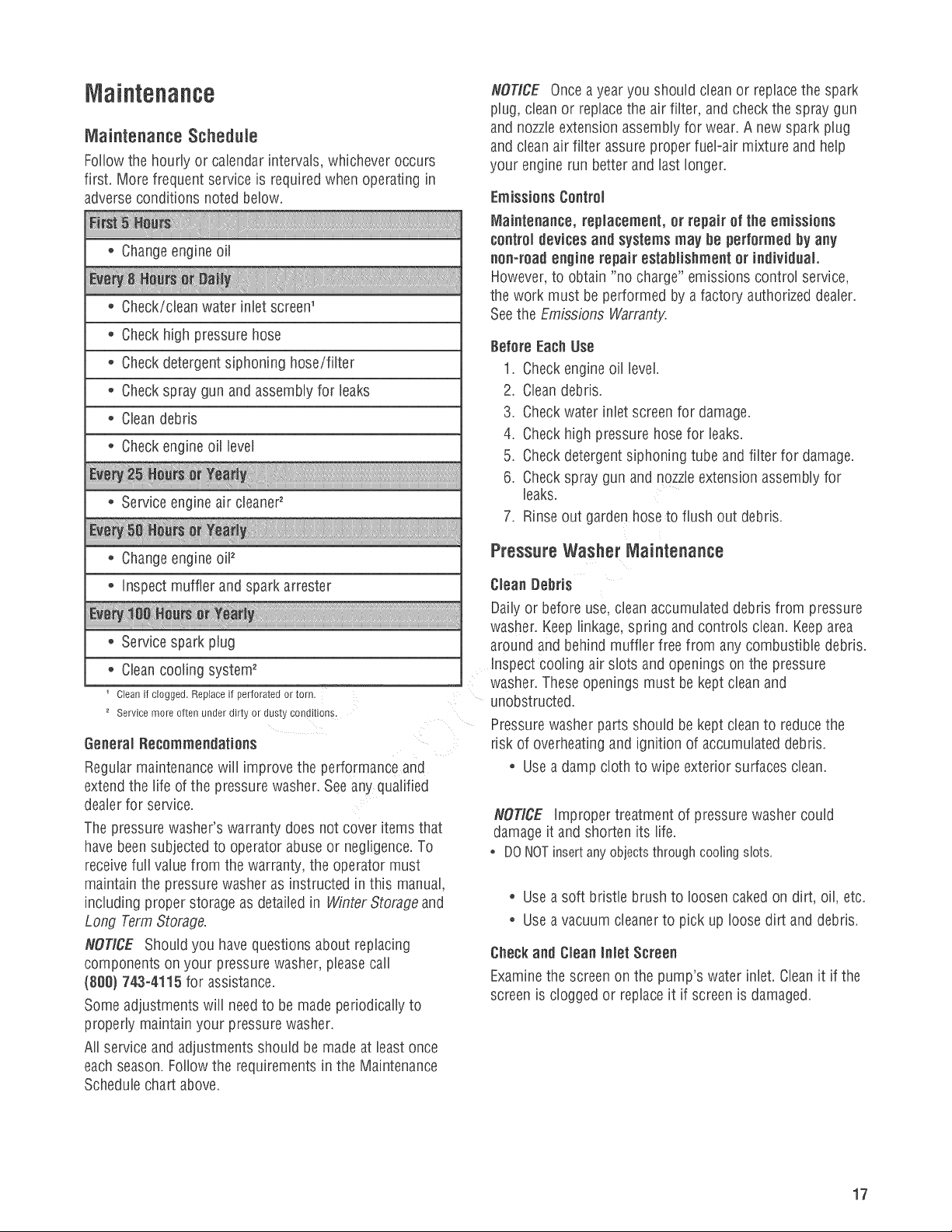

.

increase (decrease) spray pressure by turning pressure

control knob (A) clockwise (counterclockwise). Use

lower pressureto wash items suchas acar or boat,

Usehigher pressureto strip paint and degrease

driveways.

Cleaning Detergent $iphenJng Tube

if you used the detergentsiphoning tube, you must flush it

with cleanwater before stopping the engine.

1. Placedetergent siphoning tube/filter in a bucket full of

cleanwater.

2. Removehigh pressure spray tip from nozzleextension.

3. Select and install black detergent spray tip following

instructions How to UseSpray Tips.

4. Flush for 1°2 minutes.

5. Shut off engine following instructions How to Stop

Pressure VVasherandturn off watersupply_

6. ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to release

retained highwater pressure.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray guntraps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

5. Apply a high pressure sprayto asmall area andthen

check surfacefor damage, if no damage usfound you

can assumeit is okayto continue rinsing.

6. Start at top of areato be rinsed, working down with

same overlapping strokes asyou Jsedfor cleaning.

Automatic Coo[ Down System (Thermal Relief)

if you run the engineon your pressure washerfor

3-5 minutes without pressingthe trigger on the spray gun,

circulating water in the pump can reachtemperatures above

125°F (51°C),The system engagesto cool the pump by

discharging the warm water ente the ground.

16 BRJGGSandSTRATTON.CONJ

Maintenance

Maintenance Schedule

Follow the hourly or calendarintervals, whichever occurs

first. More frequent serviceis required when operating in

adverseconditions noted below.

o Changeengineoil

o Check/clean water inlet screen1

o Checkhigh pressure hose

o Checkdetergentsiphoning hose/filter

o Checkspray gun and assemblyfor leaks

o Cleandebris

o Checkengineoil level

o Service engineair cleaned

HOTICE Once ayear you should clean or replacethe spark

plug, clean or replacethe air filter, and check the spray gun

and nozzleextension assembly for wear. A new spark plug

and cleanair filter assure properfuebair mixture and help

your enginerun better and last longer.

EmissionsCantrai

IViaintenance, repiacemenL ar repair af the emissians

central devices and systems may he performed by any

nan-read engine repair esial_lisi_ment or individual,

However,to obtain "no charge" emissions control service,

the work must be performed by afactory authorized dealer.

Seethe Emissions V@rranty.

Before Eacll Use

1, Checkengineoil level.

,

Cleandebris.

3.

Checkwater inlet screen for damage.

4.

Check

high pressure hose for leaks.

5.

Check

detergentsiphoning tube and filter for damage.

6.

Check

spray gun and nozzleextension assemblyfor

leaks.

.

Rinse

out gardenhoseto flush out debris.

o Service spark plug

o Cleancooling system_

1 Clean if clogged, Replace if perforated or torn.

Service more often under dirty or 8us_y conamons.

General Recommendations

Regular maintenancewill improve the performance and

extendthe life of the pressure washer. Seeany qualified

dealerfor service.

The pressurewasher's warranty does not cover items that

havebeen subjectedto operator abuseor negligence.To

receivefull valuefrom the warranty,the operator must

maintain the pressure washer as instructed in this manual,

including proper storage as detailedin Winter Storageand

Long TermStorage.

HOT/CE Should you have questions about replacing

components on your pressure washer, pleasecall

(888) 743o4115for assistance.

Someadjustments will needto be made periodically to

properly maintainyour pressure washer.

All serviceand adjustments should bemade at bast once

eachseason. Follow the requirementsin the Maintenance

Schedulechart above.

PressureWasher l aintenance

Clean Behris

Dailyor before use, cleanaccumulated debris from pressure

washer. Keeplinkage,spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

inspect cooling air slots and openings on the pressure

washer.These openings must be kept cleanand

unobstructed.

Pressurewasher pads should bekept cleanto reducethe

risk of overheatingand ignition of accumulated debris.

o Use a damp cloth to wipe exterior surfaces clean.

HOTICE improper treatment of pressure washer could

damageit and shorten its life.

DONOTinsertanyobjectsthroughcoolingslots,

o Use a soft bristle brush to loosen cakedon dirt, oil, etc.

o Use a vacuum cleanerto pick up loose dirt and debris.

Checkand Clean Inlet Screen

Examinethe screenon the pump's water inlet. Cleanit if the

screen is clogged or replaceit if screen is damaged.

17

Loading...

Loading...