Briggs & Stratton 020477-00 Owner’s Manual

$$ure

®

This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association

(PWMA) standard PWI01 (Testing and Rating Performance of PressureWashers).

BRMGG$& STRATTONPOWER PROBUCT$ GROUP, LLC

0

MMLWAUKEE,WM$CONSMN,U.S.A. Manual No. 315264GS Revision-

Thank youfor purchasingthis quality-built Briggs & Stratton@ pressurewasher. We are pleasedthat you've placedyour

confidence inthe Briggs & Stratton brand. When operatedand maintainedaccording to the instructions in this manual, your

Bdggs & Stratton pressurewasher will provide manyyears of dependableservice.

Thismanual contains safety information to makeyou awareof the hazardsand risks associatedwith pressure washersand

how to avoid them. BecauseBriggs & Stratton does not necessarily know allthe applications this pressure washer could be

usedfor, it is important that you readand understandthese instructions thoroughly before attempting to stad or operatethis

equipment. Savethese original instructionsfar future reference.

This pressurewasher requires final assembly before use. Referto the Assembly section of this manualfor instructions on

final assembly procedures.Follow the instructions completely.

Where te Find Us

Younever haveto lookfar to find Briggs & Stratton support and servicefor your pressure washer.Thereare thousands of

Briggs & Stratton authorizedservicedealers worldwide who provide quality service. You canalso find the nearestAuthorized

Service Dealerin our dealer Iocator map on the Internet at BRIGGSandSTRATTON.COM.

Pressul'e Washer

Model Number

Revision

Serial Number

Engine

Model Number

Type Number

Code Number

Date Purchased

Copyright © 2011. Briggs & Stratton PowerProducts Group, LLC

Milwaukee, Wl, USA.All rights reserved.

BRIGGS& STRATTONPOWERPRODUCTSis aregistered

trademark of Briggs & Stratton Corporation

Milwaukee, Wl, USA

2 BRIGGSandSTRATTON.COM

Table of Contents

Operation .................................... 12

PressureWasher Location..................................... 12

How to Stad Your PressureWasher ............................. 12

How to Stop Your PressureWasher ............................. 14

How to UseAccessory Tray.................................... 14

How to Use SprayTips ....................................... 15

Cleaningand Applying Detergent................................ 15

PressureWasher Rinsing ..................................... 16

CleaningDetergent Siphoning Tube.............................. 16

Automatic Cool Down System (Thermal Refiefl..................... 16

Maintenance .................................. 17

MaintenanceSchedule........................................ 17

PressureWasher Maintenance ................................ 17

Engine Maintenance.......................................... 19

After EachUse.............................................. 21

Winter Storage.............................................. 22

Long Term Storage .......................................... 22

Treubiesheeting ................................ 23

Warranties .................................... 24

PressureWasher OwnerWarranty............................... 24

Espa_ol Portugu_,s

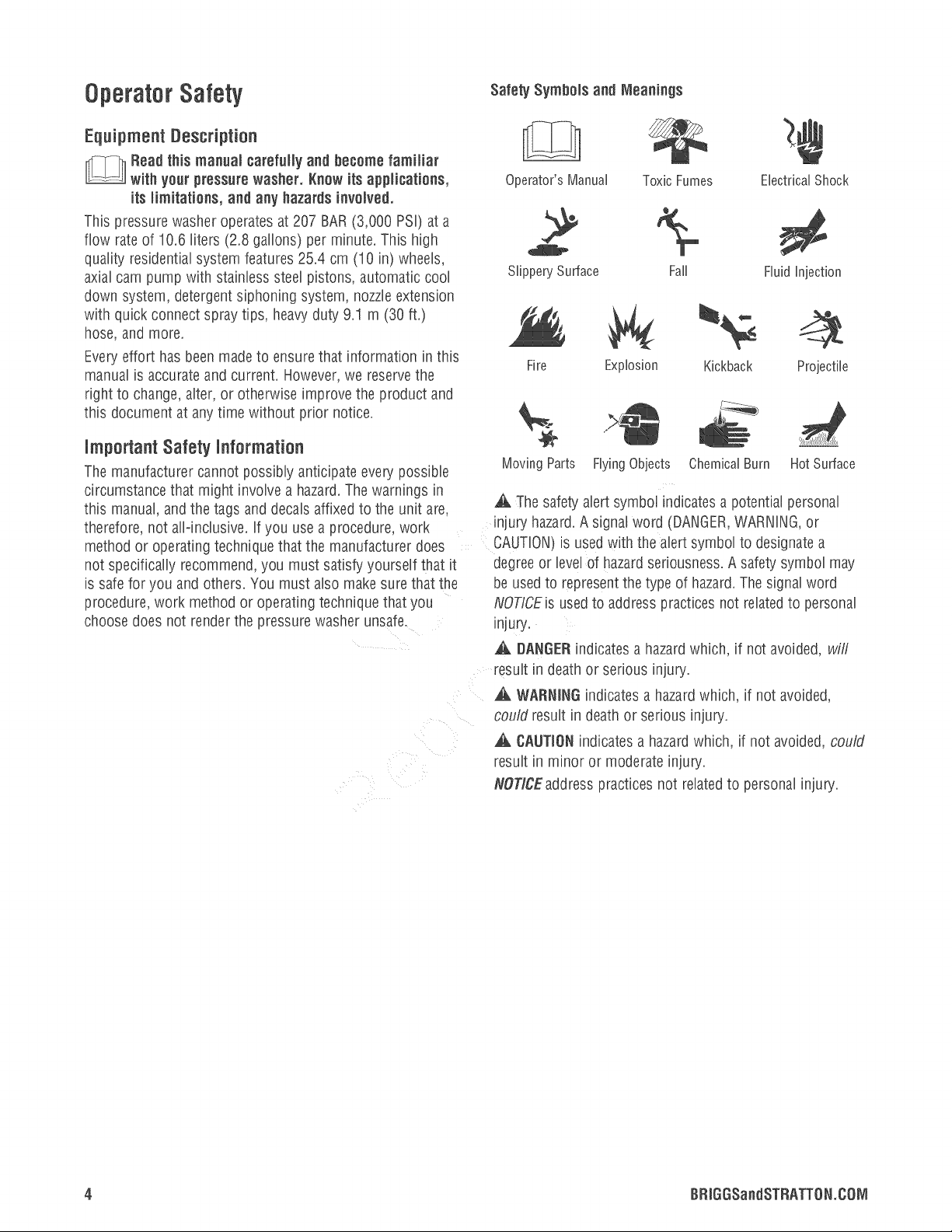

OperatorSafety

Equipment Description

Safety Symbols and Meanings

Read _hi$ ITlanuaJ carefuJJy and become familiar

withyourpressurewasher. Enowits applications,

its limitations,and any hazardsinvolved.

This pressurewasher operatesat 207 BAR(3,000 PSi) ata

flow rateof 10.6 liters (2.8 gallons) per minute. This high

quality residential system features 25.4 cm (10 in) wheels,

axialcam pump with stainless steel pistons, automatic cool

down system, detergentsiphoning system, nozzleextension

with quick connect spray tips, heavy duty 9.1 m (30 ft.)

hose, and more.

Everyeffort has been madeto ensurethat information in this

manual is accurate and current. However,we reservethe

right to change,alter, or otherwise improve the product and

this document at any time without prior notice.

Mmpertant Safety Mnfermatien

The manufacturercannot possibly anticipateevery possible

circumstance that might involve a hazard.The warnings in

this manual,and the tags and decalsaffixedto the unit are,

therefore, not all-inclusive, if you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safefor you and others. You must also make surethat the

procedure, work method or operating techniquethat you

choose does not renderthe pressurewasher unsafe.

Operator's Manual Toxic Fumes

SlipperySurface

Fire Kickback Projectile

Moving Parts FlyingObjects ChemicalBurn Hot Surface

Explosion

Fall

ElectricalShock

Fluid Injection

The safetyalertsymbol indicatesa potential personal

injury hazard A signalword (DANGER,WARNING,or

CAUTION_s usedwith the alert symbol to designatea

degreeor levelol hazardseriousness.A safety symbol may

be usedto representthetype of hazard.Thesignal word

NOTICEis usedto address practicesnot relatedto personal

injury.

BANGERindicatesa hazardwhich, if not avoided, wifl

result in death or serious injury.

WARNINGindicates a hazardwhich, if not avoided,

couid result in death or serious injury.

,a_CAUTIONindicates ahazardwhich, if not avoided, couid

result in minor or moderate injury.

NOT/CEaddresspractices not relatedto personal injury.

4 BRIGGSBndSTRATTON.COM

WARNENG Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

Some chemicals or detergents could be harmful if inhaled

or ingested, resulting in death, serious injury, nausea,

fainting or poisoning.

o Operatethis product ONLYoutdoors.

Keepexhaustgas from entering a confined areathrough

windows, doors, ventilation intakes, or other openings.

DO NOToperatethis product insideany building, carport,

porch, mobile equipment, marine applications, or enclosure,

evenif windows and doors are open.

Use a respirator or maskwheneverthere is a chancethat

vapors may beinhaled when using chemicals.

Readall instructions with mask so you are certain the mask will

provide the necessaryprotection against inhaling harmful

vapors when using chemicals.

A WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

DO NOTtouch hot parts and AVOID hotexhaust gases.

Allow equipment to cool before touching.

Keepat least1.5 m (5 ft) of clearanceon all sides of pressure

washer including overhead.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrester designed for the exhaust system

installed on this engine.

Replacement parts must be the sameand installed in the same

position as the original parts.

A WARNENG Riskof electrocution. 1

Contactwith power source could causeelectric 1

shock or burn resulting in death or seriou s injury. 1NEVERspraynearpowersource.

A WARNING Use of pressure washer could create puddles

and slippery surfaces causing you to fall

resulting in death or serious injury.

Kickback from spray gun could cause

you to fall resulting in death or serious injury.

Operatepressurewasher from a stable surface.

Thecleaning areashould have adequateslopesanddrainageto

reducethe possibility of a fall due to slippery surfaces.

Beextremely careful if you must use the pressurewasher from

a ladder,scaffolding, or any other similar location.

Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

,a, WARNING Fueland its vapors are extremely flammable

and explosive which could cause burns,

fire or explosion resulting in death,

serious injury and/or property damage.

WHENADDING ORBRAiNiNG FUEL

. Turn pressurewasher engineOFFand let it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

o Fill or drain fuel tank outdoors.

. DONOToverfill tank. Allow spacefor fuel expansion.

, if fuel spills, wait until it evaporates beforestarting engine.

Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

Checkfuel lines, tank, cap and fittings frequently for cracks or

leaks. Replaceif necessary.

DONOTlight a cigarette or smoke.

WHENSTARTINGEQUIPMENT

* Ensurespark plug, muffler,fuel cap,and air cleanerare in place.

* DO NOTcrank enginewith spark plugremoved.

WHENOPERATINGEQUIPMENT

* DO NOToperatethis product inside any building, carport,

porch, mobile equipment, marine applications, or enclosure.

o DONOTtip engine or equipment at anglewhich causes fuel to

spill

DONOTsprayfiammabb liquids.

WHENTRANSPORTING,MOVING OR REPAiRiNG EQUIPMENT

Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

DONOTtip engine or equipment at anglewhich causesfuel to

spill.

Disconnectspark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUEL iN TANK

Store awayfrom furnaces, stoves,water heaters,clothes

dryers, or otherappliancesthat have pilot light or other ignition

source becausethey could ignite fuel vapors.

_, WARNING Starter cord kickback (rapid retraction) will

pull hand and arm toward engine faster than you

can let go which could cause broken bones,

fractures, bruises, or sprains resulting in serious

injury.

NEVERpull starter cord without first relieving spray gun

pressure.

When starting engine, pull cord slowly until resistanceis felt

andthen pull rapidly to avoid kickback.

After each starting attempt, where enginefails to run, always

point spray gun in safedirection, pressred button and squeeze

spray guntrigger to releasehigh pressure.

Firmly grasp spray gun with both handswhen using high

pressure sprayto avoid injury when spray gun kicks back.

,a, WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in death,

serious injury, and/or property damage.

DO NOTuse caustic liquid with pressure washer.

Use ONLYpressurewasher safe detergents/soaps. Followall

manufacturers instructions.

WARNING The high pressure stream of water that

_, his equipment produces could cut through skin

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

. if cut byfluid, call physician immediately. DONOTtreat as a

* DONOT allow CHILDRENto operate pressure washer.

* NEVERrepairhigh pressure hose.Replaceit.

* NEVERrepairleaking connections with sealantof any kind.

* NEVERconnect high pressure hose to nozzleextension.

* Keep high pressure hose connectedto pump and spraygun

* ALWAYS point spray gun in safedirection, press red button

* NEVERaim spray gun at people,animals, or plants.

* DO NOTsecure spraygun in open position.

* DO NOTleavespray gun unattendedwhile machine is running.

* NEVERusea spray gun which does not have atrigger lock or

* Always be certain spray gun, nozzlesand accessoriesare

and its underlying tissues, resulting in serious

injury and possible amputation.

simple cut.

Replaceo-ring or seal.

while system is pressurized.

andsqueezespray gun trigger to releasehigh pressure, every

time you stop engine.

trigger guardin placeand in working order.

correctly attached.

A WARNING Unintentionalsparking could causefire or

electric shock resulting n death or

serious injury.

WRENADJUSTINGOR MAKING REPAIRSTO YOURPRESSURE

WASHER

* Disconnect the spark plug wire from the spark plugand place

the wire where it cannot contact spark plug_

WHENTESTINGFORENGINESPARK

* Use approved spark plug tester.

, DONOTcheckfor spark with spark plugremoved.

A WARNING Starter and other rotating parts could

resulting in serious injury.

entangle hands, hair, clothing, or accessories

, NEVERoperatepressure washerwithout protective housing or

covers.

° DO NOTwear looseclothing, jewelry or anythingthat could be

caught in the starter or other rotating parts.

° Tie up long hair and removejewdry.

A WARNING Riskof eyeor bodily injury.

Spraycould splash back or propel

objects resulting in serious injury.

,, Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSi Z87.1 when using or in vicinity of

this equipment.

* NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

* Always wear protective clothing such asa long-sleeved shirt,

long pantsand close-toed shoes.

* NEVERoperate pressure washerwhen barefoot or wearing

sandalsor shorts.

A CAUTION Excessively high operating speeds could

result in minor injury and/or pressure washer damage.

Excessively low speeds impose a heavy load.

. DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Pressurewasher supplies correct rated

pressure and flow when running at governed speed.

* DO NOTmodify pressure washer in any way.

NOTICE High pressure spraycould damage fragile items

including glass.....

DONOTpointspraygunatglasswhenusingred(0°)spraytip.

, NEVERaimspraygunat plants.

NOTICE mproper treatment of pressure washer could

damage it and shorten its life.

,, if you havequestions about intended use,ask dealeror contact

qualified service center.

* NEVERoperate units with brokenor missing parts, or without

protective housing or covers.

* DO NOTby-pass any safety device on this machine.

* DONOTtamper with governedspee&

* DONOT operate pressurewasher above ratedpressure.

DONOTmodify pressurewasher in any way.

Beforestarting pressure washer in cold weather, check all parts of

the equipment to be sure ice has not formed there.

NEVERmove machine by pulling on hoses. Use handleprovided

on uniL

This equipment is designed to be usedwith Briggs & Stratton

Power Products authorized parts ONLY.if equipment is used with

parts that DONOTcomply with minimum specifications, user

assumesall risks andliabilities.

6 BRIGGSandSTRATTON.COM

Yourpressurewasherrequiressomeassemblyandisready

foruseafterithasbeenproperlyservicedwiththe

recommendedoilandfuel.

if you have anyproblems with the assemblyof your pressure

washer, contactyour local Briggs &Stratton service center.

if you needassistance, pleasehavethe model, revision, and

serial number from the identification label available.

Unpack Pressure Washer

1. Removethe parts bag,accessories, and inserts

included with pressure washer.

2. Opencarton completely by cutting eachcorner from

top to bottom.

3. Ensureyou haveaft included items prior to assembly.

Hems inthe cartoninclude:

o Main Unit

o Handle

o High Pressure Hose

o Spray Gun

o NozzleExtensionwith Quick ConnectFitting

o Plastic AccessoryTray

o Oil Bottle

o Parts Bag(which includesthe following/:

o Operator's Manual

o GardenHose Adapters (3)

o Bag containing 5 Multi-Colored Spray Tips

o HandleFasteningHardwareKit(which includes_:

o CarriageBolts (2)

o Plastic Knobs (2)

o TreeClips (4)

Ta prepareyourpressurewasherfar aperatien, youwiii

need to perform these tasks:

1. Attach handleand accessorytray to main unit.

2. Add oil to engine crankcase.

3. Add fuel to fuel tank.

4. Connecthigh pressure hoseto spray gun and pump.

5. Connectwater supply to pump.

6. Attach nozzleextensionto spray gun.

7. Select/attachquick connect spray tip to nozzle

extension.

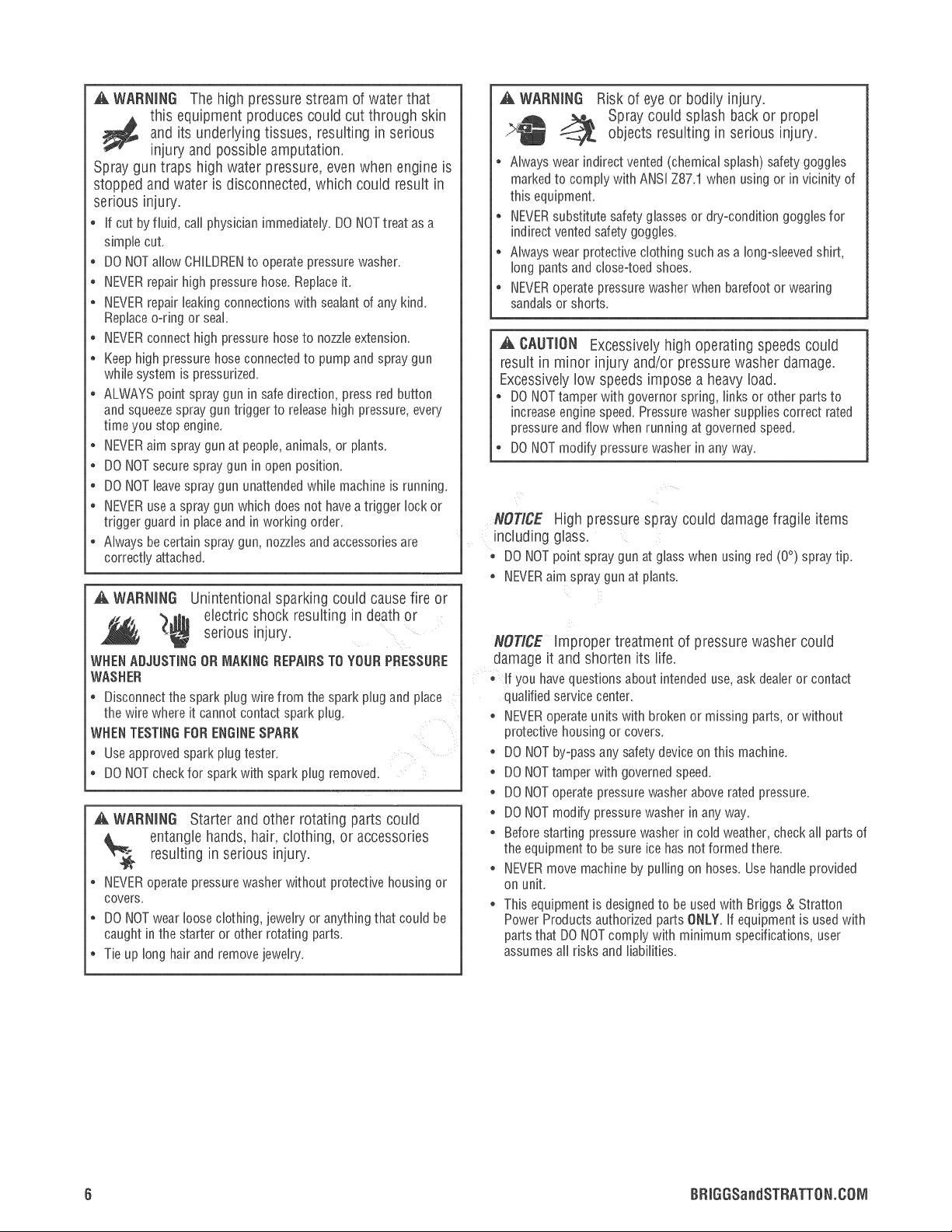

Attach Nandle and Accessery Tray

1. Placehandle (A) onto handlesupports (B) connectedto

main unit. Makesure holes (C) in handle afignwith

holes (C) on handlesupports.

NOTICE it may benecessaryto movethe handle supports

from sideto side in order to align the handle so it will slide

over the handle supports.

2. insert carriage bolts (B) through holesfrom back of

unit andattacha plastic knob (F) from front of unit.

Tighten by hand.

Placeaccessory tray (F) over holes (G) on handle

(viewing from front of unit). Pushthe tree clips (N) into

the holes until they sit fiat against the accessorytray.

4_

insert multi-colored spray tips and other supplied

accessoriesin spacesprovided in accessorytray. See

How to UseAccessory Tra}:

Add Engine Oil

1. Placepressure washeron a fiat, level surface.

2, Cleanareaaround oil fill and removeyellow oil fill cap.

3, Using oil funnel (optional), slowly pour contents of

supplied oil into oil fill opening, frequently checkingoil

level, DONOTOVERFILL.

NOTICE improper treatment of pressure washer could

damage it and shorten its life.

, DO NOTattempt to crank or start the engine beforeit has been

properly servicedwith the recommended oil.This could result in

an enginefailure.

4, Replaceoil fill cap and fully tighten.

Add Fuel

Fuel must meet these requirements:

, Clean,fresh, unleadedgasoline.

, A minimum of 87 octane/87 AKI (91 RON).Forhigh

altitude use, see Nigh Aititude.

, Gasolinewith up to 10%ethanol (gas@@ or up to

15% MTBE(methyl tertiary butyl ether) is acceptable.

WARNING Fueland its vapors areextremelyflammable

andexplosivewhich could causeburns,

fire or explosionresulting in death,

seriousinjury and/orproperty damage.

WHENADDINGFUEL

* Turn pressurewasher engineOFFandlet it cool at least 2

minutes before removingfuel cap. Loosen cap slowly to relieve

pressure in tank.

Fill fuel tank outdoors.

* DONOT overfill tank. Allow spacefor fuel expansion.

if fuel spills, wait until it evaporatesbefore starting engine.

Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

Checkfuel fines,tank, cap andfittings frequently for cracks or

leaks. Replaceif necessary.

DONOTlight a cigarette or smoke.

1, Cleanarea aroundfuel fill cap, remove cap,

2. Slowly add regular unleadedfuel (A) to fuel tank (B). Be

careful notto overfill, Allow about 4 cm (1,5 in,) (C) of

tank space for fuel expansion.

NOTICE Avoid pressure washer damage.

Failureto follow Operator's Manual for fuel

recommendations voidswarranty,

DONOTuseunapprovedgasolinesuchasE85,

DONOTmixoil ingasoline,

DONOTmodifyengineto runonalternatefuels,

To protect the fuel system from gum formation, mix in a fuel

stabilizerwhen adding fuel. SeeStorage.AI fuel is not the

same. if you experiencestarting or performance problems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline.The

emission control system for this engine is EM IEngine

Modifications).

3. Install fuel cap and let anyspilled fuel evaporatebefore

starting engine.

High Altitude

At altitudes over 1524 m (5,000 ft), a minimum 85 octane

85 AKI (89 RON)gasoline is acceptable.To remain

emussionscompliant, high altitude adjustment is required.

Operationwithout this adjustment will causedecreased

performance, increasedfuel consumption, and increased

emussions.SeeanAuthorized Briggs & Stratton dealerfor

high altitude adjustment information. Operationof the engine

at altitudes below 762 m (2,500 ft) with the high altitude kit

is not recommended.

8 BRIGGSandSTRATTON.CONI

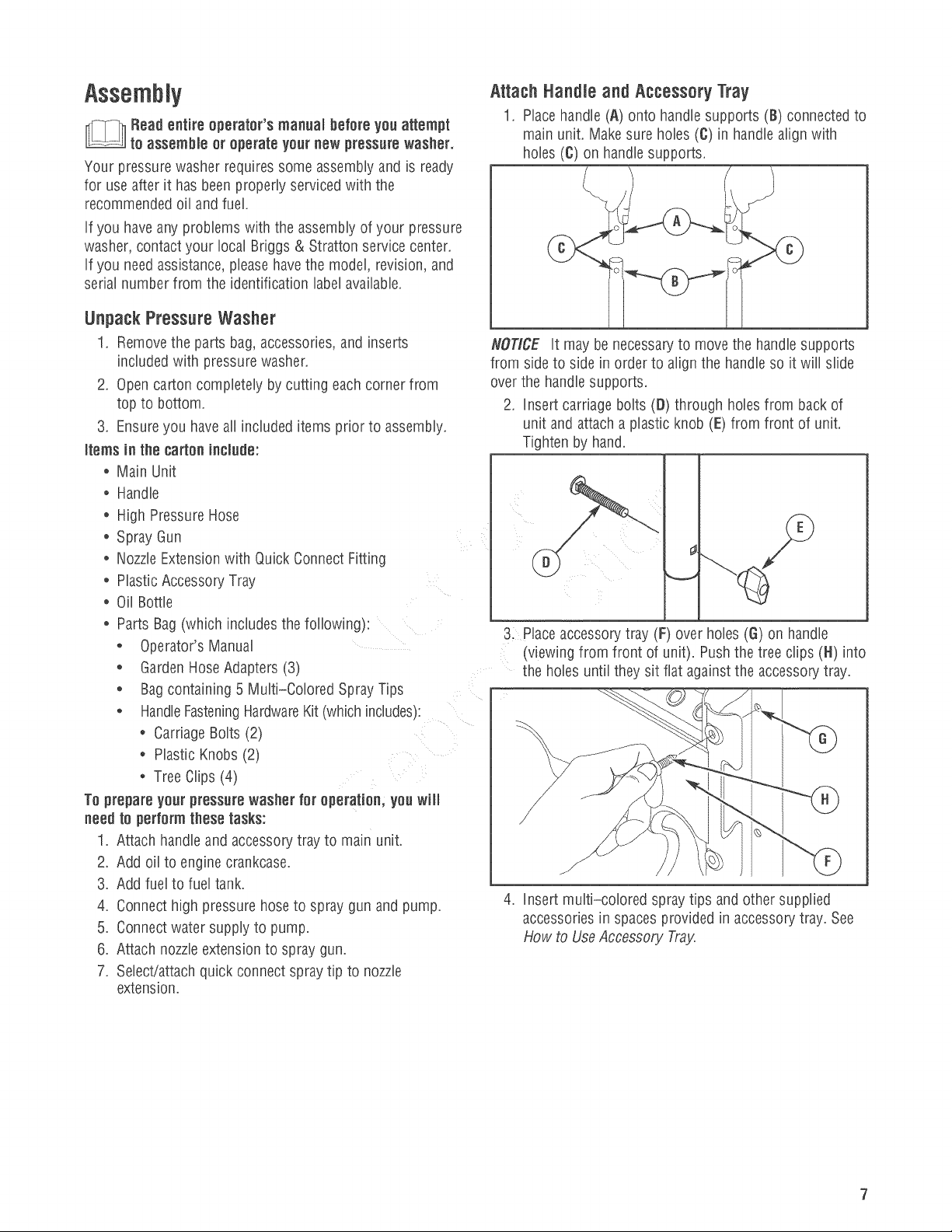

Lubricate OoRings

Lubrication of o-rings is extremelyimportant for installation

and operation. The useof a lubricant (petroleum or synthetic

grease)during assembly helpsseat o-rings properly and

provides an improved seal. it also helps protect the o-ring

from damageby abrasion,pinching or cutting and extends

the life of the o-ring.

NOTICE ALWAYSapplya small amount of lubricant on

o-rings prior to assemblingthe garden hoseto the pump (A),

high pressure hose (B), spraygun (C), and nozzle

extension(D).

Lubricateaii connections shownbelow, following these

instructions:

1. inspect and cleanconnecting surfaces priorto

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light film is

all that is required.

3. Use a small brush or cotton swabto apply grease

directly to oorings wherethey are not accessible(QC

fitting, M22 fitting).

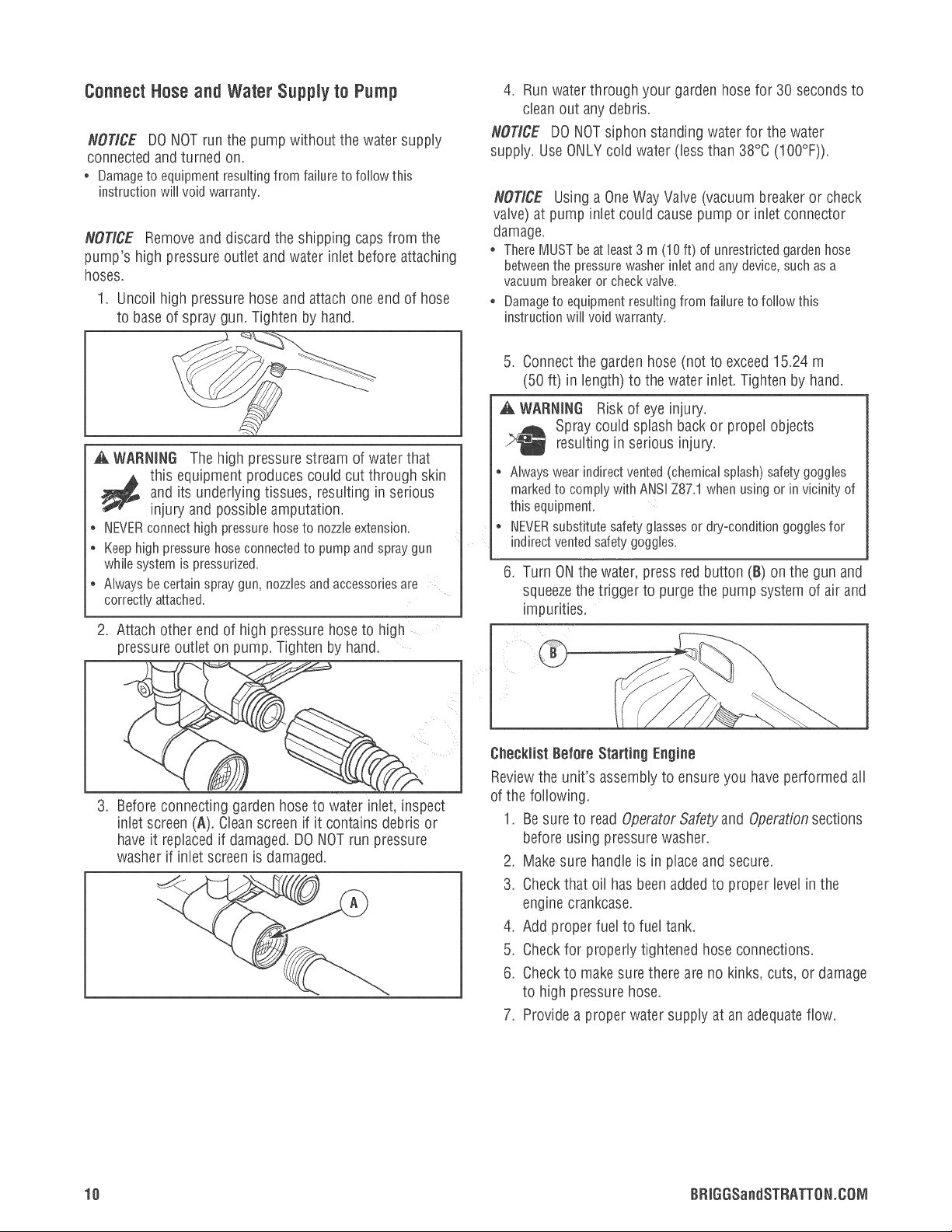

Connect Hose and Water Supply to Pump

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

, Damagetoequipmentresultingfrom failuretofollowthis

instructionwillvoidwarranty.

NOTICE Removeand discard the shipping caps from the

pump's high pressure outlet and water inlet before attaching

hoses.

1. Uncoil high pressure hoseand attach one end of hose

to baseof spray gun. Tighten by hand.

WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

* NEVERconnect high pressure hose to nozzleextension.

* Keep high pressure hose connectedto pump and spraygun

while system is pressurized.

* Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

2. Attach other end of high pressure hoseto high

pressure outlet on pump. Tighten by hand.

4. Run water through your garden hosefor 30 secondsto

cleanout anydebris.

HOTICE DONOTsiphon standing water for the water

supply. UseONLYcold water (less than 38°C (100°F)).

NOTICE Usinga OneWayValve (vacuum breaker or check

valve) at pump inlet could cause pump or inlet connector

damage.

ThereMUSTbeatleast3 m(10ft) ofunrestrictedgardenhose

betweenthe pressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

* Damageto equipment resulting from failure to follow this

instruction will void warranty.

5. Connectthe garden hose (not to exceed15.24 m

(50 ft) in length) to the water inlet. Tighten by hand.

A WARNING Riskof eyeinjury.

Spray could splash back or propel objects

resulting in serious injury.

* Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSi Z8X1 when using or in vicinity of

this equipment.

* NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

6. Turn ONthe water, press red button (B) onthe gun and

squeezethetrigger to purgethe pump system of air and

impurities.

,

Beforeconnecting garden hoseto water inlet, inspect

inlet screen(A). Cleanscreen if it contains debris or

haveit replacedif damaged.DONOTrun pressure

washer if inlet screenis damaged.

I

Checklist Before Starting Engine

Reviewthe unit's assemblyto ensureyou haveperformed all

of the followi%

1. Be sureto read Operator Safetyand Operafionsections

before using pressure washer.

2. Make sure handle is in placeand secure.

3. Checkthat oil has been addedto proper level in the

engine crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor properly tightened hoseconnections.

6. Checkto make surethere are no kinks, cuts, or damage

to high pressure hose.

7. Provide aproper water supply at an adequateflow.

10 BRIGGSandSTRATTON.C01Vl

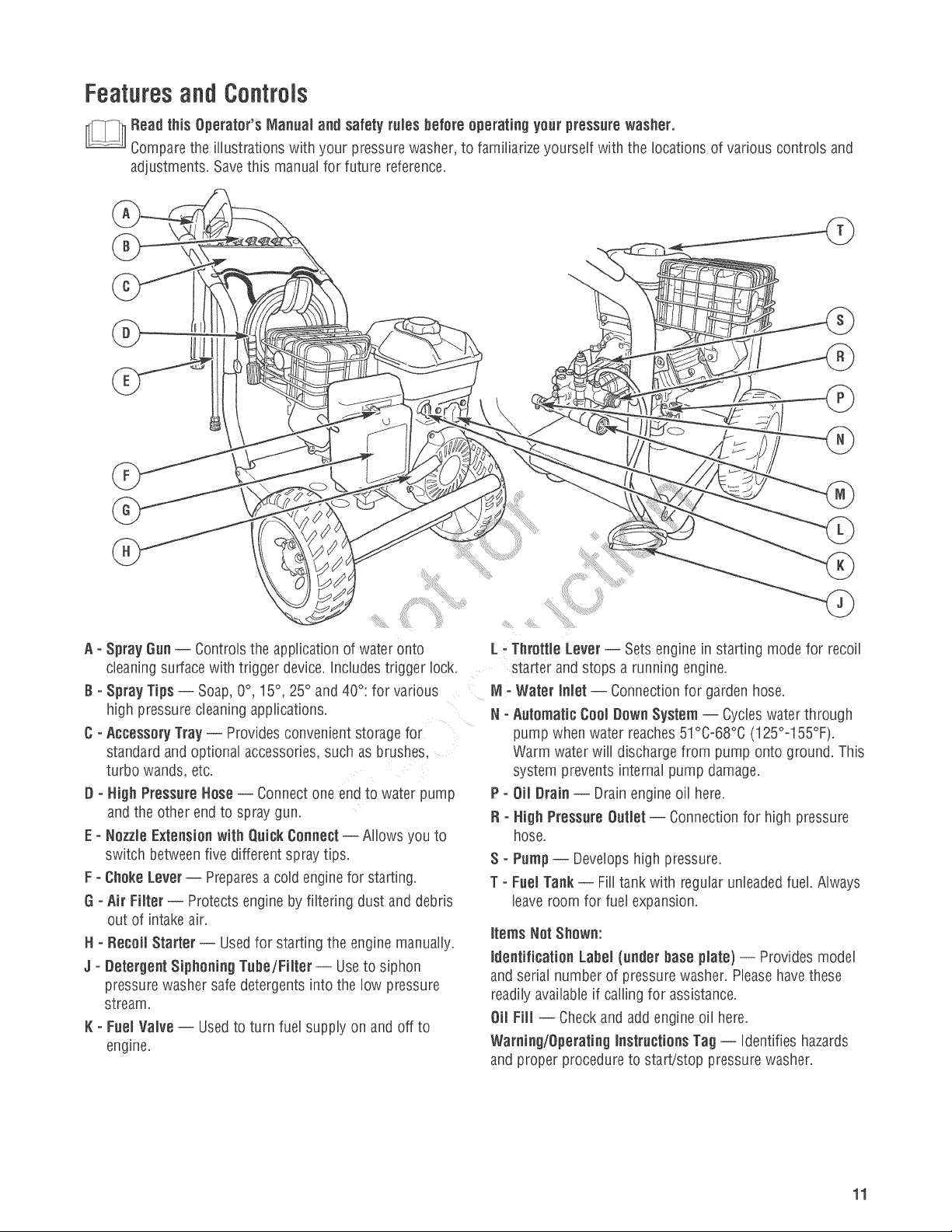

Featuresand Controts

Readthis Operator's Manual and safety rules before operating yourpressurewasher.

Comparethe illustrations with your pressure washer, to familiarizeyourself with the locations of various controls and

adjustments. Savethis manual for future reference.

A ° Spray Gun-- Controlsthe application of water onto

cleaningsurface with trigger device.Includestrigger lock.

B ° Spray Tips Soap,0°, 15°, 25° and 40°: for various

high pressure cleaning applications.

C° Accessory Tray Provides convenient storage for

standard and optional accessories, such as brushes

turbo wands, etc.

D ° High Pressure Nose Connectone endto water pump

and the other end to spray gun.

E ° NozzleExtension with QaiekConnect-- Allows you to

switch betweenfive different spray tips.

F -Choke Lever Preparesacold enginefor starting.

G - Air Filter Protects engineby filtering dust and debris

out of intake air.

H - Recoil Starter Usedfor starting the engine manually.

S- Detergent Siphoning Tube/Filter- Useto siphon

pressure washer safedetergents into the low pressure

stream.

K - Fuel Valve-- Usedto turn fuel supply on and off to

engine,

L =Throttle Lever Setsenginein starting mode for recoil

starter andstops a running engine.

IVl- Water Inlet Connectionfor garden hose.

N ° Automatic Cool Down System Cycleswater through

pump when water reaches51°0-68°0 (125°o155°F).

Warm water will discharge from pump onto ground. This

system prevents internal pump damage.

P = 0il Brai_ Drainengine oil here.

R ° High Pressure Outlet Connectionfor high pressure

hose.

S ° Pump Developshigh pressure.

T ° Fuel Tank Fill tank with regular unleadedfuel. Always

leaveroom for fuel expansion.

items Not Shown:

identification Label(under base plate} -- Provides model

and serial number of pressure washer. Pleasehavethese

readilyavailable if calling for assistance.

0il Fill -- Checkand add engine oil here.

Warning/Operating EnstructionsTag- identifies hazards

and proper procedure to staWstop pressure washer.

11

ifyouhaveanyproblemsoperatingyourpressurewasher,

pleasecontactthelocalBriggs&Strattonservicecenter.

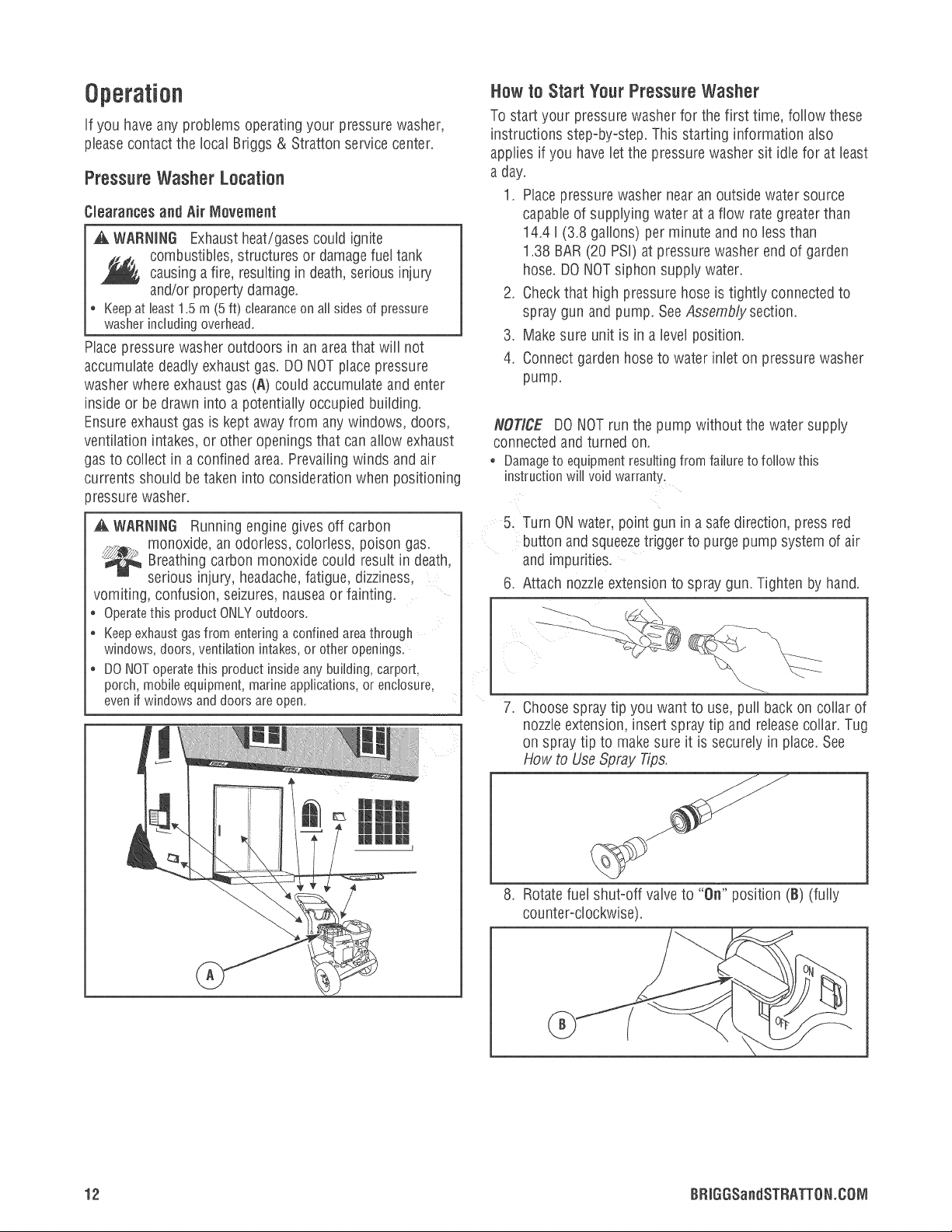

Pressure Washer Location

Clearances and Air Movement

WARNINt] Exhaustheat/gasescould ignite

combustibles, structuresor damagefuel tank

causing afire, resultingin death,serious injury

and/or property'damage.

o Keepat least1.5 m (5ft)clearanceonail sidesof pressure

washerincludingoverhead.

Placepressure washeroutdoors in an areathat will not

accumulate deadlyexhaustgas. DO NOTplacepressure

washer where exhaustgas (A) could accumulate and enter

inside or be drawn into a potentially occupiedbuilding.

Ensureexhaust gas is kept awayfrom anywindows, doors,

ventilation intakes,or other openingsthat can allow exhaust

gasto collect in aconfined area. Prevailing winds and air

currents should be takeninto considerationwhen positioning

_ressurewasher.

A WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide could result in death,

serious injury, headache, fatigue, dizziness,

vomiting, confusion, seizures, nausea or fainting.

Operatethis product ONLY outdoors.

Keepexhaustgas from entering a confined areathrough

windows, doors, ventilation intakes, or other openings.

DO NOToperatethis product insideany building, carport,

porch, mobile equipment, marine applications, or enclosure,

evenif windows and doors are open.

Haw to Start Your Pressure Washer

To start your pressure washer for the first time, foflow these

instructions step-by-step. This starting information also

@pries if you haveletthe pressure washer sit idle for at bast

a day.

1. Placepressure washernear an outside water source

capableof supplying water at a flow rategreaterthan

14.4 I (3.8 gallons) per minute and no lessthan

1.38 BAR(20 PSi) at pressure washer end of garden

hose. DONOTsiphon supply water.

2. Checkthat high pressure hoseis tightly connectedto

spray gun and pump. SeeAssembly section.

3. Make sure unit is in a level position.

4. Connectgarden hoseto water inlet on pressure washer

pump.

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

Damageto equipmentresultingfromfailuretofollowthis

instructionwillvoidwarranty,

.

Turn ONwater, point gun in a safedirection, press red

button andsqueezetrigger to purge pump system of air

and impurities.

6. Attach nozzleextensionto spray gun. Tighten by hand.

.

Choosespray tip you want to use, puff back on collar of

nozzleextension, insert spray tip and releasecollar. Tug

on spray tip to makesure it is securely in place. See

How to Use@ray Tips.

.

/

12 BRIGGSandSTRATTON.CONI

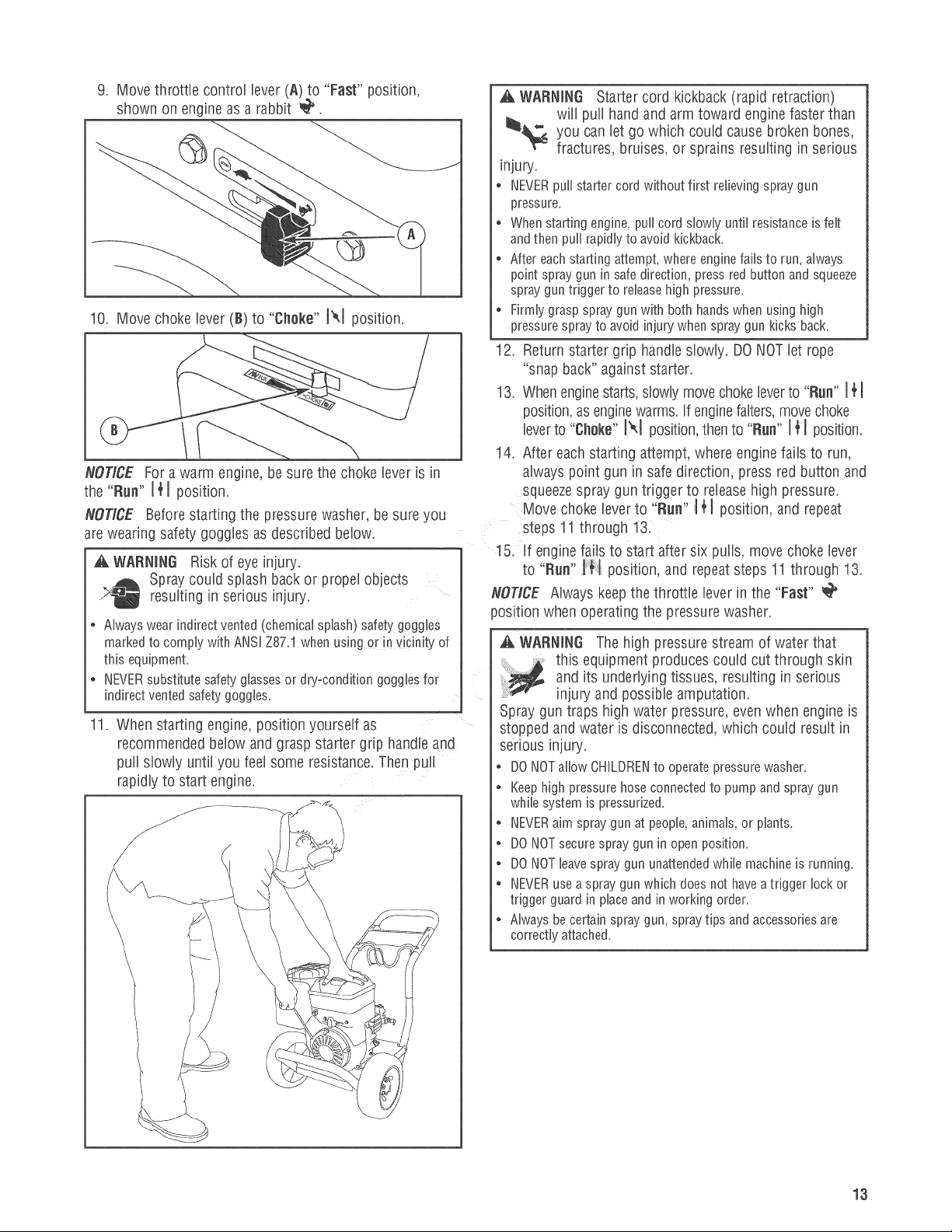

Rotatefuel shut-off valve to "On" position (B) (fully

counter-clockwise).

,

Move throttle control lever (A) to "Fast" position,

shown on engineas a rabbit @.

10. Move choke lever (B) to "Cheke" IX1 position.

NOTICE Fora warm engine, be sure the choke lever is in

the "Run" I{J position.

NOTICE Beforestarting the pressurewasher, besure you

are wearing safety goggles asdescribed below.

WARNING Riskof eyeinjury.

Spraycould splash back or propel objects

resulting in serious injury.

* Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSi Z87.1 when using O(in vMnity of

this equipment.

* NEVERsubstitute safetyglasses or dry-condition goggles for

indirect vented safety goggles.

11.

When starting engine, position yourself as

recommended below and grasp starter grip handle and

pull slowly until you feel some resistance. Thenpuff

rapidly to start engine.

A WARNING Starter cord kickback (rapid retraction)

will pull hand and arm toward engine faster than

_ you can let go which could cause broken bones,

fractures, bruises, or sprains resulting in serious

injury.

, NEVERpull starter cord without first relieving spray gun

pressure.

* When starting engine,pull cord slowly until resistance isfelt

andthen pull rapidly to avoid kickback.

* After eachstarting attempt, where enginefails to run, always

point spray gun in safedirection, pressred button and squeeze

spray guntrigger to releasehigh pressure.

* Firmly grasp spray gun with both handswhen using high

pressure sprayto avoid injury when spray gun kicks back.

12. Return starter grip handle slowly. DONOTlet rope

"snap back" against starter.

13. Whenenginestarts, slowlymovechokeleverto "Run" J_tI

position,as enginewarms, if enginefalters,movechoke

leverto "Cheke" IXI position,thento "Run" IJtl position.

14. After eachstarting attempt, where engine fails to run,

always point gun in safe direction, press red button and

squeezespray gun trigger to releasehigh pressure.

Move choke lever to "Run" I _tt position, and repeat

steps 11through 13.

15. if engine fails to start after six pulls, move choke lever

to Nun I position, and repeatsteps 11 through 13.

NOTICE Alwayskeepthe throttle leverin the "Fast" @

sosition when operating the pressurewasher.

A WARNING The highpressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray guntraps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

, DONOTallowCHILDRENto operatepressurewasher.

* Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* NEVERaimspraygunat people,animals,or plants.

* DONOTsecuresprayguninopenposition.

* DONOTleavespraygununattendedwhilemachineis running.

* NEVERuseaspraygunwhichdoesnothaveatriggerlockor

triggerguardinplaceandin workingorder.

* Alwaysbecertainspraygun,spraytipsandaccessoriesare

correctlyattached.

13

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

, DO NOTtouch hot parts and AVOID hotexhaust gases.

Allow equipment to cool before touching.

Keepat least1.5 m (5 ft) of clearanceon all sides of pressure

washer including overhead.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrestor designed for the exhaust system

installed on this engine.

Replacement parts must be the sameand installed in the same

position as the original parts.

Now to Stop Your Pressure Washer

1. Releasespray gun trigger and let engine idlefor two

minutes.

2. Move throttle control lever onengine to "Slow"

position then to "Stop" _ position.

3. Move fuel valve to "Off" position.

4. ALWAYSpoint gun in a safe direction, press red button

and squeezespray gun trigger to releaseretainedhigh

water pressure.

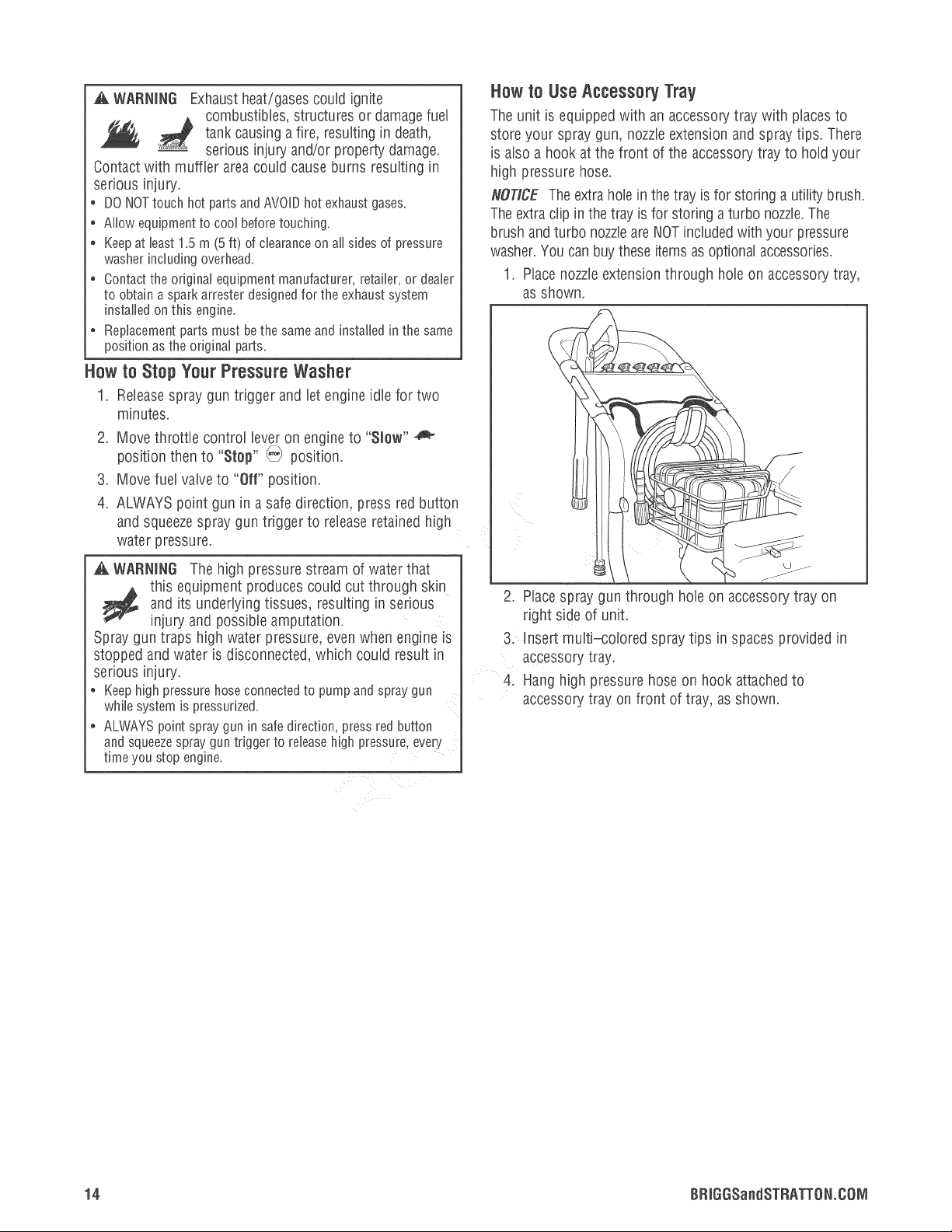

Newte UseAccessory Tray

Theunit is equipped with an accessorytray with placesto

store your spray gun, nozzb extension and spray tips. There

is abe a hook atthe front of the accessorytray to holdyour

high pressure hose.

NOTICE Theextrahob in the tray is for storing a utility brush.

Theextraclip in the tray isfor storing a turbo nozzle.The

brush andturbo nozzleare NOTincluded with your pressure

washer.You canbuytheseitemsas optionalaccessories.

1. Placenozzleextension through hob on accessorytray,

as shown.

A WARNING The high pressure stream of waterthat

and its underlying tissues, resulting in serious

this equipment produces could cutthrough skin

injury and possible amputation.

Spraygun traps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

2. Placespray gun through hob on accessory tray on

right side of unit.

3. insert multi-colored spray tips in spacesprovided in

accessorytray.

4. Hang high pressure hoseon hook attachedto

accessorytray onfront of tray, as shown.

14 BRIGGSendSTRATTON.CONI

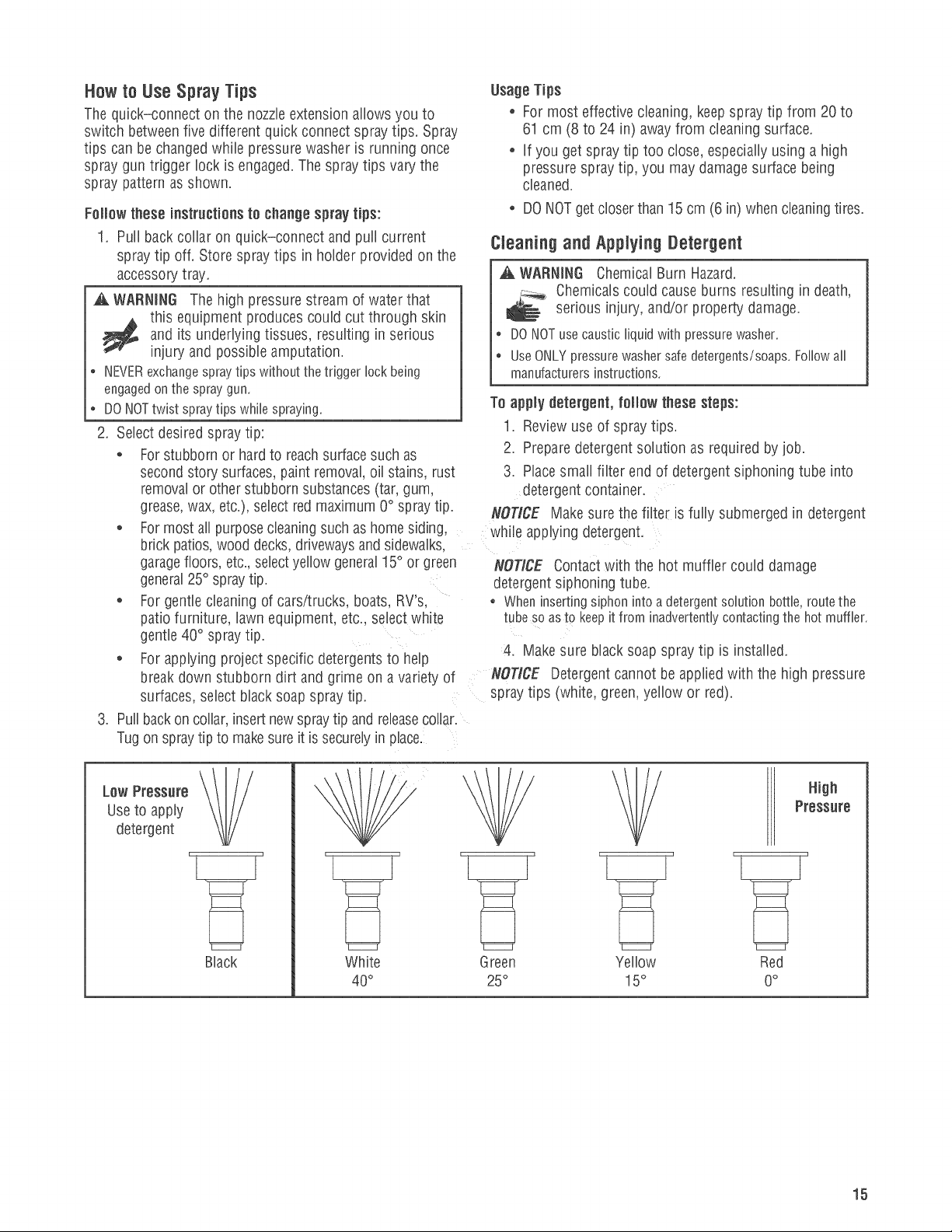

Hewto Use Spray Tips

The quick-connect on the nozzleextension allows you to

switch betweenfive different quick connect spray tips. Spray

tips can be changedwhile pressurewasher is running once

spray gun trigger lock is engaged.Thespray tips vary the

spray pattern as shown.

Fallow these instructionsto change spray tips:

1. Pull back collar on quick-connect andpull current

spray tip offi Store spray tips in holder provided on the

accessorytray.

WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cutthrough skin

injury and possible amputation.

o NEVERexchangespraytipswithoutthetriggerlockbeing

engagedonthe spraygun.

o DONOTtwist spraytips whilespraying.

2. Select desired spray tip:

o Forstubborn or hardto reachsurface such as

secondstory surfaces,paint removal,oil stains, rust

removal or other stubborn substances(tar. gum.

grease,wax, etc.),selectred maximum 0° spraytip.

o Formost all purpose cleaningsuchashome siding,

brick patios,wood decks,drivewaysand sidewalks.

garagefloors, etc.,selectyellow general15° or green

general25° spraytip.

o For gentlecleaning of cars/trucks, boats, RV's.

patio furniture, lawn equipment, etc., selectwhite

gentle40° spray tip.

o For applying project specific detergentsto help

breakdown stubborn dirt and grime on a variety of

surfaces, selectblack soap spray tip.

3. Pull backon collar, insertnewspraytip and releasecollar.

Tugon spraytip to makesureit is securely n place.

Usage Tips

o For most effective cleaning, keepspray tip from 20 to

61 cm (8 to 24 in) away from cleaning surface.

o if you get spraytip too close, especiallyusing a high

pressure spray tip, you may damagesurface being

cleaned.

o DONOTgetcloserthan 15 cm (6 in) whencleaningtires.

Cleaning and Applying Detergent

A WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in death,

serious injury, and/or property damage.

o DO NOTuse caustic liquid with pressure washer.

Use ONLYpressurewasher safe detergents/soaps. Followall

manufacturers instructions.

Ta apply detergent, fallow these steps:

1. Reviewuse of spray tips.

2. Preparedetergent solution as requiredby job.

3. Placesmall filter end of detergent siphoning tube into

detergent container.

NOTICE Makesurethe filter is fully submerged in detergent

whil_ applying detergent.

NOTICE Contactwith the hot muffler could damage

detergent siphoning tube.

Wheninsertingsiphonintoa detergentsolutionbottle,routethe

tubesoasto keepitfrom inadvertentlycontactingthehotmuffler.

4. Make sure black soap spray tip is installed.

NOTICE Detergentcannot be appliedwith the high pressure

spray tips _white,green,yellow or red).

LOwPressure

Useto apply

detergent

Nigh

Pressure

Black White Green Yellow Red

40° 25° 15° 0°

15

5, Make sure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray

gun and pump. Turn on water.

HOTICE Youmust attach all hoses beforeyou start the

engine.

, Startingtheenginewithoutallthehosesconnectedandwithout

thewaterturnedONcoulddamagethepump.

Damageto equipmentresultingfrom failuretofollowthis

instructionwillvoidwarranty.

6. Start enginefollowing instructions How to Start Your

Pressure Washer.

7. Apply detergentto a dry surface,starting at lower

portion of areato bewashed andwork upward, using

long, even,overlapping strokes.

8. Allow detergent to "soakin"for 3-5 minutes before

washing and rinsing. Reapplyasneededto prevent

surfacefrom drying. DO NOTallow detergentto dry on

(prevents streaking).

HOTICE Youmust flush the detergentsiphoning system

after each use by placingthe filter into a bucket of clean

water,then run the pressure washerin low pressure for 1o2

minutes.

Pressure Washer Rinsing

For Rinsing:

1. Removeblack soap spray tip from nozzleextension.

2. Select and install desired high pressure spray tip

following instructions How to UseSpray Tips.

3. Keepspray gun a safedistance from areayou planto

spray.

WARNING Kickbackfrom spray gun could causeyou

to fall resulting in deathor serious injury.

Cleaning Detergent $iphening Tube

if you used the detergentsiphoning tube, you must flush it

with cleanwater before stopping the engine.

1. Placedetergent siphoning tube/filter in a bucket full of

cleanwater.

2. Removehigh pressure spray tip from nozzleextension.

3. Select and install black soap spray tip following

instructions How to UseSpray Tips.

4. Flush for 1-2 minutes.

5. Shut off engine following instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint gun in a safe direction, press red button

and squeezespray gun trigger to releaseretainedhigh

water pressure.

,a, WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cut through skin

injury and possible amputation.

Spray guntraps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

o ALWAYSpointsprayguninsafedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

Autematic Cool Dewn System (Thermal Relief}

if you run the engineon your pressure washerfor

3-5 minutes without pressingthe trigger onthe spray gun,

circulating water in the pump can reachtemperatures above

52°C(125°F). The system engagesto cool the pump by

discharging the warm water ente the ground.

Operatepressurewasherfroma stablesurface.

Beextremelycarefulif youmust usethepressurewasherfrom

a ladder,scaffolding,oranyothersimilarlocation.

o Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

4. Applya high pressuresprayto asmall areaandthen

checksurfacefor damage,if no damage isfound, you

canassume it isokayto continue rinsing.

5. Start attop of areato be rinsed,working down with same

overlappingstrokesas you usedfor cleaning.

16 BRIGGSandSTRATTON,CONI

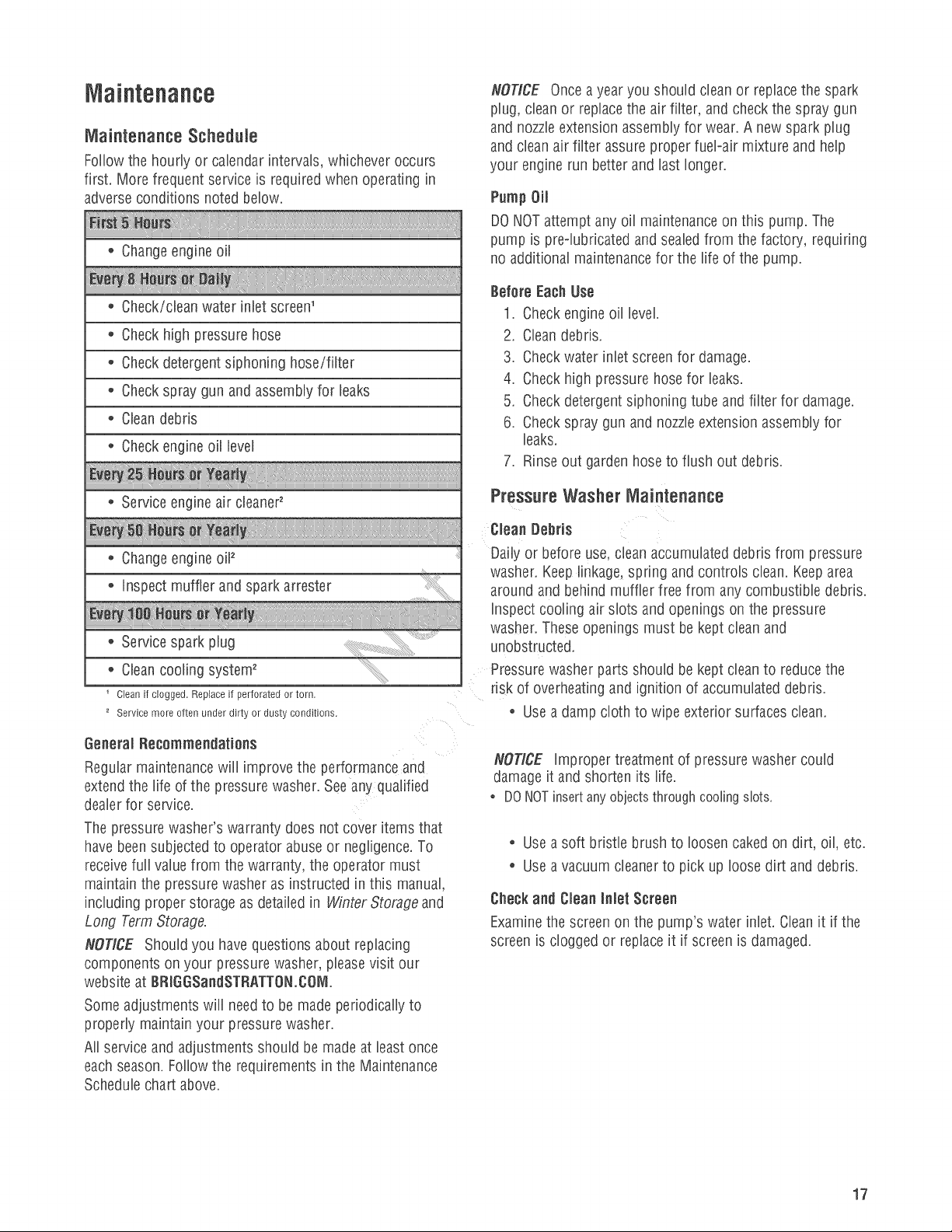

Maintenance

Maintenance Schedule

Follow the hourly or calendarintervals, whichever occurs

first. More frequent serviceis required when operating in

adverseconditions noted below.

o Changeengineoil

NOTICE Onceayear you should clean or replacethe spark

plug, clean or replacethe air filter, and check the spray gun

and nozzleextension assemblyfor wear. A new spark plug

and cleanair filter assure properfuebair mixture and help

your enginerun better and last longer.

Pump Oil

DONOTattempt any oil maintenanceon this pump. The

pump is prequbricated and sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

o Check/clean water inlet screen1

o Checkhigh pressure hose

o Checkdetergentsiphoning hose/filter

o Checkspray gun and assemblyfor leaks

o Cleandebris

o Checkengineoil level

o Service engineair cleaned

o Service spark plug

o Cleancooling system_

Clean if clogged, Replace if perforated or torn,

Service more often under dirty or dusty conditions.

General Recemmendations

Regular maintenancewill improve the performance and

extendthe life of the pressure washer. Seeany qualified

dealerfor service.

The pressurewasher's warranty does not cover items that

havebeen subjectedto operator abuseor negligence.To

receivefull valuefrom the warranty,the operator must

maintain the pressure washer as instructed in this manual,

including proper storage as detailedin Winter Storageand

Long TermStorage.

NOTICE Shouldyou have questions about replacing

components on your pressure washer, pleasevisit our

website at BRIGGSandSTRATTON.CONI.

Someadjustments will needto be made periodically to

properly maintainyour pressure washer.

All serviceand adjustments should bemade at bast once

eachseason. Follow the requirementsin the Maintenance

Schedulechart above.

Before EachUse

1. Checkengineoil level.

2. Cleandebris.

3. Check

4. Check

5. Check

6. Check

7. Rinse

water inlet screen for damage.

high pressure hose for leaks.

detergentsiphoning tube and filter for damage.

spray gun and nozzleextension assemblyfor

leaks.

out gardenhoseto flush out debris.

PressureWasherNJaintenance

Clean Debris

Daily or before use, cleanaccumulated debris from pressure

washer. Keeplinkage,spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

inspect cooling air slots and openings on the pressure

washer.These openings must be kept cleanand

unobstructed.

Pressure washer pads should be kept cleanto reducethe

risk of overheatingand ignition of accumulateddebris.

o Use a damp cloth to wipe exterior surfaces clean.

NOTICE mproper treatment of pressure washer could

damageit and shorten its life.

o DONOTinsertanyobjectsthroughcoolingslots.

o Use a soft bristle brush to loosen cakedon dirt, oil, etc.

o Use a vacuum cleanerto pick up loose dirt and debris.

Cheekand Clean Inlet Screen

Examinethe screenon the pump's water inlet. Cleanit if the

screen is clogged or replaceit if screen is damaged.

17

CheekNigh Pressore Hose

The highpressure hosecan developleaksfrom wear,

kinking, or abuse, inspectthe hoseeach time before using it.

Checkfor cuts, leaks,abrasions or bulging of cover, damage

or movement of couplings, if anyof these conditions exist,

replacethe hose immediately.

WARNING The high pressure stream of water that

this equipment produces could cutthrough skin

and its underlying tissues, resulting in serious

injury and possible amputation.

, NEVERrepairhighpressurehose.Repbceit.

o ReplacementhoseratingMUSTequalorexceedmaximum

pressureratingof unit.

CheekDetergent Siphoning Tube

Examinethe filter on the detergent tube and clean if clogged.

Thetube should fit tightly on the barbed fitting. Examinethe

tube for leaks or tears. Replacethe filter or tube if either is

damaged.

Detergent Siphoning CheekBail

Occasionallycheck ball in detergent siphoning system may

become stuck from storage, dried soap, or minerals inwater.

Thecheck ball can be freed by performing the following:

HOTtCE Beforeperforming this procedure, be sure you are

wearing safetygoggles as described below.

A WARNING Riskof eyeinjury.

Spraycould splash back or propel objects

resulting in serious injury.

5. Slowly push down until you feel the ball move slightly,

push no more than 3 mm (1/8 in). Slight pressure may

be requiredto freethe ball.

6. Repeatsteps 4and 5 if necessary.

7. Reinstall detergentsiphoning hose onto barb fitting.

8. Treat with PumpSaveras describedin Protecting the

Pump during storage to prevent reoccurrence.

CheekSpray Gun

Examinethe hose connectionto the spray gun and make

sure it is secure.Test the trigger by pressing the red button

and making sure the trigger "springs back" into placewhen

you releaseit. You should not be able to press the trigger

without pressingthe red button. Replacespray gun

immediately if it fails anyof these tests.

Nozzle Maintenance

A pulsing sensationfelt while squeezingthe spray gun

trigger may becaused by excessivepump pressure_The

principal causeof excessivepump pressure is a spray tip

clogged or restricted with foreign materials, such asdirt, etc_

To correct the problem, immediately clean the spray tip

following these instructions:

1. Shut off engine and turn off water supply_

2_ ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to release

retained highwater pressure_

Always wear indirect vented (chemical splash) safetygoggles

markedto comply with ANSi Z87.1 when using or in vicinity of

this equipment.

NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

Shut off engineand turn off water supply.

2_

ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to release

retainedhigh water pressure.

A WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cutthrough skin

injury and possible amputation.

Spraygun traps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

3_

Removedetergent siphoning hosefrom barbedfitting

on pump.

4_

Usinga firm, blunt object2 mm (7/64 in) in diameteror

smaller,by atbast £5 cm (1 in) long,such asanAllen

wrench,slowly insertthe objectintothe barbedfitting until

you meetresistance.This resistanceis thecheck ball.

A WARNmNGThe high pressurestream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray guntraps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

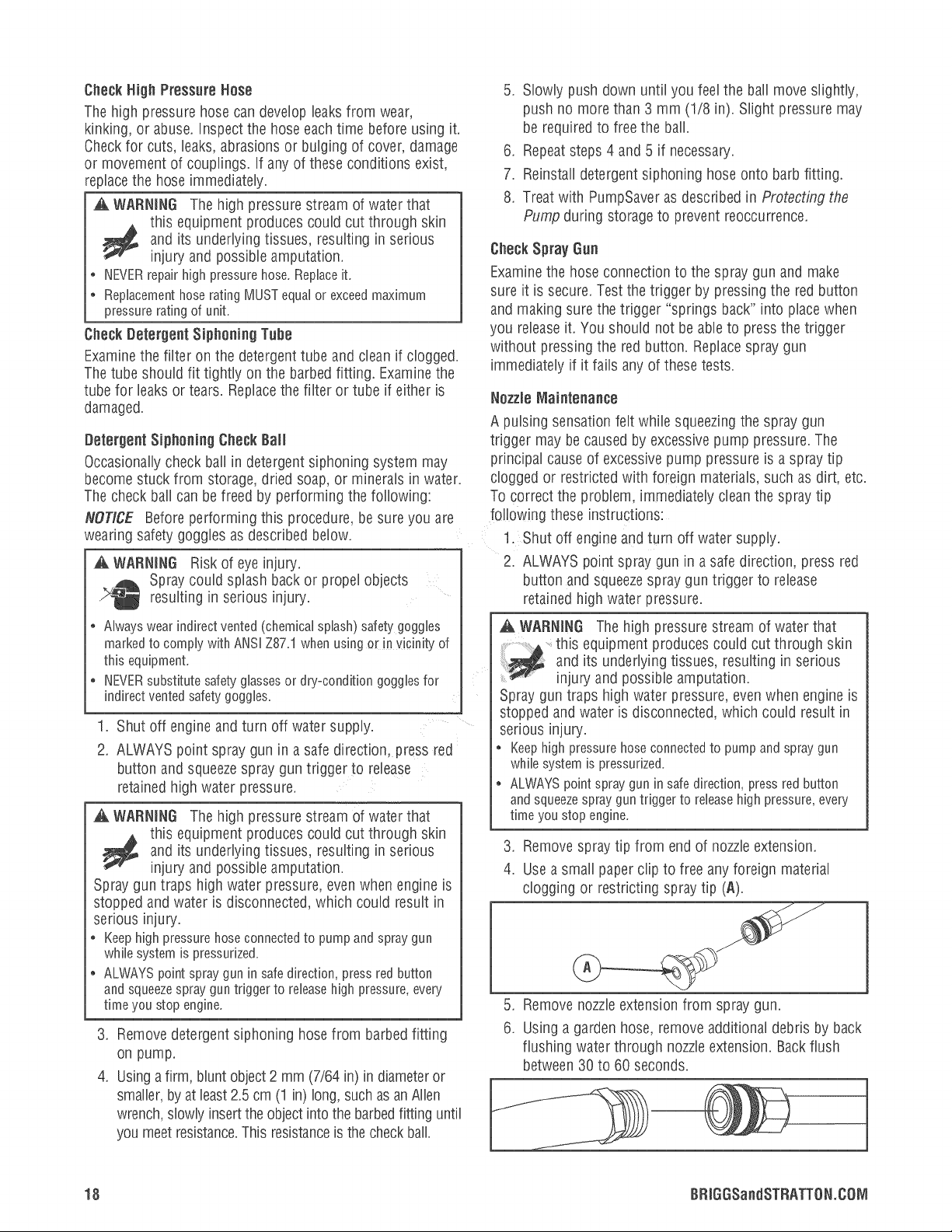

3. Removespray tip from end of nozzleextension.

4. Use a small paperclip to free anyforeign material

clogging or restricting spray tip (A).

5. Removenozzleextension from spray gun.

6. Using a garden hose,remove additional debris by back

flushing water through nozzleextension. Backflush

between 30 to 60 seconds.

18 BRIGGSandSTRATTON.CONI

7_

Reinstall spraytip into nozzleextension.

8.

Reconnect nozzleextensionto spray gun.

9.

Make sure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray

gun and pump. Turn on water.

10.

Start enginefollowing instructions How to Start Your

Pressure Washer.

11.

Test pressurewasher by operating with each quick

connect spraytip.

O°RingMaintenance

Through the normal operationof your pressurewasher,

o-rings are used to keepthe connections of the hoses and

spray gun tight and leak-free. These o-rings may become

worn or damaged.

An O-Ring MaintenanceKit is provided with your pressure

washer which includes replacement oorings, rubber washer

and water inlet filter. Referto the instruction sheet provided

in the kit to serviceyour unit's o-rings. Notethat you will not

use allof the parts in the kit.

To removea worn or damagedo-ring, usea small flathead

screwdriver to get underneaththe o-ring and pry it off.

WARNING The high pressure stream of water that

and its underlying tissues, resulting in serious

this equipment produces could cutthrough skin

injury and possible amputation.

NEVERrepairleakingconnectionswithsealantof anykind.

Replaceo-ringor seal.

Engine Maintenance

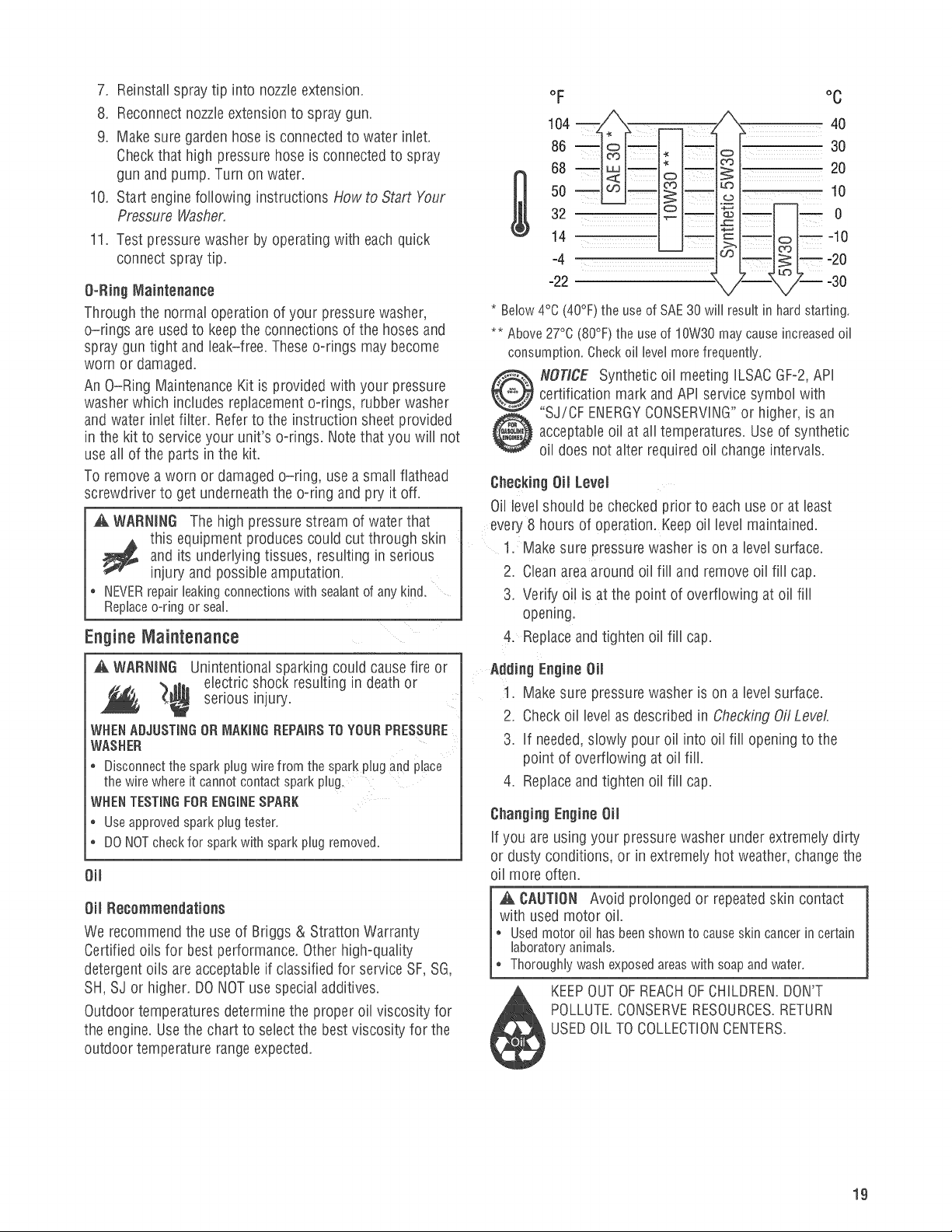

°F °C

104 --_"_ __ _ " 40

86 _ • _1- 30

50 _ 10

68 _ i[_o_ 20

14 __ ._, -10

-4 ........ -20

32 __ l--_ 0

-22 ' -30

• Below4°C(40°F)theuseof SAE30 will resultin hardstarting.

** Above 27°C (80°F) the useof 10W30 may cause increasedoil

consumption. Checkoil level more frequently.

NOTICE Synthetic oil meeting ILSACGF-2,API

@

Checking Oil Level

Oil levelshould bechecked prior to each useor at bast

every 8 hours of operation. Keepoil level maintained.

certification markand API servicesymbol with

"SJ/CF ENERGYCONSERVING"or higher, is an

acceptableoil at all temperatures. Useof synthetic

oil does not alter required oil change intervals.

1. Make sure pressure washer is on a levelsurface.

2. Cleanarea aroundoi fill and remove oil fill cap.

3. Verify oil is at the point of overflowing at oil fill

opening.

4. Replaceand tighten oil fill cap.

o

A WARNING Unintentionalsparking could cause fire or

electric shock resulting n death or

serious injury.

WHENADJUSTINGOR MAKING REPAIRSTO YOURPRESSURE

WASHER

Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

Use approvedspark plug tester,

o DONOTcheckfor spark with spark plug removed,

Oil

Oil Recommendations

We recommendthe useof Briggs & Stratton Warranty

Certified oils for best performance. Otherhigh-quality

detergent oils are acceptableif classified for service SF, SG,

SH, SJ or higher. DONOTuse specialadditives.

Outdoor temperaturesdeterminethe proper oil viscosity for

the engine. Usethe chart to selectthe bestviscosity for the

outdoor temperature rangeexpected.

Adding Engine Oil

1. Make sure pressure washer is on a levelsurface.

2. Checkoil levelas described in Checking 0/1Level

3. if needed,slowly pour oil into oil fill opening to the

point of overflowing at oil fill.

4. Replaceand tighten oil fill cap.

Changing Engine Oil

if you are using your pressurewasher under extremely dirty

or dusty conditions, or in extremely hot weather, changethe

oil more often.

A CAUTION Avoid prolonged or repeatedskin contact

with usedmotor oil.

Usedmotoroil hasbeenshowntocauseskincancerin certain

Thoroughlywashexposedareaswithsoapandwater.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOiL TOCOLLECTIONCENTERS.

19

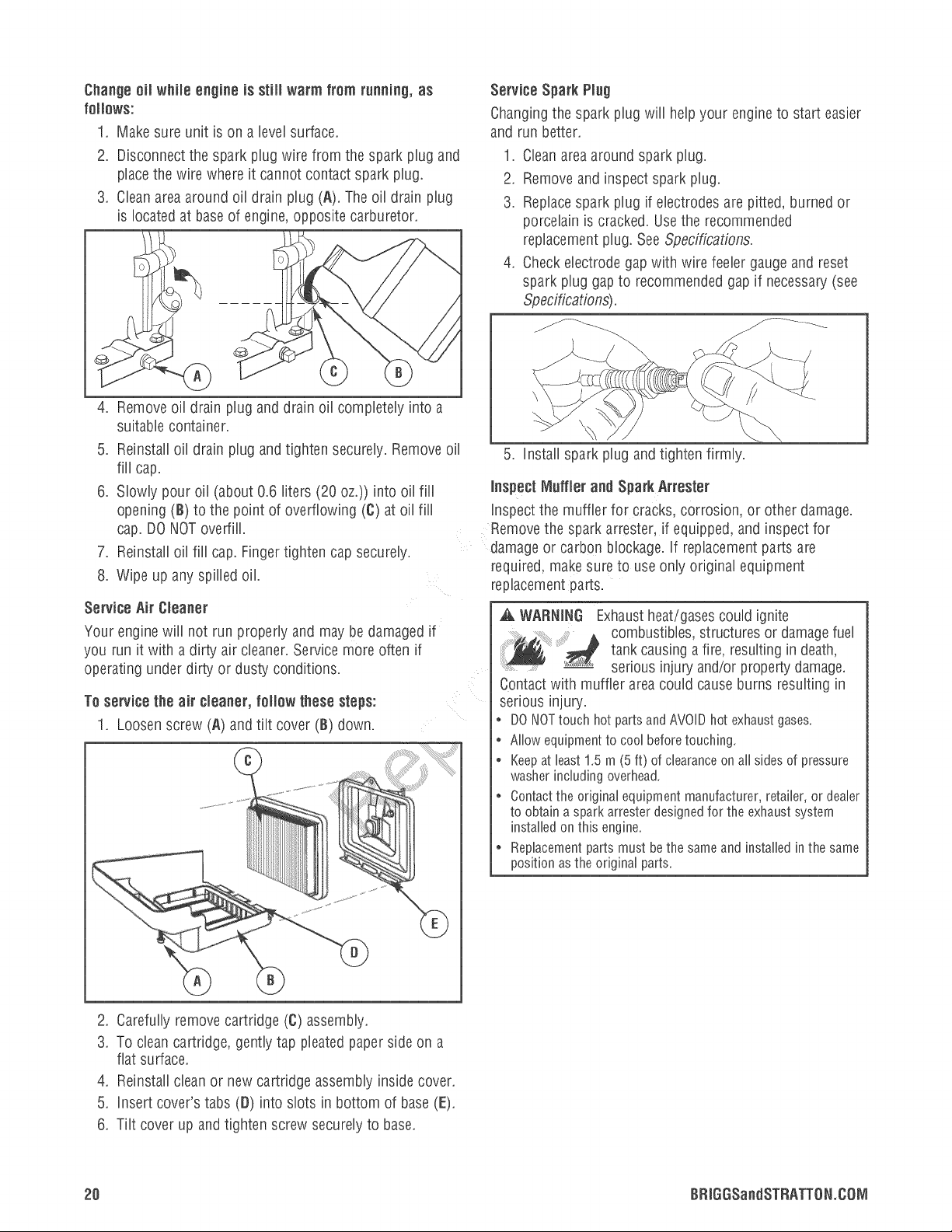

Changeoil while engine is still warm from running, as

follows:

1. Make sure unit is on a levelsurface.

.

Disconnectthe spark plug wire from the spark plug and

placethe wire where it cannot contact spark plug.

.

Cleanarea aroundoil drain plug (A). The oil drain plug

is locatedat baseof engine,opposite carburetor.

m

J

4.

Removeoil drain plug and drain oil completely into a

suitable container.

5.

Reinstall oil drain plug andtighten securely. Removeoil

fill cap.

6.

Slowly pour oil (about 0.6 liters (20 oz.)) into oil fill

opening (B) to the point of overflowing (C) at oil fill

cap. DONOToverfill.

.

Reinstall oil fill cap.Fingertighten cap securely.

8.

Wipe upany spilled oil.

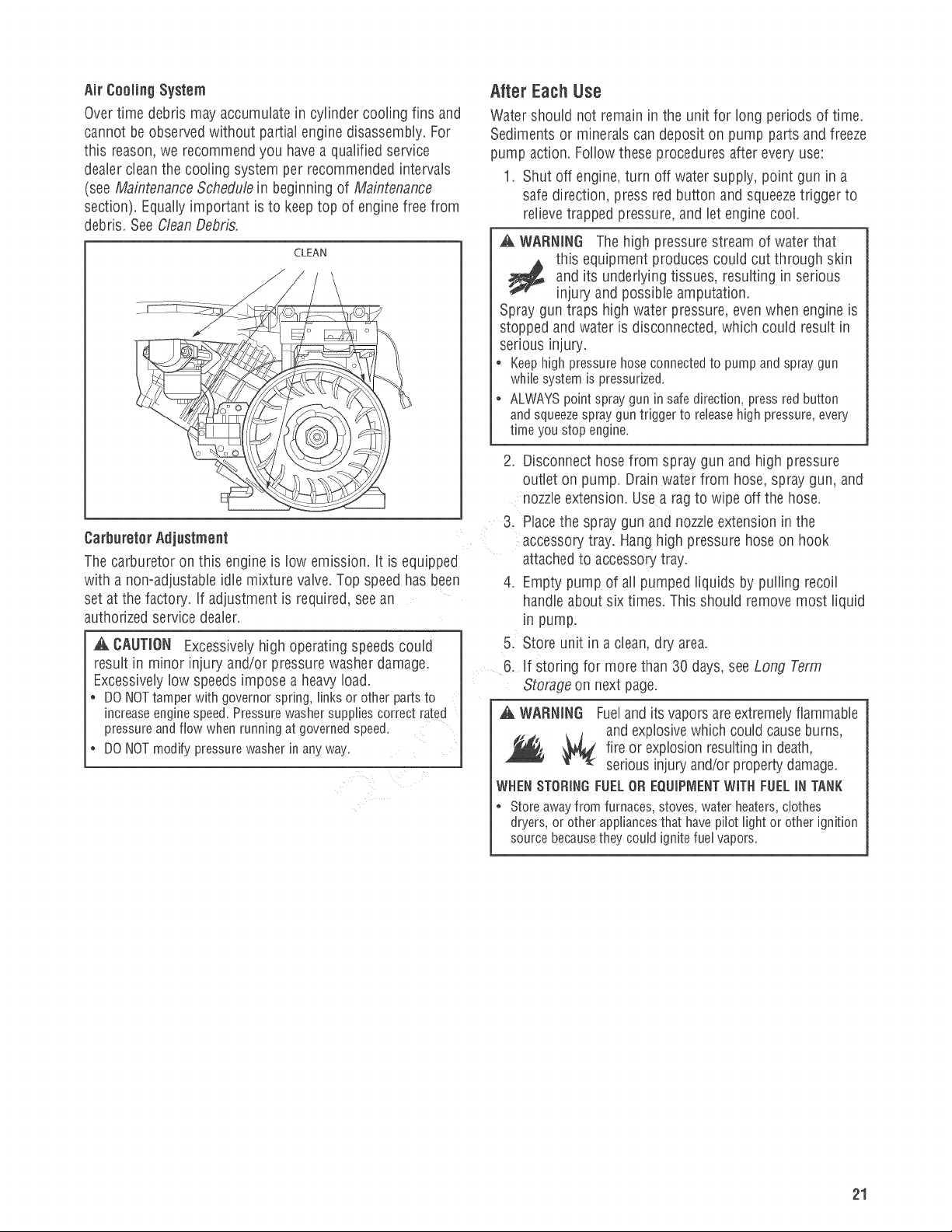

Service Air Cleaner

Your enginewill not run properly and may bedamaged if

you run it with a dirty air cbaner. Service more often if

operating under dirty or dusty conditions.

Tosewiee the air cleaner, feiiew these steps:

1. Loosen screw (A) andtilt cover (B) down.

Service Spark Plug

Changingthe spark plug will helpyour engineto start easier

and run better.

1. Cleanarea aroundspark plug.

2. Removeand inspect spark plug.

3. Replacespark plug if electrodes are pitted, burned or

porcelain is cracked. Usethe recommended

replacementplug. See Specifications.

4, Checkelectrode gapwith wire feeler gauge and reset

spark plug gap to recommended gap if necessary(see

Specifications).

5, Install spark plug and tighten firmly,

inspect Muffler and Spark Attester

inspectthe muffler for cracks,corrosion, or other damage.

Remove the spark arrester, if equipped,and inspect for

damageor carbon blockage, if replacementparts are

required, makesureto use only original equipment

replacementparts.

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel

tank causing a fire, resulting in death,

serious injury and/or property damage.

Contact with muffler area could cause burns resulting in

serious injury.

o DO NOTtouch hot parts andAVOID hot exhaust gases.

Allow equipment to cool beforetouching.

Keepat least 1.5 m (5 ft) of clearanceon all sides of pressure

washer including overhead.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a spark attester designed for the exhaust system

installed on this engine.

Replacement parts must be the sameand installed in the same

position as the original parts.

2. Carefully removecartridge (C) assembly.

3. To cleancartridge, gently tap pleatedpaper side on a

fiat surface.

4. Reinstall cleanor new cartridge assembly inside cover.

5. insert cover's tabs (t}) into slots in bottom of base (F).

6. Tilt cover up andtighten screw securelyto base.

20 BRIGGSandSTRATTON.CONI

AirCoolingSystem

Overtimedebrismayaccumulateincylindercoolingfinsand

cannotbeobservedwithoutpartialenginedisassembly.For

thisreason,werecommendyouhaveaqualifiedservice

dealercleanthecoolingsystemperrecommendedintervals

(seeMaintenanceSchedulein beginning of Maintenance

section). Equallyimportant is to keeptop of engine freefrom

debris. SeeCleanDebris.

CLEAN

Carburetor Adjustment

Thecarburetor onthis engine is low emission. It is equipped

with a non-adjustable idle mixture valve. Top speedhas been

set at the factory, if adjustment is required, seean

authorized servicedealer.

CAUTION Excessively high operating speeds could

result in minor injury and/or pressure washer damage.

Excessively low speeds impose a heavy load.

, DO NOTtamper with governor spring, links or other partsto

increase enginespeed. Pressurewasher supplies correct rated

pressure and flow when running at governed speed.

* DO NOTmodify pressure washer in any way.

After Each Use

Water should not remain in the unit for long periods of time.

Sediments or minerals can depositon pump parts and freeze

pump action. Followthese procedures after every use:

1. Shut off engine,turn off water supply, point gun in a

safe direction, press red button and squeezetrigger to

relievetrapped pressure, andlet enginecool.

,a, WARNING The high pressure stream of water that

_, his equipmentproduces could cut through skin

Spray guntraps high water pressure, evenwhen engineis

stopped and water is disconnected, which could result in

serious injury.

2. Disconnect hosefrom spray gun and highpressure

3. Placethe spray gun and nozzleextension in the

4. Empty pump of all pumped liquids by pulling recoil

5. Store unit in a clean,dry area.

6. if storing for more than 30 days,see Long Term

_k WARNING Fuelandits vapors areextremelyflammable

WHENSTORINGFUELOREQUIPMENTWITHFUELINTANK

° Store away from furnaces, stoves,water heaters,clothes

and its underlying tissues, resulting in serious

injury and possible amputation.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

outlet on pump. Drain water from hose, spray gun, and

nozzleextension. Usea rag to wipe off the hose.

accessorytray. Hanghigh pressure hose on hook

attachedto accessorytray.

handle about six times. This should remove most liquid

in pump.

Storageon next page.

andexplosivewhich could causeburns,

fire or explosionresulting in death,

seriousinjury and/orproperty damage.

dryers, or otherappliancesthat have pilot light or other ignition

source becausethey could ignite fuel vapors,

21

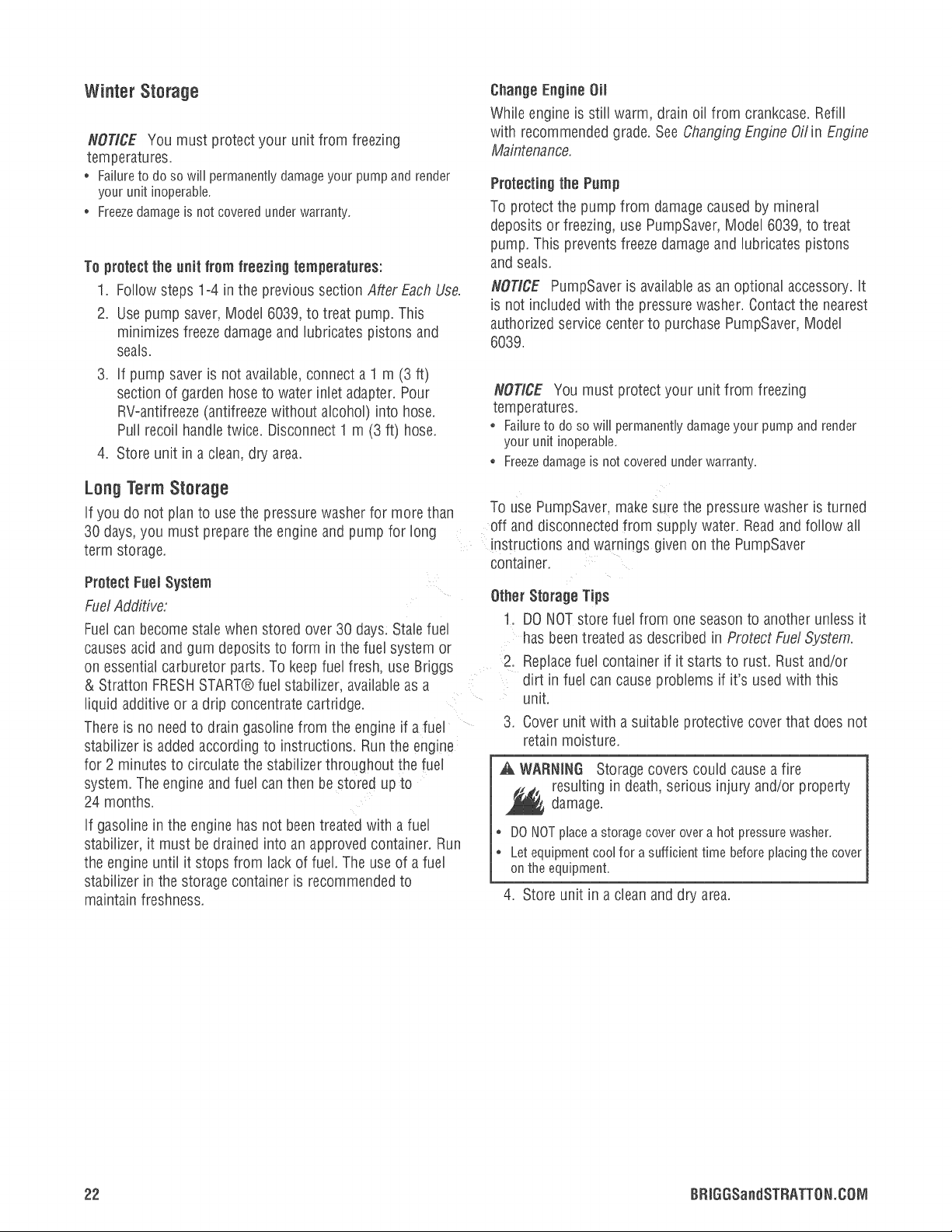

Winter Storage

NOTICE You must protect your unit from freezing

temperatures.

, Failureto do so will permanentlydamageyour pump and render

your unit inoperable.

* Freezedamageis not covered underwarranty.

Te prefectthe unit from freezing temperatures:

1. Follow steps 1-4 in the previous section After Each Use.

2. Use pump saver, Modal 6039, to treat pump. This

minimizes freezedamageand lubricates pistons and

seals.

3. If pump saver is not avaiiabb, connect a 1 m (3 ft)

section of garden hose to water inbt adapter. Pour

RV-antifreeze(antifreezewithout alcohol) into hose.

PuiIrecoil handb twice. Disconnect 1m (3 ft) hose.

4. Store unit in a cban, dry area.

Long Term Storage

if you do not plan to usethe pressure washer for more than

30 days,you must preparethe engine and pump for long

term storage.

Protect Fuel System

FuelAdditive:

Fuelcan becomestab when stored over 30 days. Stalefuel

causesacid and gum deposits to form in the fuel system or

on essentialcarburetor parts. To keep fuel fresh, use Briggs

& Stratton FRESHSTART@fuel stabilizer, availableasa

liquid additive or a drip concentrate cartridge.

Thereis no needto drain gasolinefrom the engne if afuel

stabilizer is added according to instructions. Runthe engine

for 2 minutesto circulate the stabilizerthroughout the fuel

system. The engine andfuel canthen bestored up to

24 months.

if gasoline in the engine hasnot beentreated with a fuel

stabilizer, it must be drainedinto an approvedcontainer. Run

the engineuntil it stops from lack of fuel. The useof a fuel

stabilizer inthe storage containeris recommendedto

maintain freshness.

ChangeEngineOil

While engineis still warm, drain oil from crankcase. Refill

with recommendedgrade.See C,ffangingEngine 0il in Engine

Maintenance.

Protecting the Pump

To protect the pump from damagecaused by mineral

deposits or freezing, use PumpSaver,Model 6039, to treat

pump. This prevents freezedamageand lubricates pistons

and seals.

NOTICE PumpSaveris availableas an optional accessory, it

is not included with the pressurewasher. Contactthe nearest

authorized servicecenter to purchase PumpSaver,Model

6039.

NOTICE Youmust protect your unit from freezing

temperatures.

, Failureto dosowill permanentlydamageyourpumpandrender

yourunit inoperable.

* Freezedamageisnotcoveredunderwarranty.

To use PumpSaver, makesurethe pressure washeris turned

off and disconnectedfrom supply water. Readandfollow all

instructions andwarnings given on the PumpSaver

container.

Other Sterage Tips

1. DONOTstore fuel from one seasonto another unlessit

has beentreatedas described in Protect FuetSystem.

2. Replacefuel container if it starts to rust. Rust and/or

dirt in fuel can cause problems if it's usedwith this

unit.

3. Cover unit with a suitableprotective cover that does not

retain moisture.

A WARNING Storage covers could causea fire

resulting in death,serious injury and/or property

damage.

* DO NOTplace astorage cover overa hot pressure washer.

* Let equipment cool for a sufficient time before placing the cover

4. Store unit in a cleanand dry area.

22 BRIGGSandSTRATTON.CONI

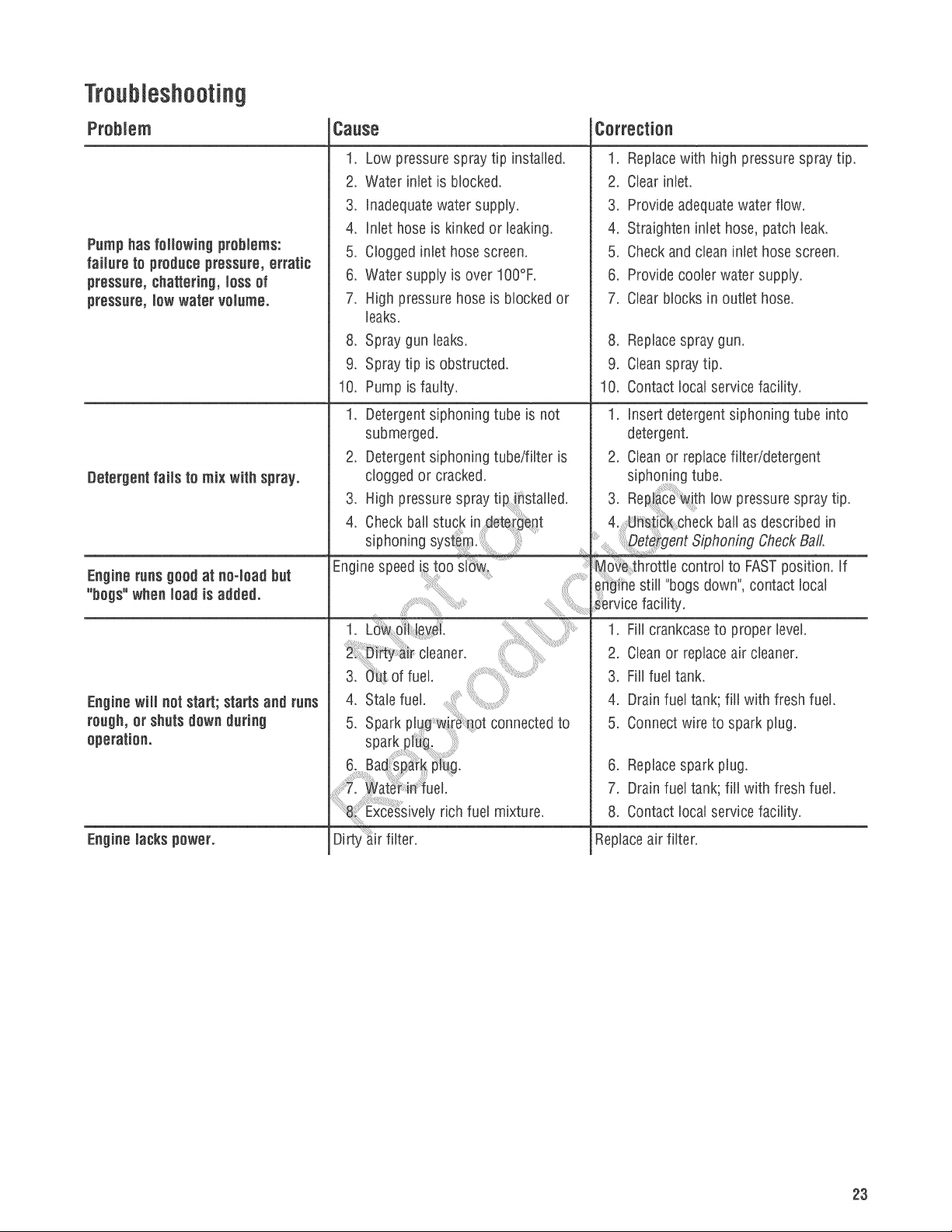

Problem

Cause

Correction

Detergent faiJs to mix with spray.

Enginetuns good at no-Joadbut

"bogs" when Joadis added.

EnginewiJJnot start; starts and tuns

tough, or shuts down during

operation.

EngineJackspower.

1. Low pressure spray tip installed.

2. Water inlet is blocked.

3. Inadequatewater supply.

4. Inlet hose is kinkedor leaking.

5. Cloggedinlet hose screen.

6. Water supply is over IO0°F.

7. High pressure hose is blocked or

leaks.

8. Spraygun leaks.

9. Spraytip is obstructed.

10. Pump is faulty.

1. Detergentsiphoning tube is not

submerged.

2. Detergentsiphoning tube/filter is

clogged or cracked.

3. High pressure spray tip i_stafled.

4. Checkball stuck indete[_eDt

siphoning system. ...........

Enginespeed istoo

4. Stalefuel

5. Spark pl_g w_:8ot connectedto

spark pi_g_

...... a iuel.

..... rich fuel mixture.

filter.

1. Replacewith high pressure spraytip.

2. Clearinlet.

3. Provide adequatewater flow.

4. Straighten inlet hose, patch leak.

5. Checkand cleaninlet hosescreen.

6. Provide cooler water supply.

7. Clearblocks in outlet hose.

8. Replacespray gun.

9. Cleanspraytip.

10. Contact local servicefacility.

1. Insert detergentsiphoning tube into

detergent.

2. Cleanor replacefilter/detergent

siphon!rig tube.

3. Rep!_c_with low pressure spray tip.

throttle control to FASTposition. If

still "bogs down", contact local

srvicefacility.

1. Fill crankcaseto proper level.

2. Cleanor replaceair cleaner.

3. Fill fuel tank.

4. Drainfuel tank; fill with fresh fuel.

5. Connectwire to spark plug.

6. Replacespark plug.

7. Drainfuel tank; fill with fresh fuel.

8. Contact local servicefacility.

Replaceair filter.

23

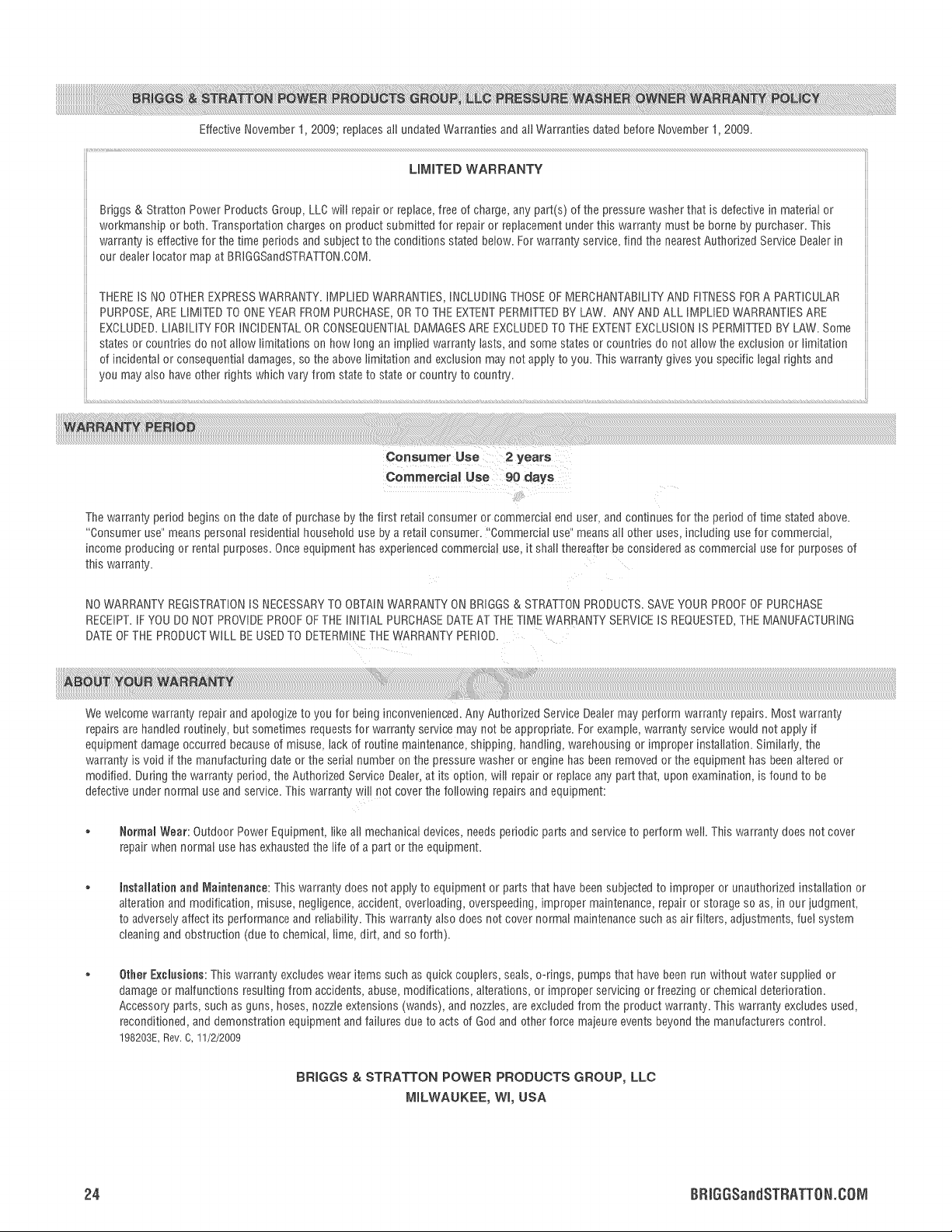

EffectiveNovember1,2009; replacesall undatedWarrantiesandallWarrantiesdatedbeforeNovember1,2009.

LiMiTED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace,free of charge, any part(s) of the pressure washerthat is defective in material or

workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty' is effective for the time periods and subject to the conditions stated below. For warranty' service, find the nearest Authorized Service Dealer in

our dealer Iocator map at BRIGGSandSTRATTON.COM.

THEREIS NOOTHEREXPRESSWARRANTY. IMPLIEDWARRANTIES,INCLUDINGTHOSEOFMERCHANTABILITYAND FITNESSFORA PARTICULAR

PURPOSE,ARELiMiTED TOONEYEARFROMPURCHASE,ORTOTHE EXTENTPERMITTEDBY LAW. ANYAND ALL IMPLIED WARRANTIESARE

EXCLUDED.LIABILITY FOR INCIDENTALORCONSEQUENTIALDAMAGESARE EXCLUDEDTO THE EXTENTEXCLUSIONIS PERMITTEDBY LAW. Some

states or countries do not allow limitations on how long an implied warranty' lasts, and some states or countries do not allow the exclusion or limitation

of incidental or consequential damages, sothe above limitation and exclusion may not apply to you. This warranty' gives you specific legal rights and

you may also have other rights which vary'from state to state or country'to country'.

Consumer Use 2 years

Commercial Use 90 day's

The warranty' period begins on the date of purchase by the first retail consumer or commercial end user and continues for the period of time stated above.

"Consumer use" means personal residential aousehold useby a retail consumer. "Commercial use meansall other uses, including usefor commercial,

income producing or rental purposes. Once equipmen_has experienced commercial use. it shall thereafter be considered as commercial use for purposes of

this warranty'.

NOWARRANTY REGISTRATIONIS NECESSARYTO OBTAINWARRANTY ON BRIGGS& STRATTONPRODUCTS.SAVEYOUR PROOFOFPURCHASE

RECEIPT.IF YOU DONOT PROVIDEPROOFOFTHE INITIAL PURCHASEDATEAT THETIMEWARRANTYSERVICEiS REQUESTED,THEMANUFACTURING

DATEOFTHE PRODUCTWILL BE USEDTO DETERI'vIINETHEWARRANTY PERIOD.

We welcome warranty' repair and apologize to you for being inconvenienced. Any Authorized Service Dealermay perform warranty repairs. Most warranty'

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example,warranty' service would not apply if

equipment damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the

warranty'is void if the manufacturing date or the serial number onthe pressure washer or engine has been removed or the equipment has been altered or

modified. During the warranty period, the Authorized Service Dealer,at its option, will repair or replaceany part that, upon examination, is found to be

defective under normal use and service. This warranty will not cover the following repairs and equipment:

Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not cover

repair when normal use has exhausted the life of a part or the equipment.

Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjectedto improper or unauthorized installation or

alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment,

to adversely affect its performance and reliability'. This warranty also does not cover normal maintenance such as air filters, adjustments, fuel system

cleaning and obstruction (due to chemical, lime, dirt, and so forth).

Other Exclusions: This warranty' excludes wear items such as quick couplers, seals,o-rings, pumps that have been run without water supplied or

damage or malfunctions resulting from accidents, abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration.

Accessory parts, such as guns, hoses,nozzle extensions (wands), and nozzles,are excluded from the product warranty. This warranty' excludes used,

reconditioned, and demonstration equipment and failures due to acts of God and other force majeure eventsbeyond the manufacturers control.

198203E,Rev.C,11/2/2009

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

mVIILWAUKEE, Wi, USA

24 BRIGGSBndSTRATTON.CONI

Loading...

Loading...