Briggs & Stratton 020228 Owner’s Manual

Safety Rules

SAVE THESE iNSTRUCTiONS

TABLE OF CONTENTS

Section I Safety Rules .......................... 2-4

Section 2 Features and Controls ................... S

Section 3 Assembly ............................ 6-8

Section 4 Operation .......................... 9-13

Section S Product Specifications ................... 14

Section S Maintenance ........................ 14-16

Section 6 Storage .............................. 17

Section 7 - Troubleshooting ........................ 18

Warranty ...................................... 19

EQUIPHENT

DESCRIPTION

Read this manual carefully and become familiar

[11--,/

I! ;Jwithyourpressurew.,her.Knowits

applications, its limitations and any hazards

involved.

This manual contains information for a pressure washer

that operates up to a maximum of 2,200 PSI and at a

maximum flow rate of 2.2 gallons per minute.This high

quality residential system features 14" wheels, axial cam

pump with stainless steel pistons, automatic cool down

system, chemical injection system, and a variety of nozzle

sizes.Also includes safety goggles, heavy duty 25' hose, and

more.

Every effort has been made to ensure that information in

this manual is accurate and current. However_ we reserve

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

SAFETY RULES

This is the safety alert symbol, it is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol (_) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CALIT|ON

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

_WARNING

The engine e_duct contains

chemicals known to the State of California to cause

cancer, b rth defects, or other reproduct ve harm.

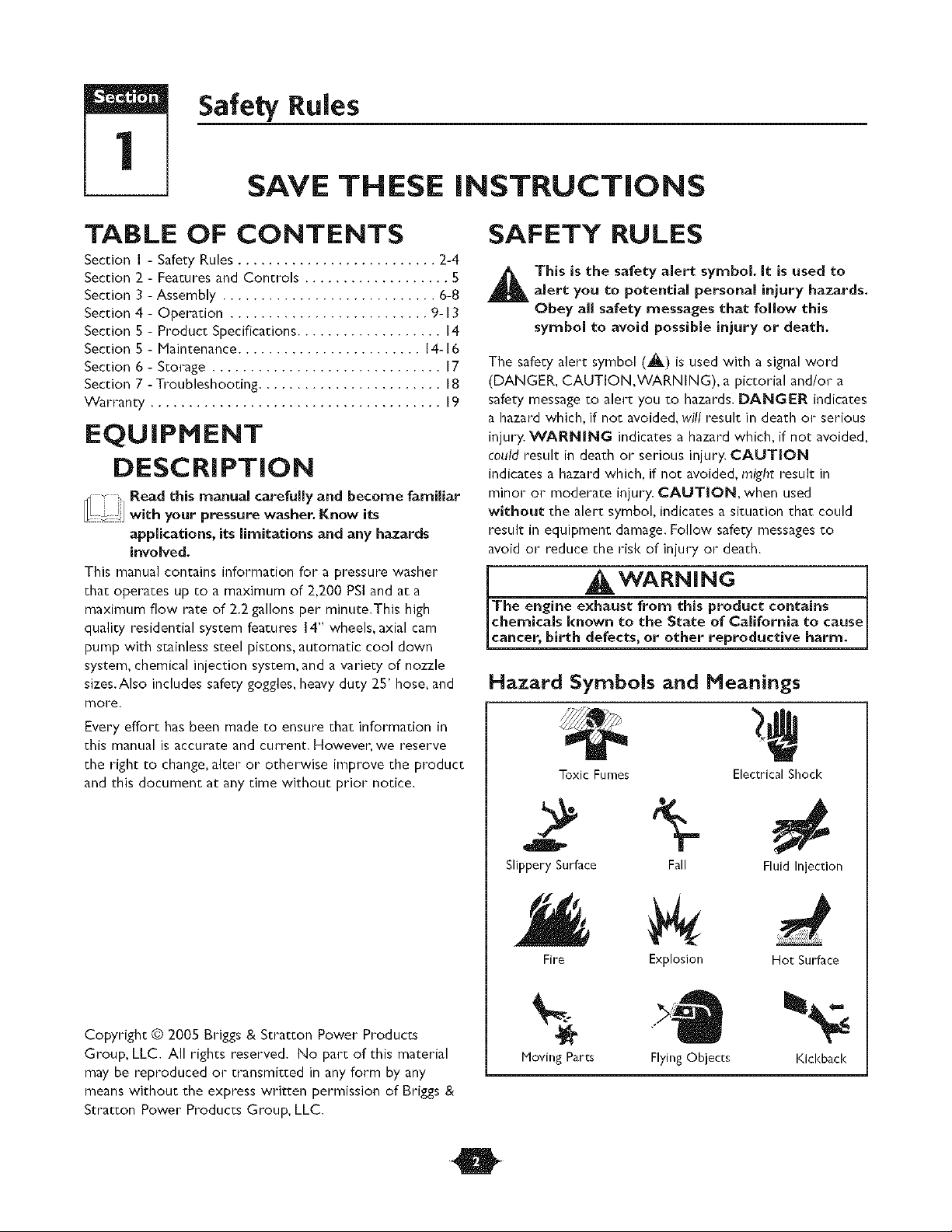

Hazard Symbols and Meanings

Toxic Fumes Electrical Shod<

Copyright © 2005 Briggs & Stratton Power Products

Group, LLC. All rights reserved. No part of this material

may be reproduced or transmitted in any form by any

means without the express written permission of Briggs &

Stratton Power Products Group, LLC.

O

2 5-

Slippery Surface Fall Fluid Injection

Fire

Moving Parts FlyingObjects

Explosion Hot Surface

Kickback

WARNING

Operate pressure washer ONLY outdoors.

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate pressure washer inside any building or

enclosure, even if doors or windows are open.

Use a respirator or mask whenever there is a chance that

vapors may be inhaled.

Read all instructions with mask so you are certain the mask will

provide the necessary protection against inhaling harmful vapors.

WARNING

Section 1: Safety Rules

WHEN ADDING FUEL

Turn pressure washer OFF and let it cool at least 2 minutes

before removing gas cap.

Fill fuel tank outdoors.

DO NOT overfill tank.Allow space for fuel expansion.

Keep fuel away from sparl<s, open flames, pilot lights, heat, and

other ignition sources.

DO NOT light a cigarette or smoke.

_VHEN OPERATING EQUIPNENT

DO NOT tip engine or equipment at angle which causes fuel

to spill.

DO NOT spray flammable liquids.

_VHEN TRANSPORTING OR REPAIRING EQUIPHENT

Transport/repair with fuel tank EHPTY or with fuel shutoff

valve OFE

_VHEN STORING FUEL OR EQUIPHENT WITH FUEL

IN TANK

Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Keep spray nozzle between 8 to 24 inches away from cleaning

surface.

Operate this unit on a stable surface.

The cleaning area should have adequate slopes and drainage to

reduce the possibility of a fall due to slippery surfaces.

Be extremely careful if you must use the pressure washer from

a ladder, scaffolding or any other relatively unstable location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun Idcks bacl<.

WARNING

When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid Idcl<bacl<.

If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze trigger

on spray gun.

WARNING

NEVER aim spray gun at people, animals or plants.

DO NOT allow CHILDREN to operate pressure washel_

NEVER repair high pressure hose. Replace it.

NEVER repair leaking connections with sealant of any Idnd.

Replace o-ring or seal.

Keep high pressure hose connected to pump and spray gun

while system is pressurized.

Squeeze trigger on spray gun to relieve trapped pressure,

every time you stop engine. Engage trigger lock on spray gun.

WARNING

Keep water spray away from electric wiring or fatal electric

shock may result.

O

Section 1: Safety Rules

WARNING

DO NOT touch hot surfaces and avoid hot exhaust gases.

Allow equipment to cool before touching.

The pressure washer must be at least 5 feet from structures

having combustible walls and/or other combustible materials.

Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

Reflective exhaust heat may damage fuel tank causing fire.

Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spark arrestet_ maintained in

effective worl<ing ordet_ complying to USDA Forest service

standard 5100- I C or later revision. In the State of California a

spark art*ester is required under section 4-442 of the California

Public resources code. Other states may have similar laws.

WARNING

CAUTION

DO NOT tamper with governed speed.

DO NOT operate pressure washer" above rated pressure.

DO NOT secure spray gun in open position.

DO NOT leave spray gun unattended while machine is

running.

NEVER use a spray gun which does not have a trigger lock or

trigger guard in place and in working orden

Always be certain spray gun, nozzles and accessories are

correctly attached.

CAUTION

DO NOT point spray gun at glass when using MAX (pin

point) nozzle.

NEVER aim spray gun at plants.

DO NOT wear loose clothing, jewelry or anything that may

be caught in the starter or other rotating parts.

Tie up long hair and remove jewelry.

WHEN ADJUSTING OR MAKING REPAIRSTOYOUR

PRESSURE WASHER

Disconnect sparl< plug wire from sparl< plug and place wire

where it cannot contact spark plug.

tVHENTESTING FOR ENGINE SPARK

Use approved spark plug testen

DO NOT check for spark with sparl< plug removed.

WARNING

Always wear eye protection when using this equipment or in

vicinity of where equipment is in use.

If you have questions about intended use, ask dealer or

contact Briggs & StraEon Power Products.

NEVER operate units with broken or missing parts, or

without protective housing or covers.

DO NOT by-pass any safety device on this machine.

Before starting pressure washer in cold weather, check all

parts of the equipment to be sure ice has not formed there.

NEVER move machine by pulling on high pressure hose. Use

handle provided on unit.

Check fuel system for leaks or signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washen

This equipment is designed to be used with Briggs & Stratton

Power Products authorized parts ONLY. If equipment is used

with parts that DO NOT comply with minimum specifications,

user assumes all risks and liabilities.

O

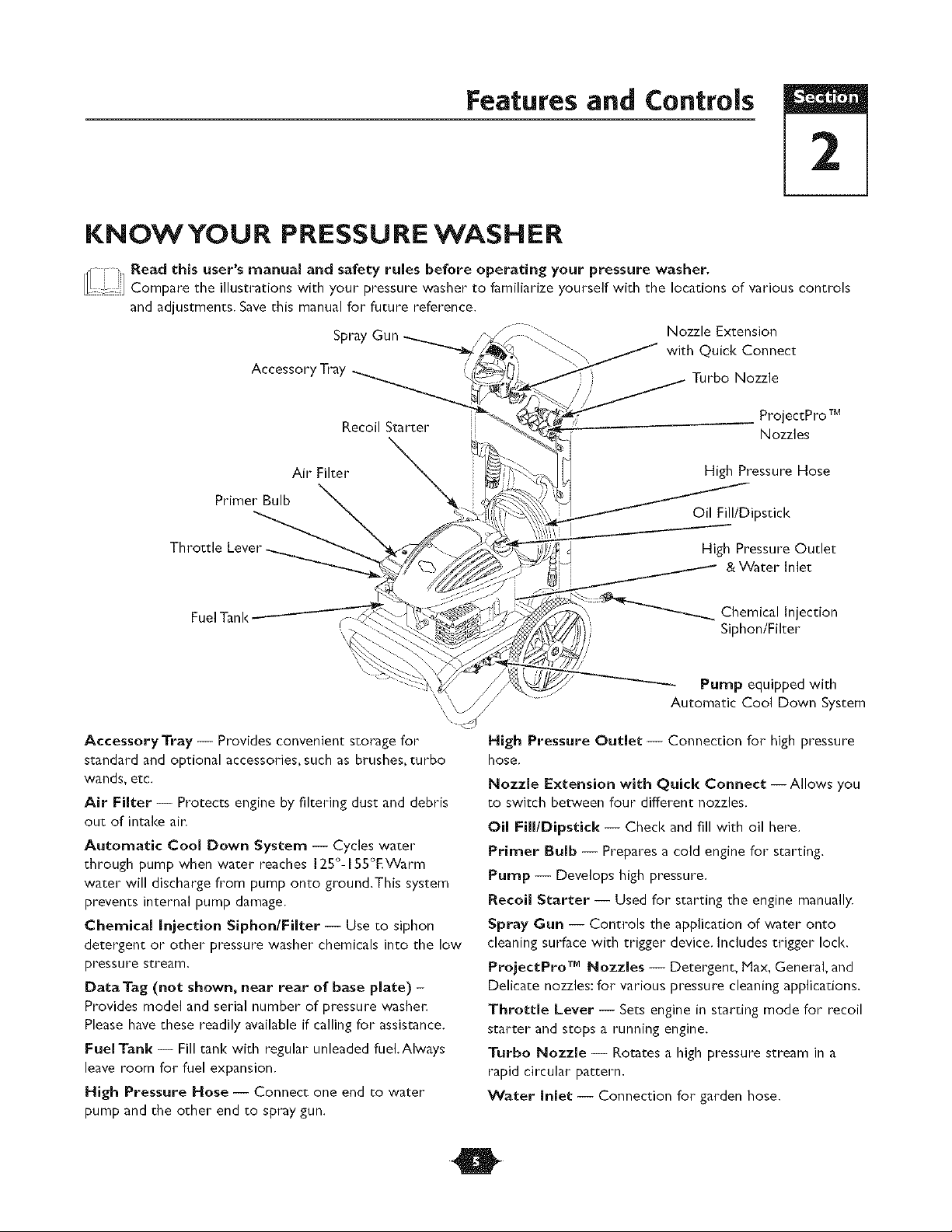

Features and Controls

KNOWYOUR PRESSURE WASHER

r _ Read this user's manual and safety rules before operating your pressure washer.

I!: _'o!;:1Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Nozzle Extension

Accessor

Spray Gun_._,_

with Quick Connect

Turbo Nozzle

Recoil Starter

Air Filter

Primer Bulb

Fuel Tanl<

Accessory Tray -- Provides convenient storage for

standard and optional accessories, such as brushes, turbo

wands, etc.

Air Filter -- Protects engine by filtering dust and debris

out of intake ain

Automatic Cool Down System -- Cycles water

through pump when water reaches 125°- [55°EWarm

water will discharge from pump onto ground.This system

prevents internal pump damage.

Chemical injection Siphon/FUter -- Use to siphon

detergent or other pressure washer chemicals into the low

pressure stream.

Data Tag (not shown, near rear of base plate) -

Provides model and serial number of pressure washen

Please have these readily available if calling for assistance.

Fuel Tank -- Fill tank with regular unleaded fuel. Always

leave room for fuel expansion.

High Pressure Hose -- Connect one end co water

pump and the other end co spray gun.

i

k

\

\

- ProjectPro TM

Nozzles

High Pressure Hose

Oil Fill/Dipstick

High Pressure Outlet

& Water Inlet

Chemical Injection

Siphon/Filter

Pump equipped with

Automatic Cool Down System

Nigh Pressure Outlet -- Connection for high pressure

hose.

Nozzle Extension with Quick Connect- Allows you

to switch between four different nozzles.

Oil Fill/Dipstick -- Check and fill with oil here.

Primer Bulb -- Prepares a cold engine for starting.

Pump -- Develops high pressure.

Recoil Starter -- Used for starting the engine manually.

Spray Gun -- Controls the application of water onto

cleaning surface with trigger device. Includes trigger loci<.

ProjectPro TMNozzles -- Detergent, Max, General, and

Delicate nozzles: for various pressure cleaning applications.

Throttle Lever -- Sets engine in starting mode for recoil

starter and stops a running engine.

Turbo Nozzle -- Rotates a high pressure stream in a

rapid circular pattern.

Water Inlet -- Connection for garden hose.

O

Assembly

ASSEMBLY

iMPORTANT: Read entire user's manual before you

attempt to assemble or operate your new pressure washel_

Remove Pressure Washer From

Carton

I. Remove the parts bag,accessories, and inserts included

with pressure washei:

2. Slice two corners at the end of carton from top to

bottom so the panel can be folded down flat.

3. Remove pressure washer from carton.

Carton Contents

items in the carton include:

Main Unit

Handle

High Pressure Hose

Spray Gun

Nozzle Extension with Quick Connect Fitting

Plastic Accessory Tray

Safety Goggles

Oil Bottle

Turbo Nozzle with Quick Connect

Parts Bag (which includes the following):

User's Manual

Engine User's Manual

Owner's Registration Card

Bag containing 4 multi-colored ProjectPro Tu

Nozzles

Handle/Tray Fastening Hardware Kit (which

includes):

Carriage Bolts (2)

Plastic Knobs (2)

Tree Clips (4)

PREPARING PRESSURE

WASHER FOR USE

If you have any problems with the assembly of your

pressure washer or if parts are missing or damaged, call the

pressure washer helpline at 1-800-743-4115. If calling for

assistance, please have the model, revision, and serial

number from the data tag available.

To prepare your pressure washer for operation, you

will need to perform these tasks:

I. Fill out and send in registration card.

2. Attach handle to main unit, then attach accessory tray

to handle.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connect high pressure hose to spray gun and pump.

6. Connect water supply to pump.

7. Attach nozzle extension to spray gun.

8. Select/attach quick connect ProjectPro Tu nozzle to

nozzle extension.

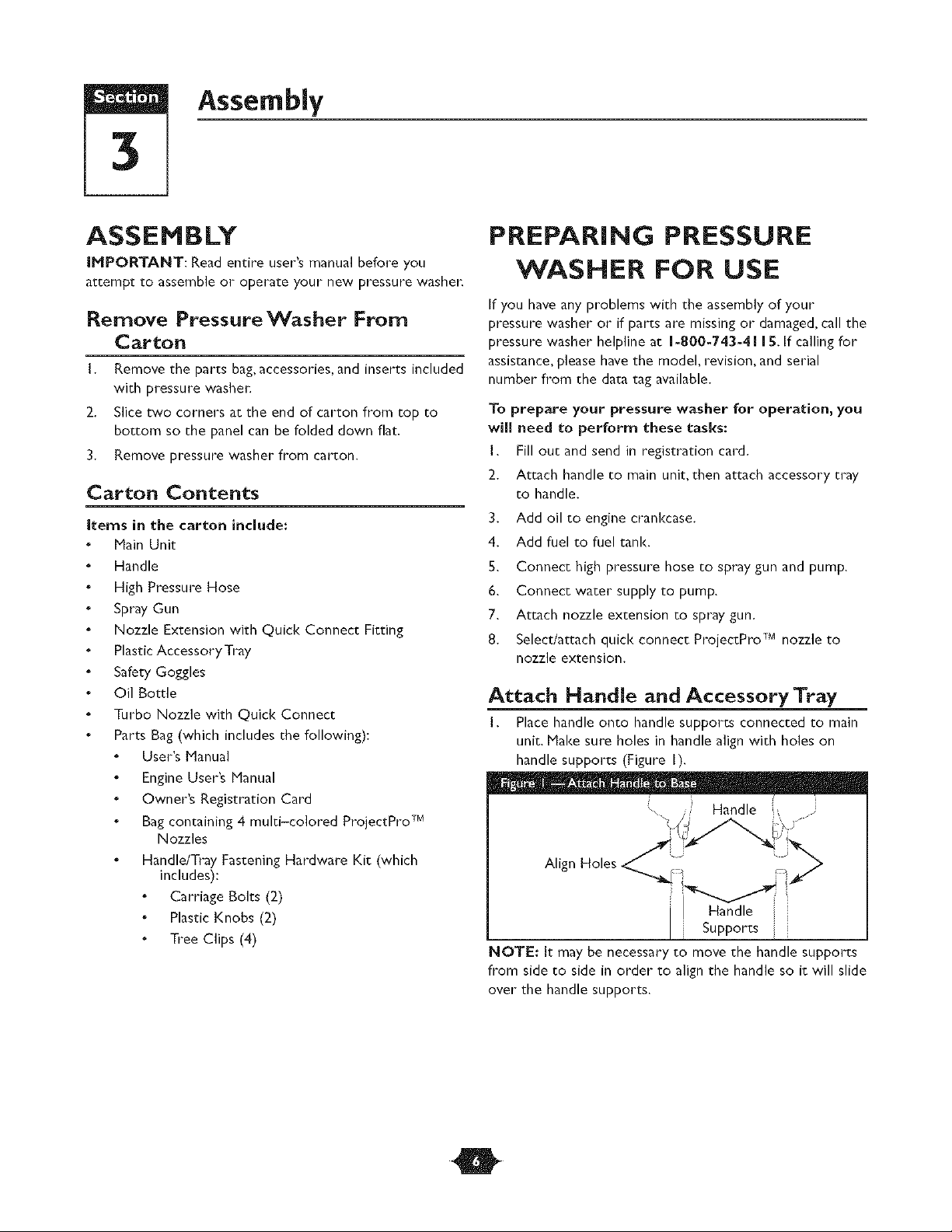

Attach Handle and Accessory Tray

I. Place handle onto handle supports connected to main

unit. Make sure holes in handle align with holes on

handle supports (Figure I).

_, . Handle

j(i

A,,goHo,es f

I Handle i

Supports

NOTE: It may be necessary to move the handle supports

fl*om side to side in order to align the handle so it will slide

over the handle supports.

O

Section 3: Assembly

2. Insert carriage bolts through holes from outside of unit

and attach a plastic knob from inside of unit (Figure 2).

Tighten by hand.

3. Place accessory tray over holes on handle (viewing

from front of unit). Push the tree clips into the holes

until they sit flat against the accessory tray (Figure 3).

4. Insert mulu-colored ProjectPro Tmnozzles and other

supplied accessories in spaces provided in accessory

tray. See "How to Use AccessoryTray'.

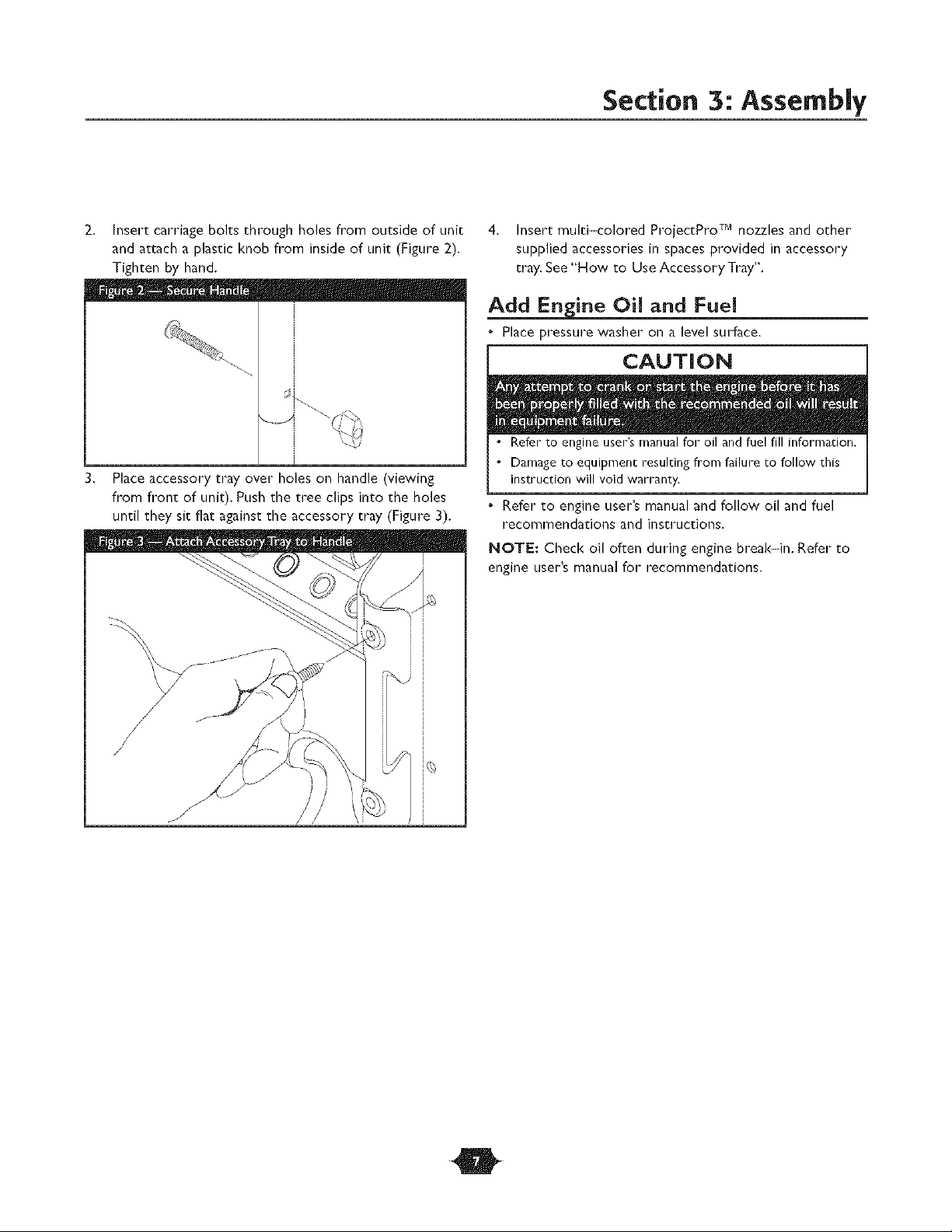

ine Oil and Fuel

• Place pressure washer on a level surface.

CAUTION

* Refer to engine user's manual for oil and fuel fill information.

* Damage to equipment resulting from failure to follow this

instruction will void warranty.

• Refer to engine user's manual and follow oil and fuel

recommendations and insu*uctions.

NOTE: Check oil often during engine breal<-in. Refer to

engine user's manual for recommendations.

O

Section 3: Assembly

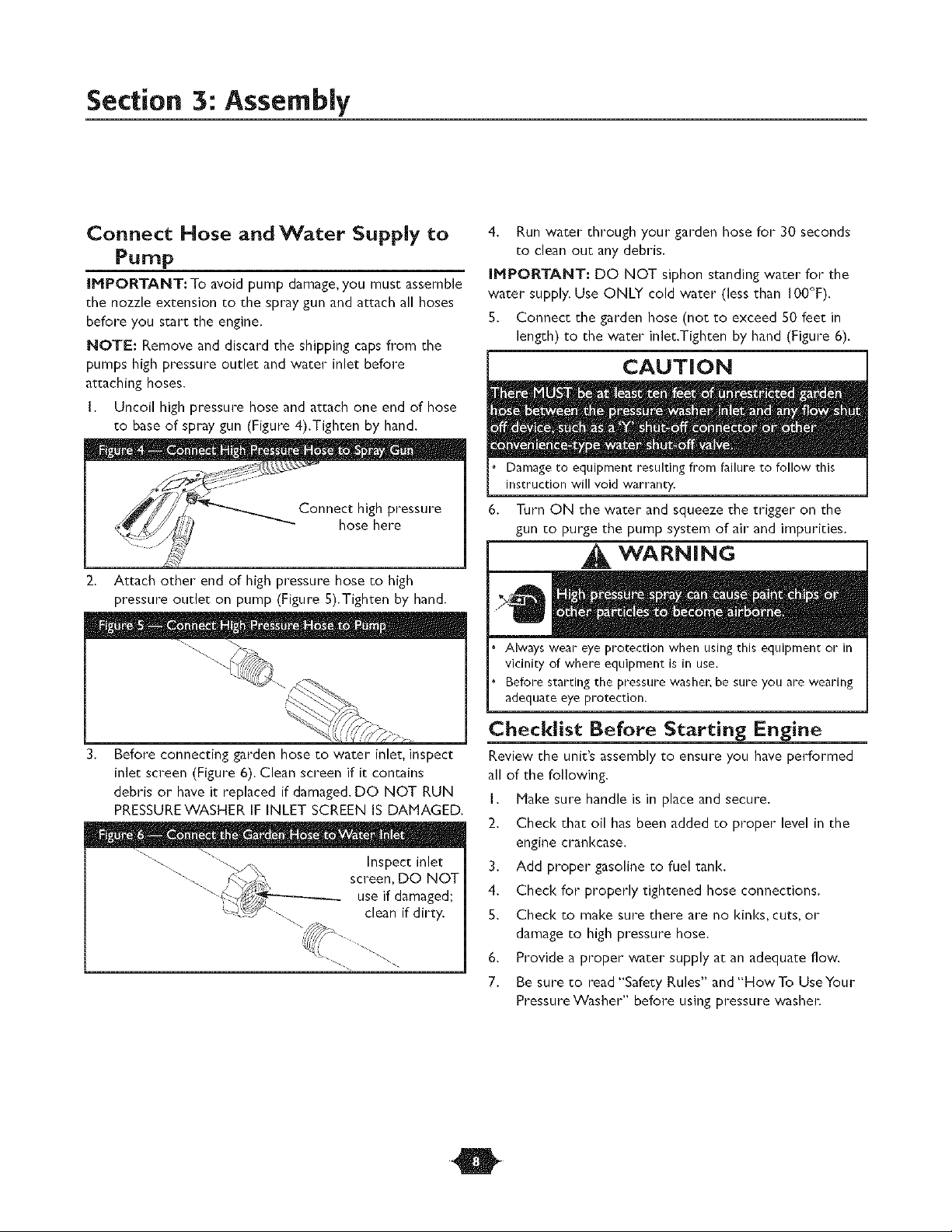

Connect Hose and Water Supply to

Pump

IMPORTANT: To avoid pump damage, you must assemble

the nozzle extension co the spray gun and attach all hoses

before you start the engine.

NOTE: Remove and discard the shipping caps from the

pumps high pressure outlet and water inlet before

attaching hoses.

I. Uncoil high pressure hose and attach one end of hose

co base of spray gun (Figure 4).Tighten by hand.

hose here

2. Attach other end of high pressure hose co high

pressure outlet on pump (Figure 5).Tighten by hand.

4. Run water through your garden hose for 30 seconds

co clean ouc any debris.

IMPORTANT: DO NOT siphon standing water for the

water supply.Use ONLY cold water (lessthan 100°F).

5. Connect the garden hose (not to exceed 50 feet in

length) to the water inlet.Tighten by hand (Figure 6).

CAUTION

Damage to equipment resulting from failure to follow this

instruction will void warranty.

6.

Turn ON the water and squeeze the trigger on the

gun co purge the pump system of air and impurities.

WARNING

Always wear eye protection when using this equipment or in

vicinity of where equipment is in use.

Before starting the pressure washer, be sure you are wearing

adequateeye protection.

3.

Before connecting garden hose co water inlet, inspect

inlet screen (Figure 6). Clean screen if it contains

debris oi" have it replaced if damaged. DO NOT RUN

PRESSUREWASHER IF INLET SCREEN IS DAMAGED.

Inspect inlet

screen, DO NOT

use if damaged;

clean if dirty.

Checklist Before Starting Engine

Review the unit's assembly to ensure you have performed

all of the following.

I. Make sure handle is in place and secure.

2. Check that oil has been added co proper level in the

engine crankcase.

3. Add proper gasoline co fuel tank.

4. Check for properly tightened hose connections.

5. Check to make sure there are no kinks, cuts, or

damage co high pressure hose.

6. Provide a proper water supply at an adequate flow.

7. Be sure co read "Safety Rules" and "HowTo UseYour

P_essu_eWashe _ befo e using p essu e washe_

O

Operation

HOWTO USE YOUR

PRESSU RE WASH ER

If you have any problems operaung your pressure washer,

please call the pressure washer helpline at 1-800-743-4115.

Pressure Washer Location

Pressure Washer Clearance

WARNING

Operate pressure washer ONLY outdoors.

Keep exhaust gasfl*omentering aconfined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate pressure washer inside any building or

enclosure, even if doors or windows are open.

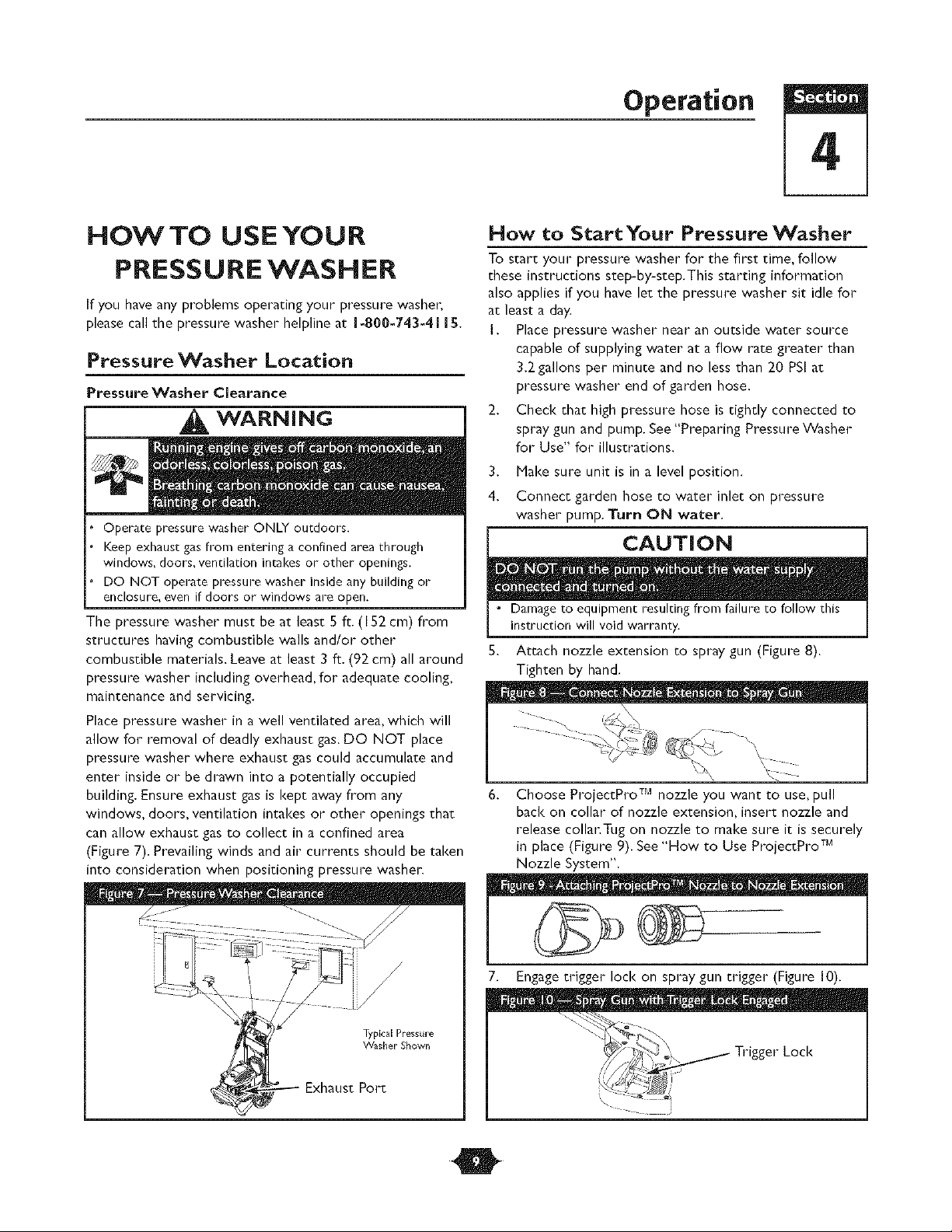

The pressure washer must be at least 5 ft. (I 52 cm) from

structures having combustible walls and/or other

combustible materials. Leave at least 3 ft. (92 cm) all around

pressure washer including overhead, for adequate cooling,

maintenance and servicing.

Place pressure washer in a well ventilated area, which will

allow for removal of deadly exhaust gas. DO NOT place

pressure washer where exhaust gas could accumulate and

enter inside or be drawn into a potentially occupied

building. Ensure exhaust gas is kept away from any

windows, doors, ventilation intakes or other openings that

can allow exhaust gas to collect in a confined area

(Figure 7). Prevailing winds and air currents should be taken

into consideration when positioning pressure washer.

How to Start Your Pressure Washer

To start your pressure washer for the first time, follow

these instructions step-by-step.This starting information

also applies if you have let the pressure washer sit idle for

at least a day.

I. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

3.2 gallons per minute and no less than 20 PSI at

pressure washer end of garden hose.

2. Check that high pressure hose is tightly connected to

spray gun and pump. See"Preparing Pressure Washer

for Use" for illustrations.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump. Turn ON water.

CAUTION

* Damage to equipment resulting from failure to follow this

instruction will void warranty.

5. Attach nozzle extension to spray gun (Figure 8).

Tighten by hand.

\

6. Choose ProjectPro TMnozzle you want to use, pull

back on collar of nozzle extension, insert nozzle and

release collanTug on nozzle to make sure it is securely

in place (Figure 9). See "How to Use ProjectPro TM

Nozzle System".

Typical Pressure

Washer Shown

Exhaust Port

7. Engage trigger loci< on spray gun trigger (Figure I0),

_ _7-r_,_J,_ / Trigger Loci<

J

O

Section 4: Operation

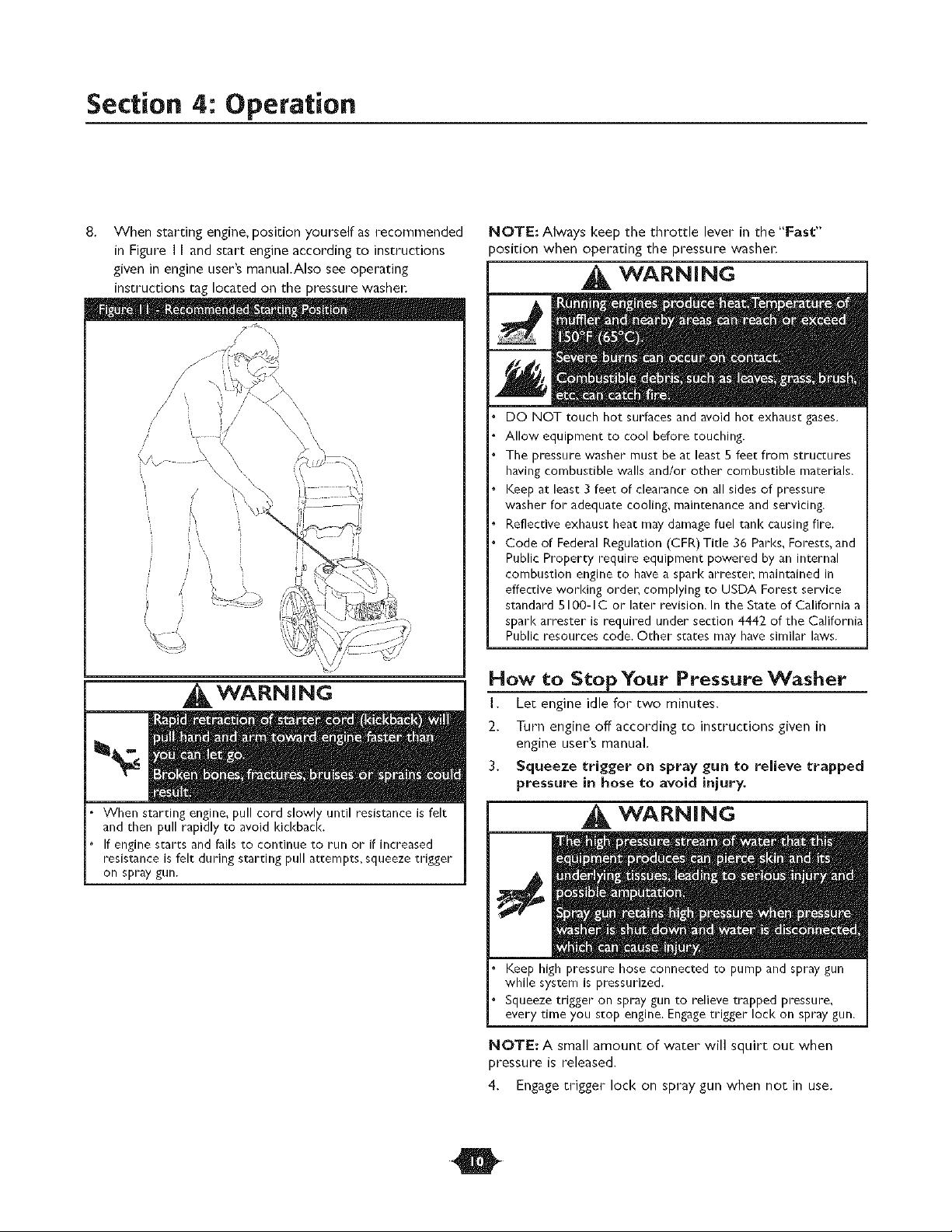

8. When starting engine, position yourself as recommended

in Figure I I and start engine according to instructions

given in engine user's manual.Also see operating

instructions tag located on the pressure washel:

I WARNING

NOTE: Always keep the throttle lever in the "Fast"

)osiuon when operaung the pressure washen

WARNING

DO NOT touch hot surfaces and avoid hot exhaust gases.

Allow equipment to cool before touching.

The pressure washer must be at least 5 feet from structures

having combustible walls and/or other combustible materials.

Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

Reflective exhaust heat may damage fuel tank causing fire.

Code of Federal Regulation (CFR) Title 36 Parks, Forests, and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100- IC or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

How to Stop Your Pressure Washer

I. Let engine idle for two minutes.

2. Turn engine off according to insu*ucdons given in

engine user's manual.

3. Squeeze trigger on spray gun to relieve trapped

pressure in hose to avoid injury.

When starting engine, Full cord slowly until resistance is felt

and then Full rapidly to avoid Idcl<bacl<.

If engine starts and fails to continue to run or if increased

resistance is felt during starting pull aEempts, squeeze trigger

on spray gun.

WARNING

Keep high pressure hose connected to pump and spray gun

while system is pressurized.

Squeeze trigger on spray gun to relieve trapped pressure,

every time you sto F engine. Engage trigger lock on spray gun.

NOTE: A small amount of water will squirt out when

pressure is released.

4, Engage trigger loci< on spray gun when not in use.

O

Section 4: Operation

How to Use AccessoryTray

The unit is equipped with an accessory tray with places to

store your spray gun, nozzle extension, turbo nozzle, and

ProjeetPro TMnozzles.There is also a hook at the front of

the accessory tray to hold your high pressure hose.

NOTE:The extra hole in the tray is for storing a utility

brush.The brush is NOT included with your pressure

washenYou can buy the brush as an optional accessory.

I. Place nozzle extension through hole on accessory tray,

as shown in Figure 12.

2.

Place spray gun through hole on accessory tray on

right side of unit (Figure 12).

3.

Push turbo nozzle up and into clip on accessory tray

until it snaps in, as shown in Figure 12.

4.

Hang high pressure hose on hook attached to accessory

tray on front of tray, as shown in Figure 12.

How to Use Projed:Pro TM Nozzle

System

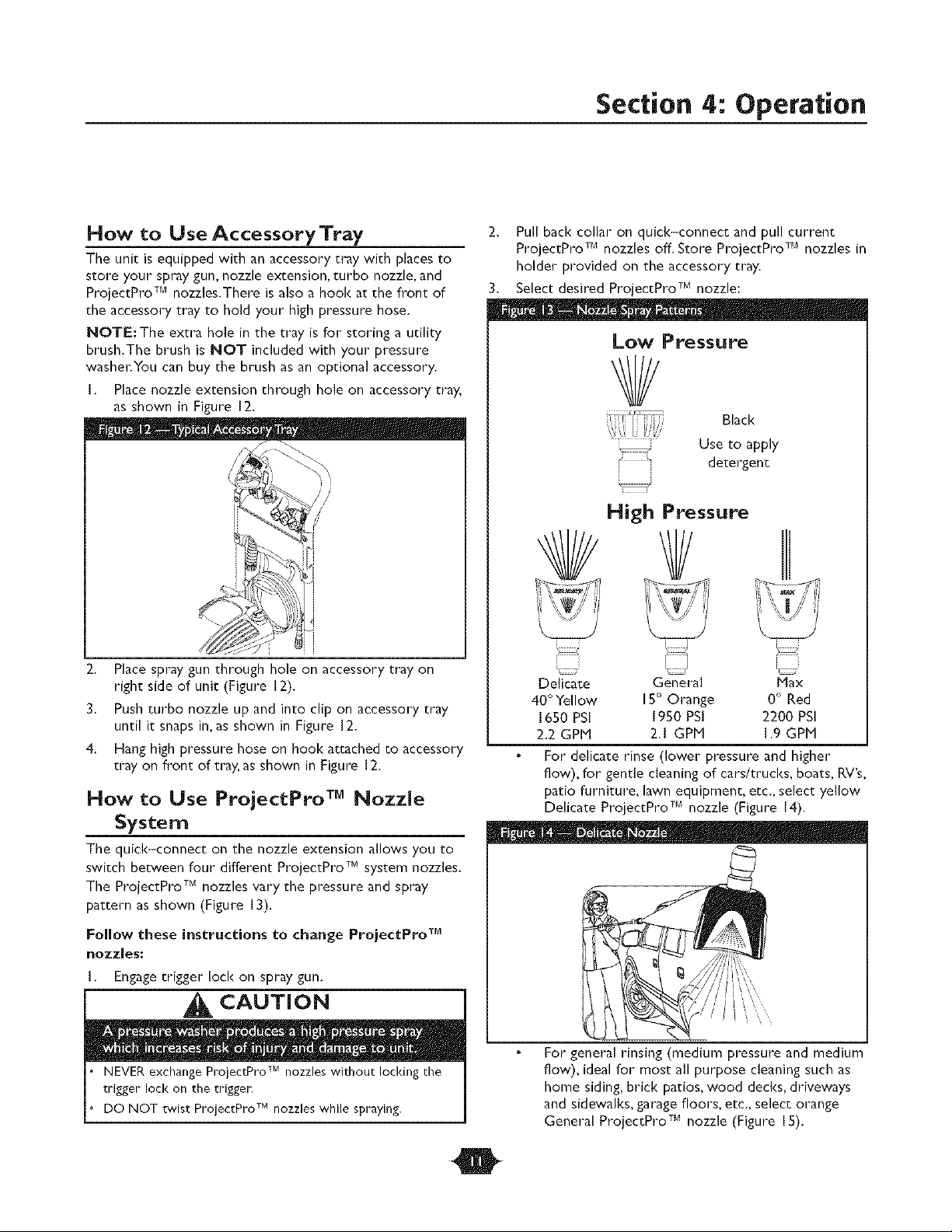

The quick-connect on the nozzle extension allows you to

switch between four different ProjectPro TMsystem nozzles.

The ProjectPro TMnozzles vary the pressure and spray

pattern as shown (Figure 13).

2. Pull back collar on quick-connect and pull current

ProjectPro TMnozzles off. Store ProjectPro TMnozzles in

holder provided on the accessory tray.

3. Select desired ProjectPro Tu nozzle:

Low Pressure

Black

Use to apply

detergent

High Pressure

Delicate General Max

40°Yellow IS° Orange 0° Red

1650 PSI 1950 PSi 2200 PSI

2.2 GPM 2.1 GPM 1.9 GPM

For delicate rinse (lower pressure and higher

flow), for gentle cleaning of cars/trucl<s, boats, RV's,

patio furniture, lawn equipment, etc., select yellow

Delicate ProjeetPro TM nozzle (Figure 14).

Follow these instructions to change ProjectPro TM

nozzles:

I. Engage trigger lock on spray gun.

CAUTION

NEVER exchangeProjectPro nozzles without locking the

trigger lock on the triggel_

DO NOT twist ProjectPro nozzles while spraying.

TM

TM

For general rinsing (medium pressure and medium

flow), ideal for most all purpose cleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garage floors, etc., select orange

General ProjectPro TM nozzle (Figure IS).

O

Loading...

Loading...