Briggs & Stratton 020224-0 Operator's Manual

Operator’s Manual / Manuel d'opérateur / Bedienungsanleitung /

Manual do Operador / Manual del Operario

Model No. 020224 (2700 PSI Pressure Washer) Manual No. 195259GS Revision 1 (11/04/2005)

2700 PSI

185 BAR

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

2

TABLE OF CONTENTS

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Know Your Pressure Washer. . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

EQUIPMENT

DESCRIPTION

Read this manual carefully and become

familiar with your pressure washer. Know its

applications, its limitations and any hazards

involved.

This manual contains information for a high pressure

washer that operates at 2,700 PSI at a flow rate of

2.5 gallons per minute.This powerful, high quality system

features large 10” wheels, a pump equipped with an

automatic cool down system, chemical injection system,

nozzle extension with quick connect nozzles, safety goggles,

heavy duty 25’ hose, and more.

Every effort has been made to ensure that information in

this manual is accurate and current. However, we reserve

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

SAFETY RULES

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

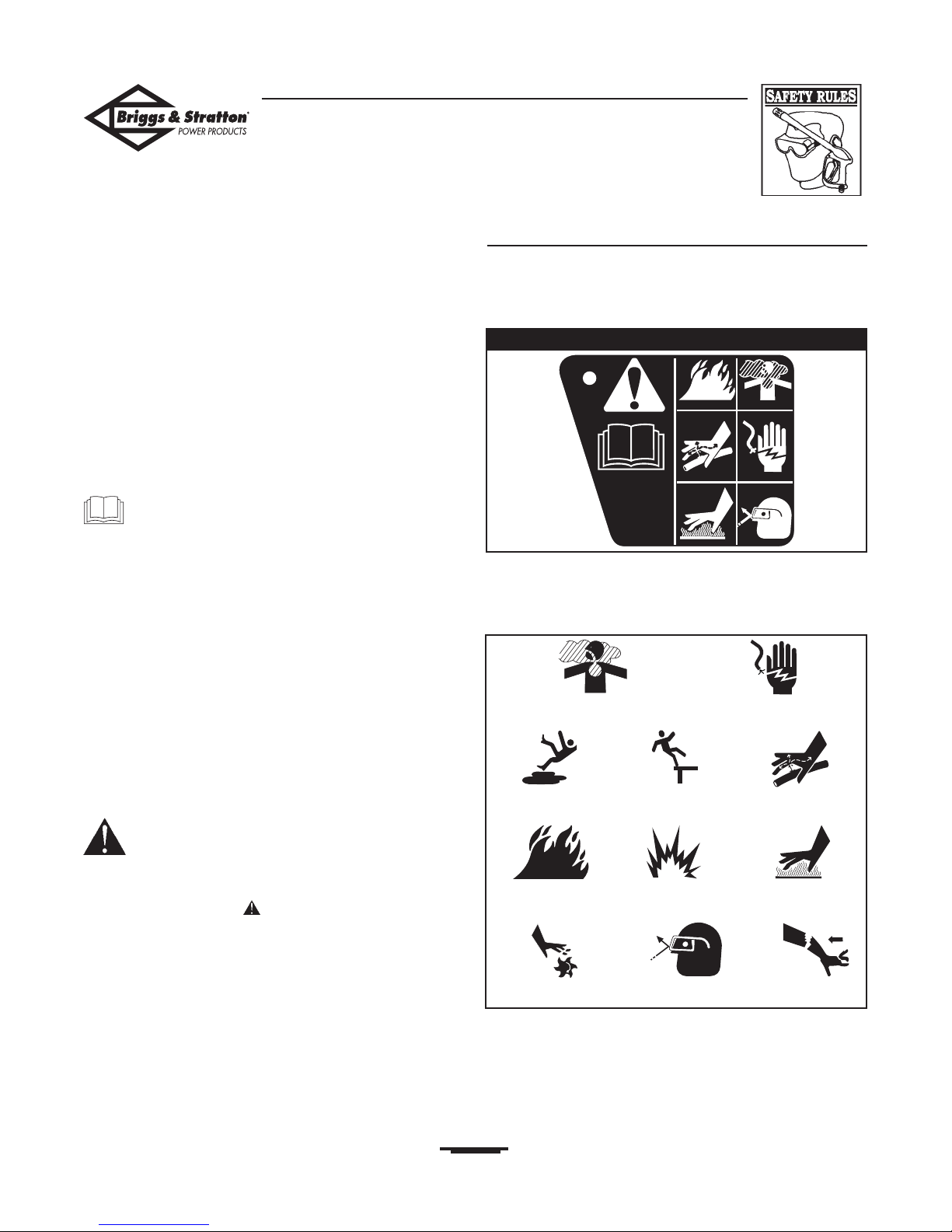

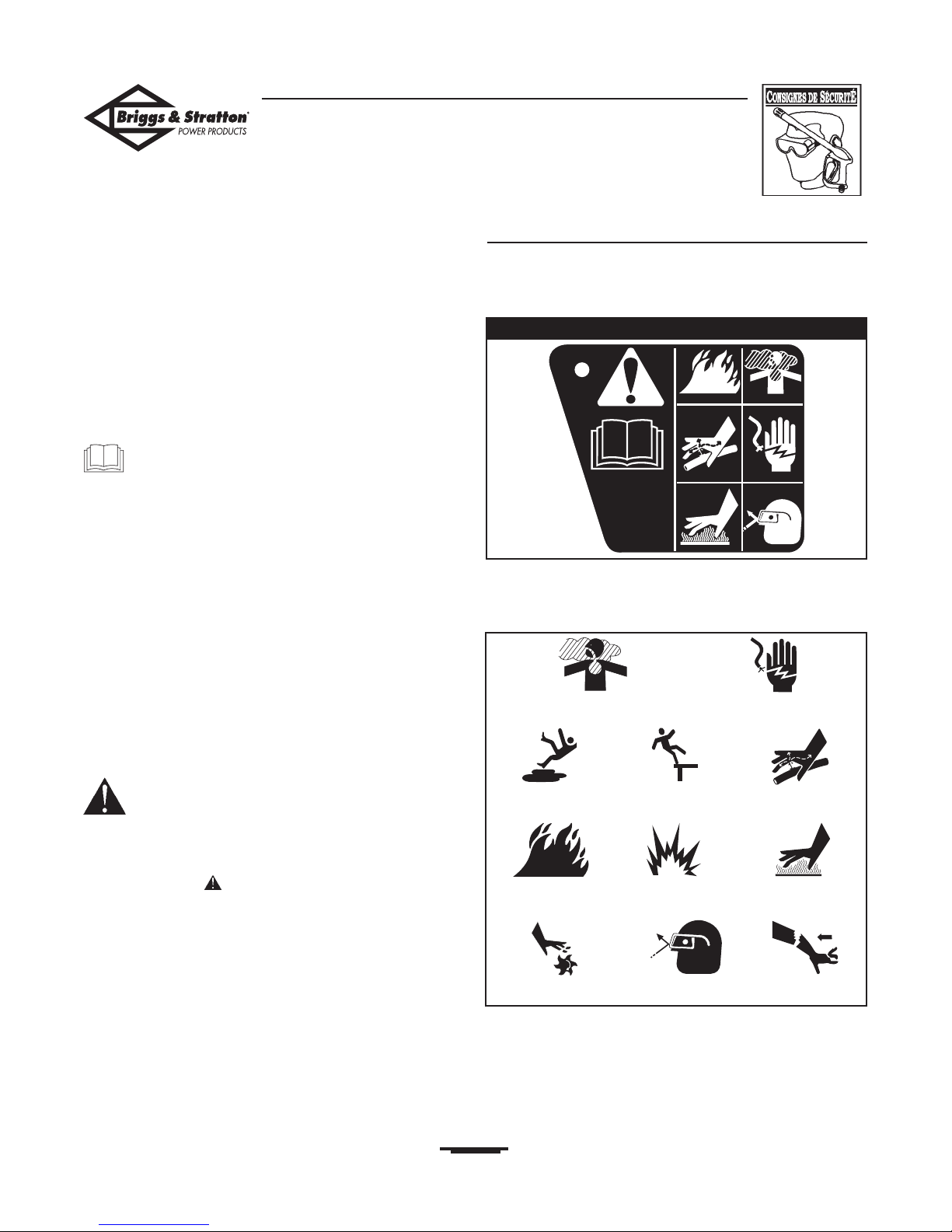

Warning Tag

A warning tag (Figure 1) is provided on your unit to inform

you of potential safety hazards. If the tag becomes damaged

or illegible, replace it by contacting your local Briggs &

Stratton dealer to obtain a new one.

The icons on the warning tag are shown and described in

detail later in the next section.

Hazard Symbols and Meanings

Fire

Explosion

Toxic Fumes

Hot Surface

Moving Parts

Electrical Shock

Slippery Surface

Fall

Kickback

Flying Objects

Fluid Injection

Figure 1 — Warning Label

Copyright © 2005 Briggs & Stratton Power Products

Group, LLC. All rights reserved. No part of this material

may be reproduced or transmitted in any form by any

means without the express written permission of Briggs &

Stratton Power Products Group, LLC.

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

3

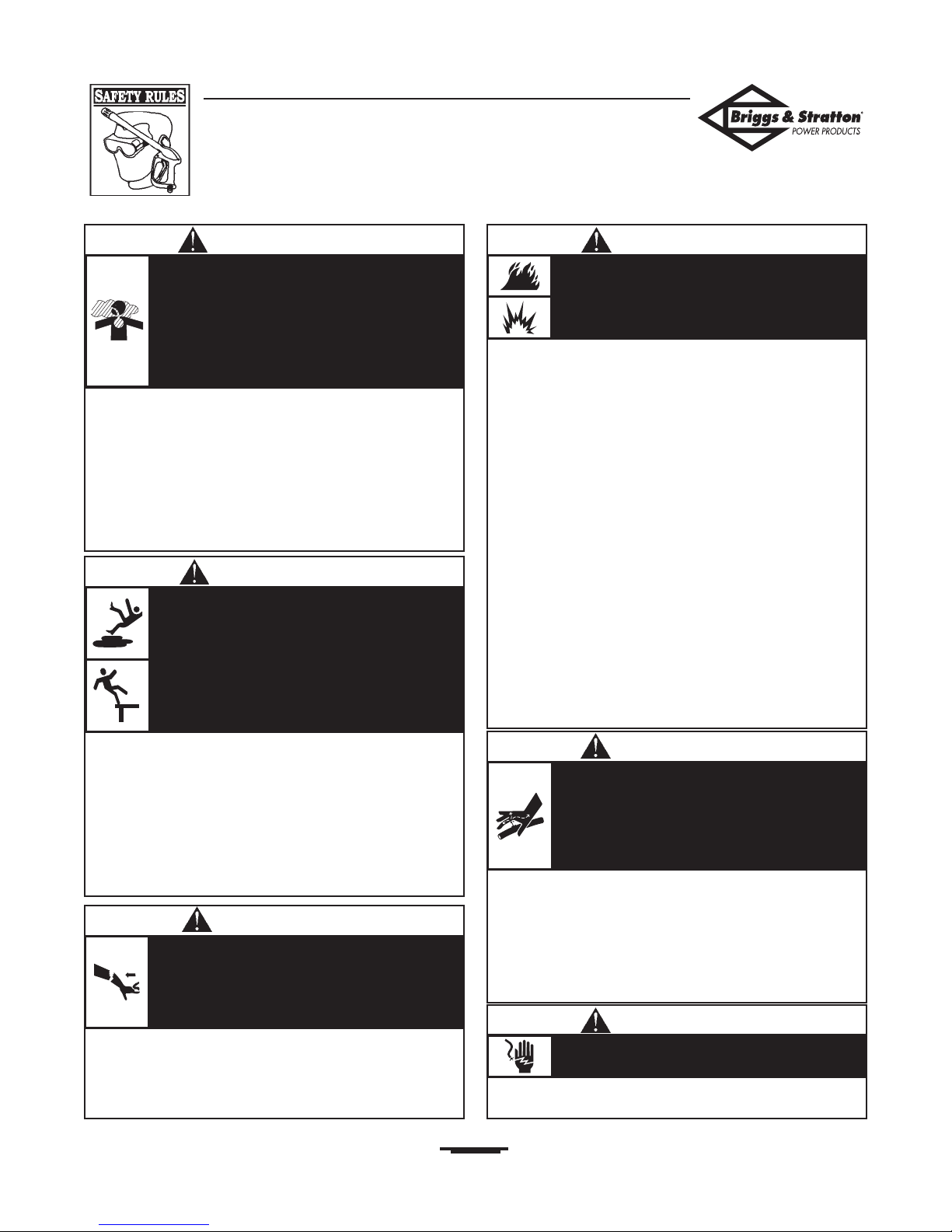

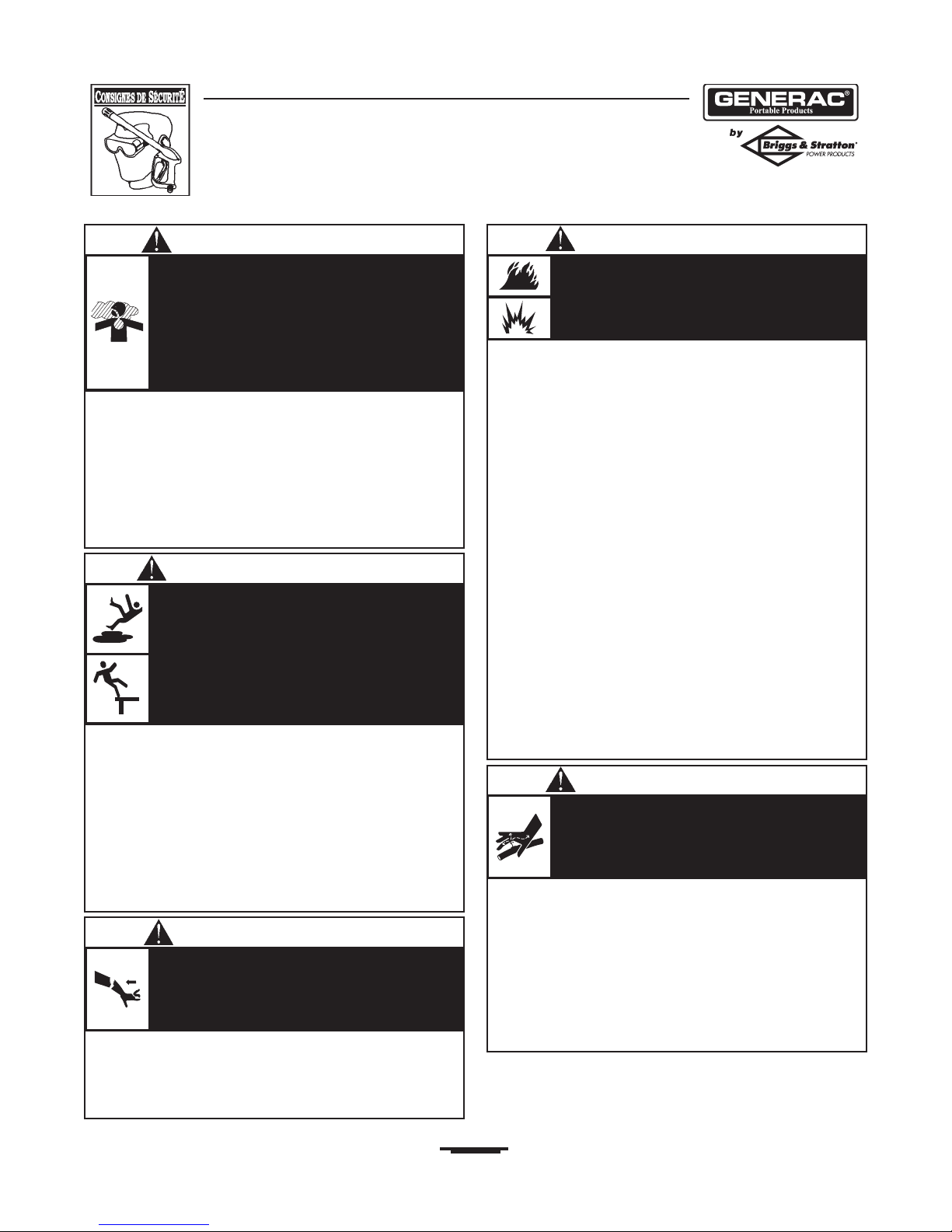

• Keep water spray away from electric wiring or fatal electric

shock may result.

Spray contact with electrical wiring can result in

electrocution.

WARNING

• Operate pressure washer ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

• DO NOT operate pressure washer inside any building or

enclosure.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled.

• Read all instructions with mask so you are certain the mask will

provide the necessary protection against inhaling harmful vapors.

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide will cause nausea,

fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting or poisoning.

WARNING

• Keep spray nozzle between 8 to 24 inches away from cleaning

surface.

• Operate this unit on a stable surface.

• The cleaning area should have adequate slopes and drainage to

reduce the possibility of a fall due to slippery surfaces.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding or any other relatively unstable location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

Use of pressure washer can create puddles and

slippery surfaces.

High pressure spray could cause you to fall if

you are too close to the cleaning surface.

WARNING

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze trigger

on spray gun.

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains could

result.

WARNING

• NEVER aim spray gun at people, animals or plants.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• Squeeze trigger on spray gun to relieve trapped pressure,

every time you stop engine. Engage trigger lock on spray gun.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun retains high pressure when pressure

washer is shut down, which can cause injury.

WARNING

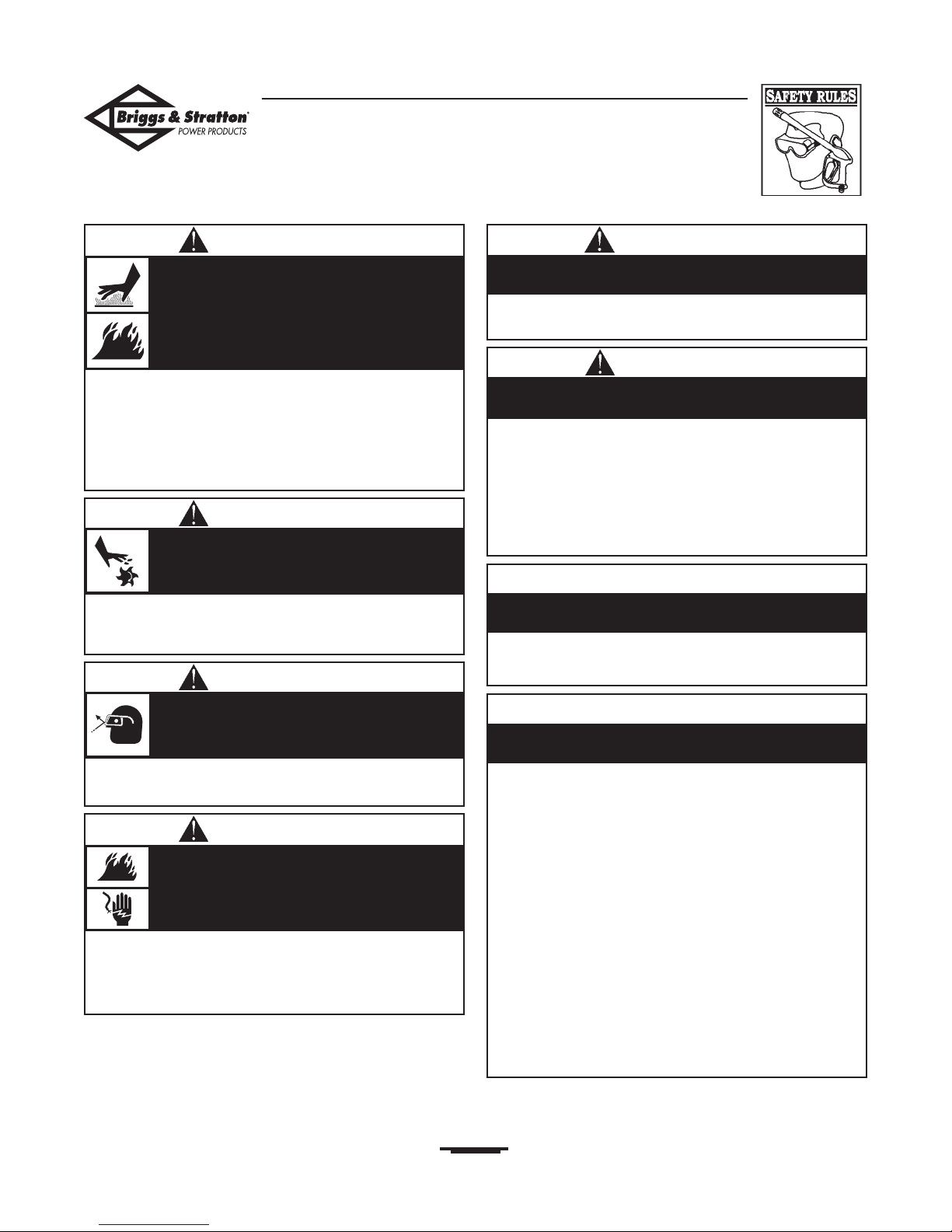

WHEN ADDING FUEL

• Turn pressure washer OFF and let it cool at least 2 minutes

before removing fuel cap.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which causes fuel

to spill.

• DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• Secure pressure washer upright when transporting so that it

does not tip and spill fuel and oil.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Fuel and its vapors are extremely flammable an

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

4

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

Excessively high or low operating speeds increase risk

of injury and damage to pressure washer.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect spark plug wire from spark plug and place wire

where it cannot contact spark plug.

Unintentional sparking can result in fire or

electric shock.

WARNING

• DO NOT point spray gun at glass when in jet spray mode.

• NEVER aim spray gun at plants.

High pressure spray may damage fragile items including

glass.

CAUTION

• DO NOT wear loose clothing, jewelry or anything that may

be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

WARNING

• Always wear eye protection when using this equipment or in

vicinity of where equipment is in use.

High pressure spray can cause paint chips or

other particles to become airborne.

WARNING

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger lock or

trigger guard in place and in working order.

• Always be certain spray gun,nozzles and accessories are

correctly attached.

A pressure washer produces a high pressure spray

which increases risk of injury and damage to unit.

CAUTION

• If you have questions about intended use, ask dealer or

contact Briggs & Stratton Power Products.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by–pass any safety device on this machine.

• Before starting pressure washer in cold weather, check all

parts of the equipment to be sure ice has not formed there.

• NEVER move machine by pulling on high pressure hose. Use

handle provided on unit.

• Check fuel system for leaks or signs of deterioration, such as

chafed or spongy hose, loose or missing clamps,or damaged

tank or cap. Correct all defects before operating pressure

washer.

• This equipment is designed to be used with Briggs & Stratton

Power Products authorized parts ONLY. If equipment is used

with parts that DO NOT comply with minimum specifications,

user assumes all risks and liabilities.

Improper treatment of pressure washer can damage it

and shorten its life.

CAUTION

• DO NOT touch hot surfaces.

• Allow equipment to cool before touching.

• The pressure washer must be at least 5 feet from structures

having combustible walls and/or other combustible materials.

• Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Combustible debris, such as leaves, grass, brush,

etc. can catch fire.

WARNING

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

5

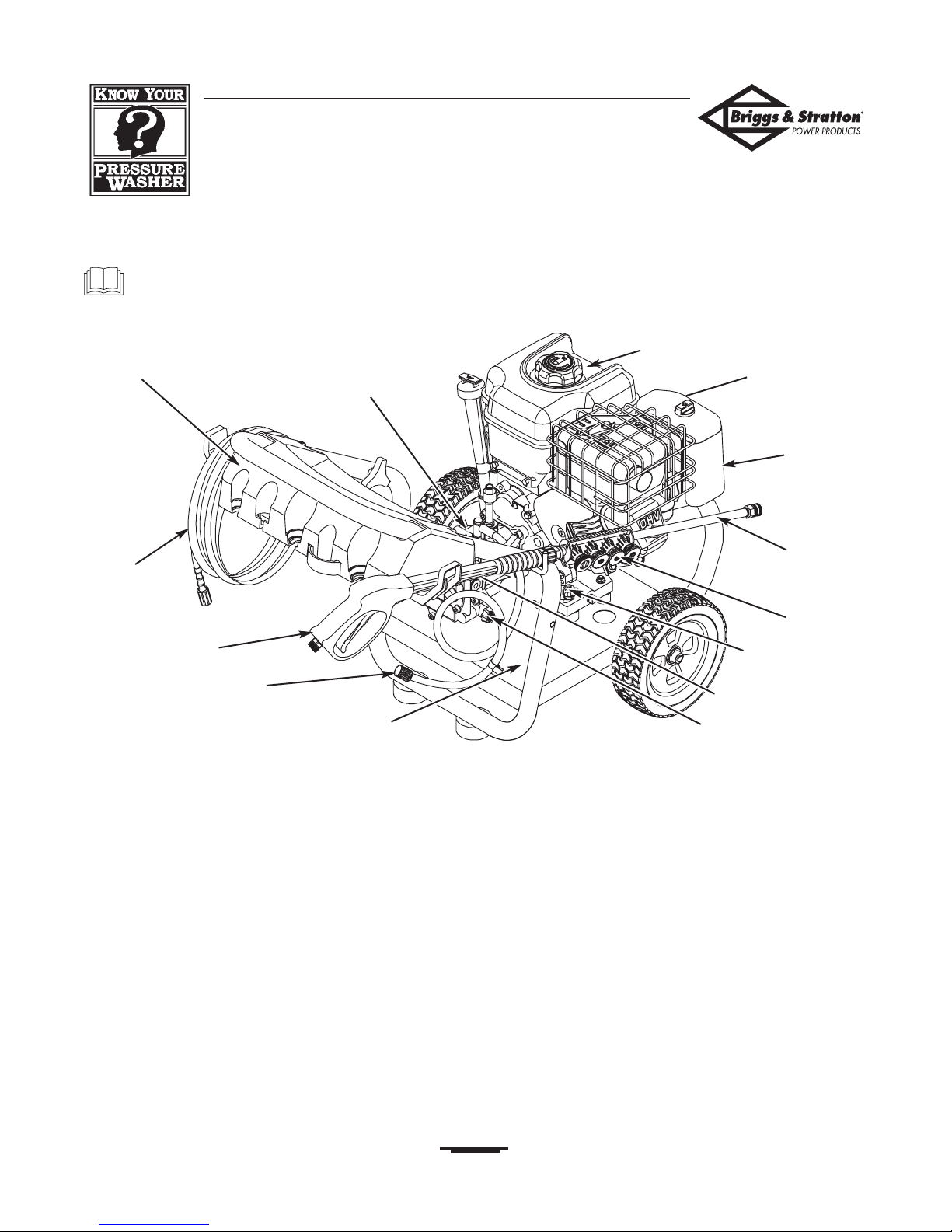

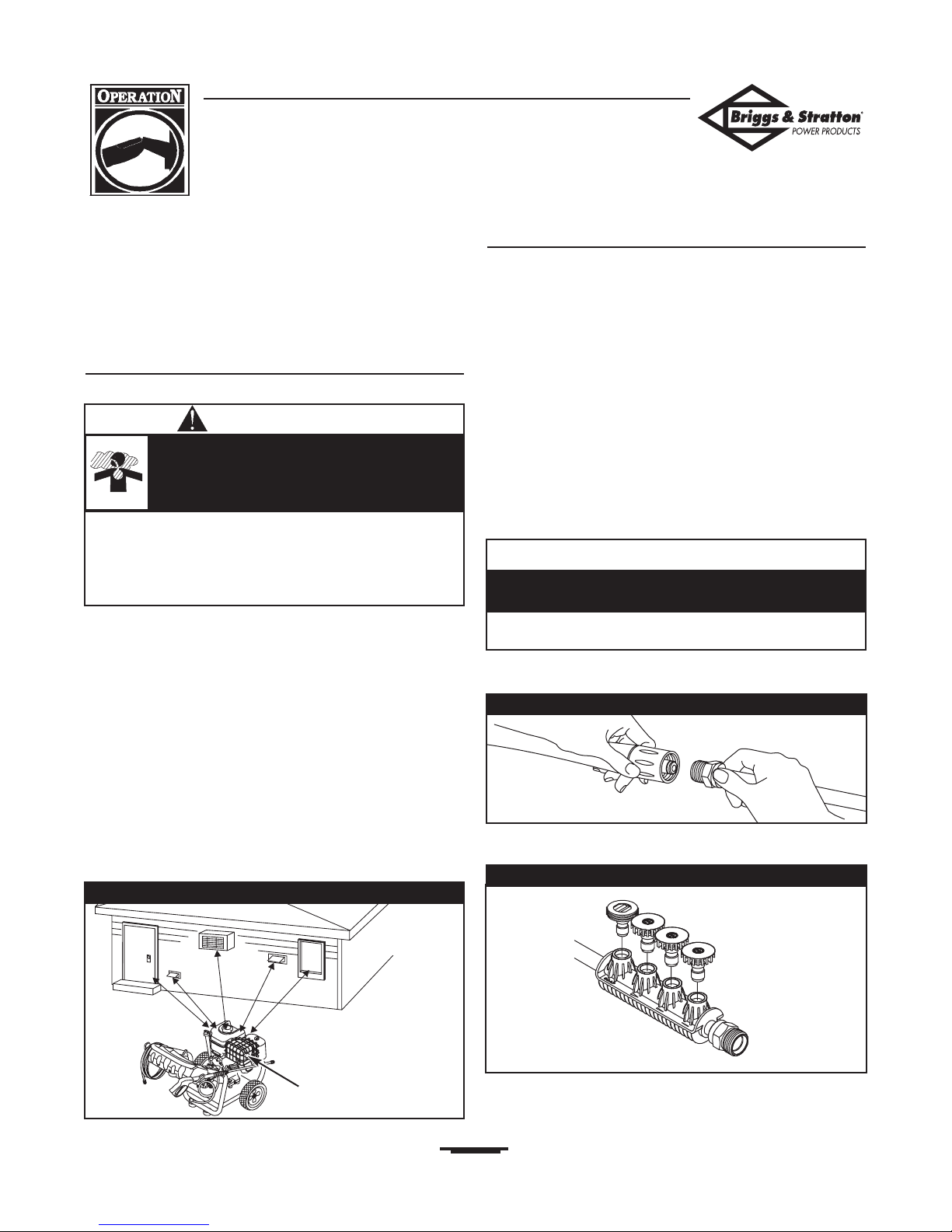

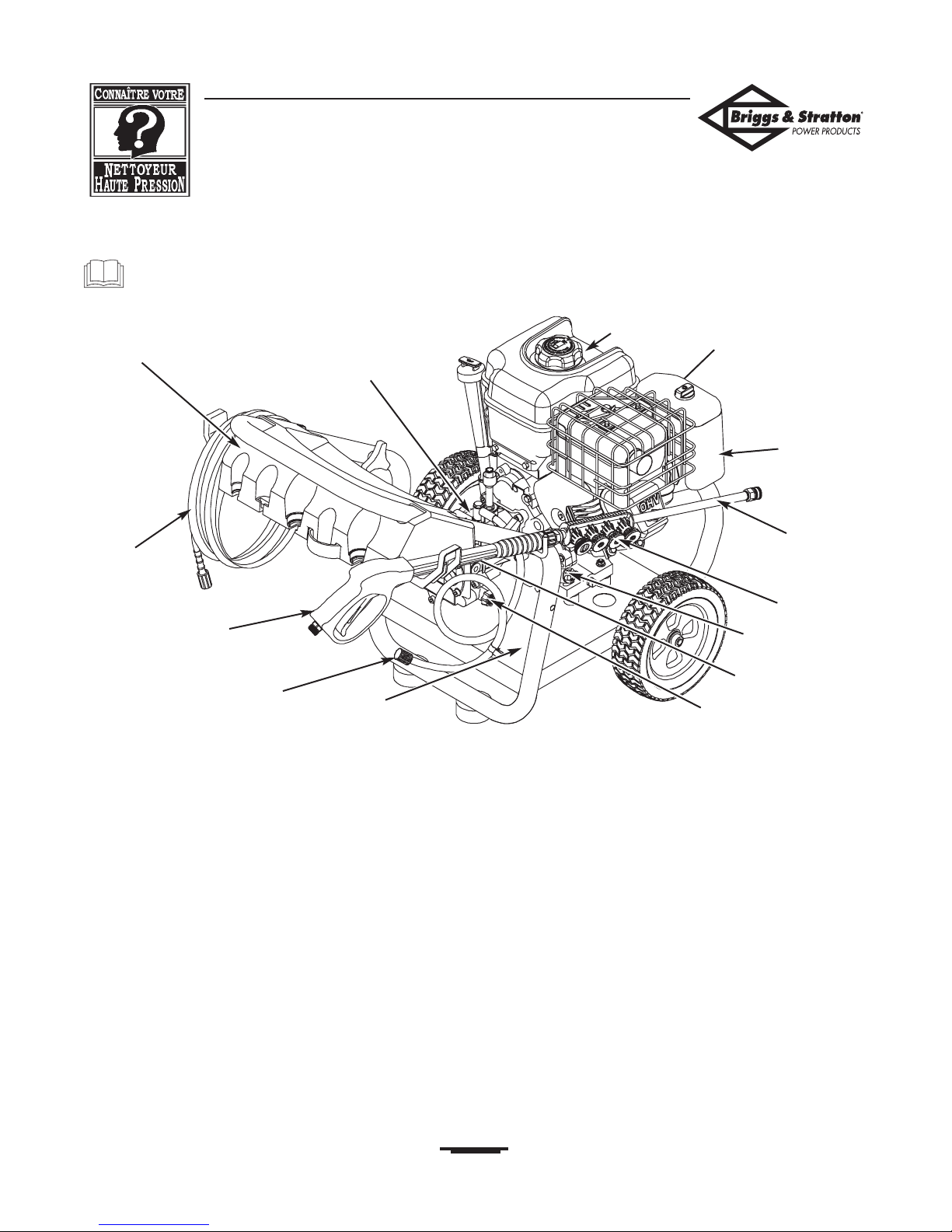

KNOW YOUR PRESSURE WASHER

Read this operator’s manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Chemical Injection

Siphon/Filter

Spray Gun

Nozzle Extension

with Quick Connect

Throttle Lever

Choke Lever

Fuel Valve

Recoil Starter

(on front of engine)

Air Filter

Fuel Tank

Pump equipped

with Automatic

Cool Down System

Water Inlet

Oil Fill Cap

Spray Tips

High Pressure Outlet

Accessory Tray — Provides convenient storage for

standard and optional accessories, such as brushes, turbo

wands, ect.

Air Filter — Protects engine by filtering dust and debris out

of intake air.

Automatic Cool Down System — Cycles water through

pump when water reaches 125°-155°F. Warm water will

discharge from pump onto ground.This system prevents

internal pump damage.

Chemical Injection Siphon/Filter — Use to siphon

detergent or other pressure washer chemicals into the low

pressure stream.

Choke Lever — Prepares a cold engine for starting.

Data Tag — Provides model, revision and serial number of

pressure washer. Please have these readily available if calling

for assistance.

Fuel Tank — Fill tank with regular unleaded fuel.Always leave

room for fuel expansion.

Fuel Valve — Used to turn fuel on and off to engine.

High Pressure Hose — Connect one end to the water

pump and the other end to the spray gun.

High Pressure Outlet — To connect high pressure hose.

Nozzle Extension with Quick Connect — Allows you to

switch between four different spray tips.

Oil Fill Cap — Fill engine with oil here.

Pump — Develops high pressure.

Recoil Starter — Use for starting the engine manually.

Safety Goggles (not shown) — Always use the enclosed

goggles or other eye protection when running your

pressure washer.

Spray Gun — Controls the application of water onto

cleaning surface with trigger device. Includes safety latch.

Spray Tips — Chemical injection, 0°, 15°, and 40°: for various

high pressure cleaning applications.

Throttle Lever—Sets engine in starting mode for recoil

starter and stops a running engine.

Water Inlet — Connect garden hose here.

Accessory Tray

Data Tag

High Pressure

Hose

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

6

ASSEMBLY

IMPORTANT: Read entire operator’s manual before you

attempt to assemble or operate your new pressure washer.

Remove Pressure Washer From

Carton

• Remove the parts bag, accessories, and inserts included

with pressure washer.

• Slice two corners at the end of carton from top to

bottom so the panel can be folded down flat.

• Roll pressure washer out of carton.

Carton Contents

Items in the carton include:

• Main Unit

• Safety Goggles

• Handle

• Plastic Accessory Tray

• High Pressure Hose

• Spray Gun

• Nozzle Extension with Quick Connect Fitting

• Parts Bag (which includes the following):

• Operator’s Manual

• Engine Manual

• Maintenance Kit

• Hose Fittings

• Quick Connects

• Bag containing 4 multi–colored Quick Connect Spray

Tips

• Handle Fastening Hardware Kit (which includes):

• Carriage Bolt

• “L” Bolt

• Plastic Knobs (2)

• “J” Hook

• Chemical Hose Clip

• Self Tapping Screws (4)

If parts are missing or damaged, contact the local Briggs &

Stratton service center.

PREPARING PRESSURE

WASHER FOR USE

To prepare your pressure washer for operation,you

will need to perform these tasks:

1. Attach accessory tray to handle, then attach handle to

main unit.

2. Add oil to engine crankcase.

3. Add fuel to fuel tank.

4. Connect high pressure hose to spray gun and pump.

5. Connect water supply to pump.

6. Attach nozzle extension to spray gun.

7. Select/attach quick connect spray tip to nozzle

extension.

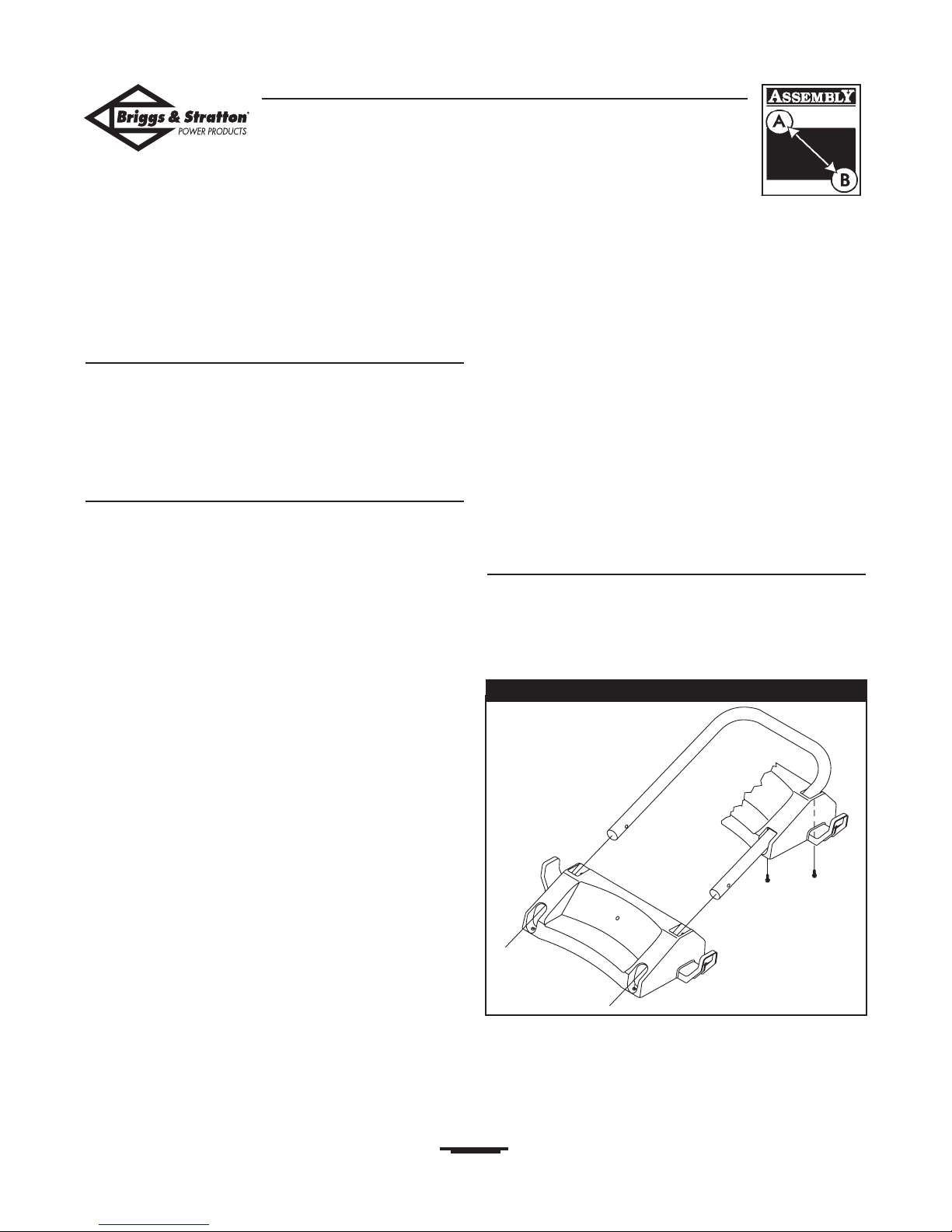

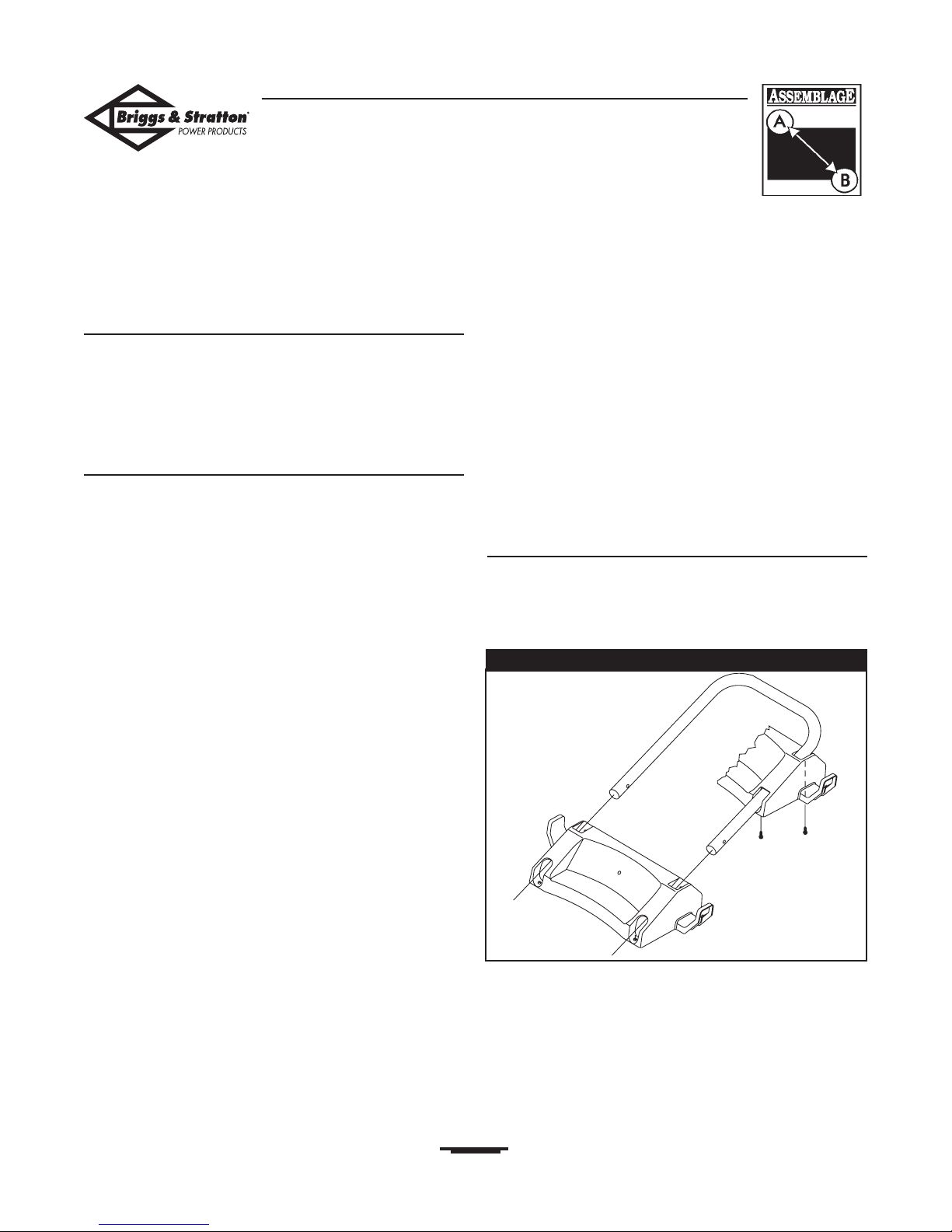

Attach Handle and Accessory Tray

NOTE:All assembly operations given in this section will

be described from the perspective of assembling the

pressure washer from the rear.

1. Slide plastic accessory tray onto handle and align holes

in accessory tray with holes on handle (Figure 2).

2. Secure tray to handle with self tapping screws using a

#2 phillips screwdriver. Ensure screws are tight but not

crushing the plastic accessory tray.

Figure 2 — Attach Accessory Tray

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

7

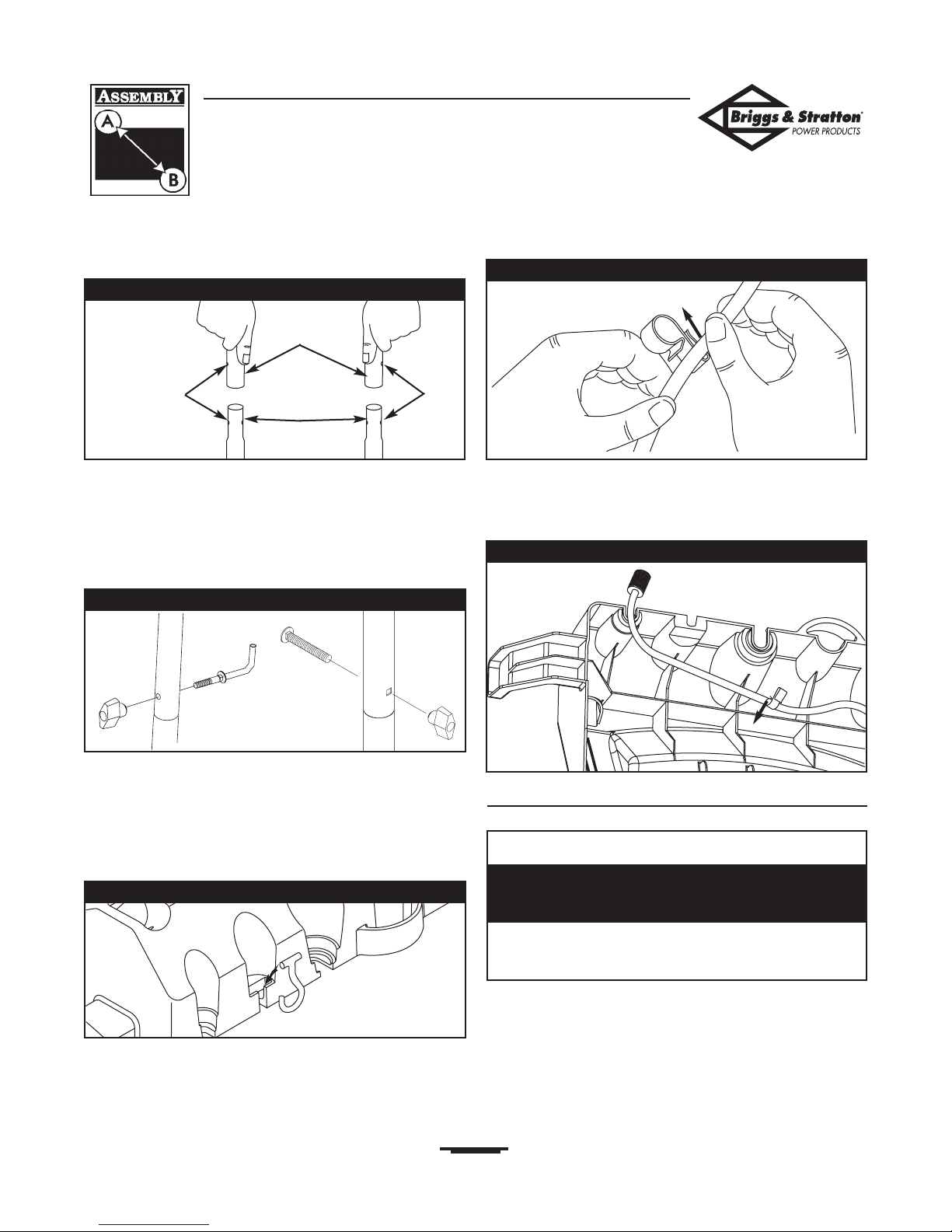

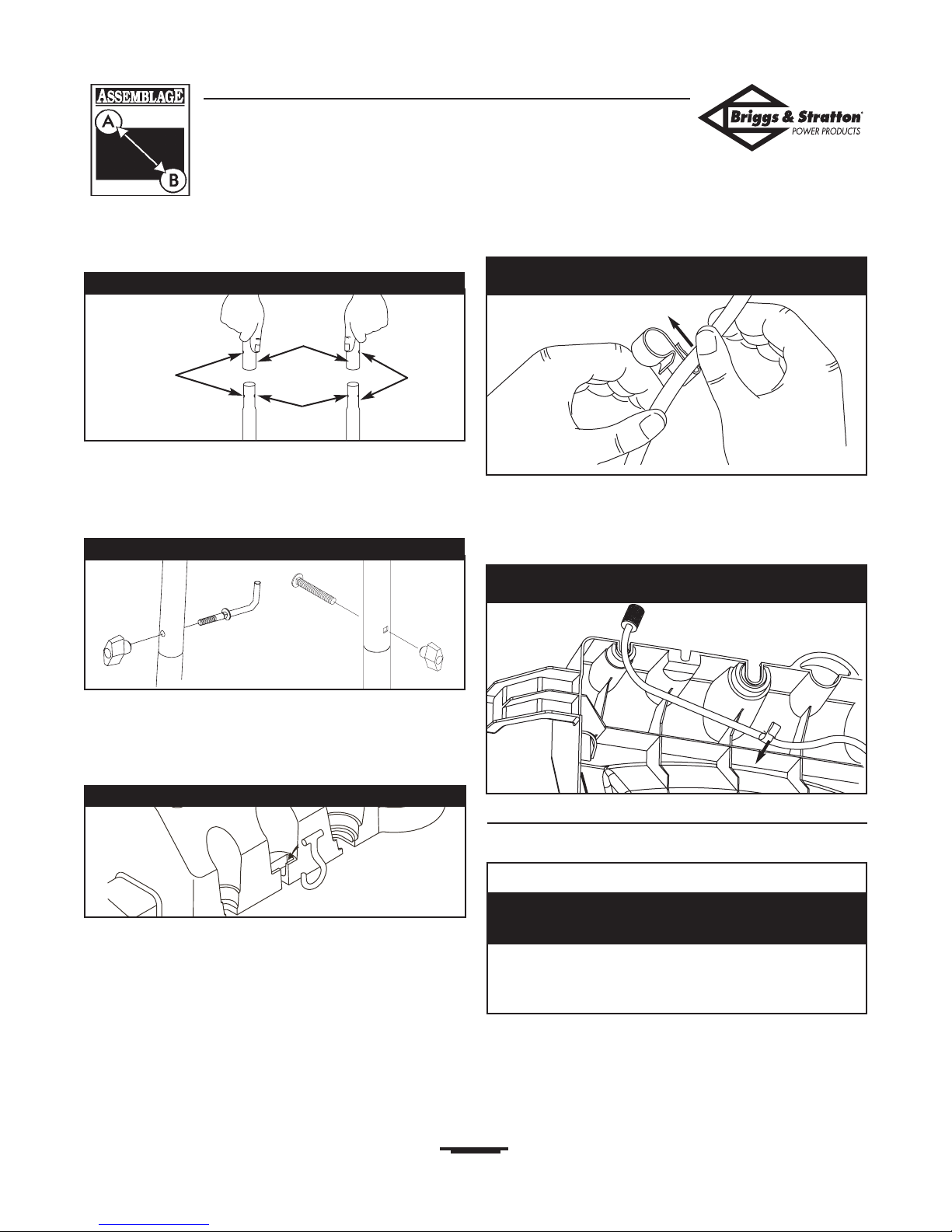

3. Place handle assembly onto handle supports connected

to main unit. Make sure holes in handle align with holes

on handle supports (Figure 3).

NOTE: It may be necessary to move the handle supports

from side to side in order to align the handle so it will slide

over the handle supports.

4. Insert “L” bolt through hole on right side of handle

(viewing from handle side of unit) and attach plastic

knob.Tighten knob by hand (Figure 4).

5. Insert carriage bolt through left side hole from outside

of unit and attach a plastic knob from inside of unit

(viewing unit from the handle side).Tighten by hand

(Figure 4).

6. Insert “J” hook into second from left slot in accessory

tray (Figure 5).

7. Pinch chemical hose and slide it into metal clip as

shown in Figure 6.

8. Tilt unit up by handle and attach metal clip to rib on

center underside of accessory tray (Figure 7). Slide

chemical hose through metal clip so that it is tight but

not kinked.

Add Engine Oil and Fuel

• Place pressure washer on a level surface.

• Refer to engine operator’s manual and follow oil and fuel

recommendations and instructions.

NOTE: Check oil often during engine break–in. Refer to

engine operator’s manual for recommendations.

CAUTION

• Refer to engine manual for oil and fuel fill information.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Any attempt to crank or start the engine before it has

been properly filled with the recommended oil will result

in equipment failure.

Figure 5 — Install “J” Hook on Accessory Tray

Figure 6 — Slide Chemical Hose into Metal Clip

Figure 7 — Slide Metal Clip onto Accessory Tray Flange

Align Holes

Handle

Handle

Supports

Figure 3 — Attach Handle to Base

Figure 4 — Secure Handle

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

8

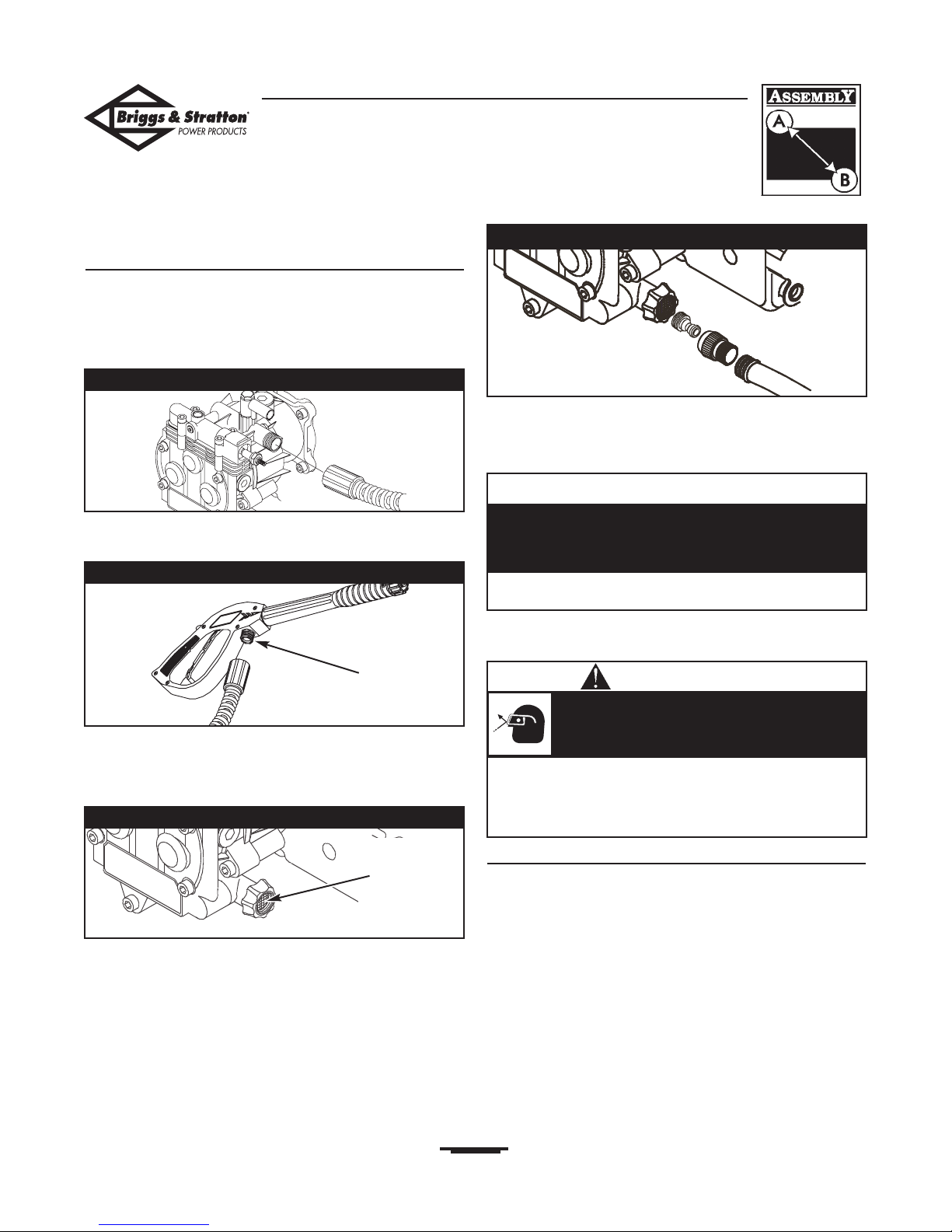

Connect Hose and Water Supply to

Pump

IMPORTANT: To avoid pump damage, you must assemble

the nozzle extension to the spray gun and attach all hoses

before you start the engine.

1. Attach one end of high pressure hose to high pressure

outlet on pump (Figure 8).Tighten by hand.

2. Attach other end of hose to base of spray gun

(Figure 9).Tighten by hand.

3. Before connecting garden hose to water inlet, inspect

inlet screen (Figure 10). Clean screen if it contains debris

or replace if damaged. DO NOT RUN PRESSURE

WASHER IF SCREEN IS DAMAGED.

4. Run water through garden hose for 30 seconds to clean

out any debris.

IMPORTANT: DO NOT siphon standing water for water

supply. Use ONLY cold water (less than 100°F).

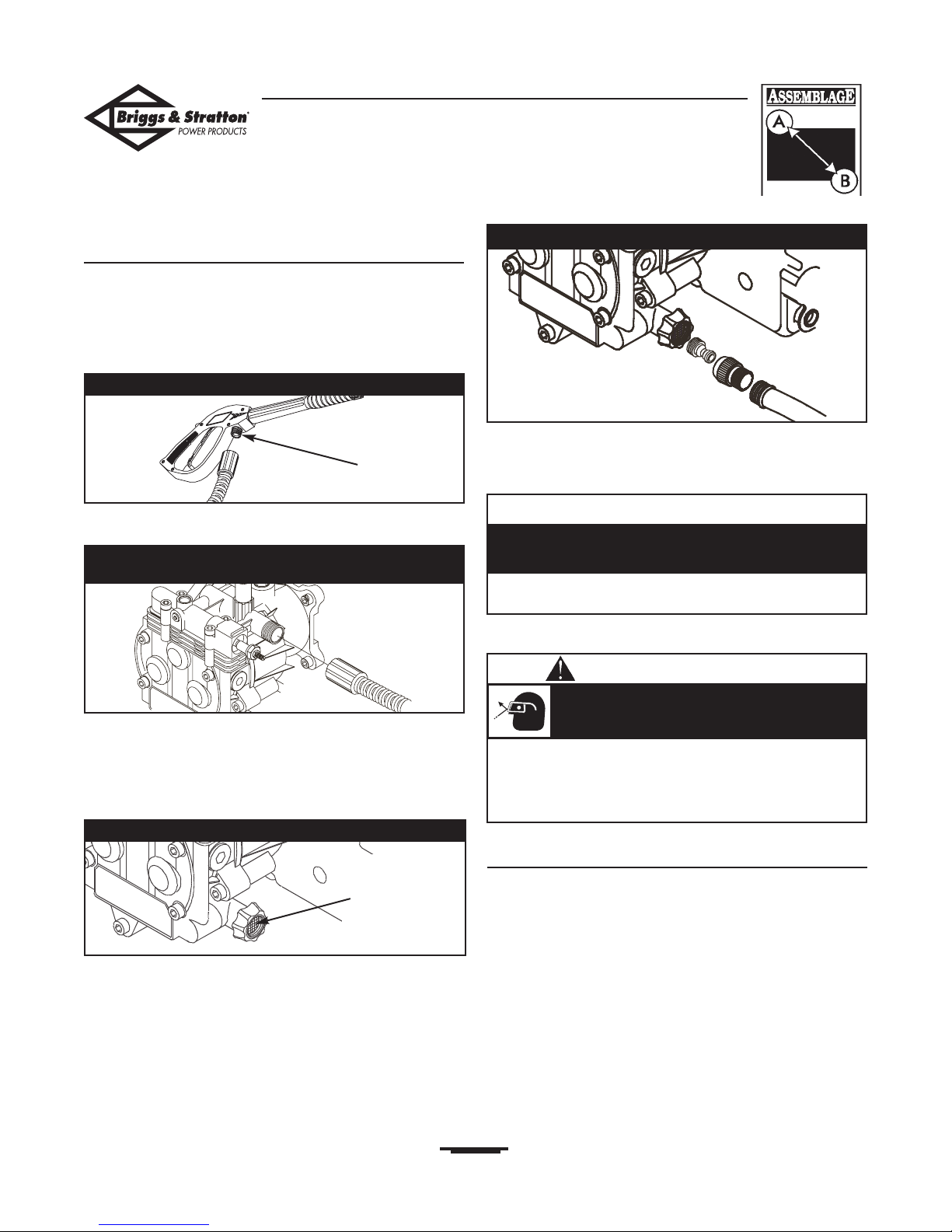

5. Attach female quick connect to garden hose.Attach male

quick connect to water inlet on pump (Figure 11).

6. Connect garden hose (not to exceed 50 feet in length)

to water inlet (Figure 11). Pull back on collar of quick

connect, slide fitting onto pump and let go of collar. Pull

on hose to be sure of a tight connection.

7. Turn ON water and squeeze trigger on spray gun to

purge pump system of air and impurities.

Checklist Before Starting Engine

Review the unit’s assembly to confirm you have performed

all of the following:

1. Make sure handle is in place and secure.

2. Check that oil has been added to the proper level in

engine crankcase.

3. Add proper fuel to fuel tank.

4. Check for properly attached hose connections.

5. Check to make sure that there are no kinks, cuts, or

damage to high pressure hose.

6. Provide a proper water supply at an adequate flow.

7. Be sure to read “Safety Rules” and “How To Use Your

Pressure Washer” before using pressure washer.

• Always wear eye protection when using this equipment or in

vicinity of where equipment is in use.

• Before starting the pressure washer, be sure you are wearing

adequate eye protection.

High pressure spray can cause paint chips or

other particles to become airborne.

WARNING

CAUTION

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

There MUST be at least ten feet of unrestricted garden

hose between the pressure washer inlet and any flow

shut off device, such as a ‘Y’ shut-off connector or other

convenience-type water shut-off valve.

Connect high

pressure hose

here

Figure 9 — Connect High Pressure Hose to Spray Gun

Figure 8 — Connect High Pressure Hose to Pump

Figure 10 — Connect Garden Hose to Water Inlet

Inspect inlet

screen, DO

NOT use if

damaged, clean

if dirty.

Figure 11 — Connect the Garden Hose to Water Inlet

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

9

HOW TO USE PRESSURE

WASHER

If you have any problems operating your pressure washer,

please contact the local Briggs & Stratton service center.

Pressure Washer Location

Pressure Washer Clearance

The pressure washer must be at least 5 ft. (152 cm) from

structures having combustible walls and/or other

combustible materials. Leave at least 3 ft. (92 cm) all around

pressure washer including overhead, for adequate cooling,

maintenance and servicing.

Place pressure washer in a well ventilated area, which will

allow for removal of deadly exhaust gas. DO NOT place

pressure washer where exhaust gas could accumulate and

enter inside or be drawn into a potentially occupied

building. Ensure exhaust gas is kept away from any

windows, doors, ventilation intakes or other openings that

can allow exhaust gas to collect in a confined area

(Figure 12). Prevailing winds and air currents should be

taken into consideration when positioning pressure washer.

How To Start Pressure Washer

To start your pressure washer for the first time, follow

these instructions step-by-step.This starting information

also applies if you have let the pressure washer sit idle for

at least a day.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

3.5 gallons per minute and no less than 20 PSI at

pressure washer end of garden hose.

2. Check that high pressure hose is tightly connected to

spray gun and to pump. See “Preparing Pressure

Washer for Use” for illustrations.

3. Make sure unit is in level position.

4. Connect garden hose to water inlet on pressure

washer pump. Turn ON the water.

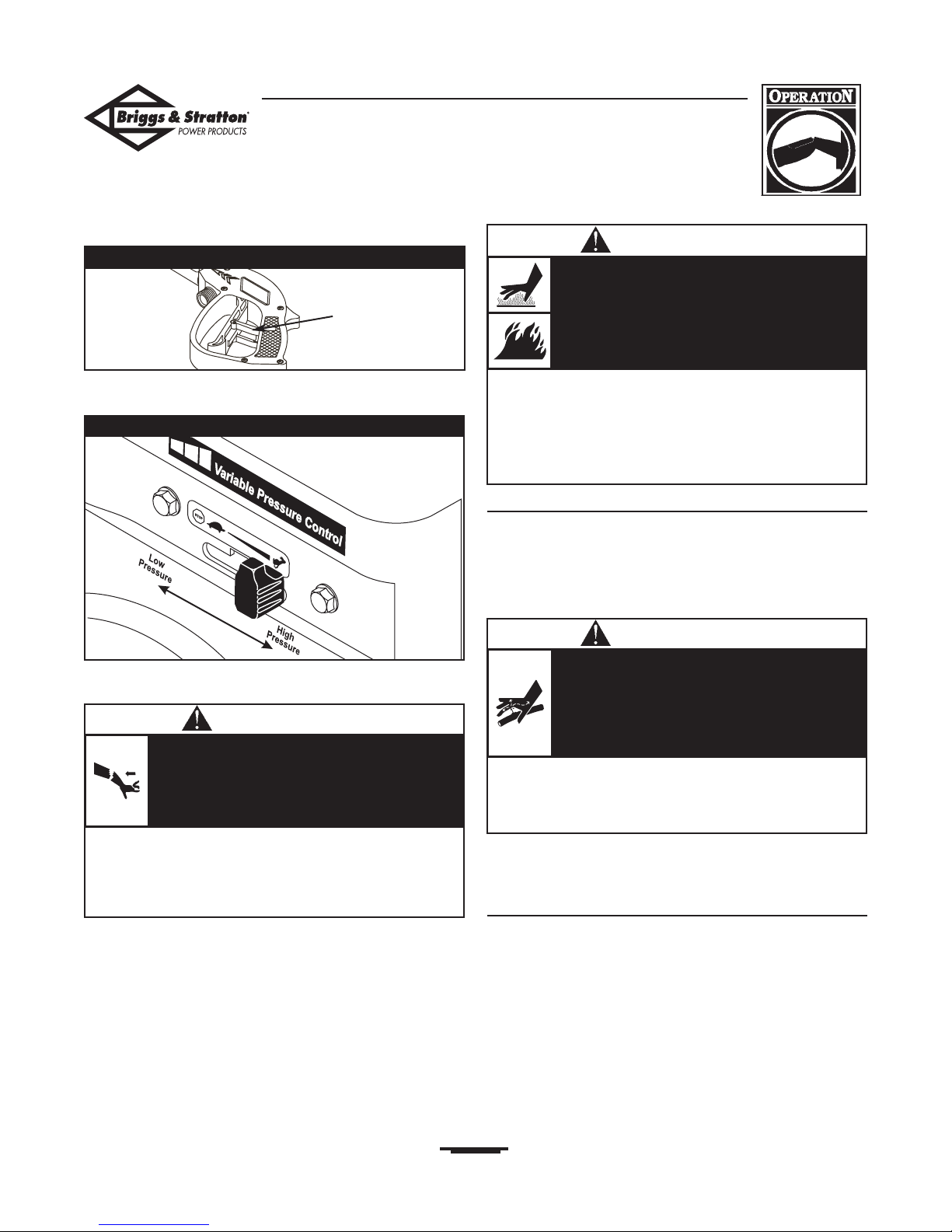

5. Attach adjustable nozzle extension to spray gun

(Figure 13).Tighten by hand.

6. Place colored quick connect spray tips in slots on

holder that’s attached to nozzle extension (Figure 14).

7. Choose spray tip you want to use and insert it into

nozzle extension. See “How to Use Spray Tips”.

Figure 13 — Connect Nozzle Extension to Spray Gun

CAUTION

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

DO NOT run the pump without the water supply

connected and turned on.

• Operate pressure washer ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

• DO NOT operate pressure washer inside any building or

enclosure.

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide will cause nausea,

fainting or death.

WARNING

Figure 12 — Pressure Washer Clearance

Exhaust Port

Typical Pressure

Washer Shown

Figure 14 — Install Spray Tips in Holder

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

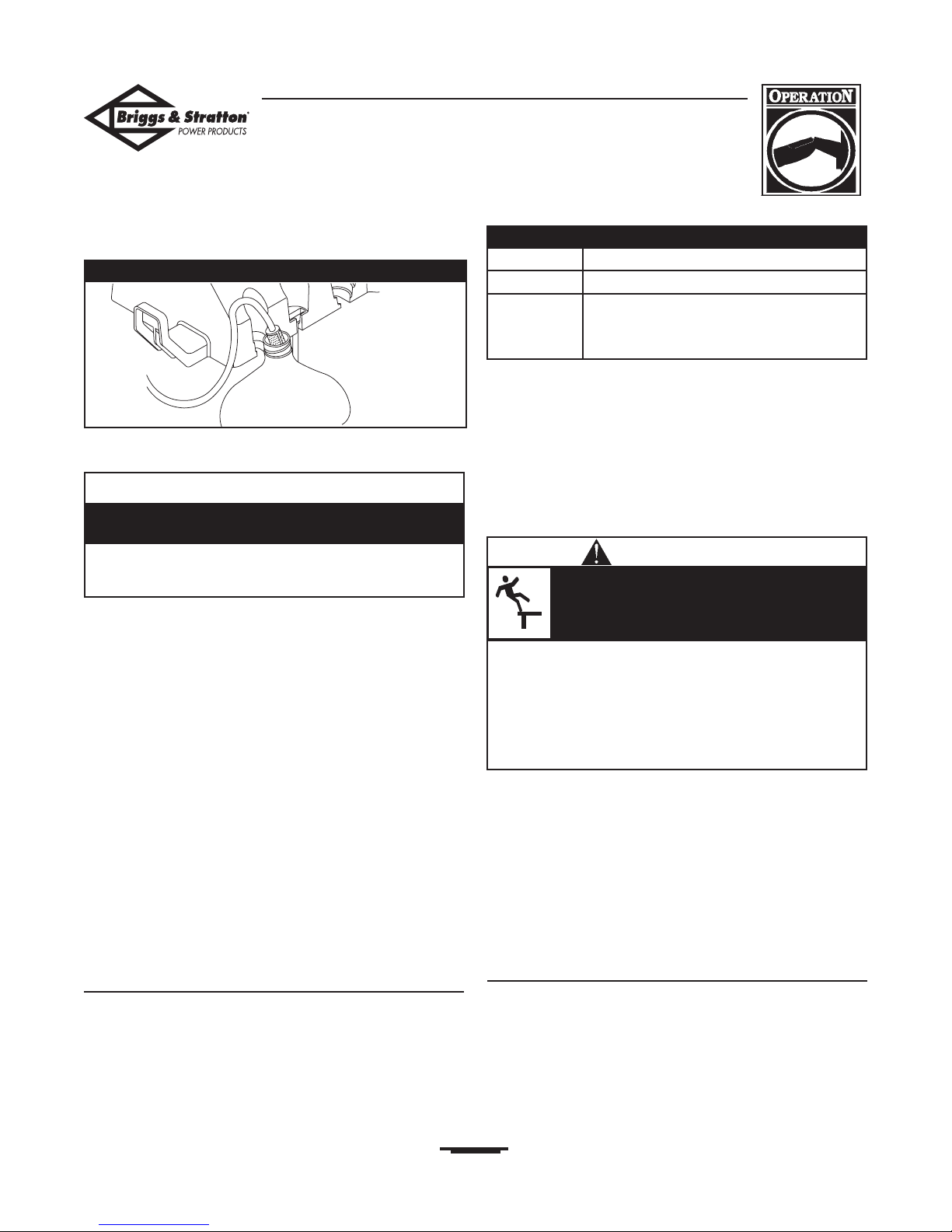

8. Engage safety latch to spray gun trigger (Figure 15).

9. Move variable pressure control lever to “High”

position, shown on engine as a rabbit (Figure 16).

10. Start engine according to instructions given in engine

operator’s manual.

How To Stop Pressure Washer

• Move variable pressure control lever to “Stop” position.

• Turn engine off according to instructions given in the

engine operator’s manual.

• Squeeze trigger on the spray gun to relieve

pressure in the hose.

NOTE:A small amount of water will squirt out when

pressure is released.

How to Use Accessory Tray

The unit is equipped with an accessory tray with places to

store your nozzle extension , and slots to hold the cleaning

solution bottle and the detergent siphoning filter.There are

also two hooks at the ends of the handle to hold your

spray gun and high pressure hose.

NOTE:The extra holes in the tray are for storing a brush

and a turbo wand.The brush and turbo wand are NOT

included with your pressure washer.You can buy these

items as optional accessories.

BSPP 2700 PSI Pressure Washer

10

Figure 16 - Variable Pressure Control Lever

Safety Latch

Figure 15 — Spray Gun with Safety Latch Engaged

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze trigger

on spray gun.

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains could

result.

WARNING

• DO NOT touch hot surfaces.

• Allow equipment to cool before touching.

• The pressure washer must be at least 5 feet from structures

having combustible walls and/or other combustible materials.

• Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Combustible debris, such as leaves, grass, brush,

etc. can catch fire.

WARNING

• Keep high pressure hose connected to pump and spray gun

while system is pressurized.

• Squeeze trigger on spray gun to relieve trapped pressure,

every time you stop engine. Engage trigger lock on spray gun.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun retains high pressure when pressure

washer is shut down, which can cause injury.

WARNING

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

11

1. Place nozzle extension through hole on accessory tray,

as shown in Figure 17.

2. Hang chemical solution bottle on “J” hook and place

detergent siphoning filter in last slot on left (Figure 17).

3. Place spray gun on hook attached to accessory tray on

right side of unit (Figure 17).

4. Hang high pressure hose on hook attached to

accessory tray on left side of unit as shown on page 5.

How to Use Spray Tips

The quick–connect on the nozzle extension allows you to

switch between four different spray tips.The spray tips vary

the spray pattern as shown (Figure 18).

Follow these instructions to change spray tips:

1. Engage safety latch on spray gun.

2. Pull back collar on quick–connect and pull current

spray tip off. Store spray tips in space provided on

handles storage panel.

3. Select desired spray tip:

• For gentle rinse, select white 40° spray tip.

• To scour surface, select yellow 15° or red 0° spray

tip.

• To apply chemical, select black spray tip.

4. Pull back on collar,insert new spray tip and release collar.

Tug on spray tip to make sure it is securely in place.

5. For most effective cleaning, keep spray tip from 8 to

24 inches away from cleaning surface. If you get spray

tip too close, you may damage cleaning surface.

6. DO NOT get closer than 6 inches when cleaning tires.

Cleaning and Applying Chemical

IMPORTANT: Use soaps designed specifically for

pressure washers. Household detergents could damage

the pump.

To apply detergent follow these steps:

1. Review spray tip use.

2. Prepare detergent solution as required by

manufacturer.

Figure 17 — Typical Accessory Tray

• NEVER exchange spray tips without locking the safety latch

on the trigger.

A pressure washer produces a high pressure spray

which increases risk of injury and damage to unit.

CAUTION

40° White 15° Yellow 0° Red

Black

Use to apply

chemical

Figure 18 — Spray Tip Spray Patterns

Low Pressure

High Pressure

CAUTION

• Starting the engine without all the hoses connected and

without the water turned ON will damage the pump.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

You must attach all hoses before you start the engine.

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

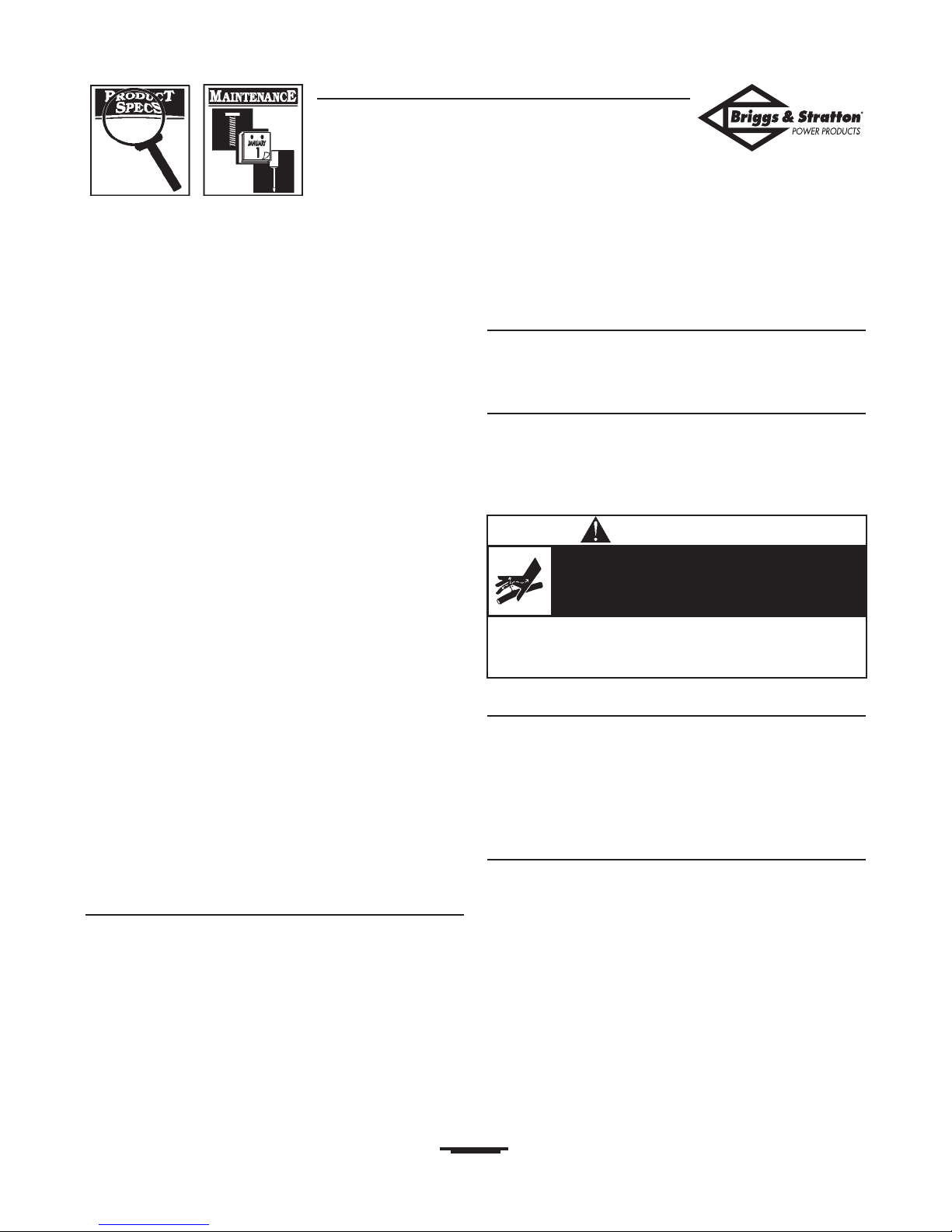

3. Hang detergent solution on “J” hook attached to

accessory tray, as shown in Figure 19.

4. Place small filter end of detergent siphoning tube into

detergent container.

5. Make sure black spray tip is installed.

NOTE: Detergent cannot be applied with the high

pressure spray tips (White, Green,Yellow, or Red).

6. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun and pump and start engine.

7. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward, using

long, even, overlapping strokes.

8. Allow detergent to soak in between 3–5 minutes

before washing and rinsing. Reapply as needed to

prevent surface from drying. DO NOT allow detergent

to dry on (prevents streaking).

IMPORTANT: You must flush the chemical injection

system after each use by placing the filter into a bucket of

clean water, then run the pressure washer in low pressure

for 1-2 minutes.

Pressure Washer Rinsing

Wash and Rinse Surface

This pressure washer permits regulation of output water

pressure by varying the engine speed.The variable pressure

control lever found on the front of the engine may be set,

as shown in Figure 20:

After you have applied detergent, scour the surface

and rinse it clean as follows:

1. Apply safety latch to spray gun.

2. Remove black chemical nozzle from nozzle extension.

3. Select and install desired high pressure nozzle following

instructions “How to Use Spray Tips” on page 11.

4. Keep spray gun a safe distance from the area you plan

to spray.

5. Adjust spray pressure by sliding variable pressure control

lever left or right, as shown in Figure 16 on page 10.

6. Apply a high pressure spray to a small area and then

check the surface for damage. If no damage is found,

you can assume it is okay to continue rinsing.

7. Start at top of area to be rinsed, working down with

same overlapping strokes as you used for cleaning.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures

above 125°F.The system engages to cool the pump by

discharging the warm water onto the ground.

BSPP 2700 PSI Pressure Washer

12

• Keep spray nozzle between 8 to 24 inches away from cleaning

surface.

• Operate this unit on a stable surface.

• Be extremely careful if you must use the pressure washer from

a ladder, scaffolding or any other relatively unstable location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

High pressure spray could cause you to fall if

you are too close to the cleaning surface.

WARNING

Figure 19 — Insert Filter into Container

CAUTION

• When inserting the filter into a detergent solution bottle,

route the tube so as to keep it from inadvertently contacting

the hot muffler.

Keep the chemical injection tube from coming in contact

with the hot muffler.

Pressure Low to High

Duty Light Medium Heavy

Application Auto Concrete Paint Removal

Boat Driveway Degreasing

Furniture Deck

Figure 20 - Variable Pressure Control

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

13

SPECIFICATIONS

Outlet Pressure . . . . . . . . . . . . . . . . . . . . . . . . . 2700 psi

Flow Rate . . . . . . . . . . . . . . 2.5 gallons per minute (gpm)

Detergent Use detergent approved for pressure washers

Water Supply Temperature . . . . Not to Exceed 100°F

Automatic Cool . . . . . . . . . . . . . Will cycle when water

Down System reaches 125°-155°F

Measured LwA . . . . . . . . . . . . . . . . . . . . . .104 dB(A)/pW

Guaranteed LwA . . . . . . . . . . . . . . . . . . .104 dB(A)/pW

Sound Pressure Level @ 7m . . . . . . . . . . . . . .79 dB(A)

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . .84 lbs.

GENERAL MAINTENANCE

RECOMMENDATIONS

The pressure washer warranty does not cover items that

have been subjected to operator abuse or negligence.To

receive full value from the warranty, the operator must

maintain the pressure washer as instructed in this manual.

NOTE: Should you have questions about replacing

components on your BSPP pressure washer, please visit

our website at www.briggsandstratton.com.

• Some adjustments will need to be made periodically to

properly maintain your pressure washer.

• All maintenance in this manual and the engine operator’s

manual should be made at least once each season.

• Once a year you should check the spray gun and nozzle

extension assembly for wear.Also clean or replace the

spark plug and clean or replace the engine air filter. Please

refer to engine operator’s manual for more details.

Before Each Use

1. Check engine oil level.

2. Check water inlet screen for damage.

3. Check in-line filter for damage.

4. Check high pressure hose for leaks.

5. Check chemical injection hose and filter for damage.

6. Check spray gun and nozzle extension assembly for

leaks.

7. Rinse out garden hose to flush out debris.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine the screen on the water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect the hose each time before using

it. Check for cuts, leaks, abrasions or bulging of cover,

damage or movement of couplings. If any of these

conditions exist, replace the hose immediately.

Check Chemical Injection Hose

Examine the filter on the detergent tube and clean if

clogged.The tube should fit tightly on the barbed fitting.

Examine the tube for leaks or tears. Replace the filter or

tube if either is damaged.

Check Gun and Adjustable Nozzle

Extension

Examine the hose connection to the spray gun and make

sure it is secure.Test the trigger by pressing it and making

sure it “springs back” into place when you release it. Put

the safety latch in the ON position and test the trigger.You

should not be able to press the trigger.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST exceed maximum pressure

rating of unit.

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury and

possible amputation.

WARNING

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

14

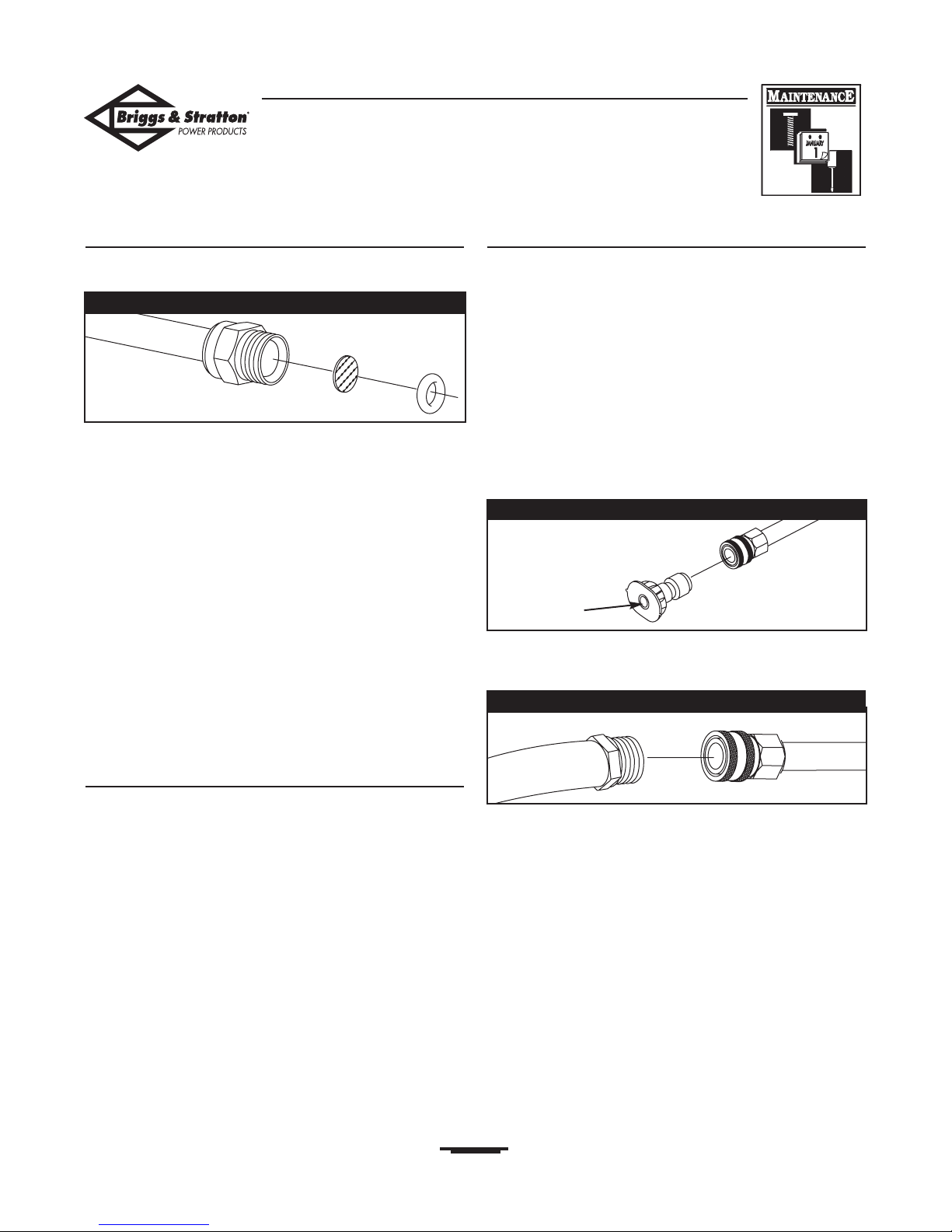

Check In-Line Filter

Refer to Figure 21 and service the in-line filter if it

becomes clogged, as follows:

1. Detach spray gun and nozzle extension from high

pressure hose. Detach nozzle extension from spray gun

and remove o-ring and screen from nozzle extension.

Flush screen, spray gun, and nozzle extension with clean

water to clear debris.

2. If screen is damaged, o-ring kit contains a replacement

in-line filter screen and o-ring. If undamaged, reuse

screen.

3. Place in-line filter screen into threaded end of nozzle

extension. Direction does not matter. Push screen in

with eraser end of pencil until it rests flat at bottom of

opening.Take care to not bend screen.

4. Place o-ring into threaded end of nozzle extension. Push

o-ring snugly against in-line filter screen.

5. Assemble nozzle extension to spray gun, as described

earlier in this manual.

Cleaning Chemical Injection Hose

If you used the chemical injection hose, you must flush it

with clean water before stopping the engine.

1. Place chemical injection siphon/filter in a bucket full of

clean water.

2. Attach black low pressure spray tip.

3. Flush for 1-2 minutes.

4. Shut off engine.

IMPORTANT: Simply shutting OFF engine will not

release pressure in the system. When the engine has

shut down, squeeze the trigger on the spray gun to

relieve the pressure in the hose.

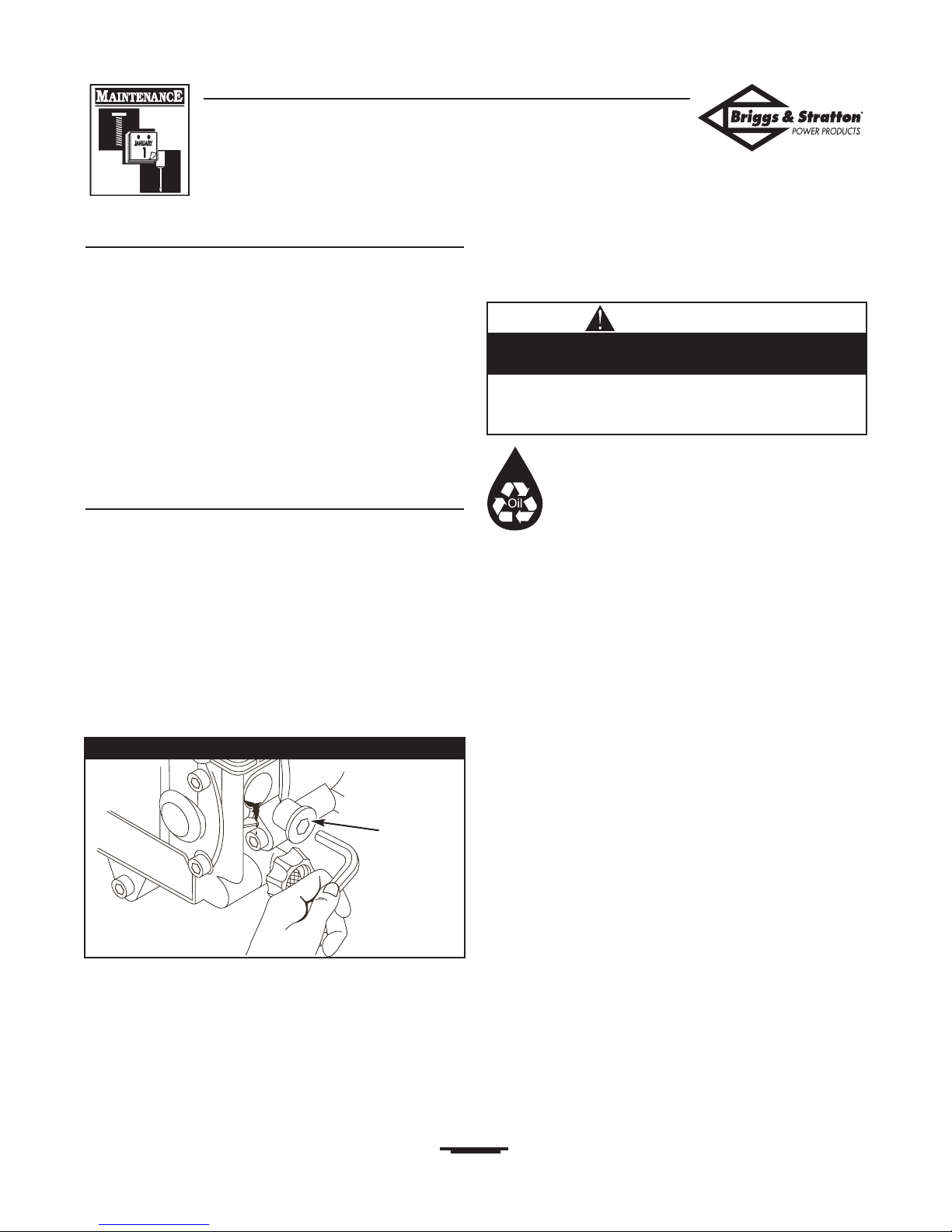

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.The

principal cause of excessive pump pressure is a spray tip

clogged or restricted with foreign materials, such as dirt,

etc.To correct the problem, immediately clean the spray tip

following these instructions:

1. Shut off engine and turn off water supply.

2. Remove spray tip from end of nozzle extension.

3. Remove in-line filter from other end of nozzle

extension.

4. Use a small paper clip to free any foreign material

clogging or restricting spray tip (Figure 22).

5. Using a garden hose, remove additional debris by back

flushing water through nozzle extension (Figure 23).

Back flush between 30 to 60 seconds.

6. Reinstall spray tip and in-line filter into nozzle

extension.

7. Reconnect nozzle extension to spray gun.

8. Reconnect water supply, turn on water, and start

engine.

9. Test pressure washer by operating with each Quick

Connect spray tip.

Nozzle Extension

Filter Screen

O-ring

Figure 21 — Clean In-Line Filter

Use wire here

to remove

debris.

Figure 22 — Nozzle Maintenance

Figure 23 — Backflushing the Nozzle Extension

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

15

O–Ring Maintenance

Through the normal operation of your pressure washer,

o–rings are used to keep the connections of the hoses and

spray gun tight and leak–free.These o-rings may become

worn or damaged.

An O–Ring Maintenance Kit is provided with your pressure

washer which includes replacement o-rings, rubber washer

and water inlet filter. Refer to the instruction sheet

provided in the kit to service your unit’s o-rings. Note that

you will not use all of the parts in the kit.

To remove a worn or damaged o–ring; use a small flathead

screwdriver to get underneath the o-ring and pry it off.

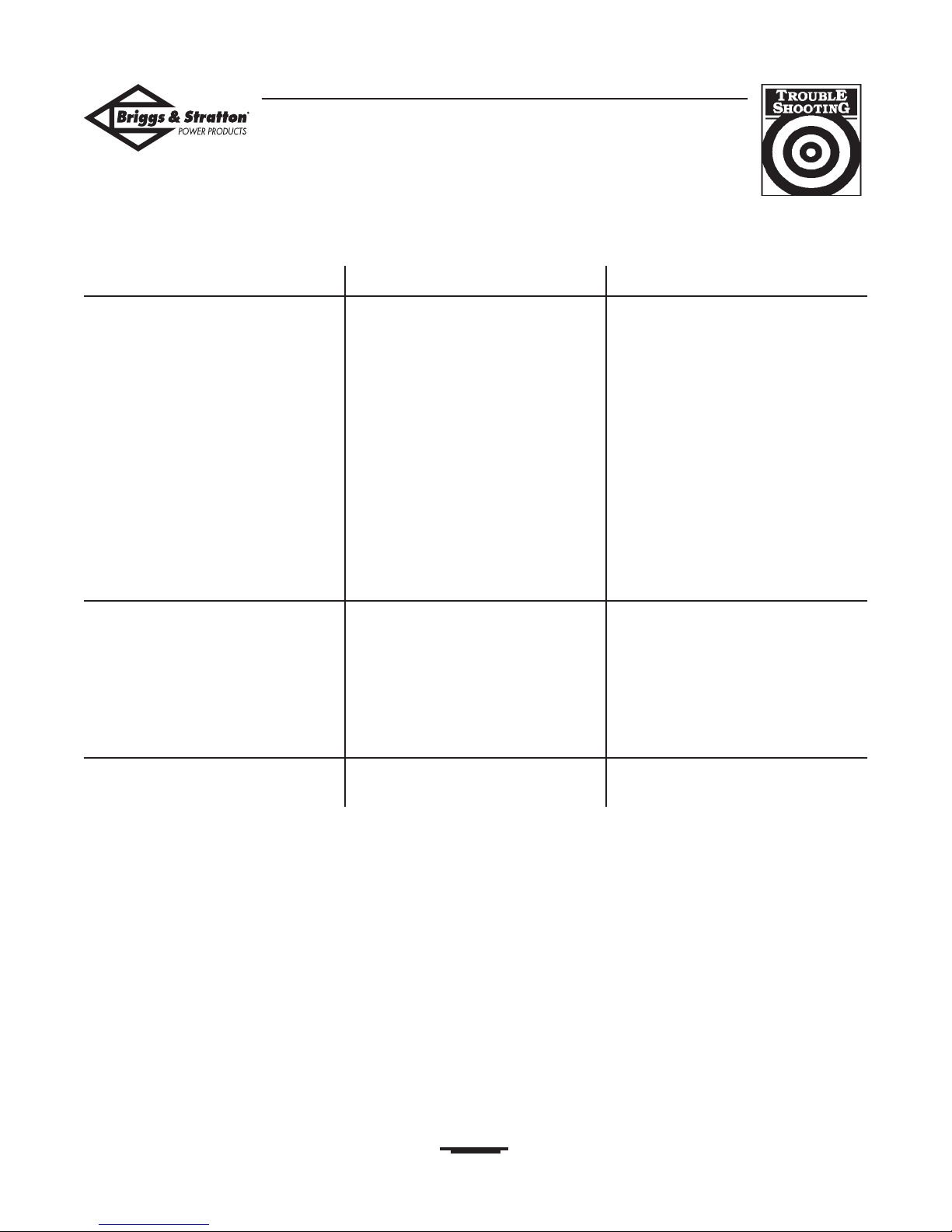

Pump Maintenance

Changing Pump Oil

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE:You must purchase a premeasured bottle of pump

oil, item number 190585GS, by contacting the nearest

authorized service center.

Change pump oil as follows:

1. Drain engine oil and fuel from pressure washer.

2. Use a 8mm allen wrench to remove black pump oil

cap between high pressure outlet and garden hose

inlet (Figure 24).

3. Tilt pressure washer to drain oil into an approved

container until it drips slowly from pump.

4. Tilt pressure washer in opposite direction and empty

premeasured pump oil bottle into same opening (a

small funnel may be helpful).

5. Install black pump oil cap and tighten firmly.

6. Set pressure washer in upright position.Add fuel and

engine oil.

ENGINE MAINTENANCE

See the engine operator’s manual for instructions on how

to properly maintain the engine.

KEEP OUT OF REACH OF CHILDREN. DON'T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

PREPARING THE UNIT

FOR STORAGE

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump parts and

“freeze” pump action. If you do not plan to use the pressure

washer for more than 30 days, follow this procedure:

1. Flush detergent siphoning tube by placing the filter into

a pail of clean water while running pressure washer in

low pressure mode. Flush for one to two minutes.

2. Shut off the engine and let it cool, then remove all

hoses. Disconnect spark plug wire from spark plug.

3. Empty the pump of all pumped liquids by pulling the

recoil handle about 6 times.This should remove most

of the liquid in the pump.

4. Draw RV antifreeze (non-alcohol) into the pump by

pouring the solution into a 3-foot section of garden

hose connected to inlet adapter and pulling recoil

handle twice.

If available, use PumpSaver in place of RV antifreeze

and follow package instructions.

5. Store unit in a clean, dry area.

STORING THE ENGINE

See the engine operator’s manual for instructions on how

to properly prepare the engine for storage.

Oil Cap

Figure 24 - Changing Pump Oil

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Avoid prolonged or repeated skin contact with used

motor oil.

CAUTION

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

16

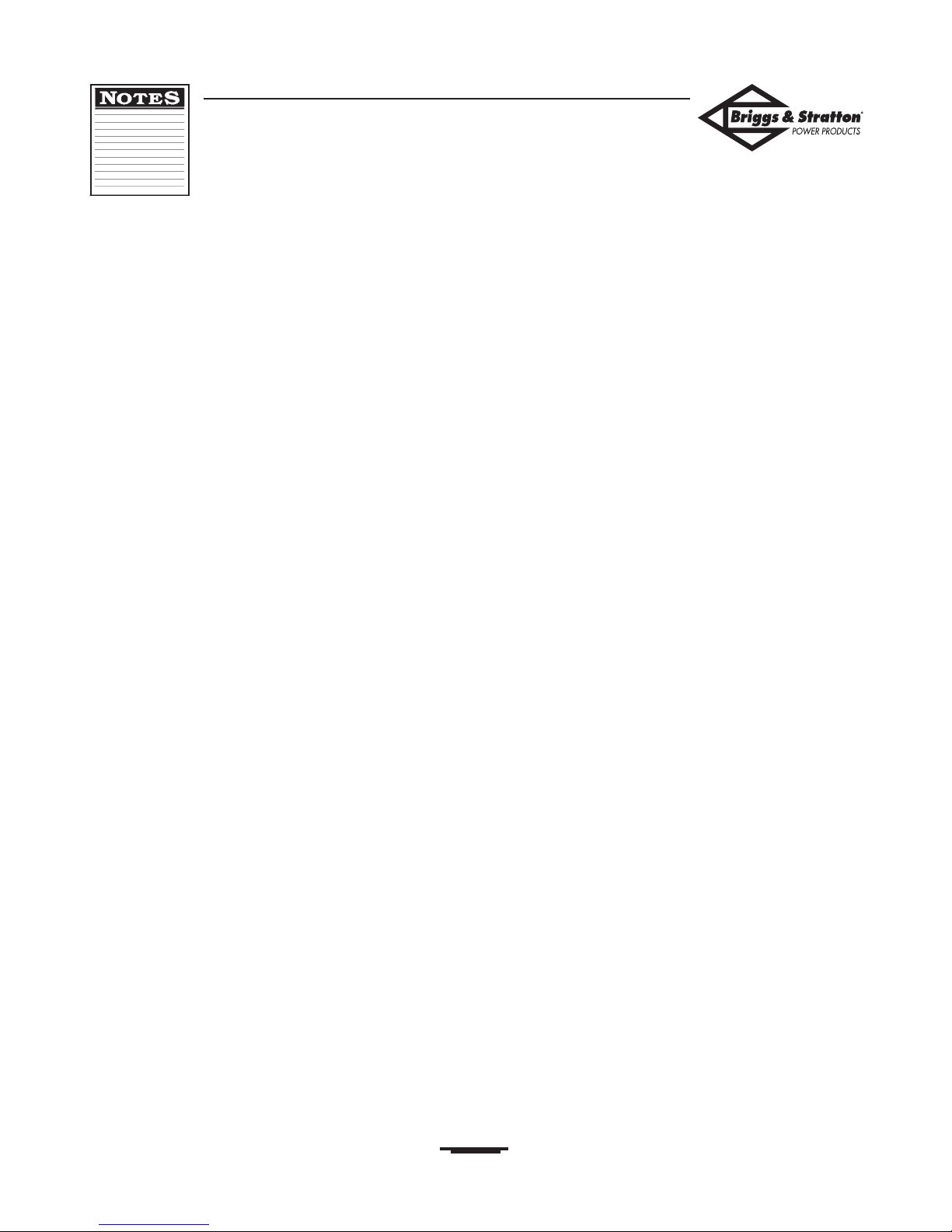

TROUBLESHOOTING

Problem Cause Correction

Pump has following problems:

failure to produce pressure,

erratic pressure, chattering, loss

of pressure, low water volume.

1. Low pressure spray tip installed.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose strainer.

6. Water supply is over 100°F.

7. High pressure hose is blocked or

leaks.

8. Gun leaks.

9. Spray tip is obstructed.

10. Pump is faulty.

1. Replace spray tip with high

pressure spray tip.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch leak.

5. Check and clean inlet hose

strainer.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace gun.

9. Clean spray tip.

10. Contact Authorized service facility.

Detergent fails to mix with spray.

1. Detergent siphoning tube is not

submerged.

2. Chemical filter is clogged or

cracked.

3. Dirty in-line filter.

4. High pressure spray tip installed.

1. Insert detergent siphoning tube

into detergent.

2. Clean or replace filter/detergent

siphoning tube.

3. See "Check In-Line Filter".

4. Replace spray tip with low

pressure spray tip.

Engine shuts down during

operation.

Out of gasoline. Fill fuel tank.

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

17

NOTES

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BSPP 2700 PSI Pressure Washer

18

NOTES

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC EQUIPMENT OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the equipment that is defective in material

or workmanship or both. Transportation charges on parts submitted for repair or replacement under this warranty must be borne by

purchaser. This warranty is effective for the time periods and subject to the conditions stated below. For warranty service, find the nearest

Authorized Service Dealer in our dealer locator map at www.briggspowerproducts.com.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW ANY

AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED

TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or countries do not allow limitations on how long an implied warranty

lasts, and some states or countries do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary from state

to state or country to country.

OUR EQUIPMENT*

OUTBOARD

MOTOR

PRESSURE

WASHER

WATER PUMP

(Not available in the

USA)

PORTABLE

GENERATOR

WELDER

LLeessss tthhaann 1100 KKWW 1100 KKWW oorr ggrreeaatteerr

TTrraannssffeerr sswwiittcchh

2 years

none

1 year

90 days

1 year

90 days

2 years

1 year

2 years

none

3 years or

1500 hours

none

3 years

none

WARRANTY PERIOD**

HOME STANDBY GENERATOR SYSTEM

Consumer Use

Commercial Use

* The engine and starting batteries are warranted solely by the manufacturers of those products.

** 2 years for all consumer products in the European Union. Parts only on 2nd year for consumer use of Portable Generator and

Home Standby Generator System - Less than 10 KW, outside of European Union.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time

stated in the table above. “Consumer use" means personal residential household use by a retail consumer. “Commercial use" means all other

uses, including use for commercial, income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter

be considered as commercial use for purposes of this warranty. Equipment used for prime power in place of utility are not applicable to

this warranty. Electric powered pressure washers used for commercial purposes are not warranted.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR

PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY

SERVICE IS REQUESTED, THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY

PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most

warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not

apply if equipment damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation.

Similarly, the warranty is void if the manufacturing date or the serial number on the equipment has been removed or the equipment has been altered

or modified. During the warranty period, the Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to

be defective under normal use and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not

cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized

installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as,

in our judgment, to adversely affect its performance and reliability. This warranty also does not cover normal maintenance such as adjustments,

fuel system cleaning and obstruction (due to chemical, dirt, carbon, lime, etc.).

• Other Exclusions: This warranty excludes wear items such as quick couplers, oil gauges, belts, o-rings, filters, pump packing, etc., pumps that

have been run without water supplied or damage or malfunctions resulting from accidents, abuse, modifications, alterations, or improper servicing

or freezing or chemical deterioration. Accessory parts such as guns, hoses, wands and nozzles are excluded from the product warranty. This

warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers control. Also excluded is used,

reconditioned, and demonstration equipment; equipment used for prime power in place of utility power and equipment used in life support

applications.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

Effective September 1, 2004 replaces all undated Warranties and all Warranties dated before September 1, 2004

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Nettoyeur Haute Pression 2700 PSI de BSPP

20

TABLE DES MATIÈRES

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-22

Connaître Votre Nettoyeur Haute Pression . . . . . . . . . . . . . . . . 23

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-30

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-33

Entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Diagnostic des problèmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DESCRIPTION DE L'ÉQUIPEMENT

L'utilisateur doit lire ce manuel soigneusement et

se familiariser avec le nettoyeur haute pression. Il

doit prendre connaissance de ses applications,de

ses limites et des risques inhérents à son utilisation.

Ce manuel contient les informations relatives à un nettoyeur

haute pression fonctionnant sous 185 bars (2 700 PSI) avec un

débit de 9,46 l/mn (2,5 gallons/mn). Ce système puissant de

grande qualité comporte de grosses roues de 25 cm (10 pouces),

une pompe dotée d'un système de refroidissement automatique,

un système d'injection de produit chimique, une rallonge de buse

à embouts à fixation rapide, des lunettes de sécurité, un tuyau

flexible de 7,60 m (25 pieds) et plus encore.

Tout a été fait pour s'assurer que les renseignements contenus

dans le présent guide soient exacts et à jour.Toutefois, le

fabriquant se réserve le droit de changer, de modifier ou encore

d'amélorer le système en tout temps et ce, sans préavis.

CONSIGNES DE SÉCURITÉ

Voici le symbole d'avertissement de sécurité. Ces

symboles attirent votre attention sur le risque de

blessure corporelle. Pour éviter toute blessure

mortelle ou non, observer toutes les consignes de

sécurité associées à ces symboles.

Le symbole d'alerte

() apparaît complété par un qualificatif

(DANGER,ATTENTION, AVERTISSEMENT), une image ou un

message de sécurité pour attirer l'attention sur les risques. Un

DANGER signale un risque qui - s'il n'est pas écarté - entraîne des

blessures graves ou la mort.Un AVERTISSEMENT signale un

risque qui - s'il n'est pas écarté - pourrait entraîner des blessures

graves ou la mort.La mention ATTENTION signale un risque qui

- s'il n'est pas écarté - pourrait entraîner des blessures légères ou

modérées. La mention ATTENTION,utilisée sans le symbole

d'alerte, signale une situation qui pourrait entraîner une

détérioration de l'équipement. Respectez scrupuleusement les

consignes de sécurité pour éliminer ou réduire les risques de

blessures ou dangers de mort.

Plaque d'avertissement

Une plaque d'avertissement (figure 25) figure sur l'appareil pour

signaler les risques pour la sécurité. Si cette plaque vient à être

endommagée ou illisible, la remplacer par une étiquette neuve

disponible auprès de votre représentant local Briggs & Stratton.

Les pictogrammes de la plaque d'avertissement sont explicités

plus bas dans cette section consacrée à la sécurité.

Pictogrammes des risques et signification

Incendie

Explosion

Vapeurs toxiques

Surface chaude

Pièces en mouvement

Risque de choc électrique

Surface glissante

Risque de chute

Risque de recul

Projection d'objets

Injection de fluide

Figure 25 — Plaque d'avertissement

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Nettoyeur Haute Pression 2700 PSI de BSPP

21

• Maintenir la buse de pulvérisation à une distance de 20 à

60 centimètres de la surface à nettoyer.

• Utiliser cet appareil sur une surface stable.

• La pente et le drainage de l'aire de nettoyage doivent être suffisants

pour réduire le risque de chute accru sur des surfaces glissantes.

• Agir avec une extrême prudence en cas d'utilisation du nettoyeur

haute pression sur une échelle, un échafaudage ou tout autre

emplacement relativement instable.

• Pour éviter tout risque de blessure en cas de recul du pistolet de

pulvérisation, le tenir fermement à deux mains lors de la pulvérisation

à haute pression.

L'utilisation du nettoyeur haute pression peut causer

l'apparition de flaques d'eau et rendre les surfaces

glissantes et dangereuses.

Le jet à haute pression peut également faire tomber

l'utilisateur s'il se tient trop près de la surface à

nettoyer.

AVERTISSEMENT

• Utiliser le nettoyeur EXCLUSIVEMENT en extérieur.

• Empêchez les gaz d'échappement de pénérer dans un lieu confiné par

les fenêtres, portes, entrées d'aération et d'autres ouvertures.

• NE FAITES PAS fonctionner le nettoyeur haute pression à l'intérieur

d'un bâtiment ou d'un lieu clos.

• S'il y a un risque d'inhalation de vapeurs, utiliser un appareil ou un

masque respiratoire.

• Lire soigneusement les instructions d'emploi du masque afin d'être certain

qu'il protège efficacement contre l'inhalation de vapeurs dangereuses.

En fonctionnement, le moteur dégage du monoxyde

de carbone, un gaz inodore, incolore et mortel.

Respirer du monoxyde de carbone peut provoquer

des nausées, l'évanouissement ou la mort.

Certains produits chimiques ou détergents peuvent

être dangereux et, s'ils sont inhalés ou ingérés,

provoquer des nausées importantes, des

évanouissements ou des empoisonnements.

AVERTISSEMENT

• Lors du démarrage du moteur,tirer lentement sur la corde jusqu'à

sentir une résistance, puis tirer rapidement afin d'éviter l'effet de recul.

• Si le moteur démarre et cale ou si une résistance accrue est ressentie

au cours des tentatives de démarrage, appuyer sur la détente du

pistolet de pulvérisation.

Le recul rapide du câble de démarreur peut tirer la

main et le bras en direction du moteur plus

rapidement que vous ne vous y attendez.

Ce peut être la cause de fêlures, fractures, contusions

ou foulures.

AVERTISSEMENT

METTRE DE L'ESSENCE

• ARRETER le nettoyeur haute pression et le laisser refroidir au moins

deux minutes avant d'ouvrir le bouchon d'essence.

• Faire le plein du réservoir à l’air libre.

• NE PAS trop remplir le réservoir. Laisser un espace suffisant pour

l’évaporation de l'essence.

• Manipuler l'essence à l'abri des étincelles, des flammes nues,des

veilleuses, de la chaleur ainsi que d'autres sources potentielles

d'inflammation.

• NE PAS allumer de cigarettes, ni fumer.

UTILISATION DE L'ÉQUIPEMENT

• NE JAMAIS incliner le moteur ni l'équipement au point que l'essence

se mette à couler.

• NE PAS vaporiser de liquides inflammables.

TRANSPORT ET RÉPARATION DE L'ÉQUIPEMENT

• VIDER le réservoir et FERMER le robinet d'essence pour transporter

et réparer l'équipement.

• Fixez le nettoyeur haute pression en position debout pendant le

transport pour qu'il ne bascule pas et ne répande pas d'essence et

d'huile.

ENTREPOSAGE D'ESSENCE OU D'UN ÉQUIPEMENT

DONT LE RÉSERVOIR CONTIENT DE L'ESSENCE.

• NE PAS entreposer à proximité de fours, poêles, chauffe-eau, sèche-linge

ou d'autres équipements susceptibles de comporter une veilleuse ou

une source potentielle d'inflammation des vapeurs d'essence.

L'essence sous forme liquide ou vapeur est

extrêmement inflammable et explosive.

Un incendie ou une explosion peuvent provoquer de

graves brûlures ou la mort.

AVERTISSEMENT

• NE JAMAIS diriger le jet vers des personnes, des animaux ou des

plantes.

• NE PAS laisser des ENFANTS manipuler le nettoyeur haute pression.

• NE JAMAIS tenter de réparer le flexible haute pression. Le remplacer

systématiquement.

• Ne jamais déconnecter le flexible haute pression de la pompe et du

pistolet de pulvérisation lorsque le système est sous pression.

• Pressez la détente du pistolet de pulvérisation pour libérer la pression

dans le tuyau chaque fois que vous arrêtez le moteur. Engagez le

verrou de la détente du pistolet de pulvérisation.

Le jet d'eau à haute pression produit par l'appareil est

capable d’entraîner des blessures graves.

Le pistolet de pulvérisation reste sous haute pression

lorsque le nettoyeur haute pression est arrêté,ce qui

peut provoquer des blessures.

AVERTISSEMENT

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Nettoyeur Haute Pression 2700 PSI de BSPP

22

• NE PAS toucher les surfaces chaudes.

• Laisser l'équipement refroidir avant d'y toucher.

• Il faut éloigner le nettoyeur haute pression d'au moins 1,5 m des

structures dont les murs sont inflammables et/ou d'autres matériaux

inflammables.

• Conservez un débattement d'au moins 1 m tout autour du nettoyeur

haute pression pour le refroidissement,l'entretien et les réparations.

Un moteur en marche dégage de la chaleur et des

gaz d'échappement brûlants. La température du

échappement et de certaines pièces voisines peut

atteindre ou dépasser 65 °C (150 °F).

Un incendie ou des blessures graves peuvent survenir.

Les débris inflammables, tels que feuilles, herbes,

broussailles, peuvent prendre feu.

AVERTISSEMENT

• NE PAS verrouiller le pistolet de pulvérisation en position ouverte.

• NE PAS laisser le pistolet de pulvérisation sans surveillance lorsque

l'appareil est en marche.

• Ne JAMAIS utiliser un pistolet de pulvérisation dont le verrou de

détente ou le pontet n'est pas installé et en ordre de marche.

• Toujours s'assurer que le pistolet de pulvérisation, les buses et les

accessoires sont bien fixés.

Les nettoyeurs haute pression produisent un jet à haute

pression qui accroît les risques de blessure et de dommage à

l'appareil.

ATTENTION

• En cas de questions à propos de l'utilisation conforme de cet appareil,

consulter le distributeur ou prendre contact avec Briggs & Stratton

Power Products.

• Ne JAMAIS utiliser un appareil dont des pièces sont cassées,

manquantes ou non munies de leur capot ou de leurs couvercles

protecteurs.

• NE neutraliser AUCUN dispositif de sécurité de cette machine.

• Par temps froid, avant de démarrer le nettoyeur à haute pression,

vérifier tous ses éléments pour vérifier l'absence de gel.

• Ne JAMAIS utiliser le flexible haute pression comme poignée pour

déplacer l'appareil.Toujours utiliser pour cela la poignée de l'appareil.

• Vérifier la présence de fuites ou de signes de détérioration du circuit

de carburant, comme un flexible usé ou spongieux, des brides de

serrage desserrées ou manquantes, ou un réservoir ou un bouchon

endommagé. Réparer toutes les défectuosités avant d'utiliser le

nettoyeur haute pression.

• Cet appareil est conçu pour être utilisé uniquement avec des pièces

Briggs & Stratton Power Products d'origine. Si l'équipement est utilisé

avec des pièces qui NE sont PAS conformes aux caractéristiques

minimales, tous les risques et responsabilités incomberont à

l'utilisateur.

Un traitement inadéquat du nettoyeur haute pression peut

l'endommager et réduire sa durée de vie utile.

ATTENTION

• NE PAS porter de vêtements amples, de bijoux ni d'autres effets qui

pourraient être happés par le démarreur ou les autres pièces en rotation.

• Retenir les cheveux longs en chignon et retirer les bijoux.

Prendre garde au fait que le démarreur et les pièces

en rotation peuvent happer les mains, les cheveux, les

vêtements ou des accessoires (colliers, lacets...).

AVERTISSEMENT

• Toujours porter une protection oculaire pendant l'utilisation de

l'équipement ou si vous vous trouvez à proximité d'un équipement en

fonctionnement.

Le jet à haute pression peut mettre en suspension

dans l'air des particules de peinture ou d'autres

matériaux.

AVERTISSEMENT

POUR RÉGLER OU RÉPARER LE NETTOYEUR

HAUTE PRESSION

• Débrancher le fil de bougie d'allumage et l'écarter de sorte qu'il ne

puisse toucher la bougie.

La production involontaire d'étincelles peut

provoquer un incendie ou une électrocution.

AVERTISSEMENT

• NE PAS modifier la vitesse régulée du moteur.

• NE PAS faire fonctionner le nettoyeur à une pression supérieure à la

pression nominale.

Une vitesse de fonctionnement du moteur trop élevée ou

trop faible augmente le risque d'occasionner des blessures ou

d'endommager le nettoyeur.

ATTENTION

• En mode haute pression, ne pas diriger le jet sur des vitres.

• NE JAMAIS diriger le jet sur des plantes.

Le jet à haute pression peut endommager les matériaux

fragiles, le verre par exemple.

ATTENTION

• NE JAMAIS pulvériser d'eau sur les circuits électriques sous peine

d'électrocution.

La pulvérisation d'eau sur les circuits électriques peut

entraîner une électrocution.

AVERTISSEMENT

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Nettoyeur Haute Pression 2700 PSI de BSPP

23

CONNAÎTRE VOTRE NETTOYEUR HAUTE PRESSION

Lisez ce manuel d'opérateur et ces règles de sécurité avant d'utiliser le nettoyeur haute pression.

Reportez-vous aux illustrations pour repérer l'emplacement des divers réglages et commandes de votre nettoyeur. Conservez ce

manuel pour pouvoir vous y référer ultérieurement.

Admission d'eau - Raccorder le tuyau d'arrosage à cet endroit.

Bouchon de remplissage d'huile - Orifice de remplissage de

l'huile du moteur.

Embouts de pulvérisation - Injection de produits chimiques,

0°, 15° et 40° : pour diverses applications de nettoyage sous haute

pression.

Filtre à air - Protège le moteur en filtrant la poussière et les

débris avant la prise d'air.

Flexible haute pression - Raccorder une des extrémités du

flexible à la pompe à eau et l'autre au pistolet de pulvérisation.

Lanceur - Sert à démarrer le moteur manuellement.

Levier d'étranglement - Prépare le moteur froid au démarrage

lorsqu'il est froid.

Lunettes de sécurité (non représentées) - Lors de

l'utilisation du nettoyeur haute pression, toujours utiliser les

lunettes de sécurité fournies ou une autre protection oculaire.

Manette de poussée - Cette manette place le moteur en mode

démarrage pour le lanceur et arrête le moteur lorsqu'il est en

marche.

Pistolet de pulvérisation - Un dispositif de détente permet de

contrôler le jet d'eau sur la surface à nettoyer. Le pistolet est

muni d'un verrou de sécurité de la détente.

Plaque d'identité - Indique le modèle, la révision et le numéro

de série du nettoyeur haute pression.Tenir ces renseignements à

disposition lors d'un appel pour assistance.

Pompe - Fournit la haute pression.

Porte-accessoires - Permet de ranger les accessoires standard

et en option, tels que brosses, turbo-lances, etc.

Rallonge de buse à raccord rapide - Permet de passer de l'un

à l'autre des quatre embouts de pulvérisation différents.

Réservoir de carburant - Remplir le réservoir avec du

carburant sans plomb normal. Ne jamais remplir complètement le

réservoir pour permettre la dilatation du carburant.

Robinet de carburant - Sert à ouvrir et à fermer l'arrivée du

carburant au moteur.

Siphon/Filtre d'injection de produits chimiques - Sert à

siphoner les détergents ou autres produits chimiques de

nettoyage sous pression dans le circuit basse pression.

Sortie haute pression - Sert au branchement du flexible haute

pression.

Système de refroidissement automatique - Fait circuler de

l'eau dans la pompe lorsque la température de l'eau atteint 51,6 à

68,3 ºC. L'eau chaude de la pompe est évacuée au sol. Ce

système prévient tout dommage interne à la pompe.

Siphon/Filtre d'injection

de produits chimiques

Pistolet de pulvérisation

Rallonge de buse à

raccord rapide

Levier d'étranglement

Manette de poussée

Lanceur

Robinet de carburant

(à l'avant du moteur)

Filtre à air

Réservoir

de carburant

Pompe équipée du système de

refroidissement automatique

Admission d'eau

Bouchon de

remplissage d'huile

Embouts de

pulvérisation

Sortie haute pression

Porte-accessoires

Plaque d'identité

Flexible haute

pression

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Nettoyeur Haute Pression 2700 PSI de BSPP

24

ASSEMBLAGE

IMPORTANT: Lire entièrement le manuel d'opérateur avant de

monter et d'utiliser l'appareil.

Deballer le nettoyeur haute pression de

son carton

• Sortir tous les accessoires et composants livrés avec le

nettoyeur haute pression.

• Couper le carton du haut en bas le long de deux arêtes

consécutives et rabattre au sol le côté ainsi libéré, retirer

ensuite tous les matériaux d'emballage.

• Sortir le nettoyeur du carton en le faisant rouler.

Contenu de la boîte

La boîte contient les éléments suivants :

• Unité principale

• Lunettes de sécurité

• Poignée

• Porte-accessoires en plastique

• Flexible haute pression

• Pistolet de pulvérisation

• Rallonge de buse à raccord rapide

• Sachet de pièces détachées (contenant les éléments suivants) :

• Manuel d'opérateur

• Manuel du moteur

• Kit d'entretien

• Raccords de tuyau

• Raccords rapides

• Sachet contenant 4 embouts de pulvérisation à raccord

rapide de différentes couleurs

• Kit de quincaillerie de fixation de la poignée (comprenant):

• Boulon

• Boutons en plastique (2)

• Crochet en "L"

• Crochet en "J"

• Attache du flexible pour produits chimiques

• Vis auto-taraudeuses (4)

Si des pièces manquent ou sont endommagées, contacter le

centre de réparation Briggs & Stratton le plus proche.

PRÉPARATION DU NETTOYEUR

HAUTE PRESSION AVANT

UTILISATION

Pour mettre le nettoyeur haute pression en état de

fonctionnement, les tâches suivantes doivent être effectuées:

1. Fixer le porte-accessoires à la poignée, puis fixer la poignée à

l'unité principale.

2. Faire le niveau d'huile.

3. Faire le plein d'essence.

4. Raccorder le flexible haute pression au pistolet et pompe.

5. Raccorder l'alimentation en eau à la pompe.

6. Monter la lance sur le pistolet.

7. Choisir et fixer l'embout de pulvérisation à raccord rapide à

la rallonge de buse.

Fixer la poignée et le porte-accessoires

REMARQUE: Toutes les opérations de montage décrites dans

cette section se rapportent à un montage par rapport à l'arrière

du nettoyeur haute pression.

1. Faire glisser le porte-accessoires en plastique sur la poignée et

aligner les trous du plateau avec ceux de la poignée (figure 26).

2. Fixer le plateau sur la poignée avec des vis auto-taraudeuses

à l'aide d'un tournevis cruciforme n° 2.Vérifier que les vis

sont serrées sans pour autant écraser le porte-accessoires

en plastique.

Figure 26 - Fixer le porte-accessoires

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

3. Placer la poignée sur les supports déjà reliés à l'unité

principale.Vérifier que les trous de la poignée et des

supports sont alignés (figure 27).

REMARQUE: Il peut être nécessaire de déplacer les supports

d'un côté à l'autre.

4. Insérer le boulon en "L" dans le trou du côté gauche de la

poignée (en regardant depuis l'avant de l'appareil) et fixer le

bouton en plastique (figure 28).

5. Insérer le boulon dans le trou du côté droit de la poignée

(en regardant depuis l'avant de l'appareil) et fixer le bouton

en plastique (figure 28). Serrer le bouton à la main.

6. Insérer le crochet en "J" dans le porte-accessoires, dans la

deuxième fente en partant de la gauche (figure 29).

7. Pincer le flexible pour produits chimiques et le faire glisser

dans la fixation métallique comme indiqué sur la figure 30.

8. Incliner l'unité vers le haut par la poignée et fixer la fixation

métallique à la nervure située au centre de la face inférieur

du porte-accessoires (figure 31). Passer le flexible pour

produits chimiques dans la fixation métallique de telle sorte

qu'il soit maintenu sans être plié ni pincé.

Charger en huile moteur et en carburant

• Placer le nettoyeur haute pression sur une surface

horizontale.

• Consulter le manuel d'opérateur du moteur et suivre les

instructions et les recommandations relatives à l'huile et au

carburant.

REMARQUE: Toujours vérifier le niveau d’huile avant utilisation,

comme expliqué dans le manuel d'opérateur du moteur.

Nettoyeur Haute Pression 2700 PSI de BSPP

25

• Consulter le manuel d'opérateur du moteur au sujet de l'huile et du

carburant.

• La garantie sera annulée si l'équipement est endommagé par suite du

non-respect de cette instruction.

Toute tentative de démarrage du moteur sans qu'il ait été

rempli avec l'huile recommandée entraînera une panne de

l'équipement.

ATTENTION

Aligner

les trous

Poignée

Supports de

poignée

Figure 27 — Fixer la poignée sur la base

Figure 28 — Immobiliser la poignée

Figure 29 - Installer le crochet en "J" sur le porte-accessoires

Figure 30 — Faire glisser le flexible pour produits chimiques

dans la fixation métallique

Figure 31 — Faire glisser la fixation métallique sur la bride du

porte-accessoires

Briggs & Stratton Generac Generator Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Nettoyeur Haute Pression 2700 PSI de BSPP

26

Raccorder le flexible et l'alimentation en

eau à la pompe

IMPORTANT: Pour éviter d'endommager la pompe, il est

impératif de monter la rallonge de buse au pistolet de

pulvérisation et raccorder tous les flexibles avant de lancer le

moteur.

1. Dérouler le flexible haute pression et fixer une extrémité à

la base du pistolet (figure 32). Serrer à la main.

2. Fixer l'autre extrémité du flexible haute pression à la sortie

haute pression de la pompe (figure 33). Serrer à la main.

3. Avant de raccorder le tuyau d'arrosage à l'entrée d'eau du

nettoyeur, inspecter le tamis d'entrée (figure 34). Nettoyer le

tamis s'il contient des débris, le remplacer s'il est

endommagé. NE JAMAIS UTILISER UN NETTOYEUR

HAUTE PRESSION DONT LE TAMIS D'ENTRÉE EST

ENDOMMAGÉ.

4. Faire couler l'eau dans le tuyau d'arrosage pendant trente

secondes pour éliminer tous les débris en suspension.

Refermer l'eau.

IMPORTANT: NE PAS siphonner une eau stagnante pour

alimenter le nettoyeur. Utiliser EXCLUSIVEMENT de l'eau froide

(moins de 35 °C).

5. Fixer un raccord rapide femelle au tuyau d'arrosage. Fixer un

raccord rapide mâle à l'admission d'eau de la pompe (figure 35).

6. Brancher le tuyau d'arrosage (de moins de 15m) à l'orifice

d'admission d'eau (figure 35). Repousser le collier du raccord

rapide, emboîter le raccord sur la pompe et relâcher le collier.

Tirer sur le tuyau pour vérifier la solidité du branchement.

7. OUVRIR l'eau et appuyer sur la gâchette du pistolet pour

purger l'air et d'éventuels débris de la pompe.

Liste de vérifications avant le démarrage

du moteur

Inspecter le montage de l'appareil pour confirmer que les tâches

suivantes ont été accomplies:

1. S'assurer que la poignée est bien fixée sur le chariot.

2. Vérifier que le niveau d'huile du carter moteur est correct.

3. Vérifier que l'essence ajoutée dans le réservoir est d'un type

approprié.

4. Vérifier que les raccords du flexible haute pression sont

correctement serrés.Vérifier que le flexible haute pression est

exempt de pincements, de coupures ou de tout autre dommage.

5. Vérifier que l'alimentation en eau et son débit sont appropriés.

6. S'assurer que l'utilisateur a pris connaissance des "Consignes

de sécurité" et du paragraphe "Utilisation du nettoyeur haute

pression" avant d'utiliser l'appareil.

ATTENTION

• Les dommages causés au nettoyeur haute pression en raison du nonrespect de cette mise en garde ne sont pas couverts par la garantie.

Il FAUT laisser au moins 3 mètres de tuyau d'arrosage libre entre

l'entrée du nettoyeur haute pression et un dispositif d'arrêt,par