Page 1

Not for

Reproduction

Pressure Washer

Operator’s Manual

This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association (PWMA)

standard PW101-2010 (Testing and Rating Performance of Pressure Washers).

BRIGGS & STRATTON CORPORATION

MILWAUKEE, WISCONSIN, U.S.A.

Manual No. 80028196 Rev-

Page 2

Not for

Reproduction

Thank you for purchasing this quality-built Briggs & Stratton® pressure washer. We are pleased that you’ve

placed your condence in the Briggs & Stratton brand. When operated and maintained according to the

instructions in this manual, your Briggs & Stratton pressure washer will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with pressure

washers and how to avoid them. Because Briggs & Stratton does not necessarily know all the applications this

pressure washer could be used for, it is important that you read and understand these instructions thoroughly

before attempting to start or operate this equipment. Save these original instructions for future reference.

This pressure washer requires nal assembly before use. Refer to the Assembly section of this manual for

instructions on nal assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to nd Briggs & Stratton support and service for your pressure washer. Consult your

Yellow Pages. There are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality

service. You can also contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet

at BRIGGSandSTRATTON.COM.

Register Your Product

To ensure prompt and complete warranty coverage, register your product online at www.onlineproductregistration.com.

Pressure Washer Engine

Model Number _____________________ Model Number ______________________

Revision __________________________ Type Number _______________________

Serial Number ______________________ Code Number _______________________

Date Purchased ___________________

Table of Contents

Operator Safety....................... 3

Assembly............................ 6

Features and Controls ................ 10

Operation........................... 11

Maintenance ........................ 16

Troubleshooting ..................... 22

Warranty ........................... 23

Product Specications ................ 24

Common Service Parts ............... 24

Copyright © 2018. Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

2 BRIGGSandSTRATTON.COM

Page 3

Not for

Reproduction

Operator Safety

Equipment Description

Read this manual carefully and become

familiar with your pressure washer. Know

its applications, its limitations, and any

hazards involved.

This pressure washer operates at a maximum of

3,300 PSI (228 BAR) at a ow rate of up to 2.5 gallons

(9.5 liters) per minute. This high quality residential

system features 10 in. (25 cm) wheels, triplex pump

with stainless steel pistons, automatic cool down

system, detergent siphoning system, quick connect

spray tips, heavy duty 30 ft. (9 m) hose, and more.

Every eort has been made to ensure that information

in this manual is accurate and current. However, we

reserve the right to change, alter, or otherwise improve

the product and this document at any time without prior

notice.

The Emission Control System for this pressure washer

is warranted for standards set by the Environmental

Protection Agency and the California Air Resources

Board.

Important Safety Information

Safety Symbols and Meanings

Operator’s

Manual

Slippery

Surface

Fire

Moving

Parts

Toxic Fumes

Explosion

Flying

Objects

Fall

Kickback

Chemical

Electrical Shock

Fluid Injection

Projectile

Hot Surface

Burn

The safety alert symbol indicates a potential

personal injury hazard. A signal word (DANGER,

WARNING, or CAUTION) is used with the alert symbol

to designate a degree or level of hazard seriousness. A

safety symbol may be used to represent the type of

hazard. The signal word NOTICE indicates information

considered important, but not hazard-related.

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE indicates information considered important, but

not hazard-related.

WARNING POISONOUS GAS HAZARD.

Engine exhaust contains carbon monoxide,

a poisonous gas that could kill you in

minutes. You CANNOT smell it, see it, or

taste it. Even if you do not smell exhaust fumes, you

could still be exposed to carbon monoxide gas.

Some chemicals or detergents could be harmful if

inhaled or ingested, resulting in death, serious

injury, nausea, fainting or poisoning.

• Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or

plug-in carbon monoxide alarms with battery back-up

according to the manufacturer’s instructions. Smoke

alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other partiallyenclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for hours,

even after this product has shut o.

• ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces.

If you start to feel sick, dizzy, or weak while using this

product, get to fresh air RIGHT AWAY. See a doctor. You

may have carbon monoxide poisoning.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled when using chemicals.

• Read all instructions with mask so you are certain the

mask will provide the necessary protection against

inhaling harmful vapors when using chemicals.

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in

death or serious injury.

• DO NOT use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents /soaps.

Follow all manufacturers instructions.

3

Page 4

Not for

Reproduction

WARNING This product can expose you to

chemicals including gasoline engine exhaust, which

is known to the State of California to cause cancer,

and carbon monoxide, which is known to the State

of California to cause birth defects or other

reproductive harm. For more information go to

www.P65Warnings.ca.gov.

WARNING This product contains lead and lead

compounds, known to the state of California to

cause birth defects or other reproductive harm.

Wash your hands after handling this product.

Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage

fuel tank causing a re, resulting in

death or serious injury.

Contact with muer area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (1.5 m) of clearance on all sides of

pressure washer including overhead.

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forestcovered, brush-covered, or grass-covered land unless

the exhaust system is equipped with a spark arrester, as

dened in Section 4442, maintained in eective working

order. Other states or federal jurisdictions may have

similar laws.

Contact the original equipment manufacturer, retailer,

or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

• Replacement parts must be the same and installed in the

same position as the original parts.

WARNING Risk of electrocution.

Contact with power source could cause

electric shock or burn resulting in death or

serious injury.

• NEVER spray near power source.

WARNING Use of pressure washer could

create puddles and slippery

surfaces causing you to fall

resulting in death or serious injury.

Kickback from spray gun could cause you to fall

resulting in death or serious injury.

• Operate pressure washer from a stable surface.

• The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery

surfaces.

• Be extremely careful if you must use the pressure washer

from a ladder, scaolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

WARNING Fuel and its vapors are extremely

ammable and explosive which

could cause burns, re or explosion

resulting in death or serious injury.

WHEN ADDING OR DRAINING FUEL

• Turn pressure washer engine OFF and let it cool at least

2 minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overll tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open ames, pilot lights,

heat, and other ignition sources.

• Check fuel lines, tank, cap and ttings frequently for

cracks or leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muer, fuel cap, and air cleaner are in

place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT operate this product inside any building,

carport, porch, mobile equipment, marine applications, or

enclosure.

• DO NOT tip engine or equipment at angle which causes

fuel to spill.

• DO NOT spray ammable liquids.

WHEN TRANSPORTING, MOVING OR REPAIRING

EQUIPMENT

• Transport/move/repair with fuel tank EMPTY or with fuel

shuto valve OFF (0).

• DO NOT tip engine or equipment at angle which causes

fuel to spill.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers, or other appliances that have pilot light or other

ignition source because they could ignite fuel vapors.

WARNING Starter cord kickback (rapid

retraction) will pull hand and arm toward

engine faster than you can let go which

could cause broken bones, fractures,

bruises, or sprains resulting in serious injury.

• NEVER pull starter cord without rst relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

• After each starting attempt, where engine fails to run,

always point spray gun in safe direction, press red button

and squeeze spray gun trigger to release high pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

4 BRIGGSandSTRATTON.COM

Page 5

Not for

Reproduction

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• If cut by uid, call physician immediately. DO NOT treat

as a simple cut.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

WARNING Unintentional sparking could cause

re or electric shock resulting in

death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

WARNING Starter and other rotating parts

could entangle hands, hair, clothing, or

accessories resulting in serious injury.

• NEVER operate pressure washer without protective

housing or covers.

• DO NOT wear loose clothing, jewelry or anything that

could be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

WARNING Risk of eye or bodily injury.

Spray could splash back or propel

objects resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

• Always wear protective clothing such as a long-sleeved

shirt, long pants and close-toed shoes.

• NEVER operate pressure washer when barefoot or

wearing sandals or shorts.

CAUTION

could result in minor injury.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other

parts to increase engine speed. Pressure washer

supplies correct rated pressure and ow when running at

governed speed.

• DO NOT modify pressure washer in any way.

NOTICE High pressure spray could damage fragile

items including glass.

• DO NOT point spray gun at glass when using red (0°) spray

tip.

• NEVER aim spray gun at plants.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

• If you have questions about intended use, ask dealer or

contact qualied service center.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

• DO NOT modify pressure washer in any way.

• Before starting pressure washer in cold weather, check all

parts of the equipment to be sure ice has not formed there.

• NEVER move machine by pulling on hoses. Use handle

provided on unit.

• This equipment is designed to be used with Briggs &

Stratton authorized parts ONLY. If equipment is used with

parts that DO NOT comply with minimum specications,

user assumes all risks and liabilities.

Excessively high operating speeds

5

Page 6

Not for

Reproduction

Assembly

Read entire operator’s manual before you

attempt to assemble or operate your new

pressure washer.

Your pressure washer requires some assembly and is

ready for use after it has been properly serviced with

the recommended oil and fuel.

If you have any problems with the assembly of your

pressure washer, please call the pressure washer

helpline at (800) 743-4115. If calling for assistance,

please have the model, revision, and serial number

from the identication label available.

Unpack Pressure Washer

1. Remove the parts bag, accessories, and inserts

included with pressure washer.

2. Open carton completely by cutting each corner

from top to bottom.

3. Ensure you have all included items prior to

assembly.

Items in the carton include:

• Main Unit

• Handle

• High Pressure Hose

• Spray Gun

• Nozzle Extension with Quick Connect Fitting

• Oil Pouch

• Parts Bag (which includes the following):

• Operator’s Manual

• Ba g containing 5 Multi–Colored Spray Tips

• Hardware Kit (which includes):

• Carriage Bolts (4)

• Plastic Knobs for Handle (2)

• Metal Spring Clips (2)

• Plastic Knobs (2)

• Grommets (5)

To prepare your pressure washer for operation,

you will need to perform these tasks:

1. Attach handle to main unit.

2. Add oil to engine crankcase.

3. Add fuel to fuel tank.

4. Connect high pressure hose to spray gun and pump.

5. Connect water supply to pump.

6. Attach nozzle extension to spray gun.

7. Select/attach quick connect spray tip to nozzle

extension.

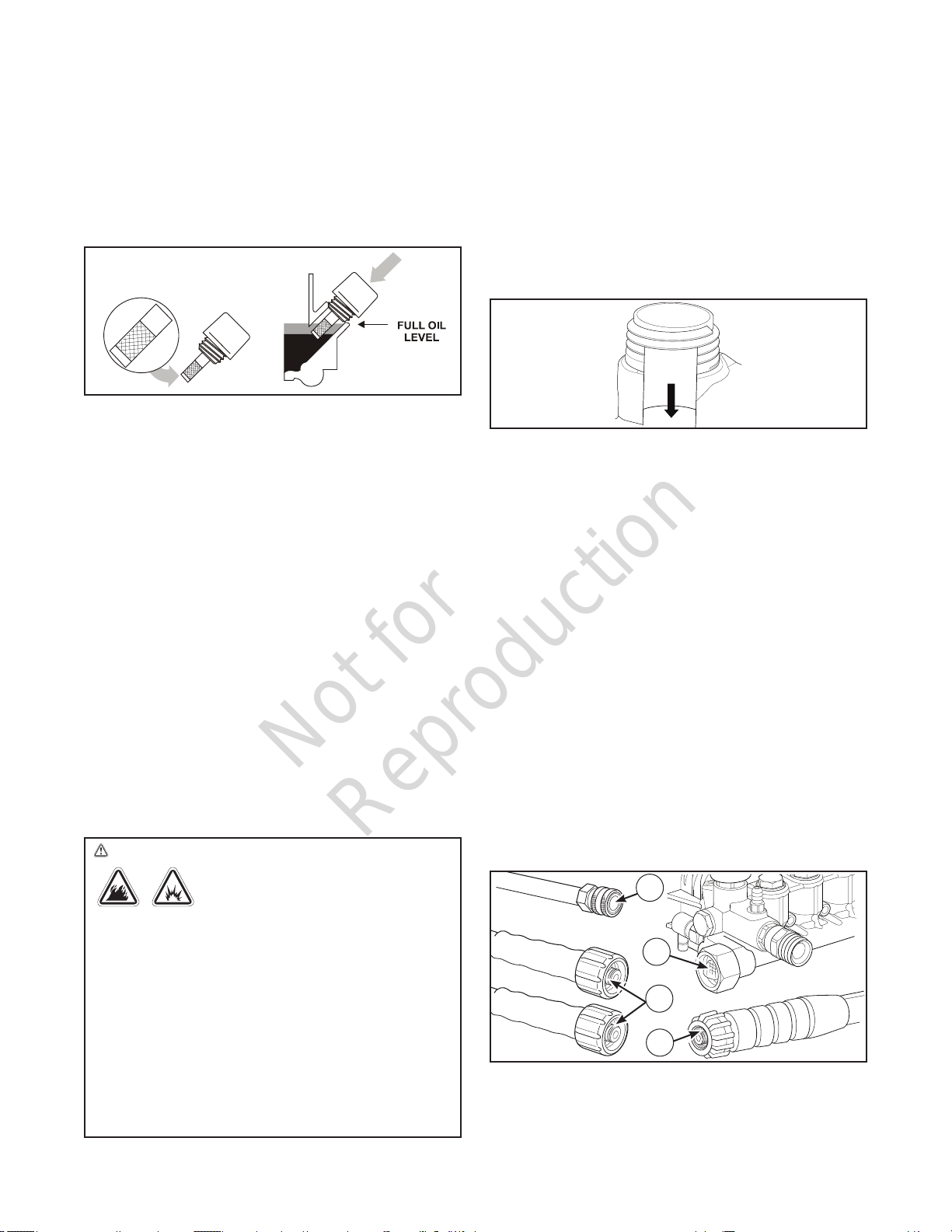

Remove Pump Oil Shipping Cap

A shipping cap has been installed on the pump to

prevent oil from leaking.

NOTICE Failure to install vented plug/dipstick will

result in a pump failure and void the warranty.

1. Remove the red shipping cap (A) from pump.

2. Install the vented plug/dipstick (B) in the pump.

A

B

Attach Handle

1. Place handle (C) onto handle supports connected

to main unit. Make sure holes in handle align with

holes on handle supports.

C

D

2. Insert handle carriage bolts (D) through holes from

inside of unit and attach a plastic knob (E) from

outside of unit. Tighten by hand.

3. Attach metal spring clips (F) by installing carriage

bolts (D) through holes on left side of handle

(facing front of unit). Attach plastic knobs (G) and

tighten by hand.

G

4. Insert rubber grommets (H) in holes at top of

billboard.

E

H

F

D

NOTICE For ease of installation, dip rubber grommets

in soapy water rst.

6 BRIGGSandSTRATTON.COM

Page 7

Not for

Reproduction

Add Engine Oil

1. Place pressure washer on a at, level surface.

2. Clean area around oil ll and remove yellow oil ll

cap/dipstick.

3. Hold neck of supplied oil pouch and remove cap.

4. Slowly pour contents of oil pouch into oil ll

opening. Checking oil level frequently, ll to point

of overowing.

NOTICE Pause to permit oil to settle. Wipe dipstick

clean each time oil level is checked. DO NOT overll.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

• DO NOT attempt to crank or start the engine before it has

been properly serviced with the recommended oil. This

could result in an engine failure.

5. Replace oil ll cap/ dipstick and fully tighten.

Add Fuel

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). For

high altitude use, see High Altitude.

• Gasoline with up to 10% ethanol (gasohol) is

acceptable.

NOTICE Use of unapproved fuels could damage

pressure washer and voids warranty.

• DO NOT use unapproved gasoline such as E15 and E85.

• DO NOT mix oil in gasoline or modify engine to run on

alternate fuels.

WARNING Fuel and its vapors are extremely

ammable and explosive which

could cause burns, re or explosion

resulting in death or serious injury.

WHEN ADDING FUEL

• Turn pressure washer engine OFF and let it cool at least

2 minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

• Fill fuel tank outdoors.

• DO NOT overll tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

• Keep fuel away from sparks, open ames, pilot lights,

heat, and other ignition sources.

• Check fuel lines, tank, cap and ttings frequently for

cracks or leaks. Replace if necessary.

• DO NOT light a cigarette or smoke.

To protect the fuel system from gum formation, mix

in a fuel stabilizer when adding fuel. See Storage.

All fuel is not the same. If you experience starting or

performance problems after using fuel, switch to a

dierent fuel provider or change brands. This engine is

certied to operate on gasoline. The emission control

system for this engine is EM (Engine Modications).

1. Clean area around fuel ll cap, remove cap.

2. Slowly add clean, fresh, UNLEADED fuel to fuel

tank. Be careful not to overll. To allow for fuel

expansion, do not ll above the bottom of the fuel

tank neck.

3. Install fuel cap and let any spilled fuel evaporate

before starting engine.

High Altitude

At altitudes over 5,000 ft. (1,524 m), a minimum

85 octane / 85 AKI (89 RON) gasoline is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause

decreased performance, increased fuel consumption,

and increased emissions. See an Authorized Briggs &

Stratton dealer for high altitude adjustment information.

Operation of the engine at altitudes below 2,500 ft.

(762 m) with the high altitude kit is not recommended.

Lubricate O-Rings

Lubrication of o-rings is extremely important for

installation and operation. The use of a lubricant

(petroleum or synthetic grease) during assembly helps

seat o-rings properly and provides an improved seal. It

also helps protect the o-ring from damage by abrasion,

pinching or cutting and extends the life of the o-ring.

NOTICE ALWAYS apply a small amount of lubricant

on o-rings prior to assembling the garden hose to the

pump inlet (A), high pressure hose (B), spray gun (C),

and spray wand (D).

D

A

B

C

Lubricate all connections shown, following these

instructions:

1. Inspect and clean connecting surfaces prior to

lubrication and assembly.

7

Page 8

Not for

Reproduction

2. Use lubricants sparingly during assembly; a light

lm is all that is required.

3. Use a small brush or cotton swab to apply grease

directly to o-rings where they are not accessible

(QC tting, M22 tting).

Connect Hose and Water Supply to Pump

NOTICE DO NOT run the pump without the water

supply connected and turned on.

• Damage to equipment resulting from failure to follow

this instruction will void warranty.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

NOTICE DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 100°F (38°C)).

NOTICE Using a One Way Valve (vacuum breaker

or check valve) at pump inlet could cause pump or

inlet connector damage.

• There MUST be at least 10 ft. (3 m) of unrestricted

garden hose between the pressure washer inlet and

any device, such as a vacuum breaker or check valve.

• Damage to equipment resulting from failure to follow

this instruction will void warranty.

5. Connect the garden hose (not to exceed 50 ft.

(15 m) in length) to the water inlet. Tighten by

hand.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

6. Turn ON the water, press red button (C) on the

gun and squeeze the trigger to purge the pump

system of air and impurities.

C

2. Attach other end of high pressure hose to high

pressure outlet (A) on pump. Tighten by hand.

B

A

3. Before connecting garden hose to water inlet,

inspect inlet screen (B). Clean screen if it contains

debris or have it replaced if damaged. DO NOT

run pressure washer if inlet screen is damaged.

4. Run water through your garden hose for

30 seconds to clean out any debris.

Checklist Before Starting Engine

Review the unit’s assembly to ensure you have

performed all of the following.

1. Make sure handle is in place and secure.

2. Verify oil dipstick has been installed into pump.

3. Check that oil has been added to proper level in

the engine crankcase.

4. Add proper fuel to fuel tank.

5. Check for properly tightened hose connections.

6. Check to make sure there are no kinks, cuts, or

damage to high pressure hose.

7. Provide a proper water supply at an adequate ow.

8. Be sure to read Operator Safety and Operation

before using pressure washer.

8 BRIGGSandSTRATTON.COM

Page 9

Not for

Reproduction

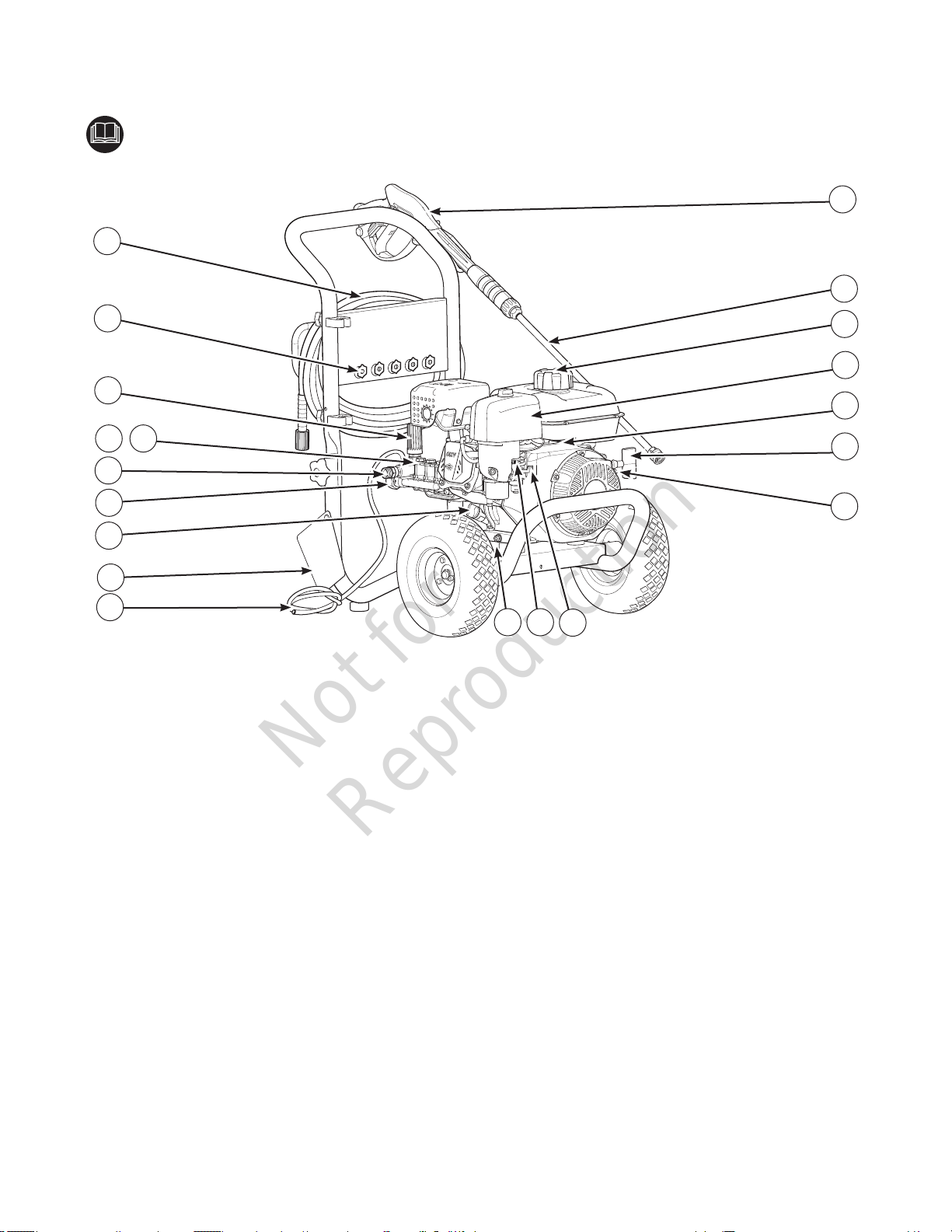

Features and Controls

Read this Operator’s Manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer, to familiarize yourself with the locations of various

controls and adjustments. Save this manual for future reference.

A

W

V

B

C

D,E

F

G

H

J

K

A - High Pressure Hose — Connect one end to water

pump and the other end to spray gun.

B - Spray Tips — Detergent, 0°, 15°, 25° and 40°: for

various high pressure cleaning applications.

C - Pressure Control Knob — Varies pressure of

high pressure spray.

D - Pump — Develops high pressure.

E - Automatic Cool Down System — Cycles water

through pump when water reaches 125°-155°F

(51°-68°C). Warm water will discharge from pump

onto ground. This system prevents internal pump

damage.

F - High Pressure Outlet — Connection for high

pressure hose.

G - Water Inlet — Connection for garden hose.

H - Oil Fill/Dipstick — Check and add engine oil here.

J - Warning/Operating Instructions Tag — Identies

hazards and proper procedure to start/stop pressure

washer.

K - Detergent Siphoning Tube/Filter — Use to

siphon pressure washer safe detergent into the low

pressure stream.

U

T

S

R

P

ML

N

L - Identication Label — Provides model and serial

number of pressure washer. Please have these

readily available if calling for assistance.

M - Choke Lever — Prepares a cold engine for

starting.

N - Fuel Lever — Turns fuel supply on and o to

engine.

P - Engine Rocker Switch — Rotate this switch to

ON (I) position before using recoil starter. Rotate

switch to OFF (0) position for shutting o engine.

R - Recoil Starter — Used for starting the engine manually.

S - Throttle Lever — Sets engine in starting mode for

recoil starter.

T - Air Filter — Protects engine by ltering dust and

debris out of intake air.

U - Fuel Tank — Fill tank with regular unleaded fuel.

Always leave room for fuel expansion.

V - Nozzle Extension with Quick Connect — Allows

you to switch between ve dierent spray tips.

W - Spray Gun — Controls the application of water

onto cleaning surface with trigger device. Includes

trigger lock.

9

Page 10

Not for

Reproduction

Operation

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

(800) 743-4115.

Pressure Washer Location

Carbon Monoxide Poisoning

WARNING POISONOUS GAS HAZARD.

Engine exhaust contains carbon monoxide,

a poisonous gas that could kill you in

minutes. You CANNOT smell it, see it, or

taste it. Even if you do not smell exhaust fumes, you

could still be exposed to carbon monoxide gas.

• Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or

plug-in carbon monoxide alarms with battery back-up

according to the manufacturer’s instructions. Smoke

alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other partiallyenclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for hours,

even after this product has shut o.

• ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces.

If you start to feel sick, dizzy, or weak while using this

product, get to fresh air RIGHT AWAY. See a doctor. You

may have carbon monoxide poisoning.

How to Start Your Pressure Washer

To start your pressure washer for the rst time,

follow these instructions step-by-step. This starting

information also applies if you have let the pressure

washer sit idle for at least a day.

1. Place pressure washer near an outside water

source capable of supplying water at a ow rate

greater than 3.5 gallons (13.25 liters) per minute

and no less than 20 PSI (1.4 BAR) at pressure

washer end of garden hose. DO NOT siphon

supply water.

2. Check that high pressure hose is tightly

connected to spray gun and pump. See Assembly

section.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump.

NOTICE DO NOT run the pump without the water

supply connected and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

5. Turn ON the water, press red button on spray gun

and squeeze the trigger to purge the pump system

of air and impurities.

6. Attach nozzle extension to spray gun. Tighten by

hand.

Risk of Fire Clearances

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage fuel tank

causing a re, resulting in death or serious

injury.

• Keep at least 5 ft. (1.5 m) clearance on all sides of

pressure washer including overhead.

7. Choose spray tip you want to use, pull back on

collar of nozzle extension, insert spray tip and

release collar. Tug on spray tip to make sure it is

securely in place. See How to Use Spray Tips.

10 BRIGGSandSTRATTON.COM

Page 11

Not for

Reproduction

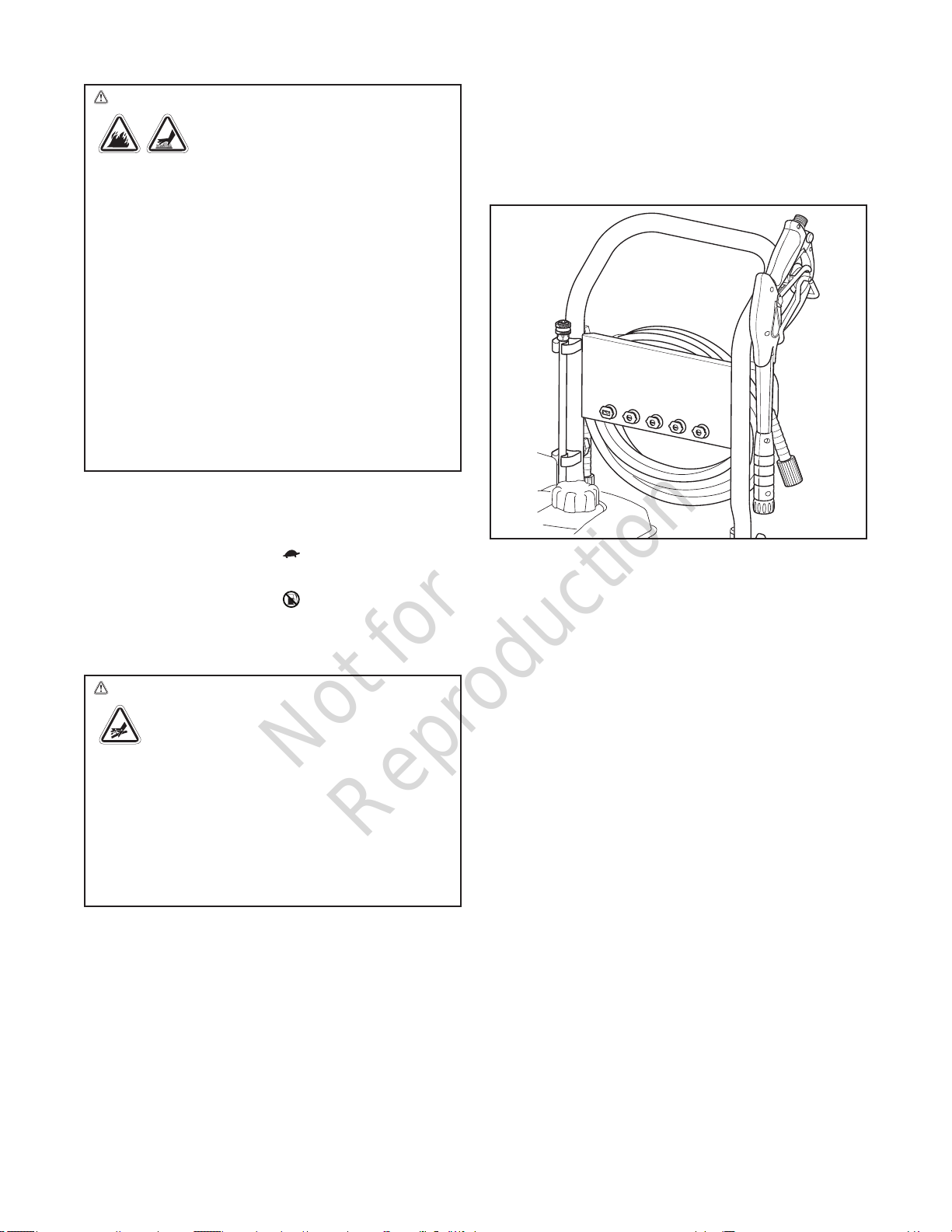

8. Move fuel lever (A) to ON ( ) position.

C

D

A

B

9. Rotate engine switch (B) to ON (I) position.

10. Move throttle control lever (C) to FAST ( )

position, shown on engine as a rabbit.

11. Move choke lever (D) to CHOKE ( ) position.

NOTICE For a warm engine, be sure choke lever is in

RUN ( ) position.

NOTICE Before starting the pressure washer, be sure

you are wearing safety goggles as described below.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

12. When starting engine, position yourself as

recommended below and grasp starter grip

handle and pull slowly until you feel some

resistance. Then pull rapidly to start engine.

WARNING Starter cord kickback (rapid

retraction) will pull hand and arm toward

engine faster than you can let go which

could cause broken bones, fractures,

bruises, or sprains resulting in serious injury.

• NEVER pull starter cord without rst relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

• After each starting attempt, where engine fails to run,

always point spray gun in safe direction, press red button

and squeeze spray gun trigger to release high pressure.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

13. Return starter grip handle slowly. DO NOT let

rope “snap back” against starter.

NOTICE After each starting attempt, where engine

fails to run, always point gun in safe direction, press

red button and squeeze spray gun trigger to release

high pressure.

14. When engine starts, slowly move choke lever to

RUN (

falters, move choke lever to CHOKE ( )

position, then to RUN ( ) position.

NOTICE Always keep the throttle lever in the

FAST ( ) position when operating the pressure

washer.

NOTICE If engine fails to run or shuts down, make

sure unit is on a level surface and check oil level. Unit

may be equipped with a low oil protection device and

oil must be at a proper level.

WARNING The high pressure stream of water

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• DO NOT allow CHILDREN to operate pressure washer.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is running.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

) position, as engine warms. If engine

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

11

Page 12

Not for

Reproduction

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage

fuel tank causing a re, resulting in

death or serious injury.

Contact with muer area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (1.5 m) of clearance on all sides of

pressure washer including overhead.

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forestcovered, brush-covered, or grass-covered land unless

the exhaust system is equipped with a spark arrester, as

dened in Section 4442, maintained in eective working

order. Other states or federal jurisdictions may have

similar laws.

Contact the original equipment manufacturer, retailer,

or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

• Replacement parts must be the same and installed in the

same position as the original parts.

How to Stop Your Pressure Washer

1. Release spray gun trigger and let engine idle for

two minutes.

2. Move throttle to SLOW ( ) position.

3. Rotate engine switch to OFF (0) position.

4. Move fuel lever to OFF ( ) position.

5. ALWAYS point spray gun in a safe direction,

press red button and squeeze spray gun trigger to

release retained high water pressure.

How to Store Accessories

The unit is equipped with multiple places to store your

spray gun, nozzle extension, high pressure hose and

spray tips.

1. Place spray gun into spray gun holder wireform as

shown.

2. Place nozzle extension into metal spring clips on

side of unit as shown.

3. Coil high pressure hose onto hook on back of handle.

4. Insert multi–colored spray tips in spaces provided

on handle.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

12 BRIGGSandSTRATTON.COM

Page 13

Not for

Reproduction

How to Use Spray Tips

The quick–connect on the nozzle extension allows you

to switch between ve dierent quick connect spray

tips. Spray tips can be changed while pressure washer

is running once spray gun trigger is locked. The spray

tips vary the spray pattern as shown.

Follow these instructions to change spray tips:

1. Pull back collar on quick–connect and pull current

spray tip o. Store spray tips in holder provided on

the handle.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

• NEVER exchange spray tips without the trigger lock

being engaged on the spray gun.

• DO NOT twist spray tips while spraying.

2. Select desired spray tip:

• For delicate rinse, for gentle cleaning of cars/

trucks, boats, RV’s, patio furniture, lawn

equipment, etc., select white 40° or green 25°

spray tip.

• For general rinsing, ideal for most all purpose

cleaning such as home siding, brick patios,

wood decks, driveways and sidewalks, garage

oors, etc., select yellow 15° spray tip.

• For maximum rinsing, for stubborn or hard to

reach surface such as second story surfaces,

paint removal, oil stains, rust removal or other

stubborn substances (tar, gum, grease, wax,

etc.), select red 0° spray tip.

• To apply detergent, applies project specic

cleaners to help break down stubborn dirt and

grime on a variety of surfaces, select black

detergent spray tip.

3. Pull back on collar, insert new spray tip and

release collar. Tug on spray tip to make sure it is

securely in place.

Usage Tips

• For most eective cleaning, keep spray tip from 8 -

24 inches (20 - 61 cm) away from cleaning surface.

• If you get spray tip too close, especially using a

high pressure spray tip, you may damage surface

being cleaned.

• DO NOT get closer than 6 in. (15 cm) when cleaning

tires.

Cleaning and Applying Detergent

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting in

death or serious injury.

• DO NOT use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents /soaps.

Follow all manufacturers instructions.

To apply detergent, follow these steps:

1. Review use of spray tips.

2. Prepare detergent solution as required by job.

3. Place small lter end of detergent siphoning tube

into detergent container.

NOTICE Make sure the lter is fully submerged in

detergent while applying detergent.

NOTICE Contact with the hot muer could damage

detergent siphoning tube.

• When inserting the siphon into a detergent solution bottle,

route the tube so as to keep it from inadvertently contacting

the hot muer.

4. Make sure black detergent spray tip is installed.

NOTICE Detergent cannot be applied with the high

pressure spray tips (White, Green, Yellow or Red).

5. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump. Turn on water.

NOTICE You must attach all hoses before you start

the engine.

• Starting the engine without all the hoses connected and

without the water turned ON could damage the pump.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

6. Start engine following instructions How to Start

Your Pressure Washer.

Low Pressure

Use to apply

detergent

Black

13

White 40°

3100 PSI

2.5 GPM

Green 25°

3300 PSI

2.4 GPM

Yellow 15°

3300 PSI

2.4 GPM

Pressure

Red 0°

3300 PSI

2.4 GPM

High

Page 14

Not for

Reproduction

7. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward,

using long, even, overlapping strokes.

8. Allow detergent to “soak in” for 3-5 minutes

before washing and rinsing. Reapply as needed

to prevent surface from drying. DO NOT allow

detergent to dry on (prevents streaking).

NOTICE You must ush the detergent siphoning

system after each use by placing the lter into a bucket

of clean water, then run the pressure washer in low

pressure for 1-2 minutes.

Pressure Washer Rinsing

For Rinsing:

1. Remove black detergent spray tip from nozzle

extension.

2. Select and install desired high pressure spray tip

following instructions How to Use Spray Tips.

3. Keep spray gun a safe distance from area you

plan to spray.

WARNING Kickback from spray gun could

cause you to fall resulting in death or serious

injury.

• Operate pressure washer from a stable surface.

• Be extremely careful if you must use the pressure washer

from a ladder, scaolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks

back.

4. Increase (decrease) spray pressure by

turning pressure control knob (A) clockwise

(counterclockwise). Use lower pressure to wash

items such as a car or boat. Use higher pressure

to strip paint and degrease driveways.

Cleaning Detergent Siphoning Tube

If you used the detergent siphoning tube, you must

ush it with clean water before stopping the engine.

1. Place detergent siphoning tube/lter in a bucket

full of clean water.

2. Remove high pressure spray tip from nozzle

extension.

3. Select and install black detergent spray tip

following instructions How to Use Spray Tips.

4. Flush for 1-2 minutes.

5. Shut o engine following instructions How to Stop

Pressure Washer and turn o water supply.

6. ALWAYS point spray gun in a safe direction,

press red button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

Automatic Cool Down System (Thermal

Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the

spray gun, circulating water in the pump can reach

temperatures above 125°-155°F (51°-68°C). The

system engages to cool the pump by discharging the

warm water onto the ground.

A

5. Apply a high pressure spray to a small area and then

check surface for damage. If no damage is found,

you can assume it is okay to continue rinsing.

6. Start at top of area to be rinsed, working down with

same overlapping strokes as you used for cleaning.

14 BRIGGSandSTRATTON.COM

Page 15

Not for

Reproduction

Maintenance

Maintenance Schedule

Follow the hourly or calendar intervals, whichever

occurs rst. More frequent service is required when

operating in adverse conditions noted below.

First 5 Hours

• Change engine oil

Every 8 Hours or Daily

• Clean debris

• Check engine oil level

Every 25 Hours or Yearly

• Clean engine air cleaner and pre-cleaner

Every 50 Hours or Yearly

• Change engine oil

• Service exhaust system

Yearly

• Replace spark plug

• Replace engine air cleaner and pre-cleaner

• Service cooling system

1 Service more often under dirty or dusty conditions.

General Recommendations

Regular maintenance will improve the performance

and extend the life of the pressure washer. See any

qualied dealer for service.

The pressure washer’s warranty does not cover

items that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain the pressure washer as

instructed in this manual, including proper storage as

detailed in Winter Storage and Long Term Storage.

NOTICE Should you have questions about replacing

components on your pressure washer, please call

(800) 743-4115 for assistance.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. A new spark plug and clean

air lter assure proper fuel-air mixture and help

your engine run better and last longer. Follow the

requirements in the Maintenance Schedule.

1

1

Emissions Control

Maintenance, replacement, or repair of the

emissions control devices and systems may

be performed by any non-road engine repair

establishment or individual. However, to obtain

”no charge” emissions control service, the work must

be performed by a factory authorized dealer. See the

Emissions Warranty.

Before Each Use

1. Check engine oil level.

2. Clean debris.

3. Check water inlet screen for damage.

4. Check high pressure hose for leaks.

5. Check detergent siphoning tube and lter for

damage.

6. Check spray gun and nozzle extension assembly

for leaks.

7. Rinse out garden hose to ush out debris.

Pressure Washer Maintenance

Clean Debris

Daily or before use, clean accumulated debris from

pressure washer. Keep linkage, spring and controls

clean. Keep area around and behind muer free from

any combustible debris. Inspect cooling air slots and

openings on the pressure washer. These openings must

be kept clean and unobstructed.

Pressure washer parts should be kept clean to reduce

the risk of overheating and ignition of accumulated

debris.

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of pressure washer

could damage it and shorten its life.

• DO NOT insert any objects through colling slots.

• Use a soft bristle brush to loosen caked on dirt,

oil, etc.

• Use a vacuum cleaner to pick up loose dirt and

debris.

Check and Clean Inlet Screen

Examine the screen on the pump’s water inlet. Clean

it if the screen is clogged or replace it if screen is

damaged.

15

Page 16

Not for

Reproduction

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect the hose each time before

using it. Check for cuts, leaks, abrasions or bulging

of cover, damage or movement of couplings. If any of

these conditions exist, replace the hose immediately.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST equal or exceed

maximum pressure rating of unit.

Check Detergent Siphoning Tube

Examine the lter on the detergent tube and clean

if clogged. The tube should t tightly on the barbed

tting. Examine the tube for leaks or tears. Replace the

lter or tube if either is damaged.

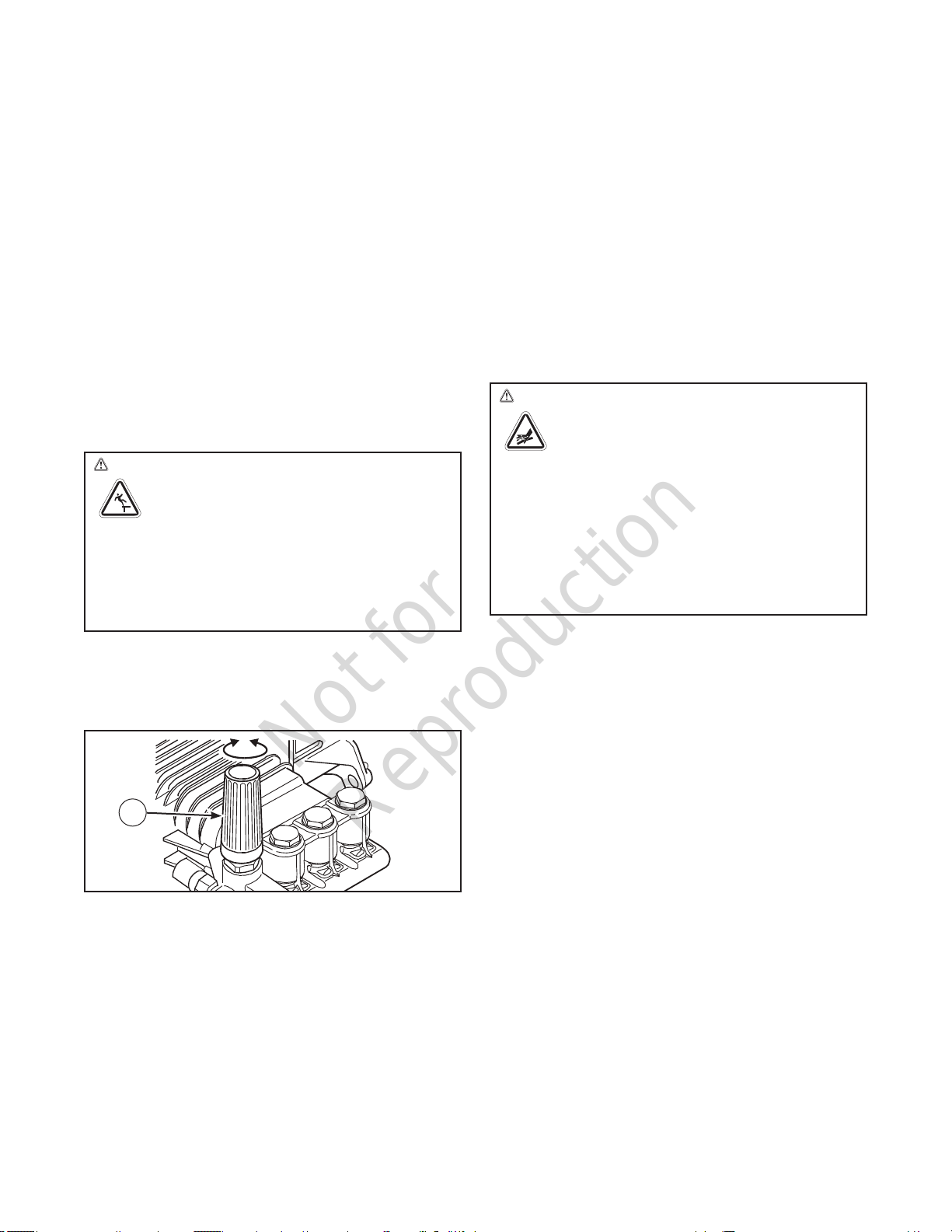

Detergent Siphoning Check Ball

Occasionally check ball in detergent siphoning

system may become stuck from storage, dried soap,

or minerals in water. The check ball can be freed by

performing the following:

NOTICE Before performing this procedure, be sure

you are wearing safety goggles as described below.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

1. Shut o engine and turn o water supply.

2. ALWAYS point spray gun in a safe direction,

press red button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

4. Using a rm, blunt object 7/64” in diameter or

smaller, by at least 1” long, such as an Allen

wrench, slowly insert the object into the barbed

tting until you meet resistance. This resistance is

the check ball.

5. Slowly push down until you feel the ball move

slightly, push no more than 1/8”. Slight pressure

may be required to free the ball.

6. Repeat steps 4 and 5 if necessary.

7. Reinstall detergent siphoning hose onto barb

tting.

8. Treat with PumpSaver as described in Protecting

the Pump during storage to prevent reoccurrence.

Check Spray Gun

Examine the hose connection to the spray gun and

make sure it is secure. Test the trigger by pressing the

red button and making sure the trigger “springs back”

into place when you release it. You should not be able

to press the trigger without pressing the red button.

Replace spray gun immediately if it fails any of these

tests.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

spray tip clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the spray tip following these instructions:

1. Shut o engine and turn o water supply.

2. ALWAYS point spray gun in a safe direction,

press red button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

3. Remove spray tip from end of nozzle extension.

4. Use a small paper clip to free any foreign material

clogging or restricting spray tip (A).

A

3. Remove detergent siphoning hose from barbed

tting on pump.

5. Remove nozzle extension from spray gun.

16 BRIGGSandSTRATTON.COM

Page 17

Not for

Reproduction

6. Using a garden hose, remove additional debris

by back ushing water through nozzle extension.

Back ush between 30 to 60 seconds.

7. Reinstall spray tip into nozzle extension.

8. Reconnect nozzle extension to spray gun.

9. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump. Turn on water.

10. Start engine following instructions How to Start

Your Pressure Washer.

11. Test pressure washer by operating with each

quick connect spray tip.

O-Ring Maintenance

Purchase an O-Ring /Maintenance Kit, model 705001,

by contacting the nearest authorized service center.

It is not included with the pressure washer. This kit

includes replacement o-rings, rubber washer and water

inlet lter. Refer to the instruction sheet provided in the

kit to service your unit’s o-rings.

Engine Maintenance

WARNING Unintentional sparking could cause

re or electric shock resulting in

death or serious injury.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

• Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Oil

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certied oils for best performance. Other high-quality

detergent oils are acceptable if classied for service

SF, SG, SH, SJ or higher. DO NOT use special

additives.

Outdoor temperatures determine the proper oil

viscosity for the engine. Use the chart to select the

best viscosity for the outdoor temperature range

expected.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

• NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal.

Pump Oil Maintenance

Changing Pump Oil

NOTICE When changing pump oil, use only high

quality SAE 30 weight oil. Use no special additives.

Change pump oil as follows:

1. Clean area around brass oil drain plug at bottom

of pump.

2. Remove oil drain plug. Drain oil completely into an

approved container.

3. When oil has completely drained, install oil drain

plug and tighten rmly.

4. Clean area around pump oil dipstick. Remove

dipstick and ll pump with recommended oil

(approximately 10 oz. (300 ml)) to the point of

overowing.

5. Install pump oil dipstick.

6. Wipe up any spilled oil.

* Below 40°F (4°C) the use of SAE 30 will result in hard

starting.

** Above 80°F (27°C) the use of 10W30 may cause

increased oil consumption. Check oil level more frequently.

Checking Oil Level

Oil level should be checked prior to each use or

at least every 8 hours of operation. Keep oil level

maintained.

1. Make sure pressure washer is on a level surface.

2. Clean area around oil ll, remove oil cap/dipstick

and wipe dipstick with clean cloth. Insert dipstick,

DO NOT screw in. Remove and check oil level.

3. Verify oil is at FULL mark on dipstick. See

Changing Engine Oil.

4. Replace and tighten oil cap/dipstick.

17

Page 18

Not for

Reproduction

Adding Engine Oil

1. Make sure pressure washer is on a level surface.

2. Check oil level as described in Checking Oil

Level.

3. If needed, slowly pour oil into oil ll opening to the

point of overowing.

4. Replace and tighten oil cap/dipstick.

Changing Engine Oil

If you are using your pressure washer under extremely

dirty or dusty conditions, or in extremely hot weather,

change the oil more often.

CAUTION Avoid prolonged or repeated skin

contact with used motor oil.

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN.

DON’T POLLUTE. CONSERVE

RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

Change oil while engine is still warm from

running, as follows:

1. Make sure unit is on a level surface.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Clean area around oil drain plug. The oil drain

plug is located at base of engine.

4. Remove oil drain plug and drain oil completely

into a suitable container.

5. Reinstall oil drain plug and tighten securely.

Remove oil cap/dipstick.

6. Slowly pour recommended oil (about 20 oz.

(0.6 liter)) into oil ll opening. Pause to permit oil

to settle. Fill to point of overowing.

7. Reinstall oil cap/dipstick. Tighten cap securely.

8. Wipe up any spilled oil.

9. Reconnect spark plug wire to spark plug.

Service Air Cleaner

Your engine will not run properly and may be damaged

if you run it with a dirty air cleaner. Service more often

if operating under dirty or dusty conditions.

To service the air cleaner, follow these steps:

1. Remove the fastener (B) and the cover (C).

C

F

2. Remove the fastener (D) and the lter (E).

3. Remove the pre-cleaner (F), if equipped, from

the lter. To loosen debris, gently tap the lter

on a hard surface. If the lter is excessively dirty,

replace with a new lter.

4. Wash the pre-cleaner in liquid detergent and

water. Then allow it to thoroughly air dry. Do not

oil the pre-cleaner.

5. Assemble the dry pre-cleaner to the lter.

6. Install the seal washer (G), the lter, and the pre-

cleaner, if equipped, into the base (H) and onto

stud (J). Make sure lter is properly assembled

into base and secure with the fastener.

7. Install the cover and secure with the fastener (B).

Make sure the fastener is tight.

Service Spark Plug

Changing the spark plug will help your engine to start

easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug if electrodes are pitted,

burned or porcelain is cracked. Use the

recommended replacement plug. See

Specications.

4. Check electrode gap with wire feeler gauge and

reset spark plug gap to recommended gap if

necessary (see Specications).

B

D

E

J

G

H

5. Install spark plug and tighten rmly.

18 BRIGGSandSTRATTON.COM

Page 19

Not for

Reproduction

Inspect Muer and Spark Arrester

Inspect the muer for cracks, corrosion, or other

damage. Remove the spark arrester, if equipped, and

inspect for damage or carbon blockage. If replacement

parts are required, make sure to use only original

equipment replacement parts.

WARNING Exhaust heat/gases could ignite

combustibles, structures or damage

fuel tank causing a re, resulting in

death or serious injury.

Contact with muer area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (1.5 m) of clearance on all sides of

pressure washer including overhead.

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forestcovered, brush-covered, or grass-covered land unless

the exhaust system is equipped with a spark arrester, as

dened in Section 4442, maintained in eective working

order. Other states or federal jurisdictions may have

similar laws.

Contact the original equipment manufacturer, retailer,

or dealer to obtain a spark arrester designed for the

exhaust system installed on this engine.

• Replacement parts must be the same and installed in the

same position as the original parts.

Air Cooling System

Over time debris may accumulate in cylinder cooling

ns and cannot be observed without partial engine

disassembly. For this reason, we recommend you have

a qualied service dealer clean the cooling system per

recommended intervals (see Maintenance Schedule in

beginning of Maintenance section). Equally important

is to keep top of engine free from debris. See Clean

Debris.

Carburetor Adjustment

The carburetor on this engine is low emission. It is

equipped with a non-adjustable idle mixture valve.

Top speed has been set at the factory. If adjustment is

required, see an authorized service dealer.

CAUTION

could result in minor injury.

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other

parts to increase engine speed. Pressure washer

supplies correct rated pressure and ow when running at

governed speed.

• DO NOT modify pressure washer in any way.

Excessively high operating speeds

After Each Use

Water should not remain in the unit for long periods

of time. Sediments or minerals can deposit on pump

parts and freeze pump action. Follow these procedures

after every use:

1. Flush detergent siphoning tube by placing the

lter into a pail of clean water while running

pressure washer in low pressure mode. Flush for

one to two minutes.

2. Shut o engine, turn o water supply, point gun

in a safe direction, press red button and squeeze

trigger to relieve trapped pressure, and let engine

cool.

WARNING The high pressure stream of water

that this equipment produces could cut

through skin and its underlying tissues,

resulting in serious injury and possible

amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

button and squeeze spray gun trigger to release high

pressure, every time you stop engine.

3. Disconnect hose from spray gun and high

pressure outlet on pump. Drain water from hose,

gun, and nozzle extension. Use a rag to wipe o

the hose.

4. Place the spray gun, nozzle extension, spray tips

and high pressure hose on the handle.

5. Empty pump of all pumped liquids by pulling recoil

handle about six times. This should remove most

liquid in pump.

6. Store unit in a clean, dry area.

7. If storing for more than 30 days, see Long Term

Storage.

WARNING Fuel and its vapors are extremely

ammable and explosive which could

cause burns, re or explosion resulting

in death or serious injury.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers, or other appliances that have pilot light or other

ignition source because they could ignite fuel vapors.

19

Page 20

Not for

Reproduction

Winter Storage

NOTICE You must protect your unit from freezing

temperatures.

• Failure to do so will permanently damage your pump and

render your unit inoperable.

• Freeze damage is not covered under warranty.

1. Follow steps 1-5 in the previous section After

Each Use.

NOTICE Store spray gun indoors and keep from

freezing.

2. Use pump saver, Model 6039, to treat pump. This

minimizes freeze damage and lubricates pistons

and seals.

3. If pump saver is not available, connect a 3 ft.

(1 m) section of garden hose to water inlet

adapter. Pour RV-antifreeze (antifreeze without

alcohol) into hose. Pull recoil handle twice.

Disconnect 3 ft. (1 m) hose.

4. Store unit in a clean, dry area.

Long Term Storage

If you do not plan to use the pressure washer for more

than 30 days, you must prepare the engine and pump

for long term storage.

Protect Fuel System

Fuel Additive:

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel

system or on essential carburetor parts. To keep fuel

fresh, use Briggs & Stratton® Advanced Formula

Fuel Treatment & Stabilizer, available wherever

Briggs & Stratton genuine service parts are sold.

There is no need to drain gasoline from the engine

if a fuel stabilizer is added according to instructions.

Run the engine for 2 minutes to circulate the stabilizer

throughout the fuel system before storage.

If gasoline in the engine has not been treated with a

fuel stabilizer, it must be drained into an approved

container. Run the engine until it stops from lack

of fuel. The use of a fuel stabilizer in the storage

container is recommended to maintain freshness.

Change Oil

While engine is still warm, drain oil from crankcase.

Rell with recommended grade. See Changing Engine

Oil in Engine Maintenance.

Protecting the Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver, Model 6039,

to treat pump. This prevents freeze damage and

lubricates pistons and seals.

NOTICE PumpSaver is available as an optional

accessory. It is not included with the pressure washer.

Contact the nearest authorized service center to

purchase PumpSaver.

NOTICE You must protect your unit from freezing

temperatures.

• Failure to do so will permanently damage your pump and

render your unit inoperable.

• Freeze damage is not covered under warranty.

To use PumpSaver, make sure the pressure washer is

turned o and disconnected from supply water. Read

and follow all instructions and warnings given on the

PumpSaver container.

Other Storage Tips

1. DO NOT store fuel from one season to another

unless it has been treated as described in Protect

Fuel System.

2. Replace fuel container if it starts to rust. Rust and/

or dirt in fuel can cause problems if it’s used with

this unit.

3. Cover unit with a suitable protective cover that

does not retain moisture.

WARNING Storage covers could cause a re

resulting in death or serious injury.

• DO NOT place a storage cover over a hot pressure washer.

• Let equipment cool for a sucient time before placing the

cover on the equipment.

4. Store unit in a clean and dry area.

20 BRIGGSandSTRATTON.COM

Page 21

Not for

Reproduction

Troubleshooting

Problem Cause Correction

Pump has following problems:

failure to produce pressure,

erratic pressure, chattering, loss

of pressure, low water volume.

Detergent fails to mix with spray.

1. Low pressure spray tip installed.

2. Inadequate water supply.

3. Clogged inlet hose screen.

4. Spray tip is obstructed.

5. Connections leak.

6. High pressure hose or spray

gun leaks.

1. High pressure spray tip

installed.

2. Check ball stuck in detergent

siphoning system.

3. Detergent tube is clogged or

cracked.

1. Replace with high pressure

spray tip.

2. Provide adequate water ow.

3. Check and clean inlet hose

screen.

4. Clean spray tip.

5. Tighten connections or replace

o-ring.

6. Replace.

1. Replace with low pressure

spray tip.

2. Free check ball. See Detergent

Siphoning Check Ball.

3. Clean or replace detergent tube.

Engine lacks power; will not start;

starts and runs rough or shuts

down during operation.

1. Engine rocker switch set to

OFF (0) position.

2. Out of fuel.

3. Dirty air cleaner.

4. Spark plug wire not connected

to spark plug.

1. Set engine rocker switch to

2. Fill fuel tank.

3. Clean or replace air cleaner.

4. Connect wire to spark plug.

For all other issues, see a Briggs & Stratton authorized dealer.

ON (I) position.

21

Page 22

Not for

Reproduction

BRIGGS & STRATTON WARRANTY POLICY

Briggs & Stratton warrants that, during the warranty period specied below, it will repair or replace, free of charge, any part that is defective in material or

LIMITED WARRANTY

workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is

eective for and is subject to the time periods and conditions stated below. For warranty service, nd the nearest Authorized Service Dealer in our dealer locator

map at BRIGGSandSTRATTON.COM. The purchaser must contact the Authorized Service Dealer, and then make the product available to the Authorized

Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of merchantability and tness for a particular purpose, are limited to

the warranty period listed below, or to the extent permitted by law. Liability for incidental or consequential damages are excluded to the extent

exclusion is permitted by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you

specic legal rights and you may also have other rights which vary from state to state or country to country.**

WARRANTY PERIOD

Item Consumer Use Commercial Use

Equipment 24 months 3 months

Engine* 24 months 3 months

Battery (if equipped) 3 months None

* Applies to Briggs & Stratton engines only. Warranty coverage of non-Briggs & Stratton engines is provided by that engine manufacturer. Emissions-related

components are covered by the Emissions Warranty Statement.

** In Australia - Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a

major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount to a major failure. For warranty service, nd the nearest Authorized Service Dealer in our dealer

locator map at BRIGGSandSTRATTON.COM, or by calling 1300 274 447, or by emailing or writing to salesenquires@briggsandstratton.com.au, Briggs & Stratton

Australia Pty Ltd, 1 Moorebank Avenue, NSW, Australia, 2170.

The warranty period begins on the date of purchase by the rst retail or commercial consumer. “Consumer use” means personal residential household use by a

retail consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once a product has experienced

commercial use, it shall thereafter be considered as a commercial use product for purposes of this warranty.

Save your proof of purchase receipt. If you do not provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the

product will be used to determine the warranty period. Product registration is not required to obtain warranty service on Briggs & Stratton products.

ABOUT YOUR WARRANTY

Warranty service is available only through Briggs & Stratton Authorized Service Dealers. This warranty covers only defects in materials or workmanship. It does not

cover damage caused by improper use or abuse, improper maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using the product in a way not described in the

Operator’s Manual or using the product after it has been damaged will not be covered under this warranty. Warranty coverage will also not be provided if the serial

number on the product has been removed or the product has been altered or modied in any way, or if the product has evidence of abuse such as impact damage

or water/chemical corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the Operator’s Manual, and serviced

or repaired using genuine Briggs & Stratton parts or equivalent. Damage caused by lack of maintenance or use of non-original parts is not covered by warranty.

Normal Wear and Tear - Like most mechanical devices, your unit is subject to wear even when properly maintained. This warranty does not cover repairs when

normal use has exhausted the life of a part or the equipment. Maintenance and wear items such as lters, belts, cutting blades, and brake pads (except engine

brake pads) are not covered by warranty due to wear characteristics alone, unless the cause is due to defects in material or workmanship.

Stale or Unapproved Fuel - In order to function correctly, this product requires fresh fuel that conforms to the criteria specied in the Operator’s Manual. Engine or

equipment damage caused by stale fuel or the use of unapproved fuels (such as E15 or E85 ethanol blends) is not covered by warranty.

Other Exclusions - This warranty excludes damage due to accident, abuse, modications, alterations, improper servicing, freezing or chemical deterioration.

Attachments or accessories that were not originally packaged with the product are also excluded. There is no warranty coverage on equipment used for

primary power in place of utility power or on equipment used in life support applications. This warranty does not include used, reconditioned, second-hand, or

demonstration equipment or engines. This warranty also excludes failures due to acts of God and other force majeure events beyond the manufacturer’s control.

80010169_EN Rev C

22 BRIGGSandSTRATTON.COM

Page 23

Not for

Reproduction

23

Page 24

Not for

Reproduction

Pressure Washer

Product Specications

Max Pressure ...................3,300 PSI (228 BAR)* @ 2.4 GPM (9.1 LPM)

Max Flow Rate ..................2.5 GPM (9.5 LPM)* @ 3,100 PSI (214 BAR)

Water Supply Temperature ........................41°F (5°C) - 100°F (38°C)

Displacement .......................................12.69 cu. in. (208 cc)

Spark Plug Gap.......................................0.030 in. (0.76 mm)

Fuel Capacity ........................................3.0 Qt. (2.84 Liters)