Page 1

Not for

Reproduction

Electric Pressure Washer

OPERATOR’S MANUAL

This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association (PWMA)

standard PW101-2010 (Testing and Rating Performance of Pressure Washers).

BRIGGS & STRATTON CORPORATION

MILWAUKEE, WISCONSIN, U.S.A.

Manual No. 80027050 Revision -

Page 2

Not for

Reproduction

Thank you for purchasing this quality-built Briggs & Stratton® electric pressure washer. We are pleased that you’ve

placed your confidence in the Briggs & Stratton brand. When operated and maintained according to the instructions in this

manual, your Briggs & Stratton electric pressure washer will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with electric pressure

washers and how to avoid them. Because Briggs & Stratton does not necessarily know all the applications this electric

pressure washer could be used for, it is important that you read and understand these instructions thoroughly before

attempting to start or operate this equipment. Save these original instructions for future reference.

This electric pressure washer requires final assembly before use. Refer to the Assembly section of this manual for

instructions on final assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your electric pressure washer. There are over

30,000 Briggs & Stratton authorized service dealers worldwide who provide quality service. You can also contact Briggs &

Stratton Customer Service by phone at (800) 743-4115, or on the Internet at BRIGGSandSTRATTON.COM.

Electric Pressure Washer

Model Number _____________________________

Revision __________________________________

Serial Number ______________________________

Date Purchased ___________________________

Register Your Product

To ensure prompt and complete warranty coverage, register your product online at www.onlineproductregistration.com.

Table of Contents

Operator Safety.............................. 3

Assembly................................... 6

Features and Controls ........................ 8

Operation................................... 9

Maintenance ...............................12

Storage ...................................13

Troubleshooting ............................14

Warranty ..................................15

Specifications ..............................16

Copyright © 2017. Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

2 BRIGGSandSTRATTON.COM

Page 3

Not for

Reproduction

Operator Safety

SAVE THESE INSTRUCTIONS

Equipment Description

WARNING Failure to read and follow the operator’s

manual and all operating instructions before

using could result in death or serious injury.

• Read this manual carefully and become familiar with

your electric pressure washer. Know its applications, its

limitations, and any hazards involved.

This electric pressure washer operates at a maximum of

2,200 PSI with yellow spray tip and a flow rate of up to 1.2

GPM (gallons per minute) with turbo spray tip.

Every effort has been made to ensure that the information

in this manual is accurate and current. However, we

reserve the right to change, alter, or otherwise improve the

product and this document at any time without prior notice.

This ISM device complies with Canadian ICES-001.

Ground Fault Circuit Interrupter Protection

This pressure washer is provided with a ground-fault

circuit-interrupter (GFCI) built into the plug of the power

supply cord. This device provides additional protection

from the risk of electric shock. Should replacement of

the plug or cord become necessary, use only identical

replacement parts that include GFCI protection.

Automatic Shut-Off

The electric pressure washer is equipped with a sensor

that will detect that water flow has stopped when releasing

or locking the spray gun trigger. The sensor will cause the

motor to shut off for as long as the spray gun trigger is

released or locked.

If the motor continues to run when the spray gun trigger is

released or locked, DO NOT USE THE MACHINE. Call the

electric pressure washer helpline at (800) 743-4115 for

assistance.

NOTICE The electric pressure washer is equipped with a

main power ON/OFF switch. The switch should always be

moved to the OFF position (0) when the electric pressure

washer is not being used to prevent possible damage.

Motor Overload

The electric motor in this electric pressure washer is

equipped with an overload protection device (thermostat).

This device will automatically shut off the motor if the motor

overheats or draws excessive current.

If the overload protection device is tripped, disconnect the

power supply by turning the master ON/OFF switch to the

OFF (0) position. Let unit cool for 30 minutes. Then turn

the master ON/OFF switch to the ON (I) position to resume

operation.

Important Safety Information

Please read and understand this entire manual before

attempting to assemble, operate or service the product.

Follow the maintenance instructions specified in this manual.

If you have any questions regarding the product, please call

customer service at (800) 743-4115, 8 a.m. - 5 p.m., CST,

Monday - Friday.

Safety Symbols and Meanings

Read Manual

Slippery Surface Fall

Projectile

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a

degree or level of hazard seriousness. A safety symbol

may be used to represent the type of hazard. The signal

word NOTICE indicates information considered important,

but not hazard-related.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE indicates information considered important, but

not hazard-related.

Electrical Shock

Flying Objects

Fire

Fluid Injection

Chemical Burn

3

Page 4

Not for

Reproduction

WARNING Risk of electrocution. Use of an

extension cord could cause electric shock or

burn resulting in death or serious injury.

WARNING Risk of eye or bodily injury. Spray could

splash back, propel objects or cause

internal harm resulting in serious injury.

• DO NOT use an extension cord with this electric

pressure washer. Your home’s electrical circuit

receptacle or extension cord may not provide lifesaving

ground-fault circuit-interruption protection.

WARNING Risk of electrocution. Contacting both

power conductors, at the same time could

cause electric shock or burn resulting in death

or serious injury.

• Connect only to a properly grounded outlet. DO NOT

remove ground pin from plug.

• Inspect cord before each use, DO NOT use if cord is

damaged.

• The product is equipped with a ground fault circuit

interrupter (GFCI) built into the power cord plug. If

replacement of the plug or cord is required, use only

identical replacement parts.

• Keep all connections dry and off the ground.

• DO NOT touch plug with wet hands.

• DO NOT run cord through doorways, windows, holes in

ceilings, walls, or floors.

• DO NOT walk on cord.

• DO NOT drive over, drag or place objects over cord.

• DO NOT spray near power source.

WARNING Use of electric pressure washer could

create puddles and slippery surfaces.

Risk of kickback. Spray gun could

kickback causing you to fall resulting in

death or serious injury.

• Operate the electric pressure washer from a

stable surface.

• Do not overreach or stand on unstable support. Keep

good footing and balance at all times.

• The cleaning area should have adequate slopes

and drainage to reduce the possibility of a fall due to

slippery surfaces.

• Be extremely careful if you must use the electric

pressure washer from a ladder, scaffolding, or any

other similar location.

• Firmly grasp spray gun with both hands when using

power spray modes to avoid injury when spray gun

kicks back.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment. NEVER substitute safety

glasses or dry-condition goggles for indirect vented

safety goggles.

• Know how to stop the pressure washer and bleed

pressure quickly. Be thoroughly familiar with the

controls.

• DO NOT allow CHILDREN to operate the electric

pressure washer.

• Keep operating area clear of all persons.

• Inspect high pressure hose before each use. NEVER

repair high pressure hose; replace it.

• DO NOT repair leaking connections with sealant of any

kind; replace o-rings and gaskets.

• Keep hose connected to electric pressure washer and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction while system

is pressurized and squeeze spray gun trigger to release

high pressure, every time you turn off the pressure

washer.

• DO NOT aim spray gun at people or animals.

• DO NOT

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while the electric

pressure washer is in ON (I) position.

• DO NOT use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun and accessories are

correctly attached.

• Stay alert – watch what you are doing.

• DO NOT operate the product when fatigued or under

the influence of alcohol or drugs.

• Close supervision is necessary when this product is

used near children.

WARNING The high pressure stream of water that

Spray gun traps high water pressure, even when motor

is stopped and water is disconnected, which could result

in serious injury.

• NEVER aim spray gun at people, animals, or plants.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you turn off pressure washer.

drink from hose connected accessories.

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

4 BRIGGSandSTRATTON.COM

Page 5

Not for

Reproduction

WARNING Risk of fire. Spraying flammable liquids

could result in death or serious injury.

• DO NOT spray flammable liquids.

WARNING Risk of fire. Overheated cord could result

in death or serious injury.

• Uncoil cord completely prior to use.

• DO NOT cover cord with any material.

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting

in death or serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

chemicals.

• DO NOT substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

• DO NOT use caustic liquid with electric pressure

washer.

• Use ONLY pressure washer safe detergents/soaps.

Follow all manufacturers instructions.

WARNING This product contains lead and lead

compounds, known to the state of California to cause

birth defects or other reproductive harm. Wash your

hands after handling this product. Cancer and

Reproductive Harm - www.P65Warnings.ca.gov

NOTICE High pressure spray could damage fragile

items including glass.

• DO NOT point spray gun at glass when using turbo

spray tip.

• NEVER aim spray gun at plants.

NOTICE You must protect your unit from freezing

temperatures.

• Failure to do so will permanently damage your pump

and spray gun rendering your unit inoperable.

• Freeze damage is not covered under warranty.

NOTICE Improper treatment of electric pressure washer

could damage it and shorten its life.

• If you have questions about intended use, ask dealer or

contact authorized service center.

• DO NOT operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by-pass any safety device on the electric

pressure washer.

• DO NOT modify the electric pressure washer in any

way.

• Before starting the electric pressure washer in cold

weather, check all parts of the equipment to be sure ice

has not formed there.

• DO NOT move the electric pressure washer by pulling

on hoses. Move unit using the transport handle

supplied.

• Use ONLY branded accessories intended for use with

this product.

5

Page 6

Not for

Reproduction

Assembly

Read entire Operator’s Manual before you

attempt to assemble or operate your new

electric pressure washer.

Your electric pressure washer requires some assembly

but is quickly ready for use. If you have any problems with

the assembly of your electric pressure washer, please call

the electric pressure washer helpline at (800) 743-4115. If

calling for assistance, please have the model, revision, and

serial number from the identification label available.

Tools Needed

• Philips screwdriver #2

Unpack Electric Pressure Washer

1. Remove everything from carton.

2. Ensure you have all included items prior to assembly.

Items Included in the Carton

• Main unit

• Handle with accessory tray

• Spray gun

• High pressure hose

• Spray wand

• Quick Connect (QC) spray tips (3)

• Quick Connect (QC) foamer spray tip with detergent

bottle

• Handle support tubes (2)

• Screws (2)

• Operator’s Manual

Check all contents. If any parts are missing or damaged,

DO NOT use, call the electric pressure washer helpline at

(800) 743-4115.

Become familiar with each component before assembling

the electric pressure washer. Identify contents with the

illustration shown in Features and Controls.

Attach Handle and Support Tubes

1. Push and hold lock-pin buttons (A) on each side of

the handle. Slide handle (B) down into each handle

support tubes (C) until lock-pins buttons snap into the

holes.

2. Slide handle support tubes (C) into slots on both

sides of main unit. Align holes and insert screws (D).

Tighten with a #2 philips screwdriver.

D

C

D

Lubricate O-Rings

Lubrication of o-rings is extremely important for installation

and operation. The use of a lubricant (petroleum or

synthetic grease) during assembly helps seat o-rings

properly and provides an improved seal. It also helps

protect the o-ring from damage by abrasion, pinching or

cutting and extends the life of the o-ring.

NOTICE ALWAYS apply a small amount of lubricant on

o-rings prior to assembling the garden hose to the pump

(E), high pressure hose (F), spray gun (G), and spray

wand (H).

G

H

E

F

Lubricate all connections shown below, following

these instructions:

1. Inspect and clean connecting surfaces prior to

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light film

is all that is required.

3. Use a small brush or cotton swab to apply grease

directly to o-rings where they are not accessible (QC

fitting, M22 fitting).

B

A

C

6 BRIGGSandSTRATTON.COM

Page 7

Not for

Reproduction

Connect Hose and Water Supply to Pump

NOTICE DO NOT run the pump without the water supply

connected and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

1. Uncoil high pressure hose (A) and attach black end of

hose to base of spray gun (B). Tighten by hand.

A

B

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

• NEVER connect high pressure hose to spray wand.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

2. Attach red end of high pressure hose (A) to high

pressure outlet (C) on pump. Tighten by hand.

NOTICE Using a One Way Valve (vacuum breaker or

check valve) at pump inlet could cause pump or inlet

connector damage.

• There MUST be at least 10 ft. (3 m) of unrestricted

garden hose between the pressure washer inlet and any

device, such as a vacuum breaker or check valve.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

5. Connect the garden hose (D) (not to exceed 50 ft. (15

m) in length) to the water inlet (E). Tighten by hand.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when

using or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

6. Turn ON the water, press red button (G) on the gun

and squeeze the trigger to purge the pump system of

air and impurities.

G

C

A

3. Run water through your garden hose for 30 seconds

to clean out any debris.

NOTICE DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 100°F (38°C)).

4. Before connecting garden hose (D) to water inlet (E),

inspect inlet screen (F). Clean screen if it contains

debris or have it replaced if damaged. DO NOT run

pressure washer if inlet screen is damaged.

F

D

E

Checklist Before Starting Pump Motor

Review the unit’s assembly to ensure you have performed

all of the following.

1. Be sure to read Operator Safety and Operation before

using the electric pressure washer.

2. Check for properly tightened hose connections.

3. Check to make sure there are no kinks, cuts, or damage

to hoses.

4. Provide a proper water supply at an adequate flow.

5. Plug electrical power cord into a dedicated electrical circuit

rated for 120 Volts AC at 15 Amps that is properly installed

in accordance with all local codes and ordinances. Check

that circuit is not used to supply any other electrical needs.

7

Page 8

Not for

Reproduction

Features and Controls

Read the Operator’s Manual and safety rules before operating your electric pressure washer.

Compare the illustrations with your electric pressure washer to familiarize yourself with the locations of various

controls and adjustments. Save this original manual for future reference.

A

B

C

D

E

F

M

L

K

J

G

A - Spray Gun — Controls the application of water onto

cleaning surface with trigger device. Includes trigger lock.

B - Spray Tips — Yellow and white spray tips are for

various high pressure applications.

C - High Pressure Hose — Connect red end to high

pressure water outlet and black end to spray gun.

D -Warning Label — Identifies hazards to be avoided

when using your pressure washer.

E - Master ON/OFF Toggle Switch — Push top of switch

in (I) to turn pressure washer ON. Push bottom of switch

in (0) to turn pressure washer OFF.

F - Water Supply Inlet — Connect to water supply using a

50 ft. (15.24 m) maximum garden hose.

G - Electric Cord with GFCI — The electric pressure

washer and operator is protected by a ground fault

circuit interrupter (GFCI).

8 BRIGGSandSTRATTON.COM

H - Foamer Spray Tip with Detergent Bottle — Use to

apply pressure washer safe detergent to surfaces.

J - Identification Label (under housing)— Provides model

and serial number of pressure washer. Please have

these readily available if calling for assistance.

K - High Pressure Outlet — Connection for high pressure

hose.

L - Spray Wand — Allows you to switch between different

spray tips.

M -Turbo Spray Tip — Whirls a powerful pin-point jet of

water for intense cleaning.

H

Page 9

Not for

Reproduction

Operation

How to Start Your Electric Pressure Washer

Follow the instructions below in the order presented. If

you have any problems operating your electric pressure

washer, please call the electric pressure washer helpline at

(800) 743-4115.

WARNING Risk of eye injury. Spray could splash

back or propel objects resulting in serious

injury. Always wear indirect vented (chemical

splash) safety goggles marked to comply with

ANSI Z87.1 when using or in vicinity of this equipment.

NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

3.0 gallons (11.4 l) per minute and no less than 20 PSI

(1.3 BAR) at pressure washer end of garden hose. DO

NOT siphon supply water.

2. Check that high pressure hose is tightly connected to

spray gun and pump. See Assembly section.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump.

NOTICE DO NOT run the pump without the water supply

connected and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

5. Turn ON water, point gun in a safe direction, press red

button and squeeze trigger to purge pump system of air

and impurities.

6. Attach spray wand to spray gun. Tighten by hand.

WARNING Risk of electrocution. Use of an

extension cord could cause electric shock or

burn resulting in death or serious injury.

• DO NOT use an extension cord with this electric

pressure washer. Your home’s electrical circuit

receptacle or extension cord may not provide lifesaving

ground-fault circuit-interruption protection.

9. Plug electrical power cord into a dedicated electrical

circuit rated for 120 Volts AC at 15 Amps that is

properly installed in accordance with all local codes and

ordinances. Circuit is not to supply any other electrical

needs. The indicator light on the GFCI should be ON.

NOTICE The indicator light must be ON for the electric

pressure washer to operate.

WARNING Risk of electrocution. Non-operating

ground fault circuit interrupter (GFCI) could

result in death or bodily injury. If indicator light

does not stay ON after test and reset, do not

use GFCI.

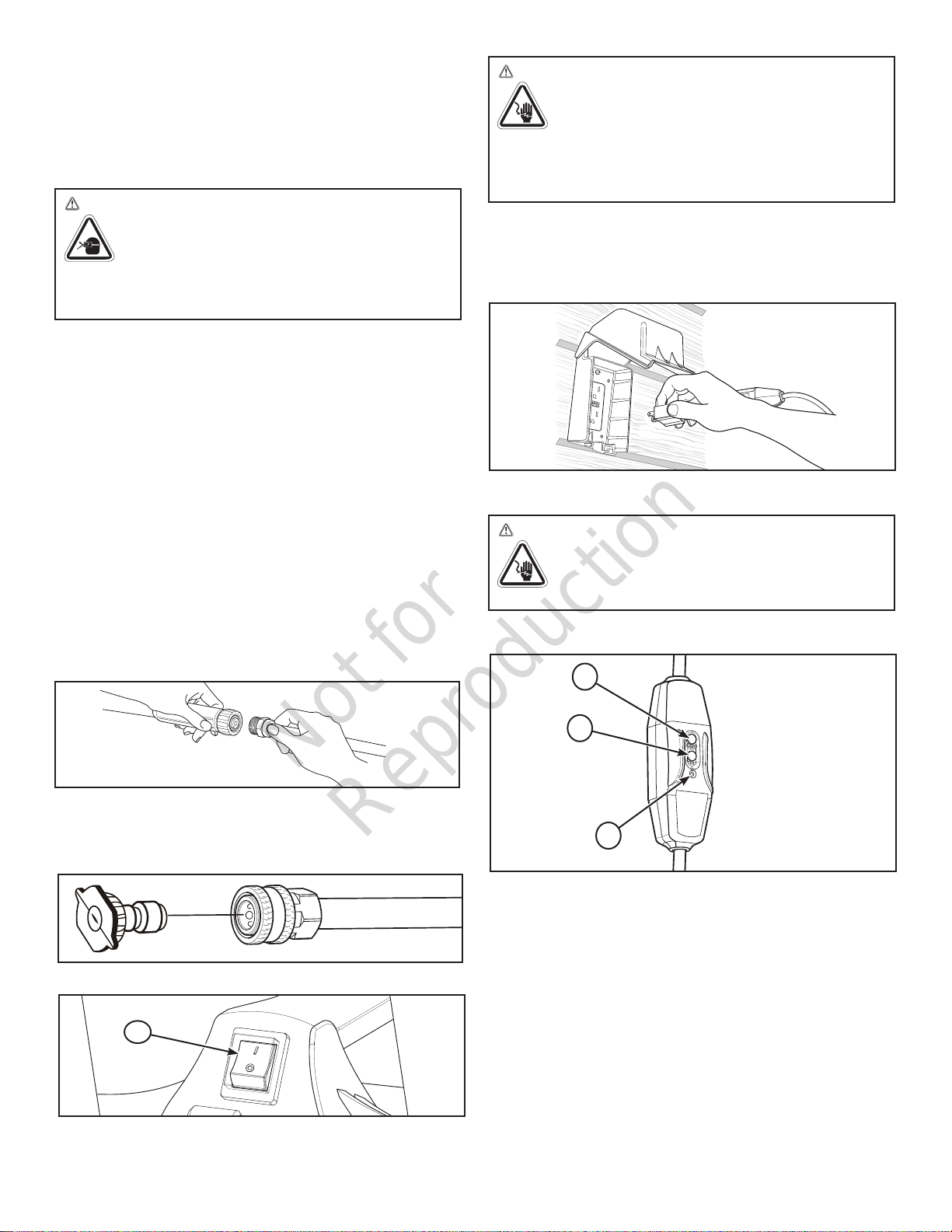

10. Press TEST button (B). The indicator light (C) should

be OFF.

D

7. Choose spray tip you want to use, pull back on collar

of spray wand, insert spray tip and release collar. Tug

on spray tip to make sure it is securely in place. See

How to Use Spray Tips.

8. Push master ON/OFF switch (A) to OFF (0) position.

A

B

C

11. Press RESET button (D). The indicator light (C)

should be ON.

NOTICE DO NOT use the electric pressure washer if

above test fails.

12. Press the master ON/OFF switch (A) to the pressure

washer ON (I) position.

13. Point gun in a safe direction, press trigger lock button

and squeeze trigger.

The electric pressure washer motor will start and stop as

spray gun trigger is depressed and released.

The electric pressure washer is now ready for use.

Instructions for use of the supplied accessories are given

later in this section.

9

Page 10

Not for

Reproduction

How to Stop Your Electric Pressure Washer

Applying Detergent

The electric pressure washer motor runs only when the

trigger is engaged. To stop the electric pressure washer

and turn off the motor:

1. Release spray gun trigger.

2. Press the master ON/OFF switch to the OFF (0) position.

NOTICE Releasing the trigger will shut off the motor but

does not shut off electrical power to the unit.

3. Turn off water supply.

4. ALWAYS point spray gun in a safe direction, press

trigger lock button and squeeze trigger to relieve built

up pressure in the unit.

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when motor

is stopped and water is disconnected, which could result

in serious injury.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you turn off pressure washer.

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting

in death or serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

chemicals.

• DO NOT substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

• DO NOT use caustic liquid with electric pressure

washer.

• Use ONLY pressure washer safe detergents/soaps.

Follow all manufacturers instructions.

To apply detergent, follow these steps:

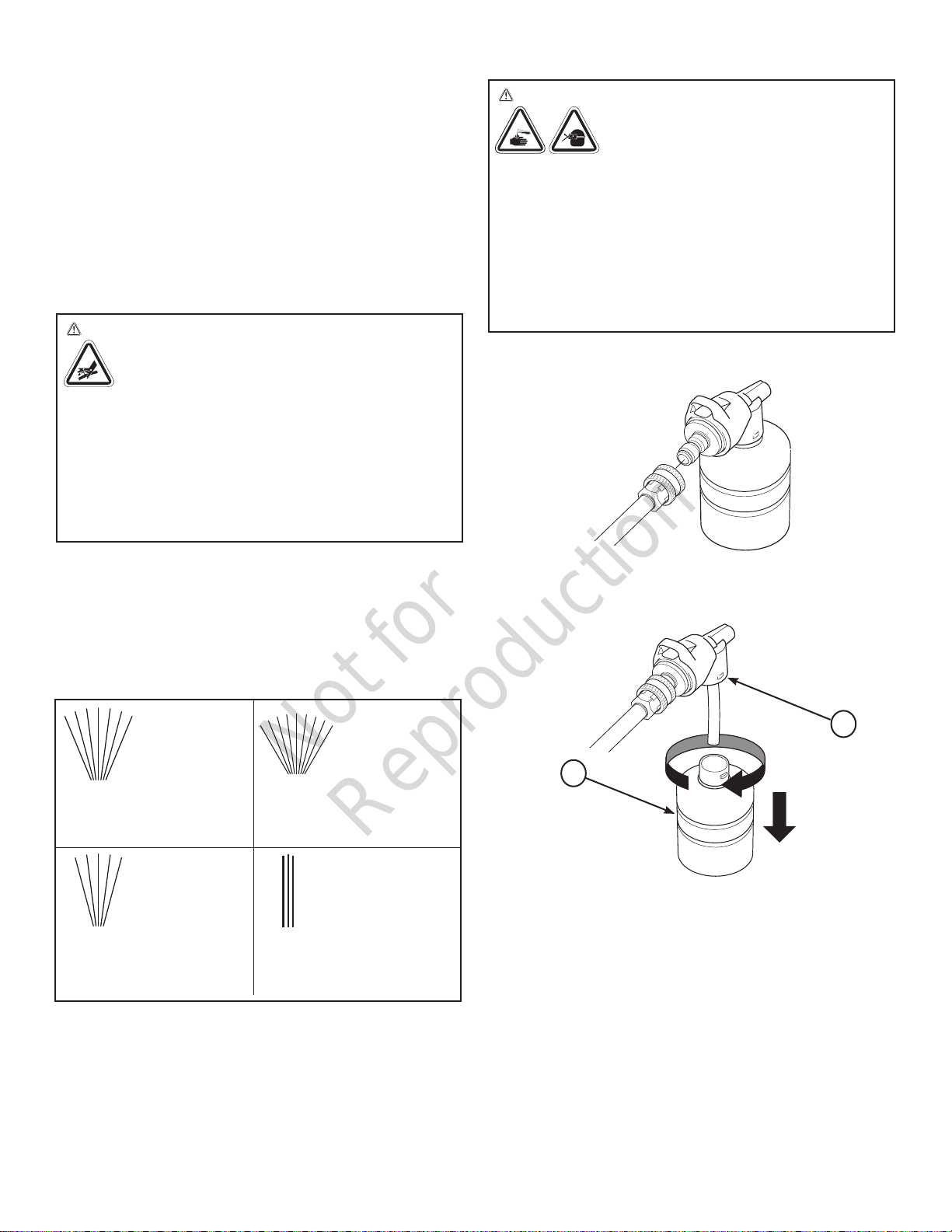

1. Install foamer spray tip with detergent bottle.

5. Disconnect GFCI plug from outlet.

How to Use Spray Tips

There are four spray tips supplied with the pressure

washer. The turbo spray tip whirls a powerful pin-point jet

of water for intense cleaning. The yellow and white spray

tips are for various high pressure applications. The foamer

spray tip is for general soap applications.

Low Pressure

Foamer

Use to apply

detergent

1.1 GPM (4.1 LPM)

General Rinse

Yellow, 15°

Siding / Patios

Decks /

Driveways / Garage Floors

2200 PSI (152 bar)

1.0 GPM (3.7 LPM)

Usage Tips

• For most effective cleaning, keep spray tip from 8 to

24 inches away from cleaning surface.

• If you get spray tip too close, especially using a high

pressure spray tip, you may damage surface being

cleaned.

• DO NOT get closer than 6 inches when cleaning tires.

1.2 GPM (4.5 LPM)

Delicate Rinse

White, 40°

Cars / Vans /

Trucks / Outdoor

Furniture

1300 PSI (90 bar)

Intense Cleaning

Turbo

Paint Removal /

Oil Stains / Rust

Removal

900 PSI (6 bar)

2. Prepare detergent solution as required by job.

3. Rotate detergent bottle (A) counter-clockwise and

remove from foamer spray tip (B).

B

A

4. Fill bottle with detergent solution.

5. Reinstall detergent bottle onto foamer spray tip and

turn clockwise until it clicks into place.

6. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun and high pressure outlet. Turn on water.

NOTICE You must attach all hoses before you start the

pressure washer.

10 BRIGGSandSTRATTON.COM

Page 11

Not for

Reproduction

7. Start the pressure washer as instructed in How to

Start Your Electric Pressure Washer.

8. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward using

long, even, overlapping strokes.

9. Allow detergent to “soak in” for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. To prevent streaking, do not allow

detergent to dry on surface.

Electric Pressure Washer Rinsing

1. Remove foamer spray tip from wand.

2. Install white or yellow spray tip.

3. Keep spray gun a safe distance from area you plan to

spray.

WARNING Risk of kickback.

Spray gun could kickback causing you to fall

resulting in death or serious injury.

• Operate the electric pressure washer from a

stable surface.

• Be extremely careful if you must use the electric

pressure washer from a ladder, scaffolding, or any

other similar location.

• Firmly grasp spray gun with both hands when using

power spray modes to avoid injury when spray gun

kicks back.

How to Store Accessories

The unit is equipped with areas to store your high pressure

hose, spray gun, spray wand, and power cord. Coil power

cord on brackets on ends of main unit. Wrap high pressure

hose and store on hook on back of accessory tray. Store

spray gun in slots on left side of accessory tray. Snap

spray wand in slots on right side of accessory tray. Store

spray tips in holes on front of accessory tray. Identify all

accessories with the illustrations in Features and Controls.

4. Apply a high pressure spray to a small area and then

check surface for damage. If no damage is found, you

can assume it is okay to continue rinsing.

5. Start at top of area to be rinsed, working down with

same overlapping strokes as you used for cleaning.

Other Cleaning Tips

• NEVER leave the electric pressure washer unattended

while it is plugged into an electrical outlet and while

water is supplied to the equipment.

• If you have the spray tip too far away from the surface

being washed, the cleaning may not be as effective.

11

Page 12

Not for

Reproduction

Maintenance

General Recommendations

Regular maintenance will improve the performance and

extend the life of the electric pressure washer.

The electric pressure washer’s warranty does not cover

items that have been subjected to operator abuse or

negligence. To receive full value from the warranty, the

operator must maintain the electric pressure washer as

instructed in this manual, including proper storage.

NOTICE Should you have questions about replacing

components on your electric pressure washer, please call

(800) 743-4115 for assistance.

Check Spray Gun

Examine the hose connection to the spray gun and

make sure it is secure. Test the trigger (A) by pressing

the triggger lock button (B) and making sure the trigger

“springs back” into place when you release it. You should

not be able to press the trigger without pressing the trigger

lock button. Replace spray gun immediately if it fails any of

these tests.

B

A

Before Each Use

1. Clean debris.

2. Check water inlet screen for debris or damage.

3. Check high pressure hose for leaks.

4. Check spray gun operation.

Electric Pressure Washer Maintenance

Clean Debris

Daily or before use, clean accumulated debris from electric

pressure washer. Inspect cooling air slots and openings on

the front, rear and bottom of the electric pressure washer.

These openings must be kept clean and unobstructed.

The electric pressure washer parts should be kept clean to

reduce the risk of overheating and ignition of accumulated

debris.

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of the electric pressure

washer can damage it and/or shorten its life.

• DO NOT insert any objects through cooling slots.

Check and Clean Water Inlet Screen

Examine the screen on the unit’s water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect the hose each time before

using it. Check for cuts, leaks, abrasions or bulging of

cover, damage or movement of couplings. If any of these

conditions exist, replace the hose immediately.

Spray Tip Maintenance

Excessive pump pressure can cause a pulsing sensation

felt while squeezing the spray gun trigger. The principal

cause of excessive pump pressure is a spray tip clogged or

restricted with foreign materials such as dirt, etc. A clogged

spray tip could lead to pump cycling ON/OFF or not turning

on even when there is some flow.

1. Press the master ON/OFF switch to the OFF (0)

position. Remove power cord plug from electrical outlet.

2. Disconnect water supply at the electric pressure

washer.

3. ALWAYS point spray gun in a safe direction, press

trigger lock button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when motor

is stopped and water is disconnected, which could result

in serious injury.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you turn off pressure washer.

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST equal or exceed

maximum pressure rating of unit.

12 BRIGGSandSTRATTON.COM

Page 13

Not for

Reproduction

4. Remove spray tip from end of spray wand.

5. Use a small paper clip to free any foreign material

clogging or restricting any of the spray tips.

6. Using a garden hose, remove additional debris by

back flushing water through spray wand. Back flush

between 30 to 60 seconds.

7. Reinstall spray tip into spray wand.

8. Reconnect spray wand to spray gun.

9. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun. Turn on water.

10. Plug power cord into electrical outlet and press the

master ON/OFF switch to the pressure washer ON (I)

position.

11. Test the electric pressure washer by operating with

each spray tip.

Pump and Motor Maintenance

The electric pressure washer does not require any

maintenance to the pump or motor. Both assemblies

are pre-lubricated and sealed, requiring no additional

lubrication ever.

10. Store spray gun and spray wand in slots on accessory

tray. Store spray tips in holes on accessory tray.

11. Store unit in a clean, dry area.

12. If storing for more than 30 days see Winter or Long

Term Storage.

Winter or Long Term Storage

Follow steps 1-10 in After Each Use.

NOTICE Water left in pump could freeze and permanently

damage pump. Freeze damage is not covered under

warranty.

Protecting the Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver, Model 6039, to treat

pump. This prevents freeze damage and lubricates plunger

and seals.

NOTICE PumpSaver is available as an optional

accessory. It is not included with the electric pressure

washer. Contact the nearest authorized service center to

purchase Pump Saver.

NOTICE You must protect your unit from freezing

temperatures.

• Failure to do so will permanently damage your pump

and spray gun rendering your product inoperable.

• Freeze damage is not covered under warranty.

To use PumpSaver, make sure the electric pressure

washer is turned off and inlet and outlet hoses are

disconnected. Read and follow all instructions and

warnings given on the PumpSaver container.

After Each Use

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and “freeze”

pump action. Follow these procedures after every use:

1. Flush detergent bottle (if used) by removing it from the

foamer spray tip and pouring out all remaining solution.

2. Rinse detergent bottle out with fresh clean water and

reinstall onto foamer spray tip.

3. Run the electric pressure washer with foamer spray

tip. Flush for one or two minutes.

4. Press the master ON/OFF switch to the OFF (0) position.

5. Turn off water supply, point gun in a safe direction,

press red button and squeeze trigger to relieve trapped

pressure, and let engine cool.

6. Disconnect hose from spray gun and high pressure

outlet on pump. Drain water from hose, spray gun,

and spray wand. Use a rag to wipe off the hose.

7. Drain water from pump by tipping unit to the side (water

inlet facing down) for two minutes. Tip to the other side

(high pressure outlet facing down) for an additional two

minutes.

8. Wrap high pressure and store on hook on back of

accessory tray.

9. Coil power cord on brackets.

Final Storage Procedures

1. Wrap high pressure and store on hook on back of

accessory tray.

2. Coil power cord on brackets.

3. Store spray gun and spray wand in slots on accessory

tray. Store spray tips in holes on accessory tray.

4. Store unit in a clean, dry area that is protected from

freezing temperatures.

5. Cover unit with a suitable protective cover that does

not retain moisture.

13

Page 14

Not for

Reproduction

Troubleshooting

Problem Cause Correction

Pump has following

problems: failure to produce

pressure, erratic pressure,

chattering, loss of pressure,

low water volume.

1. Water inlet is blocked.

2. Inadequate water supply.

3. Garden hose is kinked or leaking.

4. Clogged water inlet screen.

5. Water supply is over 100°F (38°C).

6. High pressure hose is blocked or

leaks.

7. Spray tip is obstructed.

1. Clear inlet.

2. Provide adequate water flow.

3. Straighten garden hose or replace if leaking.

4. Check and clean water inlet screen.

5. Provide cooler water supply.

6. Clear blocks in high pressure hose or

replace hose.

7. Clean spray tip.

Unit fails to start when spray

gun trigger is squeezed.

Detergent fails to mix with

spray.

Hose connections leaking.

1. Water supply is not turned on.

2. Unit is not turned on.

3. Garden hose is too long.

4. Fuse blown or circuit breaker tripped.

1. High pressure spray tip is installed. 1. Install foamer spray tip.

1. Garden hose loose to water inlet.

2. Loose high pressure hose

connections.

3. Damaged o-ring.

1. Turn on water supply.

2. Press the master ON/OFF switch to the

ON (I) position. Reset GFCI.

3. Use only 50 ft. (15.24 m) maximum

garden hose.

4. a.) Check fuse box for blown fuse and

replace as necessary or reset circuit

breaker. Do not use a fuse or circuit

breaker with a higher rating than that

specified for your particular branch

circuit.

b.) Disconnect other electrical

appliances and turn off lights in the

circuit or operate the pressure washer

on its own dedicated circuit.

c.) Run pressure washer with any spray

tip for 5 minutes. Motor break in may be

necessary.

1. Hand tighten garden hose to water

inlet.

2. Remove hose completely and reinstall

hand tight.

3. Replace o-ring.

For all other issues, see a Briggs & Stratton authorized dealer.

14 BRIGGSandSTRATTON.COM

Page 15

Not for

Reproduction

BRIGGS & STRATTON WARRANTY POLICY

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or replace, free of charge, any part that is defective in material or workmanship

or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for and

is subject to the time periods and conditions stated below. For warranty service, contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the

internet at BRIGGSANDSTRATTON.COM.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to the

warranty period listed below, or to the extent permitted by law. Liability for incidental or consequential damages are excluded to the extent exclusion

is permitted by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state or country to country.**

** In Australia - Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be

of acceptable quality and the failure does not amount to a major failure. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at

BRIGGSandSTRATTON.COM, or by calling 1300 274 447, or by emailing or writing to salesenquires@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1

Moorebank Avenue, NSW, Australia, 2170.

The warranty period begins on the date of purchase by the first retail or commercial consumer. “Consumer use” means personal residential household use by a retail

consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once a product has experienced commercial

use, it shall thereafter be considered as a commercial use product for purposes of this warranty.

Save your proof of purchase receipt. If you do not provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the

product will be used to determine the warranty period. Product registration is not required to obtain warranty service on Briggs & Stratton products.

LIMITED WARRANTY

WARRANTY PERIOD

Consumer Use Commercial Use

12 months None

ABOUT YOUR WARRANTY

Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. This warranty covers only defects in materials or

workmanship. It does not cover damage caused by improper use or abuse, improper maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using the product in a way not described in the Operator’s

Manual or using the product after it has been damaged will not be covered under this warranty. Warranty coverage will also not be provided if the serial number on the

product has been removed or the product has been altered or modified in any way, or if the product has evidence of abuse such as impact damage or water/chemical

corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the Operator’s Manual, and serviced or

repaired using genuine Briggs & Stratton parts or equivalent. Damage caused by lack of maintenance or use of non-original parts is not covered by warranty.

Normal Wear and Tear - Like most mechanical devices, your unit is subject to wear even when properly maintained. This warranty does not cover repairs when normal

use has exhausted the life of a part or the equipment. Maintenance and wear items such as filters, belts, cutting blades, and brake pads (except engine brake pads) are

not covered by warranty due to wear characteristics alone, unless the cause is due to defects in material or workmanship.

Stale or Unapproved Fuel - In order to function correctly, this product requires fresh fuel that conforms to the criteria specified in the Operator’s Manual. Engine or

equipment damage caused by stale fuel or the use of unapproved fuels (such as E15 or E85 ethanol blends) is not covered by warranty.

Other Exclusions - This warranty excludes damage due to accident, abuse, modifications, alterations, improper servicing, freezing or chemical deterioration.

Attachments or accessories that were not originally packaged with the product are also excluded. There is no warranty coverage on equipment used for primary power in

place of utility power or on equipment used in life support applications. This warranty does not include used, reconditioned, second-hand, or demonstration equipment or

engines. This warranty also excludes failures due to acts of God and other force majeure events beyond the manufacturer’s control.

80018419_EN Rev A

15

Page 16

Not for

Reproduction

Electric Pressure Washer

Specifications

Max Pressure ...............2,200 PSI (152 BAR)* @ 1.0 GPM (3.8 liters/min)

Max Flow Rate .................1.2 GPM (4.5 liters/min)* @ 900 PSI (62 BAR)

Detergent Mix .................................... See MFR’s Instructions

Water Supply Temperature ........................41°F (5°C) - 100°F (38°C)

Motor ...................................................Induction Type

Rated Voltage .............................................120 Volts AC

Current..................................................... 14.5 Amps

This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association (PWMA) standard

*

PW101-2010 (Testing and Rating Performance of Pressure Washers).

Briggs & Stratton Corporation

16 BRIGGSandSTRATTON.COM

Milwaukee, Wisconsin, 53201-0702 U.S.A.

P.O. Box 702

(800) 743-4115

Page 17

Not for

Reproduction

Hidrolavadora eléctrica

MANUAL DEL OPERARIO

Esta limpiadora a presión está clasificada conforme a la norma PW101-2010

(Comprobación y Clasificación de Rendimiento de Limpiadoras a Presión) de la

Asociación de Fabricantes de Limpiadoras a Presión (PWMA).

BRIGGS & STRATTON CORPORATION

MILWAUKEE, WISCONSIN, EE. UU.

Page 18

Not for

Reproduction

Gracias por comprar esta hidrolavadora eléctrica Briggs & Stratton® de alta calidad. Nos complace que haya depositado

su confianza en la marca Briggs & Stratton. Si la operación y el mantenimiento de su producto Briggs & Stratton se realiza

según las instrucciones de este manual, le proporcionará muchos años de servicio confiable.

Este manual contiene información de seguridad para alertarlo sobre los peligros y riesgos asociados con las

hidrolavadoras eléctricas, y para indicarle cómo evitarlos. Dado que Briggs & Stratton no conoce necesariamente todas

las aplicaciones para las cuales se podría utilizar esta hidrolavadora eléctrica, es importante que usted lea detalladamente

y entienda estas instrucciones antes de hacer arrancar o utilizar este equipo. Guarde estas instrucciones originales

para futuras consultas.

Esta hidrolavadora eléctrica requiere su montaje final antes de su uso. Consulte la sección Montaje de este manual

para conocer las instrucciones sobre los procedimientos de montaje final. Siga las instrucciones detalladamente.

Contacto

Nunca debe ir demasiado lejos para encontrar el soporte y el servicio de Briggs & Stratton para su hidrolavadora eléctrica.

Existen más de 30.000 distribuidores de servicio autorizado por Briggs & Stratton en todo el mundo, quienes suministran

servicio de calidad. También puede ponerse en contacto con Atención al Cliente de Briggs & Stratton por teléfono al (800)

743-4115 o en Internet en BRIGGSandSTRATTON.COM.

Hidrolavadora eléctrica

Número de modelo __________________________

Revisión __________________________________

Número de serie ____________________________

Fecha de compra __________________________

Registrar su producto

Para asegurar pronta y completa cobertura de la garantía, registre su producto en línea en

www.onlineproductregistration.com.

Índice

Seguridad del operador . . . . . . . . . . . . . . . . . . . . . . . 3

Montaje .................................... 6

Características y controles..................... 8

Operación .................................. 9

Mantenimiento .............................12

Almacenamiento............................ 14

Solución de problemas.......................15

Garantía...................................16

Especificaciones............................18

Copyright © 2017. Briggs & Stratton Corporation

Milwaukee, WI, USA. Reservados todos los derechos.

2 BRIGGSandSTRATTON.COM

Page 19

Not for

Reproduction

Seguridad del operador

CONSERVE ESTAS INSTRUCCIONES

Descripción del equipo

ADVERTENCIA No leer ni seguir las instrucciones del

manual del operador y todas las instrucciones de

funcionamiento antes de usar la unidad podría

ocasionar la muerte o lesiones graves.

• Lea este manual cuidadosamente y familiarícese con la

hidrolavadora eléctrica. Conozca sus aplicaciones, sus

limitaciones y los peligros involucrados.

Esta lavadora de presión eléctrica opera a un máximo

de 152 bar (2200 PSI) con una punta de pulverización

amarilla y a un caudal de hasta 4.5 LPM (litros) (1,2 GPM

(galones)) por minuto con una punta de pulverización

turbo.

Hemos hecho todo lo posible para asegurarnos de que la

información de este manual sea precisa y esté actualizada.

No obstante, nos reservamos el derecho a cambiar,

modificar o mejorar el producto y este documento en

cualquier momento y sin previo aviso.

Este dispositivo ISM cumple con la norma canadiense

ICES-001.

Circuitos protegidos con interruptores a tierra

Esta arandela de presión se proporciona con un circuito

protegido con interruptores a tierra (GFCI) integrado en

el enchufe del cable de alimentación. Este dispositivo

aporta una mayor protección frente al riesgo de descarga

eléctrica. En el caso de que sea necesario sustituir

el enchufe o el cable, utilice piezas de repuestos

exactamente idénticas que dispongan de protección GFCI.

Apagado automático

La hidrolavadora eléctrica está equipada con un sensor

que detectará si el flujo de agua se detuvo al activar o

bloquear el gatillo de la pistola pulverizadora. El sensor

hará que el motor se apague siempre que el gatillo de la

pistola pulverizadora se active o bloquee.

Si el motor continúa en funcionamiento cuando se activa o

bloquea el gatillo de la pistola pulverizadora, NO USE LA

MÁQUINA. Llame al teléfono de ayuda de la hidrolavadora

eléctrica: (800) 743-4115 para obtener asistencia.

AVISO La hidrolavadora eléctrica está equipada con

un interruptor de encendido/apagado de la alimentación

principal. El interruptor siempre debe estar en la posición

de apagado (0) cuando no se usa la hidrolavadora

eléctrica para evitar probables daños.

Sobrecarga del motor

El motor eléctrico de esta hidrolavadora eléctrica está

equipado con un dispositivo de protección por sobrecarga

(termostato). Este dispositivo apagará automáticamente el

motor si este se recalienta o utiliza corriente en exceso.

Si se activa el dispositivo de protección por sobrecarga,

desconecte la alimentación. Para ello, coloque el

interruptor principal de encendido/apagado en la posición

de apagado (0). Deje que la unidad se enfríe durante

30 minutos. Luego, coloque el interruptor principal de

encendido/apagado en la posición de encendido (I) para

continuar con el funcionamiento.

Información de seguridad importante

Lea y comprenda todo el manual antes de armar,

hacer funcionar o realizar operaciones de reparación/

mantenimiento en el producto. Siga las instrucciones de

mantenimiento especificadas en este manual. Si tiene

alguna pregunta relacionada con este producto, por favor,

póngase en contacto con el servicio de atención llamando

al cliente al (800) 743-4115, de lunes a viernes, de 8.00 a

17.00, CST.

Símbolos de seguridad y significados

Lea el manual

Superficie

resbaladiza

Proyectil

El símbolo de alerta de seguridad indica un posible

riesgo para su integridad física. Se utiliza una palabra de

señalización (PELIGRO, ADVERTENCIA o PRECAUCIÓN)

junto con el símbolo de alerta para designar un grado o

nivel de gravedad de riesgo. Se puede utilizar un símbolo

de seguridad para representar el tipo de riesgo. AVISO

indica una información considerada importante, pero no

relacionada con un peligro potencial.

PELIGRO indica un peligro que, si no se evita,

ocasionará la muerte o una lesión grave.

ADVERTENCIA indica un peligro que, si no se evita,

podría ocasionar la muerte o una lesión grave.

PRECAUCIÓN indica un peligro que, si no se evita,

podría ocasionar en lesión leve o moderada.

AVISO indica una información considerada importante, pero

no relacionada con un peligro potencial.

Descarga eléctrica

Caídas

Objetos

voladores

Fuego

Inyección

de fluidos

Quemadura

química

3

Page 20

Not for

Reproduction

ADVERTENCIA Riesgo de electrocución. El uso

de un cable de prolongación podría ocasionar

descarga eléctrica o quemaduras que pueden

provocar lesiones graves o la muerte.

• NO use un cable de prolongación con esta

hidrolavadora eléctrica. Es posible que el cable de

prolongación o el enchufe del circuito eléctrico de su

casa no proporcione la protección del interruptor de

circuito por fallos con conexión a tierra que resguarda

la vida de las personas.

ADVERTENCIA Riesgo de electrocución.

El contacto con ambos conductores de

alimentación al mismo tiempo podría ocasionar

descarga eléctrica o quemaduras que pueden

provocar lesiones graves o la muerte.

• Conectarla solo a un toma corriente con una buena

descarga a tierra. NO quite el terminal de tierra del enchufe.

• Inspeccione el cable antes de cada uso, NO lo utilice si

está dañado.

• El producto está equipado con un interruptor de circuito

por fallos con conexión a tierra (GFCI) montado en el

enchufe del cable de alimentación. Si es necesario

cambiar el enchufe o el cable, utilice solamente piezas

de repuesto idénticas.

• Mantenga todas las conexiones secas y alejadas del

suelo.

• NO toque el enchufe con las manos mojadas.

• NO pase el cable a través de puertas, ventanas,

agujeros en los techos, paredes o pisos.

• NO camine sobre el cable.

• NO conduzca sobre el cable ni arrastre o coloque

objetos sobre él.

• NO pulverice cerca de una fuente de alimentación.

ADVERTENCIA El uso de la hidrolavadora eléctrica

podría formar charcos y generar

superficies resbaladizas.

Riesgo de contragolpe. La pistola de

pulverización podría causar un contragolpe, con riesgo de

caída que podría provocar la muerte o lesiones graves.

• Opere la hidrolavadora eléctrica desde una superficie

estable.

• No se estire ni se pare sobre un apoyo inestable.

Mantenga una postura firme y un buen equilibrio en

todo momento.

• La zona de limpieza debe tener inclinaciones

adecuadas y sistema de drenaje para reducir la

posibilidad de caída debido a superficies resbaladizas.

• Sea extremadamente cuidadoso si debe usar la

hidrolavadora eléctrica desde una escalera, un

andamio u otro lugar similar.

• Sujete firmemente la pistola de pulverización con

ambas manos al utilizar modos de pulverización

eléctrica para evitar lesiones en caso de contragolpe de

la pistola.

ADVERTENCIA Riesgo de lesiones oculares o

corporales. La pulverización podría

salpicar, propulsar objetos o causar

daños internos, lo que puede provocar

lesiones graves.

• Siempre use gafas de seguridad con ventilación indirecta

(salpicaduras de productos químicos) identificadas en

cumplimiento de la norma ANSI Z87.1 cuando utilice

este equipo o esté cerca de él. NUNCA sustituya las

gafas de seguridad con ventilación indirecta con gafas de

seguridad o gafas de condición seca.

• Sepa cómo detener la hidrolavadora y descargar la

presión rápidamente. Familiarícese completamente con

los controles.

• NO permita que ningún NIÑO opere la hidrolavadora

eléctrica.

• Mantenga el área de operación libre de personas.

• Inspeccione la manguera de alta presión antes de

cada uso. NUNCA repare la manguera de alta presión;

reemplácela.

• NO repare las conexiones con fugas con sellador de

ningún tipo; reemplace las juntas tóricas y juntas.

• Mantenga la manguera conectada a la hidrolavadora

eléctrica y a la pistola de pulverización cuando el

sistema esté presurizado.

• SIEMPRE apunte con la pistola de pulverización

hacia una dirección segura mientras el sistema esté

presurizado y apriete el gatillo de la pistola para liberar

la alta presión, cada vez que apague la hidrolavadora.

• NO apunte la pistola de pulverización hacia personas o

animales.

• NO beba de los accesorios conectados a la manguera.

• NO fije la pistola de pulverización en la posición abierta.

• NO deje la pistola de pulverización desatendida

cuando la hidrolavadora eléctrica está en la posición de

encendido (I).

• NO utilice una pistola de pulverización que no tenga

un bloqueo o seguro de gatillo instalado y en buenas

condiciones.

• Asegúrese siempre de que la pistola de pulverización y

los accesorios estén conectados correctamente.

• Manténgase alerta, observe lo que está haciendo.

• NO haga funcionar el producto si está cansado o bajo

la influencia de alcohol o drogas.

• Se requiere supervisión minuciosa cuando este

producto se utiliza cerca de niños.

ADVERTENCIA El chorro de agua a alta presión que

este equipo produce podría atravesar la piel y

los tejidos subcutáneos, y provocar lesiones

graves y posible amputación.

La pistola de pulverización acumula agua a alta

presión, incluso con el motor detenido y el agua

desconectada, lo que puede provocar lesiones graves.

• NUNCA apunte la pistola de pulverización hacia

personas, animales o plantas.

• SIEMPRE apunte con la pistola de pulverización hacia

una dirección segura y apriete el gatillo de la pistola

para liberar la alta presión, cada vez que apague la

hidrolavadora.

4 BRIGGSandSTRATTON.COM

Page 21

Not for

Reproduction

ADVERTENCIA Riesgo de incendio. Pulverizar

líquidos inflamables podría causar la muerte o

lesiones graves.

• NO pulverice líquidos inflamables.

ADVERTENCIA Riesgo de incendio. Un cable

sobrecalentado podría provocar la muerte o

lesiones graves.

• Desenrolle el cable completamente antes de su uso.

• NO cubra el cable con ningún material.

ADVERTENCIA Este producto contiene plomo y

compuestos de plomo que, de acuerdo al estado de

California, pueden causar defectos de nacimiento u

otros problemas reproductivos. Lávese las manos

después de manipular este producto. Cáncer y

problemas reproductivos – www.P65Warnings.ca.gov

AVISO La pulverización a alta presión podría dañar

objetos frágiles, incluido el vidrio.

• NO apunte la pistola de pulverización hacia objetos de

vidrio cuando se utiliza el punta de rociado turbo.

• NUNCA apunte la pistola hacia plantas.

ADVERTENCIA Peligro de quemaduras químicas.

Los productos químicos podrían

ocasionar quemaduras que podrían

provocar la muerte o lesiones graves.

• Siempre use gafas de seguridad con ventilación

indirecta (salpicaduras de productos químicos)

identificadas en cumplimiento de la norma ANSI Z87.1

cuando utilice ese tipo de productos.

• NO sustituya las gafas de seguridad con ventilación

indirecta con gafas de seguridad o gafas de condición

seca.

• NO use líquido cáustico con la hidrolavadora eléctrica.

• Utilice SOLAMENTE detergentes o jabones de uso

seguro en hidrolavadoras. Siga todas las instrucciones

del fabricante.

AVISO Deberá proteger su unidad de las temperaturas

de congelación.

• Si no lo hace, dañará permanentemente la bomba y la

unidad no podrá funcionar.

• Los daños producidos por congelación no están

cubiertos por la garantía.

AVISO Un tratamiento inadecuado de la hidrolavadora

eléctrica podría dañarla y acortar su vida útil.

• En caso de dudas sobre su uso previsto, diríjase al

distribuidor o comuníquese con un centro de servicio

autorizado.

• NO opere unidades con piezas rotas o faltantes, o sin

sus carcasas o cubiertas de protección.

• NO eluda ningún dispositivo de seguridad en la

hidrolavadora eléctrica.

• NO modifique la hidrolavadora eléctrica de ninguna

manera.

• NO mueva la hidrolavadora eléctrica tirando de las

mangueras. Mueva la unidad utilizando la manija de

transporte suministrada.

• Utilice SOLO accesorios de marca destinados para su

uso con este producto.

5

Page 22

Not for

Reproduction

Montaje

Lea todo el manual del operador antes de

intentar armar o hacer funcionar su

hidrolavadora eléctrica nueva.

Deberá armar la hidrolavadora eléctrica, pero no tardará

mucho en poder tenerla lista para usarla. Si tiene problemas

con el ensamblado de la hidrolavadora eléctrica, por favor,

llame al número de teléfono de ayuda de la hidrolavadora

eléctrica (800) 743-4115. Si solicita asistencia, tenga a mano

el número de modelo, de revisión y de serie que puede ver

en la etiqueta de identificación.

Herramientas necesarias

• Destornillador Phillips, n.º 2

Desembale la hidrolavadora eléctrica

1. Saque todos los elementos de la caja.

2. Asegúrese de tener todos los elementos que se

incluyen antes de ensamblarla.

Artículos incluidos en la caja

• Unidad principal

• Manija con bandeja de accesorios

• Pistola de pulverizadora

• Manguera de alta presión

• Varilla de rociado

• Puntas de rociado de conexión rápida (3)

• Punta de rociado espumante de conexión rápida con

botella de detergente

• Tubos de soporte de la manija (2)

• Tornillos (2)

• Manual del operario

2. Deslice los tubos de soporte de la manija (C) en las

ranuras en ambos lados de la unidad principal. Alinee

los orificios e inserte los tornillos (D). Ajuste con un

destornillador Philips n.° 2.

D

C

D

Lubrique las juntas tóricas

La lubricación de las juntas tóricas es extremadamente

importante para la instalación y el funcionamiento. El uso

de un lubricante (grasa lubricante o sintética) durante

el montaje ayuda a que las juntas tóricas se asienten

correctamente y ofrece un mejor sellado. También ayuda

a evitar que la junta tórica resulte dañada por abrasión,

pellizcado o cortes, y aumenta la vida útil de la junta tórica.

AVISO SIEMPRE aplique una pequeña cantidad de

lubricante en las juntas tóricas antes de montar la manguera

de jardín a la bomba (E), manguera a alta presión (F), la

pistola rociadora (G), y el varilla de rociado (H).

G

H

Revise todo el contenido. Si falta alguna de las piezas o

alguna está dañada, NO los use, llame a la línea de ayuda

de la hidrolavadora eléctrica: (800) 743-4115.

Familiarícese con todos los componentes antes de armar

la hidrolavadora eléctrica. Identifique los contenidos con la

ilustración que se muestra en Características y controles.

Conecte la manija y los tubos de soporte

1. Mantenga presionados los botones de los pasadores

de seguro (A) a cada lado de la manija. Deslice la

manija (B) dentro de cada tubo de soporte (C) hasta

que los botones de los pasadores de seguro se

encajen en los orificios.

B

A

C

E

F

Lubrique todas las conexiones mostradas debajo.

Para ello, siga estas instrucciones:

1. Revise y limpie las superficies de conexión antes de

lubricar y armar.

2. Sea moderado en el uso de lubricantes durante el

armado. Solo necesita una pequeña lubricación.

3. Use un cepillo pequeño o un bastoncillo de algodón

para aplicar la grasa directamente a las juntas tóricas

en los lugares donde no son accesibles (adaptador

QC, adaptador M22).

6 BRIGGSandSTRATTON.COM

Page 23

Not for

Reproduction

Conecte la manguera y el suministro de

agua a la bomba

AVISO NO haga funcionar la bomba si no tiene el

suministro conectado y abierto.

• El daño a la limpiadora a presión, resultado de la desatención

a esta precaución, no será cubierto por la garantía.

1. Desenrolle la manguera de alta presión y conecte el

extremo negro la manguera de alta presión (A) a la

base de la pistola rociadora (B). Apriete con la mano.

A

B

ADVERTENCIA El chorro de agua a alta presión que

este equipo produce podría atravesar la piel y los

tejidos subcutáneos, que podrían provocar lesiones

graves y la posible amputación de un miembro.

• NUNCA conecte la manguera de alta presión al

prolongador de la boquilla.

• Mantenga conectada la manguera a la máquina o a la

pistola de rociado cuando el sistema esté presurizado.

• Asegúrese en todo momento de conectar

correctamente la pistola rociadora, las boquillas y los

accesorios.

2. Conecte el extremo rojo de la manguera de alta

presión (A) a la salida de alta presión (C) de la

bomba. Apriete a mano.

AVISO El uso de una válvula unidireccional (igualador

de presión o válvula de retención) en la entrada de

la bomba podría producir daños en la bomba o en el

conector de entrada.

• DEBE haber un mínimo de 3 metros (10 pies) de

manguera de riego libre entre la entrada de la limpiadora

a presión y cualquier dispositivo, como un igualador de

presión o una válvula de retención).

• El daño a la limpiadora a presión, resultado de la

desatención a esta precaución, no será cubierto por la

garantía.

5. Conecte la manguera de jardín (D) (no exceder 15

m (50 pies) en la longitud) a la entrada del agua (E).

Apriete con la mano.

ADVERTENCIA Riesgo de lesiones oculares.

El agua rociada podría salpicar o propulsar

objetos, lo que puede provocar lesiones graves.

• Cuando utilice este equipo o esté cerca de él, siempre

use gafas de seguridad con ventilación indirecta

(contra salpicaduras de productos químicos) marcadas

para cumplir con ANSI Z87.1.

• NUNCA se ponga gafas de seguridad ni gafas para

entornos secos como sustituto de las gafas de

seguridad con ventilación indirecta.

6. Abra el grifo, pulse el botón rojo (G) de la pistola

rociadora y apriete el gatillo para eliminar el aire y las

impurezas del sistema de bombeo.

G

C

A

3. Haga correr el agua a través de la manguera de

su jardín por 30 segundos para limpiar cualquier

escombro que se encuentre en ella. Corte el agua.

AVISO Hace no agua de parar de siphon para el

abastecimiento de agua. Use agua SOLO fría (menos que

38°C (100°F)).

4. Antes de que conecte la manguera de jardín (D) a

la entrada de agua (E), inspeccione el colador de

la entrada (F). Limpie el colador si tiene residuos

o solicite su remplazo si está dañado. NO haga

funcionar la máquina limpiadora a presión si el

colador de la entrada está dañado.

F

D

E

Lista de verificación previa al arranque del

motor de la bomba

Revise el montaje de la unidad para asegurarse de que

haya realizado todas las siguientes acciones.

1. Asegúrese de leer Seguridad del usuario y

Funcionamiento antes de usar la hidrolavadora

eléctrica.

2. Compruebe que las conexiones de manguera estén

correctamente apretadas.

3. Asegúrese de que las mangueras no tengan nudos, cortes

ni daños.

4. Coloque un suministro de agua adecuado con el flujo

correcto.

5. Enchufe el cable de alimentación eléctrica a un

circuito eléctrico dedicado para 120 V CA a 15 A que

haya sido instalado conforme a todos los códigos y

normativas locales. Compruebe que el circuito no se

use para ningún otro suministro eléctrico.

7

Page 24

Not for

Reproduction

Características y controles

Lea el manual del usuario y las reglas de seguridad antes de hacer funcionar su hidrolavadora eléctrica.

Compare las ilustraciones con la hidrolavadora eléctrica para familiarizarse con la ubicación de los distintos

controles y ajustes. Guarde este manual original para consultarlo en el futuro.

A

B

C

D

E

M

L

F

G

A - Pistola pulverizadora — Controla la aplicación de agua

sobre la superficie por limpiar con un gatillo. Incluye

traba de gatillo.

B - Puntas de rociado — La punta de rociado con

casquillo amarillo y blanca es para diversas

aplicaciones de alta presión.

C - Manguera a alta presión — Conecte un rojo extremo

a la salida de agua a alta presión y el extremo negro la

manguera de alta presión a la pistola pulverizadora.

D - Etiqueta de advertencia — Identifique los peligros que

deben evitarse cuando utiliza la hidrolavadora eléctrica.

E - Interruptor principal de encendido/apagado —

Presione el extremo superior del activador (I) para

encender la hidrolavadora eléctrica. Presione el botón

(0) del activador para apagar la limpiadora.

F - Entrada del suministro de agua — Conecte el

suministro de agua utilizando una manguera para jardín

de un máximo de 50 ft (15,24 m).

K

J

H

G - Cable eléctrico con GFCI — La hidrolavadora eléctrica

y el operador están protegidos por un interruptor de

circuito con fallos a tierra.

H - Punta de rociado espumante con botella de

detergente —Se usa para aplicar detergente apto para

uso en lavadoras a presión sobre supercies.

J - Etiqueta de identificación (debajo de la cubierta)

— Proporciona el modelo y el número de serie de la

hidrolavadora eléctrica. En caso de llamar y solicitar

ayuda, tenga la etiqueta cerca.

K - Salida de agua a alta presión — Conexión de la

manguera a alta presión.

L - Varilla de rociado — Le permite cambiar entre puntas

de rociado distintos.

M - Punta de rociado turbo — Hace girar un poderoso

chorro de agua de precisión para una limpieza profunda.

8 BRIGGSandSTRATTON.COM

Page 25

Not for

Reproduction

Funcionamiento

Cómo arrancar la hidrolavadora eléctrica

Siga las instrucciones que aparecen a continuación en el

orden en el que se muestran. Si tiene problemas con el

funcionamiento de la hidrolavadora eléctrica, por favor,

llame al número de teléfono de ayuda de la hidrolavadora

eléctrica (800) 743-4115.

ADVERTENCIA Riesgo de lesión ocular. El

pulverizador podría salpicar o empujar

objetos y esto podría causar lesiones graves.

Cuando utilice o esté cerca de este dispositivo,

colóquese gafas de seguridad con ventilación indirecta

(salpicadura química) que cumplan con la disposición

ANSI Z87.1. Jamás reemplace las gafas de seguridad o

las gafas para tareas secas por gafas de seguridad con

ventilación indirecta.

1. Coloque la máquina limpiadora a presión en un área

cercana a una suministro de agua exterior capaz de

abastecer agua a un volumen mayor de 11.4 litros

por minuto (3.0 galones por minuto) en no menos que

1.38 BARS (20 PSI) en el fin de arandela de presión

de la manga del jardín.

2. Revise que la manguera de alta presión se encuentre

conectada firmemente a la pistola de rociado y a la

bomba. Vea Montaje.

3. Asegúrese que la unidad esté nivelada.

4. Conecte la manguera de jardín a la entrada del agua.

Aprietela con la mano.

AVISO NO haga funcionar la bomba si no tiene el

suministro conectado y abierto.

• El daño a la limpiadora a presión, resultado de la

desatención a esta precaución, no será cubierto por la

garantía.

5. Abra el grifo, pulse el botón rojo de la pistola

rociadora y apriete el gatillo para eliminar el aire y las

impurezas del sistema de bombeo.

6. Conecte la varilla de rociado a la pistola rociadora.

Apriétela con las manos.

ADVERTENCIA Riesgo de electrocución. El uso de un

cable prolongador podría provocar electrocución y

quemaduras, y tener como resultado lesiones graves

o la muerte.

• NO utilice un cable prolongador con esta hidrolavadora

eléctrica. Es posible que la toma eléctrica residencial o el

cable prolongador no le brinde protección con interrupción

de circuito de fallo de conexión a tierra, crucial para la vida

de una persona.

9. Enchufe el cable de alimentación eléctrica a un

circuito eléctrico dedicado para 120 V CA a 15 A que

haya sido instalado conforme a todos los códigos y

normativas locales. El circuito no debe utilizarse para

ningún otro suministro eléctrico. La luz de indicación

en el GFCI debe estar ENCENDIDA.

AVISO La luz del indicador debe estar visible para que la

hidrolavadora eléctrica pueda funcionar.

ADVERTENCIA Riesgo de electrocución. Si no

se utiliza un interruptor con circuito de fallo de

conexión a tierra (GFCI), se podría producir daños

materiales, lesiones o incluso la muerte. Si el luz

del indicador no se mantiene encendido después de la

prueba y el rearme, no utilice al GFCI.

10. Presione el botón TEST (prueba) (B). Se debería

apagar la luz del indicador (C).

D

B

C

7. Seleccione la puntas de rocío de conexión rápida que

usted desee e insértela en el extremo de varilla de

rociado. Vea Como Usar las Puntas de Rocío.

8. Sitúe el interruptor principal de encendido/apagado

(A) en la posición de ON (I).

A

11. Presione el botón RESET (reiniciar) (D). Se debería

encender la luz del indicador (C).

AVISO NO use la hidrolavadora eléctrica si falla la prueba

mencionada anteriormente.

12. Presione el interruptor principal de encendido/

apagado de la hidrolavadora eléctrica y llévelo a la

posición de encendido (I).

13. Apunte la pistola hacia una dirección segura, presione

el botón de bloqueo del gatillo y apriete el gatillo.

El motor de la hidrolavadora eléctrica arrancará y se

detendrá mientras se presiona y se suelta el gatillo de

la pistola pulverizadora. Ahora la hidrolavadora eléctrica