Page 1

t

vv

N

£

iv,-

x

OPERATING

i

V

R2E3

MILLING,

0

$

V

V

DRILLING

FOR

SERIES

MANUAL

THE

;

\

I

&

SCJfiJNG

CNO

K

\»

MACHINE

*v

1

{.

K

s

*

.

*4

/;•

%ÿ

*

l

1

;

4

*

!

Page 2

m

m

tty

y

MILLING,

OPERATING

FOR

R2E3

DRILLING

SERIES

MAY,

MANUAL

x,

THE

I

BMJ!3C-

«

1983

GNC

V.

MACHINE

HrrdijefMtri

Bridgeport

TEXTRON

Machines

Division

Textron

of

Inc.

REV

11040531

0

5/83

Page 3

mm

SHH

1

1

m

iftV.

v

mm

'J

&

i

II

mm

m

M

r

mm

r'!-4

Pm

1

"

Machines

for

does

1983

the

BRIDGEPORT

provides

use

or

dissemination

is

in

this

not

of

Textron

ALL

Division

maintenance

and

prohibited.

document

constitute

COPYRIGHT

This

Bridgeport

available

reproduction,

written

m

The

notice

Machines

»*•

;s;::

V-

document

permission

information

and

Division

MACHINES

RIGHTS

information

of

Inc.

ii

RESERVED

is

Textron

of

of

subject

a

DIVISION

which

our

this

is

Inc.

products.

information

to

commitment

TEXTRON

OF

proprietary

change

by

and

INC.

is

Any

withou

withou

Bridgepor

t

mad

use

Ill

H.:-.

\

till

Page 4

Ill,

1

prevent

To

ing,

operating

These

and

entitled

Machines

publication

This

servicing

or

1.

2.

3.

4.

bodily

Follow

Wear

not

Do

other

Keep

serious

gears,

Use

5.

safety

other

Safety

(ANSIB11.8-1974).

Requirements

is

available

injury,

your

instructions

all

approved

wear

loose

all

proper

precautions

items

parts

etc.)

point

from:

SAFETY

you

should

Bridgeport

industrial

gloves,

that

your

of

of

are

for

the

The

1430

New

observe

milling

in

the

safety

long

sleeves,

could

body

operation

discussed

Construction,

American

Broadway

York,

New

INFORMATION

following

the

machine.

machine

glasses

long

from

the

Care,

caught

American

become

away

safeguarding.

in

National

York

10018

manual.

and

hair,

moving

Standards

and

basic

safety

rings,

in

National

Use

moving

parts

safety

shoes.

watches,

parts.

(belts,

Standards

of

Drilling,

Institute

precautions

jewelry

cutters,

Institute

Milling,

or

when

Standard

and

install¬

Boring

Safeguarding

parameters

states

guarding

To

tions,

Techniques

This

that

assist

the

publication

device,

machine

Occupational

for

of

the

shall

“it

Machine

of

protection

particular

be

the

awareness

users

is

in

Safety

Safeguarding

available

point

the

at

operation

responsibility

barrier,

designing

from:

and

awareness

Health

The

200

Washington,

of

have

point

(O.S.H.A.

Publication

Department

U.S.

Constitution

operation

been

determined.

of

of

Administration

employer

the

device,

operation

Publication

Office

of

Avenue,

D.C.

only

can

to

or

shield...".

safeguarding

published

has

Number

—

Labor

20210

be

designed

result,

a

As

provide,

3067).

O.S.H.A.

NW

for

and

their

a

booklet

and

ANSI

ensure

specific

constructed

1.8-1974,

B1

the

machine

entitled

Section

of,

use

Concepts

when

guard,

a

applica¬

the

5.1,

and

.

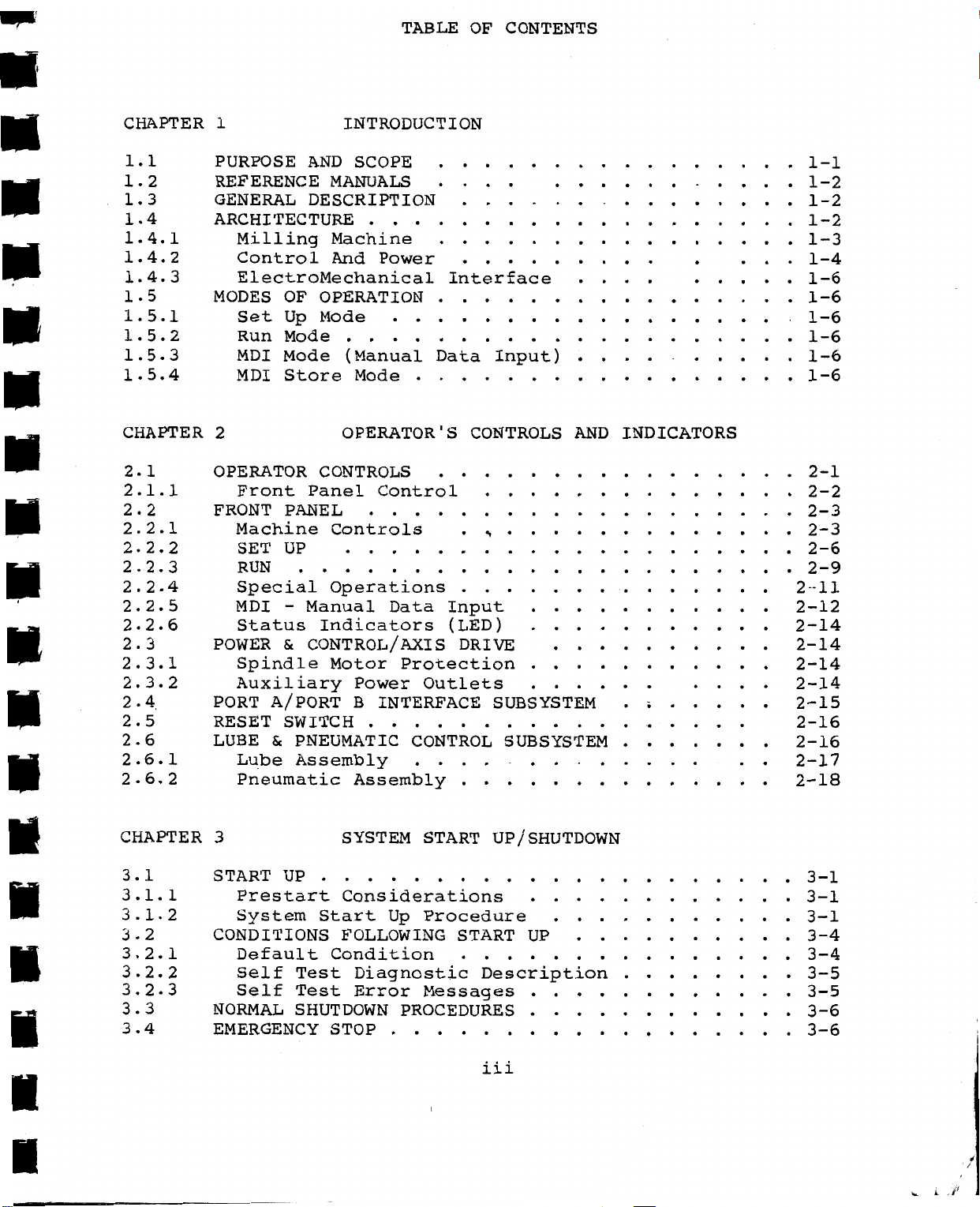

Page 5

TABLE

P

OF

CONTENTS

m

M

m

M

CHAPTER

1.1

1.2

1.3

1.4

1.4.1

1.4.2

1.4.3

1.5

1.5.1

1.5.2

1.5.3

1.5.4

CHAPTER

2.1

2.1.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.3

2.3.1

2.3.2

2.4.

2.5

2.6

2.6.1

2.6.2

1

PURPOSE

REFERENCE

GENERAL

ARCHITECTURE

Milling

Control

ElectroMechanical

MODES

Set

Run

MDI

MDI

2

OPERATOR

Front

FRONT

Machine

SET

RUN

Special

MDI

Status

POWER

Spindle

Auxiliary

PORT

RESET

LUBE

Lube

Pneumatic

AND

DESCRIPTION

OF

OPERATION

Up

Mode

Mode

Mode

Store

CONTROLS

Panel

PANEL

UP

Manual

-

Indicators

&

CONTROL/AXIS

PORT

A/

SWITCH

&

PNEUMATIC

Assembly

INTRODUCTION

SCOPE

MANUALS

Machine

And

Power

(Manual

Mode

OPERATOR'S

Control

....

Controls

Operations

Data

Motor

Protection

Power

B

INTERFACE

Outlets

CONTROL

........

Assembly

Interface

Data

CONTROLS

.

Input

(LED)

DRIVE

Input)

AND

.

.

.

. . . .

. .

.

.

.

. . . .

SUBSYSTEM

SUBSYSTEM

INDICATORS

.

.

.

1-1

1-2

1-2

1-2

1-3

1-4

1-6

1-6

1-6

1-6

1-6

1-6

2-1

2-2

2-3

2-3

2-6

2-9

2-11

2-12

2-14

2-14

2-14

2-14

2-15

2-16

2-16

2-17

2-18

i

i

H

H

M

CHAPTER

3.1

3.1.1

3.1.2

3.2

3.2.1

3.2.2

3.2.3

3.3

3.4

3

START

Prestart

System

CONDITIONS

Default

Self

Self

NORMAL

EMERGENCY

UP

Test

Test

SHUTDOWN

SYSTEM

Considerations

Start

Condition

STOP

Up

FOLLOWING

Diagnostic

Error

START

Procedure

Messages

PROCEDURES

UP

START

Description

iii

/SHUTDOWN

.

.

. .

.

.

.

.

UP

. .

.

.

.

.

.

.

.

3-1

3-1

3-1

3-4

3-4

3-5

3-5

3-6

3-6

4

,f

w

L

Page 6

6.2.4

6.3

6.3.1

6.3.2

6.4

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

6.4.6

AUTO/

SPECIAL

The

DRY

SPECIAL

Travel

EMERGENCY

Spindle

Feed

Hold

Screen

BLOCK

OPERATIONS

OPTION

RUN

Key

CONDITIONS

Limit

Feed

Override

Error

Operation

Key

....

Switch

STOP

Hold

Messages

. .

. . .

. .

. . .

.

. .

6-4

6-4

6-4

6-5

6-7

6-7

6-7

6-7

6-8

6-8

6-8

CHAPTER

7.1

7.2

7.2.1

7.3

CHAPTER

8.1

8.2

8.3

8.4

8.5

8.5.1

8.6

8.7

CHAPTER

9.1

9.1.1

9.2

7

OVERVIEW

MDI

MODE

CANNED

STORE

MDI

8

OPTIONAL

PAPER

TAPE

EZ-FILE~

QUICK

#30

1-4

COOLANT

INDEXER

Physical

EZ-CAM~

9

TOOL

TOOL

HOLDERS

General

SETTING

OPERATION

CYCLE

OPTIONAL

EQUIPMENT

READER

MASS

CHANGE

Description

SYSTEM

TOOLS

....

Description

....

OPERATING

EQUIPMENT

STORAGE

TOOL

MIST

-

AND

IN

MDl/MDI

NOTES

DEVICE

KIT*

AND/OR

TOOL

HOLDERS

.

STORE

.

.

. .

FLOOD

MODE

7-1

7-1

7-2

7-10

8-1

.

8-1

.

.

8-1

,

8-2

8-2

8-3

8-3

8-3

9-1

9-1

9-2

APPENDIX

1

A.

APPENDIX

.1

B

B.

2

.

3

B

.

4

B

.

5

B

A

SYSTEM

B

OVERVIEW

STANDARD

MACHINE

CONTROL

TOTAL

LEADING

SYSTEM

SYSTEM

ERROR

SYSTEM

FEATURES

FEATURES

DATA

STATUS/

MESSAGES

SPECIFICATIONS

OF

FEATURES

(SERIES

THE

I

R2E3)

V

ERROR

BRIDGEPORT

MESSAGES

R2E3

SERIES

A-l

B

1

—

I

B-l

B-2

B-4

B-5

Page 7

3.5

3.6

3.6.1

3.6.2

POWER

RESET

RESET

RESET

FAILURE

PROGRAM

Pushbutton

Key

. .

Switch

3-6

3-6

3-7

3-7

CHAPTER

4.1

4.2

4.3

4.4

4.4.

1

4.4.

2

4.4.3

4.4.4

4.5

4.5.1

4.5.2

4.5.3

4.6

4.7

4.7.1

4.7.2

4.8

4.9

CHAPTER

4

SYSTEMS

MACHINE

AXIS

ENTERING

SETTING

MOVE

LOADING

CLEARING

EDITING

5

JOG

Manual

TLO

Tool

Cutter

Reference

Part

Clearance

OPERATION

Baud

Input

OPERATION

OPERATION

COORDINATE

TOOL

Knee

Input

Diameters

Diameter

REFERENCE

Point

Program

Point

PART

Rate

From

DATA

.

EDITING

SYSTEM

DATA

Adjustment

Compensation

POINTS

Zero

PROGRAMS

Peripheral

IN

(SET

SET

UP

.

.

....

....

XYZ)

. .

Equipment

MODE

.

.

.

4-1

4-2

4-4

4-5

4-6

4-7

4-10

4-10

4-11

4-12

4-13

4-14

4-14

4-15

4-15

4-16

4-18

4-19

5.1

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

5.2.9

5.3

5.3.1

5.3.2

CHAPTER

6.1

6.2

6.2.1

6.2.2

6.2.3

PROGRAM

QUICK

AUX

FULL

Description

Editor

6

OVERVIEW

NORMAL

Pre-Start

Starting

EDIT

FIND

INSERT

DELETE

RECALL

INCR

POLAR

"0

-

(Minus

EDIT

Program

EDITING

9",

Sign)

METHOD

Commands

OPERATION

OPERATION

The

Run

METHODS

(Decimal)

.

.

.

. . .

.

. .

Spindle

.

. . .

. .

.

IN

.

.

RUN

MODE

5-1

5-1

5-2

5-3

5-4

5-4

5-4

5-4

5-4

5-5

5-5

5-5

5-5

5-5

6-1

.

6-1

6-2

6-2

6-3

iv

Page 8

6.2.4

6.3

6.3.1

6.3.2

6.4

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

6.4.6

AUTO/BLOCK

SPECIAL

The

DRY

SPECIAL

Travel

EMERGENCY

Spindle

Feed

Hold

Screen

OPERATIONS

OPTION

RUN

Key

CONDITIONS

Limit

Feed

Override

Error

Operation

Key

....

Switch

STOP

Hold

Messages

. .

.

.

. .

. . .

.

.

.

6-4

6-4

.

.

6-4

6-5

6-7

6-7

6-7

6-7

6-8

6-8

6-8

CHAPTER

7.1

7.2

7.2.1

7.3

CHAPTER

8.1

8.2

8.3

8.4

8.5

8.5.1

8.6

8.7

CHAPTER

9.1

9.1.1

9.2

7

OVERVIEW

MDI

MDI

OPTIONAL

1-4

MODE

CANNED

STORE

8

PAPER

#30

Physical

ILE~

QUICK

INDEXER

EZ-F

COOLANT

TAPE

EZ-CAM~

9

TOOL

TOOL

HOLDERS

General

SETTING

OPERATION

CYCLE

OPTIONAL

EQUIPMENT

READER

MASS

CHANGE

Description

SYSTEM

TOOLS

....

Description

....

OPERATING

EQUIPMENT

STORAGE

TOOL

MIST

-

AND

IN

MDl/MDI

NOTES

DEVICE

KIT’

AND/OR

TOOL

HOLDERS

.

STORE

. .

. .

FLOOD

MODE

7-1

7-1

7-2

7-10

8-1

8-1

.

.

8-1

,

8-2

8-2

8-3

8-3

8-3

9-1

9-1

9-2

APPENDIX

1

A.

APPENDIX

.

B

1

B.

2

.

3

B

.

B

4

.

5

B

A

SYSTEM

B

OVERVIEW

STANDARD

MACHINE

CONTROL

TOTAL

LEADING

SYSTEM

SYSTEM

ERROR

SYSTEM

FEATURES

FEATURES

DATA

STATUS/

MESSAGES

SPECIFICATIONS

OF

FEATURES

(SERIES

ERROR

THE

BRIDGEPORT

R2E3)

I

v

MESSAGES

R2E3

SERIES

A-l

B-l

I

B-l

B-2

B-4

B-5

Page 9

APPENDIX

C

CONNECTORS

APPENDIX

D

GLOSSARY

vi

\

Page 10

LIST

OF

ILLUSTRATIONS

FIGURE

1-1

1-2

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

4-1

4-2

4-3

4-4

5-1

9-1

9-2

The

R2E3

R2E3

Series

Operator's

Machine

Speed

Speed

SET

RUN

MDI

Tape

Lube

Set

UP

Mode

Mode

Reader

&

up

Machine

Preset

Plug

Quick

Tool

Tool

Connectors

and

Setting

System

Controls

Range

Dial

Mode

Keys

-

Pneumatic

Mode

Coordinate

TLO

Edit

Tool

Functional

-

I

Front

Control

Panel

R2E3

Controls

Application

Adapter/

Controls

Keys

Measurement

for

Controls

Holder

Drawing

Keys

Remote

System

Tape/Local

Front

Serial

Panel

Blocks

I/O

Interface

PAGE

1-3

1-5

2-2

2-3

2-4

2-5

2-7

2-9

2-11

2-15

2-17

4-2

4-3

4-9

4-16

5-2

9-1

9-3

TABLE

4-1

7-1

A-l

A-2

Reference

MDI

Error

&

Error

LIST

Points

MDI

Store

Message

Combinations

OF

Sets

TABLES

and

Mode

vii

Tracking

Hex

-

To

Registers

Binary

PAGE

4-12

7-3

A-

2

A-

3

Page 11

CHAPTER

INTRODUCTION

1

1.1

This

necessary

Machine.

Control

Software,

This

PURPOSE

manual

The

(CNC),

Series

manual

o

Operator

o

System

o

System

o

Editing

AND

provides

to

is

MDI

SCOPE

operate

R2E3

using

I).

divided

Start

Operating

SET

RUN

MDI

Capabilities

the

is

Controls,

UP

STORE

the

totally

BOSS

into

Up/

operator

Bridgeport

8

the

and

Shutdown

Modes

with

dedicated

(Bridgeport

I

following

Indicators

information

R2E3

Series

to

major

and

I

Computer

Operating

sections:

CNC

examples

Milling

Numeric

System

o

o

o

Optional

Tool

Appendix

Holders

System

System

Equipment

*

Status/Error

Specifications

Messages

1-1

/

Page 12

o

Glossary

1.2

Two

REFERENCE

other

1.

2.

1.3

The

operated

It

GENERAL

Bridgeport

provides

interpolation

large

A

scale

communication

conjunction

known

as

checking

codes:

Transmission.

End

manuals

R2E3

R2E3

via

3

integration)

Port

transmitted

<DC1>

MANUALS

exist

Installation

Programming

DESCRIPTION

R2E3

a

axis

.

with

B.

Start

Series

Front

linear

The

protocol

the

The

Read,

for

Panel

design

.

remote

protocol,

data

this

and

Manual

CNC

I

with

and

embedded

serial

for

<DC2>

product.

Maintenance

(11040532)

is

an

axis

2

makes

,EIA

errors

Device

a

Vertical

LCD

(liquid

switchable

extensive

in

interface

RS-491,

using

on,

Manual

BOSS

<DC3>

Milling

crystal

use

8

port,

includes

the

Stop

(11040529)

plane

VLSI

of

is

I

which

means

following

Read,

Machine

display).

circular

(very

used

will

ASCII

<E0T>

in

be

for

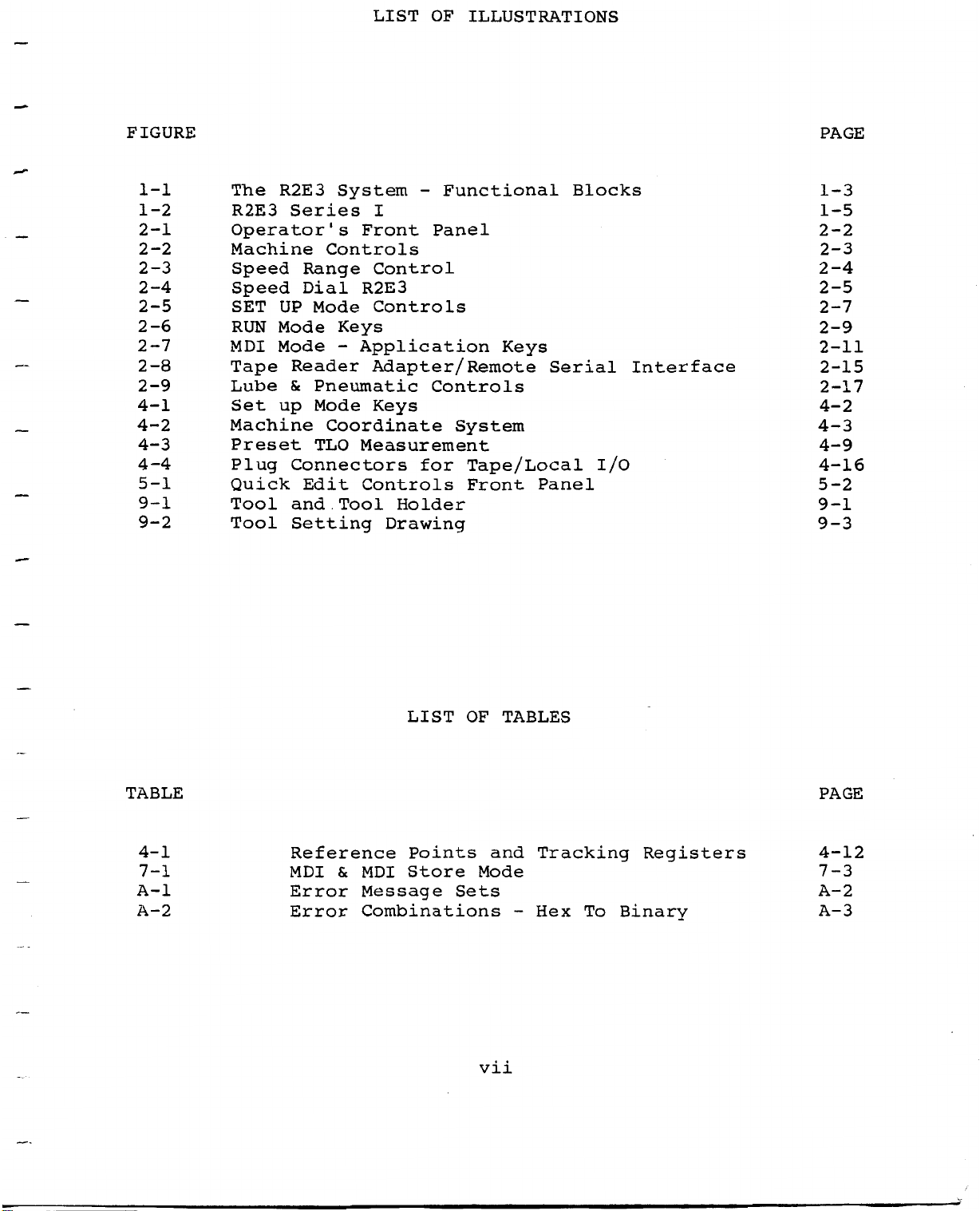

1.4

The

together

Each

make

contains

ARCHITECTURE

system

as

2.

3.

section

the

Milling

Control

Interface

all

1.

contains

electromechanical

machine

and

contains

one.

is

system

mechanical

all

the

three

individual

The

Machine

and

Power

(electromechanical)

specialized

function

electronic

interface

control.

sections,

(mechanical)

(electrical)

and

as

aspects

provides

sections

interacts

a

of

aspects

1-2

see

whole.

the

the

Figure

are:

with

machine

of

link

1-1,

the

The

and

the

between

all

other

milling

the

machine.

working

machine

controller

milling

the

two

to

The

Page 13

HVIILLING

MACHINE"!

AO

H

E

ASSEMBLY

CONTROL

AND

POWER

FRONT

PANEL

SUBSYSTEM

|

1.4.1

Figure

Milling

BASE

ASSEMBLY

LUBE

ANO

M

1ST

ASSEMBLIES

zrLJ

1-1:

Machine

(TLECTROMECHANICATI

,

[

I

TACHOMETERS

i<=>!

[

L'

The

R2E3

INTERFACE

MOTORS

ENCOOERS

SOLENOIOS

System

I

I

tc=>

I

n

Functional

-

L

CENTRAL

PROCESSING

SUBSYSTEM

MACHINE

CONTROL

SUBSYSTEM

POWER

SUBSYSTEM

J

Blocks

This

section

1.

2.

3.

contains

Head

the

structure.

mounted

Base

axis),

and

Y

Lube

and

assembly.

the

way

lubricant.

Assembly

quill

to

this

Assembly

knee,

axis

and

filter,

drive

Mist

These

distribution

(

see

Contains

-

(Z

axis),

The

support

Contains

-

and

Assemblies

the

Figure

Z

axis

their

motors

lubrication

components

of

1-2

the

the

drive

structure.

the

support

are

pressurized

1-3

)

:

mechanical

pneumatics

motor

saddle

mounted

Contains

pump

are

structure.

the

and

(Y

to

•>

the

and

starting

air,

components

and

spindle

axis)

this

air

the

mist

their

,

The

structure.

optional

points

coolant

support

motor

table

X

regulator

of

are

(X

axis

mist

for

and

Page 14

1.4.2

Control

And

Power

This

section

1.

2.

3.

4.

consists

Front

Panel,

up.

These

Input),

Front

Up

mode

Control

feedback

Power

distributed

parts

Controllers

voltage

Panel

in

Panel,

allowing

-

Incoming

-

by

and

and

All

is

this

of

Most

-

any

modes

MDI

however

operator

analyzed

to

subsystem.

current

(see

operator

one

of

are;

Store.

modification

electrical

the

These

to

Figure

four

Set

is

it

and

by

this

controller

convert

the

1-2):

control

modes

Up,

Editing

intended

to

electronic

subsystem.

power

electrical

DC

motors.

following

Run,

existing

and

through

is

MDI

is

for

input

is

(Manual

possible

use

part

conditioned

electromechanical

signals

system

in

programs.

plus

the

via

the

machine

Front

start

Data

the

Set

and

into

1-4

Page 15

w

4L

3

3

1

LV

=sfeCNC

£3

E

"wj

gft£

mi

&

•

3*

i,

s

f

"3’

IC33

.V.

V;

ET““

fp<.

;

f

••';••-

i

:?rV

/'ÿif.,1:

l'.

*•

"/$

.‘A?

"af

A

IF

*#

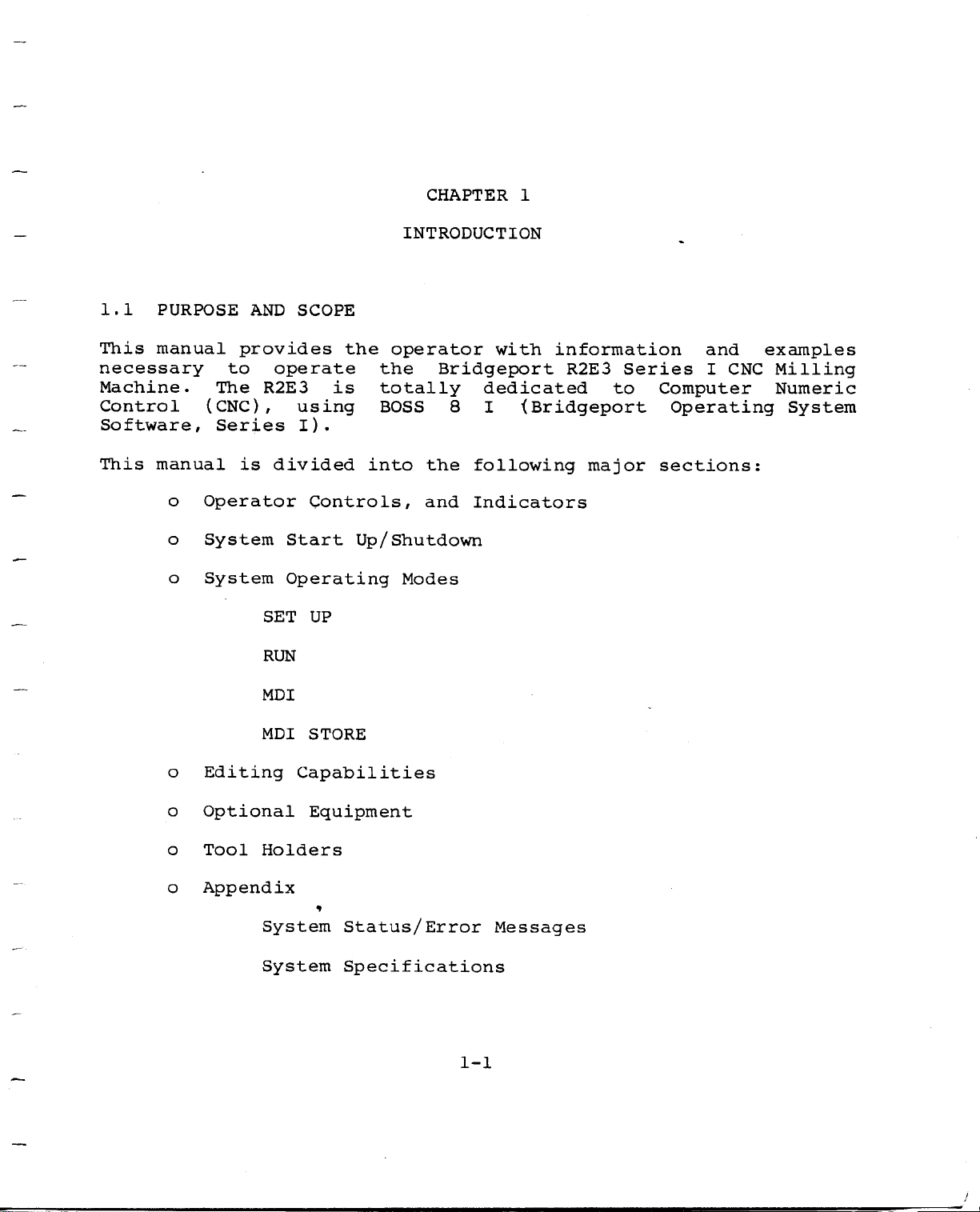

Figure

1-2:

R2E3

1-5

Series

I

CNC

Page 16

1.4.

3

ElectroMechanical

Interface

This

section

convert

1.

2.

3.

1.5

MODES

1.5.1

Set

Up

establishing

initial

electrical

DC

and

Encoders

from

can

Solenoids

pneumatic

OF

Up

Set

prepares

axis

contains

Motors

convert

the

decode.

OPERATION

Mode

the

machine

positions,

signals

and

motor

and

three

These

them

into

Tachometers

into

These

hydraulic

machine

reference

and

parts,

into

take

the

mechanical

drive

axis

electrical

convert

power.

for

points,

loading

Figure

see

current

movements.

These

electrical

part

of

motion.

convert

signals

making.

tool

part

1-2.

from

axis

which

characteristics,

programs.

This

These

the

movements

the

signals

parts

control

system

to

includes

1.5.2

Runs

either

work

1.5.3

In

block

1.5.4

The

part

the

this

MDI

end

Run

a

complete

with

MDI

mode

.

MDI

Store

program

of

in

Mode

Automatic

DNC

Mode

the

Store

the

LINK.

(Manual

mode

on

part

part

operator

Mode

allows

a

block-by-block

program

program

or

Block-by-Block

Data

can

the

Input)

input

operator

text

previously

and

basis,

buffer.

mode.

execute

to

and

loaded

input

Run

a

store

into

mode

single

and

each

memory,

will

program

execute

block

also

a

at

1-6

Page 17

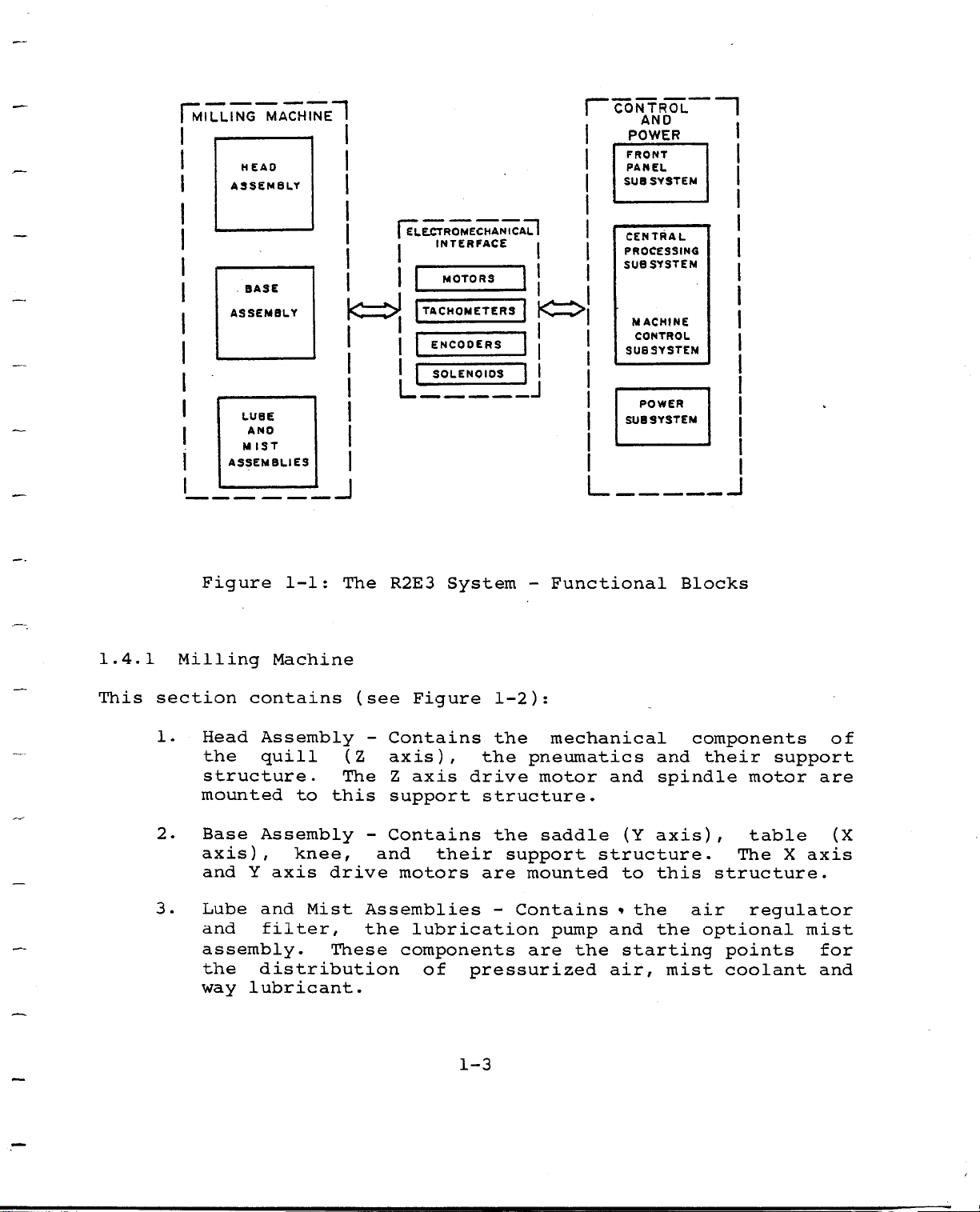

CHAPTER

2

This

with

include

2.1

There

chapter

operator

the

OPERATOR

are

1.

2

3.

4.

four

Front

.

Power

Tape

Lube

OPERATOR'S

describes

controls

location

CONTROLS

groups

Panel

&

Control/Axis

Reader

and

the

and

of

Control

Adapter/

Pneumatic

CONTROLS

keys,

on

the

purpose

operator

Drive

Remote

Control

AND

knobs

milling

of

controls.

INDICATORS

and

each

Serial

machine.

control.

Interface

switches

associated

Descriptions

2-1

Page 18

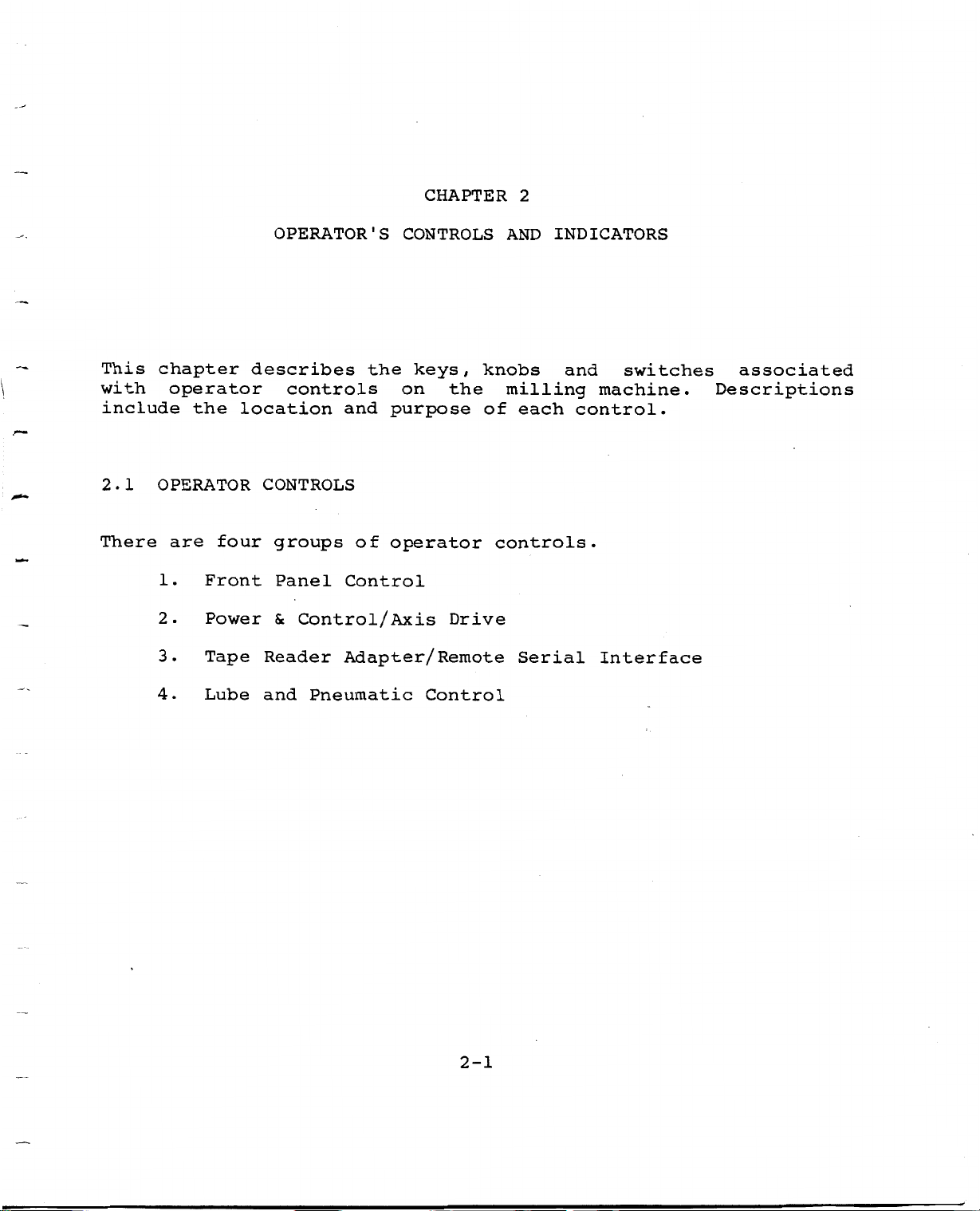

2.1.1

The

Front

control

Panel

Front

Panel

keys

in

the

Control

and

following

operating

switches

groups:

are

color

coded

on

the

The

1.

.

2

.

3

4.

5.

6.

.

7

groups

Machine

EMERGENCY

UP

SET

RUN

Manual

Data

Display

Status

LEDs

mentioned

Controls

STOP

Screen

Input

above

(

MDI

are

)

and

shown

MDI

in

STORE

Figure

2-1.

°£AOCUT

EKCM3CNCY

STOP

|;-i

Figure

i

+

2-1:

COCHWf

I-,

OMU-

i

Iff

Operator's

2-2

'>•

si

''V:

Front

i

Panel

nmwm*

!

i

I

;

nmmm'ÿwuemmr

0

I

J'Ol

9

8

»

*-

,

,

•

!

Page 19

.

2

All

sensitive.

activation

2

FRONT

48

keys

.

PANEL

on

You

the

must

Operator's

apply

NOTE

slight,

Front

but

Panel

firm,

are

pressure

pressure

for

This

keys,

alphanumeric

the

2.2.1

is

24

head

Machine

EMERGENCY

the

color

LED

assembly.

STOP

LCD

Controls

coded

indicators,

screen.

I

£

a

panel

The

P

containing

4

panel

COOCAwT

manual

m

switches

is

48

located

pressure

and

on

a

the

40

sensitive

character

front

4

m

of

Figure

2-2:

Machine

2-3

m

da

|S

Controls

Page 20

Spindle

Controls

.

1

SPINDLE

The

the

pressing

SPINDLE

2.

Simultaneously

moving

or

will

green

safe

LOW

be

OFF:

LED

condition.

SPINDLE

ENABLE:

SPINDLE

GEAR

off)

will

.

will

FOR

be

OFF

pressing

CW

turn

on

when

When

will

ROTATION

the

stop

the

spindle

spindle

the

the

SPINDLE

lever

ON

is

spindle

spindle.

to

(SPINDLE

OFF;

is

ENABLE

either

this

running,

key

HIGH

OFF

is

and

GEAR

LED

3.

SPINDLE

This

and

spindle

speed

assembly,

FOR

a

is

LOW.

selector

rotation

range

see

Sslftfi

SPL

CW

The

lever

Ml

m

ROTATION:

switch

switch

(

CW

(located

Figure

m

wag!

is

or

2-3.

with

used

CCW)

on

gear

two

to

select

conjunction

in

the

right

A

positions:

the

direction

side

of

with

the

HIGH

of

the

head

Figure

With

spindle

combinations,

cause

SPEED

4.

This

*

only

unless

the

and

was

dial

1

the

GEAR

will

counterclockwise

INCREASE/

allows

while

the

stops

key

speed

released.

located

remains

LO/

GEAR

increases

the

spindle

at

2-3:

Speed

SPEED

rotate

HI/SPEED

DECREASE

key

motor

further

the

at

Spindle

the

center

LO

the

in

rotation.

Key:

or

decreases

is

has

action

level

speed

2-4

Range

or

LO,

pressed.

of

Control

GEAR

clockwise

or

been

the

in

reached

is

the

HI/SPEED

its

to

the

It

turned

direction

indicated

head

direction;

complement,

spindle

will

not

on.

when

the

by

assembly,

HI,

other

speed

operate

Releasing

selected,

button

the

speed

the

will

see

Page 21

Figure

2-4.

NOTE

5.

The

information

spindle

AXIS

This

after

time

memory

system.

successful

green

will

S

DRIVE

key

power

and

LED

$

value

ENABLE:

enables

reflect

The

shows

i

m

to

to

no

U

l

program

has

the

error

communications

this

power

the

i

\

ooÿÿ00*”"!

VV

%

no

axis

messages

key

axis

5*

m

part

a

in

power

any

the

internal

LED

but

m

r\

a°r>oo

SKL

and

condition

in

f

/

only

speed.

up,

the

red

test

power

ligsysg

\m

......

life

is

effect

of

when

to

drives.

drives.

the

the

displayed

on

the

displayed

battery

lit

axis

When

or

will

drives.

actual

backed

axis

for

pressed

at

drive

show

this

up

a

The

Feed

Override

.

1

2.

FEED

This

entered

Below

even

OVR

Pressing

at

the

Knob

OVERRIDE:

knob

via

10%,

if

OVERRIDE

ENABLE:

this

immediate

Figure

allows

the

the

part

system

key

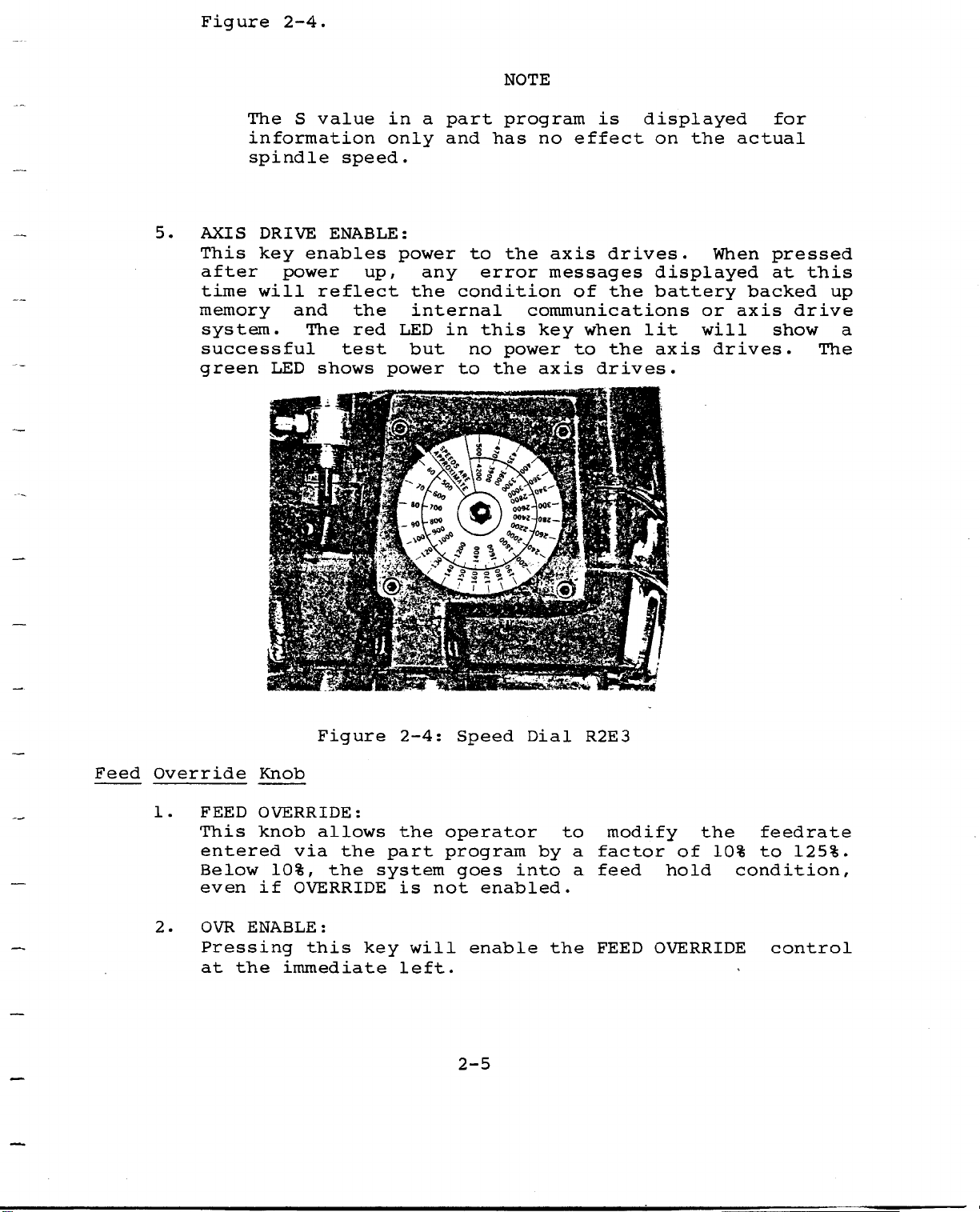

2-4:

the

is

will

left.

Speed

operator

program

goes

not

enable

2-5

into

enabled.

Dial

by

the

to

a

a

R2E3

modify

factor

feed

FEED

the

10%

of

hold

OVERRIDE

feedrate

to

condition,

control

125%.

Page 22

COOLANT

FLOOD

The

available

operations

OVERRIDE

as

affects

and

for

are

In

MIST

the

well

the

active

Set

as

the

keys

machine.

Up,

control

the

operate

with

Block

feedrate.

feedrate.

the

affects

When

spindle.

NOTE

Run

the

and

the

In

optional

in

MDI

rapid

Auto

use

modes,

(LED

traverse

Run

coolant

on)

the

it

the

FEED

rate

only-

devices

coolant

EMERGENCY

This

is

spindle

and

the

When

destroyed,

STOP,

ENABLE

EMERGENCY

first

sequence

This

threatened.

used

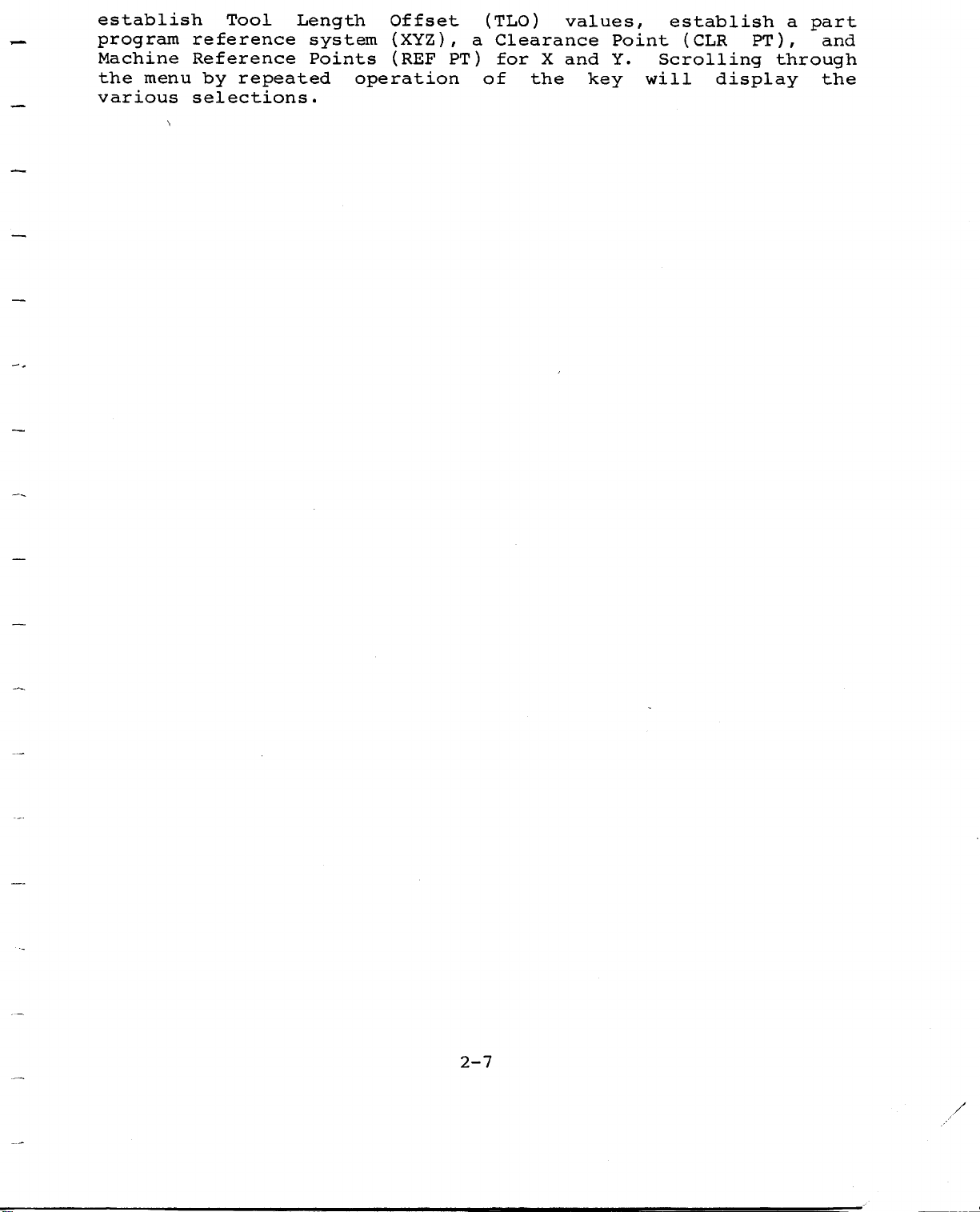

2.2.2

Set

Up

SET

is

milling

includes

diameters,

is

also

paper

data

dark

green

to

activate

tape

from

green

keys

STOP

a

red

motor

system

button

to

intended

machine,

the

axis

used

the

are

but

pull

interrupt

UP

when

or

text

section

the

mushroom

axes

and

set

is

STOP

axis

out

which

is

should

In

in

position

the

returns

normal

axis

for

before

loading

Reference

employing

EZ-LINK

buffer.

of

multifunction

desired

button.

drives.

the

pressed

button,

be

use

of

Points

part

the

function.

System

the

is

each

NOTE

used

use,

motion.

in

the

operation

tool

the

programs

The

Front

and

lost.

and

full

Set

must

When

Program

Start

part

then

axis

only

the

initial

of

length

the

Up

Panel.

be

pressed,

execution

Up

program

To

execute

to

HOLD

the

offset

Clearance

edit

and

keys

pressed

mode.

recover

the

when

button

preparation

part

capability,

clearing

are

Several

and

the

Home

located

more

it

is

TLOs

from

position.

safety

should

program.

values

Point.

part

of

stops

terminated

are

EMERGENCY

AXIS

is

be

of

,

Set

loading

program

in

these

than

the

not

DRIVE

the

This

tool

Up

the

light

once

SET

The

key

SET

key

a

is

multifunction

key

which

allows

the

operator

to

2-6

Page 23

establish

program

Machine

menu

the

various

Tool

reference

Reference

repeated

by

selections.

Length

system

Points

Offset

(XYZ),

(REF

operation

PT

(TLO

a

Clearance

)

for

of

)

the

X

values,

and

key

Point

Y.

establish

(

Scrolling

will

CLR

PT

display

a

part

)

,

through

and

the

2-7

Page 24

OPTION

/OB.

BOPSTOF

i«nwc

3IKCT

MOVE

MOVE

any

Reference

display

new

QUILL

Key

is

keyed

UP

a

multifunction

in

Point.

to

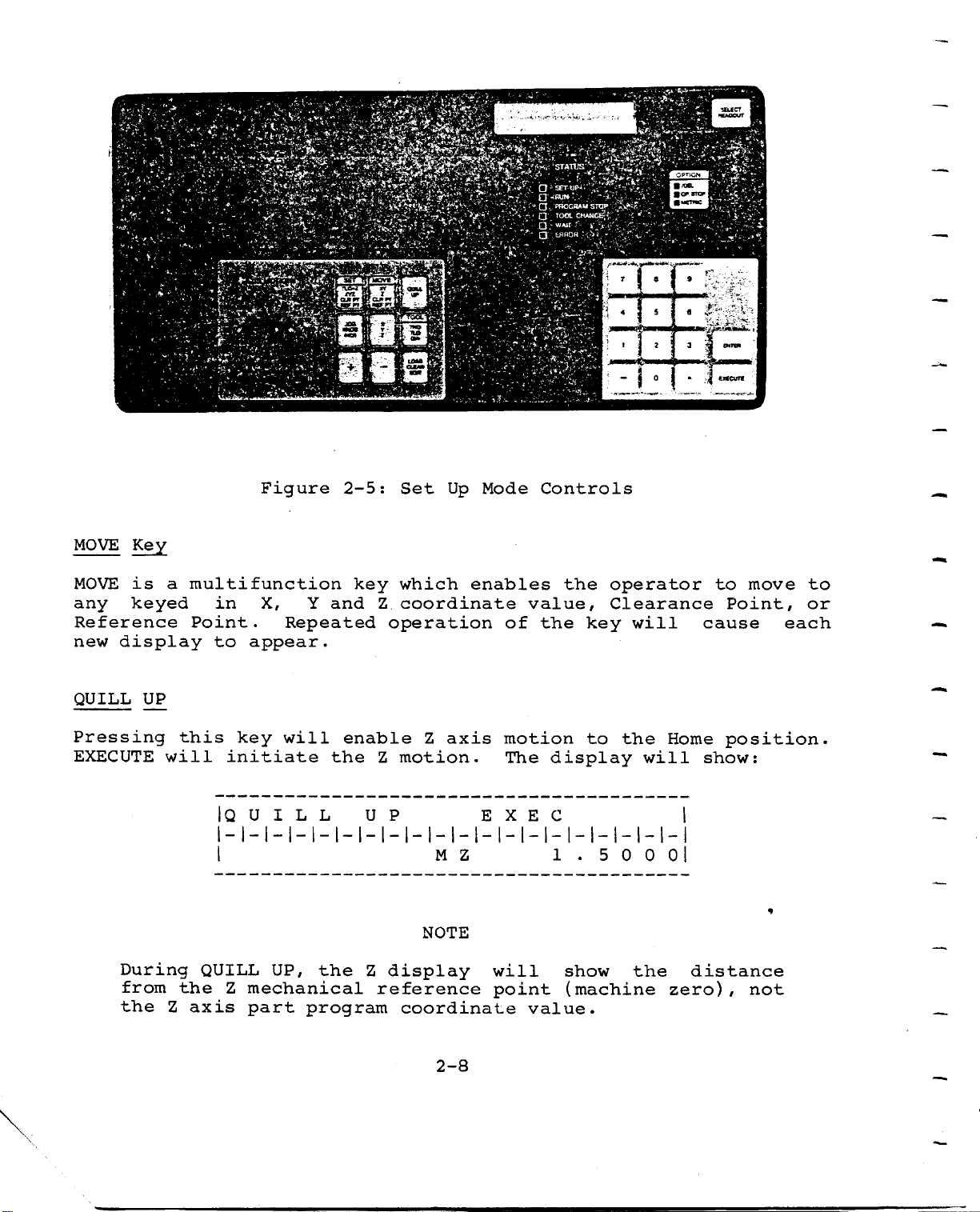

Figure

X,

Repeated

appear.

jfggffir

Y

and

tfr

2-5:

key

mMovgVr

_

Z

operation

i

8ÿ.

Set

which

Up

coordinate

Mode

enables

of

Controls

value,

the

the

i

r~i

1

operator

Clearance

key

i

7

9

I

1

—

5

*

I

iitjSi&mk,',

*

3

an*

0

will

ExCCUTC

to

Point,

cause

move

to

or

each

Pressing

EXECUTE

During

from

the

will

the

Z

this

axis

initiate

|Q

QUILL

Z

key

will

U

I

L L

UP,

mechanical

part

enable

the

the

program

Z

motion.

U

P

display

Z

reference

coordinate

Z

axis

M

NOTE

2-8

Z

motion

The

EXEC

will

point

display

1.50001

show

(machine

value.

to

the

the

will

Home

distance

zero)

position.

show:

,

*

not

Page 25

JOG/KNOB/

INCR

Key

JOG

The

any

to

TOOL

Repeated

24

tools

the

LOAD/CLEAR/

This

clearing

entering

screen

2.2.3

Run

program

can

through

paper

A

key

AXIS

and

desired

Key

pressing

currently

screen

multifunction

system

part

display

RUN

assumes

exists,

be

entered

the

tape

together

display

EDIT

MOTION

location

program

advances

that

from

EZ-CAM

reader

Key

a

it

of

in

through

key

data

part

will

via

may

with

knob),

the

the

will

text.

remote

the

allows

increments

in

TOOL

tool

T,

enable

from

through

program

necessary

be

serial

be

used

associated

key

buffer.

TLO

various

Each

LOAD,

exists

computer

Port

via

the

will

and

time

operator

as

scroll

DIA

loading

buffers,

the

CLEAR

in

to

terminals,

or

B

the

key

small

The

load

Port

port

ENTER

inputs

key

or

the

functions

to

as

through

for

part

and

is

EDIT.

text

one.

using

A

marked

move

.0001

key

each

program

pressed

buffer.

Part

DNC

C.

(XYZ,

each

inch/

each

will

editing

programs

LINK,

the

"+"

axis

of

scroll

tool.

text,

If

Editor.

,

jog.

the

or

the

no

or

During

program

part

screen

LCD

part

block

program

program

coordinates.

will

Run,

information.

on.

be

the

Run

LCD

The

LED

screen

axis

in

the

will

position

status

display

data

column

the

will

under

current

be

in

the

2-9

Page 26

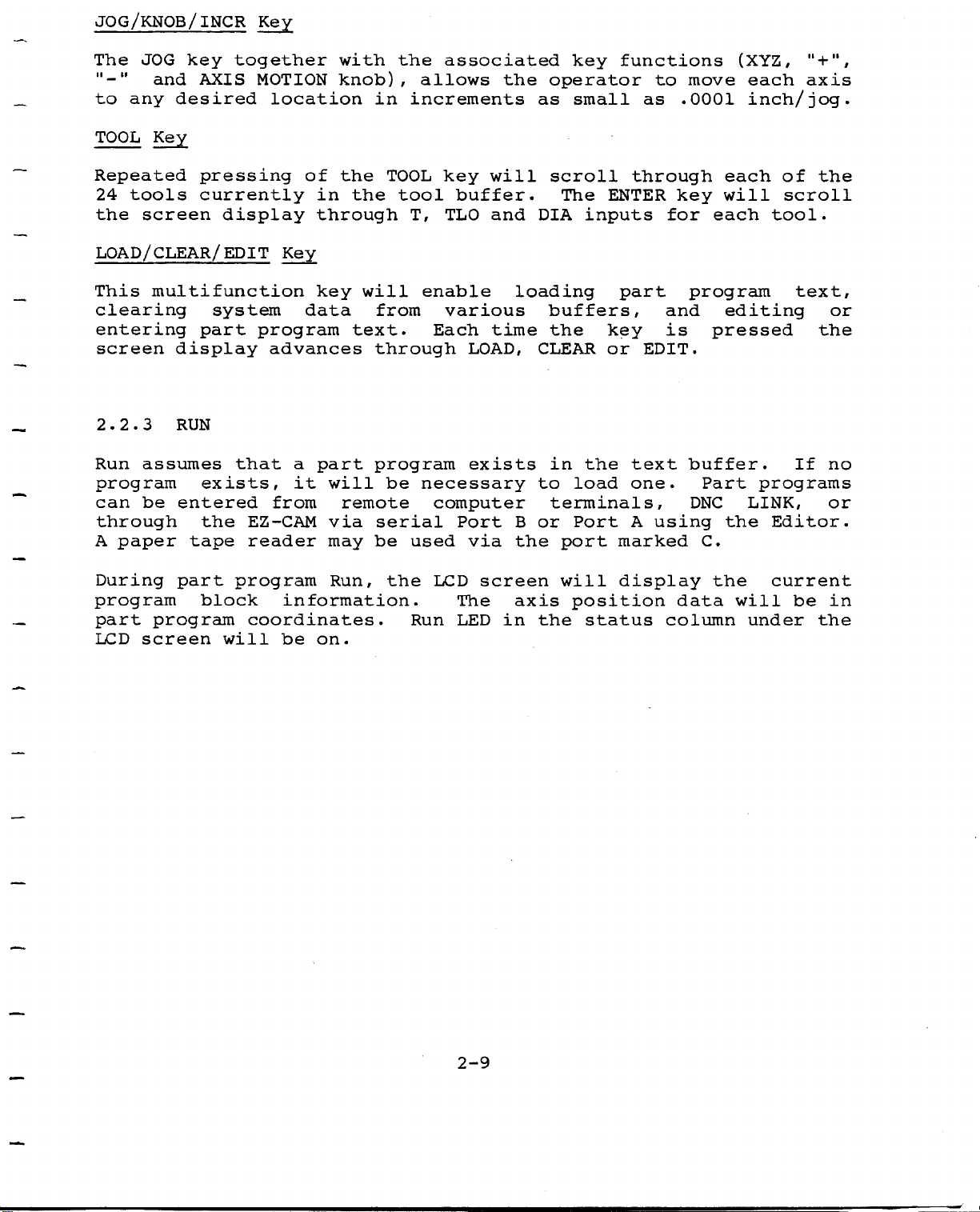

'

V

&8MB

m

Y&

jl

ffi

'•41

'ÿ

r

COOLANT

*

koQO-.

a

am

SPEED

5W*ttX

ysr-.

Cf*

Wtf

*

rr.

*VJW

OPTION

I'OCL

tit

•UCTMC

_>r*y

StljECT

HCADOUT

*uto

"LOCK

8

Y

33

«U

NO

HOLD

RON

XY2

Si

II

II

£>**,-

SELECT

During

are

positions

axes

RESET

This

initialize

first

the

READOUT

part

being

or

the

PROGRAM

will

data

program

displayed

displayed

axis

Z

Key

return

run

Key

the

registers

block.

Figure

.

execution

on

.

part

the

the

2-6:

and

SELECT

screen

program

and

Run

when

to

to

display

idt:

jf

!ÿ}

—

1-1-

part

toggle

the

the

Keys

beginning

Mode

READOUT

WXN*

&

g*

program

will

between

first

rffe

•

T

1

2

•

20

•

Hi

|

3

•

1—1

I

coordinates

cause

the

of

characters

the

-

X

the

and

axis

Y

text,

in

AUTO/

Pressing

BLOCK

either

block-by-block

the

AUTO,

Key

AUTO/

BLOCK

automatic

execution

key

execution

of

will

a

part

2-10

enable

program.

of

the

a

part

system

program

to

or

run

BLOCK,

in

Page 27

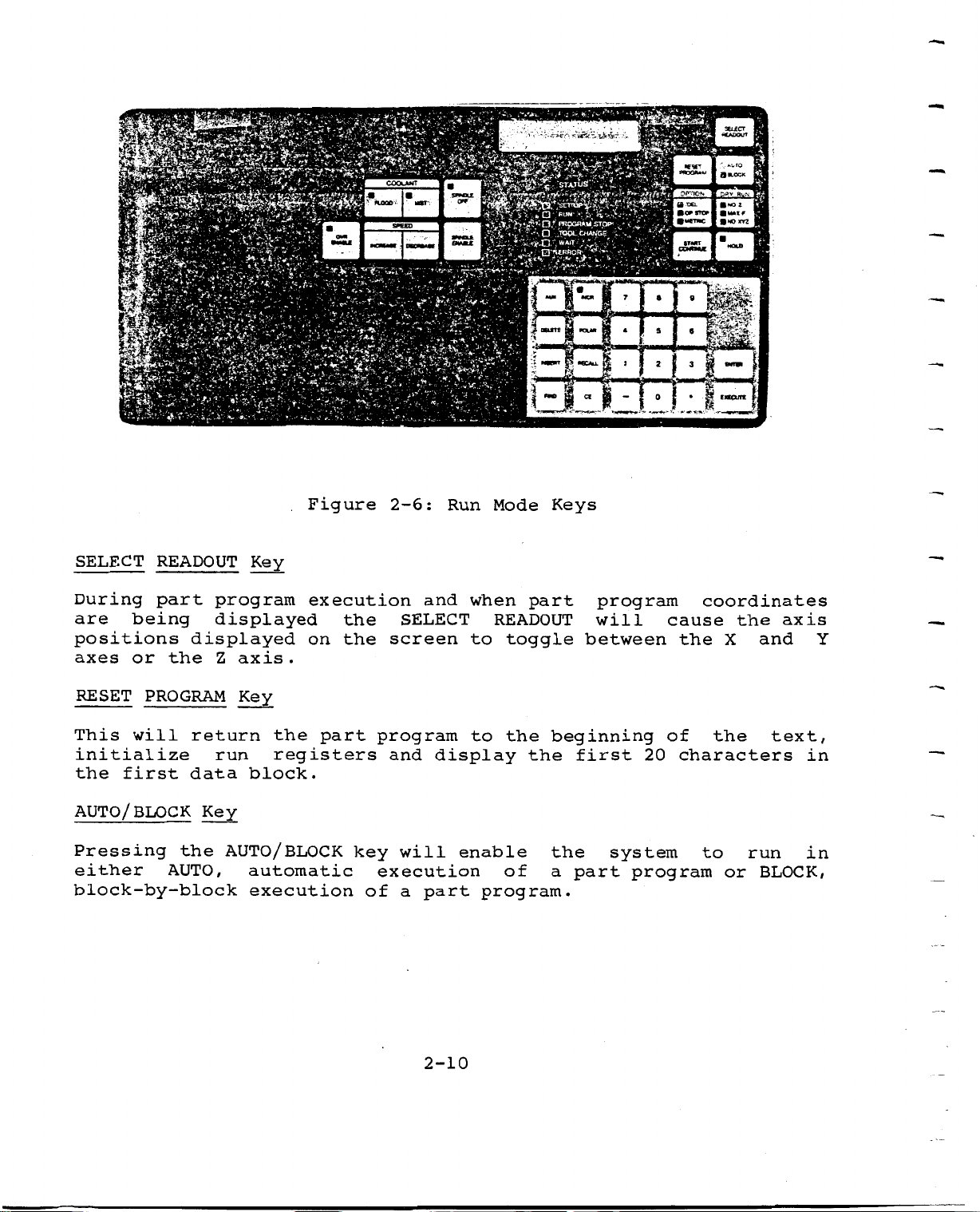

2.2.4

Special

Operations

OPTION

OPTION

options

BAUD.

START

START

AUTO/

/CONTINUE

begins

BLOCK

sequence

interruption

It

continue

HOLD

This

key

without

a

to

smooth

Key

is

is

a

multifunction

such

operation

key)

number

such

not

.

stops

loss

stop.

/DEL,

as

Key

either

.

as

necessary

part

of

the

of

at

CONTINUE

PROGRAM

program

program

key

OP.

the

to

which

STOP,

part

top

the

STOP

NOTE

press

execution

position.

allows

METRIC,

program

of

resumes

system

or

this

the

and

the

BOSS

(after

text,

execution

HOLD.

key

interrupts

All

operator

twice

axes

8

i/BOSS

enabling

at

or

will

a

after

to

axis

decelerate

to

choose

4-7,

by

specified

use

motion

and

the

an

In

inches

active

START/

PPRINT

There

represent

part

display

quotation

display

comment

RAPID

is

no

program

will

the

is

TRAVERSE

after

registers

CONTINUE.

key

the

labeled

effect

(MOO,

exhibit

marks

(

first

shown

INSERT

HOLD

M01

1

below:

.500

)

(GO),

,

a

•

40

pressed.

is

are

PPRINT,

a

of

)

M06

comment

Comments

characters.

D

NOTE

motion

not

program

.

When

statement

TOOL

A

I

may

The

lost.

but

beyond

stop

this

END

continue

unused

the

40

An

1

continue,

To

term

command

command

from

characters

example

=

MIL

portion

the

up

is

embedded

reached,

is

program

of

L|

to

of

press

included

will

possible

a

0.2

the

in

between

only

to

the

the

2-11

Page 28

NOTE

When

have

used

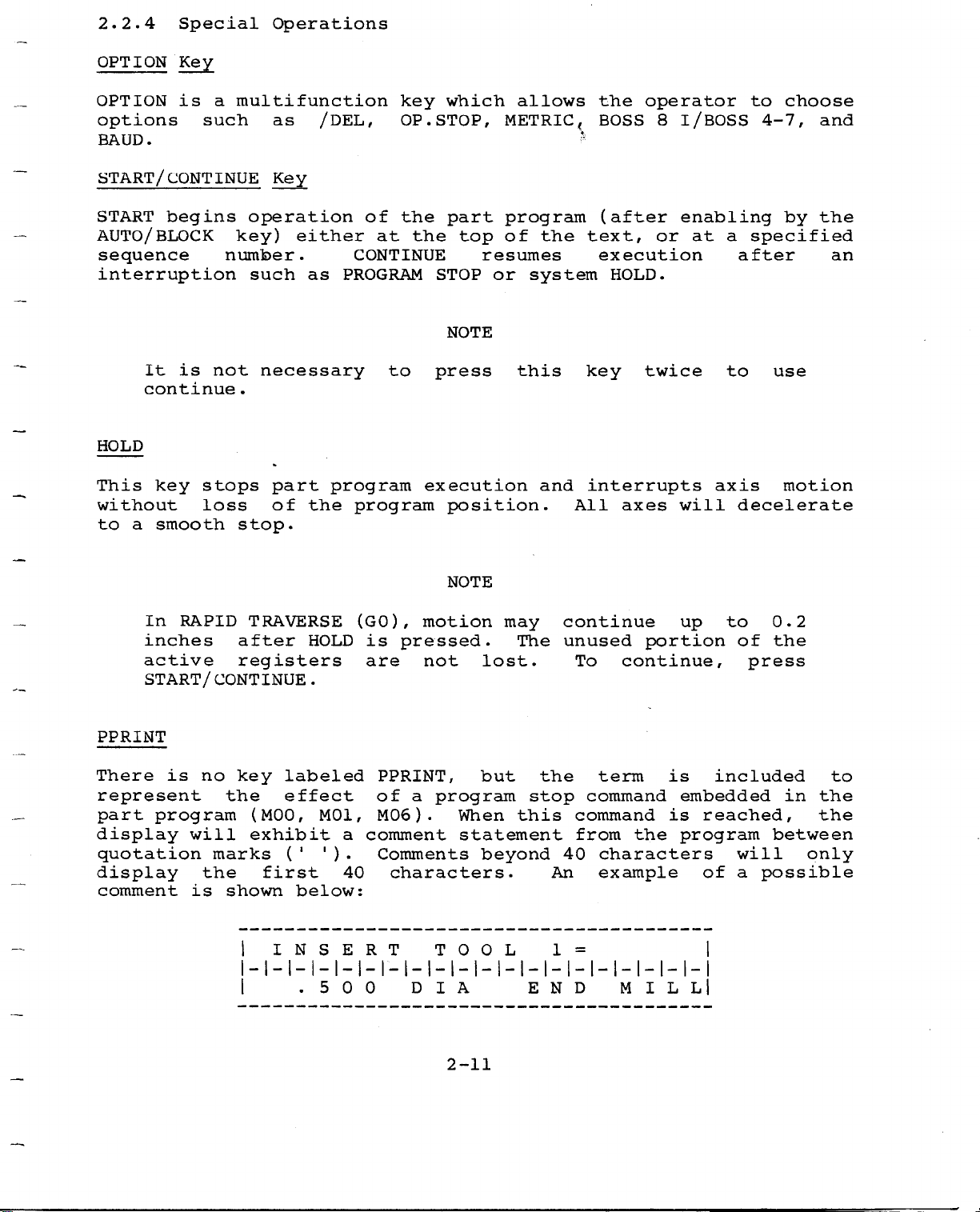

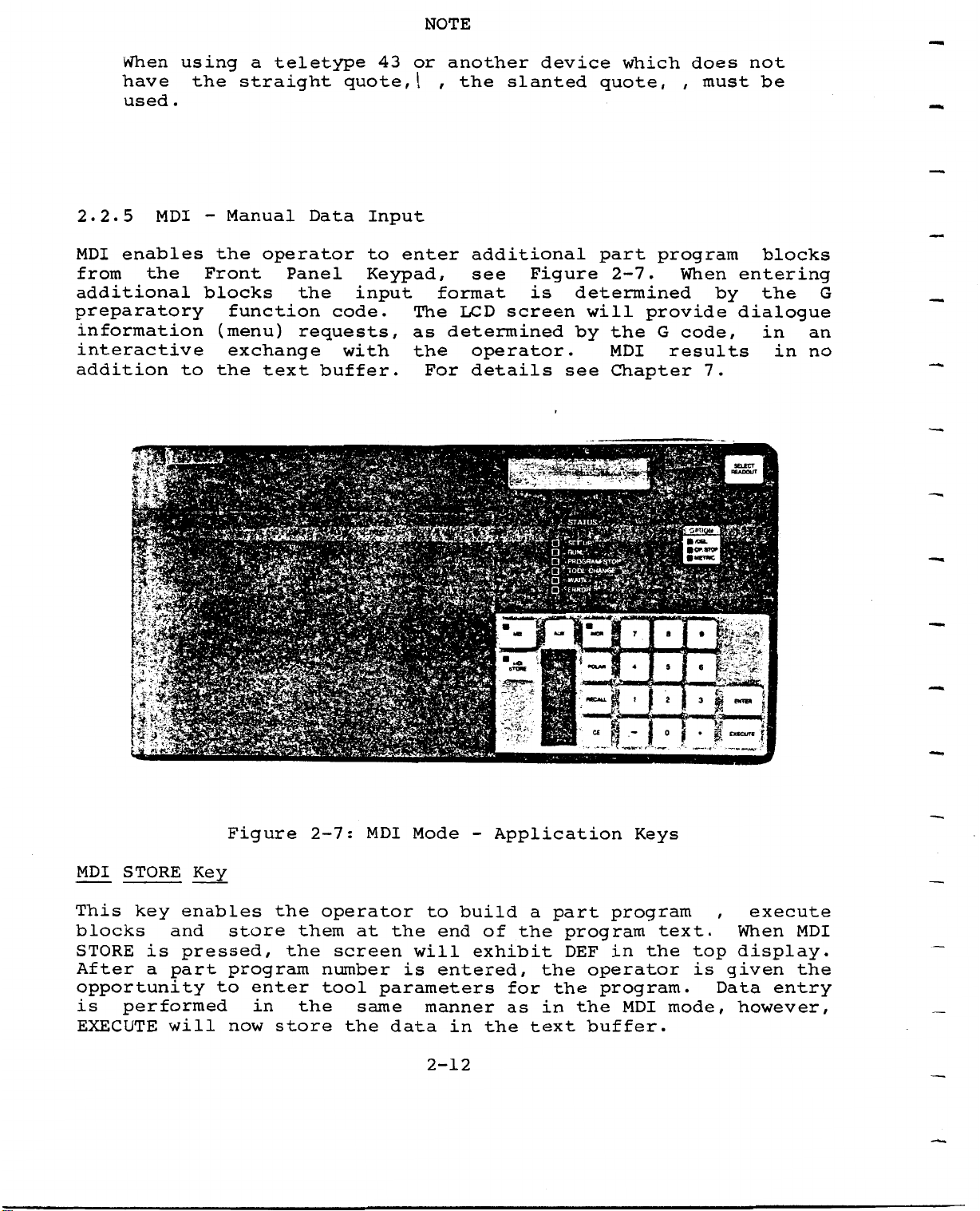

2.2.5

enables

MDI

from

additional

preparatory

information

interactive

addition

the

tm

MDI

!

using

.

to

'

the

-

Front

blocks

a

straight

Manual

the

function

(menu)

exchange

the

teletype

operator

Panel

the

requests,

text

m

Data

code.

buffer.

quote,

Input

to

Keypad,

input

with

43

or

I

enter

The

as

the

For

another

,

the

additional

see

format

LCD

determined

operator.

details

device

slanted

Figure

is

screen

quote,

part

2-7.

determined

will

by

the

MDI

Chapter

see

which

provide

does

,

must

program

When

code,

G

results

7.

entering

by

dialogue

S£L£CT

not

be

blocks

the

in

in

G

an

no

ifp

It

m

la

STORE

MDI

This

blocks

STORE

After

opportunity

is

EXECUTE

key

is

a

performed

Key

enables

and

pressed,

part

will

Figure

store

program

enter

to

in

now

m

sm

nr

M

the

the

store

2-7:

them

the

operator

at

screen

number

tool

same

the

MDI

Mode

the

will

is

parameters

data

-

to

build

end

entered,

manner

in

sram

Application

of

exhibit

for

as

the

the

*

a

the

in

text

4

«OLM

•—.tv.

tr

•

»

/JuTiZI

Keys

part

the

program

program

in

DEF

operator

program.

the

buffer.

text.

the

MDI

JOFSTC**

*

i

mi

«

I

£

S*

£«CUTI

,

top

given

is

Data

mode,

i

5

MB

i

I

.

T

execute

When

display.

entry

however,

MDI

the

2-12

Page 29

Quick

Edit.

Keys

FIND

INSERT

DELETE

RECALL

AUX

-

details

For

INCR

Use

of

specify

to

moves.

cause

go

on.

without

status

the

When

change

addition

-

To

To

search

To

-

To

-

To

-

enable

this

When

G91

a

The

modifying

not

enable

delete

backup

see

key

INCR

of

the

the

the

in

to

to

the

for

the

a

the

MDI

entry

Section

MDI,

in

incremental

LED

inserted

be

key

the

machine.

MDI,

current

part

the

N,

part

in

will

MDI

or

T

entry

edit

of

5.2.

MDI

the

also

part

STORE,

operation

program.

(part

of

program

pointer

S,

STORE,

dimensioning

INCR

in

program

NOTE

new

T

the

work

or

program

text

block

by

or

M

or

key

is

part

independently

buffer.

INSERT

of

one

codes

INSERT

off,

program

the

the

number)

block

allows

system

pressing

The

INCR

system

for

and

of

LED

without

the

key

future

the

the

will

operator

INCR

LED

MDI

will

axis

will

will

mode

reflect

any

POLAR

POLAR

where

axis,

available

"0

-

Numerals

(Minus

"

Minus

this

negative

and

9",

sign

sign

input

R

is

I

in

"

as

Sign)

is

move.

enables

the

&

are

J

MDI,

(Decimal)

needed

required

assumes

replacement

polar

the

Store,

MDI

for

a

radius,

pole

data

for

positive

centers

or

input.

entering

of

A

is

Insert

value.

X,

angular

input

Y

.

The

mode

negative

It

with

distance

POLAR

only.

data,

is

not

R,

function

used

A,

from

absence

for

I,

the

J,

+X

is

of

a

JOG

2-13

Page 30

2.2.6

Status

Indicators

(LED)

current

The

provided

2.3

The

Power

machine,

the

fusible

Main

facing

voltage

voltages

2.3.1

by

POWER

Disconnect

the

is

is

Spindle

status,

24

indicator

&

CONTROL/

Equipment

and

contains

disconnect

Power

volts

600

available

208

230

380

420

460

Motor

or

AXIS

Enclosure

switch

Equipment

AC.

in

VAC

VAC

VAC

VAC

VAC

Protection

mode

lamps.

DRIVE

the

switch.

located

The

kit

50/60

50/60

50/60

50/60

50/60

condition,

is

single

All

Enclosure.

option

form

Hz

Hz

Hz

Hz

Hz

mounted

electrical

incoming

on

of

through

of

the

The

selecting

the

machine

on

the

power

power

upper

maximum

Bridgeport

right

5

control

rear

connection

enters

corner

allowable

incoming

as

of

at

follows:

is

the

to

the

when

line

line

spindle

The

220,

against

becomes

stopping

before

RESETTING

TECHNICIAN,

JOB.

TO

2.3.2

Five

Enclosure.

located

cabinet,

230

the

HEED

Auxiliary

power

motor

or

excessive

excessive,

current

spindle

SERIOUS

THIS

receptacles

They

on

the

see

440

THE

right

Figure

a

is

3

VAC.

currents.

these

to

the

motor

HEATERS

LEVEL

PERSONAL

WARNING.

Power

are

II.

Outlets

found

side

2-8.

phase

Three

spindle.

can

REQUIRES

INJURY

are

directly

of

*

HP

2

heaters

the

If

overload

These

be

restarted.

WARNING

OPERATORS

COULD

provided

cabinet,

the

Correct

AC

protect

current

heaters

QUALIFIED

A

SHOULD

above

as

follows:

motor.

heaters

RESULT

on

the

the

the

It

spindle

the

drawn

by

will

must

MAINTENANCE

NOT

ATTEMPT

FROM

Power

communication

operator

operates

the

shut

be

THIS

FAILURE

Equipment

facing

on

motors

load

down,

reset

ports

the

2-14

Page 31

o

o

o

Dual

4A.

power

and

flood

purchased

Dual

a

standard

When

will

button

Another

option

is

It

receptacles

It

to

the

off

when

coolant

receptacles

the

Main

be

on

is

pushed.

receptacle

when

also

is

for

and

this

fused

are

interlocked

receptacle

spindle

pump

the

are

machine

Disconnect

are

accessory

at

powered

is

when

machine.

powered

light,

NOT

is

available

115/1/60.

with

on

is

off.

switch

affected

is

with

the

when

This

this

with

a

purchased

115/1/60

spindle

the

is

accessory

115/1/60

Tape

on,

is

when

for

Reader

these

the

the

each

motor

spindle

used

and

EMERGENCY

spray

for

fused

drive

to

has

fused

or

EZ-FILE.

receptacles

machine.

the

so

that

is

been

STOP

coolant

at

on,

the

for

2.4

The

PORT

Communications

side

This

panel

interfaces:

PORT

TTY)

RS-232

PORT

A

B

programs.

this

control)

is

Equipment.

remote

supported

Appendix

PORT

C

of

provides

for

are

is

and

C

is

A/PORT

the

provided

for

provided

Power

is

configured

part

provided

There

interface,

Bridgeport's

by

RS-232

pin-outs.

the

both

B

INTERFACE

Panel,

Control

interface

program

on

for

are

EZ-CAM

and

for

see

to

editing.

this

remote

two

RS-491

EZ-LINK

RS-422

the

SUBSYSTEM

Figure

Panel

accept

for

port,

loading

communication

level

and

EZ-FILE

are

Remex

paper

2-8,

is

(operator

three

types

communications

Both

see

2

protocol.

Appendix

and

(EIA

20

down

protocols

standard

systems,

both

available

tape

located

facing

ma

C

The

reader.

the

communication

of

terminal

current

for

loading

for

EZ-LINK

see

on

on

the

machine).

loop

pin-outs.

of

provided

numerical

protocol

Optional

Port

(CRT

B,

left

or

and

part

for

see

2-15

Page 32

.-iÿi

SMfe*

a

-ÿalrSSgSBfe

-<:

rg$j

iÿsii

2i

31ÿ1

JKJ

_

m

'$ÿ1

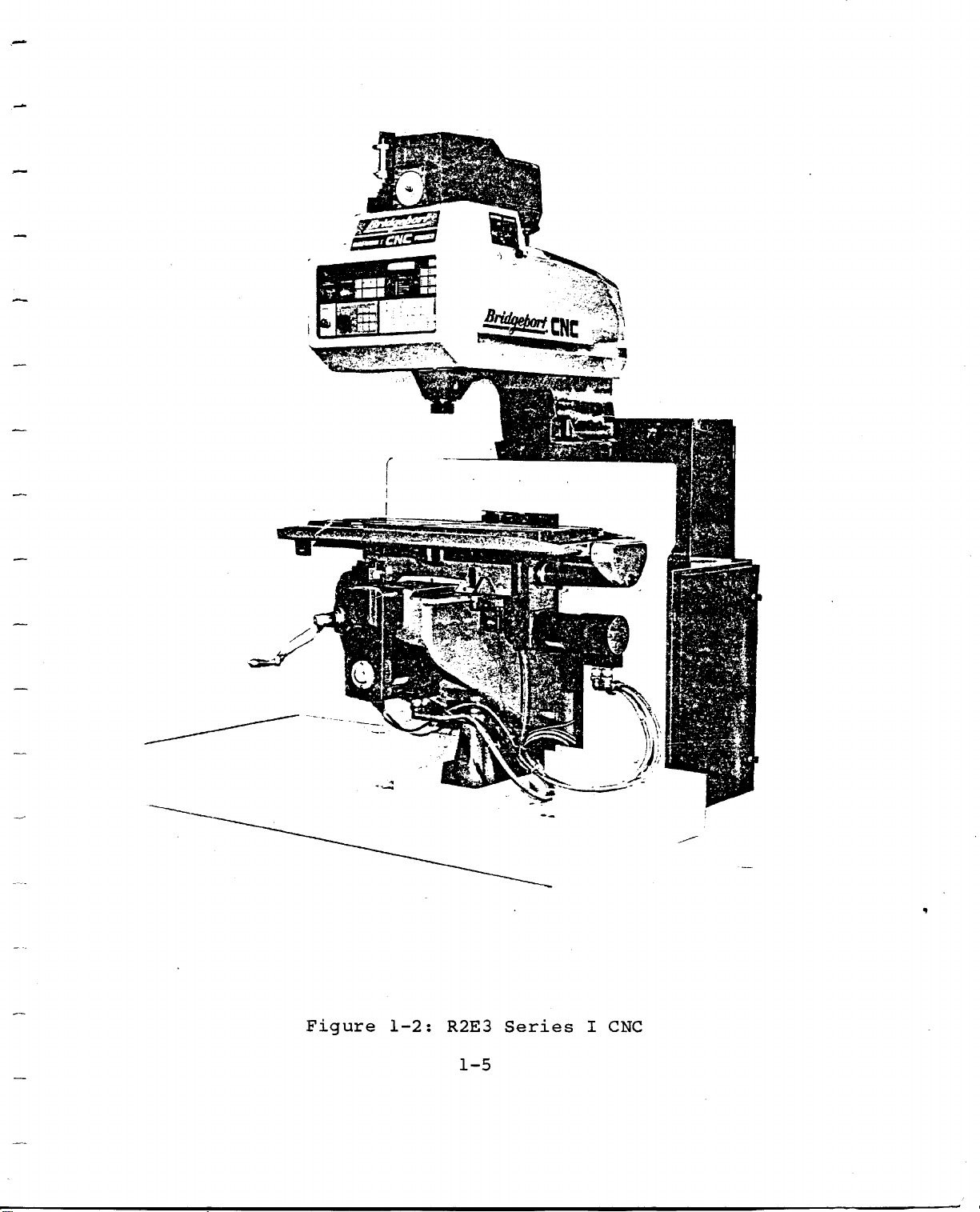

Figure

2.5

Pressing

start

2.6

The

an

machine),

filling

adjustments

RESET

up.

LUBE

lubrication

enclosure

2-8:

SWITCH

the

RESET

Refer

&

PNEUMATIC

see

oil

.

Tape

and

on

Figure

reservoir

switch

to

the

Reader

Section

CONTROL

pneumatic

left

2-9.

Input

will

3.6.2.

The

levels,

Port

cause

SUBSYSTEM

controls,

side

operator

the

of

&

the

air

the

R2E3

are

is

Serial

located

column

limited

pressure

to

Interfaces

go

into

together

(operator

to

checking,

checks

system

in

facing

and

2-16

Page 33

v>r>-

-j

,.>i—

'

a

;

>&;ÿ

:V-*:

-

rq

-ÿ

;

I

I

A1

v

H

*-VK

-

y

2.6.1

The

automatic

mechanical

this

inspect

refill

system

Lube

the

if

Assembly

surfaces

is

level

the

Figure

lubricating

the

Bijur

of

level

is

<S>

s:

2-9:

in

oil

H

low.

Lube

system

the

tank.

(Sunoco

©

Pneumatic

&

distributes

machine.

The

Waylube

d

•User

tm

Bsa

operator

&

Controls

The

#1180

oil

primary

should

or

all

to

component

periodically

equivalent)

sliding

of

and

An

interlock

SPINDLE

Low

prevent

ENABLE

oil

level

the

is

built

from

spindle

will

into

working

not

from

the

if

stop

lubricator

the

NOTE

being

2-17

low.

but

next

prevent

job.

the

will

which

oil

a

job

started

in

level

progress

for

will

is

too

the

Page 34

2.6.2

Pneumatic

Assembly-

Supply

pressure

Figure

air

reservoirs

glass

marks

The

pressure

pressure

2-9.

filter;

should

.

on

followed

knurled

the

The

to

of

the

be

screw

the

the

indicator

inlet

checked

side

pressure

the

by

over

desired

pneumatic

of

air

daily

the

level.

should

the

indicator

lubricator.

NOTE

air

system

be

pressure

and

filter

is

maintained

regulator

is

between

The

kept

between

will

100

oil

adjust

psi.

at

the

level

the

psi,

80

contains

two

in

indicated

the

air

Normal

see

an

glass

this

2-18

Page 35

CHAPTER

3

.

3

1

four

3.1.1

Before

the

following

following

The

After

operation

START

successful

modes

Prestart

attempting

1.

2.

3.

UP

.

Level

Position

other

Air

procedure

operation

of

Considerations

to

conditions.

of

lubricating

of

parts

pressure

SYSTEM

is

completion

start

X,

Y,

left

level

START

necessary

may

the

oil

&

Z

on

the

adjust

-

UP

/SHUTDOWN

of

the

be

machine,

-

axes

table.

to

system

entered

refill

with

to

start

make

if

respect

nominal

up

start

to

a

low.

the

careful

to

80

up,

begin

psi

R2E3

one

check

fixtures

.

System.

of

the

machine

of

or

3.1.2

Power

power

To

position

the

On

Power

System

up

.

Equipment

the

This

Start

system

switch

Up

Procedure

move

Enclosure

is

the

located

.

MAIN

3-1

DISCONNECT

the

upper

on

switch

right

to

corner

the

ON

of

Page 36

Initial

Condition

There

will

message

During

extensive

successfully

displayed

be

There

corner

problem

When

the

AXIS

following

is

this

be

displayed:

I

|W

period

internal

passes

and

may

be

of

in

DRIVE

:

a

system

A

the

the

ENABLE

I

the

an

T

all

the

red

error

LCD.

system.

self

diagnostic

diagnostic

LEDs

test,

LED

message

This

is

pressed,

the

in

NOTE

are

AXIS

will

illuminated

check.

message

DRIVE

in

alert

the

test,

the

LCD

When

ENABLE

ENABLE

upper

operator

the

screen

as

the

as

AXIS

will

left

part

the

will

following

DRIVES

go

on.

hand

any

of

exhibit

of

system

will

an

EXECUTE

1.

2.

The

AXIS

applied

machine

will

Quill

The

sequence

DRIVE

to

is

in

IMOV

initiate

moves

X

and

ENABLE

the

the

.

Y

axis

Set

ZXY

a

up

axes

green

Up

machine

to

Home

will

drives.

mode.

HOME

LED

homing

position.

move

will

The

sequence:

to

indicate

LED

the

in

X

>

E

E

Cl

I

power

UP

will

positions

has

show

in

been

the

Home

SET

3-2

Page 37

At

the

conclusion

of

this

sequence,

the

display

will

show:

If

the

the

they

LCD

Axis

an

If

the

DRIVE

of

quill

system

bottom

will

will

and

a

If

system

continue

Limit

axis

red

ENABLE

axis

(Z),

be

CRC

LED

limit

|B

(

I

left

displayed

only

prom

will

with

Check

limit

will

is

and

S

0

C

detects

of

has

pressed

the

S

)

1

9

the

displayed

be

error

display

the

been

go

switches,

screen

8

8

a

dead

LCD.

as

is

power

on

the

I

3

error

found

the

up

exceeded

the

in

internal

located

will

TEXTRON

battery,

other

If

codes

after

NOTE

during

error

sequence

AXIS

show:

BAT

system

on

the

message,

.

or

EMERGENCY

DRIVE

logic

in

will

the

system

the

the

INC.

be

faults

lower

has

selftests,

CRC

STOP

ENABLE.

will

check

and

X

and

Y

I

displayed

are

portion

been

will

is

When

the

axes,

detected

of

homed.

the

not

active,

the

status

and

on

the

AXIS

the

The

drive

red

has

automatically

will

appear:

The

AXIS

been

operator

l>

lAXI

DRIVE

disabled.

set

0

IJ

|A

x

ENABLE

S

ENABLE

the

must

G

i

s

LIMIT

LED

Pressing

system

determine

LIMIT

AXIS

indicates

the

in

NOTE

which

X

3-3

AXIS

the

Jog

axis

l-l-l-l-M-l-l

D

R

that

DRIVE

submode.

is

V

I

power

on

S|

E

to

ENABLE

The

a

limit.

the

key

following

f

axis

will

Page 38

The

limit

normal

JOG

"+"

switch.

travel

or

>

I

range

E

keys

When

N

A

the

B

can

the

display

L

E

then

slide

will

AXIS

CAUTION

be

has

used

show:

to

been

DRIVES

move

positioned

away

from

within

the

the

To

correct

active

This

lost

machine

display

the

validate

3.2

3.2.1

Immediately

be

TLO

LED

the

CONDITIONS

Tl.

.

The

indicator

system

1.

guard

coordinate

all

Default

When

system

BOSS

against

jog

until

after

is

forced

relationship

previously

FOLLOWING

Condition

following

quill

the

will

will

is:

8

I

damage

direction.

Home

successful

then

come

Operation

-

the

on

stored

goes

to

next

the

between

position.

START

"Home",

go

on.

the

Software

homing

operator

part

coordinates.

UP

start

into

The

Mode

the

start

machine

travel

operation.

because

program

This

up,

Z

will

Set

up

tool,

coordinates

operation

the

set

be

Up

mode

(default)

limits

the

active

select

equal

and

are

system

and

will

tool

to

the

condition

the

not

the

SET

has

the

now

will

Tl

UP

of

8.

3.

4.

6.

2.

5.

7.

GO

G17

G30

G40

G44

G70

G72

-

-

-

-

-

Rapid

X,

Mirror

Diameter

Constant

Inch

Trans

Traverse

Plane

Y

Data

formation

Circular

Image

-

Compensation

Surface

Input

OFF

3-4

Interpolation

Feed

OFF

OFF

-

Control

OFF

Page 39

9.

G75

Multiquadrant

-

Input

3.2.2

During

error

10.

11.

Self

execution

conditions:

o

o

o

o

o

o

o

G90

DNC

Part

Cutter

Illegal

-

-

Test

program

Absolute

OFF

Diagnostic

of

Compensation

interpolation

Communications

System

Front

Auxiliary

fault

Panel

function

Programming

programs,

data

fault

check

fault

Description

the

input

calculations

command

check

check

controller

following

fault

checks

check

are

made

for

These

code

3.2.3

Errors

screen

messages

Hex

A.

o

o

o

checks

is

Self

which

code

Axis

Tool

Axis

displayed

Test

as

a

and

to

drive

table

overtravel

are

are

4

detailed

a

the

fault

or

not

on

Error

found

character

specific

part

apparent

LCD

the

Messages

by

explanation

check

program

to

during

software

Hex

error

memory

the

the

checking

code.

of

messages

operator

wait

A

the

is

fault

unless

message.

are

displayed

listing

relationship

discussed

check

of

an

the

in

error

on

error

of

Appendix

the

the

3-5

Page 40

3.3

NORMAL

SHUTDOWN

PROCEDURES

To

shutdown

following

3.4

This

activated,

Program

start

The

position

axis

overnight,

procedure:

o

Select

o

Turn

Switch

o

EMERGENCY

should

be

it

execution

up

when

part

program

positions

Block

spindle

machine

STOP

used

deenergizes

is

power

is

lost.

after

or

mode

OFF.

Main

only

terminated

is

restored

and

for

an

or

wait

Disconnect

when

spindle

the

and

to

NOTE

TLO/DIA

will

It

EMERGENCY

an

extended

for

safety

the

spindle

data

necessary

be

a

to

motor

system

are

STOP,

period

tool

not

OFF.

is

and

see

change

threatened.

and

reverts

axes

lost,

to

section

time,

of

block.

axes

the

drives.

but

reestablish

to

axis

4.2.

use

When

drives.

system

the

.

5

3

Loss

cycle)

system

.

6

3

There

POWER

power