bridgeport M-156 User Manual

*-156

MILLING,

STUDENT

BRIDGEPORT

DRILLING

JUNE

MANUAL

FDR

THE

$

1981

CNC

GORING

MACHINES

This

manual

and

is

use,

prohibited

This

the

reproduction,

manual

requirements

CMr?

Mo.

-IQiMOJ

made

provides

available

without

carries

or

written

additional

the

of

information

to

you

dissemina

permission.

preface

for

safety

and

which

the

use

tion

of

the

Bridgeport

is

proprietary

and

this

information

precautions

entire

Macn

BRIDGEPORT

to

maintenance

and

procedures

of

for

any

warnings.

contained

our

products.

other

Read

TEXTRON

i

es

n

Di

o

si

vi

n

of

Text

ron

tnc

.

MA'CHTNES

purpose

and

observe

this

in

Any

is

manual.

id

G.'IH

0.(3.

P.

Day

COMPENDIUM

(

1

Day

Day

Day

Day

Machine

Machine

Setting

Film

Basic

Introduction

Basic

Speeds,

Drilling

P

ract

Editor

2

Revi

Explain

Canned

Polar

Practice

safety

-

rectangular

miscellaneous

ce

i

—

ew

cycles

coordinate

3

Review

Basic

Mul

Deceleration

Prorated

Practice

Circular

ti

-Quadrant

4

Review

Loops

Multi-hole

Cutter

Practice

£

compensation

5

Review

Polar

Transformation

Plant

of

coordinate

Tour

description--

operations

£

p

rog

length

in

to

£

Boring

rams

Tool

Feeds

M-128

"G"

code

--

programs

Interpolation

Circular

override

Feedrates

programs

Macros

program

week

(Repetitive

drilling

(Rotation

--

offsets

milling,

coordinate

"G"

codes

functions

Tool

selection

cycles

4-5

system

M-129

drilling

-

M-129

routines

-

milling

M-128

M-128

drilling

(

(G8O-G89,

M-129

—

5"7

—

Interpolation

(G99)

5~

programming)

M-129

-

M-129

Scaling

£

1-1,

2-1,

M-128

system

GO,

(M2,

—

M-129

(G74)

“

M-129

34

-

M-129

9“3

3-1

—

G90,

M-129

5-1

9_38

3~5

boring

and

--

M-129

G91

M6)

--

Dwell)

G04

9-37

M-129

(G75)

5"24

5~20

G73)

,

G92,

M-129

5~33

5_3

-

M-129

-

M-129

4-1

--

“

M-129

G70,

5-9

M-129

6-1

9-42

G71)—

5~11

9“2

M-129

5-1

Notes

.

1

the

2.

3-

and

be

Hands

end

of

All

students

Familiarity

a

calculator

brought

on

each

with

machine

day,

will

with

with

you.

and

plus

be

right

trig

editor

two

responsible

angle

functions,

time

evenings

will

per

homework

for

trigonometry

if

available,

be

week.

available

nightly.

expected,

is

at

I

should

TJ

X

o

Q

X

>

2

2

z

o

>

D

V)

PROGRAMMING

AIDS

IiridtK>/>orf

Bridgeport

Machines

TEXTRON

DivisionofTextron

Inc

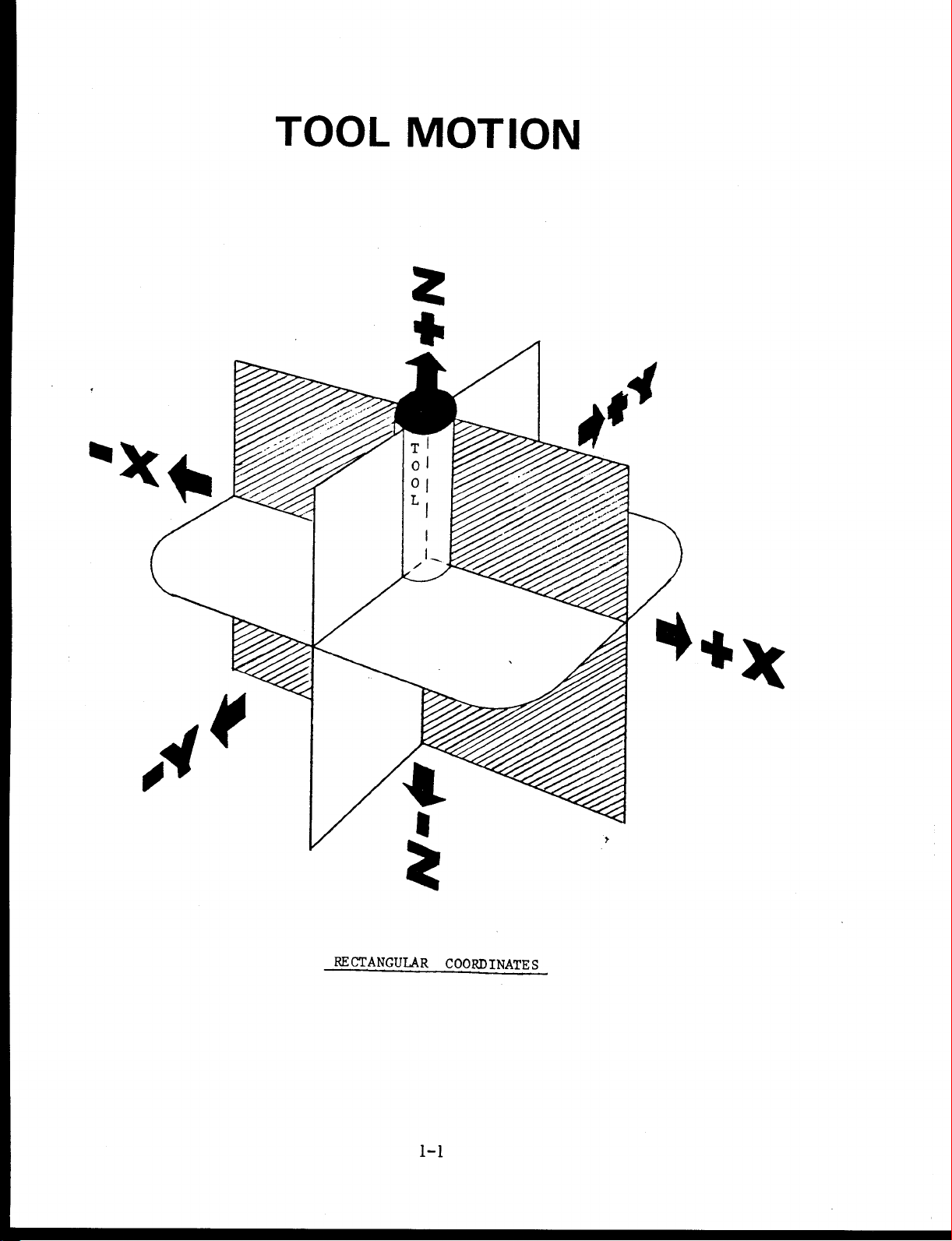

TOOL

MOTION

s*

*

m

mm

i

*

I

4

m

**

m

RECTANGULAR

1-1

COORDINATE

S

ABSOLUTE

AND

INCREMENTAL

PROGRAMMING

\A9Jc

}'v|

I'L

4

'(’-A'L

X-

ABSOLUTE

4b

Y+

9

7

I

u

2

o

n

9

7

4

i

3

1

7

4

it

2

1

7

it

ORIGIN

<(XO,YO)

4b

9

«

<

-9

4

J

4

x+

10

«

3

6

4

3

--ib

2

1

2

Y-

ib

a

ib

T

6

INCREMENTAL

MO

-l

yu

o

VI

i

-

j.

X

1

X-Zh—

2#

-3.

x

3

5

7.

x

X-V.

x_i

x

a.

Y

x

4

X

—

System:

i,

6

7

8

9

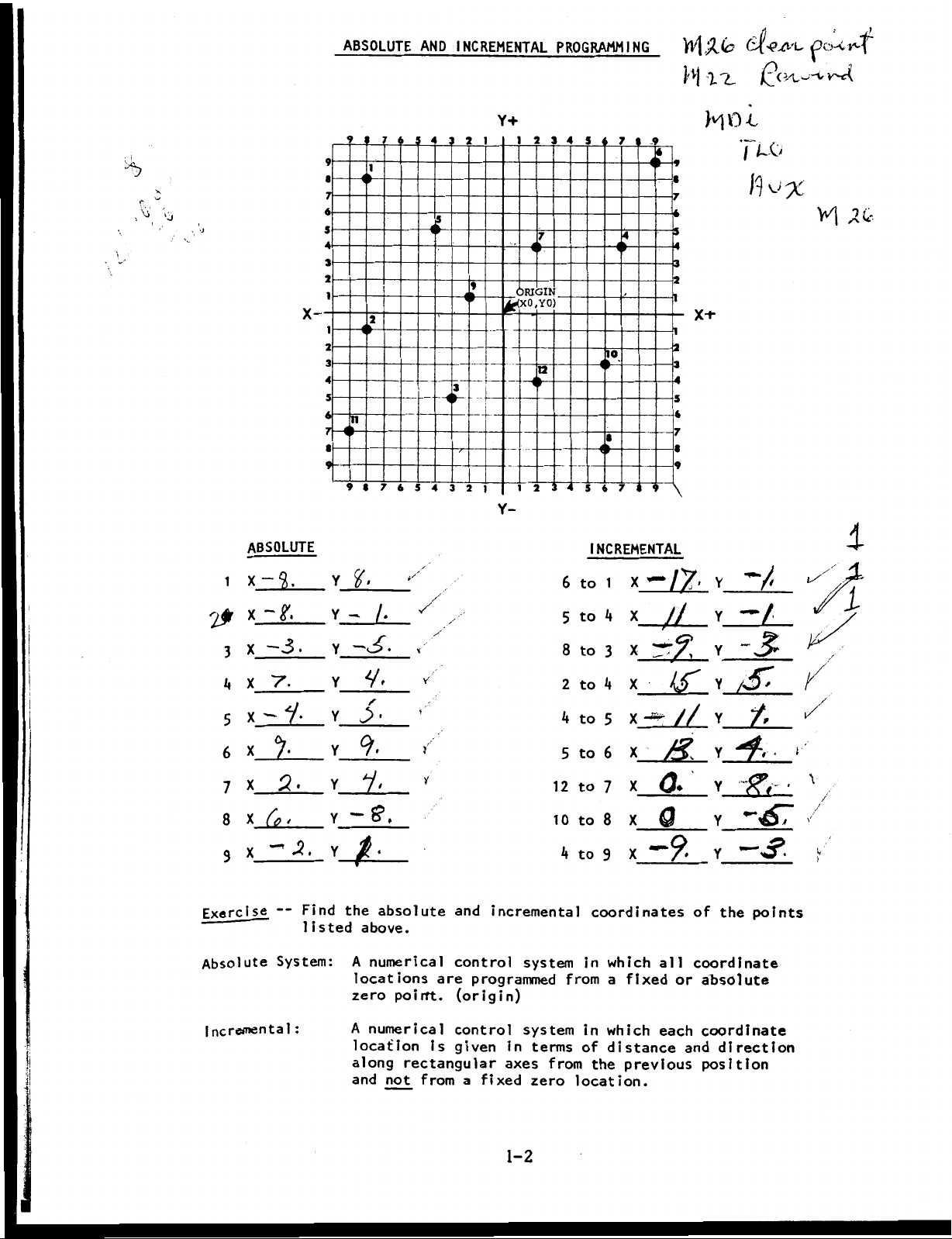

Exercise

Absolute

Incremental

jj,

Find

listed

:

Y

y

~

Y

_

Y

Y

>

Y

Y

*“

Y

Yÿ

the

A

locations

zero

A

location

along

and

/ÿ

V:

9.

y.

f?.

absolute

above.

numerical

poirft.

numerical

rectangular

not

,

Y

i

y

from

are

is

and

control

(origin)

control

given

incremental

system

programmed

system

in

axes

a

fixed

terms

from

zero

6

5

8

2

4

5

12

to

10

to

4

to

from

location.

to

to

to

to

to

to

in

in

of

1

X

4

x_ÿ2_

3

4

X

5

6

X

x

7

a*

8

_n2_

x

9

coordinates

which

a

which

distance

the

all

fixed

each

previous

n>

[J

kS'

//

or

and

v

Y

-/

Y

Y

S-

Y

£

Y

V

ffV

y

Y_mÿ.

of

coordinate

absolute

coordinate

position

points

the

direction

1/

i

\

/

V

1-2

&

z{0>

%

o

c-vC'h'i*'

yÿycÿvw—

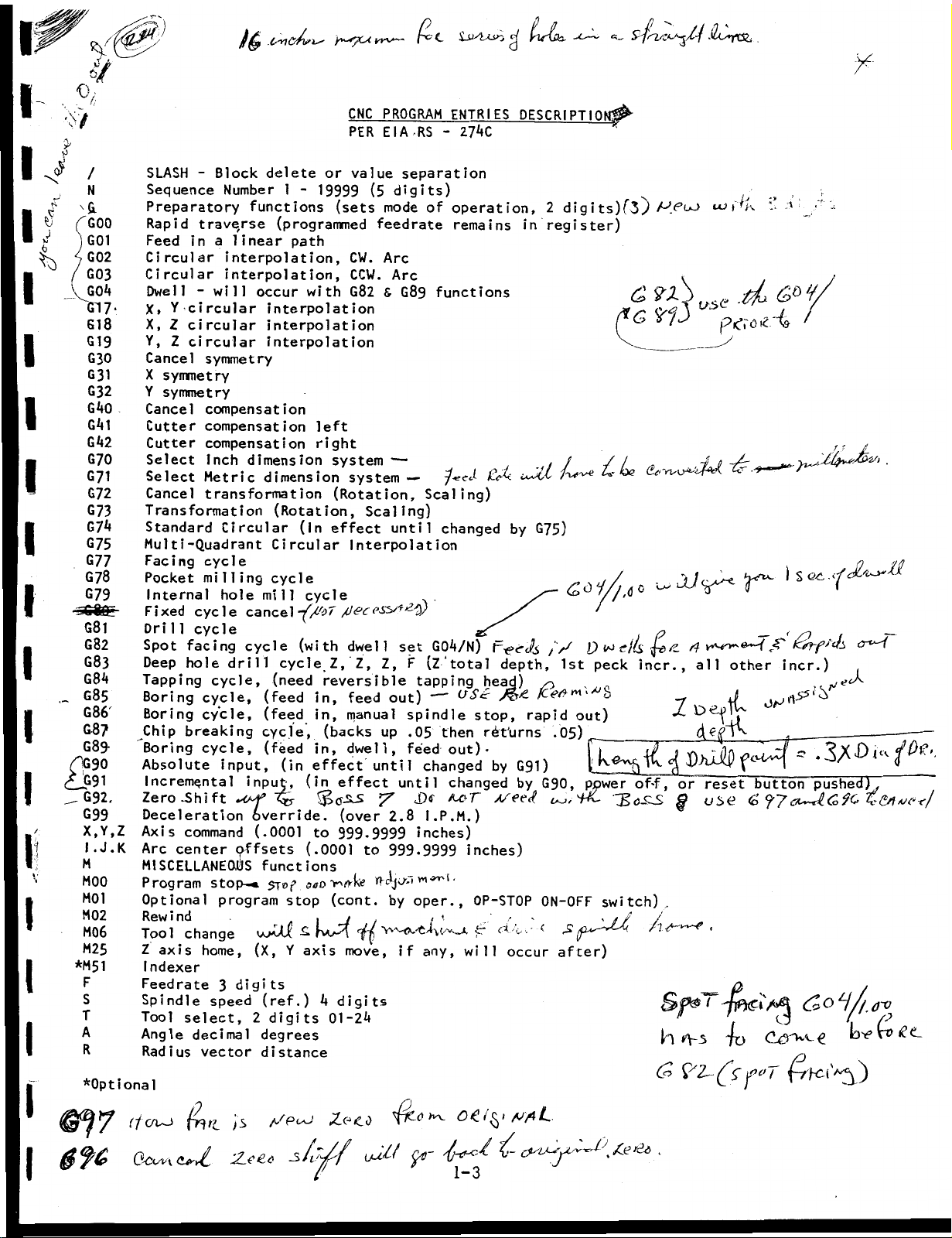

CNC

PER

a

PROGRAM

RS

EIA

-

ENTRIES

nkZ

Irlrbh.

ej

DESCRIPTIO

s

.HL*YC&

X

£

i

V

/

N

a

GOO

G01

G02

G03

XGOi»

GT7-

G

8

1

G19

G30

G31

G32

G40

G41

GA2

G70

G71

G72

G73

G7ÿ

G75

G77

G78

G79

G8l

G82

G83

G8A

G85

G86

G87

G8ÿ

(f;G90

<tp9i

G92.

G99

X,Y,Z

I.J.K

M

MOO

M01

M02

M06

M25

*M51

F

s

T

A

R

*0ptional

SLASH

Sequence

Preparatory

Rapid

Feed

Circular

Circular

Dwell

X,

X,

Y,

Cancel

X

symmetry

Y

symmetry

Cancel

Cutter

Cutter

Select

Select

Cancel

Transformation

Standard

Multi-Quadrant

Facing

Pocket

Internal

Fixed

Drill

Spot

Deep

Tapping

Boring

Boring

Chip

Boring

Absolute

Incremental

Zero

Deceleration

Axis

Arc

MISCELLANEOUS

Program

Optional

Rewind

Tool

Z

axis

I

ndexer

Feedrate

Spindle

Tool

Angle

Radius

Block

-

Number

traverse

a

n

i

interpolation,

interpolation,

-will

Y

circular

Z

circular

Z

circular

symmetry

compensation

compensation

compensation

Inch

Metric

transformation

Circular

cycle

milling

hole

cycle

cycle

facing

hole

cycle,

cycle,

cycle,

breaking

cycle,

input,

ft

-Shi

command

center

stop-«

program

change

home,

3

speed

select,

decimal

vector

functions

near

1

i

occur

dimension

cancel

cycle

drill

i

npu

override,

(.0001

offsets

(X,

digits

2

1

path

(In

(with

cycle

(in

stop

£

Y

or

-

19999

with

left

right

system

effect

cycle

Z, Z,

reversible

In,

in,

(backs

in,

effect

(in

to

(.0001

(cont.

XX

axis

*4

01-2A

delete

(programmed

interpolation

interpolation

interpolation

dimension

(Rotation,

Circular

cycle

mill

(need

(feed

(feed

cycle,

(feed

Jt,

functions

570ÿ

(ref.)

digits

degrees

distance

value

(5

(sets

(Rotation,

mode

feedrate

CW.

Arc

CCW.

Arc

G82

6

system

Scaling)

until

Interpolation

dwell

Z,

out)

feed

manual

up

dwell,

until

effect

(over

2.8

999-9999

to

999-9999

by

Y*'ÿeivi/vu.

move,

digits

separation

digits)

of

functions

G89

—

—

Scaling)

.

GOA/N)

set

(Ztotal

F

tapping

—

spindle

then

.05

feed

changed

until

I.P.M.)

inches)

oper.,

any,

if

operation,

remains

keÿ<-

•J-eeS

changed

F*><rJs

depth,

head)

O

Sc

stop,

returns

out)-

by

changed

kto

inches)

•

0P-ST0P

4r

will

occur

2

register)

in

G75)

by

/

—

,V

Kerf™'

rapid

.05)

G91)

by

G90,

0N-0FF

f

after)

ts)f3.)

digi

&

c>

c

be

/*.-

p

c/&

1st

peck

incr.,

,

b

out)

power

S

QUZJX

of-f,

switch),

?l)>

3

vf

p

/Z

St

fe

1

or

H

*V3

(s>

.

'K

i

-•

-

US<?

pic’ro-e

/

"X-

-

e-~

{

JC

all

other

vA.

reset

uSt?

button

(o

•

~fo

yt>T

,

'

X

incr.)

Z

'

‘X

55

pushed),

Co

(T>

€

(L

@*ÿ7

0

Octsn

fh'l

(V>/

/3

ZxCc

!J9lÿ

_s

Zeco

0

K

oetÿi

vfiL

1-3

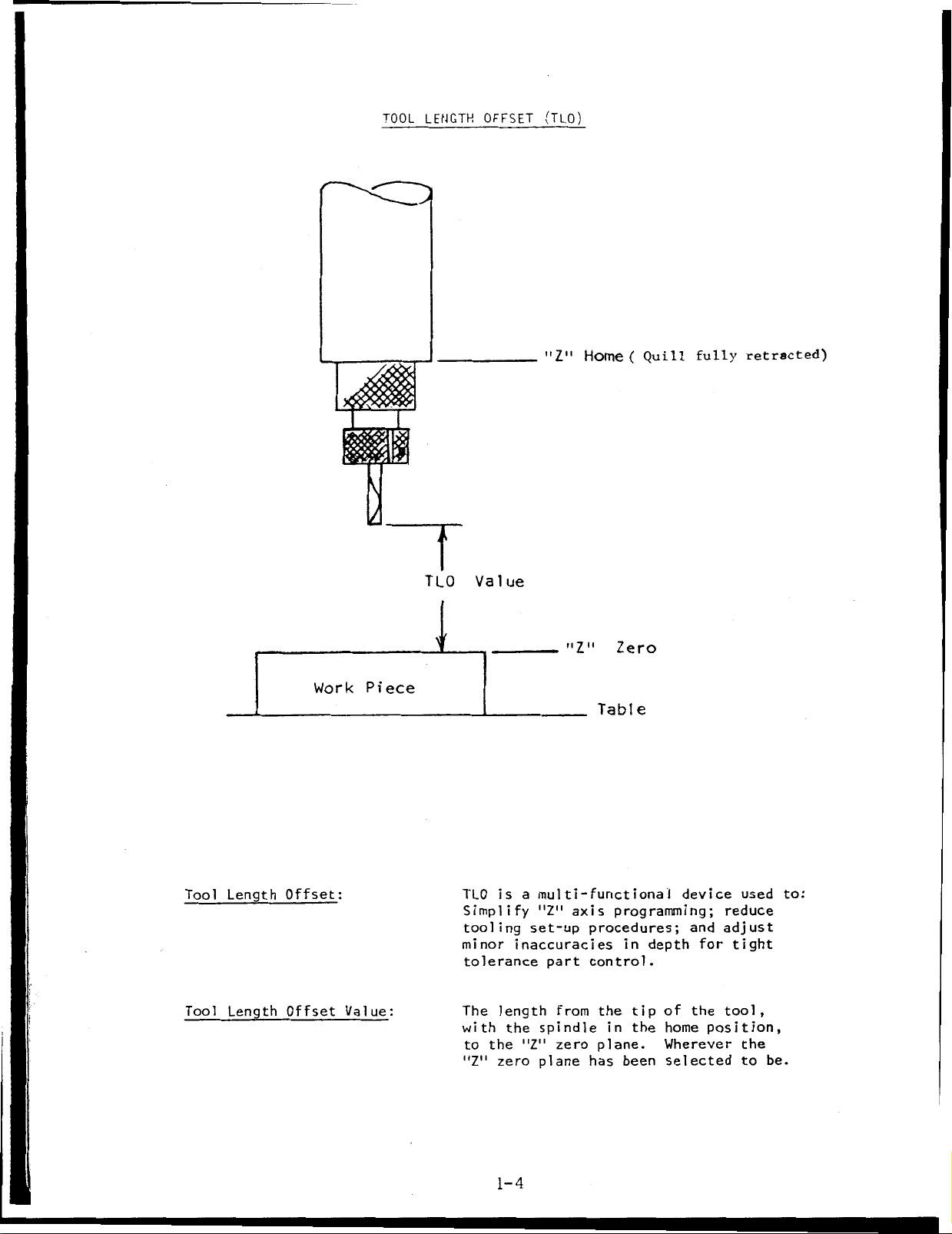

TOOL

LENGTH

OFFSET

(TLO)

III

Work

L

Piece

T

TLO

Nr

Value

"Z"

II

Home

II

7

Zero

Table

(

Quill

fully

retracted)

Tool

Tool

Length

Length

Offset:

Offset

Value:

TLO

is

Simplify

tooling

minor

tolerance

length

The

with

the

to

"Z"

zero

1-4

a

multi-functional

"Z"

set-up

inaccuracies

part

from

spindle

the

zero

"Z"

plane

programming;

axis

procedures;

control.

the

in

plane.

has

in

tip

the

been

depth

of

home

Wherever

selected

device

and

for

the

position,

used

reduce

adjust

tight

tool,

the

to

to:

be.

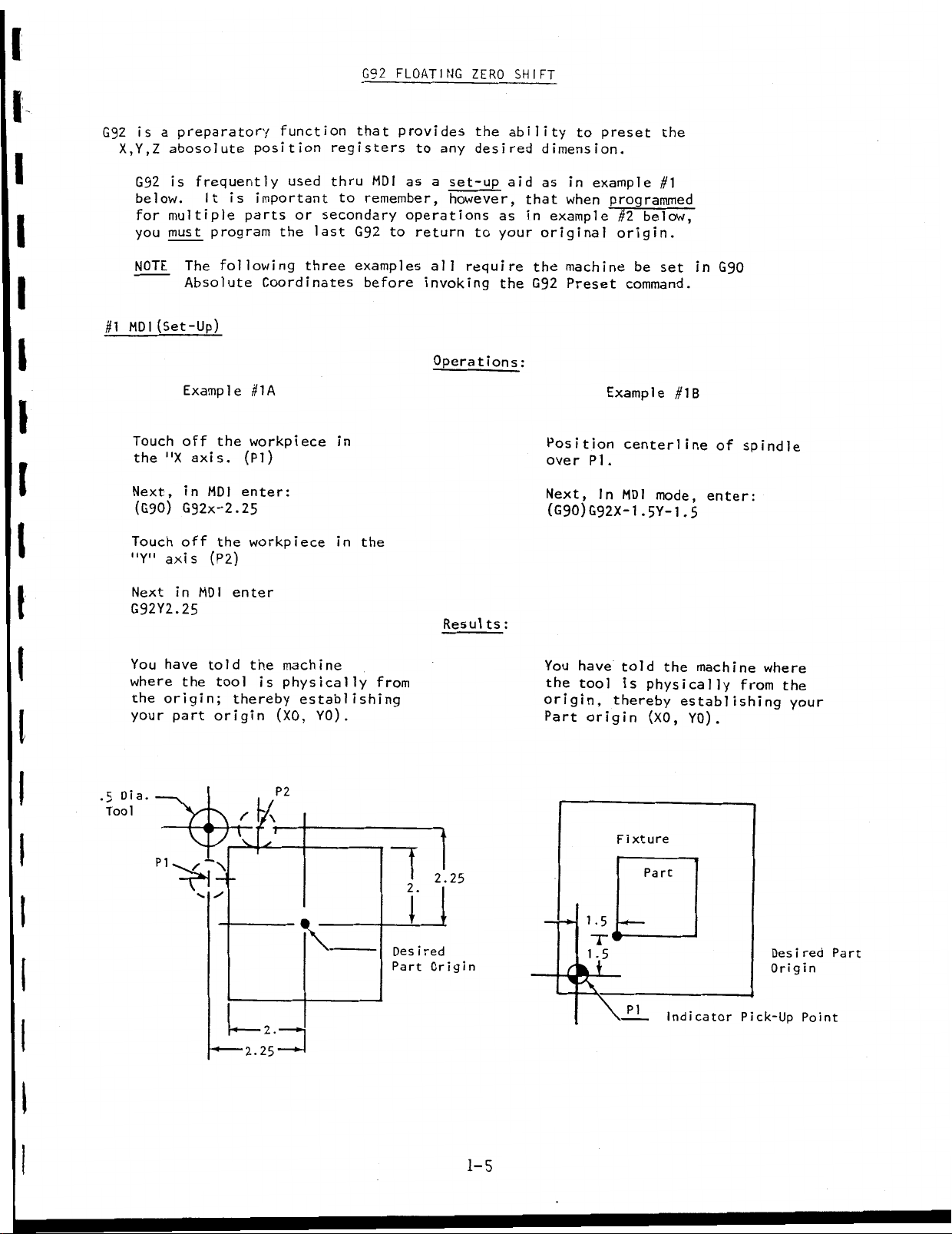

G92

FLOATING

ZERO

SHIFT

I

G92

X,Y,Z

#1

is

G92

below.

for

you

NOTE

MDI

Touch

the

Next,

(G90)

Touch

"Y"

a

preparatory

abosolute

frequently

is

It

multiple

t

mus

The

Absolute

(Set-Up)

Example

off

"X

axis.

in

G92x-2.25

off

axis

is

program

following

the

MDI

the

(P2)

function

position

used

important

parts

the

Coordinates

#1A

workpiece

(PI)

enter:

workpiece

or

last

three

that

registers

MDI

thru

to

remember,

secondary

G92

examples

before

in

the

in

provides

to

as

operations

to

return

invoking

the

any

desired

a

set-up

however,

to

require

all

Operations:

ability

aid

as

your

the

to

dimension.

as

in

that

when

example

in

original

the

machine

Preset

G92

Position

over

PI

Next,

(G90)G92X-1

preset

example

programmed

#2

below,

origin.

be

command.

Example

centerline

.

In

MDI

.5Y-1

the

#1

set

#1B

mode,

.5

in

G90

of

enter:

spindle

I

I

I

I

I

.5

Dia

Tool

Next

in

G92Y2.25

You

have

where

the

your

the

origin;

part

PI

MDI

told

V.

enter

tool

thereby

origin

\

the

/

2.25

is

u

2.

P2

r

machine

physically

establishing

YO)

(XO,

Resul

from

.

"M

2.25

•

l

red

Des

i

Origin

Part

:

ts

You

have

told

the

the

origin,

Part

tool

origin

1-5

1.5

is

physically

thereby

(XO,

Fixture

Part

IL

machine

establishing

YO)

.

Indicator

where

from

Des

Origin

Pick-Up

the

your

i

red

Point

Part

1-5

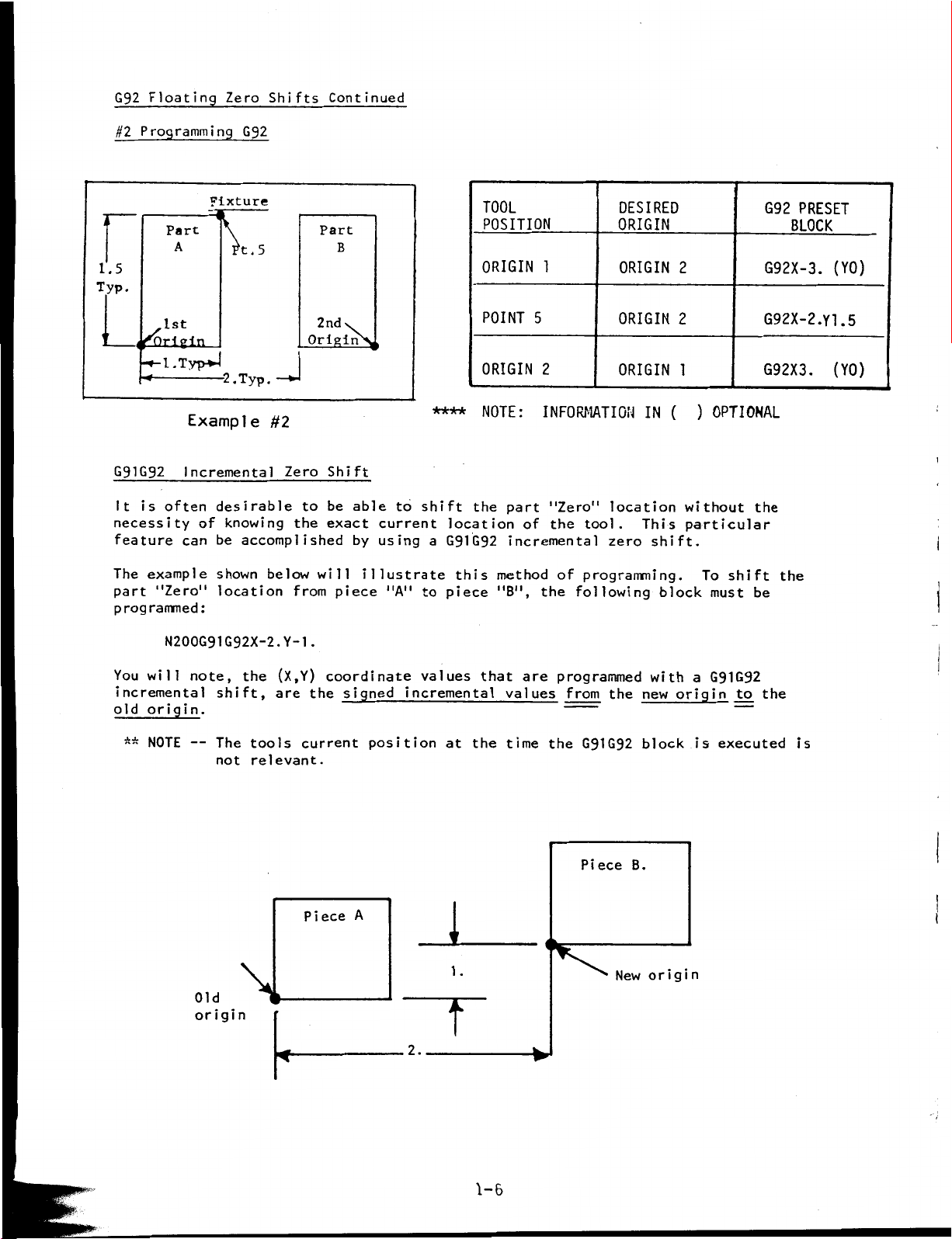

Floating

G92

Programming

#2

Zero

G92

Shifts

Continued

1.5

Typ.

G91G92

is

It

necessity

feature

example

The

part

programmed:

Fixture

Part

A

1st

\

5

t.

l.Typ-*4

Typ.

-2.

Example

Incremental

often

can

"Zero"

desirable

of

be

shown

location

#2

knowing

accomplished

below

Zero

the

from

N200G91G92X-2.Y-1

Part

B

2nd

Originÿ,

Shift

be

to

exact

will

piece

.

v

able

by

illustrate

to

current

using

"A"

****

shift

location

a

G91G92

piece

to

TOOL

POSITION

ORIGIN

POINT

ORIGIN

NOTE:

the

this

1

5

2

INFORMATION

part

"Zero"

of

the

incremental

method

the

"B",

tool.

of

programming.

following

DESIRED

ORIGIN

ORIGIN

ORIGIN

ORIGIN

IN

location

This

shift.

zero

2

2

1

(

block

)

OPTIONAL

without

particular

To

shift

must

G92

PRESET

BLOCK

G92X-3.

(YO)

G92X-2.YI.5

G92X3.

the

the

be

(YO)

You

will

incremental

origin.

old

NOTE

**

note,

--

Old

origin

shift,

The

not

the

tools

relevant.

\l

(X,Y)

are

coordinate

the

current

Piece

signed

position

A

values

incremental

the

at

1

1

.

T

2.

that

are

values

time

programmed

from

the

the

G91G92

Piece

New

B.

with

new

block

origin

a

origin

is

G91G92

to

executed

the

is

1-6

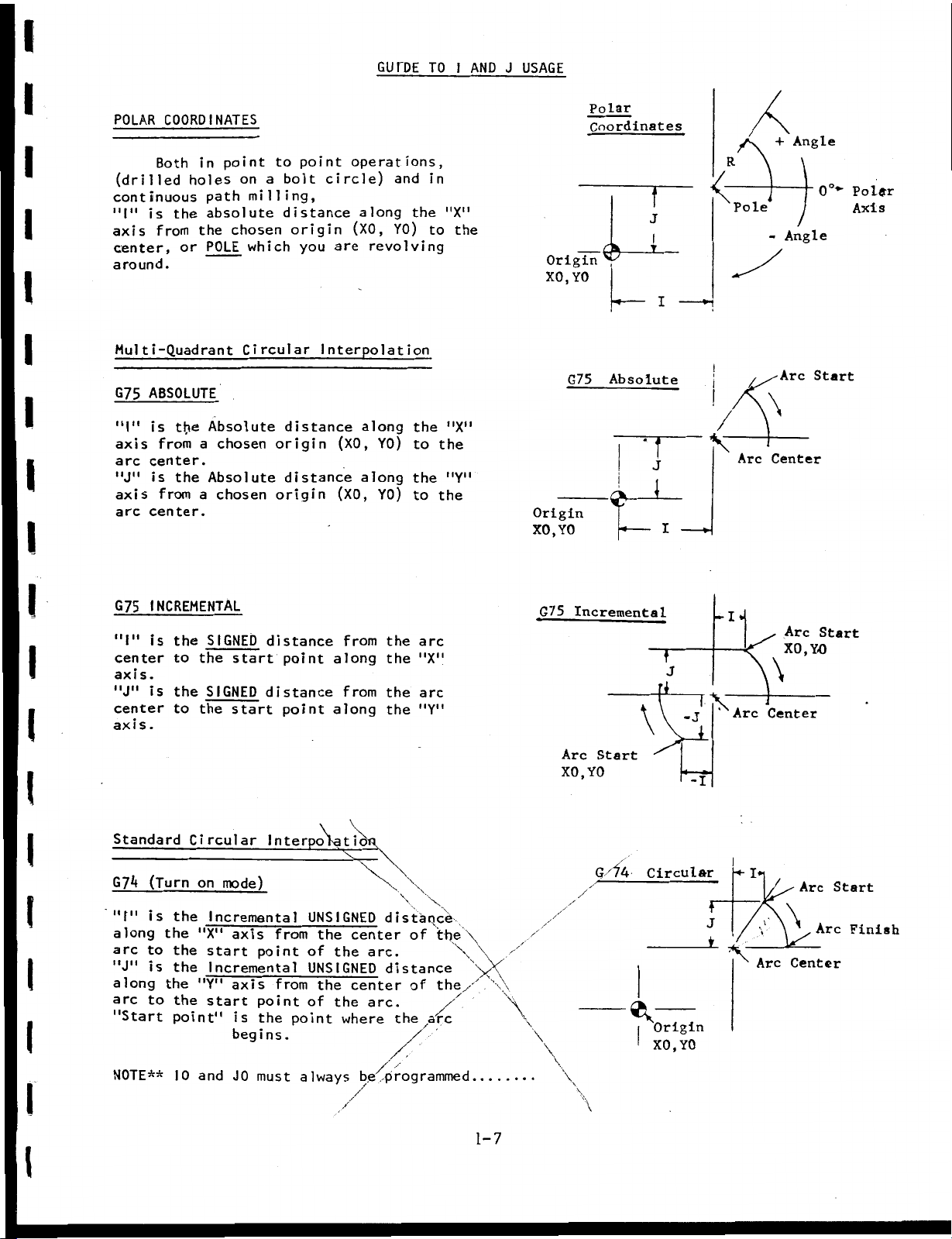

GUTDE

TO

I

AND

J

USAGE

POLAR

(drilled

continuous

"I"

axis

center,

around.

COORDINATES

in

Both

holes

path

the

or

absolute

the

POLE

is

from

Multi-Quadrant

ABSOLUTE

G75

is

"I"

axis

arc

"J"

axis

arc

the

from

center.

is

the

from

center.

Absolute

a

Absolute

a

point

on

milling,

chosen

which

Circular

chosen

chosen

to

bolt

a

distance

origin

distance

origin

distance

origin

point

circle)

you

are

Interpolation

(XO,

(XO,

operations,

and

along

(XO,

YO)

revolving

along

YO)

along

YO)

the

the

to

the

to

Polar

Coordinates

in

"X"

the

to

Origin

YO

XO,

G75

T

J

I

T

I

Absolute

Z

i

+

-

Angle

Angle

Arc

0°~

Start

Polgfr

Axis

\

"X"

the

"Y"

the

Origin

XO,

YO

'

J

Arc

Center

i

I

INCREMENTAL

G75

"I"

is

center

axis.

"J"

is

center

axis.

Standard

(Turn

G7*<

II

pi

is

along

arc

to

"J"

is

along

arc

to

"Start

NOTE**

the

to

the

to

Circular

the

the

the

the

the

the

point"

10

S

GNED

I

start

the

SIGNED

the

start

mode)

on

Incremental

"X"

axis

start

point

Incremental

"Y"

axis

start

point

is

begins.

and

JO

must

distance

point

distance

point

Interpolat

from

from

point

the

always

from

along

from

along

ioi

UNSIGNED

the

center

of

UNSIGNED

the

of

the

center

the

where

arc.

arc.

beÿprogrammed

the

arc

the

"X"

the

arc

"Y"

the

distaqcd

of

distance

of

a

the

/

the

the

're

G75

Incrementa

1

T

j

1

-

*

Arc

XO,

Start

YO

i

Arc

-J

Center

\

Arc

Start

XO,

YO

G'lh

/

V

/

\

\

\

\

\

\

u

Circular

Origin

YO

XO,

!ÿ

K

Arc

Start

f

J

Arc

Arc

Center

Finish

1-7

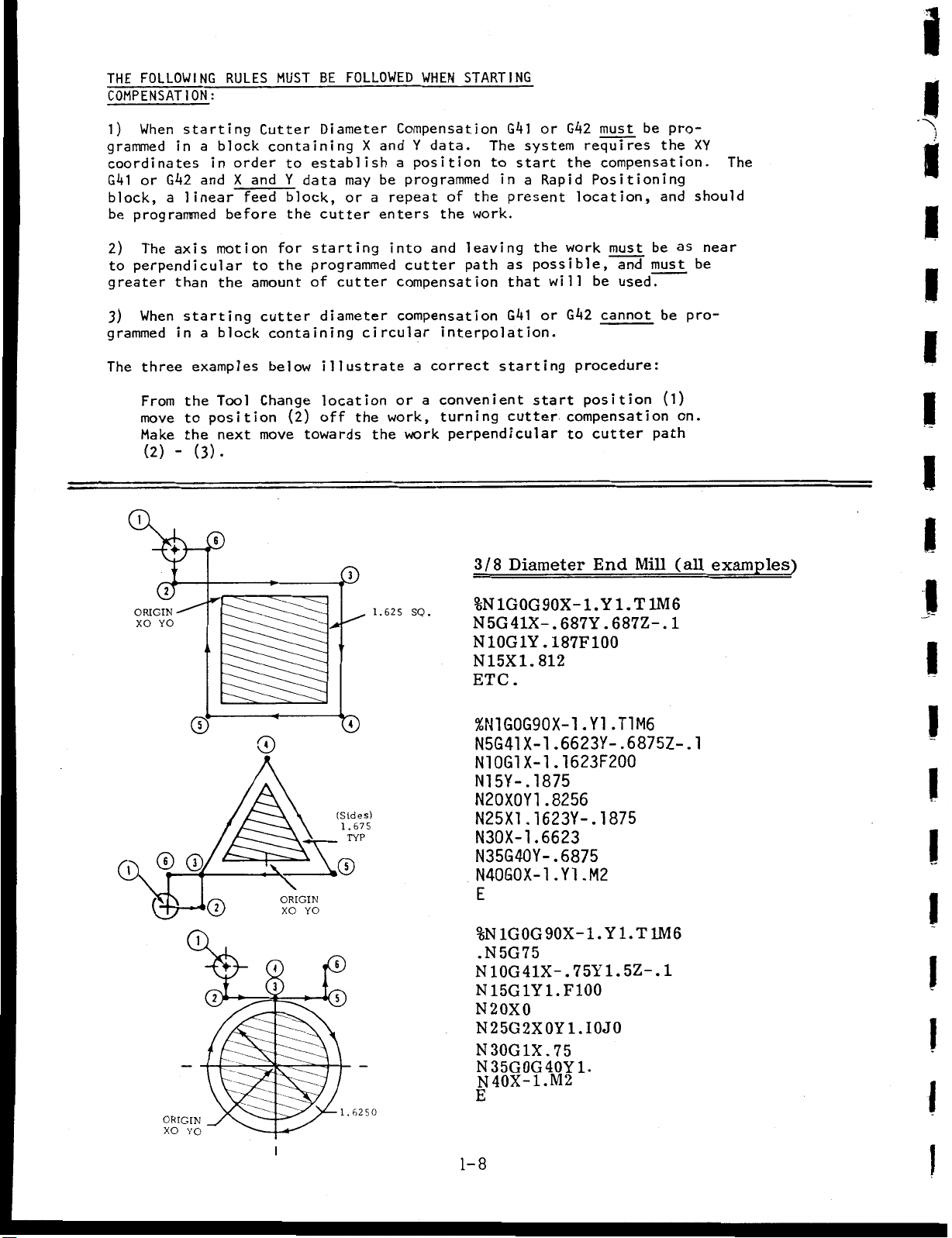

FOLLOWING

THE

COMPENSATION:

1)

grammed

coordinates

G41

block,

programmed

be

2)

perpendicular

to

greater

3)

grammed

The

When

G

or

a

The

When

three

starting

a

in

in

andXand

k2

linear

axis

than

starting

a

in

examples

RULES

block

order

feed

before

motion

the

block

MUST

Cutter

containing

to

Y

block,

for

the

to

amount

cutter

containing

below

BE

Diameter

establish

data

the

cutter

starting

programmed

of

diameter

illustrate

FOLLOWED

X

and

may

be

a

repeat

or

enters

into

cutter

circular

STARTING

WHEN

Compensation

Y

data.

position

a

programmed

of

the

work.

the

leaving

and

cutter

compensation

compensation

a

path

interpolation.

correct

G4l

The

to

start

in

present

as

that

G4l

starting

or

system

Rapid

a

the

possible,

will

or

G42

must

requires

compensation.

the

Positioning

location,

work

must

and

be

used.

G42

cannot

procedure:

be

the

and

be

must

be

pro¬

as

XY

should

near

be

pro¬

1

I

/

The

1

I

I

I

From

move

Make

(2)

1

ORIGIN

XO

\

the

to

the

-

cK®

at

YO

©

ORIGIN

XO

(3).

®,

1

YO

Tool

position

next

'©

2

Change

(2)

move

CD

\

ORIGIN

XO

4

i

location

off

towards

J®

ID

(Sides)

1.675

YO

f

%

1.6250

TYP

the

the

1

.625

or

work,

work

SO.

a

convenient

turning

perpendicular

3/8

%N

N5G41X-.

N10G1Y.187F100

N

ETC.

%N1G0G90X-1.Y1

N5G41X-1

N10G1

N15Y-.1875

N20X0Y1

N25X1

N30X-1

N35G40Y-.6875

N40G0X-1.Y1.M2

N

N15G1Y1.F100

N2OX0

N25G2X0Y1.I0J0

N30G1X.75

N35G0G40Y1.

E

1-8

start

cutter

Diameter

1G0G90X-1.Y1.T

15X1.

compensation

to

687Y.687Z-.

812

.6623Y-.6875Z-.1

1623F200

X-l

.

.8256

.1623Y-.1875

.6623

E

1G0G90X-1.

%N

.N5G75

10G41X-

75Y1.

.

N40X-1.M2

position

cutter

End

.T1M6

Yl.T

Mill

5Z-

(1)

path

1M6

1M6

1

.

on.

(all

1

I

I

I

examples)

I

I

I

\

|

I

I

I

I

I

I

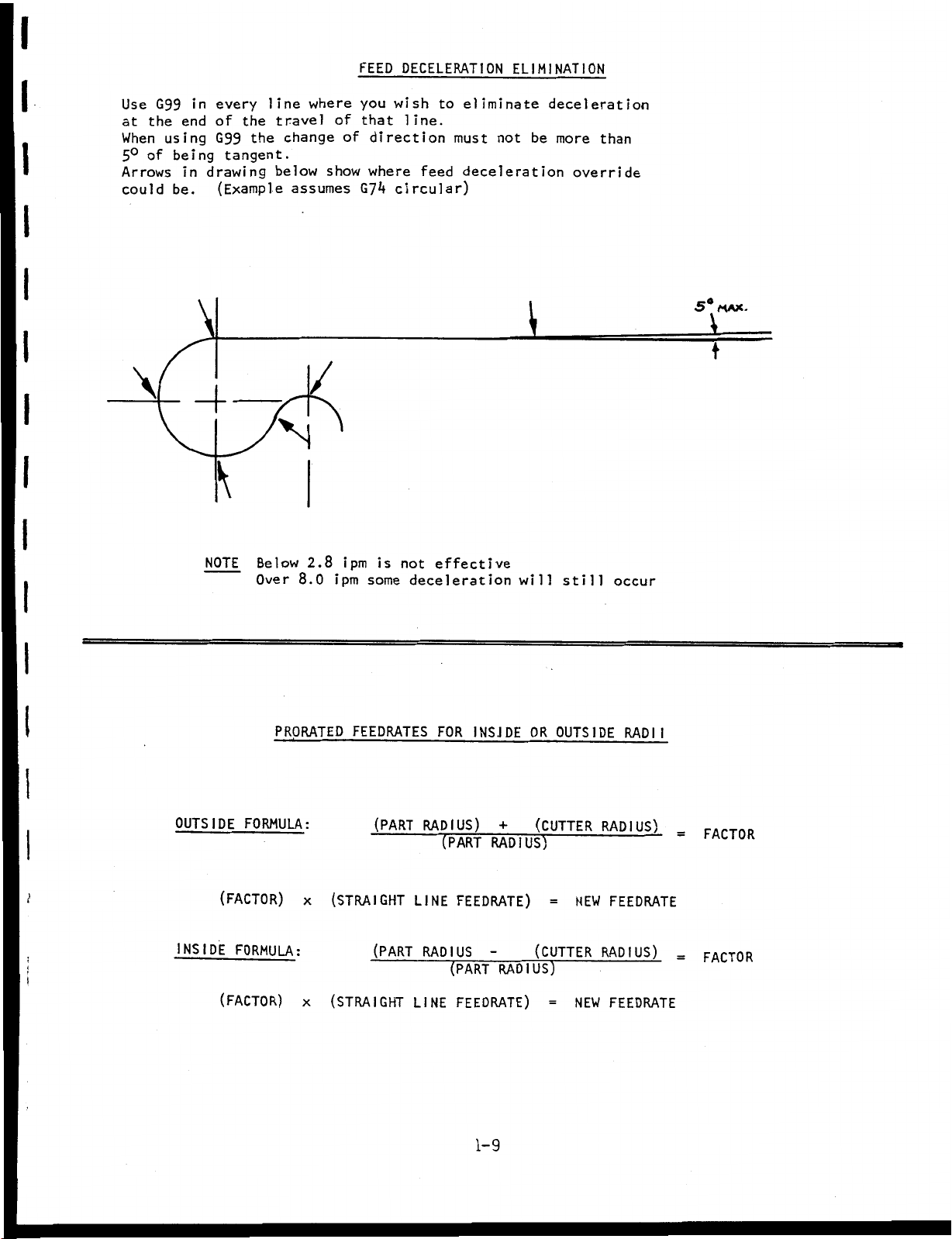

FEED

DECELERATION

ELIMINATION

I

I

I

I

I

I

I

Use

the

at

When

of

5°

Arrows

could

\

G99

using

being

be.

in

end

in

\

every

of

the

G99

tangent.

drawing

(Example

\

NOTE

line

the

below

N

Below

Over

travel

change

assumes

1/

8.0

where

show

2.8

of

of

ipm

ipm

you

wish

that

direction

where

circular)

G7*4

is

some

to

line.

must

feed

not

effective

deceleration

eliminate

not

be

deceleration

\

will

deceleration

more

than

override

still

occur

5°

MAX.

V

t

PRORATED

OUTSIDE

t

INSIDE

FORMULA:

(FACTOR)

FORMULA:

(FACTOR)

x

x

FEEDRATES

(PART

(STRAIGHT

(PART

(STRAIGHT

FOR

RADIUS)

(PART

FEEDRATE)

LINE

RADIUS

(PART

FEEDRATE)

LINE

I

NS

J

+

RADIUS)

RADIUS)

1-9

DE

OR

OUTSIDE

(CUTTER

=

NEW

(CUTTER

=

NEW

RADII

RADIUS)

FEEDRATE

RADIUS)

FEEDRATE

=

FACTOR

FACTOR

BASIC

PROGRAMMING

i

EXAMPLES

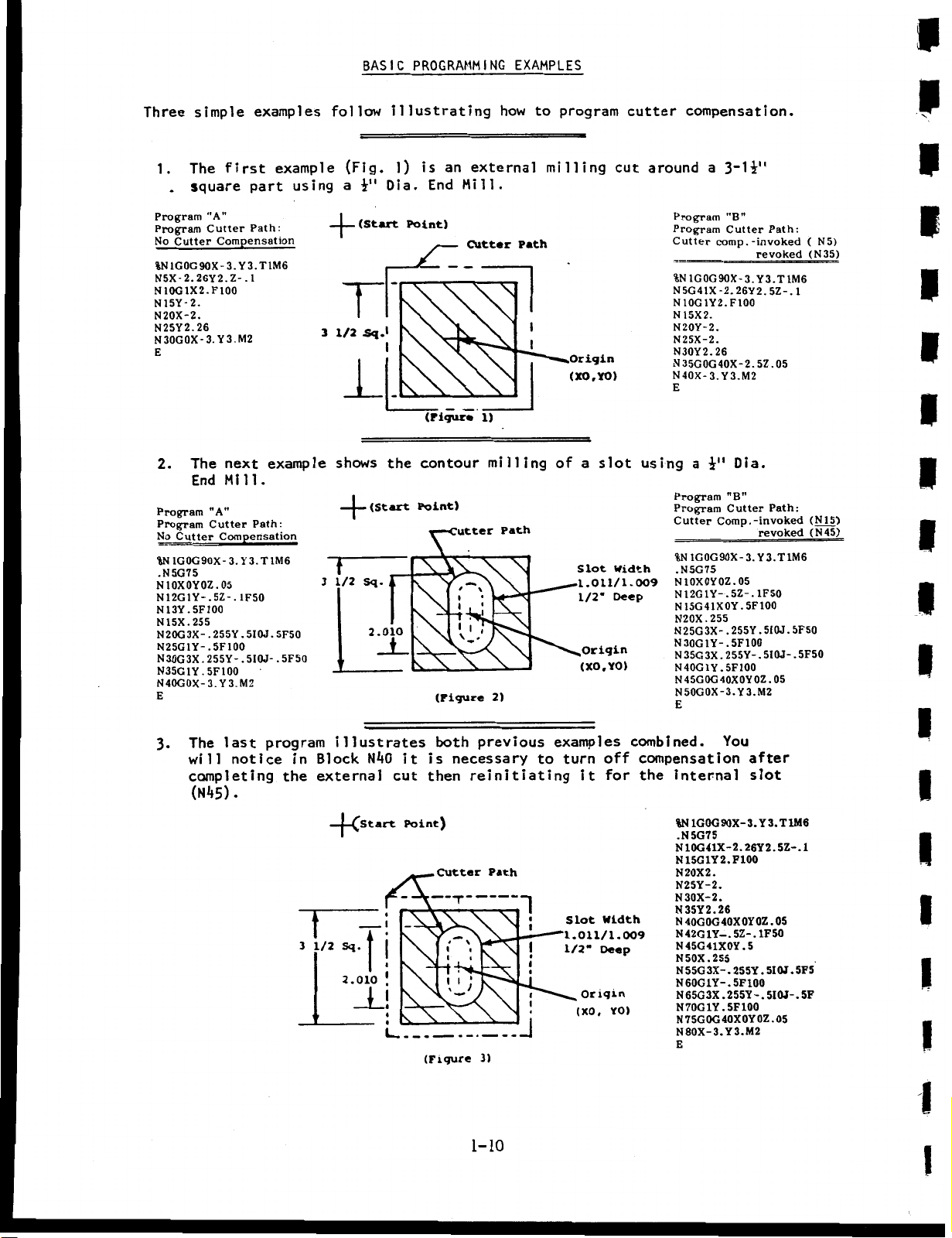

Three

simple

The

1.

square

.

Program

Program

No

%N

N5X-2.26Y2.Z-.1

N10G1X2.F100

N15Y-2.

N20X-2.

N25Y2.26

N30G0X-3.

E

2.

Program

Program

No

%N

.N5G75

N

N12G1Y-.5Z-.1F50

N13Y.5F100

N15X.255

N20G3X-

N25G1Y-

N30G3X

N35G1Y

N40G0X-3.

E

"A”

Cutter

Cutter

1G0G9OX-

The

End

"A"

Cutter

Cutter

1G0G90X-

10X0Y0Z

.

.

.

255Y-.5I0J-.5F50

.

5F100

examples

first

part

Path:

Compensation

3.

Y3.T

Y3.M2

next

Mill.

Path:

Compensation

T

3.

Y3.

.

05

5I0J.

255Y.

5F100

Y3.M2

example

using

1M6

example

1M6

5F50

follow

+

3

1/2

shows

T

3

1/2

(Fig.

a

(Start

T

1

—

iH

SqJ

(Start

Sq.

2.010

illustrating

1)

is

End

Dia.

Point)

(Figure

the

contour

Point)

X

(Figure

an

Mill.

Gutter

l

1

V

how

external

Cutter

1)

milling

Path

\

,1

,

I

.

2)

Path

I

l

to

milling

program

Origin

(XO,YO)

of

a

Slot

.1.011/1.009

1/2-

Origin

(XO,

slot

Y0)

cutter

cut

Width

Deep

compensation.

around

using

a

3~1i"

Program

Program

Cutter

%N1GOG90X-3.Y3.T1M6

N5G41X-2.26Y2.5Z-.1

N10G1Y2.F100

N

N20Y-2.

N25X-2.

N30Y2.26

N

N40X-3.Y3.M2

E

Program

Program

Cutter

%N

.N5G75

N10X0Y0Z.05

N12G1Y-.5Z-.1F50

N

N20X.255

N25G3XN30G1Y-.5F100

N35G

N40G1Y.5F100

N

N50G0X-3.

E

"B"

Cutter

__

comp.

15X2.

35G0G40X-2.

Dia.

a

iH

"B”

Cutter

Comp.

1G0G90X-

15G41X0Y

.255Y.5I0J.5F50

3X

255Y-.

.

45GOG40X0Y

Y3.M2

-invoked

revoked

5Z

-invoked

revoked

3.

Y3.T

.

5F100

0Z.05

Path:

.

Path:

5I0J-

05

1M6

.

(

(N35)

(N15)

(N45)

5F50

N5)

P

P

i

I

V

I

i

I

I

I

3.

last

The

notice

will

completing

(N45).

program

in

the

3

illustrates

Block

external

(start

|—

—

\

Sq.

1/2

2.010

HkO

J_!

«

I

:

4

it

cut

Point)

both

is

then

Cutter

v;

(Figure

previous

necessary

reinitiating

Path

3)

1-10

i

to

t

I

I

«

i

i

examples

off

turn

it

Width

Slot

1.011/1.009

Deep

1/2"

Origin

(X0,

combined.

compensation

for

the

YO)

You

after

255Y

.

255Y-

.

Y3.M2

slot

Y3.T1M6

5

5I0J

.

5IQJ-

.

internal

%N

1G0G90X-3.

.N5G75

N10G41X-2.26Y2.5Z-.

N15G1Y2.F100

N20X2.

N25Y-2.

N30X-2.

N35Y2.26

N4OGOG40X0Y0Z.05

N42G1Y-.5Z-.1F50

N45G41X0Y.

N50X.255

N55G3X-

N60G1Y-.5F100

N65G3X

N70G1Y.5F100

N75G0G40X0Y0Z.05

N80X-3.

E

.

1

5F5

5F

.

I

i

I

I

I

I

I

I

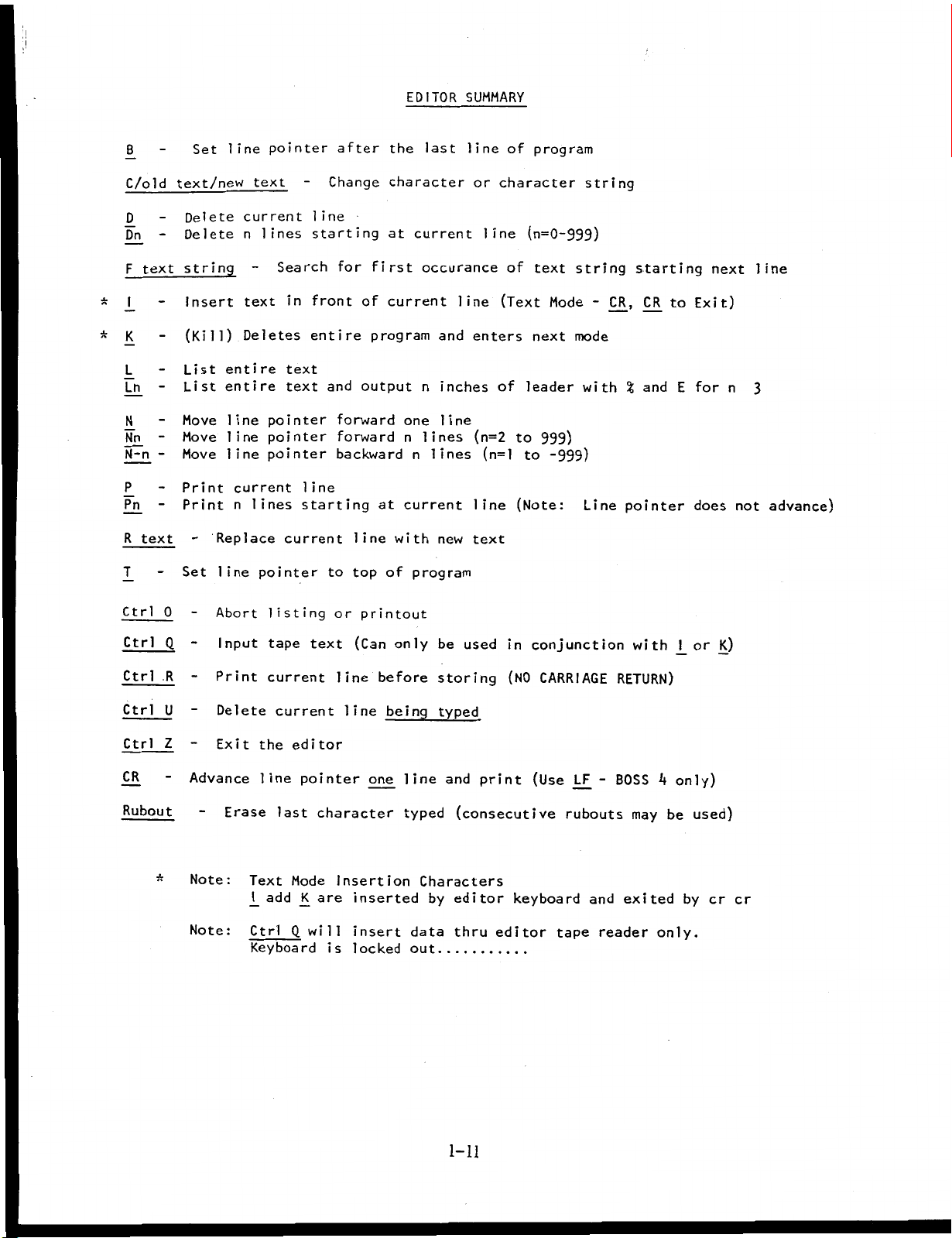

EDITOR

SUMMARY

*

*

B

C/old

D

Dn

F

text

I

K

L

Ln

N

Nn

N-n

P

Pn

R

text

T

Set

text/new

Delete

Delete

string

Insert

(Kill)

entire

List

entire

List

Move

line

Move

line

Move

Print

Print

Replace

line

Set

line

current

n

text

Deletes

line

current

n

pointer

text

lines

pointer

pointer

pointer

lines

pointer

Search

in

text

text

line

starting

current

after

Change

the

character

line

starting

for

front

entire

and

at

first

of

current

program

output

forward

forward

backwardnlines

at

line

with

top

to

of

last

current

occurance

and

n

inches

line

one

lines

n

current

new

program

line

line

or

line

enters

(n=2

(n=l

line

text

of

program

character

(n=0-999)

of

text

(Text

next

of

leader

999)

to

to

(Note:

Mode

-999)

string

string

-

mode

with

Line

CR,

%

pointer

starting

CR

to

and

E

next

Exit)

for

does

n

not

line

3

advance)

Ctrl

Ctrl

Ctrl

Ctrl

Ctrl

CR

Rubout

*

0

Q

R

U

Z

Abort

Input

Print

Delete

Exit

Advance

Erase

:

Note

:

Note

listing

tape

current

current

the

editor

line

last

Text

Mode

add

J_

Ctrl

Q,

Keyboard

text

pointer

character

K

are

will

is

printout

or

(Can

line

before

line

one

Insertion

inserted

insert

locked

only

being

line

typed

be

storing

typed

and

(consecutive

Characters

by

editor

data

thru

out

used

print

in

(NO

keyboard

editor

conjunction

CARRIAGE

(Use

LF

rubouts

and

tape

with

RETURN)

BOSS

-

may

exited

reader

J_

only)

4

be

only.

or

used)

by

cr

J<)

cr

1-11

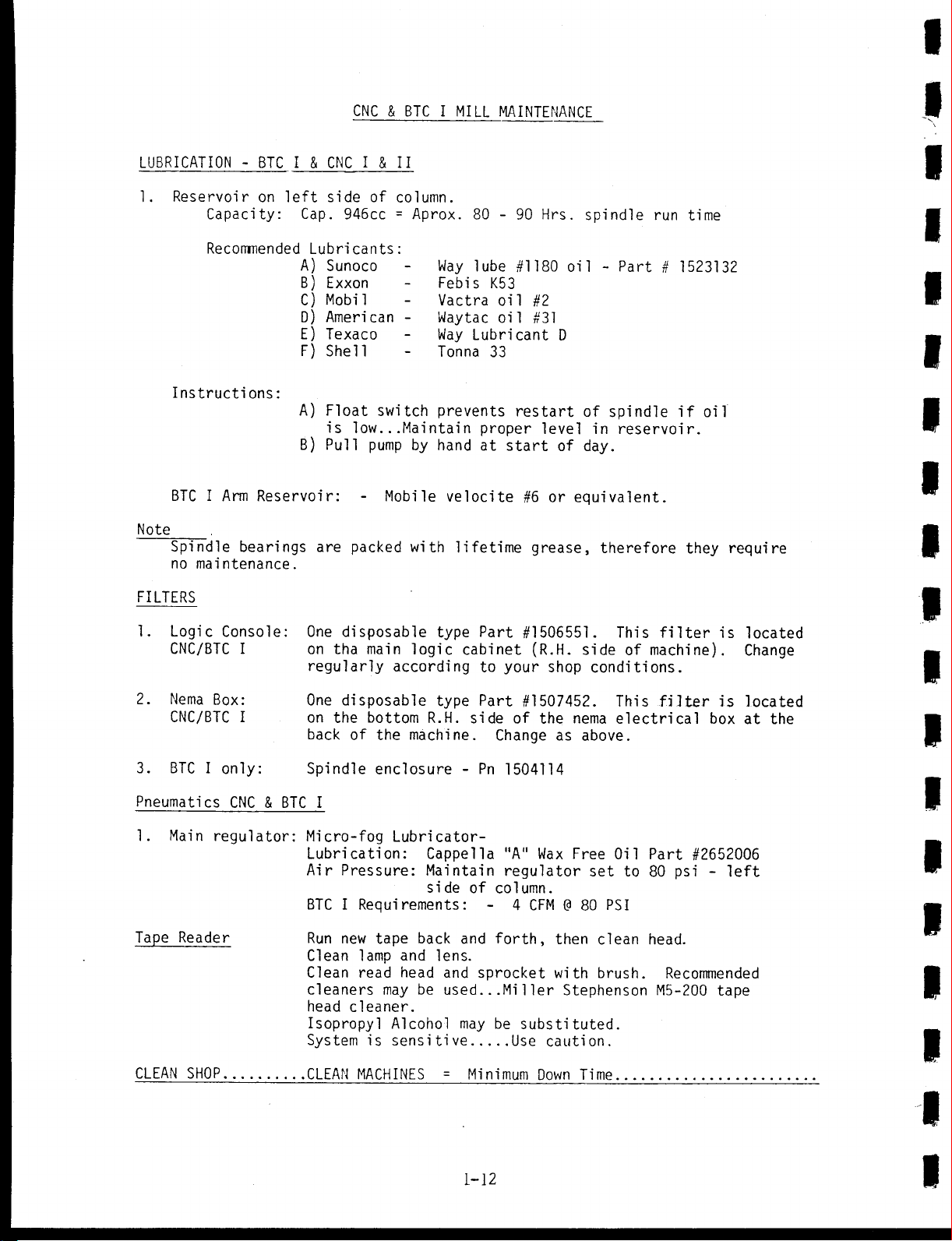

CNC

&

BTC

I

MILL

MAINTENANCE

I

I

LUBRICATION

1.

Reservoir

Capacity:

Recommended

Instruct!-

I

BTC

Note

Spindle

no

FILTERS

Logi

.

1

Arm

maintenance.

c

Console:

CNC/BTC

2.

Nema

Box:

CNC/BTC

3.

BTC

I

only:

BTC

-

on

ons

:

Reservoir:

bearings

I

I

CNC

I

&

side

left

Cap.

Lubricants:

A)

Sunoco

B)

Exxon

C)

Mobil

D)

American

E)

Texaco

F)

Shell

A)

Float

is

B)

Pull

are

One

on

regularly

One

on

back

Spindle

I

&

of

946cc

switch

low...Mai

pump

Mobile

packed

disposable

main

tha

disposable

the

bottom

the

of

enclosure

II

column.

=

Aprox.

Way

Febis

Vactra

Waytac

-

Way

Tonna

prevents

ntain

by

hand

velocite

with

type

logic

according

type

R.H.

machine.

80

lube

K53

Lubricant

33

proper

at

lifetime

Part

cabinet

to

Part

side

Pn

-

90

-

#1180

oil

#2

oil

#31

restart

start

#6

grease,

#1506551.

(R.H.

your

#1507452.

of

Change

1504114

Hrs.

oil

D

level

of

or

shop

the

as

spindle

Part

-

of

spindle

in

reservoir.

day.

equivalent.

therefore

This

side

of

conditions.

This

nema

electrical

above.

run

time

1523132

#

if

oil

they

filter

machine).

filter

is

is

box

require

located

Change

located

at

I

I

I

I

1

I

I

I

I

the

R

Pneumati

Main

1.

Tape

Reader

CLEAN

SHOP

cs

CNC

regulator:

&

BTC

I

Micro-fog

Lubrication:

Air

Pressure:

Requirements:

I

BTC

Run

Clean

Clean

cleaners

head

Isopropyl

System

CLEAN

tape

new

lamp

read

cleaner.

is

MACHINES

Lubricator-

Cappella

Maintain

side

back

and

lens.

head

may

be

Alcohol

sensitive

of

and

and

used...

may

=

Minimum

1-12

"A"

regulator

column.

4

forth,

sprocket

Mi

Her

be

substituted.

Use

Wax

@

CFM

then

with

Stephenson

caution.

Down

Free

set

80

Time

Oil

to

PSI

clean

brush.

Part

#2652006

psi

80

head.

Recommended

M5-200

-

left

tape

V

R

R

R

R

R

R

"U

J3

o

CD

m

1

C/5

m

H

PROBLEM

SET

Bridgeport

Machines

TEXTRON

DivisionofTextron

Inc.

I

I

I

I

I

I

I

I

Program

3.2fO

-----

250

---

U—

1.250—

2

J

>-

---

l

~7)_

I

1.750

t

1.000

H

i

750

-G

-

H

I

!

-2.000

—

i

»J

i

{j

1

i>

1

>

R

.200

N

\

\K

\

x

-

i

f

.7

So

f

.500

i

1

\

\

N

\

\

DEE

>1

-J

3

8

2.2SO

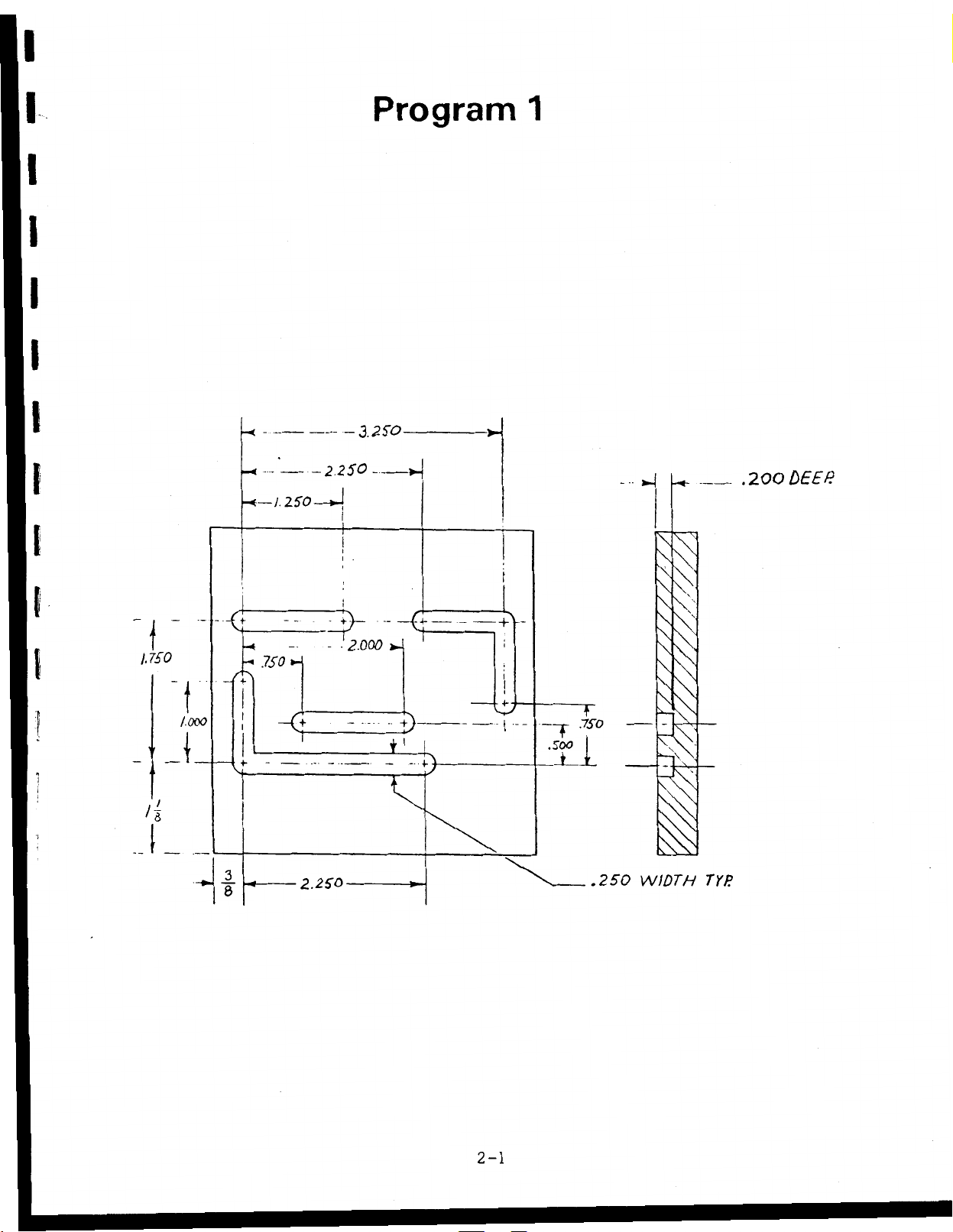

2-1

.250

WIDTH

TYP

£

CD

o>

o

CL

m

m

o

o

r)

uJ

£

o

h

\f)

hJp

0

\

a

U

0

a

o

h

UJ

oi

o

jJlfl

-

o

y

ui

<0

ifl

P

o

h

i-

UJ

UJ

<

2

B

0

0

0

u

®

®\K

i

a-

h

0

iP

H.

2>

Kg)

®fh

d

l»

H

S>

JyOoOODQOOoGO

£Otfiniflinifl°gooo

vj

fO

-

>

s>

Q

,„o0000000O0

o

xq-

I

h

iP

o

S

SoOrJNHHOr-rJOO

U

X

—

iP

_

—

—

$

iP

m

ol

1/]

ro

o

(\|

i/)

i/i

j

*

'

-I

c\j

CN

o

°

j

-J

J

<

$

jw

o

fl

ui

u.

h

5

h

IP

0

0

lO

r1

z

V0

0

(0

o

o

0

r

r

71

*n

n

13

r

N

>

2

p

H

o

p

m

m

(II

5

>.

H

pi

H

2

$

hjf

[dÿJ

UI

.

O

OOOQOOQJ)

f°:::n

brÿboO

o

O

(ji

>

fo

i

O'

H

X

©

0,

o

0

0

-0-

©

©

0

7}

--0

o

0

!

z

4

r*

o

o

o

t

(fl

H

>

JO

H

z

(T

T>

o

CO

f

Q)

3

ro

6'

in

>

(P

O

m

H

0

TJ

O

T>

0>

H

*0

r

i

i

i

ec1;::.

i/ioouitnogo

OOO-OOOOjQ

i

i

i

c°

o

0

©

SS

0

X

©

0

p

PP

m

*

CP

in

o

0

®

0

00

E

CD

O)

O

CL

Q

2

J

J

Of

$

2

U

J

0

0

h

h

DC

<c

K

IP

o

o

3

©r

©

z

0

a

0

-%*ÿ

o:

Q

x-y

0

0

I

0

N

NO

©

©

or

0

in

H

x

J

d

9

o?

V

©

w

©

a

jfoi/)o°iOoiniPo

Q

°

U

S82rt°°90

2

0

IÿOOcJOholO

N

I

I

>

a

UOOnOOoO

0

U

U

x

n

-1

it-

o

H

<

£

0

If)

o

•••ÿ<•«

•

NÿOiOfOrOpj

—

N

-'

<0

0

?

i

xr

u

o

h

N

0

<0

—

I

o

in

H

I

OO

0

r-

N

I

o

04

«

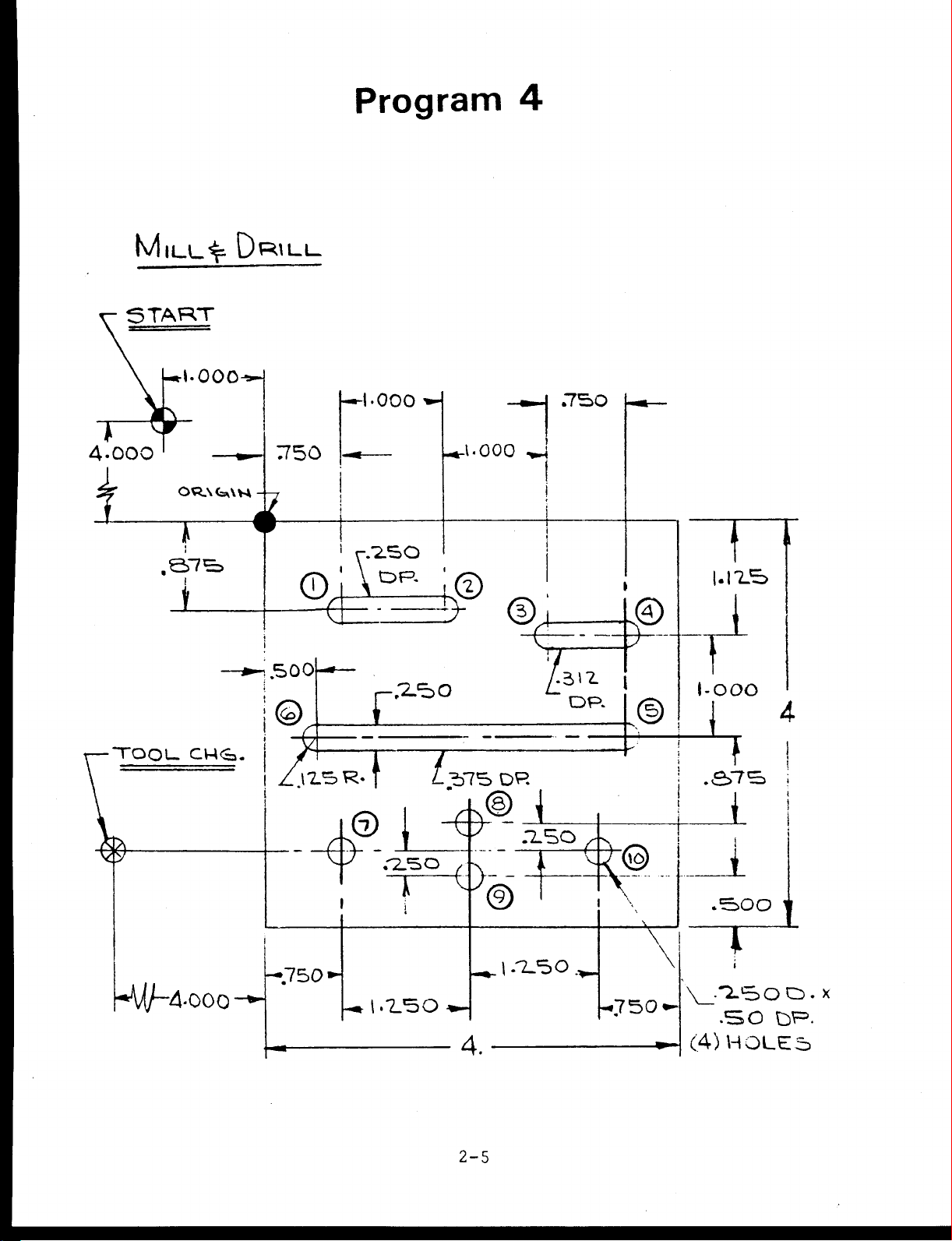

Program

4

i

MiLt_%

5

000

A.

TOOL

TART

-•ÿ1.000

I

,e>7=3

1

CHÿj.

DRILL

750

o

500

©

.125

R.

250

DP.

r

f

—

.1.000

k©

o

1

575

DR

.750

-*1

i

©

lÿ\-L

DP.

©

©

f

1.123

i

t

1-000

i

T

.e>7=>

4

!

-*M/-

4*000

--0--

-750

®

.250

-1250

©

I

I

O;

©

4.

2-5

J

.7.50

L

i

1-250

©

i

-750-

X

(4)

i

1

.500

4

i

.*30

HOLE

0.

DR.

5

x

Loading...

Loading...