Vertical Machining Center

Operator’s Manual

DX32 CNC Control

October 1997

Code No. 1104-2832

Rev . A

®

COPYRIGHT 1997 BRIDGEPORT MACHINES, INC., ALL

RIGHTS RESERVED

This manual describes software that contains published and unpublished works of authorship

proprietary to Bridgeport Machines, Inc. It is made available for use and maintenance of our products.

Under copyright laws, this manual, or the software it describes may not be copied in whole, or in part,

without prior written consent of Bridgeport Machines, Inc., except in normal software use, as

described in the software license agreement.

The information in this document is subject to change without notice and should not be construed as a

commitment by Bridgeport Machines, Inc.

ii

/19960710

Changes from first edition (January 1996):

Updated Control Panel (Chapter 1)

iii

READ THIS FIRST!

Like most manufacturers, we go

to great lengths to make our

products as safe as possible—

but operators can still get hurt.

In virtually every case, the injury

is the result of:

■ Not knowing how to properly operate the machine;

■ Not following proper operating and safety procedures;

■ Carelessness or inattention;

■ Trying to “take a short cut;”

■ Poor maintenance.

For your personal safety, and to

get the maximum efficiency out

of this precision machine, read

and follow operation instructions

carefully.

Standard Safety Precautions for

operating the Vertical Machining

Center are:

■ NEVER operate machine without safety glasses.

■ DO NOT wear gloves,tie,scarf,ID bracelet,neck chain or

other object that could become entangled in the machine

or workpiece.

■ ALWAYS wait for the spindle to stop before bringing your

hands to the table or workpiece.

■ MAKE CERTAIN workpiece is SECURELY held in place.

■ NEVER attempt to hand hold or hand feed a workpiece.

■ Stop the machine and correct any malfunction

immediately (see Maintenance manual or contact your

supervisor).

■ Inspect and maintain machine by schedule—not by

chance.

■ Keep hands and clothing away from moving parts.

■ If you’re not a qualified electrician,do NOT tamper with

electrical connections or wiring. Report any suspected

electrical malfunction immediately.

■ Other important safety information is contained in the

Installation and Maintenance Manual.Make sure you

understand all safety procedures before operating the

machine.

IMPORTANT NOTICE

Although reasonable care has been exercised in the preparation of this manual and the relevant

VMC Installation & Maintenance Manual to make them complete and accurate,they do not

purport to cover all conceivable problems or applications pertaining to this machine.

IMPORTANT

Safety Information

iv

IMPORTANT SAFETY NOTICE

WARNING

It is the user's responsibility to be acquainted with the legal obligations and requirements in the use and

application of the machine, particularly as discussed in the American National Standards Institute

Standard Entitled Safety Requirements for the Construction, Care, and Use of Drilling, Milling, and

Boring Machines.

The Bridgeport Milling Machine

SAFE INSTALLATION

The Bridgeport Milling Machine is fitted with safety interlocked table guards as standard. In certain

cases and tooling applications, additional guarding may have to be provided by the user.

The standard machine guarding has special safety interlocks on the guard doors that comply with the

Standard Code of Practice for Safety of Machinery. Guards and interlock shall be kept fully maintained

and tested by the customer and shall not be removed.

The guards are made with clear plastic, having high impact resistance to provide operator safety and a

clear, unobstructed view of the operations in progress. The opening of any guard door provides access

to potential hazard areas. Opening the working area guard doors will automatically stop the spindle, but

it is still possible, by means of operator controls, to manually initiate all other machine functions.

Extreme care must therefore be used at all times.

SOFTWARE

Any unauthorized changing of control parameters is not permitted. Bridgeport Machines will not accept

any liability whatsoever for the alteration of any set parameters to those programmed at installation.

AUTHORIZED PERSONNEL AND TRAINING

Operating, service and maintenance engineers shall be authorized by the 'User Company' and properly

trained in the use of the machine.

SAFE WORKING PRACTICES

Workholding devices, cranage, tooling and their use shall be the responsibility of the user. It is the user's

responsibility to protect against the hazards caused by chips, leaking oil or coolant and their use.

Use of proprietary oil or coolant is the responsibility of the user. Special instructions from the suppliers

concerning their use should be carefully read and understood before use.

To prevent bodily injury, safe working practices should be employed when operating or servicing the

machine.

INTRODUCTION

ABOUT THIS MANUAL

This manual provides detailed information and procedures for setting up and operating the

Bridgeport DX32 Computerized Numerical Control. The DX32 CNC combines the advanced

part-programming ability of the Bridgeport BOSS 9 and BOSS 10 controls with a PC-based

user interface, which provides even more sophisticated capabilities. The DX32 is more

powerful than ever and its user-friendly screen displays make it easier to learn and use than

previous CNC systems.

Updates and enhancements to the BOSS Operating System can be loaded entirely from

computer disk. This feature prevents the DX32 from quickly becoming obsolete. The

completely reprogrammable DOS-based PC technology provides a springboard into the

future, much more so than the Application Specific Design now prevalent in today’s CNCs.

WHAT IS INCLUDED IN THIS MANUAL

Chapter 1 Getting Started provides a brief overview of the parts of the DX32, describes

what each part does, and explains how the system hardware and software run

together. Also included are instructions on setting up the DX32 for operation.

Chapter 2 System Start-Up/Shut-Down describes the system start-up and shut-down

procedures.

Chapter 3 BASIC OPERATION describes the most frequently used commands.

Chapter 4 SET-UP describes how to set-up the part for subsequent machining.

Chapter 5 RUN describes the various Run options.

Chapter 6 EDIT/MDI summarizes the commands available for editing part-program text.

Chapter 7 DOS Commands gives some information on the DOS system software

necessary to run the control.

Appendix A Axes and Coordinates explains the basic principles of axis function within

the context of machine tools.

Appendix B Rotary Table explains how to operate the machine with a fourth axis rotary

table option.

Appendix C DX 32 Workshift describes the "workshift" feature used when multiple setups

are required on the machine at the same time.

Appendix D Common Error Messages lists the error message users commonly get while

using the machine, with an explanation of the error causes.

v

vi

TABLE OF CONTENTS

SECTION PAGE

Chapter 1

DX32 HARDWARE/SOFTWARE

Introduction .................................................................................................................1-1

General Description ....................................................................................................1-1

Basic Hardware ...........................................................................................................1-2

Operator’s console ......................................................................................................1-2

Basic BOSS DX32 Software ........................................................................................1-4

Chapter 2

STARTING UP THE DX32

Introduction .................................................................................................................2-1

Before Starting the DX32 ............................................................................................2-1

Turning on the DX32 ..................................................................................................2-1

Modes of Operation ....................................................................................................2-2

Reading the CRT Display ............................................................................................2-5

Homing the Axes .........................................................................................................2-7

Normal Shutdown Procedures ....................................................................................2-7

Power Failure ..............................................................................................................2-7

System Reset ................................................................................................................2-8

System Configuration ..................................................................................................2-8

Chapter 3

BASIC OPERATION

Basic Operation ...........................................................................................................3-1

Key Functions ..............................................................................................................3-2

0 EXIT BASIC MENUS ..........................................................................................3-2

1 AUTO .................................................................................................................3-2

2 BLOCK ...............................................................................................................3-2

3 FEED OVR .........................................................................................................3-2

4 FIND :_N_T_ ......................................................................................................3-2

5 RESET PGM .......................................................................................................3-2

6 S_T_M_ ..............................................................................................................3-2

7 SET T// ...............................................................................................................3-2

8 SET TNO.............................................................................................................3-2

9 JOG ....................................................................................................................3-2

F2 S_/OFF .............................................................................................................3-2

F3 SETUP ..............................................................................................................3-2

F4 RUN ..................................................................................................................3-2

F5 PREVIEW .........................................................................................................3-2,8

F6 EDIT .................................................................................................................3-3

F7 LOAD ...............................................................................................................3-3,9

F8 COOLANT ........................................................................................................3-3

vii

F9 QUILL UP .........................................................................................................3-3

Jogging the Axes .........................................................................................................3-3

F2 TEACH .............................................................................................................3-4

F4 GEOM ..............................................................................................................3-4

F5 GOTO CLR PT .................................................................................................3-11

F6 SET X ...............................................................................................................3-11

F7 SET Y ...............................................................................................................3-11

F8 TLO = Z ...........................................................................................................3-11

F9 QUILL UP .........................................................................................................3-12

F10 ABS/INC .........................................................................................................3-12

Chapter 4

SETUP MODE

Introduction .................................................................................................................4-1

Setup Screen .................................................................................................................4-1

Key Functions ..............................................................................................................4-2

0 EXIT SETUP MENU.............................................................................................4-2

1 WORKSHIFT.......................................................................................................4-2

2 MOVETO X_Y_Z_ ..............................................................................................4-2

3 JOG .....................................................................................................................4-2

5 SET CLRPT.. ........................................................................................................4-2

6 GO CLRPT...........................................................................................................4-2

7 SET T//................................................................................................................4-2

8 SET REFPT ..........................................................................................................4-2

9 GOTO REFPT .....................................................................................................4-2

F6 EDIT..................................................................................................................4-2

F7 LOAD.. ..............................................................................................................4-2

F9 QU UP.. .............................................................................................................4-3

F10 ABS/INC..........................................................................................................4-3

Coordinate Systems ....................................................................................................4-3

Setting Up Tool Change Clearance Point ...................................................................4-3

Entering Tool Table Data ............................................................................................4-4

Tool Length Offsets .....................................................................................................4-5

Cutter Diameter Compensation ..................................................................................4-6

Filling and Loading Part Program................................................................................4-7

Chapter 5

RUN MODE

Run Mode ....................................................................................................................5-1

Key Functions ..............................................................................................................5-1

1 AUTO .................................................................................................................5-1

2 BLOCK ...............................................................................................................5-1

3 FEED OVR ..........................................................................................................5-1

5 RESET PROGRAM .............................................................................................5-1

6 S R/0=PR/ACT ...................................................................................................5-1

7 SET OPTION ......................................................................................................5-2

9 CLEAR CNC ........................................................................................................5-2

0 EXIT RUN MENU ...............................................................................................5-2

F2 S/OFF ...............................................................................................................5-2

viii

ix

F4 EDT CNC .........................................................................................................5-2

F5 MDI ..................................................................................................................5-2

F6 FND:NT ............................................................................................................5-2

F8 COOLNT ..........................................................................................................5-2

F9 QU UP ..............................................................................................................5-2

D10 SET DNC .......................................................................................................5-2

Resuming Operation After Power to the Drives has been Disabled ........................5-3

Modifying Feed Rates ..................................................................................................5-4

Run Options ................................................................................................................5-4

Chapter 6

EDIT MODE

Edit Mode ....................................................................................................................6-1

Commands for Editing Text ........................................................................................6-1

F2 EXIT .................................................................................................................6-2

F3 READ* ..............................................................................................................6-2

F4 WRITE* .............................................................................................................6-2

F5 FIND .................................................................................................................6-2

F6 REPLACE ..........................................................................................................6-2

F7 PRINT................................................................................................................6-2

F9 CUT ..................................................................................................................6-2

F10 COPY .............................................................................................................6-2

<ALT A> MARK ....................................................................................................6-2

<ALT D> DEL LN ..................................................................................................6-2

<ALT I> INSERT ...................................................................................................6-2

<INS KEY> PASTE ................................................................................................6-2

<HOME> ...............................................................................................................6-3

<END> ..................................................................................................................6-3

<PGUP> ................................................................................................................6-3

<PGDOWN> .........................................................................................................6-3

UP/DOWN/LEFT/RIGHT ARROW .......................................................................6-3

Direct MDI Input .........................................................................................................6-3

Using the G-code Help Mode .....................................................................................6-3

Chapter 7

DOS COMMANDS

DOS System Commands .............................................................................................7-1

Execute Program ..................................................................................................7-1

List Directory ........................................................................................................7-1

Format Disk ..........................................................................................................7-1

Copy Files .............................................................................................................7-2

Disk Copy .............................................................................................................7-3

Re-Booting DOS ...................................................................................................7-3

Setting up the System Configuration ...................................................................7-4

Appendix A

AXES AND COORDINATES..........................................................................................A-1

Appendix B

4

TH

ROTARY AXIS .............................................................................................................B-1

Appendix C

DX-32 WORKSHIFT .........................................................................................................C-1

Appendix D

COMMON ERROR MESSAGES...................................................................................D1

x

CHAPTER 1

HARDWARE/SOFTWARE

Introduction

This chapter describes the hardware and software associated with the DX32 CNC.

Included in this chapter are:

❏ A brief overview of the parts of the DX32.

❏ A description of what each part does and how the system hardware and

software function together.

General Description

The DX32 control integrates a PC computer and a BOSS (Bridgeport Operating System

Software) CNC control. The PC DOS-based computer combines full-feature capability with

ease of use by incorporating VGA color graphics and multiple windows that prompt the user

through all control functions. The various machine functions are selected with the numeric

keypad and function keys on the keyboard. The keys required to perform the necessary

operator functions are linked to a color-coded, on-screen display.

An on-screen Editor incorporates a unique G-code conversational mode that prompts the

operator for the information required to execute a machine command. User-selectable HELP

screens provide detailed information about the G-code being entered. The editor provides

an immediate MDI (Manual Data Input) mode to execute a programmed block of data after

it is formatted on the screen. The DX32 features an extensive selection of canned cycles that

allow easy execution of frequently used cycles, such as: bolt circles; multi-hole row and

frame drilling; slot, frame, and pocket milling, with only a single block of programmed data.

The control includes all the standard high performance features associated with the BOSS 9

and 10 controls:

❏ 3D Linear, 2D Circular, Helical, and Spiral interpolation.

❏ XYZ/Polar/Spherical coordinates.

❏ Cutter compensation with automatic corner-rounding.

❏ Parametric programming that includes Algebraic and Trigonometric functions,

and IF-THEN conditional block execution.

❏ Repetitive programming using looping techniques and MACROs with call-

modifiable variables.

❏ 256,000 characters (more than 200 ft.) of part-program storage.

❏ DNC data transfer between the PC based front end and the CNC machine

controller which allows programs of unlimited length to be executed

from disk.

1-1

The control includes a built-in 3.5 inch floppy disk drive and a hard disk drive.

The hard-cased 3.5 inch floppy disk has a spring loaded, positive cover over

the read area for additional protection in the typical shop environment. Each

disk has a 1.44Mbyte capacity (12,000 ft.). A user friendly DOS Shell enables

the user to list file directories and to copy, delete, and rename files, as well as

format disks. Communications software is provided to link to remote

computer systems, such as EZ-CAM, via a provided RS-232 interface.

Basic Hardware

The DX32 consists of three separate and coordinated microprocessor based sub-systems.

These are:

PC: This is a fully integrated IBM PC compatible computer with hardware

controllers for a hard disk, a 3.5 inch 1.44 Mbyte floppy disk drive, a 14”

color VGA monitor with 640 x 480 pixel resolution, an alpha-numeric

keyboard, and 1 RS-232 serial ports. The primary purpose of the PC is to

serve as the user interface for the system. The PC runs under the MS-DOS

Operating System.

BMDC: This is a single board Motorola 68030 microprocessor-based motor drive

controller. The BMDC board performs the processing functions that control

the positioning of the four servo drives for the X, Y, Z, and C axes. The

BMDC board also monitors system status and coordinates all machine tool

related processes. The BMDC board runs under the BOSS DX32 Operating

System.

AUF: This is a single board microprocessor-based auxiliary function controller.

The AUF provides the conditioned input/output signals that perform various

machine related functions, such as spindle and coolant control, jogging, and

spindle speed control. The AUF is connected via internal serial link to the

BMDC.

1-2

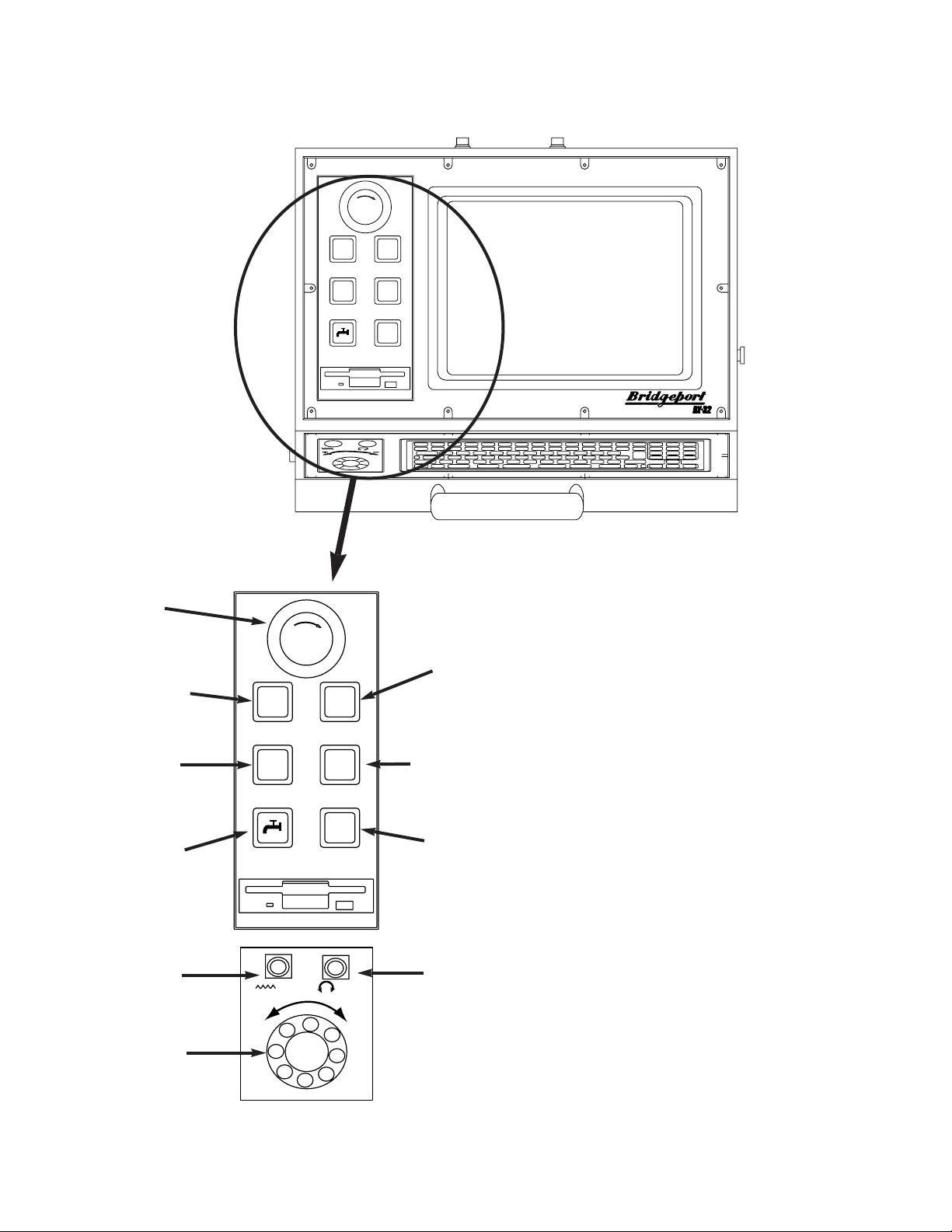

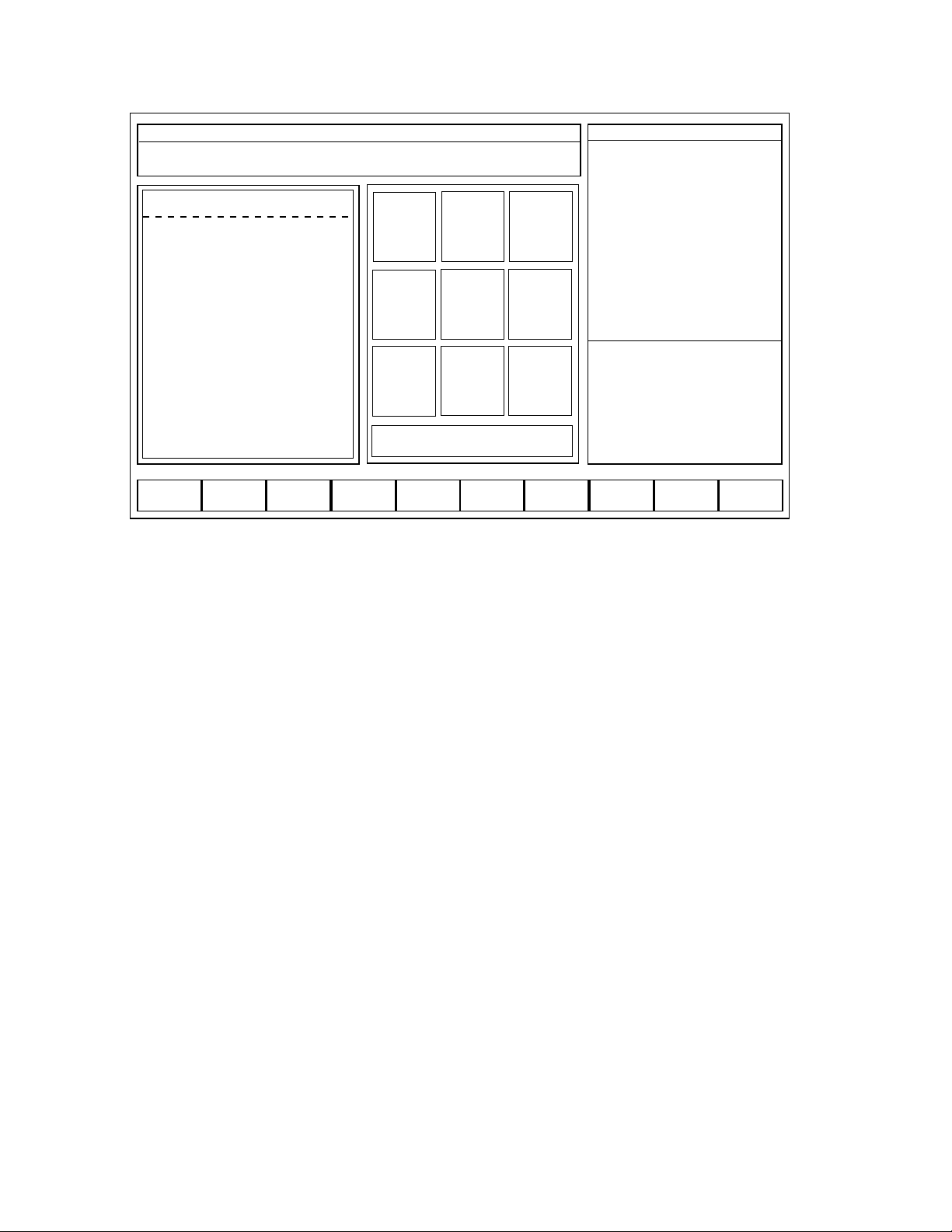

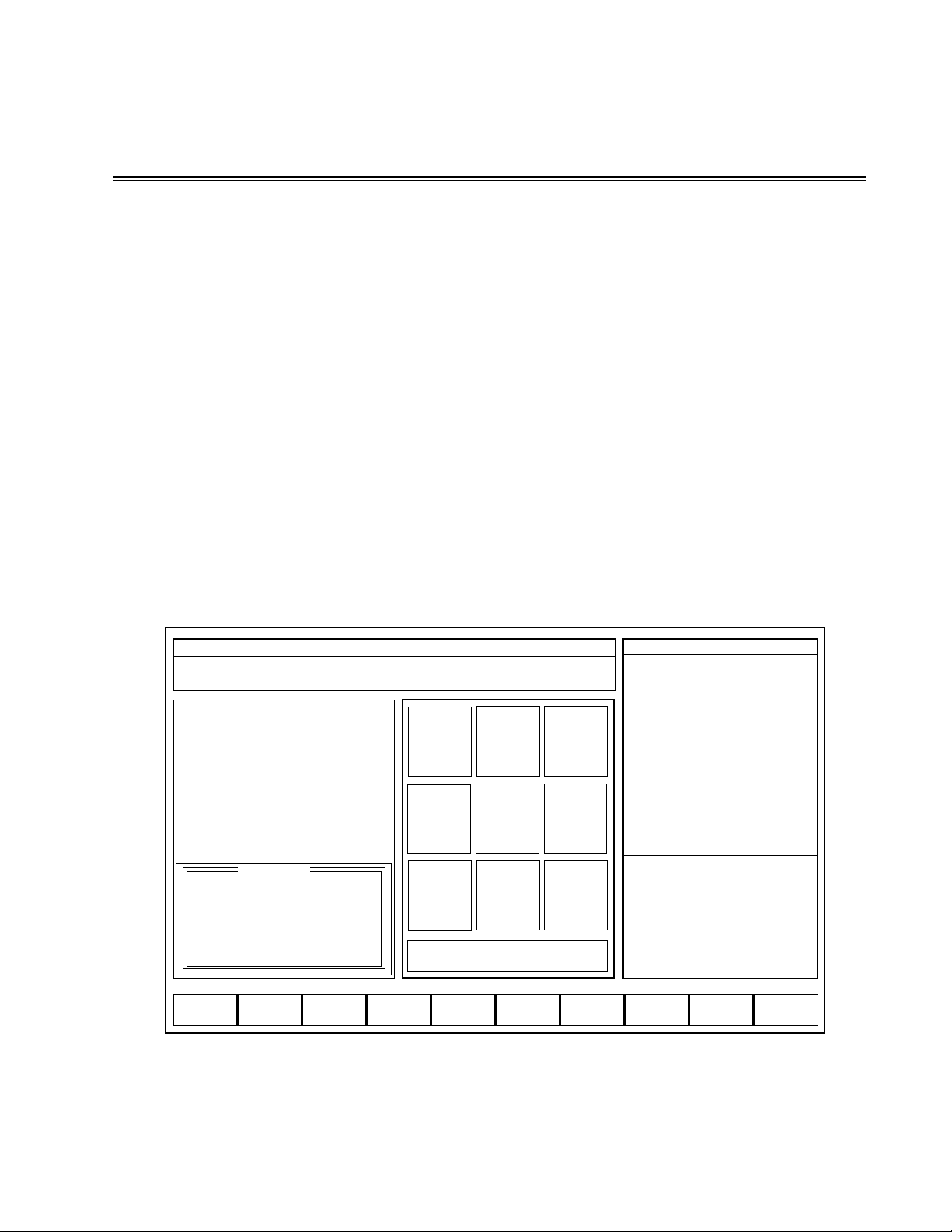

The Operator’s Console (Figure 1-1)

consists of a pendant-mounted VGA Color

monitor, a keyboard, and control buttons.

These controls are used to operate all

functions of the CNC.

The VGA Color monitor displays the

screen menus from which the operator can

select control functions.

The keyboard provides the basic means

for communicating with the DX32 control.

The keys are organized into five groups,

they are:

1. Main Keyboard This includes all

the keys normally found on a

typewriter.

2. Numeric Keypad This includes

numbers 0-9, decimal point and

mathematical function keys. It is

used with pop-up menus on the

screen to select various control

functions.

1-3

S%

F%

E

T

EE

NN

C

Y

-

S

G

R

P

-

S

T

O

E

M

Y

E

M

E

R

O

P

G

E

N

C

START

STOP

+

_

SPINDLE

STOP

E

T

EE

NN

C

Y

-

S

G

R

P

-

S

T

O

E

M

Y

E

M

E

R

O

P

G

E

N

C

START

STOP

+

_

SPINDLE

STOP

F%

S%

STOP

SWITCH

START

SWITCH

JOG +

JOG –

COOLANT

ON/OFF

SPEED %

POT

EMERGENCY

STOP

FEED %

POT

AXIS

MOTION

ENCODER

SPINDLE

STOP

Figure 1-1

OPERATOR'S CONSOLE

3. Function Keys These enable the operator to select special functions that are

assigned to each key.

4. Screen Control Keys These enable the operator to select data from different

locations on the screen display, particularly in Edit mode.

5. Special Keys These keys communicate directly to the operating system.

The control buttons each have a specific function. These functions are used in setting up a

part and running a part program.

START Pressing the START button begins operation of the part program at the

current line of the part program text. START also resumes execution

after an interruption such as PROGRAM STOP or system HOLD.

STOP This button stops part program execution and interrupts axis motion

without loss of the program position. All axes decelerate to a smooth

stop unless a tapping (G84) cycle is in progress. During a tapping or

tool change cycle, the machine motion continues until the end of the

cycle. The perimeter door guards can be opened at this time, which

causes the spindle and coolant to shut off. When the doors are closed,

the spindle and coolant will return to their previous conditions.

NOTE: In RAPID TRAVERSE (G0) motion may continue up to 0.2

inches after STOP is pressed. The active registers are not lost. To

continue, use START.

EMERGENCY

STOP This is a red mushroom button which, when pressed, stops the spindle

motor and axes drives. Program execution is terminated and the system

is set in the System Start Up mode. When EMERGENCY STOP is

pressed, the part program and the tool length offsets (TLOs) are not

destroyed and axis position is not lost. The EMERGENCY STOP button

should only be used when an immediate halt of all motion is absolutely

necessary or when safety is threatened. In normal use the HOLD

button should be used to interrupt axis motion.

To recover from EMERGENCY STOP, first correct the problem which

caused the use of the button. Next, pull out the button and then

execute the AXIS DRIVE ENABLE sequence. Under certain

circumstances the axes drives may need to be re-homed. In this case

the machine will prompt the operator to re-home the machine.

1-4

JOG +/- These are two push-button selector switches. They are used for either

jogging an axis continuously, or in 0.0001 steps.

When 9 JOG is selected from the BASIC menu, pressing the push-

button causes the axis selected from the screen menu to move. There

are two selectable jog motions: FAST and SLOW.

% SPEED This potentiometer is used to change the speed of the spindle. The

requested spindle speed is adjustable from 50 to 200%.

% FEED This potentiometer is used to change the speed of the axis traverse and

programmed feed after the override function has been activated. The

requested feed or traverse rate is adjustable from 0 to 150%.

COOLANT

ON/OFF This switch is a normally-open,momentary push-button which acts like a

toggle switch.If the flood coolant is off,depressing the switch starts the

flow of flood coolant (M8 flood coolant ON).If the flood coolant is on,

depressing the switch stops the flow of flood coolant (M9 flood coolant

OFF).

AXIS MOTION

ENCODER This encoder will generate axis motion on the axis selected by the

operator.The knob,when rotated,causes 0.1 inches of motion for each

revolution when the fast jog is selected,and 0.01 inches of motion when

the slow jog is selected.The speed on the axis motion is controlled by

the speed of the rotation of the knob.

Basic BOSS DX32 Software

PC Software used on the PC consists of System Software, Applications

Software, and User Data.

System

Software System software is the essential collection of programs the DX32 needs

before you can use it. The operating system used on the PC is MSDOS. MS-DOS (DOS) is a collection of routines that perform basic

tasks such as starting (or booting up) the computer, moving data to and

from disks and peripheral devices, and managing and allocating

memory space in RAM. The most frequently used DOS System

commands are described in this manual. For more information on

DOS, refer to the MS-DOS User’s Reference Manual.

1-5

DOS is the bottom layer of software used on the PC. In normal

operation, it is not necessary to access the DOS level. Upon start-up, a

routine called AUTOEXEC.BAT automatically loads the DX32 specific

applications software. For advanced users DOS can be accessed via the

START-UP menu.

Applications

Software The routines that call the front panel screens and perform the

commands selected from the screen menus are contained in a program

named BXX.EXE. The software driver which controls axis drive

functions, and executes machine instructions is called BMDC.BIN. For

information on updating the applications software, see Chapter 7.

NOTE: The programs BXX.EXE (which runs on the PC) and BMDC.BIN

(which runs on the BMDC) are essentially independent of each other.

Status and text data are passed between the two programs as required.

This enables concurrent use of the systems. For example, the PC can

be used to edit a program while the BMDC is machining a part, or the

PC can be in the Diagnostic Mode monitoring the servo performance

while the BMDC is running diagnostic moves.

There are DOS level errors that can stop execution of BXX.EXE. The

most frequent error occurs when no disk or an improper disk is

mounted in the disk drive. DOS flags the error and breaks to the DOS

system level. To resume operation, type RUN when the DOS prompt

(C>) appears.

User Data User Data consists of part programs and tool data. The file extension

.TXT is appended to part program text. The file extension .DAT is

appended to tool data.

BMDC BOSS DX32 is the Operating System used on the BMDC. Previous

Bridgeport CNC systems had BOSS imbedded in ROM. On the DX32,

BOSS is loaded into RAM located on the BMDC board.

DX32 SYSTEM DISK

The software described above is stored on the hard disk, as well as a

3.5 inch floppy backup disk. System software and user data may reside

on the same disk, however, this does limit the amount of available

space for storing user data. It is strongly suggested that backup copies

of the system software be kept in a safe place (away from extreme heat,

cold, or humidity, magnets, oil and dust).

1-6

CHAPTER 2

STARTING UP THE DX32

Introduction

The procedure detailed in this chapter is necessary to properly start the DX32 System. Make

certain that all set up and pre-start maintenance has been completed before attempting to

start the machine.

Before Starting the DX32

Make a careful check of the following conditions before applying power.

1) Check level of lubricating oil, refill if low.

2) Check position of all axes with respect to fixtures or other parts left on the

table.

3) Check air pressure level, adjust to nominal psi.

CAUTION!!

If there are ANY problems with any of the prestart checks, DO NOT start the

machine. Check the Maintenance Manual for proper start up maintenance

procedures. Failure to do so may result in machine damage.

Turning on the DX32

The DX32-controlled machines boot automatically from the standard hard disk contained

within the control cabinet. Before turning on the MAIN DISCONNECT, make sure that the

floppy disk drive is empty. To power up the system, move the MAIN DISCONNECT switch,

located toward the rear of the machine, to the ON position.

The system will then run through its STARTUP diagnostics and loads the BMDC.BIN software

to the BMDC. The system also verifies the integrity of the driver code stored in the BMDC

RAM. If the driver code has been corrupted, the system prompts the operator to load a new

version of the driver code. This would require inserting the backup software disk and

following the update or install instruction found in Chapter 7. If the driver code is okay, the

STARTUP routine then automatically loads and executes the DOS-based DX32 System

Software. The START-UP SYSTEM Menu then appears on the screen. See Figure 2-1 below.

2-1

Figure 2-1

To start the system from a floppy disk, (System Disk only), put the disk into the disk drive

BEFORE turning the MAIN DISCONNECT on.

NOTE: The SYSTEM MODE status window (top line in the screen) displays the

current version number of the DX-32 software. Always reference this

number when calling Bridgeport for technical support.

Modes of Operation

The DX32 uses any one of four basic modes during machine operation. They are:

STARTUP BASIC OPERATION SETUP RUN

The default mode after system initialization is STARTUP. The BASIC OPERATION menu is

automatically displayed after the axis drives are enabled and the axes are homed. The

SETUP mode is made active by selecting F3 SETUP from the BASIC menu. The RUN mode

is made active by selecting F4 RUN from the BASIC menu.

STARTUP

This mode is the first active mode after the system is booted up.

The system commands available from the STARTUP screen are:

2-2

BOSS DX/32 V4.08/6.41

MON JAN 14 03:15:04 PM

Copyright (c) 1988-1995 BRIDGEPORT MACHINES, INC.

[C;\ bytes free = 259596288]

BRIDGEPORT DX/32 CNC

This software is subject to revision

and enhancement. To receive

software updates register your

system by calling BRIDGEPORT

CONTROLS at 215-788-8484.

Please give us your NAME/ TITLE/

COMPANY/ ADDRESS/ CITY/

STATE/ ZIP/ PHONE/ FAX/

DEALER/ and CNC SERIAL NO.

[FAX 215-788-0734]

1

SET

PARAMs

23

JOGoff

LIMITS

4

LOAD

Remote

5

FILES

6

Tool

Change

7

AXSDRV

ENABLE

8

HOME

AXES

9

DOS

0 SELECT BASIC MENUS

F1

F2

N-SEE

F3

WINDOWS

F4

EZ-SPS

F5 F6

dataNET

F7

DIGITIZF8SUProbe

F9

LDmdcSW

F10

Params

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

OFF

OFF

OFF

OFF

OFF

1 SET PARAMs

Refer to Maintenance Manual.

3 JOGoff LIMITS

This provides the ability to jog-off the axis limit switches. This may be necessary

prior to homing if the axis position is such that a limit switch is actuated.

4 LOAD Remote

This provides a communications link to remote devices.

5 FILES

This provides the ability to DELETE, RENAME, COPY and APPEND DATA and

TEXT files.

6 TOOL CHANGER

This command accesses Tool Changer settings. This command gives the user the

ability to load the tool magazine with tools and home the magazine when done.

This command is also where the tool change setup is done (refer to the

maintenance manual on tool change setup).

7 AXSDRV ENABLE

This command turns on power to all the axis drives.

8 HOME AXES

This command initiates the machine homing sequence.

9 DOS

This command exits to the MS-DOS operating system.

0 SELECT BASIC MENUS

This command selects the BASIC OPERATIONS screen display.

The displayed STARTUP commands which can be executed using the Function keys are:

F2 N-SEE

[Enhanced Performance Option] This command executes the N-SEE software.

F3 WINDOWS

[Enhanced Performance Option] This command exits to the Microsoft Windows

environment.

F4 EZ-SPS

[Option] This command exits to the Bridgeport Simplified Programming System.

2-3

F6 dataNET

This command links with a high-speed data network for client-server based

communications. This network option is not offered by Bridgeport, it must be

installed by the user.

F7 DIGITIZ

[Digitizing Software Option] This command exits to the Bridgeport Digitizing

software.

F8 SUProbe

This command enables or disables the Probe.

F9 LDmdcSW

This command enables reloading the machine software (BMDC.BIN) into the

BMDC.

F10 Params

This command enables the operator to configure certain system parameters.

(i.e. backlash, rapid and jog rates)

The [ESC] key is used to clear the EVENT STATUS messages.

NOTE: Pressing [ESC] does not correct the cause of the ERROR message. The error

condition must be corrected before the machine can continue to operate.

During an alarm condition, the blinking “ALARM” message needs to be cleared

with the “ESC” key BEFORE any other command will be executed, such as

spindle off, quill up, etc.

BASIC OPERATION

For simplified operation, the BASIC OPERATION menu contains the most frequently

used operator commands. In normal operation, all the commands necessary to set up

and run the DX32 can be selected from this screen.

Less frequently used DX32 commands can be accessed from the BASIC OPERATION

menu by accessing the STARTUP, SETUP, and RUN menus.

This mode is discussed in greater detail in Chapter 3 in this manual.

SETUP

The SETUP screens prepare the machine for part making. This includes establishing

machine reference points, tool characteristics, initial axis positions, and loading part

programs.

The EDIT function can be accessed through the SETUP mode. This mode is discussed

in greater detail in Chapter 4 in this manual.

2-4

RUN

This mode runs a part program that has been previously loaded into BMDC RAM either

in Automatic or Block mode. RUN mode also works with DNC LINK (Direct Numerical

Control).

The MDI function can be accessed in the RUN mode. This mode is discussed in

greater detail in Chapter 6 in this manual.

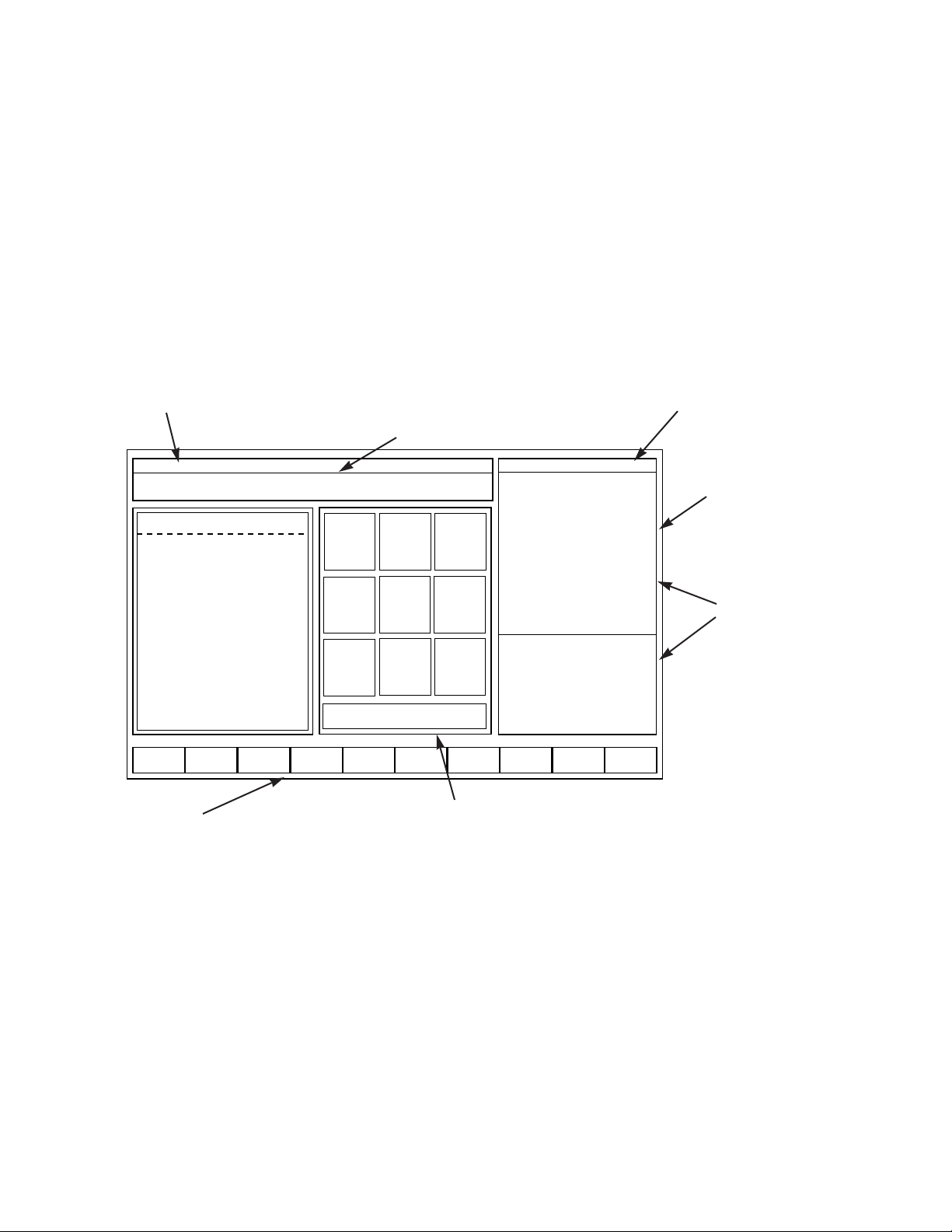

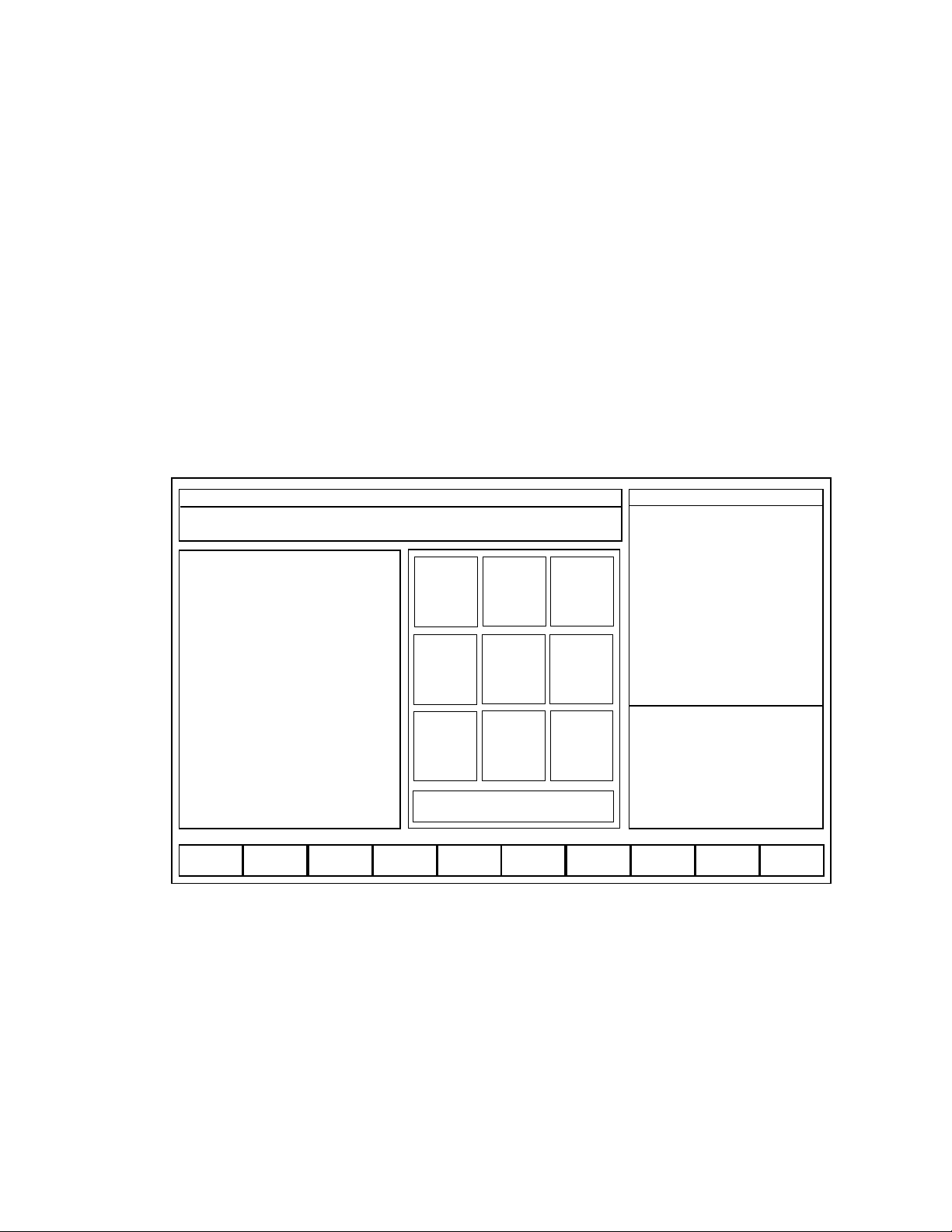

Reading the CRT

The DX32 screen contains the fields shown in Figure 2-2, below.

Although the initial reaction to the DX display may be that the screen looks cluttered with

data, the screens are actually set up in a consistent, informative manner. The object is to

present as much information as possible without requiring the operator to access additional

layers of data.

The screen display consists of the following windows:

2-5

BOSS DX/32 V4.08/6.41

MON JAN 14 03:15:04 PM

Copyright (c) 1988-1995 BRIDGEPORT MACHINES, INC.

[C;\ bytes free = 259596288]

BRIDGEPORT DX/32 CNC

This software is subject to revision

and enhancement. To receive

software updates register your

system by calling BRIDGEPORT

CONTROLS at 215-788-8484.

Please give us your NAME/ TITLE/

COMPANY/ ADDRESS/ CITY/

STATE/ ZIP/ PHONE/ FAX/

DEALER/ and CNC SERIAL NO.

[FAX 215-788-0734]

1

SET

PARAMs

23

JOGoff

LIMITS

4

LOAD

Remote

5

FILES6Tool

Change

7

AXSDRV

ENABLE

8

HOME

AXES

9

DOS

0 SELECT BASIC MENUS

F1

F2

N-SEE

F3

WINDOWS

F4

EZ-SPS

F5 F6

dataNET

F7

DIGITIZF8SUProbe

F9

LDmdcSW

F10

Params

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

OFF

OFF

OFF

OFF

OFF

System Mode

Operator Instructions

Data Display Areas

Numeric Keypad Commands

Special Function Commands

System Run and Aux Status

MDC Event Message

Figure 2-2.

System Mode

This is a one line status message which displays the System MODE. A real time clock

is also displayed on this line.

Operator Instructions

This is a two line message containing information for the operator. A blinking arrow

at the top right hand side of the window indicates when operator input is required.

NOTE: There are two kinds of input required from the operator:

1) A <NUMERIC KEY> or <FUNCTION KEY> selection may be required to

perform the desired command.

2) A DATA field entry may be required. The only way to complete a DATA field is

to press the <ENTER> key once the data has been satisfactorily entered, or the

<ESC> key to CANCEL the command.

Data Display Areas

The data display areas are used to show important system information, such as AXIS

POSITION, PART PROGRAM TEXT, TOOL TABLES, etc.

Numeric Keypad Commands

These show the available commands which can be selected with individual keys on

the keypad.

Special Function Commands

These show the available commands which can be selected with individual function

keys on the keyboard.

System Run and Aux Status

These show the state of the MDC controller. All key data registers and mode bit flags

are displayed. The TOP line of the RUN STATUS display is particularly important, it

shows whether the system is OFF, in MANual mode, in RUN mode, or in HOLD. It

also indicates whether input is ABS or INC and whether the system is in B4-7 or B8&

mode.

MDC Event Message

This is a one line event status message that displays run time dependent messages.

For example, it will show fault or error messages.

2-6

Homing the Axes

From the STARTUP screen, press 7 AXSDRV ENABLE to power up the drives. Next, press 8

HOME AXES twice to initiate the machine homing sequence. This causes the Z axis to

move up to the “Home” position and the X and Y axes, and C if installed, to move to their

“Home” positions in sequence. The tool changer will also position itself to the current tool

position.

NOTE: Perimeter guard doors need to be closed to initiate the homing process.

Once the tool carousel is finished homing the doors can then be opened.

The SYSTEM STATUS window shows the X ABS, Y ABS, and Z ABS position,

and C ABS if installed. Prior to homing, Not Homed is displayed. If an Axis

LIMIT has been exceeded, the OPERATOR’S INSTRUCTION window reads:

Following the directions, use the JOG knob to move the axis off the Limit.

CAUTION!! Be sure to select the correct jog direction.

Additionally, the EVENT STATUS window may display an ERROR message describing a

System Fault.

Normal Shutdown Procedures

Use the following procedure to shutdown the machine for either overnight or extended

periods of time.

1) Select BLOCK mode or wait for a tool change block if a program is

running.

2) Turn spindle OFF.

3) Depress EMERGENCY STOP.

4) Switch machine Main Disconnect to OFF.

Power Failure

Loss of power to the machine for more than 1/60 of a second (1 cycle) causes a system

shutdown. Use the initial system start up procedure to restart the machine after power

failure.

2-7

—>X AXIS LIMIT —— Use JOG KNOB to MOVE OFF LIMIT

NOTE: System RESET may be required if power was off for less than

one half second.

System Reset

Pressing the RESET push-button switch sets the DX32 in an initial start up condition. Follow

the start up procedure.

System Configuration

Pressing the F10 XT Params key allows the operator to set various system parameters. The

UP and DOWN arrow keys are used to select the parameter to be changed. The system

parameters that can be set via the Params screen are:

MAX RATE

Entering a value here sets the rapid traverse rate (G0).

JOG RATE

Entering a value here sets the jogging traverse rate.

BACKLASH COMPENSATION

Entering a two (2) digit number from 2 – 25 sets the designated backlash

value into the system.

The system configuration values are saved in a file named BMDCPRMS.SYS.

It is VERY important that the DX32 BACKUP DISK is matched with the

machine that it is to be used with, otherwise, configuration values may

not be set properly.

2-8

Chapter 3

BASIC OPERATIONS

The BASIC OPERATION mode contains the commands most frequently used by the

operator. The following operations are available from the BASIC OPERATIONS menu.

1) Axis jog, axis motion and establishment of machine/part program coordinate

system.

2) Entering, storing, and loading Tool Data.

3) Setting of RUN mode – RESET program, AUTO, BLOCK.

4) Operation of machine functions – COOLANT, FEEDRATE OVERRIDE.

5) Loading part programs.

6) Editing part programs.

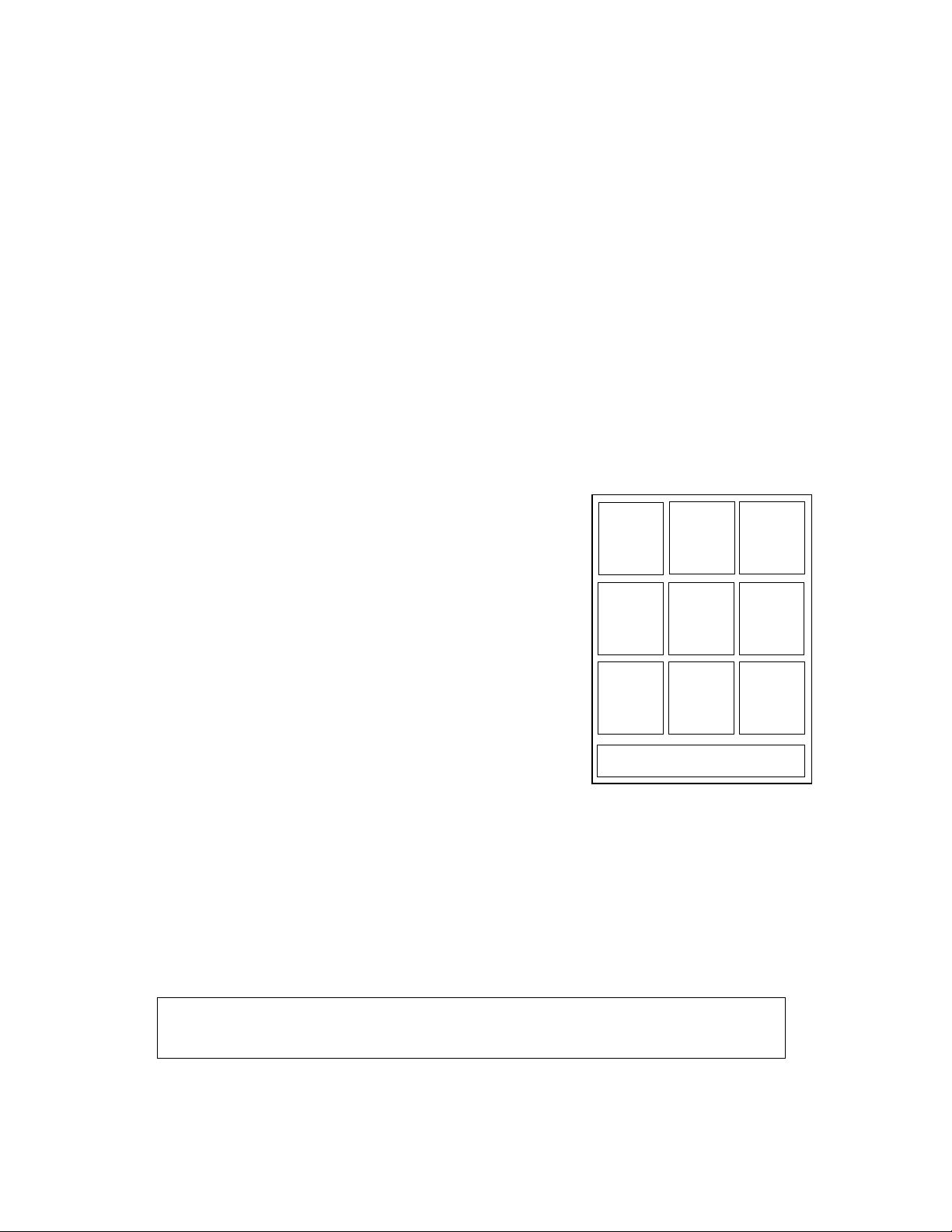

Basic Operation Screen

The BASIC OPERATION screen appears as shown in Figure 3-1.

Figure 3-1

3-1

BASIC | |

MON JAN 14 03:15:04 PM

Use <f KEY> or <NUM KEY> to select FUNCTION

Cursor Up/Dn for Feed Override (5% increments)

1

AUTO

2

BLOCK3FEED

OVR

4

FND

:_ N_ T_

5

RESET

PGM

6

S_ T_ M_

7

SET

T//

8

SET

TNO

9

JOG

0 EXIT BASIC MENUS

F1

F2

S_/OFFF3SETUPF4RUN

F5

PREVIEW

F6

EDIT

F7

LOAD

F8

COOLANT

F9

QU UP

F10

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

OFF

OFF

OFF

OFF

OFF

C:

PRV:

CUR:

NXT:

X

Y

Z

12.4214

8.9717

7.1614

The key commands available from the BASIC OPERATIONS screen are as follows:

0 EXIT BASIC MENUS This command will exit the BASIC OPERATIONS mode and

return the operator to the STARTUP screen.

1 AUTO This command sets the system in RUN/AUTO mode. Hitting the START button

begins automatic execution of the part program.

2 BLOCK This command sets the system in RUN/BLOCK mode. Hitting the START

button begins block by block execution of the part program.

3 FEED OVR In RUN mode, this enables the use of the feed override potentiometer to

override programmed feedrates. When feed override is set to ON, the feed override

knob enables the overriding of rapid traverse and feed motion commands from 0% to

150%. When the feed override function is set to OFF, all motion commands return

back to executing at 100%, regardless of the feed override knob position.

NOTE: Spindle override – Whenever the spindle is rotating, the spindle override

knob is active, which enables the override of the programmed RPM from

50% to 200%.

4 FIND :_N_T_ This command searches the part program for a particular :,

N (Sequence Number), or T (Tool Number) value.

5 RESET PGM This command will reset the part program text pointer back to the top of

the program. It also initializes the system RUN registers.

6 S_T_M_ This command allows the input of S, T, and M values. (Spindle Speed,

Tool #, or Miscellaneous function)

7 SET T// This command allows the direct input of TLO and DIA values.

9 JOG This command calls the JOG screen. In addition to Axis JOG and MOTION

commands, the JOG screen contains a convenient set of commands for setting the

machine up. It will be discussed further in this chapter.

F2 S_/OFF This command shuts off the spindle.

F3 SETUP This command will bring up the SETUP screen. It will be discussed further in

Chapter 4 of this manual.

F4 RUN This command will bring up the RUN screen. It will be discussed further in

Chapter 5 of this manual.

F5 PREVIEW This command will provide a graphical display of the tool path. It will be

discussed further in this chapter.

3-2

F6 EDIT This command brings up the editor to allow the operator to make changes to

the part program. See Chapter 6 in this manual.

F7 LOAD This command loads a part program that is stored on disk to the CNC. It also

executes a RESET PGM command. It will be discussed further in this chapter.

F8 COOLNT This command selects FLOOD or MIST coolant, and turns the coolant

either ON or OFF.

F9 QUILL UP This command moves the Z axis to the UP (HOME) position.

Jogging the Axes

After the axes drives have been enabled and the axes have been homed, the BASIC

OPERATION mode can be used to set up and run the DX32. Pressing the 9 JOG key from

the BASIC OPERATION menu will bring up the screen shown in figure 3-2.

Figure 3-2

The commands available from the JOG screen are:

1 JOG X

4 JOG Y

7 JOG Z

5 JOG C (if installed)

These commands are used to select the axis that is to be jogged. A blinking number

indicates which axis has been selected.

3-3

SETUP || JOG |

MON JAN 14 03:15:04 PM

Select AXIS/MODE: <+> = MOVE X_Y_Z_ <-> = MOVETO PT [ ]

<.> = PROBEPT </> = SAVEPTS

1

JOG

X

2

JOG

SLOW

3

JOG

FAST

4

JOG

Y

56

7

JOG

Z

89

0 EXIT JOG MENU

F1

F2

TEACHF3Z PTS

F4

GEOM

F5

GoCLRPT

F6

SET X

F7

SET YF8TLO = Z

F9

QU UP

F10

ABS/INC

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

FXAXS

FXAXS

OFF

OFF

OFF

X

Y

Z

12.4214

8.9717

7.1614

1

2

3

4

5

6

7

8

-4.2150

6.0698

6.0698

-1.5723

1.8024

2.1276

1.9650

0.0000

9.0225

-0.5076

5.3724

1.5063

3.3186

3.2730

3.2958

0.0000

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

0.0000

2 JOG SLOW

3 JOG FAST

These commands select the resolution for jog motion. Jog is executed by rotating the

incremental jog knob or by pressing one of the two jog switches (+,-). In JOG SLOW

the resolution of the incremental jog knob is 0.01/rev and the selected jog axis is

moved 0.0001” each time the jog switch is pressed. In JOG FAST the resolution of

the incremental job knob is 0.1/rev and continuous motion occurs when the jog

switch is pressed.

F2 TEACH

This command enters the TEACH mode. It allows the operator to create a part once,

entering the required points, then having the machine save the moves as a part

program. This will be explained in greater detail further in this chapter.

F3 Z PTS

This command accesses a set of options for positioning the Z-Axis.

3-4

1

2

JOG

SLOW

3

JOG

FAST

4

JOG

Y

56

7

JOG

Z

89

0 EXIT JOG MENU

SAVE Z

UP PT

GO TO Z

UP PT

SAVE Z

DWN PT

GO TO Z

DWN PT

JOG

X

Z Up Point: This is a Z-axis position usually

some safe distance above the

workpiece which can be saved

for use in the Setup Mode.

Z Down Point: This is a Z-axis position usually

close to or on the workpiece

surface which can be saved for

use in the Setup Mode.

Go to Z Up Pt.

Go to Z Down Pt.:

These commands are used to

position the Z-axis to the Z Up

Point or Z Down Point location

in the Setup Mode.

F4 GEOM

The GEOMETRY mode is used in conjunction with the SAVE POINTS coordinates to

calculate intersections of lines, centers of rectangles or radii.

While in the JOG mode, the OPERATOR INSTRUCTION window displays the following

message:

Select AXIS/MODE: <+>=MOVE X_Y_Z_ <->=MOVETO PT

<.>=PROBEPT </>=SAVEPTS

If <+> MOVE XYZ is pressed, the OPERATOR INSTRUCTION window will display:

ABS indicates the input mode. Press <ENTER> without a value to advance the input pointer

past a field. After the X,Y, and Z move values are entered, the OPERATORS INSTRUCTION

window displays:

Pressing the <+> key moves the axes to the desired position.

If </> SAVE PTS is pressed, the OPERATOR INSTRUCTION window will display:

Entering a value from 1 through 8 stores the coordinates of the point in the saved

POINT table.

If <-> MOVE TO PT is pressed, the axes can be moved to a previously saved point in the

POINT table. The OPERATOR INSTRUCTION window displays:

After the desired saved point has been entered the OPERATOR INSTRUCTION window

displays:

Hitting the <+> key moves the table to the previously save position.

The <.> key selects the PROBEPT mode. This mode is used with a touch probe to touch off

points on the part surface. When the <.> key is pressed, the keypad display reads:

3-5

—>MOV X__________<ENTER> Y_________<ENTER> Z_________<ENTER>

ABS Hit <ESC> to CANCEL

—>MOVE X 1.0000 <ENTER> Y 2.0000 <ENTER> Z 0.0000 <ENTER>

<+> to MOVE XYZ or <ESC> to CANCEL

—>SAVE XY PT [1 thru 8] [ ] <ENTER> <ESC>=CANCEL

@ X1.0000 Y2.0000 Z0.0000

—>GOTO XY PT [1 thru 8] <HIT 1–8> or <ESC> to CANCEL

<+>=GOTO XYZ PT.

—>MOVETO PT [ 1 ] X1.0000 Y2.0000

<+> to MOVE XY or <ESC> to CANCEL

Figure 3-3

Use 2 PROBE -X, 3 PROBE +X, 5 PROBE -Z, 6 PROBE -Y, or 9 PROBE +Y to move the

probe into the part. After the probe hits the part, it automatically prompts the operator to

save the touch point and backs off from the part. The OPERATOR INSTRUCTION window

displays:

Entering a value from 1 through 8 stores the saved probe touch point in the stored POINT

table.

NOTE: The probe keys are situated so as to help the operator determine the

direction of the probe motion. If the probe does not come in contact

with the part before traveling 1.5”, it will return to its start point.

The F2 TEACH key selects the TEACH mode. In this mode, after the axes have been moved

using the JOG commands, TEACH commands are available to write the current coordinate

values into a file called TEACH.TXT.

WARNING!! Entering the TEACH mode will overwrite the contents of the previous TEACH

file. If another TEACH.TXT file exists, use the 5 FILES selection in the STARTUP menu

(Chapter 2) to rename the existing TEACH file.

3-6

—> SAVE XY PT [1 THRU 8]: <ENTER> <ESC>=CANCEL

@X1.0000 Y2.0000

SETUP | | JOG |

MON JAN 14 03:15:04 PM

PROBE XYZ | | Select PROBE AXIS:

or <ESC> = CANCEL

1

JOG

Z

2

PROBE

-X

3

PROBE

+X

4

JOG

Y

5

PROBE

-Z

6

PROBE

-Y

7

JOG

Z

89

PROBE

+Y

0 EXIT JOG MENU

F1

F2

TEACHF3Z PTS

F4

GEOM

F5

GoCLRPT

F6

SET X

F7

SET YF8TLO = Z

F9

QU UP

F10

ABS/INC

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

PROBE

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

ON

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

FXAXS

FXAXS

OFF

OFF

OFF

1

2

3

4

5

6

7

8

X

Y

Z

12.4214

8.9717

7.1614

2.5338

6.0698

6.0698

-1.5723

1.8024

2.1276

1.9650

0.0000

6.2763

-0.5076

5.3724

1.5063

3.3186

3.2730

3.2958

0.0000

-2.9828

-4.4115

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

0.0000

When the F2 TEACH key is pressed, the display reads:

Figure 3-4

Upon entering the TEACH mode, N0G0G90 is written as the first block of code in the file

TEACH.TXT.

The key functions for the TEACH mode are:

* This command enters the current coordinate value as a block of text in TEACH.TXT.

If ACK is ON, the <ENTER> key needs to be pressed to enter the data. If ACK is

OFF the data is entered as soon as the * key is pressed.

NOTE: use <ALT I> to toggle ACK OFF/ON. (ACK is the abbreviation for

Acknowledge.)

O This command ends the program. NG0M22 is written and the TEACH mode is

terminated.

T This command enables a T value to be entered. An NG0T1M26 block is written.

S This command enables a PROGRAM STOP. An NG0M20 block is written.

E This command ends the TEACH program.

R This command enables the RAPID mode. The current coordinates are prefixed with

a G0 code. For example, NG0X12.Y7.Z10.

3-7

SETUP || JOG |

MON JAN 14 03:15:04 PM

Select AXIS/MODE: <+> = MOVE X_Y_Z_ <-> = MOVETO PT [ ]

<.> = PROBEPT </> = SAVEPTS <*> = [WR] X_Y_Z_ PT

1

JOG

X

2

JOG

SLOW

3

JOG

FAST

4

JOG

Y

56

7

JOG

Z

89

0 EXIT TEACH MENU

F1

F2

EDI TCHF3Z PTS

F4

GEOM

F5

GoCLRPT

F6

SET X

F7

SET YF8TLO = Z

F9

QU UP

F10

ABS/INC

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

<T>

<S>

<E>

<R>

<M>

<D>

<F>

<ALT_I> ACK OFF

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

TEACH.TXT

X

Y

Z

12.4214

8.9717

7.1614

ACK ON RAPID

M This command enables the MILL mode. A prompt requires the feedrate to be

entered. The current coordinates are prefixed with a G1 code. The F code will

appear at the end of the block. For example: NG1X12.Y7.Z10.F10.

F This command enables a quick simplified FACE routine. The axes are assumed to be

at the extreme left and bottom of the surface to be faced, and the current depth is

assumed as the facing depth. A prompt asks for X, total X distance; Y, total Y

distance; Y, step Y distance; and F, feedrate. A routine to face the surface is

automatically generated.

F2 EDI TCH

This command sets the system in the EDIT mode for modifying the TEACH.TXT file.

On exiting from the editor, the system returns to the TEACH mode.

F3 Z PTS

This command accesses a set of screen commands for positioning the Z-Axis.

(See Page 3-4.)

The F4 GEOM key selects the GEOMETRY mode. This mode is used together with the

stored POINT table to construct the Midpoint of a Line, Midpoint of a Parallelogram,

Intersection of Two Lines, or the Center of a Circle. When the F4 GEOM key is pressed, the

keypad display reads:

Figure 3-5

3-8

SETUP || JOG |

MON JAN 14 03:15:04 PM

CALCULATE Geometry | | Select FUNCTION

or <ESC> = CANCEL

1

JOG

X

2

JOG

SLOW

3

JOG

FAST

4

JOG

Y

5

MID PT

RECT

6

CENTER

3 PTS

7

JOG

Z

8

MID PT

2 PTS

9

INT OF

2 LNS

0 EXIT JOG MENU

F1

F2

TEACHF3Z PTS

F4

GEOM

F5

GoCLRPT

F6

SET X

F7

SET YF8TLO = Z

F9

QU UP

F10

ABS/INC

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

FXAXS

FXAXS

OFF

OFF

OFF

X

Y

Z

12.4214

8.9717

7.1614

1

2

3

4

5

6

7

8

-4.2150

6.0698

6.0698

-1.5723

1.8024

2.1276

1.9650

0.0000

9.0225

-0.5076

5.3724

1.5063

3.3186

3.2730

3.2958

0.0000

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

-4.3115

0.0000

The key functions for the GEOMETRY mode are:

5 MID PT RECT This command calculates the midpoint of a rectangle by finding the

midpoints of two separate lines of the rectangle. The first two points entered are to

construct the first line, and the second two entered are to construct the second line.

The OPERATOR INSTRUCTION window displays:

For each of the four points, enter the number from 1 through 8 identifying the desired

previously stored point. After four points have been entered, the OPERATOR

INSTRUCTION window displays:

Entering a value from 1 through 8 stores the coordinates of the calculated midpoint in

the saved POINT table.

6 CENTER 3 PTS This command calculates the center point of an arc or circle from

three points lying on the circumference of the circle. The OPERATOR INSTRUCTION

window displays:

For each of the three points enter the number 1 through 8 identifying the desired

previously stored point. Probe diameter is equal to the diameter used when obtaining

the points (probe stylus diameter or edge finder diameter) and In/Out is for whether the

Inside or Outside of the Circumference was touched. After the data is entered the

OPERATOR INSTRUCTION window displays:

Entering a value from 1 through 8 stores the coordinates of the calculated center point in

the saved POINT table.

3-9

—>MIDPT RECT| P [ ] <ENTER> P [ ] <ENTER>

Y = PT: [ ] <ENTER> PT:[ ] <ENTER> <ESC>=CANCEL

—>SAVE XY PT [1 thru 8] ENTER <1–8> <0>=CANCEL

MID PT RECT| X5.0820 Y0.4999

—>CENTER 3 PTS| PT: [ ] <ENTER> PT:[ ] <ENTER> PT: [ ] <ENTER>

Probe Dia: [0.0000] <ENTER> In/Out: [ ] <ENTER> <ESC>=CANCEL

—>SAVE XY PT [1 thru 8] ENTER <1–8> <0>=CANCEL

CENTER 3 PTS. X5.0820 Y0.4999

8 MID PT 2 PTS This command calculates the midpoint between two points, and also

provides information about the two points. The OPERATOR INSTRUCTION window

displays:

For each of the two points, enter the number from 1 through 8, identifying the desired

previously stored point. Probe diameter is equal to the diameter used when obtaining

the points (probe stylus diameter or edge finder diameter) and In/Out is for whether the

Inside or Outside of the Surface was touched. After two points have been entered, the

OPERATOR INSTRUCTION window displays:

D is the distance between the points. A is the angle with respect to the X axis.

Entering a value from 1 through 8 stores the coordinates of the calculated center point in

the saved POINT table.

9 INTOF 2 LNS This command calculates the intersection of two lines. Each line is

determined by two points along the line. Probe diameter is equal to the diameter used

when obtaining the points (probe stylus diameter or edge finder diameter) and LEFT/

RIGHT is for which side of the surface was touched. The OPERATOR INSTRUCTION

window displays:

NOTE: The rules for cutter compensation apply to the left/right selection. The lines

need to be constructed as a typical cutter path would be described (i.e. pt1

pt2 pt3 pt4 not pt1 pt2 pt4 pt3).

For each of the two lines enter the number from 1 through 8, identifying the desired

previously stored points. After four points are entered, the OPERATOR INSTRUCTION

window displays:

3-10

—>INTOF 2 LNS| Probe Dia [0.0000] <ENTER> Left/Right: [ L ] <ENTER>

LN1 PT: [ ] <ENTER> PT:[ ] <ENTER> LN2 PT: [ ] <ENTER> PT: [ ] <ENTER>

—>SAVE XY PT [1 thru 8] ENTER <1–8> <0>=CANCEL

X2LN1 X7.2945 Y-5.3249 Z-0.7087 A89.9301 A-4.6637

—>MIDPT 2 PTS| PT: [ ] <ENTER> PT:[ ] <ENTER>

Probe Dia: [0.0000] <ENTER> In/Out: [ ] <ENTER> <ESC>=CANCEL

—>SAVE XY PT [1 thru 8] ENTER <1–8> <0>=CANCEL

MIDPT X5.0820 Y0.4999 Z-0.7087 D0.8191 A89.9309

Entering a value from 1 through 8 stores the coordinates of the calculated intersection in

the saved POINT table.

Other functions that can be used in JOG mode are:

F5 GOTO CLR PT This command moves the table to the clear point position. The point

from which the move is made is temporarily stored and is automatically entered as

default X and Y values when a MOVETO XYZ PT command is selected. The OPERATOR

INSTRUCTION window displays:

Hitting the <+> key moves the table to the clear point.

F6 SET X

F7 SET Y These commands enable the operator to set a part program coordinate value

to the current position. The OPERATOR INSTRUCTION window displays:

F8 TLO = Z This command sets the TLO (Tool Length Offset) for the designated tool

equal to the current Z coordinate value and provides the ability to enter a cutter

diameter. The OPERATOR INSTRUCTION window displays:

After a tool number is entered, the OPERATOR INSTRUCTION window displays:

Entering a value sets the DIAMETER for that tool number in the stored TOOL table.

The TIME represents the total time that the tool has been used.

<*> SET GAGE HEIGHT When the <*> is depressed, the control will prompt for a gage

height distance. If a 1” gage block is being used to set TLO’s, by entering 1.0 the control

will automatically add 1” to the current Z axis location for establishing the correct Z

datum for that particular tool.

3-11

—>Use <+> = MOVETO CLRPT or <anyKEY> to CANCEL

—>SET X [ ] <ENTER>

Hit <ESC> to CANCEL

—>TLO=Z|| SET TOOLNO: [ ] <ENTER> <*>=SET GAGE HEIGHT

GAGE HEIGHT: [0.0000] <ESC>=CANCEL

TNO: 5 TLO: 0.5000 DIA: [ ] <ENTER> TIME 00:00:00

Hit <ESC> to CANCEL

NOTE: Gage Height will remain active until it is changed.

F9 QUILL UP This command moves the Z axis to the UP (HOME) position.

F10 ABS/INC This command toggles the system between the Absolute and Incremental

input modes.

Using the PREVIEW mode

Pressing the F5 PREVIEW key changes the screen display from BASIC OPERATIONS

SCREEN to the one shown in Figure 3-6.

Figure 3-6

The PREVIEW mode shows a graphical representation of the part program that is loaded into

the CNC. The screen commands available in this mode are:

ESC Exits the PREVIEW mode

F2 Toggle between PAUSE and RUN for pausing or running the file

F3 Toggle between AUTO/BLOCK for continuous execution or block by block

execution of the file

F4 Block between AUTO/BLOCK for continuous execution or block by block

execution of the file

F5 RESPGM resets the part program to the top of the text

3-12

PRGM PREVIEW

ESC EXIT F2 RUN F3 BLOCK F4 F5 RES PGM F6 SKIP F7 CLR SCR F10 ZOOM

F9 VIEW 3D

F9 VIEW 2D

PARTPROGRAM

PAUSE AUTO

N

T

D

X

Y

Z

VIEWSIZE

[MIN, MAX]

X-5.0, 5.0

Y-5.0, 5.0

[2D VIEW]

F6 SKIP allows searching to a (N) sequence or (T) tool number

F7 CLRSCR clears the screen

F8 VIEW 2D selects the 2D view mode

F9 VIEW 3D selects the 3D view mode

F10 ZOOM allows the user to zoom in on a feature in the 2D mode

F7 LOAD from BASIC OPERATIONS SCREEN is used to load a part program from the disk to

the CNC. After a part program is loaded it can be run. Pressing the F7 LOAD key changes

the screen display as shown in Figure 3-7.

Figure 3-7

Depress the ESC key twice to select another directory, i.e., A:\ for selecting the floppy disk.

Use the cursor keys (arrow keys) to select the file to be loaded for execution. Select the

correct path and file name for the part program that is desired. The display will then appear

as shown in Figure 3-8 (next page):

3-13

LOAD [CNC] |||

Use <cursor keys> = OLD FILENAME <ESC> = NEW PATH

F1

F2 F3 F4

F5 F6

F7 F8

F9

F10

PATH 1 C:\ FILE <ENTER>

DEMO.TXT

217.TXT

529.TXT

PART1.TXT

PROJECT.TXT

DIRECTORIES

Figure 3-8

Once the program is selected and the ENTER key is pressed, you will be prompted to load

the program which overwrites the previous program that was running.

NOTE: Overwriting the existing file only applies to the file being deleted from the

part program execution (BMDC) memory and has no effect on the file itself. It

will still reside in its original location, i.e.: C:\.

Pressing <Y> will load the program to the CNC. Press 5 to RESET the program and to set

the system in AUTO mode.

LOAD [CNC] |||

Use <CURSOR KEYS> to move cursor, <ESC> to EXIT

F1

F2 F3 F4

F5 F6

F7 F8

F9

F10

PATH 1 C:\ FILE <ENTER>

DEMO.TXT

217.TXT

529.TXT

PART1.TXT

PROJECT.TXT

DIRECTORIES

WIND

PARTS

TONY

3-14

Chapter 4

SET UP MODE

Introduction

The SET UP mode is used to prepare the machine for part program execution.

The following operations are available:

1) Establishment of machine/part program coordinate system

2) Axis motion to set up positions

3) Axis jog

4) Entering, storing and loading Tool Data

5) Loading part programs

6) Editing part programs

Set Up screen

To enter the SET UP mode, press the F3 SETUP key from the BASIC OPERATIONS screen.

The SET UP screen appears as shown in Figure 4-1.

Figure 4-1

4-1

SETUP | |

MON JAN 14 03:15:04 PM

Use <F KEY or Num KEY> to select FUNCTION

1

WORK

SHIFTS

2

MOVETO

X_Y_Z_

3

JOG

4

SET

TNO

5

SET

CLRPT

6

GO TO

CLRPT

7

SRT

T / /

8

SET

REFPT

9

GO TO

REFPT

0 EXIT SETUP MENU

F1

F2 F3 F4

F5 F6

EDIT

F7

LOAD

F8

F9

QU UP

F10

ABS/INC

CNC MAN ABS B8&

MODE:

SEQ NO:

TOOL NO:

TLO:

DIA:

TIME:

S, ACT

F, IPM

F, OVR (OFF)

X ABS

Y ABS

Z ABS

SPINDLE:

COOLANT:

BAPID, IPM:

OPSELSW:

OPROTSW:

DRYRUN:

/ DELETE:

OPSTOP:

SETUP

0

9

7.0000

0.5000

000:00:00

0 75%

000.0

80%

12.4214

8.9717

7.1614

OFF

OFF

OFF

OFF

OFF

OFF

OFF

CNC T / /