Page 1

WIFI 3D Printer

Art. No. 2010200

WARNING!

Quickstart Guide

1. Do not remove the housing of the nozzle!

2. Hot surface! Do not touch the heating nozzle in operation!

3. Danger! Moving parts in printer may cause injury.

Do not wear gloves or other sources of entanglement in

operation!

Page 2

UNPACKING

1. Open the box and remove both top foam

sheets.

3. The bottom PE foam should contain: a spool

of PLA filament, a spool holder, a solid glue, an

USB cable, a filament guide tube and an

accessory bag.

2. Take the printer out of the box.

4. Remove the bubble wrap.

5. Remove the top PE foam piece, which

contains one power cable, one USB Stick,

the Quickstart guide and the After Sales Service

Card.

6. Remove the three buckles which are in

the circled area showed in the picture.

03

Page 3

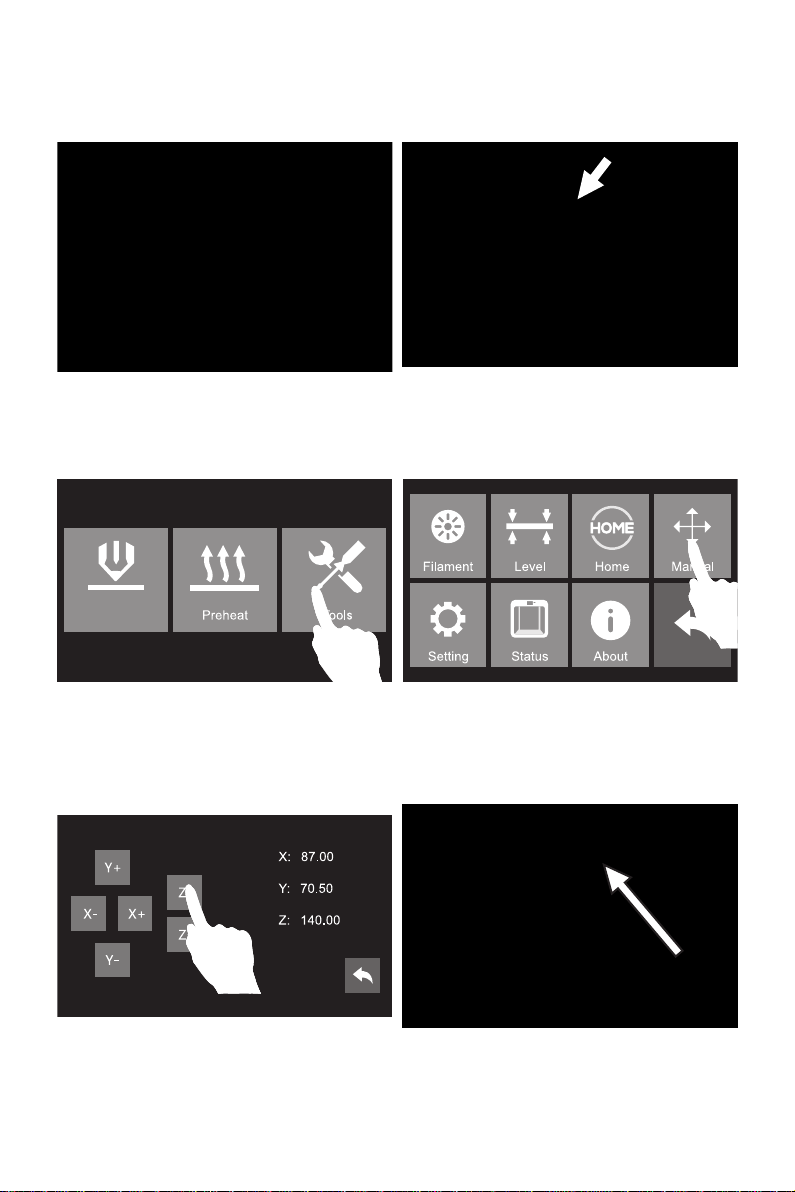

Power Switch

7. Tear off tape and the stretch wrap of front door.

Squeeze top lid slightly from both sides to the middle

so as to take top lid successfully.

Remove the stretch wrap of top lid.

Build

9. T ap [Tools].

8. Take out power cable and plug the power cable into

the input on the back and turn on the power switch.

10. T ap [Manual].

Tear off

the stretch

wrap!

11. Tap [Z-] to partially elevate the build plate.

Tap touch screen button on the right side of touch screen,

go back to home screen.

12. Remove both bottom foam pieces.

Tear off the stretch wrap.

04

Page 4

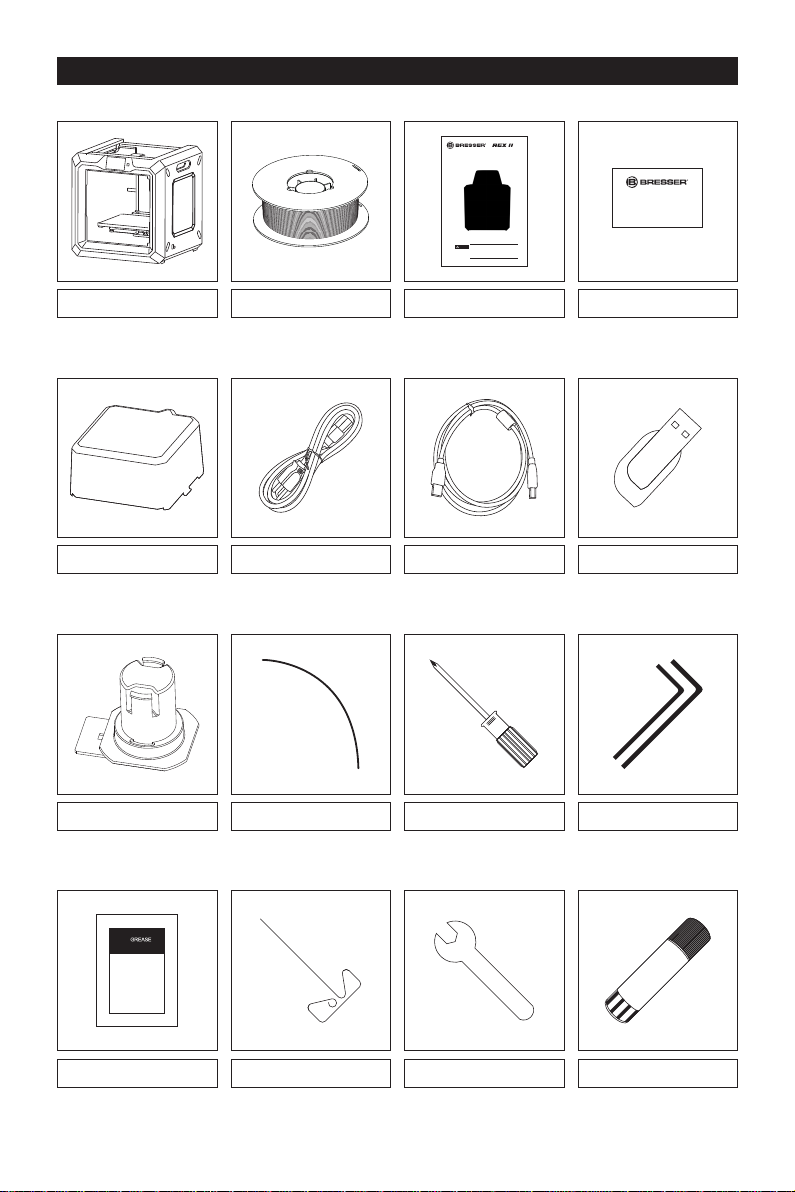

PRINTER KIT CONTENTS

WIFI 3D Printer

Art. No. 2010200

Warranty & Service

Quickstart Guide

1. Do not remove the housing of the nozzle!

WARNING!

2. Hot surface! Do not touch the heating nozzle in operation!

3. Danger! Moving parts in printer may cause injury.

Do not wear gloves or other sources of entanglement in

operation!

3D Printer Filament spool Quickstart guide Warranty & Service Card

Lid Power cable USB cable USB stick

Spool holder Filament guide tube Screwdriver Allen wrench

Grease Unclogging pin tool Wrench Solid glue

05

Page 5

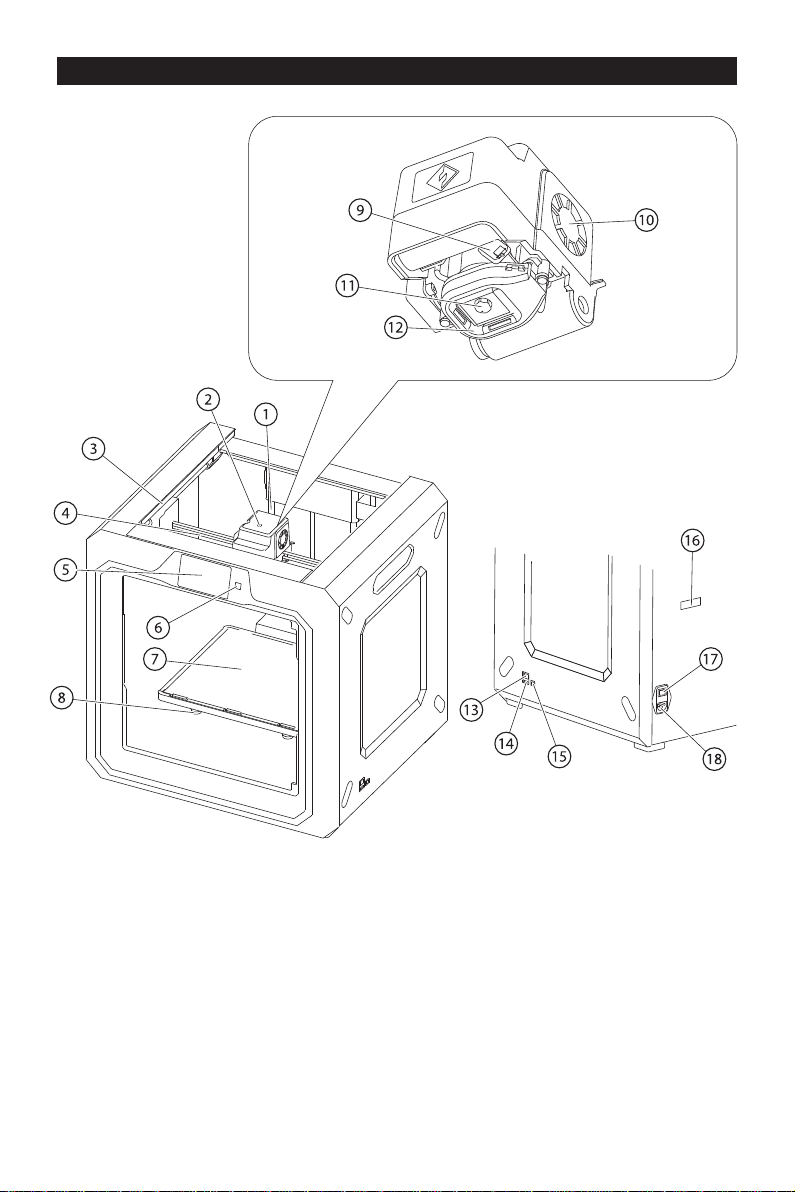

GETTING TO KNOW THE PRINTER

17. Power Switch 18. Power Input

3. Y-Axis Guide Rod 4. X-Axis Guide Rod1. Z-Axis Guide Rod 2. Filament Intake

7. Build Plate 8. Nut5. T ouch Screen 6. Touch Screen Button

11. Nozzle 12. Turbo Fan Baffle9. Servo 10. Turbo Fan

15. USB Cable Input 16. Spool Holder Slot13. Network Interface 14. USB Stick Input

06

Page 6

GETTING TO KNOW THE PRINTER

3. Air-Filter 4. Y-Axis Guide Rod1. Z-Axis Guide Rod 2. Filament Intake

7. Touch Screen Button 8. Build Plate5. X-Axis Guide Rod 6. Touch Screen

(Inside the printer)

17. USB Cable Input 18. Spool Holder Slot 19. Power Switch 20. Power Input

11. Servo 12. Turbo Fan9. Nut 10. Camera

15. Network Interface 16. USB Stick Input13. Nozzle 14. Turbo Fan Baffle

07

Page 7

HARDWARE ASSEMBLY

1. Locate the spool holder. Install the spool holder

into the left quadrangular opening on the back

3. Squeeze the spool holder top and mount the filament

spool to the holder.

Press here

Filament intake

2. Turn down the spool holder to make the holder

bottom cleave to the printer back.

4. Secure the filament guide tube with R-shaped buckles

and thread the filament through the tube. The filament spool

must be oriented correctly [see above] and should feed

filament from bottom to top.

5. After filament goes through guide tube, press spring

presser on the left side of extruder, and insert filament

vertically into filament intake.

6. After inserting into filament intake, insert guide tube

into extruder filament intake to fix.

08

Page 8

LEVELING THE BUILD PLATE

HOW TO CHANGE THE LANGUAGE

0201

Tools

0403

Before leveling, let's learn the function of nuts.

HOW TO USE THE NUTS

Build plate goes up

Rotate the nuts clockwise

Raise the build plate to reduce the distance

between the nozzle and build plate.

Build

1. T ap [Tools].

Build plate goes down

Rotate the nuts anticlockwise

Lower the build plate to increase the distance

between the nozzle and build plate.

2. T ap [Level].

09

Page 9

Screw the three nuts under the platform

counterclockwise until they are tight,

then tap the [OK] button.

3. Please wait while the extruder and platform finish initial movements. Screw three nuts under the

platform anticlockwise, then tap [OK] button.

Attention! Three nuts may be tightened up before going out, please skip this step if you find three nuts

have been tightened up, and continue to following steps

4. After tapping [OK] button, the extruder will

move towards the first point and the plate will

move up and down to verify the distance

between nozzle and plate.

6. Then tap the [Verify] button to check whether

the distance is appropriate.

5. If the distance between the nozzle and plate

is too large, rotate the three nuts underneath

the platform clockwise for the same rounds

until you hear a steady beep.

Congratulations

Tap the [OK] button to move to

the next leveling point.

7. If the distance is appropriate, tap [ok] to next step.

If the distance still not appropriate, please follow the

prompts on the touch screen to adjust till you see [ok].

10

Page 10

8. After first leveling point completed, start the other two leveling points.

Attention! When starting the second and the third leveling points, just need to adjust one

corresponding nut under extruder.

Distance Too Big

Turn the corresponding nut under

the platform clockwise until

you hear the beep.

Distance Too Small

Turn the corresponding nut under

the platform anticlockwise until

you hear the beep.

9. Follow the prompts on the touch screen to adjust the corresponding nut till you hear a steady

beep.

Congratulations

Tap the [OK] button to move to

the next leveling point.

10. If the distance is appropriate, tap [ok] to next step.

If the distance still not appropriate, please follow

the prompts on the touch screen to adjust till you

see [ok].

11. Start the third leveling point according to the method

of the second leveling point.

After leveling completed, tap return arrow to go back

to home screen.

Leveling completed!

Finish

11

Page 11

LOADING FILAMENT

1. T ap [Tools]. 2. T ap [Filament].

3. Tap [Load], extruder starts to heat.

Loading started, push filament vertically

into extruder and press [Done] when you see

filament come out of the extruder

Done

4. Once heated, filament will be drawn through the extruder. Continue extruding until the extruder

provides a steady flow of filament. Tap touch screen button, go back to home screen.

Attention! If extruder can not load filament for a long time, please check if you have inserted filament

into the bottom of extruder.

12

Page 12

SUGGESTIONS

1. Ensure that the build plate has been leveled before

printing.

2. Ensure that the filament has been loaded in an

appropriate approach.

3. Load the filament for a while to extrude all the

melted filament you printed last time out of the

extruder.

4. Please clean extruder before printing.

5. Do not leave the printer unattended during

operation.

FIRST PRINT

1. Please insert the USB stick into USB slot on the right

side of the printer. Tap [Build].

Flashprint

Quick Start Guide

Test Files

User Guide

2. Tap [USB Stick].

4. T ap [40mm_Box-PLA.gx].

PLA

6. The printer starts to heat and it prints automatically

after heating is completed.

3. Tap [Test Files].

PLA

5. T ap [Build].

13

Page 13

UNLOADING FILAMENT

Please follow steps below if you need to unload filament in

daily use.

1. Pull filament guide tube out of filament intake, leave

2. T ap [Tools].

filament 10cm to pull filament easily.

Load Unload

3. T ap [Filament]. 4. T ap [Unload].

Unload started, press down on the

spring lever and withdraw filament

Extruder

Press here

Push filament down through

for 3 seconds

Extruder

Done

5. When heating to target temparture, press spring presser

and push filament down through for 3 seconds, until you

see steady filament coming out of the nozzle.

14

Page 14

Withdraw

Press here

6. Then pull out vertically quickly and release spring presser.

Tap [Done], go back. Tap return arrow to go back to home screen.

filament

CHANGING THE NOZZLE

NOTE! Changing the nozzle requires a certain level of technical knowledge and experience in using this

device. If necessary, have the work carried out by a specialist.

The manufacturer assumes no liability for damage caused by incorrectly executed work!

We have provided detailed video instructions for changing the nozzle on the product page at

www.bresser.de/P2010200.

15

Page 15

Errors and technical changes reserved.

Quickstart_2010200_3D-Printer-REX-II_en_BRESSER_v052020a

Bresser GmbH

Gutenbergstr. 2 · DE-46414 Rhede

Germany

www.bresser.de · service@bresser.de

Page 16

More information, updates or software

Visit our website using the following QR codes or web links to find additional information,

available updates or software for this product or related accessories:

3D printer Accessories

www.bresser.de/P2010200

www.bresser.de/P2080210000000

After Sales Support / Service

We offer an individual service for this product beyond the purchase. If you have any

problems with the product, our support team will be happy to assist you.

For a smooth process, please keep the following information handy for possible

inquiries:

• Warranty/Service card

• Article number and Product description

• Date of purchase and dealer

Contact details:

e-Mail:

Internet:

Phone*:

Service hours:

Monday to Friday (except national public holidays)

* free hotline throughout Europe

service.3d@bresser.de (preferred communication)

www.bresser.de/c/en/service

00 800 – 63 43 7000

9:00 a.m. to 3:00 p.m. CET

Warranty

Please refer to the separate warranty & service card for any warranty information.

02

Loading...

Loading...