Page 1

RPX900D

INDUSTRIAL

EVAPORATIVE

AIR COOLERS

Assembly

Instructions

A

dvanced natural cooling

Page 2

RPX ASSEMBLY INSTRUCTIONS

INDEX

Description Page

Index 2

Important Notice/ Tools required 3

Installing Fan Housing to Tank 1/5 5

Installing Top Channel 10

Sealing Fan Housing to Tank 1/2 11

Sealing Fan Housing to Tank Bottom 13

Prepare Motor and Controls 1/4 14

Fan Pulley Attachment 18

Fit and Tension V Belts 19

Fitting the Water Pumps 20

Connecting the Water System 21

Corner Pillar Installation 22

Centre Rail Installation 23

Top Rail Installation 1/2 24

Bottom Rail Installation 26

Centre Pillar Installation 27

Water Spreader Installation 28

Distributor Cap Installation 29

Water Distributor Connection 1/2 30

Installing Cab Top Blanking Cover 32

Cabinet Top Installation 1/2 33

Squaring the Cooler 35

Cabinet Top Final Assembly 1/3 36

Final Riveting 39

Installing the Bleed Tap 40

Clean and Test Cooler 41

Washer Part Numbers 42

Bolt and Nut Part Numbers 43

Screw and Rivet Part Numbers 44

Panel Part Numbers 45

Miscellaneous Part Numbers 1/2 47

Special jig securing Flashing Angle 49

RPX 900 D Kit 1/2 50

RPX 900 D&T Pallet Specifications. 52

RPX 900 T Exploded View 53

3 Phase Wiring Diagram 54

2

Page 3

RPX ASSEMBLY INSTRUCTIONS

IMPORTANT NOTICE

The assembly of evaporative air conditioning units has the potential to create Occupational Health and Safety issues

for those involved. Assemblers are advised to ensure they are familiar with relevant State and Federal legislation, such

as Acts, Regulations, approved Codes of Practice and Relevant Standards, which offer practical guidance on these health

and safety issues. Companies with these regulations will require appropriate work practices, equipment, training and

qualification of workers.

Note:

Stainless steel bolts and nuts are used in the assembly of coolers.

A thread lubricating compound anti seize should be used at assembly.

(Anti Seize not supplied)

Tools Required

Pneumatic Drill. Pneumatic Driver.

Pneumatic Riveter

Long nose type.

3

Pneumatic Silicone

Applicator.

Page 4

RPX ASSEMBLY INSTRUCTIONS

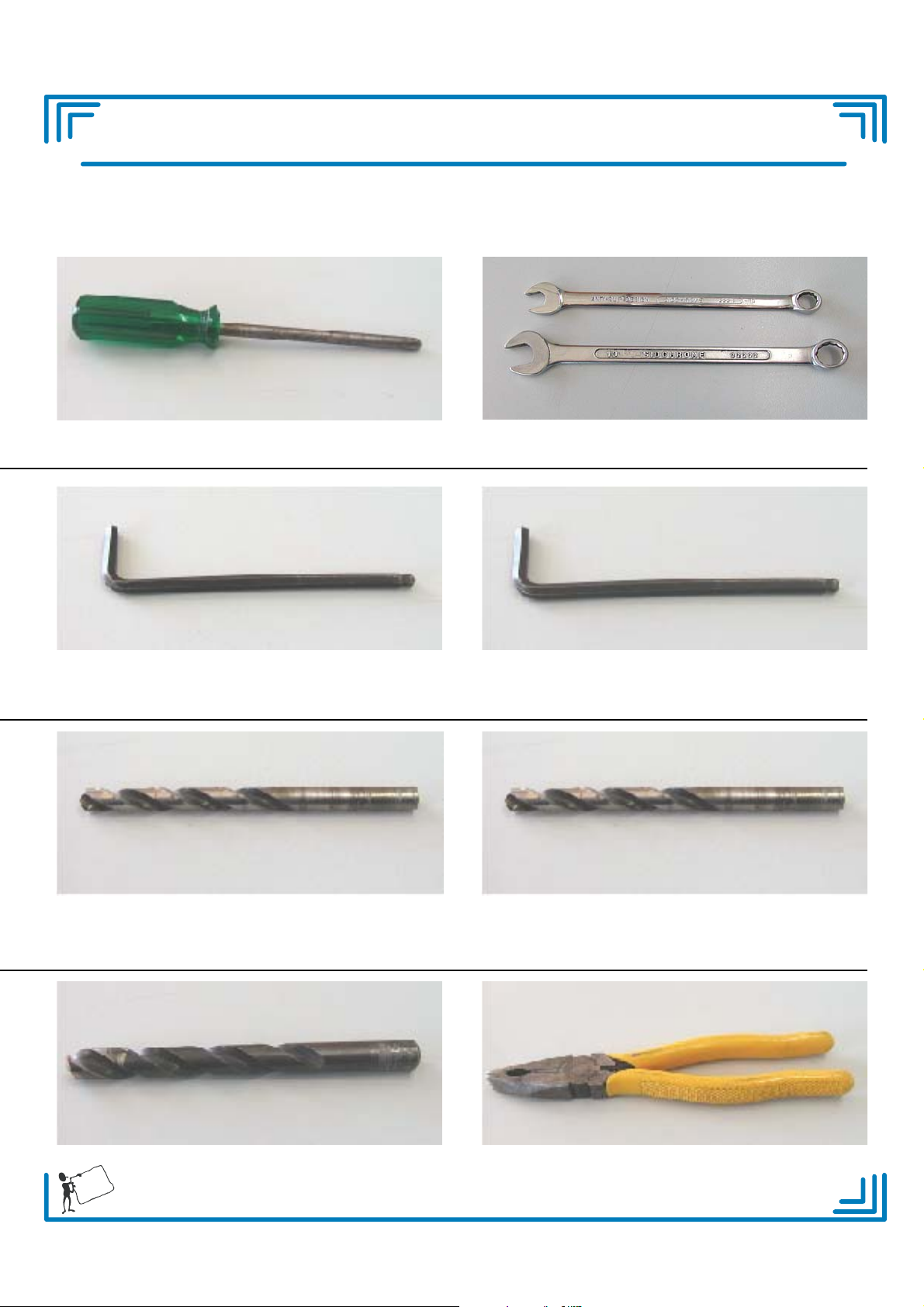

Tools Required cont.

Screwdriver No3. Spanners 10 and 13mm

Hex Key 4mm. Hex Key 5mm.

Metal twist drill 5mm Metal twist drill 6.5mm

Metal twist drill 12.5mm. Pliers.

4

Page 5

RPX ASSEMBLY INSTRUCTIONS

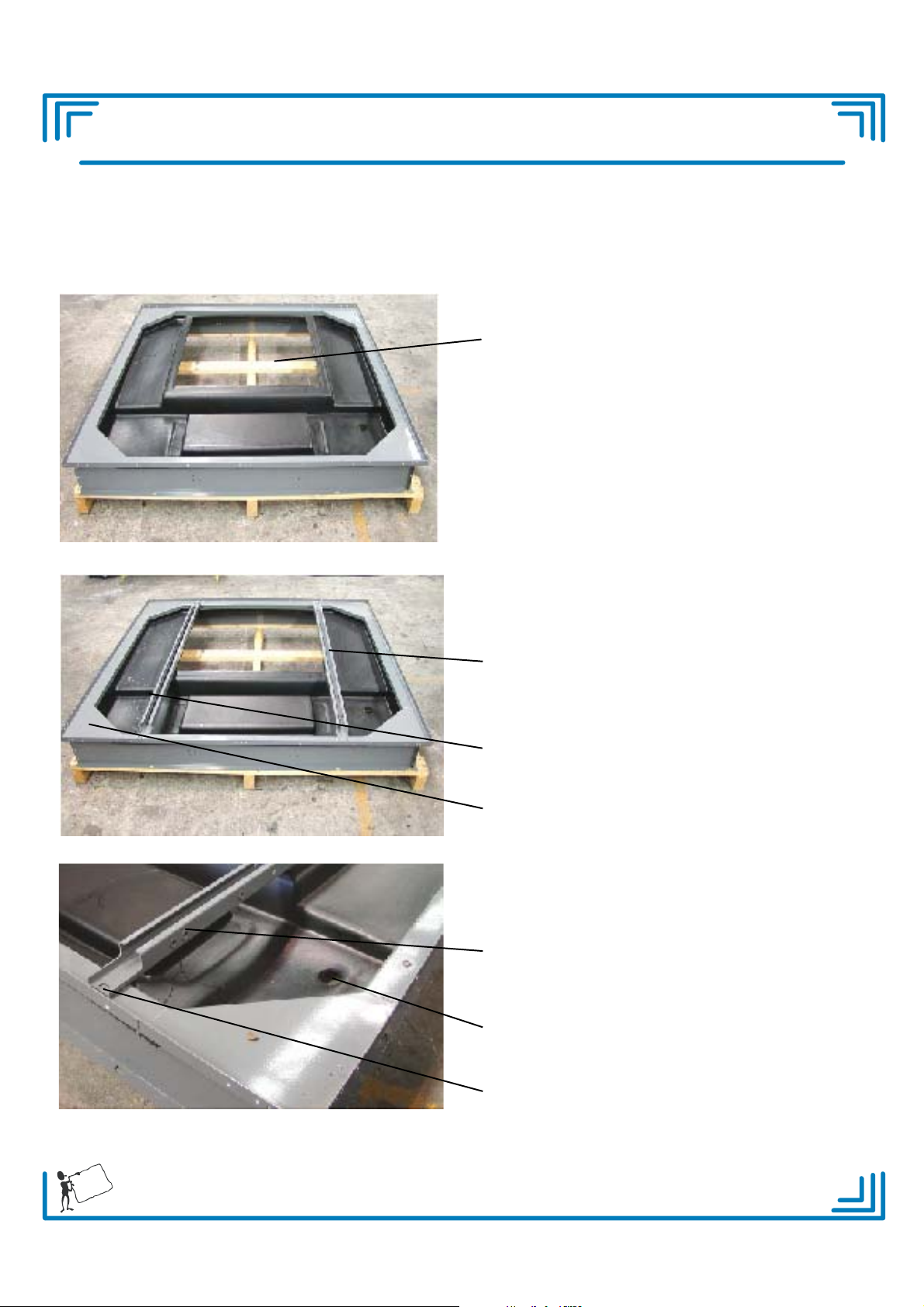

Installing Fan Housing to Tank. Step 1 of 5.

Select Base Frame and Tank Assembly

for Down discharge model.

2

1

Place supplied

Template to

top of Tank.

Align holes with

3

template bolts.

4

Mark with text pen, inside

edge of template.

Remove template, place

20 mm hole saw to 6mm

hole and drill through.

Total four.

5

5

Drill 6 mm hole to corners

of template. Total four.

6

Use Jig saw and cut

along marked line.

Page 6

RPX ASSEMBLY INSTRUCTIONS

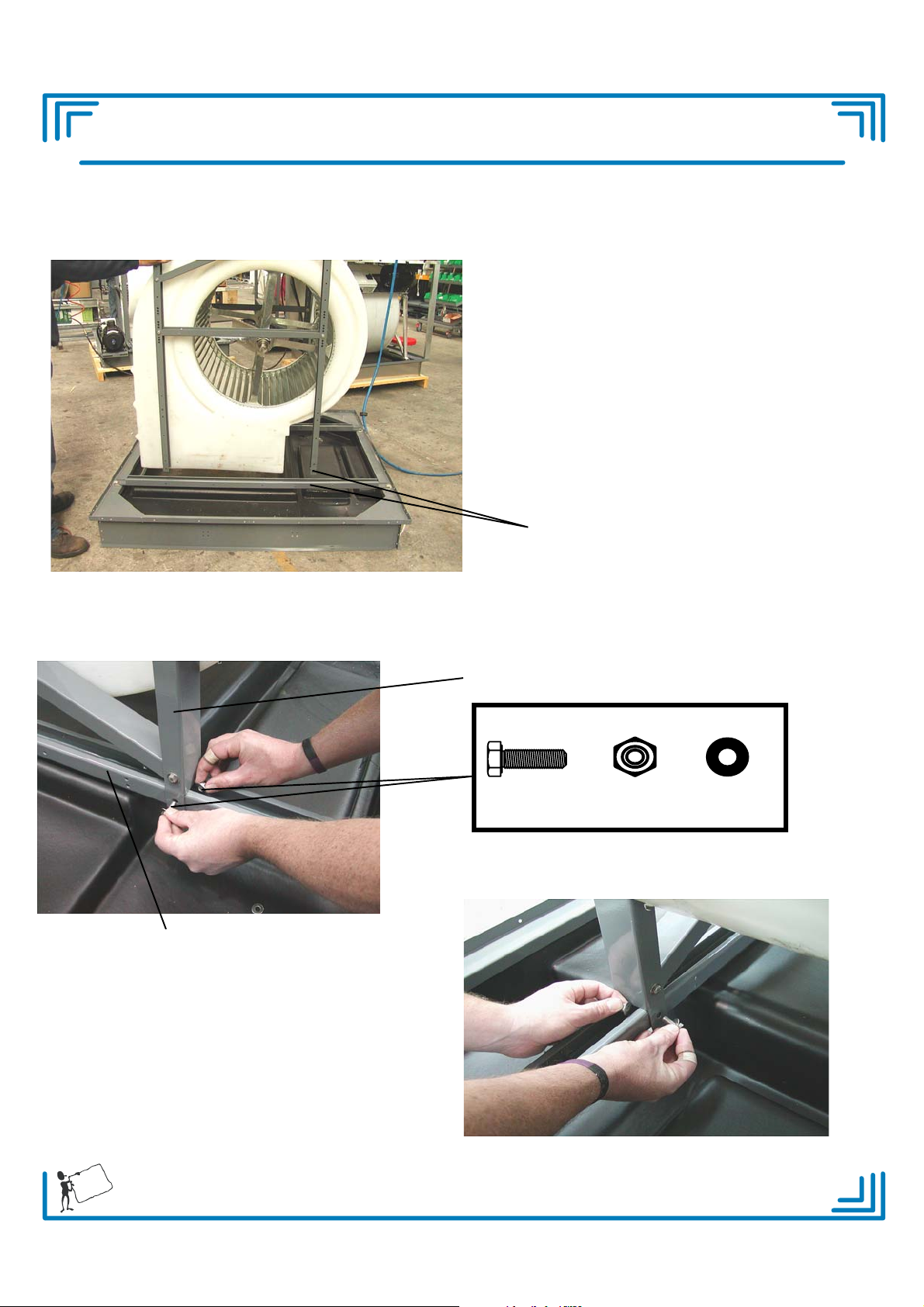

Installing Fan Housing to Tank. Step 2 of 5.

Installing Base Channels.

Tank to accept square

end of Fan Housing.

Place Base Channels on

Base Frame Assembly.

R/H Base Channel

Part No 623160.

L/H Base Channel

Part No 627168.

Base Frame Assembly.

Note:

Position of Base Channel

to Base Frame Assembly

Insert holes for motor

platform nearest to drain hole.

Drain Hole.

Align Base Channel holes

with Base Frame holes.

6

Page 7

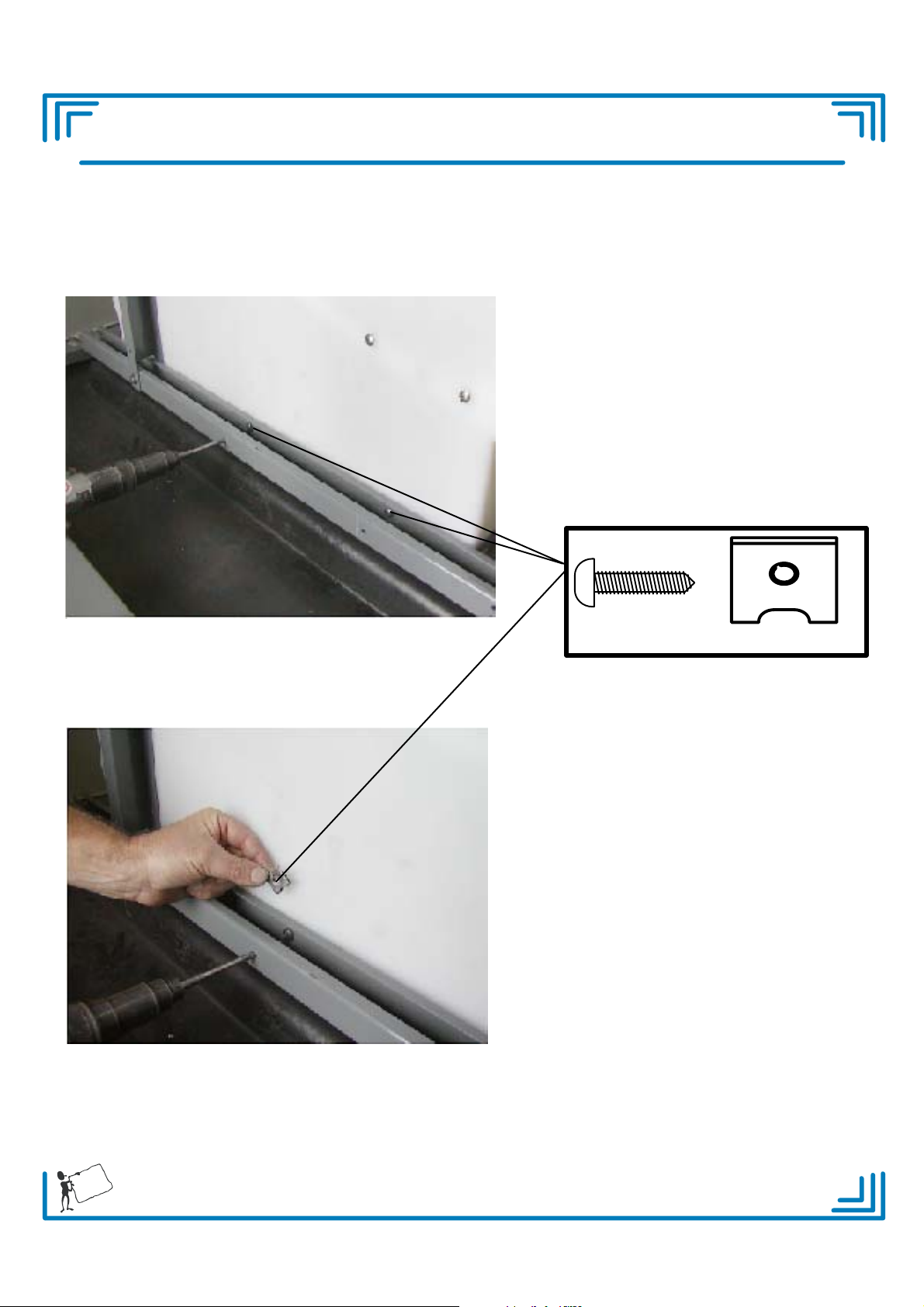

RPX ASSEMBLY INSTRUCTIONS

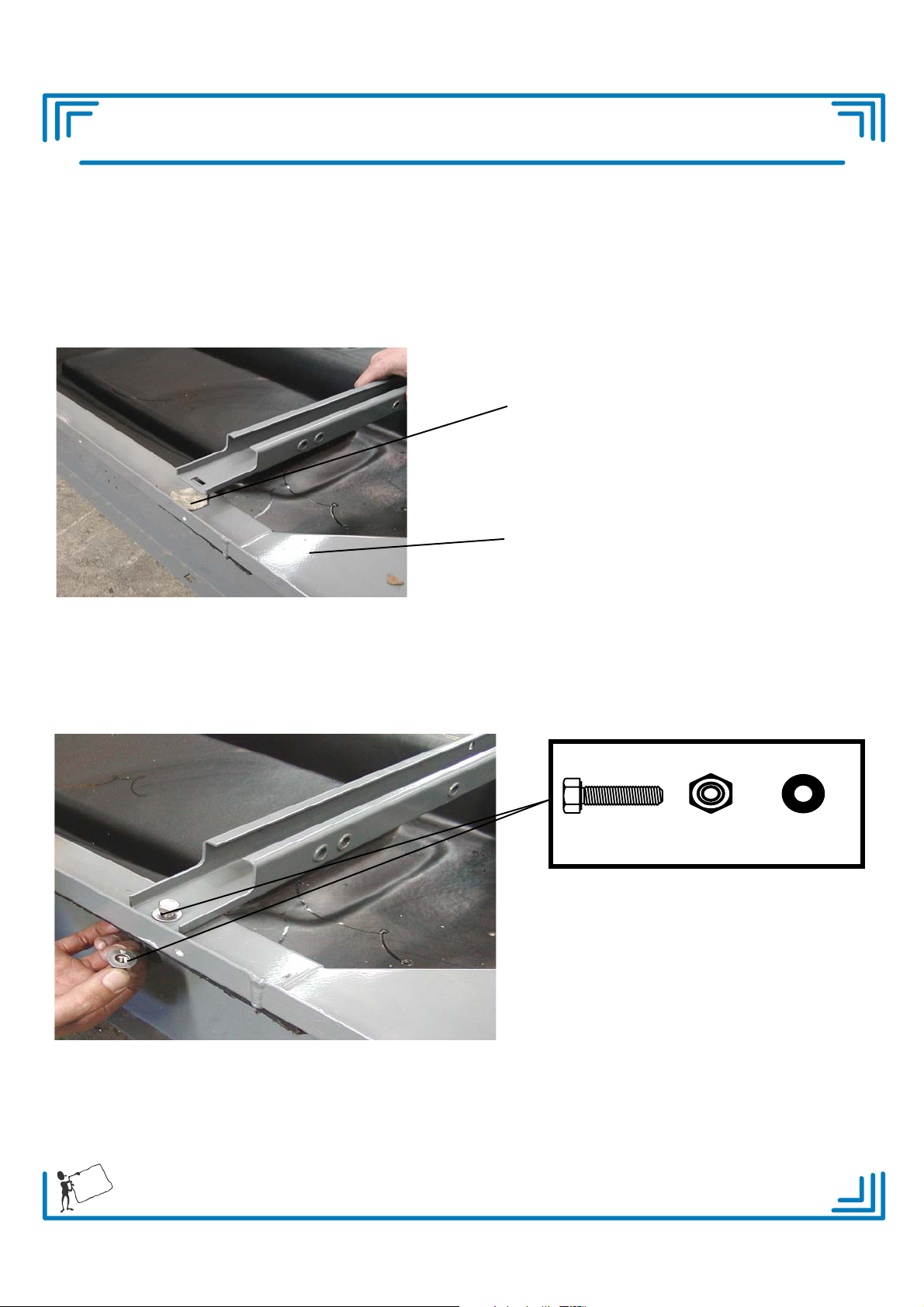

Installing Fan Housing to Tank. Step 3 of 5.

All holes and fasteners will need to be sealed to ensure

there are no water leaks outside the cooler.

"Virginia" Sealing Putty has been supplied for this task.

Place Sealing Putty to

Base Frame Assembly.

Clear hole before fitting

channel.

Base Frame Assy.

Secure Base Channel to Base Frame.

At this stage do not fully tighten bolts.

Refer to notes on Page 17.

BOLT NUT WASHER

M8x30 M8 8x19mm

P/N0 628257 P/No 628288 P/No WAS163

Repeat process for other ends of Base Channels.

7

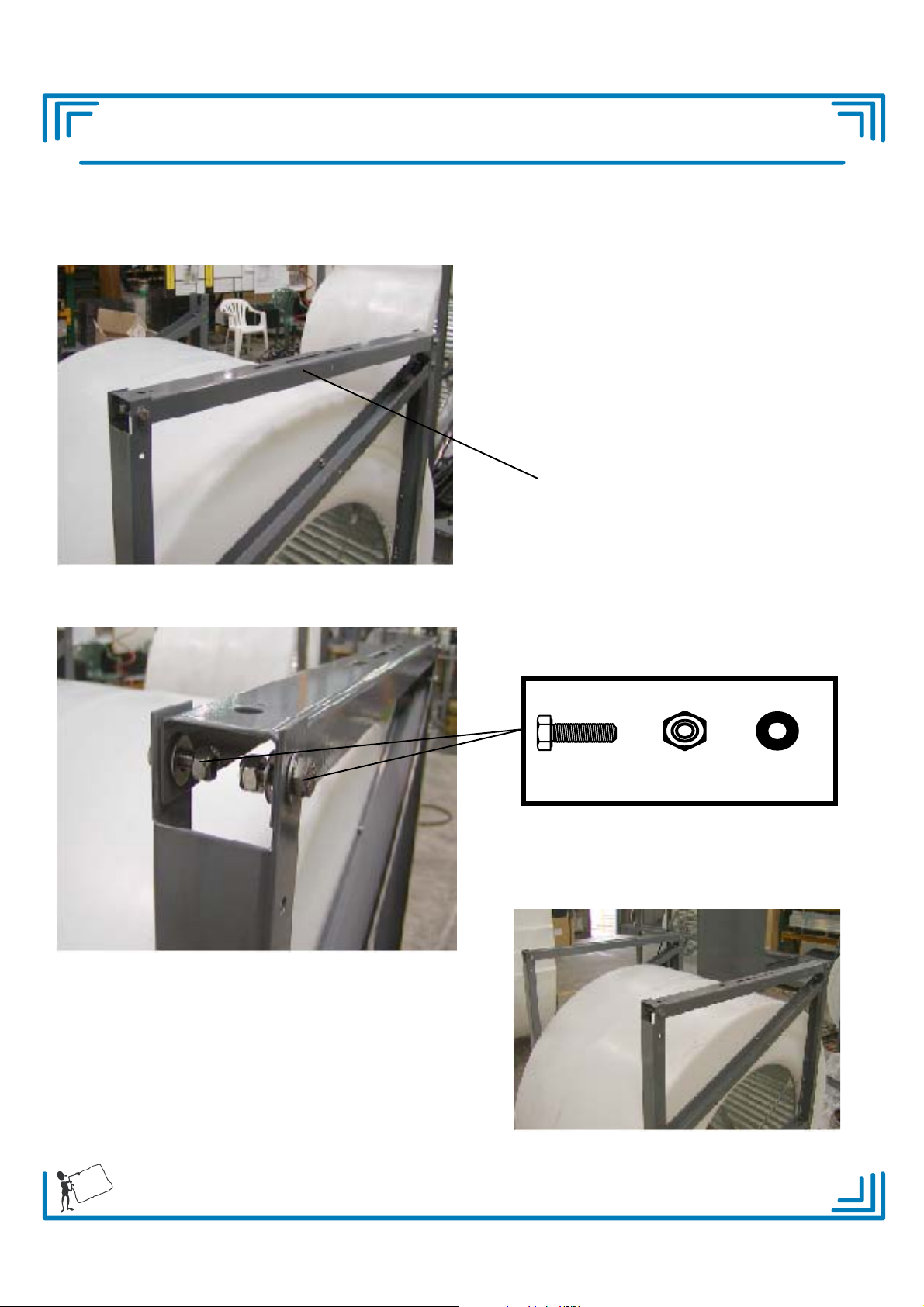

Page 8

RPX ASSEMBLY INSTRUCTIONS

Installing Fan Housing to Tank. Step 4 of 5.

Use lifting crane to raise

Fan Housing and H-Frame

Assembly over Base Frame

Assembly.

Align and lower

bottom of fan housing

to Tank cut out.

Align bottom hole of

vertical channel to

Base channel holes.

Secure Vertical Channel to Base Channel

H-Frame Vertical Channel.

BOLT NUT WASHER

M8x20 M8 8x19mm

P/N0 628240 P/No 628288 P/No WAS163

Note: 2 Bolts, 4 Washers and

2 Nuts per vertical Channel.

Base Channel.

8

Repeat process for other three vertical channels.

Page 9

RPX ASSEMBLY INSTRUCTIONS

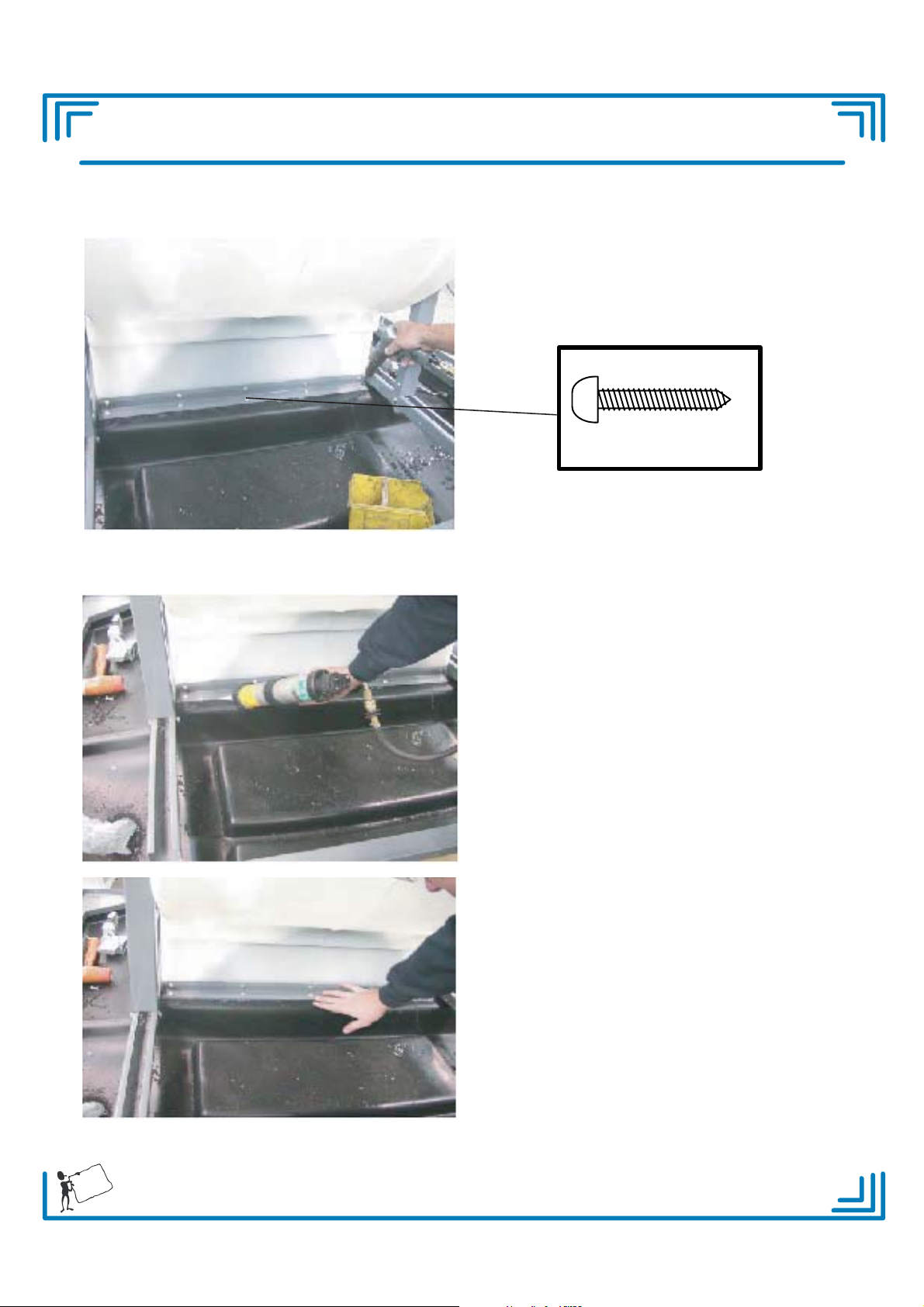

Installing Fan Housing to Tank. Step 5 of 5.

Securing Base Channel to Fan Housing.

Secure Base Channel

to Fan Housing.

Fix two Screws between

Fan Housing and Base

Channel.

SCREW - Phlp.

6x25 mm

P/No SCR 384

SPIRE NUT - P/No FAS115.

Fit Spire Nut to

end of Screws.

Inside of Fan Housing.

Note: The Spire Nut can

be fitted when Fan

Housing assembly is tilted.

Refer to notes on Page 13.

Repeat process for opposite side.

9

Page 10

RPX ASSEMBLY INSTRUCTIONS

Installing Top Channel.

Install Top/Bearing

Channel to Vertical

Channels.

Part N/o 623139

Secure Channels.

Tighten all bolts.

BOLT NUT WASHER

M8x20 M8 8x19mm

P/N0 628240 P/No 628288 P/No WAS163

Repeat process for

other end.

10

Repeat process for opposite side.

Page 11

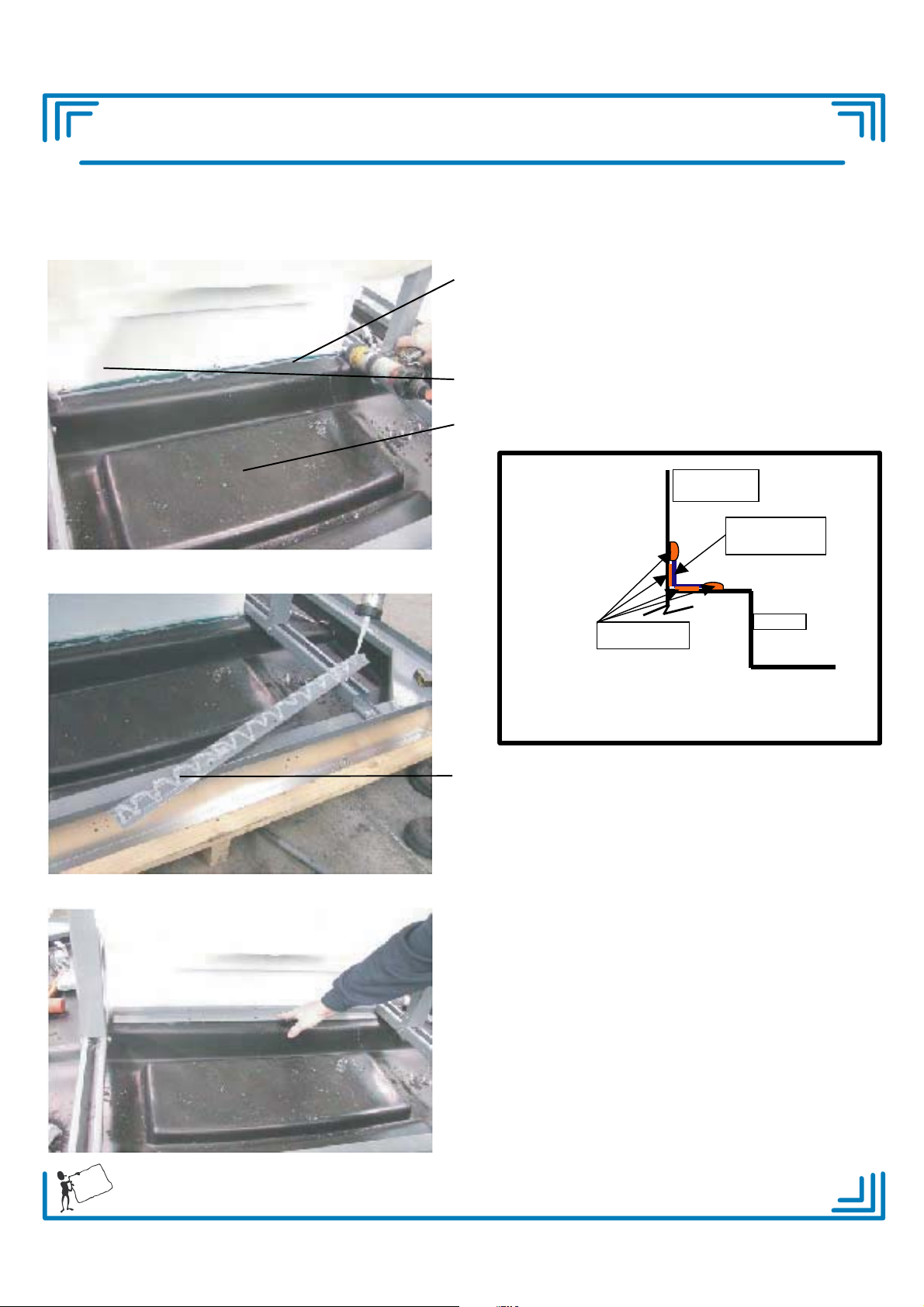

RPX ASSEMBLY INSTRUCTIONS

Sealing Fan Housing to Tank. Step 1 of 2.

Apply a generous bead of

silicone sealant along

Fan Housing and Tank.

Fan Housing

Tank

FAN

HOUSING

FLASHING

ANGLE

SILICONE

TANK

Illustrated

assembly view.

Apply silicone sealant bead

to Flashing Angle.

Flashing Angle

P/No 100152

Place Flashing Angle

to Fan Housing and Tank.

11

Page 12

RPX ASSEMBLY INSTRUCTIONS

Sealing Fan Housing to Tank. Step 2 of 2.

Secure Flashing

Angle to Fan Housing

and Tank, with supplied

screws: Total 10 places.

SCREW - Phlp.

4x25 mm

P/No SCR506

Note: If end of fan housing

bows inwards and cannot

be easily fixed, a special

clamp can be utilised to

aid fixing. P49 has details

to enable manufacture

of clamp.

12

Apply additional silicone

to top and bottom

edge of Flashing Angle.

Check that silicone

has a good seal to

Fan Housing and Tank.

Smooth out silicone to

give neat appearance.

Repeat Steps1&2foropposite side.

Page 13

RPX ASSEMBLY INSTRUCTIONS

Sealing Fan Housing to Tank Bottom.

Use crane to tilt cooler.

Silicone sealant

between Fan Housing

and Tank,

apply thick bead to

all four sides.

Fit spire nut to ends

of screws.

Refer to notes on Page 9.

SPIRE NUT - P/No FAS 115.

Use crane and

raise cooler to

up right position.

13

Page 14

RPX ASSEMBLY INSTRUCTIONS

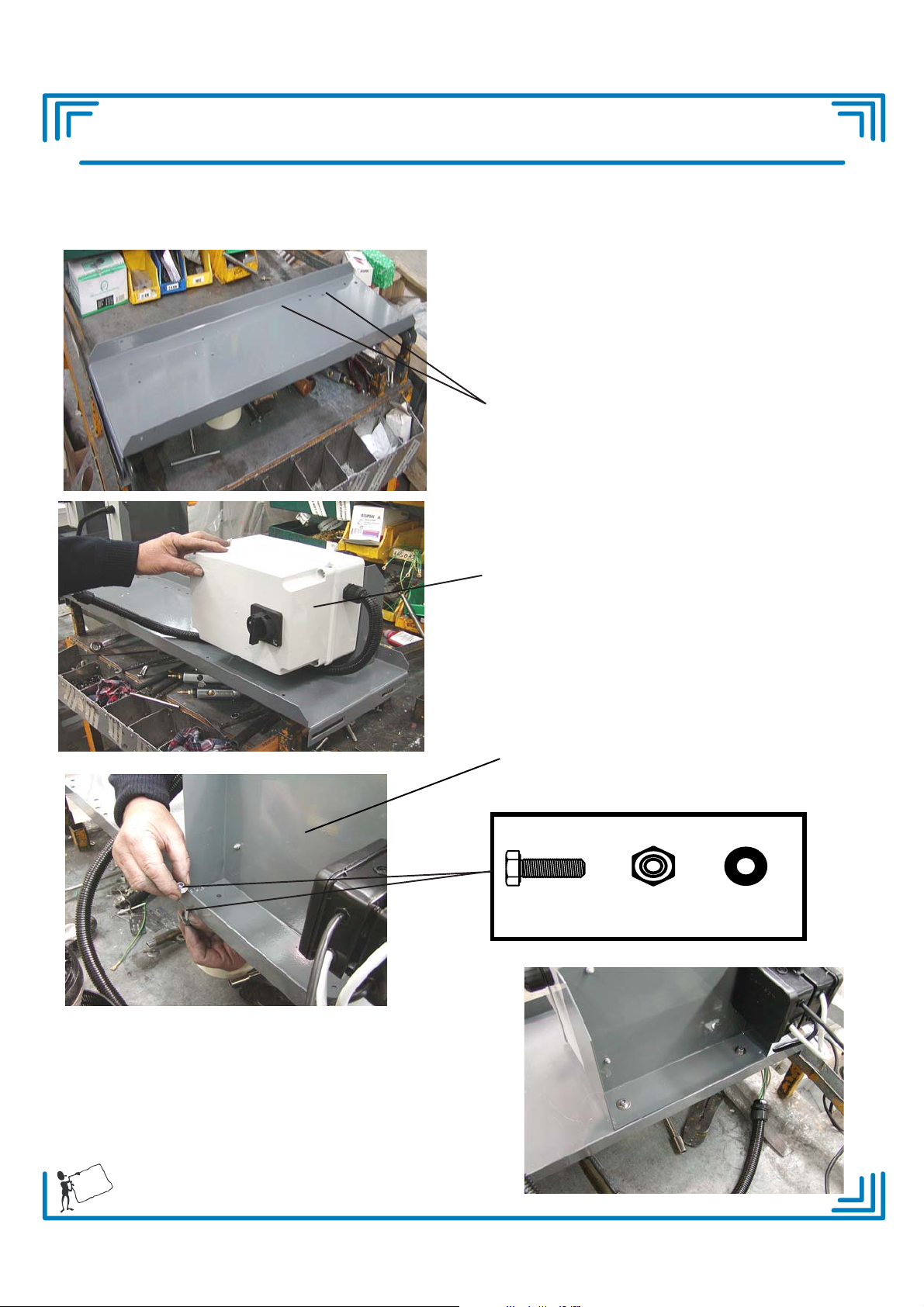

Prepare Motor and Controls. Step 1 of 4.

Place Motor Platform to a

suitable work bench.

Note: Control box

mounting holes.

Place Control Box and

water pump assembly to

motor platform.

14

Securing Control Box

panel to Motor Platform.

BOLT NUT WASHER

M6x20 M6 6x14mm

P/N0 628226 P/No 628271 P/No WAS029

Page 15

RPX ASSEMBLY INSTRUCTIONS

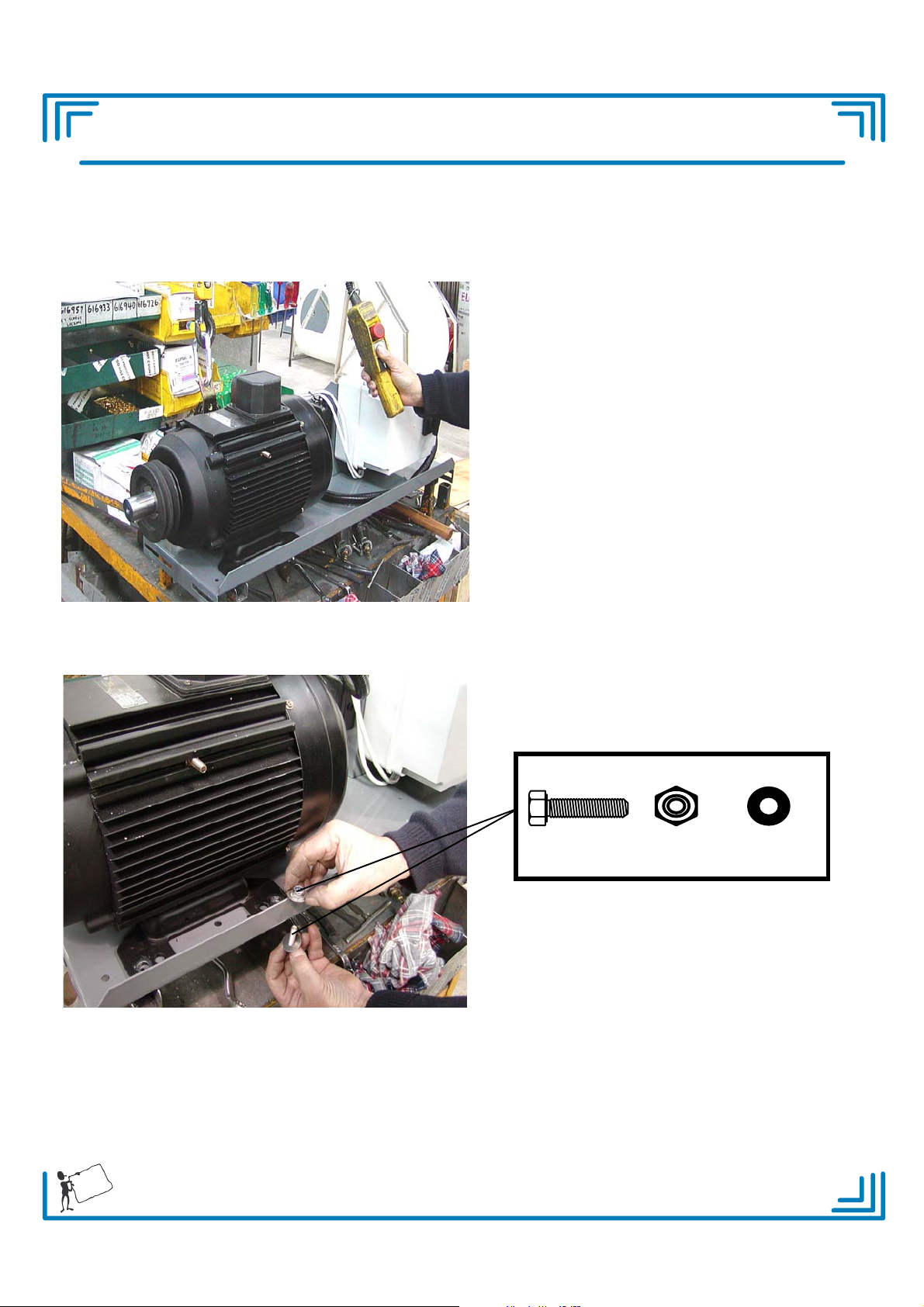

Prepare Motor and Controls. Step 2 of 4.

Use crane and fit electric

motor to platform,

align holes and

secure with

supplied fasteners.

15

Secure Motor to Platform.

BOLT NUT WASHER

M8x30 M8 8x19mm

P/N0 628257 P/No 628288 P/No WAS163

Repeat for all 4 motor mounting bolts.

Ensure motor is square to Platform.

Tighten all bolts.

Page 16

RPX ASSEMBLY INSTRUCTIONS

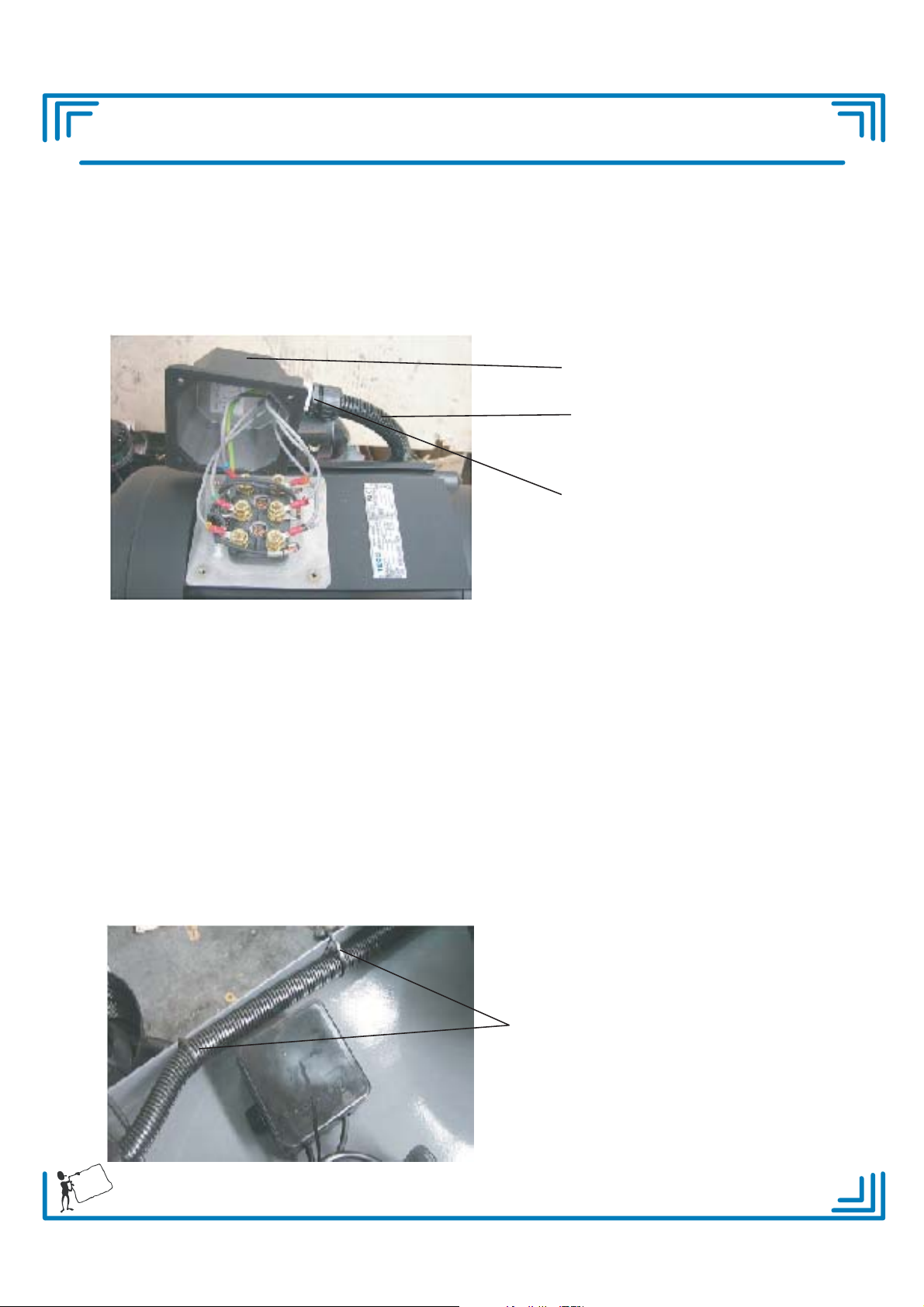

Prepare Motor and Controls. Step 3 of 4.

Feed seven wires from the electrcal control box wiring

loom through the motor terminal cover opening.

Attach all wires and secure motor terminal cover.

Motor terminal cover.

Wiring loom to

electrical control box.

Gland

Wire connection.

For low speed connect.

Wire, tag numbered 1 to U1

2to V1

3toW1

For high speed connect.

Wire, tag numbered 4 to W2

5toU2

6toV2

Connect earth wire to motor casing earth point.

Cable tie wire loom

to Motor Platform.

16

Page 17

RPX ASSEMBLY INSTRUCTIONS

Prepare Motor and Controls. Step 4 of 4.

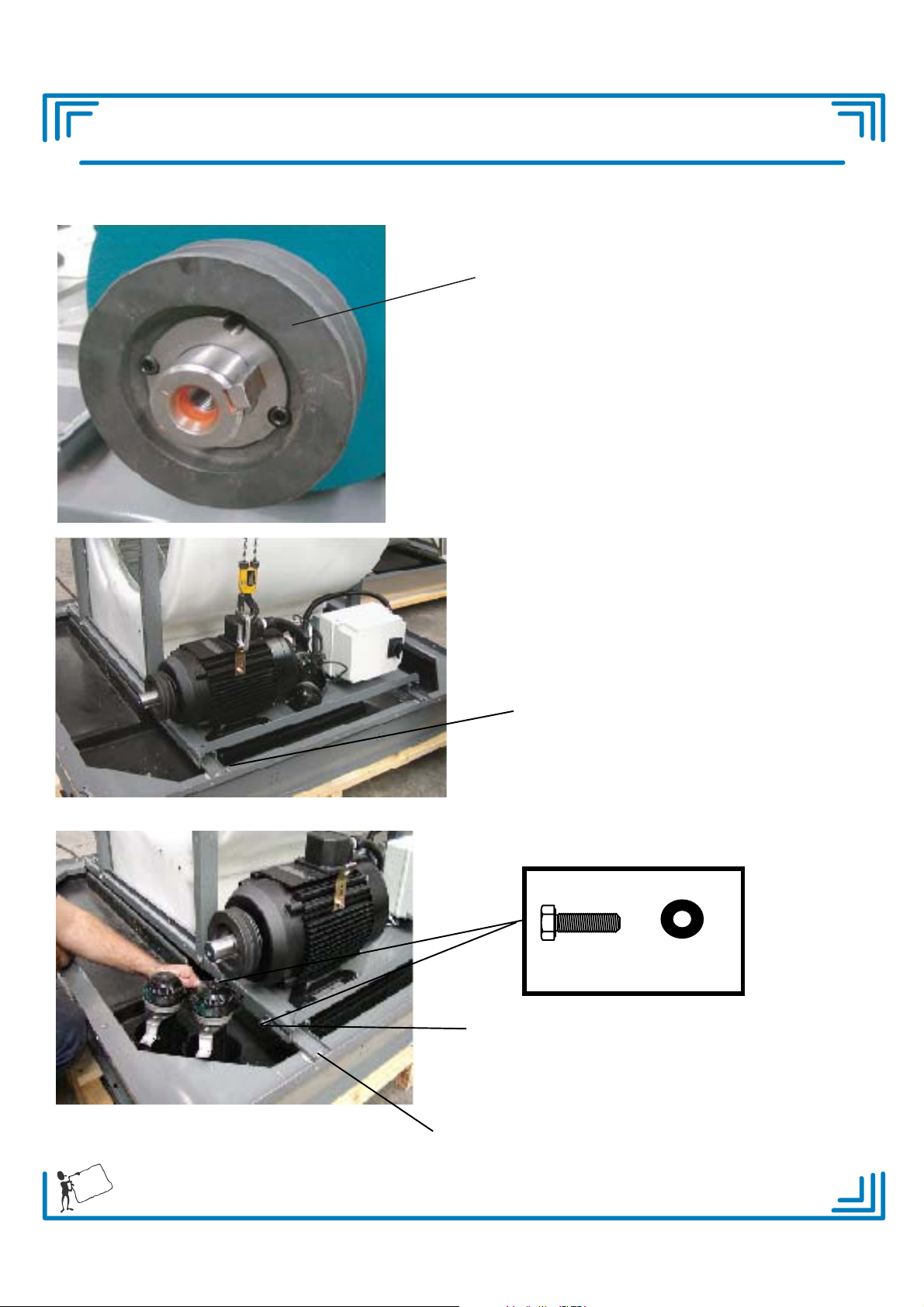

Motor Pulley Attachment

The motor pulley attaches

to the motor shaft via a

Taper Lock Bush screwed

to the Pulley.

Do not fully tighten Bush

locking screws now, Pulley

may need to move on shaft

to align V-Belts.

Use crane to install

Motor Platform to

Base Channels.

Base Channel.

Secure Motor Platform to

Base Channels.

BOLT WASHER

M8x30 8x25mm

P/N0 628257 P/No 627984

At this stage do not fully

tighten. Refer to notes

Belt Tension, P19.

17

Repeat same for

opposite side.

Note:

Fully tighten all Bolts securing

Base Channel to Base frame.

Page 18

RPX ASSEMBLY INSTRUCTIONS

Fan Pulley Attachment.

Fit 460 mm Aluminium

Pulley to the fan shaft.

Apply small amount

Loctite 222 (not supplied)

to Grub screws.

Total 3 Grub screws.

GRUB SCREW

5/16 BSW 19 mm Long

P/No SCR433

Tighten All screws.

Allow shaft to extend

approx 15mm passed

pulley.

Use suitable straight

edge, align Fan Pulley

to Motor Pulley.

Align Fan Pulley and

Motor Pulley.

18

Lock Screws on Motor

Pulley Taper Bush.

Page 19

RPX ASSEMBLY INSTRUCTIONS

Fit and Tension V-belts.

Fit two A91

supplied belts.

Apply tension to belts.

Tighten all bolts.

Repeat same for

opposite side.

Use a suitable

belt tension

measuring tool,

Set for

recommended

belt tension.

Deflection (cm) 1

Force (Kg) 1.5/1.7

If belt tension is not correct, loosen bolts and move

Motor Assembly,re-tension and tighten bolts.

19

Page 20

RPX ASSEMBLY INSTRUCTIONS

Fitting the Water Pumps.

Position the two pumps

at the corner of the tank,

nearest control box.

Use pump brackets

as template

drill 4 mm holes.

Secure pumps with

supplied screws.

SCREW - Phlp.

5x19 mm

P/No 9610013

Ensure pumps leads

are out of water.

Secure pumps leads with

supplied cable ties,

P/No FAS 213.

20

Page 21

RPX ASSEMBLY INSTRUCTIONS

Connecting the water system.

Connecting the Water Inlet and Float

Connect water

hoses to pumps.

Restrictor Valve.

Bleed Tap assembly,

(see later notes p40).

Installing the Anti-Vortex panels.

Secure with

supplied fasteners.

BOLT NUT WASHER

M6x20 M6 6x14mm

P/N0 628226 P/No 628271 P/No WAS029

Remove plastic film

from panel, and secure

with supplied rivets.

RIVET 5X12 mm P/No FAS 032

21

Note: Align Centre of

Anti-Vortex panel to

fan housing.

Repeat same for opposite side.

Page 22

RPX ASSEMBLY INSTRUCTIONS

Corner Pillar Installation.

Remove plastic

protective film.

Corner Pillar.

Plastic protective film.

At this stage two rivets only,

other rivets will be fitted, when

cooler is squared, see notes

Final Riveting P39.

Rivet Corner Pillar

to Base Frame.

Note: Hole location

on corner pillar.

RIVET 5X12 mm P/No FAS 032

22

Repeat for all corners of Base Frame.

Page 23

RPX ASSEMBLY INSTRUCTIONS

Centre Rail Installation.

Corner Pillar.

Align two tabs on

Centre Rail to slots

on Corner Pillar.

Centre Rail.

RIVET 5X12 mm P/No FAS 032

23

Repeat same for other end.

One Rivet,

for each end.

Apply silicone

to folded tag.

Page 24

RPX ASSEMBLY INSTRUCTIONS

Top Rail Installation. Step 1 of 2.

Note: Tab at each

end of rail.

Remove protective

plastic cover.

Fit Universal Bracket to Top Rail

before fitting to Corner Pillar.

Rivet Universal

Bracket to Top Rail.

RIVET 5X12 mm P/No FAS 032

Two Rivets.

Universal Bracket

P/No 626567.

24

Page 25

RPX ASSEMBLY INSTRUCTIONS

Top Rail Installation. Step 2 of 2.

Fit Top Rail to

Corner Pillar.

Align one tab on

Top Rail, to slots on

Corner Pillar.

Ensure Top Rail is

hard against

Corner Pillar.

Use suitable pliers

twist Top Rail end tab

inside Corner Pillar.

This to ensure that

assembly will not

dislodge.

Top Rail.

Centre Rail.

25

Repeat same for all Top Rails.

Page 26

RPX ASSEMBLY INSTRUCTIONS

Bottom Rail Installation.

Bottom Rail.

Base Frame.

Place Bottom

Rail to inside edge

of Base Frame

and Rivet,to eight

points.

RIVET 5X12 mm P/No FAS 032

Repeat same for other three sides.

Completed Assembly

Top, Centre and Bottom Rails.

26

Page 27

RPX ASSEMBLY INSTRUCTIONS

Centre Pillar Installation

Select Centre Pillar and slide

through Centre Rail slot.

Centre Rail.

Centre Pillar.

Bottom Rail.

Ensure Centre Pillar end tab

slots to Bottom Rail.

Slightly raise centre of Top Rail,

until Centre Pillar end tab

passes through slot.

27

Do not fold tab.

Page 28

RPX ASSEMBLY INSTRUCTIONS

Water Spreader Installation.

Water Spreaders.

Align holes on Water

Spreader to Top Rail

and Rivet.

RIVET 3.2X8 mm P/No FAS 300

Repeat same for other three sides.

Water Distributor Cap.

28

Page 29

RPX ASSEMBLY INSTRUCTIONS

Distributor Cap Installation.

Fit Distribution Cap

to top of Water

Spreader.

No securing is required,

ensure cap is tightly

pressed in position.

Complete assembly of

Water Spreaders and

Distributor Cap.

Repeat same for other

three sides.

Repeat same for all

Water Spreaders.

Note: Position of

Distribution Cap to

Water Spreader.

29

Page 30

RPX ASSEMBLY INSTRUCTIONS

Water Distribution Connection. Step 1 of 2.

Cooler is fitted with two Water Pumps.

L/H side Water Pump

supply hose.

R/H side Water Pump

supply hose.

Typical hose connection

to Water Spreders Inlet.

8 places.

30

Page 31

RPX ASSEMBLY INSTRUCTIONS

Water Distribution Connection. Step 2 of 2.

CONNECT

1

TO PUMP 1

2

CONNECT

TO PUMP 2

Typical Hose Connection to

Water Spreaders. D&T Models.

Hoses may

need to be

trimmed

to suitable

length.

Water Pump (2)

Supply hose.

Fit saddle to secure four

way Distributor.

Incorrect length

Water supply hose.

Repeat same for All water supply Hoses.

31

Hoses when fitted

should not touch pads.

Page 32

RPX ASSEMBLY INSTRUCTIONS

Installing Cab Top Blanking Cover.

12

Select T Model Cabinet Top,

place to suitable work frame.

Apply small bead of Silicone

along cut out inside line of

rivet holes.

Remove film from cut out.

4

3

Fit Cab Top Blanking Cover.

6

5

Check alignment, for

rivet clearance holes.

32

Rivet Blanking Cover

to Cab Top.

RIVET 5X12 mm P/No FAS 032

Page 33

RPX ASSEMBLY INSTRUCTIONS

Cabinet Top Installation. Step 1 of 2.

Place Cabinet Top onto Corner Pillars.

Note: Position of

Cabinet Top

joined section.

33

Page 34

RPX ASSEMBLY INSTRUCTIONS

Cabinet Top Installation. Step 2 of 2.

Cabinet Top.

Remove plastic

protective cover

from corners of

Cabinet Top.

,

Repeat same for all co

Rivet Cabinet

Top Corners.

RIVET 5X12 mm P/No FAS 032

At this stage two

rivets only.

Other rivets will be

added when cooler

is squared. See notes

Final Riveting P39.

rners.

34

Page 35

RPX ASSEMBLY INSTRUCTIONS

Squaring the Cooler for Final Assembly.

Use Supplied

Braces to

diagonally

square cooler.

Fitall4Braces

If necessary drill 5 mm hole Distance between hole

to clear aligning holes.

35

centres 1868mm.

Page 36

RPX ASSEMBLY INSTRUCTIONS

Cabinet Top Final Assembly. Step 1 of 3.

Top Channel.

Drill two 12.5mm holes

through Top Channel

and Cab Top.

Drill one 6mm hole

to centre Top Channel.

Note: Use 12.5 and

6 mm holes on Top

Channel as guide.

Repeat same for other side.

Place plastic Washers

between Cabinet Top

and Top Channel.

Place one Washers

at each end.

Two washers to centre.

Dome effect to Cab Top, for water run off.

PLASTIC

FLAT WASHER

6.5X50X5MM

P/No WAS121

PLASTIC

FLAT WASHER

13X50X5MM

P/No 608303

36

Top Channel.

Note: Number of washers may vary, between coolers.

Page 37

RPX ASSEMBLY INSTRUCTIONS

Cabinet Top Final Assembly. Step 2 of 3.

Fit screw and washer,

to centre hole of Top

Channel, through to

plastic washers

and Top Channel.

SCREW - Phlp. Washer

6x50 mm

P/No SCR 507

6x14mm

P/No WAS029

SPIRE NUT

P/No FAS 115.

Note: Position of Spire Nut.

Screw (air) driver.

Pliers

.

Use suitable pliers to

hold Spire nut.

Secure Cabinet Top.

Repeat same for

opposite side.

37

Page 38

RPX ASSEMBLY INSTRUCTIONS

Cabinet Top Final Assembly. Step 3 of 3.

Attach Lifting Eyenut

to Cooler

EYE NUT WASHER

P/No 608358

Fit washer under Eyenut.

BOLT WASHER

M12x30 13x44mm

P/N0 608174 P/No 608372

14x25mm

P/No 802138.

Fit bolt and washer,

thru 12.5 mm holes

in Top Channel,

through two plastic

Washers, Cabinet Top

and Eyenut.

Secure and tighten.

Repeat same for

other three lifting

Eyenuts.

When completed,

remove all

squaring braces.

38

Page 39

RPX ASSEMBLY INSTRUCTIONS

Final Riveting

Rivet to four Cabinet

Top corners.

RIVET 5X12 mm P/No FAS 032

Rivet the four Corner

pillars at the Base Frame.

If necessary drill 5mm

to clear holes.

Fasten thru Cabinet

Top Rail and Bracket.

RIVET 5X18 mm NYLON WASHER

39

P/No FAS 118 P/No 629872

Cab Top

Nylon Washer.

Universal Bracket.

Fit Nylon Washer between

Cab Top and Universal

Bracket.

Repeat same for

other three sides.

Page 40

RPX ASSEMBLY INSTRUCTIONS

Installation of Bleed Valve.

Place Bleed Sticker on

Corner Pillar over hole

Pass bleed tap valve

through hole opening

and fit rubber Grommet

over valve body.

GROMMET

BLEED VALVE

P/No 999236

Note: Apply some White

Petroleum Jelly, or other

similar lubricant to

Grommet for ease

of installation.

Cable tie bleed

hoses together.

GROMMET

BLANK

P/No 626932

40

Fit Blank Grommet

to other three holes.

Page 41

RPX ASSEMBLY INSTRUCTIONS

Clean and Test Cooler.

Step 1: Check that all fasteners are tightly secured,

and all riveting is completed.

Step 2: Remove all plastic covering from panels.

Step 3: Vacuum clean inside tank.

Step 4: Use cloth and suitable cleaning solution,

wipe down inside and outside of cooler.

Step 5: Set overloads for High and Low speeds,

as per electric motor ratings.

Step 6: Test cooler for normal running conditions.

refer to Appendix 1 - RPX Test Procedure

Step 7: Apply Serial Number to unit.

Step 8: Fit pads to cooler.

41

Completed RPX 900D

Page 42

RPX ASSEMBLY INSTRUCTIONS

Washers part numbers.

Washer 5.6x11x 0.8mm. SS

P/No WAS031

Washer 9x25x1.5mm. SS

P/No WAS035

Washer 6x14x1.2mm. SS

P/No WAS029

Washer 14x25x1.5mm. SS

P/No 802138

Washer 8x19x1.2mm. SS

P/No WAS163

Washer13x44x2.5mm G/Bond

P/No 608372

Washer 6.5x50 x5mm Poly.

P/No WAS 121

Nylon Washer

P/No 629872

42

Washer 13x50x5mm Poly.

P/No 608303

Washer 9x25x2.5mm G/Bond

P/No 627984

Spire nut U type

P/No FAS115

Page 43

RPX ASSEMBLY INSTRUCTIONS

Bolts and nuts part numbers.

Bolt M6x20. SS.

P/No 628226

Bolt M12x30. SS.

P/No 608174

Nut M6 Nyloc SS. Nut M8 Nyloc SS.

Grub screw 5/16 BSW 19mm long.

Bolt M8x20. SS.

P/No 628240

P/No SCR433

Bolt M8x30. SS.

P/No 628257

Eyenut M12

P/No 608358

Note:

Stainless steel bolts and

nuts are used in the

assembly of coolers.

A thread lubricating

compound anti seize

should be used at assembly.

P/No 628271 P/No 628288

43

Anti Seize not supplied.

Page 44

RPX ASSEMBLY INSTRUCTIONS

Screws and rivets part numbers.

Screw 19x5mm Phlp. SS. Screw 50x6mm Phlp. SS.

P/No 9610013

Wafer Screw 25x4mm Phlp.

P/No SCR506

P/No SCR507

Screw 25x6mm Phlp. SS.

P/No SCR 384

Rivet 5x18mm Al.

P/No FAS118

Rivet 3.2x8mm Al.

44

P/No FAS300

Rivet 5x12mm Al.

P/No FAS032

Rivet 5x25mm Al.

P/No FAS204

Page 45

RPX ASSEMBLY INSTRUCTIONS

Panels part numbers.

Bottom Rail

P/No 626789

Centre Rail

P/No 626772

Top Rail

P/No 626482

Anti Vortex

P/No 627229

Corner Pillar

P/No 626697

45

Universal Bracket

P/No 626567

Page 46

RPX ASSEMBLY INSTRUCTIONS

Panels part numbers, cont.

Motor Platform

P/No 623184

Water spreader

P/No 506609

Centre Pillar

P/No 627892

Top/Bearing Channel

P/No 623139

Flashing Angle.

P/No 100152

46

Base Channel

R/H P/No 623160

L/H P/No 627168

Page 47

RPX ASSEMBLY INSTRUCTIONS

Misc. part numbers.

Label Bleed Control.

P/No 998053.

Grommet Blank.

P/No 626932

Label Serial Number.

P/No 025101

Grommet Bleed Valve.

P/No 999236

Label O/Load Instructions.

P/No 111500

Cable Tie 140mm.

P/No FAS213.

125 x2A Mtr Pulley.

P/No 626987.

47

Bush Taper Lock..

P/No 822044.

460mm Pulley.

P/No 111500

Page 48

RPX ASSEMBLY INSTRUCTIONS

Misc. part numbers, cont.

Overflow Assy.

P/No 609737.

A Section V Belts.

P/No Vba91.

2 Speed switch Assy.

P/No 626680

Silicone Sealant.

P/No MIS508.

Mounting block.

P/No 200103

Down Discharge

Template cutout.

48

Distance between pin centres 1868mm.

Diagonally square braces.

Page 49

RPX ASSEMBLY INSTRUCTIONS

Special jig to assist when securing Flashing Angle

to Fan Housing.

49

Note: Cooler must be on pallet

Place tool to centre of cooler, lever upwards

to push inside of fan housing to flashing angle.

Page 50

RPX 900 'D' KIT.

RESERVOIR, BASE FRAME AND ACCESSORIES.

50

FAN HOUSING AND 'H' FRAME ASSEMBLY.

Page 51

RPX 900 'D' KIT.

CABINET TOP 'D' ASSEMBLY.

51

HARDWARE KIT 9655147.

PADS ASSEMBLY.

Page 52

RPX PALLET SPECIFICATIONS

C

REV

1

OF

DRG NO

1

SHT

100601

A4

DP

RJK DP

RJK

DRN APP

UNLESS SHOWN OTHERWISE

ALL DIMENSIONS SHOWN ARE

OUTSIDE AND IN MILLIMETRES

NA 4/12/98

NA 10/8/95

ECN DATE

1046 24/03/2004

ANGULAR ± 30'

REVISIONS

LINEAR ± 0.5mm

Pallet - 1560 x 1560

FINISH: NATURAL U.O.S.

DESC

-

BLANK

GENERAL TOLERANCE

DESCRIPTION

3 Self drilling screws added to centre slats

Redrawn to curent specifications

Production Release

100 ±2

B

A

C

DETAIL A

SCALE 1 : 5

C

NOTE:

2mm of thickness.

1. Pallet to be made from suitable timber unless otherwise specified.

2. Nails Min. 75mm glued type & punched below surface.

affect strength of pall et.

3. Sizes stated for slats & blocks are Min. required & to be parallel within

4. Bearers to be free from defects, as shown by shaded area, that adversly

5. Any changes to pallet requires authorisation from Braemar Engi n eering.

6. Dimensions circled are critical.

REV.

SCALE

DATE

RPA/RPX 700/900

DRN

UNIT REF

-

-

CHKD

PRINTED: 15/07/2005

PARTS/BLANK

1:1

10/08/1995

DP

20

22

100 x 20 Slats

65mm Self drilling

5perpallet

screws to be placed

on each slat in areas

shown(3intotal)

SUPPLIER

Aspect packaging

Rough Sawn Pine

MATERIAL

Z:\Vault\000000 To 169999\Part Files\100601

Z:\Vault\000000 To 169999\Part Files\

Drawing Loc:

Part Loc:

52

1560

1560

980

730

480

90

C

45

L

TEL (02) 60411611

FAX (02) 60412208

www.braemar.com.au

This drawing is the property of

Seeley International and must

77 North Street, Albury N.S.W.

not be reproduced or c opied

without the written consent of

the proprietors of the copyright

Page 53

RPX 900D EXPLODED VIEW

15

10

14

9

11

12

16

28

19

59

13

47

62

20

61

18

35

17

48

41

2625

42

40

34

3130

23

27

24

32

29

50

63

33

51 20

46

7

1 2

6

8

58

49

39

44

383736

52

53

54

57 60 56

55

Y

11241

QT

ION

Support

voir

DESCRIPTP

y

ir-Pol

hannel - Reser

Reservo

C

N

/

100121

623993

21687

ITEM NO.

eezairr

Label B

855288

intedP

a

ssy -

ame A

se Fr

a

B

627854

t

r

uppo

S

e

Fra

ase

B

623948

16Pad -Small Celdek 597Wx585Hx60D9 626727

lGrey

ame Ead Fr A S

505732

55 x 21 x 545mm

Fngle P A

627816

161632

A 55 x 21 x 250mm

Angle Bottom PFPA

627809

121011

16

21 x 21 x 300mm

Fngle P A

A

627823

13

128

/S

o8 x 5/8 S

Ntreaker

SR266

C

14 S

16

ame

ad Fr

P

reezair" EA

Label "B

51580915

4

ey

inted Gr

entre Rail - Pa

C

627885

16

1

1

4

RPB1000"T"

Y

mmon "T"

E

ear

il GR

ttom R

abinet Top R

abinet Top Co

oa

C

C

B

627915

628455

628479

17

19

18

6

sal

iver

n

acket Ur

B

626567

20

SP

sh Funnel 1 1/2" B

u

B

535500

111

128 1 1/2" x 3/32"

S

ng B

i

t 1 1/2" BuSP

N

OR

535401

804415

252324

1

pe 40mm

flow Pi

Over

608884

26

1

48

58*

Rubber

Washer

200105

27

4

1

ey 82x82x64

ousing 16/19

rGr

n

C

lower H

B

Pillar

627922

111401

28

29

1

inted-Pa

H

hannel Rase C

B

623160

303231

4

ainted

ical P

hannel - Vert

C

626710

4

d

t

Top P

ing &

hannel Bear

C

623139

1

inted-Pa

H

hannel Rase C

B

627168

33

1

t Off 16/19

u

100150

34

1

ssy 16/19 1 1/4"

111455

35

2

ollar

1 1/4 " inc Locking C

Bearing -CBlower Wheel A

067004

36

2

11/4"

Inserubber t

R

067002

37

2

ousing 1 1/4"

ing Hear

B

067003

38

1

Shaft 1 1/4" x 960mm SS

10024039

111

1

Float 4"

Float V lve 1/2"aBMotor

020802

020803

40

415842

Inlet

acket Waterr

616056

td

700/900 P

Platfor

623184

1

ge

h Lar

ox 3P

Isolation B

100155

44

1

peed

hase 2 S

Motor 4.5kW 3 P

111221

2

1

td

x Painted

ame P

Mount Isolation Bo

Brace "H" Fr

628981

620992

47

464548

2

PX

tex R

nanel A ti-Vor

P

627229

8

all EA

S

pS reader

Water

506609

49

4

Top Rail - Water Spreader

626482

50

8

Sall

D

eaderap Spr IN

C

523002

2

2

z&JBox

240V 50 H

sket Moulded

aump B

P

Pump EB

999293

608907

535152

2

p

Pu

ket EBM

c

Bra

627236

54

1

Taper

125 x 2A

lley Motoru

P

626987

55

1

1

x 31.75 (1x2 A 1/4")

18")

lley Fan 450 (u

sh TL 1610 x 38 #2

u

PBE

111500

822044

575660

2

4

lt A9ee Be 1

ebolt NyutM12

V

1

608358

VBA9

59

4

ey

Pillar Gr

entre

C

627892

61

1

2

npaintedFlashing Strip U

Blanking Plate - RPX "T" Cab Top

63034262

100156

63

53

Page 54

RPX INDUSTRIAL AIR CONDITIONERS

Wi

Wiring Diagram - Two Speed Three Phase.

A

dvanced natural cooling

3PHASE

WIRING DIAGRAM

WALL S WITCH

1

C

2

Lo/Hi

FAN LO

FAN HI

FIE L D W IR ING

Fan

1

1

C

C

ACT IV E

2

Cool

PUMP

BROWN

BLUE

2

TO

TER MINAL

POINT 6

1

2

3

4

5

6

BLAC

7

8

9

RED

K

RED

5A FU S E

IS O L AT ING

R P X 600-1000

3AG 250V

L1 L2 L3 N E

SWITCH

RED

BLACK

BLUE

WHITE

BLACK (Neutral)

A1 A2

1L1 3L2 5L3 21NC

CONTACTOR

2T1 4T2 6T3 22NC

MAINS IN

TO E ARTH

POINT 1

BLUE

WHITE

BLACK

GREY

GREY

E N L1 L2 L3

IS O L AT ING

SWITCH

R P X 1200-1800

RED

RED

A1 A2

GREY

RED

1L1 3L2 5L3 21NC

CONTACTOR

2T1 4T2 6T3 22NC

BLUE

WHITE

BLUE

WHITE

BROWN

BLUE

EARTH

WATER

PUMP

WATER PUMP

CONNECTION

MOD E LS

RPX 600

TO R P X 1800

10

11

12

GREY

GREY

OVE R LOAD OVE R LOAD

NC NO

95 96 97 98

2T14T26T3

12 3 4 56

GREY

EARTH

GREY

GREY

GREY

NC NO

95 96 97 98

2T14T26T3

GREY

GREY

GREY

MO T OR

EARTH

EARTH

POINT 1

(TO MOT OR PLAT F OR M)

54

It is the policy of Seeley International to introduce continual product improvement. Accordingly, specifications are subject to

Manufacturers and Designers of Technically Advanced Quali

change without notice. Please consult with your dealer to confirm the specifications of the model selected.

ty Heating and Cooling Products...........Sept 2005

Loading...

Loading...