Page 1

Installation and Operating ManualInstallation and Operating Manual

N A T U R A L L Y C O O L E R

N A T U R A L L Y C O O L E R

EXV Series

Evaporative Air Coolers

EXV Series

Evaporative Air Coolers

Page 2

11

Index

INDEX

SAFETY.........................................................................................................1

OPERATING INSTRUCTIONS

Thermostat Range.........................................................................................2

Using the SENSORTOUCH Remote Control...................................................3

Using the SENSORTOUCH Wall Control.........................................................7

Maintenance.................................................................................................. 9

Pre-Assembly Inspection............................................................................... 10

INSTALLATION INSTRUCTIONS

Installation Details..........................................................................................11

Water Installation........................................................................................... 12

Electrical Installation......................................................................................13

SENSORTOUCH Wall Control........................................................................13

SENSORTOUCH Remote Control...................................................................14

Testing the cooler...........................................................................................16

Installation Checklist......................................................................................18

TROUBLE SHOOTING .................................................................................19

APPENDIX A - Wiring Diagrams.....................................................................21

Page 3

SAFETY INSTRUCTIONS

Important Safety Instructions and

Warnings

WARNING: The warnings and safety

instructions in this manual must be

followed to reduce the risk of fire,

electric shock or injury, and to provide

reasonable safety and efficiency in

using this Evaporative Air Cooler. The

operator is responsible for following

the warnings and instructions in this

manual and on the cooler.

Read this entire manual before

proceeding to install the cooler.

Restrict the use of this cooler to

persons who read, understand and

can follow the warnings and

instructions in this manual and on

the cooler. NEVER ALLOW

CHILDREN TO OPERATE THE

COOLER.

Failure to observe these warnings

and instructions will void

manufacturer's warranties and will

discharge the manufacturer of all

liability.

CAUTION!

ALWAYS disconnect the cooler

from the power supply before

commencing maintenance

procedures.

During maintenance procedures,

NEVER use a naked flame for any

inspection or cleaning purpose as a

fire could be caused by a flame

coming into contact with the cooler

materials.

Avoid Dangerous Situations:

Protect the cooler from all sources

of ignition because polymers and

cooling pads will burn.

NEVER use a water hose to squirt

the interior of the cooler for cleaning

as residual water could damage

electrical components and create the

risk of fire and /or electric shock to

the user after re-assembly.

11

11

Safety

WATER PUMP

The water pump is supplied with this

cooler and is factory fitted into its

correct location.

Ensure that it is properly secured and

upright as intended.

There is no need to adjust the water

flow since the cooler is designed to

operate with maximum cooling at low

air velocities.

Water pump replacement

Factory authorized pumps are fitted

with thermal overload protection.

Water pumps may seize up and

overheat, creating a fire risk. Pumps

that have thermal overload protection

are designed to shut off the pump if the

motor overheats.

Factory Authorized water pump

Seeley "Tornado" pump (part no.

095851)

“Power Clean" Style Timed Pumps

Under no circumstances are "Power

Clean" style timed pumps to be

used in any Breezair evaporative air

cooler. Use of these devices or any

other non-approved device will cause

serious damage to the special safety

circuits of this cooler. Failure to follow

this instruction will VOID ALL

WARRANTY and may create severe

risk of electric shock and fire!

FAN MOTOR

This cooler is supplied with a fan motor

made by the cooler manufacturer.

USE ONLY THE AUTHORIZED FAN

MOTOR SUPPLIED.

Failure to follow this instruction will

VOID ALL WARRANTY and may

create severe risk of electric shock

and fire!

Factory Authorized Fan Motor

Seeley Variable Speed motors:

550W (3/4HP) motor part # 095118

750W (1HP) motor part # 095125

The fan motor is equipped with inbuilt

overheating protection that will reset

automatically on cool-down to a safe

temperature. This may take up to 45

minutes.

CIRCUIT BREAKER

PROTECTION

This cooler is fitted with circuit breaker

protection for the fan motor and pump.

! Use only the power supply voltage

shown on the motor/cabinet

nameplate.

! Do not install or service the air

cooler during rain, high wind or severe

weather conditions.

! Keep children, bystanders and

animals at a safe distance, a minimum

of 30ft (10m) away from working

areas.

! Dress safely. Wear non-skid shoes

when working at high levels and roofs.

Do not wear loose clothing or personal

accessories while installing or

servicing the air cooler as they may

become caught in moving parts.

! Keep loose hair, loose clothing,

fingers and all other parts of the body

away from openings and moving

parts.

! Check the cooler for worn, loose,

missing, or damaged parts before

operation.

! If you work with power tools, wear

protective eyewear and gloves.

! Take care when lifting or raising the

air cooler to its final location. Use safe

equipment and never attempt to lift the

cooler alone. Always have assistance.

Otherwise you might damage the

cooler or the building or injure

yourself.

! Ground Fault Circuit Interrupter

(GFCI) protection should be provided

on the circuit supplying this air cooler.

Receptacles are available with built-in

GFCI protection.

! Air coolers installed on roofs must

not have the waste water directed

onto the roof as stains will occur.

Connect the cooler drain outlet to a

gutter or drain pipe using a suitable

hose.

! Always use the correct tools.

! WARNING! the packaging plastic

on this cooler can be a safety hazard.

Dispose of carefully.

! Never drill holes in the pan or walls

of the cooler.

! Avoid dangerous situations. Do not

use the cooler in the presence of

flammable liquids or gasses to avoid

creating fire or explosion. This air

cooler is NOT flame retardant. A fire

may result from contact with a flame

or from an electrical short.

! Use of wrong replacement parts

creates risk of severe electric shock

and fire which may result in serious

property damage, personal injury or

death.

INSTALLATION, REPAIR AND

OPERATION

! All installation and repair work

must conform to local electrical, water

supply and environmental codes,

rules and regulations and applicable

national standards.

! All installation, maintenance and

repair work must be done by a

licensed and qualified electrician

and/or a qualified, experienced

heating, ventilating, air

conditioning technician. All such

work must be effected with factory

authorized spare parts only.

! Disconnect electrical power at the

fuse or circuit breaker box before

installation commences. ALWAYS

turn OFF the isolating switch

(disconnect) located on the electronic

module inside the cooler BEFORE

commencing any maintenance

Page 4

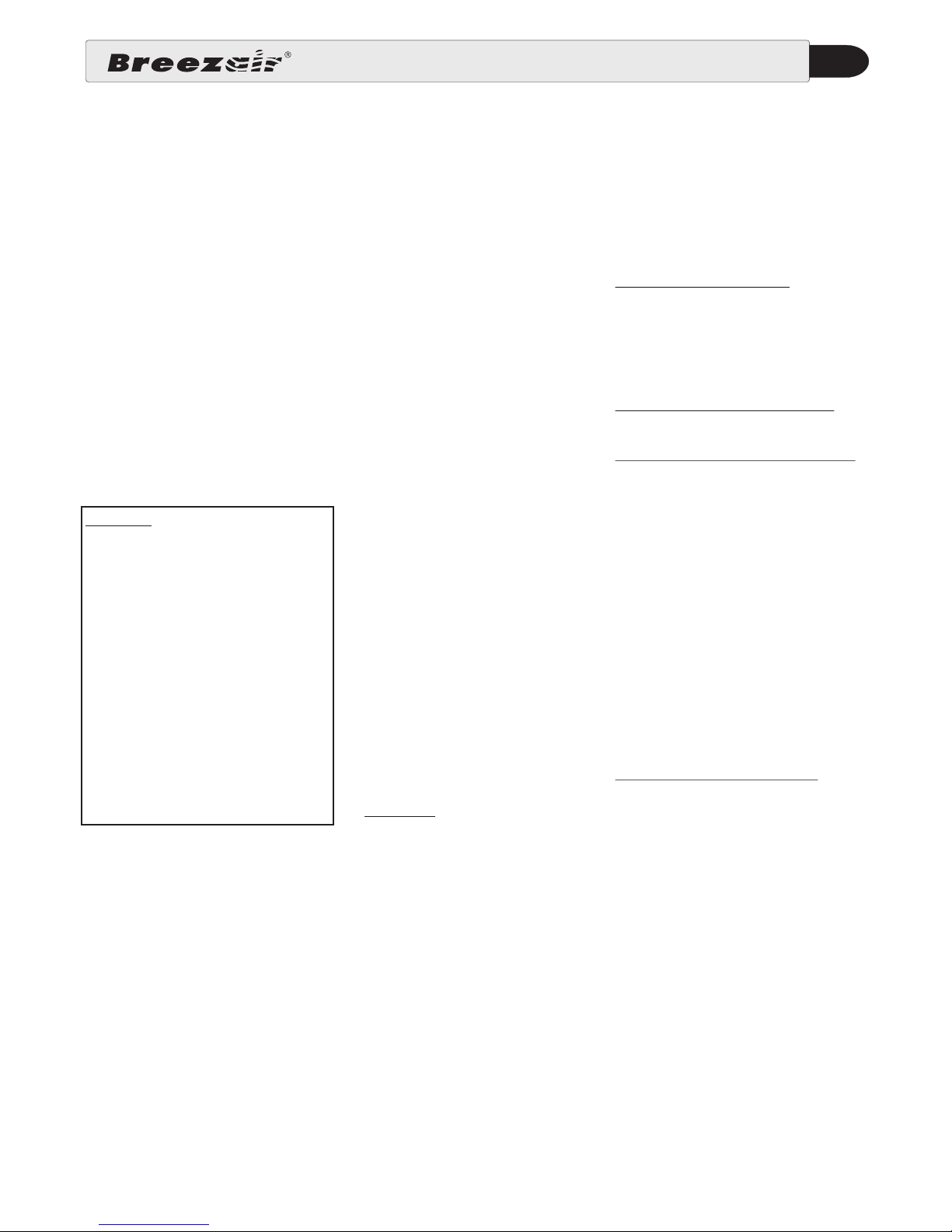

11

22

Thermostat Range

2

Wall Mounted Thermostat Control

(wall control)

Remote Thermostat Control

(remote control)

AUTO COOL

PM

FAN

SPEED

ECONOMY

REMOTE CONTROL

ILL239-D

ILL1140-A

®

thermostat range

SENSORTOUCH

SENSORTOUCH

Page 5

11

33

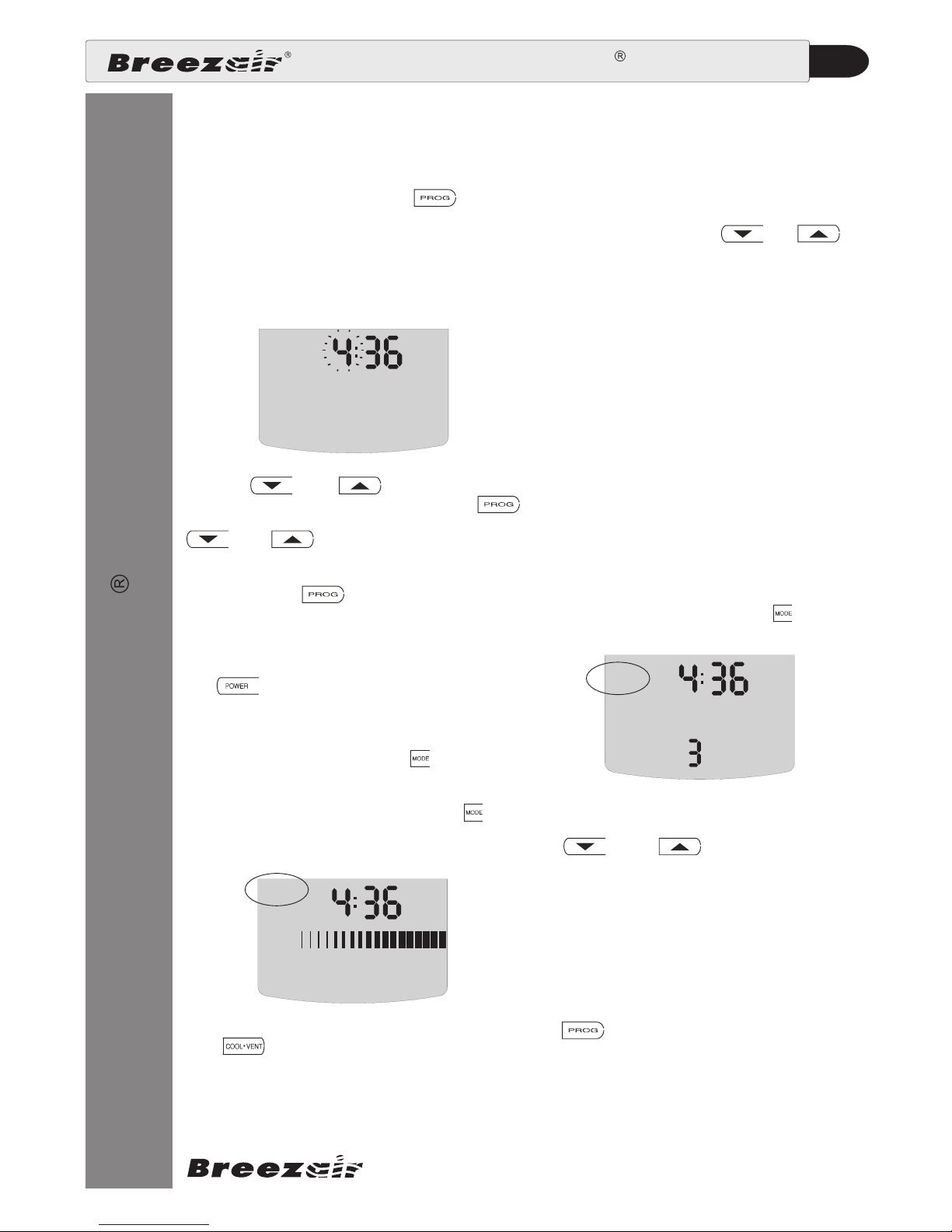

Using the SENSORTOUCH Remote Control

SETTING THE CLOCK

Set the clock on the remote control before

proceeding with any other programming.

The clock can only be set with the remote

control switched OFF. Hold the button

down for over 2 seconds, until the hour flashes.

The clock can be set to either 12 or 24 hours

(see page 6). If the clock is set to 12 hours

make sure that the AM/PM displayed on the

screen is correct. AM/PM will change with

adjustment of the hour.

Use the and buttons to change

the hour. To change minutes, press the

button again. Change the minutes using the

and buttons.

To lock in the time setting, and enter the OFF

state, press the button. The display will

stop flashing.

TURNING ON THE COOLER

The remote control is switched on and off using

the button. The memory will store and

use the settings from when the cooler was last

used. Once the remote control is on, you can

choose between MANUAL, AUTO and AUTO

TIMER modes by pressing the button.

MANUAL MODE

With the remote control ON, press the

button until MANUAL is shown in the top left

corner of the display.

The button is used to select VENT

(where fresh air is being delivered without

being cooled) or COOL.

ILL1104-A

PM

®

MANUAL MODE

Once either COOL or VENT has been

selected, the remote control will maintain a

constant fan speed. This is indicated by the

bar graph in the centre of the display.

To decrease or increase the fan speed

required, press either the or

buttons.

AUTO MODE

The remote control contains a thermostat. In

AUTO mode the cooler is controlled

automatically, based on your pre-selected

comfort level. The cooler will adjust the fan

speed, switch between COOL and VENT and

turn itself off. However, the sequence and

regularity at which these settings change will

differ with each operation of the cooler.

As the remote control senses room conditions,

the comfort control settings will be influenced

by heat from direct sunlight or electrical

appliances. Likewise placing the remote

control in cupboards or drawers or under

cooling vents will affect the cooler’s operation.

To set the AUTO mode press the button

until AUTO is displayed.

Ten levels of comfort are available with the

remote control. While in AUTO mode pressing

the and buttons will adjust the

level of required comfort. The display will show

your selection by indicating a level between 1

and 10. WARMER or COOLER will be

displayed on the screen as settings are

changed.

AUTO TIMER MODE

AUTO TIMER mode can be selected by using

the button. Once the AUTO TIMER

mode is selected the cooler will only operate

during the programmed time period.

AUTO

FAN

SPEED

ILL1105-A

PM

3

SENSORTOUCH Remote Control

MANUAL VENT

FAN

SPEED

ILL1109-A

Page 6

AUTO

TIMER

OFF

ILL1115-A

44

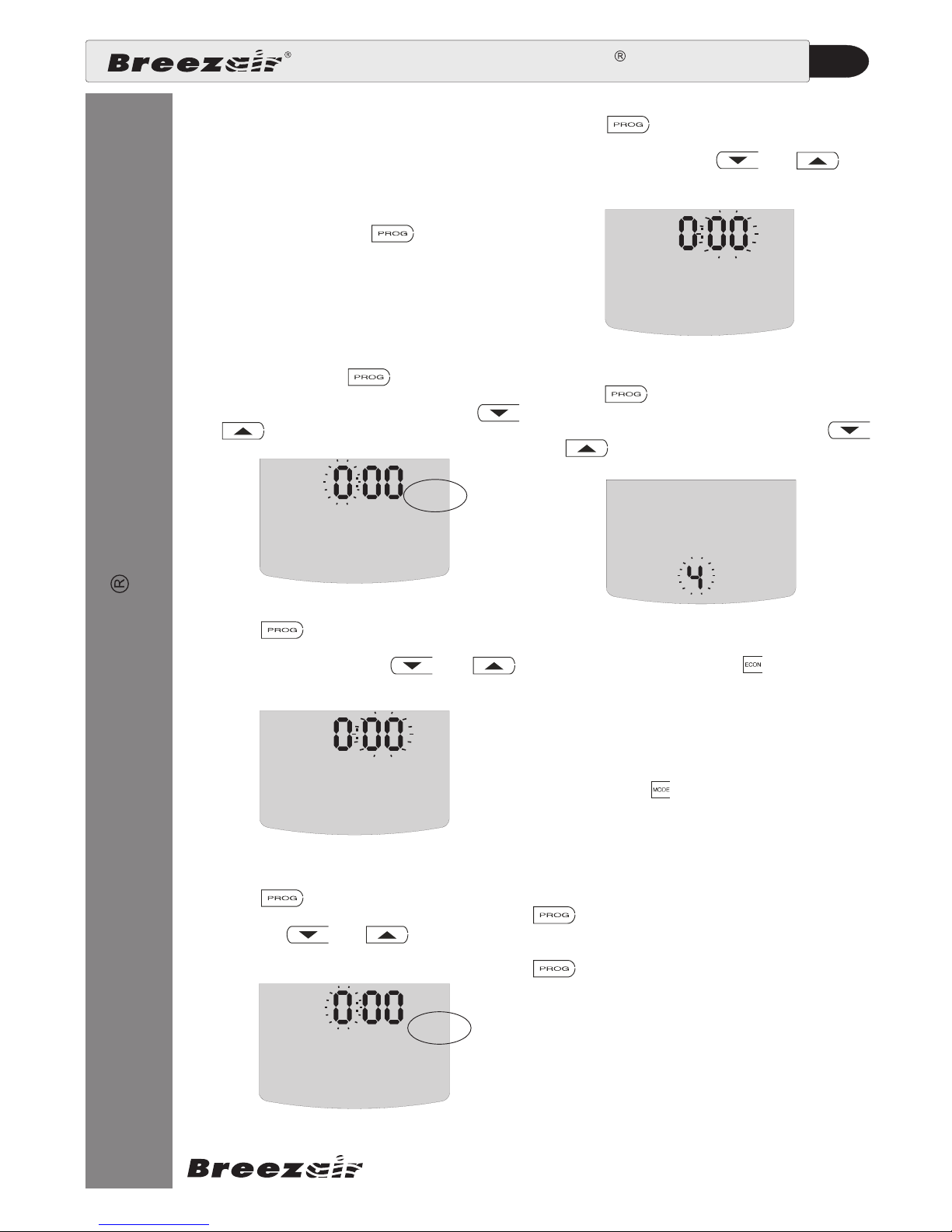

AUTO TIMER MODE

Programming the timer must be performed

before AUTO TIMER can be activated. This

can be done while in any mode, even when it is

OFF. There are 7 steps involved in setting the

AUTO TIMER.

NOTE: After pressing the button the

display will revert back to the previous setting if

no buttons are pressed within 4 seconds.

To program the timer use the following

sequence:

(1) Setting the ON time hour

Begin by pressing the button. The hour

displayed will start flashing and the word ON

will appear on the screen. Then use the

and buttons to change the hour value.

(2) Setting the ON time minutes

Press the button. The minutes displayed

will start flashing and the word ON will appear

on the screen. Then use the and

buttons to change the minute setting.

(3) Setting the OFF time hour

Press the button. The hour displayed

will start flashing and OFF will be displayed.

Then use the and buttons to

change the hour.

®

(4) Setting the OFF time minutes

Press the button. The minutes

displayed will start flashing and the word OFF

will appear. Then use the and

buttons to change the minute setting.

(5) Setting the comfort level

Press the button and the comfort level

number (1 to 10)

displayed will start flashing. Then use the

and buttons to change this setting.

(6) Setting ECONOMY

To select economy press the button so that

it is displayed on the screen.

(7) Activating AUTO TIMER

Now that you have programmed the settings

for AUTO TIMER they will be stored in the

remote control’s memory until you change

them. Press the button until AUTO TIMER

is displayed on the screen. Your cooler will

now only operate during the programmed time

period.

NOTE: To change any AUTO TIMER settings

when the remote control is switched off, the

button needs to be pressed and

released within 1 second. To change settings

when the remote control is turned on press the

button until the desired number is

flashing.

4

AUTO

TIMER ON

ILL1112-A

AUTO

TIMER ON

ILL1113-A

AUTO

TIMER

OFF

ILL1114-A

AUTO

TIMER

ILL1116-A

SENSORTOUCH Remote Control

Using the SENSORTOUCH Remote Control

Page 7

55

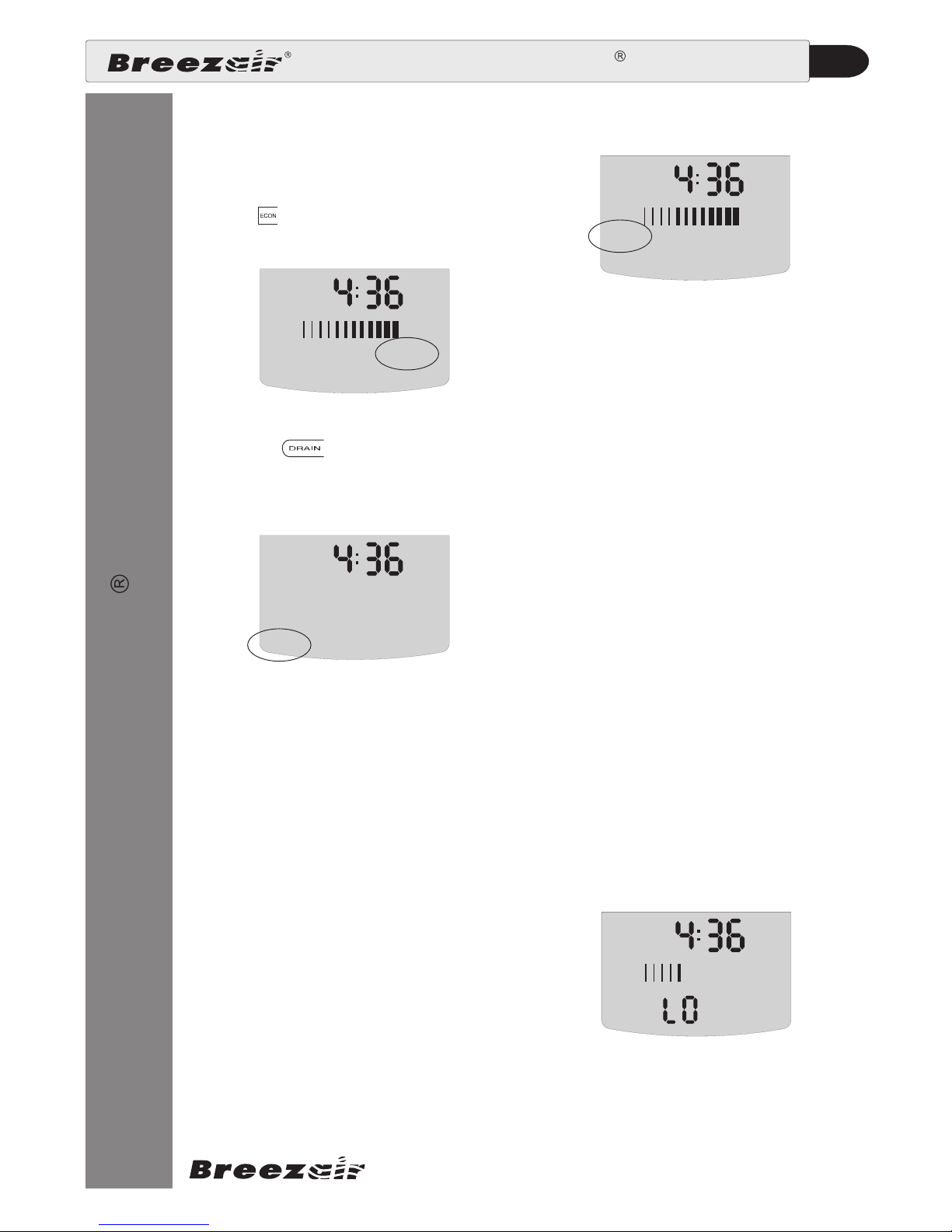

ECONOMY MODE

Selecting the ECONOMY mode limits the

maximum available cooling or ventilation and

reduces the power used by up to 20%. The

ECONOMY function can be used in either

AUTO or MANUAL modes. To select this mode

press the button so that ECONOMY

appears on the display.

DRAIN MODE

Pressing the button opens the drain

valve in the cooler and empties the water in the

tank. This will leave the tank clean and dry and

turn the cooler off.

If the cooler has not been used for 3 days or 3

hours, depending on the DIP switch setting see page 6, the tank will automatically be

drained to ensure the system remains clean.

PRE-COOL MODE

Your remote control is designed to allow for the

saturation of the cooler’s cooling pads before

the fan is switched on. This function, referred

to as PRE-COOL mode, is enabled at DIP

switch D (refer to page 6). Once it is enabled

the cooler, when first switched on, will operate

as follows:

(1)...... If the pan is empty the drain system will

be closed. The pan will then be filled.

(2)...... The water inlet system allows water to

fill the pan, until the water level reaches the

lower pins of the water probe. After a 30

second delay, the pump will turn on and

saturate the cooling pads.

(3)...... After the pump has been running for 2

minutes the fan will start.

®

During this operation the word PRE-COOL will

be displayed on the remote control’s screen.

NOTE: PRE-COOL mode will not be activated

if VENT is selected on the remote control or

the cooler is used again shortly after having

been turned off.

WATER MANAGER

The Breezair remote control is fitted with the

WaterManager feature which automatically

monitors the quality of the water in the cooler.

The WaterManager drains the existing water

in the cooler to allow it to be replaced with

fresh water, only when it is needed. Therefore,

you may notice your cooler draining water

occasionally. How often the WaterManager

performs this operation depends upon the

quality of the water supply and the rate of

evaporation.

In areas of poor water quality, the

WaterManager will operate more often as it

tries to maintain the optimum water quality in

the cooler. This maximizes the cooling effect

and life of the cooling pads.

The remote control has a unique feature

attached to the WaterManager that allows

you to specify either high or low salinity

settings. The low salinity setting is used in

specific circumstances only. We recommend

talking with your dealer before adjusting this

setting.

5

MANUAL

COOL

PM

FAN

SPEED

ECONOMY

ILL1125-A

DRAIN TANK

ILL1107-A

MANUAL

COOL

PM

FAN

SPEED

ECONOMY

ILL1142-A

PRE-COOL

®

®

®

®

®

MANUAL

COOL

FAN

SPEED

ECONOMY

ILL1111-A

SENSORTOUCH Remote Control

Using the SENSORTOUCH Remote Control

Page 8

66

The high salinity setting is designed to operate

the cooler at a maximum safe salinity level to

maintain a normal working life. It also results in

a minimum usage of water.

NOTE: High salinity outlet water should not be

used on salt sensitive grass or plants. It has a

high salt content.

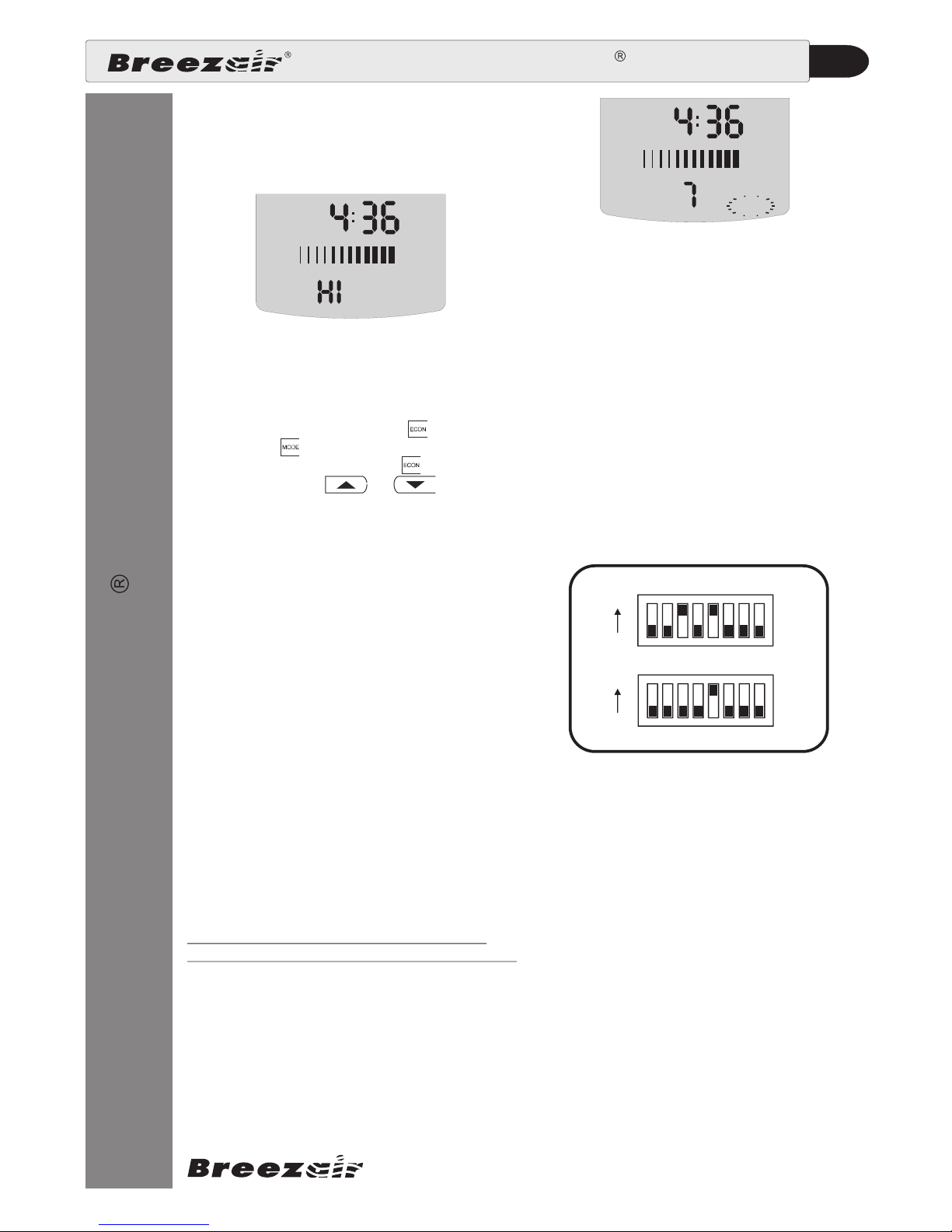

The current WaterManager setting is

displayed by holding down the button and

pressing the button. The setting can be

changed by holding down the button and

pressing either the or button for

HI and LO respectively.

The factory default WaterManager setting is

HI. For areas operating with bore water, DIP

switch F should be switched to off (see page

6). This will disable the salinity measuring

circuit and simply drain water from the tank

every 65 minutes of operation.

POWER FAILURE RECOVERY

After a power disruption is restored, the cooler

will automatically restart within 10 minutes, if

the remote control has remained “ON” during

the power failure.

BATTERIES

If the batteries are installed when the display is

completely blank, the display will remain blank

for 5 seconds. After 5 seconds the display will

show “Id” for 1 second, then display the clock.

The remote control is now ready to use.

The remote control requires 3 AAA batteries.

The use of good quality alkaline batteries is

recommended. Under normal conditions a set

of batteries will operate for 18 months.

Do not use rechargeable batteries as their

voltage rating is too low for the remote control.

When the batteries are getting low on power,

BATTERY LOW is displayed on the screen (the

cooler may also switch off while the display

remains ON). This indicates that the batteries

have only a small amount of life remaining.

®

To change the batteries remove the cover from

the back of the remote control. Pull out the old

batteries and replace them all with the new

ones. Do not mix new batteries with old

batteries.

The remote control has 2 minutes of back-up

power to retain its memory while the batteries

are being changed.

DIP SWITCHES

There are 2 rows of DIP switches located

under the battery cover on the remote control.

WARNING: Do not alter DIP switches 1 to 8

on top row and 7 & 8 on bottom row as the

cooler will cease to work.

Definition of DIP switch positions (first 6 in

bottom row only) are as follows:

BOTTOM ROW

(1)...... Reserved for later use.

(2)...... OFF, 24 hour clock.

ON, 12 hour clock.

(3)...... OFF, 1.0, 3/4HP Motor.

ON, 1/2HP Motor

(4)...... OFF, no pre-cool.

ON, pre-cool.

(5)...... OFF, drains 3 days after power off.

ON, drains 3 hours after power off.

(6)...... OFF, drains every 65 minutes of

operation.

ON, activates water salinity circuit

(WaterManager ).

6

MANUAL

COOL

PM

FAN

SPEED

ECONOMY

ILL1110-A

®

®

ILL217-H

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

OFF

OFF

EXAMPLE ONLY

AUTO COOL

PM

FAN

SPEED

BATTERY LOW

ILL1106-A

®

SENSORTOUCH Remote Control

Using the SENSORTOUCH Remote Control

Page 9

77

STARTING YOUR COOLER

AUTOMATIC MODE

MANUAL MODE

button until MAN

is shown on the display.

The button turns the air cooler on and

off.

There are two modes of operation to choose

from, Automatic mode or Manual mode. When

the air cooler is turned on, it will start in the

mode of operation it was in when last turned

off. If your air cooler has been off for more

than (about) 10 minutes, when you start it,

“Preparing to Start” may flash on the display as

shown. This shows that the water pump will

operate to saturate the cooling pads for a few

minutes, before the fan is turned on. This

ensures that when the fan starts, only cool air

enters the building.

The button is used to select Automatic

mode or Manual mode. When “Auto” is

displayed the cooler is under Automatic control

and will operate according to the temperature

sensed at the wall control.

When the air cooler is turned on, it will read the

temperature and set the cooler operation

accordingly. If the temperature increases at the

wall control, then the fan speed will increase.

As the temperature decreases the fan speed

will decrease until the cooler turns off.

Press or to overide the automatic

cooling level setting and adjust your room

temperature.

To switch to Manual mode, press until

“Man” appears in the display.

®

In Manual mode the cooling level can be

manually adjusted.

In Manual mode, press to choose

between circulating cool air or uncooled air.

When “Cool” is displayed, fresh cool air will

circulate into the building. When “Vent” is

displayed as shown, fresh uncooled air will

circulate through the building.

Press to increase the fan speed and

circulate more air. Press to decrease

the fan speed and circulate less air. Press

once to change the speed by one increment.

Hold the button down to change the speed

more quickly.

You can set the air cooler so that it will turn on

after a set number of hours.

1. To set the delayed start time, press

with the cooler turned OFF. “Starting in” will be

displayed as shown with the last mode of

operation (Manual or Automatic).

2. If you want the air cooler to turn on in

Automatic mode with the previous settings,

then press until “Auto” is displayed.

Alternatively, if you want the air cooler to turn

on in Manual mode, press until “Man” is

displayed, then press and then

or to set the required fan speed.

3. To set the time until the start, press

4. Then press or to adjust the

time. The cooler can start up to 24 hours in

advance.

5. Press again to initiate the timed

automatic start. The timed start will not repeat.

TIMED AUTOMATIC START

.

7

ILL1122-A

ILL1122-A

ILL1124-A

AUTOMATIC MODE DISPLAY

MANUAL COOL DISPLAY

MANUAL VENT DISPLAY

ILL1123-A

ILL1117-A

SENSORTOUCH Wall Control

Using the SENSORTOUCH Wall Control

Page 10

88

TIMED AUTOMATIC STOP

USING THE COOLER

AIR TOO COLD

AIR NOT COLD ENOUGH

You can also set the air cooler so that it will

turn off after a set number of hours.

1.To set a delayed stop time, press with

the cooler RUNNING. ”Stopping in” will display.

2.Press or to adjust the number

of hours before the air cooler will stop. The

maximum delay setting is 24 hours.

3. Press again to begin the timed stop.

Now that you have read these instructions,

press the button to turn your air cooler

on. If the air cooler has not operated for a while

“Preparing to Start” will flash on the display

(see page 7). The pre cool cycle will begin and

will take only a few minutes to complete. After

this time, the fan will start automatically, and

you can enjoy the comfort of cool fresh air!

With the cooler running in Automatic mode, you

may find that you are too cold or that the air

cooler is blowing too much air. Press

to reduce the amount of cooling.

If you are too cold with the cooler running in

Manual mode, then press to reduce the

fan speed. You can also circulate fresh

uncooled air by pressing until “Vent”

displays.

You may find that with the air cooler running in

Automatic mode, you are not cool enough.

Simply press to increase cooling.

If you are not cool enough with the air cooler

running in Manual mode, then press

to increase the fan speed. Ensure that cooled

air is circulating by pressing until “Cool”

displays.

You can experiment with the settings on

your wall control. This is the best way to

decide what suits your needs.

.

®

DRAIN VALVE

This air cooler is supplied with an automatic

drain that performs two primary functions:

1. It opens and closes automatically to control

salt concentrations in the tank.

2. It opens to drain all water and keep your

tank dry during prolonged “off” cycles.

Your cooler will automatically change some of

the water during operation when the water

salinity becomes too high. This ensures the

water is always fresh and helps maintain your

cooler in good condition to ensure optimum

cooling performance. This is called “salinity

sensor” method. Alternatively and if necessary,

the air cooler can be set to change some water

after a set time of cooling operation. The

frequency of the automatic drain function may

have been adjusted by your installer. This is

called “timed drain” method.

You can select either method of water

replacement with the following steps.

1.When the cooler is OFF, press and hold

2.While still pressing , press .

3. A number will display which corresponds to

the selected salinity control method as shown

in the table below.

Press or to change the

displayed number to the desired salinity control

method.

4.Press to set your selection.

When the air cooler is not operated for 72

hours, the drain valve will open automatically

to empty all water from the cooler. If

necessary, you can adjust this delay time with

the following steps.

1.When the cooler is off, press and hold .

2.While still pressing , press .

3.A number will display indicating the current

water drain delay time according to the table.

8

ILL1119-A

Display Number

Salinity Control Method

00

01

Salinity Sensor

Timed Drain

STANDARD

SENSORTOUCH Wall Control

Using the SENSORTOUCH Wall Control

Page 11

99

Press or to select your desired

delay time.

4. Press to set your selection.

DRAIN MODE

At any time when the wall control is OFF, you

can manually drain the cooler by pressing and

holding and for 1 second. The

display will show “dr” to confirm the operation

has activated.

WARNING! Maintenance must be carried

out by an authorized service agent. Power

to the cooler must be disconnected before

pad frames are removed or you may risk

personal injury.

WARNING! If the supply cord is damaged, it

must be replaced by a special cord

available from the manufacturer or it’s

service agent.

Note that some regulating authorities require

servicing to be conducted at specific intervals.

END OF SEASON SERVICE

• Turn off the power supply to the air cooler.

• Turn off the water supply to the air cooler.

• Remove the pad frames as shown. (Fig. B)

MAINTENANCE

HEALTH REGULATIONS

• Turn off power switch inside the cooler.

(Fig. A)

• Check and clean the lid water spreaders

(Fig. C)

• Thoroughly clean the tank and pump filter.

• Gently wash the pads to remove any dust.

• If freezing conditions can occur at any

time, a drain down facility must be

provided at the lowest point of the water

supply pipe.

• Re-fit the pad frames.

PRE SEASON SERVICE

• Turn off the main power supply to the air

cooler

• Remove the pad frames as shown.

• Ensure the power switch in the cooler is off.

• Gently wash the pads to remove any dust

build up during the winter period. If the

pads are in poor condition, replace them.

IMPORTANT! Do not damage the pads with

high pressure water spray.

• Turn on the power switch inside the cooler.

• Turn on the water and then the main power.

• Re-fit the pad frames and run the cooler.

REMOVAL OF PAD FRAMES

To remove a pad frame, insert a flat screw

driver tip into the slot as shown and lever until

disengagement occurs. Take hold of the pad

frame and pull it towards you until the internal

side clips disengage. Pivot the pad frame

outwards and lift up. Take care not to damage

the pad. Repeat these steps for the remaining

pad frames. (Fig. B)

The pads supplied have been selected to

give the highest possible cooling

performance. WHEN REPLACING PADS DO

NOT USE ALTERNATIVES. The

manufacturer is not responsible for the

performance, damage to, or safety of the air

cooler when alternative pads are used.

Using poor quality or incorrect pads may

cause water carry-over that might enter

electrical components creating an electric

shock or fire hazard.

9

Drain Delay Time

Display Number

00

01

02

03

04

4 hours

1 Day

2 Days

3 Days

4 Days

STANDARD

A

ILL187-E

1

2

3

B

SENSORTOUCH Wall Control

Using the SENSORTOUCH Wall Control

®

ILL1383-A

C

Page 12

11

1010

Pre-Assembly Inspection

PRE-ASSEMBLY INSPECTION

! Check that the correct cooler has been supplied. The cooler should have the following parts:-

(Check the parts are inside the cooler by removing a cooling pad frame.)

Page 13

SLIDE UNIT ON ITS LID

TO AVOID DAMAGE TO

CUTOFF PLATE

ILL939-A

11

1111

Installation Details

UNPACKING THE COOLER

Cut and remove the shrink wrap from

around the cooler. Using 2 people,

carefully lift the cooler up and away

from it’s skid (Fig 1).

REMOVING PAD FRAMES

Firstly remove the corner clips, which

are located above the top louvre and

third louvre from the bottom on all

corner joins. The clips will require a

screw driver to aid removal.

Each frame is clipped into the cooler

and is removed by use of a medium

sized screwdriver. Insert the

screwdriver into the small slots at the

top of the frame and lever upwards

until the clips disengage. The frame

is now free to be lifted out of the

cooler cabinet (Fig.2).

1

2

Keep the cooler away from heater

flues, exhaust vents (especially

kitchens) and sources of ignition.

Avoid dangerous situations.

Allow for adequate, SAFE access

around the cooler for maintenance,

especially for pad cleaning, water

connections, electrical connections,

drain connections.

It is mandatory that water cannot enter

the building as a result of poor sealing

(caulking or flashing) of the various

penetrations into the building (ducts,

necks, water pipes, electrical

conduits).

The cooler must be mounted at least

10ft (preferably 15ft) away from the

closest element of any TV antenna.

Make sure the cooler is not between

the antenna and the transmission

tower that is providing the television

signal to the home. Ensure that all

antenna cables are at least 10ft from

the cooler.

REPLACING PAD FRAMES

Ensure the pad frame is the correct

way up by checking that the louvres

face upwards. Fit the frame in at the

bottom along the edge of the pan and

rotate it in at the top. Take care not to

damage the Chillcel as the frame

approaches the plastic water

spreader under the top panel. Then

two sharp hits by hand should locate

the frame into its correct location

under the top panel. Replace the pad

frame clips at the corners

COOLER LOCATION

Check the proposed cooler location

first, to ensure it is structurally

capable of supporting the weight of

the cooler. Polymer coolers are lightweight but they require adequate

support. The largest cooler in the

EXV range is about 185 lbs (84 Kgs).

Always locate the cooler where there

is a plentiful supply of clean fresh air,

and not in a recess or close to the

ground where the air may be dusty or

polluted.

MOUNTING THE AIR

COOLER.

Handling and installing the cooler is

always much easier if you remove

the pad frames first.

New installation, roof jacks

Use 24 G or stronger metal roof jack.

The cooler may then be attached

directly to the jack.

Replacement installation, roof

jacks

Roof Jack recommended wall

thickness should be 24 G steel or

stronger. The supplied roof jack

adaptor may be required to attach the

cooler to the existing roof jack.

For assembly of the roof jack adaptor,

see Fig. 4.

5

6

RAISING COOLER TO IT’S

FINAL LOCATION

HANDLE WITH CARE. DO NOT DROP.

For lifting or pulling the cooler, always

apply the ropes around the full cabinet

or the fan housing and NEVER tie

them to any of the four corner posts.

WARNING! Take care when moving

the cooler that nothing is allowed to

penetrate into the discharge

opening (such as the end of a

ladder), as damage may occur to the

internal cooler components. If a

ladder is used as a slide for the

cooler to be pulled onto a roof or

platform, we strongly recommend

the cooler be turned upside-down

first. Protect the lid from scratching.

After placing the cooler on the roof jack

check that water spreaders and other

internal components are all securely in

place.

Attach the cooler to the roof jack from

inside the cooler (Fig. 7), using 1¼"

long self-tapping screws. Use a

minimum of six (6) screws. In high

wind areas or when not using leg

supports use a minimum of eight (8)

screws, 3 per side and 2 at the front.

4

NOTE! It is recommended that a strip

of foam or sealant is applied to the

upper flange on the roof jack before

securing the cooler to provide an

airtight seal.

Ensure that the top of the roof jack is

level, then check the lip of the pan for

level when the cooler is in position on

the roof jack. (Fig. 5)

3

Page 14

1212

Installation Details

SECURING LEG SUPPORTS

After levelling and securing the cooler

onto the roof jack you are ready to fix

the four leg supports. The telescopic

leg supports (with feet attached) slide

up and down inside the four cooler

corner posts.

By removing the screw from the lower

end of the corner post you enable the

leg support to slide down to roof level.

Refer figs 9, 10 & 11 for the

procedure for adjusting and securing

the leg supports.

9

10

12

Install a manual water shut-off valve

near the point of entry of the water

supply to the cooler, in the permanent

water supply. In areas subject to

winter freezing, install a drain down

feature. DO NOT FIT SHUT OFF

VALVES DIRECTLY ONTO THE

FLOAT VALVE NIPPLE OR

SOLENOID VALVE.

WARNING!

Flush foreign matter from water supply

pipe before final connection to the

flexible hose, to avoid damage to the

water solenoid and float valve.

14

7

The sump of the pan is designed to

be located on the low side of the roof

(Fig. 8)

8

11

The support legs are not full weight

bearing and are only intended for

additional support in case of high

winds, etc.

WATER INSTALLATION

A permanent water supply is required

to be connected to the water inlet

solenoid valve assembly that is

supplied with the cooler. The float

valve then controls the water level in

the pan automatically. (Fig. 12)

The permanent water supply

connection point is located underneath

the pan, and is attatched to the flexible

hose and tube assembly. (Fig 14, item

“F”)

INSTALLING THE INLET

SOLENOID VALVE

Fit the inlet solenoid valve under the

pan as shown (Fig 14).

Insert the solenoid valve cable through

the hole (behind the drain valve) and

connect the plugs to the solenoid

valve. (Fig. 13) Make sure the cable is

fitted to the groove underneath the

pan. The electrical cable leads may be

connected to the solenoid valve either

way around.

13

Use thread seal tape between

solenoid hose assembly and brass

½” BSP to 1/4” compression

adaptor or 1/2” BSP Nut.

If freezing conditions can occur at

any time, a drain down facility must

be provided at the lowest point of

the water supply pipe.

A = Solenoid.

B = Nut & Gland (connects to float valve)

C = Nut (connects flexible hose to Solenoid)

D = Tube Assy (solenoid to float valve)

E = Nut (connects Solenoid to tube assy)

F = Flexible hose assy

G = Solenoid cover

H = Solenoid power leads (In Unit).

I = Float Valve Nipple ½”BSP

J = ½”BSP to 1/4” Compression Fitting

Or

1/2” BSP Nut & Olive

ILL1228-E SIA2008

Page 15

SENSORTOUCH

1313

Installation Details

INSTALLING THE DRAIN KIT

The drain adaptor allows the

attachment of a ¾" drain hose to run

water to a waste point. Attach it to the

drain valve fitting underneath the pan

by using the drain nut. (Fig. 16)

It is a requirement of Seeley

International - Never drain the

water directly on to the roof (This

applies to all types of control/drain

systems).

Assemble drain valve as shown (Fig

15).

Make sure that the o-ring is fitted

before placing the drain valve into the

hole. Screw the nut up tightly by

hand underneath the cooler. Do not

over-tighten. Now connect the cable

(Fig 15, item B) to the electronic

module.

19

20

21

15

16

ELECTRICAL INSTALLATION

The cooler requires a 115V, 60Hz power

supply.

The electronic module is factory

sealed; do not attempt to open it;

there are no field serviceable parts

inside

The electronic module contains plug

receptacles for fan motor, water pump,

and other optional features if used.

Sub-circuit wiring must be rated at

cooler rated amperes or higher, and

must be protected by a suitable fuse

or circuit breaker. Sub-circuit cables

are to be double insulated all the way

into the main power termination box.

WARNING! When retro-fitting the

cooler to an existing installation

always turn off the electrical power at

the source of the wiring. DO NOT

TAKE RISKS! Turn off and tape over

the circuit breaker or remove the fuses

and keep them with you until the job is

complete. Set cooler, isolator switch,

wall switch, motor and pump to "off".

Be sure to tell other occupants of the

building what you are doing.

WARNING! Check to be sure that the

voltage rating of the cooler matches

your electrical system voltage.

The electrical installation must be

carried out by a licensed and qualified

electrician.

INSTALLING THE MAIN

POWER CABLES

The point of entry into the cabinet of

the cooler is by knockouts in the pan.

Seal the gap between the conduit and

knock-out hole with silicone sealant

after making connections and clamping

the conduit cable.

Running the Wall Control Cable

Plug the Wall Control cable to point Fig

22 “Receiver” on the electronic

controller. Run the cable to the roof

space and then to the controller via the

mains power cable entry point and plug

to the rear of the Wall Control.

Ensure that all electrical connections

are tight. Loose connections will cause

overheating that may lead to machine

damage or fire.

Replace all covers on completion of the

work, using only the screws supplied.

Do not tamper with factory wiring.

Before leaving the job, a trained,

licensed technician must check that the

cooler is operating correctly.

This cooler contains an electronic

module with main power supply

termination box separated and

connected via a cable and plug

assembly.

The main power termination box is

provided to facilitate easy wiring

connections. Cable glands are

provided for ½" ID conduit. (Fig. 19)

OPERATING ADJUSTMENTS

Water level:

The water level in the cooler is

important. Adjust the level at the float

valve inside the cooler. Rotate the

large plastic float CCW or CW to

change the level. CW will lower the

level; CCW will raise the level. (Fig.

17)

NEVER ADJUST THE WATER

LEVEL WITH THE COOLER

RUNNING because the residual

water in the pads and pipes will

cause the water to over flow when it

runs back into the pan.

Water level should be about ¼"

above the float valve support shelf.

(Fig. 18)

17

18

ILL1140-A

Wall Mounted Thermostat Control

(wall control)

65’

Wall Control

SENSORTOUCH

Page 16

1414

22

CONNECTOR

ORIENTATION

(side view)

NOTE: SPLASH COVER NOT SHOWN FOR CLARITY.

Nota: Para mayor claridadno se muestra la tapa protectora..

WATER PROBE

Sonda del agua

MINIMUM SPEED

ADJUST

Ajuste de la velocidad

PUMP

DRAIN

Valvula

de drenaje

INLET

Entrada

del agua

RECEIVER

Receptor

DIAGNOSTIC

LED’S

LED’s de diagnóstico

Bomba

ILL1392-A

Orientación del

conectador

(vista lateral)

MOTOR POWER (AMPS)

Important: Install all the pad frames

except the one on the motor side.

Ensure that all intended doors,

windows or other means of exhaust

are open in the building, and that all

outlet grilles are open fully.

WARNING:

Beware of rotating fan, belt and

pulleys whilst making adjustments

to motor speed, pulley or belt

tension settings. Ensure the cooler

is switched OFF via the electronic

module’s isolation switch whilst

working inside the cooler.

Set the cooler running at the highest

speed for about 10 minutes, or until

the motor has reached its normal

operating temperature (hot!).

Motor load must be checked

without the pump running.

Clip your ammeter onto the free cable

in the main termination box. (Fig. 23)

This should be done by a trained

licensed electrician.

23

For convenience, the rated motor

current, in amps, is printed on a

small label attached near the cable

fork (in addition to the normal

motor nameplate label located at

the back of the motor).

Check the measured amps against

the motor nameplate amps.

If the measured amps are less than

the nameplate amps the adjustable

motor pulley sheave must be altered

to increase the fan speed, thereby

delivering the full capability of the

cooler to your installation.

The measured amps must be equal

or close to, but never more than the

nameplate amps. (see heading

"Pulley (Sheave) Adjustment")

If the measured amps are greater than

the motor nameplate amps the fan

MUST be slowed down by adjusting

the motor pulley sheave in the

opposite manner. Failure to do this

will cause overheating in the motor

and may cause the motor’s thermal

protector to trip.

Replace all covers when adjustments

are completed using the screws

provided

PULLEY (SHEAVE)

ADJUSTMENT

The motor pulley is adjustable in order

to set the motor amperes at the

correct (nameplate) level, and thus

provide the owner with full machine

cooling capacity.

DO NOT USE THE PULLEY

ADJUSTMENT TO SET BELT

TENSION.

The adjustment is made with the

cooler switched OFF. Never attempt

this procedure with the cooler

operating.

Remove the drive belt.

To increase the fan speed (and

therefore the motor amps), the two

halves of the pulley must be closer

together, ie: turn the adjustable half

clockwise. (Fig. 24)

To decrease the fan speed (and

therefore the motor amps), the two

halves of the pulley must be further

apart, ie: turn the adjustable half

counter-clockwise. (Fig. 24)

A = Fixed Sheave

B = Grub Screw

C = Adjustable Sheave

D = Locking Cap

E = Locking Cap Screw

24

The outer half of the pulley is on a

thread and can be moved in or out by

removing the locking cap and then

turning the outer half by hand in the

desired direction.

When an adjustment is made, replace

the locking cap, aligning the screw

hole with the nearest hole in the

adjustable half. Lock it into place with

the securing screw. Refit the belt, reset

the belt tension, then run the cooler

and check the amps. Repeat the

process until the amp level is set.

You can start and stop the cooler for

this procedure by using the isolating

switch inside the cooler.

BELT TENSION

Belt tension is important. If it is too

tight there will be excessive belt and

bearing wear. If it is too loose there will

be belt slip, excessive belt wear and

loss of cooler performance.

There are two adjuster bolts with

locking nuts attached to the motor

mounting.

The tension should be adjusted so that

the deflection on one side of the belt is

5/8" to 13/16". To make the

adjustment, loosen the locking nuts

and screw the bolts in or out as

required to change the belt tension.

Re-tighten the locking nuts.

It is important to recheck the motor

amps again after re-setting the belt

tension.

Correct belt tension ensures the belt

will not slip. Check the temperature of

the belt by hand after each adjustment,

by turning off the cooler and holding

one side of the belt in your hand. If the

belt is warm to touch, it is slipping!

Continue to tighten until it runs cool.

(Fig. 25)

25

Installation Details

Page 17

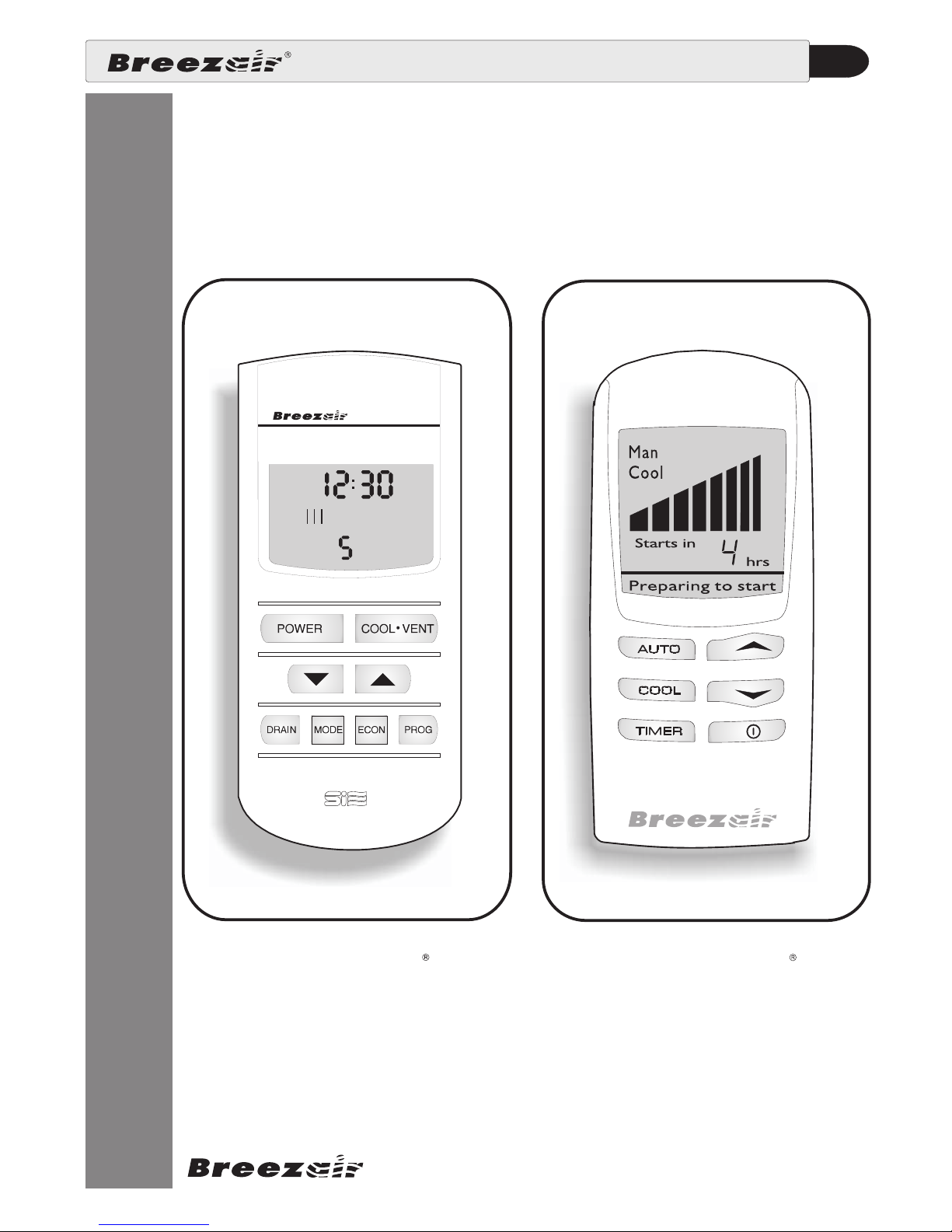

1515

SENSORTOUCH Remote Control

26

Remote Thermostat Control

(remote control)

AUTO COOL

PM

FAN

SPEED

ECONOMY

REMOTE CONTROL

ILL239-D

SENSORTOUCH

LOCATING THE REMOTE

CONTROL

The remote control should be placed

approximately 5 feet (1.5 meters)

above the floor, in the most used

room in the home. This will give the

optimum temperature sensing and

operating position for the user.

Placement is critical for correct

functioning of the thermostat

(incorporated in the remote control).

The following points must be taken

into consideration:

• Avoid direct sunlight exposure.

• Avoid mounting on external walls.

• Avoid mounting the remote control

near heat sources such as stoves

and televisions.

• Do not locate in the direct airflow

of the duct outlets.

• Do not locate in strong drafts or in

dead spots such as cupboards /

drawers.

INSTALLING THE RECEIVER

Note: The following section

describes installation of the

receiver, which requires

positioning of the receiver external

to the cooler, inside the attic or

below the ceiling. The supplied

receiver lead is 16’ (5.0m) long,

sufficient to reach into the attic or

below the ceiling, from the cooler

electronic module.

1. Fix the top screw to

the wall, without

tightening completely.

2. Fix the second screw

through the lower oval

hole, without

tightening completely.

3. Straighten and align

the mounting bracket,

tighten screws to hold

the bracket in it’s

correct position.

Running the Receiver Cable

Plug the receiver cable to point Fig 22

“Receiver” on the electronic controller.

Run the cable to the attic space or

below the ceiling to the receiver

location and plug the 6 pin end (with

sticker) to the receiver. (Fig 30)

Aim to secure the receiver away

from the ductwork, but as near as

possible to the location of the

remote control.

For installations where the roof is

framed in steel, position the receiver

between the metal joists keeping the

antenna as far away from metal joists

as possible and directing the antenna

perpendicular (right angle) to the joists

will give the best results.

For most installations, mounting the

receiver to the roof rafter as shown

(Fig 29) will provide satisfactory

performance.

Other Options for Mounting

Receiver

The standard installation arrangement

will satisfy the majority of applications.

However you may find difficult cases

as follows:

Signal Problems

For signal problems in houses with a

metal roof, position the receiver as

close as possible to the metal roof

with the antenna pointing directly

away from the roof (Fig 29).

Flat Roof Installation

Where the installation is on a building

with a flat roof and the attic space is

less than 4’ (1.2 meters) deep,

alternative mounting locations may

need to be found for the receiver.

For example, install the receiver below

the ceiling in the top of a nearby

cupboard.

Do not wrap any excess receiver

cable around the receiver. Do not

extend the receiver cable.

28

16’

SENSORTOUCH Remote Control

ILL665-D

AUTO COOL

PM

FAN

SPEED

ECONOMY

REMOTE CONTROL

A = Metal Roofing.

B = Wood or Metal Beam.

C = Receiver (Mount as close as

possible to the metal roof).

A = The 6 pin plug (the end with the

"RECEIVER" sticker attached)

connects into the socket on the

underside of the receiver.

30

Important:

The orientation and position of the

receiver may affect the receiver's

performance. Other factors that may

also influence performance are:

(1)..Shielding from metal in the attic

lying between the receiver and

Remote Control. This may include

Sisalation/sarking (foil sheets), and

ductwork.

(2)..Reflections from metal around the

receiver.

(3)..Interference from nearby

transmitters (e.g. mobile phone, AM

radio, Television, RF security systems).

29

SETTING THE ADDRESS CODE

The Breezair electronics module will

automatically recognize the remote

control connection, provided the

address code has been correctly set.

This is simply achieved by fitting the

batteries into the remote control within

4 minutes after turning on the main

power at the electronics module.

The screen will stay blank for 5

seconds then display “Id” for 1 second.

The communication address code will

take a few seconds to set, then the

remote control can be turned on. (Fig.

31)

If communication cannot be achieved,

the power to the cooler will need to be

turned off, and the batteries need to be

removed from the remote control. Wait

until the screen goes completely blank,

then repeat the above procedure.

31

27

Page 18

11

1616

Testing the Cooler

LOCATION AND TESTING

Important! One of the most critical

parts of the installation is the location

of the remote control and receiver. If

this combination of components are

not set up / located correctly, it can

result in chargeable service calls.

After the cooler has been installed,

place the remote control in the

selected wall position and operate the

cooler.

Switch the cooler to high speed and

switch on and off 20 times at

approximately 3 second intervals. 1

missed transmission in 20 is

acceptable, 2 missed transmissions is

not. This procedure is done to check

that the location you have chosen is

not prone to interference or blocks the

radio transmission. If the operation is

intermittent, try another location.

COMMISSIONING USING THE

REMOTE CONTROL

Take the remote control to the roof

and control the Cooler from there.

This will save you a lot of time.

Power up the cooler using the on/off

switch on the Electronics Module.

Test motor and pump operation. Look

at the front of the Module where 2

light emitting diodes (LEDs) are

situated (Fig. 32). The left LED is

“tricolour” and can glow green, red or

amber. The right LED is red only. If

the left LED is double flashing green,

everything is OK, this is normal

operation.

The following information allows

quick diagnosis at start up -

The "Tricolour (left) LED" acts as a

general diagnostic indicator, and

will function as follows:

• Green double flash every 2 seconds

indicates the control is running

normally.

If it does not glow at all, then there is

either no power to the Electronics

Module (check isolating switch, circuit

breaker, plug and socket

connections), or a failure has

occurred.

• Amber for 1 second (remote

controls only) indicates that the

Electronics Module has received a

command at an incorrect ID address.

(See the remote control - setting

address code section above, to re

establish the code)

• Red flashing indicates one or more

of the following faults:

1 Red Flash indicates

....Fault Code #1 – Communication

Failure.

2 Red Flashes indicates

....Fault Code #2 – Failure to Detect

Water at Probes.

4 Red Flashes indicates

...Fault Code #4 – Failure to Clear

Probes during drain.

7 Red Flashes indicates

....Fault Code #7 - Incorrect Main

Power Supply Frequency.

The "Red (bottom) LED" indicates

the status of the WaterManager

measurement circuit and will

function as follows:

1 Flash indicates

....WaterManager is operating and the

measured salinity is below the set

point.

2 Flashes indicates

....WaterManager is operating and the

measured salinity is above the set

point.

3 Flashes indicates

....The Salinity Control Method = Drain

every 65 minutes.

4 Flashes indicates

....Incorrect Salinity Control Method

selected.

Continuously On indicates:

The probes are open circuit, or

measured salinity is less than

20us/cm (the water is very pure, ie

has very little salt content).

MOTOR LOW SPEED SETTING

EXV coolers will function across a

wide speed range. The minimum

speed has been factory set, and

should not require adjustment under

normal circumstances. However,

some adjustment may be necessary

to suit specific installations.

After you have set the motor amps and

belt tension correctly, check the speed

variation of the cooler. When the

control is changed from maximum to

minimum settings, there should be an

easily recognizable difference in fan

speed.

If there is not, check the following:

! That windows and doors are open.

Rule of thumb is to have 2 times the

area of the outlet grille open for

exhaust in each room.

If the above is correct then proceed as

follows:

! Set the fan speed to minimum

using the remote control, so that only

two bars are displayed on the remote

control.

! Turn the minimum speed

adjustment knob (Fig 33) clockwise or

anti-clockwise, until the belt is running

at approximately one revolution per

second (this equates to a fan speed

of approximately 600 rpm).

32

33

SPEED

ADJUSTMENT

Page 19

11

1717

Testing the Cooler

TESTING THE COOLER

Once you are satisfied that the cooler

is installed and commissioned

correctly, it is important to run the

cooler and ensure that everything is

working as it should.

Try turning the cooler on and off with

the remote control in all of the rooms

in the house. This will make sure that

the receiver is located correctly.

Check that the cooler runs quietly and

with a balanced distribution of air to

all outlets.

Make sure there are no water leaks.

Initiate a drain of the pan by pressing

the drain button on the remote

control or & button

together on Wall Control.

Check the drain fittings and pipes,

making sure there are no leaks.

DIP SWITCHES

There are 2 rows of DIP switches

located under the battery cover on the

remote control.

WARNING: Do not alter DIP

switches 1 to 8 on top row and

7 & 8 on bottom row as the

cooler will cease to work.

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

OFF

OFF

ILL217-H

EXAMPLE ONLY

Definition of DIP switch positions (first

6 in bottom row only) are as follows:

(1) Reserved for later use.

(2) OFF, 24 hour clock.

ON, 12 hour clock.

(3) OFF, 1.0, 3/4HP Motor.

ON, Not Used

(4) OFF, no pre-cool.

ON, pre-cool.

(5) OFF, drains 3 days after

power off.

ON, drains 3 hours after

power off.

(6) OFF, drains every 65 minutes

of operation.

ON, activates water salinity

circuit (WaterManager).

Page 20

REMOTE CONTROL DIP

SWITCHES

Record the dip switch settings for this

cooler below (if applicable)

WARNING: Do not alter DIP

switches 1 to 8 on top row and 7

& 8 on bottom row as the cooler

will cease to work.

Definition of DIP switch positions (first 6

in bottom row only) are as follows:

(1) Reserved for later use.

(2) OFF, 24 hour clock.

ON, 12 hour clock.

(3) OFF, 1.0, 3/4HP Motor.

ON, Not Used

(4) OFF, no pre-cool.

ON, pre-cool.

(5) OFF, drains 3 days after power

off.

ON, drains 3 hours after power

off.

(6) OFF, drains every 65 minutes

of operation.

ON, activates water salinity

circuit (WaterManager).

ILL217-H

ON

ON

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

OFF

OFF

EXAMPLE ONLY

Cooler level and secure.

All roof work properly sealed.

Ductwork and air distribution checked and outlets correctly set.

All wiring complete.

Control switch correctly installed.

Motor and pump correctly plugged into sockets.

Drain/overflow fitting correctly installed.

Water level and float adjustment checked.

Pump runs and water evenly distributed to all cooling pads.

All control functions checked.

Owner instructed on correct operating procedure and supplied with

operating instructions.

Signed by Installer: …………………………………………………

Dated: ………………………………………………………………

SERVICE ENQUIRIES:

Contact your local Dealer or Installer

for assistance.

Owners Name:______________________

__________________________________

Telephone:_________________________

Address:___________________________

__________________________________

__________________________________

Dealer:____________________________

__________________________________

Installer:___________________________

__________________________________

Date Installed:_______________________

Model No.:__________________________

Serial No.:__________________________

Motor Type:_________________________

Motor Power:_________________________

11

1818

Installation Checklist

Page 21

11

1919

Installation Troubleshooting

PROBLEM PROBABLE CAUSE SUGGESTED REMEDY

Under-sized cooler.

Replace with larger cooler.

Replace with larger ducts.Under-sized ducts.

Clean or replace pads.

Clogged or dirty cooling pads.

Check water distribution system for

possible obstruction in hoses. Check

pump.

Tighten belt by re-adjusting the motor

position. Replace belt if worn.

Dry pads or lack of water while cooler

is operating.

Belt slipping

Make sure there is adequate provision

for exhausting stale air from building

(open windows and doors).

Check motor amps. If below

nameplate amps, re-adjust motor

pulley to increase fan speed.

Insufficient air discharge openings or

inadequate exhaust from building,

causing high humidity and discomfort.

Fan running too slow.

Remove backdraft damper and

substitute manual slide damper.

Excessive resistance from poorly

located backdraft damper.

On days during summer when

ambient humidity is high the cooler will

not reduce the temperature as much

as on drier days. There is no remedy

except to shut off the pump.

Excessive ambient humidity (see also

item above re inadequate exhaust).

Inadequate Cooling

Air distribution system creating too

much back pressure, or changes of

direction too sudden, or grilles too small.

Have contractor re-evaluate his design;

use bends instead of elbows; change

grille sizes.

Fan out of balance due to dirt. etc. Clean the fan.

Noisy cooler.

Pump motor failure.

Pump fails to operate.

Pump circuit breaker tripped. Check pump for faults. Replace if

necessary.

Replace pump.

Fan fails to start.

Replace motor.

Check and tighten pulley and belt

Replace belt

Consult with power supply authority.

Replace controller.

Check fault condition via the tri-colour

LED on electronic module.

Rectify fault as indicated and restart the

cooler. (Refer Pg. 15-16)

Main power circuit breaker tripped or

fuse blown.

Fan motor burned out.

Belt or pulley loose

Belt broken

Check cause of overload. Reset circuit

breaker or replace fuse. Adjust motor

amp setting if necessary.

Low system voltage.

Controller failed.

Page 22

11

2020

PROBLEM PROBABLE CAUSE SUGGESTED REMEDY

Float valve adjustment not correct.

Adjust float valve.

Continuous overflow of water.

Insufficient water in pan.

Adjust float level.

Pump runs but no water circulation.

Pump runs but pads lack water.

Water hoses blocked. Check and clean out blockage.

Pump strainer blocked.

Clean pump strainer.

Auto Drain Valve malfunctioning

Check and remedy function.

Installation Troubleshooting

Heavy pad deposits.

Clean or replace pads.

Pads not fitted correctly into pad

frames.

Make sure pads properly installed.

Water level too low, causing pump to

create fountain that is being sucked

into air stream.

Increase water level.

Incorrect or damaged pads fitted.

Replace with manufacturer's

recommended pads.

Loosen water hose connections.

Tighten all connections.

Water being blown into the

building.

Water hose broken.

Cover not fitted on float valve.

Replace any cracked or broken hoses.

Install correct cover on float valve to

prevent spray.

Unpleasant odour.

New cooler pads.

Cooler located near source of

unpleasant odour.

Algae in pan water.

Pads remain wet after shut down.

Heavy pad deposits.

Drain pan, refill, run pump for a while.

Remove source of odour or relocate

cooler.

Drain pan, clean thoroughly with strong

cleansing agent, refill, change pads.

Run fan on "vent" for 10 minutes after

cooling cycle to dry pads out.

Clean or replace pads.

Belt slipping or wearing

excessively.

Belt loose.

Pulleys out of line.

Worn belt.

Worn or warped pulleys.

Moisture on belt.

Tighten belt.

Align pulleys.

Replace belt.

Replace and re-align pulleys.

Stop any water leaks.

Page 23

11

2121

Appendix A - Wiring Diagram

65’

16’

SENSORTOUCH Wall Control

SENSORTOUCH Remote Control

ILL665-D

AUTO COOL

PM

FAN

SPEED

ECONOMY

REMOTE CONTROL

Page 24

US 0710847078-A

Evaporative Air Cooling Manual. Seeley International Pty Ltd, Adelaide, South Australia. ACN 054 687 035.

As the policy of the company is one of continuous product improvement, all specifications are subject to change without notice.

Seeley International (Americas)

Phone: 602-353-8066

Fax: 602-353-8070

Toll Free: 1-800-926-6824

www.convaircooler.com

TM

Loading...

Loading...