Breckwell The Big E Owner's Manual

BRECKWELL

THE BIG E

OWNER’S MANUAL

Exceptional Heat, Outstanding Value

THE BIG E

OWNER’S MANUAL

®

Economical to Buy

E cient to Operate

Easy to Use

• Warning: If your appliance is not properly installed a house fi re may result. For your safety,

follow the installation directions. Contact local building or fi re offi cials about restrictions and

installation inspection requirements in your area.

• PLEASE read this entire manual before installation and use of this pellet fuel-burning room

heater. Failure to follow these instructions could result in property damage, bodily injury, or

even death.

• Save these instructions.

PROFESSIONAL INSTALLATION IS HIGHLY RECOMMENDED

0

This unit is not intended to be used as a primary source of heat.

Manufactured by

Breckwell Hearth Products

Eugene, Oregon

www.breckwell.com

© BRECKWELL HEARTH PRODUCTS

6/2012

INTRODUCTION

INTRODUCTION

2

Thank you for purchasing the Breckwell Pellet Burning Stove. You are now prepared to burn wood in the

most effi cient, convenient way possible. To achieve the safest, most effi cient and most enjoyable perfor-

mance from you stove, you must do three things: 1) Install it properly, 2) Operate it correctly, and 3) Maintain

it regularly. The purpose of this manual is to help you do all three.

PLEASE read this entire manual before installation and use of this pellet-burning room heater. Failure to follow these instructions could result in property damage, bodily injury or even death.

Keep this manual handy for future reference.

This stove has been independently tested ASTM E 1509-04 Standard Specifi cations for Room Heaters,

Pellet Fuel Burning Type 1, ULC/ORD 1482-90 Standard for Solid Fuel Room Heaters, and Oregon Administrative Rules for Mobile Homes (814-23-900 through 814-23-909) and installation as a Stove Heater.

This pellet stove, when installed, must be electrically grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

The authority having jurisdiction (such as municipal building department, fi re department, fi re pre-

vention bureau, etc.) should be consulted before installation to determine the need to obtain a permit.

This appliance is designed specifi cally for use only with pelletized wood. It is designed for residential in-

stallation according to current national and local building codes as a freestanding room heater. It is also

approved as a mobile home heater which is designed for connection to an outside combustion air source.

The stove will not operate using natural draft or without a power source for the blower systems and fuel feed

system and must not be burned with any type of coal (see PROPER FUEL).

This stove is designed to provide the optimum proportions of fuel and air to the fi re in order to burn free of

smoke and soot. Any blockage of the air supply to or from the stove will seriously degrade its performance

and will be evidenced by a smoking exhaust and a sooting window. For best operation, the ash content of

the pellet-fuel should be less than 1% and the calorifi c value approximately 8200 BTU/LB. Avoid high ash

content fuels because this will rapidly fi ll up the burn pot and eventually cut off the combustion air supply.

Commercial and industrial installations of Breckwell Pellet Stoves should not be used since operational

control is often not well managed in these settings.

Model: _____The Big E _____________

Style: ____________________________

Serial Number:_____________________

Purchase Date: ____________________

Purchased From:___________________

___________________

___________________

IMPORTANT INFORMATION

MAIL YOUR WARRANTY CARD TODAY

To receive full warranty coverage, you will

need to show evidence of the date you

purchased your stove. We suggest that

you attach your sales invoice to this page,

and fill in the form on the left, so that you

will have all the information you need in

one place should the need for service or

information occur.

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

3

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Ԧ

Do not operate stove if you smell smoke coming from it.

Turn it off, monitor it, and call your dealer.

Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fl uid, or similar liquids to start or “freshen

up” a fi re in this heater. Keep all such liquids well away

from the stove while in use.

Never block free airfl ow through the open vents of the

stove.

Keep foreign objects out of hopper.

The stove will not operate during a power outage. If an

outage does occur, check the stove for smoke spillage

and open a window if any smoke spills into the room.

Disconnect the power cord before performing any maintenance or repairs on the stove.

NOTE: Turning the stove “off” does not disconnect all

power from the stove.

Never try to repair or replace any part of the stove unless

instructions are given in this manual. All other work should

be done by a trained technician.

Do not throw this manual away. This manual has important operating and maintenance instructions that you will

need at a later time. Always follow the instructions in this

manual.

Do not place clothing or other fl ammable items on or near

the stove.

The viewing door must be closed and latched during operation.

Do not operate the stove if the fl ame becomes dark and

sooty or if the burnpot overfi lls with pellets. Turn the stove

off, periodically inspect it, and call your dealer.

Hot while in operation. Keep children, clothing and furniture away. Contact may cause skin burns. Educate all

children of the danger of a high temperature stove. Young

children should be supervised when they are in the same

room as the stove.

During the start-up period; 1) DO NOT open the viewing

door, 2) DO NOT open the damper more than 1/4,” 3)

DO NOT add pellets to the burnpot by hand, 4) DO NOT

use the Fuel Feed button (unless you are priming the

auger after running out of pellets) as a dangerous condition could result.

Do not unplug the stove if you suspect a malfunction.

Turn the stove off, periodically inspect it, and call your

dealer.

Contact your local building offi cials to obtain a permit and

information on any installation restrictions or inspection

requirements in your area. Notify your insurance company of this stove, as well.

This unit must be properly installed to prevent the possibility of a house fi re. The instructions must be strictly ad-

hered to. Do not use makeshift methods or compromise

in the installation.

Your stove requires periodic maintenance and cleaning.

Failure to maintain your stove may lead to smoke spillage.

This stove must be connected to a standard 120V., 60HZ

grounded electrical outlet. Do not use an adapter plug or

sever the grounding plug. Do not route the electrical cord

underneath, in front of, or over the stove.

The exhaust system should be checked, at a minimum,

at least twice a year for any build up of soot or creosote.

Do not use abrasive cleaners and NEVER clean the heater when hot.

If the stove is installed in a room without air conditioning,

or in an area where direct sunlight can shine on the unit,

this could possibly cause the temperature of the stove to

rise to operational levels. One of the sensors could, then,

make the stove start on its own. It is recommended that

the stove be unplugged when not in use for extended

amounts of time (i.e. during summer months.)

The exhaust system must be completely airtight and properly installed. The pellet vent joints must be sealed with

RTV 500

foil tape.

Allow the stove to cool before carrying out any maintenance or cleaning. Ashes must be disposed in a steel

container with a tight lid and placed on a non-combustible

surface well away from the home structure.

This stove is designed and approved for pelletized wood

fuel only. Any other type of fuel burned in this heater will

void the warranty and safety listing.

When installed in a mobile home, the stove must be bolted

to the fl oor, have outside air, and NOT BE INSTALLED

IN A BEDROOM (Per H.U.D. requirements). Check with

local building offi cials.

Breckwell Hearth Products grants no warranty, implied or stated, for the installation or maintenance of

your stove, and assumes no responsibility of any consequential damage(s).

o

F (260oC) silicone sealant, and with UL-181-AP

4 TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................2

SAFETY PRECAUTIONS .............................................................................................................. 3

SPECIFICATIONS ..........................................................................................................................5

INSTALLATION ..............................................................................................................................5

Preparation ............................................................................................................................ 5

Clearances ............................................................................................................................5

Combustion Air Supply ..........................................................................................................6

When Outside Air Is Not Used ..............................................................................................6

Venting .................................................................................................................................. 6

Big E Installation ...................................................................................................................7

Electrical Installation .............................................................................................................9

Special Mobile Home Requirements ................................................................................... 10

OPERATION ................................................................................................................................ 11

Panel Controls .................................................................................................................... 11

Proper Fuel .........................................................................................................................12

Pre-Start-Up Check .............................................................................................................12

Building a Fire .....................................................................................................................12

The Hot Rod

Damper Control ................................................................................................................... 12

Opening Door ...................................................................................................................... 12

Room Air Fan ...................................................................................................................... 12

Re-Starting a Warm Stove ..................................................................................................13

If Stove Runs Out OF Pellets .............................................................................................. 13

Refueling .............................................................................................................................13

Breckwell Maintenance Tool ................................................................................................ 13

Shutdown Procedure ...........................................................................................................13

Safety Features ................................................................................................................... 13

Optional Thermostat ............................................................................................................14

(Please Read This) Operating Safety Precautions ............................................................15

MAINTENANCE ...........................................................................................................................16

Ash Removal ....................................................................................................................... 16

Ash Disposal .......................................................................................................................16

Vacuum Use ........................................................................................................................ 16

Cleaning ..............................................................................................................................17

Blowers ...............................................................................................................................17

Chimney Cleaning ...............................................................................................................18

Recommended Maintenance Schedule ..............................................................................18

Removal & Replacement Of Broken Glass Door ................................................................ 18

TROUBLE SHOOTING GUIDE ....................................................................................................19

Smoke Smell or Soot Build-Up ............................................................................................ 24

ELECTRICAL DIAGRAM .............................................................................................................25

REPLACEMENT PARTS LIST ....................................................................................................26

WARRANTY .................................................................................................................................27

TM

Automatic Fire Starter ................................................................................ 12

TABLE OF CONTENTS

5

INSTALLATION

INSTALLATION

SPECIFICATIONS

Width: 25 3/4”

Height: 32 5/8”

Depth: 23 7/8”

Weight: 275 lbs.

Flue Size: 3” or 4”

Hopper Capacity: Up to 140lbs.

(This can vary widely depending on pellet size,

length, and diameter.)

EPA status: exempt

Burn Time: 1lb to 5.5lbs. per hour

BTU range: 8,200 to 55,000

Approved installations: mobile home, conventional

PREPARATION

Factory packaging must be removed, and some minor assembly work is required prior to installation.

Access to the rear of the stove is necessary.

NOTE: Normally, your dealer will perform these

functions.

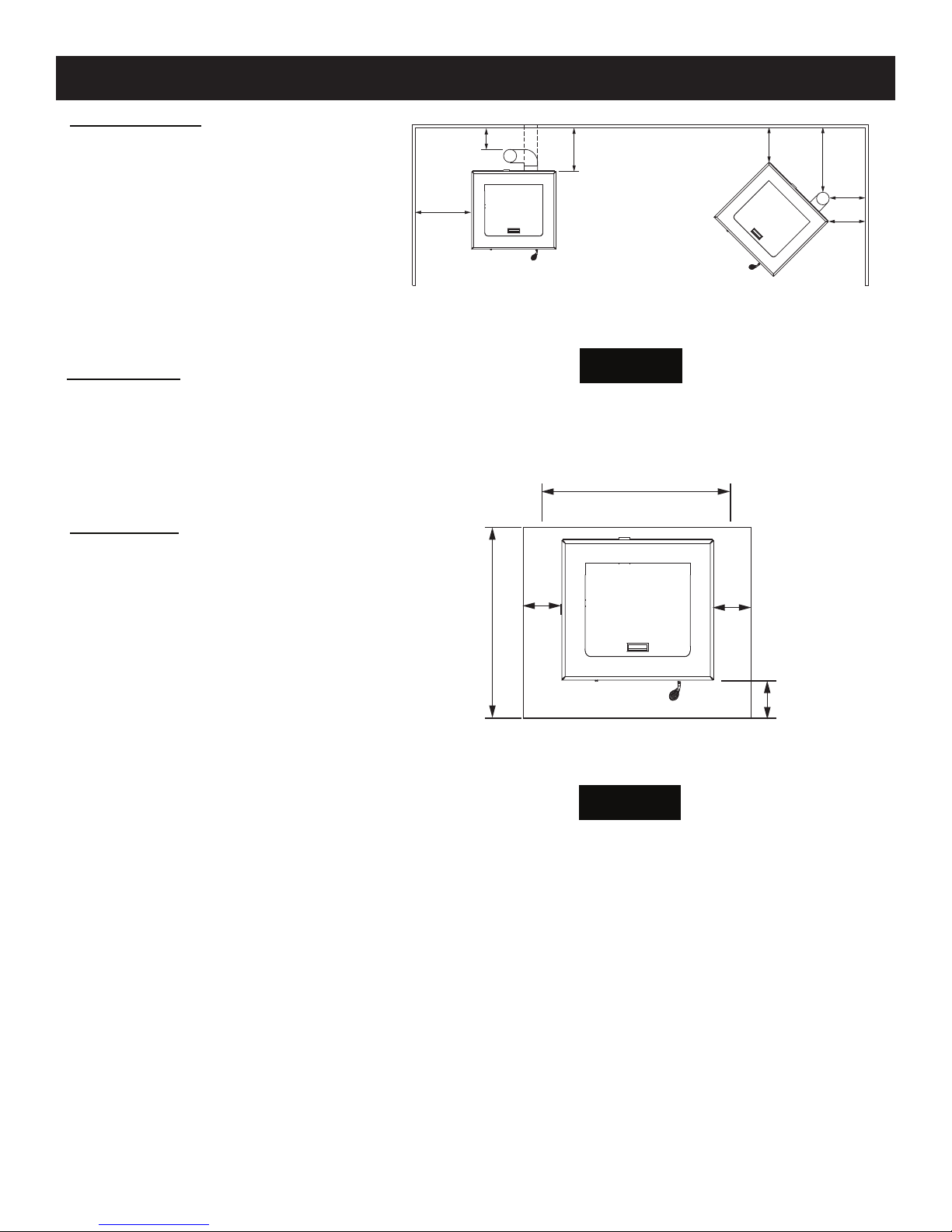

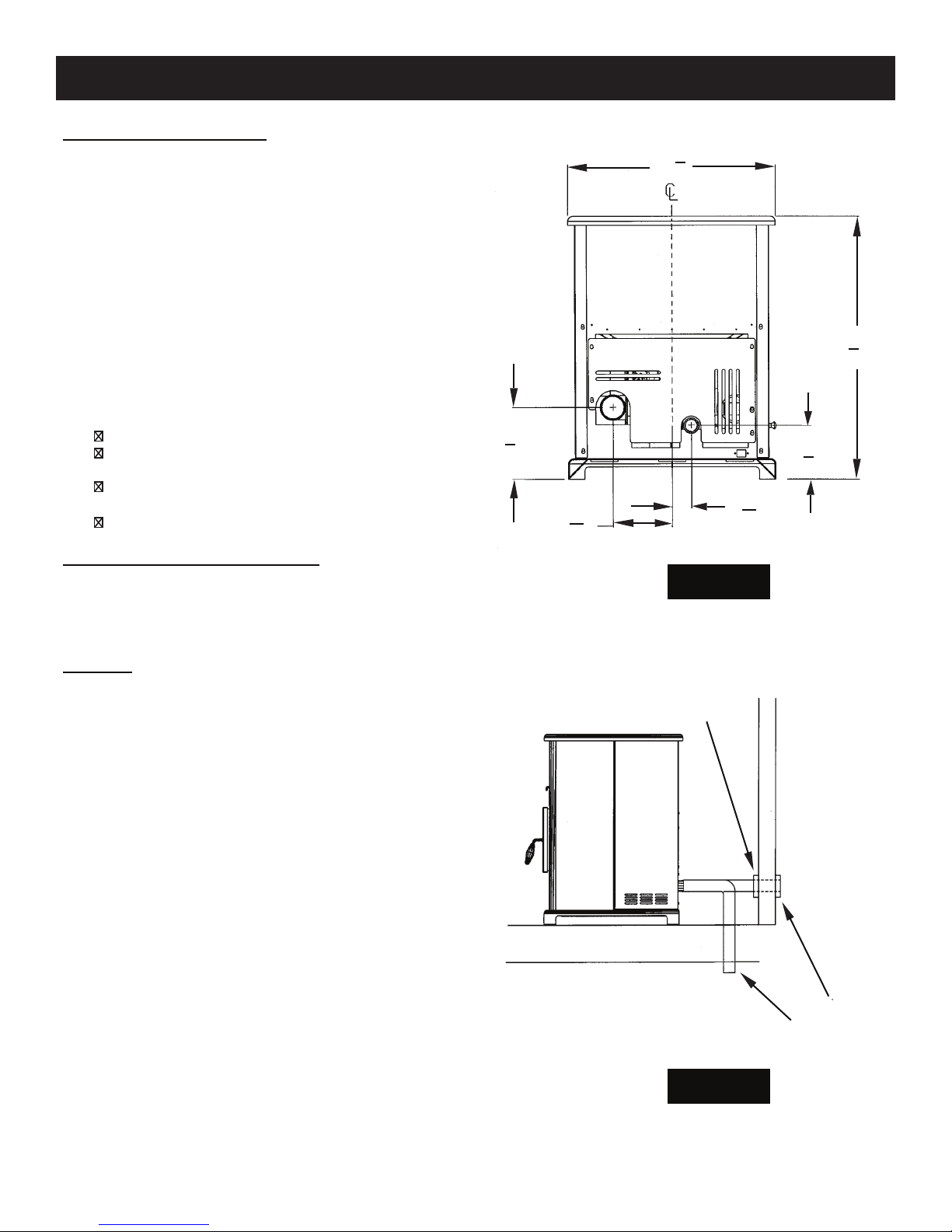

CLEARANCES

The Big E has been tested and listed for installation

in residential and mobile homes.

SIDE WALL

WITH

VERTICAL

EXHAUST

12”

BACK WALL

3”

HORIZONTAL

1”

EXHAUST

WITH

ADJACENT WALL

MINIMUM SIDEWALL CLEARANCES

FIGURE 1

30”

1”

3”

3”

1”

ADJACENT WALL

FLOOR PROTECTION: Freestanding installations,

minimum 30” wide by 32” deep. The stove must

be placed on a continuous (grouted joints) noncombustible material such as ceramic tile, cement

board, brick, 3/8” millboard or equivalent, or other

approved or listed material suited for fl oor protec-

tion.

THE MATERIAL(S) USED MUST HAVE, OR COMBINE TO HAVE, A MINIMUM INSULATIVE RATING OF ‘R1.’

NOTE: ceramic tile, or any tile, requires a continuous sheet beneath to prevent the possibility of

embers falling through to the combustible if cracks

or separation should occur in the fi nished surface,

this would include fl oor protection for Built-in raised

hearths. Check local codes for approved alternatives.

Clearances are measured from the sides, back and

face (door opening) or stove body (refer to fi g.2).

Clearances may only be reduced by means approved by the regulatory authority having jurisdiction.

DO NOT USE MAKESHIFT MATERIALS OR

COMPROMISES IN THE INSTALLATION OF

THIS UNIT.

32”

6”

6”

6”

FLOOR PROTECTION

(MINIMUM 30” W X 32” D)

FIGURE 2

CAUTION: DO NOT CONNECT TO OR USE IN CONJUNCTION WITH ANY AIR DISTRIBUTION DUCTWORK UNLESS SPECIFICALLY APPROVED FOR SUCH INSTALLATIONS.

INSTALL VENT AT CLEARANCES SPECIFIED

BY THE VENT MANUFACTURER.

6

INSTALLATION

INSTALLATION

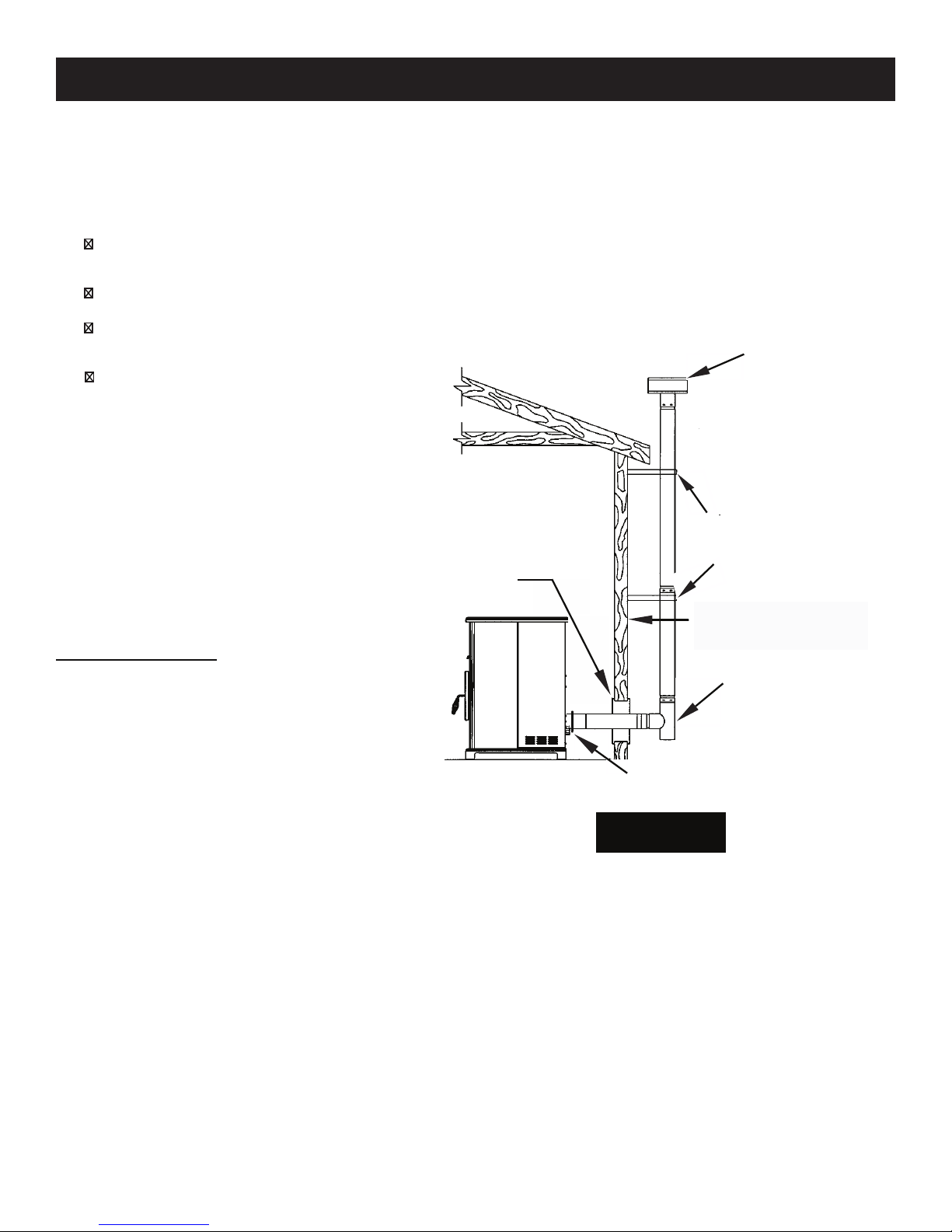

COMBUSTION AIR SUPPLY

For a mobile home installation, the stove must be connected

to an outside source of combustion air. A 2” inside diameter

metallic pipe, either fl exible or rigid, may be attached to the inlet

at the stove’s rear (refer to fi gure 3). A rodent guard (minimum

1/4” wire mesh) wind hood must be used at the terminus (refer

to fi gure 4). All connections must be secured and airtight by

either using the appropriately sized hose clamp and/or UL-181AP foil tape.

For mobile home installations only: 2” inside diameter pipe

may be used for the fi rst 5 feet of combustion air supply run.

From 5 to 10 feet, use 2 3/4” inside diameter pipe. No combustion air supply may exceed 10 feet.

Sources of Outside Combustion Air

a. In fi replaces

Chimney top.

Ash clean out door.

b. For freestanding installations

A hole in fl oor near stove rear terminating only a ven-

tilated crawl space.

A hole in the wall behind the stove.

WHEN OUTSIDE AIR IS NOT USED

If outside air is not used, it is important that combustion air is

easily available to the air inlet. A closeable outside air register

can be used in tightly insulated homes.

3

25

“

4

5

32

“

8

7

8

“

8

7

2

5

7

“

16

FIGURE 3

16

“

5

6

“

8

VENTING

The Big E is certifi ed for use with listed TYPE L-Vent, 3” or 4”

diameter in size. The stove was tested with Simpson Duravent

brand. CLass “A” chimney is not required. Refer to the instructions provided by the vent manufacturer, especially when passing through a wall, ceiling or roof.

This is a pressurized exhaust system. All vent connector joints

must be sealed with 500oF (260oC) RTV silicone sealant to

ensure consistent performance and avoid smoke spillage. All

horizontal connector joints must be sealed with UL-181-AP foil

tape. All vertical vent connector joints are required to be secured with a minimum of 3 screws.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST

VENTING SYSTEM OF THIS UNIT.

INSTALL VENT AT CLEARANCES SPECIFIED BY THE

VENT MANUFACTURER.

The chimney connector shall not pass through an attic or

roof space, closet or similar concealed space, or a fl oor,

or ceiling. Where passage though a wall, or partition of

combustible construction is desired, the installation shall

conform to CAN/CSA-B365, Installation Code for Solid-Fuel-Burning Appliances and Equipment

COLLAR

VENTILATED

CRAWL SPACE

TRIM

RODENT

GUARD

FIGURE 4

INSTALLATION

INSTALLATION

7

Equivalent Vent Length (EVL)

The longer the run of pipe in your installation, the more restrictions there is in the system. Therefore, larger diameter

pipe should be used.

Use 4” pipe if you have more than 15 feet of

equivalent vent length.

Horizontal runs shall not exceed 10’ of EVL

Recommended vertical runs to be a minimum of

8’.

To calculate EVL, use the following conversions:

90

45o elbow = 3 equivalent feet

Horizontal Pipe Run = 1 equivalent foot per

actual foot

Vertical Pipe Run = 0.5 equivalent foot

per actual foot

NOTE: At altitudes above 3,000 feet, we suggest the use of

4” diameter vent at an EVL of 7 feet or more.

o

elbow or “T” = 5 equivalent feet

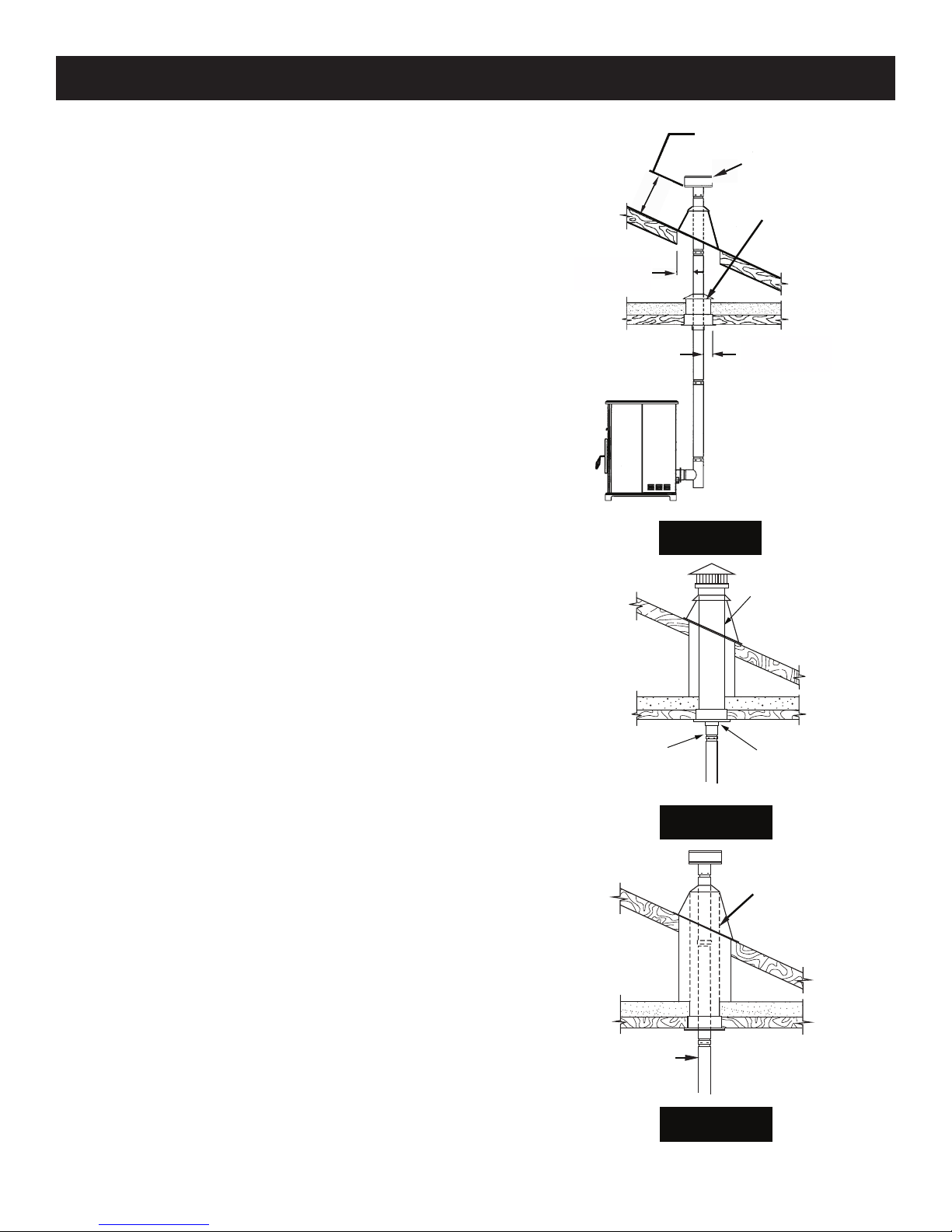

BIG E INSTALLATION

A. HORIZONTALLY THROUGH WALL (refer to Figure 5)

NOTE: Follow L-Vent chimney manufacturer’s instructions.

VERTICAL ROOF VENT

WALL STRAP

SEE VENT MANUFACTURER

FOR NUMBER AND SPACING

WALL

THIMBLE

6” MINIMUM CLEARANCE

TO ANY COMBUSTIBLE

SURFACE

CLEAN-OUT TEE

A 90 DEGREE ELBOW

MAY ALSO BE USED

1. Positions stove, adhering to clearances shown in Figure

1.

2. Locate position of hole in wall; directly behind stove

exhaust vent (refer to fi gure 3).

3. Always maintain 3” clearance from combustible materials.

4. Install L-Vent wall thimble per L-Vent manufacturer’s

instructions.

5. Attach enough piping to penetrate and extend at least

6” beyond exterior walls. An 8-foot vertical pipe run is suggested where possible to reduce the possibility of smoke

spillage in the event of a loss of negative pressure.

6. Attach cap and seal outside wall thimbles with nonhardening waterproof mastic.

7. Terminations should not be located so that hot exhaust

gases can ignite trees, shrubs, or grass or be a hazard to

children. Exhaust gases can reach temperatures of 500oF

and cause serious burns if touched.

L-VENT

ADAPTER

FIGURE 5

Locate terminations: a) not less than 3 feet above any forced air

inlet located within 10 feet; b) not less than 4 feet below or horizontally from, or 1 foot above any door, window or gravity air inlet into

any building; c) not less than 2 feet from an adjacent building and

not less than 7 feet above grade when located adjacent to a public

walkway. Mobile home installations must use a spark arrester.

INSTALLATION

8

INSTALLATION

B. VERTICALLY WITH NEW CHIMNEY SYSTEM

(Refer to Figure 6)

NOTE: Follow L-Vent chimney manufacturer’s instructions.

o

OPTION: To achieve a center vertical installation, a 45

can be used to offset the pipe from the exhaust outlet to the rear center of the stove.

OPTION: Install L-Vent elbow in place of clean-out tee. Locate stove. Drop plumb

bob to center of tee outlet , mark point on ceiling. Install ceiling support and L-Vent

pipe per L-Vent manufacturer’s instructions.

1. Always maintain 3” clearance from combustible materials. When passing through

additional fl oors or ceilings, always install fi restop spacer.

2. After lining up for hole in roof, cut either a round or square hole in roof, always 3”

larger all the way around pipe. Install upper edge and sides of fl ashing under roof-

ing materials, nail to the roof along upper edge. Do not nail lower edge. Seal nail

heads with non-hardening waterproof mastic.

3. Apply non-hardening, waterproof mastic where the storm collar will meet the

vent and fl ashing. Slide storm collar down until it sits on the fl ashing. Seal and

install cap. Mobile home installations must use a spark arrester.

C. VERTICALLY INTO EXISTING CHIMNEY SYSTEM

Adapters are available to adapt from 3” L-Vent to 6” or 8” Class-A chimney. (Figure 7)

As an alternative, 3” or 4” L-Vent can be run inside existing chimney to termination.

(Figure 8)

This is the preferred method.

elbow and a clean-out tee

3” MINUMUM

CLEARANCES TO

COMBUSTIBLES

12” MINIMUM CLEARANCE

TO ROOF

VERTICAL ROOF VENT

3” MINUMUM

CLEARANCES TO

COMBUSTIBLES

FIGURE 6

EXISTING

CHIMNEY

SYSTEM

ATTIC

INSULATION

SHIELD

Follow guidelines for equivalent vent length.

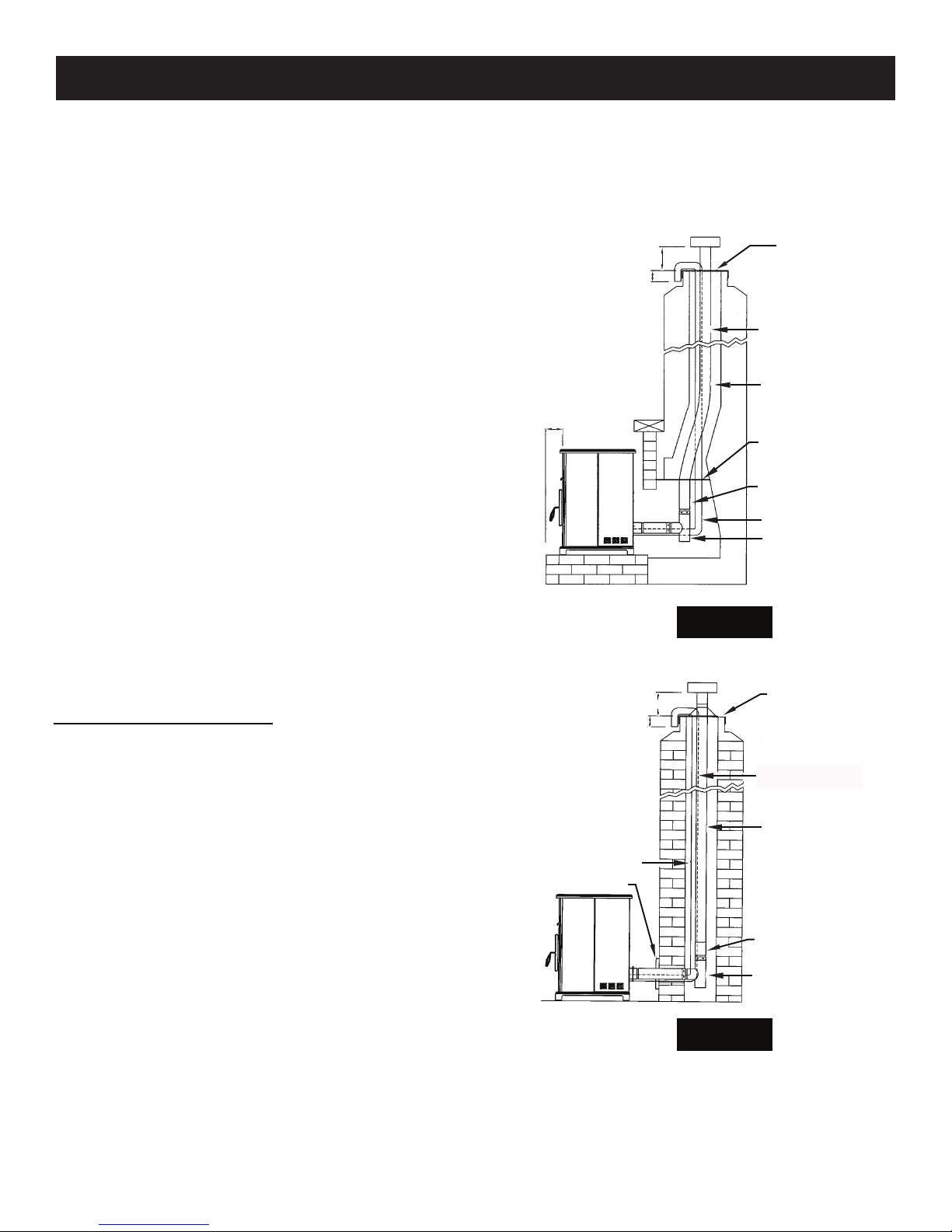

D. VERTICALLY INTO EXISTING MASONRY FIREPLACE

NOTE: Follow L-Vent chimney manufacturer’s instructions.

1. Have the masonry chimney inspected by a qualifi ed chimney sweep or installer to

determine its structural condition.

2. You will need a pipe length equal to the chimney height from the hearth. If outside combustion air is to be used, you will need a pipe length equal to the chimney

height plus 18 inches.

3. Install a blanking plate and the chimney pipe, and if used the outside air pipe,

as shown in Figure 9

4. Attach the L-Vent adapter, a section of pipe and clean-out tee, making sure the

clean-out tee is centered in the chimney fl ue area. Use RTV, metallic tape, and a

minimum of three self-taping screw at all joint connections to ensure a tight seal.

5. Position the stove, adhering to the clearances in Figure 1.

6. Measure and build chimney top plate. Cut out holes for chimney pipe, and if used

the outside air pipe. Install and seal with non-hardening mastic to prevent water

leakage. Install vent cap.

PELLET VENT TO

CHIMNEY ADAPTER

(SPV-CA)

PELLET

VENT

UNIVERSAL

CONNECTOR

FIGURE 7

THIS METHOD

IS PREFERRED

FIGURE 8

EXISTING

CHIMNEY

SYSTEM

NOTE:

INSTALLATION

INSTALLATION

9

E. INSTALLATION THROUGH SIDE OF MASONRY CHIMNEY

NOTE: Follow L-Vent chimney manufacturer’s instructions.

1. Position the stove, adhering to the clearances in Figure 1. Mark the

center of the hole where the pipe is to pierce the masonry chimney.

2. It will be necessary to break out the masonry around the location of the

pipe center mark. Use a 4-inch diameter hole for 3-inch pipe and 5-inch

diameter hole for 4-inch pipe.

3. Measure and build chimney top plate. Cut out holes for chimney pipe,

and if used, the outside air pipe.

3”

NOTE:

FOLLOW METAL

CHIMNEY INSTALLATION

INSTRUCTIONS

TOP PLATE

6”

(SEAL TO CHIMNEY TOP

WITH NON-HARDENING

MASTIC)

EXTENSION TO CHIMNEY TOP

REQUIRED.

4. Install the tee on the bottom of the vertical pipe system and lower it

down the chimney until the center branch of the tee is level with the

center of the hole in the masonry, as shown in Figure 10.

5. Install and seal the top plate from Step 3 with non-hardening mastic.

Slip the storm collar over the pipe, and while holding the pipe at the

proper elevation, affi x the collar with a minimum of 3 1/4” stainless steel

sheet metal screws. Seal all joints and seams around the collar.

6. Connect the horizontal pipe by pushing it through the hole in the masonry and lining it up with the branch in the tee. Push the pipe into the

tee while twisting it to lock it into the tee.

7. If desired, once the horizontal pipe is in place, the space between the

pipe and masonry may be fi lled with high-temperature grout.

8. Install the trim collar. An adjustable pipe length and adapter may be

needed to fi nish the connection to the stove.

ELECTRICAL INSTALLATION

This stove is provided with a 6-foot grounded electrical cord

extending from the rear of the stove.

We recommend connecting to a good quality surge protector

that is plugged into a standard three-prong, 120V, 60Hz electrical outlet.

DO NOT connect the unit to a GFCI socket.

6”

NOTE:

FOLLOW METAL

CHIMNEY INSTALLATION

INSTRUCTIONS

OPTIONAL OUTSIDE AIR

TRIM COLLAR

3 OR 4 INCH STAINLESS STEEL

SINGLE WALL PIPE OR FLEX PIPE.

BLANKING PLATE (SEAL WITH

NON-HARDENING MASTIC).

3 OR 4 INCH STAINLESS STEEL

FLEX PIPE.

OPTIONAL OUTSIDE AIR

CLEAN-OUT-TEE (TYPE L)

OR 90 DEGREE ELBOW

HEARTH

FIGURE 9

TOP PLATE

6”

3”

(SEAL TO CHIMNEY TOP

WITH NON-HARDENING

MASTIC)

EXTENSION TO CHIMNEY TOP

REQUIRED.

L-VENT OR OPTIONAL

3 OR 4 INCH STAINLESS STEEL

SINGLE WALL PIPE OR FLEX PIPE.

Voltage variations can lead to serious performance problems. The

Breckwell electrical system is designed for 120V AC with no more

than 5% variation. Breckwell cannot accept responsibility for poor

performance or damage due to inadequate voltage. If connected

to an older, two-prong outlet, a separate ground wire should be

run to a proper ground (refer this to a qualifi ed technician). Always

route the electrical cord so that it will not come in contact with any

hot part of the stove.

FIGURE 10

PIPE ADAPTER

CLEAN-OUT TEE (TYPE L)

Loading...

Loading...