Page 1

•

OWNER’S MANUAL

ECONOMY SERIES

P22

P22FSL

P22I

P22FSL

WARNING: If your appliance is not properly installed a house fire may result. For your safety,

follow the installation directions. Contact local building or fire officials about restrictions and

installation inspection requirements in your area.

• PLEASE read this entire manual before installation and use of this pellet fuel-burning room heater.

Failure to follow these instructions could result in property damage, bodily injury, or even death.

• Save these instructions.

PROFESSIONAL INSTALLATION IS HIGHLY RECOMMENDED

Manufactured by

Breckwell Hearth Products

Eugene, Oregon

Grand Prairie, Texas

www.breckwell.com

BRECKWELL HEARTH PRODUCTS

C-L-067 1/05

Page 2

Thank you for purchasing the Breckwell Pellet Burning Stove. You are now prepared to burn

INTRODUCTION

2

IMPORTANT INFORMATION

MAIL YOUR WARRANTY CARD TODAY

wood in the most efficient, convenient way possible. To achieve the safest, most efficient and

most enjoyable performance from your stove, you must do three things: 1) Install it properly;

2) Operate it correctly; and 3) Maintain it regularly. The purpose of this manual is to help you

do all three.

PLEASE read this entire manual before installation and use of this pellet fuel-burning

room heater. Failure to follow these instructions could result in property damage,

bodily injury or even death.

Keep this manual handy for future reference.

Your Breckwell P22 comes as a fireplace insert or as a freestanding stove with legs or a

pedestal.

This stove has been independently tested to ASTM E1509-95 Standard Specification for

Room Heaters, Pellet Fuel Burning Type 1, UL 1482-1998 Standard for Solid Fuel Room

Heaters, Oregon Administrative Rules for Mobile Homes (814-23-900 through 814-23-909)

and Installation as a Stove Heater.

This pellet stove, when installed, must be electrically grounded in accordance with local

codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

This appliance is designed specifically for use only with pelletized wood. It is designed for

residential installation according to current national and local building codes as a freestanding

room heater. It is also approved as a mobile home heater which is designed for connection to

an outside combustion air source.

The stove will not operate using natural draft or without a power source for the blower

systems and fuel feed system and must not be burned with any type of coal (see PROPER

FUEL).

This stove is designed to provide the optimum proportions of fuel and air to the fire in order to

burn free of smoke and soot. Any blockage of the air supply to or from the stove will seriously

degrade its performance and will be evidenced by a smoking exhaust and a sooting window.

For best operation the ash content of the pellet fuel should be less than 1% and the calorific

value approximately 8200 BTU/LB. Avoid high ash content fuels because this will rapidly fill

up the burn pot and eventually cut off the combustion air supply.

Commercial and industrial installations of Breckwell Pellet Stoves should not be used since

operational control is often not well managed in these settings.

Model: _____P22___________________

Style: ____________________________

Serial Number:_____________________

Purchase Date: ____________________

Purchased From:___________________

___________________

___________________

To receive full warranty coverage, you will

need to show evidence of the date you

purchased your stove. We suggest that

you attach your sales invoice to this page,

and fill in the form on the left, so that you

will have all the information you need in

one place should the need for service or

information occur.

Page 3

SAFETY PRECAUTIONS

3

Do not operate your stove if you smell smoke

coming from it. Turn it off, monitor it, and call your

dealer.

Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids to

start or “freshen up” a fire in this stove. Keep all

such liquids well away from the stove while in use.

Never block free airflow through the open vents of

the stove.

Never try to repair or replace any part of the

stove unless instructions are given in this

manual. All other work should be done by a

trained technician.

Do not throw this manual away. This manual

has important operating and maintenance

instructions that you will need at a later time.

Always follow the instructions in this manual.

Do not place clothing or other flammable

items on or near the stove.

Keep foreign objects out of the hopper.

The stove will not operate during a power outage.

If an outage does occur, check the stove for

smoke spillage and open a window if any smoke

spills into the room.

Disconnect the power cord before performing any

maintenance or repairs on the stove.

NOTE: Turning the stove “off” does not disconnect

all power from the stove.

During the start up period; 1) DO NOT open the

viewing door; 2) DO NOT open the damper more

than ¾”; 3) DO NOT add pellets to the burnpot

by hand; 4) DO NOT use the Fuel Feed button

(unless you are priming the auger after running

out of pellets) as a dangerous condition could

result.

Do not unplug the stove if you suspect a

malfunction. Turn the stove off, periodically

inspect it, and call your dealer.

The viewing door must be closed and latched

during operation.

Do not operate the stove if the flame

becomes dark and sooty or if the burnpot

overfills with pellets. Turn the stove off,

periodically inspect it, and call your dealer.

Hot while in operation. Keep children,

clothing, and furniture away. Contact may

cause skin burns. Educate all children of the

danger of a high temperature stove. Young

children should be supervised when they are

in the same room as the stove.

If the stove is installed in a room without air

conditioning, or in an area where direct

sunlight can shine on the unit, it is possible

this can cause the temperature of the stove to

rise to operational levels; one of the sensors

could then make the stove start on its own. It

is recommended that the stove be unplugged

when not in use for extended amounts of time

(i.e. during the summer months).

Contact your local building officials to obtain a

permit and information on any installation

restrictions or inspection requirements in your

area. Notify your insurance company of this stove

as well.

This unit must be properly installed to prevent the

possibility of a house fire. The instructions must be

strictly adhered to. Do not use makeshift methods

or compromise in the installation.

Your stove requires periodic maintenance and

cleaning. Failure to maintain your stove may lead

to smoke spillage in your home.

This stove must be connected to a standard 120

V., 60 Hz grounded electrical outlet. Do not use an

adapter plug or sever the grounding plug. Do not

route the electrical cord underneath, in front of, or

over the stove.

The exhaust system should be checked, at a

minimum, at least twice a year for any build up of

soot or creosote.

The exhaust system must be completely

airtight and properly installed. The pellet vent

joints must be sealed with RTV 500°F

(260°C) silicone sealant, and with UL-181-AP

foil tape.

Allow the stove to cool before carrying out

any maintenance or cleaning. Ashes must be

disposed in a metal container with a tight lid

and placed on a no combustible surface well

away from the home structure.

This stove is designed and approved for

pelletized wood fuel only. Any other type of

fuel burned in this heater will void the

warranty and safety listing.

When installed in a mobile home, the stove

must be bolted to the floor, have outside air,

and NOT BE INSTALLED IN A BEDROOM

(Per H.U.D. requirements). Check with local

building officials.

Breckwell Hearth Products grants no

warranty, implied or stated, for the

installation or maintenance of your stove,

and assumes no responsibility of any

consequential damage(s).

Page 4

TABLE O

F CONTENTS

4

INTRODUCTION --------------------------------------------------------------------------------------------- 2

SAFETY PRECAUTIONS ---------------------------------------------------------------------------------- 3

SPECIFICATIONS ------------------------------------------------------------------------------------------- 5

INSTALLATION --------------------------------------------------------------------------------------------- 5

Preparation ----------------------------------------------------------------------------------------- 5

Clearances ----------------------------------------------------------------------------------------- 5

Combustion Air Supply -------------------------------------------------------------------------- 6

When Outside Air Is Not Used ----------------------------------------------------------------- 6

Venting ----------------------------------------------------------------------------------------------- 6

Freestanding Installations ---------------------------------------------------------------------- 7

Insert Installations -------------------------------------------------------------------------------- 10

Electrical Installation ------------------------------------------------------------------------------ 13

Special Mobil Home Requirements ---------------------------------------------------------- 13

OPERATION --------------------------------------------------------------------------------------------------- 14

Proper Fuel ----------------------------------------------------------------------------------------- 14

Pre-Start-Up Check ------------------------------------------------------------------------------- 14

Building a Fire ------------------------------------------------------------------------------------- 14

The HotRod™ Automatic Fire Starter -------------------------------------------------------- 14

Panel Controls ------------------------------------------------------------------------------------- 14

Opening Door -------------------------------------------------------------------------------------- 15

Room Air Fan -------------------------------------------------------------------------------------- 15

Re-Starting a Warm Stove ---------------------------------------------------------------------- 15

If Stove Runs Out Of Pellets -------------------------------------------------------------------- 16

Damper Control ------------------------------------------------------------------------------------ 16

Refueling --------------------------------------------------------------------------------------------- 16

Breckwell Maintenance Tool -------------------------------------------------------------------- 16

Shutdown Procedure ----------------------------------------------------------------------------- 16

Safety Features ------------------------------------------------------------------------------------ 16

Optional Thermostat ------------------------------------------------------------------------------ 17

Thermostat Installation -------------------------------------------------------------------------- 17

MAINTENANCE ---------------------------------------------------------------------------------------------- 19

Ash Removal ---------------------------------------------------------------------------------------- 19

Ash Disposal ---------------------------------------------------------------------------------------- 19

Vacuum Use ---------------------------------------------------------------------------------------- 19

Cleaning ---------------------------------------------------------------------------------------------- 19

Blowers ---------------------------------------------------------------------------------------------- 20

Chimney Cleaning -------------------------------------------------------------------------------- 21

Recommended Maintenance Schedule ----------------------------------------------------- 21

Removal & Replacement of Broken Door Glass ------------------------------------------ 21

TROUBLE SHOOTING GUIDE -------------------------------------------------------------------------- 22

Smoke Smell or Soot Build-Up ---------------------------------------------------------------- 27

ELECTRICAL DIAGRAM --------------------------------------------------------------------------------- 28

REPLACEMENT PARTS LIST -------------------------------------------------------------------------- 29

(Please Read This) Operating Safety Precautions

-------------------------------------- 18

Page 5

SPECIFICATIONS

INSTALLATION

5

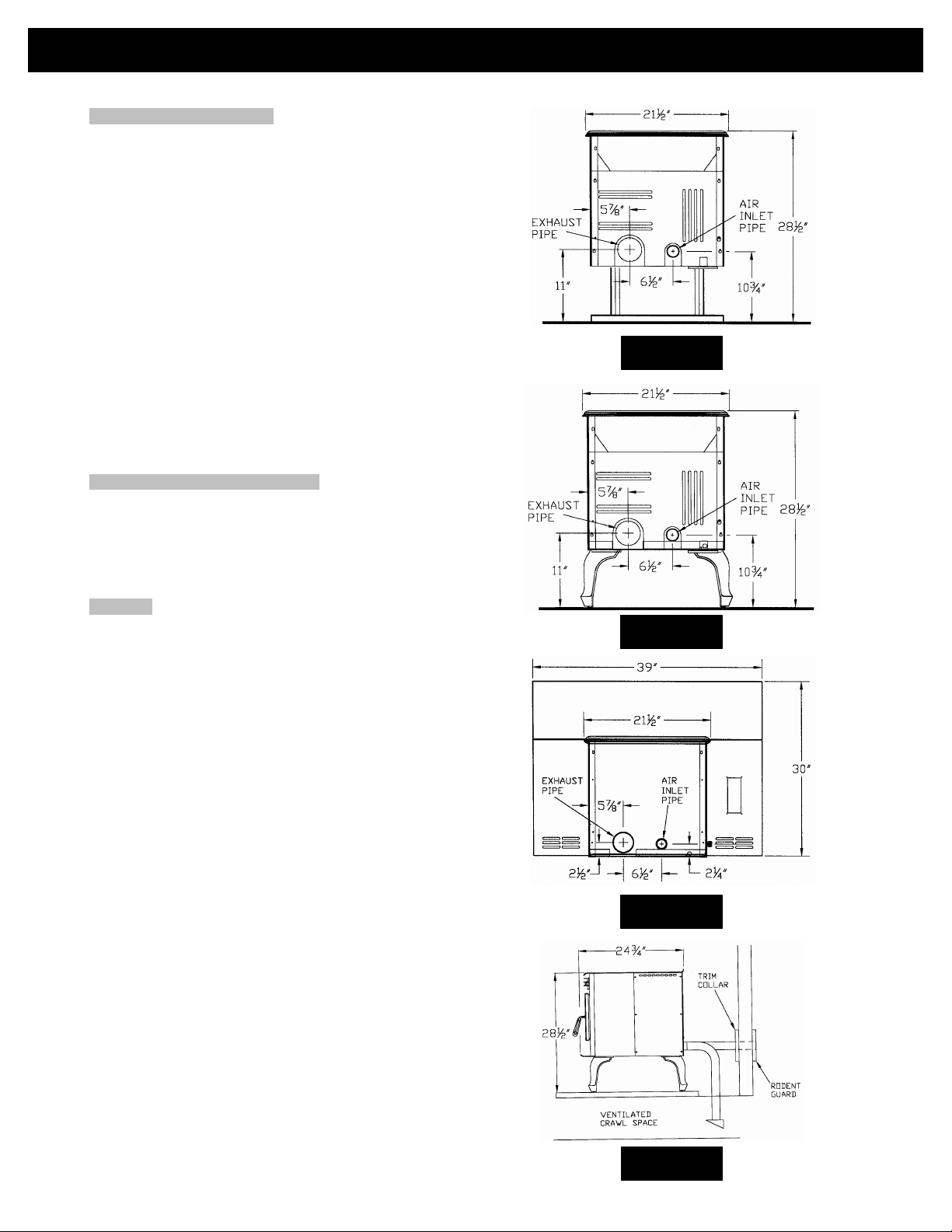

FREESTANDING:

Width: 21 ½”

Height: 28 ½” (with legs or pedestal)

Depth: 24”

Weight: 185 lbs.

Pedestal: 40 lbs.

Legs: 13 lbs.

Flue size: 3” or 4”

Hopper Capacity: Up to 45 lbs.

(this can vary widely depending on pellet size, length, and diameter)

EPA status: exempt

Burn time: 1 lb. to 4 ½ lbs. per hour

BTU range: 8,200 to 40,000

Approved installations: mobile home, alcove, conventional

FIREPLACE INSERT:

Width: 21 ½” (With flashing: 39”)

Height: 20” (With flashing: 30”)

Depth: 24” (In fireplace: 10 ¾”)

Weight: 185 lbs.

Flashing: 13 lbs.

Flue size: 3” or 4”

Hopper Capacity: Up to 45 lbs.

(this can vary widely depending on pellet size, length, and diameter)

EPA status: exempt

Burn time: 1 lb. to 4 ½ lbs. per hour

BTU range: 8,200 to 40,000

Approved installations: zero-clearance, masonry, as a built-in

PREPARATION

Factory packaging must be removed, and some minor assembly work is required

prior to installation. Access to the rear of the stove is necessary.

The circuit board/control panel must be unpacked and installed in the side

flashing on the insert or side panel on the freestanding.

(See installation instructions provided with the circuit board)

NOTE: Normally, your dealer will perform these functions.

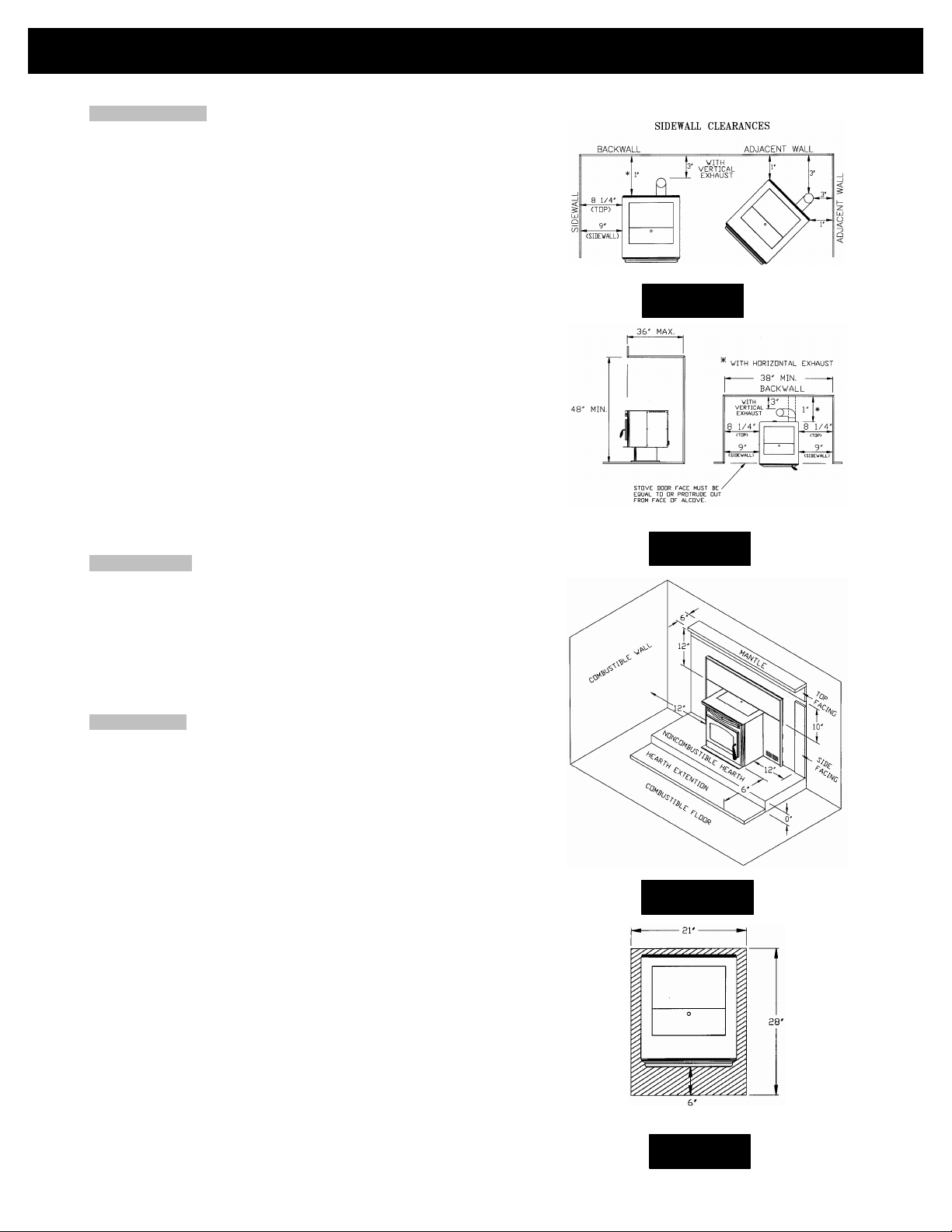

CLEARANCES

The Breckwell P22 Freestanding has been tested and listed for installation in

residential, mobile home and alcove applications.

The P22 Insert is approved for installation into code complying masonry

fireplaces. It is also approved for use in listed factory built fireplaces (UL 127)

and standard residential built-ins (see As A Built-In Fireplace), including Mobile

Home built-in installations, of the following description: all brands at least 34”

wide and 20 ½” high.

FLOOR PROTECTION: Freestanding installations, minimum 21” wide by 28”

deep. The stove must be placed on a continuous (grouted joints) noncombustible

material such as ceramic tile, cement board, brick, 3/8” millboard or equivalent,

or other approved or listed material suited for floor protection.

THE MATERIAL(S) USED MUST HAVE, OR COMBINE TO HAVE, A MINIMUM

INSULATIVE RATING OF ‘R1’.

NOTE: ceramic tile, or any tile, requires a continuous sheet beneath to prevent

the possibility of embers falling through to the combustible floor if cracks or

separation should occur in the finished surface, this would include floor

protection for Built-in raised hearths. Check local codes for approved

alternatives.

Clearances are measured from the sides, back and face (door opening) or stove

body (refer to fig. 4).

FIGURE 1

ALCOVE CLEARANCES

FIGURE 2

FIGURE 3

DO NOT USE MAKESHIFT MATERIALS OR COMPROMISES IN THE

INSTALLATION OF THIS UNIT.

INSTALL VENT WITH CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

FLOOR PROTECTION

FIGURE 4

Page 6

COMBUSTION AIR SUPPLY

INSTALLATION

6

For a mobile home installation the stove must be connected to an

outside source of combustion air. A 2” inside diameter metallic pipe,

either flexible or rigid, may be attached to the inlet at the stove’s rear

(refer to figures 5a, 5b, and 6). A rodent guard (minimum ¼” wire

mesh)/wind hood must be used at the terminus (refer to figure 7). All

connections must be secured and airtight by either using the

appropriately sized hose clamp and/or UL-181-AP foil tape.

For mobile home installations only: 2” inside diameter pipe may

be used for the first 5 feet of combustion air supply run. From 5 to 10

feet use 2 ¾” inside diameter pipe. No combustion air supply may

exceed 10 feet.

Sources of Outside Combustion Air

a. In fireplaces

• Chimney top.

• Ash clean out door.

b. For freestanding installations

• A hole in floor near stove rear terminating only in a

ventilated crawl space.

• A hole in the wall behind the stove.

WHEN OUTSIDE AIR IS NOT USED

If outside air is not used, it is important that combustion air is easily

available to the air inlet. A closeable outside air register can be used

in tightly insulated homes. In insert installations, flashing vents

should not be restricted. The flashing should not necessarily seal the

fireplace face.

FIGURE 5a

VENTING

The Breckwell P22 Freestanding is certified for use with listed TYPE

L-Vent, 3” or 4” diameter in size. The stove was tested with Simpson

Duravent brand. Class “A” chimney is not required. Refer to the

instructions provided by the vent manufacturer, especially when

passing through a wall, ceiling or roof.

This is a pressurized exhaust system. All vent connector joints must

be sealed with 500°F (260°C) RTV silicone sealant to ensure

consistent performance and avoid smoke spillage. All horizontal

connector joints must be sealed with UL-181-AP foil tape. We

recommend that all vertical vent connector joints be secured with a

minimum of 3 screws.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING

SYSTEM OF THIS UNIT.

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

FIGURE 5b

FIGURE 6

FIGURE 7

Page 7

Equivalent Vent Length (EVL)

INSTALLATION

7

The longer the run of pipe in your installation (both with inserts and

freestandings), the more restriction there is in the system. Therefore,

larger diameter pipe should be used.

• Use 4” pipe if you have more than 15 feet of equivalent vent

length.

• Horizontal runs shall not exceed 10 feet of EVL.

• It is recommended that vertical runs be a minimum of 8 feet.

• To calculate EVL, use the following conversions:

90º elbow or “T” = 5 equivalent feet

45º elbow = 3 equivalent feet

Horizontal Pipe Run = 1 equivalent foot per actual foot

Vertical Pipe Run = 0.5 equivalent foot per actual foot

NOTE: At altitudes above 3,000 feet, we suggest the use of 4”

diameter vent at an EVL of 7 feet or more.

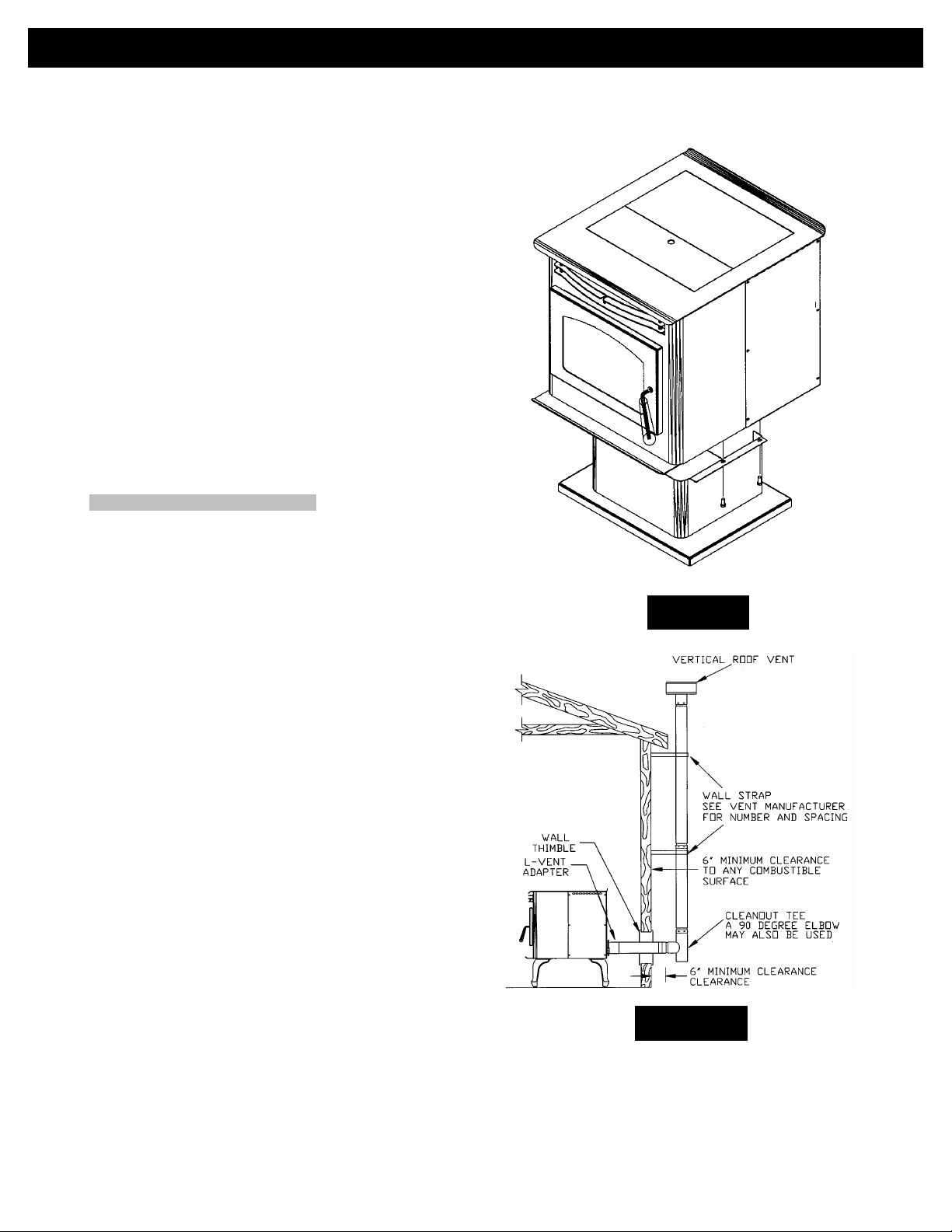

FREESTANDING INSTALLATIONS

A. ASSEMBLING PEDESTAL OR LEG SET

If using a pedestal, follow the instructions inside the Breckwell P22

Pedestal Set Part # A-22-P (refer to figure 8).

If using cast legs, follow the instructions inside the Breckwell P22 Leg

Set Part # A-CGL-22 or # A-CL-22.

Legs are installed by using the four bolts provided in the kit into the

four holes under the stove at each corner, thread on nuts from the top

and tighten. Make sure to save the hole plugs.

NOTE: If converting from legs to pedestal the hole plugs must be

installed in the unused holes.

B. HORIZONTALLY THROUGH WALL (refer to Figure 9)

NOTE: Follow L-Vent chimney manufacturer’s instructions.

1. Position stove, adhering to clearances shown in Figures 1 & 2.

2. Locate position of hole in wall; directly behind stove exhaust vent

(refer to figure 5).

3. Always maintain 3” clearance from combustible materials.

4. Install L-Vent wall thimble per L-Vent manufacturer’s instructions.

5. Attach enough piping to penetrate and extend at least 6” beyond

exterior walls. An 8-foot vertical pipe run is suggested where

possible to reduce the possibility of smoke spillage in the event of

a loss of negative pressure.

6. Attach cap and seal outside wall thimbles with non-hardening

waterproof mastic.

7. Termination should not be located so that hot exhaust gases can

ignite trees, shrubs, or grasses or be a hazard to children.

Exhaust gases can reach temperatures of 500ºF and cause

serious burns if touched.

FIGURE 8

FIGURE 9

Locate terminations: a) not less than 3 feet above any forced air

inlet located within 10 feet; b) not less than 4 feet below or

horizontally from, or one foot above, any door, window or gravity

air inlet into any building; c) not less than two feet from an

adjacent building and not less than 7 feet above grade when

located adjacent to a public walkway. Mobile home installations

must use a spark arrester.

Page 8

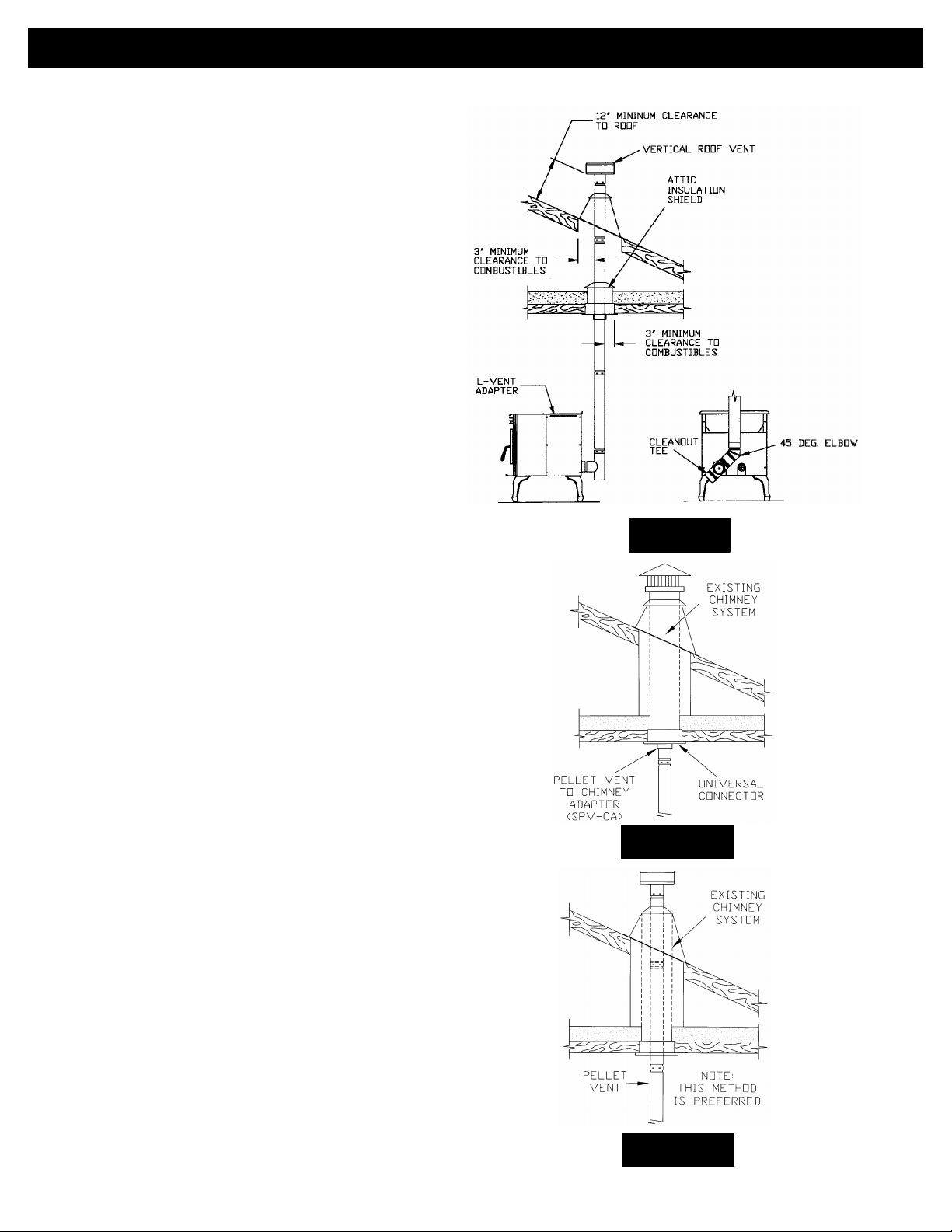

C. VERTICALLY WITH NEW CHIMNEY SYSTEM (Refer to

INSTALLATION

8

Figure 10)

NOTE: Follow L-Vent chimney manufacturer’s instructions.

OPTION: To achieve a center vertical installation a 45º elbow

and a clean-out tee can be used to offset the pipe from the

exhaust outlet to the rear center of the stove.

OPTION: Install L-Vent elbow in place of clean-out tee. Locate

stove. Drop plumb bob to center of tee outlet, mark point on

ceiling. Install ceiling support and L-Vent pipe per L-Vent

manufacturer’s instructions.

1. Always maintain 3” clearance from combustible materials.

When passing through additional floors or ceilings, always

install firestop spacer.

2. After lining up for hole in roof, cut either around or square

hole in roof, always 3” larger all the way around pipe. Install

upper edge and sides of flashing under roofing materials,

nail to the roof along upper edge. Do not nail lower edge.

Seal nail heads with non-hardening waterproof mastic.

3. Apply non-hardening, waterproof mastic where the storm

collar will meet the vent and flashing. Slide storm collar

down until it sits on the flashing. Seal and install cap. Mobile

home installations must use a spark arrester.

D. VERTICALLY INTO EXISTING CHIMNEY SYSTEM

Adapters are available to adapt from 3” L-Vent to 6” or 8” Class-A

chimney. (Figure 11a)

As an alternative, 3” or 4” L-Vent can be run inside existing

chimney to termination. (Figure 11b)

This is the preferred method.

Follow guidelines for equivalent vent length.

FIGURE 10

FIGURE 11a

FIGURE 11b

Page 9

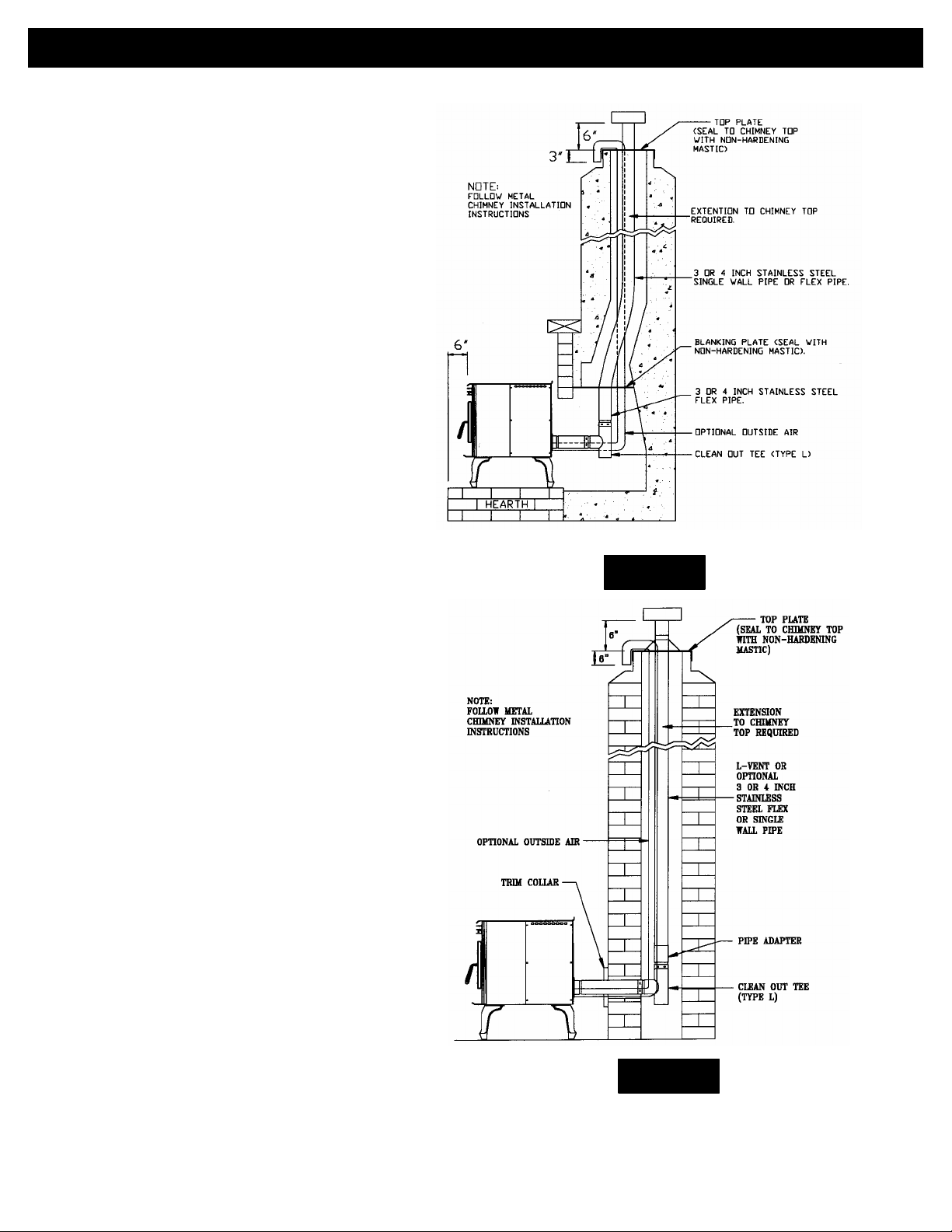

E. VERTICALLY INTO EXISTING MASONRY

INSTALLATION

9

FIREPLACE

NOTE: Follow L-Vent chimney manufacturer’s instructions.

1. Have the masonry chimney inspected by a qualified

chimney sweep or installer to determine its structural

condition.

2. You will need a pipe length equal to the chimney

height from the hearth. If outside combustion air is to

be used, you will need a pipe length equal to the

chimney height plus 18 inches.

3. Install a blanking plate and the chimney pipe, and if

used the outside air pipe, as shown in Figure 12.

4. Attach the L-Vent adapter, a section of pipe and clean

out tee, making sure the clean out tee is centered in

the chimney flue area. Use RTV, metallic tape, and a

minimum of three self-taping screws at all joint

connections to ensure a tight seal.

5. Position the stove, adhering to the clearances in

Figures 1 & 2.

6. Measure and build chimney top plate. Cut out holes for

chimney pipe, and if used the outside air pipe. Install

and seal with non-hardening mastic to prevent water

leakage. Install vent cap.

F. INSTALLATION THROUGH SIDE OF MASONRY

CHIMNEY

NOTE: Follow L-Vent chimney manufacturer’s instructions.

1. Position the stove, adhering to the clearances in

Figures 1 & 2. Mark the center of the hole where the

pipe is to pierce the masonry chimney.

2. It will be nec essary to break out the masonry around

the location of the pipe center mark. Use a 4-inch

diameter hole for 3-inch pipe and 5-inch diameter hole

for 4-inch pipe.

3. Measure and build chimney top plate. Cut out holes for

chimney pipe, and if used the outside air pipe.

4. Install the tee on the bottom of the vertical pipe system

and lower it down the chimney until the center branch

of the tee is level with the center of the hole in the

masonry, as shown in Figure 13.

5. Install and seal the top plate from step 3 with nonhardening mastic. Slip the storm collar over the pipe,

and while holding the pipe at the proper elevation, affix

the collar with a minimum of three ¼” stainless steel

sheet metal screws. Seal all joints and seams around

the collar.

6. Connect the horizontal pipe by pushing it through the

hole in the masonry and lining it up with the branch in

the tee. Push the pipe into the tee while twisting it to

lock it into the tee.

7. If desired, once the horizontal pipe is in place, the

space between the pipe and masonry may be filled

with high-temperature grout.

8. Install the trim collar. An adjustable pipe length and

adapter may be needed to finish the connection to the

stove.

FIGURE 12

FIGURE 13

Page 10

INSERT INSTALLATIONS

INSTALLATION

10

Insert installations must be vented with 3” or 4” pipe. Pipe

may be single wall stainless steel flexible pipe. Vent may

terminate within chimney beyond a blanking plate or

extend to the chimney top. See “COMBUSTION AIR

SUPPLY” for outside air access information.

The fireplace and chimney should be cleaned thoroughly

before starting the installation. We suggest painting the

interior of particularly old and dirty fireplaces to seal any

odors. In zero-clearance fireplace installations, when the

fireplace opening is above the floor or raised hearth, the

adjustable “Breckwell P22 Z-C Legs” can be used to

bridge the gap between the hearth and stove bottom.

Refer to figure 14.

A. ASSEMBLING THE FLASHING SET

Follow the instructions packaged with the P22 Flashing

set part C-P22-MED (refer to Figure 15).

FIGURE 14

FIGURE 15

Page 11

B. WHEN VENT PIPE EXTENDS TO CHIMNEY TOP

INSTALLATION

11

(Refer to Figures 16 and 17)

1. You will need a pipe length equal to the chimney

height (from hearth) plus 6 inches. If outside

combustion air is to be used, you will need a pipe

length (see “COMBUSTION AIR SUPPLY”) equal to

the chimney height plus 12 inches.

2. Attach cerablanket wrap (not included) to that end of

vent pipe that will connect to the stove. Use 12-inch

lengths of light gauge metal wire (not included) or

metallic tape (not included). This is to protect interior

components from excess heat.

3. Set the insert on the hearth and slide it in far enough

to attach the vent pipe (and combustion pipe if

used).

4. Attach flashing (refer to Figure 15), route power cord

out the side nearest a 120V receptacle. Slide in

insert.

5. Measure and build chimney top. Cut out hole for

vent pipe (and combustion air intake pipe, if used).

Install and seal with a non-hardening mastic to

prevent water leakage. Install the vent cap.

C. WHEN VENT PIPE EXTENDS THROUGH

CHIMNEY BLANKING PLATE

(Masonry Fireplaces Only)

(Refer to Figures 16 and 17)

1. You will need a pipe length that extends 12”

above the blanking plate. NOTE: This

installation is optional but not recommended.

Outside combustion air cannot be drawn from

the chimney cavity in this installation.

2. Attach cerablanket wrap (not included) to that

end of vent pipe that will connect to the stove.

Use 12-inch lengths of light gauge metal wire

(not included) or metallic tape. This is to protect

interior components from excess heat.

3. Measure and build blanking plate. Cut out hole

for vent pipe (and combustion air intake pipe, if

used). Install and carefully seal blanking plate

with non-hardening mastic. Failure to properly

seal may result in smoke spillage.

4. Slide vent pipe (and intake pipe if used) up

through the blanking plate hole, leaving enough

to pull back down.

5. Set the insert on the hearth, adjust the leveling

bolts on the rear sides, slide it in far enough to

attach the vent pipe (and combustion air pipe if

used). Be sure to seal where the pipe passes

through the blanking plate.

6. Attach flashing (refer to Figure 15), route power

cord out the side nearest a 120V receptacle.

Slide in insert.

FIGURE 16

FIGURE 17

Page 12

D. AS A BUILT-IN FIREPLACE

occur in the finished surface.

INSTALLATION

12

Figures 18 and 19 describe a P22

installation vented into either a

special chase built outside an outer

wall or a false inside wall. This is

especially suited for new

construction or remodeling.

The equipment compartment (sides

and rear of the stove in fireplace)

must be enclosed per the

applicable electrical standards.

This can be accomplished by the

use of Breckwell’s panel kit part

#A-PANEL-22.

NOTE: Floor protection for Built-in

raised hearths requires a

continuous sheet beneath to

prevent the possibility of embers

falling through to the combustible

floor if cracks or separation should

The chase dimensions shown

are minimums and must be

maintained.

FIGURE 18

FIGURE 19

Page 13

E. INSTALLATION IN TO A FACTORY

INSTALLATION

13

BUILT (METAL) FIREPLACE

(Refer to figure 20)

When installing into a factory built fireplace,

the firebox must accept the insert without

modification other than removing bolted or

screwed together pieces such as smoke

shelf/deflectors, ash lips, screen or door tracks

and damper assemblies. These items must be

reinstalled to restore the fireplace to its original

operating condition if the insert is removed

and not replaced. The removal of any part

must not alter the integrity of the listed

fireplace in any way. In zero-clearance

fireplace installations, when the fireplace

opening is above the floor or raised hearth, the

adjustable “Breckwell P22 Z-C Legs” can be

used to bridge the gap between the hearth

and stove bottom. Refer to figure 14.

The factory built fireplace must be listed per

UL 127. Installation must include a full height

listed chimney liner meeting type HT

requirements (2100? F) per 1777 (U.S.). The

liner must be securely attached to the insert

flue collar and the chimney top. The damper

area must be sealed to prevent room air

passage to chimney cavity.

Alteration of the fireplace in any manner is not

permitted except with the following exceptions:

• External trim pieces, which do not affect the

operation of the fireplace, may be removed

proving they can be stored on or within, the

fireplace for re-assembly if the insert is

removed.

• The fireplace damper may be removed to

install the chimney liner.

Circulating air chambers, louvers or cooling air

inlet or outlet ports (i.e. in a steel fireplace liner

or metal heat circulator) shall not be blocked.

Means must be provided for removal of the

insert to clean the chimney flue.

A permanent metal warning label must be

attached to the back wall of the fireplace

opening stating the following:

• “This fireplace has been altered to

accommodate a fireplace insert and should

be inspected by a qualified person prior to

re-use as a conventional fireplace.”

• This label is available upon request.

Final approval is contingent on the

authority having jurisdiction.

ELECTRICAL INSTALLATION

This stove is provided with a 6-foot grounded

electrical cord extending from the rear of the

stove. We recommend connecting to a good

quality surge protector that is plugged into a

standard three-prong, 120V, 60hz electrical

outlet. Voltage variations can lead to serious

performance problems. The Breckwell

electrical system is designed for 120V AC with

no more than 5% variation. Breckwell cannot

accept responsibility for poor performance or

damage due to inadequate voltage. If

connected to an older, two-prong outlet, a

separate ground wire should be run to a

proper ground (refer this to a qualified

technician). Always route the electrical cord so

that it will not come in contact with any hot part

of the stove.

FIGURE 20

FIGURE 21

SPECIAL MOBILE HOME REQUIREMENTS

WARNING: DO NOT INSTALL IN A SLEEPING ROOM.

For installation in a mobile home, an outside source of combustion air must be used (see

“COMBUSTION AIR SUPPLY”).

The P22 must be grounded to the steel chassis of the home with 8 Ga. copper wire using

a serrated or star washer to penetrate paint or protective coating to ensure grounding.

The P22 must be securely fastened to the floor of the mobile home through the two holes

in the rear of the stove using 2, ¼” lag bolts that are long enough to go through both a

hearth pad, if used, and the floor of the home. (See figure 21)

Refer to “VENTING” for proper exhaust configurations.

CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE HOME FLOOR, WALL

AND CEILING/ROOF MUST BE MAINTAINED.

Page 14

PANEL CONTROLS (See Figure 22)

OPERATION

14

The blowers and automatic fuel supply are controlled from a panel on the left-hand side of the P22. The

control panel functions are as follows.

a. ON/OFF SWITCH

• When pushed the stove will automatically ignite. No other firestarter is necessary. The igniter will

stay on for at least 10 and up to 15 minutes, depending on when Proof of Fire is reached. The fire

should start in about 5 minutes.

• The green light located above the On/Off button (in the On/Off box) will flash during the ignition

start-up period. (See figure 22)

• The Feed Rate Advance is inoperable during the ignition start period. When the red light

continuously stays on the Feed Rate Advance can be adjusted to achieve the desired heat output.

NOTE: If the stove has been shut off, and you want to re-start it while it is still warm, the “on/off” button

must be held down for 2 seconds.

b. FUEL FEED SWITCH

• When the “Fuel Feed” button is pushed and held down the stove will feed pellets continuously into

the burnpot.

• While the stove’s auger system is feeding pellets the amber light (in the “Fuel Feed” box) will be

on. (See figure 22)

CAUTION: DO NOT USE THIS CONTROL DURING NORMAL OPERATION BECAUSE IT COULD

SMOTHER THE FIRE AND LEAD TO A DANGEROUS SITUATION.

c. HIGH FAN SWITCH

• The room air fan speed varies directly with the feed rate. The “HIGH FAN” switch overrides this

variable speed function. It will set the room air blower speed to high at any feed rate setting.

• When the “HIGH FAN” button is pushed the room air fan will switch to its highest setting.

• When this button is pushed again the room air fan will return to its original setting based on the

Feed Rate Advance setting.

d. RESET TRIM

Different size and quality pellet fuel may require adjustment of the “1” feed setting on the Feed Rate

Advance bar graph. This is usually a one-time adjustment based on the fuel you are using. The

“RESET TRIM” button when adjusted will allow for 3 different feed rate settings for the #1 feed setting

only. To adjust simply push the “RESET TRIM” button while the stove is operating at setting “1” and

watch the bar graph.

• When the “1” and “3” lights are illuminated on the bar graph the low feed rate is at its “lowest”

setting. (approx. 0.9 pounds per hour)

• When the “1” light is illuminated on the bar graph the low feed rate is at its “normal” setting.

• When the “1” & “4” lights are illuminated on the bar graph the low feed rate is at its “highest”

setting.

NOTE: When the stove is set on “1” the “reset trim” values will be shown on the Feed Rate Advance bar

graph. For example if the Reset Trim is set to its lowest setting every time the stove is set to low the “1”

and “3” lights will be illuminated on the bar graph.

e. HEAT LEVEL ADVANCE

• This button when pushed will set the pellet feed rate, hence the heat output of your stove. The

levels of heat output will incrementally change on the bar graph starting from level “1” to “4”.

NOTE: When dropping more than 2 heat level settings (i.e. 4 to 1) push the ‘High Fan’ button and allow

the room air fan to run at that setting for at least 5 minutes to prevent the stove from tripping the high

temp thermodisk. If the high temp thermodisk does trip see “SAFETY FEATURES”.

CAUTION: THE “4” SETTING IS DESIGNED FOR TEMPORARY USE ONLY. IF USED FOR

EXTENDED PERIODS, IT CAN SHORTEN THE LIFE EXPECTANCY OF THE UNITS COMPONENTS.

AVOID USE AT THIS SETTING FOR MORE THAN ONE HOUR AT A TIME.

FIGURE 22

Page 15

PROPER FUEL

OPERATION

15

THIS STOVE IS APPROVED FOR BURNING PELLETIZED WOOD FUEL ONLY! Factory-approved pellets are those ¼” or 5/16” in

diameter and not over 1” long. Longer or thicker pellets sometimes bridge the auger flights, which prevents proper pellet feed. Burning wood

in forms other than pellets is not permitted. It will violate the building codes for which the stove has been approved and will void all

warranties. The design incorporates automatic feed of the pellet fuel into the fire at a carefully prescribed rate. Any additional fuel introduced

by hand will not increase heat output but may seriously impair the stoves performance by generating considerable smoke. Do not burn wet

pellets. The stove’s performance depends heavily on the quality of your pellet fuel. Avoid pellet brands that display these characteristics:

a. Excess Fines – “Fines” is a term describing crushed pellets or loose material that looks like sawdust or sand. Pellets can be screened

before being placed in hopper to remove most fines.

b. Binders – Some pellets are produced with materials to hold them together, or “bind” them.

c. High ash content – Poor quality pellets will often create smoke and dirty glass. They will create a need for more frequent

maintenance. You will have to empty the burnpot plus vacuum the entire system more often. Poor quality pellets could damage the

auger. Breckwell cannot accept responsibility for damage due to poor quality pellets. Your dealer can recommend a good quality pellet

dealer in your area.

PRE-START-UP CHECK

Remove burnpot, making sure it is clean and none of the air holes are plugged. Clean the firebox, and then reinstall burnpot. Clean door

glass if necessary (a dry cloth or paper towel is usually sufficient). Never use abrasive cleaners on the glass or door. Check fuel in the

hopper, and refill if necessary.

NOTE: The P22 Hopper can hold up to 45 lbs. of pellets.

BUILDING A FIRE

Never use a grate or other means of supporting the fuel. Use only the Breckwell approved burnpot.

During the start up period:

1) DO NOT open the viewing door.

2) DO NOT open the damper more than ¾”.

3) DO NOT add pellets to the burnpot by hand.

4) DO NOT use the Fuel Feed button (unless you are priming the auger after running out of pellets).

A dangerous condition could result.

NOTE: During the first few fires, your stove will emit an odor as the high temperature paint cures or becomes seasoned to the metal.

Maintaining smaller fires will minimize this. Avoid placing items on stovetop during this period because paint could be affected.

THE HOTROD AUTOMATIC FIRESTARTER

a. Fill hopper and clean burnpot.

b. Press “Power” button. Make sure light is on.

c. Adjust damper to ½” to ¾” open (pushed in is closed). This will vary depending on your installation and elevation. Once fire is

established adjust for desired flame increasing the amount the damper is open as the heat setting is increased.

(See “DAMPER CONTROL”)

d. Adjust feed rate to desired setting by pressing “Feed Rate Advance” button.

If fire doesn’t start in 15 minutes, press “Power”, wait a few minutes and start procedure again.

DAMPER CONTROL

The damper control rod on the stove’s lower left side adjusts the combustion air. This control is necessary due to the varied burn

characteristics of individual installations, different pellet brands and pellet feed rates. It allows you to improve the efficiency of your stove.

Providing correct combustion air will reduce the frequency of cleaning your glass door and prevent the rapid buildup of creosote inside your

stove and chimney.

You should adjust the damper based on the fire’s appearance. A low, reddish, dirty fire can be improved by pulling the damper out slightly. A

“blow torch” fire can be improved by pushing the damper in a bit.

As a general rule, on lower feed rate settings, the damper should be in farther. On higher feed rates, the damper should be more open.

Through trial and error, you will find the best setting. Consult your dealer if you need help.

NOTE: On “1”, damper should be out approximately ½” to ¾”. If damper is out too far, it can cause the fire to go out.

OPENING DOOR

If the door is opened while the stove is in operation it must be closed within 30 seconds or the stove will shut down. If the stove shuts down

push the “Power” button to continue the operation of your stove.

ROOM AIR FAN

When starting your stove the Room Air Fan will not come on until the stove’s heat exchanger warms up. This usually takes about 10 minutes

from start-up.

Page 16

OPERATION

16

RE-STARTING A WARM STOVE

If the stove has been shut off, and you want to re-start it while it is still warm, the “on/off” button must be held down for 2 seconds.

IF STOVE RUNS OUT OF PELLETS

The fire goes out and the auger motor and blowers will run until the stove cools. This will take 30 to 45 minutes.

After the stove components stop running the “Power” and the BAR GRAPH lights stay on for 10 minutes.

After the 10 minutes the “3” light on the bar graph will flash and the “Power” light will go off.

To restart, refill hopper, press “Power” button, and then press “Fuel Feed” button until pellets begin to fall into burnpot.

REFUELING

We recommend that you not let the hopper drop below ¼ full.

KEEP HOPPER LID CLOSED AT ALL TIMES EXCEPT WHEN REFILLING. DO NOT OVERFILL HOPPER.

BRECKWELL MAINTENANCE TOOL

A tool has been provided to help with the following functions:

FIGURE 23

a. Stirring pellets in hopper – unlike liquids in a tank, pellets do not drain evenly into the auger. Bridging across the opening can occur.

Pellets can hang up on the sides of the hopper. Occasionally “stirring” the hopper can help.

NOTE: To help prevent bridging of pellets, common wax paper can be rubbed on the sidewalls and bottom of the hopper.

b. Cleaning heat exchanger tubes – see instructions in “CLEANING”.

c. Scrape ashes from burnpot.

SHUTDOWN PROCEDURE

Turning your Breckwell stove off is a matter of pressing the “Power” control panel switch. The red light will go out. The blowers will continue

to operate until internal firebox temperatures have fallen to a preset level.

SAFETY FEATURES

a. Your stove is equipped with a high temperature thermodisc. This safety switch has two functions.

1. To recognize an overheat situation in the stove and shut down the fuel feed or auger system.

2. In case of a malfunctioning convection blower, the high-temperature thermodisc will automatically shut down the auger, preventing

NOTE: On some units, once tripped, like a circuit breaker, the reset button will have to be pushed before restarting your stove. On other

units the thermodisk has no reset button and will reset itself once the stove has cooled. The manufacturer recommends that you call your

dealer if this occurs as this may indicate a more serious problem. A service call may be required.

b. If the combustion blower fails, an air pressure switch will automatically shut down the auger.

NOTE: Opening the stove door for more than 30 seconds during operation will cause enough pressure change to activate the air switch,

shutting the fuel feed off. Close the door and press “On/Off” button to continue operation of your stove.

the stove from overheating.

Page 17

THERMOSTAT INSTALLATION

17

OPTIONAL THERMOSTAT

A thermostat may help you maintain a constant house temperature

automatically. A millivolt thermostat is required. A fixed wall mount

or Breckwell’s hand held model can be used. The control panel can

be set up two ways to operate your stove in thermostat mode.

NOTE: YOUR THERMOSTAT SHOULD BE INSTALLED BY AN

AUTHORIZED DEALER OR SERVICE PERSON.

THERMOSTAT INSTALLATION

• A MILLIVOLT THERMOSTAT IS REQUIRED.

• Unplug stove from power outlet.

• Remove control board from stove.

• The two thermostat wires connect to the terminal block on the

lower left side of the back of the control board.

(See figure 24)

• Insert the wires in the terminal side and tighten the two screws.

MODES

TO SWITCH BETWEEN ANY OF THE THREE MODES THE

STOVE MUST BE SHUT OFF, THE NEW MODE SELECTED, AND

THE STOVE RESTARTED.

MANUAL MODE

• In this mode the stove will operate only from the control panel

as detailed in the “OPERATION” section of this owner’s

manual.

HIGH/LOW THERMOSTAT MODE

• When engaged in this mode the stove will automatically switch

between two settings. When warm enough, it will switch to the

#1 or low setting. The room air blower will also slow to its

lowest speed.

• The Heat Level Advance setting on the bar graph will stay

where it was initially set. When the house cools below the

thermostat setting, the stove will switch to the feed rate of the

heat level advance setting.

ON/OFF THERMOSTAT MODE

• In this mode when the home is warm enough the stove will

shut off. The fans will continue to run until the stove cools.

• When the home cools below the thermostat setting, the stove

will automatically restart and run at the last feed rate setting.

NOTE: When in “high/low” or “on/off” thermostat mode –

• Do not operate the stove higher than the #3 setting.

• Set damper control rod approximately ½” to ¾” out. This will

vary depending on elevation and weather conditions. Observe

stoves operation and adjust damper as necessary.

FIGURE 24

Page 18

OPERATING SAFETY PRECAUTIONS

OPERATION

18

PLEASE READ THIS!

a. Hot while in operation. Keep children, clothing, and furniture away. Contact may cause skin burns.

b. If you notice a smoldering fire (burnpot full but no visible flame) AND a heavy smoke buildup in firebox,

immediately TURN OFF the stove, but DO NOT unplug it. Do not open the door, change the damper

setting or tamper with any controls on the stove. Wait until firebox clears, and blowers shut down, do as

instructed in “PRE-START-UP CHECK” and “BUILDING A FIRE”, then attempt to restart the fire. If the

problem persists contact your dealer.

c. WARNING: DO NOT ADD PELLETS TO THE BURNPOT BY HAND AT ANY TIME, A DANGEROUS

CONDITION COULD RESULT.

d. WARNING: DURING THE START UP CYCLE; 1) DO NOT OPEN THE VIEWING DOOR; 2) DO NOT

OPEN THE DAMPER MORE THAN ¾”; 3) DO NOT USE THE FUEL FEED BUTTON (UNLESS PRIMING

THE AUGER AFTER RUNNING OUT OF PELLETS). A DANGEROUS CONDITION COULD RESULT.

e. Pellets should be stored in a dry place. The pellets should not be stored within 12” of the stove.

f. DO NOT STORE OR USE FLAMMABLE LIQUIDS, ESPECIALLY GASOLINE, IN THE VICINITY OF

YOUR BRECKWELL STOVE. NEVER USE A GAS OR PROPANE TORCH, GASOLINE, GASOLINE-

TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID OR SIMILAR FLUIDS TO START

OR “FRESHEN UP” A FIRE IN THIS HEATER.

g. WARNING: DO NOT OVERFIRE THIS STOVE. This may cause serious damage to your stove and void

your warranty. It also may create a fire hazard in your home. IF ANY EXTERNAL PART OF THE UNIT

BEGINS TO GLOW, YOU ARE OVERFIRING. Immediately press the “POWER” switch on the control

panel.

h. KEEP ALL LOOSE OR MOVEABLE HOUSEHOLD COMBUSTIBLES, SUCH AS FURNITURE, DRAPES,

TOYS, ETC. AT LEAST THREE FEET FROM THE OPERATING STOVE.

i. Maintain proper ventilation. It is important that adequate oxygen be supplied to the fire for the combustion

process. Modern houses are often so well insulated that it may become necessary to open a window

slightly or install an outside air vent to provide sufficient combustion air.

j. Since heating with a solid fuel is potentially hazardous, even with a well made and thoroughly tested stove,

it would be wise to install strategically placed smoke detectors and have a fire extinguisher in a convenient

location, near an exit.

k. Do not open stove door when operating unless necessary. This will create a dirty, inefficient burn and could

allow smoke spillage or sparks to escape.

l. Do not permit operation by young children or those unfamiliar with stove’s operation.

m. Do not service or clean this appliance without disconnecting the power cord.

n. Do not abuse the door glass by striking, slamming or similar trauma. Do not operate the stove with the glass

removed, cracked or broken.

o. If the stove is installed in a room without air conditioning, or in an area where direct sunlight can shine on

the unit, it is possible this can cause the temperature of the stove to rise to operational levels; one of the

sensors could then make the stove start on its own. It is recommended that the stove be unplugged when

not in use for extended amounts of time (i.e. during the summer months).

Page 19

FAILURE TO CLEAN AND MAINTAIN THIS UNIT AS INDICATED CAN

MAINTENANCE

19

RESULT IN POOR PERFORMANCE AND SAFETY HAZARDS. NEVER

CLEAN WHEN HOT.

NOTE: Inspect burn pot periodically to see that holes have not become

plugged, if so, clean thoroughly.

ASH REMOVAL

Ashes should be placed in a metal container with a tight-fitting lid. The

closed container or ashes should be placed on a noncombustible surface

or on the ground, well away from all combustible materials pending final

disposal. If ashes are disposed of by soil burial or otherwise locally

dispersed, they should be retained in the closed container until all cinders

have thoroughly cooled.

ASH DISPOSAL

Remove ashes periodically as they fill the firebox. To remove ashes:

a. Make sure fire is out and firebox is cool.

b. Clean heat exchanger tubes (see “CLEANING” and Figure 25).

c. Remove the burnpots inner section by grasping it and pulling straight

up (see Figure 26).

d. Empty ashes from the inner section and scrape with cleaning tool;

make sure holes are not plugged.

e. Vacuum to remove ashes from the burn chamber interior and the

burnpot shell.

WARNING: Make sure ashes are cool to the touch

before using a vacuum. See “VACUUM USE”.

f. Dispose of ashes properly. (See “ASH REMOVAL” above)

a. Replace inner section into burnpot; make sure it is level and pushed

all the way back down and that the igniter hole is to the rear when it is

reinstalled (see Figure 26).

b. Make sure the burnpot is level and pushed all the way in, if the collar

on the burnpot attached to the fresh air tube is not pushed back to

meet the firebox wall, the Hot Rod will not work properly.

VACUUM USE

If a vacuum is used to clean your unit, we suggest using a vacuum

designed for ashes. (We recommend LoveLess Ash Vac, 1-800-568-3949

Ext. #27) Some regular vacuums and shop vacs leak ash into the room.

Your vacuum or shop vac may have a special filter or bag available to

eliminate this leakage.

CLEANING

a. Heat Exchange Tubes – Your Breckwell stove is designed with a

built-in heat exchange tube cleaner. This should be used every two or

three days to remove accumulated ash on the tubes, which reduces

heat transfer on the P22. Insert the handle end (with hole) of the

cleaning tool onto the cleaning rod (refer to figure 25). The cleaner

rod is located in the grill above the stove door. Move the cleaner rod

back and forth several times to clean the heat exchanger tubes. Be

sure to leave tube cleaner at the rear of the stove.

b. Interior Chambers – Four ash doors and two upper baffles in the

firebox in the P22 can be removed for periodic cleaning (Figure 27).

These doors allow access to the chamber surrounding the firebox.

NOTE: When removing the upper baffles do not remove the screws;

just loosen them enough to allow the baffles to be removed.

Periodically, you must vacuum ashes from this chamber. In some

cases you will need to remove creosote, which can accumulate

rapidly under certain conditions. A small wire brush can be used. It is

important to remove this creosote because it is highly combustible.

INSPECT BEHIND THESE CLEANING PLATES AT LEAST ONCE

PER TON OF PELLETS BURNED UNTIL YOU ARE FAMILIAR

WITH HOW ASHES AND CREOSOTE ACCUMULATE WITH YOUR

OPERATING PRACTICES. Use the small wire brush to also clean

the inside of the chamber walls, above the access doors.

FIGURE 25

Igniter Hole

FIGURE 26

Baffle Plates

Air Switch Tube

Ash Doors

FIGURE 27

Page 20

BLOWERS

MAINTENANCE

20

DANGER: RISK OF ELECTRIC SHOCK.

DISCONNECT POWER BEFORE SERVICING UNIT.

Cleaning – Over a period of time, ashes or dust may

collect on the blades of both the combustion blower

and convection blower. Periodically the blowers should

be vacuumed clean as these ashes can impede

performance. Creosote can also accumulate in the

combustion blower. This needs to be brushed clean.

The convection blower is accessed by removing the

stove’s left side panel. The combustion blower can be

accessed by removing the stove’s right side panel. The

convection blower is on the left (facing stove), and the

combustion blower is on the right.

NOTE: When cleaning, be careful not to dislodge

balancing clip on convection blower or to bend fan

blades. Some stove owners lightly spray an anticreosote chemical on the fire to help reduce creosote

formation within the stove.

Combustion

Blower

(A-E-027)

Auger Motor

(C-E-017)

Convection

Blower

(A-E-033)

FIGURE 28

High Temp

Thermodisk

(C-E-090-21)

Air Switch

(C-E-200)

Auger Shaft

(A-AUG-22)

Combustion

Blower

(A-E-027)

POF

Thermodisk

(C-E-090-22C)

FIGURE 29

Pellet

Hopper

Air Inlet

Tube

Page 21

MAINTENANCE

21

CHIMNEY CLEANING

a. Creosote Formation – When any wood is burned slowly, it produces tar and other organic vapors, which

combine with expelled moisture to form creosote. The creosote vapors condense in the relatively cool

chimney flue or a newly started fire or from a slow-burning fire. As a result, creosote residue accumulates on

the flue lining. When ignited, this creosote makes an extremely hot fire, which may damage the chimney or

even destroy the house. Despite their high efficiency, pellet stoves can accumulate creosote under certain

conditions.

b. Fly Ash – This accumulates in the horizontal portion of an exhaust run. Though noncombustible, it may

impede the normal exhaust flow. It should therefore be periodically removed.

c. Inspection and Removal – The chimney connector and chimney should be inspected annually or per ton to

determine if a creosote or fly ash build-up has occurred. If creosote has accumulated, it should be removed

to reduce the risk of a chimney fire. Inspect the system at the stove connection and at the chimney top.

Cooler surfaces tend to build creosote deposits quicker, so it is important to check the chimney from the top

as well as from the bottom.

The creosote should be removed with a brush specifically designed for the type of chimney in use. A qualified

chimney sweep can perform this service. It is also recommended that before each heating season the entire

system be professionally inspected, cleaned and, if necessary, repaired.

To clean the chimney, detach the vent at the combustion blower transition where it is attached to the blower.

RECOMMENDED MAINTENANCE SCHEDULE

Use this as a guide under average-use conditions.

Daily Weekly Annually or per Ton

Burn Pot Stirred Emptied

Glass Wiped Cleaned

Combustion Chamber Brushed

Ashes Emptied

Interior Chambers Vacuumed

Heat Exchange Tubes Two passes

Combustion Blower Blades Vacuumed / Brushed

Convection Blower Impeller Vacuumed / Brushed

Vent System Cleaned

Gaskets Inspected

Hopper (end of season) Emptied and vacuumed

Gasket around door and door glass should be inspected and repaired or replaced when necessary.

(See “REPLACEMENT PARTS”)

REMOVAL AND REPLACEMENT OF BROKEN DOOR GLASS

While wearing leather gloves (or any other gloves suitable for handling broken glass), carefully remove any

loose pieces of glass from the doorframe. Dispose of all broken glass properly. Return the damaged door to

your Breckwell Dealer for repair or replacement.

Neither the appliance owner nor any other unauthorized person(s) should replace the door glass. An authorized

Breckwell dealer must perform all repairs involving door glass.

Page 22

TROUBLESHOOTI

NG GUIDE

22

When your stove acts out of the ordinary, the first reaction is to call for help. This guide may save time and money by enabling you to solve

simple problems yourself. Problems can be caused by to only five factors: 1) poor fuel; 2) poor operation or maintenance; 3) poor

installation; 4) component failure; 5) factory defect. You can usually solve those problems related to 1 and 2. Your dealer can solve

problems relating to 3, 4 and 5. Refer to figures 28, 29 and 30 to help locate indicated parts.

STOVE SHUTS OFF AND THE # 2 LIGHT FLASHES

Possible Causes: Possible Remedies: (Unplug stove first when possible)

1. Airflow switch hose or stove attachment pipes for hose are

blocked.

2. The air inlet, burnpot, interior combustion air chambers,

combustion blower, or exhaust pipe are blocked with ash or

foreign material.

3. The firebox is not properly sealed.

4. Vent pipe is incorrectly installed.

5. The airflow switch wire connections are bad.

6. The gray wires are pulled loose at the Molex connector on the

wiring harness.

7. Combustion blower failure.

8. Control board not sending power to combustion blower.

9. Control board not sending power to air switch.

10. Air switch has failed (very rare).

Unhook air hose from the air switch and blow through it. If air flows

freely, the hose and tube are fine. If air will not flow throw the hose,

use a wire coat hanger to clear the blockage.

Follow all cleaning procedures in the maintenance section of the

owner’s manual.

Make sure the door is closed and that the gasket is in good shape.

If the ash door has a latch, make sure the ash door is properly

latched and the gasket is sealing good. If the stove has just a small

hole for the ashes to fall through under the burnpot, make sure the

slider plate is in place to seal off the firebox floor.

Check to make sure vent pipe installation meets criteria in owner’s

manual.

Check the connectors that attach the gray wires to the air switch.

Check to see if the gray wires are loose at the Molex connector.

With the stove on, check to see if the combustion blower is running.

If it is not, you will need to check for power going to the combustion

blower. It should be a full current. If there is power, the blower is

bad. If there is not, see #8.

If there is no current going to the combustion blower, check all wire

connections. If all wires are properly connected, you have a bad

control board.

There should be a 5-volt current (approximately) going to the air

switch after the stove has been on for 30 seconds.

To test the air switch, you will need to disconnect the air hose from

the body of the stove. With the other end still attached to the air

switch, very gently suck on the loose end of the hose (you may want

to remove the hose entirely off the stove and the air switch first and

make sure it is clear). If you hear a click, the air switch is working.

BE CAREFUL, TOO MUCH VACUUM CAN DAMAGE THE AIR

SWITCH.

Page 23

TROUBLESHOOTING GUIDE

23

STOVE SHUTS OFF AND THE # 3 LIGHT FLASHES

Possible Causes: Possible Remedies: (Unplug stove first when possible)

1. The hopper is out of pellets.

2. The air damper is too far open for a low feed setting.

3. The burnpot is not pushed completely to the rear of the firebox.

4. The burnpot holes are blocked.

5. The air inlet, the interior chambers, or exhaust system has a

partial blockage.

6. The auger shaft is jammed.

7. The auger motor has failed.

8. The Proof of Fire (POF) thermodisc has malfunctioned.

9. The high limit thermodisc has tripped or is defective.

10. The fuse on the control board has blown.

11. The control board is not sending power to the POF thermodisc

or other auger system components.

Refill the hopper.

If burning on the low setting, you may need to close the damper all

the way (push the knob in so it touches the side of the stove).

Make sure that the air intake collar on the burnpot is touching the

rear wall of the firebox.

Remove the burnpot and thoroughly clean it.

Follow all cleaning procedures in the maintenance section of the

owner’s manual.

Start by emptying the hopper. Then remove the auger motor by

removing the auger pin. Remove the auger shaft inspection plate in

the hopper so that you can see the auger shaft. Gently lift the auger

shaft straight up so that the end of the auger shaft comes up out of

the bottom auger bushing. Next, remove the two nuts that hold the

top auger biscuit in. Then rotate the bottom end of the auger shaft

up towards you until you can lift the shaft out of the stove. After you

have removed the shaft, inspect it for bent flights, burrs, or broken

welds. Remove any foreign material that might have caused the

jam. Also, check the auger tube for signs of damage such as burrs,

rough spots, or grooves cut into the metal that could have caused a

jam.

Remove the auger motor from the auger shaft and try to run the unit.

If the motor will turn the shaft is jammed on something. If the motor

will not turn, the motor is bad.

Temporarily bypass the POF thermodisc by disconnecting the two

brown wires and connecting them with a short piece of wire. Then

plug the stove back in. If the stove comes on and works, you need

to replace the POF thermodisc. This is for testing only. DO NOT

LEAVE THE THERMODISC BYPASSED. Your blowers will never

shut off and if the fire went out the auger will continue to feed pellets

until the hopper is empty if you leave the POF thermodisc bypassed.

Wait for the stove to cool for about 30 - 45 minutes. It should now

function normally. If not use the owner’s manual to locate the high

limit thermodisk. To test if the thermodisk is bad, you can bypass it

as described previously for the POF thermodisk.

Remove the control board. If the fuse appears to be bad, replace it

with a 5 Amp 250 Volt fuse. Plug the stove back in and try to run the

unit.

There should be a 5-volt (approximately) current going to the POF

thermodisc after the stove has been on for 10 minutes.

Page 24

TROUBLESHOOTING GUIDE

24

STOVE FEEDS PELLETS, BUT WILL NOT IGNITE

Possible Causes: Possible Remedies:

1. Air damper open too far for ignition.

2. Blockage in igniter tube or inlet for igniter tube.

3. The burnpot is not pushed completely to the rear of the firebox.

4. Bad igniter element.

5. The control board is not sending power to the igniter.

SMOKE SMELL COMING BACK INTO THE HOME

Possible Causes: Possible Remedies:

1. There is a leak in the vent pipe system.

2. The gasket on the combustion blower has gone bad.

CONVECTION BLOWER SHUTS OFF AND COMES BACK ON

Possible Causes: Possible Remedies:

1. The convection blower is overheating and tripping the internal

temperature shutoff.

2. Circuit board malfunction.

Push the air damper in closer to the side of the stove for startup. In

some situations it may be necessary to have the damper completely

closed for ignition to take place. After there is a flame, the damper

can then be adjusted for the desired feed setting.

Find the igniter housing on the backside of the firewall. The air

intake hole is a small hole located on bottom side of the housing.

Make sure it is clear. Also, look from the front of the stove to make

sure there is not any debris around the igniter element inside of the

igniter housing.

Make sure that the air intake collar on the burnpot is touching the

rear wall of the firebox.

Put power directly to the igniter element. Watch the tip of the igniter

from the front of the stove. After about 2 minutes the tip should

glow. If it does not, the element is bad.

Check the voltage going to the igniter during startup. It should be a

full current. If the voltage is lower than full current, check the wiring.

If the wiring checks out good, the board is bad.

Inspect all vent pipe connections. Make sure they are sealed with

RTV silicone that has a temperature rating on 500 degree F or

higher. Also, seal joints with UL-181-AP foil tape. Also, make sure

the square to round adapter piece on the combustion blower has

been properly sealed with the same RTV.

Inspect both gaskets on the combustion blower to make sure they

are in good shape.

Try lubricating the convection blower. Put 1-2 drops of SAE 20 oil in

each of the two oiling ports. Also, clean any dust off of the windings

and fan blades. If oiling the blower does not help, the blower may

be bad.

Test the current going to the convection blower. If there is power

being sent to the blower when it is shut off, then the control board is

fine. If there is NOT power being sent to the blower when it shuts off

during operation, then you have a bad control board.

Page 25

TROUBLESHOOTING GUIDE

25

STOVE WILL NOT FEED PELLETS, BUT FUEL FEED LIGHT COMES ON AS DESIGNED

Possible Causes: Possible Remedies:

1. Fuse on control board blew

2. High limit switch has tripped or is defective

3. Bad auger motor

4. Auger jam

5. Loose wire or connector

6. Bad control board

Remove the control board. If the fuse appears to be bad, replace it

with a 5 Amp 250 Volt fuse. Plug the stove back in and try to run the

unit.

Wait for the stove to cool for about 30 - 45 minutes. It should now

function normally. If not use the owner’s manual to locate the high

limit thermodisk. To test if the thermodisk is bad, you can bypass it

as described previously for the POF thermodisk.

Remove the auger motor from the auger shaft and try to run the unit.

If the motor will turn, the shaft is jammed on something. If the motor

will not turn, the motor is bad.

Start by emptying the hopper. Then remove the auger motor by

removing the auger pin. Remove the auger shaft inspection plate in

the hopper so that you can see the auger shaft. Gently lift the auger

shaft straight up so that the end of the auger shaft comes up out of

the bottom auger bushing. Next, remove the two nuts that hold the

top auger biscuit in. Then rotate the bottom end of the auger shaft

up towards you until you can lift the shaft out of the stove. After you

have removed the shaft, inspect it for bent flights, burrs, or broken

welds. Remove any foreign material that might have caused the

jam. Also, check the auger tube for signs of damage such as burrs,

rough spots, or grooves cut into the metal that could have caused a

jam.

Check all wires and connectors that connector to the auger motor,

high limit switch, and the Molex connector.

If the fuse is good, the wires and connectors check out good, and

the high limit switch did not trip, test for power going to the auger

motor. If there is not a full current going to the auger motor when

the fuel feed light is on, you have a bad control board.

Page 26

TROUBLESHOOTING GUIDE

26

• GLASS “SOOT’S” UP AT A VERY FAST RATE

• FLAME IS LAZY, DARK, AND HAS BLACK TIPS

• AFTER STOVE HAS BEEN ON FOR A WHILE, THE BURNPOT OVERFILLS

Possible Causes: Possible Remedies:

1. Stove or vent pipe is dirty, which restricts airflow through the

burnpot.

2. Vent pipe installed improperly.

3. Air damper is set too far in (closed) for a higher setting.

4. Burnpot holes are blocked.

5. Air damper is broken.

6. Blockage in air intake pipe.

7. Circuit board malfunction.

8. Combustion blower is not spinning fast enough.

9. Bad Pellets

(Applies to GLASS “SOOT’S” UP AT A VERY FAST RATE Only)

10. The trim setting on the low feed rate is to low

(Applies to GLASS “SOOT’S” UP AT A VERY FAST RATE Only)

Follow all cleaning procedure in the maintenance section of the

owner’s manual.

Check to make sure the vent pipe has been installed according to

the criteria in the owner’s manual.

Pull the damper knob farther out away from the side of the stove and

try to burn the unit again.

Remove the burnpot and thoroughly clean it.

Visually inspect the damper assembly. Make sure the damper plate

is attached to the damper rod. When the damper rod is moved the

plate should move with it.

Visually inspect the air intake pipe that leads into the burnpot for

foreign material.

Time the fuel feed light at each setting (after the stove has

completed the startup cycle). Make sure the times match the auger

timing chart. If the auger motor runs constantly, the board is bad.

Test the RPM on the blower after the blades have been cleaned.

The RPM should be approximately 3000 RPM.

The brand of pellets or the batch of pellets that are being used may

be of poor quality. If possible, try a different brand of pellets. You

might also want to try a brand that is made from a different type of

wood (softwood vs. hardwood). Different woods have different

characteristics when being burned.

Use the “Reset Trim” button to increase the low feed rate setting. If

the 1 & 3 are on, the stove is currently on the lowest setting. If only

the 1 light is on, the stove is in the default (medium) setting. If the 1

& 4 lights are on, the stove is in the high trim setting for the low feed

rate. If the stove is being burned on one of the two lower settings,

advance to the next trim setting and try burning the stove.

Page 27

TROUBLESHOOTING GUIDE

27

HIGH LIMIT SWITCH KEEPS TRIPPING

Possible Causes: Possible Remedies:

1. The convection blower is overheating and tripping the internal

temperature shutoff.

2. The stove is being left on the highest setting for extended

periods of time.

3. Fuel other than wood pellets is being burned in the stove.

4. Power surge or brown out situation.

5. High limit switch is malfunctioning.

Clean any dust off of the windings and fan blades. If cleaning the

blower does not help, the blower may be bad.

The highest heat level setting is designed for use over short periods

of time. Burning the stove on the highest setting for longer than 1 –

2 hours could lead to potential overheating situations.

Breckwell pellet stoves are designed and tested to use wood pellets.

While it is possible to burn a corn mixture (corn mixed in with wood

pellets) in the stove, it is not recommended to burn above the

number 3 heat level. Check for signs of fuel other than wood

pellets. If there are signs of corn being used, find out what mixed

was being used and what setting. No other types of fuel have been

approved for Breckwell pellet stoves. If there are signs of other

types of fuel being used, advise the consumer to stop using them

immediately.

A power surge, spike, or voltage drop could cause the high limit

switch to trip. Check to see if a surge protector is being used on the

stove. If not, recommend one to the consumer.

If the other items check out ok, replace the high limit switch.

DIGITAL CIRCUIT BOARD TIMING RATES

Heat Level Setting P22

1 & 3 1.4 seconds

1 2 seconds

1 & 4 2.5 seconds

2 4 seconds

3 7 seconds

4 9 seconds

Total Cycle Time 14.5 seconds

SMOKE SMELL OR SOOT BUILD-UP

Because it is a wood-burning device, your Breckwell may emit a faint wood-burning odor. If this increases beyond normal, or if you notice

any soot build-up on walls or furniture, check your exhaust system carefully for leaks. All joints should be properly sealed. Also clean your

stove, following instructions in “MAINTENANCE”. If problem persists, contact your dealer.

Page 28

ELECTRICAL DIAGRAM

28

FIGURE 30

Page 29

REPLACEMENT PARTS

29

Contact an Authorized Breckwell Pellet Stove Dealer to obtain any of these parts. Never use

substitute materials. Use of non-approved parts can result in poor performance and safety

hazards.

Air Switch C-E-201

Air Switch Hose C-M-340-T

Auger Motor C-E-017

Breckwell Maintenance Tool A-TOOL-96

Burnpot A-S-BURNPOT

Circuit Board / Control Panel C-E-101

Combustion Blower A-E-027

Convection Blower A-E-033

Door Gasket C-G-050

Door Glass C-D-031

Exhaust Adapter 3” C-M-050

Exhaust Adapter 4” A-4-VA

Hot Rod Igniter C-E-IGN

Gold Legs - Optional A-CLG-22

Painted Legs - Optional A-CL-22

Pedestal - Optional A-P22-P

Thermodisc, Proof of Fire C-E-090-22C

Thermodisc, High Temp C-E-090-21

Door Handle C-D-050

Damper Knob C-M-013

Window Clips, Bottom / Airwash C-S-398

Window Clips, Side C-S-110

Window Gasket (6’-1”) C-G-033

Remote Thermostat (Acumen) – RF - Optional AG-RCN

Ceramic Brick Panel Set - Optional A-M-BRICK22

Ceramic Log Set (imitation) - Optional A-M-LOG

Zero Clearance Legs (insert model only) - Optional A-S-ZCLEGS

Page 30

LIFETIME LIMITED WARRANTY

Breckwell Hearth Products warrants to the original consumer purchaser that the Breckwell stove

in its original installation is free from defects in material and workmanship from the original date

of purchase as follows: