Breas Medical PV 501-2, PV 501 Service Manual

Service Manual PV 501/501-2

Table of contents

1 INTRODUCTION ....................................................................................................... 1

1.1 The scope of this manual ............................................................................ 1

1.2 Intended use of the ventilator ...................................................................... 1

1.3 Design and function of the ventilator ........................................................... 1

1.4 Intended audience ....................................................................................... 1

1.5 Service personnel's training requirements .................................................. 2

2 OPERATING MANUAL

3 MAINTENANCE SERVICE INSTRUCTIONS ........................................................... 1

3.1 Verifying the components and software installed ........................................ 1

3.2 Maintenance Service Schedule................................................................... 1

3.3 Special safety precautions .......................................................................... 2

3.4 Equipment required ..................................................................................... 3

3.5 Replacement parts required ........................................................................ 3

3.6 Maintenance instructions ............................................................................. 3

3.6.1 Registration ................................................................................. 3

3.6.2 Information from the user ............................................................ 3

3.6.3 Validity of documentation ............................................................ 3

3.7 External checks ........................................................................................... 4

3.7.1 External damage and wear ......................................................... 4

3.7.2 Power cables and plugs.............................................................. 4

3.7.3 Minimum function check ............................................................. 4

3.8 Internal Checks ........................................................................................... 4

3.8.1 Open hood and rear panel .......................................................... 4

3.8.2 Cleaning...................................................................................... 4

3.8.3 Cables and connectors ............................................................... 4

3.8.4 Component fastening.................................................................. 4

3.8.5 Mains supply ............................................................................... 5

3.8.6 Remove and check / replace the motor unit. .............................. 5

3.8.7 Grease the ball screw ................................................................. 5

3.8.8 Replace the membranes in the check valves ............................. 5

3.8.9 Leakage check of hoses and bellows ......................................... 5

3.8.10 Reassemble the motor unit ......................................................... 5

3.8.11 Checking the offset and gain of the pressure transducer ........... 5

3.8.12 Checking the instrument accuracy.............................................. 5

3.8.13 Internal battery test ..................................................................... 5

3.8.14 Reassemble the casing .............................................................. 6

3.9 Electrical safety ........................................................................................... 6

3.10 Final checks before delivery........................................................................ 6

3.10.1 Function check/leakage .............................................................. 6

3.10.2 Check the tidal volume/frequency ............................................... 6

3.10.3 Calculating the tidal volume/patient pressure ............................. 7

3.10.4 Checking the pressure limit ........................................................ 7

3.10.5 Checking low pressure alarm/alarm mute .................................. 8

3.10.6 Trigger ........................................................................................ 8

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 1 – 0

Service Manual PV 501/501-2

3.10.7 Battery operation ........................................................................ 8

3.10.8 Checking accessories ................................................................. 8

3.10.9 Cleaning the PEEP adapter ........................................................ 9

3.10.10 Set the correct values for the patient ........................................ 10

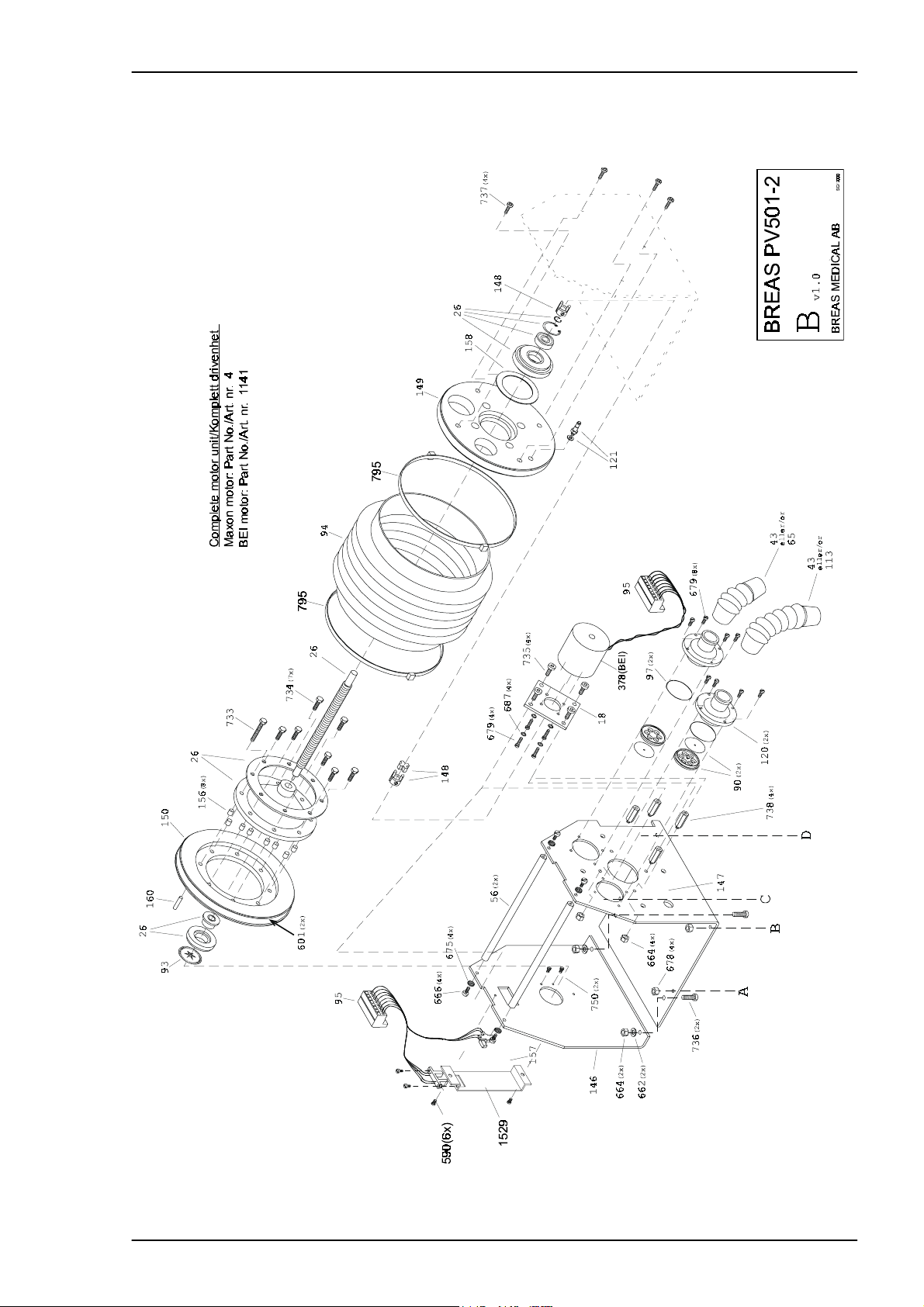

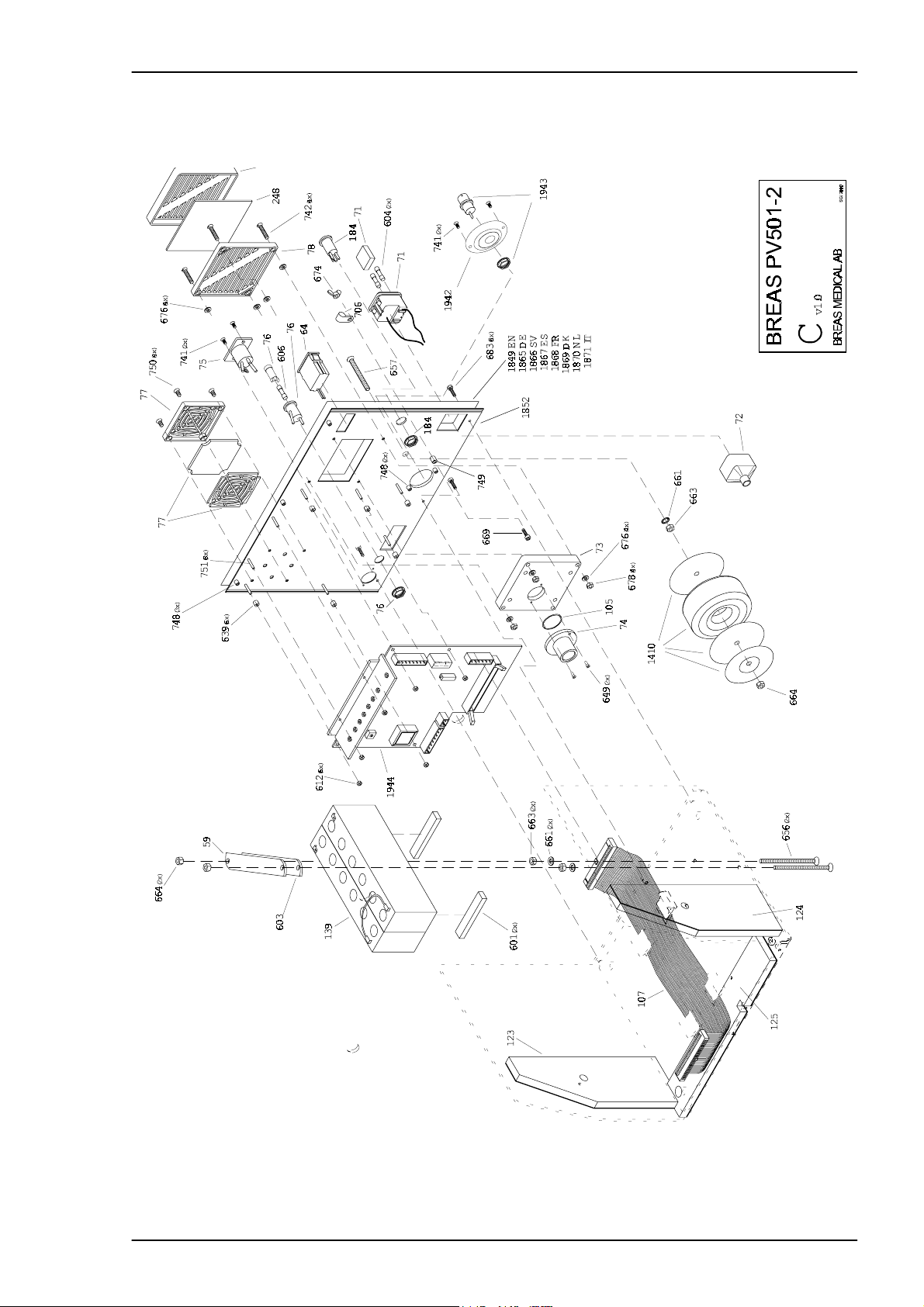

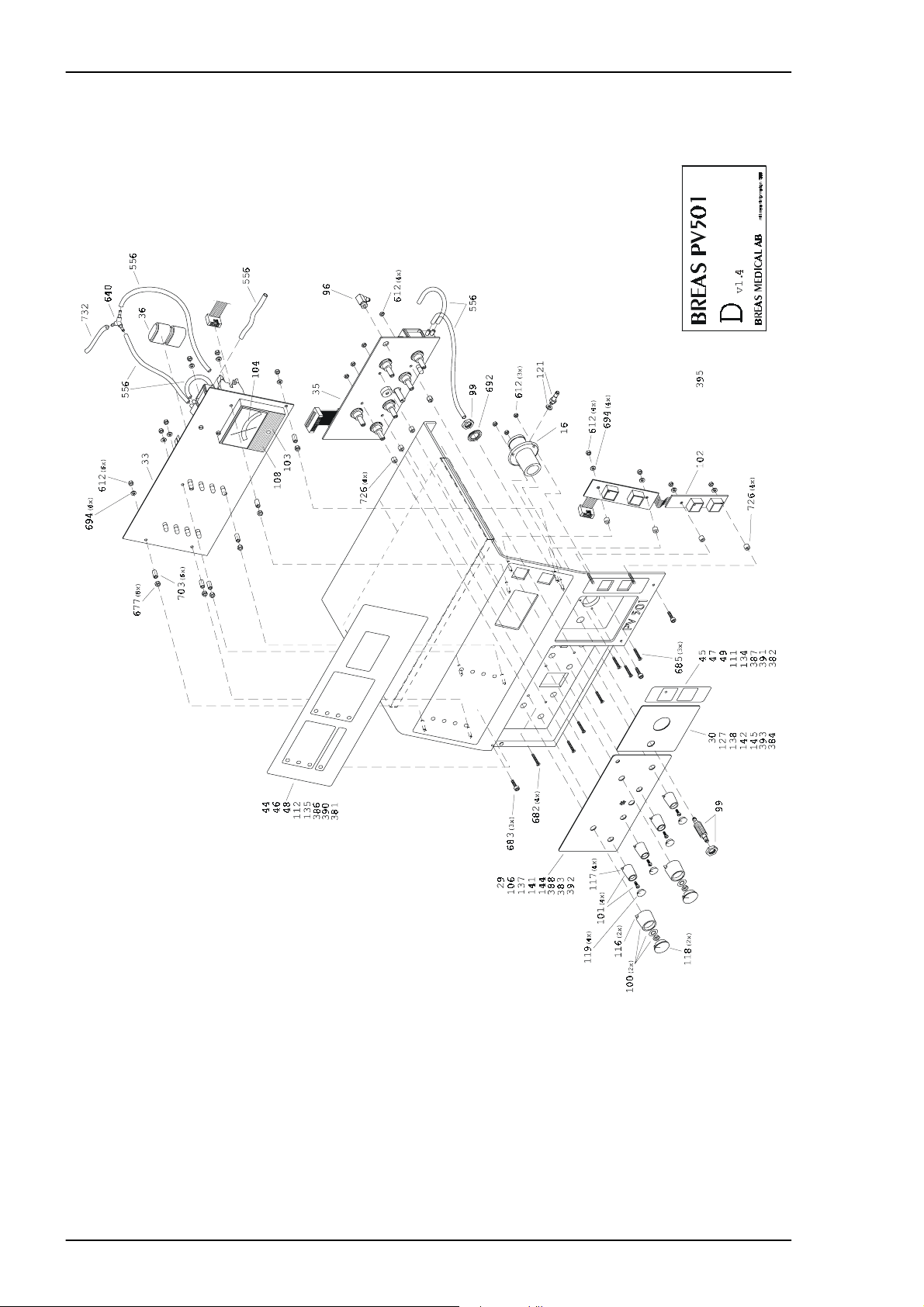

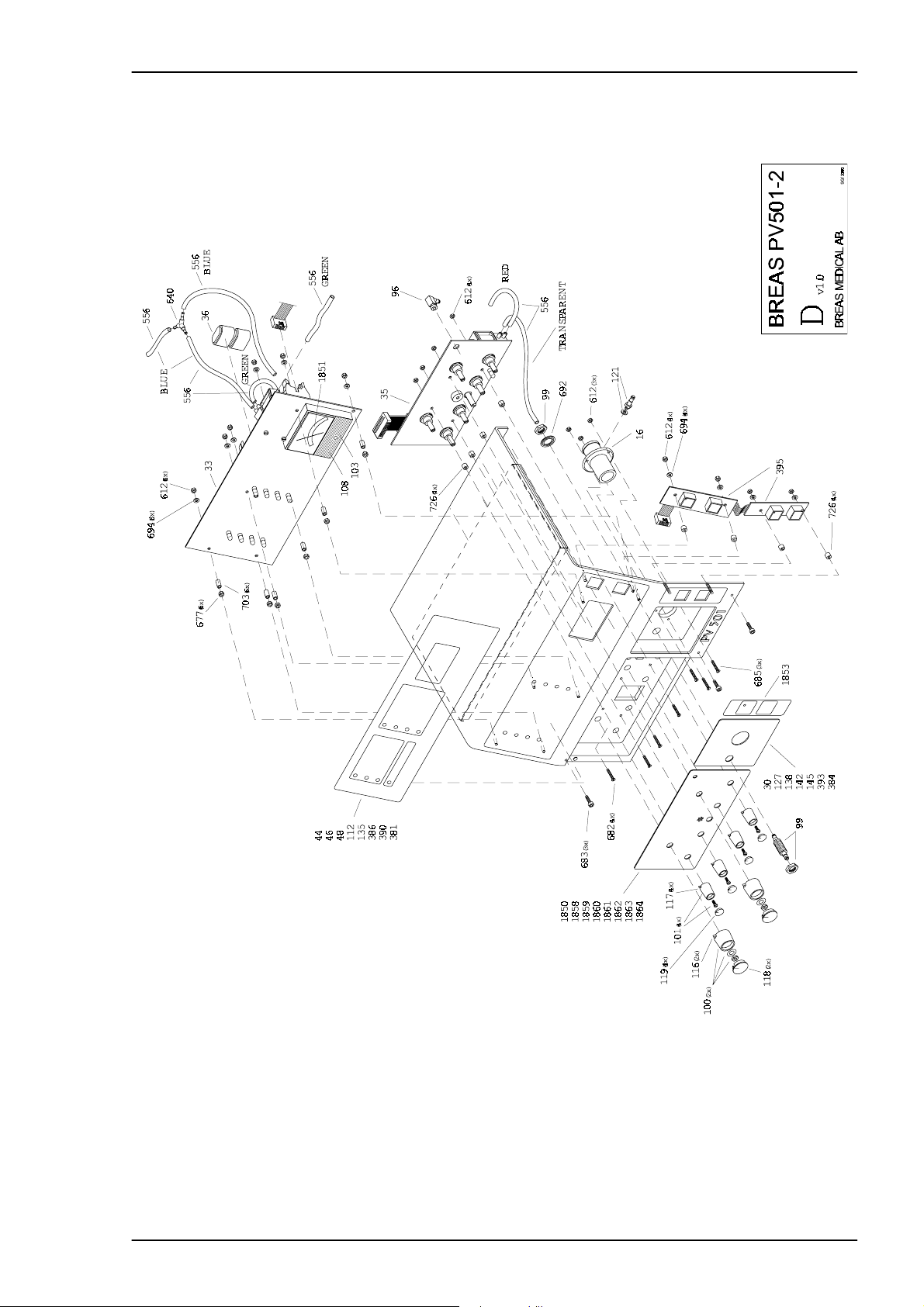

4 REPLACEMENT PARTS .......................................................................................... 1

4.1 OVERVIEW DIAGRAM ............................................................................... 1

4.2 Exploded drawing, Base Plate Assembly PV 501 ....................................... 2

4.3 Exploded drawing, Base Plate Assembly PV 501-2 .................................... 3

4.4 Exploded drawing, Motor Unit Assembly PV 501........................................ 4

4.5 Exploded drawing, Motor Unit Assembly PV 501-2 ..................................... 5

4.6 Exploded drawing, Rear Panel Assembly PV 501 ...................................... 6

4.7 Exploded drawing, Rear Panel Assembly PV 501-2 ................................... 7

4.8 Exploded drawing, Hood Assembly 501 ...................................................... 8

4.9 Exploded drawing, Hood Assembly 501-2 .................................................. 9

4.10 Part Number List ....................................................................................... 10

5 FUNCTIONAL DIAGRAMS ....................................................................................... 1

5.1 Pneumatic diagram ..................................................................................... 1

5.2 Functional block diagram ............................................................................ 2

6 DISMANTLING AND ASSEMBLING THE PV 501/PV501-2 ..................................... 1

6.1 Opening the hood ........................................................................................ 1

6.2 Replacing pushbutton boards ...................................................................... 2

6.3 Replacing the CPU board ............................................................................ 3

6.4 Replacing the potentiometer board ............................................................. 4

6.5 Opening the rear panel................................................................................ 5

6.6 Replacing the MDA board ........................................................................... 5

6.7 Removing the motor unit ............................................................................. 6

6.8 Reassembling the motor unit ....................................................................... 7

6.9 Assembling the hood and rear panel ........................................................... 7

7 MOTOR UNIT ............................................................................................................ 1

7.1 Construction ................................................................................................ 1

7.2 Lubricating the ball screw ............................................................................ 2

7.3 Replacing the membranes in the check valves ........................................... 3

7.4 Hoses and bellows, leakage check ............................................................. 3

7.5 Wiring diagram, Motor unit .......................................................................... 4

8 ELECTRONICS ......................................................................................................... 1

8.1 Function, Construction ................................................................................ 1

8.2 PV 501/PV 501-2's circuit boards ................................................................ 2

8.3 Pushbutton board ........................................................................................ 3

8.4 Potentiometer board .................................................................................... 3

8.5 MDA board .................................................................................................. 4

8.5.1 Checking the pressure transducer offset and gain ..................... 5

8.5.2 Checking the instrument accuracy .............................................. 5

8.6 CPU board ................................................................................................... 6

8.7 Terminal diagram, test points ....................................................................... 7

8.8 Measuring points on the motor unit ........................................................... 10

1 – 1 BREAS MEDICAL Doc. No.: 1523EN Issue:N-1

Service Manual PV 501/501-2

8.9 Internal Battery test ................................................................................... 11

8.10 Replacing the internal power batteries (lead acid cells) ............................ 11

8.11 Replacing the alarm batteries (Ni-Cd) ....................................................... 12

8.12 Electrical safety ......................................................................................... 13

8.12.1 Mains ........................................................................................ 13

8.12.2 Isolation .................................................................................... 13

8.12.3 Leakage current ........................................................................ 13

8.12.4 Leakage current from the cabinet ............................................. 13

8.12.5 Patient leakage ......................................................................... 13

8.12.6 Leakage current at mains voltage at patient connected part .... 13

8.13 Wiring Diagrams PV 501/501-2 ................................................................. 14

8.14 Functional block diagram PV6 T1 ............................................................. 30

8.15 COMPONENT LOCATION DRAWINGS PV 501 ...................................... 31

8.15.1 Pushbutton Boards PV 501, Versions B & E ............................ 31

8.15.2 Potentiometer Board PV 501 ................................................... 31

8.15.3 CPU Boards PV 501, Version B & E ......................................... 32

8.15.4 MDA Boards PV 501 ................................................................. 33

8.16 COMPONENT LOCATION DRAWINGS PV 501-2 ................................... 35

8.16.1 Pushbutton Boards PV 501-2 ................................................... 35

8.16.2 Potentiometer Board PV 501-2 ................................................. 36

8.16.3 CPU Boards PV 501-2 .............................................................. 37

8.16.4 MDA Boards PV 501-2 XA ........................................................ 38

8.17 List of components PV 501 ....................................................................... 39

8.18 List of components PV 501-2, Rev. XD ..................................................... 44

9 FAULT TRACING...................................................................................................... 1

9.1 Fault tracing guide ....................................................................................... 1

9.2 Error codes .................................................................................................. 3

9.3 Recalling error codes .................................................................................. 3

9.4 Erasing the error code memory ................................................................... 3

9.5 ERROR CODE TABLE................................................................................ 4

9.6 Fault tracing using the error codes .............................................................. 5

10 ENGINEERING CHANGE HISTORY PV501 AND PV501-2 .................................... 1

10.1 Service record for BREAS PV501/PV501-2

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 1 – 2

Service Manual PV 501/501-2 INTRODUCTION

1 INTRODUCTION

1.1 The scope of this manual

This manual provides information for the maintenance and service of both the PV 501

and PV 501-2 ventilators. The PV 501-2 is a further development of the PV 501. The

main differences are that the PV 501-2 delivers a maximum patient pressure of 60 mbar

(compared to the PV 501’s 50 mbar) and that theTrigger setting is adjustable between -

-2 to 6 mbar (compared to the PV 501’s -4 to 6 mbar).

The PV 501and PV 501-2 are designed to give many years of trouble-free breathing

assistance to the user provided that preventative maintenance is done at the specified

intervals described in this manual. Correctly performed maintenance will increase the

ventilator's service life considerably.

All points to be checked and service instructions for the PV 501 and the PV 501-2 are

described in this manual. Where information is only relevant to one of the models it is

clearly marked which model the text/figure refers to, otherwise all information is valid for

both models.

It is also important that any peripheral equipment is checked at the same time as the

maintenance service is done.

Also included is a reference copy of the Operation Manual.

1.2 Intended use of the ventilator

PV 501 and the PV 501-2 are volume-controlled, pressure-limited ventilators, specially

designed for long term ventilator assistance at home.

The internal batteries are connected automatically should the mains supply fail or is disconnected. Fully-charged batteries will give a running time of 4 hours.

Thanks to its design, the PV 501 and the PV 501-2 are easy to operate. It does not

require any gas, and together with its low weight, it is ideal for breathing therapy both in

hospital and while travelling.

The PV 501and the PV 501-2 are not intended for intensive care and are aimed for

adults and children weighing about 30 kg or more.

1.3 Design and function of the ventilator

The PV 501and the PV 501-2 are built around a bellows that is compressed and drawn

out by a ball screw driven by an electronically controlled servo motor. The micro-processor controlled electronics calculate the correct speed and running time for the motor by

reading the settings for tidal volume, frequency and the I/E-relationship. The setting limits for pressures and the trigger level are monitored. If the mains supply or the external

battery supply should fail during operation, the internal batteries are automatically connected and an indication of this is given on the front panel. If the battery supply voltage

drops too low, both audible and visual alarms are given. The ventilator's modular design

makes maintenance easy.

1.4 Intended audience

This Service Manual is intended for technicians who have medical/technical training and

knowledge about the construction and function of the ventilator.

It is not intended for clinic personnel or patients.

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 1 – 1

INTRODUCTION Service Manual PV 501/501-2

Breas Medical reserves the right to make changes to the product and the contents of

this manual without prior notice.

1.5 Service personnel's training requirements

Thanks to their simple construction using a modular system, no special competence is

required other than general medical technical training on ventilators.

Always contact BREAS MEDICAL if there are any questions or if training is required.

All service must, however, be performed according to the instructions in this manual.

1 – 2 BREAS MEDICAL Doc. No.: 1523EN Issue:N-1

Service Manual PV 501/501-2 MAINTENANCE SERVICE INSTRUCTIONS

3 MAINTENANCE SERVICE INSTRUCTIONS

All routine maintenance checks and additional se rvice instructions for the PV

501and PV 501-2 are described in this chapter. For information about fault-tracing, detailed drawings, board schematics, spare parts etc, please refer to the

respective chapters in this Service Manual.

The checks described in the Patient Instruction delivered with the ventilator

should be followed by the patient and/or care provi ders.

3.1 Verifying the components and software installed

Check the Engineering Change History document in the Appendices section

(Chapter 10) for a history of all the changes made and at which serial No they

were introduced.

If in any doubt, read the component designation on the motor unit, circuit boards

and PROMs as upgrades can have been made but not recorded.

3.2 Maintenance Service Schedule

IMPORTANT!

A complete maintenance service (as described in this chapter) must be done

every 12th month. If the ventilator is used for continuous operation (24 hours

per day) a complete maintenance service must be done every 6th month.

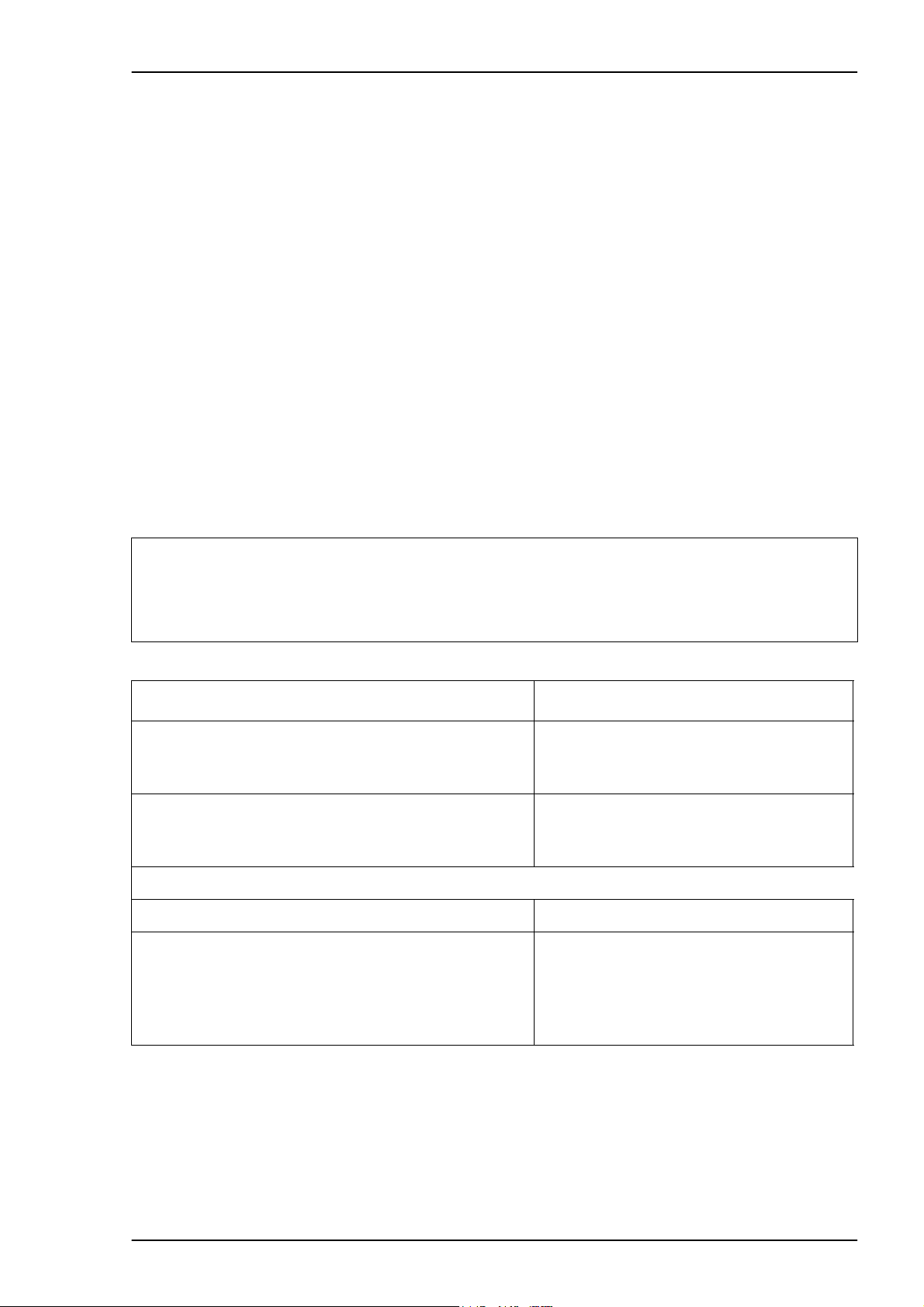

Interval Action

At every 500th operation hour or more frequent if

necessary (especially in town environments).

Every 6 months if the ventilator is used for continuous operation i.e. 24 hours per day, otherwise

every 12th month.

Additional service action (when required)

At 20.000 running hours Replace motor unit and hoses.

The internal batteries should be replaced every 24

months.

• Replace the alarm batteries every 5th year

counted from date of delivery or when

required.

Replace the patient air inlet filter.

Done by the patient/care provider.

Replace during maintenance service.

Complete maintenance service according to this instruction.

Replace the internal batteries

Replace the alarm batteries.

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 3 – 1

MAINTENANCE SERVICE INSTRUCTIONS Service Manual PV 501/501-2

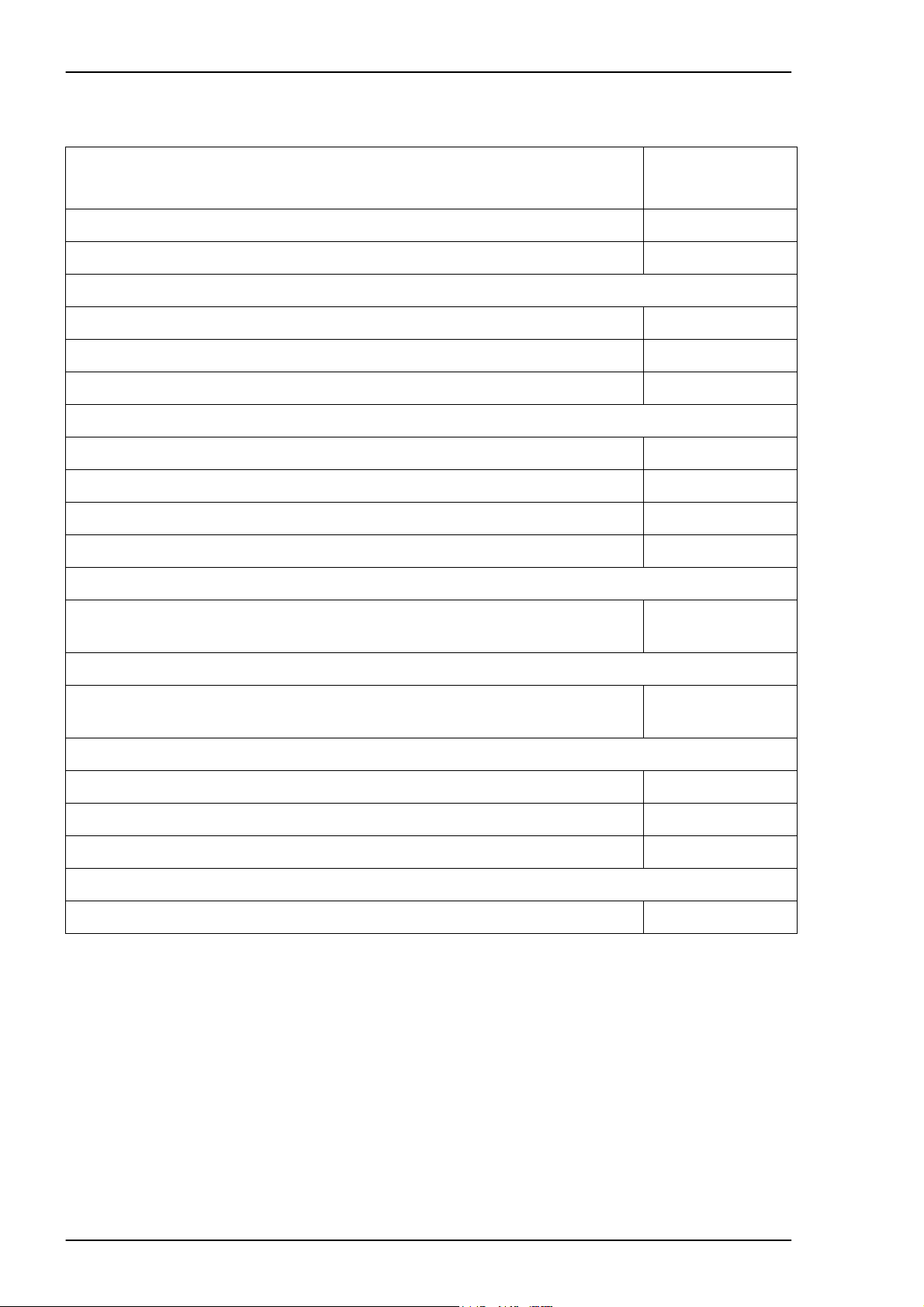

Every 12th month or every 6th month if the ventilator is used

for continuous operation (24 hours per day)

Replace the patient air inlet filter. 2

Clean the ventilator air intake filter 2

Motor Unit

Lubricate the ball screw 7.2

Replace the check valve membranes in bellows end cover 7.3

Leakage test of motor unit and tubes 7.4

Electronics

Checking the pressure sensor offset and gain. 8.5.1

Check operation using internal battery 8.9

Check operation using external battery 2

Check electrical safety levels 8.13

Internal Batteries (lead-ac id)

The internal batteries should be replaced every 24 months or when necessary.

Section No.

8.10

See Ch./

Alarm Batteries

Replace every 5th year counted from date of delivery or when last

replaced.

Accessories (where applicable)

Inspect patient circuit 2

Replace membrane in exhalation valve 2

Clean PEEP adapter, replace O-ring 2

Every 20000 operation hours

Replace the complete Motor unit 6.6

3.3 Special safety precautions

• Avoid working with the mains c onnect ed when the casi ng is r emoved. Always tes t

run using internal battery power.

• Insulate the wires for the inter nal batte ri es when they are di sconne cted to prev ent

short circuits.

• Explosive gases or liquids must not be kept or used close to the ventilator.

8.11

• Always follow good ESD practices when working with the ventilator.

3 – 2 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 MAINTENANCE SERVICE INSTRUCTIONS

3.4 Equipment required

• Test lung (1L) with exhalation valve.

• Measuring equipment for tidal vol ume and minut e volume/frequency. (Timeter,

Spirometeor or equivalent).

• Voltmeter.

3.5 Replacement parts required

Have the following spare parts at hand:

Part No.

000 139 Internal battery (lead)

000 036 Alarm battery (Ni-Cd)

001 141 Motor unit, BEI

000 557 Grease (BREAS 283 AZ)

000 004 Motor unit, Maxon

000 248 Filter, patient air

002 123 Service kit, check valves

002 178 Membrane kit, exhalation valve

Description

3.6 Maintenance instructions

3.6.1 Registration

• Fill out the registration part of the Service Record. Check that the following markings can be read:

• Make, model designation and serial number.

• All warning texts on labels.

• Any inventory control markings.

• Document the current patient settings.

• Note the number of running hours. Does the motor unit need to be replaced?

• Check any comments or events made on the previous service record.

3.6.2 Information from the user

• Before starting the service request the following information from the patient:

• Has the ventilator functioned problem-free, such as running failure?

• How does the patient check the function of the ventilator? How often?

• How often is the filter changed?

• What is the patient's need of filters unt il the next service point?

3.6.3 Validity of documentation

• Check that the patient instructions are up-to-date.

• Check if any modification or update of the ventilator is to be performed during the

service.

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 3 – 3

MAINTENANCE SERVICE INSTRUCTIONS Service Manual PV 501/501-2

3.7 External checks

3.7.1 External damage and wear

• Clean the surface with a mild detergent.

• Clean the filter for the machine ventila tor air inlet. Use a vacuum cleaner or wash

and dry the filter before fitting.

• Check that there is no visible damage on the surfaces and other components.

• Check that all texts for controls etc. are readable.

• Turn all knobs and check that their operation feels OK.

• Check that nothing is loose, (including the handles).

• Check that the cover for the adjustment panel is secu red properly.

3.7.2 Power cables and plugs

• Check the power cable and its plugs, and the power socket in the rear panel.

• Check that the cable securing clamp is undamaged.

• Check other external battery cables, where applicable.

3.7.3 Minimum function check

• Connect the ventilator to the mains and check that the LED for Mains/Charging is

lit.

• Start the ventilator and check that it oper ates normally and no abnormal noise is

heard. Check that the lighting for the press u re gauge is on.

• Check the condition of the internal batteries. They should, when fully charged, be

able to run the PV 501 for at least 2 hours. If not they must be replaced.

3.8 Internal Checks

3.8.1 Open hood and rear panel

• Remove the mains power cable.

• Open the hood and rear panel. Remove stabiliser bar, see chapter 6.

3.8.2 Cleaning

• Remove any dirt or dust that has collected in the ventil ator, also from the folds in

the bellows.

3.8.3 Cables and connectors

• Check all cables and thei r connectors for an y damage. Check at the fr ont and rear

panels where cables can be pinched.

3.8.4 Component fastening

• Check that the batteries are properly fastened.

• Check that the motor unit is properly fastened.

• Check that all parts on the front and rear panels are properly fastened.

3 – 4 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 MAINTENANCE SERVICE INSTRUCTIONS

3.8.5 Mains supply

• Check that the power inlet socket is undamaged and that it is properly fastened.

• Check that the touch protection cover is undamaged and that it is properly fastened over the power inlet socket.

• Check that the transformer is properly fastened.

• Check the wiring to the transformer.

3.8.6 Remove and check / replace the motor unit.

The motor unit must be checked at each service. At 20.000 running hours the

entire motor unit assembly must be replaced. See Chapter 6 for removing the

motor unit.

Checking the motor unit

• Check that the motor is properly fastened.

• Check that the shaft coupling screws are properly tightened.

• Check that the encoders are undamaged and properly fastened.

3.8.7 Grease the ball screw

Use only BREAS grease type 283 AZ. See chapter 7.

3.8.8 Replace the membranes in the check valves

• The membranes must be changed at each maintenance service. See chapter 7.

3.8.9 Leakage check of hoses and bellows

• Check the function of the outlet check valves. See chapter 7.

3.8.10 Reassemble the motor unit

Before reassembling the motor unit, check if the internal batteries need to be

replaced as this is best done with the motor unit removed, see 3.8.6.

• Reassemble the motor unit. See Chapter 6.

3.8.11 Checking the offset and gain of the pressure transducer

• See Chapter 8, Section 8.5.1 for detail ed inf o rmation.

3.8.12 Checking the instrument accuracy

• Check using a manometer conne cted to the exh. valve connec tion t hat the i ndic ating instrument gives the correct indicati on and that the needle moves "softly".

See Chapter 8, Section 8.5.1.1.

NOTE! Make small pressure changes, the indicating instrument should be

"slower" compared with the manometer.

3.8.13 Internal battery test

The internal batteries should be fully charged or charged for at l east 12 hours with

the ventilator turned off before this test is carried out. The batteries, when fully

charged, should operate the PV 501 for at least 2 hours, if not t he batteries must

be replaced. See Chapter 8, Section 10.

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 3 – 5

MAINTENANCE SERVICE INSTRUCTIONS Service Manual PV 501/501-2

3.8.14 Reassemble the casing

See Chapter 6 for information.

3.9 Electrical safety

Follow the instructions for the following checks in Chapter 8.

• Check mains supply value

• Check isolation against the value obtained at the delivery inspection

• Check leakage current. Do not forget to reverse the polarity.

• Check patient leakage current.

• Leakage current at mains voltage at patient connected part

3.10 Final checks before delivery

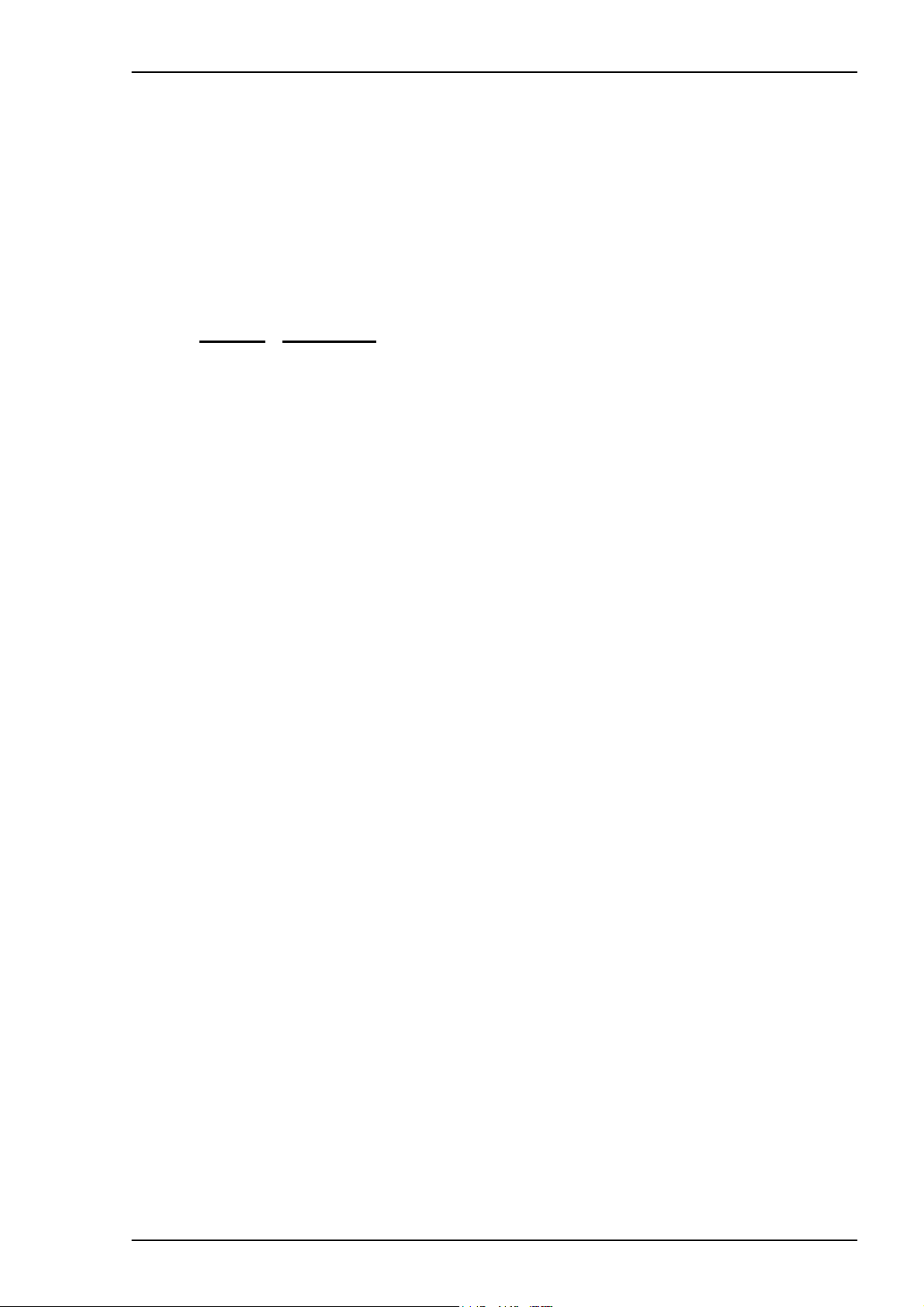

3.10.1 Function check/leakage

• Start the ventilator with the pat ient circuit and reservoir bag connected as shown

in the figure below. Check that everything seems normal. Create a pressure of

approximately 30 cm H

0 and listen for any leakage.

2

3.10.2 Check the tidal volume/frequency

Set: Tidal vol ume: 1L

Frequency: 12

I/E: 1:2

• Measure the tidal volume and that the volume per minute is cor rect.

(Accuracy ± 10%).

When checking using a volume monitor, an exhalation valve with a peep valve

connector can be required. The volume monitor is then connected to the peep

valve outlet on the exhalation valve.

LOW PRESSURE

HIGH PRESSURE

LOW BATTERY

FUNCTION FAIL URE

TIDAL VOLUME

Litre

Setting error

Setting error

Setting errorSetting error

PATIENT PRESSUREALARMS

Peep valve connector

EXHALATION

VALVE

BPM

BPMcm HO

BPMBPM

POWER

PATIEN T

AIR

ON

OFF

LOW PRESSURE

cm HO

cm HOcm HO

POWER

AC/CHARGING

EXTERNAL BATTERY

INTERNAL BATTERY

TRIGGER

Off

Off

OffOff

TRIGGER

cm HO

2

HIGH PRESSURE

2222

Signal

Signal

SignalSignal

I/E BREATH RATE

cm HO

cm HO

Ratio

Ratio

cm HOcm HO

RatioRatio

2222

mbar

Volume monitor

Test lung / Reservoir bag

Fig. 3-1 Tidal volume check

3 – 6 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 MAINTENANCE SERVICE INSTRUCTIONS

3.10.3 Calculating the tidal volume/patient pressure

The tidal volume delivered is always slightly less than the tidal volume setting.

This difference is due to the effect of the patient pressure on the compliance of

the bellows.

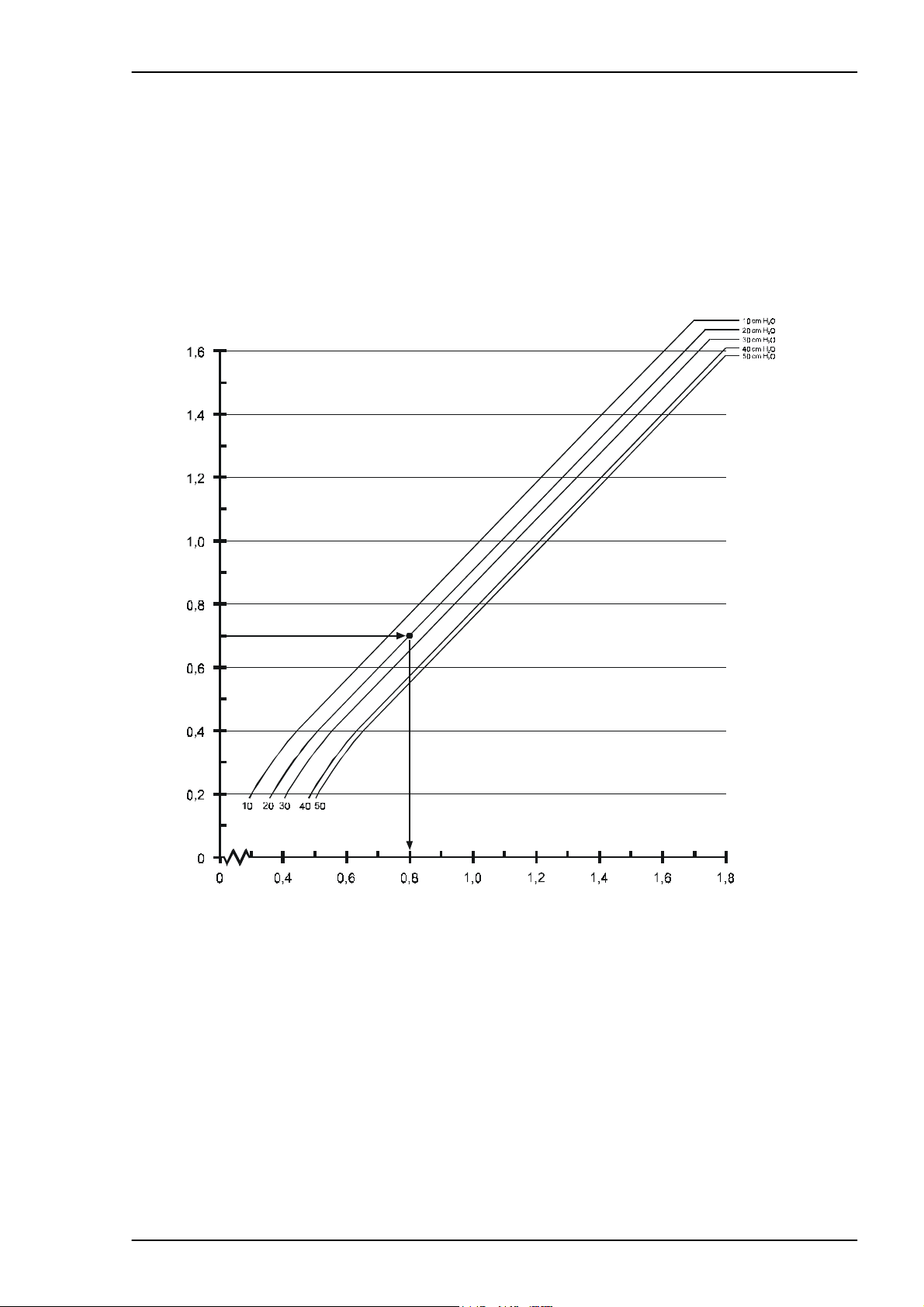

The diagram below shows these differences at different patient pressures.

Settings: I/E = 1:2, Breath rate = 15 breaths/min. with the patient circuit con-

nected.

Set volume/l itr e s

Fig. 3-2 Volume/Patient pressure diagramme

Example:

A patient needs a tidal volume of 0,7 litres and has an airway pressure of 20 cm

O. Start from 0.7 on the axis for “ Delivered volume”. Draw a horizont al line unti l

H

2

it crosses the line for 20 cm H

O patient pressure. From this point, go straight

2

down and read off the value the tidal vol ume setti ng should be. In this case the

ventilator setting is 0.8 litres.

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 3 – 7

MAINTENANCE SERVICE INSTRUCTIONS Service Manual PV 501/501-2

1

3.10.4 Checking the pressure limit

Set: Low pressure 10 cmH2O

High pressure 40 cmH

• Check the accuracy (±10%). Check that LED indicati on is given as well as an

audible alarm.

• Also check that the solenoid valve for high pressure "clicks". You can clearly hear

the solenoid valve activate at the following inhalation.

O

2

3.10.5 Checking low pressure alarm/alarm mute

• Turn the vent ilator on without anything connected to the patient air outlet. Wait 15

sec until the alarm for "Low pressure" is activated. Press the alarm mute button

and check that the alarm is heard again after approx. 2 min.

3.10.6 Trigger

• Set the trigger knob to -1 c m H20. Create a negative pressure an d check that ther e

is a triggered inhalation. The green LED should light.

3.10.7 Battery operation

• Disconnect the mains cable while the ventilat or is running. Check that the ventilator automatically changes over to internal battery and an alarm is given.

• Reconnect the mains power and check that indication "MAINS" comes on.

3.10.8 Checking accessories Patient circuit

• Inspect the patient circuit and replace it if necessary.

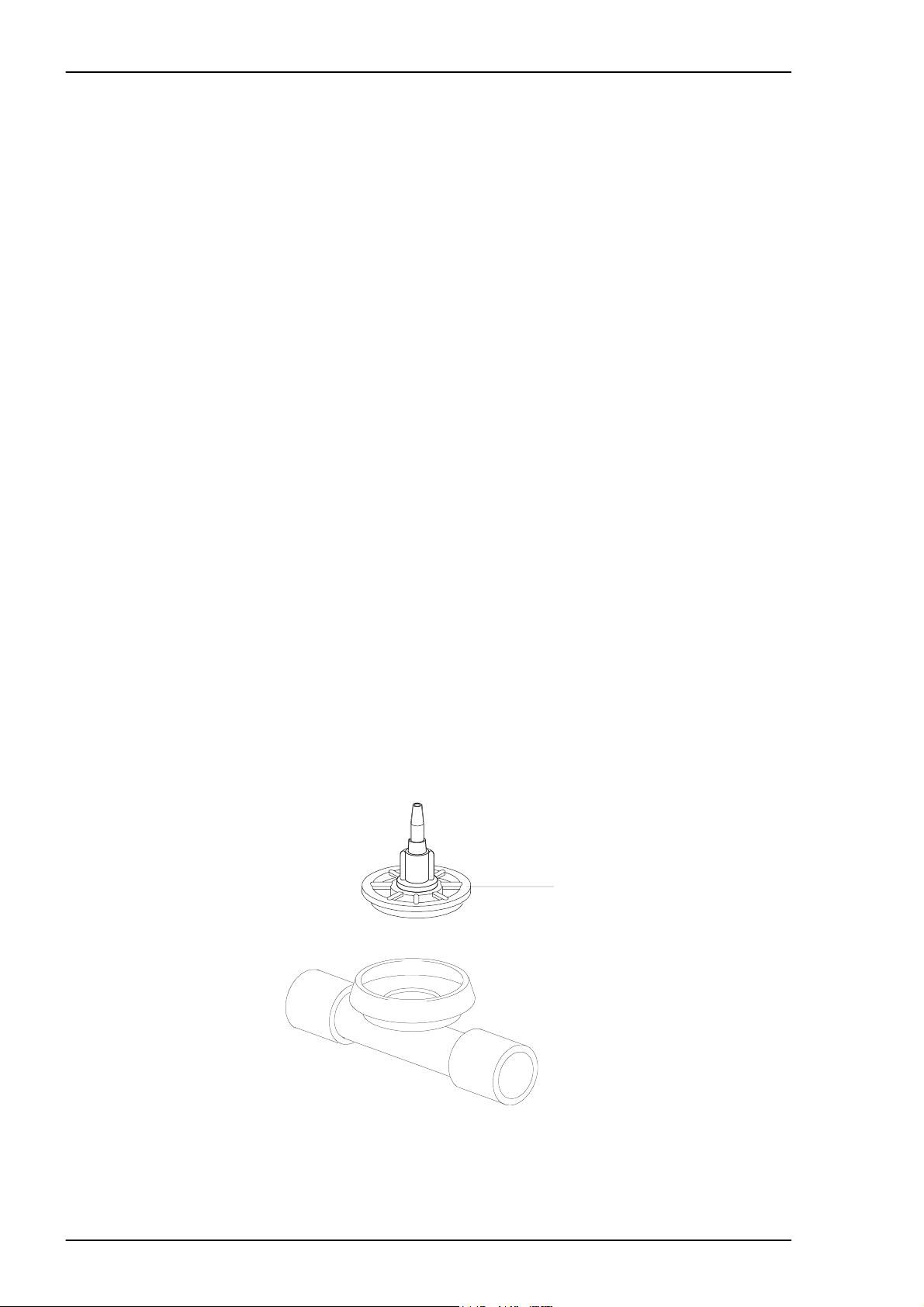

Replacing the membrane assembly in the exhalation valve

This instruction applies to BREAS exhalation valves, see figure below.

Fig. 3-3 Mounting the exhalation valve

• Remove the PEEP adapter , if installed. See "Cleaning the PEEP adapter".

3 – 8 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 MAINTENANCE SERVICE INSTRUCTIONS

• Unscrew and remove the complete membrane assembly (1).

• Clean the inside of the exhalation valve using a moist rag or wash in hot water

using a washing-up liquid. Let it air dry.

• Screw on the new membrane assembly

• If a PEEP valve is to be used, fit the O-ring seal for the PEEP valve as shown in

fig. 3-5.

• Connect the exhalation valve to a test lung. Check that no leakage occurs during

the exhalation phase.

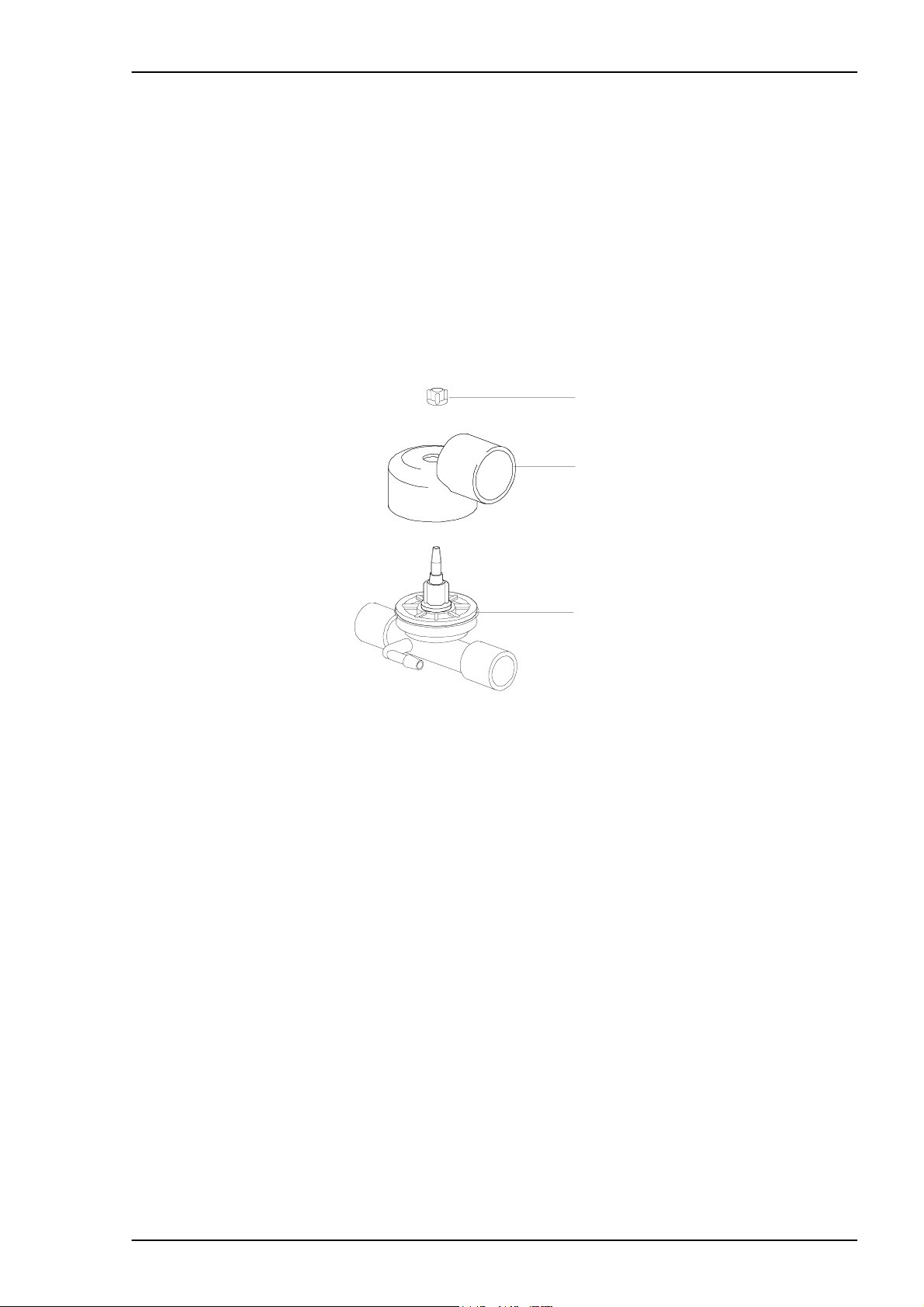

3.10.9 Cleaning the PEEP adapter

1

2

3

Fig. 3-4 Mounting the exhalation valve with PEEP adapter

• Remove the plastic nut (1) holding the PEEP adapter.

• Pull the adapter (2) up from the exhalation valve.

• Clean using a moist rag or wash in hot water using a washing-up l iqui d. Let the

adapter air dry.

• Check that the O-ring seal (3) is properly in place on the exhalation valve (under

the edge of the membrane assembly cover as shown in the figure below).

Note! Do not fit the O-r ing to the membrane assembly before screwing it on.

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 3 – 9

MAINTENANCE SERVICE INSTRUCTIONS Service Manual PV 501/501-2

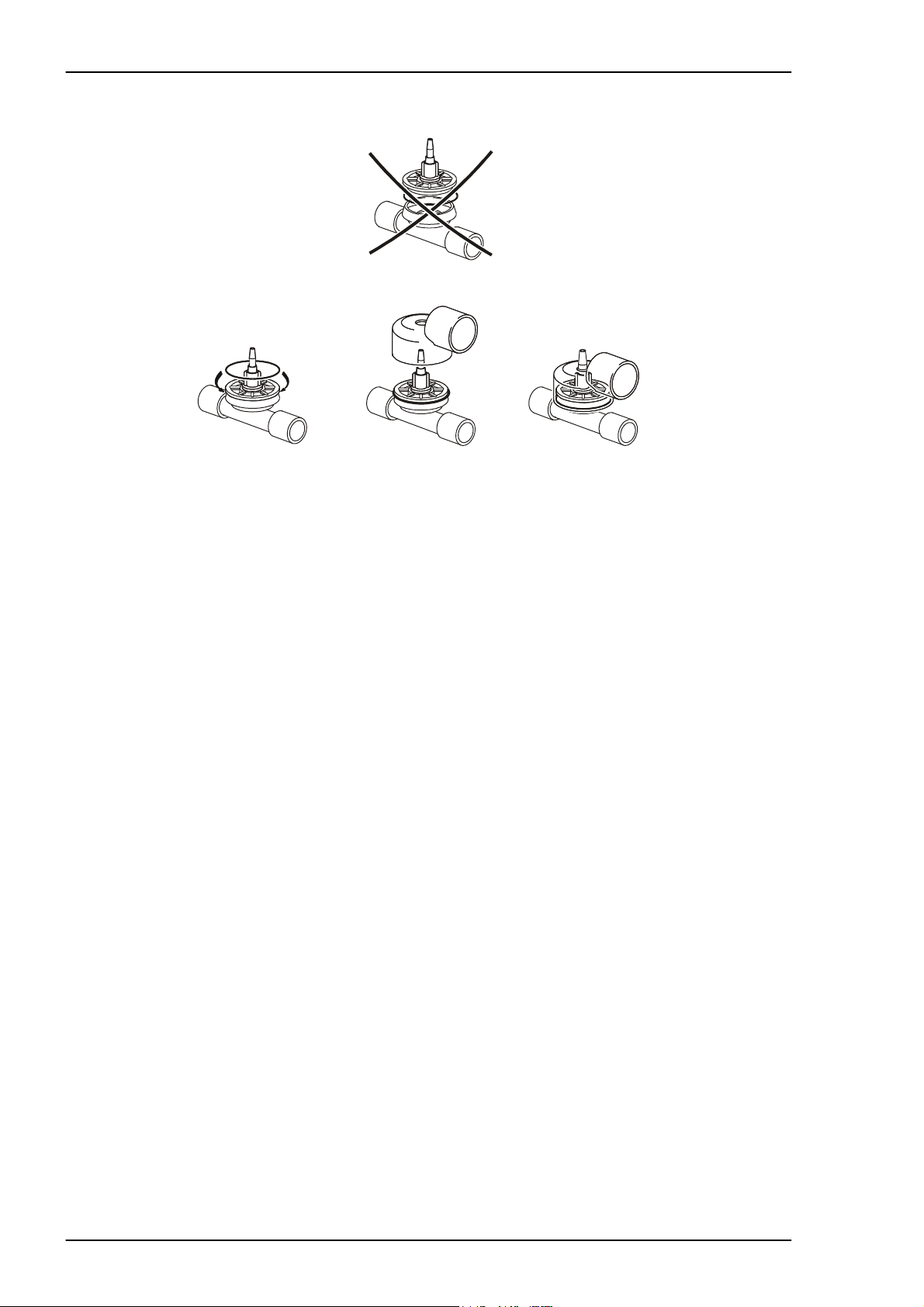

Fig. 3-5 Mounting the O-ring for the PEEP adapter

• Fit the PEEP adapter to the exhalation valve and screw on the plastic nut

• Check any other accessories.

3.10.10Set the correct values for the patient

• Adjust the settings to the prescribed values for the patient.

• Change the air filter. Check that the patient has enough filters to last until the next

service.

The patient settings should be checked by a physician at least once a year.

3 – 10 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

4 REPLACEMENT PARTS

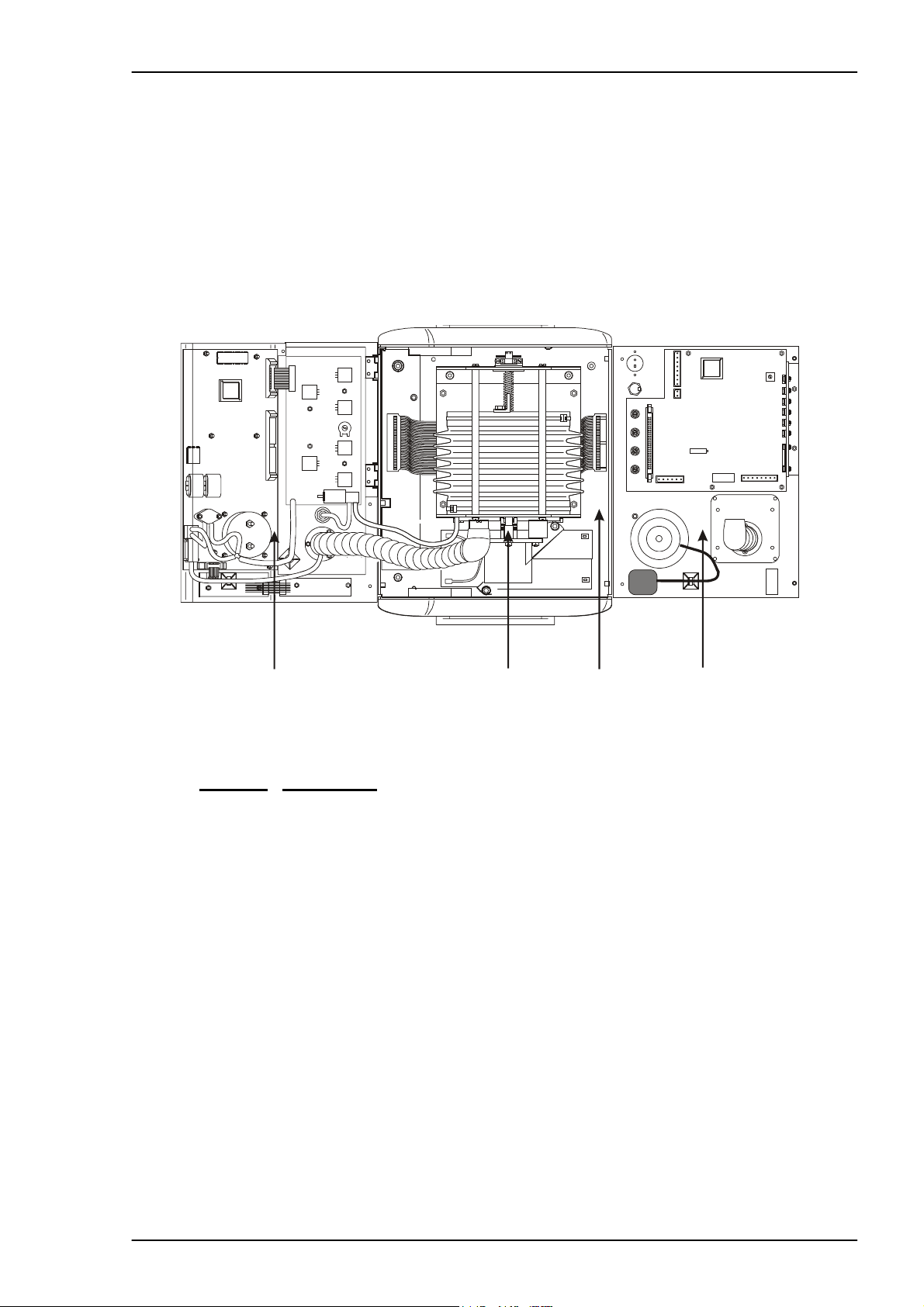

4.1 OV ERVIEW DIAGRAM

The illustration belo w shows the PV501/PV501-2, seen f rom above, with the ho od

and rear panel unscrewed and laid flat against the work surface.

The figure below shows the main units making up the PV501/PV501-2. The following pages contain detailed exploded drawings for each of the main units and

model. Last in this chapter is a complete list of part numbers.

1

Pos. No.

1 Hood assembly

2 Motor unit

3 Base plate assembly

4 Rear panel assembly

Component

2

3

4

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 1

REPLACEMENT PARTS Service Manual PV 501/501-2

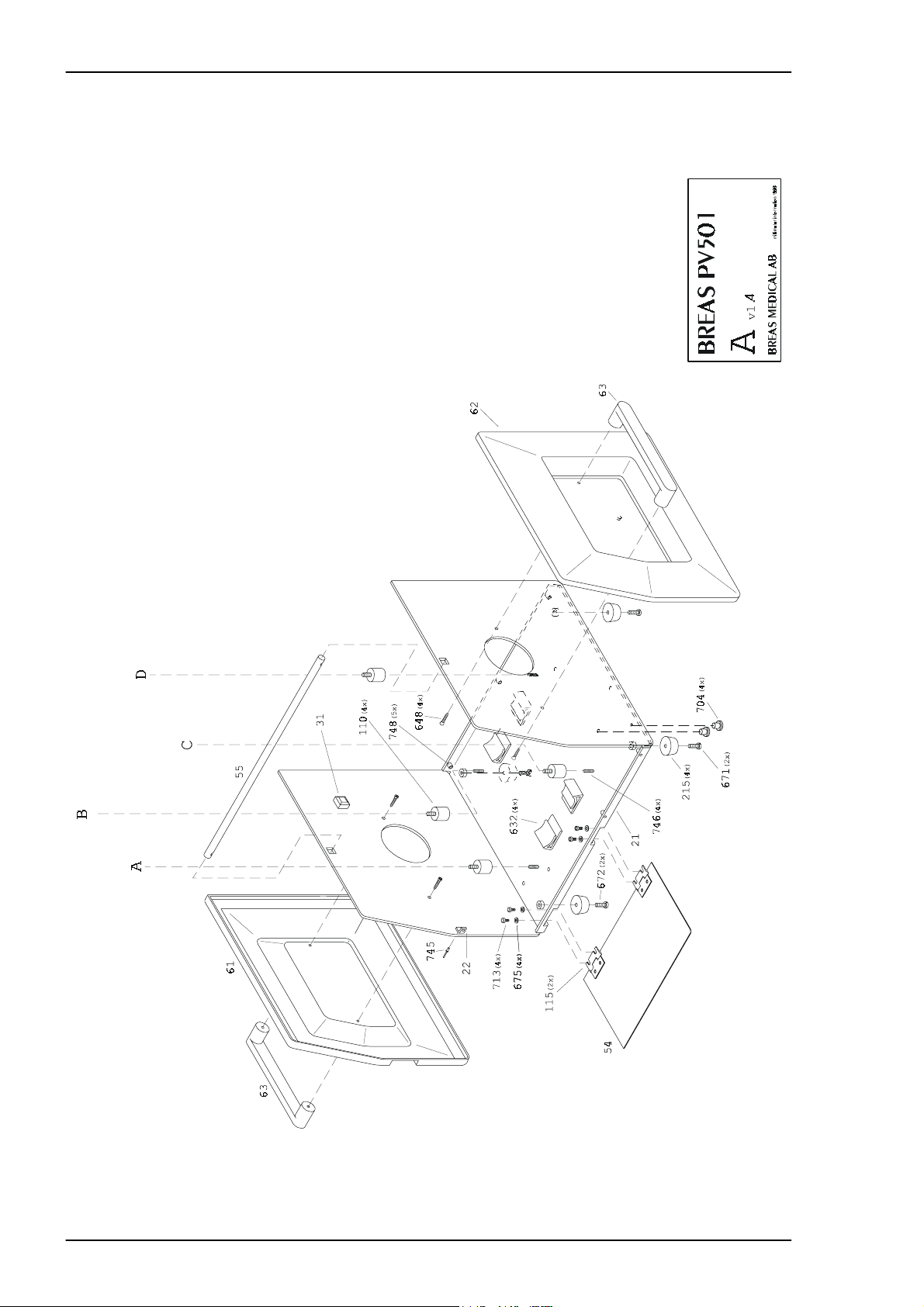

4.2 Exploded drawing, Base Plate Assembly PV 501

4 – 2 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

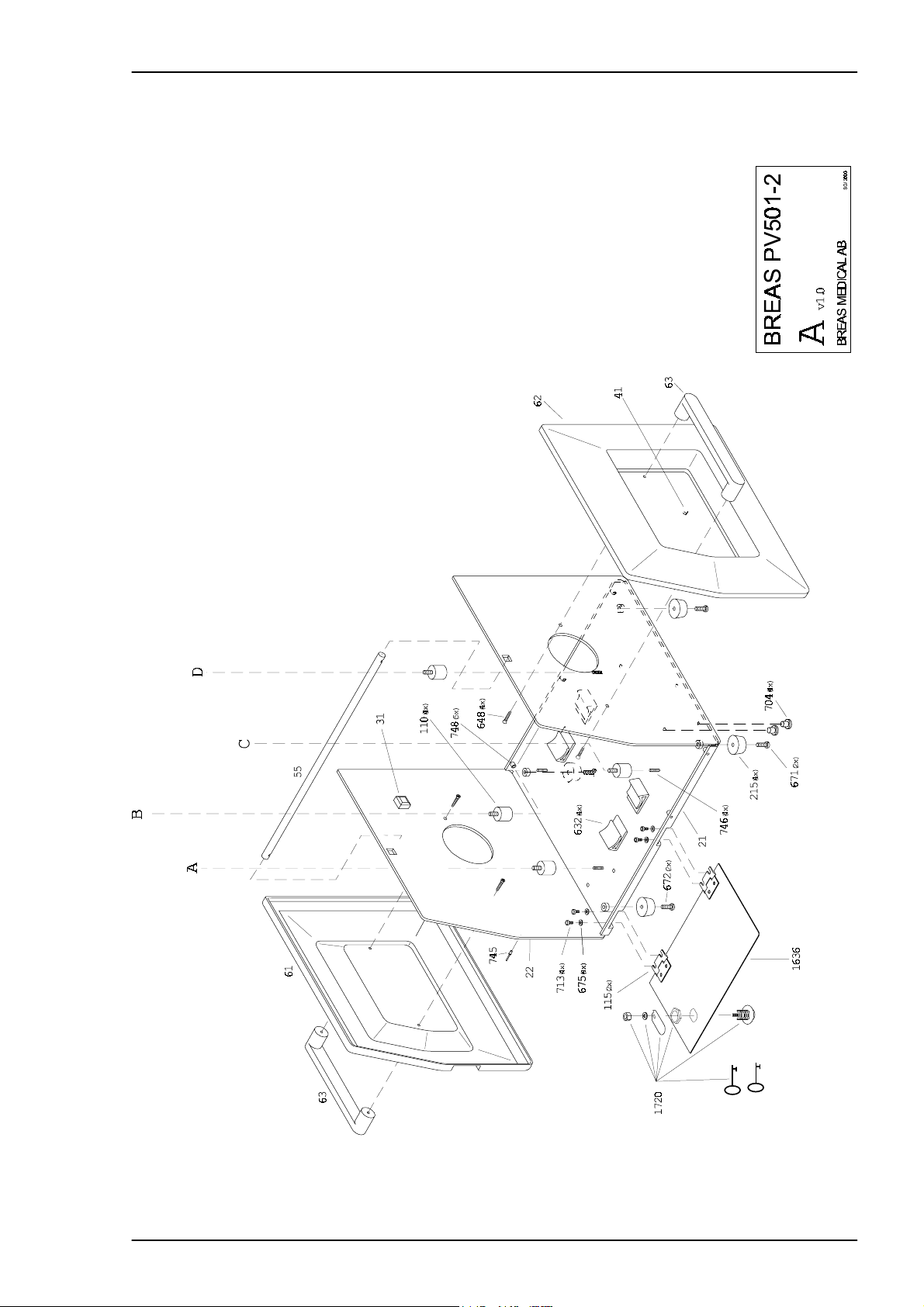

4.3 Exploded drawing, Base Plate Assembly PV 501-2

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 3

REPLACEMENT PARTS Service Manual PV 501/501-2

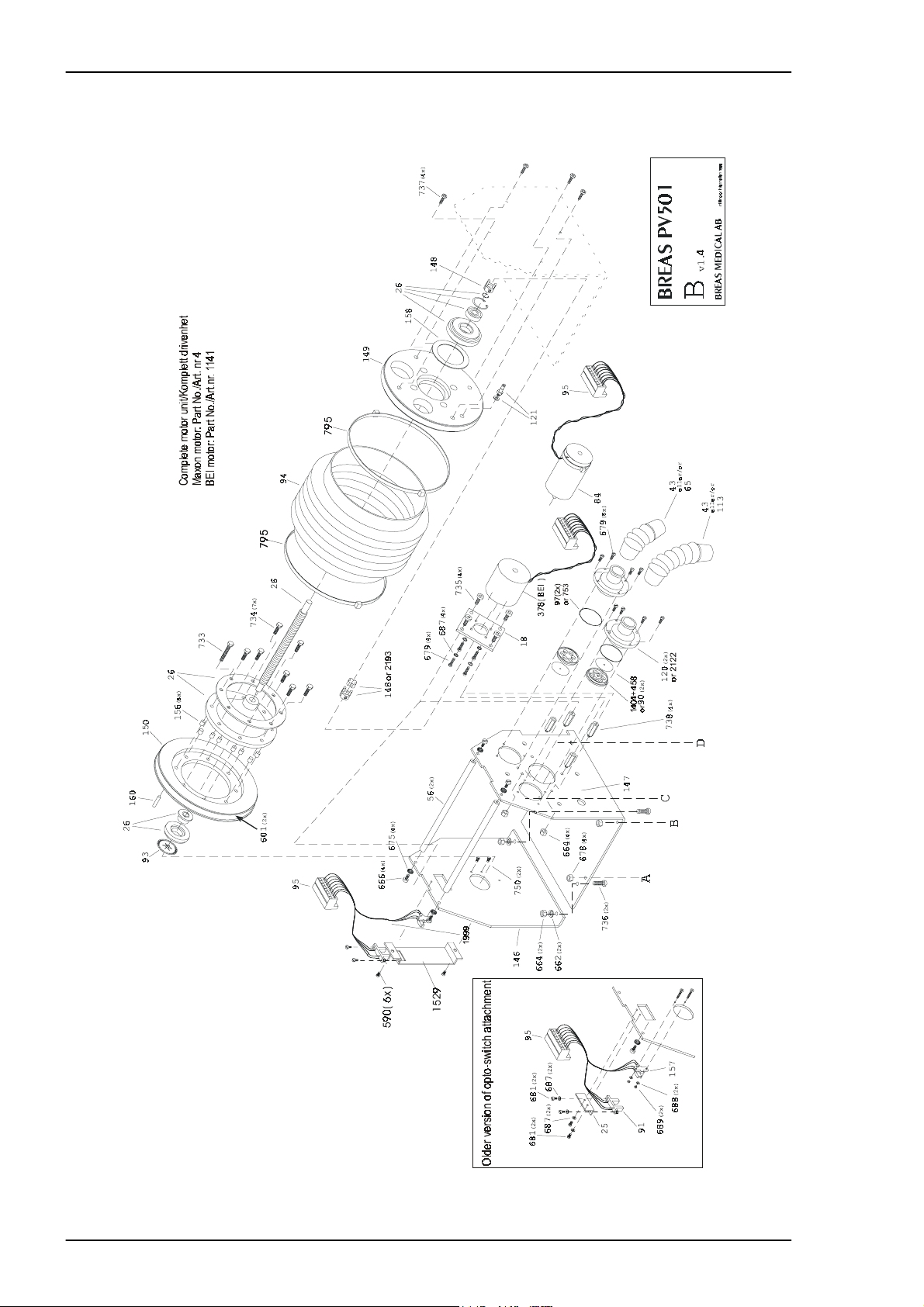

4.4 Exploded drawing, Motor Unit Assembly PV 501

4 – 4 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

4.5 Exploded drawing, Motor Unit Assembly PV 501-2

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 5

REPLACEMENT PARTS Service Manual PV 501/501-2

4.6 Exploded drawing, Rear Panel Assembly PV 501

4 – 6 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

4.7 Exploded drawing, Rear Panel Assembly PV 501-2

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 7

REPLACEMENT PARTS Service Manual PV 501/501-2

4.8 Exploded drawing, Hood Assembly 501

∂ρ#ελλερ

4 – 8 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

4.9 Exploded drawing, Hood Assembly 501-2

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 9

REPLACEMENT PARTS Service Manual PV 501/501-2

4.10 Part Number List

Part No. DescriptionNotes

2 Base plate, complete

4 Motor unit, Maxon - complete

5 Hood, complete, SE

6 Complete, Eng

7 Complete, Ger

8 Rear panel, complete, Eng

9 Rear panel, complete, Ger

10 Hood, complete, Eng

11 Hood, complete, Ger

12 Rear panel, blank

13 Potentiometer box

14 Magnet - potentiometer box

15 Air-hose connection - patient exhale

17 Side unit - motor bracket

18 Motor plate

19 Rear panel - Swedish text

20 Hood

21 Bottom plate

22 Angle bracket - front / hood

24 Cooler angle element

25 Angle bracket - reading prong (l imit position)

26 Ball screw - complete

27 Motor bracket

29 Panel - potentiometer panel Swedish text

30 Panel - patient air Swedish text

31 Rubber mount, shock absorbing (opto-switch)

32 Pressure sensor

33 Circuit board - CPU, PV501

34 Circuit board- MDA, PV501

35 Circuit board- potentiometer board

36 Battery Ni/Cd or Ni/Mh alarm back-up

44 Decal - "PATIENT PRESSURE"

45 Decal - "ON / OFF"

50 Cylomer - G12

51 Cable marking - plus

52 Cable marking - minus

53 Transf ormer - 115V

54 Opening - front

55 Cross bar

56 Spacing- motor bracket

57 Software

4 – 10 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

58 Battery - large 24 V lead

64 Hour counter - 24V

65 Flexible tube - inlet (2.5")

66 WAGO - 6-pole angled

67 WAGO - 2-pole angled

68 Reference pressure - valve

70 Reference pressure - reducer sleeve

71 Mains inlet

72 Touch protection

73 Air-filter box

74 Air-hose connection - inhale

75 Chassis pinning device XLR

76 Fuse holder

77 Screen guard - 60x60

78 Filter holder

79 Contact housing - black

80 Contact housing - red

82 Marking point - black

83 Marking point - red

84 Motor

85 Motor connection

86 Angle bracket- reading prong (column plate)

87 Air-hose connection - drive pack

88 Bellows side unit - fixed

89 Angle element - limit position (plastic)

90 Non-return valve

91 Opto switch - limit position

92 Opto switch - column plate

93 Column plate

94 Bellows

95 WAGO - 8-pole angled

96 Nipple - LCN-M5-PK3

97 O-ring - air-hose connection drive pack

98 Bellows side unit - moveable

99 Nipple - SCN-M10-PK4

100 Guide - large

101 Guide - small

102 Push-button board - on / off

103 Push-button board - battery test

104 Scale - graduated

105 O-ring - air-hose connection inlet

106 Panel - potentiometer panel English text

107 Ribbon cable

108 Instrument

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 11

REPLACEMENT PARTS Service Manual PV 501/501-2

109 Magnetic valve

110 Cyl, isolator

111 Decal - "ON / OFF"

112 Decal - "PATIENT PRESSURE"

113 Flexible tube - out (5")

114 Angle pipe - out

115 Pivot

116 Arrow - large guide

117 Arrow - small guide

118 Cover - large guide

119 Cover - small guide

121 Nipple - CN-M5-PK3

122 Rear panel - English text

123 Insulation - side unit left

124 Insulation - side unit right

125 Insulation - bottom

126 Insulation - hood

127 Panel - patient air English text

128 Mains cable

130 Packing - bellows side unit

134 Decal - "EIN / AUS"

135 Decal - "BEATMUNGSDRÜCK"

136 Rear panel - German text

137 Panel - potentiometer panel German text

138 Panel - patient air German text

139 Battery pack, complete

140 Text plate (IT)

141 Panel, pot. panel (IT)

142 Panel, patient air (IT)

143 Text plate (SP)

144 Panel, pot. panel (SP)

145 Panel, patient air (SP)

146 End cover for motor console, new version

147 Motor console, new version

148 Motor coupling, Rotex

149 Bellows end cover fixed, new version

150 Bellows end cover moving, new version

156 Spacer sleeve, moving end cover

157 Opto-switch, Optek

158 Seal

160 Shrink tubing - end position

184 115/230 switch, PV501-2

215 Rubber foot

220 Hook - WAGO-terminal block

4 – 12 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

248 Filter, air (5 pcs/packet)

287 Patient circuit (L-C)

378 Motor (BEI)

381 Decal "Pression de service" Fr

382 Decal "Reglage/Arret" Fr

383 Panel, pot. panel (Fr)

384 Panel, patient air (Fr)

385 Text plate (Fr)

386 Decal "PATIENTTRYK" DK

387 Decal "TIL/FRA" DK

388 Panel, pot. panel (Dk)

389 Text plate (DK)

390 Decal "PATIENT DRUK" NL

391 Decal "TIL/FRA" NL

392 Panel, pot. panel (NL)

393 Panel, patient air (NL)

394 Text plate (NL)

395 Bearing sleeve (PUR drive screw)

396 Bearing sleeve for bearing (drive screw)

397 Flange (PUR drive package)'

398 Flange (drive package)

458 Membrane, check valve

515 Serial No. decal with EAN code

516 Filter for machine ventilation

600 Tape - potentiometer box

601 Cellular rubber border

602 Air-hose 4 x 6 - frosted

604 Fuse TT 315mA

605 Fuse - T160mA

606 Fuse - F3,15A

611 M3 x 8 with washer

612 M3 - tooth nut

613 Heat conducting paste - HTC10S

614 Shrink tubing - 6.4 mm

615 Shrink tubing- 3.2 mm

616 Shrink tubing - 2.4 mm

617 Shrink tubing - 12.7 mm

618 Shrink tubing- 1.6 mm

632 Clips for ribbon cable

633 Strain relief - 4 mm

634 Strain relief - 3.5 mm

635 Cable tie brace

636 Cable tie- 8"

637 Cable tie- 4"

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 13

REPLACEMENT PARTS Service Manual PV 501/501-2

638 Cable tie- 14"

639 5 mm plate spacing

640 Y-connection

641 Blue Festo tubing

642 Mains cable straps

643 Black screw 201 - RXS 3.5 x 19

644 Clear tubing 9 x 12

645 Clear tubing 4 x 7

646 Clear tubing 3 x 6

647 Clear tubing 3 x 5

648 SPAX 4 x 20

649 SPAX 3 x 12

650 SGA 22

651 Seeger - AK-26 , or Sgh 32

652 M6 x 25 - bolt

653 M6 x 22 - washer

654 M6 - flat washer

655 M6 - locking nut

656 M5 x 80 F

657 M5 x 50 F

658 M5 x 20 socket head cap screw

659 M5 x 16 F

660 M5 x 16

661 M5 - toothed plate connector

662 M5 - flat washer

663 M5 - nut

664 M5 - locking nut

665 M4 x 8 F

666 M4 x 8

667 M4 x 45

668 M4 x 30

669 M4 x 20

670 M4 x 16 F

671 M4 x 16

672 M4 x 12

673 M4 x 10 F

674 M4 - wing nut

675 M4 - toothed plate connector

676 M4 - flat washer

677 M4 - nut

678 M4 - locking nut

679 M3 x 8

680 M3 x 6 F

681 M3 x 6

4 – 14 BREAS MEDICAL Doc. No.: 1523EN Issue: N-1

Service Manual PV 501/501-2 REPLACEMENT PARTS

682 M3 x 16 F

683 M3 x 12 black socket head cap screw

684 M3 x 12

685 M3 x 10 F

686 M3 x 10

687 M3 - toothed plate connector

688 M3 - flat plate

689 M3 - nut

690 M3 - threaded bar

691 M2 x 10

692 M10 - toothed plate connector

693 KFXS 2.9 x 9.5 F

694 Fibre washer

699 Hook - for WAGO-terminal block

700 Packing - battery base

701 Plastic spacing - 4 x 15

702 Plastic spacing - 4 x 10

703 Plastic spacing - 3 x 10

704 Blind plug - angle bracket hole

705 Double-sided tape

706 Mains cable discharger

708 O-ring - potentiometer board

709 Fuse - 1.25 A

711 Cable tie - mini

713 M4 x 6 socket head cap screw

714 IC - MDA

716 Pressure sensor

723 Magnetic strip (0.01 m)

727 Cable tie, driller

740 Screw MFZ steel M4*10 Black, chrome Poz

741 M3 x 6 F - black, PV501-2

753 O-ring, check valve

795 Metal cable tie

796 Washer, support washer (drive unit)

797 Sliding bearing sleeve (drive unit)

798 Sliding bearing sleeve (PUR drive unit)

799 Spacer sleeve (drive unit)

800 Seal (drive unit)

1141 Drive unit complete (BEI)

1145 Rubber washer for transformer

1146 Metal washer for transformer

1410 Transformer, PV501-2

1636 Opening front, PV501-2

1720 Lock/keys, PV501-2

Doc. No.: 1523EN Issue: N-1 BREAS MEDICAL 4 – 15

Loading...

Loading...