Breaching Technologies Strip Lock Explosive Breaching Door User Manual

BTI Strip/Lock Explosive Door Manual

ised: 01 January 2011

ev

Model Type: 08

BTI Part Number: EDSL

BTI Door Installation

The installation of the BTI training door is straightforward and most likely selfexplanatory by visual examination.

Caution: Through our physical testing of actual doors during the development of

this product, forces in excess of 3000 lbs. have been seen during a breach. Therefore

it is advisable to anchor or mount your product accordingly. Typical house

construction methods are not adequate for the numerous breaches for which this

product has been designed. If you are unsure of your mounting methods, please

consult a professional about these loads.

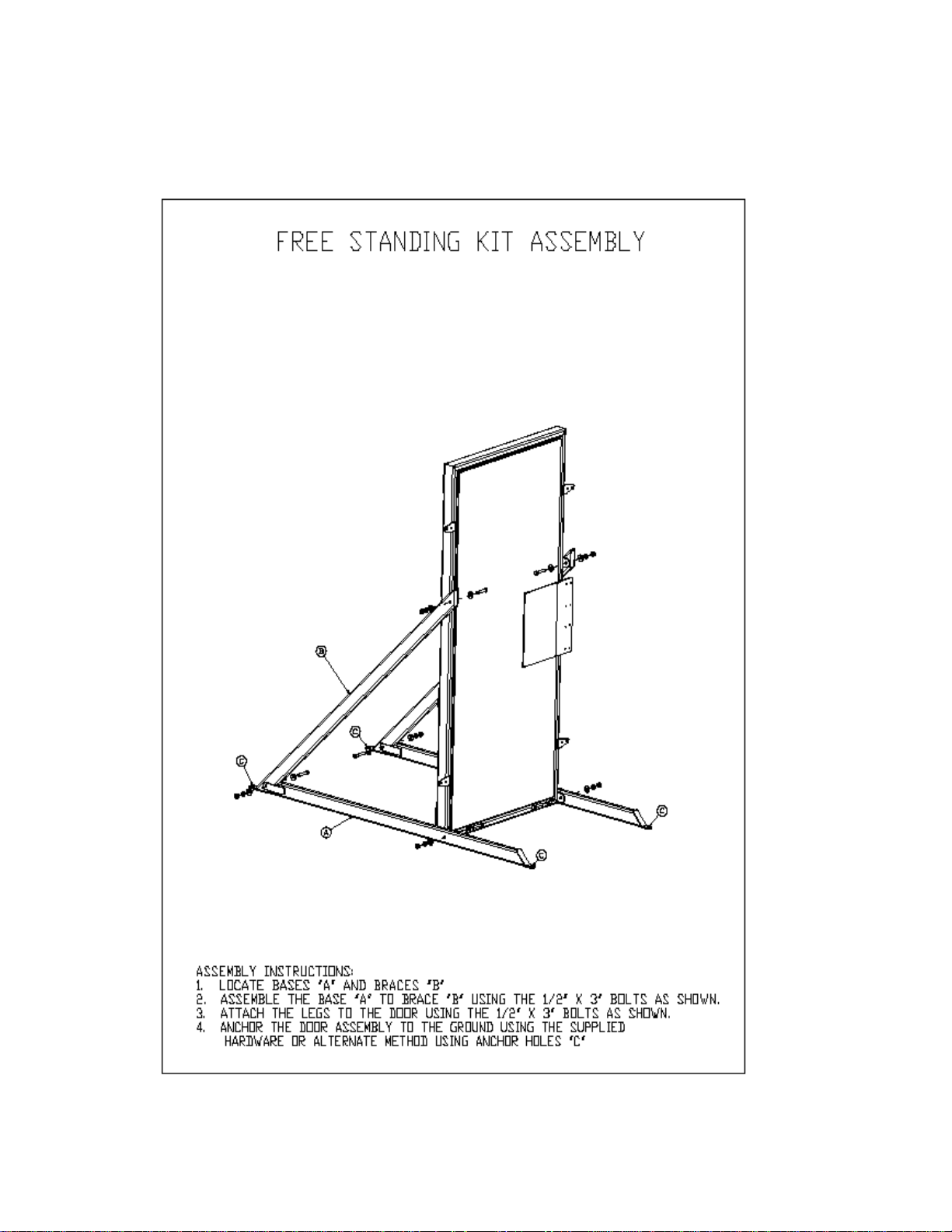

Free Standing. The Free Standing Kit may be installed to allow the door to be utilized

in a multitude of locations and scenarios. The accompanying diagram shows the

assembly method and mounting hole locations for a typical BTI training door.

Your freestanding kit includes stakes for anchoring on soft surfaces such as gravel and

asphalt. Alternate methods using “ram set” or similar methods may be used on hard

surfaces.

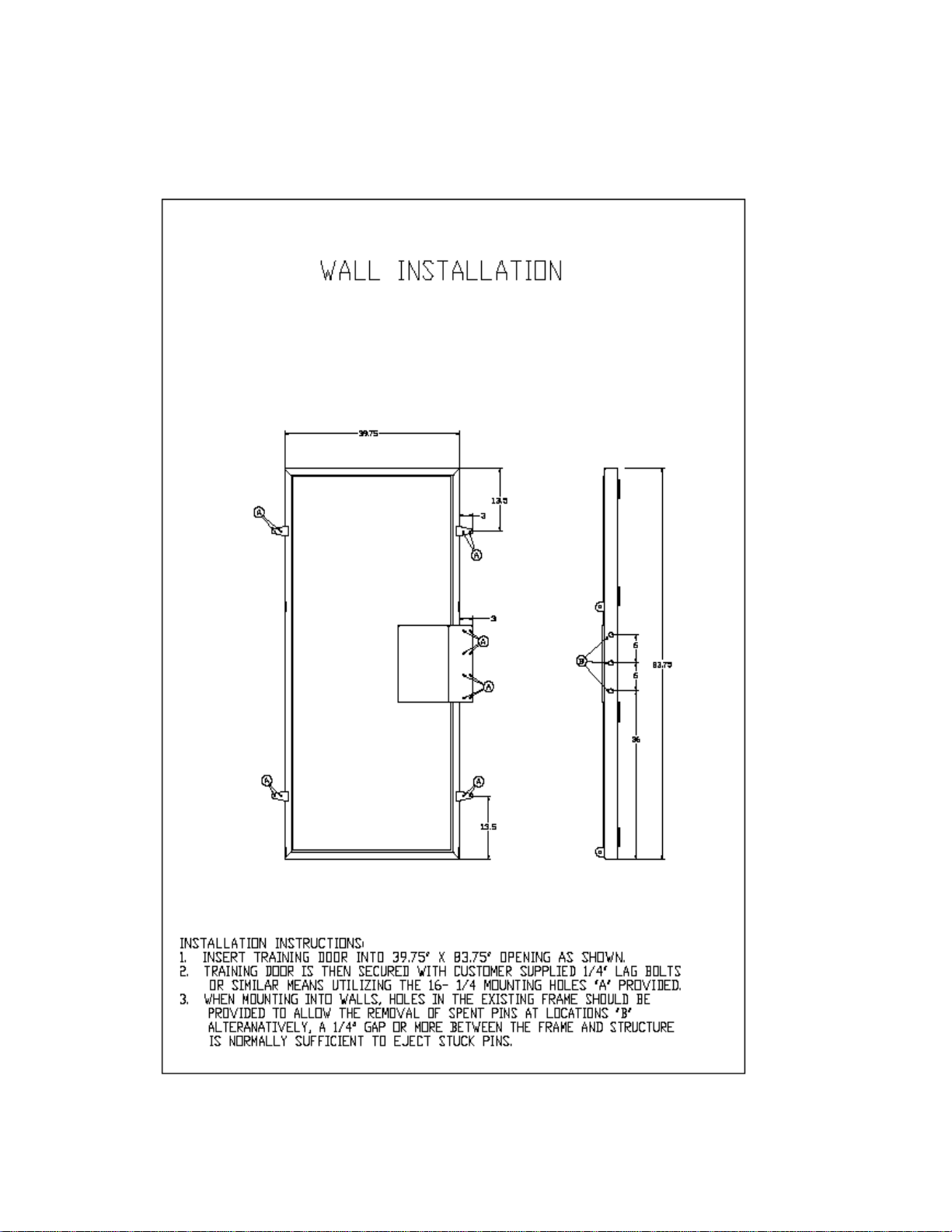

Wall Installation. Installation of a typical BTI training door into an existing or new

frame type structure is shown in the accompanying diagram. Provisions for mounting the

training door in a “pre-hung” fashion have been provided in the four metal mounting ears

and the frame guard as shown.

Alternate means of mounting such as face mounting or welding are up to the purchaser.

However, BTI Inc. cannot warrantee products, which are mounted in ways that weaken

the frame or structure, or are inconsistent with our design and testing.

Note: When installing the door into the opening of a structure, it is advised that a

provision be made to allow the ejection of stuck spent pins by poking from the backside

of the doorjamb.

One method of accomplishing this is to place aligned holes into the structure

corresponding to the socket hole.

Another method is to shim the door in the opening and allow ½ to 1 inch of clearance in

the area of the socket. This will allow enough access to the backside to eject the stuck

pins.

Although spent pins that occasionally stick into the socket after breaching may be

removed by pulling with a hook-type tool, it is consistently easier to poke them out rather

than pull them out.

Loading...

Loading...