HANDBOOK

on SEQUENT 24

TA010976 - N. 1 - 17 - 11 - 2004

M.T.M. s.r.l.

Via La Morra, 1

12062 - Cherasco (Cn) - Italy

Tel. ++39 0172 48681

Fax ++39 0172 488237

2

INDEX

1. INTRODUCTION

1.1 WHAT IS SEQUENT 24?

1.2 MAIN DIFFERENCES WITH THE PREVIOUS SEQUENT SYSTEMS

2. UNDERSTANDING THE SEQUENT 24 SYSTEM

2.1 SEQUENT 24 ECU

2.2 CHANGEOVER SWITCH

2.2.1 C

HANGEOVER SWITCH IN ITS PETROL POSITION

2.2.2 CHANGEOVER SWITCH IN ITS GAS POSITION

2.2.3 ERROR INFORMATION

2.3 GENIUS FOR SEQUENT 24

2.4 ENGINE WATER TEMPERATURE SENSOR

2.5 FUEL “RAIL”

2.6 BRC INJECTORS

2.7 GAS PRESSURE AND TEMPERATURE SENSOR

2.8 MAP SENSOR

2.9 HARNESS

2.9.1 I

NJECTORS CUT

3. PROGRAMMING

3.1 FILE TYPES

3.2 ASSISTED PERSONALISED PROCEDURE

4. TUNE-UP

4.1 CHANGING OVER

4.2 SELF-MAPPING

5. UTILITIES

5.1 INFORMATION

6. PROBLEMS AND SOLUTIONS

7. ANNEXES

A - LIST OF THE PINS AND THEIR FUNCTIONS

B - LOCATION OF THE ECU PINS

C - GENERAL ELECTRICAL DIAGRAM

D - INJECTORS CUT DIAGRAM

E - PETROL INJECTOR CONNECTION SEQUENT 24

HARNESS RIGHT OR LEFT

F - UNIVERSAL 4-PETROL INJECTOR CONNECTION SEQUENT 24 HARNESS

3

1. INTRODUCTION

1.1 WHAT IS SEQUENT 24?

SEQUENT 24 is the BRC sequential injection system in the gaseous

phase that is easy to install, quick

to map and low-cost. Its installation

gets simpler owing to the new philosophy adopted for sensors and

emulators. The SEQUENT 24

actually does not contemplate any

additional devices; the emulators

are integrated in the ECU and the

sensors are integrated in the main

components (Genius and RAIL).

The connections are quicker owing

to the specific connectors; moreover, it is not necessary anymore to

connect the TPS signal whereas

the choice to connect the lambda

oxygen sensor signal is still optional. For the RPM signal it will be

possible to choose a coil signal too,

in addition to a standard RPM

signal or crankshaft position sensor

signal. The new SEQUENT 24 PC

programme is easier to use and

completely separated from the

standard SEQUENT and from the

SEQUENT FAST, also as regards

the filing of the mappings, but it

anyway keeps their basic philosophy unchanged.

1.2 MAIN DIFFERENCES

WITH THE PREVIOUS

SEQUENT SYSTEMS

In the following table you will find

the list of the main differences

between standard SEQUENT /

SEQUENT FAST and SEQUENT

24:

Sensors

• P1-MAP (case)

• Tgas on the reducer

• P1-Tgas integrated on rail

• Twater integrated on the reducer

• MANIFOLD PRESSURE ONLY WHILE

SELF-MAPPING

Injectors Cut

• Cut on the negative inside the ECU

• Emulation with the Modular LD

• Cut on the POSITIVE inside the ECU

and simultaneous for the 4 injectors (the

orange wires do not enter the ECU)

Key contact and Petrol Injectors

Positive

• To connect to the key contact positive

(brown) and to the petrol injectors positive

(white-green)

• The key contact positive becomes

petrol injectors positive that goes into and

out from the ECU. ECU ignition only if the

petrol injectors positive is active

Communication

•Active with key contact positive ON

• Active with the engine switched on;

once it is connected it remains active

even disconnecting the key contact (if the

PC/ communication is not disconnected)

Changeover switch

• 10 pins connected with the ECU

• 3 pins connected with the ECU + one

for the level on the changeover switch

Screen

• Connected with the ECU case with a

specific pin

• Connected with the battery ground

TPS connection

• Necessary or Optional

• Not connected

RPM Connection

• Necessary or Optional

• It is possible to use the RPM counter

signal, the crankshaft position sensor

signal (only one wire) or the coils negative)

Filing of the mappings

• FSF+AAP file or only FSF for vehicle

parameters and mapping

• FLS file for vehicle parameters and

mapping..

• Separated from the previous Sequent

systems

Advance variator

• Inside

• Outside

SEQUENT / SEQUENT FAST

SEQUENT 24

4

2 UNDERSTANDING

THE SEQUENT 24

SYSTEM

The SEQUENT 24 system maintains, in general, the philosophy of

the previous SEQUENT systems it

derives from; it nevertheless introduces some changes and improvements as regards installation and

operation, as well as some modifications in the components the BRC

installer already knows well.

2.1 SEQUENT 24 ECU

A detailed description of the ECU

would be beside the point of this

handbook. The main point is to

underscore that it is the operational

unit controlling the system. As the

previous ones it complies with the

automotive and EMC standards

and is tight. What distinguishes it

from the previous ones is the fullyplastic case and the much more

compact dimensions advantaging

its installation on the vehicle. For

installation please carefully follow

the indications given for the standard Sequent and Sequent Fast

that are already familiar to the BRC

installers.

2.2 CHANGEOVER SWITCH

Although it is similar to the typical

two-position changeover switch

provided with a buzzer, already

used on Sequent and Sequent

Fast, the differences distinguishing

it from the previous ones are

nevertheless substantial. This new

changeover switch can be considered like a small ECU: it is not only a

switch regulating the petrol-gas

changing over, but it actually communicates with the ECU and controls the visualisation of the gas

level in the tank on the 4 green

LEDs.

2.2.1 CHANGEOVER SWITCH IN

ITS PETROL POSITION

With the button of the changeover

switch in its petrol position, the

vehicle works in forced petrol mode

(as in all the previous systems).

The rectangular red LED lit informs

the user, while the gas level information disappears, that is to say

the four level green LEDs are off.

2.2.2 CHANGEOVER SWITCH IN

ITS

GAS POSITION

In this position the vehicle starts up

on petrol – the level LEDs are therefore off – and, with the changeover conditions configured by the

programme attained (see chapter

3.1 for further information), automatically changes over to GAS. The

user is informed by the rectangular

LED that first becomes orange and

then green (gas operation). Only

while running on gas the gas level

in the tank is visualised on the four

green LEDs.

2.2.3 ERROR INFORMATION

As it has already been underscored, this changeover switch is an

“intelligent” device communicating

with the ECU. When the communication fails, the two level central

green LEDs and the rectangular

orange LED blinking inform the

user of the malfunction.

In such conditions it is always possible to force the petrol operation

turning the switch in its petrol position, as it is possible to run on gas

with the changeover switch in its

gas position, though losing the level

information.

In these cases it is recommended

to make a diagnosis and, if need

be, to repair/or replace the changeover switch.

2.3 GENIUS FOR SEQUENT

24

The pressure reducer is like the

LPG GENIUS for SEQUENT, unlike

it is provided with a new water temperature sensor, that is not compatible with the ones of the previous

systems.

Pict. 1

ECU Sequent 24

Pict. 2

Changeover switch

5

2.4 ENGINE WATER TEMPERATURE SENSOR

The water temperature sensor is

directly fitted on the GENIUS on the

water side. The sensor is of the

resistive two-wire type, based on

an NTC thermistore. The gas changing over strategies are grounded

on the measurement of the engine

water temperature. This sensor differs from the previous ones for its

new mechanical structure: it is

actually more compact and integrates inside it the part connected to

the sensor and to the connector.

2.5 FUEL “RAIL”

It is the element bearing the injectors fitted. Unlike the previous

sequential systems, the gas pressure and temperature sensor (not

compatible with the previous

systems) is also fitted on the rail in

addition to the injectors (BRC type

only).

2.6 BRC INJECTORS

The SEQUENT 24 equipment only

uses BRC injectors. See in the following table (pitc. 5) the powers, for

guidance.

2.8 GAS PRESSURE AND

TEMPERATURE SENSOR

This sensor is absolutely new, in a

compact body and already integrated with the connector; it contains

the P1 gas pressure and temperature sensor. The sensor is directly

fitted on the fuel rail. In this position

the measurement of gas pressure

and temperature is more careful

and allows rectifying the gas mixtures more rapidly.

MAP SENSOR

The MAP sensor is identical with

the MAP sensor of the Standard

SEQUENT, already familiar to the

BRC installer. The material difference distinguishing it from the other

systems is that in the SEQUENT 24

this sensor is used ONLY DURING

THE SELF-MAPPING. During the

Pict. 3

Genius for

SEQUENT 24 and

engine water temperature sensor

Pict. 4

Rail and Gas pressure and temperature sensor

Pict. 6

MAP sensor

Pict. 5

LPG powers

LPG powers

Genius 800 Genius 1200 Genius 1500

Injectors Max Type Inducted - 26 kW/cyl. 30 kW/cyl.

Supercharged - 32 kW/cyl. 36 kW/cyl.

Iniettori Normal Type Inducted 17 kW/cyl. 21 kW/cyl. -

Supercharged 22 kW/cyl. 26 kW/cyl. -

6

vehicle’s normal operation, the

MAP is estimated: an approximate

value of the manifold pressure is

therefore visualised on the

SEQUENT 24 interface.

For the self-MAPPING the MAP

sensor is provided with the pipes

necessary for the connection on the

vehicle, inside the SEQUENT 24

CALIBRATION KIT Code

09SQ10990001.

2.9 HARNESS

The SEQUENT 24 harness is slenderer than the previous systems’

ones. The 56-pole connector harness of the Standard SEQUENT is

replaced by the 24-pole connector

harness of the SEQUENT 24. To

make installation easier the main

devices of the system are connected through a specific connector

and the quantity of wires to weld is

very small.

Shielded conductors have been

used in order to comply with the

EMC standards. The connectors on

the harness are waterproof with the

exception of the connector of the

changeover switch that is however

housed in the passenger’s compartment and is therefore protected

from water. The injectors ought to

be cut with great care: the injectors

cut is the main novelty of the whole

system and of the harness.

2.9.1 INJECTORS CUT

Unlike the previous systems, the

injectors are cut on the positive:

this allows having less wires entering the ECU.

Two wires are actually enough to

cut all the injectors: the

White/Green wire (injectors positive, original equipment side) and the

White/Brown wire (injectors positive, injectors side).

On the other hand, it won’t be possible to change over from petrol to

gas and vice versa injector by injector; the changing over could possibly be abrupt and we might change

over only while decelerating on

some vehicles.

The White/Green wire has also the

key contact positive function, i.e. it

is the wire that turns the gas ECU

ON. It is proper to bear in mind, in

this connection, that some vehicles

do not actuate the injectors positive

until the starting up: it is not therefore sufficient to turn the key contact on. In this case, the only way to

turn the gas ECU on is to start up.

As while programming, the gas

ECU needs this wire to be highpotential, programming will be carried out with the vehicle running.

The injectors positive normally is

not low-potential as soon as the

engine and the key contact are

switched off, but it can remain high

for some seconds with the vehicle

switched off. In this case, the ECU

too will remain ON for some

seconds.

The White/Brown wire is directly

connected with the petrol injectors.

It supplies tension on the injectors

positive while running on petrol,

whereas it takes this power supply

off while running on gas, in order to

cut injectors.

It is highly recommended to use

right and left harnesses specifically

conceived for Sequent 24 whenever it is possible. They actually

allow making quick connections

with the injectors, without welding

and cutting down any error possibility.

It is necessary not to mix up the

right with the left harnesses and to

carefully follow the instructions supplied with these harnesses.

The exchange of the two harnesses

brings about the vehicle’s malfunction both on petrol and on gas and

the short-circuit of the injectors piloting outputs of the petrol ECU to

the positive. This short-circuit

strains the petrol ECU only when

the engine is running (it is anyway

not possible to start up).

Furthermore, the petrol ECU is

generally protected against this

type of short circuit. Nonetheless it

is recommended to act very cautiously. In particular, it is recommended not to insist excessively if

the vehicle does not start up after

reconnecting the injectors, but to

check immediately whether the

connection harness is correct.

Should the right and left harnesses

not be used, it is anyway possible

to use the universal harness, following the enclosed instructions

with the utmost care.

In particular, bear in mind that:

- The White/Green wire can be

generally connected only with a

positive wire coming from the petrol

original harness, even if it is best, in

general, to reunify all the positives

of the injectors (ECU side) on this

wire, in order not to supply overcurrent to one single wire of the petrol

original harness.

- All the positives of the petrol injectors ought to be cut, by disconnecting them from the original positive

and connected only with the

White/Brown wire. Indeed, should

the original positive still get to a

petrol injector, the injector will also

work while running on gas and therefore provoke the bad combustion

of the attendant cylinder.

- The petrol injectors positive to be

cut ought to be as close as possible

to the petrol injectors. If we cut the

positive far from the petrol injectors,

we actually run the risk of cutting, in

addition to the injectors, other

actuators or sensors of the vehicle

supplied with the same wire of the

original equipment.

- The injectors negatives ought to

be cut and connected, as in the

past, to the violet (petrol ECU side)

and orange (injectors side) wires

and ought to be connected in the

same order, from 1 to 4, as the gas

injectors.

At the end of this handbook (Annex

7

B on page 14) you will find an

explanatory diagram regarding the

injectors cut.

The petrol injectors are emulated

through special coils similar to the

coils used in the Modular LD of the

Sequent systems that are fitted

inside the ECU.

The codes of the connection harnesses for the 4 petrol injectors

are listed below:

06LB50010121 – UNIVERSAL Harness

06LB50010122 – RIGHT Harness

06LB50010123 – LEFT Harness

3 PROGRAMMING

The software structure is maintained as similar as possible to the

BRC sequential systems already on

the market and familiar to the BRC

installer. Only the material differences introduced for SEQUENT 24

will be therefore here-after indicated.

3.1 FILE TYPES

The SEQUENT 24 ECU is programmed by downloading two different types of files:

1. File .S19

2. File .FSL

the information necessary for the

vehicle’s operation is contained in

the file. FSL.

3.2 ASSISTED PERSONALISED PROCEDURE

Let’s find out, in brief, about the

assisted personalised programming

procedure. The procedure is to be

carried out with the engine switched on and the changeover switch

on petrol mode (the programme will

show the installer when changing

over to gas).

The steps to follow are not far

removed from the ones analysed

for the Standard SEQUENT and for

the SEQUENT FAST, that’s why

you are kindly requested to refer to

the attendant handbooks for a more

detailed description.

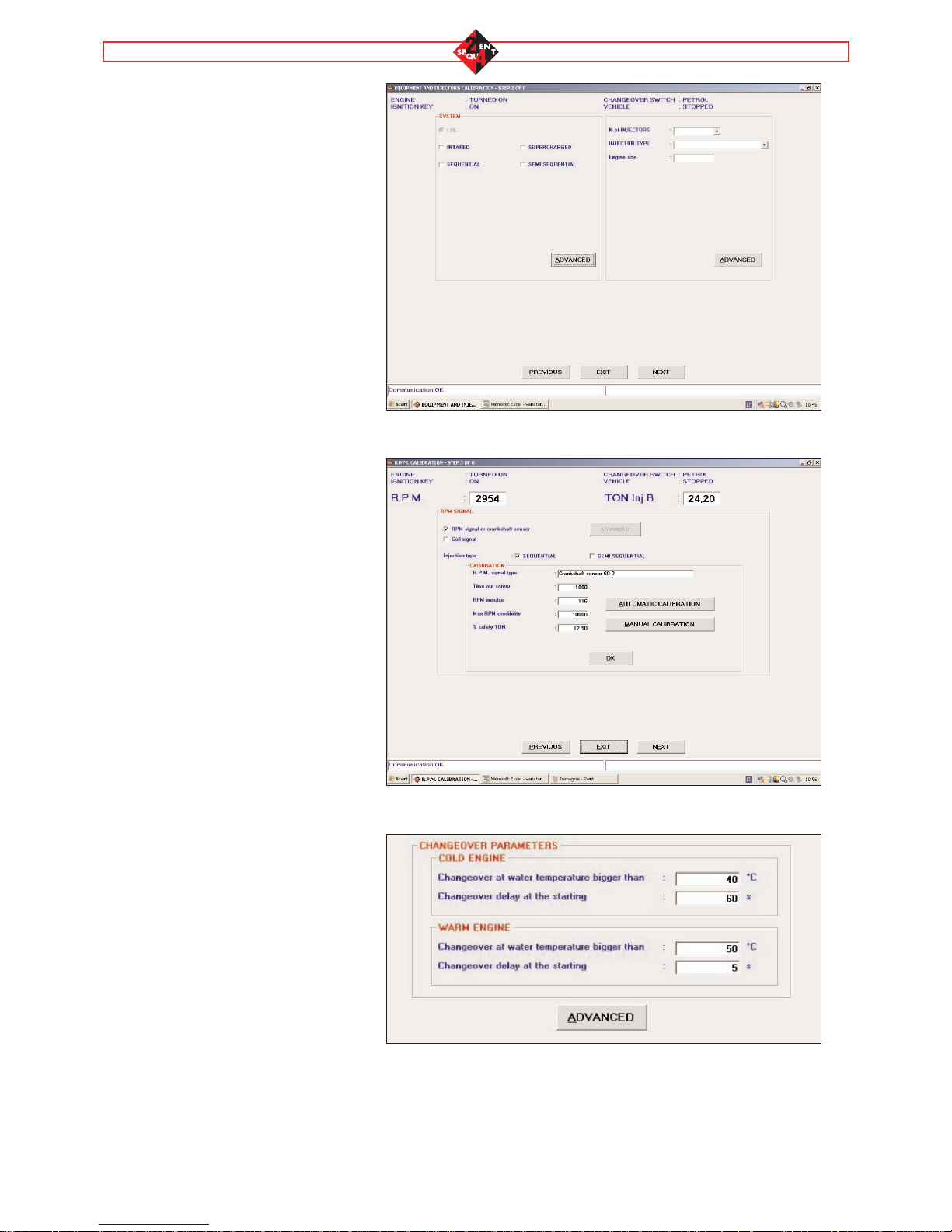

Assisted personalised procedure

The main novelties have been

introduced in the equipment type

screen and in the RPM calibration

screen.

The equipment type screen (Picture

8 pag. 8) requires to enter an extra

information: the vehicle volume.

The RPM calibration screen

(Picture 9 pag. 8) allows selecting a

coil RPM signal besides selecting

and calibrating a normal RPM

signal or crankshaft position sensor.

WARNING: by selecting an

RPM signal from the negative coil, the RPM won’t be correctly

visualised in all the working conditions. In some of them as, for

example, in the cut-off, the visuali-

sed RPM signal could not correspond to the vehicle’s real one;

nevertheless it doesn’t affect the

vehicle’s working.

4 TUNE-UP

This chapter will only examine the

differences with the previous

SEQUENT systems, otherwise you

are kindly requested to make reference to the handbooks on the

Standard SEQUENT and

SEQUENT FAST.

4.1 CHANGING OVER

The changing over operation has

substantial differences distinguishing it from the previous Sequent

software, owing to the completely

different injectors cut on Sequent

Beginning of the

procedure

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Selection of the equipment

and injectors type

RPM calibration

Lambda calibration

(optional)

Save file

Self-mapping

Save file

End of the procedure

ASSISTED PERSONALISED PROCEDURE

Pict. 7

8

Pict. 10

24. In particular, the injectors are

simultaneously cut and changeover

can be rough while in the Standard

Sequent or Sequent Fast it was

clean in all conditions. In these

cases it is proper to avoid changing

over in the most critical conditions

that normally are idle speed or conditions requiring much torque to the

engine.

It is obvious from the first screen

(Picture 10) that changing over is

always a function of the engine

water temperature measured through the special sensor positioned on

the Genius Reducer for Sequent

24.

On Standard Sequent and Sequent

Fast the changing over temperature

was the gas one unless you connect to the vehicle’s original engine

water temperature sensor.

As a rule, the changing over is divided into two sections according as

you change over with the warm

vehicle (temperature higher than

50°C) or the cool vehicle (temperature higher than 40°C).

In the referred example the changing over conditions are attained if:

1. 60 seconds at least have passed

after the vehicle starting up and gas

temperature ranges from 40° and

50°C.

2. 5 seconds at least have passed

after the vehicle starting up and gas

temperature is higher than 50°C.

By clicking on the ADVANCED button it is possible to set some parameters affecting changing over or

changing back to petrol for lack of

fuel.

In particular, it is possible to distinguish the conditions for changing

over from petrol to gas (Box 1 of

Pict. 11) from the conditions for

changing over from gas to petrol

(Box 2 of Pict. 11).

In particular, the following configurations are possible:

- “Changing over at the idle speed”

Pict. 8

Pict. 9

9

indicates that changing over can be

possible at RPM lower than 4000

and with a MAP value close to the

idle speed one.

- “Changing over in deceleration”

indicates that changing over can be

possible in deceleration conditions,

that is to say with RPM ranging

between 2000 and 4000 and a

MAP value close to the idle speed

one. In these conditions the torque

required to the engine is practically

null; this obviously allows avoiding

jerks during this phase. (This changing over is very similar to the

Flying Injection system). Changing

over in deceleration is suitable for

vehicles whose OBD detects missfires. On these vehicles, petrol-gas

changing over and gas-petrol changing back are particularly delicate

and they are therefore recommended only in deceleration conditions.

(NOTE: the manual action on the

changeover switch has anyway

priority on the software; by forcing

the changeover switch on its petrol

mode the gas-petrol changing over

is therefore immediate even if the

changing over in deceleration is

configured in the software).

- “Always changing over” indicates

that changing over is possible in all

conditions and therefore at any

RPM and engine load values.

The standard configurations are:

- Petrol-Gas changing over (Box 1

of Pict. 11): changing over in deceleration

- Gas-Petrol changing over (Box 2

of Pict. 11): always changing over

In the “Changing back to petrol for

lack of gas” Box there are all the

parameters controlling this function.

They are the same parameters

already seen for the Standard

Sequent and Sequent FAST. Every

time a new mapping is created,

some given values are already configured; normally they do not need

any modification.

Pict. 11

Pict. 12

The “Changing back to petrol at the

idle speed” Box allows changing

back to petrol every time the engine

is below certain revs; this function

is identical with the Sequent one

and is only used on vehicles whose

return to idle speed is so critical

that it can provoke the engine stall

as a consequence.

4.2 SELF-MAPPING

The self-mapping can be carried

out from the tune-up function too.

The procedure is the same as the

assisted personalised one. The

only novelty is the initial question

(Pict. 12) asking the installer to

decide whether self-mapping from

the CURRENT MAP, that is the one

already existing in the ECU or from

the BASIC MAP, that is by using

the standard maps existing on the

PC.

WARNING: It is necessary to

connect the manifold pressu-

re.

5 UTILITIES

This chapter will only examine the

differences with the previous

SEQUENT systems, otherwise you

are kindly requested to make reference to the handbooks on the

Standard SEQUENT and

SEQUENT FAST.

5.1 INFORMATION

This section allows controlling the

updating of the software versions

existing on the PC that can be

downloaded on the ECU, visualising the software name and version

(Picture 13).

10

Pict. 13

11

6 PROBLEMS AND SOLUTIONS

This chapter supplies some useful indications for the installer to solve some problems that could arise with this

new system.

The ECU does not communicate

• Lack of power supply to the ECU

• The communication port configured on

the PC is not correct

• The communication cable is faulty

• Turn the engine on

• Verify whether the configured COM port

is correct in UTILITIES-COMMUNICATION

• Replace the communication cable

The ECU does not switch off

• The communication with the PC is still

active

• Disconnect the communication cable or

exit from the SEQUENT 24 programme

and wait till the ECU is switched off

The changeover switch does not visualise the GAS level

• The changeover switch is in its petrol

position (level LEDs are switched off)

• The changeover switch does not communicate (level central LEDs are blinking)

• Changeover to gas and verify the level

visualisation.

• Verify the changeover switch harness or

replace the changeover switch. In these

cases, the cause could also be the ECU.

Therefore verify whether the ECU communicates with the PC interface and, if

necessary, try to replace it.

The changeover switch does not communicate

• The level green central LEDs and the

orange rectangular LED are blinking

• In this condition the vehicle goes on running on petrol or on gas according to the

changeover switch position. Nevertheless

there is no information on the operation

and it is therefore proper to verify the harness or replace the changeover switch.

The changeover switch does not switch

on

• The changeover switch harness is cut off

• The 5Afuse is cut off

• The changeover switch fails

• The ECU does not switch on

• Verify the changeover switch harness

continuity.

• Replace the 5A fuse

• Replace the changeover switch.

• Verify the ECU operation.

The vehicle works wrongly on gas

• The injectors positives are not cut correctly

• Make sure you have cut all the petrol

injectors positives

• Verify you have cut as close as possible

to the injectors.

The Petrol and GAS injectors do not

inject simultaneously (you will find it

hard to make the self-mapping)

• The injectors positives are not cut correctly

• Try to start the vehicle up with the gas

injectors disconnected: if the vehicle

starts up (even running bad) then there is

a problem in the injectors positive cut.

The vehicle does not start up

• Inversion between RIGHT and LEFT harness

• Verify whether the injectors are connected

correctly. If the RIGHTharness and the LEFT

harness are inverted, trying to start up, the

tension on the White/Green wire is still low.

The vehicle does not change over to

gas.

• The injectors are not driven to the

ground.

•The battery bond fails.

• Verify the connection of the B1 Pin

injectors ground wire.

• Verify the connection of the C8 Pin battery ground wire.

The ECU does not switch on or it resets

itself in the gas operation

• The connection to the battery positive is

lacking or is cut off.

• The connection to the injectors positive is

lacking or is cut off.

• Verify the connection of the A1 Pin battery positive wire.

• Verify the connection of the A7 Pin

injectors positive wire.

WHAT’S HAPPENED?

WHAT TO DO

PROBLEM

The vehicle changes over to petrol in

cut-off.

• The RPM signal is taken from the coil

negative. This signal is set to zero in cutoff.

• Take an RPM signal different from the

coils one.

The vehicle stalls while changing over

to gas.

• The 15Afuse is cut off.

• Any of the actuators relay wires is

disconnected.

• The relay fails.

• The White/Green wire is inverted with the

White/Brown one (in this case you will

hear the relay ringing).

• Verify the 15Afuse.

• Verify the connections on the actuators

relay.

• Replace the relay.

• Verify the connection of the

White/Green and White/ Brown wires.

12

1 2 3 4 5 6 7 8

A

+VBATT INJ1- GAS INJ2- GAS INJ3- GAS INJ4- GAS COMINJPET-OUT COMINJPET-IN RPM-IN

B

GND-INJ INJ1PET-IN INJ2PET-IN INJ3PET-IN INJ4PET-IN LAMBDA-AIN MAP-AIN P1-AIN

C

GAS SV WATER TEMP. K-LINE SWITCH-LINE SENSPOWER LAMBDA-AOUT TGAS-AIN GNDBATT

ANNEXES A

Pins

ANNEXES B

Location of the ECU pins

N. PIN OF

THE ECU

N. PIN OF THE

REMOTE

CONNECTOR

WIRE COLOUR WIRE NAME DESCRIPTION

A1 Note 1 Red +VBATT

ECU power supply from battery /

injectors current blow-by

B1 Ring Black GND-INJ Gas injectors ground

C1 1 Green/Black EVGAS Solenoid valve piloting outlet

A2 1 White/Green INJ1-GAS Gas injector 1 piloting outlet

B2 B1 Violet INJ1BENZ-IN Petrol injector 1 inlet

C2 2 Yellow TEMP.ACQUA Water temperature

A3 1 White/Green INJ2-GAS Gas injector 2 piloting outlet

B3 B2 Violet INJ2BENZ-IN Petrol injector 2 piloting intlet

C3 4 White LINEA-K

K line diagnostic

serial communication

A4 1 White/Green INJ3-GAS Gas injector 3 piloting outlet

B4 C1 Violet INJ3BENZ-IN Petrol injector 3 piloting intlet

C4 2 Green SWITCH LINE

Changeover switch

serial communication

A5 1 White/Green

INJ4-GAS Gas injector 4 piloting outlet

B5 C5 Violet

INJ4BENZ-IN Petrol injector 4 piloting intlet

C5 Note 2 Red SENSPOWER

5V power supply for sensors and

changeover switch

A6 A2 White/Brown COMINJPET-OUT

Petrol injectors common positive,

injectors side

B6 - Yellow LAMBDA-AIN Lambda oxygen sensor analog inlet

C6 Light blue LAMBDA-AOUT Lambda oxygen sensor analog outlet

A7 A1 White/Green COMINJPET-IN

Petrol injectors common positive,

petrol ECU side (or +V key)

B7 4 White MAP-AIN MAP analog inlet

C7 4 White TGAS-AIN Temperature analog inlet

A8 - Grey RPM-IN RPM inlet

B8 2 Green P1-AIN Gas pressure analog inlet

C8 Note 3 Black GNDBATT ECU and sensors ground

Note 1: The A1 pin of the ECU (battery positive) is connected with the pin 3 of the connector for the communication with the

PC.

Note 2: The C5 pin of the ECU (sensors positive) is connected with the following pins of the remote connectors:

• Pin 3 of the gas pressure and temperature sensor

• Pin 4 of the changeover switch

• Pin 2 of the MAP sensor

Note 3: The C8 pin of the ECU (ECU and sensors ground) is connected with the following pins of the remote connectors:

• Pin 1 of the gas pressure and temperature sensor

• Pin 3 of the changeover switch

• Pin 1 of the MAP sensor

• Pin 1 of the engine coolant temperature sensor

• Pin 1 of the gas level sensor

13

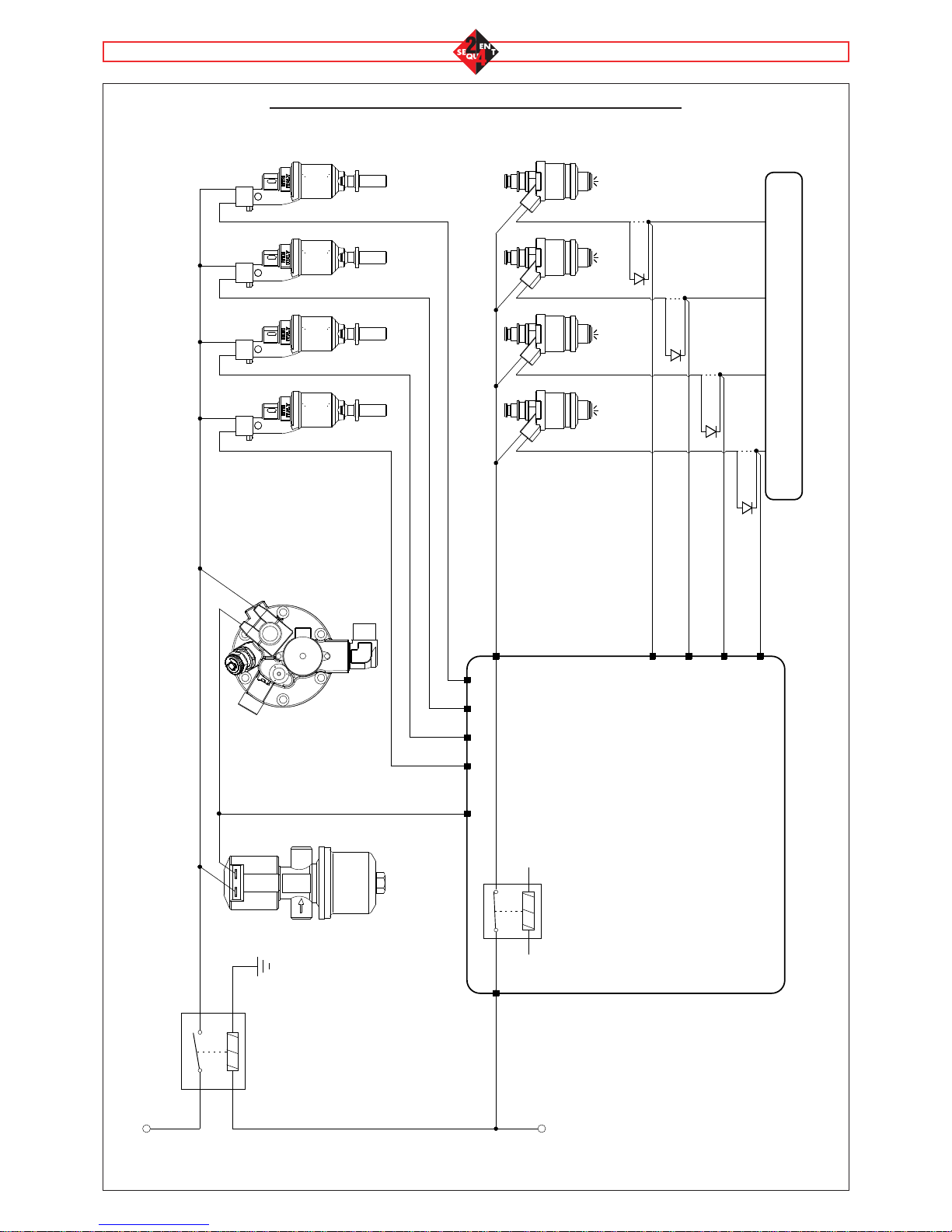

LPG SEQUENT 24

WIRING DIAGRAM

+

-

1 2 3 4

1 2 3 4

123

Relé

"I1"

"I2"

"I3"

"I4"

(-)

(+)

Sequent 24

ECU

✂

✂

✂

✂

Positive

Negative

Orange

Violet

Positive

Negative

Positive

Negative

Positive

Negative

✂

White/Brown

White/Green

To connect during is made

of mapping of the car

Caution:

- Follow carefully the petrol injectors sequence and gas injectors as indicated in the diagram.

- Never connect to the earth the front and back solenoid valve wires.

- To allow a correct diagnosis of the front solenoid valve and the back one never connect them together.

- Never substitute the fuses with others of superior carrying capacity.

Battery

Black

Black

Red

Red

LPG

Solenoid Valve

Water temperature

sensor

"GENIUS SEQUENT 24"

Reducer

Petrol

injectors

sequence

Gas

inlet

GAS injectors sequence

Gas temperature

sensor and gas

pressure sensor

1st Petrol

Inject.

2nd Petrol

Inject.

3rd Petrol

Inject.

4th Petrol

Inject.

Orange

Violet

Orange

Violet

Orange

Violet

Orange

Violet

Europa

Multivalve

Lambda Oxygen sensor

Light Blue

Grey

Yellow

Level Sensor

Connector

Back Solenoid

Valve Connector

Fuse5AFuse

15A

Diagnostic

Point

c/o switch

connector

rpm Signal

ANNEXES C

General electrical diagram

14

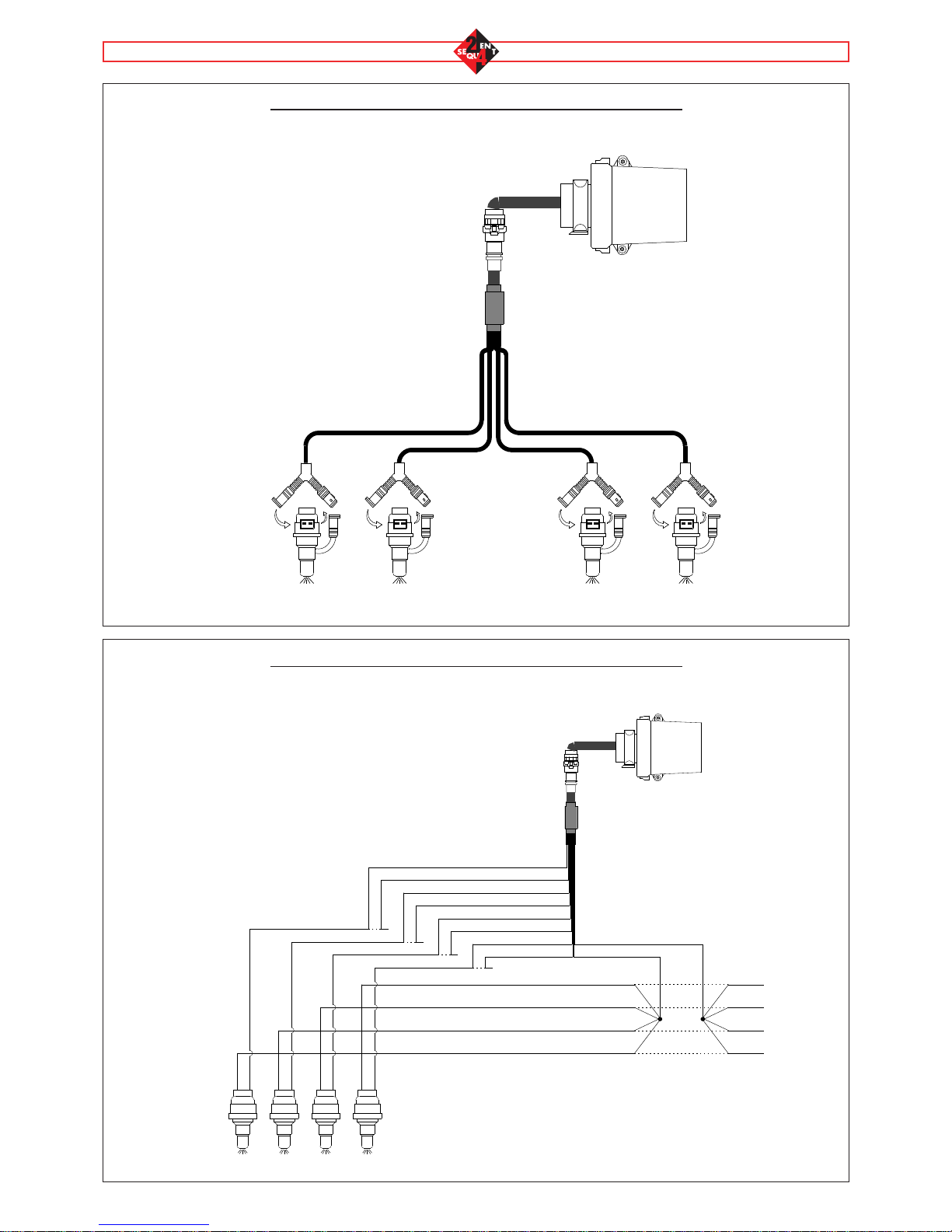

✂

✂

✂

✂

Violet

Orange

Violet

Orange

Violet

Orange

Violet

Orange

Violet

Violet

Violet

Violet

Ex

Ex

Ex

Ex

ITALY

M.T.M.

ET 98

White/Brown

Gas 1st

Injector

Gas 2nd

Injector

Gas 4th

Injector

Gas 3rd

Injector

A6

B5

B4

B3

B2

PETROL ECU

A5

White/Green

A4A3A2

White/Green

White/Green

White/Green

LPG

Solenoid Valve

SEQUENT 24

ECU

External Relé on the

wiring Sequent 24

Positive Petrol

Injector

C1

A7

White/Green

Grenn/Black

Ground

+12V After Contact

Europa

Multivalve

1st Petrol

Inject.

2nd Petrol

Inject.

3rd Petrol

Inject.

4th Petrol

Inject.

ANNEXES D

Injectors cut diagram

15

✂

✂

✂

✂

✂

✂

✂

✂

ANNEXES E

4-Petrol injector connection Sequent 24 Harness Right or Left

ANNEXES F

Universal 4-Petrol injector connection Sequent 24 Harness

Sequent 24

1° Injector 2° Injector 3° Injector 4° Injector

Negative

Positive

Violet

Orange

Violet

Orange

Violet

Orange

Violet

Orange

Inj. 1 Petr.

Inj. 1 Petr.

Inj. 2 Petr.

Inj. 2 Petr.

Inj. 4 Petr.

Inj. 4 Petr.

Inj. 3 Petr.

Inj. 3 Petr.

White/Green

White/Brown

SEQUENT 24

1°

Injector2°Injector3°Injector4°Injector

Loading...

Loading...