Page 1

SERIES 70

ELECTRIC ACTUATOR

Installation, Operation and Maintenance Manual

THE HIGH PERFORMANCE COMPANYBRAY.COM

Page 2

Page 3

1

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – bray.com

Table of Contents

Safety Instructions - Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Hazard-Free Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Part Numbering System Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrical Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mechanical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

S70 On/Off Actuator with Interposing Relay Board (I.R.B.) . . . . . . . . . . . . . . . . . . . .4

Servo NXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Mounting the Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring the Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Setting Travel Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Setting Mechanical Travel Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Field or Factory Installable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Auxiliary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Torque Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Local Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Control Station Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Backup Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Indication of Remote Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Spinner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Receptacles (Quick Connectors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

External Signal Feedback Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Basic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Actuator Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Series 70 – Size 003, 006 – Electric Actuator Exploded View . . . . . . . . . . . . . . . . . . . . 20

Series 70 – Size 008, 012, 020 – Electric Actuator Exploded View . . . . . . . . . . . . . . . . . .22

Series 70 – Size 030, 050, 065 – Electric Actuator Exploded View . . . . . . . . . . . . . . . . . .24

Series 70 – Size 130, 180 – Electric Actuator Exploded View . . . . . . . . . . . . . . . . . . . . 26

Series 70 – Size 130, 180 – 3:1 Gear Box Exploded View . . . . . . . . . . . . . . . . . . . . . . 28

Page 4

2

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Hazard-Free Use

This device left the factory in proper condition to be

safely installed and operated in a hazard-free manner.

The notes and warnings in this document must be

observed by the user to ensure hazard-free operation

of this device.

All necessary precautions need to be taken to prevent

damage due to rough handling, impact, or improper

storage. Do not use abrasive compounds to clean the

device, or scrape its surfaces with any objects.

Configuration and setup procedures for this device

are described in this manual. Proper configuration and

setup are required for the safe operation of this device.

The control system in which this device is installed must

have proper safeguards to prevent injury to personnel,

or damage to equipment, should a failure of system

components occur.

The device generates large mechanical force during

normal operation.

Qualified Personnel

The actuator must only be installed, commissioned,

operated and repaired by qualified personnel.

Installation, commissioning, operation and maintenance must be performed under strict observation of

all applicable codes, standards and safety regulations.

As per this document, a qualified person is one who

is trained in:

• The operation and maintenance of electric

equipment and systems in accordance with

established safety practices.

• Procedures to energize, de-energize, ground,

tag and lock electrical circuits and equipment in

accordance with established safety practices.

• The proper use and care of personal protective

equipment (PPE) in accordance with established

safety practices.

• First aid.

• In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in

the operation, commissioning, operation and

maintenance of equipment in hazardous locations.

Reference is specifically made here to observe all

applicable safety regulations for actuators installed in

potentially explosive (hazardous) locations.

Safety Instructions - Definition of Terms

READ AND FOLLOW THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE

indicates a potential situation which, if not avoided, may result in an

undesirable result or state, including property damage.

Page 5

3

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Introduction

The Bray Series 70 is a quarter turn electric actuator

with manual override for use on any quarter turn valve

requiring up to 18000 in-lb [2034 Nm] of torque.

Operating speeds vary between 15 to 110 seconds.

Principle of Operation

The Series 70 actuator is divided into two internal

sections, the power center below the switch plate,

and the control center above the switch plate. Below

the switch plate, the gear motor, with its spur gear

train, drives a non-backdriveable worm gear output.

The override mechanism for manual operation is also

housed here. Above the switch plate is where user

required readily accessible components are placed. The

indicator shaft assembly, limit switches, terminal strips,

torque switches, heater, and electronic controllers are

all placed here for easy access.

External to the unit are adjustable mechanical travel

stops, a large and easy to read indicator, the unique

manual override handwheel, and dual conduit entry

ports. The external coating is a high-quality polyester

powder coat which has exceptional UV protection and

chemical resistance.

Electrical Operation

The gear motors used in the Bray Series 70 are of

either permanent split capacitor (PSC) design (single

phase AC power) or permanent magnet (PM) design

(DC power). Travel limit switches are mechanical form

(SPDT) with contacts rated at 10 Amp (0.8 PF), 1/2 HP

125/250 VAC.

In cases where the torque capacity of the unit is

exceeded to the point where the motor stalls, a thermal

protector switch, built into the PSC motor windings,

will automatically disconnect the motor power and

prevent overheating. Once the motor cools sufficiently,

the thermal protector switch will reset automatically.

Optional torque switches are available in all units

to prevent the possibility of stalling the motor, thus

reducing the possibility of an inoperable thermal cool

down period. Torque switches, installed by Bray, are

factory adjusted to the output torque rating of the unit

using electronic torque testing equipment.

Mechanical Operation

Mechanically, the ratio of the gear motor determines the

speed of the unit. The gear motor utilizes high efficiency

spur gears with various ratios for the different speeds.

Initial gear reduction through the spur gears is then

transferred to the worm shaft. The final gear reduction

and output is through a non-backdriveable worm gear

set. Positioning is determined by an indicator/cam shaft,

which is linked to the output shaft. In the declutchable

condition, the manual override drives the worm shaft

when engaged.

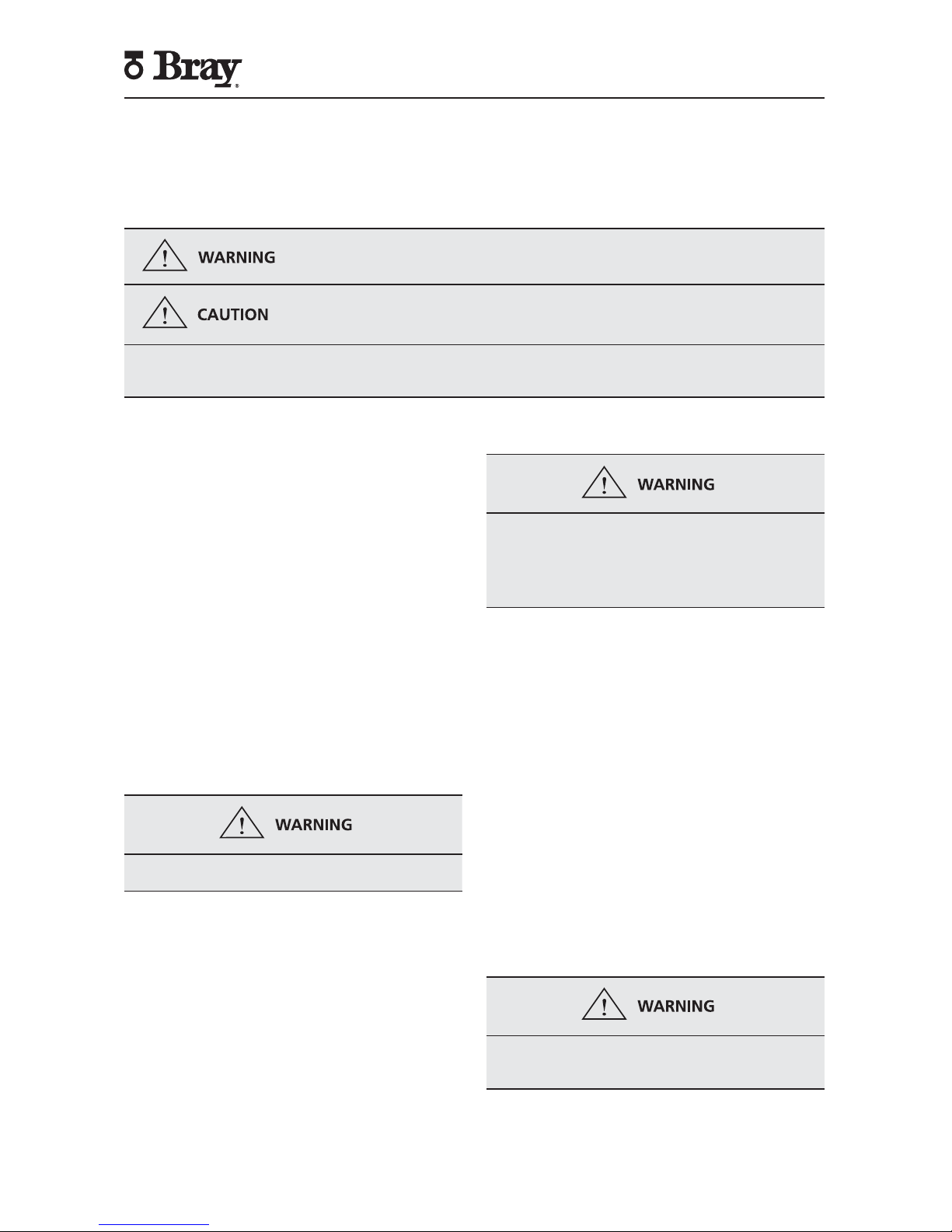

Part Numbering System Reference Chart

SerieS Torque Code Speed produCT STyle VolTage Trim

70 AAA X 113 Y Z TTT

aCTuaTor

S

ize

parT Number

Torque

In.Lbs

TorqueNmSpeed, ¼ TurN

Seconds

Supply

Z Voltage

S70-003

70-003X-113YZ-TTT 300 34 30/15 0/2/4

S70-006

70-006X-113YZ-TTT 600 68 30 0/2/3/4

S70-008

70-008X-113YZ-TTT 800 90 30/15/6 0/2/4

S70-012

70-012X-113YZ-TTT 1200 136 30/15/6 0/2/4

S70-020

70-020X-113YZ-TTT 2000 226 30/15 0/2/3/4

S70-030

70-030X-113YZ-TTT 3000 339 30/18 0/2/4

S70-050

70-050X-113YZ-TTT 5000 565 30/18 0/2/3/4

S70-065

70-065X-113YZ-TTT 6500 734 30 0/4

S70-130

70-13WX-113YZ-TTT 13000 1469 110 0/4

S70-180

70-18WX-113YZ-TTT 18000 2034 110 0/4

Use this chart as a guide to interpret the S70 electric actuator part number.

Note: Not all combinations are possible.

TTT - DESIGNATES

THE PRODUCT TRIM

536 Standard Bray Red

5F5 Bray Seacorr Coating

YZ - STYLE / VOLTAGE:

Imp. Metric

DA NA 120VAC Interposing Relay Board

DB NB 220VAC Interposing Relay Board

DC NC 24VAC On/Off with Controller

DD ND 24VDC On/Off with Controller

AA MA 120VAC Modulating with Servo Pro

AB MB 220VAC Modulating with Servo Pro

AC MC 24VAC Modulating with Servo Pro

AD MD 24VDC Modulating with Servo Pro

G0 R0 120VAC Modulating with Servo NXT

G2 R2 24VDC Modulating with Servo NXT

G3 R3 24VAC Modulating with Servo NXT

G4 R4 220VAC Modulating with Servo NXT

NOTE: 220VAC units are 230VAC compatible

W - DESIGNATES

THE OUTPUT

BORE

DIAMETER

0

2.5 Inches

[63.5 mm]

1

1.97 Inches

[50 mm]

X - DESIGNATES

THE SPEED

X: 0 1 2 6

Sec: 60 30 15/18 110

Y - DESIGNATES

STYLE

Imp. Metric

G R Servo NXT

D N I.R.B. On/Off

A M Servo Pro

Z - DESIGNATES THE

VOLTAGE

Z:

0 2 3 4

A D C B

Voltage:

120VAC

24VDC

24VAC

220VAC

Units of measure designation = Imperial [Metric]

Page 6

4

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Actuation

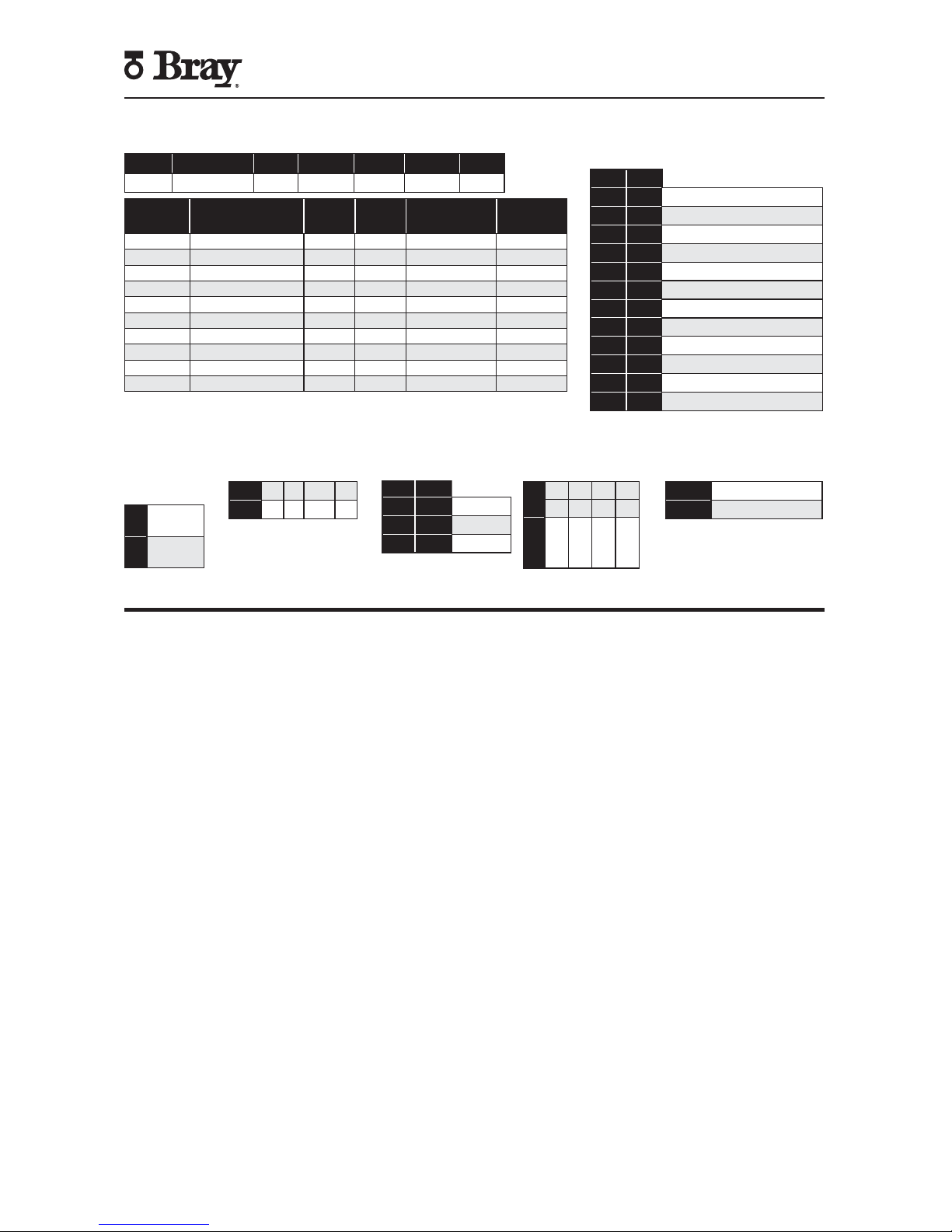

Manual Operation

The manual override operates similar to a watch

adjusting knob. To engage the manual override, simply

pull the handwheel to its outermost position. A yellow

stripe is revealed to visually indicate manual override

engagement as shown in Figure 1. The two handwheel

positions, engaged and disengaged, are held in place

with the use of spring plungers. The handwheel remains

in position until physically moved.

Yellow Stripe

Figure 1 - Handwheel is engaged, revealing the yellow stripe.

Once the manual override is engaged, rotating the

handwheel in the clockwise direction will rotate the

output shaft in the clockwise (close) direction and

vice-versa.

To disengage the manual override, the handwheel needs

to be pushed towards the actuator until the ‘yellow

stripe’ is hidden.

A label on the handwheel hub warns users not to

exceed a specific ‘rim pull’ force, for each size of

actuator.

If the ‘rim pull’ force is exceeded, the roll pin securing

the handwheel onto the manual override shaft is

designed to shear, thus preventing serious internal

gearing damage.

Remote Operation

1. Verify that the main electric power supplied to the

actuator is in compliance with the specifications on

the actuator label.

2. Engaging the handwheel before or during the

application of a supply voltage will prevent the

actuator motor from operating.

3. If torque switches are installed in the actuator, an

over-torque condition will prevent the actuator

motor from operating in the direction of fault.

S70 On/Off Actuator with Interposing Relay

Board (I.R.B.)

The back feeding of one actuator by another one

wired in parallel is eliminated by using the I.R.B. If

actuator is running Open and customer switches

“instantaneously” to run Closed, the Open relay will

take time to ‘drop-out’ and the Close relay will take

time to ‘pull-in’ this time lapse is ~ 40ms. The time

delay provided by the I.R.B. will protect the switches

and gears from the controller’s instantaneous command

signal reversal. Current draws and field wirings are not

affected by adding I.R.B.

S70 120VAC I.R.B., auxiliary switch, heater, and torque

switch option are UL certified units

NOTE: The host controller should use a one second

time delay for command signal reversal.

Apply voltage to only one direction terminal at a time.

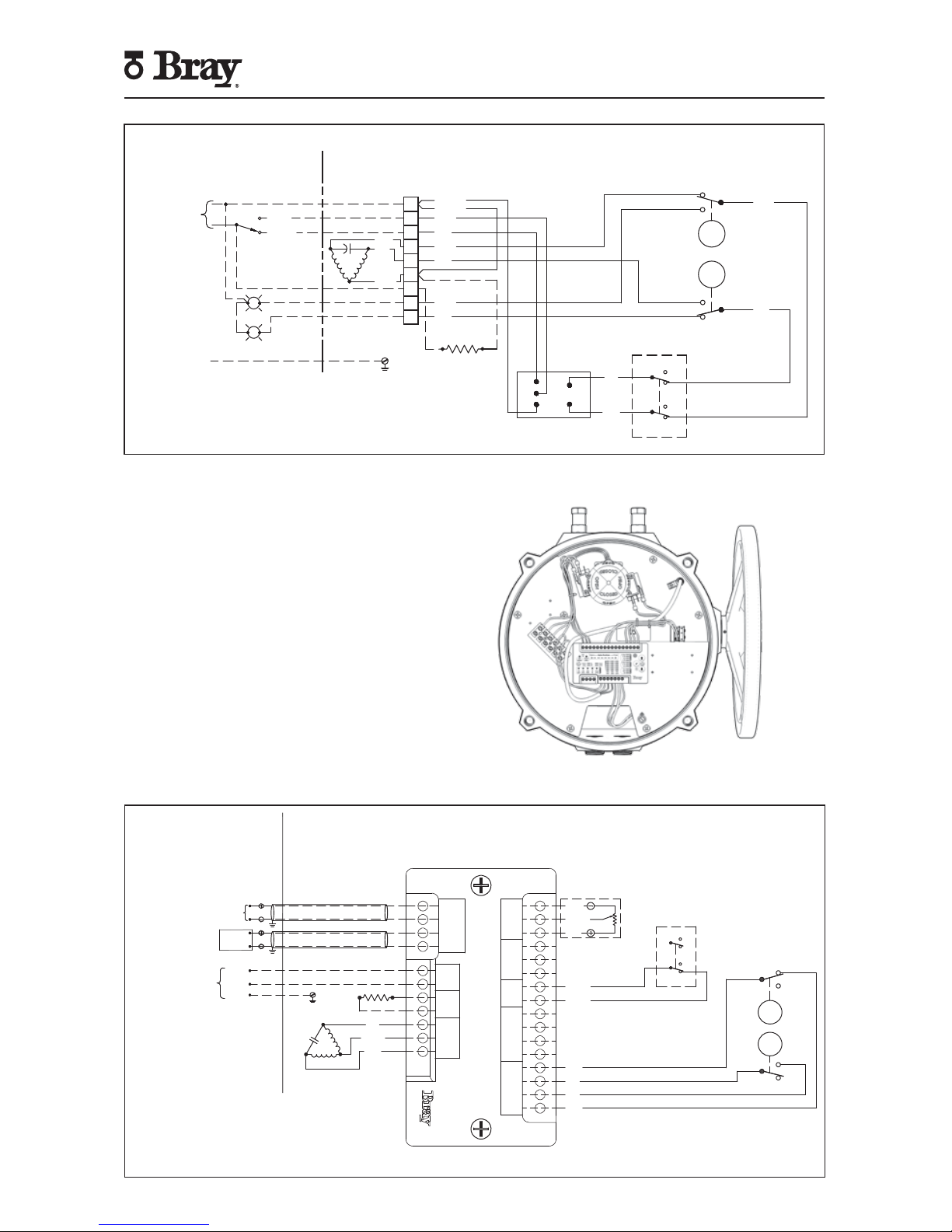

Figure 2 - S70 with I.R.B.

Page 7

5

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Servo NXT

To control the actuator remotely from a process

controller in a modulating application, user must apply

the proper supply voltage and the configured control

signal to the Servo NXT electronics package. The control

signal may be applied locally from a hand-held signal

generator or remotely from a process controller.

For more information, please refer to the S70 Servo

NXT Manual. This manual is available on the company

website (bray.com).

Figure 4 - S70 with Servo NXT

FIELD WIRING ACTUATOR

SINGLE PHASE

POWER SUPPLY

GROUND

N

L

OPEN

BLUE

CLOSE

OPEN

CLOSE

(SEE NOTE 5)

FOR HEATER OPTION ONLY

RED

YELLOW OR

BLACK

O

C

N

MOTOR

YELLOW

YELLOW

RED

RED

RED

RED

BLUE

OVERRIDE SW

CLOSE

OPEN

RED

HEATER (OPTIONAL)

BLUE

BLUE

BLUE

BLUE

GREEN

CAM

RED

CAM

N.C.

COM

N.O.

N.C.

COM

N.O.

OPEN

CLOSE

COM

COM

N.C.

N.O.

N.C.

N.O.

CL

OP

N

MC

MO

INTERPOSING RELAY

1

2

3

4

5

6

7

8

9

Actuator shown in closed position

Figure 3 - Sample field wiring diagram for Series 70 actuator with I.R.B.

Actuator specific wiring diagram located inside actuator cover.

Figure 5 - Sample field wiring diagram for Series 70 actuator with Servo NXT.

Actuator specific wiring diagram located inside actuator cover.

FEEDBACK

POTENTIOMETER

WHITE

ORANGE

GREY

YELLOW

YELLOW

OVERRIDE SW

N.C.

N.O.

N.C.

N.C.

N.O.

N.O.

N.C.

N.O.

COM

COM

COM

COM

BLUE

BLUE

RED

RED

OPEN

CLOSE

GREEN

CAM

RED

CAM

COM

INPUT+

INPUT–

OUTPUT+

OUTPUT–

NEUTRAL

LIVE

NEUTRAL

CLOSE

LIVE

NEUTRAL

OPEN

WIPER

POWER

COM

CLOSE

COM

COM1

COM2

CLOSE

OPEN

COM1

COM2

CLOSE

OPEN

HW

OPEN

LIMIT SW

MOTOR

COMMAND

INPUT

POWER HEATER

HAND

WHEEL

CTRL BOX

FB POT

TORQUE SW

RED

YELLOW

OR BLACK

BLUE

HEATER

(OPTIONAL)

MOTOR

O

N

C

FIELD WIRING ACTUATOR

SHIELDED CABLE

OUTGOING FEEDBACK SIGNAL (SHIELDED)

INCOMING COMMAND SIGNAL

(SEE NOTES 5–7)

(SEE NOTES 6–8)

LOAD DEVICE

NOT TO EXCEED

400 OHMS

(4–20mA CONFIGURATION)

SINGLE PHASE

POWER SUPPLY

NEUTRAL

LIVE

GROUND

POSITION

FEEDBACK

DEVICE

Page 8

6

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Storage

Actuators are not weatherproof unless they are

properly installed on the valve or prepared for storage.

Bray cannot accept responsibility for deterioration

caused on-site.

• Store units on a shelf or wooden pallet in order to

protect against floor dampness.

• Cover the units to protect against dust and dirt.

• To prevent condensation from forming inside these

units, maintain a near constant external temperature

and store in a well-ventilated, clean, dry room away

from vibration.

• For units with an internal heater, power should be

supplied to the heater via conduit entry with an

appropriate sealing gland.

Commissioning

Mounting the Actuator

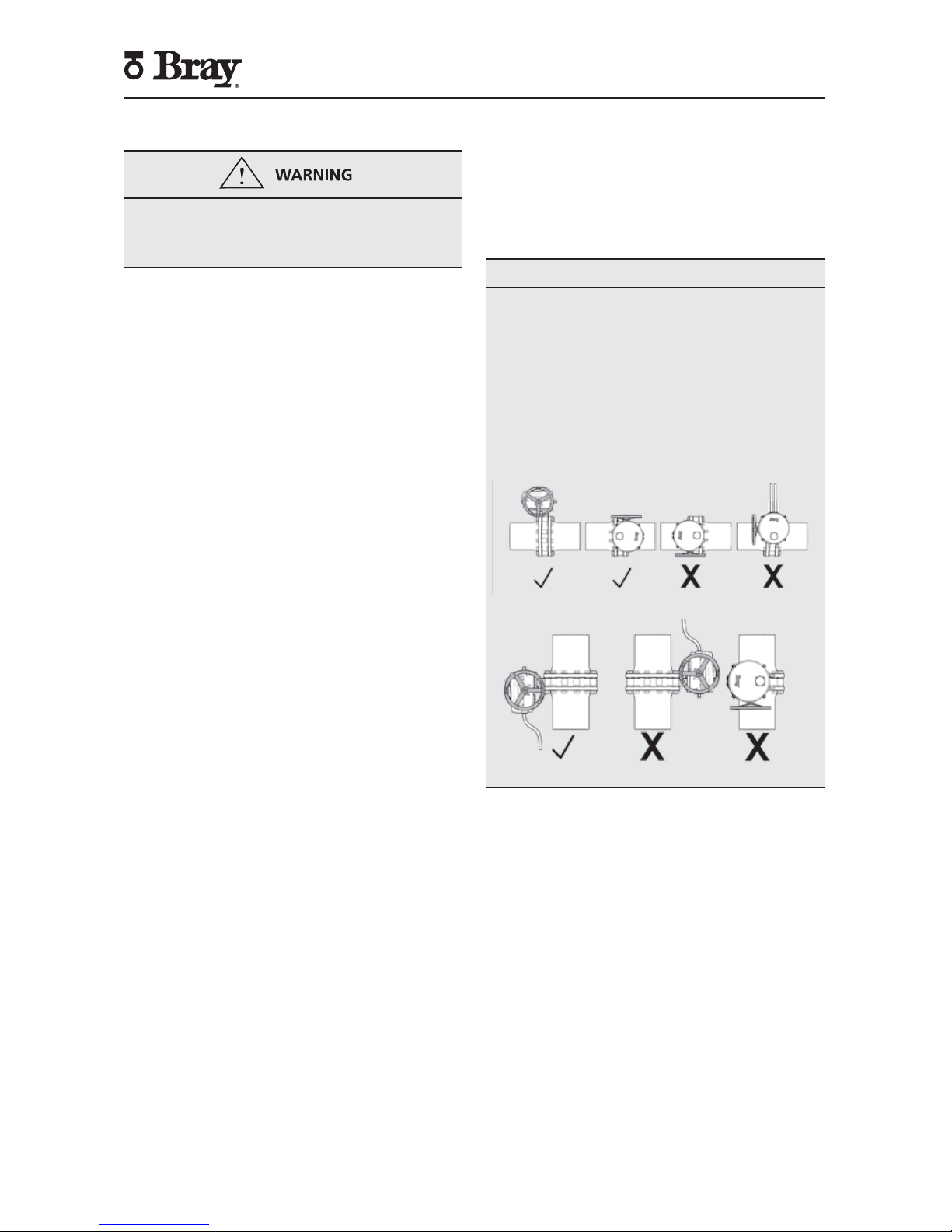

All Bray Series 70 electric actuators are suitable for

direct mounting on Bray butterfly valves. With proper

mounting hardware, the S70 actuator can be installed

onto other quarter-turn valves or devices.

NOTICE

The standard mounting position for the actuator

orients the unit with its handwheel in a vertical plane

and parallel to the pipeline.

If the actuator is mounted on a vertical pipe, it is

recommended that the unit be positioned with

the conduit entries on the bottom to prevent

condensation from entering the actuator through its

conduits.

In all cases, the conduit should be positioned

to prevent drainage into the actuator and the

handwheel should not be facing down.

Follow the steps below to mount the actuator onto

the valve.

1. Manually operate the actuator until the output shaft

of the actuator is in line with the valve stem. If

possible, select an intermediate position for both

the valve and actuator.

2. If required, place the proper adapter onto the valve

stem. It is recommended that a small amount of

‘anti-seize’ lubricant be applied to the adapter to

ease assembly.

3. Mount the actuator onto the valve stem.

4. Install the furnished mounting studs by threading

studs all the way into the actuator base. It may be

necessary to manually operate the actuator to align

the valve and actuator bolt patterns.

5. Fasten the mounting studs in place with furnished

hex nuts and lock washers

Page 9

7

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

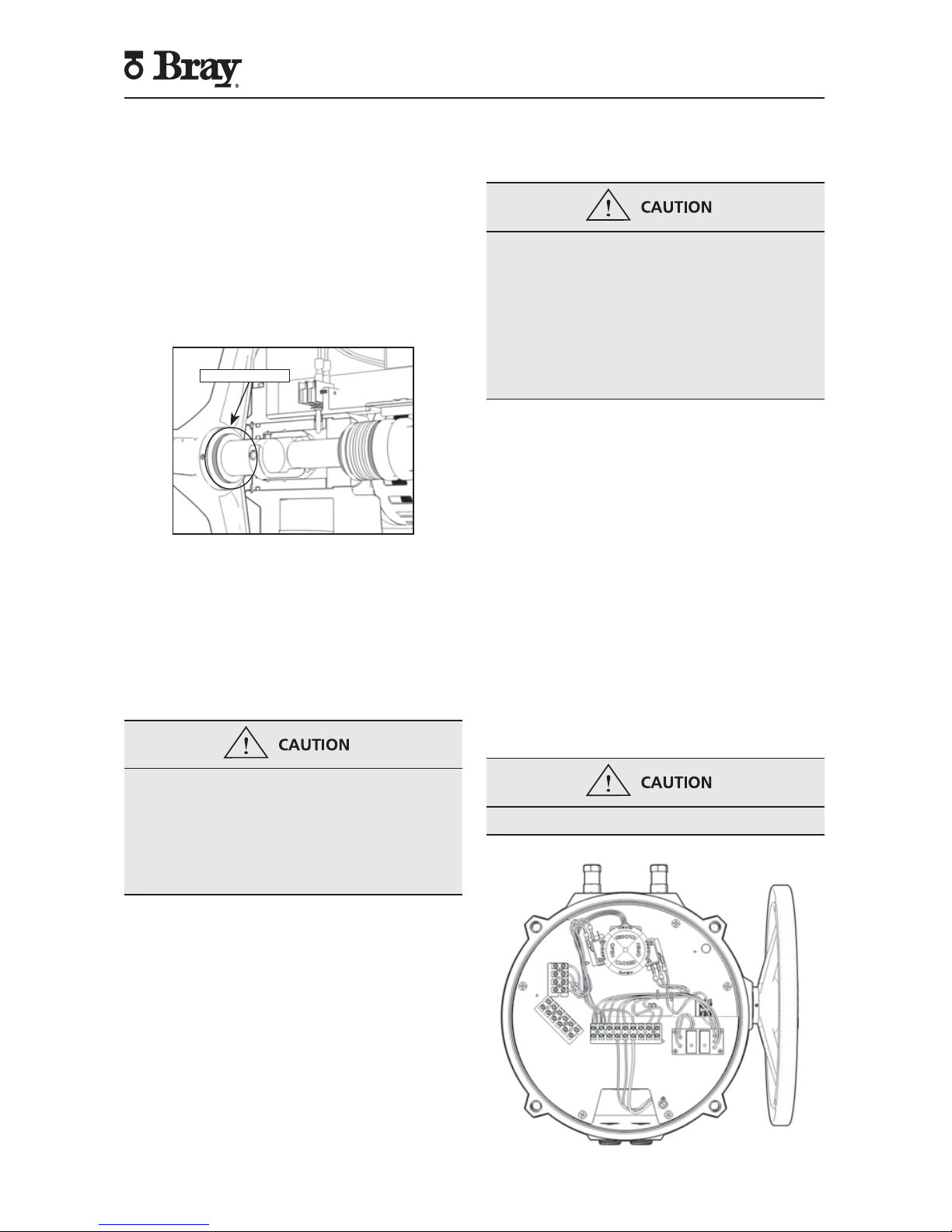

Wiring the Actuator

Turn off all power and lockout/tag out service panel

before installing or modifying any electrical wiring.

1. Take the actuator cover off. The cover should be

kept on hand for reference.

2. Wire the actuator as per the wiring diagram attached

to the inside of the actuator cover.

NOTICE

Power and control wiring should use separate conduit

entries.

NOTICE

A minimum of 18 AWG wire is recommended for all

field wiring.

Terminals directly mounted on the actuator switch

plate accept wire sizes ranging from 14 to 22 AWG.

Terminals of internally mounted electronics modules

accept wire sizes ranging from 14 to 24 AWG.

NOTICE

The conduit connections must be properly sealed to

maintain the weatherproof integrity of the actuator

enclosure.

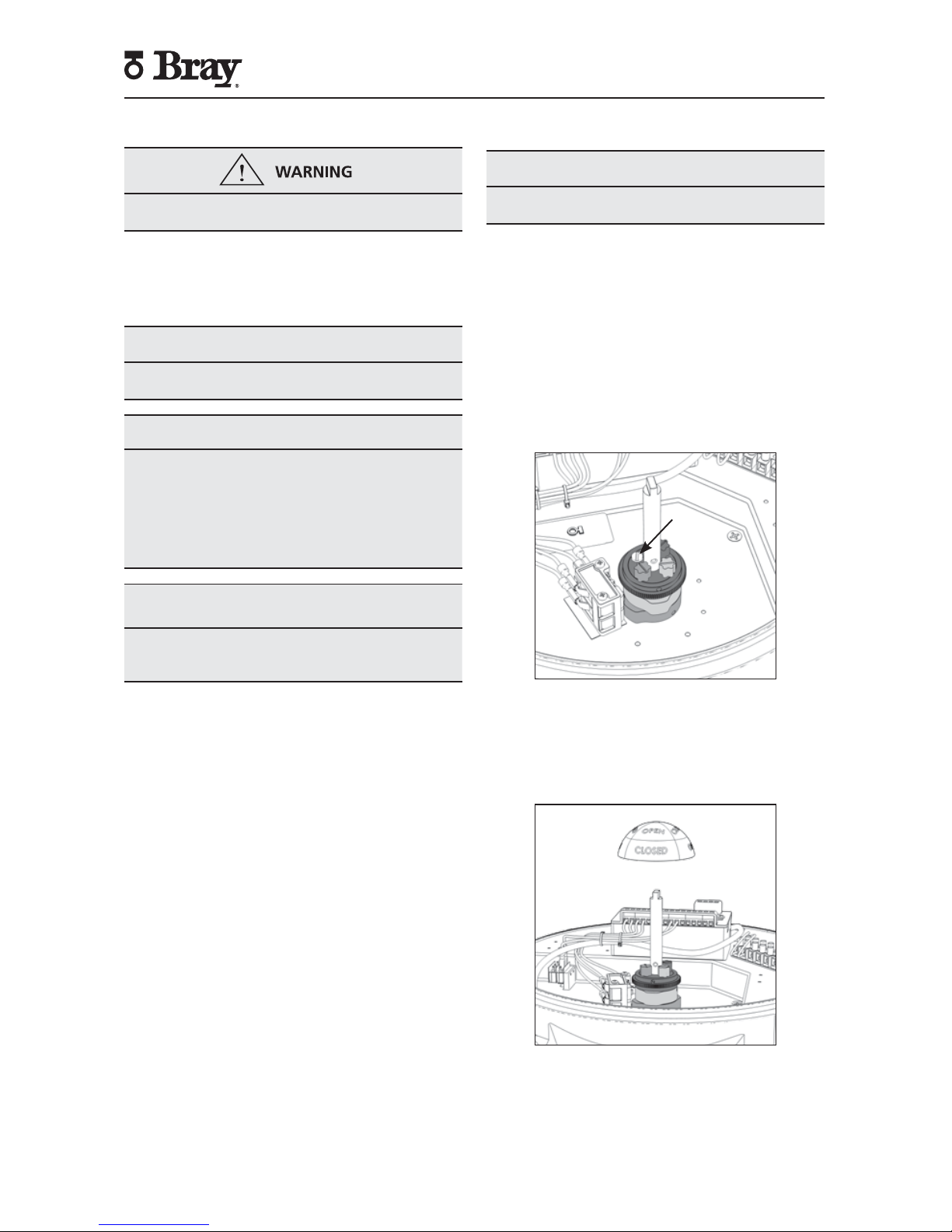

Setting Travel Limit Switches

NOTICE

If the unit came assembled to a valve, the switches

have been factory-set and DO NOT need adjustment.

Bray uses its patented cam design along with two SPDT

mechanical switches to set the ‘Open’ and ‘Closed’

position of the valve. The green cam actuates the ‘open’

switch when the actuator reaches the ‘open’ position.

Similarly, the red cam actuates the ‘closed’ switch when

the actuator reaches the ‘closed’ position.

Standard factory setting of the travel limit switches allows

90° travel between open and close positions. Cams for

each switch are adjustable for applications where less

than 90-degree travel is desired between the open and

closed positions.

Cam

Locking

Screw

Figure 6. Two SPDT Travel Limit Switches

Follow the steps below to adjust the travel limit cams.

NOTE: For Actuator Size 130, 180, ignore steps 1 and 10.

1. Remove the indicator rotor by pulling away from the

indicator shaft as shown in Figure 7.

Figure 7. Indicator rotor pulled up from the indicator shaft.

2. Manually operate the actuator clockwise until the

valve reaches the desired ‘closed’ position.

3. Loosen the cam locking screw shown in Figure 6.

Page 10

8

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

NOTICE

Cam locking screw must be slackened before cam

adjustments and re-tightened after cam adjustments.

Figure 8. Top view of the indicator shaft.

NOTE: It is possible that the rotation of one cam will

move the other cam. If this occurs, hold the other knobs

or cams during adjustment.

4. Rotate the red cam adjustment knob by hand or

with a flat head screwdriver until the red cam lobe

just activates (depresses) the ‘closed’ switch from a

clockwise direction.

NOTE: If fixed auxiliary switches are installed, the auxiliary

cam will activate prior to the main cam.

5. Tighten the cam locking screw.

6. Manually operate the actuator counterclockwise until

the valve reaches the desired ‘open’ position.

7. Loosen the cam locking screw.

8. Rotate the green cam adjustment knob until the green

cam lobe activates (depresses) the ‘open’ switch from

a counterclockwise direction.

9. Tighten the cam locking screw.

10. Place the indicator rotor back on the indicator shaft.

Setting Mechanical Travel Stops

NOTICE

If the unit came assembled to a valve, the stops have

been factory-set and DO NOT need adjustment.

Mechanical travel stops are designed to prevent over

travel while manually operating the actuator. They are

not designed to stop the electric motor.

Mechanical travel stops are located outside of the

actuator base for easy readjustment. Stainless steel lock

nuts with O-ring seals hold the travel stops securely in

place. Travel stop spacers are used to ensure that travel

stop bolts are not engaged to where they could limit 0°

to 90° electrical operation.

NOTE: Actuator Size 130, 180 does not use travel stop

spacers.

Open

Travel

Stop

Closed

Travel

Stop

Figure 9. Mechanical Travel Stops (CW Close).

Follow the steps below to set the mechanical travels

stops.

1. Manually drive the actuator to the ‘closed’ position.

2. Once the actuator is in the ‘closed’ position, rotate

the handwheel clockwise:

• ½ turn for Actuator Size 003, 006.

• 1 turn for Actuator Size 008, 012, 020.

• ½ turn for Actuator Size 030, 050, 065.

• 2 turns for Actuator Size 130, 180.

3. Adjust the ‘closed’ travel stop bolt until the travel

stop spacer is fully engaged or the travel stop bolt

contacts the output segment gear.

Page 11

9

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

4. Lock the travel stop bolt in position with the locknut.

5. Manually drive the actuator to the ‘open’ position.

6. Once the actuator is in the ‘open’ position, rotate

the handwheel counterclockwise

• ½ turn for Actuator Size 003, 006.

• 1 turn for Actuator Size 008, 012, 020.

• ½ turn for Actuator Size 030, 050, 065.

• 2 turns for Actuator Size 130, 180.

7. Adjust the ‘open’ travel stop bolt until the travel

stop spacer is fully engaged or the travel stop bolt

contacts the output segment gear.

8. Lock the travel stop bolt in position with the locknut.

Page 12

10

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Disassembly and Assembly

Turn off all power and lockout/tag out service panel

before installing or modifying any electrical wiring.

1. Disconnect external wiring from terminals.

2. Disconnect motor wires from the main terminal

strip (motor neutral, open, and close)

NOTICE

Removal of switch plate with torque switches will

void warranty.

3. To remove the switch plate:

a. Follow after disconnecting external wires and

motor wires.

b. Unscrew the seven Phillips head mounting

screws.

c. Lift the switch plate(s) out as an assembly with

the indicator shaft attached.

d. NOTE: Do not misplace shaft coupler, insert,

or mounting screws.

Figure 10. S70, Actuator Size 003, 006 – switch plate removed.

4. To replace the switch plate:

a. Engage handwheel.

b. Place insert into the worm segment.

c. Place and center shaft coupler onto insert.

d. Align indicator shaft with groove in coupler

and gently place switch plate into position.

e. Check alignment of override switch activation

pin.

f. Slowly turn handwheel to ensure that the

indicator shaft is fully engaged in coupler.

g. Secure the switch plate with seven Phillips

head mounting screws in a “star” pattern.

h. Disengage the handwheel.

5. To remove the indicator shaft from the switch plate:

a. Follow after removing the switch plate.

b. Remove the retaining ring from the shaft,

located underneath switch plate.

c. Press the shaft out, from the bottom of the

switch plate.

d. NOTE: Provide support to top of switch plate

so that components on top of the switch plate

are not damaged during this procedure.

6. To remove the bearing from the switch plate:

a. Follow after the removing the indicator shaft.

b. Press the bearing from the top of the switch

plate to remove the bearing.

c. To replace, press bearing (700000-72701534)

into switch plate from the bottom of switch

plate.

7. To replace the indicator shaft in the switch plate:

a. Gently press the indicator shaft from the top of

the switch plate until the cams are flush with

the top surface of the switch plate. NOTE:

Provide support for the press fit bearing during

this step.

b. Replace retaining ring (070375-74503534) on

the shaft, located underneath switch plate.

c. Gently press the indicator shaft from the

bottom until the retaining ring is flush with

bottom of the bearing.

d. Test indicator shaft for tight fitment and ease

of rotation.

8. Other switch plate components:

a. Most components can be removed from the

switch plate without removal of the switch

plate.

Page 13

11

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

NOTE: Override switch assemblies are typically only

removable after the switch plate has been removed.

A specialty (short or 90°) screwdriver could be used

for disassembly when the switch plate is still attached

to the actuator base.

Figure 11. S70, Actuator Size 003, 006 – switch plate exploded view.

9. To remove the gear motor:

a. Follow after removing the switch plate.

b. Disconnect the motor leads which run to the

capacitor (120/220VAC motors).

c. For Actuator Size 003, 006, unscrew the

mounting screws (two lower, one upper).

d. For Actuator Size 008, 012, 020, unscrew

the mounting screws (four lower, one upper).

e. For Actuator Sizes 030 - 180, unscrew the

mounting screws (five lower, one upper).

f. Remove the motor vertically out of the unit.

NOTE: Do not misplace the alignment pin(s),

mounting screws or lockwashers.

10. To replace the gear motor:

a. Replace alignment pin (070612-71904520).

b. Place motor into housing and align motor with

worm shaft spur gear.

c. Secure the motor with mounting screws and

lockwashers in a “star” pattern.

d. Manually operate actuator to ensure proper

alignment.

e. Connect motor leads to capacitor (PSC motors

only).

Figure 12. S70, Actuator Size 003, 006 – motor removed.

11. To remove the worm shaft spur gear:

a. Follow after removing the gear motor.

b. For Actuator Size 003, 006:

i. Remove spring pin using a 3/32” [2.0 mm]

punch.

ii. Slide the gear off the end of the worm shaft.

c. For Actuator Size 008, 012, 020:

i. Remove spiral retaining ring

ii. Remove dowel pin with 3/16” [4.5 mm]

punch.

iii. Slide the gear off the end of the worm shaft.

d. For Actuator Sizes 030 - 180:

i. Remove bowed E-clip retaining ring.

ii. Slide the gear off the end of the worm shaft.

iii. Remove key

12. To replace the worm shaft spur gear:

a. Slide the gear onto the end of the worm shaft.

b. For Actuator Size 003, 006:

i. Slide the gear (700006-75511520) onto

the end of the worm shaft.

ii. Align the mounting hole on the gear and

the shaft.

iii. Use a 3/32” [2.0 mm] punch to replace the

slot spring pin (070412-71900520).

c. Actuator Size 008, 012, 020:

i. Slide the gear (700012-75511520) onto

Page 14

12

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

the end of the worm shaft.

ii. Align the mounting hole on the gear and

shaft.

iii. Use a 3/16” [4.5 mm] punch to replace the

dowel pin (070612-71804520).

iv. Replace the spiral retaining ring (070812-

74518520).

d. Actuator Sizes 030 - 180:

i. Rotate the handwheel so that the keyway

is visible and facing upwards.

ii. Replace key (700030-73100901).

iii. Slide the gear (700030-75503520) onto

the worm shaft.

iv. Replace bowed E-clip retaining ring

(070625-74511529).

13. To remove the output drive worm wheel:

a. Follow after removing the switch plate.

b. Back off both mechanical travel stops.

c. Remove the retaining ring and thrust washer

from the bottom of the base.

d. Lift the output drive worm wheel out of its

base.

Figure 13. S70, Actuator Size 003, 006 – output drive worm wheel

and spur gear removed.

14. To replace the output drive worm wheel:

a. Ensure worm wheel contains o-ring and is in

good condition.

b. Ensure that o-ring and worm wheel teeth are

lubricated with grease.

c. Place the worm wheel into the base, meshing

teeth with worm gear.

d. Replace thrust washer and retaining ring.

e. Engage handwheel and manually drive worm

wheel to ensure smooth operation.

f. Reset mechanical travel stops after switch plate

has been replaced.

15. To remove the handwheel:

a. Engage the handwheel.

b. Use a punch to remove the slot spring pin.

i. Actuator Size 003, 006: 3/32” [2.0 mm]

punch

ii. Actuator Size 008 - 180: 1/8” [3 mm] punch

c. Slide the handwheel off of the override shaft.

Figure 14. S70 with handwheel removed.

16. To replace the handwheel:

a. Engage the override shaft.

b. Slide the handwheel onto the override shaft

and align mounting holes.

c. Use a punch to fit a replacement slot spring pin.

i. Actuator Size 003, 006 slot spring pin:

070316-71900529

ii. Actuator Size 008, 012, 020 slot spring

pin: 070424-71900534

iii. Actuator Size 030, 050, 065-180 slot spring

pin: 070428-71900534

d. Disengage the handwheel.

Further disassembly of the unit requires special tools

and procedures, and thus will not be covered in this

manual.

Page 15

13

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Field or Factory Installable Options

Auxiliary Switches

Auxiliary switch kits are a field or factory installable

option for all Series 70 actuators. Switch kits are

comprised of dry-contact (voltage free) SPDT mechanical

switches which are used to indicate travel position.

Switches are arranged into 2 stacks. For Actuator Size

003 - 065, stack 2 activates 3° prior to switches in

stack 1. For Actuator Size 130, 180, the switch that

activates 3° early depends on the direction of travel.

Auxiliary

Switches

Figure 15. Fixed auxiliary switches installed in a S70 actuator.

All Series 70 actuators can be fit with one set of fixed

auxiliary switches. These are a single set of switches

which activate 3° before the travel limit switches.

Adjustable auxiliary (Mid-Travel) switches can be fit

as single independent switches or in sets. If fitted as a

set, one of the switches in the set will activate 3° before

the other. Each switch set is activated independently

from other switch sets.

The maximum number and configuration of switches

depends on Actuator size and application of the Series

70 actuator. Terminal block availability due to installation

of other options may also limit the maximum number

of switches.

Switch Config.

for Modulating

Application

Actuator Size

003, 006

Actuator Size

008 thru 065

Actuator Size

130, 180

2 Limit Switches Standard Standard N/A

2 Limit, 2 Fixed 70A000-22901536 70A000-22901536 Standard

2 Limit, 2 Fixed, 1 Mid 70A006-22912536 70A012-22912536 70B180-22912536

2 Limit, 2 Fixed, 2 Mid N/A N/A N/A

2 Limit, 2 Fixed,

1 Set Mid

N/A 70A012-22914536 70B180-22914536

2 Limit, 2 Fixed,

2 Set Mid

N/A N/A N/A

Switch Config. for

On/Off Applications

Actuator Size

003, 006

Actuator Size

008 thru 065

Actuator Size

130, 180

2 Limit Switches Standard Standard N/A

2 Limit, 2 Fixed 70A000-22901536 70A000-22901536 Standard

2 Limit, 2 Fixed, 1 Mid 70A006-22902536 70A012-22902536 70B180-22902536

2 Limit, 2 Fixed, 2 Mid 70A006-22903536 70A012-22903536 70B180-22903536

2 Limit, 2 Fixed,

1 Set Mid

70A006-22904536 70A012-22904536 70B180-22904536

2 Limit, 2 Fixed,

2 Set Mid

N/A 70A012-22905536 70B180-22905536

Heater

Bray offers an optional heater as a field or factory

installable option for the Series 70 actuator to prevent

condensation from forming inside the actuator. This

PTC (Positive Temperature Coefficient) style heater

has a unique temperature - resistance characteristic.

The heater self-regulates by increasing its electrical

resistance relative to its temperature. The heater does

not require external thermostats or switches to control

its heat output.

Heater

Figure 16. Heater installed on a S70 switch plate.

NOTICE

The heater must have a constant power supply to be

effective

The heater surface can reach temperatures in excess

of 392°F [200°C].

Page 16

14

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Heater Kit:

• Heater with flying leads

• Mounting Bracket

• #10 Pan Head Screw, Phillips Drive

Tools Required:

• Screwdriver, 3/16” [5 mm] tip flat blade

• Screwdriver, No.1 Phillips

Installation Procedure:

Turn off all power and lockout/tag out service panel

before installing or modifying any electrical wiring.

The heater is mounted through a hole provided in

the switch plate.

1. Place the heater snugly into its mounting bracket

until approx. 1/2 to 1” [13mm to 25 mm] is left

above the bracket.

2. Slip the heater into its mounting hole.

3. Align the fastening hole in the bracket with the

threaded screw hole in the plate and fasten the

heater to the switch plate.

4. Connect the heater wires to the terminal strip as

indicated on the wiring diagram.

Torque Switches

Mechanical Torque switches are a factory installed and

calibrated option available for all Series 70 actuators.

Installation is simple, but due to the requirement for

special calibration equipment, it is not available for

field installation. Modifying the factory torque setting

voids the actuator warranty. Removal of the switch

plate invalidates factory calibration

The worm is pinned to the worm shaft, which is held in

position with a stack of disc springs at both ends. The

torque transmitted through the worm to the output

worm gear acts directly against the disc springs, which

compress proportionately. The worm and worm shaft

shift axially as a result.

A specially designed drive lever and pin is incorporated

into a groove on the worm, providing the profile for the

torque switching mechanism. A drive lever & pin rides

in the worm gear torque sensor groove, and in turn

drives a cam. The cam then actuates its electrical switch,

which interrupts the power to the motor winding when

the torque exceeds the setting. The motor can still

be powered to run in the opposite direction. When

powered in the opposite direction, the tripped torque

switch will release automatically.

NOTICE

Torque switches are not field adjustable. Adjustment

of torque switches in the field will void warranty.

Removal of switch plate with torque switches in the

field will void warranty.

Local Control Station

The local control station is a field or factory installable

option that gives the operator the ability to locally drive

the Series 70 actuator with electrical power; overriding

the control signal from the process controller. The

control station has a red (closed) and green (open)

light to provide end-of-travel indication. It also has two

3-position switches as shown in Figure 17.

Figure 17. S70 with Control Station.

Switch 1 lets the operator choose between the following

three modes of operation:

1. Local: In this mode, using switch 2 the operator

can drive the actuator to open or close position,

or stop the actuator; overriding any control signal

from the process controller.

2. Off: In this mode, the actuator can only be operated

manually.

3. Remote: In this mode, the actuator is controlled

remotely from a process controller.

Control Station Kit

• Local Control Station Assembly

• #10-24UNC x 4.5” Socket Head Cap Screws

(Qty:4)

• O-rings (Qty:4)

• Gasket

• Wiring Diagram

Tools Required:

• Screwdriver, 3/16”[5 mm] tip flat blade

• Screwdriver, No.1 Phillips

• Hex Key, 5/32”

Page 17

15

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Installation Procedure:

Turn off all power and lockout/tag out service panel

before installing or modifying any electrical wiring.

The local control station is mounted to the S70 against

the conduit openings using 4 pre-drilled and tapped

mounting holes.

1. Remove the S70 actuator cover and set aside in a

safe location.

2. Remove all conduit plugs and external connections

on the S70 that may already be in place.

3. Remove 4 short bolts and washers that were preinstalled on the exterior of the S70 base, surrounding

the conduit entries.

4. Adhere the gasket to the control station base.

5. Slide o-rings onto the long mounting bolts until

flush with bottom of bolt head.

6. Mount the control station to the actuator using the

4 mounting bolts.

7. Wire the control station to the actuator in accordance

to the wiring diagram provided.

NOTICE

Power and control wiring should use separate conduit

entries

NOTES:

• The local control station contains no terminal strips

and all wiring is direct to the switches and lights via

2 x ¾” NPT or holes in bottom of housing.

• Ordering the control station with optional pin

connector receptacles will eliminate the necessity

of field wiring. Not all possible options are available

with receptacles. Consult factory.

• Control station will be completely factory wired

and tested.

• Factory will need wiring diagram drawing number

of the existing unit if it is to be retrofit with a local

control station. New wiring diagram will be provided

based upon this information.

• Local control station can be ordered with key lockable

switches.

• Local control station requires a dedicated set of

auxiliary switches. These switches are required for

turning on or off the lights on the control station

to locally indicate actuator position.

• Alternative mounting kit can be ordered in case it is

preferred to mount the control station nearby but

not on the S70 actuator.

Battery Backup Unit

Bray offers a factory installable Battery Backup Unit

(BBU) for the 24 V Series 70 electric actuator.

In the event of power failure, the BBU will switch the

actuator to battery power to reach its fail position. After

the actuator has reached its fail position, the BBU goes

to ‘Standby Mode’ until external power is restored.

Once external power has been restored, the actuator

returns to the position corresponding to the control

signal present.

Figure 18. S70 with Battery Backup Unit.

Battery Backup Unit is available as a factory installable

option. For more information, please refer to the S70

24V Actuator with BBU Manual. This manual is available

on the company website (bray.com).

Page 18

16

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Indication of Remote Control

Bray offers two field or factory installable kits to indicate

if a process controller has remote control of the Series

70 actuator. Remote control of the actuator can be

interrupted if the actuator handwheel has been left

engaged or if a local control station has been switched

out of remote mode.

A dry contact (voltage free) mechanical switch provides

indication if the handwheel is engaged. Alternatively, an

additional dry contact (voltage free) mechanical switch

can be placed in Local Control Station to provided

indication if the local control station is switched out

of remote mode. Both kits can be installed and wired

in series to provide dual indication. Dual indication

wiring is meant to indicate that remote control has

been interrupted and does not distinguish between

modes of interruption.

NOTE:

• Factory will need wiring diagram drawing

number and model of the existing unit if it is to

be retrofitted with a Remote Control Indication

kit. New wiring diagram will be provided based

upon this information.

• Some configurations may limit use of remote

control indication kits receptacles due to number

of wires entering through the conduit.

Spinner

A spinner is field or factory installable attachment to

the actuator handwheel to ease and speed the manual

operation of the Series 70 actuator. Actuator Size 003,

006 units mount the spinner on a lever which screws

onto the back of the handwheel. Actuator Size 008 - 180

units mount the spinner on the rim of the handwheel.

Figure 19. S70 with Handwheel Spinner Attached.

NOTICE

Care should be exercised in the use of a spinner

equipped handwheel.

Rapid operation of the handwheel to close the valve

may cause water hammer.

Rapid travel into a travel stop may cause damage.

Spinner Kit, Actuator Size 003, 006:

• Spinner and Lever Assembly

• #10-32UNF x 3/8” Flat Head Socket Cap.

Spinner Kit, Actuator Size 008 - 180:

• Spinner Handle

• ¼”-20UNC x ¾” Socket Head Shoulder Bolt

Tools Required:

• Hex Key, 1/8” (Actuator Size 003, 006)

• Hex Key, 3/16” (Actuator Sizes 008 - 180)

Installation Procedure:

• For Actuator Size 003, 006 – Position the lever onto

the back of the handwheel then screw the flat head

cap screw in to place from behind.

• For Actuator Size 008, 012, 020-180 – Place the

socket head shoulder bolt through the spinner

handle and screw it firmly into the handwheel rim.

Receptacles (Quick Connectors)

Bray offers plug-in receptacles as a field or factory

option for quick and easy field wiring of Series 70

actuators. Cord sets to fit these connectors can also

be ordered in several lengths.

Unless otherwise specified, power receptacles will be

5-pin mini style, standard duty with a black anodized

aluminum finish. They conform to ANSI B93.55M except

in wire color. Euro receptacles will be used for low

power instrument and signal cable since they can be

supplied shielded.

Wiring diagrams for plug-in receptacles for either the

Bray Series 70 or the local control station will be provided

as a separate diagram. Units ordered with pin connector

receptacles factory installed are wired and tested

Receptacle Kit:

• Receptacle(s), male pin and male thread ½” NPT

[M20], in the quantity, style, and number of pins

ordered

• Reducing bushing ¾” to ½” NPT [M25 to M20] for

installation in Actuator Sizes 008 - 180 and control

stations

• Wiring Diagram

Tools Required:

• Screwdriver, 3/16” [5 mm] tip flat blade

• Wrench, 1” [25mm]

Page 19

17

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Figure 20. S70 with 5-pin receptacle and corresponding cord set.

Installation Procedure:

1. Screw the receptacle into the actuator conduit entry

using Teflon tape or similar.

2. Wire to the terminal strip according to the wiring

diagram or the field wiring requirements.

NOTES:

• Euro receptacles use 22 AWG wire rated at 250V,

4 Amp. Pin configuration interfaces with European

standards.

• Mini Receptacles use 18 AWG wire rated at 300V, 9

Amp. Pin configuration conforms to ANSI B93.55M.

• Factory will need wiring diagram drawing number

and model of the existing unit if it is to be retrofit with

receptacles. New wiring diagram will be provided

based upon this information.

• Some configurations may limit use of receptacles due

to number of wires entering through the conduit.

External Signal Feedback Potentiometer

Potentiometers are a field or factory installable option

for continuous duty actuators. Actuators which are

not continuous duty do not have a pot gear fitted

on their indicator shafts and must be fitted with a

new indicator shaft in the factory. S70 actuators fitted

with electronics for modulating applications already

fit a potentiometer and cannot fit a second. In this

case, retransmission of position is provided through

the modulating electronics package.

Feedback Potentiometer Kit:

• Potentiometer Assembly

• #6 Cross Drive Pan Head Screws (Qty:2)

• #6 Internal Lockwashers (Qty:2)

• 4-pole Terminal Strip

• Terminal Strip Marker

• Wiring Diagram

Tools Required:

• Screwdriver, 3/16” [5 mm] tip flat blade

• Screwdriver, No.2 Phillips

Figure 21. S70 Potentiometer installation.

1. Orient the actuator in the full open (counter

clockwise) position.

2. Install the potentiometer next to the indicator

shaft where two threaded holes are provided for

installation.

3. Align the raised green rib on pot gear with the

center line of the indicator shaft.

4. Push the assembly towards the cam to mesh the

gears, then tighten the mounting screws.

5. Rotate the actuator handwheel so that the red cam

lobe is facing the body of the potentiometer. Make

sure that the cam is not touching the potentiometer

assembly. Readjust the assembly position if necessary.

6. Cut the terminal marker to fit the 4-pole terminal

strip.

7. Mount the 4-pole terminal strip and marker on the

switch plate.

8. Wire the potentiometer to the terminal strip using

the new wiring diagram.

9. Adhere the new wiring diagram sticker to the inside

of the cover.

NOTE:

• Factory will need wiring diagram drawing number

and model of the existing unit if it is to be retrofit

with a potentiometer. New wiring diagram will be

provided based upon this information.

Raised

green rib

Page 20

18

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Basic Tools

Common To All Units

Terminal connections, cam adjustment Screwdriver,

1

⁄4" [6 mm] flat tip blade

All switches, terminal strip, torque switch plate Screwdriver, No.1 Phillips

Switch plate screws, capacitor Screwdriver, No. 2 Phillips

Actuator Size 003, 006

Mounting nuts Wrench,

1

⁄2" Wrench, M8

Cover captivated capscrews Hex key, 1⁄4" Hex Key, M8

Travel stop adjusting bolts and jam nuts Wrench, 7⁄16" Wrench, M6

Motor mount socket flat head capscrew Hex key,

3

⁄32"

Motor mount socket head capscrew Hex key,

9

⁄64"

Conduit Entry Plug (

1

⁄2” NPT) Hex key, 3⁄8” Hex Key, M20

Actuator Size 008, 012, 020

Mounting nuts (small pattern) Wrench,

1

⁄2” Wrench, M8

Mounting nuts (large pattern) Wrench,

3

⁄4" Wrench, M12

Cover captivated capscrews Hex key,

5

⁄16" Hex Key, M10

Travel stop adjusting bolts and jam nuts Wrench,

9

⁄16" Wrench, M10

Motor mount socket head capscrew Hex key,

5

⁄32"

Conduit Entry Plug (

3

⁄4” NPT) Hex key, 9⁄16” Hex Key, M25

Actuator Size 030, 050, 065

Mounting nuts (small pattern) Wrench,

3

⁄4” Wrench, M12

Mounting nuts (large pattern) Wrench, 11⁄8” Wrench, M20

Cover captivated capscrews Hex key,

3

⁄8" Hex Key, M20

Travel stop adjusting bolts and jam nuts Wrench,

3

⁄4” Wrench, M12

Motor mount socket head shoulder bolt Hex key,

5

⁄32” Hex Key, M12

Motor mount socket head capscrews Hex key,

3

⁄16"

Conduit Entry Plug (

3

⁄4” NPT) Hex key, 9⁄16” Hex Key, M25

Actuator Size 130, 180

Mounting nuts (small pattern) Wrench,

3

⁄4” Wrench, M12

Mounting nuts (large pattern) Wrench, 1

1

⁄8” Wrench, M20

Cover captivated capscrews Hex key,

3

⁄8” Hex Key, M12

Travel stop adjusting bolts Wrench,

5

⁄16” Wrench, M25

Motor mount socket head shoulder bolt Hex key,

5

⁄32”

Motor mount socket head capcrews Hex key,

3

⁄16”

Conduit Entry Plug (

3

⁄4” NPT) Hex key, 9⁄16” Hex Key, M25

Appendix A

Page 21

19

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Actuator Troubleshooting Chart

Appendix B

Problem Possible Cause Solutions

Actuator does not operate

Override is engaged Push handwheel in all the way

Wiring is incorrect Check wiring and power supply

Actuator motor has reached its

thermal shutdown temperature

Allow time to cool

Actuator operates in

reverse directions

Field wiring is reversed Rewire field wiring

Actuator does not fully

close valve (or open valve)

Limit switches are depressed Readjust travel limit switches

Mechanical travel stop is stopping

actuator

Adjust mechanical travel stops

Valve torque requirement is higher

than actuator output

Manually override out of seat, try angle

seating or larger actuator

Optional torque switches are

activating

Valve torque exceeds actuator torque

rating - consult factory

Voltage power supply is low Check power source.

Engaging override

handwheel does not shut

off motor

Override pin is corroded or

damaged

Clean and check for smooth operation of

the override switch pin

Override switch is damaged Replace switch

Disengaging override

hand-wheel does not

restart motor

Not completely disengaged

Push handwheel in as far as possible (no

yellow showing)

Override pin is damaged or and

does not activate switch

Replace override pin

Incorrect wiring of override switch Check wiring

Motor runs but worm and

gear segment do not

Worm gear segment is not

meshing with worm

Remove switch plate and inspect, adjust

travel stops to prevent gear disengaging

Pin/Key on Worm/Motor drive

gear sheared

Replace Pin/Key on drive gear

Corrosion inside unit

Condensation forming

Test heater wiring, should have constant

power

Water leaking in

Check all seals and possible water entry

through conduit

Page 22

20

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Series 70 – Size 003, 006 – Electric Actuator Exploded View

26

4140

34 35 36 38 39

45

47475154

58

64

70

73

72

71

44505649

61

27

53

57

62

4646

16

15

7

6

5

4

3

24

23

9

8

10

1

12

17

11

13

20

19

18

55

65

63

42 43

464852 48

68

29 30 31 32 33

22

69

67

28

60

59

- Item 74 is optional.

- Items 15, 16 and 17 are optional.

- Item 22 is installed in units when

torque switches are not required.

66

25

37

2

14

21

74

46

Page 23

21

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Item

No.

Description

1 Indicator Cover Screws

2 Lockwasher

3 Position Indicator Cover

4 O-Ring

5 Cover Fastening Screws

6 Cover

7 O-Ring

8 Position Indicator

9 Cam Assembly

10 Limit Switch Screw

11 Limit Switch Bracket

12 Main Open/Closed Limit Switches

13 Limit Switch Insulator

14 Switch Plate, Fixed

15 Heater Bracket Screw

16 Heater Mounting Bracket

17 Heater

18 Override Switch

19 Override Switch Insulator

20 Override Switch Screw

21 Override Switch Trigger Pin

22 Torque Switch Cover

23 Switch Plate Ball Bearing

24 Retaining Ring

25 Coupler

26 Worm Wheel

27 Spring Pin

28 O-Ring

29 O-Ring

30 Nylon Flat Washer

31 Travel Stop Nut

32 Travel Stop Spacer

33 Travel Stop Bolt

34 Worm Shaft

35 Override Drive Pin

36 Spring Plunger

37 Manual Override Shaft Hub

Item

No.

Description

38 Manual Override Shaft Stub

39 Manual Override Sleeve

40 O-Ring

41 O-Ring

42 Retaining Ring

43 Handwheel

44 Spring Pin

45 Manual Override Bushing

46 Thrust Washer

47 Thrust Roller Bearing

48 Disc Spring

49 Worm

50 Spring Pin

51 Retaining Ring

52 Thrust Washer

53 Base

54 Conduit Plug

55 Name Tag

56 Bushing

57 Drive Gear Pin

58 Drive Gear

59 Terminal Strip

60 Capacitor

61 Gearmotor

62 Lock Washer

63 Motor Cap Screw

64 Wire Entry Guard

65 Dowel Pin

66 Motor Screw

67 Ground Terminal Washer

68 Ground Terminal Screw

69 Switch Plate Mounting Screw

70 Removable Switch Plate

71 Terminal Strip Marker

72 Terminal Strip

73 Terminal Block Screw

74 Aux Open/Closed Limit Switches

Page 24

22

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Series 70 – Size 008, 012, 020 – Electric Actuator Exploded View

45

70

68

69

67

63

61

59 58 57 56 485054

42414036

26

16

17

18

65

27

30

37 44

475155

64

43

62

49515049

38

52535352

31 32 33 34 35

71

72

73

76

77

9

8

6

5

4

3

2

1

12

13

14

15

10

11

24

23

22

21

20

75

74

25

66

28

29

39

19

- Item 77 is optional.

- Items 16, 17 and 18 are optional.

- Item 76 is installed in units when

torque switches are not required.

46

60

7

Page 25

23

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Item

No.

Description

1 Indicator Cover Screws

2 Lockwasher

3 Position Indicator Cover

4 O-Ring

5 Cover Fastening Screw

6 Cover

7 O-Ring

8 Position Indicator

9 Cam Assembly

10 Switch Plate Mounting Screw

11 Switch Plate

12 Limit Switch Screw

13 Limit Switch Bracket

14 Main Open/Closed Limit Switches

15 Limit Switch Insulator

16 Heater Bracket Screw

17 Heater Mounting Bracket

18 Heater

19 Override Switch Trigger Pin

20 Override Switch

21 Override Switch Insulator

22 Override Switch Screw

23 Switch Plate Ball Bearing

24 Retaining Ring

25 Coupler

26 Worm Wheel

27 O-Ring

28 Terminal Strip

29 Capacitor

30 Spring Pin

31 O-Ring

32 Nylon Flat Washer

33 Travel Stop Nut

34 Travel Stop Spacer

35 Travel Stop Bolt

36 Worm Shaft

37 Override Drive Pin

38 Spring Pin

Item

No.

Description

39 Manual Override Shaft Hub

40 Spring Plunger

41 Manual Override Shaft Stub

42 Manual Override Sleeve

43 O-Ring

44 O-Ring

45 Retaining Ring

46 Handwheel

47 Spring Pin

48 Manual Override Bushing

49 Thrust Washer

50 Thrust Roller Bearing

51 Thrust Washer

52 Disc Spring

53 Disc Spring

54 Worm

55 Spring Pin

56 Retaining Ring

57 Thrust Washer

58 Base

59 Conduit Plug

60 Name Tag

61 Bushing

62 Gear Spacer

63 Drive Gear

64 Spring Pin

65 Retaining Ring

66 Gearmotor

67 Lock Washer

68 Motor Cap Screw

69 Dowel Pin

70 Wire Entry Guard

71 Terminal Strip Marker

72 Terminal Strip

73 Terminal Block Screw

74 Ground Terminal Washer

75 Ground Terminal Screw

76 Torque Switch Cover

77 Aux Open/Closed Limit Switches

Page 26

24

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Series 70 – Size 030, 050, 065 – Electric Actuator Exploded View

7

8

72

43 44 45 47

56575859

67

66

68

70

75

73

69

14

15

16

18

19

24

26

28

29

30

38 42

20

27

9

23

3

1

2

5

76

6

36

25

12

13

77

11

10

4

64

63

61

60

49 50 51 52 53 55 54 53 52 51 50 49 48

4039 4137

31 32 33

34

35

74

- Item 77 is optional.

- Items 14, 15 and 16 are optional.

- Item 76 is installed in units when

torque switches are not required.

71

21

22

46

65

62

17

Page 27

25

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Item

No.

Description

1 Indicator Cover Screws

2 Lockwasher

3 Position Indicator Cover

4 O-Ring

5 Cover Fastening Screw

6 Cover

7 O-Ring

8 Position Indicator

9 Cam Assembly

10 Limit Switch Screw

11 Limit Switch Bracket

12 Main Open/Closed Limit Switches

13 Limit Switch Insulator

14 Heater Bracket Screw

15 Heater Mounting Bracket

16 Heater

17 Override Switch Trigger Pin

18 Override Switch

19 Override Switch Insulator

20 Override Switch Screw

21 Ground Terminal Screw

22 Ground Terminal Washer

23 Switch Plate Ball Bearing

24 Retaining Ring

25 Coupler

26 Worm Wheel

27 O-Ring

28 Capacitor

29 Terminal Strip

30 Spring Pin

31 O-Ring

32 Nylon Flat Washer

33 Travel Stop Nut

34 Travel Stop Spacer

35 Travel Stop Bolt

36 Worm Shaft

37 Override Drive Pin

38 Manual Override Shaft Hub

Item

No.

Description

39 Spring Pin

40 Spring Plunger

41 Manual Override Shaft

42 Manual Override Sleeve

43 O-Ring

44 O-Ring

45 Retaining Ring

46 Spring Pin

47 Handwheel

48 Manual Override Bushing

49 Thrust Washer

50 Thrust Roller Bearing

51 Thrust Washer

52 Spherical Washer

53 Disc Spring

54 Worm

55 Spring Pin

56 Retaining Ring

57 Thrust Washer

58 Base

59 Conduit Plug

60 Name Tag

61 Bushing

62 Drive Gear Key

63 Drive Gear

64 Retaining Ring

65 Gear Motor

66 Dowel Pin

67 Lock Washer

68 Motor Cap Screw

69 Motor Shoulder Screw

70 Wire Entry Guard

71 Terminal Strip Marker

72 Terminal Strip

73 Terminal Block Screw

74 Switch Plate

75 Switch Plate Mounting Screw

76 Torque Switch Cover

77 Aux Open/Closed Limit Switches

Page 28

26

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Series 70 – Size 130, 180 – Electric Actuator Exploded View

47484950

51

54

57

58

59

60

61

62

64

63

65

66

67

68

26

25

24

23

22

21

19

18

11

15

14

13

12

10

8

69

70

4

2

17

56

27 28 29 30 31 33 34 35 36 37

40 41 42 43 46 45

43 42 41 40 39

38

52

53

55

1

32

16

9

6

7

7

6

5

3

- Items 12, 13 and 14 are optional.

44 44

20

Page 29

27

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Item

No.

Description

1 Cover Fastening Screw

2 Cover

3 O-Ring

4 Limit Switch Screw

5 Flat Insulation Washer

6 Main Open/Closed Limit Switches

7 Aux Open/Closed Limit Switches

8 Switch Spacer

9 Limit Switch Insulator

10 Torque Switch Assembly

11 Override Switch Trigger Pin

12 Heater Bracket Screw

13 Heater Mounting Bracket

14 Heater

15 Override Switch

16 Override Switch Insulator

17 Override Switch Screw

18 Switch Plate Ball Bearing

19 Retaining Ring

20 Coupler

21 Worm Wheel

22 O-Ring

23 Capacitor

24 Terminal Strip

25 Spring Pin

26 Set Screw

27 Worm Shaft

28 Override Drive Pin

29 Manual Override Shaft Hub

30 Spring Pin

31 Spring Plunger

32 Manual Override Shaft Stub

33 Manual Override Sleeve

34 O-Ring

35 O-Ring

36 Retaining Ring

Item

No.

Description

37 Spring Pin

38 Handwheel

39 Manual Override Bushing

40 Thrust Washer

41 Thrust Roller Bearing

42 Thrust Washer

43 Spherical Washer

44 Disc Spring

45 Worm

46 Spring Pin

47 Retaining Ring

48 Thrust Washer

49 Base

50 Conduit Plug

51 Name Tag

52 Bushing

53 Drive Gear Key

54 Drive Gear

55 Retaining Ring

56 Gear Motor

57 Lock Washer

58 Motor Cap Screw

59 Dowel Pin

60 Motor Shoulder Screw

61 Wire Entry Guard

62 Ground Terminal Washer

63 Switch Plate Mounting Screw

64 Ground Terminal Screw

65 Switch Plate

66 Terminal Strip Marker

67 Terminal Strip

68 Terminal Block Screw

69 Cam Assembly

70 Bushing

Page 30

28

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

1

9

7

8

6

21

20

19

13

16

18

17

15

14

12

11

10

4

3

2

13

14

5

3: 1 GEAR BOX

EXPLODED VIEW

ITEM NO.

DESCRIPTION

1

FASTENING SCREW

2

POSITION INDICATOR PLATE

3

POSITION INDICATOR GASKET

4

ACTUATOR/GEAR BOX GASKET

5

DOWEL PIN

6

O-RING

7

WASHER,FLAT,NYLON

8

NUT,HEX

9

BOLT,HEX HD

10

COVER

11

WASHER, CONICAL

12

ACTUATOR/GEAR BOX FASTENING SCREW

13

OUTPUT GEAR BEARING

14

IDLER/INPUT GEAR BEARING

15

COVER GASKET

16

INPUT GEAR

17

OUTPUT GEAR

18

IDLER GEAR

19

COVER

20

LOCK WASHER

21

BASE FASTENING SCREW

Series 70 – Size 130, 180 – 3:1 Gear Box Exploded View

Page 31

29

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Item

No.

Description

1 Fastening Screw

2 Position Indicator Plate

3 Position Indicator Gasket

4 Actuator/Gear Box Gasket

5 Dowel Pin

6 O-Ring

7 Washer,Flat,Nylon

8 Nut,Hex

9 Bolt,Hex Hd

10 Cover

11 Washer, Conical

12 Actuator/Gear Box Fastening Screw

13 Output Gear Bearing

14 Idler/Input Gear Bearing

15 Cover Gasket

16 Input Gear

17 Output Gear

18 Idler Gear

19 Cover

20 Lock Washer

21 Base Fastening Screw

Page 32

All statements, technical information, and recommendations in

this bull etin are for ge neral use onl y. Consult Bray repre sentativ es

or factory for the specific requirements and material selection

for your intended application. The right to change or modify

produc t design or product without prior notice is reserved.

Patents issued and applied for worldwide.

Bray

®

is a registered trademark of BRAY INTERNATIONAL, Inc.

© 2017 Bray International. All rights reserved.

IOM-70 – 07_31_2017

HEADQUARTERS

Bray International, Inc.

13333 Westland East Blvd.

Houston, Texas 77041

Tel: 281.894.5454

bray.com

THE HIGH PERFORMANCE COMPANY

BRAY INTERNATIONAL

PRIMARY SALES AND SERVICE LOCATIONS

USA

Houston, Texas

CHINA

Hangzhou, Zhejiang

MEXICO

Zapopan, Jalisco

RUSSIA

Moscow

AFRICA

Johannesburg

COLOMBIA

Bogotá

MIDDLE EAST

Dubai

SINGAPORE

Ubi Techpark

BENELUX

Heerhugowaard

FRANCE

Voiron

PACIFIC

Melbourne, Australia

SOUTH KOREA

Seoul

BRAZIL

Paulinia, Sao Paulo

GERMANY

Krefeld

PERU

Lima

SOUTHEAST ASIA

Malaysia

CANADA

Montreal

INDIA

Vadodara

POLAND

O´swi¸ecim

UNITED KINGDOM

Glasgow

CHILE

Santiago

ITALY

Milano

FLOW-TEK RITE CORPORATION AMRESIST KUGELHAHN MÜLLER

USA

Houston, Texas

CANADA

Montreal

USA

Houston, Texas

GERMANY

Krefeld

BRAZIL

Paulinia, Sao Paulo VALVTRONIC BRAY/VAAS

CHINA

Hangzhou, Zhejiang

ARGENTINA

Buenos Aires

INDIA

Chennai

Loading...

Loading...