Page 1

SERIES 70

ELECTRIC ACTUATORS

TECHNICAL MANUAL

THE HIGH PERFORMANCE COMPANYBRAY.COM

Page 2

SERIES 70 ELECTRIC ACTUATOR

Technical Manual - Table of Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery Backup Unit (BBU) 24V Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Torque and Motor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Actuator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Imperial (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Metric (mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sizes 003-065

Sizes 130-180

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

2

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The right to change or modify product design or product without prior notice is reserved.

Page 3

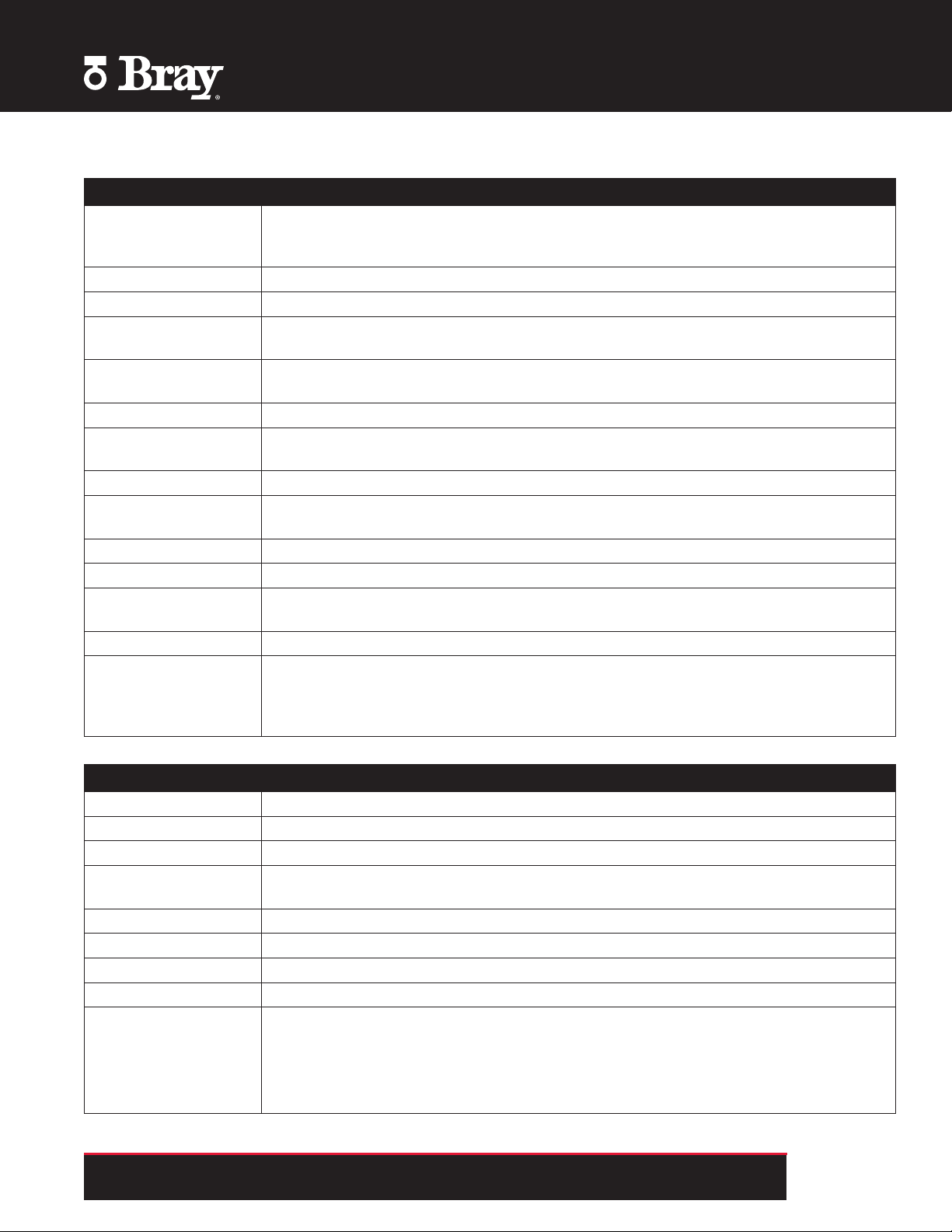

SERIES 70 ELECTRIC ACTUATOR

Specifications

CONSTRUCTION

Housing ASTM B85 pressure die cast aluminum

Polyester powder coated

Seacorr coated (optional)

Exposed Fasteners Stainless steel

Travel Stops Externally adjustable at both 0 and 90 degrees

Conduit Entries S70-003 to S70-006: 2 x 1/2” NPT or 2 x M20

S70-008 to S70-180: 2 x 3/4” NPT or 2 x M25

Worm Gearing Worm: Chromoly, self locking

Worm gear: Aluminum bronze

Spur Gearing AGMA class 9, nitride hardened alloy steel

Bearings Indicator shaft and motor gear: Permanently sealed ball bearing

Worm shaft: Sintered bronze bushing with heavy duty thrust bearing

Lubrication High temperature synthetic grease

Motor 120/220 VAC: Single phase, reversible, permanent split capacitor induction motor

24V: Permanent magnet-brush DC motor

Capacitor 110/220 VAC: Metalized polyester

Heater Optional, 5 watt PTC style

Terminal Strip Switch Plate: 12 - 22 AWG (2.0 - 0.65mm)

Servo: 14 - 24 AWG (1.63 - 0.51mm)

Torque Limiting Optional, open and close preset at factory

Limit Switches SPDT: 120VAC -10A-1/3 HP

220VAC -10A-1/2 HP

250VDC - 1/4A

12VDC - 2A

PERFORMANCE

Output Torque See Torque Chart

Voltages See Motor Chart

Ambient Temperature -20°F to 150°F (-29°C to 65°C)

Motor Insulation 120/ 220 VAC: Class F, 311°F (155°C) thermal trip at 275°F (135°C)

24V: Class B, slow blow fuse 5A@250VAC

Continuous Duty Will operate continuously at a max. ambient temperature of 104°F (40°C)

Intermittent Duty (25%): One motor-on period followed by three motor-off periods

Manual Operation Pull to engage, push to disengage

Enclosure Designed to meet NEMA Type 4, 4x and IP65 specifications

Certifications UL, CSA and CE approved (most models)

UL approved (USA & Canadian Std) for hazardous location

S70-708 to S70-720: 120VAC

Class I, DIV 1 & 2, Group C, D

Class II, DIV 1 & 2, Group E, F, G

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The right to change or modify product design or product without prior notice is reserved.

3

Page 4

SERIES 70 ELECTRIC ACTUATOR

Battery Backup Unit (BBU) 24V Specifications

CONSTRUCTION AND PERFORMANCE

Housing ASTM B85 pressure die cast aluminum

Polyester powder coated

Seacorr coated (optional)

Exposed Fasteners Stainless steel

Batteries Two 12V 1.4AH sealed lead acid batteries wired in series

Battery Monitoring Local LED indicator and voltage free 2-wire normally open contact for remote monitoring

Battery Charging Automatic smart charge

Battery Conservation Shut-off batteries after one minute or when actuator stops

Operating Temperature -4ºF (-20ºC) to 122ºF (50ºC) LED light may not function below -20ºF (-29°C)

Power Protection Two 5 amp fuses, one for the external power output circuit and the other for the battery

output circuit

Current Draw @ 24 VAC BBU only maximum 10mA standby (0.25 VA)

Max. 420mA charging (10 VA)

Current Draw of

Actuator with BBU

Power Requirements 24-27VAC or 30-38VDC

Power Output BBU output with 24VAC supply is 30-38 VDC

600 lb-in - 1.9A (with load)

2,000 lb-in - 2.7A (with load)

5,000 lb-in - 4.1A (with load)

(the minimum voltage is required to provide proper battery charging)

Use dedicated Class 2 non-bonded transformer rated 100VA per BBU

On failure of AC supply, battery output is 24-25.5 VDC

BBU will provide fail open or fail close operation

BATTERY SPECIFICATIONS

Batteries Two 12 volt 1.4 ampere-hour (AH) rechargeable sealed lead acid battery wired in series

Features Valve regulated, spill proof construction allows safe operation in any position

Rugged impact resistant ABS case and cover (UL94-HB)

U.L. Recognized under file number MH 20845

Specifications Battery case: ABS plastic

Maximum discharge current (7 minutes): 4.2 amperes

Shelf Life (% of nominal capacity at 68ºF (20ºC)

1 month = 97%

3 months = 91%

6 months = 83%

Operating Temperature Charge: -4ºF to 122ºF (-20ºC to 50ºC)

Discharge: -40ºF to 140ºF (-40ºC to 60ºC)

The BBU should be powered up for a minimum of 12 hours

Although charging will not work at -4°F (-20°C), the batteries will still hold their charge for an extended period of time as described under

Shelf Life. See Bray Series 70 BBU Operation and Maintenance Manual for detailed information.

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

4

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The right to change or modify product design or product without prior notice is reserved.

Page 5

Torque and Motor Data

SERIES 70 ELECTRIC ACTUATOR

S70-003 S70-006 S70-008

S70-708*

Torque

Actuator Weight

Approx.

MANUAL OVERRIDE

Handwheel Dia.

Gear Ratio 30:1 30:1 30:1 30:1 30:1 30:1 30:1 30:1 90:1 90:1

Rim Pull

* Hazardous Location Units

lb-in 300 600 800 1200 2000 3000 5000 6500 13000 18000

Nm 34 68 90 136 226 339 565 734 1469 2034

lbs 11 11 25 25 25 45 45 45 118 118

kg 5 5 11 11 11 20 20 20 54 54

in 3.5 3.5 8 8 8 12 12 12 12 12

mm 89 89 203 203 203 300 300 300 300 300

lbs 16 32 18 28 46 37 62 80 80 80

kg 7.2 14.5 8.2 12.7 20.8 16.8 28.1 36.3 36.3 36.3

S70-012

S70-712*

S70-020

S70-720*

S70-030 S70-050 S70-065 S70-130 S70-180

120VAC

Travel Time

90°

(Sec)

60 Hz 50 Hz FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA

10 12 1.20 2.10 1.40 2.30

15 18 0.78 2.10 1.20 2.10 1.70 2.30

18 22 1.80 3.00 2.30 3.10

30 36 0.60 1.00 0.80 1.00 0.60 2.10 0.78 2.10 1.00 2.10 1.20 3.00 1.60 3.00 2.30 3.10

110 132 2.30 3.10 2.50 3.10

* Hazardous Location Units

S70-003 S70-006 S70-008

S70-708*

S70-012

S70-712*

S70-020

S70-720*

Current Draw in Amps

S70-030 S70-050 S70-065 S70-130 S70-180

220VAC

Travel Time

90°

(Sec)

60 Hz 50 Hz FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA FLA LRA

10 12 0.50 0.76 0.60 0.81

15 18 0.38 0.90 0.50 0.76 0.55 0.90

18 22 0.78 1.40 1.10 1.40

30 36 0.60 0.75 0.65 0.75 0.38 0.90 0.45 0.90 0.50 0.81 0.75 1.2 0.90 1.40 1.10 1.40

110 132 1.30 2.70 1.50 2.70

FLA - Full Load Amperage

LRA - Locked Rotor Amperage

S70-003 S70-006 S70-008

S70-708

24VAC

Travel Time

90°

(Sec)

60 Hz 50 Hz FLA FLA FLA

60 72 1.80 2.00 4.00

For all other information such as dimensional drawings, wiring diagrams, and EDS files please visit bray.com or contact your local Bray representative.

S70-006 S70-020 S70-050

Current Draw in Amps

S70-012

S70-712

S70-020

S70-720

Current Draw in Amps

24VDC

Travel Time

90°

(Sec)

40 1.80

60 2.00 4.00

S70-006 S70-020 S70-050

Current Draw in Amps

FLA FLA FLA

S70-030 S70-050 S70-065 S70-130 S70-180

Travel Time - Motors

30, 40, 60, 110 second motors are continuous duty

10, 15, 18 second motors are intermittent duty

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The right to change or modify product design or product without prior notice is reserved.

5

Page 6

SERIES 70 ELECTRIC ACTUATOR

Actuator Mounting

Imperial (in)

Actuator

Size

S70-003 F07 2.76 4 5/16 - 18 - - - - 0.75 0.51 1.75 -

S70-006 F07 2.76 4 5/16 - 18 - - - - 0.75 0.51 1.75 -

S70-008

S70-708

S70-012

S70-712

S70-020

S70-720

S70-030 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 1.97 - 2.60 2 x 7/16

S70-050 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 1.97 - 2.60 2 x 7/16

S70-065 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 1.97 - 2.60 2 x 7/16

S70-130 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 1.97 - 5.40 4 x 7/16

S70-130 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 2.50 - 5.40 4 x 5/8

S70-180 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 1.97 - 5.40 4 x 7/16

S70-180 F12 4.92 4 1/2 - 13 F16 6.50 4 3/4 - 10 2.50 - 5.40 4 x 5/8

F07 2.76 4 5/16 - 18 F12 4.92 4 1/2 - 13 1.18 0.87 2.20 -

F07 2.76 4 5/16 - 18 F12 4.92 4 1/2 - 13 1.18 0.87 2.20 -

F07 2.76 4 5/16 - 18 F12 4.92 4 1/2 - 13 1.18 0.87 2.20 -

Inner Bolt Circle Outer Bolt Circle Stem Hole

Bolt

Circle

No.

Holes

Bolt

Size

Bolt

Circle

No.

Holes

Bolt

Size

Dia.

Across

Flats

Depth Keyway Width

Metric (mm)

Actuator

Size

S70-003 F07 70 4 M8 x 1.25 - - - - 19 13 44.5 -

S70-006 F07 70 4 M8 x 1.25 - - - - 19 13 44.5 -

S70-008 F07 70 4 M8 x 1.25 F12 125 4 M12 x 1.25 30 22 55.9 -

S70-012 F07 70 4 M8 x 1.25 F12 125 4 M12 x 1.25 30 22 55.9 -

S70-020 F07 70 4 M8 x 1.25 F12 125 4 M12 x 1.25 30 22 55.9 -

S70-030 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 50.04 - 66 2 x 12.0

S70-050 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 50.04 - 66 2 x 12.0

S70-065 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 50.04 - 66 2 x 12.0

S70-130 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 50.04 - 137.2 4 x 12.0

S70-130 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 63.50 - 137.2 4 x 16.0

S70-180 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 50.04 - 137.2 4 x 12.0

S70-180 F12 125 4 M12 x 1.75 F16 165 4 M20 x 1.75 63.50 - 137.2 4 x 16.0

Inner Bolt Circle Outer Bolt Circle Stem Hole

Bolt

Circle

No.

Holes

Bolt

Size

Bolt

Circle

No.

Holes

Bolt

Size

Dia.

Across

Flats

Depth Keyway Width

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

6

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The right to change or modify product design or product without prior notice is reserved.

Page 7

Standard Drawings

SERIES 70 ELECTRIC ACTUATOR

Standard Dimensional Drawings

Imperial Standard GA-17500

Metric Standard GA-17499

Imperial Hazardous Location ES11A-0526

Imperial 13,000-18,000 lb-in ES11A-0708

Metric 13,000-18,000 lb-in ES12A-0708

Standard Wiring Diagrams

120/220 VAC On/Off w/ IRB WD-000044

120/220 VAC Servo NXT WD-000338

120/220 VAC Servo Pro WD-000116

24 VAC On/Off w/Aux Switch - S70-003 to 006 WD-000276

24 VAC On/Off w/Aux Switch - S70-008 to 020 WD-000234

24 VAC On/Off w/Aux Switch - S70-030 to 065 WD-000111

24 VAC Servo Pro WD-000145

BBU 24V On/Off w/ Aux Switch - S70-003 to 006 WD-000285

BBU 24V On/Off w/ Aux Switch - S70-008 to 020 WD-000289

BBU 24V On/Off w/ Aux Switch - S70-030 to 065 WD-000270

BBU 24V Servo Pro w/ Aux Switch - S70-003 to 006 WD-000159

BBU 24V Servo Pro w/ Aux Switch - S70-008 to 065 WD-000266

All information herein is proprietary, confidential, and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The right to change or modify product design or product without prior notice is reserved.

7

Page 8

THE HIGH PERFORMANCE COMPANY

BRAY INTERNATIONAL

PRIMARY SALES AND SERVICE LOCATIONS

USA

Houston, Texas

AFRICA

Johannesburg

BENELUX

Heerhugowaard

BRAZIL

Paulinia, Sao Paulo

CANADA

Montreal

CHILE

Santiago

CHINA

Hangzhou, Zhejiang

COLOMBIA

Bogotá

FRANCE

Voiron

GERMANY

Krefeld

INDIA

Vadodara

ITALY

Milano

MEXICO

Zapopan, Jalisco

MIDDLE EAST

Dubai

PACIFIC

Melbourne, Australia

PERU

Lima

POLAND

O´swi¸ecim

RUSSIA

Moscow

SINGAPORE

Ubi Techpark

SOUTH KOREA

Seoul

SOUTHEAST ASIA

Malaysia

UNITED KINGDOM

Glasgow

FLOW-TEK RITE CORPORATION AMRESIST KUGELHAHN MÜLLER

USA

Houston, Texas

CANADA

Montreal

USA

Houston, Texas

GERMANY

Krefeld

BRAZIL

Paulinia, Sao Paulo VALVTRONIC BRAY/VAAS

CHINA

Hangzhou, Zhejiang

ARGENTINA

Buenos Aires

INDIA

Chennai

HEADQUARTERS

Bray International, Inc.

13333 Westland East Blvd.

Houston, Texas 77041

Tel: 281.894.5454

bray.com

All statements, technical information, and recommendations in this bulletin are for general use only. Consult

Bray representatives or factory for the specific requirements and material selection for your intended

application. The right to change or modify product design or product without prior notice is reserved.

Patents issued and applied for worldwide.

®

Bray

is a registered trademark of Bray International, Inc.

© 2017 Bray International. All rights reserved. TM-1055_Electric Actuator_09_2017

Loading...

Loading...