Bray Pneumatic Actuators Accessories User Manual

CONTROLS

A Division of BRAY INTERNATIONAL, Inc.

Bray Pneumatic Actuators & Accessories

Technical Manual

TM-1056 Pneumatic Actuator - 02/20/2013

Bray Pneumatic Actuators &

Accessories

Technical Manual - Table of Contents

Topic Page(s)

Actuator

Installation Notes ............................................................. 3

Mounting Codes ............................................................... 3

Pneumatic Actuator Data.................................................. 4

Series 92 Torque Data ....................................................... 5

Series 93 Torque Data (Imperial) ....................................... 6

Series 93 Torque Data (Metric) ......................................... 7

Proximity Switch

Series 52 Proximity Switch Models ................................... 8

Series 52 Proximity Switch and Display Dimensions ......... 9

Series 52 Specifications ................................................... 10

Series 50 Switch Options ................................................. 11

Positioner

Series 64 Positioner ......................................................... 12

Operators

Series 05 Declutchable Gear Operator ............................. 13

All statements, technical information, and recommendations in this bulletin are for

general use only. Consult Bray representatives or factory for the specic requirements

and material selection for your intended application. The right to change or modify

product design or product without prior notice is reserved.

Pneumatic Actuator & Accessories

Pneumatic Actuator & Accessories

Actuator Installation Notes

These notes apply to the installation of Bray S92/93 pneumatic valve actuators.

• Verify that the valve and the actuator are both in the same position (both open or both closed) before mounting

the actuator to the valve.

• Apply a light coating of grease to the inside of the actuator output bore before installing the actuator on the valve.

This will allow the actuator to be more easily removed from the valve stem even after years of service.

• If stem adapters are required to match the actuator output bore to the valve stem, apply a light coating of grease

to the inside of the stem adapter as well as the inside of the actuator output bore.

• Some stem adapters are kits consisting of multiple components. These kits may contain spacers that look like

stem adapters, but are designed to keep the stem adapter in place during operation of the actuator. Verify that

all stem adapters and spacers are installed in the proper position and sequence.

• If keyed stem adapters are used, the key must be held in the keyway so that it will not work loose during

operation of the actuator. The key may be retained by any one of several methods:

If the valve stem height matches the depth of the actuator output bore, use a key that ts the full length of the

keyway. Tack weld the key to the adapter before installation in the actuator.

Upset the end of the keyway after the key has been installed in the shaft by using a punch or chisel.

• If mounting studs are used instead of bolts, thread the studs completely into the actuator before placing the

actuator on the valve. This assures that the full strength of the connection is achieved.

• While the mounting bolts are only nger tight, cycle the actuator fully open and fully closed to verify proper

alignment on the valve.

• Tighten the mounting bolts or nuts in a diagonal pattern to evenly distribute stress in the bolts.

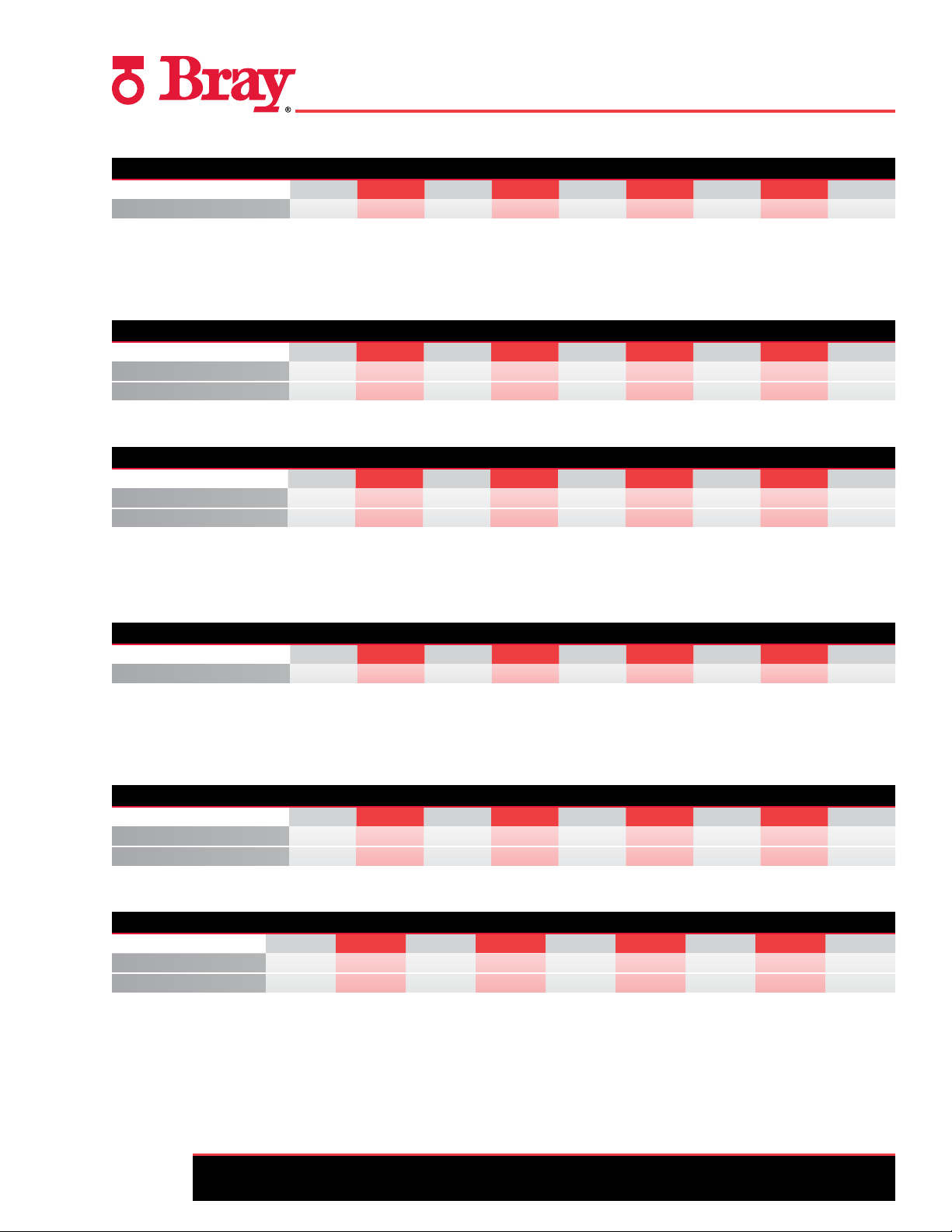

Actuator Mounting Codes for S92/93 - Imperial (In)

Actuator

Sizes

48 AA 1.42 4 #10-32 1.97 4 1/4-20 0.4 0.32 1.3 NA

63 A 1.969 4 1/4-20 2.756 4 5/16-18 0.552 0.395 1.38 NA

83 C 1.969 4 1/4-20 2.756 4 5/16-18 0.749 0.513 1.46 NA

93 C 1.969 4 1/4-20 2.756 4 5/16-18 0.749 0.513 1.46 NA

119 E 2.756 4 5/16-18 4.921 4 1/2-13 1.182 0.867 2.2 NA

128 E 2.756 4 5/16-18 4.921 4 1/2-13 1.182 0.867 2.2 NA

160A E NA NA NA 4.921 4 1/2-13 1.182 0.867 2.2 NA

160B F NA NA NA 4.921 4 1/2-13 1.38 NA 2.38 0.394

210 G 4.921 4 1/2-13 6.496 4 5/8-11 1.97 NA 2.76 0.472

255A H 6.496 4 5/8-11 4.724 X 7.874 4 5/8-11 2.505 NA 4.25 0.625

255B K 6.496 4 5/8-11 4.724 X 7.874 4 5/8-11 3.006 NA 4.25 0.750

Valve

Code

Inner Bolt Circle Outer Bolt Circle Stem Hole

Bolt Circle

(+/- .005)

No.

Holes

Bolt Size

Bolt Circle

(+/- .005)

No.

Holes

Bolt Size

Bore

Diameter

(+/- .004)

Across

Flats

(+ .002-.0)

Depth

Keyway Width

(+ .002-.0)

Actuator Mounting Codes for S92/93 - Metric (mm)

Actuator

Sizes

119 E 70 4 M8 x 1.25P 125 4 M12 x 1.75P 30 22 56 NA

128 E 70 4 M8 x 1.25P 125 4 M12 x 1.75P 30 22 56 NA

160A E NA NA NA 125 4 M12 x 1.75P 30 22 56 NA

160B F NA NA NA 125 4 M12 x 1.75P 35 NA 60 10

210 G 125 4 M12 x 1.75-6H 165 4 M20 x 2.5P 50 NA 70 12

255A H 165 4 M20 x 2.5P 120 x 200 4 M20 x 2.5P 64 NA 108 16

255B K 165 4 M20 x 2.5P 120 x 200 4 M20 x 2.5P 76 NA 108 19

Valve

Code

48 AA 36 4 M5 x 0.8P 50 4 M6 x 1.0P 10 8 33 NA

63 A 50 4 M6 x 1.0P 70 4 M8 x 1.25P 14 10 35 NA

83 C 50 4 M6 x 1.0P 70 4 M8 x 1.25P 19 13 37 NA

93 C 50 4 M6 x 1.0P 70 4 M8 x 1.25P 19 13 37 NA

Inner Bolt Circle Outer Bolt Circle Stem Hole

Bolt Circle

(+/- .127)

No.

Holes

Bolt Size

Bolt Circle

(+/- .127)

No.

Holes

Bolt Size

Bore Dia.

(+/-.102)

Across Flats

(+ .050-.0)

Depth

Keyway

Width

Installation : 3

Installation : 3

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Pneumatic Actuator & Accessories

Pneumatic Actuator & Accessories

Pneumatic Actuator Data (Imperial)

Actuator Speeds (Seconds)

Size 48 63 83 93 119 128 160 210 255

90° Travel

Note: Times shown are in seconds at 80 PSIG supply pressure with 6ft. tubing having an internal diameter of approximately 1/4”. Bray

S92/93 actuation times are very dependent on the ow capacity of their air supply. The use of smaller port solenoids, solenoid

manifolds, smaller I.D. air supply tubing and/or extended lengths of tubing can signicantly reduce the actuation time and/or

initial response to the command signal.

Size 48 63 83 93 119 128 160 210 255

Double Acting

Spring Return

Weights are in lbs. Spring Return unit weights are with full set of springs on each piston.

Size 48 63 83 93 119 128 160 210 255

Counter-Clockwise

Clockwise

Counter-clockwise: Air volume in cubic inches required to push pistons apart, full travel.

Clockwise: Air volume in cubic inches required to push pistons together, full travel.

1/4 1/4 1/4 1/4 1/2 1/2 1 2 2 3/4

Actuator Weights (lbs)

2.0 3.3 6.3 8.5 18.0 21.5 39.0 78.0 143.5

2.3 3.9 8.1 10.9 23.4 28.1 53.4 111.0 214.9

Actuator Volumes (in3)

5.7 9.6 24.8 39.0 81.0 106.5 187.5 360.0 750.0

4.8 13.4 32.6 50.1 102.7 140.6 259.6 450.0 900.0

Pneumatic Actuator Data (Metric)

Actuator Speeds (Seconds)

Size 48 63 83 93 119 128 160 210 255

90° Travel

Note: Times shown are in seconds at 5.5 bar supply pressure with 1.8 meter tubing having an internal diameter of approximately (6.35

mm). Bray S92/93 actuation times are very dependent on the ow capacity of their air supply. The use of smaller port solenoids,

solenoid manifolds, smaller I.D. air supply tubing and/or extended lengths of tubing can signicantly reduce the actuation time

and/or initial response to the command signal.

Size 48 63 83 93 119 128 160 210 255

Double Acting

Spring Return

Weights are in kg Spring Return unit weights are with full set of springs on each piston.

Size 48 63 83 93 119 128 160 210 255

Counter-Clockwise

Clockwise

Counter-clockwise: Air volume in cubic millimeters required to push pistons apart, full travel.

Clockwise: Air volume in cubic millimeters required to push pistons together, full travel.

1/4 1/4 1/4 1/4 1/2 1/2 1 2 2 3/4

Actuator Weights (kg)

0.9 1.5 2.9 3.9 8.2 9.8 17.7 35.4 65.1

1.0 1.8 3.7 4.9 10.6 12.7 24.2 50.3 115.7

Actuator Volumes (cm3)

93.4 157.3 406.4 638.6 1327.5 1744.5 3072.6 5899.3 12290.3

78.7 219.6 534.2 820.5 1683.1 2303.3 4254.1 7374.2 14748.4

Data : 4

Data : 4

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Loading...

Loading...