Page 1

Installation and Maintenance Manual

19

25a

23

1

2

3

4

6

12

28

25

26

15

14

5

A Subsidiary of BRAY INTERNATIONAL, Inc.

®

Series H, HP & HX Ball Valves

Date: August 2011 / Page 1 of 1

INSTALLATION – MAINTENANCE MANUAL

SERIES H, HP & HX

During shipment, storage, and in operation, the valve should be fully open or fully closed (“open” is preferred

for shipping and storage). Do not use in intermediate positions without knowledge of flow and pressure drop.

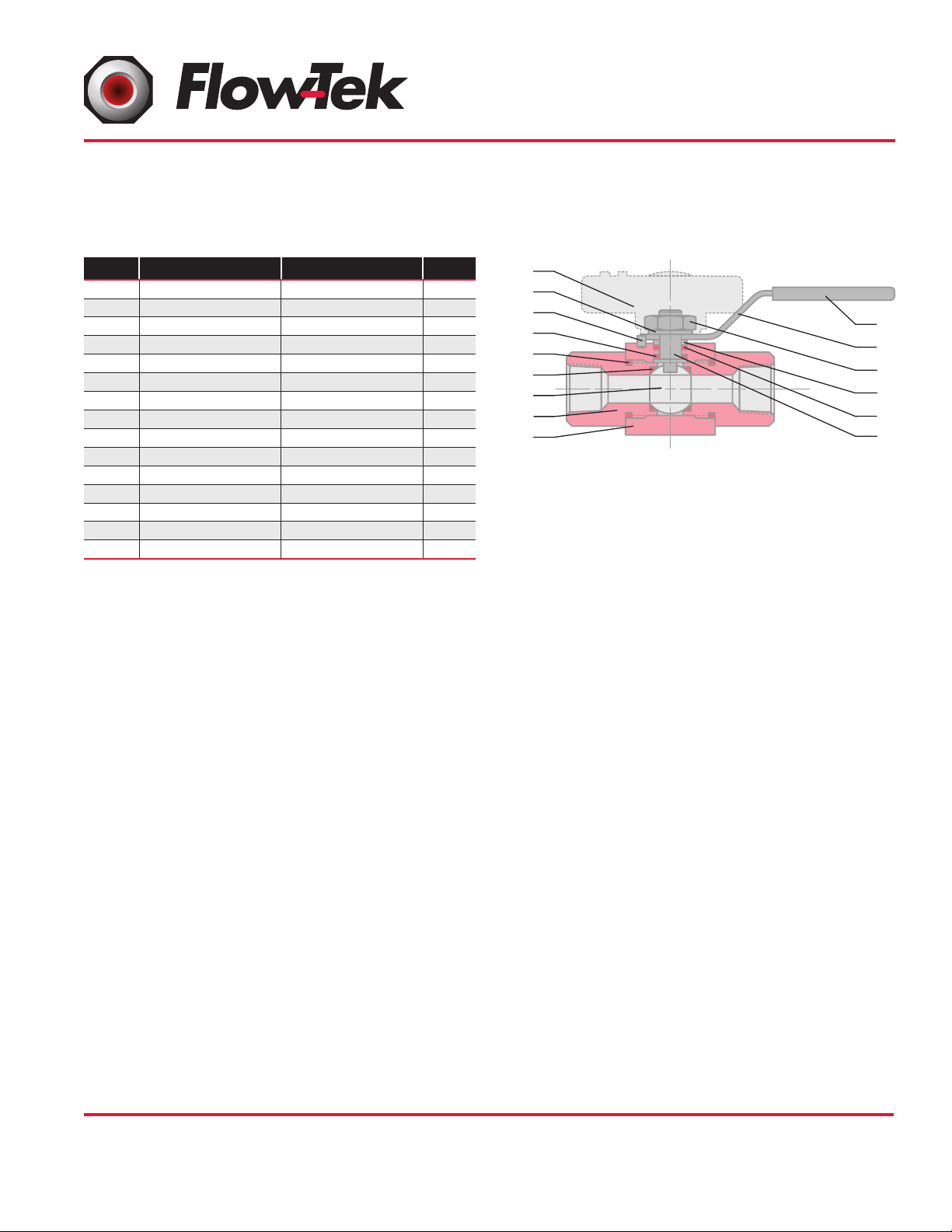

ITEM NAME MATERIAL QTY.

1 Body Stainless Steel 316 1

2 End Connector Stainless Steel 316 2

3 Ball Stainless Steel 316 1

4 Seat* PVDF / PEEK 2

5 Stem Stainless Steel 316 1

6 Body Seal* PTFE 2

12 Thrust Washer* RPTFE / PVDF 1

14 Stem Packing* RPTFE 1

15 Packing Gland Stainless Steel 1

19 Lock Washer Stainless Steel 2

23 Stop Pin Stainless Steel 1

25 Lever Handle Stainless Steel 1

25a Pointer Handle Mazak 3 1

26 Lock Nut Stainless Steel 1

28 Handle Sleeve Vinyl 1

*Items included in repair kit

Dismantling Instruction:

CAUTION- Ball Valves can trap pressurized media when

closed

1. Remove the valve from the pipeline placing the wrench

only on the end connector for each side of the pipe.

2. Clean the valve of any residual media.

3. Remove the retaining pin. Take out each end connector,

holding the body while unscrewing the ends

pressure rating of the valve (The repair kit contains the

recommended spares).

2. Ensure that all parts are cleaned prior to assembly.

3. Place the stem seal (5) onto the stem (9), being careful

not to damage it.

4. Insert the stem through the stem hole, pushing firmly

into place. Put the stem packing (10) onto the stem and

fit the packing gland (12) and lever handle (13) in that

order then apply the washer (8) and nut (11) carefully,

so as not to cross thread it. Tighten the handle nut and

ensure that the stem turns smoothly.

5. Place the valve seat (4) into the bore on one side, make

sure the flat face is pointing away from the center of

the valve.

4. Ensure that the ball is in the closed position and push

the ball and seats out, in either direction.

5. Remove the handle retaining nut and remove the handle.

6. Push the stem out through the body bore to access both

stem seals and remove them.

7. Inspect the ball to ensure no signs of wear or marks,

if it has either, consult factory for a replacement ball.

Visible lines which can not be easily felt are acceptable

on ball surface.

Assembly

6. Insert the ball ensuring that the slot fits onto drive key

on the bottom of the stem, then turn the handle 90° to

hold the ball in place. Repeat step 5 for second seat.

7. Place the new body seals (5) onto each end connector

and insert into the valve body and with the ball in the

closed position, tighten the end connectors to a torque of

163 ft lb (220 Nm) both sides. Install the retaining pins.

8. Finally adjust the handle nut so as to stop any leaks but

without tightening too tight so as to cause excessive

torque for turning the valve (Normally hand tight plus

1/4 turn.)

1. Ensure that you have the correct repair kit for the

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

© 2011 Flow-Tek, Inc.

Loading...

Loading...