Page 1

Installation and Maintenance Manual

A Subsidiary of BRAY INTERNATIONAL, Inc.

®

Multiport Threaded and Weld End Ball Valves

Date: August 2011 / Page 1 of 6

CRYOGENIC AND LOW TEMPERATURE SERVICE

TRIAD SERIES BALL VALVES

(FP2000/FP3000 and SP2000/SP3000 WITH CRYO OR LOW TEMP EXTENSION)

INSTALLATION - MAINTENANCE MANUAL

DESIGN

The extended stem assembly is designed to remove

the packing components and actuation from the cold

environment.

The three piece valve assembly allows for ease of

maintenance without special tools. These valves

feature a “free floating” ball. The ball is not fixed, but

is free to move with the line pressure. All valves are

provided with a vented ball and the flow direction

is indicated with an arrow. These valves should be

installed with the vented side of the ball upstream.

The valve is unidirectional in this configuration.

The downstream seat, opposite the pressurized side

of a closed valve, carries the load exerted by the

line pressure on the ball, while the upstream seat is

subject to little load or wear.

1. USE

The valve should be maintained as part of a

preventative maintenance program and in accordance

with Flow-Tek’s recommended pressure, temperature

and corrosion limits to ensure a long service life.

During shipment, storage, and in operation, the valve

should be fully open (“open” is preferred for shipping

and storage). Do not use in throttling service without

investigating flow and pressure conditions.

WARNING: Before installing this equipment, confirm

that it is suitable for the intended service.

The identifications tags describe the maximum

allowable service conditions for this product.

Be sure that the installation is protected by appropriate

pressure control and safety devices to ensure that

acceptable limits are not exceeded.

2. OPERATION:

a 1/4 turn (90 degree turn). Clockwise to close,

counter-clockwise to open.

A. VALVE OPEN POSITlON

The handle is parallel with the pipeline.

B. VALVE IN CLOSED POSITION

The handle is perpendicular to the pipeline.

Valves with actuators should be checked for actuator

-valve alignment. Misalignment will result in high

operational torque and damage to valve stem and seals.

3. STEM SEAL ADJUSTMENT:

1. For 1/2”- 2”, if slight leakage is noted at stem,

straighten lock washer tab, tighten stem nut to

flatten Bellville Washers, back stem nut off 1/4

turn, secure lock washer tab.

2. For sizes larger than 2”, simply tighten gland

bolts evenly until leak stops. Do not over tighten.

4. GENERAL INFORMATION FOR ON-SITE

INSTALLATION:

The valve must be installed in a horizontal piping run

with the stem vertical within +/- 25 degrees.

Before installing the valves, the pipes must be flushed

clean of dirt, burrs, and welding residues, or the

seats and ball surface will be damaged. See sections

9 thru 11 for installation details. Note direction of

flow arrow.

5. DISASSEMBLY & CLEANING PROCEDURES:

CAUTION: Line must be depressurized before

disassembly. Valve should be cycled to assure there is

no pressure is trapped in valve cavity. Ball valves can

trap pressurized media when closed. Flush line with

valve 1/2 open to remove hazardous media.

Operation of the valve is done by turning the handle

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

WARNING: DO NOT remove packing gland or any

© 2011 Flow-Tek, Inc.

Page 2

A Subsidiary of BRAY INTERNATIONAL, Inc.

Installation and Maintenance Manual

®

Multiport Threaded and Weld End Ball Valves

Date: August 2011 / Page 2 of 6

other valve parts while line is under pressure!

Stem seal leakage may be corrected without

disassembly by tightening the packing gland nut until

such leakage stops. If the leakage continues or valve

operating torque becomes excessive, the seals are

worn and replacement will be necessary.

If the valve has been used to control hazardous media,

it must be decontaminated before disassembly.

It is recommended that the following steps be taken

for safe removal and assembly.

As shipped from the factory, Valves may contain nonSilicone based lubricant. This is for break-in and may

be removed by disassembly and solvent washing, if it

is objectionable for a particular application,

6. DISASSEMBLY FOR EXTENDED STEM AND

SEAL REMOVAL:

1. Remove flange connections and lift valve from

line for servicing.

NOTE: Care should be taken to avoid scratching

or damaging mating faces.

The valve should be adequately supported and in

the open position before beginning.

2. Loosen handle set screw and remove handle and

stop plate. Next, remove gland nuts, gland flange

and gland.

3. Remove body end cap screws, using proper

wrench size. Lift off body end. One seat should

come out with body end.

4. Repeat the removal procedure for the other flange

end. Take out other seat.

5. To remove the ball, rotate the stem so ball is fully

closed. Lift the ball from body, using a strap and

lift device if necessary. NOTE: Extreme caution

should be taken to avoid damage to the ball.

6. Remove the mounting screws holding the extended

body to the valve top plate. Remove the extension

and stem components from the top plate of the valve.

7. The stem must be removed from inside the

extended body - a tap on the top of the stem

should loosen it. The thrust washer should come

out with the stem. Then remove the stem packing.

7. VISUAL INSPECTION:

Clean and inspect metal parts. It is not necessary

to replace the ball and stem unless the seating

surfaces have been damaged by abrasion or

corrosion. Replacement of all soft parts is strongly

recommend whenever the valve is disassembled for

reconditioning. This is the surest protection against

subsequent leakage after valve assembly.

The replacement parts can he ordered in kit form.

NOTE: The valve may be assembled and operated

dry where no lubricants are allowed in the system;

however, a light lubrication of mating parts will aid

in assembly and reduce initial operating torque.

Lubricant used must be compatible with the intended

line fluid.

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

© 2011 Flow-Tek, Inc.

Page 3

A Subsidiary of BRAY INTERNATIONAL, Inc.

Installation and Maintenance Manual

®

Multiport Threaded and Weld End Ball Valves

Date: August 2011 / Page 3 of 6

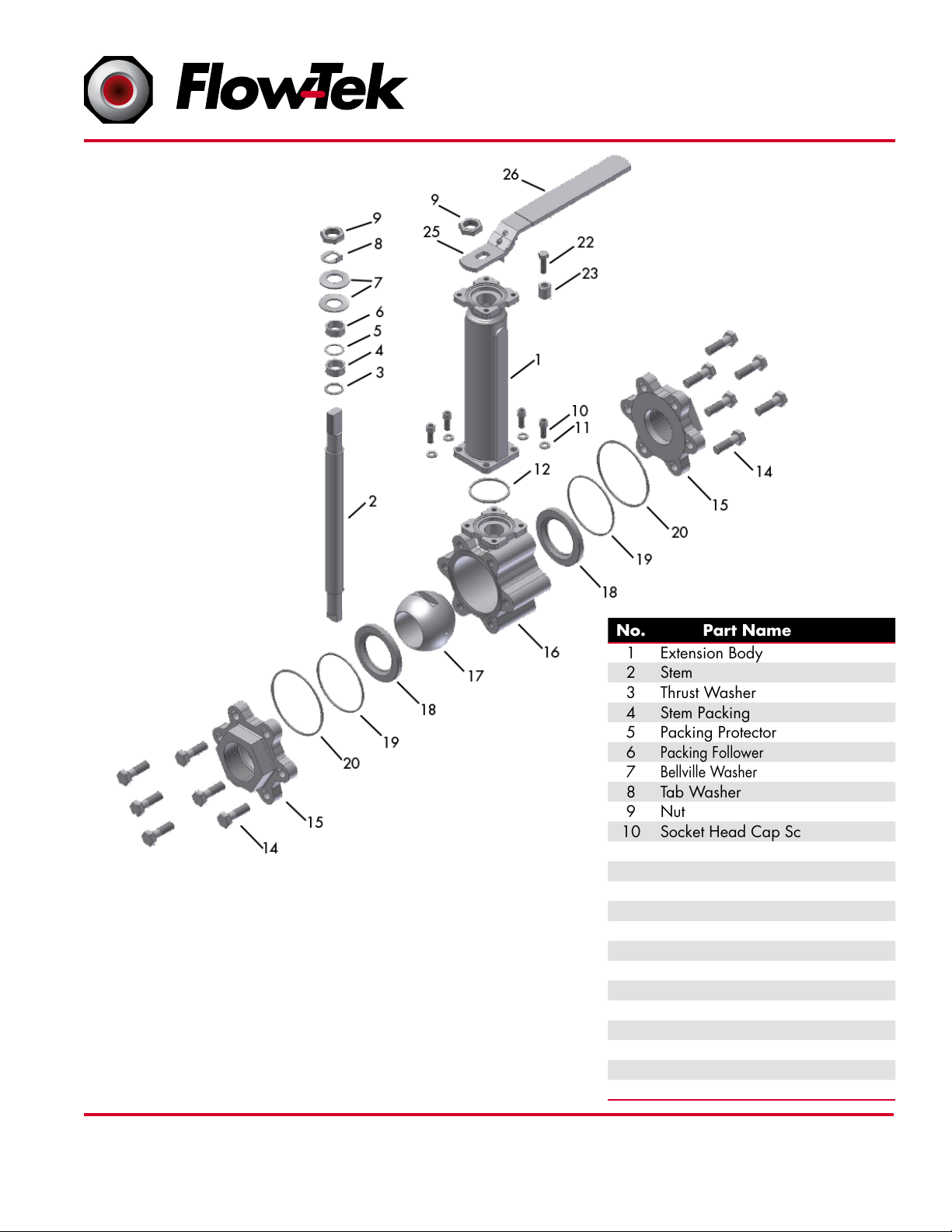

No. Part Name Qty

1 Extension Body 1

2 Stem 1

3 Thrust Washer 1

4 Stem Packing 3

5 Packing Protector 1

6

Packing Follower

7

Bellville Washer

1

2

8 Tab Washer 1

9 Nut 2

10 Socket Head Cap Screw 4

11 Cap Screw Washer 4

12 Bonnet Gasket 1

14 Body Bolt 8/12

15 End Cap 1

16 Valve Body 1

17 Ball 1

18 Seat 2

19 Valve Body Gasket 1

20 Valve Body Gakset 1

22 Valve Stop Bolt 1

23

Valve Stop Set Sleeve

1

25 Handle with Lock 1

26 Handle Sleeve 1

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

© 2011 Flow-Tek, Inc.

Page 4

A Subsidiary of BRAY INTERNATIONAL, Inc.

Installation and Maintenance Manual

®

Multiport Threaded and Weld End Ball Valves

Date: August 2011 / Page 4 of 6

8. ASSEMBLY

½”-2” VALVE ASSEMBLY PROCEDURES:

Hold the body in a vise with the stem horizontally firmly

enough so it will not move but do not crush it.

EXTENDED STEM ASSEMBLY

Put thrust washer (3) on valve stem (2) and slide the

stem into the stem hole in the extended body (1);

Slide the stem packing components (4) onto the stem

until it is sealed against the bottom of the stem hole;

Put packing protector (5). then packing gland sleeve

(6) onto the stem and the top of the stem packing;

Install extension gasket (12) into the body recess and

insert the lower end of the stem into the valve body

stem hole.

Align the four mounting screw holes and install the

four mounting screws (10).

Tighten the four cap screws to the recommended

values in table 1.

Turn the stem so that the ball is in the open position

(the ball will not fall out of the valve);

Install the second seat (18) and two body seals

(19,20) inside the body (16), make sure the spherical

curvature side of the seat will face the ball;

Install the end cap (15) with cap screws (14) and

tighten screws to the values indicated in Table 1.

Put Belleville washer (7) together in series mode (bottom

Belleville washer curve facing up, the top Belleville

washer curve facing down). and then place them onto

the stem, on top of the packing gland sleeve;

Put tab washer (8) on top of the Belleville washer and

tighten the stem gland nut (9) onto the stem to the

required stem gland nut torque value as specified in

the chart.

(Note: The use of a bore alignment tool, about 1.0 mm

(0.04 inch) less than the internal diameter of the end

cap and ball, inserted through the end cap and ball

will prevent the ball from turning as the stem gland nut

is lightened on the stem.

VALVE ASSEMBLY

Turn the stem until the stem flat is parallel to the port

centerline (so that the ball can fit onto the stem).

Install one seat (18) and two body seals (19,20) into

the body (16), make sure the spherical curvature side

of the seat will face the ball;

Install the end cap (15) with cap screws (14) and

tighten screws to the values indicated in Table 1.

Material for the bore alignment tool should be made

from a material softer than 300 Series S.S. so that it

will not inadvertently scratch the valve end cap or ball.

Suggested materials: Aluminum T6061. Acetal

or other hard polymer/plastic materials are also

suitable.)

Secure the tab washer with one ear bending up;

Place the handle (25) onto the stem, on top of the

stem gland nut (9);

Rotate the stem to the closed position and install the

ball (17) inside the valve body. The stem flats will fit

Secure the handle (25) with the stem lock nut (9).

into the slot on top of the ball;

Table 1; Tightening torques for cap screws

VALVE SIZE 1/2” 3/4” 1” 1-1/4” 1-1/2” 2” 3” 4”

EXTENSION MTG

SCREWS (lb-in.)

BODY END CAP

SCREWS (lb-in)

24 24 150 150 150 150 550 550

140 210 210 550 550 550 996 996

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

© 2011 Flow-Tek, Inc.

Page 5

A Subsidiary of BRAY INTERNATIONAL, Inc.

Installation and Maintenance Manual

®

Multiport Threaded and Weld End Ball Valves

Date: August 2011 / Page 5 of 6

IMPORTANT NOTES:

Valves with vented balls shall be installed with the

vent upstream.

All cryogenic valves shall be installed with the stem

within +/- 25 degrees of vertical.

Do not use the body screws to pull the pipe ends

together or into alignment.

9. INSTALLATION OF THREADED VALVES

Valve can be screwed on without the use of union or

with the end caps removed from the body.

The use of a thread sealant is recommended; Apply

wrench only on the valve end being tightened. Do not

tighten by applying torque to the opposite end cap or

other valve component. Tightening by using the valve

body, handle or the opposite end cap can seriously

damage the valve; Use a wrench on both the second

end cap and pipe to avoid applying torque to the

body through the bolting.

In some applications, screwed valves may be backwelded. Disassemble as per instructions for weld

end valves.

Confirm that the end cap bolt holes are aligned with

the body screw holes on both ends and that the end

caps are parallel and correctly spaced to fit the valve

body before re-assembly or back welding.

10. INSTALLATION OF EXTENDED WELD END

VALVE

Insure that appropriate weld procedures are implemented that are compatible with the materials used.

Butt weld valves with 3 inch or longer extended weld

ends do not require disassembly for installation welding.

Simply ensure that ball is in the full open position,

and perform normal welding procedures, using care

that the valve body does not reach a temperature

above 200°F.

11. INSTALLATION OF BUTT AND SOCKET

WELD END VALVES

(FP/SP2000, FP/SP3000 Series)

Insure that appropriate weld procedures are imple-

mented that are compatible with the materials used.

Socket weld ends: Insure proper stand off spacing of

pipe end to bottom of socket is 1/16” before welding.

Tack weld the valve to the pipe at four points on both

end caps.

With the valve in open position, (the valve is in the

open position when the handle is parallel to the axis

of the valve and pipe), loosen all body bolts, take the

body out.

Turn the handle in the half open position to assist in

the removal of the seats and body gaskets.

Turn handle in closed position and remove ball.

Place all removed parts in a clean and secure place.

Replace the body and all bolts and tighten them slightly.

This operation is very important, so that the body and

end caps remain perfectly parallel, thus preventing

any leakage at the body joint after welding.

Finish welding both end caps onto the pipe.

When cool, clean end caps, turn valve to closed

position and replace ball. Turn valve in open position

and replace seats and body gaskets.

Place body between the two end connections; then

replace all bolts and tighten firmly (See table 1.

Tightening torques for end cap screws).

12. Short and Long Term Storage:

Short term:

1. Short term storage is defined as storage of products

and equipment to be used in the construction of a

project for periods of one to three months.

2. Ball valves should remain in the original shipping

containers be placed on pallets of wood or other

suitable materials. End protectors should remain

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

© 2011 Flow-Tek, Inc.

Page 6

A Subsidiary of BRAY INTERNATIONAL, Inc.

Installation and Maintenance Manual

®

Multiport Threaded and Weld End Ball Valves

Date: August 2011 / Page 6 of 6

on the valve ends to prevent the entrance of dirt.

3. Valves should be stored in the open position to

protect the ball and seats.

4. Storage of ball valves can be in an open uncovered

area provided provisions are made for inclement

weather such as tarps or sheeting. Valves with

electric actuators shall be stored under cover until

ready for installation.

Long term:

1. Long term storage is storage of products and/or

equipment for periods of three months or more.

2. Valves should be stored in the open position to

protect the ball and seats.

3. Ball valves should remain in the original shipping

containers placed on pallets of wood or other

suitable materials and stored indoors. End

protectors should remain on the valve ends to

prevent the entrance of dirt.

13. Safety Summary

1. Read completely and understand all instructions

provided prior to beginning installation or

maintenance.

2. Follow all instructions as described using the

correct tools for the job.

3. Before installing this equipment, confirm that it is

suitable for the intended service. The identifications

tags describe the maximum allowable service

conditions for this product.

4. Be sure that the installation is protected by

appropriate pressure control and safety devices

to ensure that acceptable limits are not exceeded.

5. Confirm that line pressure has been removed

and that there is no pressure trapped within the

valve prior to beginning service. Do not attempt

to remove any packing components or other

fittings before confirming that pressure has been

completely removed!

The storage environment should be dry and not

have severe swings in temperature and humidity.

6. Do not begin service work without proper tools

and protective safety measures.

7. The work area should be clear of obstructions and

other safety hazards.

FLOW-TEK, Inc. Tel: 832.912.2300

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

© 2011 Flow-Tek, Inc.

Loading...

Loading...