Page 1

SERIES 70

TUNNEL DAMPER MODEL ELECTRIC ACTUATOR

OPERATION AND MAINTENANCE MANUAL

Page 2

Page 3

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

Table of Contents

Safety Instructions - Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1 Hazard-free use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Principle Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrical Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mechanical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CW vs CCW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Elevated Temperature Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Manual Override Operation (Declutchable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Pre-Installation Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Mounting to a Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Travel Limit Switch and Mechanical Travel Stop Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .5

Clockwise Travel Switch adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Counter-Clockwise Travel Switch adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Appendix A - Basic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Appendix B - Actuator Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Exploded View Series 70 Tunnel Damper Model Housing Size 12 . . . . . . . . . . . . . . . . . . . . . . . 10

Exploded View Series 70 Tunnel Damper Model Housing Size 30 . . . . . . . . . . . . . . . . . . . . . . . 11

1

Page 4

BRAY Series 70 Tunnel Damper Electric Actuator

!

!

!

!

Operation and Maintenance Manual

SAFETY INSTRUCTIONS - DEFINITION OF TERMS

READ AND FOLLOW THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WARNING

CAUTION

NOTICE

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

used without the safety alert symbol indicates a potential situation which, if

not avoided, may result in an undesirable result or state, including property

damage.

1.1 HAZARD-FREE USE

This device left the factory in proper condition to be safely

installed and operated in a hazard-free manner. The notes

and warnings in this document must be observed by the

user if this safe condition is to be maintained and hazardfree operation of the device assured.

Take all necessary precautions to prevent damage to the

actuator due to rough handling, impact, or improper

storage. Do not use abrasive compounds to clean the

actuator, or scrape metal surfaces with any objects.

The control systems in which the actuator is installed must

have proper safeguards to prevent injury to personnel, or

damage to equipment, should failure of system components

occur.

• Is trained in the proper use and care of personal

protective equipment (PPE) in accordance with

established safety practices

• Is trained in first aid

• In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in the

operation, commissioning, operation and maintenance

of equipment in hazardous locations

WARNING

The actuator must only be installed, commissioned,

operated and repaired by qualified personnel.

The device generates large mechanical force during

normal operation.

1.2 QUALIFIED PERSONNEL

A qualified person in terms of this document is one who

is familiar with the installation, commissioning and operation of the device and who has appropriate qualifications,

such as:

• Is trained in the operation and maintenance of electric

equipment and systems in accordance with established

safety practices

• Is trained or authorized to energize, de-energize,

ground, tag and lock electrical circuits and equipment

in accordance with established safety practices

2

All installation, commissioning, operation and

maintenance must be performed under strict observation

of all applicable codes, standards and safety regulations.

Reference is specifically made here to observe all

applicable safety regulations for actuators installed in

potentially explosive (hazardous) locations.

Page 5

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

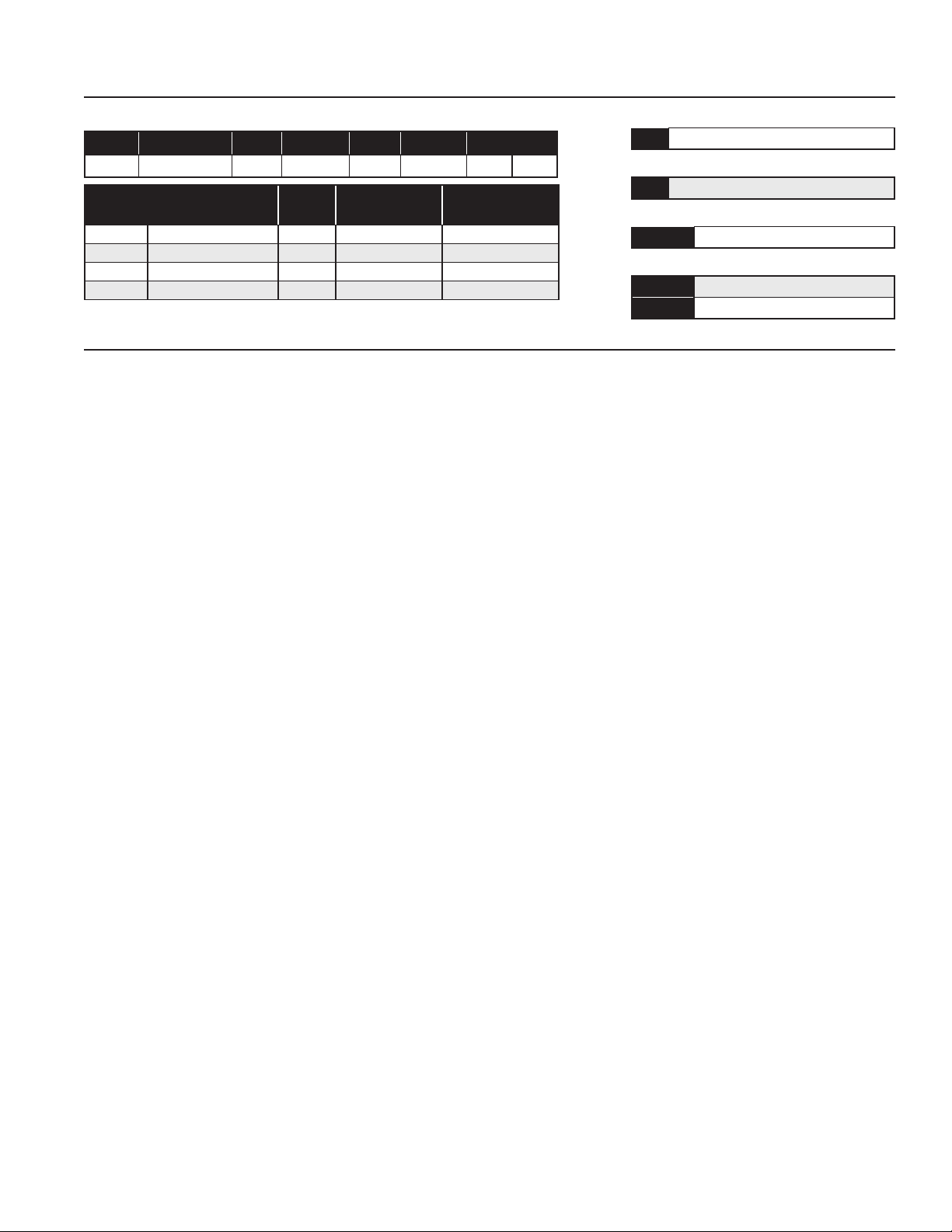

Part NumberiNg SyStem refereNce chart

SerieS torque code SPeed Product Style Voltage trim dir

70 AAA W 113 X Y 536 /Z

houSiNg

Size

Use this chart as a guide to interpret the S70 Tunnel Damper electric actuator part number.

Part Number

12 70-0122-113E0-536 1200 15 120 VAC

12 70-0202-113E0-536 2000 15 120 VAC

30 70-0302-113E0-536 3000 18 120 VAC

30 70-0502-113E0-536 5000 18 120 VAC

INTRODUCTION

The Bray Series 70 Tunnel Damper Electric Actuator is a

quarter turn electric actuator with manual override for use

on any quarter turn valve requiring up to 5000 in.lb of torque.

Operating speeds vary between 15 to 18 seconds.

PRINCIPLE OF OPERATION

The Series 70 Tunnel Damper electric actuator is divided

into two internal sections; the power center below the

switchplate, and the control center above the switchplate.

Below the switchplate the capacitor and gearmotor, with

its spur geartrain, drive a non-backdriveable worm gear

output. The override mechanism for manual operation

is also housed here. Above the switchplate is where user

required, readily accessible components are placed. The

camshaft assembly, limit switches, terminal strips, and

heater are all placed here for easy access. External to the

unit are adjustable mechanical travel stops, the unique

manual override handwheel, and dual conduit entry ports.

The external coating is a high quality polyester powder coat

which has exceptional UV as well as chemical resistance.

ELECTRICAL OPERATION

The motors used in the Bray Series 70 Tunnel Damper electric actuator are permanent induction split capacitor design

(single phase AC power). Travel limit switches are mechanical

form ZZ(DPDT-DB) with contacts rated at 10 amp (0.8 PF),

1/2 HP 125/250 VAC. In cases where the torque capacity of

the unit is exceeded to the point where the motor stalls and

overheats, a thermal protector switch built into the motor

windings will automatically disconnect the motor power.

Once the motor cools sufficiently the thermal protector

switch will reset.

torque

(In.Lbs)

SPeed, ¼ turN

(Seconds)

SuPPly

(Voltage)

MECHANICAL OPERATION

Mechanically, the ratio of the gear motor determines the

speed of the unit. The gear motor utilizes high efficiency

spur gears. Initial gear reduction through the spur gears is

then transferred to the worm shaft. The final gear reduction

and output is through a non-backdriveable worm gear set.

Positioning is determined by an indicator-cam shaft linked to

the output shaft. In the declutchable condition the manual

override drives the worm shaft when engaged.

CW VS CCW

Due to the fact that the Series 70 is a rotary actuator, there are

two directions that it can turn to actuate a device: clockwise

and counter-clockwise. Depending on the application the

actuator is going into, and the physical constraints that

application presents, it may be preferential to designate

which direction the actuator turns to open and close. This

is accomplished with the /Z designator, which assigns the

open direction of the actuator: CW for clockwise and CCW

for counter-clockwise. This can be easily determined locally

by looking at which direction the open arrow is pointing

on the actuator hand wheel, and should be kept in mind

when mounting the actuator to the device. To ensure proper

function, the direction of travel should always align with

the arrows on the hand wheel and the /Z designator in

actuator part number.

ELEVATED TEMPERATURE RATINGS

The Series 70 actuator is certified to meet NEMA type 4/4x

specifications. The actuator utilizes a thermally protected,

permanent split-capacitor (PSC) motor coupled to a gear

train, allowing operation after experiencing elevated

ambient temperatures. It has been tested to and complies

with NYCTA Master Specification 15ID dated 7/16/12 –

Dampers and Accessories for Tunnel Ventilation and Station

Smoke Management, certifying it for use after soaking at

an elevated ambient temperature of up to 302°F (150°C)

for a minimum of 1 hour without the use of an insulated

thermal blanket.

W - DESIGNATES THE SPEED

2 15/18 seconds

X - DESIGNATES STYLE

E Basic Unit - Declutchable

Y - DESIGNATES THE VOLTAGE

0

/Z - DESIGNATES DIRECTION OF OPEN TRAVEL

/CW

/CCW

120VAC

Clockwise

Counter-Clockwise

3

Page 6

BRAY Series 70 Tunnel Damper Electric Actuator

!

!

!

!

!

Operation and Maintenance Manual

MANUAL OVERRIDE OPERATION (DECLUTCHABLE)

The manual override operates similar to a watch adjusting

knob. To engage the manual override, simply pull the handwheel to its outermost position. A yellow stripe is revealed

for visual indication that the unit cannot run electrically.

The two handwheel positions, engaged and disengaged,

are held in place with the use of spring plungers. The handwheel remains in position until physically moved. Rotating

the handwheel in the clockwise direction will rotate the

output shaft in the same clockwise direction and vice-versa.

CAUTION

A label on the handwheel hub warns users not to exceed

a specific rim pull force, for each size of actuator. If the

rim pull force is exceeded, the roll pin securing the handwheel onto the manual override shaft is designed to shear,

thus preventing more serious internal gearing damage.

PRE-INSTALLATION STORAGE

Actuators are not weatherproof until properly installed

on the valve or prepared for storage. Bray cannot accept

responsibility for deterioration caused on-site once the

cover is removed.

NOTICE

The standard mounting position for the actuator is to

orient the unit with its handwheel in a vertical plane and

parallel to the pipeline. If the actuator is to be mounted

on a vertical pipe, it is recommended that the unit be

positioned with the conduit entries on the bottom to

prevent condensation from entering the actuator by

way of the conduit. In all cases, the conduit should be

positioned to prevent drainage into the actuator.

The actuator should be mounted to the valve as follows:

1. Manually operate the actuator until the output shaft

of the actuator is in line with the valve stem. If possible, select an intermediate position (i.e. valve disc/

stem and actuator both half open).

2. Place the proper adapter, if required, onto the valve

stem. It is recommended that a small amount of grease

be applied to the adapter to ease assembly.

3. Mount the actuator onto the valve stem. It may be

necessary to swing or manually override the actuator

to align the bolt patterns.

4. Install the furnished mounting studs by threading them

all the way into the actuator base.

5. Fasten in place with the furnished hex nuts and lock

washers.

FIELD WIRING

NOTICE

Units are shipped with two metal screw-in plugs to prevent foreign matter from entering the unit. To prevent

condensation from forming inside these units, maintain

a near constant external temperature and store in a wellventilated, clean, dry room away from vibration.

Power should be supplied to the heater via conduit entry

and appropriate sealing gland.

Store units on a shelf or wooden pallet in order to protect

against floor dampness.

Keep units covered to protect against dust and dirt.

INSTALLATION

MOUNTING TO A VALVE

All Bray Series 70 electric actuators are suitable for direct

mounting on Bray butterfly valves. With proper mounting

hardware, the S70 actuator can be installed onto other

quarter-turn valves or devices, such as a damper.

4

WARNING

Turn off all power and lock out service panel before

installing or modifying any electrical wiring.

Each actuator is provided with two (2) conduit entries (one

for power and one for control).

1. The motor full load current is noted on the nameplate

of the actuator. The terminal strip will accept wire

sizes ranging from 14 to 22 AWG.

NOTICE

18 AWG minimum wire is recommended for all field

wiring.

Note that heaters use approximately 0.5 amps at 110 volts.

2. All actuators have their applicable wiring diagram

attached to the inside of the cover. Field wiring

should be terminated at the actuator terminal strip

in accordance with this wiring diagram.

Page 7

!

NOTICE

!

!

Striker Bar

The conduit connections must be properly sealed to maintain the weatherproof integrity of the actuator enclosure.

CAUTION

Do not reverse motor instantaneously when it is still running. Reversing direction to actuator motor when it is

running can cause damage to motor, switches and gearing. Directional control switching can be done by PLC in

20ms or by a small relay in 46ms. Therefore time delay

of 1s has to be incorporated into the control scheme to

avoid damage.

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

CLOCKWISE TRAVEL SWITCH ADJUSTMENT

1. Loosen the mechanical stop for the CW position and

back it off so that it does not interfere with actuator

travel (CW stop located on right when viewed from

travel stop side of actuator).

TRAVEL LIMIT SWITCH AND MECHANICAL TRAVEL STOP ADJUSTMENT

CAUTION

The electrical travel switches must be set to activate

(depress) prior to reaching the mechanical travel stops.

The cams are color coded (green for CCW, red for CW).

NOTE: Manual travel stops are designed to prevent manual

overtravel from turning the handwheel, not to stop the

electric motor. The travel stops have an adjustment range

of approximately 10-degrees.

2. Reference the striker bar for damper position.

3. Manually operate the actuator handwheel clockwise

until the valve reaches the desired fully CW position.

4. Rotate the red adjusting knob by hand or with a flat

head screwdriver until the cam lobe just activates (depresses) the switch from a clockwise direction.

NOTICE: All actuators have a cam locking screw. Cam

locking screw must be slackened before cam adjustments and re-tightened after cam adjustments.

UPPER GREEN

“CCW” CAM

LOWER RED

“CW” CAM

CAM

LOCKING

SCREW

CAM ADJUSTMENT KNOB

(ONLY ADJUST IF LOCKING

POT DRIVE GEAR

“BLACK” NOT SHOWN

NOTE: It is possible that the rotation of one cam will

move the other cam. If this occurs, hold the other

knobs or cams during adjustment.

SCREW IS SLACKENED)

5. With the travel switch in the CW position, rotate the

handwheel clockwise 1 turn for Housing Size 12 and

½ turn for Housing Size 30. Adjust the CW travel stop

bolt until it bottoms against the output gear and lock

it in position with the locknut.

6. After all travel switch adjustments have been com-

pleted, secure the actuator cover.

5

Page 8

BRAY Series 70 Tunnel Damper Electric Actuator

!

11/11/2014

ERN-161731

GA-03075

DRAWING NO.

RELEASED

ERN

3

REV.

2 OF 5

SHEET

THIRD ANGLE

THE INFORMATION CONTAINED HEREIN

SHALL NOT BE COPIED, TRANSFERRED,

CONVEYED OR DISPLAYED IN ANY MANNER

THAT WOULD VIOLATE ITS PROPRIETARY

NATURE WITHOUT THE EXPRESS WRITTEN

PERMISSION OF BRAY INTERNATIONAL,INC.

BUSA Cindy Downey

SERIES 70, SIZE 30 - NYCTA MODEL

ELECTRIC ACTUATOR

ISOMETRIC EXPLODED VIEW

Operation and Maintenance Manual

COUNTER-CLOCKWISE TRAVEL SWITCH ADJUSTMENT

1. Loosen the mechanical stop for the CCW position and

back it off, so that it does not interfere with actuator travel. The CCW stop is located on the left, when

viewed from travel stop side of actuator.

2. Reference the striker bar for damper position.

3. Manually operate the actuator handwheel counterclockwise until the valve reaches the desired CCW

position.

WARNING

The heater surface can reach temperatures in excess of

200 degrees Celsius (392°F)

Heater Kit Consists of:

1. Heater with flying leads

2. Heater Mounting Bracket

3. #10 pan head screw, Phillips drive

4. Rotate the green adjusting knob until the cam lobe

just activates (depresses) the switch from a counterclockwise direction.

NOTICE: All actuators have a cam locking screw. Cam

locking screw must be slackened before cam adjustments and re-tightened after cam adjustments.

NOTE: It is possible that the rotation of one cam will

move the other cam. If this occurs, hold the other

knobs or cams during adjustment.

5. With the travel switch in the open position, rotate the

handwheel counterclockwise 1 turn for Housing Size

12 and ½ turn for Housing Size 30. Adjust the CCW

travel stop bolt until it bottoms against the output

gear and lock in position with the locknut.

6. After all travel stop adjustments have been completed,

secure the actuator cover.

HEATER

To prevent condensation from forming inside the actuator,

Bray offers a heater as standard in Series 70 Tunnel

Damper models. The heater is a PTC (Positive Temperature

Coefficient) style which has a unique temperature resistance characteristic. The heater self-regulates by

increasing its electrical resistance relative to its temperature.

The heater does not require external thermostats or

switches to control its heat output. It is constructed of

a polycrystalline ceramic, sandwiched between two

conductors, and wrapped inside a thermally conductive

electrical insulator.

Connect the heater wires to the terminal strip as indicated

on the wiring diagram.

NOTE: The heater must have a constant power supply to

be effective.

Tools required:

• For terminal wiring: Screwdriver, 1/4” tip flat blade

• For heater mounting screw: Screwdriver, No.1 Phillips

Installation procedure:

The heater is mounted through a hole provided in the

switchplate.

Before servicing unit, switch all power off at the service panel

and lock the service disconnecting means to prevent power

from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

Disconnect all power to the unit.

1. Place the heater snugly into its mounting bracket until

approx. 1/2 to 1” is left above the bracket as shown

in diagram.

2. Slip the heater into its mounting hole.

3. Align the fastening hole in the bracket with the

threaded screw hole in the plate. Fasten the heater

to the switchplate.

4. Connect the heater wires to the terminal strip as

indicated on the wiring diagram.

6

Page 9

TYPICAL WIRING DIAGRAMS

Field Wiring Actuator

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

Wiring diagram for CW OPEN unit with form-ZZ (DPDT-DB) travel

switches. (Drawn for actuator in its fully open [CW] Condition.)

Field Wiring Actuator

Wiring diagram for CCW Open Unit with form-ZZ (DPDT-DB) travel switches

(Drawn for actuator in its fully closed [CW] condition)

Note: Bray Series 70 Tunnel Damper electric actuator wiring is the same, regardless of

CW or CWW application. Control is achieved through field wiring.

7

Page 10

BRAY Series 70 Tunnel Damper Electric Actuator

!

!

A Division of BRAY INTERNATIONAL, Inc.

R

DECIMAL INCH

PRIMARY UNITS

11/11/2014

ERN-161731

GA-03075

DRAWING NO.

RELEASED

ERN

3

REV.

BUSA

DIVISION

3 OF 5

SHEET

THIRD ANGLE

CERTIFIED CORRECT BY

BUSA Jim Schmidt

11/11/2014

PRESSURE RATING

FLANGE DRILLING

BRAY ORDER NO.

THE INFORMATION CONTAINED HEREIN

SHALL NOT BE COPIED, TRANSFERRED,

CONVEYED OR DISPLAYED IN ANY MANNER

THAT WOULD VIOLATE ITS PROPRIETARY

NATURE WITHOUT THE EXPRESS WRITTEN

PERMISSION OF BRAY INTERNATIONAL,INC.

BUSA Cindy Downey

SERIES 70, SIZE 30 - NYCTA MODEL

ELECTRIC ACTUATOR

ISOMETRIC EXPLODED VIEW

DECIMAL INCH

PRIMARY UNITS

11/11/2014

ERN-161731

GA-03075

DRAWING NO.

RELEASED

ERN

3

REV.

BUSA

DIVISION

4 OF 5

SHEET

THIRD ANGLE

CERTIFIED CORRECT BY

BUSA Jim Schmidt

11/11/2014

PRESSURE RATING

FLANGE DRILLING

BRAY ORDER NO.

THE INFORMATION CONTAINED HEREIN

SHALL NOT BE COPIED, TRANSFERRED,

CONVEYED OR DISPLAYED IN ANY MANNER

THAT WOULD VIOLATE ITS PROPRIETARY

NATURE WITHOUT THE EXPRESS WRITTEN

PERMISSION OF BRAY INTERNATIONAL,INC.

BUSA Cindy Downey

SERIES 70, SIZE 30 - NYCTA MODEL

ELECTRIC ACTUATOR

ISOMETRIC EXPLODED VIEW

A Division of BRAY INTERNATIONAL, Inc.

R

DECIMAL INCH

PRIMARY UNITS

11/11/2014

ERN-161731

GA-03075

DRAWING NO.

RELEASED

ERN

3

REV.

BUSA

DIVISION

5 OF 5

SHEET

THIRD ANGLE

CERTIFIED CORRECT BY

BUSA Jim Schmidt

11/11/2014

PRESSURE RATING

FLANGE DRILLING

BRAY ORDER NO.

THE INFORMATION CONTAINED HEREIN

SHALL NOT BE COPIED, TRANSFERRED,

CONVEYED OR DISPLAYED IN ANY MANNER

THAT WOULD VIOLATE ITS PROPRIETARY

NATURE WITHOUT THE EXPRESS WRITTEN

PERMISSION OF BRAY INTERNATIONAL,INC.

BUSA Cindy Downey

SERIES 70, SIZE 30 - NYCTA MODEL

ELECTRIC ACTUATOR

ISOMETRIC EXPLODED VIEW

Operation and Maintenance Manual

DISASSEMBLY AND ASSEMBLY

Tools required:

NOTE: Assembly is

the opposite of removal

See Appendix A for a complete list of basic tools.

2. Disconnect motor wires from the 3-terminal strip (motor

neutral, open, and close).

3. The switchplate can be independently disassembled.

4. To remove the Gearmotor, first disconnect the motor

leads which run to the capacitor, and unscrew the

mounting screws (four lower, one upper). The motor

can now be removed vertically out of the unit. Note:

do not misplace the alignment pin.

5. To remove the worm shaft spur gear, remove the spring

pin using a 3⁄32" punch, then slide the gear off the end

of the worm shaft for Housing Size 12 . Remove bowed

E-clip retainer for Housing Size 30.

6. To remove the output drive worm gear, back off both

mechanical travel stops. Remove the retaining ring

and thrust washer, then lift the output drive worm

gear out of its base.

7. The handwheel is held by a spring pin.

Procedure:

Turn off all power and lock out service panel before

installing or modifying any electrical wiring.

1. Remove the switchplate by unscrewing the seven

Phillips head mounting screws. The switchplate should

lift out as an assembly with the camshaft attached.

WARNING

CAUTION

8. Further disassembly of the unit requires special tools and

procedures, and thus will not be covered in this manual.

8

Page 11

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

APPENDIX A - BASIC TOOLS

Common To All Units

Terminal connections, cam adjustment

All switches, terminal strip, torque switch plate

Switchplate screws, capacitor

Screwdriver, 1/4” tip flat tip blade

Screwdriver, No.1 Phillips

Screwdriver, No.2 Phillips

Housing Size 12 Housing Size 30

Mounting nuts (small pattern) Wrench, 1/2” Mounting nuts, travel stop jam nuts Wrench, 3/4”

Mounting nuts (large pattern) Wrench, 3/4” Cover captivated capscrews Hex key, 3/8”

Cover captivated capscrews Hex key, 5/16” Travel stop adjusting studs Wrench, 3/4”

Travel stop adjusting bolts Wrench, 9/16” Motor mount socket head shoulder bolt Hex key, 5/32”

Travel stop nuts Wrench, 9/16” Motor mount socket head cap screws Hex key, 3/16”

Motor mount socket head capscrew Hex key, 5/32” Conduit Entry Plug Hex key, 9/16”

Conduit Entry Plug Hex key, 9/16”

APPENDIX B - ACTUATOR TROUBLESHOOTING CHART

Problem PoSSible cauSe SolutioNS

Override is engaged Push handwheel in all the way

Actuator does not operate

Actuator operates in reverse

directions

Actuator does not fully close

damper (or open damper)

Engaging override handwheel

does not shut off motor

Disengaging override handwheel does not restart motor

Motor runs but worm and

gear segment do not

Corrosion inside unit

Wiring is incorrect Check wiring and power supply

Actuator motor has reached its thermal shutdown

temperature

Field wiring is reversed Rewire field wiring

Limit switches are depressed Readjust travel limit switches

Mechanical travel stop is stopping actuator Adjust mechanical travel stops

Damper torque requirement is higher than actuator

output

Voltage power supply is low Check power source.

Override pin is corroded or damaged

Override switch is damaged Replace switch

Not completely disengaged Push handwheel in as far as possible (no yellow showing)

Override pin is damaged or and does not activate

switch

Incorrect wiring of override switch Check wiring

Worm gear segment is not meshing with worm

Pin/Key on Worm/Motor drive gear sheared Replace Pin/Key on drive gear

Condensation forming Test heater wiring, should have constant power

Water leaking in Check all seals and possible water entry through conduit

Allow time to cool

Manually override out of seat, try angle seating or larger

actuator

Clean and check for smooth operation of the override

switch pin

Replace override pin

Remove switchplate and inspect, adjust travel stops to

prevent gear disengaging

9

Page 12

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

1

2

3

4

5

6

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

7

8

9

10

11

27

28

29

30

31

32

33

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

EXPLODED VIEW SERIES 70 TUNNEL DAMPER MODEL HOUSING SIZE 12

ON / OFF

1 COVER PLATE WITH STUD

2 OIL RESISTANT GASKET

3 COVER FASTENING SCREW

4 COVER

5 O RING-S271

6 STEEL BACK PLATE

7 WASHER

8 HEX NUT,NYLOCK

9 INDICATOR SHAFT ASSY

10 CCW SWITCH LABEL

11 CW SWITCH LABEL

12 SWITCH MOUNTING SCREW

13 FIBER WASHER

14 SWITCH ASSY,CCW

15 SWITCH ASSY,CW

16 COVER PLATE

17 PAN HD SCREW

18 HEATER MOUNTING BRACKET

19 HEATER

20 WIRE ASSEMBLY

21 INSULATOR

22 O’RIDE SWITCH(SPDT FORM C)

23 SCREW, PAN HEAD

24 OVERRIDE SWITCH TRIGGER PIN

25 BUSHING

26 THRUST WASHER

27 RETAINING RING

28 OUTPUT WORM GEAR SEGMENT

29 O RING-S-128

30 CAPACITOR

31 TERMINAL STRIP

32 ARMACELL TUBING

33 OVERRIDE SPRING PIN

34 TRAVEL STOP BOLT

35 HEX NUT

36 NYLON FLAT WASHER

37 O RING

34

35

36

37

38 39

40 41

42

38 WORM SHAFT

39 OVERRIDE DRIVE PIN

40 SPRING PLUNGER

41 MANUAL OVERRIDE SHAFT

42 MANUAL OVERRIDE SLEEVE

43 O RING-S-126

44 O RING-S118

45 RETAINING RING

46 HAND WHEEL, CW TO OPEN

47 HANDWHEEL WARNING LABEL

48 HANDWHEEL CCW TO OPEN

49 PIN,SLOT SPRING 1/8”DIA

50 MANUAL OVERRIDE BUSHING

51 THRUST WASHER

52 THRUST ROLLER BEARING

53 THRUST WASHER

54 DISC SPRING

55 WORM

56 WORM GEAR ROLL PIN

57 RETAINING RING

58 THRUST WASHER

59 BASE

60 3/4”-14 NPT PLUG

61 NAME TAG

62 BUSHING

63 GEAR SPACER

64 DOWEL PIN

65 DRIVE GEAR

66 RETAINING RING

67 GEARMOTOR

68 LOCK WASHER

69 SOCKET HEAD CAP SCREW

70 CONDUIT WIRE DEFLECTOR

71 SWITCH PLATE

72 WASHER TERMINAL GROUND

73 GROUND SCREW

74 FLAT HEAD SCREW

75 TERMINAL STRIP TAG: 1 - 9

76 TERMINAL STRIP

77 SCREW

78 TERMINAL STRIP TAG: 10 - 18

79 RELAY KIT

80 SCREW, PAN HEAD

10

51

52

53

54

43 44 45

59

60

58

57

54

55

56

53

25 15 05

49

48

46

47

81

Page 13

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

EXPLODED VIEW SERIES 70 TUNNEL DAMPER MODEL HOUSING SIZE 30

ON / OFF

1 COVER FASTENING SCREW

1

2 COVER

3 O-RING

4 CAM ASSEMBLY

2

3

4

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

5

6

7

8

9

10

20

21

22

23

24

25

26

27

28

11

12

13

14

15

16

17

18

19

5 SWITCH MOUNTING SCREW

6 FIBER WASHER

7 SWITCH ASSY,CCW

8 SWITCH ASSY,CW

9 CW SWITCH LABEL

10 CCW SWITCH LABEL

11 SWITCH PLATE COVER

12 PAN HD SCREW

13 HEATER MOUNTING BRACKET

14 HEATER

15 WIRE ASSEMBLY

16 INSULATOR

17 O’RIDE SWITCH(SPDT FORM C)

18 SCREW, PAN HEAD

19 OVERRIDE SWITCH TRIGGER PIN

20 BUSHING

21 THRUST WASHER

22 RETAINING RING

23 OUTPUT WORM GEAR SEGMENT

24 O RIBG-S-232

25 CAPACITOR

26 TERMINAL STRIP

27 ARMACELL TUBING

28 OVERRIDE SPRING PIN

29 TRAVEL STOP BOLT

30 LOCK NUT

31 NYLON FLAT WASHER

32 O-RING

33 WORM SHAFT

34 OVERRIDE DRIVE PIN

35 SPRING PLUNGER

36 MANUAL OVERRIDE SHAFT

29

37 MANUAL OVERRIDE SLEEVE

30

31

32

33

34

36

35

37 38 39 40

38 O RING-S-126

39 O RING-S118

40 RETAINING RING, INTERNAL

41 HAND WHEEL, CW TO OPEN

42 HANDWHEEL WARNING LABEL

43 HAND WHEEL, CCW TO OPEN

44 PIN,SLOT SPRING 1/8”DIA

45 MANUAL OVERRIDE BUSHING

46 THRUST WASHER

47 THRUST ROLLER BEARING

48 THRUST WASHER

49 DISC SPRING

50 WORM

51 WORM GEAR ROLL PIN

52 RETAINING RING,EXT

53 THRUST WASHER

54 BASE

55 3/4”-14 NPT PLUG

56 NAME TAG

57 BUSHING

58 DRIVE GEAR KEY

59 DRIVE GEAR

60 RET RING, BOWED E-RING

61 GEARMOTOR

62 LOCK WASHER

63 SOCKET HEAD CAP SCREW

64 DOWEL PIN

65 SOCKET HEAD SHOULDER SCREW

66 WIRE ENTRY GUARD

67 SWITCH PLATE

68 WASHER,GROUND TERMINAL

69 GROUND SCREW

70 FLAT HEAD SCREW

71 TERMINAL STRIP TAG: 1 - 9

72 TERMINAL STRIP TAG: 10 - 18

73 TERMINAL STRIP

74 SCREW

75 RELAY KIT

76 SCREW, PAN HEAD

46

47

48

49

54

55

5253

50

51

49

46

47

48

45

44

42

43

41

11

Page 14

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

12

Page 15

BRAY Series 70 Tunnel Damper Electric Actuator

Operation and Maintenance Manual

13

Page 16

R

CONTRO LS

A Division of BRAY INTERNATIONAL, Inc.

13333 Westland East Blvd. Houston, Texas 77041

281-894-5454 FAX 281/894-9499 www.bray.com

Bray® is a registered trademark of BRAY INTERNATIONAL, Inc.

© 2014 Bray International. All rights reserved. OM-70TD-001 11-2014

Loading...

Loading...