Page 1

SERIES 6A

ELECTRO-pnEumATIC pOSITIOnER

OPERATION AND MAINTENANCE MANUAL

Page 2

Series 6A Operation & Maintenance – Table Of Contents

CONTENTS

Safety Information - Definition of terms . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation. . . . . . . . . . . . . . . . . . . . . . . . .5

Field Connections . . . . . . . . . . . . . . . . . . . . . 6

Calibration and Commissioning . . . . . . . . . . . . 11

Factory or Field Installable Options . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 26

Service and Maintenance . . . . . . . . . . . . . . . . 29

Technical Data . . . . . . . . . . . . . . . . . . . . . . 30

Dimensional Drawings . . . . . . . . . . . . . . . . . 40

6A O & M : 2

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 3

Series 6A Operation & Maintenance – Safety

SAFETY INFORMATION - DEFINITION OF TERMS

indicates a potentially hazardous situation which, if not avoided, could result in

Q WARNING

Q CAUTION

death or serious injury.

indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

NOTICE

Hazard-free use

This device left the factory in proper condition to be safely installed

and operated in a hazard-free manner. The notes and warnings in this

document must be observed by the user if this safe condition is to be

maintained and hazard-free operation of the device assured.

• Take all necessary precautions to prevent damage due to rough

handling, impact, or improper storage. Do not use abrasive

compounds to clean, or scrape its surfaces with any objects.

• Conguration and calibration procedures are described in this

document. Proper conguration and calibration is required

for the safe operation.

• The control system in which the unit is installed must have

proper safeguards to prevent injury to personnel, or damage to

equipment, should failure of system components occur.

• This document does not cover every detail about every version

of the product described. It cannot take into account every

potential occurrence in installation, operation, maintenance

and use.

• If situations transpire that are not documented in sufcient

detail, please request the required information from the Bray

Distributor or Representative responsible for your area.

used without the safety alert symbol indicates a potential situation which, if not

avoided, may result in an undesirable result or state, including property damage.

Qualified Personel

A qualied person in terms of this document is one who is familiar

with the installation, commissioning and operation of the device and

who has appropriate qualications, such as:

• Is trained in the operation and maintenance of electric

equipment and systems in accordance with established safety

practices.

• Is trained or authorized to energize, de-energize, ground, tag

and lock electrical circuits and equipment in accordance with

established safety practices.

• Is trained in the proper use and care of personal protective

equipment (PPE) in accordance with established safety

practices.

• Is trained in rst aid.

• In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in the operation,

commissioning, operation and maintenance of equipment in

hazardous locations.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 3

Page 4

Series 6A Operation & Maintenance – Introduction

INTRODUCTION

The Bray S6A is a microcontroller based positioner for pneumatic

actuators. The S6A converts an analog current signal into a

valve position pressure signal and offers positioner, valve and

actuator diagnostics using a variety of communication protocols.

Optional modules can be added for full range valve position

feedback, valve open/close verication, preset alarm warnings

and electromagnetic compatibility.

Principles of Operation

The operation of the S6A can be described in three parts; the user

dened setpoint, the pneumatic actuator air supply, and the S6A

internal controller. The user dened setpoint, which is provided

by the incoming analog signal or the communication protocol,

tells the positioner where to set the actuator. The pneumatic

actuators air supply provides the power to work the valve, and the

S6A internal microcontroller monitors the actuator position and

provides diagnostics to the end user.

When the microcontroller sees a deviation between the actual

position of the actuator and the provided setpoint it will pulse the

internal piezo electric valve in order to let air ll the corresponding

actuator chambers and drive the actuator from the pneumatic

supply lines. Once this deviation is within a desired tolerance or

“dead band” the microcontroller will stop the pulsing. Using this

process, the S6A only consumes air when it is needed, meaning it

will pay for itself within a short period of time.

Electrical Operation

The standard S6A requires 4 to 20mA loop power for all of the

internal electronics. It can be installed in a two wire, three wire,

or four wire architecture. There is no need to run separate power

and signal wiring. The S6A positioners with communication

modules get their power directly from the network. All of the

wiring diagrams for the different versions of the S6A and any

optional modules are shown in the “Field Connections” portion

of this manual.

Mechanical Operation

The S6A requires a pneumatic supply in the range of 20 - 102 psi

(1.4 - 7 BAR). Using this pneumatic supply, the S6A will position

the actuator and valve precisely where it needs to be to regulate

the process. Once in the settled state, the S6A has one of the lowest

air bleed rates in the market. The S6A requires a pneumatic supply rated at Class 2 in accordance with ISO 8573-1. An optional

lter can be installed upstream of the S6A to clean incoming air.

Diagrams are provided showing how to make the pneumatic connections in the “Field Connections”portion of this manual.

6A O & M : 4

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 5

Series 6A Operation & Maintenance – Installation

INSTALLATION

Mounting to an Actuator

All Bray S6A positioners are suitable for mounting on Bray pneumatic actuators with the use of a standard mounting bracket. With

proper mounting hardware, the S6A positioner can be installed

onto other linear or quarter turn pneumatic actuators. The standard mounting position is to orient the unit directly over the

pneumatic actuator using the NAMUR mounting arrangement in

such a way that the LCD and pushbuttons are easily accessible.

If the positioner is to be mounted on a vertical pipe, it is recommended that the unit be positioned with the conduit entries on the

bottom to prevent condensation from entering the positioner by

way of conduit. In all cases, the conduit should be positioned to

prevent drainage into the positioner.

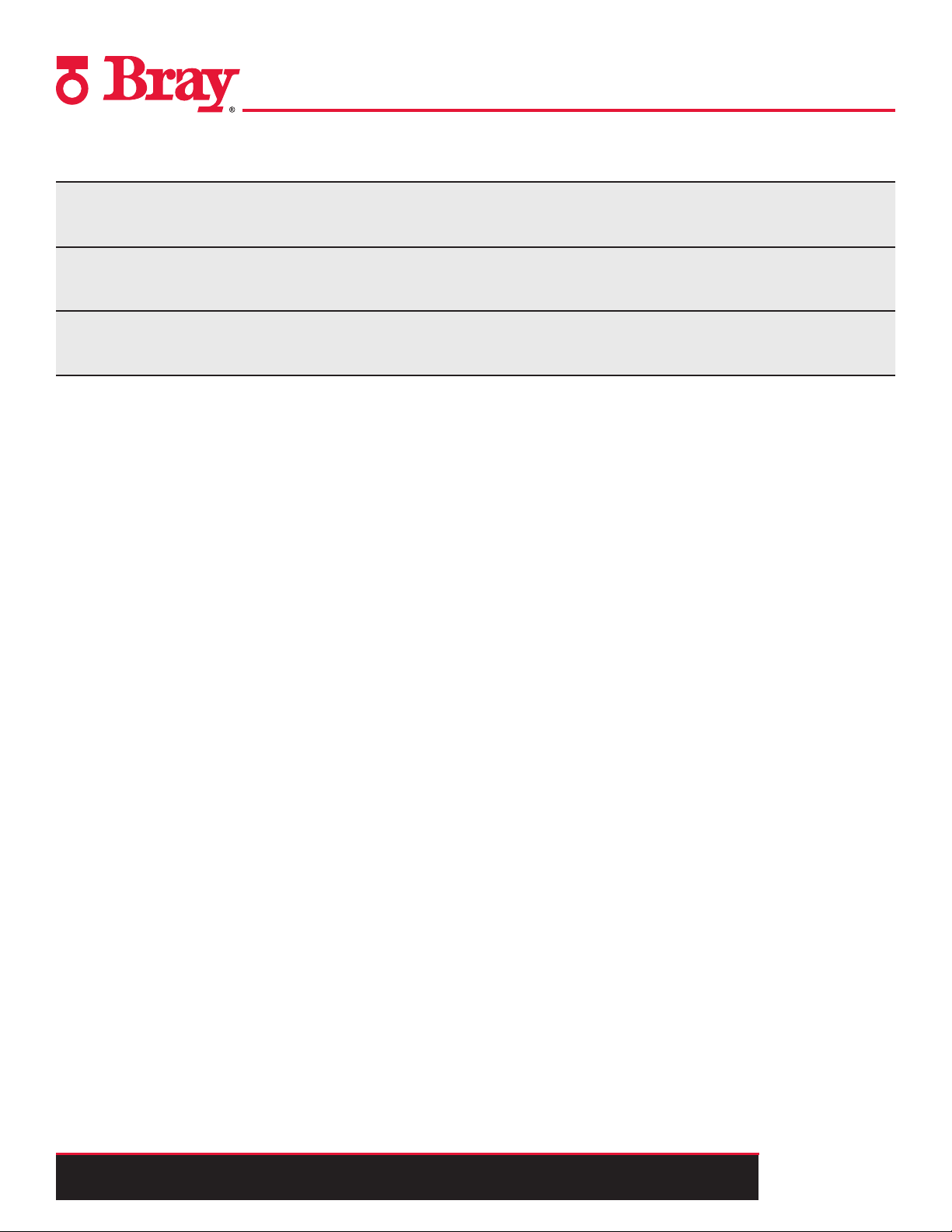

Tools Needed:

• 5mm Allen Key

• 5/16" Wrench

Parts Needed:

Item Qty.

The positioner should be mounted to

the actuator as follows:

1. Turn the positioner upside down and align the provided mounting bracket over the positioners output shaft. The bracket

should align with the four threaded holes around the output

shaft.

2. Using the 5mm allen key afx the mounting bracket to the

positioner using the four lockwashers and mounting bolts [A].

3. Turn the positioner right side up and position the output shaft

so that the atted side is facing you.

4. Insert the coupler over the output shaft, ensuring that the

couplers set screw is in alignment with the at of the shaft.

Tighten the couplers set screw.

5. Place the yellow indicator on the base of the coupler.

6. Mount the positioner on top of the actuator and tighten it using

the 5/16" wrench and the four mounting bolts [B].

Refer to the S6A Quick Start Guide for details.

Mounting Bolts [A] (4)

Lockwashers (4)

Mounting Bolts [B] (4)

Mounting Bracket (1)

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 5

Page 6

Series 6A Operation & Maintenance – Field Connections

4 ... 20 mA

BE1 = Binary Input

7

8

9

10

+

–

J

6

4 ... 20 mA

BE1 = Binary Input

7

8

9

10

+

–

J

6

2

3

4

5

+

–

J

6

7

8

9

10

4 ... 20 mA

BE1 = Binary Input

4 ... 20 mA

BE1 = Binary Input

7

8

9

10

+

–

J

6

1) Jumper between 5 and 7 only for three-wire system

2

3

4

5

+

–

J

6

7

8

9

10

4 ... 20 mA

0/4 ... 20 mA

2

3

4

5

+

–

6

7

8

9

10

18 ... 30 V

J

+

–

BE1 = Binary Input

BE1 = Binary Input

1)

4 ... 20 mA

BE1 = Binary Input

7

8

9

10

+

–

J

6

HART

modem

PC/Laptop

R 250 W if req.

1)

3

Only required with current sources not conforming to HART1)

2

3

4

5

+

–

I

l

y

= 4 ... 20 mA

6

7

8

l

W-

l

H+

1) Jumper between 5 and 7 only for three-wire system

2

3

4

5

+

–

J

6

7

8

9

10

4 ... 20 mA

0/4 ... 20 mA

2

3

4

5

+

–

6

7

8

9

10

18 ... 30 V

J

+

–

BE1 = Binary Input

BE1 = Binary Input

1)

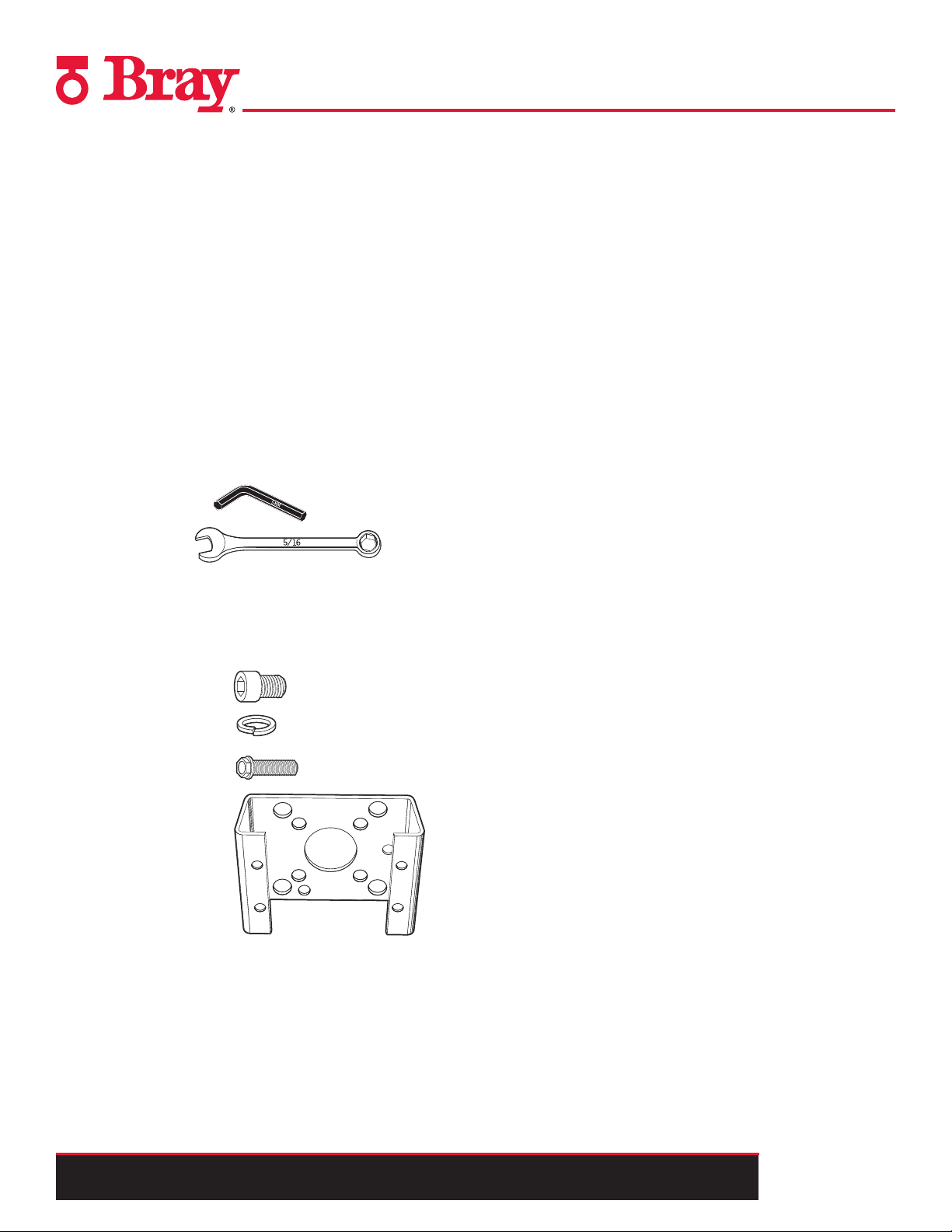

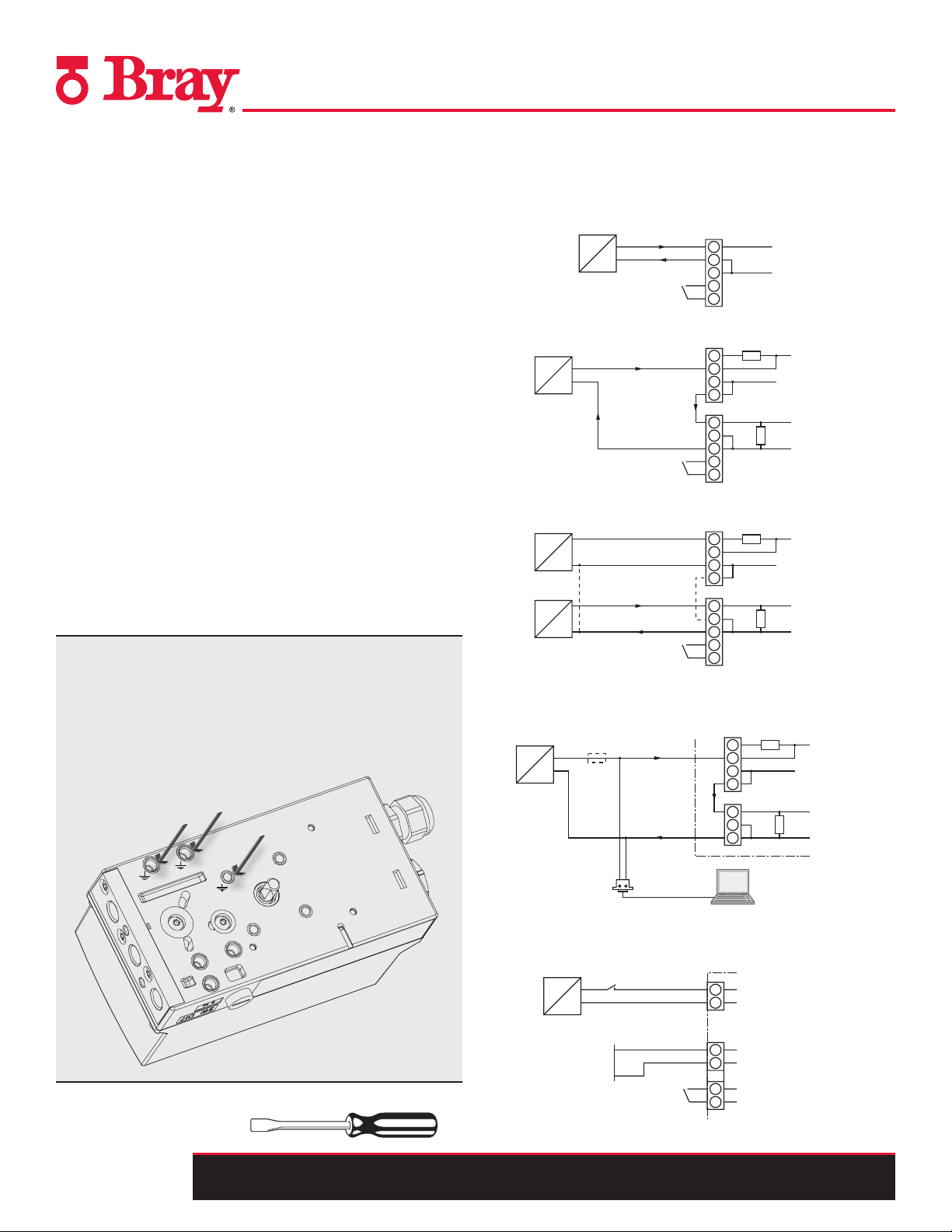

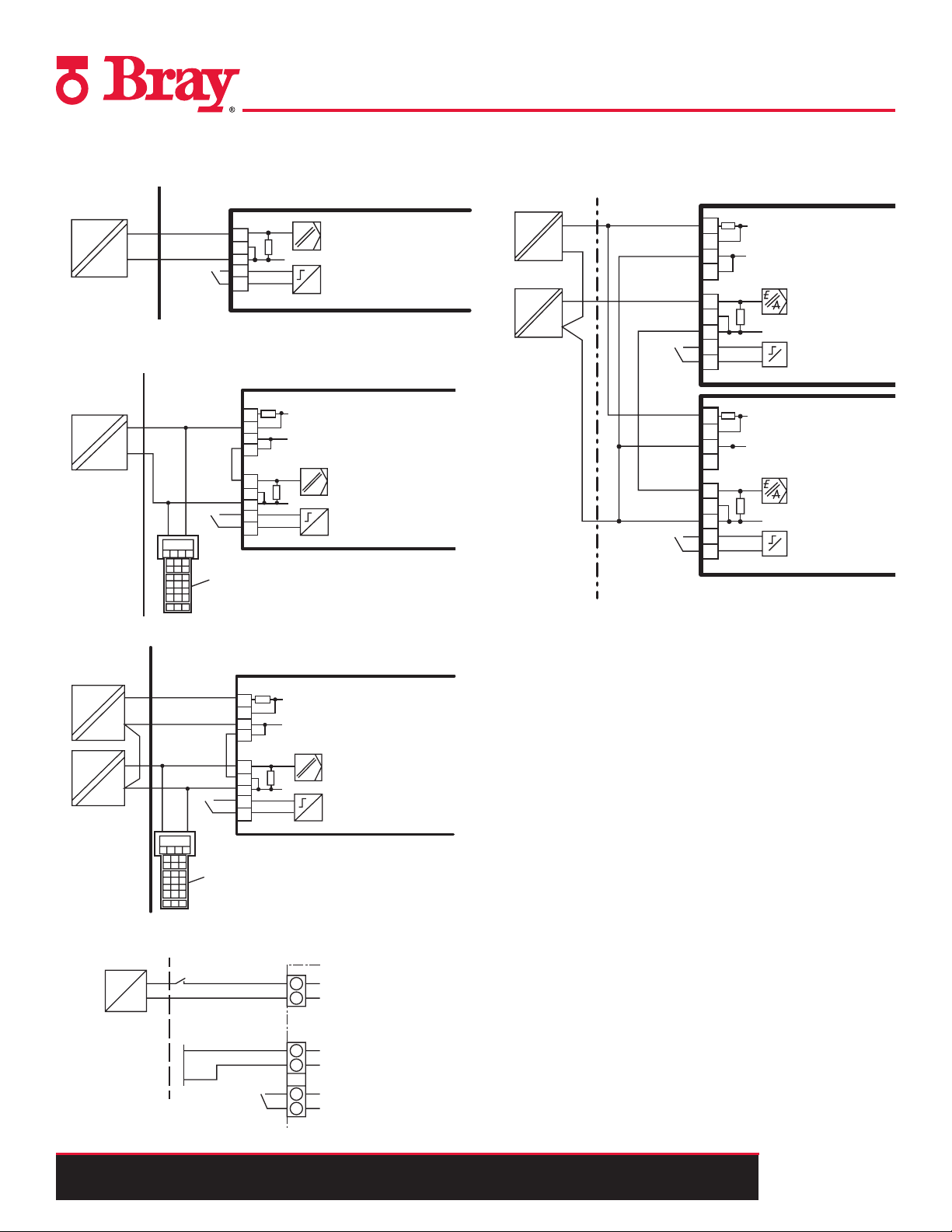

FIELD WIRING

Each S6A is provided with two conduit entries for power/incoming analog signal of the main unit and any optional modules.

Please refer to the wiring diagrams referenced in this document when connecting the positioner and any optional modules.

It is essential to install the optional modules before connecting the positioner electrically. Refer to the following “Technical

Description” portion of this manual for relevant power distribution sizing information when installing a S6A positioner and its

optional modules.

Safety Notes:

• Local regulations regarding hazardous environments must be

followed when installing this device in a hazardous location.

• The conduit connections must be properly sealed to maintain

the weatherproof integrity of the actuator enclosure.

• Never connect the current input (terminals 6 and 7 as shown

on the diagrams to the right) to a power source; the positioner

will probably be destroyed in that case. Always use a current

source with a maximum output current of I = 20 mA.

• To maintain auxiliary power, the input current must be a minimum of 3.6 mA.

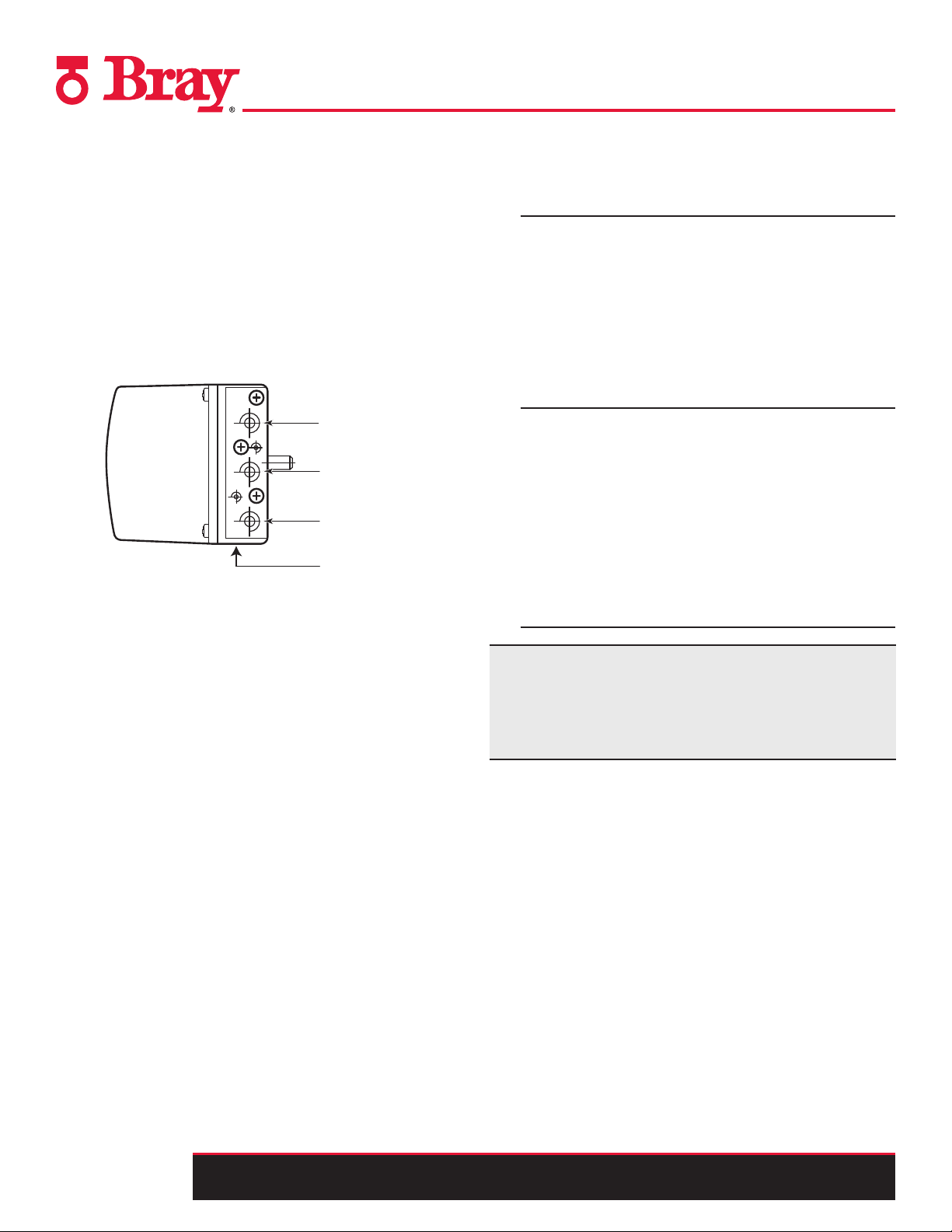

Note: The plastic enclosure is metallized from inside to

increase the electromagnetic compatibility (EMC) with

respect to high-frequency radiation. The shield is connected

to the threaded bush shown in Figure 1 such that it is electrically conductive. This protection is effective only if you

connect at least one of the bushes to the grounded control

valves through electrically conductive (bare) attachments.

1.

2.

3.

Figure 1.

Tools Needed:

• Instrument Screwdriver

I. General Area

1. Two Wire

+

4 ... 20 mA

J

6

7

–

8

9

BE1 = Binary Input

10

2. Two Wire Connection When Using a 2/3/4 Wire Device

2

+

J

4 ... 20 mA

3

4

5

6

7

–

8

BE1 = Binary Input

9

10

3. Three/Four Wire

+

2

18 ... 30 V

J

1) Jumper between 5 and 7 only for three-wire system

0/4 ... 20 mA

3

–

4

5

1)

+

6

7

–

8

9

10

BE1 = Binary Input

4. HART

1)

l

= 4 ... 20 mA

y

2

l

H+

3

4

5

6

l

7

W-

8

PC/Laptop

I

Only required with current sources not conforming to HART1)

3

R 250 W if req.

+

–

HART

modem

5. Probus DA/DP, Foundation Fieldbus

≤ 30 V

+

–

≤ 24 V

+

–

Input for safety shutdown (activated using coding jumper)

1)

1)

81

82

6

7

9

BE1 = Binary Input

10

6A O & M : 6

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 7

4 ... 20 mA

BE1 = Binary Input

7

8

9

10

+

–

J

6

Input for safety shutdown (activated using coding jumper)

1)

≤ 30 V

≤ 24 V

+

–

BE1 = Binary Input

7

9

10

+

–

6

1)

81

82

1)

HART

modem

PC/Laptop

R 250 W if req.

1)

3

Only required with current sources not conforming to HART1)

2

3

4

5

+

–

I

l

y

= 4 ... 20 mA

6

7

8

l

W-

l

H+

1) Jumper between 5 and 7 only for three-wire system

2

3

4

5

+

–

J

6

7

8

9

10

4 ... 20 mA

0/4 ... 20 mA

2

3

4

5

+

–

6

7

8

9

10

18 ... 30 V

J

+

–

BE1 = Binary Input

BE1 = Binary Input

1)

Series connection of 2 positioners, e.g. split range (auxiliary power wired separately), EEx i

Series 6A Operation & Maintenance – Field Connections

II. Hazardous Area (Intrinsically Safe)

A. Two Wire

Non-hazardous area Hazardous area, Zone 1

EEx

Intrinsically safe

power source

4 to 20 mA

B. and C. Two Wire Connection When Using a 2/3/4 Wire

Device and HART

Non-Hazardous

area

EEx

I

Intrinsically safe

power source

Hazardous area, Zone 1

+

4 to 20 mA

6

7

8

9

10

2

3

4

5

6

7

8

9

10

HART Communicator

6A-6DR52**-*E*** only

#

Positioner

E

A

#

Positioner

Binary input 1

Binary input 1

Multiple Positioners Field Wiring

Split Range

Auxiliary power

Intrinsically safe power sources

Entire positioning

Non-hazardous area Hazardous area, Zone 1

EEx

EEx

L+

V

I

I

range I

+ 18 to 30 V

M

y

M

+ 0/4 to 20 mA

y

2

3

4

5

6

7

8

9

10

2

3

4

5

6

7

8

9

10

Positioning range 1

BE1

#

Positioning range 1

BE1

#

D. Three/Four Wire

Non-hazardous area Hazardous area, Zone 1

18 to 30 V

+

EEx

I

EEx

I

Intrinsically safe

power source

E. Probus DA/DP, Foundation Fieldbus

Non-Hazardous Hazardous area, Zone 1

Power Supply

4 to 20 mA

+

*)

–

+

2

3

4

5

6

*)

7

8

9

10

HART Communicator

6A-6DR52**-*E*** only

≤ 24 V

–

Input for safety shutdown (activated using coding jumper)

Positioner

E

A

#

*) Three-wire connection only

81

82

6

7

9

BE1 = Binary Input

10

Binary input 1

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 7

Page 8

Series 6A Operation & Maintenance – Field Connections

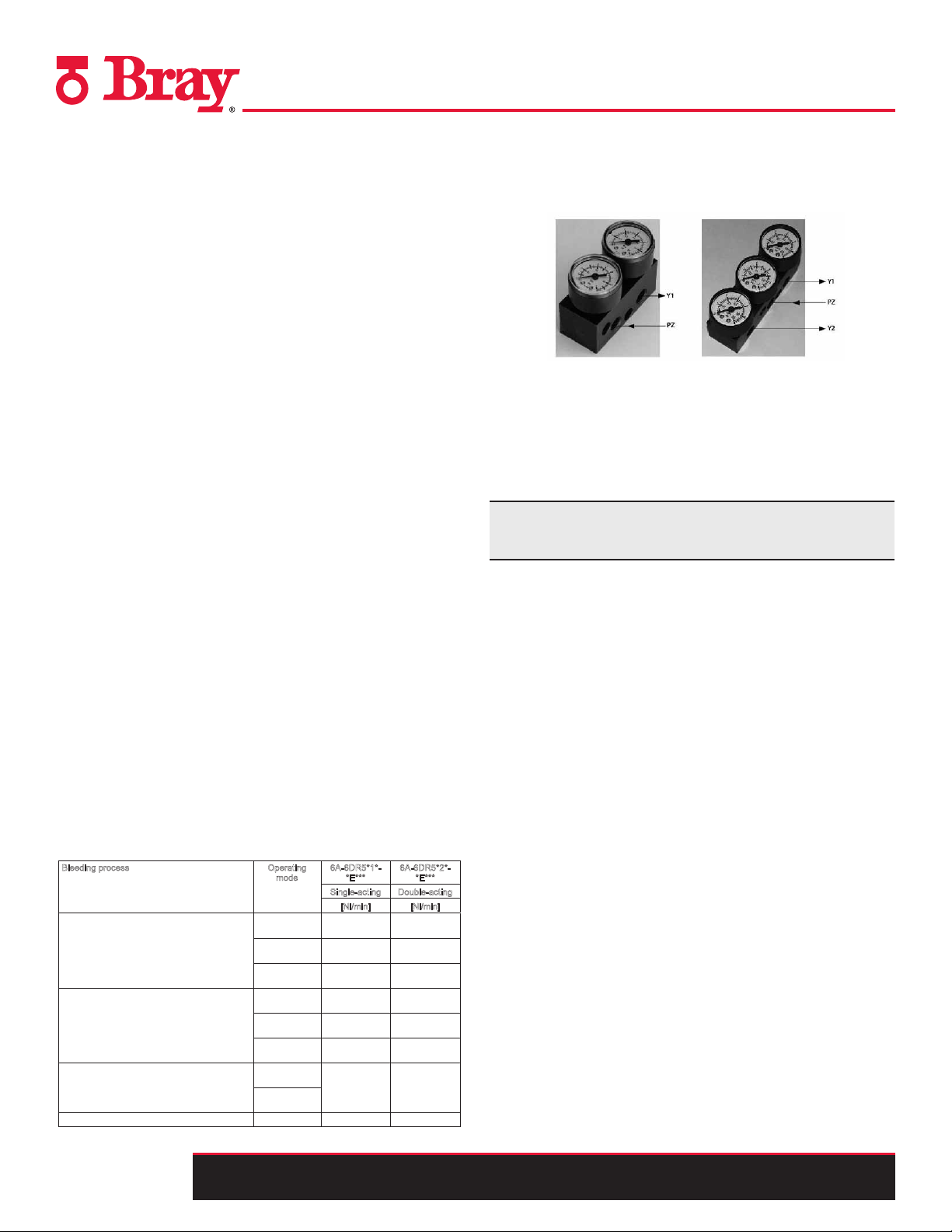

Connecting Pneumatic Supply Lines

Refer to the Technical Data portion of this manual for specications regarding air quality.

The S6A is equipped with three pneumatic connections, Y1, Y2

and PZ. PZ is for the pneumatic supply and Y1 and Y2 are used

to supply the pneumatic actuator. The S6A can also be equipped

with a pressure gauge block for monitoring supply and actuating

pressure and a lter to ensure that the S6A is receiving clean air.

Proceed as follows to make the pneumatic connections:

Refer to Figure 2.

Y1

PZ

Y2

E

Figure 2. - Pneumatic connection on the standard controller

1. If required, connect the pressure gauge block for supply air

and actuating pressure.

2. Connect supply air to PZ.

Connection using female thread G1/4 DIN 45141

or 1/4" NPT:

• PZ supply air 20psi to 102psi (1.4 to 7 bar)

• Y1: actuating pressure for single and double-acting

actuators

• Y2: actuating pressure for double-acting actuators

• E: exhaust air outlet; remove the attenuator if required.

For double-acting actuators, connect actuating pressures

Y1 or Y2 depending on the desired safety position. The

three pneumatic connections will go to the following

safety position in case of electrical auxiliary power supply failure:

• Y1: single-acting, depressurized

• Y1: double-acting, max. actuating pressure/supply air

pressure.

• Y2: double-acting, depressurized

Note: Besides continuous air consumption, the positioner may

try to compensate the position deviation due to leakage. This

will lead to premature wear in the entire control unit. To prevent

this ensure that all pneumatic connections are properly sealed

and perform regular maintenance on their ttings.

6A O & M : 8

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 9

Series 6A Operation & Maintenance – Field Connections

1

2

3

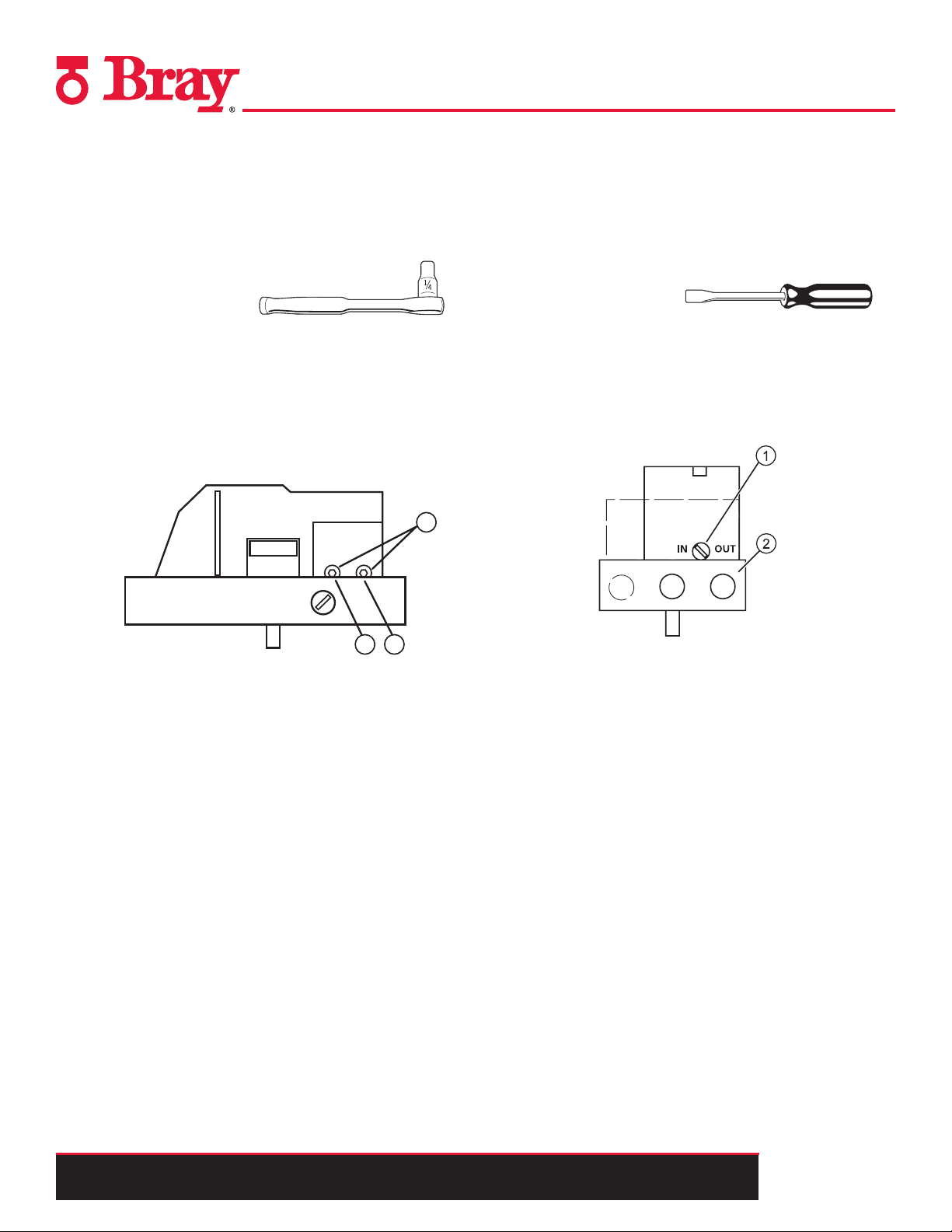

Restrictors

The S6A is equipped with air restrictors to reduce the air output to

achieve actuating times of T > 1.5 s for small actuators. Restrictors

1 and 2 are used for this purpose.

Tools Needed:

• Hexagon socket 2.5 mm

Refer to Figure 3.

When turned clockwise, they reduce the air output and nally shut

it off.

In order to set the restrictors, it is recommended to close them and

then open them slowly.

In case of double-acting actuators, ensure that both restrictors

have approximately the same setting.

Purging

The S6A is equipped with a purge air switch that allows the

actuator to purge air either inside of the unit or directly outside.

When the enclosure is open, the purge air switch above the

pneumatic terminal strip on the pneumatic block can be accessed.

Tools Needed:

• Instrument Screwdriver

Refer to Figure 4.

In the IN position, the enclosure is ushed from inside with a

small volume of clean and dry instrument air.

In the OUT position, the purge air is directed towards outside of

the unit.

Figure 3. - Air Restrictor

➀Restrictor for Y1

➁Restrictor for Y2, only in the version for double-acting

actuators

➂Hexagon socket-head screw 2.5 mm

Figure 4. - Purge Air Switch

➀Purge Air Switch

➁Pneumatic Block

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 9

Page 10

Series 6A Operation & Maintenance – Field Connections

Natural Gas as an Actuator Medium

The S6A can also be operated with natural gas as an actuator

medium. When operating the positioner with natural gas, you

must follow and adhere to the following safety notes:

1. Only the “EEx ia” version of the positioner and optional

modules with the “EEx ia” type of protection may be operated

with natural gas. Positioners with other types of protection,

i.e. ameproof enclosures for zones 1 and 2 are not permitted.

2. Do not operate the positioner with natural gas in closed spaces.

3. Natural gas is continuously blown off in the servo-drive

depending on the model. Special care must therefore be taken

during maintenance activities near the positioner. Always

ensure that the immediate surroundings of the positioner are

adequately ventilated.

4. The mechanical limit switch module may not be used when

operating the positioner with natural gas.

5. Depressurize the devices operated with natural gas adequately

during maintenance activities. Open the cover in an explosionfree atmosphere and depressurize the device for at least two

minutes.

Normally you operate the positioner with compressed air. Natural

gas has been approved as an actuator medium for intrinsically

safe positioners with the “EEx ia” type of protection. Only use

natural gas which is clean, dry and free from additives.

The positioner releases the used natural gas through the exhaust

air outlet E (see Figure 2). The exhaust air outlet E is equipped

with an attenuator. As an alternative to this standard conguration,

the exhaust air outlet can be replaced with a G¼ screwed tting.

You have to dismantle the attenuator for this purpose. Natural gas

escapes parallel to the exhaust air outlet E, from the enclosure

vent at the bottom side of the device, and from the control air

outlet near the pneumatic connections. This escaping natural gas

cannot be collected and carried off. When using natural gas as an

actuator medium refer to Figure 5 for maximum bleed off values.

Optional Accessories

1. Pressure Gauges – used to measure and indicate supply and

actuating pressures

2. Filter – used to clean the supply medium

3. Non Contacting/External Position Detection System – used

for harsh environments

4. SIMATIC PDM Operation Software – used for online

diagnostics of the S6A

Contact your Bray representative for specic requirements for

your intended application.

Figure 5. Maximim bleed off values

Bleeding process Operating

Bleed the enclosure volume through the bottom

side of the device. Purge air switch is at "IN":

Bleed through the control air outlet near the

pneumatic connections:

Bleed through the exhaust air outlet E

6A O & M : 10

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

ode

m

Operation,

typical

Operation,

max.

Error case,

max.

Operation,

typical

Operation,

max.

Error case,

max.

Operation,

max.

Error case,

max.

6A-6DR5*1*-

*E***

Single-acting Double-acting

[

Nl/min] [Nl/min]

0.14 0.14

0.60 0.60

60.0 60,0

1.0 2.0

8.9 9.9

66.2 91.0

358.21) 339

6

A-6DR5*2*-

*E***

1),

32.1 62.1 ]l[ .xaM emuloV

Page 11

Series 6A Operation & Maintenance – Calibration & Commissioning

CALIBRATION AND COMMISSIONING

Installing a New Unit

Please refer to the S6A Quick Start Guide for the Standard Unit.

Replacing a Unit

The S6A can be replaced in a running system where a S6A was

already in use without interrupting the process. By copying and

transferring the device and initialization data, it is possible to

commission a replacement positioner without needing to initialize it. The S6A uses the communication interface to transfer data.

When this is performed, it is crucial to perform a standard initialization of the replacement positioner as soon as possible because

the following properties can be ensured only after initializing:

• Optimum adjustment of the positioner as per the mechanical

and dynamic properties of the actuator.

• Unrestricted accuracy and dynamic behavior of the positioner.

• Deviation-free position of the hard-end stops.

• Accuracy of the maintenance data

Copy the initialization data and the device parameters as follows:

1. Read in the initialization data and the device parameters of the

positioner to be replaced. Use a suitable parameterization

tool for this purpose.

2. Save the data in the parameterization tool.

Note: If the positioner to be replaced has already been initialized

or congured using the parameterization tool, you need not read

in and save the device data.

Proceed as follows to replace a positioner in a running system:

3. Fix the actuator at its current position mechanically or

pneumatically.

4. Determine the actual position value.

– Read the actual position value on the digital display of

the positioner to be replaced.

Take note of the read value.

– If the electronic unit of the positioner is defective, mea-

sure the actual position value at the actuator or the valve.

Take note of the read value.

5. Dismantle the positioner.

6. Attach the lever arm of the positioner to be replaced to the

replacement positioner.

7. Install the replacement positioner on the control valve.

8. Set the transmission ratio selector of the replacement positioner

to the same position as that of the positioner to be replaced.

9. Use the parameterization tool to transfer the saved device and

initialization data to the replacement positioner.

10. If the displayed actual position value differs from the noted

value, correct the deviation by moving the friction clutch.

11. The replacement positioner is ready for operation when the

displayed and the noted values match.

Operation

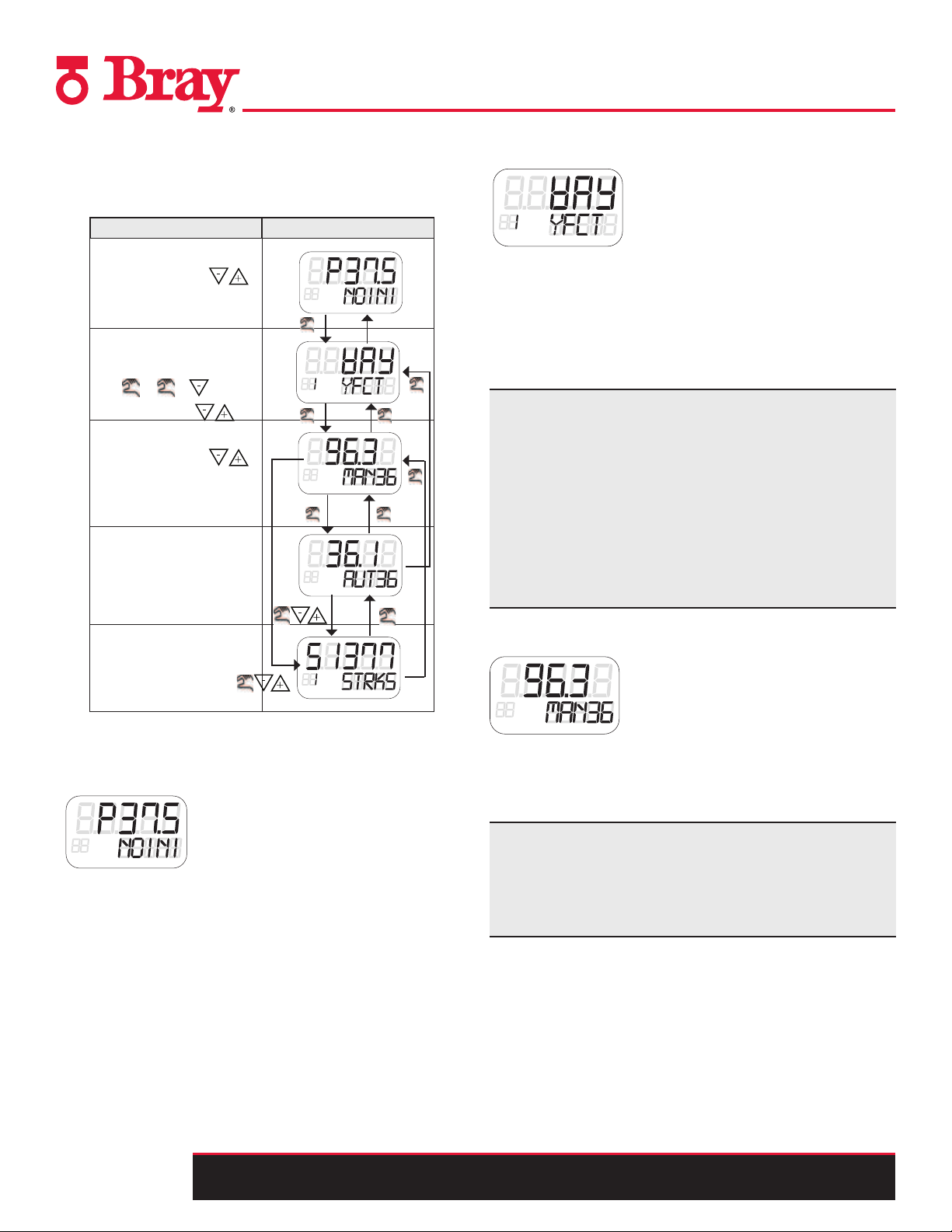

Reading the LCD screen

The S6A digital display has two lines, one on the bottom and one

on top. Each element on the top line has seven segments while

each element on the bottom line has fourteen. Contents of the display depend on the selected mode. Figure 6 below provides an

example of what the display will look like when the unit is powered on.

Figure 6.

Example Display

Note: When operated in temperature ranges below 14°F (-10°C),

the liquid crystal display of the positioner becomes sluggish and

the repetition rate display is reduced considerably.

Using the pushbuttons

The S6A is manually operated using three pushbuttons. The cover

of the positioner has to be removed in order to operate the buttons.

Note: The function of the buttons depends on the current

Operating Mode. As a general rule the following applies:

The operating mode button is used to select the modes and to

forward the parameters.

The decrement button is used to select parameter values when

conguring. You can use this button to move the actuator in

the manual mode.

The increment button is also used to select parameter values

when conguring. You can use the increment button to move

the actuator in the manual mode.

+ *Parameters are activated in the reverse order by press-

ing the operating mode button and the decrement button at

the same time

Note: The IP66/NEMA 4x degree of protection is not ensured

as long as the positioner is open.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 11

Page 12

Series 6A Operation & Maintenance – Calibration & Commissioning

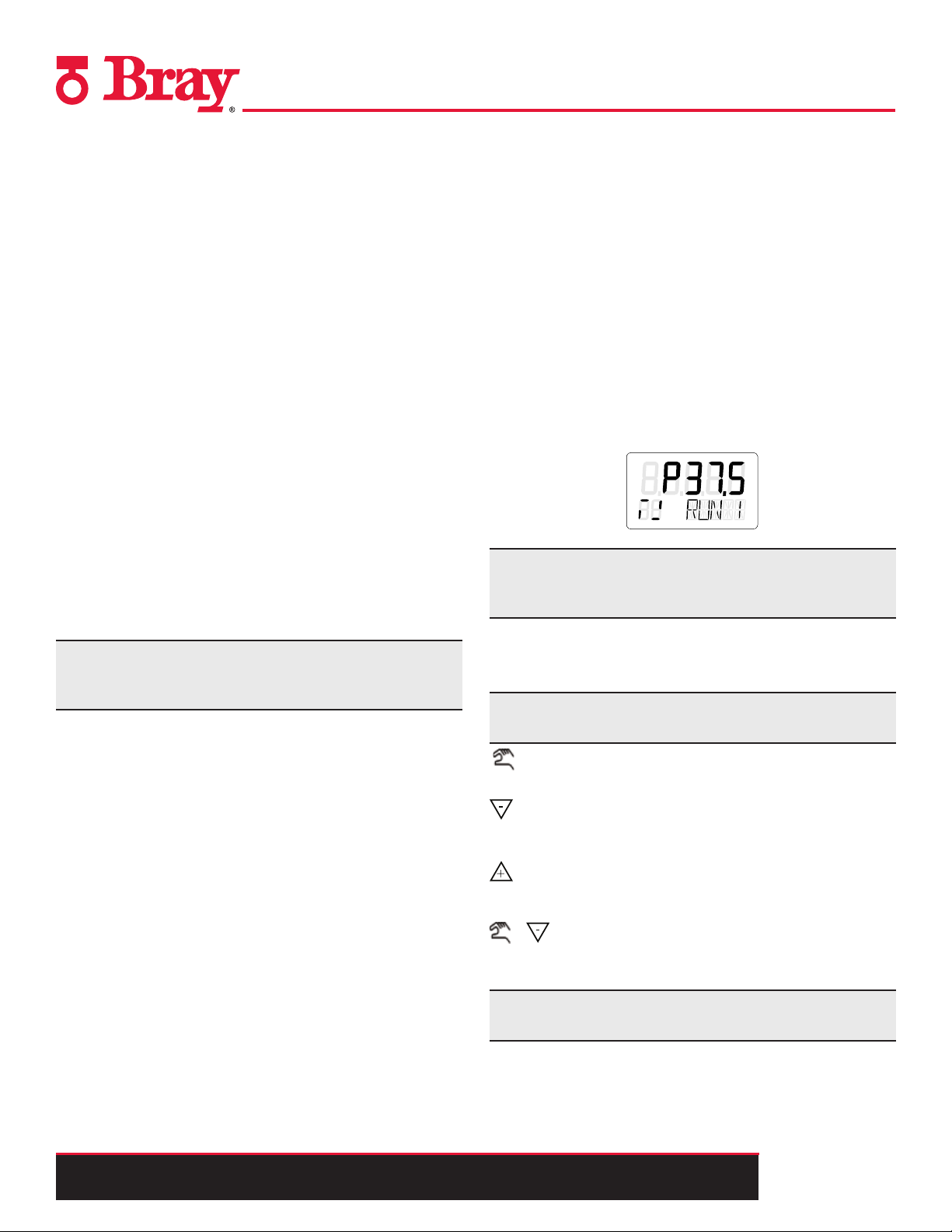

Operating Modes

The S6A has ve different operating modes described in detail

below. Refer to Figure 7 to navigate between modes.

Operating Mode Display

P- manual operation

change position with

Congure

select parameter

with

or +

change value with

Manual Operation

change position with

Automatic

> 5 s

> 5 s > 5 s

1x

PRST

> 5 s

> 2 s

1x

Configuration and initialization mode

To get to the “Conguration” mode, press the operating mode

button for at least 5 seconds. You can use the “Conguration”

mode to adjust the positioner individually as per your actuator

and start commissioning or initialization. The positioner reports

the “Conguration” mode with a congurable fault message. A

position feedback or display of limits A1 and A2 is not possible.

Note: If electrical auxiliary power supply fails when conguring,

the positioner responds as follows until the power supply is

reestablished:

• The positioner switches to the rst parameter.

• Settings of the values already congured are retained.

In order to save the changed parameter values, exit the

“Conguration” mode or switch to another parameter. When

the “Conguration” mode is restarted, the control in the digital

display switches to the last activated parameter.

Diagnostics

Figure 7. Operating Modes Display

> 2 s

> 2 s

> 2 s

P-manual mode (as-delivered condition)

The “P-manual mode” is preset for the positioner in the

as-delivered condition. The digital display of the positioner shows

the current potentiometer position in the upper line. “NOINI”

blinks in the second line of the digital display. You can move the

actuator using the decrement and increment buttons. Switch to

Conguration” and “Initialization mode” to adapt the actuator as

per the positioner.

Alarms or position feedbacks can be triggered only after

initializing the positioner completely.

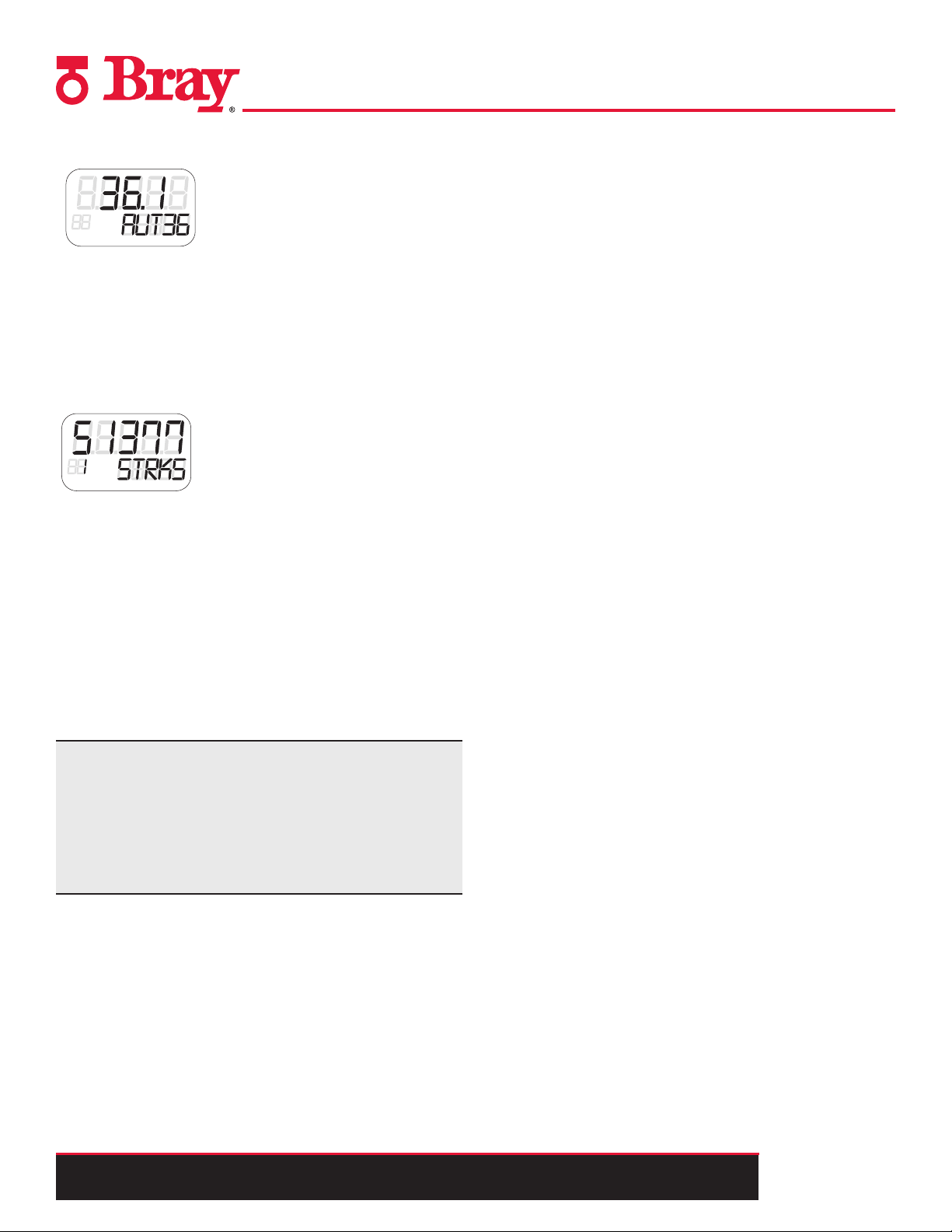

Manual mode (MAN)

You can move the actuator using the decrement and increment

buttons in this mode. The setting selected here is retained

irrespective of the setpoint current and leakages, if any.

Note: To accelerate the actuator movement keep one of the

two direction buttons pressed and simultaneously press the

remaining direction. In the event of a failure of the power

supply, once the power is reestablished the positioner switches

to “Automatic” mode.

6A O & M : 12

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 13

Series 6A Operation & Maintenance – Calibration & Commissioning

Automatic (AUT)

Automatic is the standard mode. In this mode, the positioner

compares the setpoint position with the actual position. The

positioner moves the actuator until the control deviation reaches

the congurable dead zone. A fault message is displayed if the

dead zone cannot be reached.

Diagnostics

Proceed as follows to call the “Diagnostics” mode from the

“Automatic” or “Manual” modes:

Press the three buttons of the positioner at the same time for at

least 2 seconds.

Current operating data can be called and displayed in this mode,

e.g.:

• Stroke number

• Number of changes in direction

Using the built in Diagnostics

The S6A has various monitoring functions with which changes on

the actuator and valve can be detected and signaled if applicable

when a selectable limit has been exceeded. This information may

be important for diagnosis of the actuator or valve and will help

to schedule preventative maintenance. The measuring data that is

monitored is listed below:

• Travel integral

• Number of changes in direction

• Alarm counter

• Self-adjusting dead zone

• Valve end limit position (for detection of valve seat wear or

deposits)

• Operating Hours (also according to temperature and travel

ranges) as well as min./max. temperature

• Operating Cycles of piezoelectric valves

• Valve positioning time

• Actuator leakages

The diagnostics display has similar structure to that of the

“Conguration” mode:

• The upper line shows the value of the diagnosis variable.

• The lower line shows the number and the abbreviation of the

displayed variable.

• Number of fault messages

Note: The “Automatic” and “Manual” modes remain set when

switching to the “Diagnostics” mode. The positioner responds

as per the set mode:

• The predened setpoint is used as a control variable in the

automatic mode.

• The last reached position is retained in the manual mode.

Some diagnostics values can be greater than 99999. In such a

case, the display switches over to the exponential view. Example:

The value “1234567” is shown as “1.23E6”.

In the event of a fault an error code will be shown on the lower

left hand corner of the display. There is a fault table in the

“Troubleshooting” section of this manual which explains what

each of these codes represents.

The following table provides an overview of values that can be

displayed. The last column contains “X” if the value can be set

to zero.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 13

Page 14

Series 6A Operation & Maintenance – Calibration & Commissioning

Overview of diagnostics values

Overview of Diagnostics Values

No. Abbreviation Meaning Values that can

1 STRKS Stroke number (Strokes) 0 ... 4.29E9 - X

2 CHDIR Changes of direction (Changes of Direction) 0 ... 4.29E9 - X

3 CNT Number of fault messages ( Counter) 0 ... 4.29E9 - X

4 A1CNT Number of alarms 1 (Alarm 1 Counter) 0 ... 4.29E9 - X

5 A2CNT Number of alarms 2 (Alarm 2 Counter) 0 ... 4.29E9 - X

6 HOURS Operating hours (Hours) 0 ... 4.29E9 Hours -

7 WAY Determined actuator travel (Way) 0 ... 130 mm or ° -

8 TUP Actuating time up (Travel Time Up) 0 ... 1000 s -

9 TDOWN Actuating time down (Travel Time Down) 0 ... 1000 s -

10 LEAK Leakage (Leakage) P 0.0 ... 100.0 % -

11 PST Monitoring of the partial stroke test OFF / ###.#, fdini,

12 PRPST Time since the last Partial-Stroke-Test ###, notSt, Sdtst,

13 NXPST Time until the next Partial-Stroke-Test ###, notSt, SdtSt,

14 DEVI General control valve fault OFF, 0.0 ... 100.0 % -

15 ONLK Pneumatic leakage OFF, 0.0 ... 100.0 - -

16 STIC Static friction/Slipstick effect OFF, 0.0 ... 100.0 % -

17 ZERO Zero point displacement OFF, 0.0 .. 100.0 % -

18 OPEN Displacement of upper end stop OFF, 0.0 ... 100.0 % -

19 PAVG Position average 0.0 ... 100.0 % -

20 P0 Potentiometer value of lower end stop (0%) 0.0 ... 100.0 % -

21 P100 Potentiometer value of upper end stop (100%) 0.0 ... 100.0 % -

22 IMPUP lmpulse length up (Impuls Length Up) 2 ... 160 ms -

23 IMPDN Impulse length down (Impuls Length Down) 2 ... 160 ms -

24 DBUP Dead zone up (Dead Band Up) 0.1 ... 10.0 % -

25 DBDN Dead zone down (Dead Band Down) 0.1 ... 10.0 % -

26 SSUP Slow step zone up (Short Step Zone Up) 0.1 ... 100.0 % -

27 SSDN Slow step zone down (Short Step Zone Down) 0.1 ... 100.0 % -

28 TEMP Current temperature -40 ... 85 °C -

29 TMIN Minimum temperature ("min/max pointer") -40 ... 85 °C -

30 TMAX Maximum temperature ("min/max pointer") -40 ... 85 °C -

31 T1 Number of operating hours in temperature range 1 0 ... 4.29E9 Hours -

32 T2 Number of operating hours in temperature range 2 0 ... 4.29E9 Hours -

33 T3 Number of operating hours in temperature range 3 0 ... 4.29E9 Hours -

34 T4 Number of operating hours in temperature range 4 0 ... 4.29E9 Hours -

35 T5 Number of operating hours in temperature range 5 0 ... 4.29E9 Hours -

36 T6 Number of operating hours in temperature range 6 0 ... 4.29E9 Hours -

b

e displayed

notSt, SdtSt,

fdtSt, notd, Strt

fdtSt

fdtSt

nit Reset

U

s for ###.# -

Days -

Days -

p

ossible

Series 6A with and without HART communications

Operation and Maintenance Manual, 09/2008, A5E00756809-03

6A O & M : 14

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 15

Series 6A Operation & Maintenance – Calibration & Commissioning

No. Abbreviation Meaning Values that can

b

e displayed

U

nit Reset

p

ossible

37 T7 Number of operating hours in temperature range 7 0 ... 4.29E9 Hours -

38 T8 Number of operating hours in temperature range 8 0 ... 4.29E9 Hours -

39 T9 Number of operating hours in temperature range 9 0 ... 4.29E9 Hours -

40 VENT1 Number of switching cycles of pilot valve 1 0 ... 4.29E9 - -

41 VENT2 Number of switching cycles of pilot valve 2 0 ... 4.29E9 - -

42 STORE Save the current value as "last maintenance" (press

the increment button for 5 s) (Store)

- - -

43 PRUP Prediction up 1 ... 40 - -

44 PRDN Prediction down 1 ... 40 - -

45 WT00 Number of operating hours in the actuating range

WT00

0 ... 4.29E9 Hours X

46 WT05 Number of operating hours in the actuating range

WT05

0 ... 4.29E9 Hours X

47 WT10 Number of operating hours in the actuating range

WT10

0 ... 4.29E9 Hours X

48 WT30 Number of operating hours in the actuating range

WT30

0 ... 4.29E9 Hours X

49 WT50 Number of operating hours in the actuating range

WT50

0 ... 4.29E9 Hours X

50 WT70 Number of operating hours in the actuating range

WT70

0 ... 4.29E9 Hours X

51 WT90 Number of operating hours in the actuating range

WT90

0 ... 4.29E9 Hours X

52 WT95 Number of operating hours in the actuating range

WT95

0 ... 4.29E9 Hours X

Diagnostic value 53

No. Abbreviation Meaning Values that can

b

e displayed

U

nit Reset

p

ossible

53 mA Setpoint current 0.0 to 20.0 mA --

Overview of Diagnostics Values (cont.)

No. Abbreviation Meaning Values that can

37 T7 Number of operating hours in temperature range 7 0 ... 4.29E9 Hours -

38 T8 Number of operating hours in temperature range 8 0 ... 4.29E9 Hours -

39 T9 Number of operating hours in temperature range 9 0 ... 4.29E9 Hours -

40 VENT1 Number of switching cycles of pilot valve 1 0 ... 4.29E9 - -

41 VENT2 Number of switching cycles of pilot valve 2 0 ... 4.29E9 - -

42 STORE Save the current value as "last maintenance" (press

the increment button for 5 s) (Store)

43 PRUP Prediction up 1 ... 40 - -

44 PRDN Prediction down 1 ... 40 - -

45 WT00 Number of operating hours in the actuating range

WT00

46 WT05 Number of operating hours in the actuating range

WT05

47 WT10 Number of operating hours in the actuating range

WT10

48 WT30 Number of operating hours in the actuating range

WT30

49 WT50 Number of operating hours in the actuating range

WT50

50 WT70 Number of operating hours in the actuating range

WT70

51 WT90 Number of operating hours in the actuating range

WT90

52 WT95 Number of operating hours in the actuating range

WT95

Diagnostic value 53

b

e displayed

- - -

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

0 ... 4.29E9 Hours X

nit Reset

U

No. Abbreviation Meaning Values that can

53 mA Setpoint current 0.0 to 20.0 mA --

Series 6A with and without HART communications

Operation and Maintenance Manual, 09/2008, A5E00756809-03

b

e displayed

nit Reset

U

p

ossible

p

ossible

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 15

Page 16

Series 6A Operation & Maintenance – Calibration & Commissioning

Parameter Function Parameter Values Description

1)YFCT Typeofpositionactuator

2)YAGL Angleofrotation

3)YWAY RangeofStroke

4)INITA Initialization(automatic)

5)INITM Initialization(manual)

6)SCUR Currentrangeofsetpoint

7)SDIR SetpointSetup

8)SPRA Setpointsplitrangestart

9)SPRE Setpointsplitrangeend

10)TSUP SetpointrampOPEN

11)TSDO SetpointrampCLOSED

12)SFCT SetpointFunction

13)SLO

SetpointTurningPoint

…33)SL20

34)DEBA DeadZoneofClosedLoopController

35)YA Startofthemanipulated

variablelimit

36)YE Endofthemanipulated

variablelimit

37)YNRM Manipulatedvariable

scaling

38)YDIR DirectionofManipulated

Variable

39)YCLS Manipulatedvariabletight

closing

40)YCDO Lowervaluefortight

closing

Turn Automatically sets 2) YAGL to 90◦

WAY Used for linear actuators

LWAY Used for linear actuators

ncSt Used for a non-contacting position sensor on a part

turn actuator

-ncSt Used for a non-contacting position sensor on a part

turn actuator with a reverse direction of action

ncSL Used for linear actuators

ncSLL Used for linear actuators

33◦

90

◦

Used for linear actuators

Used for linear actuators

NOINI | no/ ###.# | Strt Starts the automatic initialization process

NOINI | no/ ###.# | Strt Starts the manual initialization process

0 MA 0 MA only available for 3 to 4 wire connections.

4 MA Factory setting.

riSE

FALL

Used to reverse the direction of the action of the

setpoint. Factory setting is “rise”

0.0 … 100.0 Used to limit the setpoint. Factory setting is “0”

0.0 … 100.0 Factory setting is “100”

Auto / 0 … 400

0 … 400

1 – 25

1 – 33

Limits the speed of change of the effective setpoint.

Factory setting is “0”

Equal Percentage. Linearizes valve characteristics.

Factory setting is “Lin”

1 – 50

n1 – 25

Inverse equal percentage

n1 – 33

n1 – 50

FrEE Freely Adjustable

0.0 … 100.0 Assigns a flow metric to each setpoint interpolation

in units of 5%.

Auto / .1 … 10.0 Adjust the dead zone to the requirements of the

control loop. Factory setting is “Auto”

0.0 … 100.0

Used to limit the mechanical actuator travel from

stop to stop to the configured values. “YE” must

0.0 … 100.0

always be larger than “YA”. Factory setting is “100”

MPOS Mechanical position from 0 to 100% between hard

stops.

FLOW Scaling from 0 to 100% over the range between

“YA” and “YE”

riSE

FALL

No

uP

Do

Used to set the direction of action of the display and

the position feedback Iy. Factory setting is “riSE”

Used to move the valve into its seat with the

maximum force of the actuator. Factory setting is

“No”

uP do

0.0 … 0.5 … 100% Factory setting is “0.5”

6A O & M : 16

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 17

Series 6A Operation & Maintenance – Calibration & Commissioning

41)YCUP Uppervaluefortight

closing

42)BIN12) FunctionofBE1

43)BIN22) FunctionofBE2

44)AFCT3) AlarmFunction

0.0 … 99.5 … 100% Used to set the value for tight “Tight closing below”

and “Tight closing above”. Factory setting is “99.5”

Normally

Open

Normally

Closed

Functions while in binary input mode.

OFF Factory setting.

on -on Binary message from peripherals

bloc1 Used to lock the configuration operation

bloc2

uP -uP

doWn -doWn

Actuator regulating to the valve specified by

parameters “YA” and “YE”

StoP -StoP Piezo valves are blocked. Actuator remains at last

position.

PST -PST Used to trigger a partial stroke test

Normally

Open

Normally

Closed

Functions while in binary input mode.

OFF Factory setting.

on -on Binary message from peripherals

uP -uP

doWn -doWn

Actuator regulating to the valve specified by

parameters “YA” and “YE”

StoP -StoP Piezo valves are blocked. Actuator remains at last

position.

PST -PST Used to trigger a partial stroke test

Normal Inverted

Off

Used to determine the value at which going above or

below a given offset or angle will result in a

message.

45)A1 Triggerthreshold,alarm1

46)A2 Triggerthreshold,alarm2

47)FCT3) Functionforfault

messageoutput

48)TIM Monitoringtimefor

settingoffaultmessage

49)LIM Responsethresholdfor

faultmessage

50)PRST Preset(factorysetting)

51)XDIAG Activationofextended

diagnostics

52)FSTY SafetySeating

0.0 … 10.0 … 100 %

Used to specify when an alarm should be displayed.

0.0 … 90.0 …100%

Normal Inverted

Cannot be switched off. Can be suppressed by

switching to “No Automatic Mode”

Auto / 0 … 100 Used to set the time in seconds that the positioner

must have reached the regulated condition.

Auto / 0 … 100 Used to set a value for the permissible size of the

regulation device to trigger a fault message.

no

Strt

Used to restore factory settings and reset

initialization. Press increment button for 5 seconds.

oCAY

OFF

Used to activate extended diagnostics.

On1

On2

On3

FSVL Actuator controlled using the parameterization safety

point. Effective after a power failure.

FSSP Actuator controlled using the last effective set point

FSAC Valves move to location based on spring force.

(Factory Defined)

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 17

Page 18

Series 6A Operation & Maintenance – Calibration & Commissioning

53)FSTI MonitoringPeriodfor

settingthesafetyseating

54)FSVL SafetySetpoint

55)STNR StationNumber

56)IDENT Deviceoperatingmode

(IDNo.)

0 … 100 (s). Once this set value expires the positioner

switches to its safety position. (Factory defined at 0)

0.0 … 100.0 (%). Default value of the safety position. (Factory

setting is 0%)

0 … 126 Independent value for each station. (Default position

is 126)

0 Profile Compliant. Can be replaced with other

positioners complying with Profibus PA profile 3.0

1 Compliant with Extensions (Factory Defined).

Parameter Function Parameter Values Description

A. PST Partial Stroke Test Used to activate the partial stroke test for cyclic or

manual test of up/down and servo solenoid valves.

A1.STPOS Starting position 0.0 … 100.0 Start position in %. Factory setting is “100.0”

A2.STTOL Starting tolerance 0.1 … 2.0 … 10.0 Start position tolerance in %. Factory setting is

“2.0”

A3.STEP Step height 0.1 ..10.0 ..100.0 Step height of partial stroke test in %

A4.STEPD Step Direction uP / do / uP do Step direction of partial stroke test. Factory setting

is “do”

A5.INTRV Test Interval OFF / 1 … 365 Interval time for cyclic partial stroke in days. “Off”

A6.PSTIN Partial Stroke ref. step time NOINI / (C) ###.# /

Fdini / rEAL

A7.FACT1 Factor 1 0.1 … 1.5 … 100.0 Factor for the formation of limit threshold 1. “1.5”

A8.FACT2 Factor 2 0.1 … 3.0 … 100.0 Factor for the formation of limit threshold 2. “3.0”

A9.FACT3 Factor 3 0.1 … 5.0 … 100.0 Factor for the formation of limit threshold 3. “5.0”

b. DEVI General Control Valve Fault Test for dynamic monitoring of control valve

b1.TIM Time constant Auto / 1 … 400 Defines the attenuation effect of the low-pass filter.

b2.LIMIT Limit 0.1 … 1.0 … 100.0 Sets a base limit in %. “1.0”

b3.FACT1 Factor 1 0.1 … 5.0 … 100.0 Factor for the formation of limit threshold 1. “5.0”

b4.FACT2 Factor 2 0.1 ..10.0..100.0 Factor for the formation of limit threshold 2. “10.0”

b5.FACT3 Factor 3 0.1..15.0..100.0 Factor for the formation of limit threshold 3. “15.0”

C. LEAK Pneumatic leakage Activates the pneumatic leakage test

C1.LIMIT Limit 0.1 .. 30.0 .. 100.0 Sets the limit of the leakage indicator in %. “30.0”

C2.FACT1 Factor 1 0.1 … 1.0 … 100.0 Factor for the formation of limit threshold 1. “1.0”

C3.FACT2 Factor 2 0.1 … 1.5 … 100.0 Factor for the formation of limit threshold 2. “1.5”

C4.FACT3 Factor 3 0.1 … 2.0 … 100.0 Factor for the formation of limit threshold 3. “2.0”

d. STIC Friction (slip-stick effect) Monitors the current static friction of the final

d1.LIMIT Limit 0.1 … 1.0 … 100.0 Sets the base limit for the slipstick detection in %.

d2.FACT1 Factor 1 0.1 … 2.0 … 100.0 Factor for the formation of limit threshold 1. “2.0”

d3.FACT2 Factor 2 0.1 … 5.0 … 100.0 Factor for the formation of limit threshold 2. “5.0”

d4.FACT3 Factor 3 0.1 ..10.0..100.0 Factor for the formation of limit threshold 3. “10.0”

E. DEBA Dead zone monitoring Used to measure the automatic adjustment of the

e1.LEVEL3 Threshold 0.1 … 2.0 … 10.0 Sets the factor limit threshold to monitor the dead

Reference step time for partial stroke in s. “NOINI”

response.

“Auto”

controlling element

“1.0”

dead zones

zone adjustment

6A O & M : 18

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 19

Series 6A Operation & Maintenance – Calibration & Commissioning

F. ZERO Zero point monitoring Activates the zero point displacement test

F1.LEVEL1 Threshold 1 0.1 … 1.0 … 100.0 Sets a threshold in % of the lower hard stop. “1.0”

F2.LEVEL2 Threshold 2 0.1 … 2.0 … 100.0 Sets a threshold in % of the lower hard stop “2.0”

F3.LEVEL3 Threshold 3 0.1 … 4.0 … 100.0 Sets a threshold in % of the lower hard stop “4.0”

G. OPEN Displacement of the upper

stop

G1.LEVEL1 Threshold 1 0.1 … 1.0 … 100.0 Sets a threshold in % of the upper hard stop. “1.0”

G2.LEVEL2 Threshold 2 0.1 … 2.0 … 100.0 Sets a threshold in % of the upper hard stop. “2.0”

G3.LEVEL3 Threshold 3 0.1 … 4.0 … 100.0 Sets a threshold in % of the upper hard stop. “4.0”

H. TMIN Monitoring of the lower limit

temperature

H1.TUNIT Temperature Unit Sets the temp. parameter from “C” to “F”. “C”

H2.LEVEL1 Threshold 1 -40 … 194 Sets a threshold in degrees “C” or “F”. “-25 C”

H3.LEVEL2 Threshold 2 -40 … 194 Sets a threshold in degrees “C” or “F”. “-30 C”

H4.LEVEL3 Threshold 3 -40 … 194 Sets a threshold in degrees “C” or “F”. “-40 C”

J. TMAX Monitoring of the upper limit

temperature

J1.TUNIT Temperature Unit Sets the temp. parameter from “C” to “F”. “C”

J2.LEVEL1 Threshold 1 -40 … 194 Sets a threshold in degrees “C” or “F”. “75 C”

J3.LEVEL2 Threshold 2 -40 … 194 Sets a threshold in degrees “C” or “F”. “80 C”

J4.LEVEL3 Threshold 3 -40 … 194 Sets a threshold in degrees “C” or “F”. “90 C”

L. STRK Monitoring the path integral Monitors the entire path covered by the final

L1.LIMIT Limit for the number of

changes of direction

L2.FACT1 Factor 1 0.1 … 1.0 … 40.0 Factor for the formation of limit threshold 1. “1.0”

L3.FACT2 Factor 2 0.1 … 2.0 … 40.0 Factor for the formation of limit threshold 2. “2.0”

L4.FACT3 Factor 3 0.1 … 5.0 … 40.0 Factor for the formation of limit threshold 3. “5.0”

O. DCHG Monitoring the changes in

direction

O1.LIMIT Limit for the number of

changes of direction

O2.FACT1 Factor 1 0.1 … 1.0 … 40.0 Factor for the formation of limit threshold 1. “1.0”

O3.FACT2 Factor 2 0.1 … 2.0 … 40.0 Factor for the formation of limit threshold 2. “2.0”

O4.FACT3 Factor 3 0.1 … 5.0 … 40.0 Factor for the formation of limit threshold 3. “5.0”

P. PAVG Position mean value

calculation

P1.TBASE Time base of the mean value

generation

P2.STATE State of the position mean

value calculation

P3.LEVEL1 Threshold 1 0.1 … 2.0 … 100.0 Sets a threshold for the maximum deviation of the

P4.LEVEL2 Threshold 2 0.1 … 5.0 … 100.0 Sets a threshold for the maximum deviation of the

P5.LEVEL3 Threshold 3 0.1 ..10.0..100.0 Sets a threshold for the maximum deviation of the

Activates the test to monitor the displacement of the

upper end stop.

Activates the test to continuously monitor the lower

limit temperature

Activates the test to continuously monitor the upper

limit temperature

controlling element.

1 … 1E6 … 1E8 Sets the base limit for the number of strokes. “1.00

E6”

Continuously monitors the number of changes of

direction of the actuator caused in the dead zone.

1 … 1E6 … 1E8 Sets the base limit for the number of changes of

direction. “1.00 E6”

Activates the test to calculate and monitor the

position average

.5h / 8h / 5d / 60d / 2.5y Sets the time interval to calculate the position

average

IdLE/ rEF / ###.# / Strt Starting time for the calculation of position average.

“IdLE”

current position average from the reference avg.

“2.0”

current position average from the reference avg.

“5.0”

current position average from the reference avg.

“10.0”

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 19

Page 20

Series 6A Operation & Maintenance – Installable Options

FACTORY OR FIELD INSTALLABLE OPTIONS

The S6A comes standard with guides beneath the motherboard so

that optional modules can be added.

Tools Needed:

• T2O Torx

• Phillips Screwdriver

Step A

To install any of the optional modules proceed as follows:

1. Disconnect electrical power from the supply to the positioner

2. Remove pressure from the pneumatic supply lines to the

positioner.

3. Remove the positioner cover by loosening the 4 screws using

the Phillips screwdriver.

4. Remove the module cover by loosening the 2 screws using the

T20 torx drive.

Note: Step A must be performed before installing any of the

modules.

Installing the Feedback Module (Iy Module)

Device features

The Iy module is:

• Single channel

• Potentially isolated from the standard controller.

Note: The current actuator position is indicated only after a successful initialization of the positioner. [Refer to the “Calibration

and Commissioning” section]

Proceed as follows to install the optional Iy module:

1. Perform Step A to remove the module cover

2. Slide the Iy module up to the end stop in the lower stack of the

module rack.

3. Connect the module to the motherboard. For this purpose, use

the 6-pole at ribbon cable provided.

4. Refer to Figure 8 and Figure 9 to connect the Iy module in

standard and intrinsically safe applications.

+

≤ 35 V

UH

+

Current Meter

(Ammeter)

Figure 8.- Iy module 6DR4004-8J, not Ex

61

62

E

I

I

y module

6DR4004-8J

Feedback Module (ly Module)

Function

The optional Iy module indicates the current actuator position as a

dual line signal with Iy = 4 to 20 mA. The Iy module is potentially

isolated from the standard controller. Due to the dynamic control,

this module can report the arising operational faults automatically.

6A O & M : 20

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Non-hazardous area

Intrinsically safe

power source

Figure 9. - Iy module 6DR4004-6J, EEx i

++

H

U

≤ 30 V

EEx

U

I

+

Ammeter

Hazardous area, Zone 1 or zone 2

E

I

Iy module

6DR4004-6J

Page 21

Series 6A Operation & Maintenance – Installable Options

Installing the Mechanical Limit Switch Module

NOTICE

A pin in the actuating disc bearing is pressed. Align this pin

before it touches the special screw. You must rotate the actuating

disc bearing and the special screw simultaneously so that the pin

is inserted into the special screw.

An insulating cover is provided over the mechanical limit switch

module. Place the insulating cover to one side under the motherboard seat on the container wall. The recesses of the insulating

cover must t in the corresponding webs of the container wall.

6. Place the insulating cover on the mechanical limit switch

module by bending the container walls carefully.

Mechanical Limit Switch Module

Function

This module is used to report two limits. These two limit switches

are voltage free and rated for 4A at 24V DC or AC 250V.

Device features

The mechanical limit switch module consists of:

• One binary output to display a collective fault message.

Compare with the device features of the alarm unit.

• Two switches to report two mechanically adjustable limits.

Both of these switches are electrically independent from the

remaining electronic unit.

Note: Only qualied personnel should be allowed to install and

connect the Mechanical Limit switch module

Proceed as follows to install the mechanical limit switch module:

1. Perform Step A to remove the module cover

2. Disengage the motherboard by carefully bending the four

brackets.

7. Engage the motherboard into the four brackets.

8. Connect the motherboard and the optional modules to the

ribbon cables provided.

9. Connect the motherboard and the potentiometer to the

potentiometer cable.

10. Using both the screws, fasten the module cover provided.

Do not use the standard module cover.

11. Refer to Figures 10 and 11 to connect the Mechanical Limit

switch module in standard and intrinsically safe applications.

Mechanical limit switch

module 6DR4004-8K

+

<35 V

+

max. AC 250V

24 V DC

4A AC/DC

+

max. AC 250V

24 V DC

4A AC/DC

Figure 10. - Mechanical limit switch module 6DR4004-8K, not Ex

1K21

31

10K

32

41

42

51

52

Fault message

Limit value A1

Limit value A2

3. Insert the mechanical limit switch module from the top up to

the upper printed circuit board guide of the module rack.

4. Slide the mechanical limit switch module unit into the printed

circuit board of the module rack approximately 1/8" towards

the right.

5. Screw in the special screw through the mechanical limit

switch module into the positioner shaft. Tighten the special

screw with a torque of 17.7 in-lbs.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 21

Page 22

Series 6A Operation & Maintenance – Installable Options

Non Hazardous Area Hazardous Area, Zone 1

Intrinsically safe

switching amplifier

to DIN EN 60947-5-6

+

max. DC 8,2 V

EEx

+

Umax. DC 30 V

Imax 100 mA

=

+

Umax. DC 30 V

Imax 100 mA

=

Figure 11. - Mechanical limit switch module 6DR4004-6K, EEx i

Mechanical limit switch

module 6DR4004-6K

2K1

31

10K

32

41

42

51

52

Fault message

Limit value A1

Limit value A2

Connect the mechanical limit switch module as follows:

1. Loosen the screw on the transparent cover

2. Pull the transparent cover up to the front end stop.

3. Tighten every cable in the corresponding terminal.

NOTICE

Verify the electrical specications for these terminals based on

the wiring diagram. Do not use the non Ex board in a hazardous environment.

4. Slide the transparent cover up to the end stop of the

motherboard.

5. Tighten the screw on the transparent cover

6. Connect the cables of each switch to the lug of the printed circuit board in pairs. Use the provided cable tie for this purpose.

Installing the Alarm Module

Alarm Unit

Function

The alarm unit triggers fault messages and alarms using binary

outputs. The message function is based on the change in the signal status:

If the signal status is “HIGH”, there is no alarm message and the

binary inputs are conductive.

If the signal status is “LOW”, the module reports an alarm by

shutting down binary outputs using a high-resistance.

Due to the dynamic control, this module can report the arising

operational faults automatically. Set parameters 44 to 51 to activate and parameterize the output of alarms and fault messages.

Apart from binary outputs, the alarm unit has a double-acting

binary input BE2. Depending on the selected parameters, it is used

to block or to move the actuator it to its end position. Congure

the suitable settings on parameter 43.

Device features

The alarm unit has the following features:

6A O & M : 22

Available in two versions.

• Explosion-proof version for connecting to a switching

amplier in conformity with EN 60947-5-6.

• Non-explosion-proof version for connecting to power sources

having a maximum of 35 V.

Three binary outputs. Binary inputs are potentially isolated from

the standard controller and from each other. The binary input has

dual functionality. Both inputs are implemented as logical OR

combination.

• Isolated for voltage level

• Not isolated for dry contacts

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 23

Series 6A Operation & Maintenance – Installable Options

Proceed as follows to install the alarm unit:

1. Perform Step A to remove the module cover

2. Slide the alarm unit below the motherboard in the module

rack. Ensure that you slide it up to the end stop.

3. Connect the module to the motherboard. For this purpose, use

the 8-pole at ribbon cable provided.

4. Refer to Figures 12 and 13 to connect the Alarm unit in stan-

dard and intrinsically safe applications

Alarm module

6DR4004-8A

+

≤ 30 V

+

#

#

#

35 V

+

35 V

+

35 V

Figure 12. - Alarm unit 6DR4004-8A, not Ex

Non-hazardous area Hazardous area, zone 1 or zone 2

Intrinsically safe

switching

amplifier to DIN

EN 60947-5-6

#

#

#

11

12

21

22

31

32

41

42

51

52

+

≤ 25,2 V

EEx

+

8,2 V

EEx

+

8,2 V

EEx

+

8,2 V

EEx

+ 3 V

1K

1K

1K

#

Alarm module

6DR4004-6A

11

12

21

22

2K1

31

10K

32

2K1

41

10K

42

2K1

51

10K

52

≥ 1

Fault message

Limit value A1

Limit value A2

#

+ 3 V

Digital input 2

≥ 1

Fault message

Limit value A1

Limit value A2

Digital

input 2

Installing the Slotted Initiator Alarm Unit

Slotted Initiator Alarm Unit

Function

If the standard controller requires electrically independent limit

value messages, the slotted initiator alarm unit is used instead of

the standard alarm unit.

A binary output is used to display a collective fault message.

Compare with the function of the alarm unit. The oating binary

output is implemented as an automatic fault indicating semiconductor output.

The other two binary outputs are used for the message of two

limits L1 and L2 which can be adjusted mechanically using slotted

initiators. Both these binary outputs are electrically independent

from the remaining electronic unit.

Device features

The slotted initiator alarm unit, abbreviated as SIA unit consists

of three binary outputs.

Proceed as follows to install the SIA unit:

1. Perform Step A to remove the module cover

2. Unscrew both the screws on the motherboard.

3. Disengage the motherboard by carefully bending the four

brackets.

4. Insert the SIA unit from the top up to the upper printed circuit

Figure 13.

- Alarm unit 6DR4004-6A, EEx i

board guide of the module rack.

5. Slide the SIA unit in the printed circuit board of the module

rack approximately 1/8" to the right.

6. Screw in the special screw through the SIA unit into the posi-

tioner shaft. Tighten the special screw with a torque of 17.7

in-lbs.

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 23

Page 24

Series 6A Operation & Maintenance – Installable Options

NOTICE

A pin in the actuating disc bearing is pressed. Align this pin

before it touches the special screw. You must rotate the actuating disc bearing and the special screw simultaneously so that the

pin is inserted into the special screw.

7. An insulating cover is provided over the SIA unit. Place the

insulating cover to one side under the motherboard seat on

the container wall. The recesses of the insulating cover must

t in the corresponding webs of the container wall.

8. Place the insulating cover on the SIA unit by bending the

container walls carefully.

9. Engage the motherboard into the four brackets.

10. Tighten the motherboard using the two screws.

11. Reestablish all electrical connections between the motherboard and the optional modules. Connect the motherboard

and the optional modules to the ribbon cables provided.

Connect the motherboard and the potentiometer to the potentiometer cable.

12. Using both the screws, fasten the module cover provided. Do

not use the standard module cover.

13. Refer to Figures 14 and 15 to connect the SIA module in stan-

dard and intrinsically safe applications

SIA module

6DR4004-8G

+

#

#

#

Switching amplifier according to EN 60947-5-6

Figure 14. - SIA unit 6DR4004-8G, not Ex

Intrinsically safe

switching

amplifier to DIN

EN 60947-5-6

< 35 V

+

8,2 V

+

8,2 V

Non-hazardous area Hazardous area, zone 1 or zone 2

+

#

#

#

EEx

EEx

EEx

8,2 V

+

8,2 V

+

8,2 V

2K1

31

10K

32

41

42

51

52

SIA module

6DR4004-6G

31

32

41

42

51

52

2K1

10K

Fault message

Limit value A1

Limit value A2

Fault message

Limit value A1

Limit value A2

Setting The Limits Of The Slotted Initiator Alarm Unit

You will require a suitable display device to determine the switch

status. For example, use the initiator tester type 2 / Ex by Pepperl

+ Fuchs.

1. Connect the display device to the following terminals of the

SIA unit:

• 41 and 42

• 51 and 52

2. Read the switch status of slotted initiators

Proceed as follows to set the limits:

1. Move the actuator to the rst desired mechanical position.

2. Adjust the upper actuating disc manually until the output

signal at terminals 41 and 42 changes. Set a high-low or a

low-high switch over as follows:

• Rotate the actuating disc beyond the switching point

until you reach the next switching point.

3. Move the actuator to the second desired mechanical position.

4. Adjust the lower actuating disc manually until the output

signal at terminals 51 and 52 changes. Set a high-low or a

low-high switch over as follows:

• Rotate the actuating disc beyond the switching point

until you reach the next switching point.

Note: The actuating discs are relatively difcult to move. This

design prevents their unintentional movement during operation.

You can achieve an easier and ner adjustment by reducing

friction temporarily. Move the actuator to and fro while

simultaneously holding the actuating discs.

Figure 15.

- SIA unit 6DR4004-6G, EEx i

6A O & M : 24

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Page 25

Series 6A Operation & Maintenance – Installable Options

Installing the EMC Filter Module

EMC Module

Function

You will require the EMC lter module if you use an external

position sensor on the positioner, e.g. a potentiometer or a noncontacting position sensor. The EMC lter module forms the

interface between external position sensors and the motherboard

of the positioner. This module protects the positioner from electromagnetic effects.

Device features include:

Proceed as follows to install the EMC lter module:

1. Perform Step A to remove the module cover

2. Remove the module cover.

3. Dismantle all existing optional modules.

4. Unscrew the screws of the module rack that are opposite to

the blanking plugs.

5. The EMC lter module has a fastening hole. Tighten the

module on the module rack using the screws provided

6. Lay the ribbon cable of the EMC lter module towards left

through the opening of the module rack.

7. Unplug the connector of the internal potentiometer from the

motherboard.

8. Connect the ribbon cable of the EMC module to the

motherboard.

9. Connect the external position sensor to the terminals of the

EMC module.

10. Reinstall the other optional modules in the reverse order.

11. Refer to Figures 14 and 15 to reconnect the SIA module in

standard and intrinsically safe applications

12. Install the module cover.

• EMC protection

• Connection to motherboard

• Connecting terminals for an external potentiometer

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

6A O & M : 25

Page 26

Series 6A Operation & Maintenance – Troubleshooting

TROUBLESHOOTING

During operation of the positioner, a few important values and parameters are continually monitored. In conguration mode, you can

congure that monitoring so that the fault message output will be activated if, for instance, a limit is exceeded. Information about what

events can activate the fault message output can be found in Figure 16