Page 1

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written

consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed

knowledge and experience with their application.

SERIES 63 N4/N7 Operation & Maintenance Manual

Manual Number OM-63/N4-N7-001

Date: November 10, 2009 Page 1 of 3

Bray Series 63-N4/N7 Installation & Maintenance Instructions

General Purpose/Rain tight/Water tight and

Rain tight/Water tight/Explosion proof

For S63-N4 see O&M Instructions for information on: Operation, Positioning, Mounting,

Cleaning, Preventive Maintenance, Causes of

Improper Operation, Disassembly, and Reassembly of basic valve.

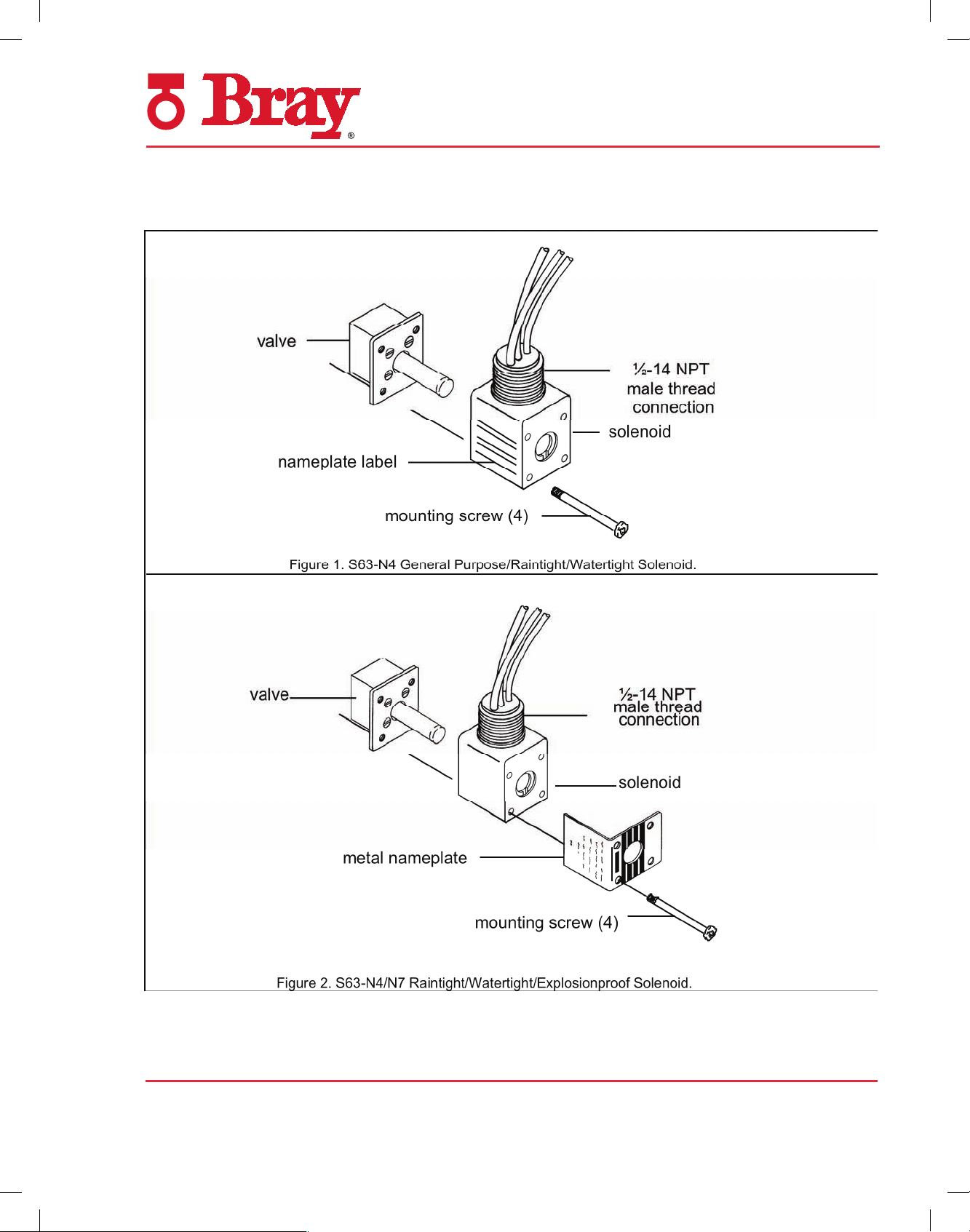

DESCRIPTION

S63 N4/N7 Solenoid coils are thermoplastic encapsulated pull-type for use with Bray solenoids.

These solenoids have three lead wires with one

wire for grounding and a ½ NPT male conduit

connection. S63 N4 Solenoids are designed to

meet Enclosure Type 1-General Purpose, Types 3

and 3S-Raintight, and Types 4 and 4X-Watertight.

S63 N4/N7 Solenoids meet Enclosure Types 3 and

3S-Raintight, Types 4 and 4X-Watertight, Type 7

Explosion proof Class I, Division 1, Groups A, B,

C, & D and Type 9 - Dust - Ignition proof Class

II, Division 1, Groups E, F, & G.

OPERATION

When the solenoid is energized, the core assembly is drawn into the plugnut/core tube subassembly. When the solenoid is de-energized,

spring force returns the core assembly to the

original position.

Enclosure Types 7 and 9 Only

CAUTION

To prevent re or explosion, do not install solenoid and/or valve where ignition temperature

of hazardous atmosphere is less than 160° C.

Open circuit before disassembling.

Positioning

Solenoid may be mounted in any position.

Valve Mounting

The solenoid is assembled onto an actuator and is

rigidly supported using the actuator body mount-

ing provisions.

CAUTION

Solenoid coil wiring must be carried out by

trained personnel.

Wiring

Wiring must comply with local codes and the National Electrical Code. The solenoid is provided

with lead wires and one grounding wire, which

is green or green with a yellow stripe. To facilitate wiring, the solenoid may be rotated 360° in

90° increments. To rotate solenoid, remove the

four mounting screws, reposition solenoid and

replace screws. Torque screws evenly in a crisscross manner to 12 in-lbs [1.3 Nm].

Solenoids have a ½-14 NPT male thread. For

connection to rigid metal conduit, metal type

NPT electrical ttings should be used.

WARNING

For the watertight and explosion proof solenoid,

electrical ttings must be approved for use in

hazardous locations.

!!!

Page 2

SERIES 63 N4/N7 Operation & Maintenance Manual

Manual Number OM-63/N4-N7-001

Date: November 10, 2009 Page 2 of 3

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written

consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed

knowledge and experience with their application.

CAUTION

Temperature of external casing of coil can burn

skin.

Solenoid Temperature

Standard solenoids are designed for continuous

duty service. When the solenoid is energized for

a long period, the solenoid becomes hot and can

be touched by hand only for an instant. This is a

safe operating temperature.

MAINTENANCE

WARNING

To prevent the possibility of personal injury

or property damage, turn off electrical power,

depressurize valve, and vent medium to a safe

area before servicing.

Cleaning

All solenoid valves should be cleaned periodically. The time between cleaning will vary depending on medium and service conditions. In

general, if the voltage to the solenoid is correct,

sluggish valve operation, excessive noise, or

leakage will indicate that cleaning is required. In

the extreme case, faulty valve operation will occur and the valve may fail to shift. Clean strainer

or lter when cleaning the valve.

Preventive Maintenance

Keep the medium owing through the sole-•

noid valve as free from dirt and foreign mate-

rial as possible.

While in service, the solenoid valve should •

be operated at least once a month to ensure

proper opening and closing.

Depending on the medium and service con-•

ditions, periodic inspection of internal valve

parts for damage or excessive wear is recommended. Thoroughly clean all parts. Replace

any worn or damaged parts.

Causes of Improper Operation

Faulty Control Circuit: • Check the electri-

cal system by energizing the solenoid. A metallic click signies that the solenoid is operating. Absence of the click indicates loss

of power supply. Check for loose or blown

fuses, open-circuited or grounded solenoid,

broken lead wires or splice connections.

Burned-Out Solenoid:• Check for open-

circuited solenoid. Check supply voltage; it

must be the same as specied on nameplate

and marked on the solenoid. Check ambient temperature and check that the core is not

jammed. If necessary, replace pilot valve.

Low Voltage: • Check voltage across the so-

lenoid leads. Voltage must be at least 85% of

rated voltage.

ORDERING INFORMATION FOR REPLACEMENT PILOT VALVE WITH SOLENOID:

Specify valve Catalog Number1.

Solenoid Catalog Number2.

Serial Number3.

Voltage4.

Frequency5.

!

!

Page 3

All information herein is proprietary and condential and may not be copied or reproduced without the expressed written

consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed

knowledge and experience with their application.

SERIES 63 N4/N7 Operation & Maintenance Manual

Manual Number OM-63/N4-N7-001

Date: November 10, 2009 Page 3 of 3

!

Loading...

Loading...