Page 1

SERIES 5A AND 5B

INTRINSICALLY SAFE VALVE STATUS MONITOR

Installation, Operation and Maintenance Manual

THE HIGH PERFORMANCE COMPANYBRAY.COM

Page 2

Page 3

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

Table of Contents

1. Safety Instructions - Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. Hazard-Free Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3. Qualified Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4. Part Numbering System Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

5. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

6. Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

7. Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

8. Pre-Installation Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

9. Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

9.1 Adjustable Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

9.2 Fixed Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

10. Accessing Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10.1 Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10.2 Cover Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

11. Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

12. Reversal of Visual Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

13. Position Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

14. Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

15. Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exploded View - 5A - Aluminum Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exploded View - 5A - Resin Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Exploded View - 5B Aluminum Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Exploded View - 5B Resin Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

16. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

16.1 Replacement Parts Aluminum Housing . . . . . . . . . . . . . . . . . . . . . . . . . . 16

16.2 Replacement Parts Resin Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

17. Basic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – bray.com

1

Page 4

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

Read and Follow These Instructions

Save These Instructions

1. Safety Instructions - Definition of Terms

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

NOTICE

Used without the safety alert symbol indicates a potential situation which, if not

avoided, may result in an undesirable result or state, including property damage.

2. Hazard-Free Use

This device left the factory in proper condition to

be safely installed and operated in a hazard-free

manner. The notes and warnings in this document

must be observed by the user if this safe condition

is to be maintained and hazard-free operation of

the device assured.

Take all necessary precautions to prevent damage

to the device due to rough handling, impact, or

improper storage. Do not use abrasive compounds

to clean the device, or scrape surfaces with any

objects.

Configuration and setup procedures for this device

are described in this manual. Proper configuration

and setup are required for the safe operation of

this device.

The control system in which this device is installed

must have proper safeguards to prevent injury to

personnel, or damage to equipment, should failure

of system components occur.

3. Qualified Personnel

A qualified person in terms of this document is one

who is familiar with the installation, commissioning

and operation of the device and who has appropriate

qualifications, such as:

• Is trained in the operation and maintenance of

electric equipment and systems in accordance

with established safety practices.

• Is trained or authorized to energize,

de-energize, ground, tag and lock electrical

circuits and equipment in accordance with

established safety practices.

2

• Is trained in the proper use and care of personal

protective equipment (PPE) in accordance with

established safety practices.

• Is trained in first aid.

• In cases where the device is installed in a

potentially explosive (hazardous) location - is

trained in the operation, commissioning,

operation and maintenance of equipment in

hazardous locations.

The VSM must only be installed, commissioned,

operated and repaired by qualified personnel.

All installation, commissioning, operation and

maintenance must be performed under strict

observation of all applicable codes, standards and

safety regulations.

Reference is specifically made here to observe

all applicable safety regulations for electrical

equipment installed in potentially explosive

(hazardous) locations.

Page 5

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

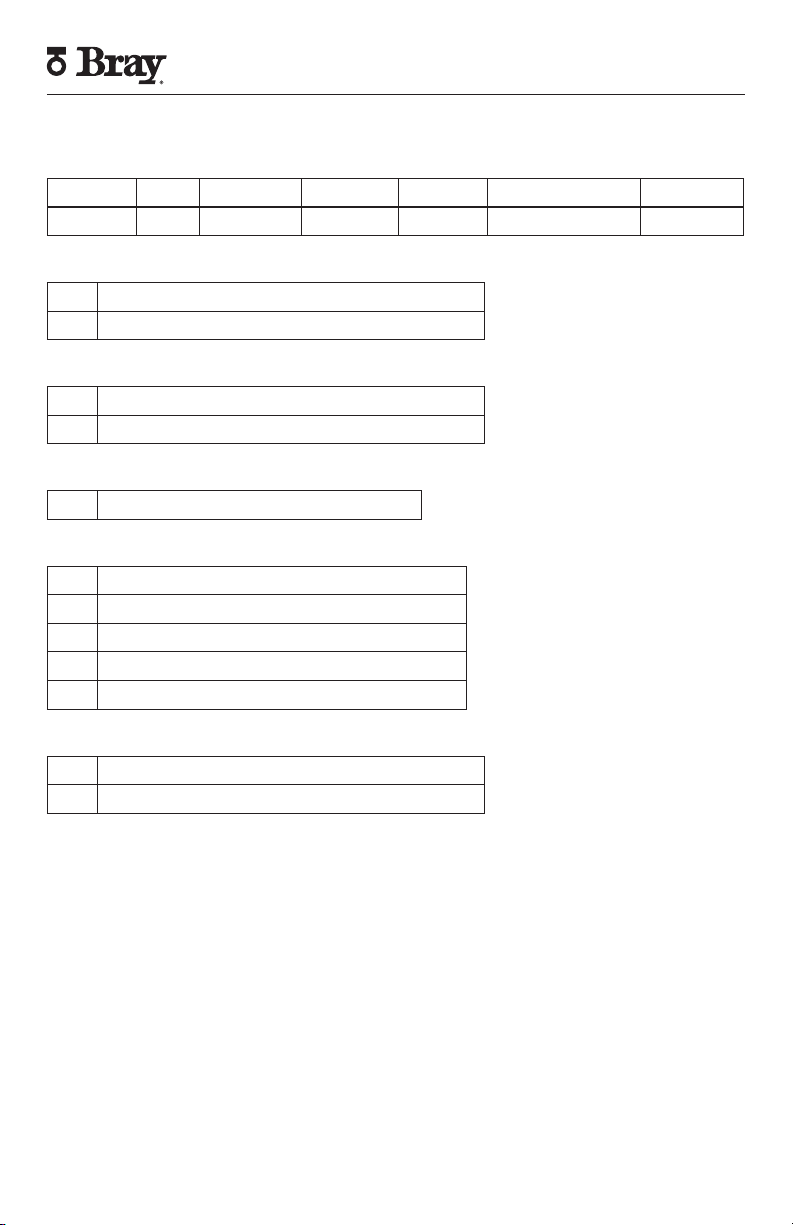

4. Part Numbering System Reference Chart

Series Housing Product Switch Configuration Trim

5X 000 H -126 S C T

5X – Designates Housing Size

5A Type 4,4x, IP 66/67, Max 2 switches

5B Type 4,4x, IP 66/67, Max 6 switches

H – Designates Housing Style

0 Imperial

5 Metric

S – Designates Switch Option

H Intrinsically Safe, 2-wire, Proximity Switch

C – Designates Switch Configuration

2 2 Switches

3 3 Switches, Independent

4 4 Switches, Independent

5 4 Switches (2 Independent, 2 Auxiliary)

6 6 Switches (4 Independent, 2 Auxiliary)

T – Trim

536 Polyester coated aluminum

517 Resin

5. Introduction

The Bray Series 5A and 5B Intrinsically Safe

Valve Status Monitors (VSMs) provide visual and

electrical indication of position of any VDI/VDE

3845 compliant quarter-turn device. The S5A and

S5B I.S. VSMs are designed to operate in multiple

hazardous locations.

6. Principle of Operation

Bray Series 5A and 5B I.S. VSMs are comprised of a

NEMA Type 4/4X, IP66/67 housing (resin housings

are IP66/67/68 (1 meter, 1 hour) with external

position indicator and two conduit entries, cam

shaft with self-locking cams, elevated terminal block,

internal grounding screw, and mounting bracket.

The VSM is coupled to the quarter turn device via the

cam shaft. Rotation of the cam shaft, in turn, drives

switch activation. The angular position in which

the switches activate can be adjusted through the

self-locking cams. Proximity activation of switches

provides electrical feedback of achieved position

through field wiring to a control network.

3

Page 6

Series 5A and Series 5B I.S. Valve Status Monitor

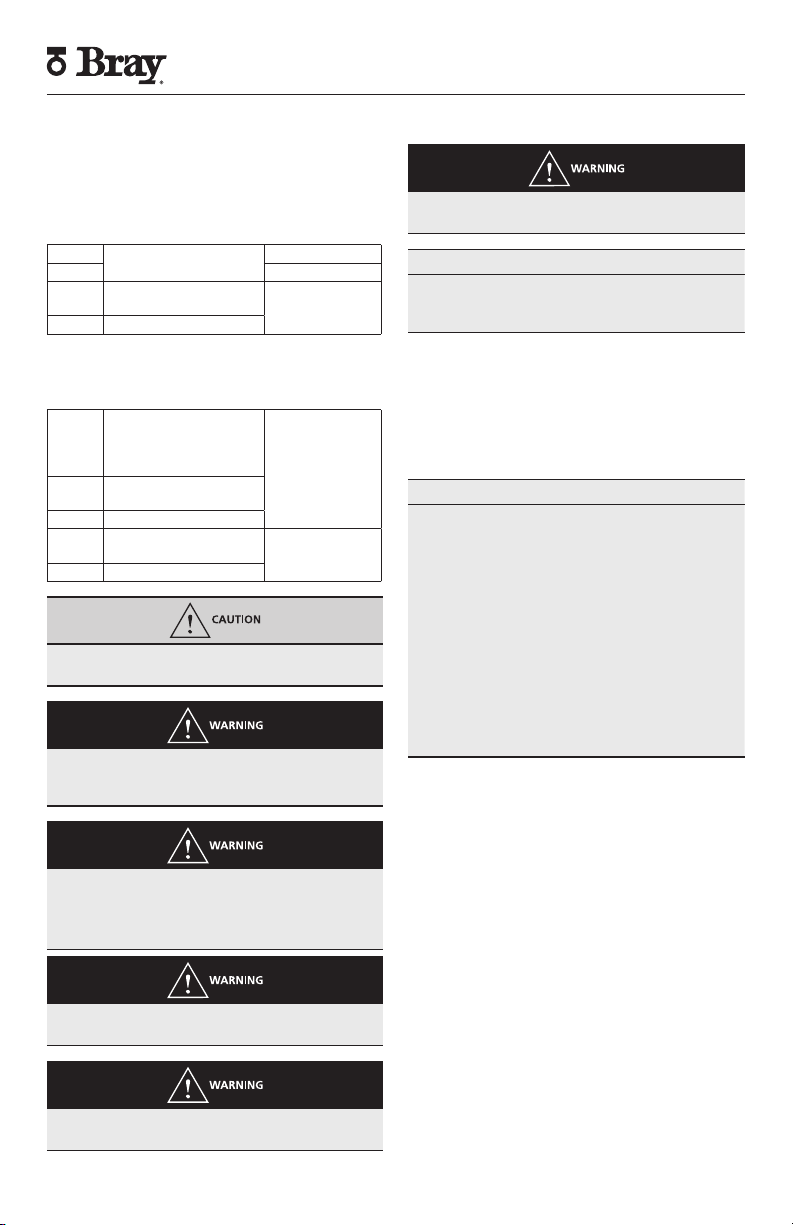

7. Hazardous Locations

The S5A and S5B I.S. (aluminum and resin trims) are

designed and certified to operate in the following

hazardous locations :

ATEX

II 1G Ex ia IIC Ga T6

II 2G Ex ia IIC Gb T6

IECEx IECEx UL 18.0073X

Ambient 1G: -25°C ≤ Ta ≤ 49°C

2G: -25°C ≤ Ta ≤ 65°C

Elevation 2000m max

The S5A (aluminum trim only) and S5B (aluminum

and resin trims) I.S. are also certified to operate in

the following hazardous locations :

NEC 500 Class I Division 1

Groups A, B, C, & D T6

Class II Division 1

Groups E, F, G T85°C

NEC 505 Class I, Zone 0, AEx ia IIC T6

Class I, Zone 1, AEx ia IIC T6

CEC Ex ia IIC Gb T6

Ambient Zone 0: -25°C ≤ Ta ≤ 49°C

Zone 1: -25°C ≤ Ta ≤ 65°C

Elevation 2000m max

For cULus applications, the S5B resin housing is

only intended for use with flexible conduit.

In addition to IO&M Manual instructions, it is

required to follow all instructions specified in

Control Drawing: WD-000393.

DEMKO 18ATEX2062X

E202292 (UL)

Installation, Operation and Maintenance Manual

Substitution of components may impair intrinsic

safety.

NOTICE

The Bray Series 5A and 5B I.S. VSMs are compliant

to the IEC/EN 60079-11 section 6.3.13 dielectric

strength requirement.

8. Pre-Installation Storage

Bray Series 5A and 5B I.S. VSMs are not weatherproof

until properly installed on the quarter-turn device

or prepared for storage. Bray cannot accept

responsibility for deterioration caused on-site once

the cover is removed.

NOTICE

Units are shipped with two screw-in plugs

(aluminum housing) or peel-off decal (resin

housing) to prevent foreign matter from

entering the unit through the conduit openings.

To prevent condensation from forming inside

these units, maintain a near constant external

temperature and store in a well-ventilated, clean,

dry room away from vibration.

Store units on a shelf or wooden pallet in order

to protect against dampness.

Keep units covered to protect against dust and

dirt.

Storage Temperature should be maintained

between -25°C and 65°C.

S5A and S5B I.S. VSMs must be used in

conjunction with a third party approved

barrier that meets conditions specified in

the control drawing: WD-000393.

Enclosure may contain aluminum. Care must be

taken to avoid hazard due to impact or friction

Resin housings pose an electrostatic charging

hazard. See Control Drawing: WD-000393

4

Page 7

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

9. Mounting

9.1 Adjustable Bracket

Bray's 3 piece adjustable bracket is designed to

mount on both NAMUR 30x80 and 30x130 pads.

Installation is as follows:

1. Disassemble two mounting bracket foot

plates from top plate.

a. Continue to Step 6 if the mounting

bracket top plate was pre-installed.

2. Lightly coat mounting bracket bolt threads

with grease.

3. Place lock washer onto bolts.

4. Place nylon washer in between mounting

bracket and bottom of the VSM.

5. Attach mounting bracket and nylon washers

to the VSM using mounting bracket bolts.

a. Tighten mounting bolts in a cross

pattern to 70.8 in-lbs. [8Nm]

b. Ensure that the bracket remains aligned

with the body of the VSM.

6. Place lock washers on foot plate mounting

bolts.

7. Attach two mounting bracket foot plates to

the quarter-turn device.

a. Tighten mounting bracket foot plates to

44.3 in-lbs. [5Nm]

30 x 130

NAMUR pad

8. Attach coupler or adapter if provided.

9. Adjust the VSM cam shaft to align with the

actuator shaft or coupler.

10. Connect the mounting bracket top plate to

both bracket feet using bolts.

a. Adjust height of the bracket by choosing

mounting hole.

b. Tighten bolts to 44.3 in-lbs. [5Nm]

30 x 80

NAMUR pad

5

Page 8

Series 5A and Series 5B I.S. Valve Status Monitor

9.2 Fixed Bracket

9.2.1 Stainless Steel Bracket

Bray's single piece stainless steel bracket is used for

NAMUR pattern 30 x 80. Installation is as follows:

1. Attach mounting bracket and nylon washers

to the VSM using mounting bracket bolts.

a. Tighten mounting bolts in a cross

pattern to 70.8 in-lbs. [8Nm]

b. Ensure that the bracket remains aligned

with the body of the VSM.

2. Place VSM and bracket assembly on actuator.

Ensure VSM shaft engages with actuator

pinion.

3. Install bracket mounting bolts with lock

washers as seen below.

a. Tighten mounting bracket bolts to

44.3 in-lbs. [5Nm].

9.2.2 Resin Brackets

Bray's single piece resin brackets are available for

NAMUR pattern 30 x 80 and 30 x 130 (based on

actuator selection). Installation is as follows:

1. Attach mounting bracket to the VSM using

mounting bracket bolts.

a. Tighten mounting bolts in a cross

pattern to 35 in-lbs. [4Nm]

b. Ensure that the bracket remains aligned

with the body of the VSM.

2. Place VSM and bracket assembly on actuator.

Ensure VSM shaft engages with actuator

pinion.

3. Install bracket mounting bolts with lock

washers as seen below.

a. Tighten mounting bracket bolts to

35 in-lbs. [4Nm].

Installation, Operation and Maintenance Manual

6

Page 9

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

10. Accessing Internal

Components

Access to the S5AB internals is done by removing

the cover from the unit. The steps for removal are

as follows:

Do not open when energized or an explosive

atmosphere is present.

10.1 Cover Removal

1. Loosen captive cover bolts. The S5A contains

4 bolts and the S5B contain 6 bolts located

around the perimeter of the unit.

2. Pull the cover up and away from unit. Do not

use a wedge device to remove cover.

X

3. Perform internal adjustment. Reference position

adjustment section.

10.2 Cover Installation

1. Ensure o-ring is seated in the o-ring groove.

2. Press on cover ensuring captive bolts are aligned

with the bolt holes.

3. Tighten cover bolts to 13-18 lb-in [1.5-2.0 Nm]

in a cross pattern.

11. Field Wiring

Bray Series 5A and 5B I.S. are assembled with

numbered terminal blocks on a printed circuit

board designed to conform to Intrinsically Safe

requirements. Bray Series 5A VSMs contain a 4-pole

terminal block, while the Series 5B VSMs contain a

12-pole terminal block. All switches are pre-wired

into the terminal block. Several features have been

designed to help ease field wiring:

• Terminal blocks are angled towards the cover

opening.

• W iring diagram is attached to the inside of cover.

• Two side conduit entries are available for all

models. Additional rear conduit entry available

on S5B resin trim.

Turn off all power and lock out service panel before

installing or modifying any electrical wiring.

Observe all applicable safety regulations for

electrical equipment installed in potentially

explosive (hazardous) locations.

NOTICE

• Do not re-machine the conduit entry threads or

create any new holes in the enclosure.

• Do not remove the screw-in conduit plugs

(aluminum housing) or peel-off decal (resin

housing) until it is time to wire into the unit's

terminal blocks.

• Do not tamper with or modify any exposed

O-rings or gaskets.

• A minimum of 18 AWG wire is recommended

for all field wiring.

• The terminals inside the VSM accept wire sizes

ranging from 14 to 20 AWG.

• The conduit connections must be properly sealed

to maintain the weatherproof integrity of the

VSM enclosure.

7

Page 10

Series 5A and Series 5B I.S. Valve Status Monitor

Bray Series 5A and 5B I.S. VSMs should be wired

as follows:

1. Remove the cover of the VSM.

2. Remove the conduit plugs (aluminum

housing) or peel-off decal (resin housing).

3. Install appropriate cable or conduit fittings

required to meet application needs, weatherproof

requirements, and hazardous location

requirements.

4. Terminate the field wiring per the wiring

diagram attached to the inside of the cover.

5. Tighten wires in terminal block to 3.5 lb-in

[0.4 Nm].

6. Re-attach VSM cover once position

adjustment has been completed.

a. Tighten cover bolts in a cross pattern to

80 lb-in [9 Nm] for aluminum housing

or 17.7 lb-in [2 Nm] for resin housing.

Reference Cover Installation.

Installation, Operation and Maintenance Manual

To ensure intrinsic safe operation, use cable ties

to mount field wiring to the printed circuit board.

NOTICE

Do not use power tools to tighten the cover screws.

If the valve status monitor is mounted

on a vertical pipe, it is recommended

that the unit be positioned with the

conduit entries on the bottom to prevent

condensation from entering through the

conduits.

In all cases, the conduit should be

positioned to prevent drainage into

the valve status monitor. In some cases

the use of an "S" pipe can be used to

prevent water ingress.

Refer to the figures on the right.

Side Conduit Entries

VSM Imperial Metric

S5A 2 x 1/2" NPT 2 x M20

S5B 2 x 3/4" NPT 2 x M25

Rear Conduit Entry (Resin Only)

S5B 1 x 1/2" NPT 1 x M20

8

NOTICE

Page 11

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

12. Reversal of Visual Indication

Visual indication can be reversed per application

requirements without the need to re-mount the

VSM. This may also be appropriate if the standard

orientation of the VSM is not convenient for the

application such as field wiring entry direction do

not align with conduit entries.

Observe all applicable safety regulations for

electrical equipment installed in potentially

explosive (hazardous) locations when making

modifications to the assembly.

NOTICE

Ensure that open and close cams are properly set

after any modification to visual indication.

Bray Series 5A and 5B I.S. VSM visual indication

can be reversed as follows:

1. Remove all four Indicator dome bolts with

lock washers.

2. Rotate the indicator dome 90° in either

direction.

3. Remount the indicator dome bolts with lock

washers.

a. Tighten bolts in a cross pattern to

13-18 lb-in [1.5-2 Nm] for aluminum

housing or 5.3-7.5 lb-in [0.6-0.85Nm]

for resin housing.

b. Ensure that o-ring is secure in indicator

dome and is not pinched when dome is

re-installed.

NOTE: The indicator dome of the 5A Resin VSM is

part of the cover. Remove the cover for indication

reversal.

1

2

90°

3

9

Page 12

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

13. Position Adjustment

A single or doubled lobed cam is provided for every

independent/main switch. Double lobed cams are

provided when the switch configuration could

include an auxiliary switch. Double lobed cams

will activate both main and auxiliary switches at

the same time.

Cams are mounted to the indicator shaft, alternating

between red and yellow and are independently

adjustable by hand in 3.6° increments. No special

tools are needed for this adjustment. The self-locking

design ensures that cams will not slip position.

The bottom red cam is intended to indicate the close

position while the bottom yellow cam is intended

to indicate the open position. Both of the switches

associated with these cams are labeled accordingly.

An additional red and yellow cam may be installed

for most switches and can be used for mid-travel

position indication or to provide an additional

auxiliary open and close indication. Mid-travel

switches are unlabeled.

Closed Travel Indication Adjustment

1. Operate the quarter turn device until it

reaches the desired closed position.

2. Pull the bottom red close cam upwards

towards the yellow cam to disengage the

cam from the fixed cam holder.

3. While the cam is disengaged, rotate the cam

to the position that will activate the close

switch.

a. NOTE: Do not attempt to adjust cams

prior to disengaging the cam from the

fixed cam holder.

4. Release the cam and allow the locking spring

to re-engage the cam with the fixed cam

holder.

Open Travel Indication Adjustment

1. Operate the quarter turn device until it

reaches the desired open position.

2. Push the bottom yellow open cam towards

the bottom red cam to disengage the cam

from the fixed cam holder.

3. While the cam is disengaged, rotate the cam

to the position that will activate the open

switch.

a. NOTE: Do not attempt to adjust cams

prior to disengaging the cam from the

fixed cam holder.

4. Release the cam and allow the locking spring

to re-engage the cam with the fixed cam

holder.

Mid-Travel Indication Adjustment

1. Operate the quarter turn device until it

reaches the desired mid-travel position.

2. Disengage the cam from the cam holder.

a. NOTE: Mid-travel cams are disengaged

similarly to the open and close cams.

3. While the cam is disengaged, rotate the cam

to the position that will activate the midtravel switch.

a. NOTE: Do not attempt to adjust cams

prior to disengaging the cam from the

fixed cam holder.

4. Release the cam and allow the locking spring

to re-engage the cam with the fixed cam

holder.

10

Page 13

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

14. Troubleshooting Chart

Problem Possible Cause Solutions

Signal is not received

Open signal is received

in close position (or vice

versa)

Corrosion inside unit

Visual indication is

opposite of actuator

position

VSM does not rotate

Wiring is not connected inside

VSM

Cams are set outside of actuator

range

Damage to switches Check power ratings of switches

Field wiring is reversed Rewire field wiring

Condensation forming Seal conduit opening

Water leaking in Check all seals and possible water

Visual indication was reversed or

VSM was mounted 90°

Bracket or adapter does not mate

properly with actuator.

Actuator is not moving as commanded

Rewire field wiring and check

applied torque to terminal block

Adjust cam position

versus application

entry through conduit

Reverse visual indication or remount VSM.

Check bracket and adapter for

proper fit and adjust as needed.

Check troubleshooting chart in

actuator IOM. Check field wiring.

11

Page 14

15. Exploded Views

Exploded View - 5A - Aluminum Trim

1

2

3

4

5

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

6

7

12

Page 15

Exploded View - 5A - Resin Trim

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

6

3

5

13

Page 16

Exploded View - 5B Aluminum Trim

1

2

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

3

4

5

6

7

14

Page 17

Exploded View - 5B Resin Trim

1

2

3

4

5

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

6

15

Page 18

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

16. Replacement Parts

16.1 Replacement Parts Aluminum Housing

No. Description Imperial Metric

1 Dome Bolts

2 Dome Washer

3 Dome Assembly

4 Dome Gasket

5 Indicator Assembly

6 Cover Bolt

7 Cover Bolt Washer

16.2 Replacement Parts Resin Housing

No. Description Imperial and Metric

1 Dome Bolts

2 Dome Washer

3 Dome Assembly

4 Dome Gasket

5 Indicator Assembly

6 Cover Bolt 5A0000-72102534

*Dome repair kit only for S5B Resin

5B0000-22900536 5B0000-22950536

5B0000-22901536 5B0000-22951536

5B0000-22952536*

17. Basic Tools

Common To All Units

Terminal Connections Screwdriver, ¼” tip flat blade

All switches, terminal strip Screwdriver, No. 1 Phillips

Ground screw Screwdriver, No. 2 Phillips

Imperial Style

Indicator Dome Wrench, 5/16”

Cover Bolt, Aluminum Housing Hex Key, 5/32”

Cover Bolt, Resin Housing Hex Key, 4mm

Conduit Entry – ½” NPT Hex Key, 3/8”

Conduit Entry – ¾” NPT Hex Key, 9/16”

Mounting Bracket Bolts Wrench, 5/16" & 7/16"

Metric Style

Indicator Dome Wrench, 8mm

Cover Bolt Hex Key, 4mm

Conduit Entry – M20 Screwdriver, No. 3 Phillips

Conduit Entry – M25 Screwdriver, No. 3 Phillips

Mounting Bracket Bolts Wrench, 8mm & 10mm

16

Page 19

Series 5A and Series 5B I.S. Valve Status Monitor

Installation, Operation and Maintenance Manual

17

Page 20

THE HIGH PERFORMANCE COMPANY

BRAY INTERNATIONAL

PRIMARY SALES AND SERVICE LOCATIONS

USA

Houston, Texas

AFRICA

Johannesburg

BENELUX

Heerhugowaard

BRAZIL

Paulinia, Sao Paulo

CANADA

Montreal

CHILE

Santiago

FLOW-TEK RITE CORPORATION AMRESIST KUGELHAHN MÜLLER

USA

Houston, Texas

BRAZIL

Paulinia, Sao Paulo VALVTRONIC

CHINA

Hangzhou, Zhejiang

CHINA

Hangzhou, Zhejiang

COLOMBIA

Bogotá

FRANCE

Voiron

GERMANY

Krefeld

INDIA

Chennai

ITALY

Milano

CANADA

Montreal

ARGENTINA

Buenos Aires

MEXICO

Zapopan, Jalisco

MIDDLE EAST

Dubai

PACIFIC

Melbourne, Australia

PERU

Lima

POLAND

O´swi¸ecim

USA

Houston, Texas

RUSSIA

Moscow

SINGAPORE

Ubi Techpark

SOUTH KOREA

Seoul

SOUTHEAST ASIA

Malaysia

UNITED KINGDOM

Glasgow

GERMANY

Krefeld

HEADQUARTERS

Bray International, Inc.

13333 Westland East Blvd.

Houston, Texas 77041

Tel: 281.894.5454

bray.com

All stat ements, technic al information, an d recommendatio ns in

this bulle tin are for gen eral use only. Consul t Bray repres entative s

or factor y for the specific requirements and material s election

for your intended appli cation. The right to change or modif y

produc t design or product wi thout prior notice is reserved.

Patents is sued and applied for worldwide.

Bray® is a registered trademark of BRAY INTERNATIONAL, Inc.

© 2019 Bray Internati onal. All rights reserved.

IOM 5A-5B_I .S. – 7_10_2019

Loading...

Loading...