Braun perfusor compact Service Manual

0 - 10

3.1

Perfusor® compact

Service Manual

0-Version 3.1 English

2.1

0

This Service Manual is valid for Designation Part No.:

Perfusor® compact (230 ...240 V, Euro cable) . . . . . . . 0871 4827

Perfusor® compact (230 ...240 V, BSI cable) . . . . . . . . 0871 4828

Perfusor® compact (100 ... 120 V). . . . . . . . . . . . . . . . . 0871 4835

This Service Manual is available under

the following part number:

Languages of this Manual The Service Manual for this unit can be supplied in the following

The complete Service Manual contains

the following pages:

Designation Part No.

Service Manual Perfusor® compact, English . . . . . . . . 8713 9112

languages:

Designation Part No.

Service Manual Perfusor® compact, German . . . . . . . . . 8713 9111

Page 0-1 to page 0-10

Page 1-1 to page 1-4

Page 2-1 to page 2-6

Page 3-1 to page 3-18

Page 4-1 to page 4-18

Page 5-1 to page 5-6

Page 6-1 to page 6-2

Page 7-1 to page 7-2

Page 8-1 to page 8-6

Page 9-1 to page 9-2

Page 10-1 to page 10-4

Page 11-1 to page 11-4

Page 12-1 to page 12-2

0- 2 Perfusor® compact, 2.1 gb

3.0

0-Table of Contents

0

Important Preliminary Remarks Service Work Page 0 - 5

Technical Safety Checks Page 0 - 5

Current Versions Page 0 - 5

Revision Service Page 0 - 5

Responsibility of the Manufacturer Page 0 - 6

Quality Management Page 0 - 6

Checks and Repair Page 0 - 6

Notes on ESD Page 0 - 6

Spare Parts and Test Equipment Page 0 - 7

Setting Off Page 0 - 7

List of Abbreviations Page 0 - 8

Contact Persons Technical Training Page 0 - 9

Entry for Technical Training Page 0 - 9

Ordering of Spare Parts and Test Equipment Page 0 - 9

Service Hotline Page 0 - 9

Return of Spare Parts and Test Equipment Page 0 - 9

Safety Officer

(§ 30 MPG) Page 0 - 9

System Overview Physical Construction Page 1 - 1

Function Page 1 - 2

Accessories Page 1 - 3

Software Approved Software Versions Page 2 - 1

Version Display during Switch-On Test Page 2 - 1

Extended Version Display during Switch-On Test Page 2 - 1

Error Messages and Alarms Page 2 - 2

Service Program Software Compatibility Page 3 - 1

Introduction Page 3 - 1

Working with the Service Program Page 3 - 4

What To Do If ... (Trouble Shooting) Page 3 - 5

Menu Description Page 3 - 7

Procedural Instructions for Inspection after

Modifications via the Service Program Page 3 - 13

Unit Calibration Page 3 - 16

Checklist after Operation of the Service Program Page 3 - 18

Unit Elements Fundamental Repair Information Page 4 - 1

Syringe Table and and Quick Reference Guide Page 4 - 5

Syringe Holder Page 4 - 6

Unit Feet Page 4 - 6

Battery Compartment Cover Page 4 - 7

Snap-in Clip Page 4 - 7

A-Module Page 4 - 8

LS-Clip Page 4 - 9

E-Module Page 4 - 10

N-Module Page 4 - 11

Housing Upper Part, Complete Page 4 - 11

Carrying Handle Page 4 - 12

Perfusor® compact, 3.0 gb 0- 3

3.0

0

Table of Contents

Drive Page 4 - 12

Axial Positioner Page 4 - 13

Drive Board Page 4 - 14

Drive Head Page 4 - 15

Housing Bottom Part, Complete Page 4 - 17

Checks after Repair General Page 5 - 1

Check List for Checks after Repair Page 5 - 1

Visual Inspection Page 5 - 2

Functional Inspection Page 5 - 2

Electrical Safety Page 5 - 5

Maintenance Page 6 - 1

Technical Safety Check TSC Page 7 - 1

Procedural Instructions on the TSC Visual Inspection Page 8 - 1

Functional Inspection Page 8 - 2

Pressure Cut-Off Page 8 - 3

Syringes Page 8 - 4

Electrical Safety Page 8 - 4

Accessories Page 8 - 4

Optional Page 8 - 5

Test Equipment and Special Tools Page 9 - 1

Spare Parts List Page 10 - 1

Revision Documentation Description of Version Page 11 - 1

Version List of the Individual Pages Page 11 - 1

Index Page 12 - 1

0- 4 Perfusor® compact, 3.0 gb

2.1

0-Important Preliminary Remarks

0

Service Work The present manual is for your information only. The possession of

this manual does not authorize the performance of service work.

Service tasks may only be executed by persons, who

- have received appropriate training on the system from

B. Braun

- are included in the revision service

- possess the necessary test equipment and mechanical aids,

and

- fulfill the personal requirements (training and knowledge).

Technical Safety Checks The user is obliged to perform or to have performed the Technical

Safety Checks on those medial products for which these checks

have been prescribed by the manufacturer and to carry them out

according to the indications of the manufacturer as well as the

generally approved technical standards while adhering to the

periods stated (§ 6 MP BetreibV).

B. Braun also recommends training on the Technical Safety

Checks, or to perform at least the steps indicated in the current

version of the manual, as:

- the TSC requires that the instructions in the manuals are

observed

- the manuals are a reference for measurements

- depending on the unit type, the Service Program must be

called which may lead to a dangerous unit condition in case

of inappropriate operation. Furthermore, a special service

connector may be necessary.

Current Versions This manual version corresponds to the state when the manual

was written. B Braun reserves the right to make technical

modifications. The state of the revision is indicated by the index

number in the footer of every page.

Revision Service The possession of this manual does not automatically mean

inclusion in the revision service. You will be included in the

revision service after:

- technical training by B. Braun Melsungen or

- a written order placed with the sales department of B. Braun

(fee required).

Perfusor® compact, 2.1 gb 0- 5

2.1

0

Important Preliminary Remarks

Responsibility of the Manufacturer The manufacturer, person who assembles, installs or imports the

device can only be held responsible for safety, reliability and

performance if

- mounting, enhancements, new settings, changes or repairs

are carried out by duly authorized persons,

- the electrical installation in the corresponding room meets

the requirements of the VDE 0107, VDE 0100 part 710 or

IEC 60364-7-710 and the national standards,

- the device is used in accordance with the instructions for use

and the Service Manual,

- the Technical Safety Checks are performed at regular

intervals,

- a current manual which corresponds to the revision state is

used when carrying out maintenance, repair and service,

- the service technician takes part in the revision service,

- the technician has participated in a technical training course

for the specific B. Braun unit.

Quality Management B. Braun is certified in accordance with DIN EN ISO 9001 and

ISO 13485. This certification also includes maintenance and

service.

The unit has the CE label. The CE label confirms that the device

corresponds to the “Directive of the Council for Medical Products

93/42/EC” of June 14, 1993.

Checks and Repair Training may only be performed by B. Braun. The possession of the

manual does not authorize the performance of repairs. The

instructions on electrostatic sensitive components (ESD

standards) must be observed.

After repair a device check or diagnosis is to be carried out.

Notes on ESD Semiconductors can be destroyed by electrostatic discharge.

Especially MOS components can be damaged by interference from

electrostatic fields, even without discharge via contact. This type

of damage is not immediately recognizable. Unit malfunctions

can even occur after a longer period of operation.

0- 6 Perfusor® compact, 2.1 gb

2.1

Important Preliminary Remarks

0

Each workstation must be equipped according to the

recommendations with the necessary static protective measures,

if ESD components or boards are handled.

Each workstation must be equipped with a conductive table

surface. The conductive surface, the soldering iron or the

soldering stations must be grounded via protective resistors.

Chairs must be of antistatic design. The floor or floor mats should

be of electrically conductive material.

Personnel must wear conductive wristbands which are connected

to a central ground potential via protective resistors, e.g. the

ground contact of a wall outlet. Furthermore it is recommended

Fig.: 0 - 1

Spare Parts and Test Equipment Only use original spare parts from the manufacturer. Do not

that personnel wear cotton clothing and electrically conductive

shoes to prevent electrostatic charge.

tamper with assembly groups which can only be exchanged

completely. The spare parts required are listed in the repair

descriptions.

Service personnel are responsible for the calibration of their test

equipment. Original test equipment can be calibrated at the

works of B. Braun. Further information is available upon request.

Setting Off Additional notes and warnings are set off as follows:

Note

Is used for additional or special notes concerning information and

working steps.

CAUTION

Is used for working steps which may result in damage to the unit,

system or to a connected device.

WARNING

!

IS USED FOR WORKING STEPS WHICH MAY RESULT IN PERSONAL

INJURY.

Perfusor® compact, 2.1 gb 0- 7

2.1

0

Important Preliminary Remarks

References to chapters are shown as follows

(see „Setting Off“ ➨ p. 0 - 7)

References to figures and tables are shown as follows

Fig.: 2 - 3 or Table 2 - 1

References to item numbers in figures are shown as follows

(Fig.: 1 - 1 / Item 1)

In this case “Fig.: 1 - 1“ is the figure number and “Item 1“ the item

number within the figure.

When the Service Manual is stored as pdf-file, these references

are displayed green. Click with the mouse button on a reference

to jump to the corresponding source.

Menu commands are described as:

Menu

File

.

List of Abbreviations Abbreviations which are not generally known, but are used in this

manual, are listed below.

A-Module Analog Module

E-Module Electronic Module

ESD Electrostatic Discharge

IfU Instructions for Use

LCD Liquid Crystal Display

MFC Multi-Function Connector

PS-Module Power Supply Module

TSC Technical Safety Checks

TEMP Temperature

0- 8 Perfusor® compact, 2.1 gb

0 - 10

3.1

0-Contact Persons

0

Technical Training Via local representative.

Entry for Technical Training Application for a technical training course must be made via the

responsible representative.

Ordering of Spare Parts and Test Equipment Please contact your local B. Braun subsidary.

International Technicians (Intercompany)

Irene Marchel

Fax: +49 (0) 5661 / 75 - 38 57

e-mail: irene.marchel@bbraun.com

Service Hotline Martin Heusner

Phone: +49 (0) 56 61 71 - 35 25

Fax: +49 (0) 56 61 71 - 35 26

E-Mail: martin.heusner@bbraun.com

Return of Spare Parts and Test Equipment B. Braun Melsungen AG

Schwarzenberger Weg 73-79

Wareneingang Werk C

34 212 Melsungen

Germany

Safety Officer (§ 30 MPG)

Dr. Ludwig Schütz

e-mail: ludwig.schuetz@bbraun.com

Perfusor® compact, 3.1 gb 0- 9

2.1

0

For your notes:

Contact Persons

0- 10 Perfusor® compact, 2.1 gb

1 - 4

2.1

Physical Construction

1-System Overview

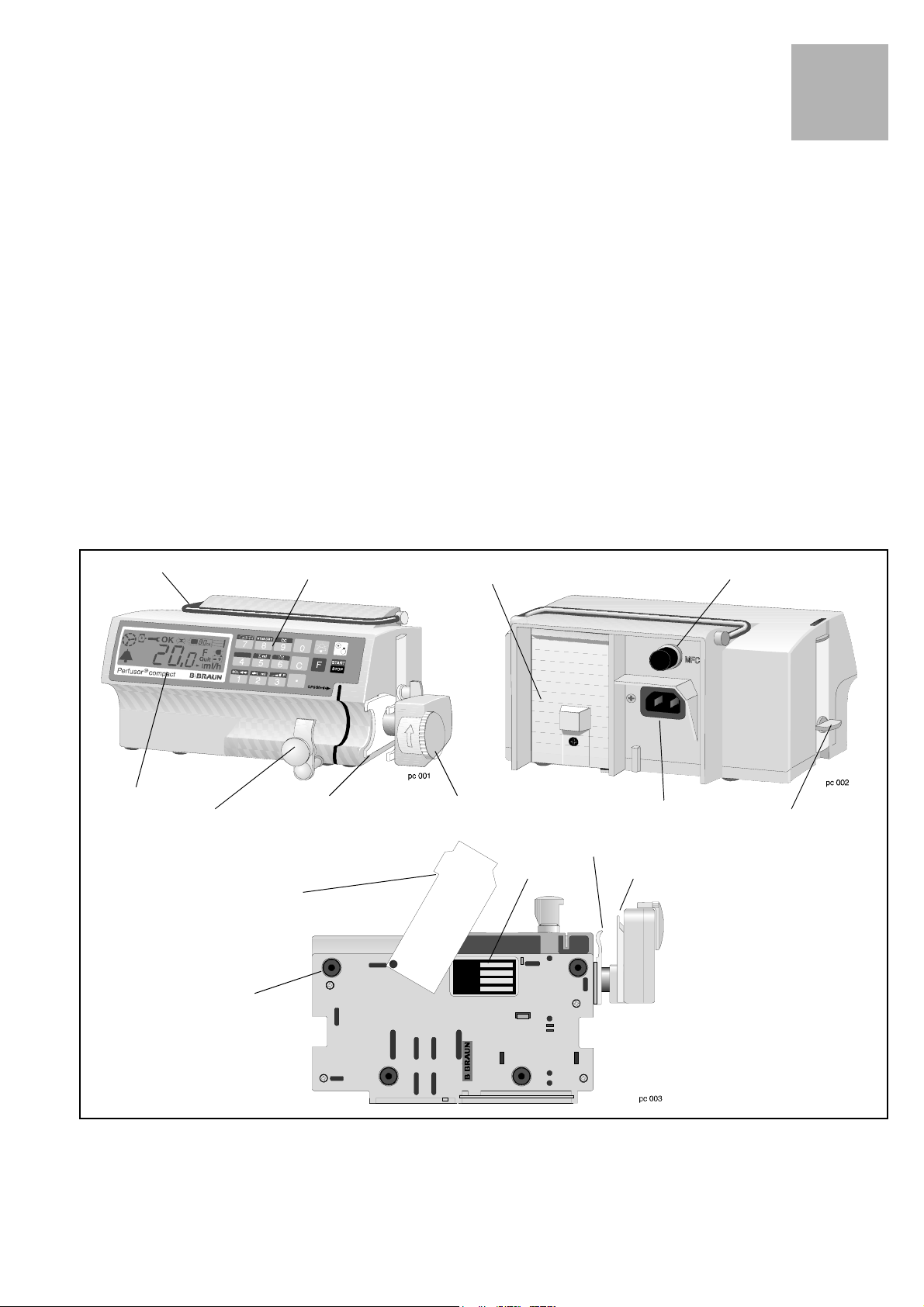

The Perfusor compact is a compact, stacking, portable and

lightweight syringe pump which is used for precise dosing of

small to high volumes of fluids in infusion and alimentary

therapies.

The standard delivery rate range is 0.1 to 99.9 ml/h (in increments

of 0.1 ml/h).

All important information is displayed on an LC-display. The

device is easy to operate via the membrane keyboard. The syringes

are changed semi-automatically. The function process and

monitoring is microprocessor controlled. The Perfusor compact

has a long service life and is easy-to-service due to its modular

design. Individual modules can be replaced easily and quickly, and

the Service Program runs on a PC.

1

Carrying handle

LC display

Syringe holder

Membrane keyboard MFC socket

Axial positioner

Syringe table

and quick reference guide

Unit feet

Battery compartment

Drive head with lock

and push-button sensor

Type plate

Mains power connection

Axial positioner

Clamp

Snap-in clip

(on both sides)(on both sides)

View from below

Fig.: 1 - 1

Perfusor® compact, 2.1 gb 1- 1

2.1

1

Function

System Overview

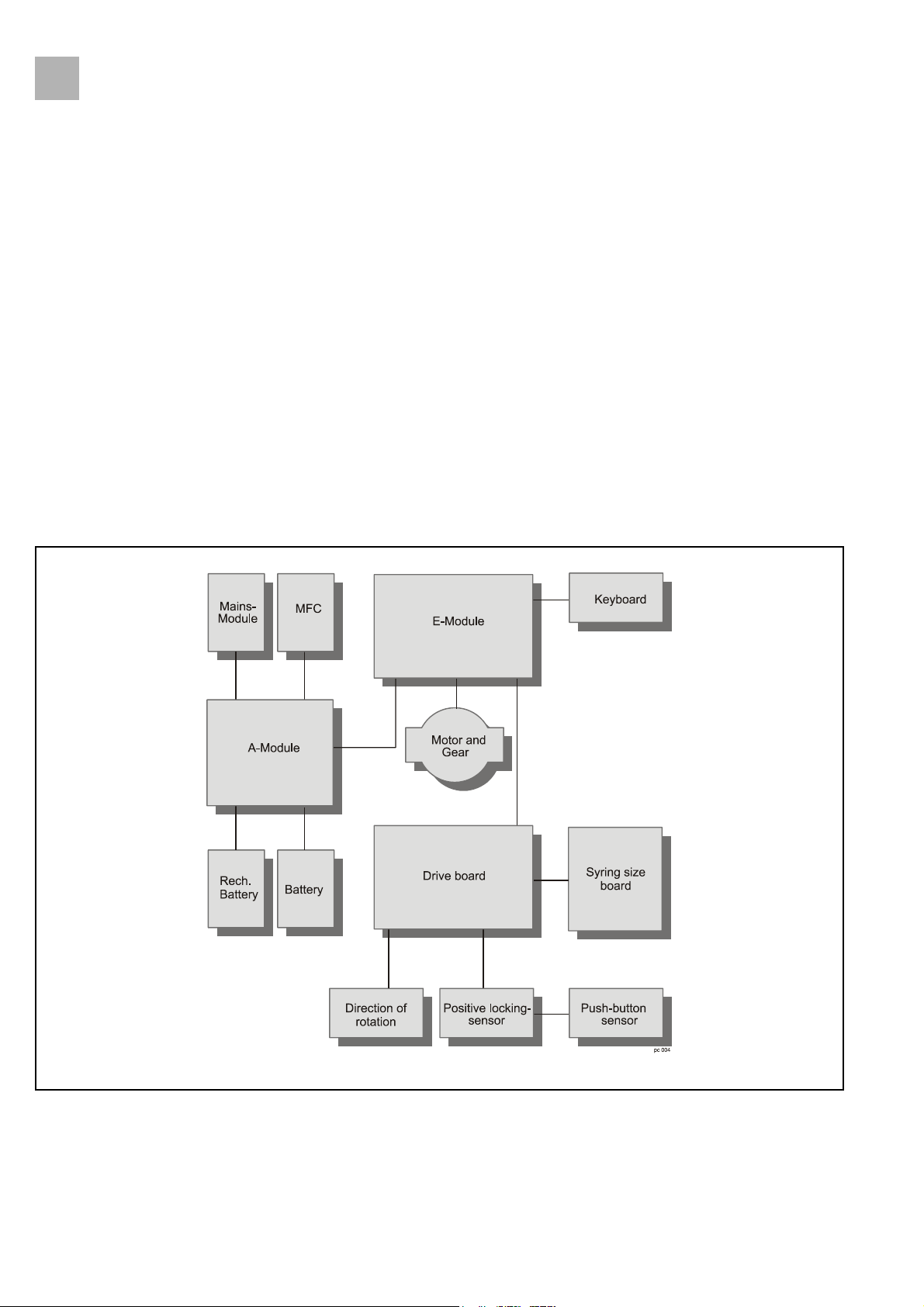

The electronics of the Perfusor compact consists of the following

components:

1. A-Module with MFC board as the central power supply and

interface

2. E-Module as operating and control unit

3. Drive unit, consisting of

- drive board with the complete sensor technology, light

barriers for syringe pre- and end-alarm, syringe size

recognition and motor operation control

- push-button sensor board for the inserted syringe

- positive locking sensor board for the frictional

connection between nut and spindle of the drive.

Fig.: 1 - 2 Block diagram

1- 2 Perfusor® compact, 2.1 gb

2.1

Accessories

System Overview

Designation Ord. No.

Unit connecting lead 200-240 V . . . . . . . . . . . . . . . . . 3450 2718

Unit connecting lead 100-240 V . . . . . . . . . . . . . . . . . 3450 5423

Pole clamp (universal clamp, rotating) . . . . . . . . . . . . 3450 9054

Battery pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3450 1690

1

Perfusor® compact, 2.1 gb 1- 3

2.1

1

For your notes:

System Overview

1- 4 Perfusor® compact, 2.1 gb

2 - 6

3.0

Approved Software Versions

Position 123456789

Digit PL AA00721

Revision level

Hardware identification

Software group

Hardware group

Perfusor® compact

Fig.: 2 - 1

2-Software

The software and hardware revision level is displayed on the LCdisplay when the unit is switched on. The characters on the

display must correspond with the indication on the instructions

for use.

The software can only be updated by replacing the E-Module.

Unit Software

PLAA00035.5 PLAA00070.0 (Dianet

PLAA00040.0 PLAA00071.1 (Dianet

PLAA00041.0 PLAA00072.1 (Dianet

PLAA00063.3 PLAA01070 (new hardware)

2

Star

Star

Star

)

)

)

Version Display during Switch-On Test

Extended Version Display during Switch-On Test

1. Switch on unit.

2. The following information is displayed one after the other on

screen:

888.

8

111 .

1

222.

2

555.

5

AA Reference to the instructions

for use (hard- and software group)

3. The Perfusor® compact switches over to normal operation.

1. Switch on unit.

2. Press the F button and keep the button pressed during normal

switch-on test. The following information (examples) appears

on screen after the information displayed during normal

switch-on test:

00 Hardware identification

071

1 Software version

123

4 1234 operating hours

999

9 Maintenance interval timer

3. Release the F button to exit. The Perfusor® compact switches

over to normal operation.

Perfusor® compact, 3.0 gb 2- 1

2.1

2

Software

Error Messages and Alarms

LC display Description

1 Different syringe recognition

2 Different FP- and CMP condition

3 Rate of FP- and CMP different

4 Different function mode

5 Different rate of delivery

6 Different target volume

In case of a unit malfunction a continuous signal is activated, and

the function processor displays an alarm and an error code. The

error code of the control microprocessor can be queried with the

F button. Please state both error codes if you have any questions.

Acknowledge alarm and switch device off.

Device Alarms of the Function Processor

7 Different step volume (low)

8 Different motor steps

19 State/motor state

20 Invalid normal state

21 return from PlcMain

22 Unexpected reset

28 No sync at Plc_Down

29 No sync at Plc_On

30 Different CMP/FP mode ports

31 Invalid mode ports

32 Invalid variable values

33 Error in ROM test

34 Different software version

40 Unexpected interrupt

49 Faulty sensor sync

51 Motor on during reverse run

52 Step cumulation > 10 steps

53 Illegal setting of Mot_Ok

54 Different recognition of direction of rotation

55 Reverse polarity of motor

Table 2 - 1 (Part 1 of 2)

2- 2 Perfusor® compact, 2.1 gb

2.1

LC display Description

56 Invalid syringe

57 Overflow of motor step counter

59 No sync at Mot_Test

61 Different SW button NEC<>H8

62 Timeout KBD watchdog

63 Error in switch-on test

70 Control timer overflow (int)

71 Control timer underflow

72 Control timer overflow

73 100 ms cycle overflow

75 Tim_WaitUntil overflow

81 Error upon reading of EEPROM

83 Error of EEP data consistency

Software

2

84 Ad difference between NEC/H8

85 Bw difference between NEC/H8

86 Md difference between NEC/H8

90 Syringe state in Oper_Syr

91 Set syringe type

92 Consistency error

93 Difference between setting and display

94 Timer synchronization

100 Division by zero

101 Illegal zero pointer

102 Illegal switch to default

105 No contact to NEC in OFF

110 Alarm on CMP side

111 ... 119 Motor test 1 ... 9

120 Motor current flow in OFF

121 Battery discharged during test

125 ASSERT error

126 Alarm synchron. (fault occurrence)

127 Alarm synchron. (back-to-normal)

248 Motor test 8 from NEC

251 NEC: Battery discharged during test

Table 2 - 1 (Part 2 of 2)

Perfusor® compact, 2.1 gb 2- 3

2.1

2

LC display Description

128 Unexpected reset

129 Unexpected hardware interrupt

130 Access of zero pointer

131 Attempted division by zero

132 Internal software error

134 State/motor state

135 Invalid variable values

136 Invalid operating condition

137 Illegal mode – port value

138 H8 indicates GA F14_H8GA_K16

150 Different software versions

Software

Device alarms of the control microprocessor

151 Double CRC error

153 Different states

154 Different rates

155 Different F-mode

156 Different mode values

157 Different alarm recognition

158 Different alarm clearance

159 Err. current volume

160 Err. preselected volume

161 Err. volume per step

170 Sensor sync. failed

171 ... 174 Sensor - dark test error

180 ROM test error

181 RAM test error

182 Keyboard test error column

183 Dynamic memory test

184 Motor test no sync

185 Keyboard test error

186 Timer test error

187 CPU test error

188 Battery test error

191 Different software buttons

Table 2 - 2 (Part 1 of 2)

2- 4 Perfusor® compact, 2.1 gb

2.1

LC display Description

192 Keyboard timeout error

200 Cycle > 100 ms

202 Time > Until

203 Watchdog interrupt

204 Error when waiting for H8

205 Time-out when switching H8 on

206 Time-out when switching H8 off

207 No sync at Plc_Down

208 No sync at Plc_On

209 CMP/FP timer – end sync error

220 Different phases (busy)

221 Different phases (idle)

222 Motor on at reverse steps

Software

2

223 Too many pending steps

224 Motor current error

225 Error of motor step number

226 Reverse polarity of motor

227 Motor steps overflow

230 Different syringe recognition

231 CMP/FP syringe state

232 CMP/FP syringe type set

241 ... 249 Motor test 1 ... 9 errors

250 Motor ON in OFF-mode

251 Battery voltage low

Table 2 - 2 (Part 2 of 2)

Note

Operating alarms are specified in the instructions for use.

Perfusor® compact, 2.1 gb 2- 5

2.1

2

For your notes:

Software

2- 6 Perfusor® compact, 2.1 gb

3 - 18

3.0

Software Compatibility

3-Service Program

Designation Ord. No.

Interface cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 1661

Compatibility

Unit Software Service Program Ord. - No.

PLAA00035.5 5.3502 . . . . . . . . . . . On request

PLAA00040.0 5.5004

PLAA00041.0 5.5004

PLAA00063.3 2.1.0.1 . . . . . . . . . . . 3452 0474

PLAA00070.0 (Dianet

PLAA00071.1 (Dianet

PLAA00072.1 (Dianet

PLAA01070 (new hardware) 2.1.0.1 . . . . . . . . . . . 3452 0474

Star

) 2.1.0.1 . . . . . . . . . . . 3452 0474

Star

) 2.1.0.1 . . . . . . . . . . . 3452 0474

Star

) 2.1.0.1 . . . . . . . . . . . 3452 0474

†

. . . . . . . . . . 3452 0474

†

. . . . . . . . . . 3452 0474

3

Introduction

Note

The following description refers to the versions 5.5004 and

2.1.0.1. of the Service Program.

The relevant version is given in square brackets in the illustrations

of each user interface and where the description contains

differences.

The Service Program runs in a user-friendly way on a PC. All

functions are easy to operate in the pulldown-menus as in

Windows.

WARNING

!

Service mode is only authorized for service tasks.

DANGER OF INJURY IF USED ON THE PATIENT!

- Never connect the MFC service connector or the service cable

when a patient is connected to the unit!

- First switch the unit off before any further use after working

with the MFC service connector.

- Carry out a check according to the procedural instructions for

inspection after the Service Program was run. (see

“Procedural Instructions for Inspection after Modifications

via the Service Program” ➨ p. 3 - 13).

†

The previous version 5.5004 is included in the installation package for 2.1.0.1.

Perfusor® compact, 3.0 gb 3- 1

e

3.0

3

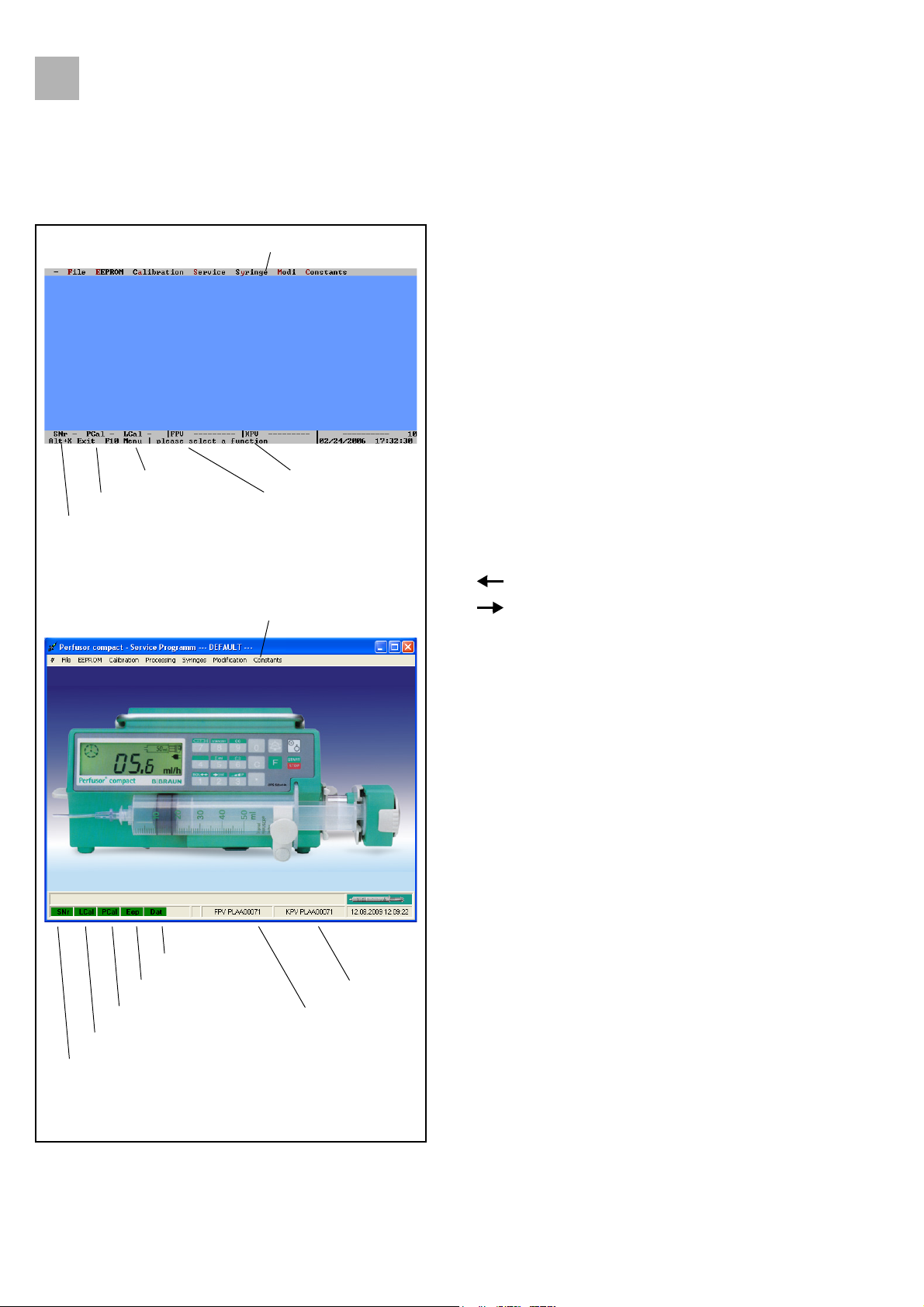

[Version 5.5004]

Service Program

Length calibration

Pressure calibration

Serial number

Selection menu

Control microprocessor

Function processor

The special keys on the keyboard have the following functions:

- ESC [Version 5.5004] Cancel

- F1 Connect

- F2 Default EEPROM

- F3 Read-out EEPROM

- F4 Serial number

- F5 Length calibration

- F6 Pressure calibration

- F7 Write EEPROM

- F8 Save

- Alt + A Alternatively: Alt + bold

- Alt + F4 [Version 2.1.0.1] Exit

- Tab to jump to next field

[Version 2.1.0.1] Selection menu

Data saved

EEPROM written

Pressure calibration

Control microproc

Function processor

- to move the cursor

- to move the cursor

When the Service Program is installed and the PC is connected to

the Perfusor compact, the following functions can be executed:

- Drive calibration

- Reading / loading pump data

- Displaying service values

- Displaying and changing parameters

- Documentation of pump hardware modifications

- Saving all data to a diskette, hard disk, or similar

Length calibration

Serial number

Fig.: 3 - 1 Overview of user interfaces

3- 2 Perfusor® compact, 3.0 gb

3.0

Fig.: 3 - 2

Service Program

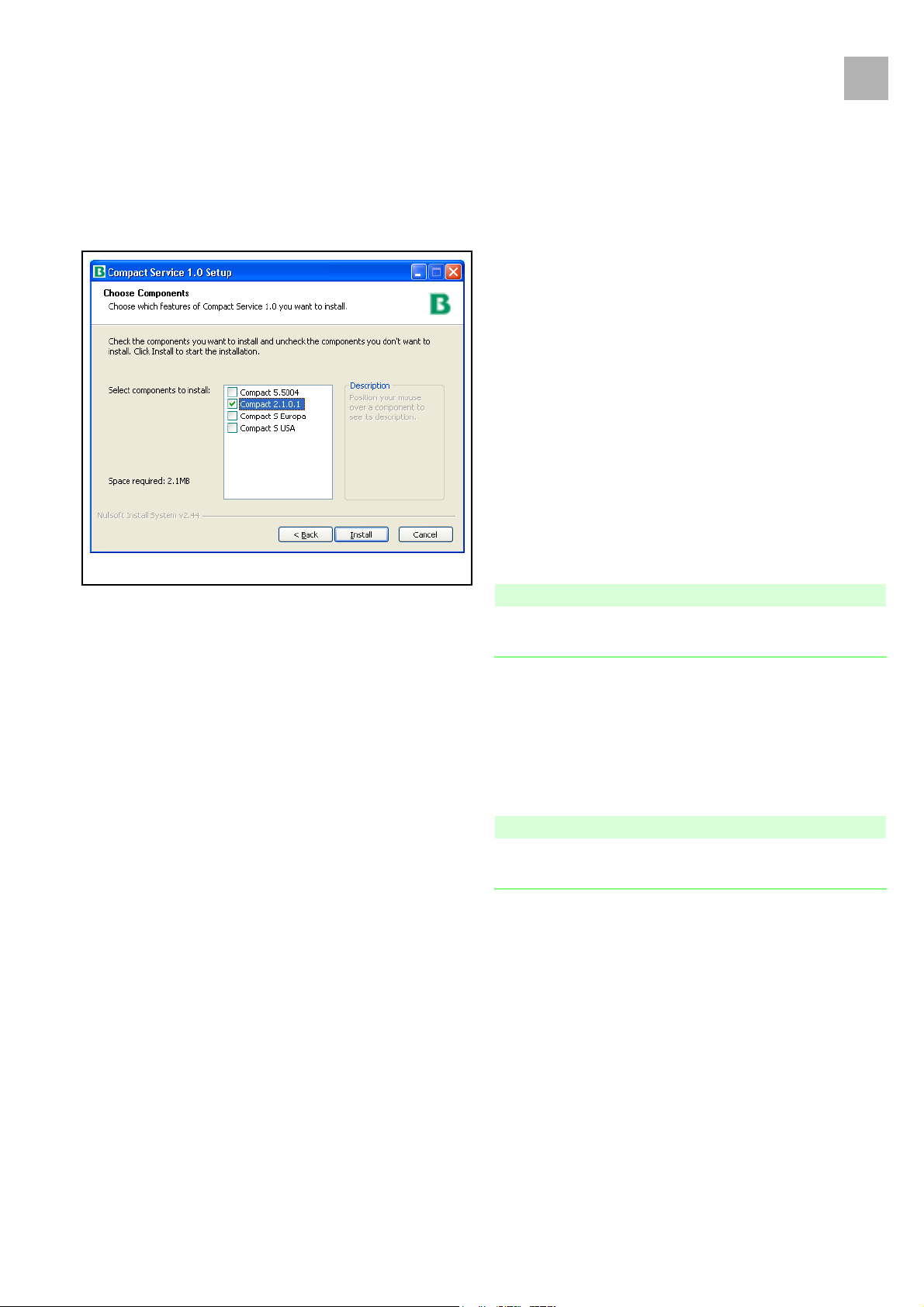

Installation

1. Insert the CD.

2. Start the File Manager or Windows Explorer.

3. Start Setup.exe with a double-click.

4. Select language for installation and confirm with

5. In the Welcome dialog box start installation with

6. Accept licenses with

7. Select a program version and continue with

(Fig.: 3 - 2).

8. During installation the program creates the directory

C:\Programme\Serviceprogramm xxx Perfusor compact\

automatically (xxx = version number). Calibration and default

data are also saved in this directory (if no other directory is

specified). The directory name can be changed without any

problems.

IAgree

.

Install

OK

.

Next

3

.

Note

The system configuration of the PC is not changed when the

Service Program was installed.

Uninstalling

1. To uninstall the service program, delete file Plc_serv.exe

[Version 5.5004] or PcsCompact.exe [Version 2.1.0.1].

To uninstall the service program incl. the service program

directory in full, double-click file uninst.exe to start it.

Note

If the entire directory \Serviceprogramm xxx Perfusor compact\ is

deleted, all unit data is deleted from the PC.

Configuration

1. Select the language and interface with the

File➨Configuration

screen display [Version 5.5004].

2. Acknowledge with

menu item. Also select the desired

OK

.

Perfusor® compact, 3.0 gb 3- 3

3.0

3

Service Program

Working with the Service Program

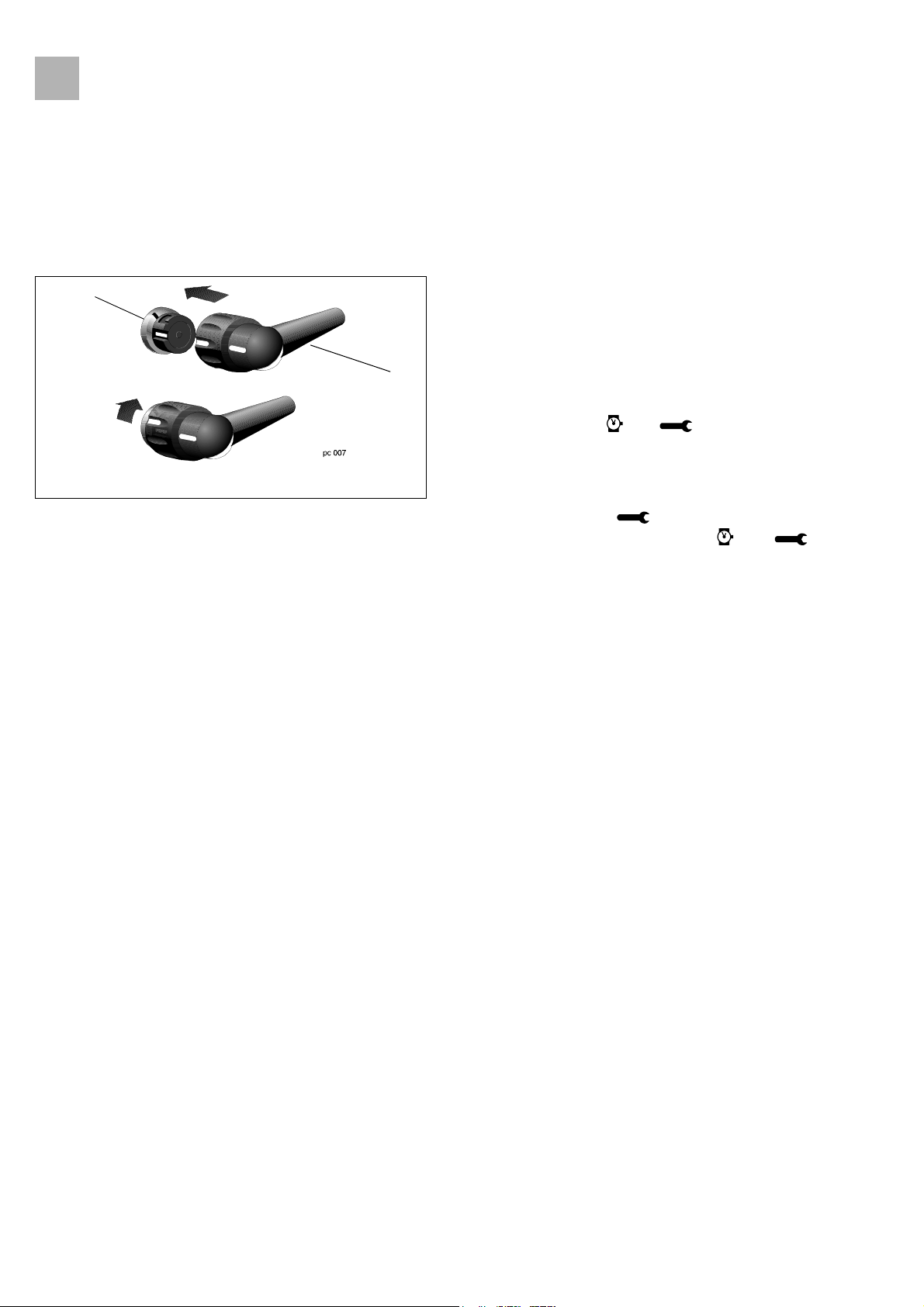

1

Fig.: 3 - 3

Legend of fig. 3 - 3:

ItemDesignation

1 MFC connector on the unit

2 MFC service cable

Preparation

1. Connect service cable (Fig.: 3 - 3 / Item 2) to MFC connector

(Fig.: 3 - 3 / Item 1) of unit and to PC serial port (COM 1 or

COM 2).

2. Connect mains power cable to the unit.

2

3. Start the Service Program on the PC.

4. [Version 5.5004]: To start communication, press the ON key

on the Perfusor® compact until "Release On/Off key" is

displayed on the PC. and are displayed on the LC

display.

[Version 2.1.0.1]: To start communication, select menu item

File ➨ Connect

compact pressed until disappears from the LC display.

After connection has been established and are

displayed.

Display / Save the Unit Settings

, then keep the On key on the Perfusor®

1. Menu item

2. Menu item

3. Menu item

4. [Version 5.5004]: Select menu item

Data

types

new E-Module).

[Version 2.1.0.1]: Select menu item

Modification data

selection

any modification (e.g. new E-module) or print out with

Print

Adjust Unit Settings

1. Menu item

2. Menu item

3. Desired modifications / display, please see:

-

Service ➨ Service Values

Processing ➨ Processing values

File ➨ Connect

EEPROM

File ➨ Save

➨

Read

.

.

.

Modi ➨ Modification

and menu item

. Note down parameters prior to any modification (e.g.

Syringe ➨ Syringe selection

Modification ➨

or

Syringe types

.

File ➨ Connect

EEPROM ➨ Read

and menu item

. Note down parameters prior to

.

[Version 5.5004] or

Syringes ➨ Syringe

.

[Version 2.1.0.1]

or

Syringe

File ➨

-

Modi

➨

Modification Data

Modification ➨ Modification data

-

Calibration ➨ Pressure calibration

bolus rate change)

3- 4 Perfusor® compact, 3.0 gb

[Version 5.5004] or

[Version 2.1.0.1]

(required in case of

3.0

Service Program

-

Syringes ➨ Syringe selection

-

Constants ➨ Service interval

4. Menu item

Menu item

5. Enter the user number 0 upon query.

6. Check unit according to the procedure instructions for

inspection (see “Procedural Instructions for Inspection after

Modifications via the Service Program” ➨ p. 3 - 13).

Unit Calibration

The unit must be calibrated (see “Unit Calibration” ➨ p. 3 - 16)

after the E-Module or the drive has been replaced or the bolus

rate changed.

EEPROM ➨ Write

File ➨ Save

saves the data to the hard disk.

transmits data to the device.

3

What To Do If ... (Trouble Shooting)

Defaut Data

The Service Program contains the Default.dat file with the factory

settings of the unit. These values can be adjusted via the Syringe

or Modes menu if required.

Max. delivery rate (basal rate) . . . . . . . . . . . . . . . . . . . . 99.9 ml/h

Bolus rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 ml/h

Staff call [Version 5.5004]. . . . . . . . . . dynamic without off alarm

[Version 2.1.0.1] . . . . . . . . . . . . . . . . dynamic with pre-alarm

Alarm tone[Version 5.5004] . . . . . . . . . . . . 0 (3 Hz interval tone)

Tone when alarms output [Version 2.1.0.1] . . . . . . . . . . . . . . .3 Hz

Tone when pre-alarms output [Version 2.1.0.1] . . . . . . . . . . static

Pressure stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dianet address [Version 5.5004] . . . . . . . . . . . . . . . . . . . . . . . . . 1

Syringe selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Table

Service interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20440 hrs.

... the length calibration does not start?

Could communication be started successfully? Does the motor

still not start?

Then: Select Termination. Switch off pump. Repeat

communication start. Switch pump on again.

Perfusor® compact, 3.0 gb 3- 5

3.0

3

Service Program

... the communication to the pump is missing?

Is the service cable connection okay? Is the MFC correctly

connected?

Then: Select Termination. Switch off pump.

Repeat communication start. Switch pump on again.

... the communication cannot be started?

Compatibility of service software and unit software checked? Was

the setting with the

item selected correctly? Is the service cable connection okay? Is

the MFC correctly connected?

... the communication starts and is then interrupted?

Then: Press the ON-key on the Perfusor compact until the

symbols and disappear.

File ➨ Configuration

(COM 1 or 2) menu

... the unit does not accept any syringe after a service was

carried out?

Is syringe selection set to "free type", but "free type" was not

loaded?

Then: Set syringe selection to table / OPS or load corresponding

syringe.

... Problems under Windows 2000 / XP [Version 2.1.0.1]

1. Data transmission during reading and writing EEPROM takes

a long time, sporadic program crashes.

- Change settings in file C:\WINNT\System32\CONFIG.NT

- This file can be modified with the program editor, for

example. Change setting for "files=40" (last line) to

"files=99". Do not forget to save.

2. Error message for syringe recognition test during operation.

- Change setting for COM interface in the Control Panel.

- To do this, open the Device Manager and find setting for

the COM interface.

- Under "Port Settings -> Advanced," activate or

deactivate the "Use FIFO Buffer" field.

- This setting can very depending on the hardware.

3- 6 Perfusor® compact, 3.0 gb

Loading...

Loading...