Page 1

\BETRANL\E16x442e I E16x442 Rev: 00 26.11.2014 Page 1 of 73

D 71334 Waiblingen-Hegnach

Esslinger Str. 26

Tel.: +49 (0)7151/956230

Fax: +49 (0)7151/956250

E-Mail: info@braun-tacho.de

Internet: www.braun-tacho.de

Quality certified according ISO 9001

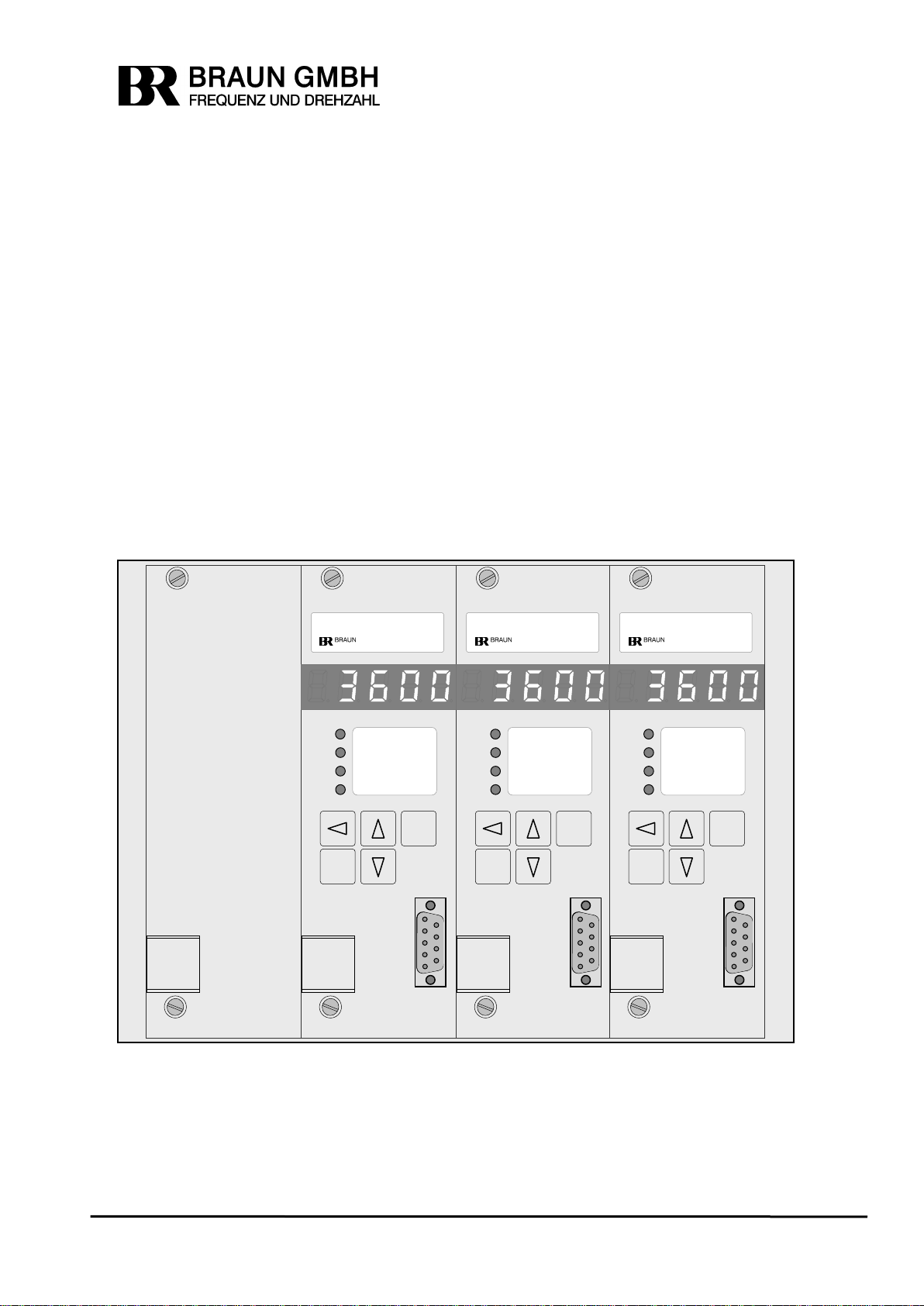

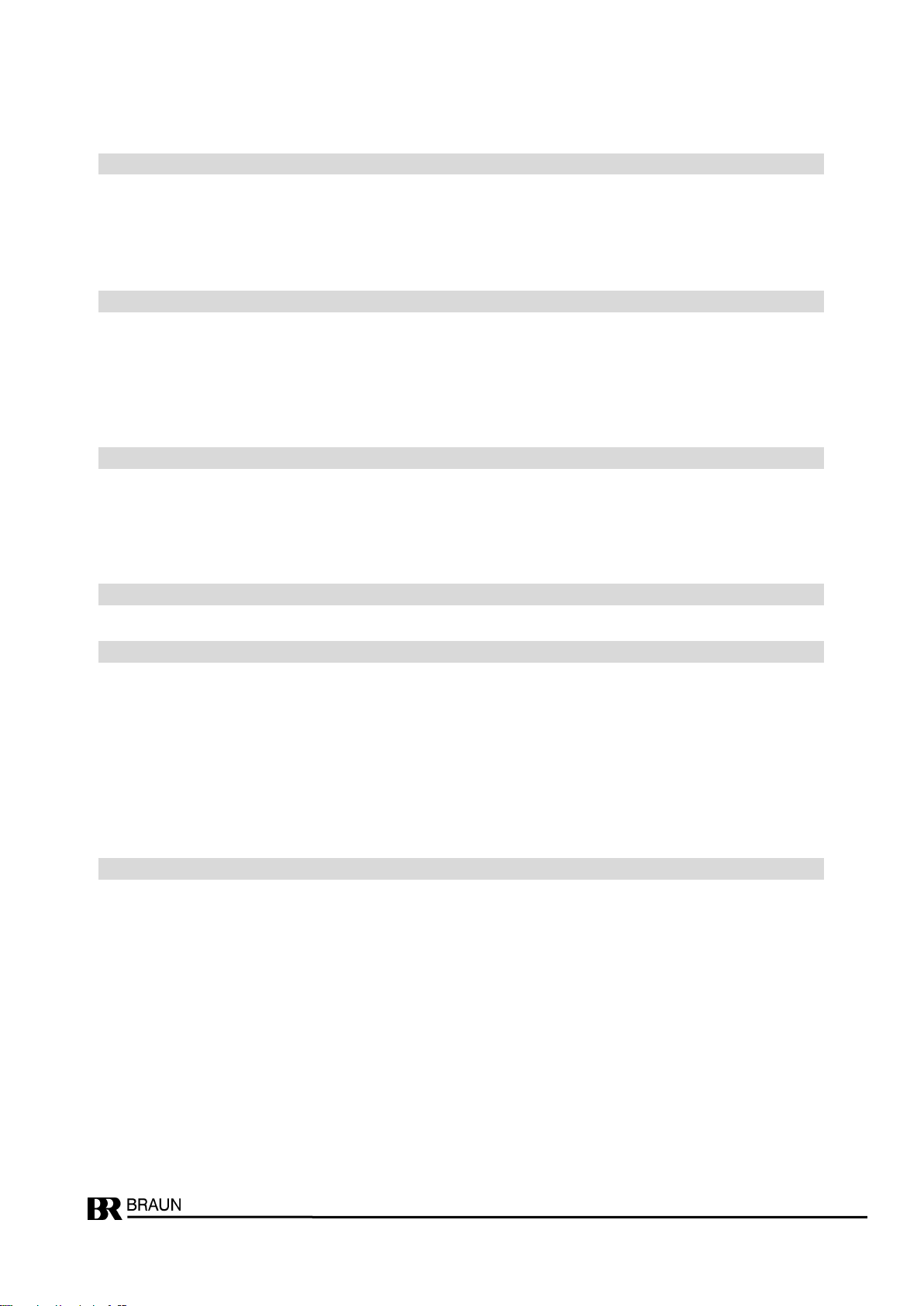

Monitor A

Monitor B

Monitor C

E1691

P

E

E1665

1

2

3

4

Trip

SP3

RPM

P

E

E1665

1

2

3

4

Trip

SP3

RPM

P

E

E1665

1

2

3

4

Trip

SP3

RPM

Monitor A

Monitor B

Monitor C

SIL2/IEC61508

SIL2/IEC61508

SIL2/IEC61508

Test Interface

Original Manual

of

Protection-System E16x442

with

Overspeed Protection

and

Voters for external Trip Release Conditions

IEC61508;SIL2 and A PI670 compliant

Figure 1: E16x442 System Front View

Page 2

I E16x442 Rev: 00 Page 2 of 73

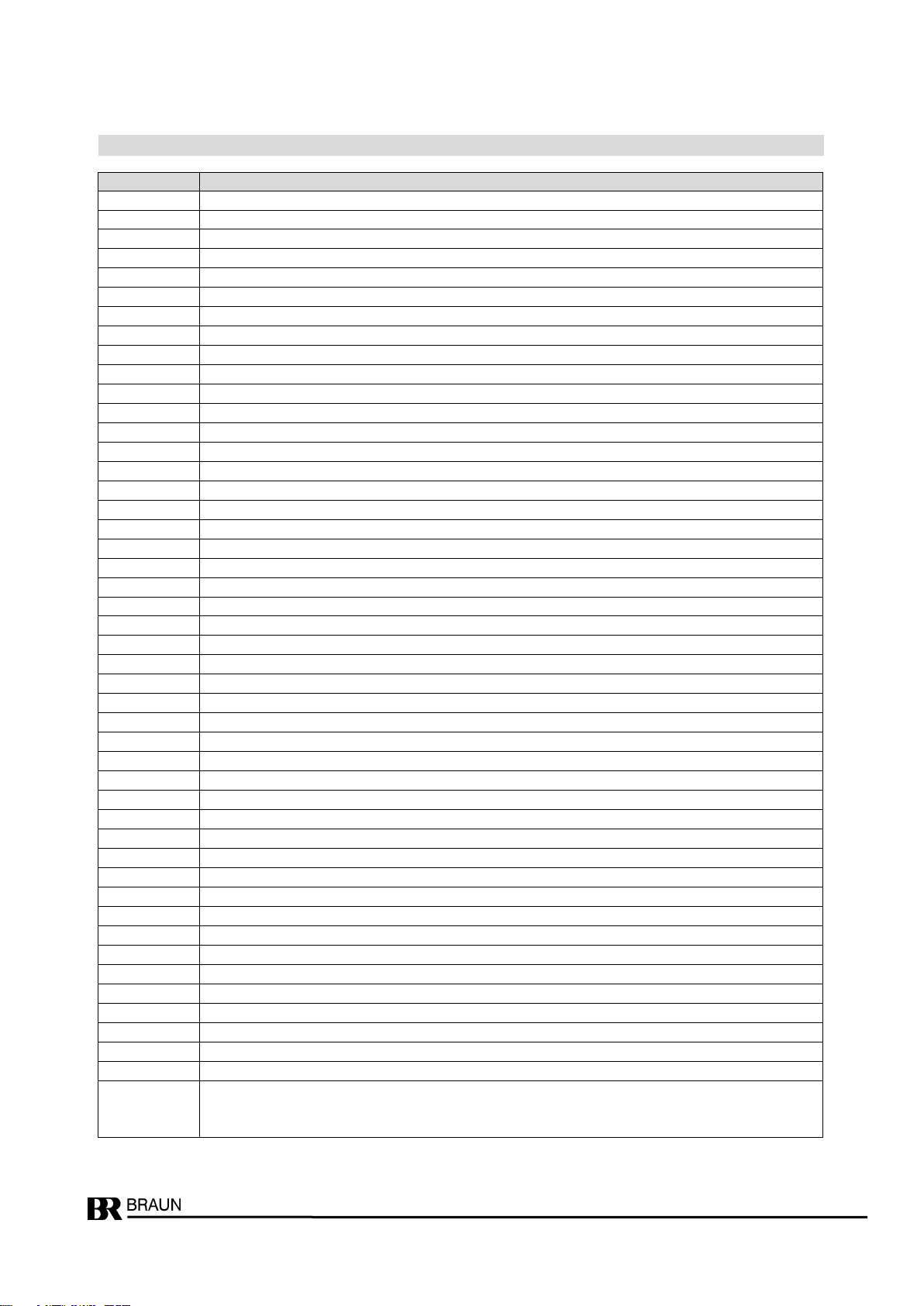

Contents Page

1. General Informations ................................................................................................ 4

1.1. List of Figures .............................................................................................................. 4

1.2. List of Abbreviations .................................................................................................... 5

1.3. System Applications and Explanation .................................................................... 7

1.4. Key Features of System E16x442 ............................................................................. 7

1.5. Ordering Key for Systems E16x442.abc ................................................................. 8

1.6. Safety Data.................................................................................................................. 9

1.6.1. Safety Data IEC61508; SIL2 ....................................................................................... 9

1.7. External Tests ............................................................................................................. 9

1.7.1. External tests during normal operation by PLC or operator ........................................ 9

1.7.2. Test of 2oo3 solenoid valve block ............................................................................... 9

2. System Structure and I/Os ...................................................................................... 10

2.1. System Structure ....................................................................................................... 10

2.1.1. Speed Sensors .......................................................................................................... 10

2.1.2. System Components ................................................................................................. 10

2.1.3. System Design .......................................................................................................... 10

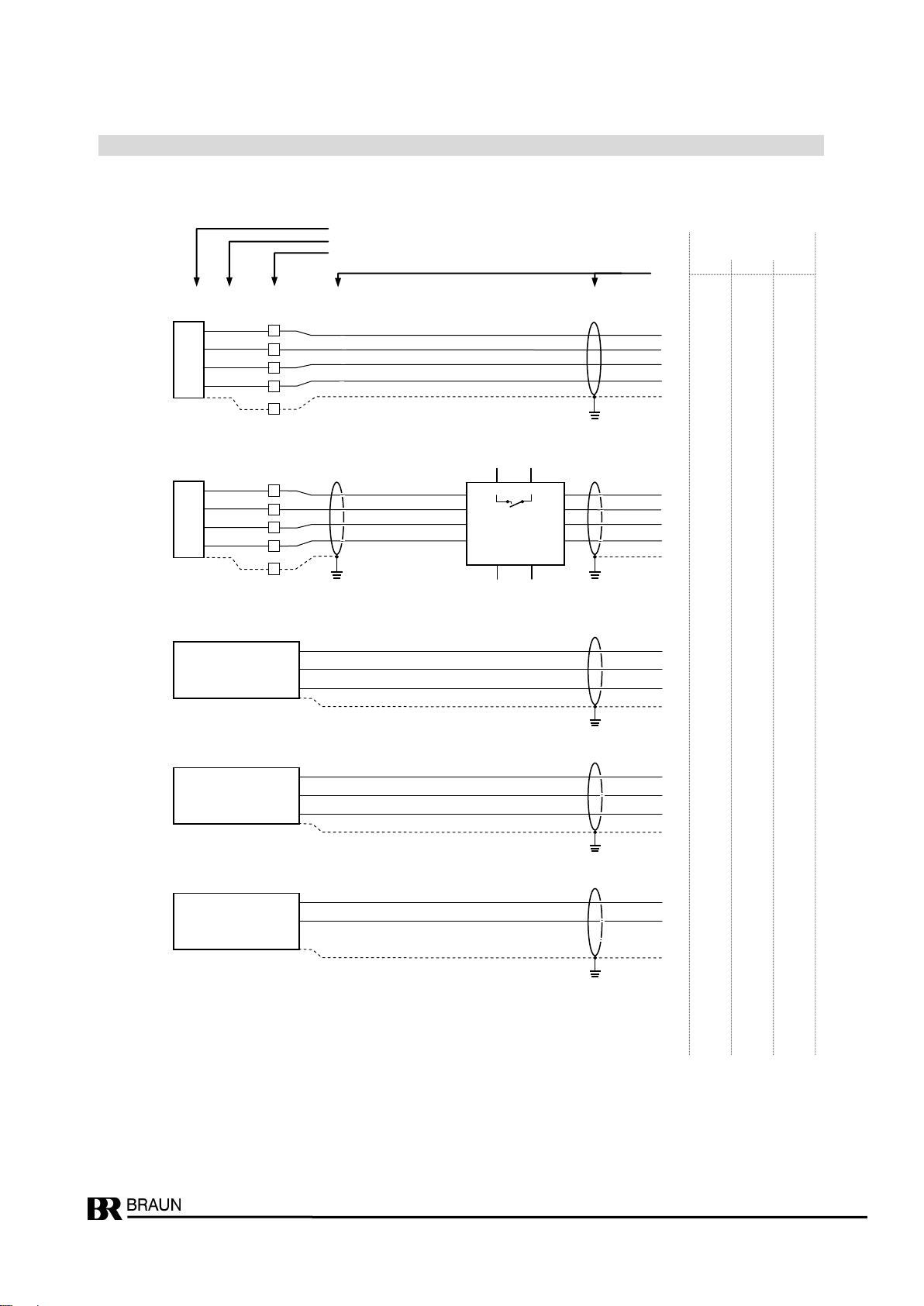

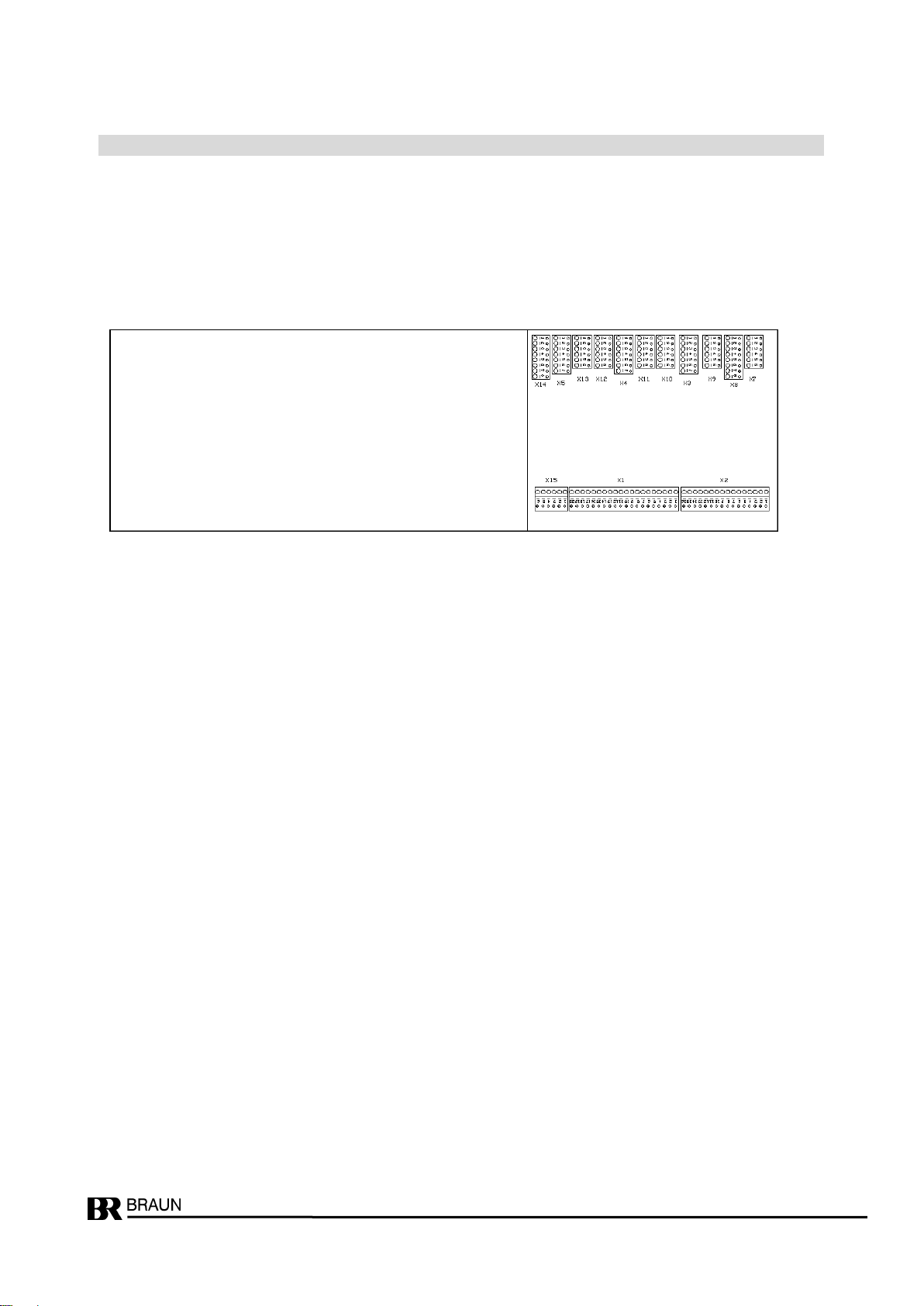

2.1.4. System Structure Diagrams ...................................................................................... 11

2.1.5. System Wiring Diagrams........................................................................................... 13

2.1.6. Connection of Sensors to the Speed Signal Inputs ................................................... 15

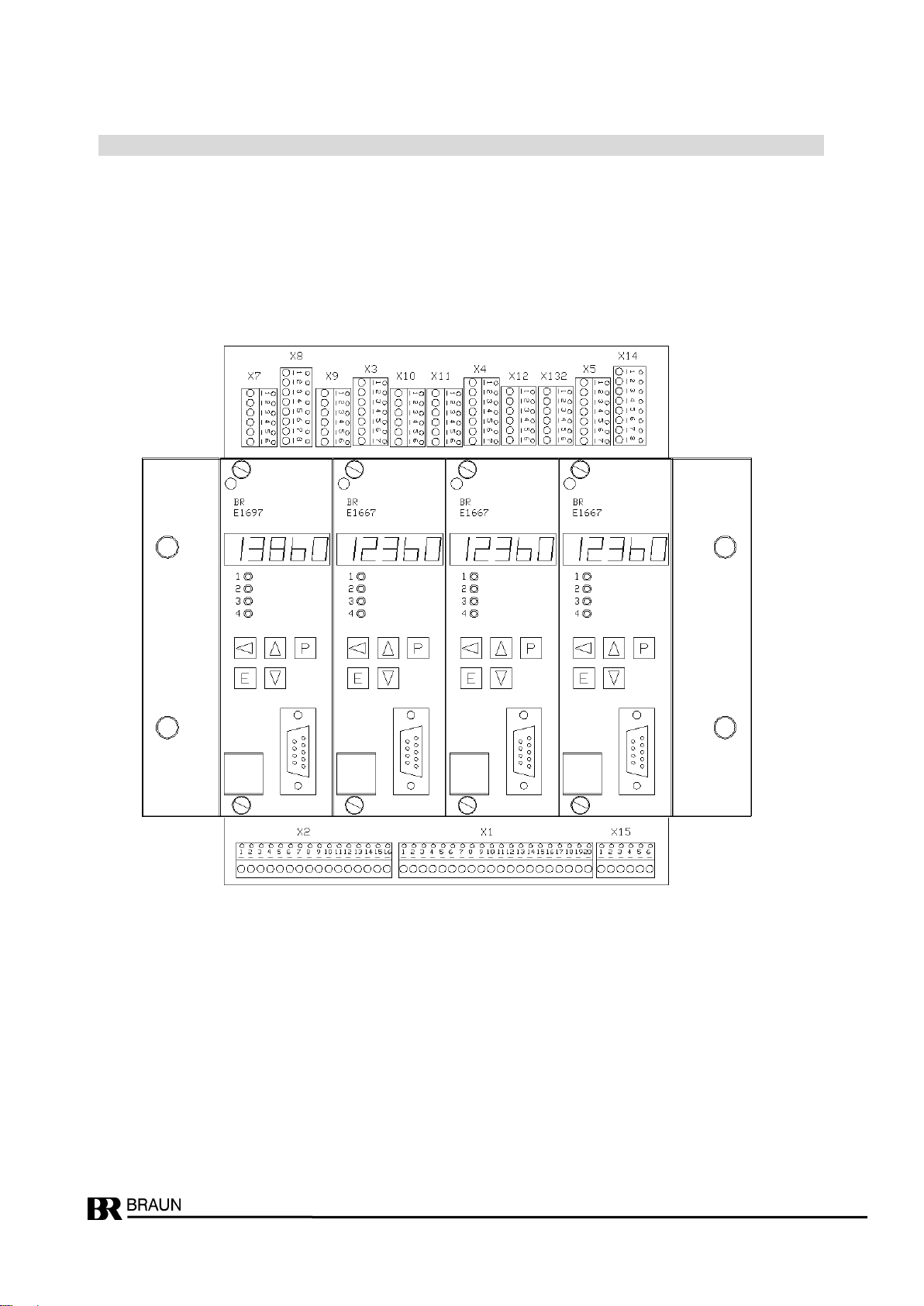

2.1.7. Position of Terminal Blocks with Version E16E442 ................................................... 16

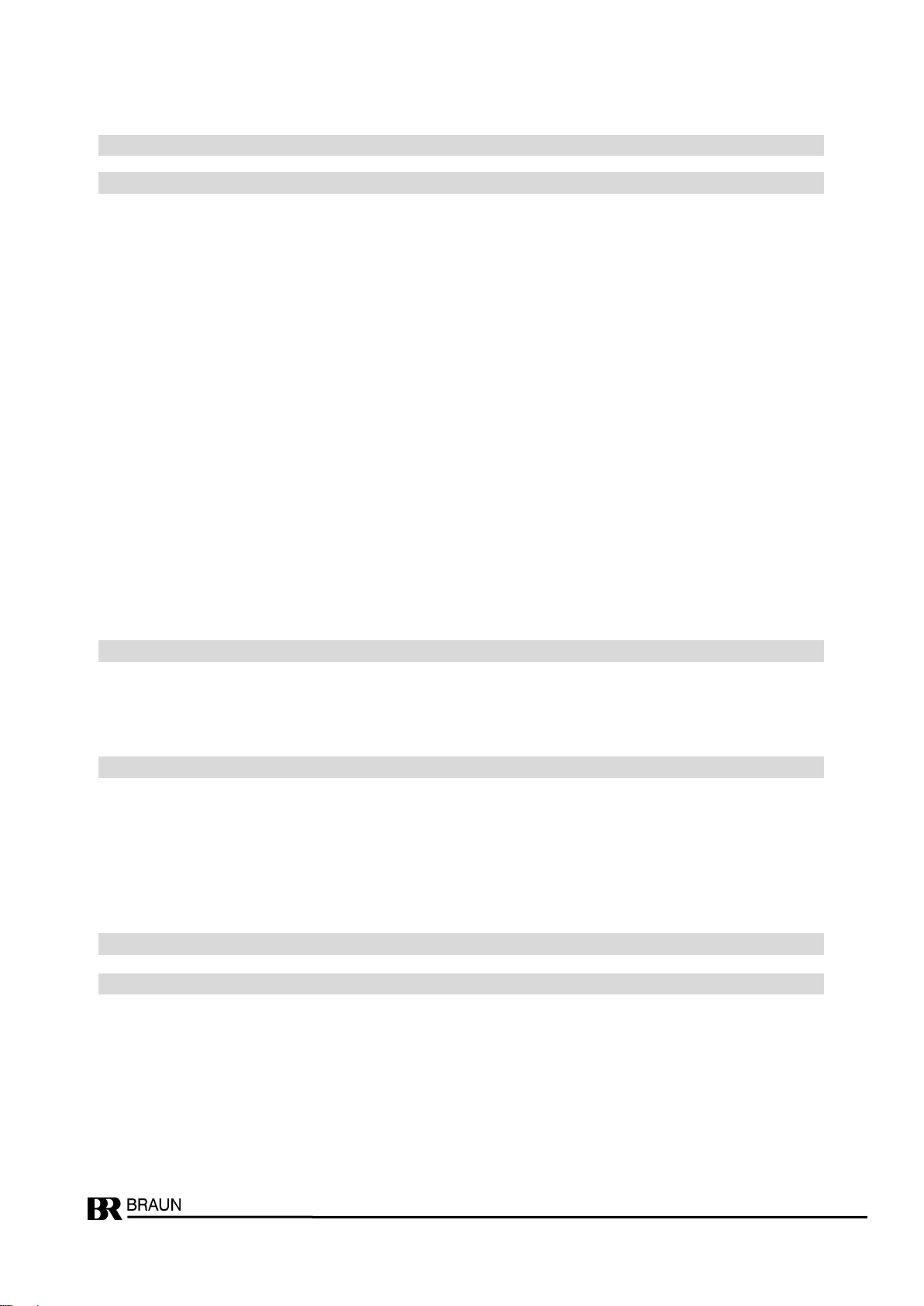

2.1.8. Position of Terminal Blocks with version E16A442 .................................................. 17

2.2. Inputs of the System ................................................................................................. 18

2.2.1. Speed Signal Inputs .................................................................................................. 18

2.2.2. Direction Signal Inputs (F/R : Forward/Reverse) ....................................................... 18

2.2.3. Input Reset of Alarms ................................................................................................ 18

2.2.4. This chapter is left blank intentionally ....................................................................... 18

2.2.5. This chapter is left blank intentionally ....................................................................... 18

2.2.6. Inputs Test I, Test II, Test III ...................................................................................... 19

2.2.7. Inputs Starter (Override of SP2) ................................................................................ 19

2.2.8. Inputs SP1B valid ...................................................................................................... 19

2.2.9. This chapter is left blank intentionally ....................................................................... 19

2.2.10. Inputs for Voter 1 ....................................................................................................... 19

2.2.11. Inputs for Voters 2 … 6 ............................................................................................. 19

2.3. Outputs of the System ............................................................................................... 20

2.3.1. Output System Warning Alarm .................................................................................. 20

2.3.2. Speed Signal Repeater Outputs................................................................................ 20

2.3.3. Outputs Monitor Warning Alarm ................................................................................ 20

2.3.4. Outputs Speed Alarm SP3 ........................................................................................ 20

2.3.5. Analog Outputs for measured speed (Option)........................................................... 21

2.3.6. Outputs Direction Detection ...................................................................................... 21

2.3.7. Speed Trip Logic Output (2oo3 voted) ...................................................................... 21

2.3.8. Output Trip-Line IV, V, VI .......................................................................................... 21

2.3.9. Outputs Trip-Line I, II, III........................................................................................... 21

2.3.10. Logic Outputs LO1 through LO6 (voted 2oo3) .......................................................... 21

2.3.11. Trip Status of Monitors ............................................................................................. 22

2.4. Power Supply ............................................................................................................ 23

2.5. Data Interface ............................................................................................................ 23

2.5.1. Profibus Interface for Status and Diagnostics of the System .................................... 23

2.5.2. RS232 Interface with Interface Software IS-RS232-E16 (for OEM only) ................... 23

2.5.3. RS232 Interface with Interface Software IS-RS232-E16-L2 (for End User) .............. 23

3. Technical Specifications ........................................................................................ 24

3.1. Technical Data of Inputs ........................................................................................... 24

3.1.1. Technical Data of Speed Signal Inputs ..................................................................... 24

3.1.1.1. Hall Sensor Inputs ..................................................................................................... 24

3.1.1.2. Eddy Current Sensor Inputs resp. MPU Inputs ......................................................... 24

3.1.2. Technical Data of Direction Inputs ............................................................................ 24

3.1.3. Technical Data of Binary Inputs (excluding Voter 1) ................................................. 24

Page 3

I E16x442 Rev: 00 Page 3 of 73

3.1.4. Technical Data of Binary Inputs of Voter 1 ................................................................ 24

3.2. Technical Data of Outputs ......................................................................................... 25

3.2.1. Technical Data of Sensor Signal Repeater Outputs .................................................. 25

3.2.2. Technical Data of Analog Outputs............................................................................. 25

3.2.3. Technical Data of Opto-Relay Outputs ...................................................................... 25

3.2.4. Technical Data of Logic Outputs ............................................................................... 25

3.2.5. Technical Data of Trip-Lines IV, V, VI ....................................................................... 26

3.2.6. Technical Data of Trip-Lines I, II, III .......................................................................... 26

3.3. Technical Data of Power Supply ............................................................................... 27

3.4. Installation Conditions ............................................................................................... 27

3.5. Protection Grade ....................................................................................................... 27

3.6. Connectors ................................................................................................................ 27

3.7. Conformity to Standards............................................................................................ 27

3.8. Dimensions of system E16A442 ............................................................................... 28

3.9. Dimensions of system E16E442 ............................................................................... 29

3.10. Dimensions and Features of E16G442 Enclosure .................................................... 30

3.11. Weight of E16x442 .................................................................................................... 30

4. Safety Notes for Installation and Operation .......................................................... 31

4.1. Safety Notes for Installation ...................................................................................... 31

4.1.1. General Instructions .................................................................................................. 31

4.1.2. EMI ............................................................................................................................ 31

4.2. Safety Notes for Operation ........................................................................................ 31

4.2.1. Safety Notes for Commissioning ............................................................................... 31

5. Description of Monitor E1665 ................................................................................. 32

5.1. Display and Frontside Operational Elements ............................................................ 32

5.1.1. Front View of Monitor E1665 ..................................................................................... 32

5.1.2. Status-LEDs .............................................................................................................. 32

5.1.3. Display during Test Procedures ................................................................................ 32

5.1.4. Values accessible during normal operation .............................................................. 33

5.1.5. Special Display Mode 1 ............................................................................................. 34

5.1.6. Special Display Mode 2 ............................................................................................. 34

5.1.7. Frontside Reset of Alarms and Event Codes ............................................................ 34

5.1.8. Data Interface ............................................................................................................ 34

5.2. Functions of Monitor 1667 ...................................................................................... 35

5.2.1. Speed Measurement ................................................................................................. 35

5.2.2. Functions for Overspeed Protection .......................................................................... 35

5.2.3. Functions for External Trip by Voters ........................................................................ 35

5.2.4. Selftest of Monitor ..................................................................................................... 35

6. Description of Test Interface E1691 ...................................................................... 36

7. Programming of the Monitors ................................................................................ 37

7.1. Programming of the Monitors via Front Keyboard ..................................................... 37

7.2. Programming of the Modules via RS232-Interface ................................................... 38

7.3. Default Values ........................................................................................................... 38

8. Parameters of Monitor E1665 ................................................................................. 39

8.1. Summary of parameters and their default values...................................................... 39

8.2. Description of Parameters and their Settings of Monitor E1665 ............................... 43

9. This chapter is left blank intentionally .................................................................. 71

10. Event codes and Troubleshooting ........................................................................ 71

10.1. Event Codes on display of E1665 ............................................................................. 71

10.2. Troubleshooting if display of Monitor reads E.0.4.x.x ............................................... 72

11. Revision notes ......................................................................................................... 73

Page 4

I E16x442 Rev: 00 Page 4 of 73

1. General Informations

1.1. List of Figures

Figure 1: E16x442 System Front View 1

Figure 2: E16x442 System Structure Diagram 1 of 2 11

Figure 3: E16x442 System Structure Diagram 2 of 2 12

Figure 4: E16x442 System Wiring Diagram 1 of 3 13

Figure 5: E16x442 System Wiring Diagram 2 of 3 14

Figure 6: E16x442 System Wiring Diagram 3 of 3 15

Figure 7: Position of terminal blocks with version E16E442 16

Figure 8: Position of terminal blocks with version E16A442 17

Figure 9: Dimensions of System E16A442 28

Figure 10: Dimensions of System E16E442 29

Figure 11: Dimensions of E16G442 Enclosure 30

Figure 12: Front view of Monitor E1665 32

Figure 13: SP1 as a variable of the acceleration 51

Page 5

I E16x442 Rev: 00 Page 5 of 73

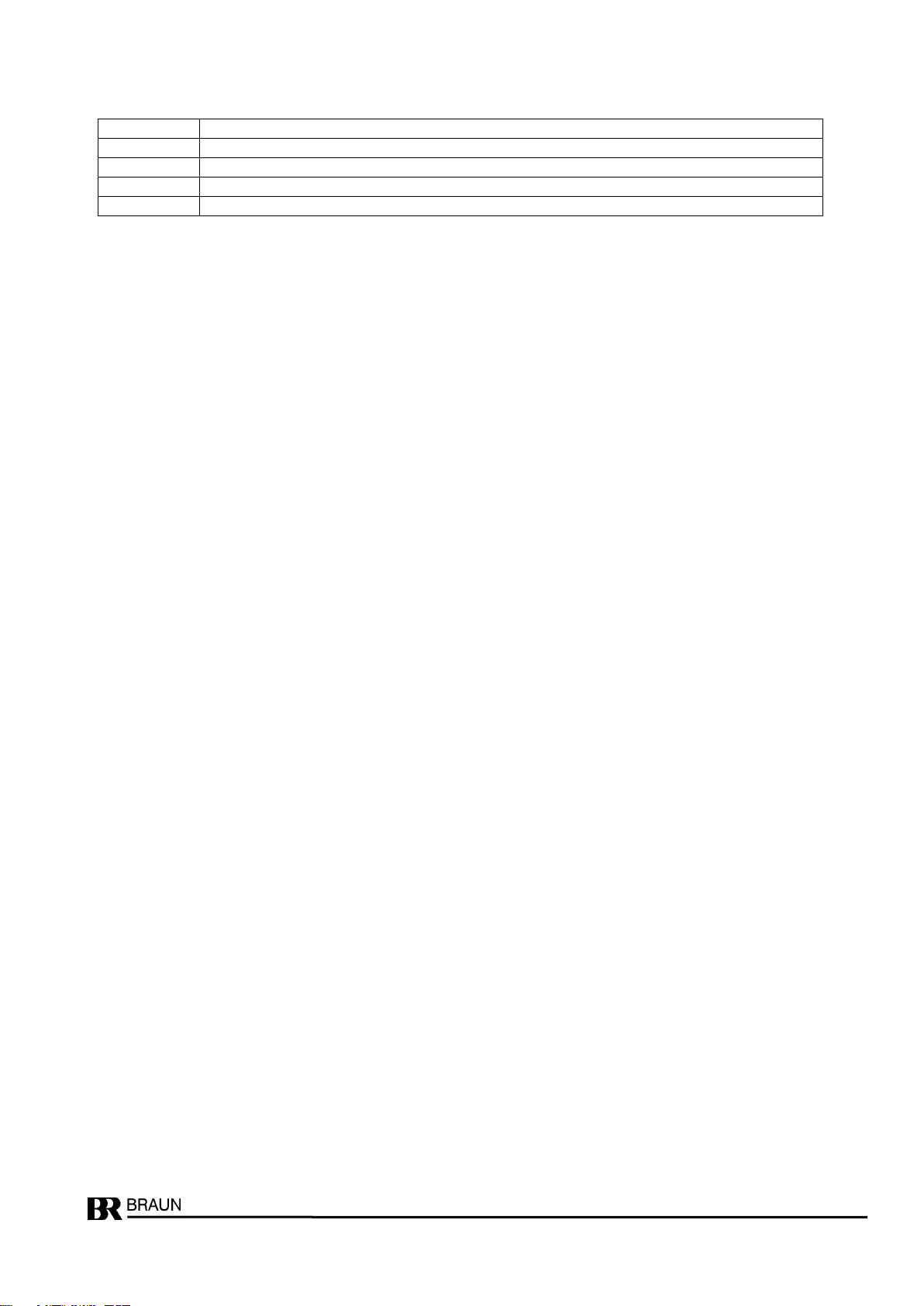

1.2. List of Abbreviations

Abbreviation

Meaning

altern.

alternative

API

Technical standards of the "American Petroleum Institute"

A5S

BRAUN GmbH Sensor series

AWG/kcmil

Code number according to the "American Wire Gauge" System

approx.

approximately

CCF

Common Cause Failure

CPU

Central Processing Unit

DCavg

Diagnostic Coverage average

DIN

Deutsches Institut für Normung (German Institute for Standardization)

dN/dt

Change of speed per time unit (Acceleration)

EEPROM

Electrically Erasable Programmable Read-Only Memory

EMV

Electro magnetic compatibility

EN

European Norm

F/R

Forward/Reverse (Forward/Backward)

HE

Height units

HFT

Hardware Failure Tolerance

IEC

International Electrotechnical Commission

incl.

inclusive

IPxx

Ingress Protection Number xx according to DIN EN 60529

ISO

International Organization for Standardization

LED

Light Emitting Diode

LOx

Logic Output x

max.

maximum

min.

minimum

MPU

Magnetic Pick Up

MTTFd

Mean Time To Failure dangerous

n

Short term for Speed

NEMAx

National Electrical Manufacturers Association Number x

PFDavg

Probability of Failure on Demand average

PELV

Protective Extra Low Voltage

RAM

Random Access Memory

RPM

Revolutions Per Minute

sec

second

SELV

Safety Extra Low Voltage

SFF

Safe Failure Fraction

SILx

Safety Integrity Level x

SPx

SetPoint x

SPVx

SetPoint Voter x

SP1var

SetPoint 1 variable

TE

Width unit

TMR

Triple Modular Redundant

Tproof

Proof Test Interval

UL/cUL

Acc. US Underwriter Laboratories resp. Canadian Underwriter Laboratories standards

Vdc

Volt direct current

Vpp

Volt peak-to-peak

resp.

respective

to be continued on next page

Page 6

I E16x442 Rev: 00 Page 6 of 73

Abbreviation

Meaning

1oo2

1 out of 2 voting logic

1oo3

1 out of 3 voting logic

2oo2

2 out of 2 voting logic

2oo3

2 out of 3 voting logic

Page 7

I E16x442 Rev: 00 Page 7 of 73

1.3. System Applications and Explanation

Protection of rotating machinery such as turbines, expanders, compressors and motors with

safety requirements SIL2/ IEC61508 and/or API 670 versus Overspeed and other Critical Conditions.

The E16x442 system incorporates one Test interface type E1691 and three Monitors (channels) A, B and C of type E1665 for the evaluation of speed signals and external trip signals.

The logic blocks for the evaluation of the external trip signals are named "Voter".

The logic results of the three channels are connected internally to form three 2oo3 trip circuits

I, II and III which are named "Trip-Lines".

The Trip-Lines can be connected to a 1oo2 or 2oo3 solenoid valve block.

A released trip status can be latched, this function is named "Trip-Lock".

Trip is released by shut down of the Trip Circuits (Trip-Lines) to the solenoid valve block if:

2oo3 monitors detect Overspeed condition

2oo3 sensor signals are detected as faulty by monitors

2oo3 monitors detect External Trip-Condition by their voters (1oo2, 2oo2, 2oo3 or 3oo3

logic selectable)

1.4. Key Features of System E16x442

Trip Release Function is SIL2/IEC61508 compliant as stand alone unit (without external

testing by DCS or by operator).

Total Response Time to Trip Condition : < 15 milliseconds

Maximum Safety at Maximum Availability by :

TMR (Triple Modular Redundancy) with three monitors E1665.

Triple speed measurement and evaluation by each monitor.

Variable overspeed setpoint depending on acceleration.

Monitoring versus Lowspeed as protection versus incorrect mounting or malfunction of

speed sensors.

Permanent monitoring of speed sensors.

Evaluation of external Trip-Condition signals by voters in each monitor. Response to sig-

nals selectable for each voter individually (logic function, low/high: trip, response time).

Each Trip Line (trip circuit) in 2oo3 technique.

Trip Lines I, II, III, IV, V, VI are formed by safety relays with force guided contact sets.

Trip-Line-Monitoring with Trip-Lock Function (selectable)

The outputs of the Trip Lines I, II and III are permanently monitored. If the Trip-Lock Func-

tion is engaged, a trip condition is detected and locked if 2oo3 trip lines are in trip condition.

By the (selectable) Trip-Lock Function a released trip is latched

Page 8

I E16x442 Rev: 00 Page 8 of 73

Additional features of the E16x442-System:

Remote test of solenoid valve block by test signals from DCS possible

Display in each module for measured values and diagnostics

Alarm outputs via opto-relays to DCS

Free extra alarm from each monitor

Up to 6 speed setpoints with 2oo3 logic outputs (if voters are not required)

Sensor signal repeater outputs, free floating and push/pull

Optional Analog Output (to represent the speed) 0/4..20 mamps for each monitor

Direction alarm (only with sensors type A5S with direction output)

Parameters may be set by front keys (protected by code-digit) or by

RS232-Interface (password protected)

1.5. Ordering Key for Systems E16x442.abc

E16x442.abc

c = 1 : Speed Signal Inputs and power supply for A5S sensors

c = 2 : Speed Signal Inputs and power supply for Eddy Current Sensors

c = 3 : Speed Signal Inputs for MPU (magnetic pick up)

b = 1 : 1 Voter in each Monitor for external trip release condition

b = 2 : 6 Voters in each Monitor for external trip release conditions

a = 0 : without Analog Output (to represent the speed)

a = 1 : 1 Analog Output in each Monitor A, B, C

a = 2 : 1 Analog Output rated SIL2 in each Monitor A, B, C

x = A : Surface Mount Version

x = E : 19-Inch Rack File

x = G : Nema 4 Version with front window (surface mount)

Example:

E16A442.021 : Surface Mount Version, without Analog Output, with 6 Voters,

Speed Signal Inputs for A5S sensors

E16A442.112 : Surface Mount Version, with Analog Output, with 1 Voter,

Speed Signal Inputs for eddy current sensors or MPU

E16A442.013 : Surface Mount Version, with 1 Voter,

Speed Signal Inputs for MPU

Page 9

I E16x442 Rev: 00 Page 9 of 73

1.6. Safety Data

1.6.1. Safety Data IEC61508; SIL2

System Type B; HFT = 1; Architecture 2oo3, Service Time 20 years

PFDavg = 1,81*10

-4

at T1 (Proof Check Interval) = 20 years

1.7. External Tests

1.7.1. External tests during normal operation by PLC or operator

The trip release ability of a 2oo3 solenoid valve block can be verified by external.

1.7.2. Test of 2oo3 solenoid valve block

Test can only be performed if the Monitors are not in trip status.

The test is performed for each trip-line separately by control signals Test of

Trip-Line I, II, III. The response of the 2oo3 solenoid valve block must be checked by the PLC

resp. the operator.

Note:

Test of two or three trip-lines at the same time will release trip of the machine.

Page 10

I E16x442 Rev: 00 Page 10 of 73

2. System Structure and I/Os

2.1. System Structure

The structure of the system is shown in chapter 2.1.4. (figures 2 and 3).

The wiring of the system is shown in chapter 2.1.5. (figures 4, 5 and 6).

The indexes ”see 2.x.x” in these figures refer to the corresponding chapters 2.x.x. which describe the according functions.

2.1.1. Speed Sensors

With versions E16x442.xx1:

Three A5S Differential-Hall-effect sensors, with integrated signal amplifier are placed at the

machine shaft.

The Differential Hall-effect sensors A5S are not susceptible to uniform external magnetic

fields. Air gap variations between machine and sensor do not create false signals.

With versions E16x442.xx2:

Three Speed signals from Eddy Current Sensors or from MPUs are evaluated.

With versions E16x442.xx3:

Three Speed signals from MPU Sensors are evaluated.

2.1.2. System Components

The system comprises three Monitors E1665 for speed monitoring and for monitoring of the

external trip conditions and one Test Interface E1691 to process the trip-line test signals and

the trip status signals between Monitors and the PLC.

The Monitors and the Test Interface are connected via a backplane. The backplane does not

hold any active components.

2.1.3. System Design

The system is available as

19-Inch Rack File, 3HE 84TE (E16E442) or

for surface mounting (E16A442) or

as NEMA4 version (E16G442).

Page 11

I E16x442 Rev: 00 Page 11 of 73

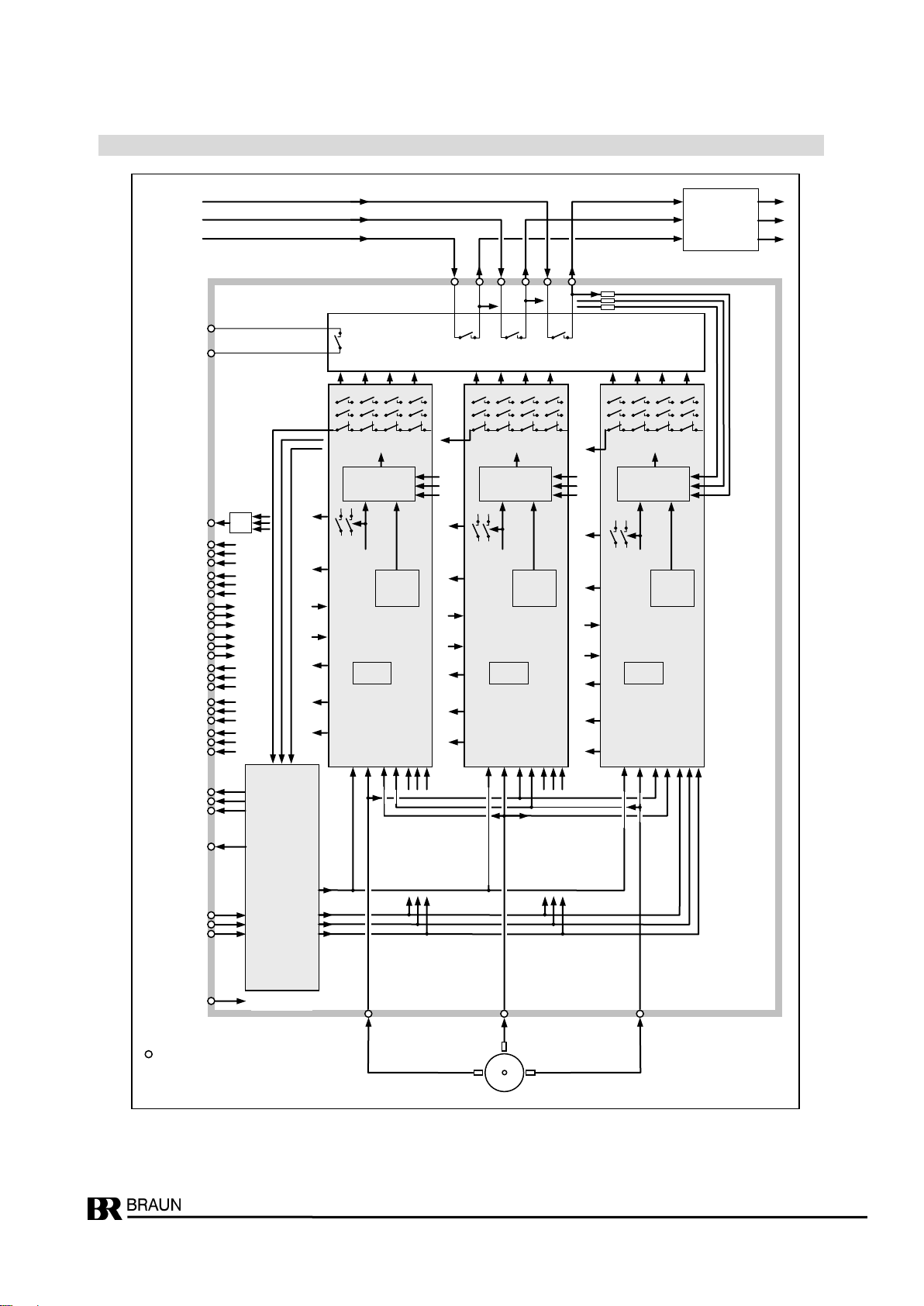

2.1.4. System Structure Diagrams

Speed Signals

see 2.2.1

Direction Signals

see 2.2.2

= terminal blocks

Speed-Trip

Logic Output

in 2oo3

see 2.3.7

Test I

Test II

Test IIII

see 2.2.6

Sensor Signal

Repeater

see 2.3.2

Alarm Reset

see 2.2.3

System

Warning Alram

see 2.3.1

Input

SP1B valid

see 2.2.8

Warning Alarm

of Monitor

see 2.3.3

Alarm SP3

see 2.3.4

Starter

Override of SP2

see 2.2.7

Direction

Alarm Output

see 2.3.6

optional

Analog Output

0/4 … 20 mamps

see 2.3.5

Trip IV

Trip V

Trip VI

in 2oo3

(only 1 of 3 trip

lines shown)

see 2.3.8

2oo3

Trip-Line III

Trip-Line II

Trip-Line I

L+

L+

L+

Trip-Line III

Trip-Line II

Trip-Line I

Trip Lines

see 2.3.9

I

II

III

Wiring of Trip Relay contacts on

System-Backplane forming six 2oo3 Trip Lines

fT

F/R

fB

F/R

fC

B

A

C

Pole Wheel

Sensor

to all modules

Test I

Test II

Test III

E1691

Testinterface

Test

Frequency fT

F/R

fC

Test III

F/R

fB

F/R

fA

fT

Test II

Test I

E1665

Monitor A

Feedback A

Feedback B

Feedback C

SP1B

Starter

I

II

III

IV

Trip- Relays

I

II

III

I

II

III

IV

Trip- Relays

I

II

III

IV

Trip- Relays

I

II

III

E1665

Monitor B

E1665

Monitor C

SP1B

SP1B

Starter

Starter

F/R

fC

Test III

F/R

fA

F/R

fB

fT

Test II

Test I

F/R

fB

Test III

F/R

fA

F/R

fC

fT

Test II

Test I

F/R

fA

Rev. 00 / 02.2012

spark extinguishing

DataInterface

DataInterface

DataInterface

Speed-

Trip

Trip by

Voter

(from

Diagram 2)

Monitoring

of Trip Lines with Trip-

Lock

Speed-

Trip

Trip by

Voter

(from

Diagram 2)

Monitoring

of Trip Lines with Trip-

Lock

Speed-

Trip

Trip by

Voter

(from

Diagram 2)

Monitoring

of Trip Lines with Trip-

Lock

V

V

V

A

B

C

A

B

C

A

B

C

A

B

C

A

B

C

A

B

C

to

PLC

2oo3

Solenoid

Valve Block

Trip-Status

of Monitors

see 2.3.11

Figure 2: E16x442 System Structure Diagram 1 of 2

Page 12

I E16x442 Rev: 00 Page 12 of 73

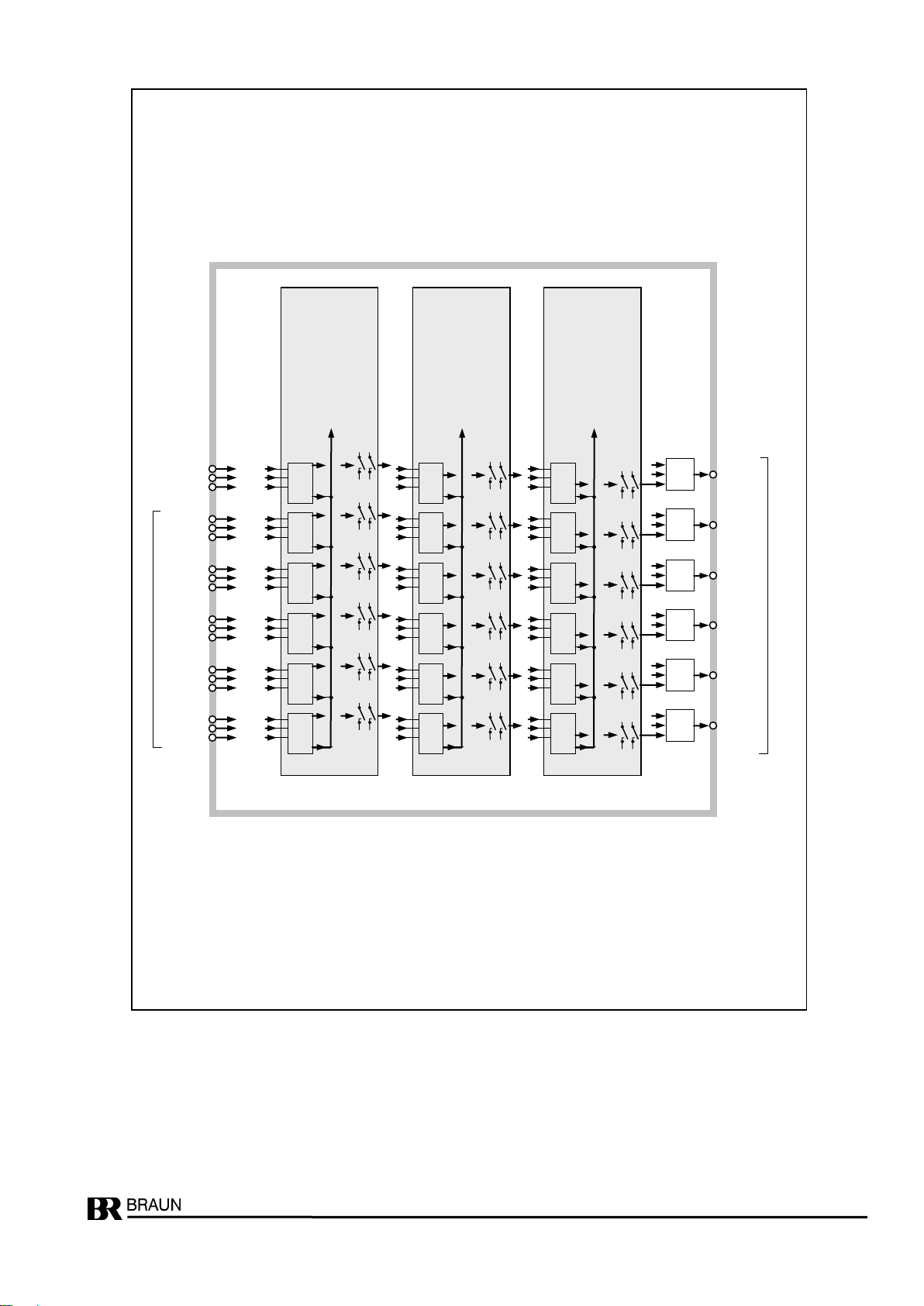

Input Signals

Voter 1

see 2.2.10

Trip by Voter

(to Diagram 1)

Part of

Monitor A

Part of

Monitor B

Part of

Monitor C

Trip by Voter

(to Diagram 1)

Trip by Voter

(to Diagram 1)

Input

Signals

Voter 2

Input

Signals

Voter 3

Input

Signals

Voter 4

Input

Signals

Voter 5

Input

Signals

Voter 6

Input Signals for Voters 2 … 6 . see 2.2.11

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

SoftwareVoter

1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2

3

Logic Outputs to DCS

If used as Output "Trip of Voter" : low = Trip

If used as Speed Alarm Output : low / high at 'n > SPV' selectable

see 2.3.10

2oo3

LO1

Trip

Voter 1

altern.

n > SPV1

2oo3

LO2

Trip

Voter 2

altern.

n > SPV2

2oo3

LO3

Trip

Voter 3

altern.

n > SPV3

2oo3

LO4

Trip

Voter 4

altern.

n > SPV4

2oo3

LO5

Trip

Voter 5

altern.

n > SPV5

2oo3

LO6

Trip

Voter 6

altern.

n > SPV6

Rev. 00 / 02.2012

Figure 3: E16x442 System Structure Diagram 2 of 2

Page 13

I E16x442 Rev: 00 Page 13 of 73

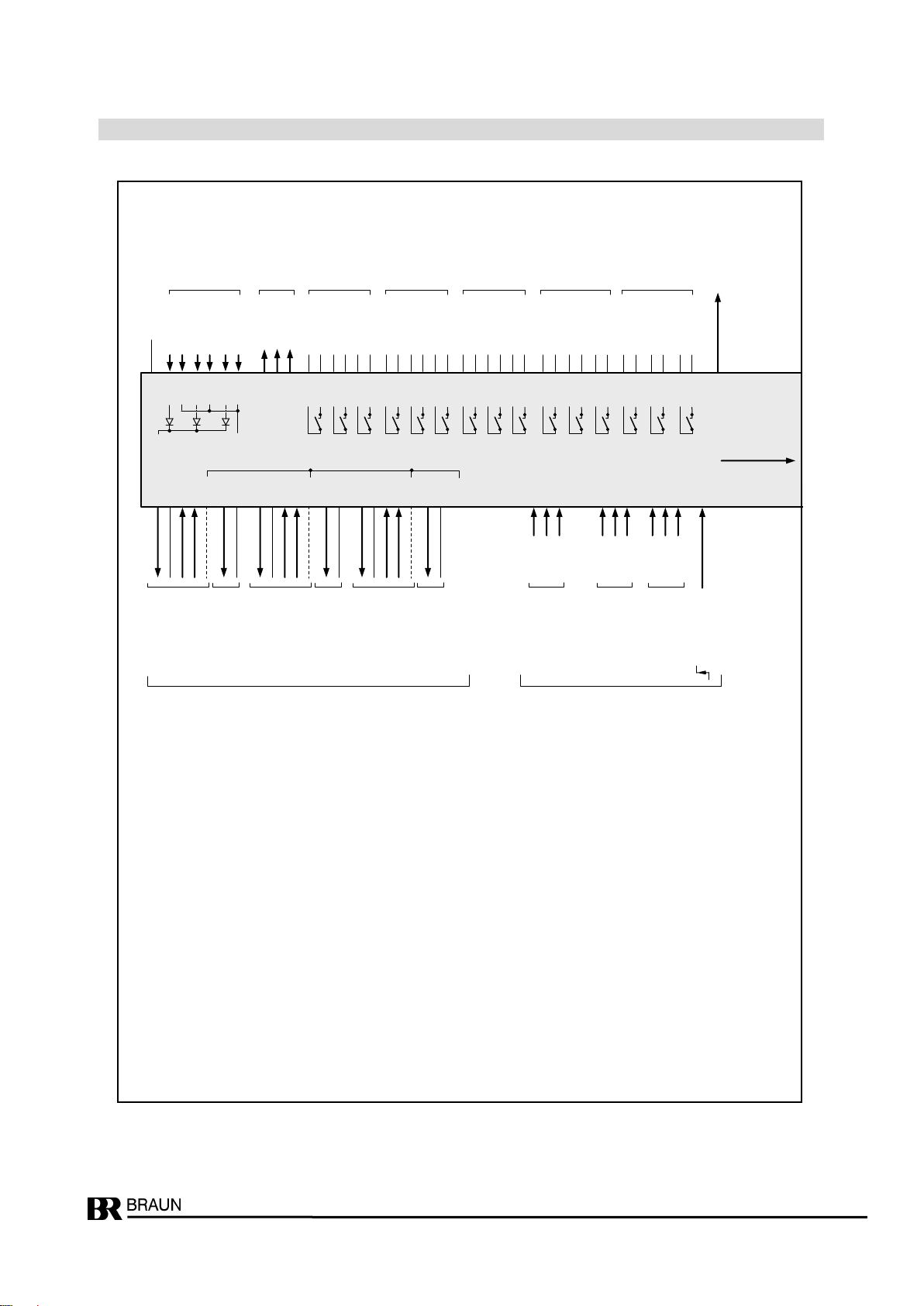

2.1.5. System Wiring Diagrams

all contacts are shown

in de-energized status

Outputs

Trip Line

I, II, III

see 2.3.9

Trip III

Trip I

Trip II

Outputs

Trip Line

IV, V, VI

see 2.3.8

Outputs

Direction Alarm

from monitor

see 2.3.6

Outputs

Speed Alarm SP3

from monitor

see 2.3.4

Outputs

Monitor

Warning Alarm

from monitor

see 2.3.3

Power Supply

24 volts dc

see 2.4 Monitor C Monitor A Monitor B Monitor C Monitor A Monitor B Monitor C Monitor A Monitor B

Monitor C

Monitor A

Monitor B

Speed Signals see 2.2.1

Direction Signals F/R see 2.2.2

Speed Sensor Signal Repeater Outputs see 2.3.3

Connection of sensors see next pages

Monitor A

Monitor B

Monitor C

high = Starter

(override SP2)

see 2.2.7 high =Test of

Trip-Line

see 2.2.6

Trip-Line I

Monitor C

Monitor A

Monitor B

Trip-Line II

Trip-Line III high =SP1B valid

see 2.2.8

= Reset of Alarms

see 2.2.3

PE

see 2.5

L+ N L+ N L+

N

Rev. 02 / 06.2013

Logic Signal Inputs

(Reference:

terminals 3.X1, 9.X1, 3.X15 of Power Supply)

1.X1_

2.X1_

3.X1_

8.X1_

9.X1_

14.X1_

15.X1_

4.X1_

5.X1_

10.X1_

11.X1_

16.X1_

17.X1_

6.X1_

7.X1_

12.X1_

13.X1_

18.X1_

19.X1_

2.X14

1.X14

10.X2_

14

9.X2_

8.X2_

14

7.X2_

6.X2_

14

5.X2_

11.X2_

14

12.X2_

14

13.X2_

14

14.X2_

14

15.X2_

14

16.X2_

14

1.X7

2.X7

3.X7

5.X7

6.X7

6.X9

6.X14

5.X9

4.X8

4.X7

Reference

Speed

Screen

F / R *

Speed

0 V

+ Supply

Sensor connections

Monitor A * = only with

sensors A5S3….

Speed Signal

Repeater Output Monitor A

1.X3

2.X3

3.X3

5.X3

4.X3

6.X3

7.X3

E16-System

Diagram 2

4.X14

3.X14

8.X14

7.X14

Trip VI

Trip IV

Trip V

Reference

Speed

Screen

F / R *

Speed

0 V

+ Supply

Sensor connections

Monitor B * = only with

sensors A5S3….

Speed Signal

Repeater Output Monitor B

1.X4

2.X4

3.X4

5.X4

4.X4

6.X4

7.X4

Reference

Speed

Screen

F / R *

Speed

0 V

+ Supply

Sensor connections

Monitor C * = only with

sensors A5S3….

Speed Signal

Repeater Output Monitor C

1.X5

2.X5

3.X5

5.X5

4.X5

6.X5

7.X5

20.X1

Output

System Alarm

see 2.3.1

Outputs

Monitor

Trip-Status

see 2.3.11

Monitor A

Monitor B

Monitor C

1.X2_

2.X2_

3.X2_

L+

E1691

N

E1691

1N

5060

4.X2_

Figure 4: E16x442 System Wiring Diagram 1 of 3

Page 14

I E16x442 Rev: 00 Page 14 of 73

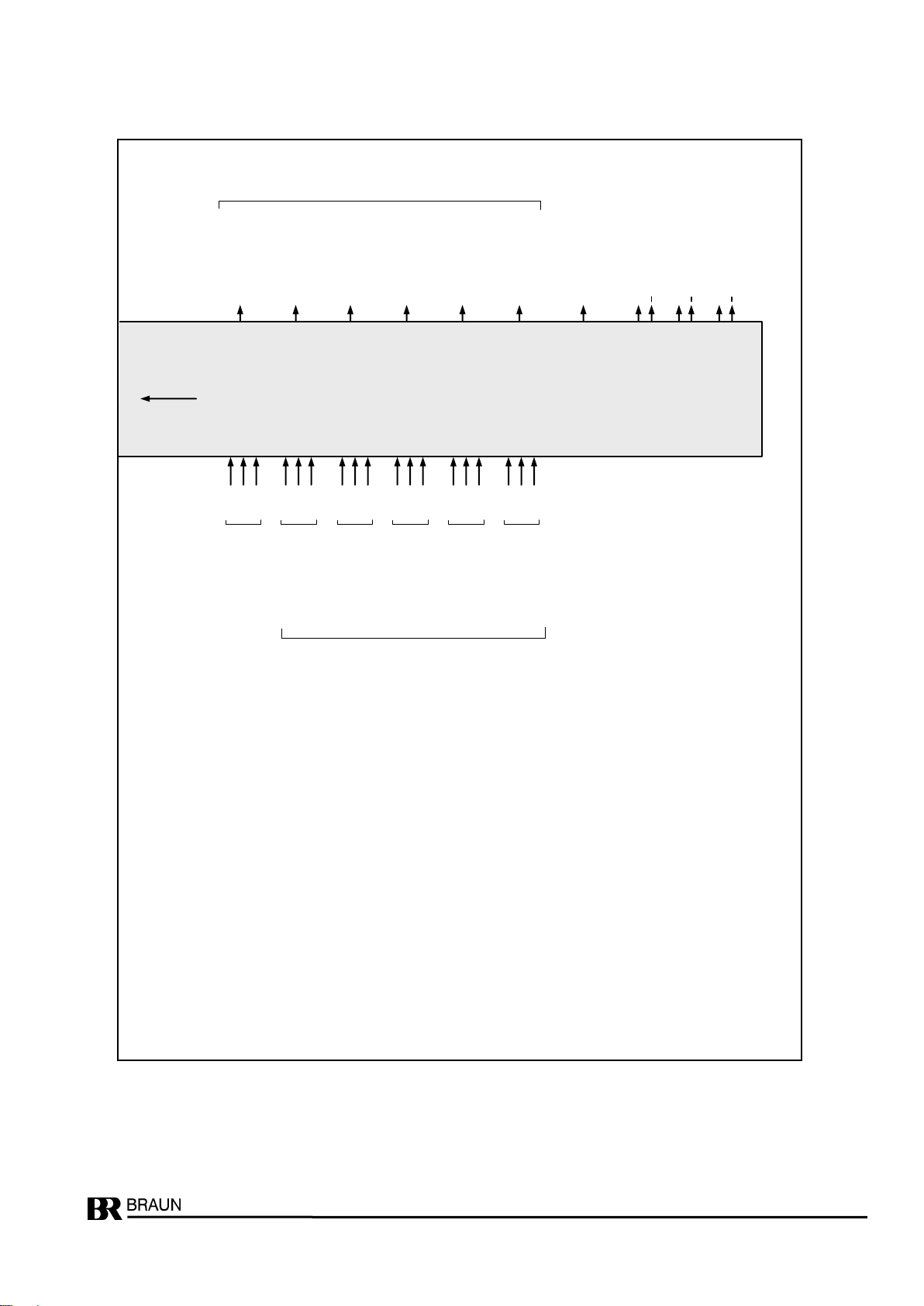

optional

Analog Outputs

0/4 … 20 mamps

see 2.3.5

(not with versions E16x442.0xx)

Logic Outputs

see 2.3.10

Signal Inputs

Voter 2 through 6

only with systems E16x442.x21

see 2.2.11

Signal Inputs

of Voter 1

see 2.2.10

Signal Inputs

of Voter 2

Signal Inputs

of Voter 3

Signal Inputs

of Voter 4

Signal Inputs

of Voter 5

Signal Inputs

of Voter 6

Speed Trip

Logic Output

see 2.3.7

Monitor A

Monitor B

Monitor C

Trip Voter 6

alternative

n > SP6

LO6

Trip Voter 5

alternative

n > SP5

LO5

Trip Voter 4

alternative

n > SP4

LO4

Trip Voter 3

alternative

n > SP3

LO3

Trip Voter 2

alternative

n > SP2

LO2

Trip Voter 1

alternative

n > SP1

LO1

Rev. 00 / 09.2012

1.X13

2.X13

3.X13

4.X13

5.X13

6.X13

5.X14

1.X15

2.X15

3.X15

4.X15

5.X15

6.X15

+ + +

4.X12

5.X12

6.X12

I

II

III

1.X12

2.X12

3.X12

I

II

III

4.X11

5.X11

6.X11

I

II

III

1.X11

2.X11

3.X11

I

II

III

4.X10

5.X10

6.X10

I

II

III

1.X10

2.X10

3.X10

I

II

III

E16-System

Diagram 1

Figure 5: E16x442 System Wiring Diagram 2 of 3

Page 15

I E16x442 Rev: 00 Page 15 of 73

- 24 volts dc

+ 24 volts dc

+ Sensor Supply

+ Sensor Supply

Alarm

2.1.6. Connection of Sensors to the Speed Signal Inputs

Rev. 00 / 09.2012

B

Terminals

Monitor

C A B

Eddy Current Sensor

with negative

power supply

1.X3

1.X4

1.X5

3.X3

3.X4

3.X5

2.X3

2.X4

2.X5

Reference 0 volts

Speed Signal

EC-

4.X3

4.X4

4.X5

Eddy Current Sensor

with positive

power supply

1.X3

1.X4

1.X5

3.X3

3.X4

3.X5

2.X3

2.X4

2.X5

Reference 0 volts

Speed Signal

EC+

4.X3

4.X4

4.X5

Reference 0 volts

Speed Signal

Direction – Signal *

C

A5S..

B A D S 1 3 4

2*

1.X3

1.X4

1.X5

2.X3

2.X4

2.X5

3.X3

3.X4

3.X5

5.X3

5.X4

5.X5

4.X3

4.X4

4.X5

brown

green

white

yellow or red

Cable screen must be connected to screen bar !

Marks for BRAUN cable leads. Mark D only with sensors equipped with direction detection

Lead colors of BRAUN cables

Pin Nos. of BRAUN Sensors A5S...

Reference 0 volts

Speed Signal

Direction – Signal **

C

A5S1..

+

D461

B A D S 1 3 4

2*

1.X3

1.X4

1.X5

2.X3

2.X4

2.X5

3.X3

3.X4

3.X5

5.X3

5.X4

5.X5

4.X3

4.X4

4.X5

L+ N

24 volts dc

13

10

11

23

25

24 8 6 2 1

D461.11U1

D461.21U1

12**

22 **

** only with D461.21 and

sensors with direction

brown

green

white

yellow or red

* only with sensors equipped with direction detection

Magnetic Pick-Up

3.X3

3.X4

3.X5

2.X3

2.X4

2.X5

Reference 0 volts

Speed Signal

MPU

4.X3

4.X4

4.X5

Figure 6: E16x442 System Wiring Diagram 3 of 3

Page 16

I E16x442 Rev: 00 Page 16 of 73

2.1.7. Position of Terminal Blocks with Version E16E442

Figure 7: Position of terminal blocks with version E16E442

Page 17

I E16x442 Rev: 00 Page 17 of 73

2.1.8. Position of Terminal Blocks with version E16A442

Figure 8: Position of terminal blocks with version E16A442

(shown is version E16A446)

Page 18

I E16x442 Rev: 00 Page 18 of 73

2.2. Inputs of the System

2.2.1. Speed Signal Inputs

The speed signals are internally wired to all three Monitors in parallel.

With versions E16x442.xx1:

The speed signal inputs match the values of sensors A5S…

The speed signal inputs are rated SIL2/IEC61508 if sensors of type A5S. (also via barriers

D461) are connected. For other sensors this is only valid, if the sensor supplier guarantees,

that the sensors will not give erratic speed signals due to a common cause failure. The instructions of the sensor supplier must be observed.

Technical Data of inputs see 3.1.1.1.

With versions E16x442.xx2:

The signal inputs match the values of eddy current sensors respective of MPUs.

The speed signal inputs are rated SIL2/IEC61508, if the sensor supplier guarantees, that the

sensors will not give erratic speed signals due to a common cause failure. The instructions of

the sensor supplier must be observed.

Technical Data of inputs see 3.1.1.2.

With versions E16x442.xx3:

The signal inputs match the values of MPUs.

The speed signal inputs are rated SIL2/IEC61508, if the sensor supplier guarantees, that the

sensors will not give erratic speed signals due to a common cause failure. The instructions of

the sensor supplier must be observed.

Technical Data of inputs see 3.1.1.2.

2.2.2. Direction Signal Inputs (F/R : Forward/Reverse)

The direction signal inputs match the values of the sensors A5S with direction signal.

The direction signals are internally wired to all three monitors in parallel.

The direction signal inputs are rated SIL2/IEC61508 (valid only for sensors A5S3..).

Technical Data of inputs see 3.1.2.

2.2.3. Input Reset of Alarms

The Reset signal is internally connected to all modules in parallel. It resets a no longer prevailing, but latched alarm or trip condition.

A signal transition from low to high will reset a latched alarm.

Minimum Time of Reset Signal: > 1 second to ensure correct reset of all modules.

The input “Reset of Alarms” is rated SIL2/IEC61508 provided that the signal source is rated

SIL2/IEC61508.

Technical Data of input see 3.1.3.

2.2.4. This chapter is left blank intentionally

2.2.5. This chapter is left blank intentionally

Page 19

I E16x442 Rev: 00 Page 19 of 73

2.2.6. Inputs Test I, Test II, Test III

If the input is high, the corresponding Trip-Line will switch to trip condition.

The inputs are not inhibited versus each other.

The input “Test I, II, III” are rated SIL2/IEC61508 provided that the signal source is rated

SIL2/IEC61508.

Technical Data of inputs see 3.1.3.

2.2.7. Inputs Starter (Override of SP2)

Each monitor has one input for the starter condition. As long as the input is high, the starter

condition is true.

During starter condition the monitoring versus Lowspeed (SP2) is disabled.

The inputs “Starter” are rated SIL2/IEC61508 provided that the signal source is rated

SIL2/IEC61508.

Technical Data of inputs see 3.1.3.

2.2.8. Inputs SP1B valid

Each monitor has one input to select SP1B as trip setpoint.

As long as the input is high, setpoint value SP1B (see step P03.03 of E1665) is true.

With open input (low), setpoint value SP1A (see P03.00 of E1665) is true. The inputs “SP!B

valid” are rated SIL2/IEC61508 provided that the signal source is rated SIL2/IEC61508.

Technical Data of inputs see 3.1.3.

2.2.9. This chapter is left blank intentionally

2.2.10. Inputs for Voter 1

The input signals for Voter 1 are internally connected to all monitors in parallel.

The input load of Voter 1 meets the requirements for the redundant outputs of a failsafe PLC

(load > 45 ma per input).

The signal truth level (high or low as trip condition), the voting principle (1oo2, 2oo2, 2oo3,

3oo3) and the response time is selectable. Configuration of the voter is done in steps P10.xx

of E1665.

The inputs “Voter 1” are rated SIL2/IEC61508 provided that the signal source is rated

SIL2/IEC61508.

Technical Data of inputs for Voter 1 see 3.1.4.

2.2.11. Inputs for Voters 2 … 6

The input signals for Voters 2 … 6 are internally connected to all monitors in parallel.

The signal truth level (high or low : trip condition), the voting principle (1oo2, 2oo2, 2oo3,

3oo3) and the response time is selectable for each voter individually. Configuration of voters is

done in steps P11.xx to P15.xx of E1665.

Technical Data of inputs for Voter 2 … 6 see 3.1.3.

The inputs “Voter 2…6” are rated SIL2/IEC61508 provided that the signal source is rated

SIL2/IEC61508.

Technical Data of inputs for Voter 2 … 6 see 3.1.3.

Note:

Systems E16x442.x1x do not have inputs for Voters 2 … 6 .

Page 20

I E16x442 Rev: 00 Page 20 of 73

2.3. Outputs of the System

2.3.1. Output System Warning Alarm

Output System Warning Alarm is released if

minimum one Monitor signalizes a nonconformity at its voter inputs

minimum one Monitor is faulty

minimum one Monitor is in trip status

Note:

The System Warning Alarm has a delay of approx. 10 seconds versus the releasing monitor.

Technical Data of output see 3.2.4

The output “System Warning Alarm” is rated SIL2/IEC61508.

Technical Data of output see 3.2.4.

2.3.2. Speed Signal Repeater Outputs

Each Monitor repeats the speed signal of its main sensor (Monitor A repeats sensor signal A)

to the periphery.

The Speed Signal Repeater Outputs are rated SIL2/IEC61508.

Technical Data of outputs see 3.2.1.

2.3.3. Outputs Monitor Warning Alarm

The Monitor Warning Alarm (for each Monitor individually) is released if at least one of the following conditions is true:

Monitor releases trip (due to overspeed resp. voter), if selected

Selection in step P02.11 of E1665

Deviation of its own sensors versus both sensors of neighbor Monitors, if monitored

Selection in steps P02.07 through P02.09 of E1665

Measured speed lower than SP2 (after starter condition), if monitored

Selection in step P02.06 of E1665

Sensor Circuit Fault, if monitored

Selections in steps P02.04 and P02.05 of E1665

If starter condition is still true and speed exceeds 50% of nominal speed (as set in step

P01.03), if selected in step P02.06

Note:

The Monitor Warning Alarm is not released, if the Monitor detects a nonconformity at its voter

inputs. This status is forwarded to the Test Interface E1691 which then releases the System

Warning Alarm.

The outputs “Monitor Warning Alarm” are rated SIL2/IEC61508.

Technical Data of outputs see 3.2.3.

2.3.4. Outputs Speed Alarm SP3

Each Monitor has a free adjustable speed alarm output SP3.

Configuration of SP3 in steps P05.xx of E1665.

The outputs “Speed Alarm SP3” are rated SIL2/IEC61508.

Technical Data of outputs see 3.2.3.

Page 21

I E16x442 Rev: 00 Page 21 of 73

2.3.5. Analog Outputs for measured speed (Option)

The (optional) analog outputs have a range of 0/4 .. 20 mamps.

Configuration of the analog output in steps P08.xx of E1665.

The analog outputs of versions E16x442.1xx are rated SIL2/IEC61508.

The analog outputs of Monitors E16x442.2xx are rated SIL2/IEC61508.

Technical Data of outputs see 3.2.2.

2.3.6. Outputs Direction Detection

If operated with sensors A5S with incorporated direction signal output, the sense of direction is

signalized.

Each Monitor votes the direction input signals 2oo3. Each Monitor has a direction alarm output.

The outputs “Direction Detection” are rated SIL2/IEC61508.

Technical Data of outputs see 3.2.3.

2.3.7. Speed Trip Logic Output (2oo3 voted)

Speed Trip Logic Output is released, if minimum 2 of the 3 monitors detect overspeed condition. If overspeed status is latched, the alarm will persist until reset.

Output high: no speed trip

Output low: speed trip

The Speed Trip Logic Output is rated SIL2/IEC61508.

Technical Data of output see 3.2.4.

2.3.8. Output Trip-Line IV, V, VI

The Trip-Lines IV, V, VI are 2oo3-circuits formed by contacts of safety trip relays IV and V of

Monitors A,B,C.

Trip is released if minimum two Monitors E1665 are in trip status.

Trip-Lines IV, V, VI are intended to signalize the trip to a DCS or PLC.

Trip-Lines IV, V, VI are rated SIL2/IEC61508.

Technical Data of output see 3.2.5.

2.3.9. Outputs Trip-Line I, II, III

The Trip-Lines I, II, III are 2oo3-circuits formed by the contacts of safety trip relays I resp. II,

resp. III of Monitors A,B,C.

Trip is released if minimum two monitors E1665 are in trip status.

Trip-Lines I, II, III are intended to supply shutdown solenoid valves.

Trip-Lines I, II, III are rated SIL2/IEC61508.

Technical Data of output see 3.2.6.

2.3.10. Logic Outputs LO1 through LO6 (voted 2oo3)

The logic outputs LO may be assigned to signalize a voter trip or to a speed setpoint.

If assigned to Voter Trip: Output high: no trip of Voter

Output low: trip of Voter

If assigned to speed alarm: Output high/low if n > SP is selectable.

The Logic Outputs LO1 through LO6 are rated SIL2/IEC61508.

Technical Data of outputs see 3.2.4.

Page 22

I E16x442 Rev: 00 Page 22 of 73

2.3.11. Trip Status of Monitors

Each Monitor reflects its trip status via the Test Interface as a logic signal to the periphery.

Output high: no trip

Output low: trip

Note:

The outputs have a delay of approx. 10 seconds versus the trip of the monitor.

The Outputs "Trip Status of Monitor" are rated SIL2/IEC61508.

Technical Data of output see 3.2.4

Page 23

I E16x442 Rev: 00 Page 23 of 73

2.4. Power Supply

Each Monitor must be supplied with 24 volts dc (18..40 volts) from a power supply with protective separation, conforming to IEC 61131-2 requirements.

The Test Interface E1691 is fed by an internal power rail.

Technical Data see 3.3.

2.5. Data Interface

Each of the Monitors E1665 carry a 9pole Sub-D-connector ( female). Implemented on this

connector are a Profibus-Interface (with standard-pinning) and a RS232-Interface (non standard pinning).

2.5.1. Profibus Interface for Status and Diagnostics of the System

The Profibus Interface reflects the standard Profibus DP and serves for the upload of status

and diagnostics of the system to a PLC or DCS.

2.5.2. RS232 Interface with Interface Software IS-RS232-E16 (for OEM only)

The RS232 Interface in conjunction with the Interface-Software IS-RS232-E16 (available for

OEM only) serves

to edit parameters

to configure parameter settings as *.brp files

to upload parameter settings from Monitors as *.brv files

to download parameter settings from *.brp or *.brv files to the Monitors

2.5.3. RS232 Interface with Interface Software IS-RS232-E16-L2 (for End User)

The RS232 Interface in conjunction with the Interface-Software IS-RS232-E16-L2 (available for

End Users) serves

to upload parameter settings from Monitors as *.brv files

to download parameter settings from *.brv files to spare part Monitors

Note: Parameter settings cannot be changed.

Page 24

I E16x442 Rev: 00 Page 24 of 73

3. Technical Specifications

3.1. Technical Data of Inputs

3.1.1. Technical Data of Speed Signal Inputs

3.1.1.1. Hall Sensor Inputs

Maximum Input Frequency : 50 kHz

Maximum Signal Voltage : 30 volts

Input low at : < 3 volts

Input high at : > 7 volts

Impedance : approx. 5 kohms

Sensor Supply : approx. 13 volts, maximum 80 mamps

The sensor inputs have the same common, but are free floating versus other potentials.

They are powered by an internal power supply.

3.1.1.2. Eddy Current Sensor Inputs resp. MPU Inputs

Maximum Input Frequency : 30 kHz

Maximum Signal Voltage : 30 volts

Trigger Hysteresis : 0.07 to 2.5 Vpp

Impedance : approx. 47 kohms

Sensor Supply: (only with versions E16x442.xx2): approx. 24 volts, maximum 120 mamps

Inputs are free floating.

The sensor inputs have the same common, but are free floating versus other potentials.

They are powered by an internal power supply.

3.1.2. Technical Data of Direction Inputs

Maximum Signal Voltage : 30 volts

Input low at : < 3 volts

Input high at : > 7 volts

Impedance : approx. 22 kohms

Same Reference as Speed Signal Inputs.

3.1.3. Technical Data of Binary Inputs (excluding Voter 1)

Input high : 18..48 volts (nominal current at 24 volts: 6 mamps)

Input low : < 3 volts or open input

Reference : negative pole of power supply

3.1.4. Technical Data of Binary Inputs of Voter 1

Input high : 18..30 volts (nominal current at 24 volts: 45 mamps)

Input low : < 3 volts or open input

Reference : negative pole of power supply

Page 25

I E16x442 Rev: 00 Page 25 of 73

3.2. Technical Data of Outputs

3.2.1. Technical Data of Sensor Signal Repeater Outputs

High-Level : > 20 volts with max. load, (maximum 26 volts without load)

Low-Level : < 2 volts, with max. load

Maximum load: 1 kohms

Outputs are short-circuit proof and free floating (also versus each other).

Outputs are supplied by free floating power sources within the monitors.

3.2.2. Technical Data of Analog Outputs

Range : 0/4…20 mamps

Resolution : 12 Bit

Maximum load : 500 ohms

Linearity error : < 0.1%

Temperature stability : ±0,02 %/°C within a range of 0...60°C.

Outputs are short-circuit proof and free floating (also versus each other).

3.2.3. Technical Data of Opto-Relay Outputs

Maximum rating : 50 volts dc / 50 mamps.

Outputs are passive, short-circuit proof and free floating (also versus each other). They must

be supplied externally.

Note:

In case of short circuit the output is latched to tristate until power supply of the monitor has

been switched off and on.

3.2.4. Technical Data of Logic Outputs

The outputs are fed from the system power supply.

Reference : N (negative pole of power supply).

High-Level : Power supply L+ minus 2 volts

Low-Level : < 3 volts

Maximum output current : 50 milliamps

Outputs are short-circuit proof.

Note:

In case of short circuit the output is latched to tri state until power supply of the monitor has

been switched off and on.

Page 26

I E16x442 Rev: 00 Page 26 of 73

3.2.5. Technical Data of Trip-Lines IV, V, VI

Maximum rating : 50 volts dc / 300 mamps.

Outputs are passive, short-circuit proof and free floating. They must be supplied externally.

3.2.6. Technical Data of Trip-Lines I, II, III

Maximum rating : 50 volts dc / 3 amps / 75 watts

Maximum rating for DC13-applications : 24 volts / 3 amps

Outputs are not short-circuit proof (permanent currents exceeding 8 amps will destroy outputs).

Impedance : 10 kohms versus L- (negative pole of power supply)

For inductive type loads, external spark extinguishing means must be provided.

Total response time (trip relays de-energize to trip) from trip event until trip circuits are in trip

condition : < 15 milliseconds.

Page 27

I E16x442 Rev: 00 Page 27 of 73

3.3. Technical Data of Power Supply

3x 24 volts dc / 0.5 amps (18…40 volts) from a power supply with protective separation, conforming to IEC 61131-2 requirements.

Maximum consumption of system : 20 watts

3.4. Installation Conditions

Ambient temperature in operation : 0° C..+55° C

Ambient temperature in storage: -20° C..+85° C

Relative humidity: 10 % to 95 %, non condensing

To be installed in dry cabinets in air-conditioned rooms

3.5. Protection Grade

Insulation Class III

Version E16A442 and E16E442 : IP20

Version E16G442: IP65 resp. NEMA4

3.6. Connectors

Plug-In Cage-Clamp Connectors, type Phoenix Combicon FK-MLP1,5/…ST-3,5,

fitting for:

Conductor cross section solid min.: 0.2 mm²

Conductor cross section solid max.: 1.5 mm²

Conductor cross section stranded min.: 0.2 mm²

Conductor cross section stranded max.: 1.5 mm²

Conductor cross section stranded, with ferrule without plastic sleeve min.: 0.25 mm²

Conductor cross section stranded, with ferrule without plastic sleeve max.: 1.5 mm²

Conductor cross section stranded, with ferrule with plastic sleeve min.: 0.25 mm²

Conductor cross section stranded, with ferrule with plastic sleeve max.: 0.75 mm²

Conductor cross section acc. to AWG/kcmil min.: No. 24

Conductor cross section acc. to AWG/kcmil max: No. 16

Minimum AWG according to UL/CUL: 28

Maximum AWG according to UL/CUL: 16

3.7. Conformity to Standards

2006/42/EU

SIL2/IEC61508, DIN EN ISO 13849-1:2008 Cat 3 PL e, API 670, API 672

2006/95/EU, EN 61010-1,

2004/108/EU, EN 61000-6-2, EN 61000-6-4, IEC 611311-2

Page 28

I E16x442 Rev: 00 Page 28 of 73

3.8. Dimensions of system E16A442

front view

Height incl. backplane + terminals

all dimensions in mm

Drawing not to scale

wiring from

top and bottom

Ø 13

88

220

201.5

109.3

21.3

21

133

195

20

6.4

Detail

Mounting holes

to hang the racks to

premounted screws

total depth (incl. Profibus plug with 35° cable outlet)

wiring

side view

wiring

premounted screws or

bolts with nuts

pluggable

terminal

blocks

265

220

Figure 9: Dimensions of System E16A442

Page 29

I E16x442 Rev: 00 Page 29 of 73

3.9. Dimensions of system E16E442

all dimensions in mm

Drawing not to scale

wiring from rear side

top view

connectors

depth incl. connectors (excl. wiring space)

mounting holes in rack

for screws or bolts

with Ø 6 mm

mounting

holes

483 (incl. mounting lugs)

Dimensions sheet of 19'' rack, 3HE, 84TE for rack or panel mounting

57.1

456.1

448 +4

133

+2

446

218

dimensions for

panel cutout

Figure 10: Dimensions of System E16E442

Page 30

I E16x442 Rev: 00 Page 30 of 73

3.10. Dimensions and Features of E16G442 Enclosure

Overall Dimensions (including mounting lugs):

Height: 510 mm

Width: 410 mm

Depth: 270 mm

Glazed Window with size 360 by 410 mm

Material: Fiberglass reinforced plastic

3.11. Weight of E16x442

E16A442 : 3,0 kg

E16E442 : 3,7 kg

E16G442: 13,0 kg

Figure 11: Dimensions of E16G442 Enclosure

Page 31

I E16x442 Rev: 00 Page 31 of 73

4. Safety Notes for Installation and Operation

4.1. Safety Notes for Installation

This unit has been designed and inspected according to standards DIN EN 61010-1 (VDE

0411-1).

Observe these instructions and wiring diagrams carefully, to ensure this standards and safe

operation of the machine.

The installation must be done only by adequately qualified personnel and with power supply

switched off.

4.1.1. General Instructions

Specifically, connect the PE terminal 1.X1 to a safe ground potential.

Do not open the instrument. Connections and all programming are done from outside. When

removing it from its enclosure however, from whatever reason, make sure that power is

switched off.

The instrument may be installed in any position, but not in the immediate neighborhood of interfering sources.

Speed signal leads must be carefully shielded, and should not be run in bundles with power or

relay control leads.

Each speed signal must have its own screen.

4.1.2. EMI

The unit complies with all relevant regulations, as determined by the Policy of the European

Committee for Electrotechnical Standardization (CENELEC), for the Electromagnetic Compatibility (2004/108/EU). Testing and inspection has been performed according to Standards

IEC 61000-4-2 and IEC 61326-3-2. Thereby, the product meets all requirements to be marked

by the CE sign.

Specifically to be observed:

Terminals must be kept off all undue access.

Terminals must be protected against electrostatic discharge.

Power supply and all input and output leads must be protected overvoltage.

4.2. Safety Notes for Operation

4.2.1. Safety Notes for Commissioning

The commissioning must be done only by adequately qualified personnel and with power supply switched off.

On initial operation of the monitored machine the operator must ensure proper function of the

measurement chains.

This includes checking of the correct speed display and of the trip release due to a real overspeed condition.

If voter inputs are used the correct trip release due to external trip condition must be verified.

The parameter settings must be documented and protected against unauthorized changes.

Page 32

I E16x442 Rev: 00 Page 32 of 73

5. Description of Monitor E1665

5.1. Display and Frontside Operational Elements

5.1.1. Front View of Monitor E1665

Figure 12: Front view of Monitor E1665

5.1.2. Status-LEDs

LED1 steady on: Trip

LED2 steady on: no Trip, SP1A is valid

blinking: SP1B is valid

LED3 steady on: n < SP3

blinking: one only of three input channels measures zero speed

LED4 steady on: n > SP3

5.1.3. Display during Test Procedures

FC-2 : External Trip-Release via Voter active

FC-3.1 : Trip-Line I is tested (Relay I to Trip-Condition)

FC-3.2 : Trip-Line II is tested (Relay II to Trip-Condition)

FC-3.4 : Trip-Line III is tested (Relay III to Trip-Condition)

SELF : Monitor self-test

5-digit display

Input keyboard

4 LEDs for status indication

Data Interface

9-pole Sub-D

P

E

E1665

1

2

3

4

Trip

SP3

RPM

Page 33

I E16x442 Rev: 00 Page 33 of 73

5.1.4. Values accessible during normal operation

Values accessible during normal operation (Standard Display Mode):

with key the value of SP1

with key the value of SP2

with key and

together: maximum stored speed value

with key and

together: minimum stored speed value

Note:

with key Reset of stored minimum/maximum value

with key and together: Reset of latched (and not persistent) alarms, if enabled

with key and together: Toggle between

Standard-Display Mode and Special Display Mode 1

with key and together: Toggle between

Standard-Display Mode and Special Display Mode 2

Page 34

I E16x442 Rev: 00 Page 34 of 73

5.1.5. Special Display Mode 1

Toggle between Standard and Special Display Mode 1 by pressing keys and

together.

In Special Display Mode 1 the measured speed values of sensors A, B, C can be shown individually as well as the signal level of the main sensor.

Toggle between the four values with

.

The LED assigned to the specific speed value is blinking (see table).

Note :

If signal level (LED4 blinking) is selected, without a key pressed the median signal value is

displayed.

The maximum measured signal level is then displayed with key

.

The minimum measured signal level is then displayed with key

.

Minimum, maximum and median values are dynamically updated with a sample rate of approx.

1 second.

5.1.6. Special Display Mode 2

Toggle between Standard and Special Display Mode 2 by pressing keys and

together.

In Special Display Mode 2 LED1 and LED4 are blinking.

This display mode is only used for trouble shooting, if external signals are missing and the monitor displays the Event code E.0.4.0.0 .

5.1.7. Frontside Reset of Alarms and Event Codes

Resetting of (no longer valid) alarms and event codes is done by pressing keys and (if

enabled in step P00.02).

5.1.8. Data Interface

9pole Sub-D for PROFIBUS and RS232.

Notes:

- RS232-Data interface only available for systems with serial nos. exceeding 193850.

- For RS232, adapter L3D02 must be used

with Monitor

LED assigned to

speed value of sensor:

LED1 LED2 LED3

signal level (in xx.x volts)

LED4

A

A C B

A

B

B A C

B

C

C B A

C

Page 35

I E16x442 Rev: 00 Page 35 of 73

5.2. Functions of Monitor 1667

For a detailed description of the individual functions refer to chapter 8.

5.2.1. Speed Measurement

Each monitor receives the signal from the three sensors and calculates the speed from each

signal. For the further evaluation it selects (depending on parameter settings) the calculated

speed value derived of its own sensor or the mean value of all three speed values.

Speed calculation is done by measuring the time in between the pulses. The minimum measurement time is 5 milliseconds.

To compensate for an imperfect gear, a predivider may be introduced to reduce the signal frequency to 1 pulse per revolution.

5.2.2. Functions for Overspeed Protection

Overspeed protection is done by :

Monitoring of Sensors

Monitoring versus Lowspeed as protection versus incorrect mounting or fault of speed

sensors.

Monitoring versus overspeed

5.2.3. Functions for External Trip by Voters

Trip is released, if one of the voters detects an external trip condition.

Voters may be configured as 1oo2, 2oo2, 2oo3 or 3oo3. High or low Input-Level as trip condition and response time is selectable.

5.2.4. Selftest of Monitor

Selftest is performed at an interval of 2 hours. Execution of Selftest is signalized on display

with message SELF. Selftest of the monitors are inhibited versus each other.

The Selftest routine includes

CPU RAM-Test

CPU EEPROM-Test

CPU Command-Test

CPU Register-Test

Voter Signal-input-Test

If the Selftest detects a malfunction, the monitor is set to trip-status.

Page 36

I E16x442 Rev: 00 Page 36 of 73

6. Description of Test Interface E1691

The Test Interface E1691 processes the signals trip-line test from the PLC to the Monitors and

the trip status from the Monitors to the PLC.

The Test Interface supplies a constant test frequency to the Monitors, which use this frequency

for their self test function.

The Test Interface releases the System Warning Alarm if:

Minimum one Monitor detects a discrepancy at its voter inputs

Minimum one Monitor detects a failed speed signal

Minimum one Monitor has a malfunction

Malfunction of Test Interface

The frontside LED is steady on if the power supply of the Test Interface is ok.

Page 37

I E16x442 Rev: 00 Page 37 of 73

7. Programming of the Monitors

7.1. Programming of the Monitors via Front Keyboard

Principle:

Select a parameter via its ‚name’ Pgg.ss,

in that gg : Parameter-group number and

ss : Step-number within the group,

then display the value and alter if required.

Procedure:

Initiate programming phase by pressing keys and together; instead of the normal display P00.00. appears

Select the group or step number with keys , .

Switch between Groups and Step Fields with the . key

Current value of the Parameters is displayed with key .

Select active position with the . key

Adjust the number in the active field with keys , .

Acknowledge and set with key , Discard (original value remains) with key .

Return to operational mode with the key. The display then returns to the current ‘is’ speed (with E1665) resp.

to the current test-speed (with E1697)

See example below: Change parameter P01.01 from 2386 to 2387 or 2385.

Move

active

digit with

Normal Display While Programming

Display active digit(s) blinking (shown underlined here)

Select Select Change

Toggle Group Toggle Step-No. Toggle Parameter Value

with with with

key(s) Key Key

+

P P E

E

E

: Enter

or

: Cancel

P

Enter : new, changed value is valid

Cancel : original value still valid

P

P

Page 38

I E16x442 Rev: 00 Page 38 of 73

7.2. Programming of the Modules via RS232-Interface

1. adapter L3D02 with cable L3D03 by BRAUN

Note:

- Adapter L3D02 has male connectors on both sides.

- Cable L3D03 has female connectors to L3D02 and to PC.

or

2. customized cable with connections PC (female connector) to E16 (male connector):

PC pin 2 to E16 pin 2

3 to 7

5 to 5 (of 9 pole Sub-D connectors)

Note:

- The RS232-Interface serves only for parameter programming purposes, not for transmission

of current data. States, alarms and measurement data are transmitted via PROFIBUSInterface only.

7.3. Default Values

If not specified otherwise, the unit is supplied with default values as listed in the summary of

parameters. In process of installation, the setting of its parameters inevitably must be adapted

to the correct values according its application.

Page 39

I E16x442 Rev: 00 Page 39 of 73

8. Parameters of Monitor E1665

8.1. Summary of parameters and their default values

Param.

No.

Default

Value

Parameter Function

P00.xx

Code figure, Parameter Lock

P00.00

0000

Code figure

.01

0000

New code figure

.02

0

Parameter Lock : 0: locked / 1: enabled

.03

0

Front side Reset: 0: not possible / 1: possible

P01.xx

Input, Scaling

P01.00

0

Reserved for future applications

.01

10000

Value of nominal input frequency in Hz

.02

0

Decimals of speed value for SP2, SP3 PROFIBUS-Output

.03

10000

Nominal speed in RPM

.04

00001

Lower limit of the speed range

.05

001

Predivider (range 001 - 255)

.06

0

Reserved for future applications

.07

0

Decimals for acceleration

.08

01000

Maximum acceleration in XXXX or XXX.X RPM/sec

.09

1

No. of acceleration measurements included in calculation of SP1var

P02.xx

Display, Starter, Tests

P02.00

0

Reserved for future applications

.01

0.3

Display updating sequence (in x.x sec)

.02

000

Time elapse of starter phase (in xxx sec)

.03

1

Reserved for future application

.04

4

Sensor monitoring: 0: off / 1: on / 2: on, latched / 4: on, no trip

.05

1

Mode of sensor monitoring: 0 ... 7 (see table)

.06

1

Lowspeed Monitoring "n < SP2": 0 ... 4 (see table)

.07

5

Speed comparison test : 0 ... 5 (see table)

.08

030

Permissible Speed Difference between Sensors (in xxx RPM)

.09

05

Number of errors before reporting

.10

1

Monitor Warning Alarm at Trip: 0 ... 4 (see table)

.11

1

Latch Monitor Warning Alarm: 0: no / 1: yes, all alarms / 2: yes, first one only

P03.xx

Overspeed Alarm SP1

P03.00

00010

Setpoint SP1A in RPM

.01

05.0

Hysteresis bandwidth (XX.X % of. SP1)

.02

0

Alarm to be latched / energized or de-energized to trip:

0: no, de-energize / 1: yes, de-energize / 2: no, energize / 3: yes, energize

.03

00001

Setpoint SP1B in RPM

.04

0

Setpoint SP1var : 0: not active / 1: active

Continued on next page

Page 40

I E16x442 Rev: 00 Page 40 of 73

Param.

No.

Default

Value

Parameter Function

P04.xx

Low Speed Alarm SP2

P04.00

00015

Setpoint SP2 in RPM

.01

05.0

Hysteresis bandwidth (XX.X % of SP2)

.02

0

Fix value = 0, do not change

P05.xx

Alarm SP3

P05.00

00003

Setpoint SP3 in RPM

.01

05.0

Hysteresis bandwidth (XX.X % of SP3)

.02

1

Hysteresis position: 0: above / 1: below

.03

1

Relay state at "n > SP3" : 0 … 3 (see table)

.04

0

Alarm state at sensor fault: 0: acc. to speed / 1: "n < SP" / 2: "n > SP"

.05

1

Setting of LEDs to status "n > SP3" : 0: LED3 on / 1: LED4 on

P06.xx

Eddy sensor

P06.00

00100

Reserved for future application

.01

00.0

Eddy sensor input check: input voltage upper limit in xx.x volts

.01

00.0

input voltage lower limit in xx.x volts

.03

00.0

current drain upper limit in xxx m

.04

00.0

current drain lower limit in xxx m

.05

0.0

Eddy sensor input hysteresis in x.x volts

P07.xx

Trip-Lines, Forward / Reverse Detection

P07.00

0

Trip-Lines Monitoring: 0: no / 1: yes

.01

0

Signal level Trip-Feedback: 0: low = Trip / 1: high = Trip

.02

1

Forward / Reverse Detection Input level: 0: low = forward / 1: high = forward

.03

1

Forward / Reverse relay state: 0: de-energized = forward / 1: energized = forward

.04

0

Reserved for future application

P08.xx

Analog Output

P08.00

10000

High end speed value

.01

00000

Low end speed value

.02

1

Zero level: 0: dead zero / 1: live zero

.03

0

Output level at sensor fault: 0: no change / 1: min / 2: max

.04

0

Output direction: 0: 0/4 … 20 ma / 1: 20 ... 4/0 ma

.05

1

Output response to test-speed: 0: test-speed / 1: frozen

.06

0

Test of Analog Output value: 0: no / 1: yes

P09.xx

Reserved for future application

P09.00

0

Reserved for future application

P10.xx

Voter No. 1 and LO1

P10.00

0

Operation Mode: 0 ... 5 (see table)

.01

0

Input Truth Level: 0: high = Trip / 1: low = Trip

.02

0

Voting logic: 0: 1oo2 / 1: 2oo2 / 2: 2oo3 / 3: 3oo3

.03

0

Truth Time until Trip: 0 ... 11 (see table)

.04

0

Trip latched: 0: no / 1: yes

.05

0

Delay of Antivalence Alarm: 0 ... 9 (see table)

.06

00110

Value for setpoint SPV1

Continued on next page

Page 41

I E16x442 Rev: 00 Page 41 of 73

Param.

No.

Default

Value

Parameter Function

P11.xx

Voter 2 and LO2

P11.00

0

Operation Mode: 0 ... 5 (see table)

.01

0

Input Truth Level: 0: high = Trip / 1: low = Trip

.02

0

Voting logic: 0: 1oo2 / 1: 2oo2 / 2: 2oo3 / 3: 3oo3

.03

0

Truth Time until Trip: 0 ... 11 (see table)

.04

0

Trip latched: 0: no / 1: yes

.05

0

Delay of Antivalence Alarm: 0 ... 9 (see table)

.06

00120

Value for setpoint SPV2

P12.xx

Voter 3 and LO3

P12.00

0

Operation Mode: 0 ... 5 (see table)

.01

0

Input Truth Level: 0: high = Trip / 1: low = Trip

.02

0

Voting logic: 0: 1oo2 / 1: 2oo2 / 2: 2oo3 / 3: 3oo3

.03

0

Truth Time until Trip: 0 ... 11 (see table)

.04

0

Trip latched: 0: no / 1: yes

.05

0

Delay of Antivalence Alarm: 0 ... 9 (see table)

.06

00130

Value for setpoint SPV3

P13.xx

Voter 4 and LO4

P13.00

0

Operation Mode: 0 ... 5 (see table)

.01

0

Input Truth Level: 0: high = Trip / 1: low = Trip

.02

0

Voting logic: 0: 1oo2 / 1: 2oo2 / 2: 2oo3 / 3: 3oo3

.03

0

Truth Time until Trip: 0 ... 11 (see table)

.04

0

Trip latched: 0: no / 1: yes

.05

0

Delay of Antivalence Alarm: 0 ... 9 (see table)

.06

00140

Value for setpoint SPV4

P14.xx

Voter 5 and LO5

P14.00

0

Operation Mode: 0 ... 5 (see table)

.01

0

Input Truth Level: 0: high = Trip / 1: low = Trip

.02

0

Voting logic: 0: 1oo2 / 1: 2oo2 / 2: 2oo3 / 3: 3oo3

.03

0

Truth Time until Trip: 0 ... 11 (see table)

.04

0

Trip latched: 0: no / 1: yes

.05

0

Delay of Antivalence Alarm: 0 ... 9 (see table)

.06

00150

Value for setpoint SPV5

P15.xx

Voter 6 and LO6

P15.00

0

Operation Mode: 0 ... 5 (see table)

.01

0

Input Truth Level: 0: high = Trip / 1: low = Trip

.02

0

Voting logic: 0: 1oo2 / 1: 2oo2 / 2: 2oo3 / 3: 3oo3

.03

0

Truth Time until Trip: 0 ... 11 (see table)

.04

0

Trip latched: 0: no / 1: yes

.05

0

Delay of Antivalence Alarm: 0 ... 9 (see table)

.06

00160

Value for setpoint SPV6

Continued on next page

Page 42

I E16x442 Rev: 00 Page 42 of 73

Param.

No.

Default

Value

Parameter Function

P16.xx

Reserved for future application

P16.00

0

Reserved for future application

.01

0

Reserved for future application

.02

0

Reserved for future application

.03

0

Reserved for future application

.04

0

Reserved for future application

.05

0

Reserved for future application

.06

00000

Reserved for future application

P17.xx

Data Interface

P17.00

016

PROFIBUS-Interface Device no.

Page 43

I E16x442 Rev: 00 Page 43 of 73

8.2. Description of Parameters and their Settings of Monitor E1665

Parameter Group P00.xx of Monitor E1665

Code Figure, Parameter Lock, Frontside Reset of Alarms

Parameter No.

Meaning of Parameter

Setting Range of Parameter

Description of Parameters and their Settings

P00.00

Code Figure

Range: 0000 .. 9999

If the parameters are locked (see P00.02), the code figure must be entered

prior to any change of other parameters.

If the code figure is not correct, -E 1- is displayed.

Without code figure and P00.02 : 0 the values of all parameters may be inspected, but not changed.

P00.01

New Code Figure

Range: 0000 .. 9999

A new code figure may be set in P00.01. Then it replaces the previous one.

P00.02

Parameter Lock

Range: 0 .. 1

Setting

0 : Parameters are locked, change only possible with code figure

1 : Parameters unlocked, change of parameter values possible

P00.03

Frontside Reset of Alarms

Range: 0 .. 1

Setting

0 : Frontside reset of alarms not possible

1 : Frontside reset of alarms possible with keys and .

Page 44

I E16x442 Rev: 00 Page 44 of 73

Parameter Group P01.xx of Monitor E1665

Input Scaling and Measurement Configuration

Parameter No.

Meaning of Parameter

Setting Range of Parameter

Description of Parameters and their Settings

P01.00

Reserved for future applications

Description of Scaling:

Scaling defines the relationship between the input signal frequency (in terms

of Hz), and the corresponding display (in terms of RPM).

Of course, they must refer to the same operation level. This reference point

is recommended close to the high end of the intended operation range. In

later operation, however, it may be overrun without error.

Example:

1500 Hz corresponds to 3000 RPM :

Step P01.01 : setting 01500

Step P01.03 : setting 03000

P01.01

Nominal Input Frequency [Hz]

Range: 00001 .. 99999

See description of Scaling.

P01.02

Decimals for P01.04, P04.00,

P05.00 and for

PROFIBUS Speed Data Output

Range: 0 .. 1

Setting

0 : Setting range for P01.04, P04.00, P05.00 : 00001 to 99999 RPM