Page 1

Aesculap Power Systems

Acculan® 3Ti

Instructions for use/Technical description

Acculan® 3Ti attachments

Gebrauchsanweisung/Technische Beschreibung

Acculan® 3Ti Aufsätze

Mode d’emploi/Description technique

Acculan® 3Ti embouts

Instrucciones de manejo/Descripción técnica

Acculan® 3Ti cabezales

Istruzioni per l’uso/Descrizione tecnica

Acculan® 3Ti terminali

Instruções de utilização/Descrição técnica

Acculan® 3Ti cabeçotes

Gebruiksaanwijzing/Technische beschrijving

Acculan® 3Ti opzetstukken

Brugsanvisning/Teknisk beskrivelse

Acculan® 3Ti tilbehør

Bruksanvisning/Teknisk beskrivning

Acculan® 3Ti tillsatserna

Инструкция по примению/Техническое

описание

Acculan® 3Ti соединительные насадки

Page 2

Page 3

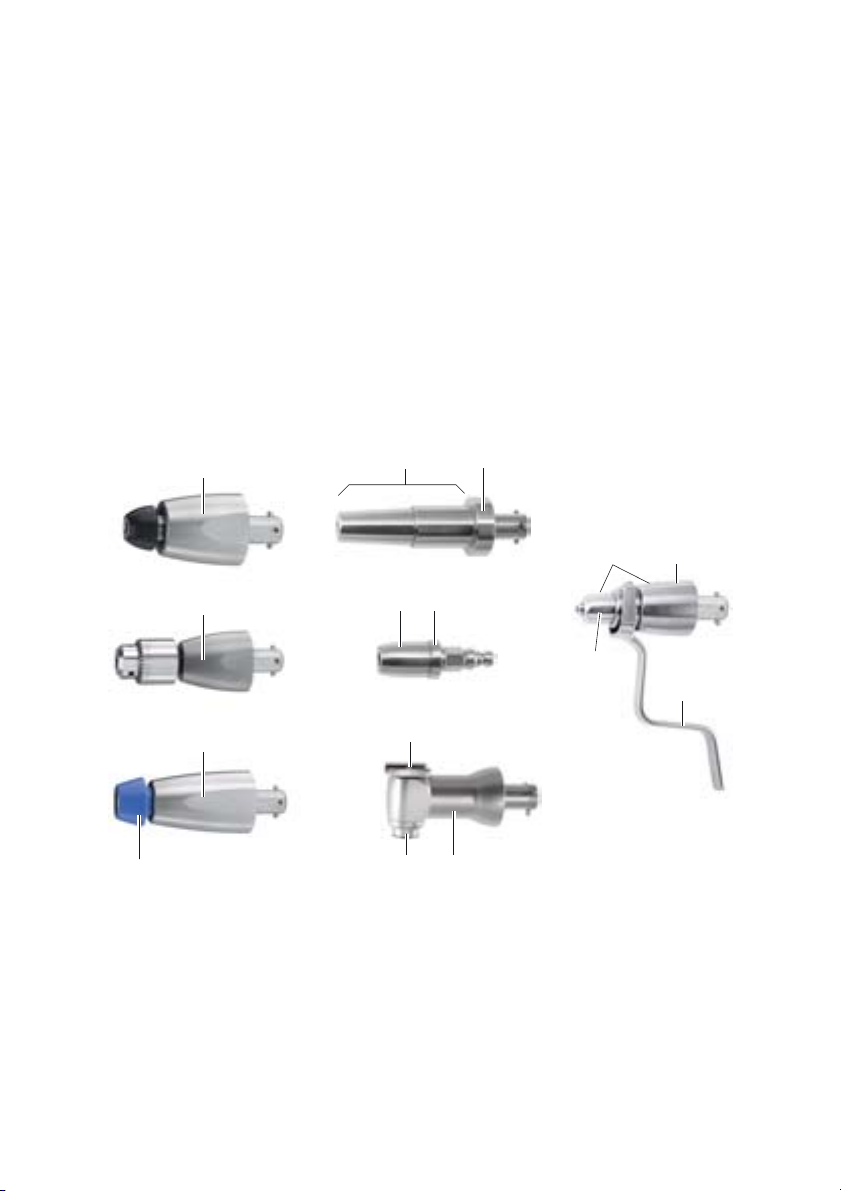

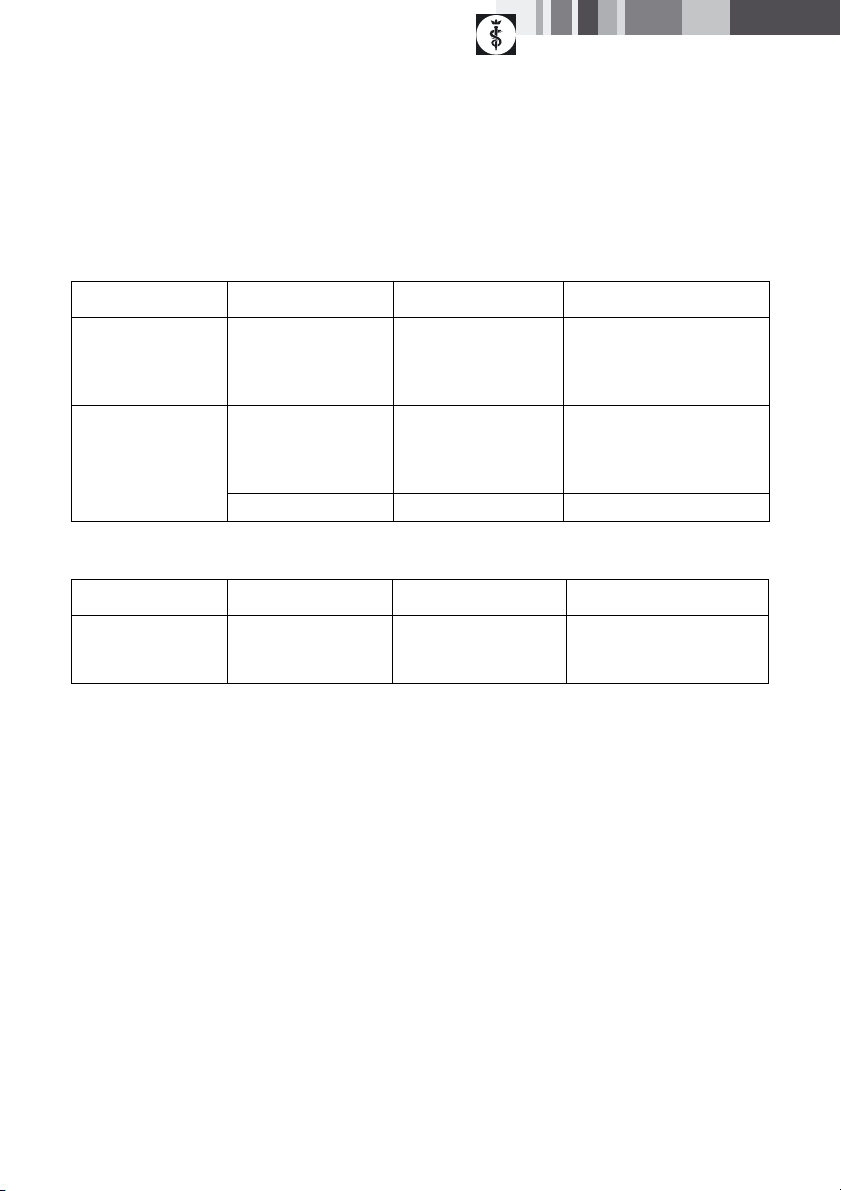

1

5.1

5

44.1

2.1

3

2

66.1

4.2

4.3

7.1

77.2

Page 4

Aesculap Power Systems

Acculan® 3Ti attachments

Legend

1 Drill attachment (black unlocking sleeve)

2 Reamer attachment (blue unlocking sleeve)

2.1 Unlocking sleeve

3 Drill attachment with Jacobs chuck

4 Kirschner wire attachment

4.1 Scale

4.2 Adjustment sleeve

4.3 Clamping lever

5 Drill attachment (for radiolucent angle

transmission)

5.1 Adapter for radiolucent angle transmission

6 Adapter (AO large to DHS/DCS)

6.1 Unlocking sleeve

7 Sagittal saw attachment

7.1 Saw blade coupling

7.2 Button for saw blade release/fixation

Symbols on product and packages

Adhere to instructions for use

Notice indicating the next scheduled service (date) by an international B. Braun/Aesculap agency,

see Maintenance

Date of manufacture

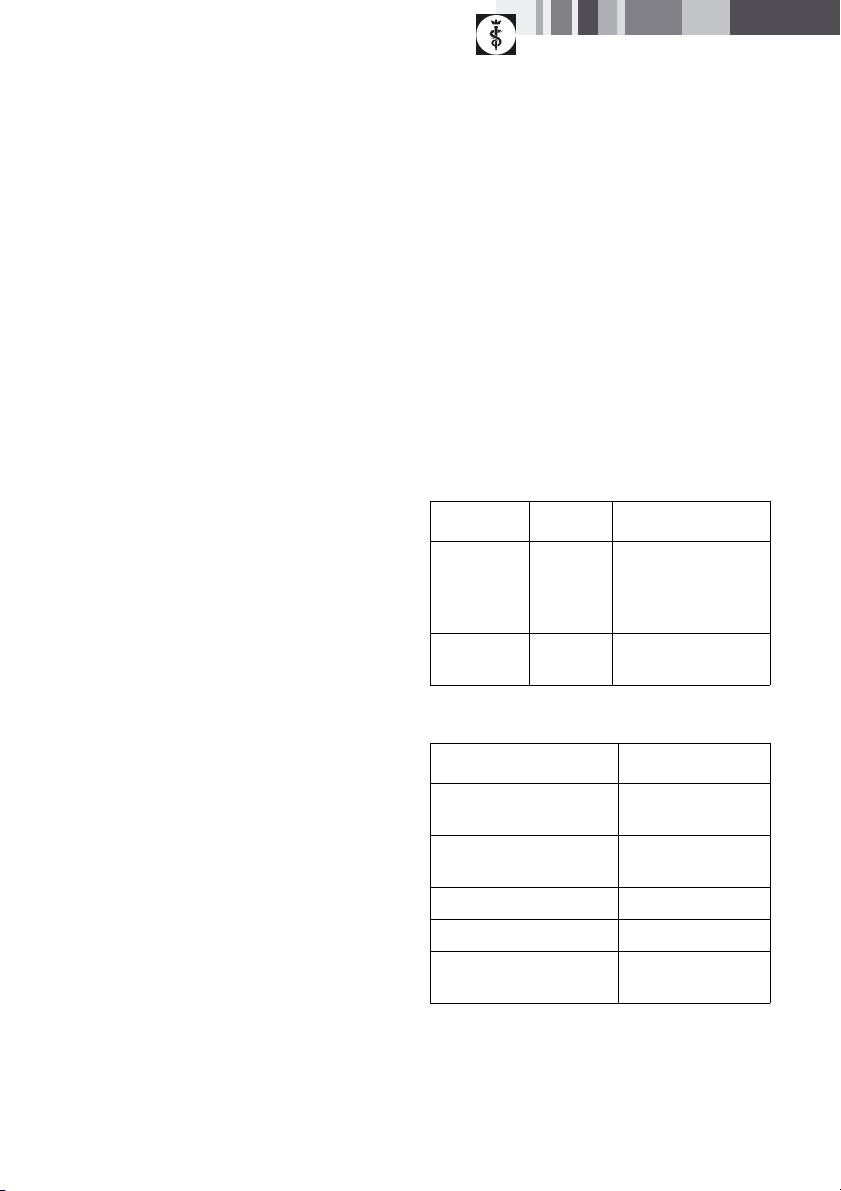

Contents

1. Safe handling ...........................................................3

2. Product description ................................................ 3

2.1 System components ............................................... 3

2.2 Components necessary for use ........................... 3

3. Drill and reamer attachments ............................. 4

3.1 Intended use .............................................................4

3.2 Operating principle ................................................. 4

3.3 Safe operation ......................................................... 4

Coupling a tool........................................................ 4

Uncoupling a tool................................................... 4

3.4 Technical specifications ........................................ 5

4. Kirschner wire attachment GB643R .................. 6

4.1 Intended use ............................................................. 6

4.2 Operating principle ................................................. 6

4.3 Safe operation ......................................................... 6

Inserting the Kirschner wire ................................ 7

Clamping the Kirschner wire............................... 7

4.4 Technical specifications ........................................ 7

5. Drill attachment GB645R (for radiolucent

angle transmission) ................................................8

5.1 Intended use ............................................................. 8

5.2 Operating principle ................................................. 8

5.3 Safe operation ......................................................... 8

Coupling the radiolucent transmission unit.... 8

Uncoupling the radiolucent transmission unit. 8

Coupling a tool........................................................ 9

Uncoupling a tool................................................... 9

5.4 Technical specifications ........................................ 9

6. Adapter GB628R (AO large to DHS/DCS) .......10

6.1 Intended use ...........................................................10

6.2 Operating principle ...............................................10

6.3 Safe operation .......................................................10

Coupling the adapter........................................... 10

Uncoupling the adapter...................................... 10

Coupling a tool...................................................... 10

Uncoupling a tool................................................. 10

6.4 Accessories .............................................................10

6.5 Technical specifications ......................................10

7. Sagittal saw attachment GB660R ...................11

7.1 Intended use ...........................................................11

7.2 Operating principle ...............................................11

7.3 Safe operation .......................................................11

Coupling the saw blade....................................... 11

Uncoupling the saw blade.................................. 11

7.4 Technical specifications ......................................11

8. Working with the attachments ........................12

8.1 System set-up ........................................................12

Connecting the accessories................................ 12

Coupling and uncoupling of attachments on

the drill and reamer motor unit........................ 12

2

Page 5

8.2 Function checks .....................................................13

8.3 General operation .................................................14

9. Validated processing procedure ........................14

9.1 General notes .........................................................15

9.2 Preparations at the place of use ......................15

9.3 Preparation prior to cleaning ............................15

9.4 Cleaning/Disinfecting ..........................................16

9.5 Manual cleaning/disinfecting ............................17

9.5 Manual cleaning and wipe disinfection ......... 17

9.6 Mechanical cleaning/disinfecting ....................18

Mechanical alkaline cleaning and thermal

disinfecting............................................................. 19

9.7 Inspection, maintenance and checks ..............20

9.8 Packaging ................................................................20

9.9 Sterilization method and parameters .............21

9.10 Sterilization for the US market .........................21

9.11 Storage .....................................................................21

10. Troubleshooting list ..............................................22

10.1 General malfunctions ..........................................22

10.2 Malfunctions of the Kirschner wire

attachment .............................................................23

10.3 Malfunctions of the sagittal saw

attachment .............................................................23

11. Maintenance ..........................................................24

12. Technical Service ...................................................24

13. Accessories/Spare parts .......................................25

14. Technical specifications ......................................26

14.1 Ambient conditions ..............................................26

15. Disposal ....................................................................26

16. Distributor in the US/Contact in Canada

for product information and complaints .......27

1. Safe handling

CAUTION

Federal law restricts this device to sale by or on

order of a physician!

¾ To prevent damage caused by improper setup or

operation and to avoid forfeiture of liability rights:

– Use the product only according to these

instructions for use.

– Observe all safety information and maintenance

advisories.

– Only combine Aesculap products with each other.

¾ Ensure that the product and its accessories are

operated and used only by persons with the

requisite training, knowledge or experience.

¾ Keep the instructions for use accessible for all O.R.

personnel.

¾ Always adhere to applicable standards.

2. Product description

2.1 System components

Designation Art. no. Enclosed

Cleaning

brush

Key for

Jacobs chuck

2.2 Components necessary for use

Designation Art. no.

Acculan® 3Ti small power

drill

Acculan® 3Ti drill and

reamer motor

Attachment Vary with indication

Adapter Vary with indication

Suitable tools and

Kirschner wires

Note

For possible combinations of attachments with the

Acculan® 3Ti small power drill GA671, follow the

information in Instructions for Use TA012033!

TA011944 All drill and reamer

attachments/Kirschner

wire attachment

GB643R

GA031201 For drill attachment

GA638R

GA671

GA672

Vary with indication

3

Page 6

Aesculap Power Systems

Acculan® 3Ti attachments

3. Drill and reamer attachments

Abb. 1

3.1 Intended use

Drill and reamer attachments are used to adapt

rotating tools applied in bone surgery for work on

bones and cartilage.

3.2 Operating principle

The drill and reamer attachments are powered by a

motor coupled through an Aesculap Acculan® 3Ti

coupling.

The drill and reamer attachments convert the motor

rotation to rotation of the tool adapted in the

respective attachment.

The drill and reamer attachments can be coupled to

the drive unit in three different angular positions at

steps of 120°.

Drill attachments are identified by their black

unlocking sleeves, whereas reamer attachments come

with blue unlocking sleeves.

3.3 Safe operation

Risk of injury due to heat necrosis!

¾ Do not use drill attachments to

operate reamer tools such as the

DANGER

Recommended application

Use GB630R, GB634R, GB635R, GB636R, GB637R and

GB638R only for drilling and tapping.

Use GB654R, GB655R and GB656R only for acetabular

reaming and medullary reaming.

¾ For information on how to connect the drill and

reamer attachments, siehe Coupling and uncoupling of attachments on the drill and reamer motor

unit.

Coupling a tool

¾ Slide back unlocking sleeve 2.1.

¾ Push the tool shaft in its proper position down to

the stop in the tool adapter of the attachment.

¾ Release unlocking sleeve 2.1.

The tool is now coupled.

Uncoupling a tool

¾ Slide back unlocking sleeve 2.1.

¾ Remove the tool.

acetabulum reamer and the

medullary reamer.

¾ Operate any reamer tool only

with a reamer attachment.

4

Page 7

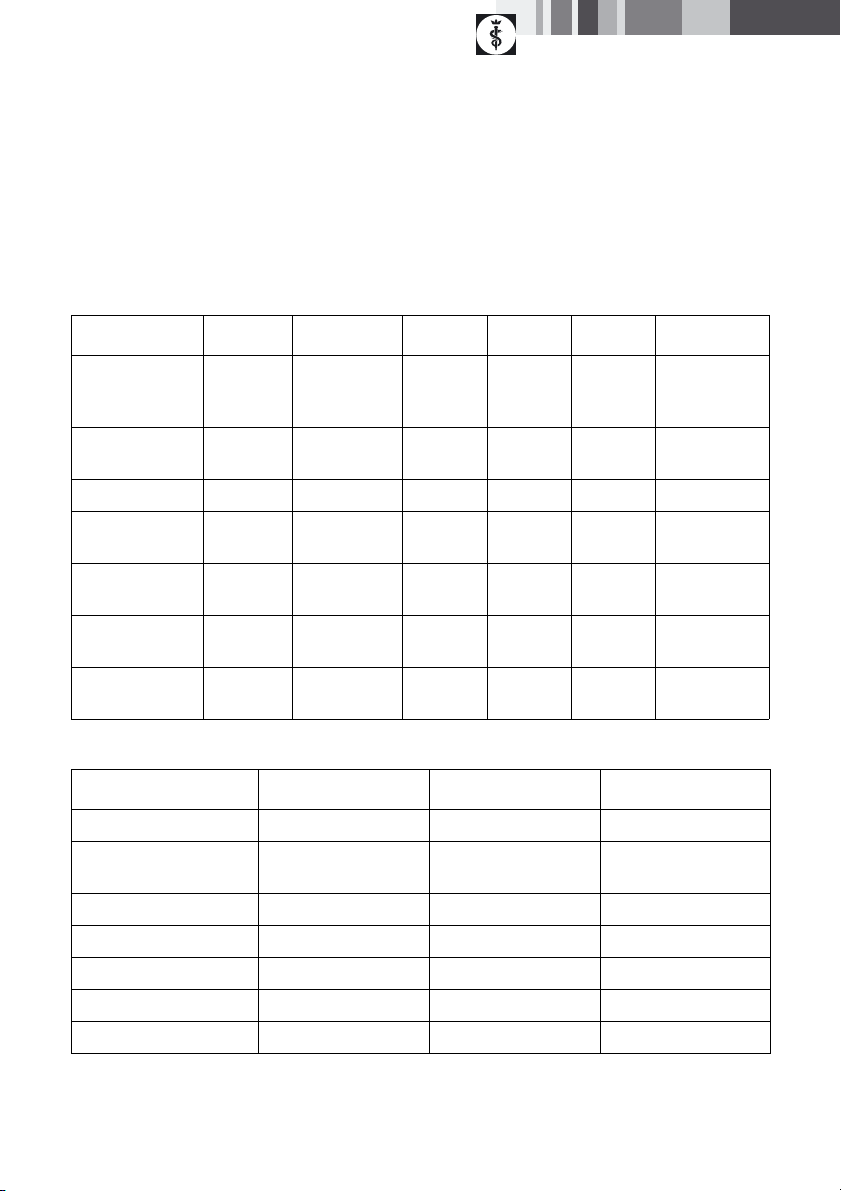

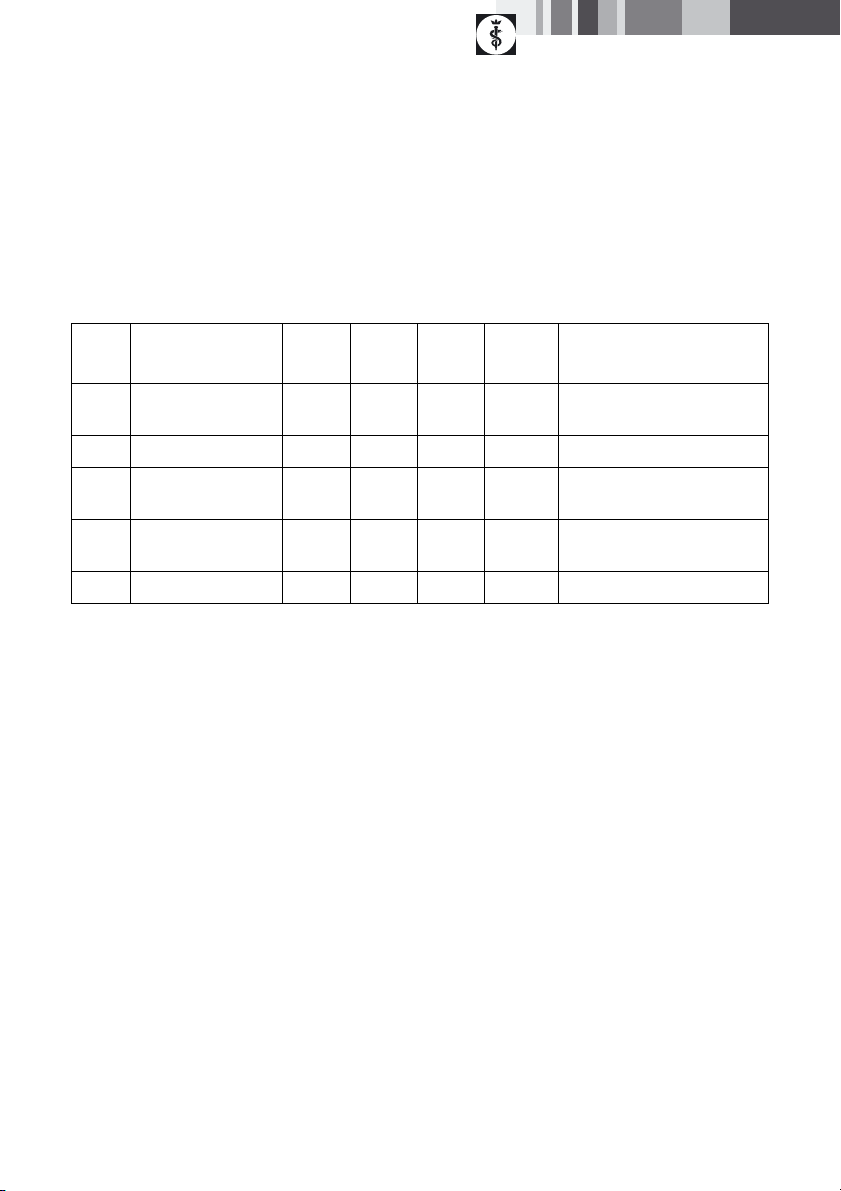

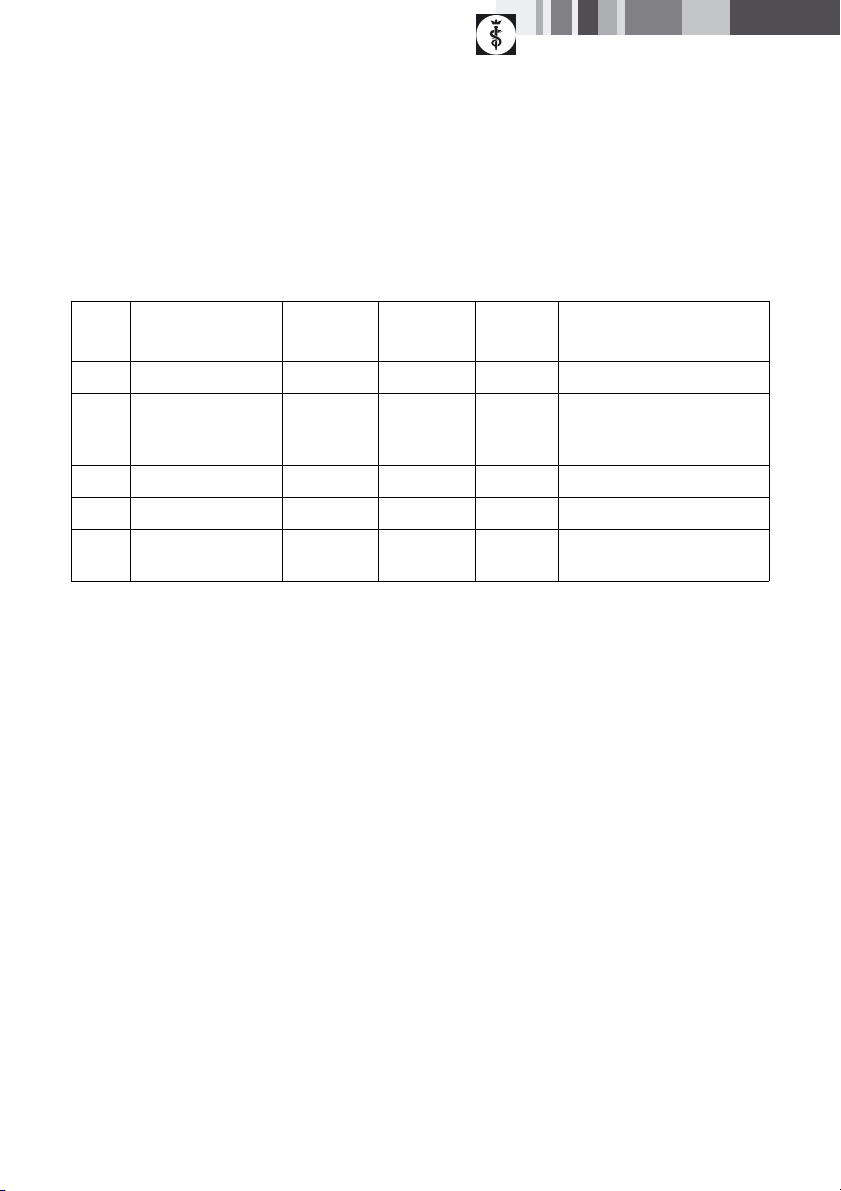

3.4 Technical specifications

Drill attachments (black unlocking sleeve)

GB630R GB634R GB635R GB636R GB637R GB638R

Connection Hudson/

Zimmer

Dimensions

Length x ∅ in mm

Weight, in grams approx. 263 approx. 430 approx. 246 approx. 253 approx. 250 approx. 333

Gear

ratio

Drive speed, in

1/min

Torque

in Nm

Cannulation

∅ in mm

Reamer attachments (blue unlocking sleeve)

Connection Harris AO large Hudson/Zimmer

Dimensions

Length x ∅ in mm

Weight, in grams approx. 323 approx. 334 approx. 344

Gear ratio 100:1 100:1 100:1

Drive speed, in 1/min max. 250 max. 250 max. 250

Torque, in Nm max. 19 max. 19 max. 19

Cannulation ∅ in mm 444

approx.

100 x 39

25:1 25:1 25:1 25:1 25:1 25:1

max. 1 000 max. 1 000 max. 1 000 max. 1 000 max. 1 000 max. 1 000

max. 5 max. 5 max. 5 max. 5 max. 5 max. 5

4 4 4444

Jacobs chuck

keyless

∅ 0.6–7.4 mm

approx.

125 x 39

GB654R GB655R GB656R

approx. 106 x 39 approx. 107 x 39 approx. 118 x 39

AO small Aesculap

hexagon

approx.

90 x 39

approx.

86 x 39

Trinkle Jacobs chuck

with key

∅ 0–6.5 mm

approx.

93 x 39

approx.

110 x 39

5

Page 8

Aesculap Power Systems

Acculan® 3Ti attachments

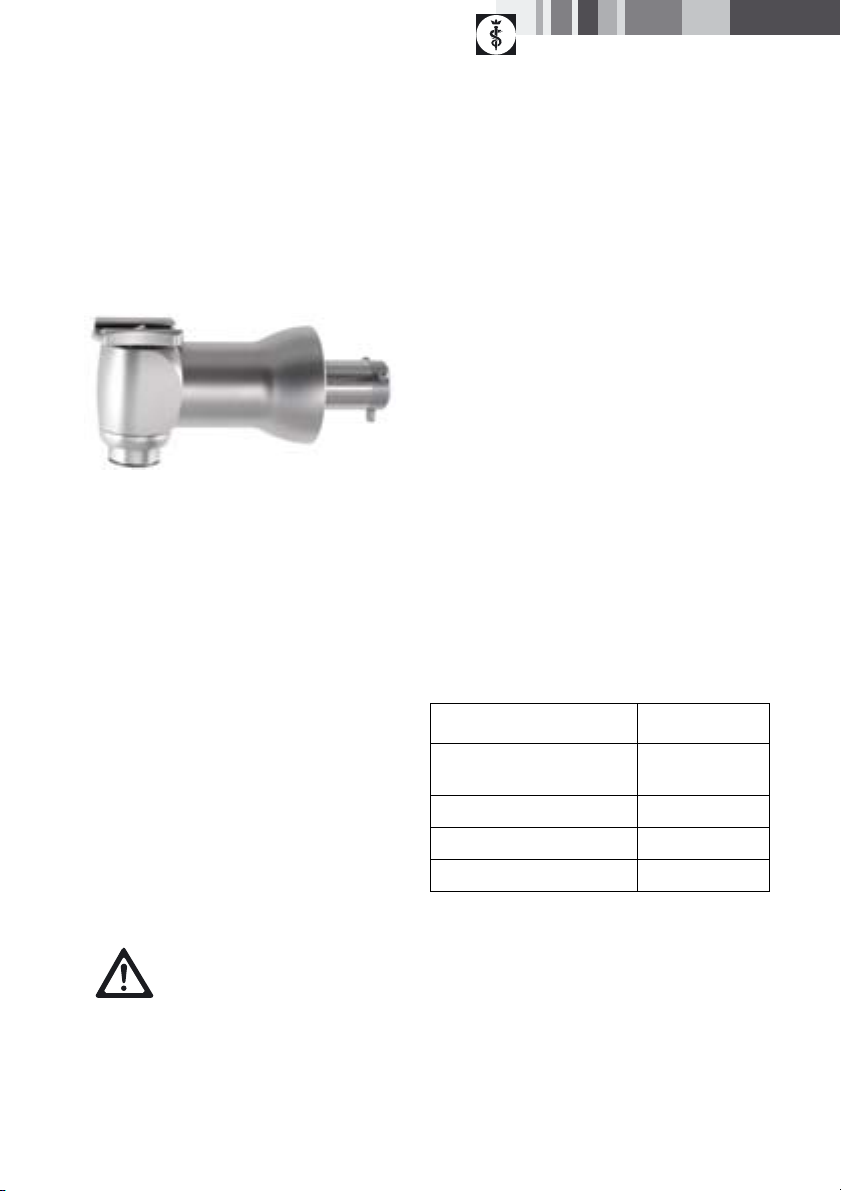

4. Kirschner wire attachment

GB643R

Abb. 2

4.1 Intended use

Kirschner wire (K-wire) attachments are used in

orthopedics and traumatology to insert Kirschner wires

into bones.

4.3 Safe operation

To protect against injuries when using long drilling

wires, screw in the Kirschner wire protection sleeve

supplied with the product.

17 15

Abb. 3

¾ Screw protection sleeve 15 into adapter 17.

¾ Connect the Kirschner wire attachment, siehe Cou-

pling and uncoupling of attachments on the drill

and reamer motor unit.

¾ Align clamping lever 4.3 over the trigger buttons of

the drill and reamer motor.

4.2 Operating principle

Kirschner wire attachments are powered by a motor

with an Aesculap Acculan® 3Ti coupling.

The Kirschner wire attachment is a quick-action chuck

that clamps and drives Kirschner wires.

6

Page 9

Inserting the Kirschner wire

The following diameter ranges can be set for the

adjustment sleeve:

∅ 0.6-1.8 mm

∅ 1.8-3.0 mm

∅ 3.0–4.0 mm

¾ Leave clamping lever 4.3 in forward position (away

from the drive unit).

¾ Set adjustment sleeve 4.2 to the correct diameter

range for the diameter of the Kirschner wire: Push

back and turn adjustment sleeve 4.2 until the

intended diameter range setting is reached.

¾ Release adjustment sleeve 4.2, making certain that

adjustment sleeve 4.2 clicks into position.

¾ Insert the Kirschner wire into the Kirschner wire

attachment until the required extension length is

reached.

The Kirschner wire is held in the intended position

in the attachment by an automatic clamping

mechanism.

Clamping the Kirschner wire

¾ Pull clamping lever 4.3 towards the motor unit (the

stronger the clamping lever is pulled, the stronger

the clamping force on the Kirschner wire).

The Kirschner wire is clamped in now.

Note

The Kirschner wire remains clamped only as long as the

clamping lever is pulled towards the motor unit. The

clamping lever automatically returns to its rest position

away from the motor unit, and the Kirschner wire can

be moved freely again as soon as the clamping lever is

released.

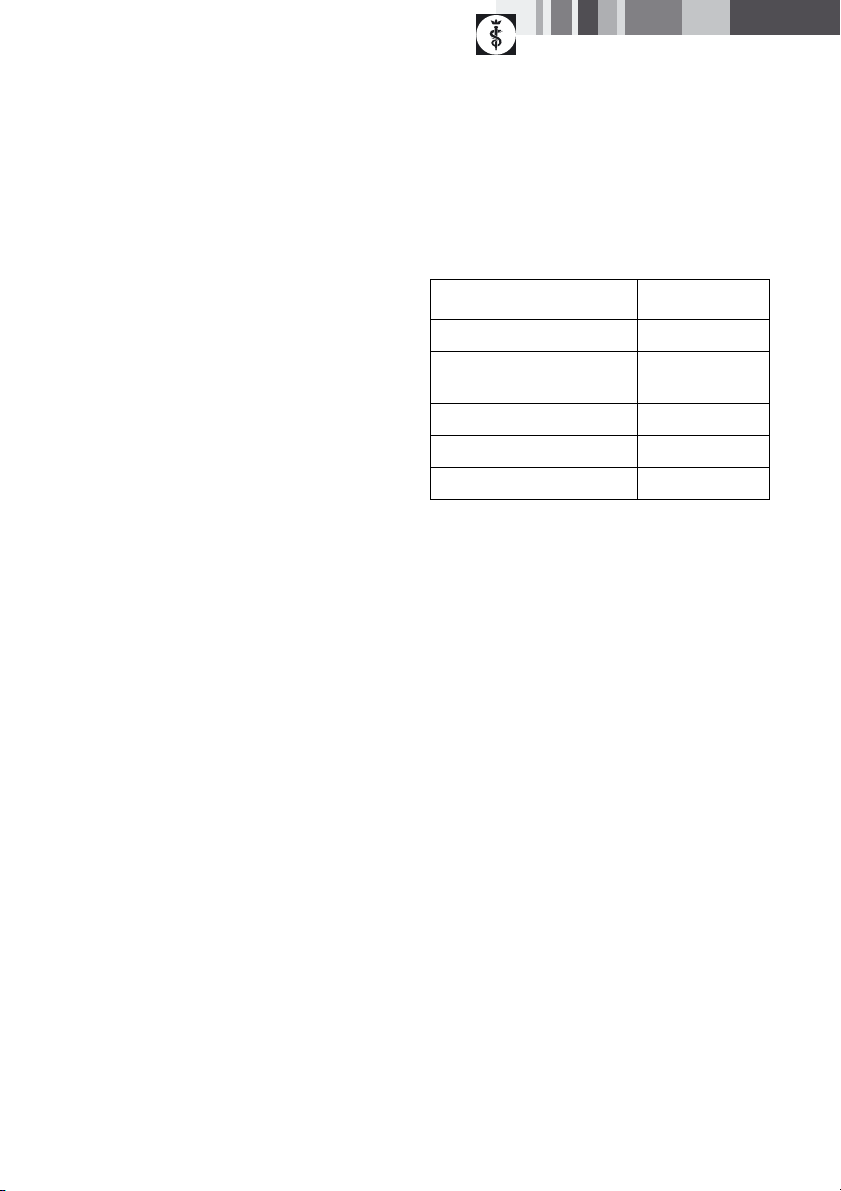

4.4 Technical specifications

GB643R

Kirschner wire ∅ in mm 0.6–4.0

Dimensions L x W x H, inmm93 x 36 x 137

Weight, in grams approx. 300

Gear ratio 25:1

Drive speed, in 1/min max. 1,000

7

Page 10

Aesculap Power Systems

Acculan® 3Ti attachments

5. Drill attachment GB645R

(for radiolucent angle

transmission)

Abb. 4

Note

The drill attachment can be used only with Synthes

Radiolucent Drive 511.300!

Note

Always observe the instructions for use of Synthes

Radiolucent Drive 511.300!

5.1 Intended use

The drill attachment allows connecting a radiolucent

angle transmission for applying drill holes in the bone

under radiographic control.

5.2 Operating principle

The drill attachment is powered by a motor fitted with

an Aesculap Acculan® 3Ti coupling.

The drill attachment transfers the rotational speed of

the motor to the adapted radiolucent angle

transmission.

The drill attachment can be coupled to the motor unit

in three different positions, separated by 120°.

5.3 Safe operation

¾ Couple the drill attachment, siehe Coupling and

uncoupling of attachments on the drill and reamer

motor unit.

Coupling the radiolucent transmission unit

¾ Fully engage the radiolucent angle transmission in

adapter 5.1 of the drill attachment.

¾ If necessary, slightly move the radiolucent unit.

Uncoupling the radiolucent transmission unit

¾ Forcefully pull out the radiolucent angle

transmission from the drill attachment.

8

Page 11

Coupling a tool

Note

Always observe the instructions for use of Synthes

Radiolucent Drive 511.300!

Uncoupling a tool

Note

Always observe the instructions for use of Synthes

Radiolucent Drive 511.300!

5.4 Technical specifications

GB645R

Dimensions L x W x H, inmm110 x 35 x 35

Weight, in grams approx. 225

Gear ratio 30:1

Drive speed, in 1/min max. 900

9

Page 12

Aesculap Power Systems

Acculan® 3Ti attachments

6. Adapter GB628R (AO large to

DHS/DCS)

Abb. 5

6.1 Intended use

The adapter is used for connecting tools with DHS/DCS

coupling to drill or reamer attachments with AOProtek coupling.

6.2 Operating principle

The adapter is driven by a drill or reamer attachment

powered by a motor fitted with an Aesculap Acculan®

3Ti coupling. The drill or reamer attachment transfers

the rotational speed of the motor to adapter GB628R

and thus to the coupled tool.

6.3 Safe operation

Note

Use the adapter only with Synthes tools with DHS/DCS

tool coupling or tools of a comparable geometry!

¾ For information on how to connect the drill and

reamer attachments, siehe Coupling and uncoupling of attachments on the drill and reamer motor

unit.

Uncoupling the adapter

¾ For uncoupling the adapter, siehe Uncoupling a

tool.

Coupling a tool

¾ Slide back unlocking sleeve 6.1.

¾ Insert the tool shaft in its correct position down to

the stop in the tool coupling of the adapter.

¾ Release unlocking sleeve 6.1.

The tool is now coupled.

Uncoupling a tool

¾ Slide back unlocking sleeve 6.1.

¾ Remove the tool.

6.4 Accessories

Designation Synthes art. no.

DHS Tripple Reamer 338.130, 338.430

DHS Reamer 357.044, 357.045

DHS Drill Bit 357.047, 351.270,

359.081, 359.079

6.5 Technical specifications

GB628R

Dimensions L x W x H, inmm61 x 22 x 22

Weight, in grams approx. 70

Drive speed, in 1/min max. 250

Coupling the adapter

¾ For coupling the adapter, siehe Coupling a tool.

10

Page 13

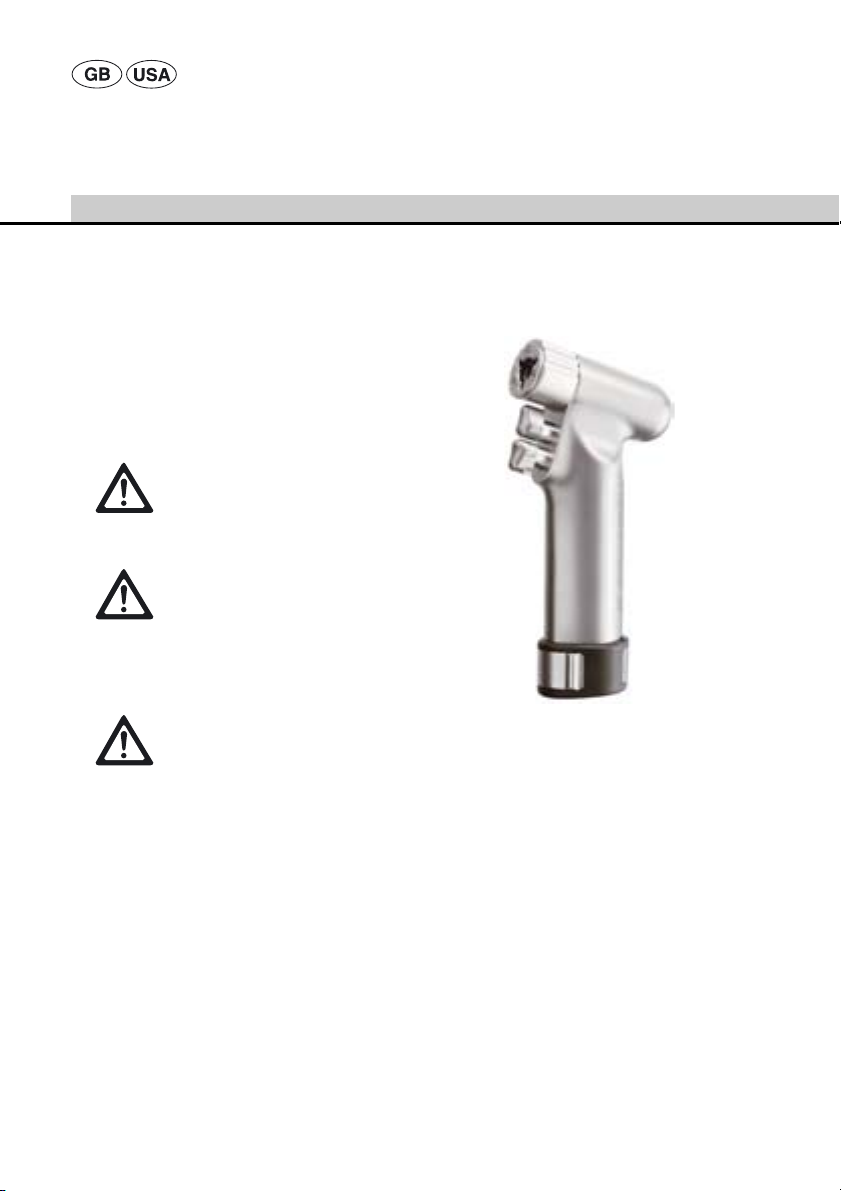

7. Sagittal saw attachment

GB660R

Abb. 6

7.1 Intended use

The sagittal saw attachment is used for intraoperative

dissection of bone and cartilage tissue.

7.2 Operating principle

The sagittal saw attachment is powered by a motor

fitted with the Aesculap Acculan® 3Ti coupling.

The sagittal saw attachment converts the motor

rotation into oscillation of the saw blade. The bone is

dissected by the oscillating movement of the saw

blade.

No key or wrench is required for inserting the saw

blades. The sagittal saw attachment can be coupled to

the drive unit in three different positions separated by

steps of 120°.

7.3 Safe operation

¾ Connect the sagittal saw attachment, siehe Cou-

pling and uncoupling of attachments on the drill

and reamer motor unit.

Coupling the saw blade

¾ Insert the saw blade with its coupling end in the

slot of saw blade coupling 7.1 as far as it will go.

Ensure that the locking pin engages in the saw

blade fenestration, and that the lateral stops of the

saw blade rest on the coupling.

¾ If necessary press button for saw blade release/fix-

ation 7.2.

¾ Check that the tool is seated properly: Pull at the

saw blade.

Uncoupling the saw blade

¾ Fully press button for saw blade release/

fixation 7.2.

¾ Extract the saw blade from saw blade coupling 7.1.

7.4 Technical specifications

GB660R

Dimensions L x W x H, inmm89 x 36 x 44

Weight, in grams approx. 270

Gear ratio 1.5:1

Stroke frequency in 1/min max. 17 000

WARNING

Risk of injury caused by inadvertent

loosening of the saw blade during

operation!

¾ Do not press the button for saw

blade release/fixation during

operation.

¾ Check for secure fixation of the

tool after any tool change.

11

Page 14

Aesculap Power Systems

Acculan® 3Ti attachments

8. Working with the

attachments

8.1 System set-up

Note

The attachments are supplied in unsterile condition.

Risk of infection and

contamination!

¾ Sterilize the attachments prior

DANGER

WARNING

CAUTION

Connecting the accessories

Combinations of accessories that are not mentioned in

the present instructions for use may only be employed

if they are specifically intended for the respective

application, and if they do not compromise the

performance and safety characteristics of the

products.

¾ Please address any questions in this respect to your

B. Braun/Aesculap partner or to Aesculap Customer

Service.

to operation.

Risk of injury due to inadvertent

activation of the motor during

coupling of an attachment/tool!

¾ Secure motors that are not

actually used against

inadvertent activation.

Damage to the attachment caused

by inappropriate tool!

¾ Use an appropriate tool for

changing the attachment tool.

Avoid contact with cutting

edges.

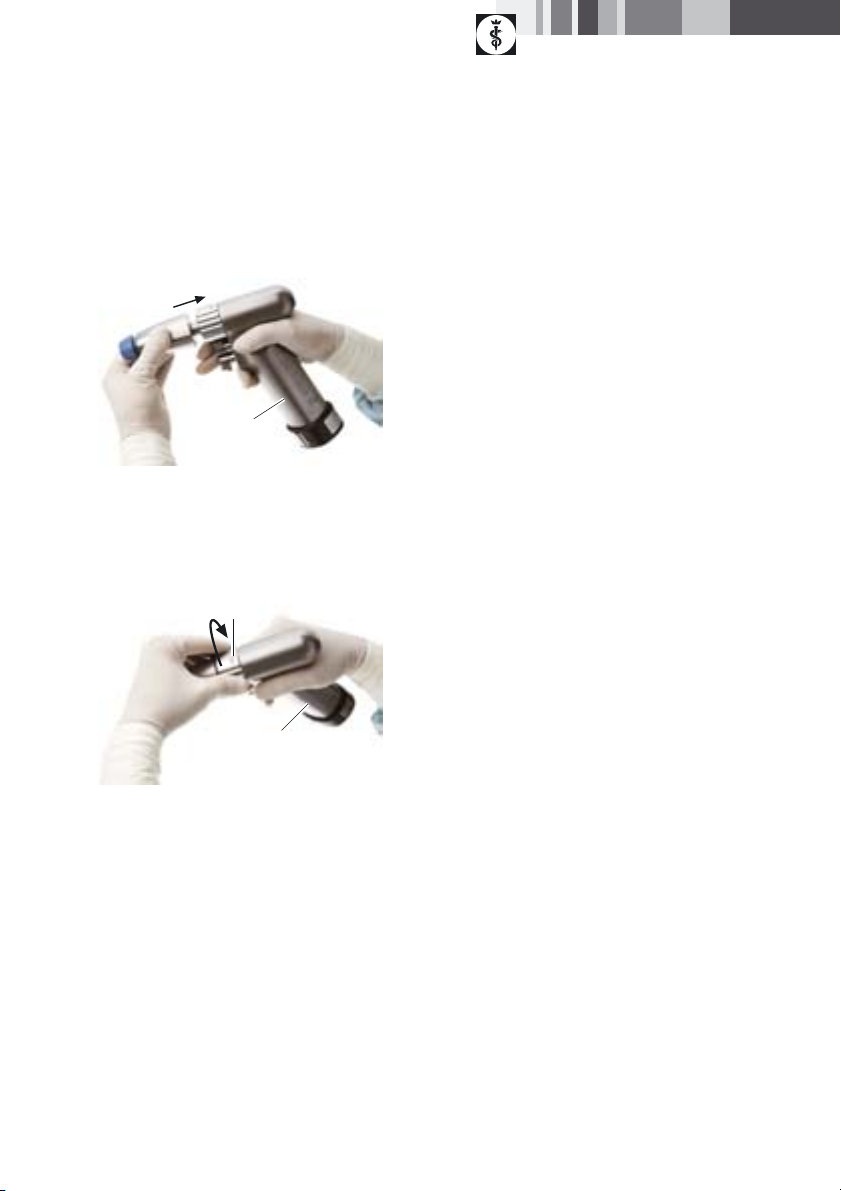

Coupling and uncoupling of attachments on

the drill and reamer motor unit

Protection against inadvertent activation

Abb. 7

The rotational speed control button can be locked to

prevent inadvertent activation of the drill and reamer

motor unit during a tool change.

Note

For further information on the drill and reamer motor

unit, see TA011869.

12

Page 15

Coupling

A

Abb. 8

¾ Push the attachment onto drill and reamer motor

A until it clicks into position.

Uncoupling

B

A

Abb. 9

¾ Turn rotating sleeve B in the direction of the arrow

(clockwise when viewed from the rear end of drill

and reamer motor unit A).

¾ Remove the attachment from drill and reamer

motor unit A.

8.2 Function checks

Note

Function checks must be performed prior to each

operation with the unit and after each intraoperative

attachment or tool change!

¾ Make certain that the attachment is securely

seated.

¾ Make certain that the tool/Kirschner wire is seated

properly.

¾ Briefly run the drill and reamer motor unit, with the

attachment coupled and a tool inserted, at

maximum speed in clockwise and

counterclockwise mode.

¾ Watch out for damage, irregular running noises,

excessive vibrations and excessive heat developed

by the handpieces.

¾ Only use the unit if it is in perfect condition.

13

Page 16

Aesculap Power Systems

Acculan® 3Ti attachments

8.3 General operation

Risk of injury caused by

aerosol formation or particles

during reaming, cutting or

WARNING

WARNING

¾ Start the motor powering the attachment at

moderate speed.

¾ To avoid slipping, apply only moderate pressure.

¾ To avoid tool breakage, do not bend the tool.

¾ Cool the tool during operation. This will improve

chip removal and reduce the risk of necrosis.

drilling!

¾ Always wear eye

protection when using the

drill and reamer motor

unit.

Risk of burns to skin and

tissue caused by hot, blunt

tools!

¾ Do not use damaged or

defective tools.

9. Validated processing procedure

Note

Adhere to national statutory regulations, international

standards and guidelines, and local, clinical hygiene

instructions for sterile processing.

Note

For patients with Creutzfeldt-Jakob disease (CJD),

suspected CJD or possible variants of CJD, observe the

relevant national regulations concerning the

reprocessing of the products.

Note

Mechanical processing should be preferred over

manual cleaning, as mechanical processing produces

better and more reliable cleaning results.

Note

Up-to-date information on processing can be found on

the Aesculap Extranet at www.aesculap-extra.net

Note

Successful processing of this medical product can only

be ensured if processing is performed through a

validated processing procedure. The user/processor is

responsible for the validation.

Due to process tolerances, the manufacturer’s

specifications can only serve as an approximate guide

for assessing the processing procedures applied by the

individual operator/processors.

14

Page 17

9.1 General notes

Encrusted or fixated residues from surgery can make

the cleaning process more difficult or ineffective, and

can cause corrosion of stainless steels. To avoid this,

the time interval between application and processing

should not exceed 6 h, and neither fixating precleaning temperatures >45 °C nor any fixating

disinfecting agents (active ingredient: aldehyde,

alcohol) be used.

Excessive doses of neutralizers or basic detergents can

cause chemical degradation and/or fading and

obliteration of laser inscriptions on stainless steel

surfaces, regarding visual reading and machinereadability of the inscriptions.

Residues containing chlorine or chlorides e.g. in

surgical residues, medicines, saline solutions and in the

service water used for cleaning, disinfection and

sterilization will cause corrosion damage (pitting,

stress corrosion) and result in the destruction of

stainless steel products. To remove such residues, the

products must be rinsed sufficiently with fully

desalinated water and dried thoroughly.

Only process chemicals that have been tested and

approved (e.g. VAH/DGHM or FDA approval or CE mark)

and which are compatible with the product’s materials

according to the chemical manufacturers’

recommendations may be used for processing the

product. All process parameters specified by the

chemical’s manufacturer, such as temperatures,

concentrations and exposure times, must be strictly

observed. Failure to do so can result in the following

problems:

• optical changes to the material, e.g. fading or

discoloration of titanium or aluminum. For

aluminum, pH >8 in the application/process can

already cause visible surface changes.

• material damage such as corrosion, cracks,

fracturing, premature aging or swelling.

¾ Do not use process chemicals that cause stress

cracking or brittleness of plastic materials.

¾ Further detailed advice on hygienically safe and

material-/value-preserving reprocessing can be

found at www.a-k-i.org, Publications Red Brochure

– Proper maintenance of instruments.

9.2 Preparations at the place of use

¾ Disassemble the product immediately after use, as

described in the respective instructions for use.

¾ Dismount all coupled components, e.g. tools (drills,

saw blades, etc.), accessories (adapters, protection

sleeves, etc.), tubes, cables, batteries, etc.

¾ Remove visible surgical residues as completely as

possible, using a lint-free wet wipe.

9.3 Preparation prior to cleaning

¾ Have the product dry in a disposal container and

ready for immediate cleaning and disinfecting

within 30 min after use.

15

Page 18

Aesculap Power Systems

Acculan® 3Ti attachments

9.4 Cleaning/Disinfecting

Damage to the product due to

inappropriate cleaning/disinfecting

agents and/or excessive

CAUTION

temperatures!

¾ Use cleaning and disinfecting

agents according to the

manufacturer’s instructions.

Cleaning and disinfecting agents

must

- be approved for plastics and

high-grade steel,

- not attack softeners (e.g.

silicone).

¾ Observe specifications regarding

concentration, temperature and

exposure time.

¾ Do not exceed the maximum

allowable cleaning temperature

of 55 °C.

¾ Do not clean the motors/handpieces in an

ultrasound bath and do not immerse them in any

fluid.

Let any fluid that penetrates into the product drain

out immediately to avoid the risk of corrosion/

malfunctioning of the product.

16

Page 19

9.5 Manual cleaning/disinfecting

Manual cleaning and wipe disinfection

Stage Step T

[°C/°F]t[min]

I Cleaning RT

(cold)

II Drying RT - - - -

III Wipe disinfection - ≥1 - - Meliseptol HBV wipes

IV Final rinse RT

(cold)

V Drying RT - - - -

D–W: Drinking water

FD–W: Fully desalinated water (demineralized)

RT: Room Temperature

Stage I

¾ Clean the product under running tap water, using

a suitable cleaning brush if necessary, until all

visible residues have been removed from the

surfaces.

¾ Mobilize non-rigid components, such as set screws,

links, etc. during cleaning.

¾ Make certain the product is positioned in such a

way that water will not enter the product e.g.

through coupling interfaces. (Immediately remove

any fluid that entered inadvertently.)

¾ Use the special cleaning brush (TA011944) for

cleaning the cannulation of drill and reamer

attachments/Kirschner wire attachment GB643R.

¾ To avoid the risk of corrosion, do not use a metal

brush or other abrasives that would damage the

surfaces for cleaning the product.

¾ Clean difficult-to-access areas with soft round

plastic brushes of fitting diameter.

Conc.

[%]

--D–W-

0.5 - FD–W -

Stage II

¾ Dry the product with lint-free tissue or medical-

Stage III

¾ Wipe all surfaces of the product with a single-use

Stage IV

¾ After the specified exposure time (of at least

¾ Hold the product in such a way that water cannot

¾ Allow water to drip off for a sufficient length of

Water

quality

50 % Propan-1-ol

quality filtered compressed air.

disinfecting wipe.

1 minute), rinse the disinfected surfaces under

running FD water.

enter it e.g. through couplings or adapters.

time.

Chemical

17

Page 20

Aesculap Power Systems

Acculan® 3Ti attachments

Stage V

¾ Dry the product with lint-free tissue or medical-

quality filtered compressed air.

9.6 Mechanical cleaning/disinfecting

Note

The disinfector must be of proven effectiveness (e.g.

DGHM or FDA approval or CE mark).

Note

For thermal disinfection, always use fully desalinated

(demineralized) water. Ensure that Ao is >3 000 for the

process.

Note

The disinfector used for processing must be serviced

and checked at regular intervals.

¾ If the washer/disinfector is not fitted with internal

rinsing, carry out manual precleaning of the

cannulation, see Manual cleaning/disinfecting,

Stage I.

¾ For Kirschner wire attachment GB643R: Set

adjustment sleeve 4.2 to the largest Kirschner wire

diameter.

¾ For sagittal saw attachment GB660R: Do not rinse

through the interior of the sagittal saw

attachment. Do not connect the Eccos® holder of

the sagittal saw attachment to the rinsing

connector of the washer/disinfector.

¾ Use the Eccos® tray fitted with Acculan® 3Ti

holders, or mount appropriate holders in a suitable

tray (instructions for use TA009721 for Aesculap

Eccos® holder system).

¾ Insert the product in its proper position in the

Eccos® holder.

¾ Connect the internal rinsing equipment at the

Eccos® holder and at the special connector of the

rinsing cart.

18

Page 21

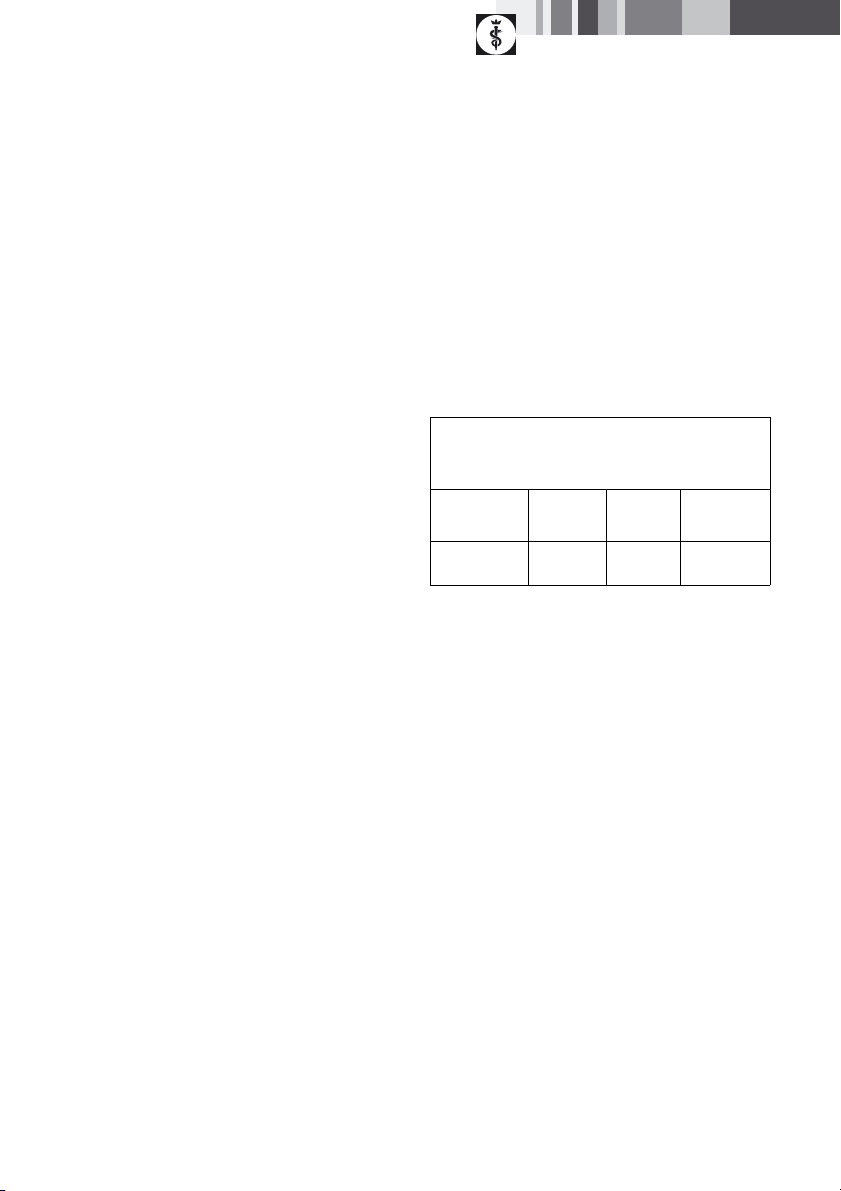

Mechanical alkaline cleaning and thermal disinfecting

Machine type: Single-chamber washer/disinfector without ultrasound

Stage Step T

[°C/°F]

I Prerinse <25/77 3 D–W -

II Cleaning 55/131 10 FD–W BBRAUN HELIMATIC CLEANER

III Intermediate rinse >10/50 1 FD–W -

IV Thermal disinfecting 90/194 5 FD–W -

V Drying - - - according to disinfecting

D–W: Drinking water

FD–W: Fully desalinated water (demineralized)

t

[min]

Water

quality

Chemical/Note

alkaline with tensides,

application solution 0.5 %

program

19

Page 22

Aesculap Power Systems

Acculan® 3Ti attachments

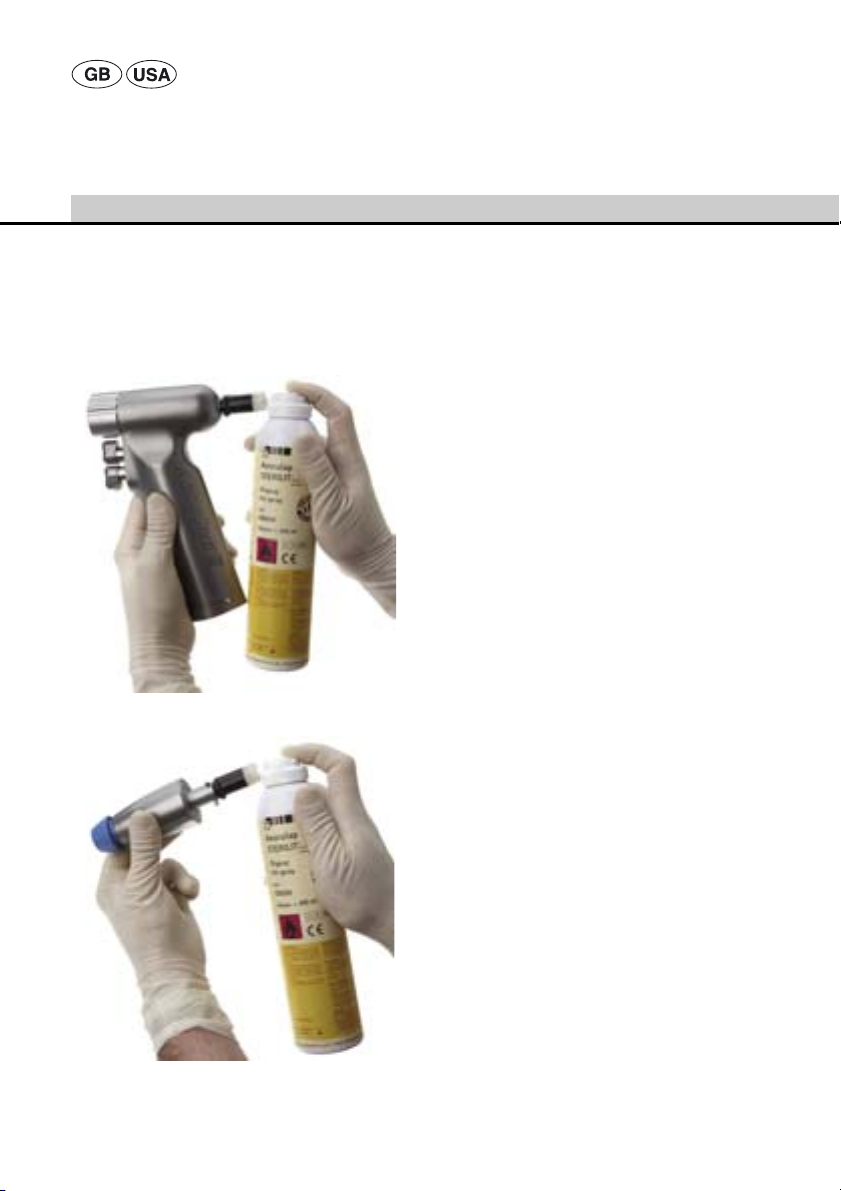

9.7 Inspection, maintenance and checks

Note

Aesculap recommends occasional spraying of moving

parts, e.g. triggers, couplings, cover lids, etc. with

Aesculap STERILIT® Power Systems Oil Spray GB600!

Fig. 10

¾ Allow the product to cool down to room

temperature.

¾ Inspect the product after each cleaning and

disinfecting cycle to be sure it is clean, functional

and undamaged.

¾ Mount the STERILIT® Power Systems adapter

supplied with the product on Aesculap STERILIT®

Power Systems Oil Spray and spray into the

cannulation of the small power drill, see Fig. 10,

and through the drill, reamer and Kirschner wire

attachments, see Fig. 11, in each case from the rear

end and for about 1 sec.

¾ After cleaning/disinfecting, inspect all surfaces and

difficult to access spots on the product for visible

dirt or debris.

¾ Check the product for any damage, atypical

running noise, overheating or excessive vibration.

¾ Inspect tools for broken, damaged or blunt edges.

¾ Set aside the product if it is damaged.

9.8 Packaging

¾ Follow the instructions for use of the respective

packaging and storage holders (e.g. instructions for

use TA009721 for the Aesculap Eccos® holder

system).

¾ Insert the product in its proper position in the

Eccos® holder, or p ut it on a tray in such a way that

the product is protected against damage. Make

certain that all cutting edges are protected.

¾ Package trays appropriately for the sterilization

process (e.g. in Aesculap sterile containers).

¾ Pack the product in such a way that the packaging

will prevent recontamination of the product

(DIN EN ISO 11607).

Fig. 11

20

Page 23

9.9 Sterilization method and

parameters

Note

The product may only be sterilized with all tools etc.

unmounted.

¾ Make certain that all external and internal surfaces

of the product will be exposed to the sterilizing

agent.

¾ Validated sterilization process

– Disassemble the product

– Steam sterilization through fractionated vacuum

process

– Steam sterilizer according to DIN EN 285 and

validated according to DIN EN ISO 17665

– Sterilization through fractionated vacuum process

at 134 °C/2 bar; holding time 5 min.

¾ When sterilizing several products at the same time

in one steam sterilizer: Make certain that the

maximum allowable load capacity of the steam

sterilizer, as specified by the manufacturer, is not

exceeded.

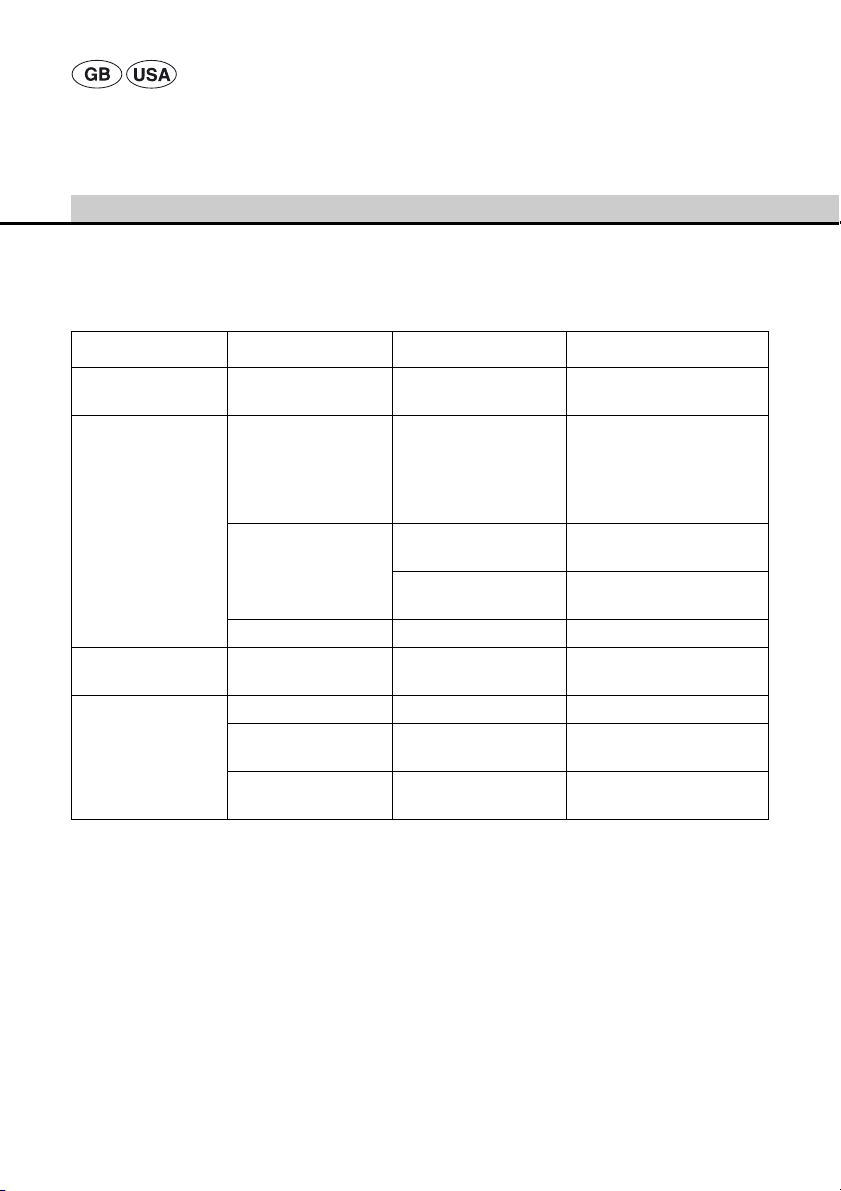

9.10 Sterilization for the US market

• Aesculap does not recommend the device sterilized

by flash or chemical sterilization.

• Sterilization may be accomplished by steam autoclave in a standard prevacuum cycle.

To achieve a sterility assurance level of 10

recommends the following parameters:

Aesculap Orga Tray/Sterilcontainer (perforated

bottom)

Minimum cycle parameters*

Sterilization

method

Pre-vacuum 270 °F—

*Aesculap has validated the above sterilization cycle

and has the data on file. The validation was accomplished in an Aesculap Sterilcontainer cleared by FDA

for the sterilization and storage of these instruments.

Other sterilization cycles may also be suitable, however individuals or hospitals not using the recommended method are advised to validate any alternative

method using appropriate laboratory techniques. Use

an FDA cleared accessory to maintain sterility after

processing, such as a wrap, pouch, etc.

Temp. Time Minimum

4 min 20 min

275 °F

-6

, Aesculap

drying time

9.11 Storage

¾ Store sterile products in germ-proof packaging

under dust protection in a dry, dark and

temperature-controlled room.

21

Page 24

Aesculap Power Systems

Acculan® 3Ti attachments

10. Troubleshooting list

10.1 General malfunctions

Malfunction Cause Finding Remedy

Loud noise Defective gearing Loud noise Have product repaired by the

manufacturer

Tool not moving Attachment not coupled

properly

Defective gearing Motor drive not turning;

- - see TA011869

Deficient cutting

performance

Tool cannot be

coupled

Blunt tool Tool overheats Use a new tool

Wrong tool Incompatible tool Insert appropriate tool

Debris Debris on tool or in

Deformation Deformed tools/coupling

Attachment can not be

extracted from the motor

unit

blocked

Motor running, but not

driving the saw

coupling

components

Couple the attachment

correctly, see Coupling and

uncoupling of attachments on

the drill and reamer motor

unit

Have product repaired by the

manufacturer

Have product repaired by the

manufacturer

Clean the tool/coupling

Have product repaired by the

manufacturer

22

Page 25

10.2 Malfunctions of the Kirschner wire attachment

Malfunction Cause Finding Remedy

Kirschner wire cannot

be inserted into

Kirschner wire

attachment

Kirschner wire not

turning

Incorrect adjustment of

Kirschner wire

attachment

Incorrect adjustment of

Kirschner wire

attachment

Clamping lever open Clamping lever open Close the clamping lever

Kirschner wire diameter

not matching the

setting of the adjustment

sleeve

Kirschner wire diameter

not matching the

setting on the

adjustment scale

Set the adjustment sleeve to

the correct Kirschner wire

diameter

Set the adjustment sleeve to

the correct Kirschner wire

diameter

10.3 Malfunctions of the sagittal saw attachment

Malfunction Cause Finding Remedy

Saw blade cannot be

uncoupled

Release button not

pressed through

properly

Locking pin not fully

releasing the saw blade

Fully press down the release

button, see Coupling the saw

blade

23

Page 26

Aesculap Power Systems

Acculan® 3Ti attachments

11. Maintenance

To ensure reliable operation, maintenance has to be

carried out as indicated on the service label, see Fig. 12,

e.g. February 2012.

Such maintenance must also include a safety

inspection according to §6 MPBetreibV (or equivalent).

The extent of the safety inspection is specified in the

Service Manual, which is available as a separate

document.

For services to this end, please contact your national B.

Braun/Aesculap agency, see Technical Service.

Fig. 12

12. Technical Service

For service and repairs, please contact your national

B. Braun/Aesculap agency.

Modifications carried out on medical technical

equipment may result in loss of guarantee/warranty

rights and forfeiture of applicable licenses.

Service addresses

Aesculap Technischer Service

Am Aesculap-Platz

78532 Tuttlingen / Germany

Phone: +49 7461 95-1601

Fax: +49 7461 14-939

E-Mail: ats@aesculap.de

Or in the US:

Aesculap Inc.

Attn. Aesculap Technical Services

615 Lambert Pointe Drive

Hazelwood, MO 63042

Aesculap Repair Hotline

Phone: +1 800 214-3392

Fax: +1 314 895-4420

Other service addresses can be obtained from the

address indicated above.

24

Page 27

13. Accessories/Spare parts

Designation Application Art. no.

Cleaning brush All drill and reamer attachments/Kirschner wire

Key for Jacobs chuck attachments Only for drill attachment GB638R GA031201

Eccos® holder, triple All attachments GB496R

Eccos® holder, single All attachments GB497R

Aesculap STERILIT® Power

Systems oil spray

STERILIT® Power Systems adapter All drill, reamer and Kirschner wire attachments GB600840

Eccos® tray with holders for

Acculan® 3Ti

Note

For further information about the Aesculap Eccos® holder system, see TA009721.

attachment GB643R

Only for Kirschner wire attachment GB644R TA011327

All attachments GB600

All attachments GB243R

TA011944

GB244R

25

Page 28

Aesculap Power Systems

Acculan® 3Ti attachments

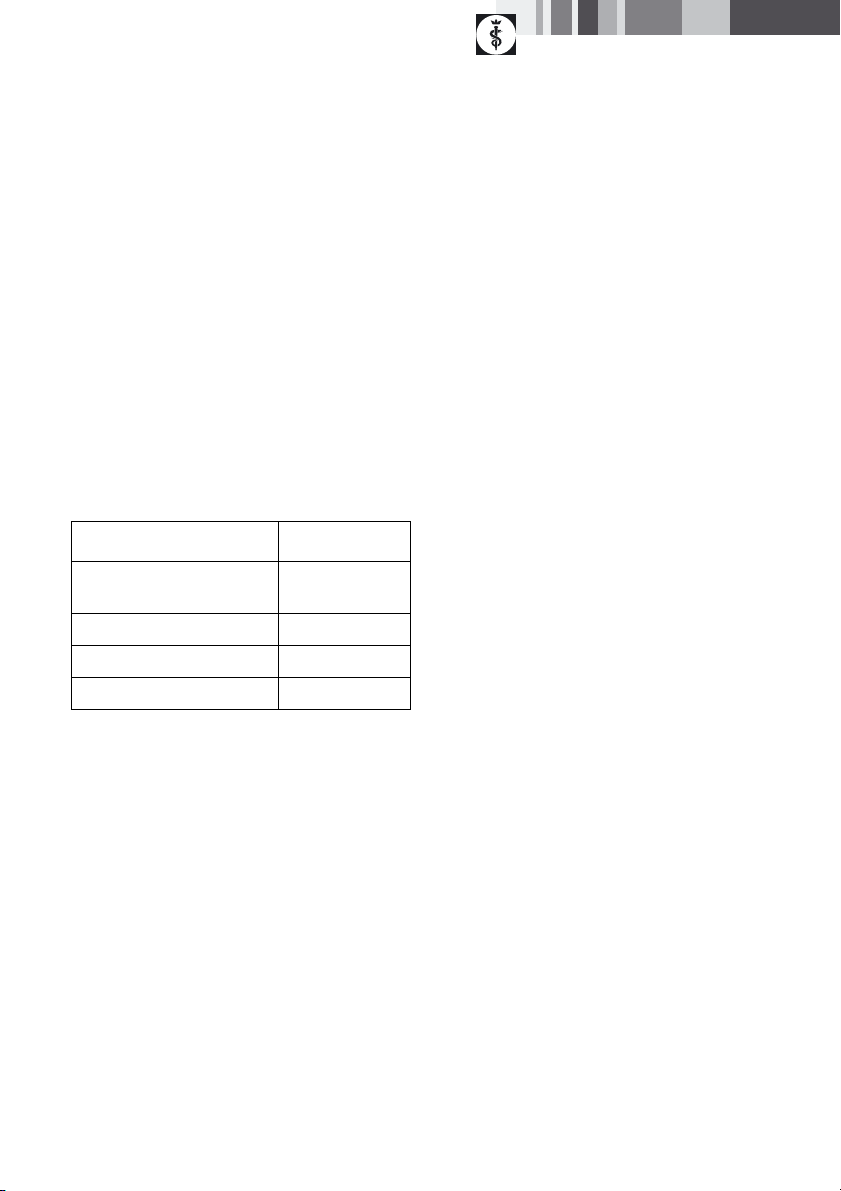

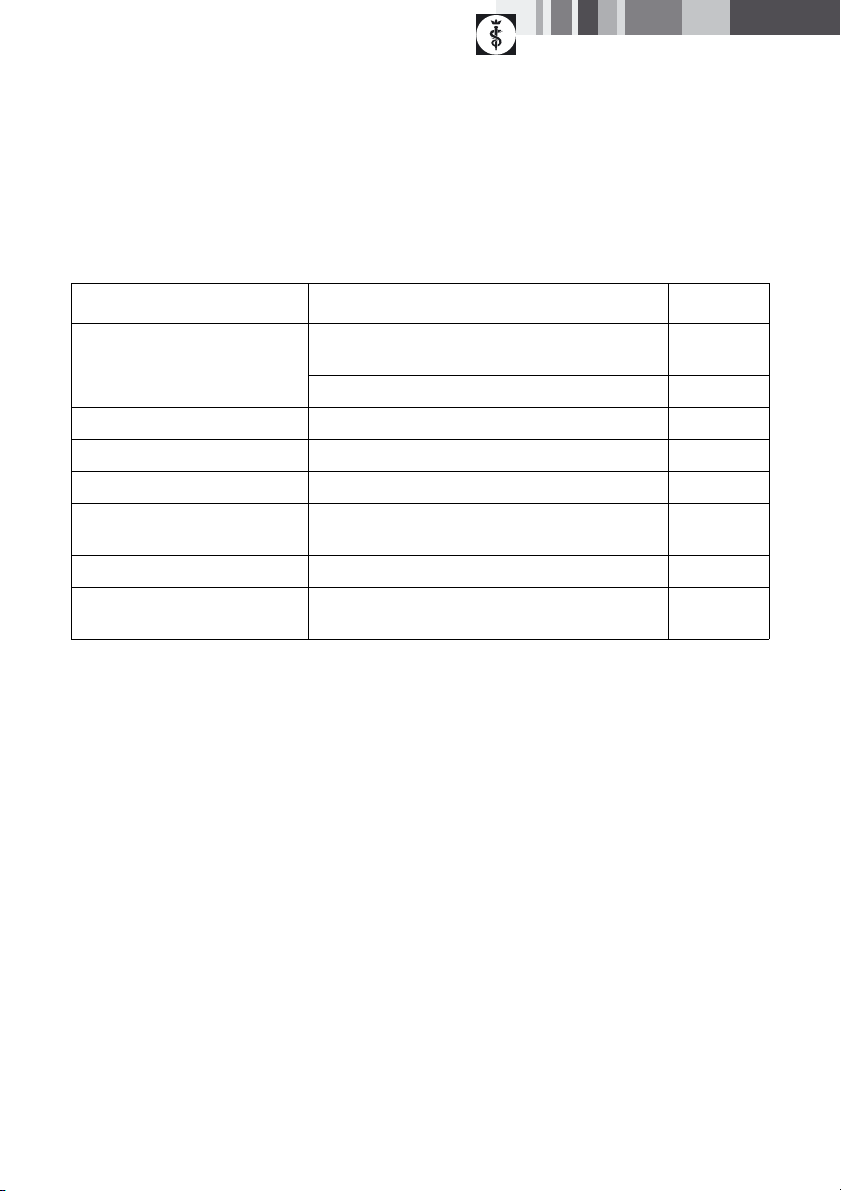

14. Technical specifications

Classification acc. to Directive 93/42/EEC

Art. no. Designation Class

GB628R Adapter IIa

GB630R Drill attachment Hudson/Zimmer IIa

GB634R Jacobs chuck, keyless IIa

GB635R Drill attachment AO small IIa

GB636R Drill attachment Aesculap

hexagon

GB637R Drill attachment Trinkle IIa

GB638R Drill attachment Jacobs chuck

with key

GB643R Kirschner wire attachment IIa

GB645R Drill attachment for radiolucent

angle transmission

GB654R Reamer attachment Harris IIa

GB655R Reamer attachment A0 large IIa

GB656R Reamer attachment Hudson/

Zimmer

GB660R Sagittal saw attachment IIa

IIa

IIa

IIa

IIa

14.1 Ambient conditions

Operation Transport and

storage

Temperature

Relative

humidity

Atmospheric

pressure

26

Page 29

15. Disposal

Note

The user institution is obliged to process the product

before its disposal, see Validated processing procedure.

Adhere to national regulations

when disposing of or recycling the

product, its components and its

packaging!

The recycling pass can be

downloaded from the Extranet as a

PDF document under the respective

article number. (The recycling pass

includes disassembling instructions

for the product, as well as

information for proper disposal of

components harmful to the

environment.)

Products carrying this symbol are

subject to separate collection of

electric and electronic devices.

Within the European Union, disposal

is taken care of by the manufacturer

as a free-of-charge service.

¾ Please contact your national B. Braun/Aesculap

agency with any inquiries regarding the disposal of

the product, see Technical Service

16. Distributor in the US/Contact

in Canada for product information and complaints

Aesculap Inc.

3773 Corporate Parkway

Center Valley, PA 18034

USA

27

Page 30

Aesculap Power Systems

Acculan® 3Ti Aufsätze

Legende

1 Bohraufsatz (schwarze Entriegelungshülse)

2 Fräsaufsatz (blaue Entriegelungshülse)

2.1 Entriegelungshülse

3 Bohraufsatz mit Dreibackenfutter

4 Spickdrahtfutter

4.1 Skala

4.2 Einstellhülse

4.3 Spannhebel

5 Bohraufsatz (für röntgenstrahldurchlässiges

Winkelgetriebe)

5.1 Aufnahme für röntgenstrahldurchlässiges

Winkelgetriebe

6 Adapter (AO groß auf DHS/DCS)

6.1 Entriegelungshülse

7 Sagittalsägeaufsatz

7.1 Sägeblattkupplung

7.2 Druckknopf zur Sägeblattentriegelung/-fixierung

Symbole an Produkt und Verpackung

Gebrauchsanweisung einhalten

Hinweis auf den nächsten

Instandhaltungstermin (Datum)

bei der internationalen B. Braun/

Aesculap-Vertretung, siehe

Instandhaltung

Herstelldatum

Inhaltsverzeichnis

1. Sichere Handhabung ............................................29

2. Gerätebeschreibung .............................................29

2.1 Lieferumfang ..........................................................29

2.2 Zum Betrieb erforderliche Komponenten ......29

3. Bohr- und Fräsaufsätze .......................................30

3.1 Verwendungszweck ..............................................30

3.2 Funktionsweise ......................................................30

3.3 Bedienung ...............................................................30

Werkzeug kuppeln................................................ 30

Werkzeug entkuppeln.......................................... 30

3.4 Technische Daten ..................................................31

4. Spickdrahtfutter GB643R ...................................32

4.1 Verwendungszweck ..............................................32

4.2 Funktionsweise ......................................................32

4.3 Bedienung ...............................................................32

Spickdraht einführen ........................................... 33

Spickdraht spannen.............................................. 33

4.4 Technische Daten ..................................................33

5. Bohraufsatz GB645R (für röntgenstrahldurch-

lässiges Winkelgetriebe) .....................................34

5.1 Verwendungszweck ..............................................34

5.2 Funktionsweise ......................................................34

5.3 Bedienung ...............................................................34

Röntgenstrahldurchlässiges Winkelgetriebe

kuppeln .................................................................... 34

Röntgenstrahldurchlässiges Winkelgetriebe

entkuppeln.............................................................. 34

Werkzeug kuppeln................................................ 35

Werkzeug entkuppeln.......................................... 35

5.4 Technische Daten ..................................................35

6. Adapter GB628R (AO groß auf DHS/DCS) .....36

6.1 Verwendungszweck ..............................................36

6.2 Funktionsweise ......................................................36

6.3 Bedienung ...............................................................36

Adapter kuppeln.................................................... 36

Adapter entkuppeln.............................................. 36

Werkzeug kuppeln................................................ 36

Werkzeug entkuppeln.......................................... 36

6.4 Zubehör ....................................................................36

6.5 Technische Daten ..................................................36

7. Sagittalsägeaufsatz GB660R .............................37

7.1 Verwendungszweck ..............................................37

7.2 Funktionsweise ......................................................37

7.3 Bedienung ...............................................................37

Sägeblatt kuppeln................................................. 37

Sägeblatt entkuppeln........................................... 37

7.4 Technische Daten ..................................................37

8. Arbeiten mit den Aufsätzen ...............................38

28

Page 31

8.1 Bereitstellen ...........................................................38

Zubehör anschließen............................................ 38

Aufsätze an Bohr- und Fräsantrieb kuppeln

und entkuppeln...................................................... 38

8.2 Funktionsprüfung ..................................................39

8.3 Allgemeine Bedienung .........................................40

9. Validiertes Aufbereitungsverfahren .................40

9.1 Allgemeine Hinweise ...........................................41

9.2 Vorbereitung am Gebrauchsort .........................41

9.3 Vorbereitung vor der Reinigung .......................41

9.4 Reinigung/Desinfektion .......................................42

9.5 Manuelle Reinigung/Desinfektion ....................43

Manuelle Reinigung und

Wischdesinfektion................................................. 43

9.6 Maschinelle Reinigung/Desinfektion ...............44

Maschinelle alkalische Reinigung und

thermische Desinfektion..................................... 45

9.7 Kontrolle, Wartung und Prüfung ......................46

9.8 Verpackung .............................................................46

9.9 Sterilisieren .............................................................47

9.10 Lagerung ..................................................................47

10. Fehler erkennen und beheben ...........................48

10.1 Allgemeine Störungen .........................................48

10.2 Störungen am Spickdrahtfutter ........................49

10.3 Störungen am Sagittalsägeaufsatz ..................49

11. Instandhaltung ......................................................49

12. Technischer Service ..............................................50

13. Zubehör/Ersatzteile ..............................................50

14. Allgemeine Technische Daten ...........................51

14.1 Umgebungsbedingungen ....................................51

15. Entsorgung ..............................................................51

1. Sichere Handhabung

¾ Um Schäden durch unsachgemäßen Aufbau oder

Betrieb zu vermeiden und Haftung nicht zu gefährden:

– Produkt nur gemäß dieser Gebrauchsanweisung

verwenden.

– Sicherheitsinformationen und Instandhaltungs-

hinweise einhalten.

– Nur Aesculap-Produkte miteinander kombinieren.

¾ Produkt und Zubehör nur von Personen betreiben

und anwenden lassen, die die erforderliche Ausbildung, Kenntnis oder Erfahrung haben.

¾ Gebrauchsanweisung für das OP-Personal zugäng-

lich aufbewahren.

¾ Gültige Normen einhalten.

2. Gerätebeschreibung

2.1 Lieferumfang

Bezeichnung Art.-Nr. Beiliegend

Reinigungsbürste TA011944 Alle Bohr- und

Schlüssel für

Dreibackenfutter

GA031201 Bei Bohraufsatz

2.2 Zum Betrieb erforderliche Komponenten

Bezeichnung Art.-Nr.

Acculan® 3Ti Kleine Bohrmaschine

Acculan® 3Ti Bohr- und Fräsantrieb

Aufsatz Je nach Indikation

Adapter Je nach Indikation

geeignete Werkzeuge und

Spickdrähte

Hinweis

Für Kombinationsmöglichkeiten der Aufsätze auf die

Acculan® 3Ti Kleine Bohrmaschine GA671, Gebrauchsanweisung einhalten, siehe TA012033 !

Fräsaufsätze/

Spickdrahtfutter GB643R

GB638R

GA671

GA672

Je nach Indikation

29

Page 32

Aesculap Power Systems

Acculan® 3Ti Aufsätze

3. Bohr- und Fräsaufsätze

Abb. 1

3.1 Verwendungszweck

Bohr- und Fräsaufsätze nehmen rotierende Werkzeuge

auf, die in der Knochenchirurgie eingesetzt werden, um

Knochen und Knorpel zu bearbeiten.

3.2 Funktionsweise

Die Bohr- und Fräsaufsätze werden durch einen

Antrieb mit Aesculap Acculan® 3Ti Kupplung angetrieben.

Die Bohr- und Fräsaufsätze nehmen die Drehzahl des

Antriebs auf und übertragen die Rotation auf das im

jeweiligen Aufsatz eingespannte Werkzeug.

Die Bohr- und Fräsaufsätze können in drei verschiedene Stellungen, um je 120° versetzt, auf den Antrieb

gekuppelt werden.

Bohraufsätze sind an der schwarzen und Fräsaufsätze

an der blauen Entriegelungshülse erkennbar.

3.3 Bedienung

Verletzungsgefahr durch Hitzenekrosenbildung!

¾ Bohraufsätze nicht zum Betrieb

GEFAHR

Empfohlene Anwendung

GB630R, GB634R, GB635R, GB636R, GB637R und

GB638R nur zum Bohren und Gewindeschneiden verwenden.

GB654R, GB655R und GB656R nur zum Fräsen und

Markraumbohren verwenden.

¾ Bohr- und Fräsaufsätze anschließen, siehe Auf-

sätze an Bohr- und Fräsantrieb kuppeln und entkuppeln.

Werkzeug kuppeln

¾ Entriegelungshülse 2.1 zurückziehen.

¾ Werkzeugschaft in richtiger Lage bis zum Anschlag

in Werkzeugaufnahme des Aufsatzes schieben.

¾ Entriegelungshülse 2.1 loslassen.

Das Werkzeug ist gekuppelt.

Werkzeug entkuppeln

¾ Entriegelungshülse 2.1 zurückziehen.

¾ Werkzeug entnehmen.

von Fräswerkzeugen wie Acetabulumfräser und Markraumbohrer verwenden.

¾ Fräswerkzeuge nur mit Fräsauf-

sätzen betreiben.

30

Page 33

3.4 Technische Daten

Bohraufsätze (schwarze Entriegelungshülse)

GB630R GB634R GB635R GB636R GB637R GB638R

Anschluss Hudson/

Zimmer

Abmessung

Länge x ∅ in mm

Gewicht in Gramm ca. 263 ca. 430 ca. 246 ca. 253 ca. 250 ca. 333

Übersetzungsverhältnis

Antriebsdrehzahl

in 1/min

Drehmoment

in Nm

Kanülierung

∅ in mm

Fräsaufsätze (blaue Entriegelungshülse)

Anschluss Harris AO groß Hudson/Zimmer

Abmessung

Länge x ∅ in mm

Gewicht in Gramm ca. 323 ca. 334 ca. 344

Übersetzungsverhältnis 100:1 100:1 100:1

Antriebsdrehzahl in 1/min max. 250 max. 250 max. 250

Drehmoment in Nm max. 19 max. 19 max. 19

Kanülierung ∅ in mm 444

ca. 100 x 39 ca. 125 x 39 ca. 90 x 39 ca. 86 x 39 ca. 93 x 39 ca.110 x 39

25:1 25:1 25:1 25:1 25:1 25:1

max. 1 000 max. 1 000 max. 1 000 max. 1 000 max. 1 000 max. 1 000

max. 5 max. 5 max. 5 max. 5 max. 5 max. 5

4 4 4444

Dreibackenfutter schlüssellos

∅ 0,6–7,4 mm

GB654R GB655R GB656R

ca. 106 x 39 ca. 107 x 39 ca. 118 x 39

AO klein Aesculap

Sechskant

Trinkle Dreibackenfut-

ter mit Schlüssel

∅ 0–6,5 mm

31

Page 34

Aesculap Power Systems

Acculan® 3Ti Aufsätze

4. Spickdrahtfutter GB643R

Abb. 2

4.1 Verwendungszweck

Spickdrahtaufsätze werden in der Orthopädie und der

Traumatologie verwendet, um Spickdrähte in Knochen

einzubringen.

4.3 Bedienung

Bei Verwendung langer Bohrdrähte ist zum Schutz vor

Verletzungen die beigelegte Spickdrahtschutzhülse

einzuschrauben.

17 15

Abb. 3

¾ Spickdrahtschutzhülse 15 in Aufnahme 17 ein-

schrauben.

¾ Spickdrahtaufsatz anschließen, siehe Aufsätze an

Bohr- und Fräsantrieb kuppeln und entkuppeln.

¾ Spannhebel 4.3 über den Drückern des Bohr- und

Fräsantriebs ausrichten.

4.2 Funktionsweise

Spickdrahtaufsätze werden durch einen Antrieb mit

Aesculap Acculan® 3Ti Kupplung angetrieben.

Das Spickdrahtfutter ist ein Schnellspannfutter. Es

spannt Spickdrähte und treibt sie an.

32

Page 35

Spickdraht einführen

Folgende Durchmesserbereiche für die Einstellhülse

können eingestellt werden:

∅ 0,6–1,8 mm

∅ 1,8–3,0 mm

∅ 3,0–4,0 mm

¾ Spannhebel 4.3 in vorderer Position belassen (von

der Antriebsmaschine weg).

¾ Einstellhülse 4.2 für Spickdrahtdurchmesser auf

gewünschten Durchmesserbereich einstellen: Einstellhülse 4.2 nach hinten drücken und drehen, bis

gewünschter Durchmesserbereich eingestellt ist.

¾ Einstellhülse 4.2 loslassen und dabei sicherstellen,

dass Einstellhülse 4.2 einrastet.

¾ Spickdraht in Spickdrahtfutter einführen, bis

gewünschte Ausspannlänge erreicht ist.

Durch eine leichte selbstständige Klemmung im

Spickdrahtfutter bleibt der Spickdraht in der

gewünschten Position.

Spickdraht spannen

¾ Spannhebel 4.3 in Richtung Antriebsmaschine zie-

hen (je stärker der Spannhebel zurückgezogen wird

desto höher die Spannkraft des Spickdrahts).

Spickdraht ist gespannt.

Hinweis

Nur solange der Spannhebel zur Antriebsmaschine

gezogen ist, bleibt der Spickdraht gespannt. Beim Loslassen des Spannhebels geht der Spannhebel eigenständig in die vordere Position zurück und der Spickdraht ist wieder frei verschiebbar.

4.4 Technische Daten

GB643R

Spickdraht ∅ in mm 0,6–4,0

Abmessung L x B x H in mm 93 x 36 x 137

Gewicht in Gramm ca. 300

Übersetzungsverhältnis 25:1

Antriebsdrehzahl in 1/min max. 1 000

33

Page 36

Aesculap Power Systems

Acculan® 3Ti Aufsätze

5. Bohraufsatz GB645R

(für röntgenstrahldurchlässiges Winkelgetriebe)

Abb. 4

Hinweis

Der Bohraufsatz ist nur für den Gebrauch des röntgenstrahldurchlässigen Winkelgetriebe s 511.300 der Firma

Synthes geeignet!

Hinweis

Gebrauchsanweisung des röntgenstrahldurchlässigen

Winkelgetriebes 511.300 der Firma Synthes einhalten!

5.1 Verwendungszweck

Der Bohraufsatz ermöglicht den Anschluss eines röntgenstrahldurchlässigen Winkelgetriebes, um Bohrungen in den Knochen unter Röntgenbildkontrolle zu setzen.

5.2 Funktionsweise

Der Bohraufsatz wird durch einen Antrieb mit der Aesculap-Acculan® 3Ti Kupplung angetrieben.

Der Bohraufsatz nimmt die Drehzahl des Antriebs auf

und überträgt die Rotation auf das adaptierte röntgenstrahldurchlässige Winkelgetriebe.

Der Bohraufsatz kann in drei verschiedenen Stellungen, um je 120° versetzt, auf den Antrieb gekuppelt

werden.

5.3 Bedienung

¾ Bohraufsatz anschließen, siehe Aufsätze an Bohr-

und Fräsantrieb kuppeln und entkuppeln.

Röntgenstrahldurchlässiges Winkelgetriebe

kuppeln

¾ Röntgenstrahldurchlässiges Winkelgetriebe bis

zum Anschlag auf Aufnahme 5.1 des Bohraufsatzes aufstecken.

¾ Ggf. röntgenstrahldurchlässiges Winkelgetriebe

leicht hin- und herbewegen.

Röntgenstrahldurchlässiges Winkelgetriebe

entkuppeln

¾ Röntgenstrahldurchlässiges Winkelgetriebe durch

kräftiges Ziehen vom Bohraufsatz abziehen.

34

Page 37

Werkzeug kuppeln

Hinweis

Gebrauchsanweisung des röntgenstrahldurchlässigen

Winkelgetriebes 511.300 der Firma Synthes einhalten!

Werkzeug entkuppeln

Hinweis

Gebrauchsanweisung des röntgenstrahldurchlässigen

Winkelgetriebes 511.300 der Firma Synthes einhalten!

5.4 Technische Daten

GB645R

Abmessung L x B x H in mm 110 x 35 x 35

Gewicht in Gramm ca. 225

Übersetzungsverhältnis 30:1

Antriebsdrehzahl in 1/min max. 900

35

Page 38

Aesculap Power Systems

Acculan® 3Ti Aufsätze

6. Adapter GB628R (AO groß

auf DHS/DCS)

Abb. 5

6.1 Verwendungszweck

Der Adapter wird verwendet, um Werkzeuge mit DHS/

DCS-Anschluss auf Bohr- oder Fräsaufsätze mit AOProtek-Anschluss anzuschließen.

6.2 Funktionsweise

Der Adapter wird durch einen Bohr- oder Fräsaufsatz

angetrieben, der von einem Antrieb mit AesculapAcculan® 3Ti Kupplung angetrieben wird. Der Bohroder Fräsaufsatz nimmt die Drehzahl des Antriebs auf

und überträgt die Rotation auf den Adapter GB628R

und somit auf das eingespannte Werkzeug.

6.3 Bedienung

Hinweis

Den Adapter nur mit Synthes-Werkzeugen mit DHS/

DCS-Werkzeuganschluss sowie Werkzeugen vergleichbarer Geometrie verwenden!

¾ Bohr- und Fräsaufsätze anschließen, siehe Auf-

sätze an Bohr- und Fräsantrieb kuppeln und entkuppeln.

Adapter entkuppeln

¾ Adapter entkuppeln, siehe Werkzeug entkuppeln.

Werkzeug kuppeln

¾ Entriegelungshülse 6.1 zurückziehen.

¾ Werkzeugschaft lagerichtig bis zum Anschlag in

Werkzeugaufnahme des Adapters schieben.

¾ Entriegelungshülse 6.1 loslassen.

Das Werkzeug ist gekuppelt.

Werkzeug entkuppeln

¾ Entriegelungshülse 6.1 zurückziehen.

¾ Werkzeug entnehmen.

6.4 Zubehör

Bezeichnung Synthes Art.-Nr.

DHS - Dreistufenbohrer 338.130, 338.430

DHS - Stufenbohrer 357.044, 357.045

DHS - Spiralbohrer 357.047, 351.270,

359.081, 359.079

6.5 Technische Daten

GB628R

Abmessung L x B x H in mm 61 x 22 x 22

Gewicht in Gramm ca. 70

Antriebsdrehzahl in 1/min max. 250

Adapter kuppeln

¾ Adapter kuppeln, siehe Werkzeug kuppeln.

36

Page 39

7. Sagittalsägeaufsatz GB660R

Abb. 6

7.1 Verwendungszweck

Der Sagittalsägeaufsatz wird zum intraoperativen

Trennen von Knochen und Knorpel verwendet.

7.2 Funktionsweise

Der Sagittalsägeaufsatz wird durch einen Antrieb mit

Aesculap-Acculan® 3Ti Kupplung angetrieben.

Der Sagittalsägeaufsatz wandelt die Motordrehzahl in

Oszillation des Sägeblatts um. Die hin- und hergehenden Bewegungen des Sägeblatts trennen den Knochen.

Die Sägeblätter werden schlüssellos eingesetzt. Der

Sagittalsägeaufsatz kann in drei verschiedene Stellungen, um je 120° versetzt, auf den Antrieb gekuppelt

werden.

7.3 Bedienung

Verletzungsgefahr durch unbeabsichtigtes Lösen des Sägeblatts

während des Betriebs!

WARNUNG

¾ Während des Betriebs Druckknopf

zur Sägeblattentriegelung/-fixierung nicht drücken.

¾ Nach jedem Werkzeugwechsel

sicheren Sitz des Werkzeugs

prüfen.

¾ Sagittalsägeaufsatz anschließen, siehe Aufsätze an

Bohr- und Fräsantrieb kuppeln und entkuppeln.

Sägeblatt kuppeln

¾ Sägeblatt mit Anschlussseite in Schlitz der Säge-

blattkupplung 7.1 bis zum Anschlag einführen.

Dabei sicherstellen, dass der Arretierbolzen in das

Fenster des Sägeblatts einrastet und die seitlichen

Anschläge des Sägeblatts an der Kupplung anliegen.

¾ Ggf. Druckknopf zur Sägeblattentriegelung/-fixie-

rung betätigen 7.2.

¾ Sicheren Sitz des Werkzeugs prüfen: Am Sägeblatt

ziehen.

Sägeblatt entkuppeln

¾ Druckknopf zur Sägeblattentriegelung/-

fixierung 7.2 ganz durchdrücken.

¾ Sägeblatt aus Sägeblattkupplung 7.1 herauszie-

hen.

7.4 Technische Daten

GB660R

Abmessung L x B x H in mm 89 x 36 x 44

Gewicht in Gramm ca. 270

Übersetzungsverhältnis 1,5:1

Hubzahl in 1/min max. 17 000

37

Page 40

Aesculap Power Systems

Acculan® 3Ti Aufsätze

8. Arbeiten mit den Aufsätzen

8.1 Bereitstellen

Hinweis

Die Aufsätze werden unsteril geliefert.

Gefahr von Infektionen und Kontaminationen!

¾ Aufsätze vor Inbetriebnahme

GEFAHR

WARNUNG

VORSICHT

Zubehör anschließen

Zubehörkombinationen, die nicht in der Gebrauchsanweisung erwähnt sind, dürfen nur verwendet werden,

wenn sie ausdrücklich für die vorgesehene Anwendung

bestimmt sind. Leistungsmerkmale sowie Sicherheitsanforderungen dürfen nicht nachteilig beeinflusst

werden.

¾ Bei Fragen wenden Sie sich an Ihren B. Braun/

Aesculap-Partner oder den Aesculap-Kundendienst.

steril aufbereiten.

Verletzungsgefahr beim Kuppeln

von Aufsatz/Werkzeug durch unbeabsichtigte Betätigung des Motors!

¾ Motoren, mit denen nicht aktiv

gearbeitet wird, gegen unbeabsichtigte Betätigung sichern.

Beschädigung des Aufsatzes durch

unpassendes Werkzeug!

¾ Beim Werkzeugwechsel pas-

sendes Werkzeug verwenden

und Kontakt mit den Werkzeugschneiden vermeiden.

Aufsätze an Bohr- und Fräsantrieb kuppeln

und entkuppeln

Sicherung gegen unbeabsichtigtes Betätigen

Abb. 7

Um zu verhindern, dass der Bohr- und Fräsantrieb beim

Werkzeugwechsel unbeabsichtigt betrieben wird, kann

der Drücker zur Drehzahlregulierung gesperrt werden.

Hinweis

Weitere Informationen zum Bohr- und Fräsantrieb,

siehe TA011869.

38

Page 41

Kuppeln

A

Abb. 8

¾ Aufsatz auf Bohr- und Fräsantrieb A schieben, bis

er hörbar einrastet.

Entkuppeln

B

A

Abb. 9

¾ Drehhülse B in Pfeilrichtung im Uhrzeigersinn (in

Blickrichtung von hinten auf Bohr- und Fräsantrieb A)

drehen.

¾ Aufsatz von Bohr- und Fräsantrieb A abnehmen.

8.2 Funktionsprüfung

Hinweis

Vor jedem OP-Einsatz und nach jedem intraoperativen

Aufsatz- und Werkzeugwechsel muss die Funktionsprüfung durchgeführt werden.

¾ Sicheren Sitz des Aufsatzes prüfen.

¾ Sicheren Sitz des Werkzeugs/Spickdrahts prüfen.

¾ Bohr- und Fräsantrieb mit gekuppeltem Aufsatz

und eingesetztem Werkzeug kurz mit maximaler

Drehzahl im Rechts- und Linkslauf betreiben.

¾ Auf Beschädigungen, unregelmäßige Laufgeräu-

sche, zu starke Vibrationen und übermäßige Erwärmung der Aufsätze achten.

¾ Nur einwandfreies Gerät verwenden.

39

Page 42

Aesculap Power Systems

Acculan® 3Ti Aufsätze

8.3 Allgemeine Bedienung

Verletzungsgefahr beim Fräsen, Sägen oder Bohren durch

Aerosolbildung oder Partikel!

WARNUNG

WARNUNG

¾ Antrieb des Aufsatzes mit mäßiger Drehzahl star-

ten.

¾ Um ein Abrutschen zu vermeiden, nur mäßigen

Druck ausüben.

¾ Um sicherzustellen, dass das Werkzeug nicht

abbricht, Werkzeug nicht biegen.

¾ Werkzeug während des Einsatzes kühlen. Die Span-

abfuhr wird verbessert und die Nekrosenbildung

verringert.

¾ Bei der Bedienung des

Bohr- und Fräsantriebs

immer Augenschutz tragen.

Verbrennungsgefahr von Haut

und Gewebe durch erhitzte,

stumpfe Werkzeuge!

¾ Keine beschädigten oder

defekten Werkzeuge verwenden.

9. Validiertes Aufbereitungsverfahren

Hinweis

Nationale gesetzliche Vorschriften, nationale und

internationale Normen und Richtlinien und die eigenen

Hygienevorschriften zur Aufbereitung einhalten.

Hinweis

Bei Patienten mit Creutzfeldt-Jakob-Krankheit (CJK),

CJK-Verdacht oder möglichen Varianten bezüglich der

Aufbereitung der Produkte die jeweils gültigen nationalen Verordnungen einhalten.

Hinweis

Der maschinellen Aufbereitung ist aufgrund eines besseren und sicheren Reinigungsergebnisses gegenüber

der manuellen Reinigung der Vorzug zu geben.

Hinweis

Aktuelle Informationen zur Aufbereitung siehe auch

Aesculap Extranet unter www.aesculap-extra.net

Hinweis

Es ist zu beachten, dass die erfolgreiche Aufbereitung

dieses Medizinproduktes nur nach vorheriger Validierung des Aufbereitungsprozesses sichergestellt werden

kann. Die Verantwortung hierfür trägt der Betreiber/

Aufbereiter.

Durch Prozesstoleranzen bedingt, dienen die Angaben

des Herstellers nur als Richtwert für die Beurteilung der

beim Betreiber/Aufbereiter vorhandenen Aufbereitungsprozesse.

40

Page 43

9.1 Allgemeine Hinweise

Angetrocknete bzw. fixierte OP-Rückstände können

die Reinigung erschweren bzw. unwirksam machen

und bei nicht rostendem Stahl zu Korrosion führen.

Demzufolge sollten ein Zeitraum zwischen Anwendung

und Aufbereitung von 6 h nicht überschritten, keine

fixierenden Vorreinigungstemperaturen >45 °C angewandt und keine fixierenden Desinfektionsmittel

(Wirkstoffbasis: Aldehyd, Alkohol) verwendet werden.

Überdosierte Neutralisationsmittel oder Grundreiniger

können zu einem chemischen Angriff und/oder zur

Verblassung und visuellen oder maschinellen Unlesbarkeit der Laserbeschriftung bei nicht rostendem

Stahl führen.

Bei nicht rostendem Stahl führen Chlor- bzw. chloridhaltige Rückstände, z. B. in OP-Rückständen, Arzneimitteln, Kochsalzlösungen, im Wasser zur Reinigung,

Desinfektion und Sterilisation zu Korrosionsschäden

(Lochkorrosion, Spannungskorrosion) und somit zur

Zerstörung der Produkte. Zur Entfernung muss eine

ausreichende Spülung mit vollentsalztem Wasser mit

anschließender Trocknung erfolgen.

Es dürfen nur Prozess-Chemikalien eingesetzt werden,

die geprüft und freigegeben sind (z. B. VAH/DGHModer FDA-Zulassung bzw. CE-Kennzeichnung) und vom

Chemikalienhersteller hinsichtlich Materialverträglichkeit empfohlen wurden. Sämtliche Anwendungsvorgaben des Chemikalienherstellers über Temperatur,

Konzentration und Einwirkzeit sind strikt einzuhalten.

Im anderen Fall kann dies zu nachfolgenden Problemen

führen:

• optische Materialveränderungen wie z. B. Verblassen oder Farbveränderungen bei Titan oder Aluminium. Bei Aluminium können sichtbare Oberflächenveränderungen bereits bei einem pH-Wert von

>8 in der Anwendungs-/Gebrauchslösung auftreten.

• Materialschäden, wie z. B. Korrosion, Risse, Brüche,

vorzeitige Alterung oder Quellung.

¾ Keine Prozess-Chemikalien verwenden, die bei

Kunststoffen zu Spannungsrissen oder zur Versprödung führen.

¾ Weitere detaillierte Hinweise zu einer hygienisch

sicheren und materialschonenden/werterhaltenden Wiederaufbereitung, siehe www.a-k-i.org

Rubrik Veröffentlichungen Rote Broschüre Instrumentenaufbereitung richtig gemacht.

9.2 Vorbereitung am Gebrauchsort

¾ Produkt unmittelbar nach dem Gebrauch nach

Anleitung demontieren.

¾ Sämtliche angebaute Komponenten entfernen,

z. B. Werkzeuge (Bohrer, Sägeblätter usw.), Zubehör (Adapter, Schutzhülsen usw.), Schläuche,

Kabel, Akkus usw.

¾ Sichtbare OP-Rückstände möglichst vollständig

mit einem feuchten, flusenfreien Tuch entfernen.

9.3 Vorbereitung vor der Reinigung

¾ Produkt trocken in Entsorgungscontainer binnen

30 min zur desinfizierenden Reinigung vorstellen.

41

Page 44

Aesculap Power Systems

Acculan® 3Ti Aufsätze

9.4 Reinigung/Desinfektion

Schäden am Produkt durch ungeeignete Reinigungs-/Desinfektionsmittel und/oder zu hohe Tempera-

VORSICHT

turen!

¾ Reinigungs- und Desinfektions-

mittel nach Anweisungen des

Herstellers verwenden,

- die für Kunststoffe und Edelstahl zugelassen sind,

- die keine Weichmacher (z. B.

Silikon) angreifen.

¾ Angaben zu Konzentration,

Temperatur und Einwirkzeit

beachten.

¾ Maximal zulässige Reinigungs-

temperatur von 55 °C nicht

überschreiten.

¾ Motoren/Handstücke nicht im Ultraschall-Bad rei-

nigen oder in Flüssigkeiten einlegen.

Eingedrungene Flüssigkeit sofort auslaufen lassen,

sonst Korrosionsgefahr/Funktionsausfall.

42

Page 45

9.5 Manuelle Reinigung/Desinfektion

Manuelle Reinigung und Wischdesinfektion

Phase Schritt T

[°C/°F]t[min]

I Reinigung RT

(kalt)

II Trocknung RT - - - -

III Wischdesinfektion - ≥1 - - Meliseptol HBV Tücher

IV Schlussspülung RT

(kalt)

V Trocknung RT - - - -

T–W: Trinkwasser

VE–W: Vollentsalztes Wasser (demineralisiert)

RT: Raumtemperatur

Phase I

¾ Unter fließendem Leitungswasser ggf. mit geeigne-

ter Reinigungsbürste so lange reinigen, bis auf der

Oberfläche keine Rückstände mehr zu erkennen

sind.

¾ Nicht starre Komponenten, wie z. B. Stellschrau-

ben, Gelenke etc., bei der Reinigung bewegen.

¾ Darauf achten, dass die Lage des Produkts so

gewählt wird, dass kein Wasser, z. B. über Kupplungsansätze, in das Produktinnere eindringt. (Versehentlich eingedrungene Flüssigkeit sofort entfernen.)

¾ Spezielle Reinigungsbürste (TA011944) zur Reini-

gung der Kanülierung der Bohr- und Fräsaufsätze/

Spickdrahtfutter GB643R verwenden.

¾ Zur Reinigung keine Metallbürste oder andere, die

Oberfläche verletzenden Scheuermittel verwenden,

da sonst Korrosionsgefahr besteht.

¾ Schwer zugängliche Stellen mit weichen Rund-

bürsten aus Kunststoff mit passendem Durchmesser reinigen.

Konz.

--T–W-

0,5 - VE–W -

Phase II

¾ Produkt mit flusenfreiem Tuch oder medizinischer

Phase III

¾ Produkt vollständig mit Einmal-Desinfektionstuch

Phase IV

¾ Desinfizierte Oberflächen nach Ablauf der vorge-

¾ Haltung des Produkts so wählen, dass kein Wasser,

¾ Restwasser ausreichend abtropfen lassen.

Phase V

¾ Produkt mit flusenfreiem Tuch oder medizinischer

Wasser-

[%]

Qualität

50 % Propan-1-ol

Druckluft trocknen.

abwischen.

schriebenen Einwirkzeit (mindestens 1 Minute)

unter fließendem VE-Wasser spülen.

z. B. über Kupplungsansätze, in das Produktinnere

eindringen kann.

Druckluft trocknen.

Chemie

43

Page 46

Aesculap Power Systems

Acculan® 3Ti Aufsätze

9.6 Maschinelle Reinigung/Desinfek-

tion

Hinweis

Der Desinfektor muss grundsätzlich eine ge prüfte Wirk-

samkeit besitzen (z. B. DGHM- oder FDA-Zulassung

bzw. CE-Kennzeichnung).

Hinweis

Bei der thermischen Desinfektion muss vollentsalztes

Wasser (demineralisiert) verwendet und ein Ao-Wert

>3 000 erreicht werden.

Hinweis

Der eingesetzte Desinfektor muss regelmäßig gewartet

und überprüft werden.

¾ Bei fehlender Innenspüleinrichtung am Reini-

gungs- und Desinfektionsgerät, manuelle Vorreinigung der Kanülierung durchführen, siehe Manuelle

Reinigung/Desinfektion, Phase I.

¾ Bei Spickdrahtfutter GB643R: Einstellhülse 4.2 auf

größten Spickdrahtdurchmesser einstellen.

¾ Bei Sagittalsägeaufsatz GB660R: Keine Reinigung

des Innenraums des Sagittalsägeaufsatzes durch

Durchspülen durchführen. Eccos®-Halterung des

Sagittalsägeaufsatzes nicht an den Spülanschluss

des Reinigungs- und Desinfektionsgerätes

anschließen.

¾ Den mit Acculan® 3Ti-Halterungen bestückten

Eccos®-Siebkorb verwenden, oder zuvor entsprechende Halterungen in einen geeigneten Siebkorb

montieren (Gebrauchsanweisung TA009721 für

Aesculap-Eccos®-Halterungssystem).

¾ Produkt lagerichtig in die Eccos®-Halterung einle-

gen.

¾ Innenspüleinrichtung an die Eccos®-Halterung

anschließen und mit dem speziellen Anschluss des

Spülwagens verbinden.

44

Page 47

Maschinelle alkalische Reinigung und thermische Desinfektion

Gerätetyp: Einkammer-Reinigungs-/Desinfektionsgerät ohne Ultraschall

Phase Schritt T

[°C/°F]

I Vorspülen <25/77 3 T–W -

II Reinigung 55/131 10 VE–W BBRAUN HELIMATIC CLEANER

III Zwischenspülung >10/50 1 VE–W -

IV Thermodesinfektion 90/194 5 VE–W -

V Trocknung - - - Gemäß Desinfektionspro-

T-W: Trinkwasser

VE–W: Vollentsalztes Wasser (demineralisiert)

t

[min]

WasserQualität

Chemie/Bemerkung

alcaline mit Tensiden,

Gebrauchslösung 0,5 %

gramm

45

Page 48

Aesculap Power Systems

Acculan® 3Ti Aufsätze

9.7 Kontrolle, Wartung und Prüfung

Hinweis

Aesculap empfiehlt das gelegentliche Einsprühen von

beweglichen Teilen wie z. B. Drücker, Kupplung, Verschlussdeckelklappen etc. mit dem AesculapSTERILIT®-Power-Systems-Ölspray!

Abb. 10

¾ Produkt auf Raumtemperatur abkühlen lassen.

¾ Produkt nach jeder Reinigung und Desinfektion

prüfen auf: Sauberkeit, Funktion und Beschädigung.

¾ Beigelegten STERILIT®-Power-Systems-Adapter

auf Aesculap-STERILIT®-Power-Systems-Ölspray

aufstecken und Kanülierung der Kleinen Bohrmaschine, siehe Abb. 10, sowie der Bohr- Fräs- und

Spickdrahtaufsätze, siehe Abb. 11, von hinten ca.

1 sec. durchsprühen.

¾ Nach der Reinigung/Desinfektion Oberflächen und

schwer zugängliche Stellen auf sichtbaren

Schmutz prüfen.

¾ Produkt auf Beschädigungen, unregelmäßige Lauf-

geräusche, übermäßige Erwärmung oder zu starke

Vibration prüfen.

¾ Werkzeug auf abgebrochene, beschädigte und

stumpfe Schneiden kontrollieren.

¾ Beschädigtes Produkt sofort aussortieren.

9.8 Verpackung

¾ Gebrauchsanweisungen der verwendeten Verpa-

ckungen und Halterungen einhalten (z. B.

Gebrauchsanweisung TA009721 für AesculapEccos®-Halterungssystem).

¾ Produkt lagerichtig in die Eccos®-Halterung einle-

gen oder gegen Beschädigungen geschützt auf

Siebkorb legen. Sicherstellen, dass vorhandene

Schneiden geschützt sind.

¾ Siebkörbe dem Sterilisationsverfahren angemessen

verpacken (z. B. in Aesculap-Sterilcontainern).

¾ Sicherstellen, dass die Verpackung eine Rekonta-

mination des Produkts verhindert (DIN EN

ISO 11607).

Abb. 11

46

Page 49

9.9 Sterilisieren

Hinweis

Das Produkt darf nur mit demontiertem Werkzeug etc.

sterilisiert werden.

¾ Sicherstellen, dass das Sterilisiermittel Zugang zu

allen äußeren und inneren Oberflächen hat.

¾ Validiertes Sterilisisationsverfahren

– Produkt zerlegen