Page 1

2008 & Up Chrysler

Foldout Entervan

®

34443

Page 2

Congratulations

We at The Braun Corporation wish to express our fullest appreciation on your new purchase. With you in mind, our skilled craftsmen

have designed and assembled the finest lowered floor vehicle available.

This manual includes safety precautions, operating instructions,

manual operating instructions, and instructions for maintenance and

lubrication procedures.

Your Entervan® is built for dependability, and will bring you years

of pleasure and independence, as long as the maintenance is performed

regularly and the Entervan® is operated by an instructed person.

W

A

RNING

Oper

ator's

Man

ual

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

Read manual

before operating.

Failure to do

so may result in

serious bodily

injury and/or

property damage.

Keep manual in

Rampvan.

Page 3

CONTENTS

Warranty and Registration

Instructions ................................................................ 2

Introduction ................................................................ 3

Entervan Operation Quick

Reference Guide .................................................... 4, 5

Features ................................................................. 6, 7

Safety Precautions .................................................... 8

Operation

Terminology .......................................................... 9

One-Touch Control System ................................... 9

Control Switches ............................................ 10-14

Ramp Access Sliding Door ........................... 14, 15

Kneel System ................................................ 16, 17

Power Ramp Operation ...................................... 18

Power Ramp Safety ........................................... 19

Power Ramp Manual Operation ......................... 20

Ramp Electrical Override .................................... 21

Ramp Safety .................................................. 22-24

Wheelchair and Occupant Restraint ................ 25-33

Seat Removal and Installation

Front Seats (General Information) ................ 34, 35

Seat Base Rear Covers ...................................... 35

Seat Electrical Harnesses ............................. 37-39

Front Seat Removal ...................................... 40, 41

Front Seat Installation ................................... 42, 43

Third Row Seats ........................................... 44, 45

Warranty .............................................................. 46-49

Return Authorization Procedure ............................ 49

Preventive Maintenance ................................... 50, 51

Auxiliary Power Supply / Below

Floor Obstructions ............................................. 52-55

Jacking and Tire Changing .................................... 56

Reporting Safety Defects ....................................... 57

Towing ...................................................................... 58

Page 1

Page 4

WARRANTY AND REGISTRATION INSTRUCTIONS

Vehicle Delivery Checklist

& Warranty Registra

tion

C

ustomer

Name________________________________________________________

W

eb

R

ef

e

rralCode _____________________

Add

ress

____________________________________________ Ci

ty

_________________________ Sta

te ________

ZIP __________

Phone ________________________________

Email

________________________________________________________________

VIN:

________________________________________________________________

Da

t

e

of

Pu

r

chase

_______

/_______ / _______

B

r

aun

Dealer#:

_____________S

ales

Person:____________________________C

i

ty

______________________________St

a

t

e_____

P

r

e-Deliver

y(T

o

becompleted b

ySalesConsultant prior toCus t

omerbeing p

r

ese

nt)

❑ V

ehicle is equipped as indic

a

t

ed in the sales

c

on

tract

❑ V

ehicle in

t

erior/

e

xte

rior clean

❑

❑ V

ehicle and cus

t

omer pape

r

work prepared

❑ OEM and Br

aun

owne

r’s manuals and other materials in gl

o

ve bo

x

Deli

ver

y(T

o

b

e

r

evi

e

wed and

e

xplained

b

y

S

alesC

onsultant with Customer prese

n

t)

E

xterior

❑ I

nspecte

xterior

t

o ensur

e it’s clean and damag

e-f

r

ee

❑

Spar

e ti

re and jack loc

a

tion

❑ Oper

a

tion of

r

emote

c

on

tr

ol

❑ Magnetic e

n

try (if applicable)

❑

Ex

t

e

r

ior oper

a

tion and activation of p

o

w

er doo

r

,kneeling and

r

amp

❑ Manual ope

r

a

tion of door and ramp f

r

ome

xterior

I

n

t

erior

❑

Gauges and instrumen

t

a

tion

❑ Loca

tion of i

n

t

e

rior switchest

o oper

at

e a

c

c

essiblef

eatu

r

es

❑ Manual ope

r

a

tion of door and

r

amp f

r

om i

nt

e

rior

❑

Oper

a

tion of ti

e

-d

o

wns

❑ Oper

a

tion of r

oll & tumble sea

ting (if applicable)

❑ Oper

a

tion of sea

t belts

❑

L

oc

a

tion of Braunc

on

troller

Additional

❑ R

eview both OEM and B

r

aunowne

r’s manual

s.

❑

Explain the

T

o

yotaServi

c

e E

xchangeI

nf

orm

a

tion

P

rogram(

T

o

yota Chassis Only)

❑ Explainr

ec

ommended pr

e

ventive mai

n

tenance and ser

vi

c

e schedules

❑

❑

I

nf

ormC

ust

omer of dealership se

rvic

e hours

❑ A

dvise

C

ustomert

o

r

e

c

ei

v

e and maintain a si

gnedr

e

c

or

d of all se

r

vi

c

e

wo

r

k pe

rf

ormed

❑ Complete and r

eturnwarran

ty

r

e

g

ist

r

ation

t

o a

ctivat

e

warran

ty

❑ List all a

fterma

rket equipme

nt. U

se b

r

and names and model numbers wher

e possible

____________________________________________________________________________________________________

____________________________________________________________________________________________________

I

h

ereby

ack

n

o

wl

ed

geth

a

tth

emo

b

i

l

i

t

y

d

evi

cesapplicab

l

e

t

o

my

v

eh

ic

l

eh

av

ebeen

demonst

ra

t

edfor me

,and

Ifully understand and

can

ope

r

a

t

ethis equipme

nt

.

Ih

av

e

beena

dvis

edtha

t

wh

ee

lchairs

maynot

maintain

th

e

ir

i

nte

gri

t

y

inth

e

ev

ent

o

f

a

collision.

I

he

reb

yrelease and hold ha

rmless

the

Ori

ginalVehicle

M

an

ufa

cturer

,

T

h

e

B

ra

u

n

C

o

rp

o

ra

tion

,

andits ind

epe

ndentd

eal

ers

froman

yliab

ilit

yass

o

ci

a

t

ed

wi

t

hinju

ry

t

o

my

person

and

p

rope

rt

y

asa resultof

my

use

of

awheelch

a

ir

du

ri

n

g

acollision.

I have

r

ead a

nd

unde

rstand

t

h

i

s

e

nti

re

f

o

r

m,

includin

g

all

disclaime

rs

an

d th

e Br

aun fa

c

t

o

ry Limi

t

ed

Wa

rran

t

y

.

A

ll of the inf

o

rmation I h

ave provided is co

rre

ct

.

S

alesConsulta

nt:

A

ll i

t

ems checked h

ave been

r

evie

w

ed with the cust

omer.

______________________________________________

Consulta

n

t Si

gna

tu

r

e / D

a

t

e

Cus

t

ome

r:

I ack

nowledge th

a

t all it

ems checked h

a

v

e been

r

evie

wed with me.

______________________________________________

C

ust

omer Signatu

r

e / D

a

t

e

PleaseFAX

c

omple

t

ed

f

ormto 1-800-946-6305 • P

.

O

.

B

o

x 310 •

W

inama

c, IN 46996 •

ref

er

rals@b

raunlift.

com • 34550 • 2/08

P

ho

VIN:

B

r

au

P

r

e

-D

Deli

v

e

r

y

E

x

t

erior

❑

❑

❑

❑ M❑

E

❑

M

I

n

t

erior

❑

G

a

❑

L

oc

❑

M

an

❑

Ope❑ Ope

r

❑

Ope

r

a

❑

L

oc

a

ti

A

dditional

❑

R

eview

❑

Explain

❑

Explain

Vehicle Delivery Checklist

& Warranty Registration

34550 • 2/08

Examine your Entervan® for any damage. Should

any damage have occurred during delivery, notify

the carrier at once with any claims.

The warranty/registration card shown

here is supplied with each Entervan.

Review the delivery checklist and fill

out the warranty/registration information with your sales representative

and mail it to The Braun Corporation

A detailed Warranty section is provided within this manual. The warranty

card must be processed to activate

the warranty.

Record the last eight digits of the vehicle identifica-

tion number (VIN) in the space provided for future

reference. This information must be provided

when filing a warranty claim or ordering parts.

Page 2

Vehicle Identification Number (VIN)

®

.

Page 5

INTRODUCTION

The Braun Entervan® lowered floor

conversion is designed to provide

years of pleasure and mobility

independence. Familiarity with

proper operation and maintenance

procedures will help ensure safe,

trouble free operation.

The Braun Corporation encourages wheelchair passengers and

their attendant(s) to review the

material contained in this manual

with your Entervan sales representative, before attempting

operation. Any questions or concerns can be answered by your

sales representative at that time.

This manual addresses Entervan standard features as well as

options. Refer to the instructions

applicable for your package, and

disregard the information that

does not apply. Contact The

Braun Corporation at 1-800-THE

LIFT® if any of this information is

not understood.

®

The Entervan

Operation Quick

Reference Guide hanging on

the mirror provides a condensed

explanation of Entervan operation

(shown at right). Read the guide

and then insert it in this manual

for future reference. Note: An

Operation Quick Reference Guide

(overview) section is provided on

pages 4 and 5 of this manual also.

Store this manual in the vehicle

along with your Chrysler owner’s

manual.

If you experience an operation

problem or there is any sign of

wear, damage, or other abnormal

condition, contact your sales representative or call The Braun Cor-

poration at 1-800-THE LIFT

®

. One

of our national Product Support

representatives will direct you to a

Braun authorized service center.

Operation Quick Reference Guide

Page 3

Page 6

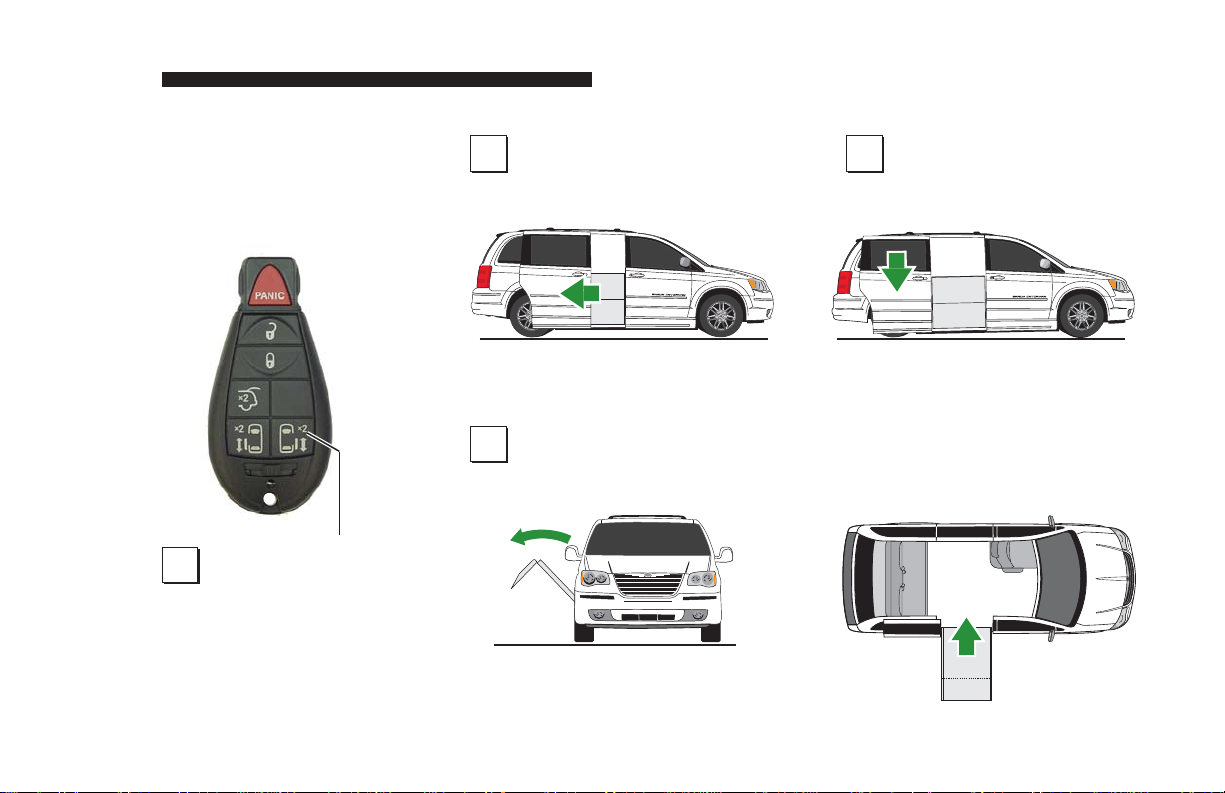

ENTERVAN OPERATION QUICK REFERENCE GUIDE

Entervan Operation Overview

This overview provides a simplified explanation

of Entervan operation. Read the entire owner’s

(operator’s) manual for complete details. Contact

®

The Braun Corporation at 1-800-THE LIFT

if any

of this information is not understood.

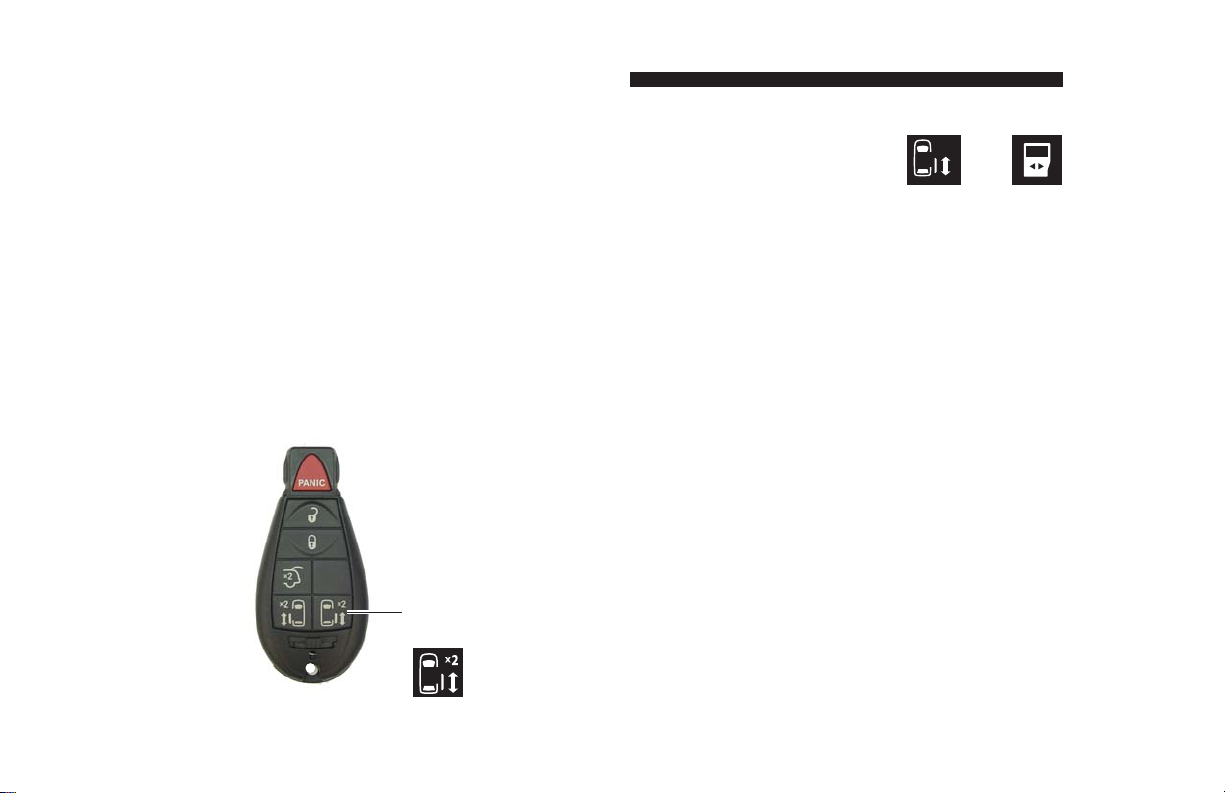

Power Operation

Entervan power functions are managed by the

electronic control system. The control system can

be activated

using the

OEM remote

keyless entry

transmitter

or one of the

interior control

switches

detailed on

OEM Remote

Keyless Entry

Transmitter

Press and

release this

switch two

x

times (

2)

pages 10-13.

Interior mounted control switches

display one of these graphics.

or

One-Touch Control Activation

Entervan power door, kneel and ramp functions are

activated by pressing and releasing a control switch

(press and release remote entry transmitter button

twice).

Open Functions: When activating the Open functions, the power door opens, the kneel system lowers

the rear of the vehicle and the ramp deploys.

Close Functions: When activating the Close functions, the ramp stows, the kneel system raises the

rear of the vehicle and the power door closes.

Manual Operation

The passenger side power sliding door and power

ramp can be manually operated. Read this manual

for further details.

Page 4

Page 7

ENTERVAN OPERATION QUICK REFERENCE GUIDE

Operating Your New

Entervan Couldn’t

Be Simpler . . .

Just press any one

1

of the buttons like

the one pictured above

or those shown on page

4 (press twice on the key

transmitter). . .

And the sliding door opens

2 3

The ramp deploys Allowing easy entrance!

4

The rear suspension lowers

A

Page 5

Page 8

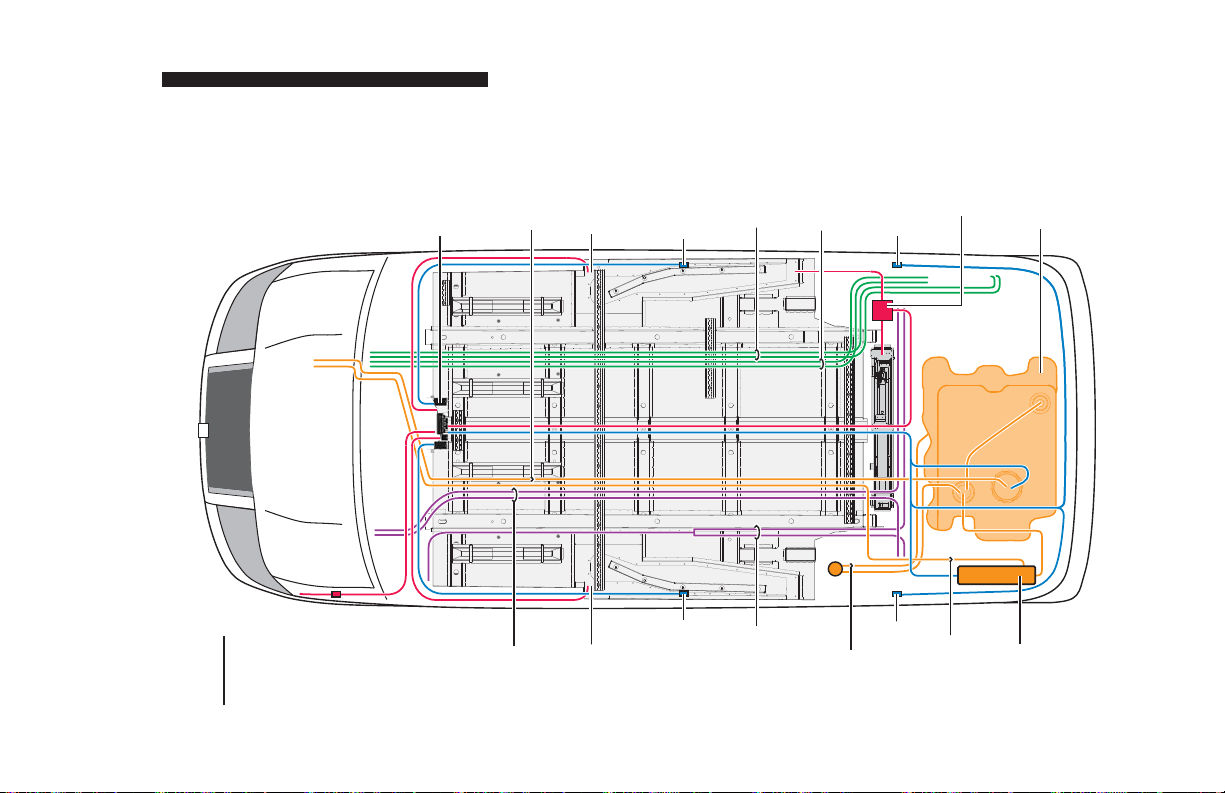

FEATURES

One-Touch Electronic Control System: The electronic

control system provides simple

one-touch activation of Entervan power functions. For your

convenience, the power features

can be activated using the OEM

remote keyless entry transmitter

or one of the interior switches

detailed on pages 10-13.

Passenger Side Power Slide

Door: The electronic control

system activates the passenger side power slide door for

ramp access. The slide door

and lowered floor configuration

provides 52-1/2" clear vertical

passageway. Note: The driverside sliding door is lowered to

provide clear passage also.

Ramp: The fully automatic

power ramp provides 29-1/4"

usable width. The power ramp

can be manually operated.

Electromechanical Power

Kneeling Rear Suspension:

“Kneeling” is the lowering motion of the electromechanical

rear suspension. The kneel

feature reduces the slope of the

ramp when deployed.

Lowered Floor from Rear

Axle to Firewall: This feature

provides additional headroom

(57-1/4" floor-to-ceiling at center

of van), and further reduces

the slope of the ramp when

deployed. Note: The floorto-ceiling height is reduced by

2-1/2" with OEM interior DVD/

rail system installed. Ground

Clearance: The lowered floor

results in reduced ground clearance. Be aware of limited ground

clearance.

Ground Effects: Exterior colormatched ground effect panels

conceal the lowered floor and

lowered sliding doors.

Floor Track for Wheelchair

and Occupant Securement in

Midpoint Lowered Floor Area:

Floor track provided in the midpoint lowered floor area (Position

C) can be utilized for restraint of

wheelchair passenger(s). Wheelchair capacity at midpoint may

have limitations based on the dimensions of specific wheelchairs.

Forward-Facing Wheelchair

and Occupant Belt/Track

System: One Forward-Facing

Page 6

Page 9

FEATURES

Wheelchair and Occupant Belt

Kit is supplied for the restraint of

one wheelchair and occupant.

The belt kit is used in conjunction with the floor track. Note:

Additional belt kits can be purchased (option).

Quick-Release Front Passenger Seat with Floor Track for

Wheelchair and Occupant Securement: The passenger seat

(Position B) is equipped with

“step & roll” quick-release seat

base attachments (making seat

removal and installation procedures simple). The seat can be

removed and the seat location

can be utilized by a wheelchair

occupant (floor track provided).

Driver Seat: For the wheelchair

occupant who chooses to drive,

this seat (Position A) can be

removed and adaptive driving

systems custom tailored for the

individual can be purchased

from and installed by your local

mobility dealer. The driver’s

seat is equipped with “step &

roll” quick-release seat base

attachments. 56-1/4" floor-to-

ceiling headroom is provided

at both front seating positions.

Auxiliary Power Supply for

Dealer-Installed Power Seat

or Electric Tie-Downs: This

power source is available to

accommodate adaptive driving

systems custom tailored for

the individual (purchased from

and installed by your local

mobility sales representative).

See pages 52-55.

Midpoint

“L”

Track

Front Seat

“L” Track

A

Midpoint

“L” Track

Available Wheelchair Positions

B

C

Front

Seat

“L”

Track

Page 7

Page 10

CAUTION

W

A

RNING

SAFETY PRECAUTIONS

Safety Symbols

SAFETY FIRST! Know That....

All information contained

A

in this manual and

supplements (if included), is provided for your safety. Familiarity

with proper operation instructions

as well as proper maintenance

procedures are necessary to ensure safe, trouble free operation.

Safety precautions are provided

to identify potentially hazardous

situations and provide instruction

on how to avoid them.

D

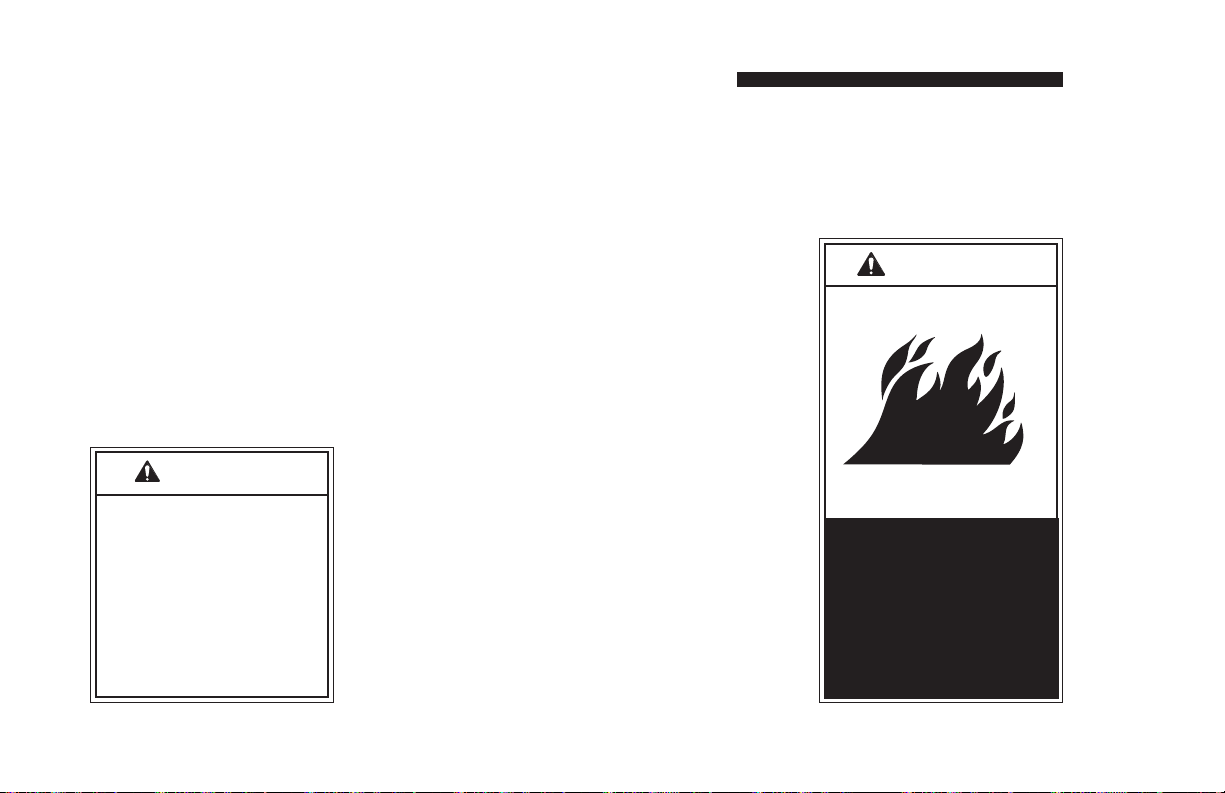

These symbols will appear throughout this manual and may appear on labels posted on your Entervan.

Recognize the seriousness of this information.

Page 8

B

This symbol indicates

important safety information regarding a

potentially hazardous

situation that could

result in serious

bodily injury and/or

property damage.

Note: Additional information provided to help clarify or detail a specific subject.

C

This symbol indicates

important information regarding how to

avoid a hazardous situation that

could result in minor

personal injury or

property damage.

Page 11

OPERATION

Whenever parking your Entervan

and before utilizing Entervan

power features, always engage

the vehicle transmission in Park

“P” and engage the vehicle

parking brake. Entervan power

function control switches can

be activated only if the vehicle

transmission is in Park or Neutral.

Terminology

“Kneeling” is the lowering motion

of the Entervan electromechanical rear suspension. The term

“deploy” (unfold) indicates the

lowering motion of the ramp to

the deployed position. “Stow”

(fold) is the raising motion of the

ramp to the vertical (stowed)

position.

The terms “Open” and “Close”

refer to sequences of power

functions that will occur when

activated by the One-Touch

electronic control system. When

activating the Open functions,

the power door opens, the kneel

system lowers the rear of the

vehicle and the ramp deploys.

When activating Close functions,

the ramp stows, the kneel system raises the rear of the vehicle

and the power door closes.

One-Touch Control System

Entervan power functions are

managed by the electronic

control system. The control

system can be activated using

the remote keyless entry transmitter or any one of the controls

addressed on pages 10-13.

Do not attempt to interface

aftermarket control systems.

Braun Corporation

Aftermarket Control

Systems Policy:

The Braun Corporation manufactures dedicated control systems

for its products. These control

systems have been designed

and tested for use in conjunction

with specific Braun products.

Braun control systems are the

only control systems authorized

for use with Braun products.

Do not attempt to interface aftermarket control systems without

authorization from The Braun

Corporation. To do so may

result in serious bodily injury

and/or property damage.

Page 9

Page 12

OPERATION

Control Switches

For your convenience, Entervan

power features can be activated

using the OEM remote keyless

entry transmitter or one of the

interior control switches identified

on pages 11-13.

The passenger power sliding door

switches provided on the remote

keyless entry transmitter and in

the overhead console will unlock

the passenger side slide door and

activate the Entervan power door,

kneel and ramp functions.

The power sliding door switches

provided in the center console and

on the wall panels to the front and

rear of the passenger side sliding

door (B-pillar and C-pillar respectively), are accessible to rear

seat passengers including small

children. These control switches

Page 10

will activate Entervan power

functions only if the passenger

side power slide door is unlocked

and the overhead console Master

Lock Out switch is in the ON position. Master Lock Out details are

provided on page 13.

Braun minivan conversions are

designed with safety and simplicity in mind for ease of operation.

If a power function has been

activated that was not intended,

simply press a control switch to

stop or reverse the function. If

the desired function has not been

activated, press the switch again.

Entervan power function control

switches can be activated only

if the vehicle transmission is in

Park or Neutral.

Control Switches

Switches that activate Entervan

power functions at all times:

• Keyless Entry Transmitter

• Overhead Console Passenger

Power Sliding Door Switch

• All Other Switches

The passenger side power slide

door must be unlocked and the

Master Lock Out switch must be

in the ON position before power

functions can be activated.

Page 13

OPERATION

One-Touch Control Activation

Entervan power door, kneel and

ramp functions will be activated

by pressing and releasing

either control switch shown on

this page. Press and release

the remote entry transmitter button twice within five seconds.

Power Sliding Door Lock and

Master Lock Out

The keyless entry and overhead

console switches will activate

Entervan power functions

whether the passenger sliding

door is locked or unlocked. The

Master Lock Out switch does

not prohibit use of these control

switches

.

Remote Keyless Entry

Transmitter

Using the Chrysler remote entry

transmitter eliminates the need

for an additional remote control.

Press and

release this

switch twice

(x2)

Press and release

x

switch twice (

2)

within five seconds.

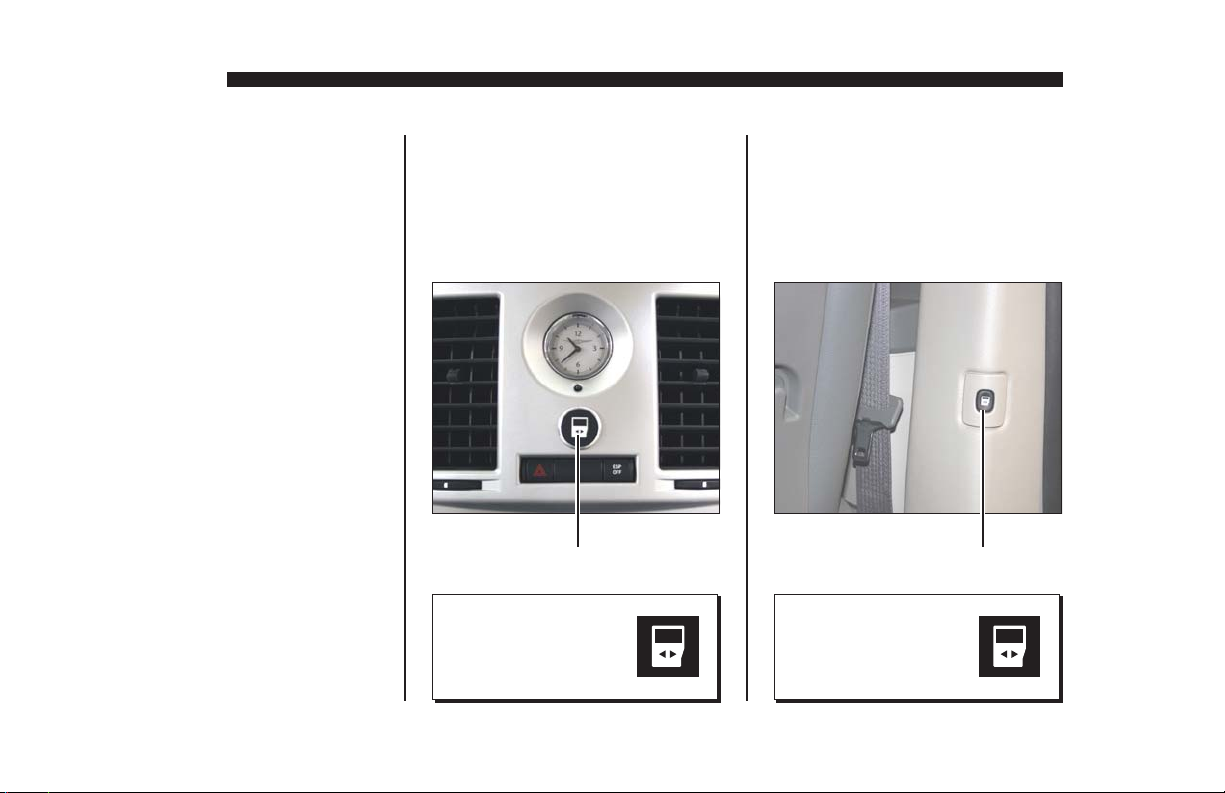

Overhead Console Switch

A control switch is located on

the overhead console.

Press and release this switch

Press and release

switch displaying

slide door graphic.

Page 11

Page 14

OPERATION

Power Sliding Door Lock and

Master Lock Out

The passenger side power

sliding door must be unlocked

and the overhead console

Master Lock Out switch must

be in the ON position before

the three power sliding door

switches identified here can

activate Entervan power functions.

One-Touch Control Activation

When the above conditions are

met - power door, kneel and

ramp functions will be activated

by pressing and releasing any

of the control switches.

Center Console Switch

For front seat passengers, a

switch is located in the center

console (dashboard).

Press and release this switch

Press and release

switch displaying

slide door graphic.

B-Pillar Switch

A switch is located on the wall

panel ahead of the passenger

slide door (B-Pillar).

Press and release this switch

Press and release

switch displaying

slide door graphic.

Page 12

Page 15

OPERATION

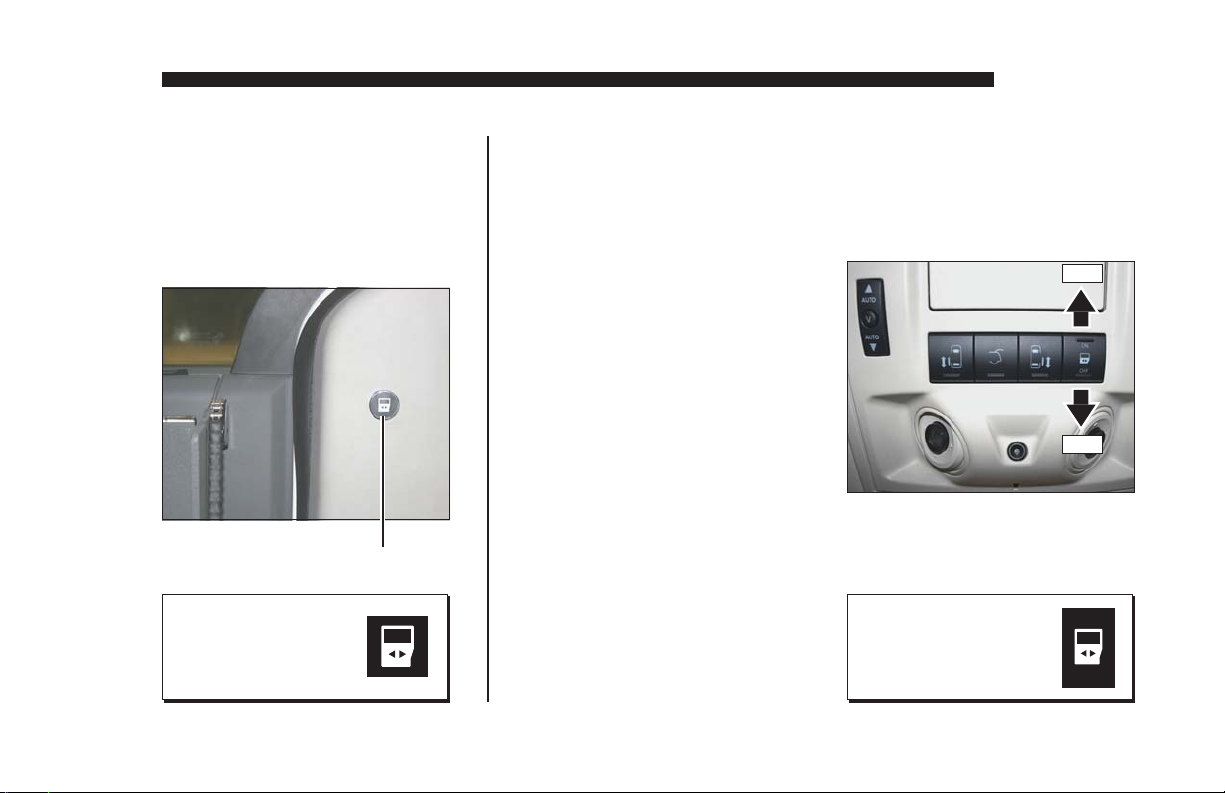

C-Pillar Switch

A switch is located on the wall

panel behind the passenger

slide door (C-Pillar).

Press and release this switch

Press and release

switch displaying

slide door graphic.

Power Sliding Door Master

Lock Out Switch

The Master Lock Out switch

is located in the overhead

console. If the Master Lock

Out switch is in the OFF

position, this OEM feature

will disable the three power

sliding door switches identified at left. Press the switch

to the ON position to enable

the control switches.

Press switch to ON to

enable control switches.

Press switch to OFF to

disable control switches.

Press switch

displaying

this graphic.

ON

OFF

ON

OFF

Page 13

Page 16

OPERATION

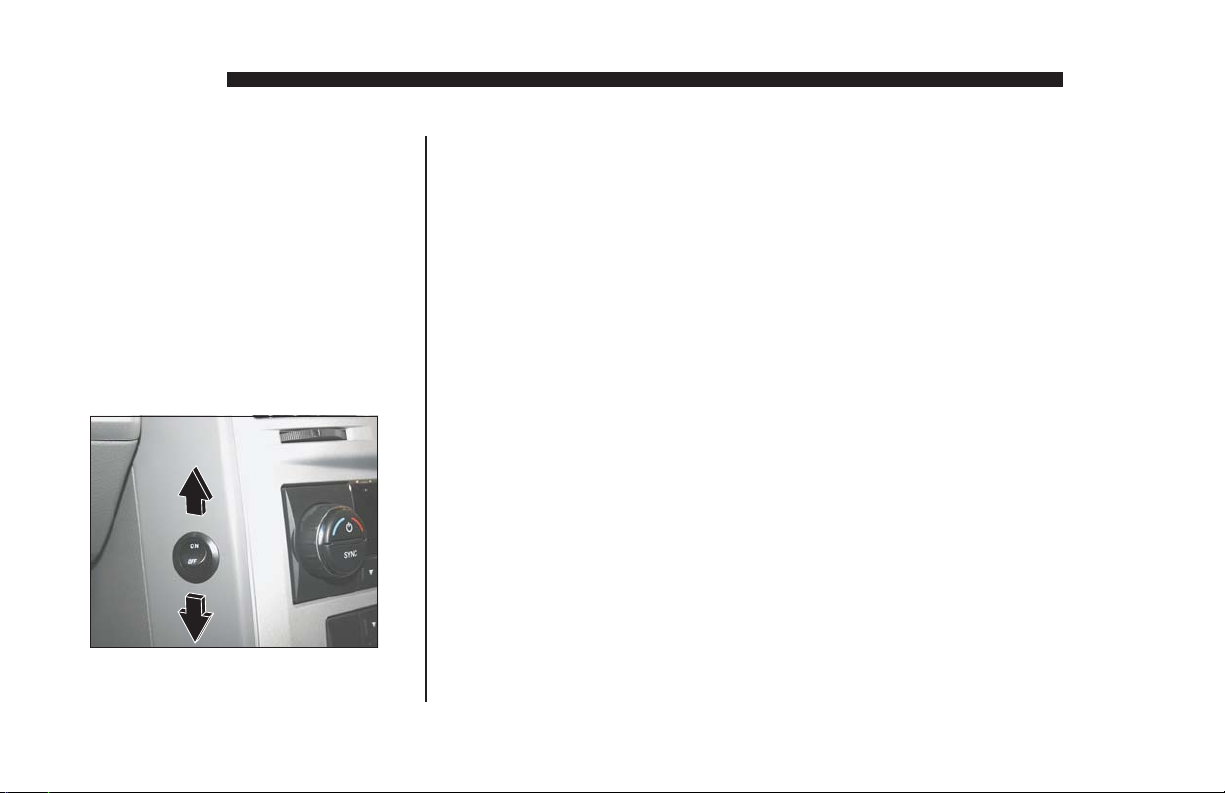

Kneel On/Off Switch

The Kneel On/Off switch is

located on the driver side of

the center console. The Kneel

On/Off switch turns the kneel

system on and off only. See

page 16 for further details.

Press this switch to ON

to activate kneel feature.

Press this switch to OFF

to disable kneel feature.

Ramp Access Sliding Door

Press and release the remote

keyless entry transmitter

or one of the interior control switches to activate the

power sliding door (control

switches detailed on pages

10-13). When a control

switch is activated, the door

will open and the Open sequence of functions will continue (rear of vehicle kneels

and ramp deploys).

Once the Open sequence

of functions is complete,

press and release a control

switch to close the door.

The door will close after the

ramp stows and the vehicle

raises (completing the Close

sequence of functions).

Note: If a control switch is activated while the power sliding

door is opening or closing, the

door will reverse direction.

Note: If the power door is

obstructed while opening or

closing, the door will reverse

direction to the fully closed or

fully open position, provided it

meets sufficient resistance.

Note: If the inside or outside

door handles are used while the

power sliding door is activated,

the power sliding door feature

will be cancelled. Simply press

a control switch and the door

will open fully. The power door

can also be opened or closed

manually as detailed at right.

Page 14

Page 17

W

A

RNING

OPERATION

Keep clear of the area in

which the power door operates. Ensure door travel path

is clear. Personal injury or

property damage may occur

during power door operation.

Be sure the door is fully closed

and latched before driving.

Keep clear of area

in which power door

operates. Failure to

do so may result in

bodily injury and/or

property damage.

Power Door Manual Operation

The passenger side power

sliding door can be operated

manually. Unlock the passenger sliding door. Open the

slide door from inside or outside

using the OEM door handles.

Always open the door smoothly.

Avoid using excessive force

when opening and closing the

door.

Note: The ramp obstructs access to the inside door handle.

The OEM handle has been

equipped with an extension

strap.

Extension Strap

Ramp

Page 15

Page 18

OPERATION

Automatic Kneel System

Kneeling is the lowering motion

of the Entervan electromechanical rear suspension. The

kneel system lowers the rear of

the vehicle. Lowering the rear

of the vehicle reduces the slope

of the ramp.

When the electronic control

system is activated to start

the Open functions, the kneel

system starts to lower the rear

of the vehicle at the same time

the power sliding door starts to

open. When the Close functions are activated, the rear of

the vehicle starts to raise at the

same time the ramp begins to

stow.

Kneel On/Off Feature

A Kneel On/Off feature is incorporated in the electronic control

system. This feature provides

the option of kneeling the vehicle

when operating the power door

and power ramp. The Kneel

switch is located on the driver

side of the center console (see

page 14). The Kneel On/Off

switch turns the kneel system on

and off only. The Kneel switch

must be in the On position in

order for the kneeling system to

be activated.

Note: If the Entervan is in the

kneeled position and the Close

functions are activated, the vehicle will raise whether the Kneel

On/Off switch is On or Off.

Note: If the Kneel On/Off

switch is switched from Off to

On during the Open sequence

of functions or within 60

seconds of ramp deployment,

the vehicle will kneel after the

ramp is fully deployed.

Kneel On/Off Switch

Press this switch to ON

to activate kneel feature.

Press this switch to OFF

to disable kneel feature.

Page 16

Page 19

OPERATION

Note: If the Entervan is in the

kneeled position (with ramp

deployed) and the transmission

is disengaged from Park “P,” the

ramp will stow and the vehicle

will raise.

Note: Do not leave your Entervan in the kneeled (lowered)

position for extended periods of

time. Doing so may result in battery drain.

In the event the kneel system is

not functioning properly, have

the kneel system repaired immediately. Do not drive with the

rear of the vehicle in the lowered

position. Attempting to do so will

result in an extremely rough and

unstable ride.

Contact your sales representative or call The Braun Corpora-

tion at 1-800-THE LIFT. One

of our national Product Support

representatives will direct you to

an authorized service center.

Kneel Electrical Override

An electrical override feature is

incorporated in the kneel system.

The override by-passes the electronic control system to electrically power the kneel actuator.

The override is available to raise

the rear of the vehicle only.

The Kneel Override Switch is

located under the driver side

rear bench seat. Press and hold

the switch to release the kneel

system (raise vehicle). Release

the switch when the rear of the

vehicle has raised fully. The

kneel actuator motor will ratchet

(make clicking sound).

Switch is located under driver side

rear bench seat (viewed from rear

with seat in raised position).

Kneel

Override

Switch

Press and hold this switch to

release kneel (raise vehicle).

Page 17

Page 20

OPERATION

CAUTION

Power Ramp Operation

The power ramp is activated by

the electronic control system

using any of the control switches

identified on pages 11-13. When

a control switch is activated to

start the Open functions, the

ramp deploys after the power

sliding door reaches the fully

open position. When the Close

functions are activated, the ramp

stow function begins immediately

(simultaneously with the kneel

system).

If a control switch is activated

while the ramp is in motion

(deploying or stowing), the ramp

motor will stop running. Activating a control switch again will

start the Close functions (ramp

will stow, vehicle will raise and

the door will close).

Note: The power sliding door

must travel from the full closed

position to the full open position in

order for the ramp to deploy.

Note: If the vehicle transmission

is disengaged from Park “P” while

the ramp is deploying (in motion)

or when the ramp is in the fully

deployed position, the ramp will

stow immediately.

Note: If the power ramp is obstructed while deploying or stowing, the ramp motor will stop running, provided it meets sufficient

resistance. Press a control switch

again and the ramp will stow and

the door will close.

Note: When deploying the ramp,

the ramp motor stops running

when the ramp reaches the nearly

horizontal position (approximately

6"- 8" above ground level). The

ramp continues to slowly lower

the remaining distance by the

force of gravity.

Forcing the Ramp: Allow the

power ramp to deploy (unfold

and lower) fully before boarding

the ramp. Forcing the ramp out

or down during the deploy/stow

functions, or boarding onto the

ramp before it is fully-deployed

may result in damage to the

ramp, motor assembly and/or

electronic controller.

Allow ramp to deploy

fully before boarding.

Failure to do so may

result in damage.

Page 18

Page 21

W

A

RNING

Power Ramp Safety

W

A

RNING

Keep clear of

area in which

ramp operates.

Be certain there is adequate clearance outside the

Entervan before deploying the power ramp. Keep

clear of area in which the ramp operates. Be certain

no person or obstruction is within the path of the ramp

when deploying or stowing the ramp. Keep clear of

all power ramp moving parts. Do not attempt to grip

or hold the ramp or ramp folding mechanism during

operation.

Provide adequate

clearance outside

of vehicle to accommodate ramp.

Failure to do so may

result in serious

bodily injury and/or

property damage.

OPERATION

Keep body

parts and

obstructions

clear of the

area in which

the ramp

operates.

Page 19

Page 22

OPERATION

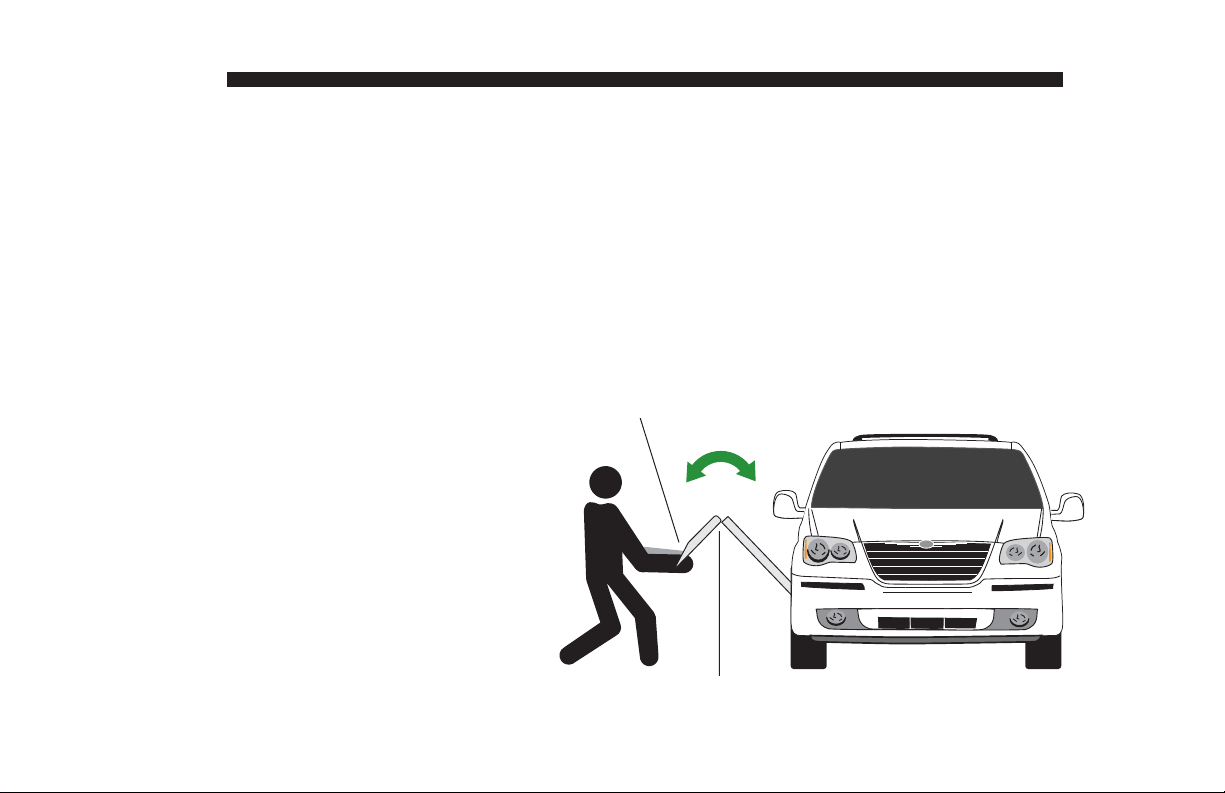

Power Ramp Manual Operation

The power ramp can be manually deployed and stowed. Ramp

manual operation procedures

must be performed by an assistant.

An oval-shaped HAND HOLD

slot is provided on the ramp.

Carefully deploy and stow the

ramp using the HAND HOLD.

The safety precautions addressed in the Power Ramp

Safety section apply to manual

ramp operation also. Read and

become familiar with all ramp

safety precautions.

Keep clear of the area in which

the hinged ramp bi-fold extension

folds and unfolds. Remember to

use good body mechanics when

manually stowing and deploying

the ramp.

Do not release the ramp when

manually deploying or stowing

the ramp. The ramp will free-fall.

Use HAND HOLD to carefully

deploy and stow ramp.

Keep clear of hinge area.

Push the ramp out from inside

the vehicle only if an assistant

is not available and it is absolutely necessary (power failure).

The ramp will free-fall.

Page 20

Page 23

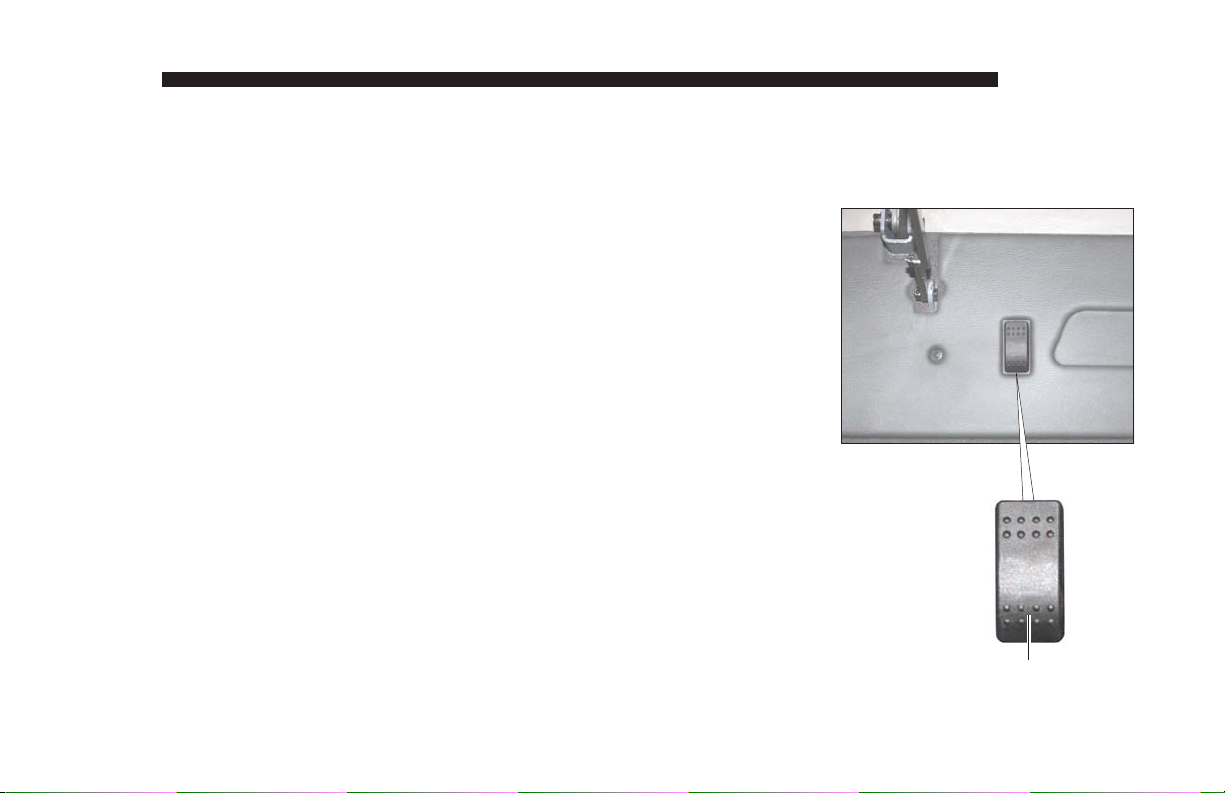

Ramp Electrical Override

An electrical override feature is

incorporated in the power ramp

system. The override by-passes the electronic control system

to electrically power the ramp.

The override is available to stow

(fold) the ramp only.

The Ramp Override Switch is

located rear of the ramp in the

lower wall panel. Press and

hold the switch to stow (fold) the

ramp. Release the switch when

the ramp is fully stowed (stops).

Caution: If you stop pressing

the override switch before the

ramp is fully stowed, the ramp

may free-fall.

OPERATION

Ramp

Override

Switch

Press and hold this switch

to stow (fold) the ramp.

Page 21

Page 24

OPERATION

W

A

RNING

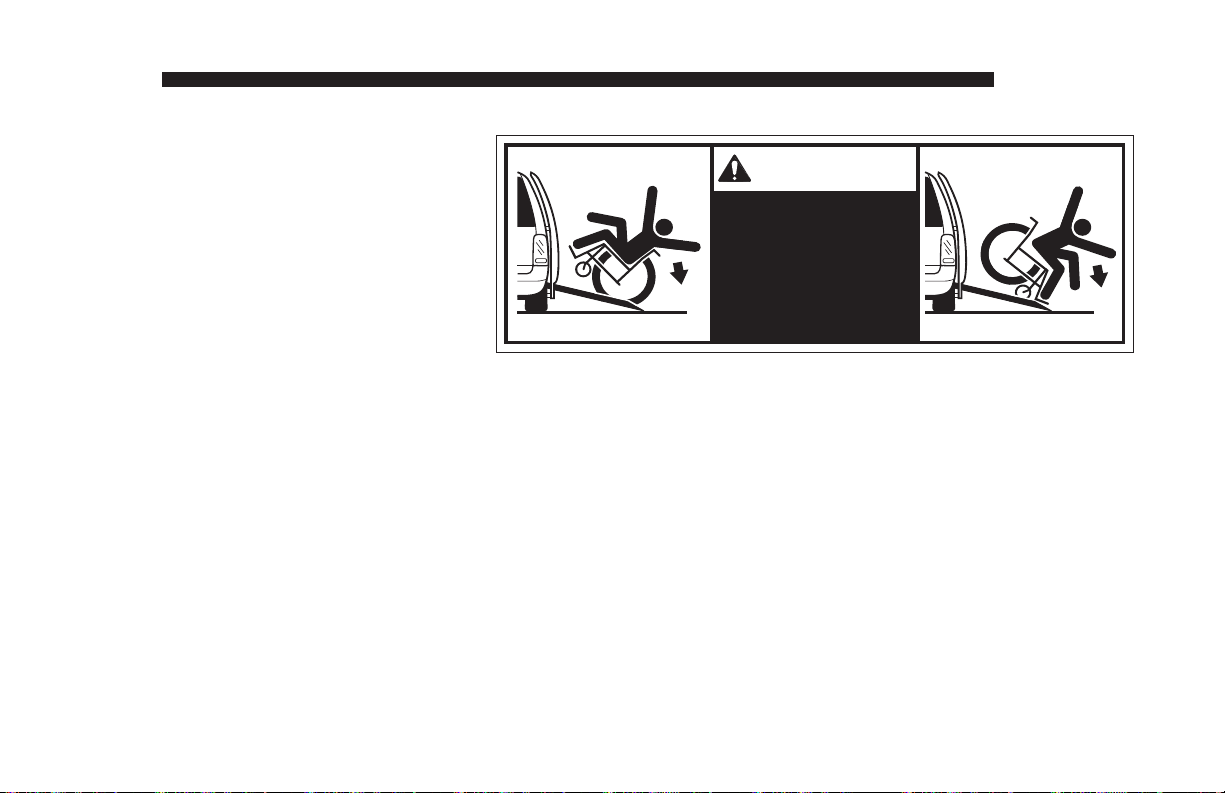

Ramp Safety

Wheelchair passengers and attendants (when applicable), must use basic common sense and good

judgment regarding ramp safety. Each wheelchair

passenger has a unique set of physical abilities,

combined with the physical characteristics of his or

her wheelchair, that dictate the method in which he or

she will enter and exit the Entervan. Consequently,

the procedures for safe operation outlined in this

manual are general in nature. Wheelchair attendants

should be instructed on any special needs and/or

procedures required for safe transport of wheelchair

passengers.

Follow all safety instructions regarding torso restraints, stability, balance, weight distribution and

use of attendants as specified in the owner’s manual

supplied with your wheelchair. Determine, establish

and practice ramp boarding and exiting procedures

under the direction of your health care professional,

your wheelchair representative, and your Entervan

sales representative to ensure your ability to do so

safely.

Never board an Entervan ramp if you or your attendant are intoxicated. The wheelchair should be

positioned in the center of the ramp at all times. You

must be able to clearly view the ramp whenever

boarding and exiting the vehicle. The wheelchair

passenger and/or attendant must ensure the ramp is

fully deployed before exiting the vehicle.

It is the responsibility of the wheelchair operator to

enter and exit the

Entervan on the

ramp in the safest

manner.

WheelchairEquipped Occupant

Seat Belts: Wheel-

chair passengers

should position and

buckle their wheelchair-equipped seat

belt (torso restraint),

Position and fasten

the wheelchairequipped occupant

seat belt before

loading onto the

wheelchair ramp.

Failure to do so may

result in serious

bodily injury and/or

property damage.

Page 22

Page 25

as specified by the manufac-

W

A

RNING

Be aware of

ramp slope.

52217

turer, before loading onto a

wheelchair ramp.

Different types of disabilities require different types

of wheelchairs and different types of wheelchairequipped occupant restraint

belt systems (torso restraint).

It is the responsibility of the

wheelchair passenger to have his or her wheelchair

equipped with an occupant restraint (seat belt) under

the direction of their health care professional.

Stabilizing Wheelchairs: Powered and manual

wheelchairs are designed to remain upright and stable

during normal operation. All activities which involve

movement in a wheelchair have an effect on the combined center of gravity of the occupant and wheelchair.

Be aware of the Entervan ramp slope (angle). The

slope of the ramp has a direct effect on the center of

gravity. Keep in mind your center of gravity and your

ability to maintain stability and balance.

OPERATION

Do not operate your wheelchair on the Entervan

ramp without assistance if you are unable to

maintain stability and balance. Counterbalance

devices (anti-tippers) may be available from your

wheelchair representative to enhance stability and

balance.

Do not tilt your wheelchair without assistance.

Operate the wheelchair at a slow and constant

speed when on the ramp. Do not accelerate suddenly when on the ramp. Do not raise the front

wheelchair wheels (pull wheelie) when on the

Entervan ramp.

Page 23

Page 26

OPERATION

The aid of an attendant stabilizing the wheelchair

is recommended for optimum safety. Wheelchair

passengers who intend to enter and exit their Entervan without the assistance of an attendant must

determine the safest and most practical method

and orientation of entering and exiting the Entervan

based on the physical characteristics of their personal wheelchair and his or her physical capabilities

to maintain stability while the wheelchair is in motion

on the Entervan ramp.

Wheelchair Attendants: When assisting a wheelchair occupant, remember to use good body mechanics. When the wheelchair is on the ramp, the

attendant must grasp the push handles (or other)

securely. Detachable wheelchair parts such as arms

or leg rests must never be used for hand holds or lifting supports. Doing so could result in the detachable

parts being inadvertently detached from the wheelchair resulting in possible injury to the wheelchair

occupant and/or the attendant.

Wheelchair Orientation and Securement During

Transport: The wheelchair and occupant must face

the front of the vehicle and must be secured using

the Forward-Facing Wheelchair and Occupant Belt

and Track System when riding in the Entervan. See

pages 25-33 for details.

Page 24

Page 27

WHEELCHAIR AND OCCUPANT RESTRAINT

One Forward-Facing Wheelchair

and Occupant Belt Kit is supplied

for the restraint of one wheelchair

and occupant (details follow). “Ltrack” is mounted in four locations

in the vehicle for belt securement

(shown in Figure 1).

Note: Wheelchair passengers

shown at right depict the available

seating positions. Wheelchair

capacity at Midpoint (Position C)

may have limitations based on the

physical dimensions of specific

wheelchairs. Additional ForwardFacing Wheelchair and Occupant

Belt Kits must be purchased for

the restraint of each additional

wheelchair passenger.

The Entervan offers the following

options for placement and securement of wheelchair passengers.

Driver Seat: This seat (Position

A) can be removed and adaptive

driving systems custom tailored

for the driving wheelchair occupant can be purchased from

and installed by your local sales

representative.

Front Passenger Seat with Floor

Track: The passenger seat (Posi-

tion B) can be removed and the

seat location can be utilized by a

wheelchair occupant.

Midpoint Lowered Floor Area

with Floor Track: The Midpoint

lowered floor area (Position C) can

be utilized by wheelchair occupants (capacity limitations apply).

Refer to the following guidelines,

illustrations, photos and instructions for proper use of the belt and

track restraint system.

Midpoint

“L”

Track

Front Seat

“L” Track

A

C

Midpoint

“L” Track

Figure 1

B

Front

Seat

“L”

Track

Page 25

Page 28

W

A

RNING

WHEELCHAIR AND OCCUPANT RESTRAINT

No product developed

to date can guarantee

successful securement

of the wheelchair, even

at low speeds, in the

event of an accident.

The Braun Wheelchair

and Occupant Belt/Track

System does meet the

most widely referenced

Federal Motor Vehicle

Safety Standards used

for contemporary

restraint equipment.

However, this equipment

does not ensure stability

of the wheelchair in the

event of an accident at

any speed.

Wheelchair Securement: Four

adjustable over-center buckle

belts are provided for securement of the wheelchair (two for

the front and two for the rear).

The belts are equipped with one

keeper fitting (attachment) which

installs in the vehicle-mounted

“L” track (details on pages 28

and 29). A hook is positioned

on the opposite end of the belts

for attachment to a solid frame

member of the wheelchair. Do

not attach belts to detachable

wheelchair components such as

armrests or leg rests. Front and

rear belt tension is required.

Refer to the illustrations, photos

and instructions on pages 28-33

for belt operation procedures.

Over-Center

Belts

(four supplied)

Lap Belt

Extension

(Midpoint)

Note: Two lap belt

extensions are supplied

(as shown). Midpoint

and front seat lap belt

extensions are not

interchangeable.

Lap Belt

Extension

(Front Seats)

Page 26

Page 29

WHEELCHAIR AND OCCUPANT RESTRAINT

Wheelchair Passenger Securement: Two lap belt

extensions are supplied for securement of the wheelchair occupant. The lap belt extensions are equipped

with a keeper fitting (attachment) which installs in the

vehicle-mounted “L” track. A female receptacle is

positioned on the opposite end of the extension for

attachment to a Chrysler factory-installed upper torso

lap and shoulder belt.

Note: The midpoint lap belt extension is a standard

belt style assembly (adjustable). The front seat

extension is equipped with a rigid cable (nonadjustable). See photos on page 26. Lap belt extensions

are not interchangeable. Attachment procedures

are identical. See the illustrations on pages 30 and

31 and photos on page 33.

Operate the Chrysler lap and shoulder belt as

instructed in your Chrysler owner’s manual. Follow

all safety precautions. Connect the Chrysler lap and

shoulder belt to the lap belt extension. Position the

upper torso (shoulder) belt across the center of the

shoulder. Position the lap belt low across the front of

the pelvis (near hip). See the illustrations on pages

30 and 31 and photos on page 33.

Position of the lap belt buckle, after adjustment, is to

be located near hip position. The belt is to be worn

low and snugly. Adjustment of the lap belt extension is

to be made at adjuster buckle. Wheelchair occupant

restraints should not be held away from the body by

wheelchair components such as armrests or wheels.

Keep belts clear of sharp objects. Do not alter belts.

Do not interchange belts from one position to another.

Keep the supplied belts together as a complete set.

Belt and Track Maintenance: Inspect belt assemblies frequently. Any defects such as belt cuts, fraying

or malfunctioning call for replacement of the entire belt

assembly. “L” track must be clean and not worn, bent

or otherwise damaged (prohibiting proper belt attachment). If there is any sign of damage, wear, abnormal

condition or improper operation of belts, belt hardware

(hooks, keepers, latch plate, receptacle), or track, discontinue use and replace components immediately.

Severe conditions (weather, environment, heavy

usage, etc.) may require more frequent inspections.

Exposure to severe conditions will dramatically reduce

the life of the system.

Page 27

Page 30

WHEELCHAIR AND OCCUPANT RESTRAINT

12"

Side View

Wheelchair Reference Plane

Rear

Securement

Points

30°

45°

10°10°

Side ViewRear View

Figure 2

Front

Securement

Points

40°

60°

12"

25° 25°

Front View

Restraint Belt Angles

Locate wheelchair in forward-facing position centering wheelchair squarely within “L” track. The front

and rear belts, when attached, should create angles

approximately as shown in Figure 2. Preferred

angles and locations of belts from wheelchair securement points to vehicle anchor points are shown.

Front tie-downs should be angled out far for lateral

stability when possible. Note: These are optimum

angles and cannot be achieved in some cases.

Keeper Fitting and “L” Track Attachment

Instructions

The belts supplied in the Forward-Facing Wheelchair

and Occupant Belt/Track System are equipped with

keeper fittings (attachments) which engage the “L”

track. Engage and release the keeper fittings as detailed and shown on the following page. Note: Refer

to pages 32 and 33 for belt attachment and release

procedures.

Page 28

Page 31

WHEELCHAIR AND OCCUPANT RESTRAINT

A

Keeper

“L” Track

Keeper Fitting and “L” Track

Attachment Instructions

a. Push down

on keeper.

To Engage Keeper Fitting:

1. Insert keeper fitting into

track (align two engagement feet with holes in

track). See Photo A.

2. Push down on fitting

Align engagement feet with holes. b. Slide keeper 1/2 slot in either direction.

and slide fitting 1/2 slot

in either direction until it

C

clicks and locks in position (see Photos B and

a. Lift plunger.

C). Pull firmly on belt to

ensure fitting is locked in

track.

To Release Keeper Fitting:

Lift plunger and slide fitting

1/2 slot in either direction

and lift fitting out of track.

Fully-engaged Keeper

b. Slide keeper and lift.

B

D

Page 29

Page 32

WHEELCHAIR AND OCCUPANT RESTRAINT

Keeper

“L” Track

Keeper

Over-center

Buckle Belt

Over-center

Buckle Belt

OEM Installed Upper Torso Lap

and Shoulder Harness

Over-center

Buckle Belt

Lap Belt

Over-center

Buckle Belt

Extension

(see note at right)

Figure 3

“L” Track

Lap Belt Extensions: Two lap

belt extensions are

supplied. Midpoint

and front seat lap

belt extensions are

not interchangeable. Midpoint lap

belt extension shown

in Figures 3 and 4.

Front seat extension

is rigid cable (shown

on page 26).

Page 30

Page 33

WHEELCHAIR AND OCCUPANT RESTRAINT

Note: Generic seat position

shown. Attachment procedures

are identical for all positions.

Photos on pages 32 and 33

depict securement of wheelchair

in midpoint position.

Keeper attachment

details are provided

on page 29.

Keeper

“L” Track

“L” Track

Over-center

Buckle Belt

Over-center

Buckle Belt

OEM Installed Upper Torso

Lap and Shoulder Harness

Figure 4

Adjustable

Lap Belt

Extension

Keeper

“L” Track

“L” Track

Page 31

Page 34

WHEELCHAIR AND OCCUPANT RESTRAINT

E

Over-Center Belt

Attachments

1. Connect chair

hook to a solid

frame member of

the wheelchair (as

shown in Photo E).

2. Position and

connect belt keeper

Hook

Keeper

F

fitting (attachment)

to appropriate track

anchorage point

(slots). Attach

keeper as detailed

on page 29.

Pull firmly on belt

to ensure fitting is

locked in track.

Note: Belt angles

should be as shown

in Figure 2 on page

28.

3. With buckle open,

G

pull loose end of belt

until tight (see Photo

G). While holding

the loose end with

one hand, close the

lever of the clamp

(buckle) down until it

locks. See Photo H.

4. Connect Velcro

tabs to keep excess

belt off floor. See

Photo I).

H

Repeat procedures

for all belts.

Note: Check to see

that front and rear

belts are tight and

the chair is secure

enough that it does

not have any movement. Lock wheelchair brakes.

™

Belt Release: Press

lever clamp (lock) to

release tension on belt.

Velcro™

Tabs

I

J

Page 32

Page 35

WHEELCHAIR AND OCCUPANT RESTRAINT

K

Extension Belt

Extension Belt

M

Receptacle

Chrysler Lap

and Shoulder Belt

Lap and Shoulder Belt Attachments

Refer to Photos K-N.

1. Position and connect the adjustable lap belt extension keeper fitting

(attachment) to appropriate track anchorage point (slots). Attach keeper

as detailed on page 29. Pull firmly

on belt to ensure fitting is locked in

track.

2. Connect the lap and shoulder belt

to the lap belt extension (insert latch

plate in female receptacle). Position

the upper torso (shoulder) belt across

the center of the shoulder. Position

the lap belt low across the front of the

pelvis (near hip). See Photos K-N.

Wheelchair occupant restraints

should not be held away from the

body by wheelchair components such

as wheelchair armrests or wheels.

Chrysler

Lap

and

Shoulder

Belt

L

Receptacle

N

Extension

Belt

Page 33

Page 36

CAUTION

W

A

RNING

SEAT REMOVAL AND INSTALLATION

Front Seats: In an effort to

produce vehicles that can be

configured to meet a variety of

customer needs, the driver and

passenger seat bases have

been designed so they may be

removed. This feature allows

the owner and sales representative to determine the appropriate

seating arrangement to accom-

Park vehicle and

turn engine off

before removing

or installing seats.

Failure to do so may

result in serious

bodily injury and/or

property damage.

modate owner needs. Once the

desired seat arrangement is determined, all power seat electrical

harnesses must be reconnected to

the appropriate fixed seat positions.

Driver’s and passenger’s side front

seats are equipped with “step &

roll” quick-release seat base attachments that engage recessed

floor strikers (supports). The “step

& roll” quick-release front seat is

installed and removed as detailed

on pages 40-43 of this manual.

Power Seats: Entervan front

seats are equipped with electrical

wiring harnesses to accommodate optional equipment such as

heated seats, air bags, etc. Be-

fore removing seats, be certain

all seat electrical harnesses are

disconnected.

When seats are removed, the

seat electrical harness plug

must be connected to the

receptacle provided at the top

of the seat base. See Photos

B and D on page 37 of this

manual.

Adjustable Pedals: The adjustable brake and accelerator

pedal feature is disabled when

the driver seat is removed.

Disconnect seat

wiring harness

before removing

seat. Failure to do

so may result in

property damage.

Page 34

Page 37

SEAT REMOVAL AND INSTALLATION

When positioning seats, it is your

responsibility to reconnect all

seat electrical harnesses. Failure

to properly connect power seat

electrical harnesses may result

in power seat functions being

disabled and/or the air bag light

illuminating.

Entervan front seats are

equipped with an exclusive “step

& roll” quick-release system.

Refer to the seat removal and

installation instructions provided

in this manual. Note: Driver and

passenger side front seats are

not interchangeable.

Contact your sales representative or call The Braun Corporation

at 1-800-THE LIFT if any of this

information is not understood.

Seat Base Rear Covers

Entervan front seats are equipped

with easy to remove rear seat

base covers. The covers must

be removed when removing and

installing seats. Refer to photo

at right. Simply pull back on the

covers to remove them (Velcro

®

secured). Align and push covers into position when reinstalling

seats.

Caution: Do not contact and

damage the seat base electrical

harness when removing and installing the rear seat base covers.

Pull back on Rear Seat Cover

Page 35

Page 38

BLANK for LAYOUT

Page 36

Page 39

SEAT REMOVAL AND INSTALLATION

A

C

Seat

Harness

Front Seat Wiring Harnesses

and Receptacles

An electrical harness receptacle

is located to the rear of each

seat base in the wall (at “B”

pillar). The seat wiring harness

plug connects to the receptacle

socket (screw-on connector

details on pages 38 and 39 of

this manual).

Before removing seats, be

certain seat wiring harnesses

are disconnected.

When seats are removed, the

seat electrical harness plug

must be connected to the

receptacle provided in the seat

base. See Photos B and D.

B-Pillar

Receptacle

Seat Storage

Receptacle

B

Seat

Plug

D

Page 37

Page 40

SEAT REMOVAL AND INSTALLATION

CAUTION

W

A

RNING

Disconnect seat

wiring harness

before removing

seat. Failure to do

so may result in

property damage.

Connect front seat

wiring harness plug

to socket provided

at top of seat base

before removing front

seat. Failure to do so

may result in serious

bodily injury and/or

property damage.

When installing seats, be certain seat wiring harnesses are

reconnected. Failure to do so

may result in power seat functions

being disabled and/or the air bag

light illuminating.

Adjustable Pedals: The adjustable brake and accelerator pedal

feature is disabled when the driver

seat is removed.

Screw-on Connectors

Front seat wiring harnesses are

equipped with a screw-on connector (plug). Operate connectors as

detailed here and on page 39.

A label is posted on the seat wiring

harness plug which identifies the

top of the connector (“TOP” decal

28891). Position the plug with the

“TOP” label facing up when con-

necting the plug to either receptacle socket. Use this feature as

an alignment guide.

Note: Alignment grooves (slots)

are provided in receptacle sockets. Receptacle sockets have a

single wider alignment groove that

is positioned at 12 o’clock (shown

on page 39). Seat wiring harness

plugs are equipped with mating

alignment guides (ears).

Page 38

Page 41

SEAT REMOVAL AND INSTALLATION

Turn this

knurled grip.

Disconnect

Position plug with

“TOP” label up.

TOP

Receptacle

(socket)

Connect

28891

Seat Wiring

Harness Plug

Screw-on Connectors

To Connect: Align the seat

harness connector by positioning the plug with the “TOP”

label facing up. Align the seat

harness connector alignment

guides with the receptacle

socket alignment grooves (will

only connect one way).

Carefully insert the seat harness plug in the receptacle

socket. Turn seat harness connector large diameter knurled

grip clockwise fully (turn gripper

nearest to socket).

To Disconnect: Turn seat harness connector large diameter

knurled grip counterclockwise

and disengage connectors.

Alignment Groove

(at 12 o’clock)

4

95

15 10

22 16

28 23

33 29

37 34

1

Receptacle Socket

Alignment Guide

4

1

5

10

16

23

29

34

9

15

22

28

33

37

Seat Harness Plug

Page 39

Page 42

SEAT REMOVAL AND INSTALLATION

Front Seat Bases

“Step & roll” quick-release seat

base attachments engage recessed floor strikers (supports).

A foot-activated release pedal

is located at the rear of the seat

base. Stepping on the pedal

disengages the attachments

and deploys the seat base rear

wheels.

Note: For ease of disengagement, move the seat to the full

forward and upright position before removing seat(s). Push the

seat back forward and upward

while stepping on foot pedal

(ensures full deployment of rear

wheels).

Foot

Pedal

Push seat back forward and upward

while stepping on foot pedal.

Front Seat Removal Instructions

1. Move seat to full forward and

upright position.

2. Caution! Disconnect seat

wiring harness before

removing a front seat base.

Connect harness to seat base

socket. See page 37-39 for

wiring harness details.

3. Depress foot pedal (push

down). Note: Push seat back

forward and upward while

stepping on foot pedal. See

Photos and Figures A-D.

4. Pull up and back on the rear

of seat (deploy front wheels).

See Figures E and F.

5. Roll seat base out of vehicle

as shown.

Page 40

Page 43

SEAT REMOVAL AND INSTALLATION

A

Illustrations depict seat base only.

Stowed

Seat Base

Foot Pedal

B

Stowed

Seat Base

Engaged Strikers

Depress

foot pedal.

C

D

Depress pedal (a)

and lift seat (b).

E

b

a

Deployed Rear Wheels

b

a

Deployed Rear Wheels Deployed Front Wheels

Deployed Front Wheels

F

Pull seat up and back.

Roll seat out of vehicle

Page 41

Page 44

SEAT REMOVAL AND INSTALLATION

W

A

RNING

Front Seat Bases

“Step & roll” quick-release seat

base attachments engage recessed floor strikers (supports). A

foot-activated release pedal is located at the rear of the seat base.

A cross bar is positioned directly

under the pedal. Stepping on the

bar engages the rear seat base attachments to lock the seat base.

Seat attachments

must be fully latched

in floor supports be-

fore occupying seats

or operating vehicle.

Failure to do so will

result in serious

bodily injury.

Engagement

Bar

Front Seat Installation

Instructions

1. Roll seat base into position, just

behind the floor mounted strikers.

See Figures A and B. Move seat

base forward to engage front

strikers. See Figures C and D.

Note: Position outside of seat

base alongside wall panel for

easy alignment.

2. Depress rear cross bar (push

down) to stow rear wheels and

engage rear seat attachments

with floor strikers. See Figures

C-F. Lift seat to ensure floor

strikers are locked in seat attachments.

3. Connect (plug) seat electrical

harness to B-pillar receptacle.

See page 37.

Page 42

Page 45

SEAT REMOVAL AND INSTALLATION

A

Floor Strikers

B

Roll seat into position.

Floor Strikers

Roll seat

into position.

C

a

Engaged Front Strikers

D

Engage front strikers (a) and

depress engagement bar (b).

a

Engaged Front Strikers

b

Engagement Bar

b

E

Engaged Strikers

F

Stowed (locked)

Engaged Strikers

Stowed

(locked)

Seat Base

Seat Base

Page 43

Page 46

SEAT REMOVAL AND INSTALLATION

W

A

RNING

Third Row Seats

Third row 60/40 split bench seats

have been modified during conver-

sion procedures. Seat backs can be

folded down to the flat position and

tipped forward to provide full access to

rear floor storage compartments. The

Stow ’n Go (stow in floor) feature is

not available.

Seat removal is allowed for the driver

side section of the seat (instructions

on opposite page). The electronic

control module assembly is mounted

under the passenger side section of

the seat. Removal of the passenger

side section of the seat is prohibited*.

* Should removal of the passenger

side section of the third row seat

be imperative, contact The Braun

Corporation at 1-800-THE LIFT

A Braun Product Support representative will direct you to an authorized

service technician.

®

.

Folding (tipping) Third Row Seats

Seat backs can be folded down to

the flat position and tipped forward.

Seats must be returned to the full

stowed (locked) position before

driving.

To Fold (tip forward) Third Row

Seats

1. From the rear of the vehicle, fold

down the back of the bench seat

(pull release strap #1).

2. Pull the release strap at the rear

of the seat (between seat base

and floor), and lift and fold (tip)

the seat forward.

To Unfold (rotate rearward) Third

Row Seats

Carefully (slowly) rotate and lower

seat rearward to stowed position.

Ensure the rear spring-loaded at-

tachments engage floor strikers.

Raise the seat back (pull release

strap #1) and attempt to move

seat back and forth.

Caution: Use extra care when

lowering passenger side section

of seat. Do not slam seat down

or allow seat to drop (free-fall).

Doing so may result in damage

to the electronic control module

assembly.

Install seats as

specified before

occupying seats or

operating vehicle.

Failure to do so may

result in serious

bodily injury and/or

property damage.

Page 44

Page 47

SEAT REMOVAL AND INSTALLATION

Third Row Seat Removal:

Note: Removal of the passenger

side section of the seat is prohibited*. Policy detailed on previous

page.

1. From the rear of the vehicle, fold

down the back of the bench seat

(pull release strap #1).

Linkage Arm

Securement Bolt

2. Pull the release strap at the rear

of the seat (between seat base

and floor), and lift and fold (tip)

the seat forward. Note: Push

top of linkage rod forward to stabilize seat (over center position)

3. Remove the bolt securing the

linkage arm to the floor-mounted

bracket.

(40) Section(60) Section Controller Assembly

4. Remove E-ring retaining clips

from the pivot pins securing the

front floor mounts.

5. Remove the pivot pins.

6. Carefully remove seat.

Third Row Seat Installation:

Reverse removal procedures.

E-Ring Retaining Clip

Pivot Pin

Page 45

Page 48

LIMITED WARRANTY

In accordance with the Chrysler 5 year/100,000

mile corrosion warranty, The Braun Corporation warrants to the purchaser of its Entervan conversion that

it will repair (or replace at Braun’s sole option) any

defect in material or factory workmanship in the metal

fabrication on or of the frame, floor and lowered door

extension for a period of 5 years or 100,000 miles on

the odometer, whichever occurs first. The Braun Corporation further warrants to the purchaser that it will

Years/Miles in Service

Entervan frame and floor structural components

Entervan ramp, door and associated structural components

36 Months

or

36,000 Miles

(whichever comes first)

Entervan electrical components including but not limited to switches,

wires, connectors and the controller

Entervan electromechanical kneel systems including but not limited

to electric actuator, chain, pulleys and associated hardware

repair (or replace at Braun’s sole option) any defect

in material or factory workmanship for the remainder

of the modifications and alterations for associated

parts for a period of 36 months or 36,000 miles,

whichever occurs first. For clarification purposes,

the following chart outlines The Braun Corporation

Entervan warranty coverage. Refer to your Chrysler

warranty information booklet for all Chrysler OEM

(factory) limited warranty details.

Specific Area Covered

Page 46

Page 49

LIMITED WARRANTY

Years/Miles in Service

36 Months

or

36,000 Miles

(whichever comes first)

Corrosion Limited

Warranty

Outer Panels

5 Year or

100,000 Miles

(whichever comes first)

All Panels

(Exceptions)

3 Years/Unlimited

Miles

Specific Area Covered

Entervan appearance items including but not limited to interior

floor covering and slide door lowered extension assemblies.

Corrosion Limited Warranty:

Outer Panels: Entervan frame, floor and lower door modification

metal fabrication corrosion applies to perforation only. Entervan

lower slide door modification corrosion applies to outer-body sheet

metal and paint. Perforation is a rust-through condition such as an

actual hole in the metal.

All Panels (Exceptions): Cosmetic or surface corrosion (resulting

from stone chips for example) would not be covered or repaired

under this coverage. If corrosion does not cause holes, and is not

the result of usage and/or environmental conditions, repair coverage lasts for 3 years/unlimited miles.

Page 47

Page 50

LIMITED WARRANTY

Both the 5 year/100,000 mile corrosion and the

3 year/36,000 mile limited warranties described on

previous page commence on the date the conversion is put into service, providing the warranty registration card is completed and received by The Braun

Corporation within thirty days of the purchase.

The Braun Corporation agrees to repair or

replace any of its Entervan factory-installed parts

found to be defective within the appropriate warranty period or mileage. This limited warranty also

covers the cost of labor for the repair or replacement

of said parts for three years provided that the repair

is authorized by The Braun Corporation and carried

out by an authorized service establishment (a Braun

labor schedule determines the cost allowance for

repairs). The Braun Corporation will not honor any

warranty claim for repairs or replacement of parts

unless the claim is submitted with the appropriate

factory warranty authorization data and the repairs

or replacement of the parts are completed by a factory-authorized repairman. The factory authorization

data, together with the name and location of the fac-

tory-authorized repairman, can be obtained by either

written or telephone contact with The Braun Corporation at the addresses appearing in this manual.

The return authorization procedure must be adhered to in order to process any warranty and repair

claims (details on following page).

The Braun Corporation reserves the right to designate where any warranty work is to be performed.

The Braun Corporation also reserves the right to

examine any defective workmanship or part prior to

any authorization of necessary repairs. This Entervan limited warranty is not intended to replace or

substitute any other warranties issued by the original manufacturer of the vehicle or other suppliers of

components. This limited warranty shall not apply to

any part or workmanship that may become defective

due to misuse, neglect, accident or other casualty,

modifications or alterations or unauthorized repairs.

Further, this limited warranty shall not extend to parts

or workmanship that may become defective because

Page 48

Page 51

LIMITED WARRANTY

of the failure of anyone to operate the same in accordance with the printed instructions of The Braun

Corporation or because of operation of the same

beyond its capacity.

This limited warranty does not cover normal maintenance, service, or periodic adjustments necessitated by use or wear.

Second buyers of a Braun Entervan conversion may transfer the remaining warranty, if any,

by obtaining a transfer of warranty application from

The Braun Corporation. This application must be

returned to The Braun Corporation within thirty days

from the date you purchase the vehicle and proof

of the date of purchasing must be supplied with the

transfer of warranty application. There will be a minimum warranty transfer fee.

The Braun Corporation shall not be liable for

any incidental or consequential damages resulting from any breach of warranty.

The Braun Corporation shall not be liable for towing charges, travel and lodging, or any other expense

incurred due to the loss of use of vehicle or other

reason.

To the extent any implied warranties exist by

operation of federal or state law, such implied

warranties are limited in duration to the period of

the express limited warranty herein.

Return Authorization Procedure

When processing any warranty claims (parts, repairs,

etc.), all requests must be processed through the

Braun Corporation Product Support Department.

®

Call 1-800-THE LIFT

during working hours. Product

Support will issue a Return Material Authorization

(RMA) number and detail the procedures required for

processing returns and/or authorizing credit.

The last eight digits of the vehicle identification num-

ber (VIN) must be provided when filing a warranty

claim or ordering parts.

Page 49

Page 52

PREVENTIVE MAINTENANCE

Maintenance is necessary to

ensure safe and trouble free

Entervan

operation. General preventive maintenance consisting

of inspections of your Entervan

systems along with cleaning and

lubricating procedures should be

a part of your routine (lubrication requirements are minimal).

Keeping the passenger slide door

lower track pan free of debris,

ice and snow is one of the most

effective preventive maintenance

practices to exercise. Regular

preventive maintenance procedures will increase the service