Brandt GRAIN VAC 5000, GRAIN VAC 5000 EX Operator And Parts Manual

GRAIN VAC

5000

5000 EX

OPERATORS

AND PARTS

Part No. B012352 Rev 15 Effective Jan., 2007

MANUAL

BRANDT WARRANTY POLICIES AND PROCEDURES -

effective May 1, 2001.

Introduction To The Warranty Policy

At Brandt Agricultural Products Ltd. (“Brandt”), it is our goal to ‘Deliver Value’ by providing you with innovative,

high-quality, trouble-free products. While we continually find new ways to improve our design and manufacturing

processes, it is unreasonable to expect flawless performance from all machines at all times. Brandt’s warranty

policy is in place to protect the end user from product defects.

Brandt will warranty each new Grain Vac 5000 to be free from factory defect in material and workmanship

under normal use and service, when operated in accordance with Brandt factory instructions as contained in

this operator’s manual, for

original purchaser. Warranty is available to the original purchaser only and is not transferable. Any equipment

that is purchased for use by commercial business operations, rental applications, or hired out on a

custom basis will be eligible for 6 months parts and labour only. The warranty term for any products

used by Brandt for demonstration purposes or Brandt product that has been reworked and sold through

Brandt’s factory will carry a 6 months parts only warranty.

Brandt will reimburse factory-authorized dealers for warrantable parts and labour for one full year from date of

delivery, and will cover warrantable parts only during the second year. Brandt’s warranty does not cover and

Brandt shall not be responsible for costs incurred in connection with repairs made outside the periods specified

in the immediately preceding sentence or for repairs made by unauthorized persons. Brandt’s obligation under

this warranty is limited to the repairing of, or supplying of replacement parts in exchange for, any parts that are

defective due to factory workmanship or material. Brandt makes no warranty as to tires, cylinders, power

take off shafts, belts, hoses or any accessories which are not manufactured by Brandt but that may be sold

along with Brandt products, as all such accessories are covered by the manufacturer’s own warranty. This

warranty is void on any unit that has been tampered with or that has been subject to misuse, neglect, accident

or which has had the serial number tampered with or removed.

two years on parts, one year on labour from the date of delivery to the

Responsibility for Providing Warranty:

• It is the customer’s responsibility to return the machine to the dealership for warranty repair or pay the

dealership call out fees.

• It is the Dealer’s responsibility to provide warranty service to the end user with support to be provided

by Brandt in accordance with this policy.

• All claims for warranty must be presented to Brandt by the Dealer and not the end user.

• The Dealer will be responsible for any warranty given by it, without the prior authorization of Brandt.

• Brandt will support our Dealers in providing this warranty service through ongoing training and

knowledgeable support staff.

• The cost to the Dealer of providing warranty service in accordance with this policy will be reimbursed

by Brandt to cover parts, labor and freight as per our published Warranty Claim Procedure.

Warranty Registration and Pre-Delivery Inspection Forms

• The Dealer must complete and send to Brandt a Warranty Registration form for each new Brandt

Product sold by the Dealer, within 30 days of delivery to customer, to ensure that the machine is

eligible for warranty. Warranty Registrations must be accompanied by a completed and signed PreDelivery Inspection (PDI) form which is filled out upon completion of the Pre-Delivery Inspection at

time of sale. Machines that do not have Warranty Registration and a copy of the PDI forms registered

on file with Brandt will not receive any warranty labor or parts compensation until such documents are

completed and filed with Brandt. Triplicate copies of the Warranty Registration as well as the PreDelivery Inspection forms are included inside the Operator’s Manual supplied with each Brandt Product.

Warranty Policy Definitions

• “Free from Defects in Material and Workmanship”

A failure of a part caused by the part itself with no abnormal external influences is a defect. An example

would be a hydraulic hose that has been shipped from the Brandt factory with a pin hole leak.

A failure caused by abnormal external force acting on a part is not a defect. For example, an auger

flight bent or broken by a rock picked up while cleaning grain off the ground is not considered defective.

• “Normal Use and Service”

Each product from Brandt has an intended use which is advertised through our brochures and videos.

A failure occurring due to an unusual condition or operation not specifically represented by Brandt will

not be warranted.

• “Operated in Accordance with Factory Instructions”

The Operator’s Manual supplied with each Brandt Product gives instructions on safe, optimal, productive

operation of the machine. Shortcuts in operation or disregard for these instructions may cause damage

to the unit, which will not be warranted.

Failure caused by misuse, accident or by a lack of required normal maintenance as specified in the

Operator’s manual will void warranty. Damage as a result of accident or shipping would not be

considered a defect and therefore not warrantable. Failures due to improper adjustment not checked

on the pre-delivery inspection are not considered defects.

THE EXPRESS WARRANTIES OUTLINED ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, CONDITIONS AND TERMS AS TO QUALITY, FITNESS OR

PERFORMANCE OF THE GOODS, WRITTEN, ORAL OR IMPLIED, STATUTORY OR

OTHERWISE, INCLUDING, WITHOUT LIMITATION, ANY WARRANTIES OR

CONDITIONS OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

AND ALL SUCH OTHER WARRANTIES, CONDITIONS AND TERMS ARE HEREBY

DISCLAIMED AND EXCLUDED.

The Customer’s sole and exclusive remedy with respect to the quality, performance or fitness of the product

shall be as provided in the express warranties described above and Brandt shall have no liability with respect

to any non-conformance of or defect whatsoever in the product (including any liability for direct, indirect,

special, incidental or consequential damages) whether in warranty, contract, tort, negligence, strict liability or

otherwise. The Customer shall not return the product to Brandt or incur any shipping or other charges in

respect of the product without Brandt’s prior written consent.

PRODUCT IS INELIGIBLE FOR WARRANTY IF NOT REGISTERED

Brandt Agricultural Products Ltd.

BOX 317 STATION MAIN

TH

AVE. AND PINKIE ROAD

13

REGINA, SASK., S4P 3A1

WARRANTY REGISTRATION FORM

Please Print Clearly

This form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery.

Customer Name Dealer Number

Customer Address Dealer Name

City Prov/State Dealer Address

Postal / Zip Code Area Code Phone Number City Prov/State

E-Mail Address Postal / Zip Code Area Code Phone Number

Delivery Date: E-Mail Address

Purchase Date:

Serial Number:

PRODUCT

______Standard Augers Model No. ___________

______

Supercharged Auger Model No. ___________

______

Direct Drive Auger Model No. ___________

______

Swing Away Auger Model No. ___________

______

Utility Auger Length______ Diameter _____

______Tailgate

______Trakker _____________ ______________

Make

Diameter & Length

_____Belt Conveyor Model No. _________________

Drive Type _____________ Intake Type ____________

1. I have performed the predelivery inspection procedure, as set out on the predelivery inspection sheet in

the operators manual and I am satisfied the above described machine is setup and adjusted properly.

2. I have thoroughly instructed the buyer on the above described equipment which included review of the

Operators Manual content, equipment care, adjustments, safe operation and applicable warranty policy.

Date:_____________________ Dealer’s Signature: ________________________________________

I have received the Operators Manual for the above described machine and I have been thoroughly

instructed on, and understand, the care, the adjustments, and the safe operation of the above described

machine and applicable warranty policy.

_____ QF 1500 Sprayer Boom Size _____

_____

QF 2500 Sprayer Boom Size _____

_____

QF 2500S Sprayer Boom Size _____

_____

3PT Sprayer ____ 70 Gal. _____ 130 Gal.

_____ SB 4000 Sprayer Boom Size _____

_____ Heavy Harrow Width ______ Tine Diameter ______

_____ Grain Vac Model No. __________

_____ Bale Processor

Date: _____________________ Owner’s Signature: _______________________________________

White Copy - Brandt Yellow Copy - Dealer Pink Copy - Customer

PREDELIVERY CHECKLIST

GRAIN VAC 5000 Serial # Date

1. The PTO shaft and the storage post have been installed as per instructions in the Operator’s

Manual, sec. 1.1, page 10.

2. The wheels have been moved to the outermost position as per the instructions in the Operator’s

Manual, sec. 1.2, page 10.

3. The hitch clevis plate is installed in the lower most position and the hose holder is vertical as per the

instructions in the Operator’s Manual, sec. 1.3, page 11.

4. The fan drive pulleys are aligned and the fan drive belt is tensioned so the idler spring is compressed

to 2 3/4” as per the instructions in the Operator’s Manual, sec. 5.1, page 35.

5. The auger drive sprockets are aligned and the drive chain tension is adjusted to allow one chain

thickness movement as shown in the Operator’s Manual, sec. 5.4, page 37.

6. Check to insure the gearbox is half full of oil by inserting a clean dip stick into the upper vent plug.

7. Check the wheel bearings to ensure they have the correct preload, no slop and no excessive

grease leakage at the seals.

8. Lubricate all grease points as shown in the Operator’s Manual, sec. 4, page 33.

9. Check the air pressure in the tires. Inflate to 35 lbs. psi.

10. Check the tightness of the wheels bolts. Tighten to 90 ft.lbs. torque.

11. Remove the locking device as per page 23 , connect the hydraulic hoses to a tractor and cycle the

auger from transport position to fully extended and back to check for hydraulic oil leaks and hose

routing problems. Fix any problems at this time.

12. Extend the auger to the fully extended position and check the tie rod adjustment as per the instructions

in the Operator’s Manual, sec. 5.11, page 41.

13. Open the upper body and check the positioning of the chaffers. The upper chaffer’s holes should

be facing the rear of the machine and the lower chaffer’s holes should be facing the front of the

machine. See sec. 5.12, page 43 in the Operator’s manual for information.

14. Connect the PTO Shaft to the tractor, rotate the tubes into working position and do the clutch run-

in procedure as described in Section 5.18, page 56. Run at operational speed for 10 minutes to

ensure the machine runs smoothly without any unusual noise or vibration.

15. Lower the plastic Exhaust Stack into transport position and replace the tube locking pin.

5

Contents

Predelivery Checklist ............................................................................................................ 5

Section 1 - Introduction ........................................................................................................ 9

1.1 PTO Post Installation ....................................................................................... 10

1.2 Trailer Wheel Mounting.................................................................................... 10

1.3 Hitch Clevis .................................................................................................... 11

1.4 Pail Hook ........................................................................................................ 11

1.5 PTO Clutch Run-In Procedure ......................................................................... 11

Section 2 - Safety ................................................................................................... 12

2.1 General Safety .................................................................................................. 13

2.2 Operating Safety .............................................................................................. 13

2.3 Maintenance Safety ......................................................................................... 14

2.4 Transport Safety .............................................................................................. 14

2.5 Grain Bin Safety .............................................................................................. 14

2.6 Safety Decals .................................................................................................. 14

2.7 Sign Off Form ................................................................................................. 15

2.8 Safety Decal Locations .................................................................................... 16

Section 3 - Operation ......................................................................................................... 19

3.1 Principles of Operation .................................................................................... 19

3.2 First Operation ................................................................................................ 20

3.3 Pre-Operation Checklist .................................................................................. 20

3.4 Equipment Matching ........................................................................................ 21

3.5 Attaching / Unhooking ...................................................................................... 21

A. To Hook to a Tractor ............................................................................ 21

B. To Hook to a Truck .............................................................................. 22

3.6 Setup For Operation ....................................................................................... 23

3.7 Operation ........................................................................................................ 23

A. General Operating Instructions .............................................................. 23

B. Full Bin Unload ..................................................................................... 24

C. Removing Grain from in a Clean Up Operation ...................................... 25

D. Optional Adjustable Height Bin Snake .................................................... 26

E. Adjustable Air Throttle and Vent ............................................................. 27

F. Folding Exhaust Deflector ....................................................................... 29

3.8 Shutdown ........................................................................................................ 29

3.9 Operation Hints ............................................................................................... 30

3.10 Soybean / Field Pea Operation ...................................................................... 30

3.11 Expected Capacities for Various Crops ........................................................... 31

3.12 Transporting .................................................................................................. 31

3.13 Storage ......................................................................................................... 32

Section 4 - Service .............................................................................................................33

4.1 Fluids and Lubricants ....................................................................................... 33

4.2 Lubrication ...................................................................................................... 33

4.3 Service Intervals .............................................................................................. 34

4.4 Service Record ................................................................................................ 34

6

Section 5 - Maintenance ..................................................................................................... 35

5.1 Fan Drive Belt Tension .................................................................................... 35

5.2 Fan Belt Replacement ..................................................................................... 35

5.3 Drive Pulley Alignment .................................................................................... 36

5.4 Auger Chain Drive .......................................................................................... 37

5.5 Airlock Plates ................................................................................................. 38

5.6 Auger Shear Bolt ............................................................................................ 38

5.7 Fan Bearing Box ............................................................................................. 39

5.8 Drive Shaft Bearings ....................................................................................... 40

5.9 Gearbox Removal ........................................................................................... 41

5.10 Suction Hoses ............................................................................................... 41

A. Clamp Adjustment: ................................................................................ 41

B. Hose / Clamp Replacement ................................................................... 41

5.11 Auger Fold Tie Rod ....................................................................................... 41

5.12 Chaffer Orientation ........................................................................................ 43

5.13 Air Throttle Function ...................................................................................... 44

5.14 Fan Rotor and Housing Inspection ................................................................. 45

5.15 Fan Rotor and Bearing Box Replacement ....................................................... 47

5.15.1 If the Fan is Rubbing ....................................................................... 48

5.15.2 Replacing the Fan Rotor ................................................................. 49

5.15.3 Replacing the Fan Rotor and Bearing Box ....................................... 50

5.16 Auger Flight Installation and Adjustment ......................................................... 52

5.16.1 Auger Flight Installation and Adjustment - Model 5000 ................... 52

5.16.2 Auger Flight Installation and Adjustment - Model 5000 EX ............. 54

5.17 Tube Lock Spring Adjustment ........................................................................ 55

5.18 PTO Clutch Assembly & Run-In Instructions .................................................. 56

5.19 PTO Shaft Slip Clutch Assembly .................................................................... 57

Section 6 - Trouble Shooting ............................................................................................... 58

Section 7 - Specifications .................................................................................................... 63

7.1 Mechanical ...................................................................................................... 63

7.2 Bolt Torque ..................................................................................................... 64

Section 8 - Parts Listing ......................... ...........................................................................P-1

Model Number Serial Number

Serial Number Location

7

This page is blank.

8

Section 1 - Introduction

CONGRATULATIONS on your choice of a Brandt Grain Vac 5000.

Use this manual as your first source of information about the machine. If you follow the instructions given

in this manual, your Grain Vac will work well for many years.

Safe, efficient, and trouble free operation of your Grain Vac requires that you and anyone else who will be

operating or maintaining the machine, read and understand the Safety, Operation, Maintenance and Trouble

Shooting information within the Operator’s Manual.

This manual covers the Brandt Grain Vac model 5000 and 5000 EX, manufactured by Brandt Agricultural

Products Ltd.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your

Brandt dealer if you need assistance or information.

OPERATOR ORIENTATION - The directions left, right, front and rear, as mentioned throughout the

manual, are as seen from the tractors driver’s seat facing in the direction of travel.

9

1.1 PTO Post Installation

Before using the Brandt Grain Vac the PTO Post

must be installed. The Post and the tractor end of

the PTO shaft are bundled together and placed inside

the vac body. The following instructions will help

with the installation of the PTO Holder.

1. Loosely attach the PTO post to the front right

side of the frame, see photo below, with the two

5/16” x 4” ubolts and 5/16” locknuts.

2. Slide the implement end of the PTO shaft into

the half mounted to the vac.

3. Grease the universal joints on both ends of the

PTO shaft. Grease the middle or telescoping

part of the PTO shaft.

4. Set the PTO shaft onto the PTO holder

assembled above.

6. Tighten the nuts on the PTO holder U-bolts.

7. Install the PTO holder pin onto the top of the

PTO holder. This will secure the PTO shaft.

1.2 Trailer Wheel Mounting.

Before using the Brandt Grain Vac, the transport

wheels must be moved to the outer (working)

position as shown below.

1. Place a jack under the frame of the Vac and

raise one wheel off the ground.

5. Slide the PTO holder as far back as possible

without the PTO shaft interfering with the fan

guard. Mounting the post farther back reduces

the chance of the PTO shaft interfering with a

towing vehicle.

2. Remove the four 1/2” x 1 3/4” hex bolts, and

the 1/2” locknuts.

3. Position the wheel and fender assembly in the

outer (working) position. Note that it is not

necessary to remove the fender first.

4. Fasten in place with the hardware removed in

step 1 above.

5. Repeat the procedure on the other wheel.

10

Transport

Position

Working

Position

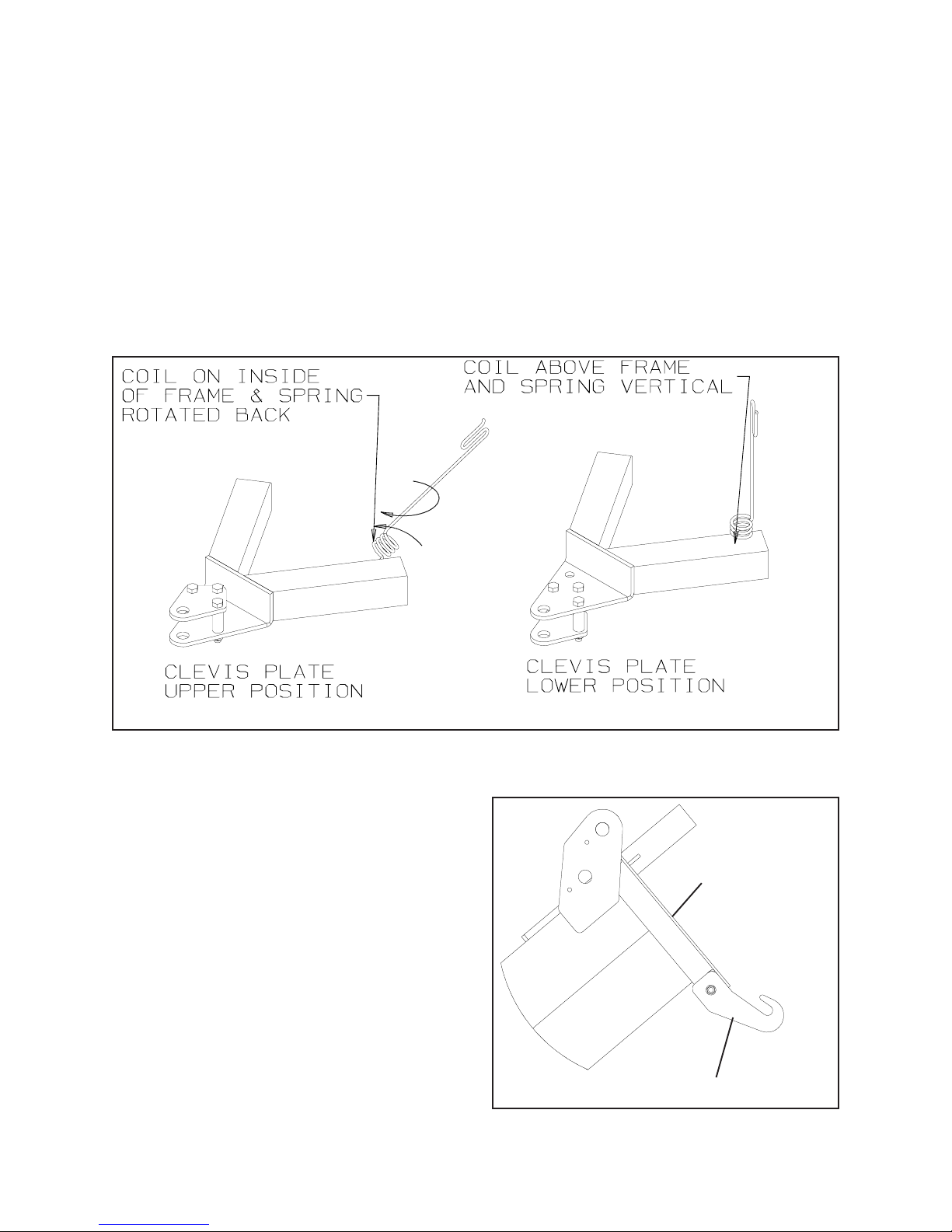

1.3 Hitch Clevis

The hitch clevis plate has been installed in the top

position for shipping and it should be relocated to

the lower working position before delivering to the

customer. As shown in the figure below, remove

the 3/4” locknuts, spacer tubes, and hitch plate and

re-install in the lower position.

In addition, the hose holder spring has been installed

inside out and rotated back. Remove the spring

retainer nut, pull off the spring and flip inside out so

that the coil is laying above the frame member.

Reinstall the retaining nut and secure with the spring

in the vertical position.

1.4 Pail Hook

The Pail Hook has been installed in the stowed

position for shipping and it should be relocated to

the working position before delivering to the customer.

As shown in the adjacent figure, remove the 3/8”

locknut and re-install in the working position.

1.5 PTO Clutch Run- In Procedure

The Clutch on the PTO Shaft has a run-in procedure

that is required to be done before the vac is put to

use. Refer to Section 5.18, page 56 of this manual

for the run-in instructions.

Transport Position

Lower Tube

Rotate the Pail Hook into working position

11

Section 2 - Safety

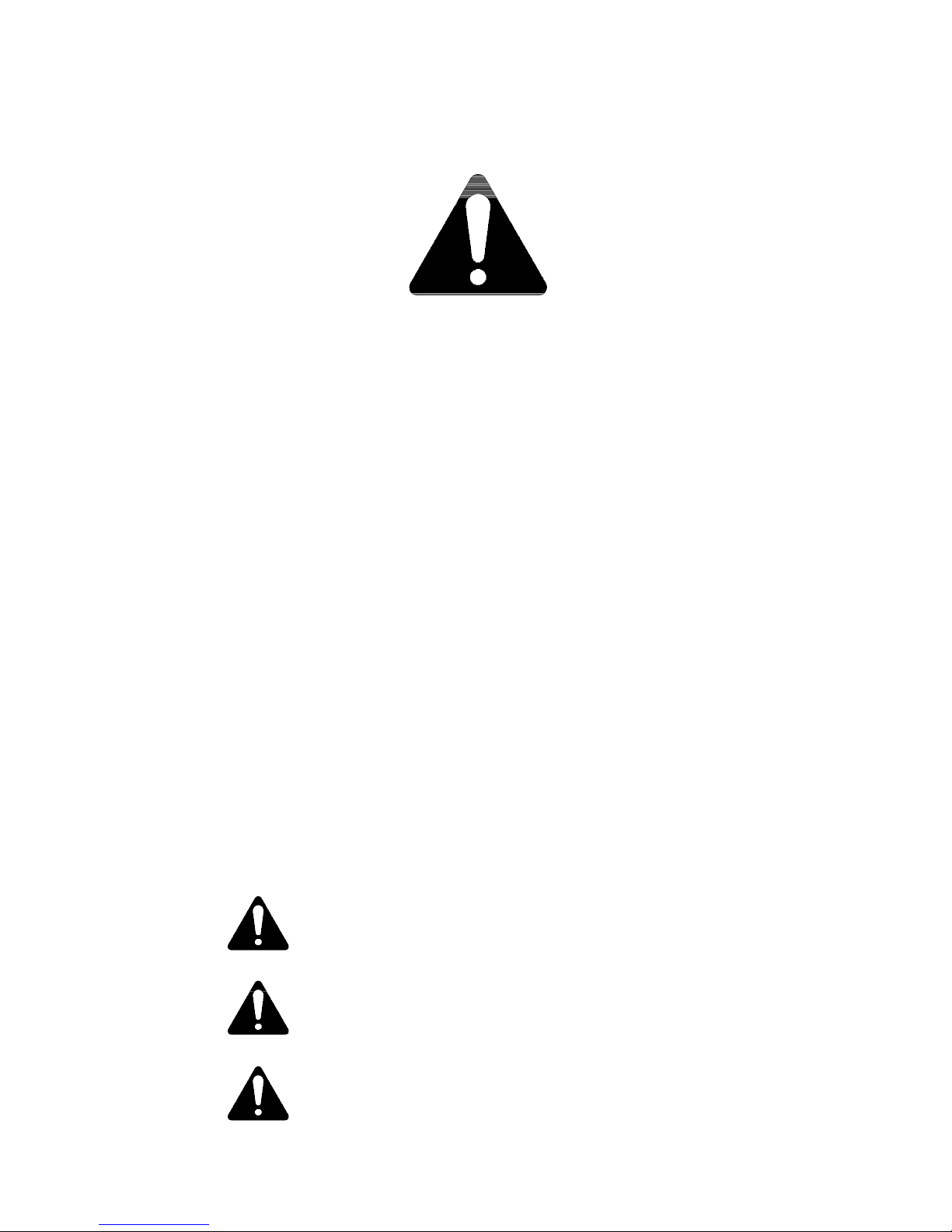

SAFETY ALERT SYMBOL

Watch This Symbol. It Points Out important precautions.

It Means “ATTENTION — Become Alert!

Your Safety Is Involved.”

Occupational safety is of prime concern to Brandt Agricultural Products Ltd. This Grain Vac Manual was

written with the safety of the operator and others who come in contact with the equipment as our prime

concern. The manual presents some of the day to day work problems encountered by the operator and

other personnel. We wrote this manual to help you understand safe operation procedures for our Grain

Vac. We want you as our partner in the safe operation of our equipment.

It is your responsibility as an owner or operator or supervisor, to know what specific requirements,

precautions and work hazards exist and to make these known to all other personnel working with the

equipment or in the area, so that they too may take any necessary safety precautions that may be required.

Failure to read this Grain Vac Manual and its Safety Instructions is a misuse of the equipment.

THREE WORDS USED IN CONJUNCTION WITH THE SAFETY ALERT SYMBOL

DANGER!

WARNING!

Tells you that a hazard exists which would result in a

high probability of death or serious injury if proper

precautions are not taken.

Tells you that a hazard exists which can result in injury

or death if proper precautions are not taken.

CAUTION!

Tells you to remember safety practices, or directs

attention to unsafe practices which could result in

personal injury if proper precautions are not taken.

12

2.1 General Safety

1. Read and understand the Operator’s manual and

all safety signs before operating, maintaining,

adjusting or unplugging the Grain Vac.

2. Grain Vac owners must give operating

instructions to operators or employees before

allowing them to operate the machine, and at

least annually thereafter per OSHA

(Occupational Safety and Health Administration)

regulation 1928.57.

3. The most important safety device on this machine

is a SAFE operator. It is the operator’s

responsibility to read and understand all safety

and operating instructions in the manual and to

follow them. All accidents can be avoided.

4. A person who has not read and understood all

operating and safety instructions is not qualified

to operate the machine. An untrained operator

exposes himself and bystanders to possible

serious injury or death.

10. Place all controls in neutral, stop the engine, set

park brake, remove ignition key, and wait for

all moving parts have come to a complete stop

before servicing, adjusting, repairing or

unplugging.

11. Know where overhead electrical lines are

located and stay away from them. Electrocution

can occur without direct contact.

12. Think Safety! Work Safely!

2.2 Operating Safety

1. Ensure all guards are in place and in good repair

before operating.

2. Keep hands, feet, hair and clothing away from

all moving or rotating parts, including the suction

inlet and the clean out door situated under the

vac body.

5. Do not modify the equipment in any way.

Unauthorized modification may impair the

function and/or safety and could affect the life

of the equipment.

6. Have a first-aid kit available for use should the

need arise and know how to use it.

7. Provide a fire extinguisher for use in case of a

fire. Store in a highly visible place.

8. Do not allow riders on the machine.

9. Wear appropriate protective gear. This list

includes but is not limited to:

-hard hat

-protective shoes

-protective goggles

-heavy gloves

-wet weather gear

-hearing protection

-respirator or filter mask

3. Clear the area of all bystanders, especially

children, before starting.

4. Attach securely to tractor using a retainer on

drawbar pin and a safety chain.

5. Be sure the PTO driveline guard telescopes and

rotates freely on shaft before installing.

6. Keep away from the unloading auger when in

motion, adjusting or setting. Keep others away.

7. Use hazard flashers on tractor when

transporting.

8. Do not place the intake tube near your feet when

standing on top of pile of grain.

9. Wear hearing protection while operating.

10. Due to the high suction of the unit, avoid the

suction end of the hoses while operating.

13

11. Escaping hydraulic fluid under pressure can

penetrate skin and cause serious injury. Relieve

pressure before disconnecting hydraulic lines.

Check / tighten all connections before applying

pressure. Use a piece of cardboard or paper

to search for leaks. NEVER use your hand.

12. If any fluid is injected into the skin, seek medical

attention immediately. Serious infection or toxic

reaction can develop from hydraulic fluid

piercing the skin.

2. Make sure the Slow Moving Vehicle emblem

and all the lights and reflectors that are required

by the local highway and transporting authorities

are in place, clean and can be seen clearly by all

overtaking and oncoming traffic.

3. Attach securely to tow vehicle or tractor using

a retainer on the draw pin and safety chain.

4. Do not exceed 32 km/h (20 m.p.h.).

5. Never transport the Grain Vac with the auger

extended in operating position.

2.3 Maintenance Safety

1. Always disengage power, shut down the tractor

and be sure all moving parts have stopped before

attempting to maintain or service the unit.

2. Support the machine with blocks or stands when

changing tires or working beneath.

3. Follow good shop practices:

-keep service areas clean and dry

-be sure electrical tools are properly grounded

-use adequate light for the job at hand

4. Use only tools, jacks and hoists of sufficient

capacity for the job.

5. Relieve pressure from hydraulic system before

servicing or disconnecting from tractor.

6. Before applying pressure to a hydraulic system,

be sure all connections and fittings are tight and

in good condition. Never check for leaks with

your hands. Always use a piece of paper or

cardboard.

6. Use hazard flashers on tow vehicle except where

prohibited by law.

2.5 Grain Bin Safety

1. Never enter a grain bin unless two people are

present.

2. Do not walk on top of the grain in a bin unless

another person is present and the person on the

grain is equipped with a safety line.

3. Do not place the intake tube near or between

your feet when standing on top of grain.

Sufficient material can be removed to draw the

operator and the intake tube into the grain pile.

2.6 Safety Decals

1. Keep safety decals and signs clean and legible

at all times.

2. Replace any safety decals and signs that are

missing or have become illegible.

2.4 Transport Safety

1. Make sure you are in compliance with all local

regulations regarding transport of Agricultural

equipment on public roads and highways.

3. Replaced parts that originally displayed a safety

sign must also display the original sign.

4. Safety decals or signs are available from your

Dealer Parts Department or the factory. See

page P-28 of the Parts Section for a complete

list of the safety decals.

14

2.7 Sign Off Form

Brandt Agricultural Products Ltd. follows the general Safety Standards specified by the American Society

of Agricultural Engineers (ASAE), Canadian Standard Association (CSA) and the Occupational Health

Administration (OSHA). Anyone who will be operating and/or maintaining the Grain Vac must read and

clearly understand all safety, operating and maintenance information presented in this manual.

Do not operate or allow anyone else to operate this equipment until such information has been reviewed.

Annually review this information before the beginning of the season.

Make these periodic reviews of Safety and Operation a standard practice for all of your equipment. We

feel that an untrained operator is unqualified to operate this machine.

A sign off sheet is provided for you record keeping to show that all personnel who will be working with the

equipment have read and understood the information in the operator’s manual and have been instructed in

the operation of the equipment.

SIGN-OFF FORM

DATE EMPLOYEE’S SIGNATURE EMPLOYER’S SIGNATURE

15

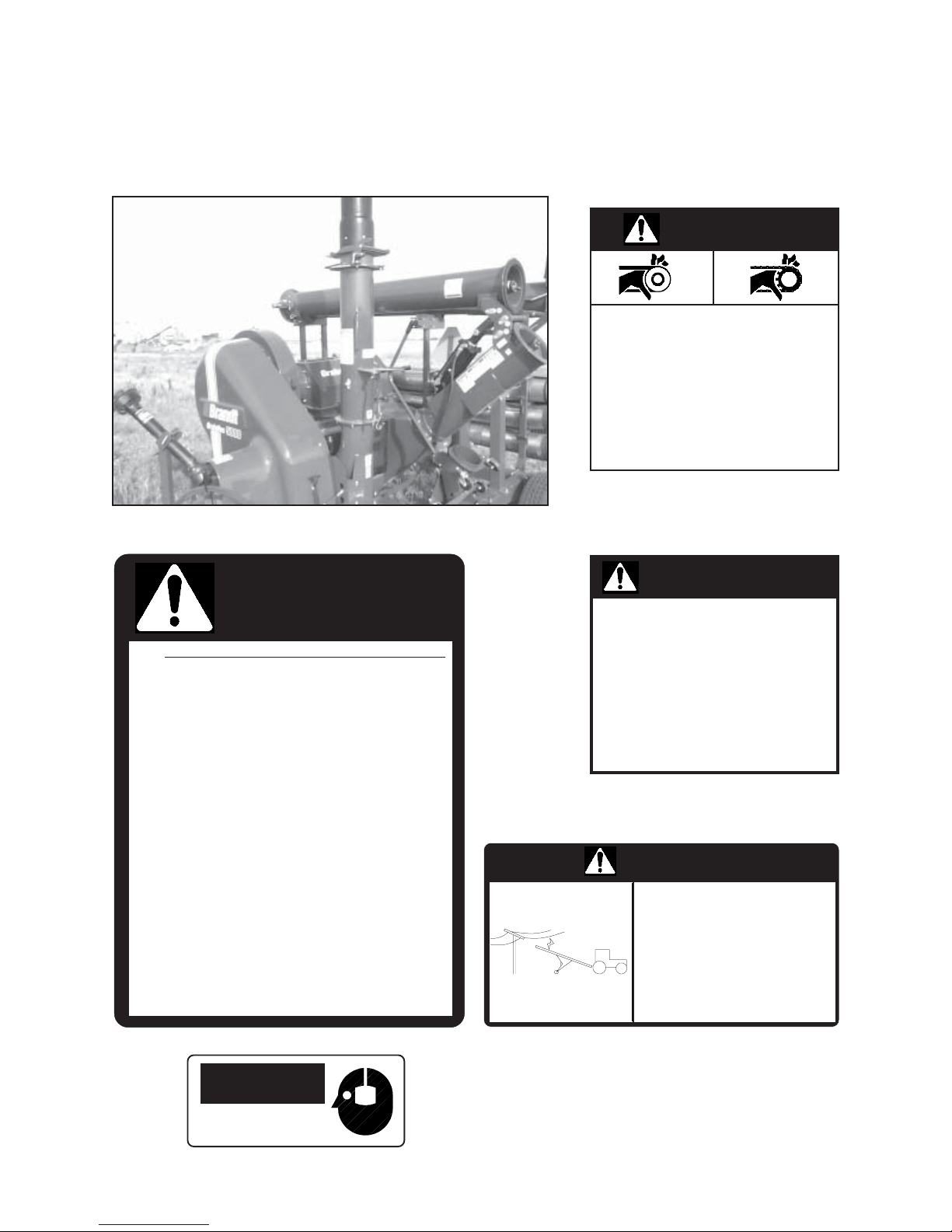

2.8 Safety Decal Locations

The following illustration shows the position and content of the various safety decals on the Brandt Grain

Vac 5000. If safety decals ever become damaged, removed or illegible, new decals must be applied.

New decals are available from your authorized dealer.

1

DANGER

8

3

4

7

9

5

6

10

2

MOVING PART HAZARD

To prevent serious injury or death from moving parts:

• KEEP AWAY, Moving parts can crush and

dismember.

• Do not operate without guards and shields in place.

• Close and secure guards and shields before

starting.

• Keep hands, feet, hair and clothing away from

moving parts.

• Disconnect and lockout power source before

adjusting or servicing.

• Do not stand or climb on machine when operating.

B029111

1

D

3

ECAL LOCATIONS

2

DANGER

CAUTION

PTO SPEED - 1000 RPM

1. Read and understand the operator’s manual before operating.

2. Keep all safety shields and devises in place.

3. Make certain everyone is clear before operating or moving

the machine.

4. Keep hands, feet and clothing away from all moving parts.

5. Shut off power to adjust, service or clean the auger.

6. Support discharge end or anchor intake to prevent upending.

(See Operator’s Manual)

7. Disconnect power before resetting motor overload. (electric

Motor Drive)

8. Empty auger before moving to prevent upending.

9. Lower auger to transport position before moving or

transporting.

10. Make certain electric motors are grounded.

11. Use only genuine Brandt replacement parts, especially

shear pins and bolts.

12. Do not run this auger empty except at idling speed.

B029010

5

KEEP ALL SAFETY

SHIELDS IN PLACE

FAILURE TO DO SO WILL

RESULT IN SERIOUS

INJURY OR DEATH

B029175

DANGER

ELECTROCUTION HAZARD

To prevent serious injury or death from

electrocution:

• Stay away from overhead power

lines when transporting or raising

wings.

This machine is not grounded.

Electrocution can occur without direct

contact.

B029050

4

CAUTION

HEARING PROTECTION

REQUIRED HERE

16

6

WARNING

HIGH-PRESSURE FLUID HAZARD

To prevent serious injury or death:

• Relieve pressure on system before

repairing or adjusting or disconnecting.

• Wear proper hand and eye protection

when searching for leaks. Use wood

or cardboard instead of hands.

• Keep all components in good repair.

B029350

7

DANGER

To prevent serious injury or death

from pinching:

•Keep all persons and objects clear

while any part of this machine is in

motion.

B029111

8

WARNING

TIPPING HAZARD

To prevent serious injury or death:

DO NOT TRANSPORT GRAIN VAC WITH

AUGER IN EXTENDED POSITION

9

ROTATING DRIVELINE HAZARD

To prevent serious injury or death from rotaing

driveline:

• Keep all guards in place when operating.

• Operate only at 1000 RPM.

• Keep hands, feet, hair and clothing away

from moving parts.

DANGER

B029071

B029170

10

10

DANGER

ROTATING AUGER AND

SUCTION HAZARD

To Prevent Serious Injury Or Death

From Rotating Auger:

- Stop engine, set park brake,

remove ignition key and wait for

all moving parts to stop before

inspecting or servicing.

- Make sure door is closed before

starting machine. B029235

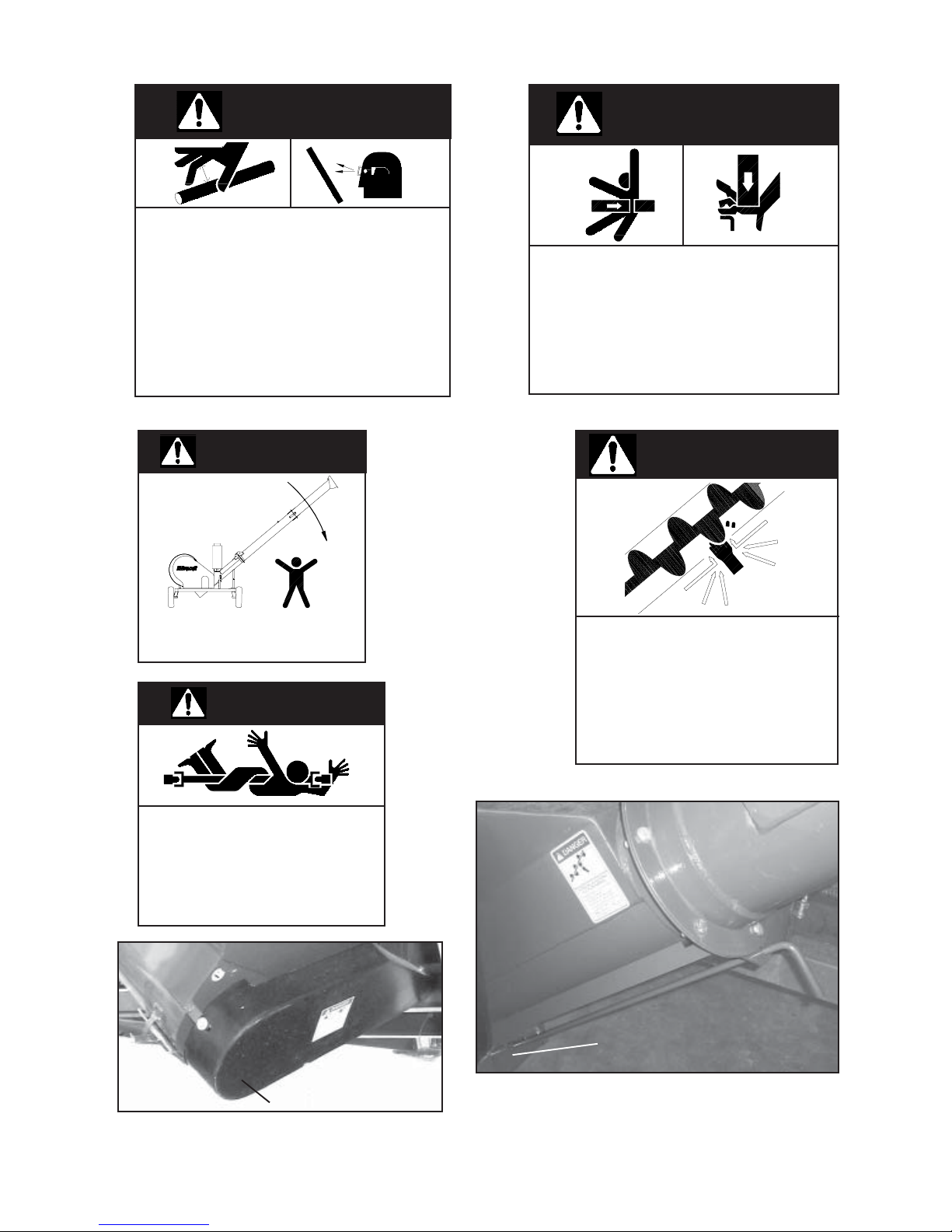

1

Lower Chain Guard

D

ECAL LOCATIONS

17

Lower Body Clean Out

Fan Inspection Cover

DANGER

MOVING PART HAZARD

To prevent serious injury or death from moving parts:

• KEEP AWAY, Moving parts can crush and

dismember.

• Do not operate without guards and shields in place.

• Close and secure guards and shields before

starting.

• Keep hands, feet, hair and clothing away from

moving parts.

• Disconnect and lockout power source before

adjusting or servicing.

• Do not stand or climb on machine when operating.

B029111

View from under the Vac

DANGER

THROWN OBJECT HAZARD

AIR BLAST HAZARD

TO PREVENT SERIOUS INJURY OR

DEATH FROM ROTATING FAN:

- Stop engine, set park brake,

remove ignition key and wait for all

moving parts to stop before

inspecting or servicing.

- Wear proper hand & eye protection when

inspecting & servicing.

- Make sure access door is secured

before starting machine.

B029276

18

Section 3 - Operation

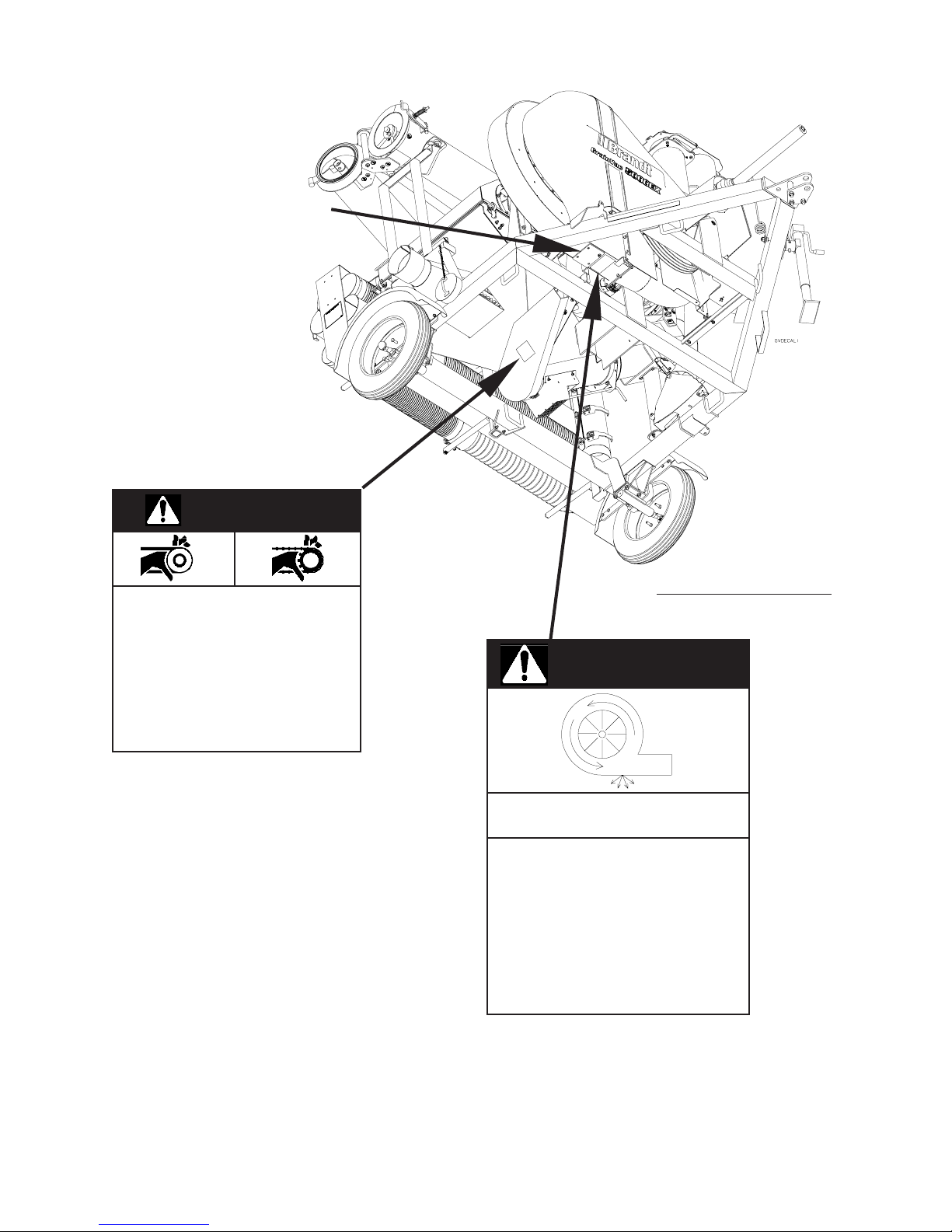

3.1 Principles of Operation

The Brandt Grain Vac 5000 uses a centrifugal fan to produce a vacuum inside a hollow body. This vacuum

creates a flow of air that conveys granular materials to the body. Once in the body of the machine, the grain

is removed by an auger and the air is drawn from the body by the centrifugal fan. The auger discharges the

grain into the awaiting transport through an airlock door. The airlock door ensures suction from the inlet

hoses only. The air, once drawn from the body, passes through the fan and is discharged through an

exhaust pipe.

The centrifugal fan is belt driven by the tractor PTO. The discharge auger position is controlled by tractor

hydraulics and the flighting is chain driven by the tractor PTO.

H

G

C

D

FIG. 1 PRINCIPLES OF OPERATION

A Fan

B Bin Snake

C Suction Hoses

D Cleanup Nozzle

E Machine Body

F Discharge Auger

G Airlock

C

B

B

D

E

E

A

A

G

F

F

19

3.2 First Operation

A. Before starting:

1. Read operator’s manual.

D. After 100 hours:

1. Check oil level in auger drive gearbox. The

gearbox should be half full of oil. Fill with

S.A.E. 80W90 gear oil if required.

2. Hand turn PTO shaft to ensure fan and auger

turn freely.

3. Tighten wheel bolts to specified torque.

4. Close the lower body clean out.

5. Check all fasteners and ensure they are tightened

to specified torque levels.

6. Do the Run-in procedure for the PTO shaft

clutch as shown on page 53.

B. Initial Break-in

Run 300 - 400 bushels slowly through the

Vac at 75% rated PTO speed to polish the

rust from the inside of the auger tubes and

then:

1. Stop and check fan drive belt tension. New

belts stretch noticeably upon initial use. It

is crucial that the belts are tightened as

specified at this time. If the fan belts are

not tightened, they will fail.

2. Check auger chain drive tension.

3. Hand turn PTO to ensure fan and auger turn

freely.

C. After 5 and after 20 hours:

1. Check fan drive belt and auger drive chain

tension.

2. Hand turn PTO shaft to ensure fan and auger

turn freely.

3. After the 20 hour inspection, go to the regular

maintenance schedule outlined in the

Maintenance section of this manual.

E. After the Vac has been unused

after approximately a month:

1. Check the inside of the auger tubes for rust build

up. If the tubes are rusty, go through the initial

break-in procedure.

3.3 Pre-Operation Checklist

Before operating the Grain Vac and each time

thereafter, the following areas should be checked.

1. Check the PTO shaft to ensure that it is locked

into position on the tractor and machine shafts.

2. Insure the PTO driveline shield turns freely on

the shaft.

3. Service the machine as per the schedule in the

maintenance section of this manual.

4. Make sure all guards and shields are in place

and in good repair.

5. Check tires for proper inflation and be sure they

are in safe road condition.

6. Use only a tractor of adequate power to operate

the Grain Vac. For the Brandt Grain Vac 5000,

we recommend minimum of 70 HP.

7. Inspect hydraulic lines and hose ends for signs

of wear and check all fittings for leaks.

8. Be sure the draw bar pin is securely fastened

and retained in place.

9. Be sure the auger fold is adjusted properly so

the auger is fully extended when ram reaches

full stroke.

20

10. Check and clean the auger of obstructions that

may have hung up on internal hanger bearing

mounts.

11. Visually check the auger drive chain for dryness.

If the chain appears to be dry, it should be

lubricated with either a commercial aerosol chain

lubricant or a light oil.

12. Besure the lower body clean out is closed.

3.4 Equipment Matching

The Brandt Grain Vac 5000 was designed to be

used with agricultural tractors with the following

specifications:

-A minimum of 70 PTO horsepower

-The tractor PTO stub shaft must be 1000 rpm, 21

spline, 1 3/8” diameter. Do not use on a tractor

with 540 rpm PTO as there will be insufficient fan

speed to convey material.

-The tractor drawbar dimension must be 16 inches

(40 cm) from the end of the PTO stub shaft and the

centre of the drawbar hitch pin hole, see Figure 2.

Consult your tractor manual for the drawbar

adjustment procedure.

16”

End of Tractor

PTO Stub Shaft

Centreline of

Drawbar Hole

FIG. 2 DRAWBAR DIMENSIONS

3.5 Attaching / Unhooking

The Grain Vac should be parked on a level, dry

area that is free of debris and foreign objects. Use

the following procedure when hooking or unhooking

the Grain Vac.

A. To Hook to a Tractor

1. Clear all bystanders, especially children from the

area.

2. Make sure there is enough room to back the

tractor up to the hitch point.

-The tractor hydraulic system must have one double

acting remote valve to operate the discharge auger

folding system. It must be capable of 2000 PSI at

an adequate flow to position the auger in a suitable

time. Either open or closed centre hydraulic systems

can be used.

-Never run the tractor RPM at greater than rated

PTO speed. Most tractors will allow speeds in

excess of the rated PTO speed. Overspeeding your

Grain Vac in this manner will reduce the life of the

machine, possibly cause serious damage and may

cause injury to the operator or bystanders.

3. Start the tractor and slowly back it up to the

hitch point.

4. Stop the tractor, place the park brake and

remove the ignition key before dismounting.

5. Install a drawbar pin with provisions for a

mechanical retainer. Install the mechanical

retainer.

6. Raise the implement hitch jack and rotate 90°

to place into it’s stowed position.

21

7. Hook up the provided safety chain to the tractor

drawbar.

B. To Hook to a Truck

1. Clear the area of bystanders, especially children.

8. Connect the PTO shaft:

-Check that the guard on the PTO shaft rotates

freely.

-Check that the PTO shaft telescopes freely and

that the shaft has been serviced as per the

lubrication schedule outlined in this manual.

-Attach to tractor by retracting the locking collar

and sliding onto the tractor PTO stub shaft. It

may be necessary to rotate the PTO shaft slightly

to get it aligned. Once the shaft is started onto

the tractor shaft, release the locking collar and

slide on until locking collar clicks into place.

-Check that it is firmly locked in place by pulling

and pushing on it to check for movement.

9. Connect the hydraulics. The Grain Vac 5000

comes factory equipped with Pioneer ends. If

your tractor has different couplers, you will need

a set of adaptors or will need to change the ends

on the Grain Vac to match your tractor. Use a

clean cloth or paper towel to clean the ends and

the area around the couplers on the tractor.

Insert the ends into the couplers until they seat

firmly.

10. Ensure the hydraulic lines are routed so they are

not dragging on the ground and are not touching

the PTO shaft.

2. Start the truck and slowly back into the hitch.

3. Stop the engine, place in park, set park brake

and remove ignition key before leaving cab.

4. Install a drawbar pin with provisions for a

mechanical locking device. Install mechanical

locking device.

5. Raise the implement hitch jack and rotate 90°

to place into it’s stowed position.

6. Hook up the provided safety chain to the frame

of the truck.

7. Ensure hydraulic hose ends are stored in the

provided storage holder and hoses are secured

on the mount.

8. The PTO shaft can be stored in the PTO storage

post and secured in place. If the tow vehicle

has a back window in the tailgate, the upper

end of the PTO shaft should be removed and

transported in the back of the truck. The PTO

shaft simply slides apart.

11. When unhooking from the tractor, reverse the

above procedure.

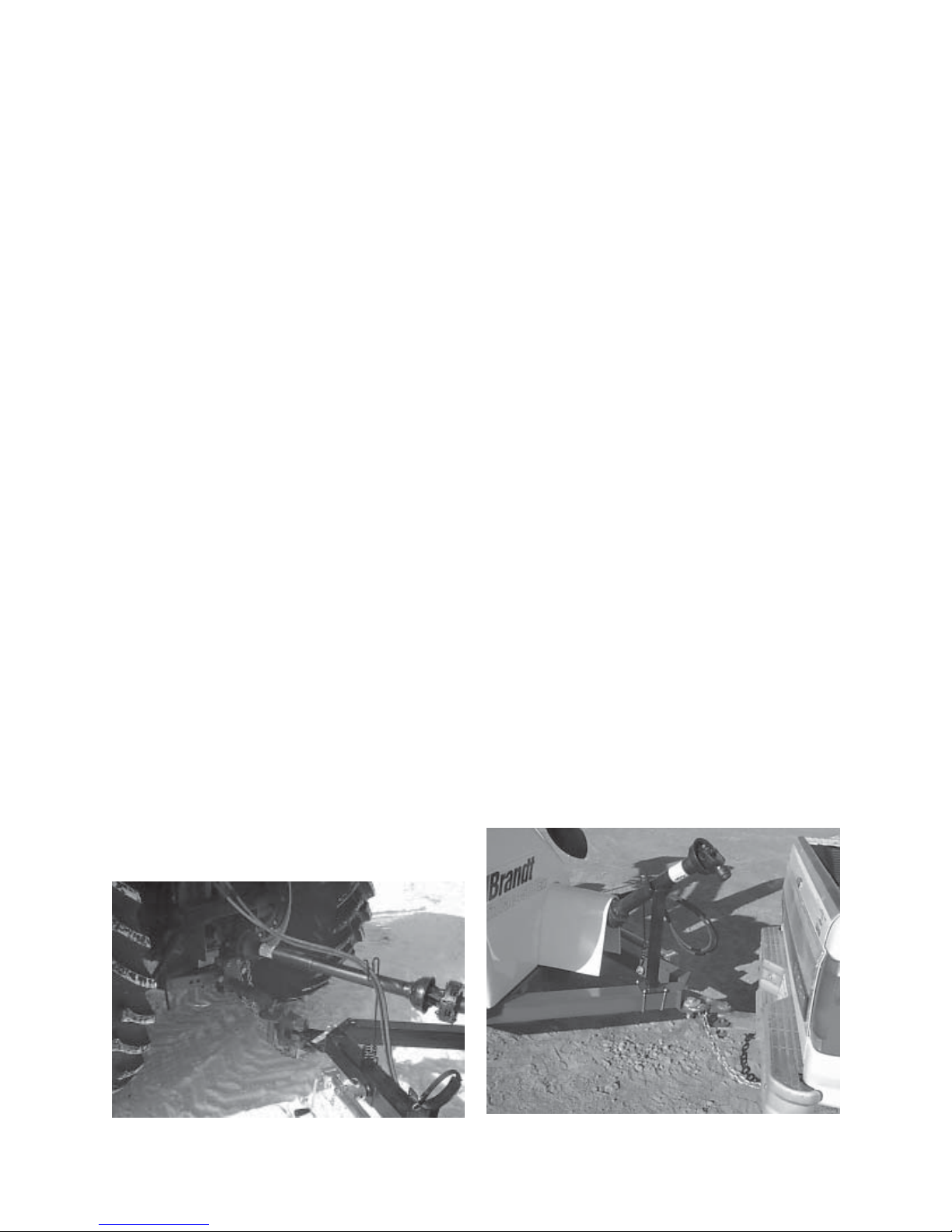

FIG. 4 ATTACHED - TRUCKFIG. 3 ATTACHED - TRACTOR

22

3.6 Setup For Operation

Before the Grain Vac can be used, it must be set up

and positioned, ready for operation. When

preparing for operation use the following procedure.

1. Clear the area of bystanders, especially children.

7. Rotate the plastic Discharge Nozzle into working

position. Point the nozzle so it will direction the

discharge air down wind.

8. Attach the PTO Shaft to the tractor, making the

safety lock is engaged.

2. Select a position so there is adequate room for

the tractor, Grain Vac, truck and operator to

manoeuvre safely.

3. Check for overhead obstructions and power

lines at the site to ensure there is enough

clearance to place the auger into operation

position.

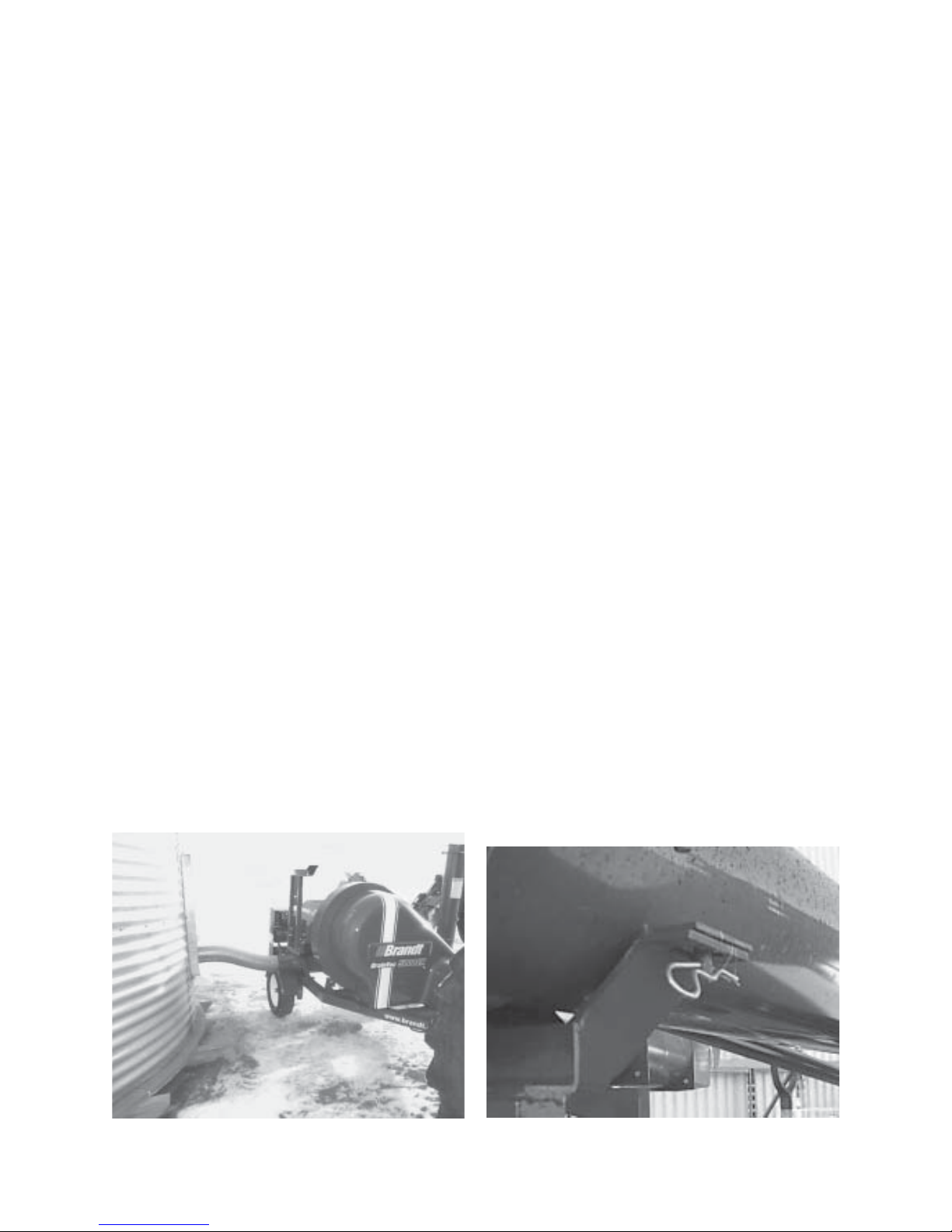

4. For unloading from a full bin, position the grain

vac as close as possible to the bin door so that

one of the 3 1/2 foot stainless steel hoses ends

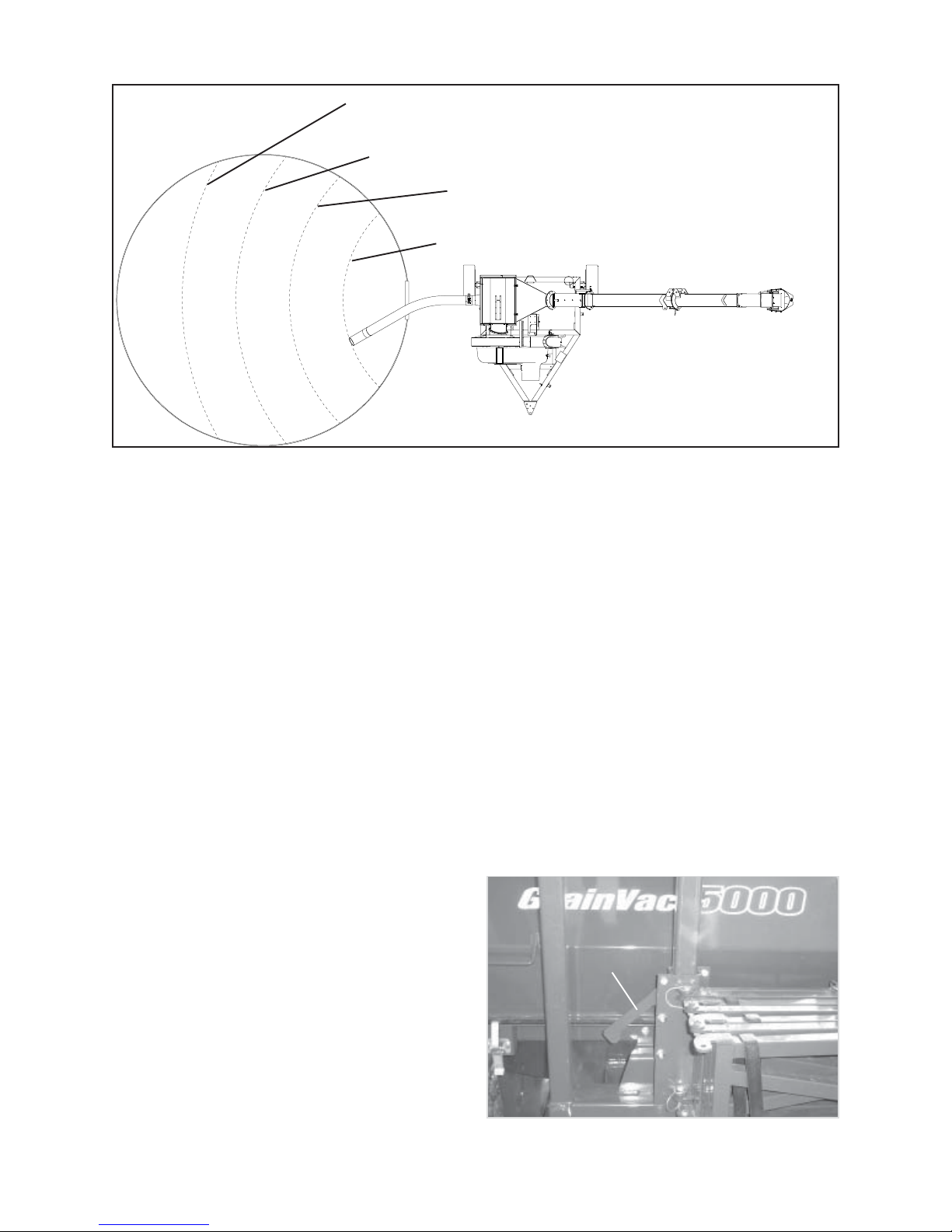

flush with the door. See Fig. 5.

5 Open bin lid to avoid bin damage.

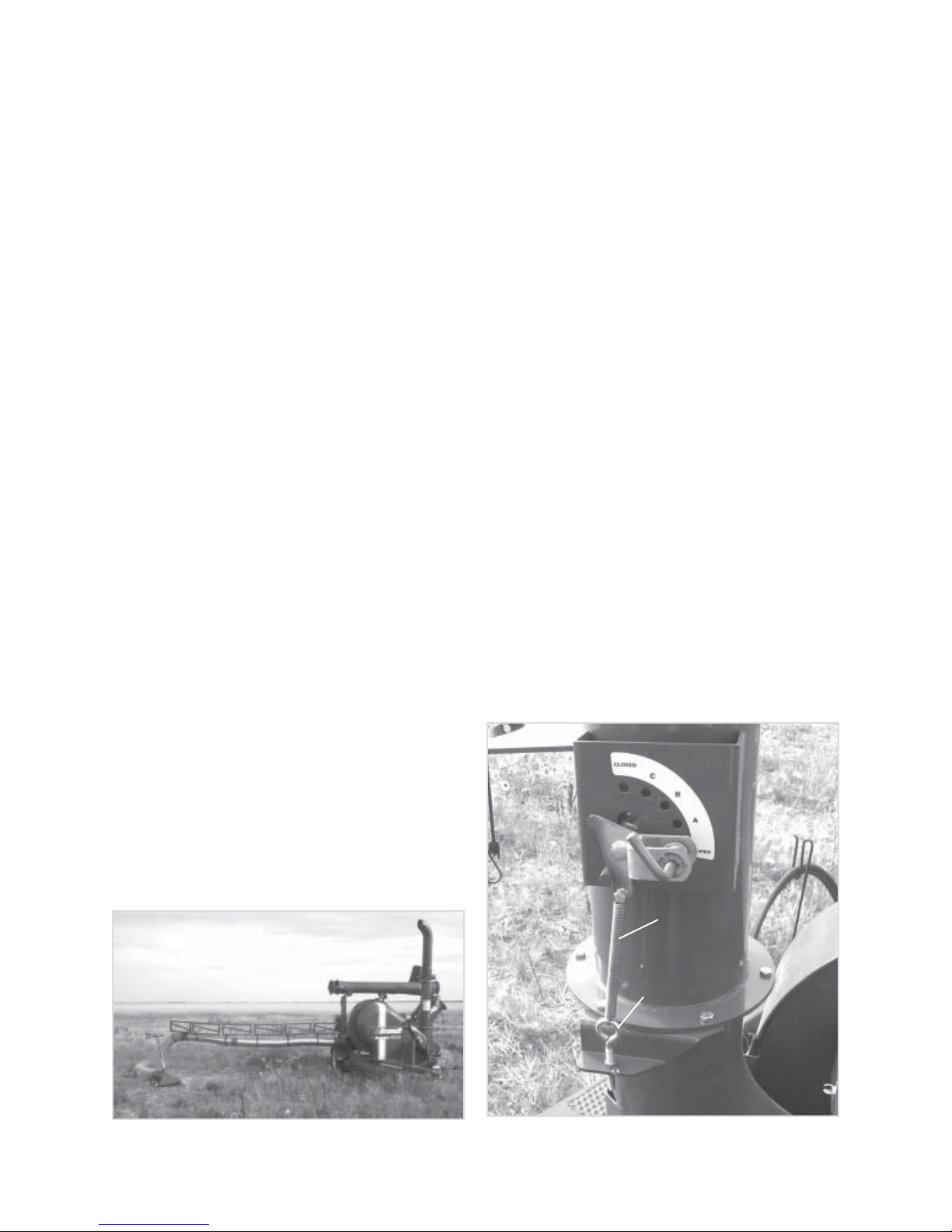

6. Unfold the auger into operating position,

remembering first to remove the safety pin in

the transport rest. See Fig. 6. Place all controls

in neutral and set park brake before dismounting.

3.7 Operation

A. General Operating Instructions

1. Clear the area of all bystanders especially

children.

2. Be sure you and all others in the area are wearing

ear protection.

3. Damp or wet grain is more difficult to convey

than dry grain. Allow more air than grain to

enter the inlet in these situations.

4. In light crops such as oats or barley, care should

be taken not to over feed the 10” unloading

auger. This will cause the vac body to fill up

with grain and possibly cause material to be

expelled out through the exhaust pipe. If this

occurs, refer to section E, page 26 for help.

NOTE: Feather the hydraulics when extending

the auger, especially at the point when the

tubes overcentre. Damage to the machine

can occur.

5. In pulse crops such as peas and lentils, that will

crack easily, we recommend the vac be slowed

down to 80% of recommended PTO speed

(800 RPM) during cleanup operations. The

material is damaged within the unloading

FIG. 6 TRANSPORT SAFETY PINFIG. 5 FULL BIN SETUP

23

augerwhen running at full speed in low capacity

situations such as cleanup.

6. The Grain Vac is a precision piece of equipment.

However it is relatively insensitive to dust and

debris. Common sense should be used to keep

dirt and debris to a minimum. Nothing big

enough to stop the internal auger should be put

through the vac. Material like cloth or plastic

should not be put through the vac as it will hang

up on the internal hanger bearings within the

auger.

7. Any dust and fine particles like chaff is passed

out of the Grain Vac through the exhaust pipe.

This feature will provide the operator with a

virtually dust free environment in the bin while

loading grain.

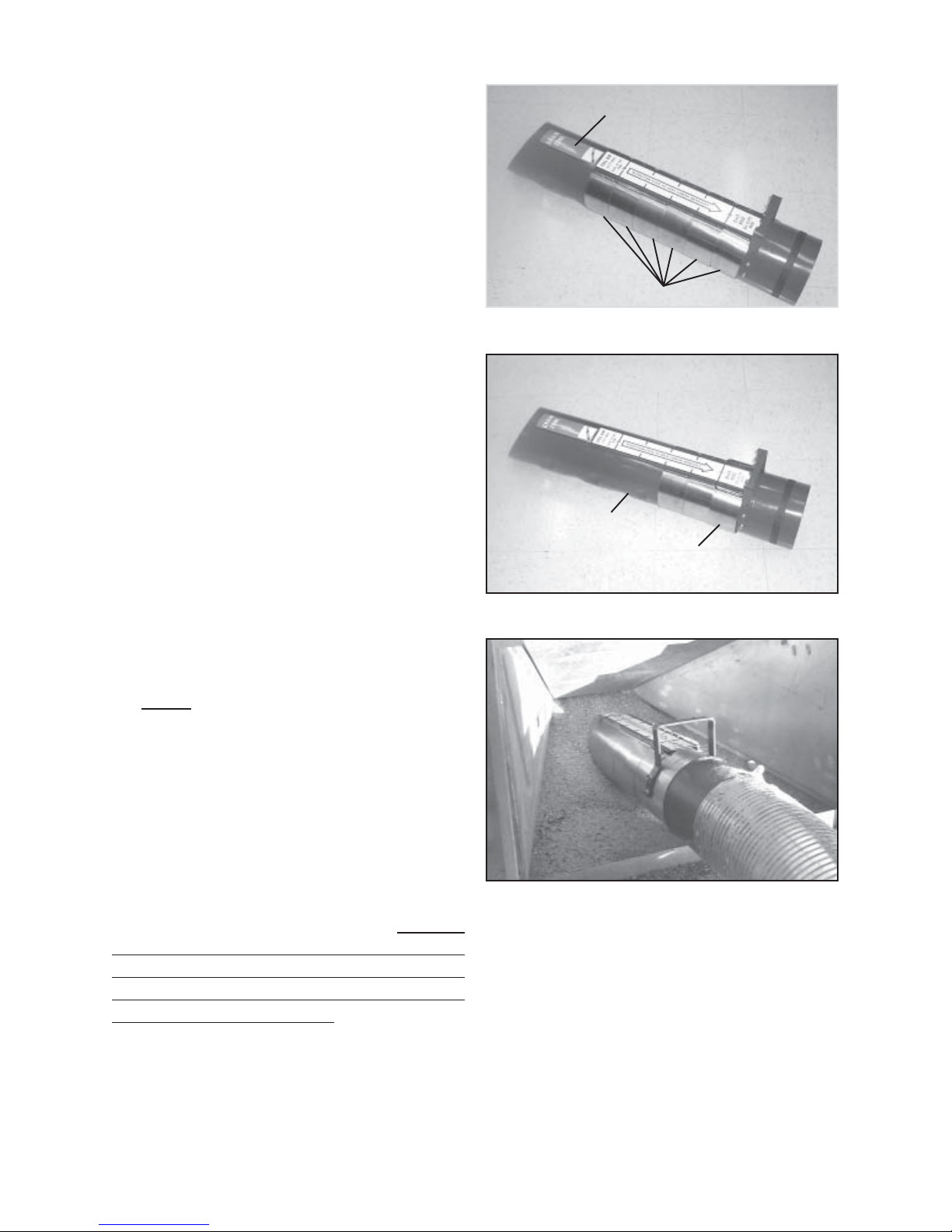

Green ‘Grain Zone’ Decal

Stainless Spring Clips

FIG. 7 MAXFLO FULL BIN NOZZLE

Exposed Holes

B. Full Bin Unload

To obtain the best capacity with your Grain Vac,

you MUST allow air in with the grain. The MaxFlo

Full Bin Nozzle has been designed to offer the

operator an easy way of adjusting the amount of air

that is allowed into the system. It has a series of

holes in the bottom which allow air into the hose.

The positioning of these holes allows the grain to

float on a cushion of air, thus making the grain easier

to move.

Six stainless spring clips are used to adjust the number

of holes that are exposed. See Fig. 7. As hoses

are added to the nozzle, more holes in the nozzle

must be exposed. The amount of pulsing or

surging at the nozzle will dictate the number of

holes that must be exposed. The clips must be

moved back towards the handle until the pulsing or

surging stops. See Fig. 7A. This will be slightly

different for every length of hose and every different

product being moved.

Spring Clips moved back

and stacked against the Handle

FIG. 7A EXPOSING HOLES IN THE NOZZLE

FIG. 8 MAXFLO NOZZLE IN A FULL BIN

1. Insert the MaxFlo Nozzle into the chute of the

bin until the green ‘Grain Zone’ decal is just

covered. See Fig. 8. All six stainless steel clips

should be in position. The only holes exposed

should be the ten holes under the ‘Grain Zone’

decal.

2. Connect the Nozzle to the Vac using a 3 1/2’

steel flex hose.

24

3. With the tractor at slightly over idle speed, gently

ease the PTO control to the ON position. With

some newer tractors, the PTO control is either

on or off with no ability to ease the clutch on.

For these tractors we recommend that the tractor

throttle be set at idle.

4. With the tractor PTO on and the Vac turning

slowly, gradually increase the throttle until it

reached full rated PTO speed. Remember not

to overspeed your Grain Vac and not to run your

brand new Grain Vac at full RPM for the first

15 minutes of operation.

5. Go to the bin and observe the grain flow into

the nozzle. If the flow of grain is erratic as

in a glupping sensation, slide the end spring

clip back towards the handle until a steady

stream of grain is flowing through the nozzle.

This ensures an adequate mix of air and grain

for optimal conveying capacity. A slight pulsing

in the hose is normal.

6. When the truck is full, there is no requirement

to empty the machine unless you intend to move

to a new site. You may just shut off the PTO.

C. Removing the Grain from in a

Clean Up Operation

1. When first entering the bin, we suggest that you

bring in all the hoses you will require to get to

the back of the bin. Also bring the flexible rubber

hose and the Clean Up Shovel. Do not attach

any of the hoses at this time. This will simply

save time when it comes time to lengthen the

hose.

2. Replace the 3 1/2’ steel flex hose ( if installed

on the vac) with a 7’ steel flex hose. The MaxFlo

Full Bin Nozzle should be used on the end of

the hose to maximize capacity.

3. When inserting the nozzle into the grain, arc the

middle of the hose up and keep the end of the

MaxFlo Nozzle on the floor. See Fig. 8A.

4. Push down on the arc in the hose and drive the

nozzle into the bottom of the pile. You can insert

the MaxFlo Full Bin Nozzle deeper into the grain

than what the “Grain Zone’ decal shows. A slight

surging may be heard or felt but it will quickly

go away. If the flow of grain completely stops,

move the end spring clip back to expose more

holes. When the end of the MaxFlo nozzle

becomes fully exposed out of the grain, move

the hose over a few feet and repeat the same

procedure.

Push down on the Hose

to insert the MaxFlo Nozzle

deeper into the pile of grain.

FIG. 8A NOZZLE INSERTED IN GRAIN PILE

25

two 7’ Steel Flex & one 3.5’ Steel Flex Hose - 4 Spring Clips

moved on MaxFlo Nozzle

two 7’ Steel Flex Hoses - 3 Spring Clips moved on MaxFlo Nozzle

one 7’ Steel Flex & one 3.5’ Steel Flex Hose - 2 Spring

Clips moved on MaxFlo Nozzle

one 7’ Steel Flex Hose - 1 Spring Clip moved on MaxFlo

Nozzle

FIG. 9 ADDING HOSE AND MOVING IN AN A RC A CROSS THE BIN

5. Move the hose in an arc, from side to side in the

bin. See Fig. 9. Add only 3.5’ of hose at a time

when required.

6. Continue moving grain until you have reached

the back of the bin. Use the steel flexible hoses

as long as possible to maximize capacity and

minimize wear. Use straight solid sections when

ever possible.

7. After you have reached the back of the bin with

the MaxFlo Nozzle, remove the last section of

steel hose and the MaxFlo Nozzle. Attach the

flexible rubber hose and the Cleanup Shovel and

proceed with final cleanup.

8. Start cleaning at the back of the bin and work

your way forward, toward the door. Clean

directly in front of the door last. You can remove

sections of flexible steel hose as you get closer

to the door.

D. Optional Adjustable Bin Snake

To ensure ease of use during bin cleanup situations

your new Grain Vac can be equipped with an

optional adjustable height Bin Snake. This will ensure

that the bin snake can accommodate most any bin

door height.

1. To raise the height of the Bin Snake assembly

simple lift the latch handle and slide the snake

upward to match your bin door.

2. Once the desired height has been reached,

simply latch the handle back into one of the

adjustment holes as indicated in Figure 10.

Latch Handle

The MaxFlo Full Bin Nozzle should

be used in all grain moving situations

except for final floor cleanup.

FIG. 10 ADJUSTABLE HEIGHT BIN SNAKE

26

3. To lower the Bin Snake assembly, raise the

assembly slightly, just enough to take the pressure

off of the latch handle.

4. Lift the latch handle open and then slide the Bin

Snake down to your desired position. Lock in

place with the latch handle.

Using the Optional Bin Snake

1. After you have reached the back of the bin with

the MaxFlo Nozzle, from within the bin, unlatch

the rubber retaining strap holding the Bin Snake

in transport and unfold it into the bin one section

at a time. As each section is unfolded, the hose

should be raised up and strapped under the Bin

Snake. When all the Bin Snake sections are

attached to the hose, you are ready to cleanup

the floor of the bin. Extra Bin Snake sections

are available to reach further into larger than

average bins.

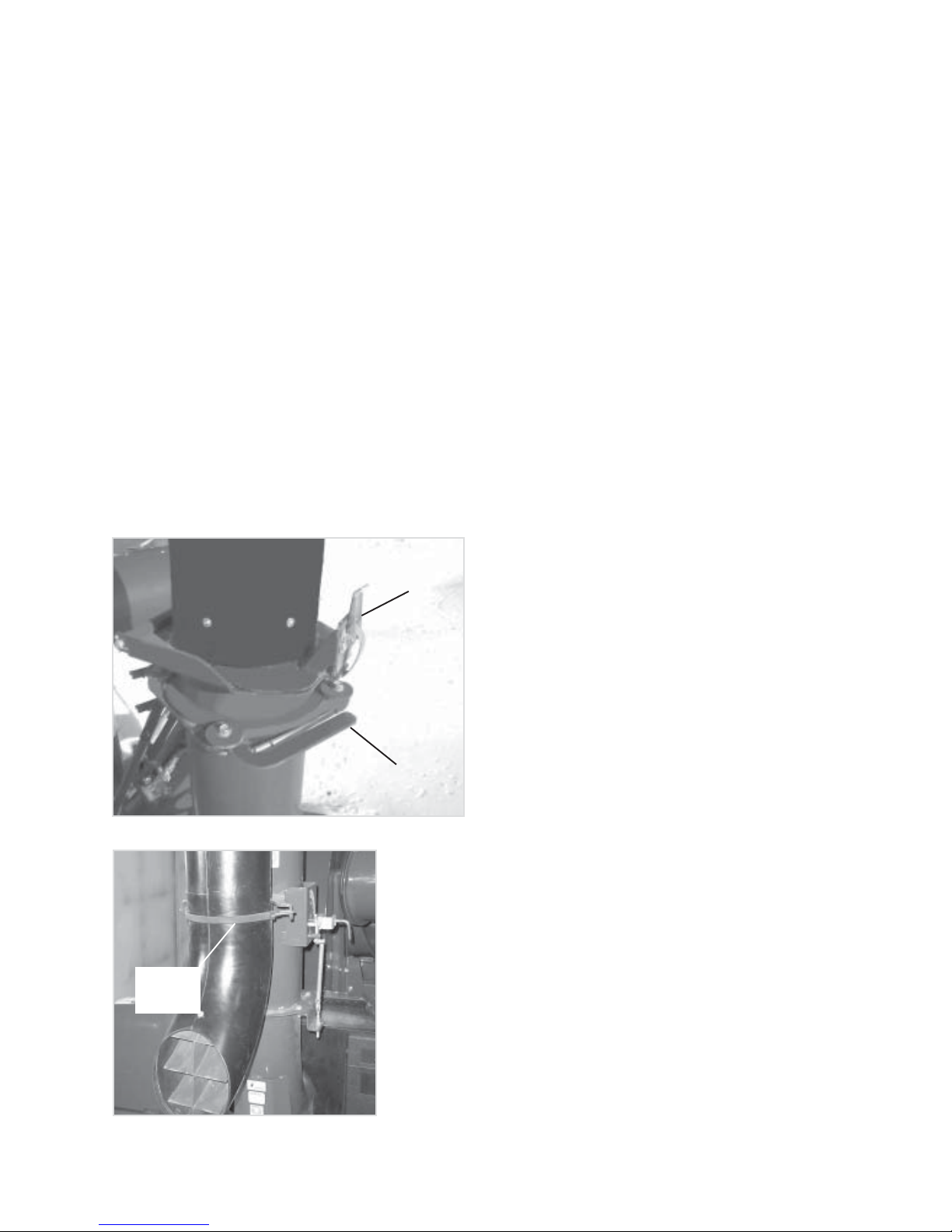

E. Adjustable Air Throttle and Vent

The Grain Vac comes equipped with a unique feature

that decreases the horsepower requirement of the

unit. It consists of an internal damper plate that senses

high airflow, and hence high horsepower situations

and moves into position to limit the condition.

The damper plate is controlled by an external spring.

The condition of this spring should be checked

visually occasionally and should be replaced if it

appears to be sprung or damaged.

The Air Throttle is normally set in the unpinned

position in which the spring controls the position of

the damper plate. This position is used for most

products.

1. If you experience the air throttle fluttering,

adjustment should be made. To correct this

problem simply tighten the adjusting bolt (see

Figure 11) until the flutter is removed.

2. Remove the last section of steel hose and the

Full Bin Nozzle. Attach the flexible rubber hose

and the Cleanup Shovel and proceed with final

cleanup.

3. Start cleaning at the back of the bin and work

your way forward, toward the door. Clean

directly in front of the door last. You can remove

sections of flexible steel hose as you get closer

to the door.

4. When bin clean up is complete, lower the Bin

Snake to it’s lowest position before lowering

the auger.

2. If the throttle is not moving, check the assembly

for binding. Loosening the tension spring may

also be required.

Spring

Adjustment

Bolt

FIG. 10A CLEANUP SETUP

FIG. 11 ADJUSTABLE A IR THROTTLE

27

FIG. 12 AIR THROTTLE PINNED CLOSED

The manual settings in the Air Throttle and the use

of the Adjustable Vent Slide, located in the top of

the upper body, should be used when you are moving

lighter products such as light oats or barley,

sunflowers or grasses, to reduce the amount of

product being discharged through the exhaust tube.

The product carrying capacity of the airstream within

the intake hoses is directly related to the velocity of

the air within the suction hose(s). Therefore, in many

cases with light bulky products, the product carrying

capacity of the Grain Vac is too great to allow

separation of the product from the airstream in the

Grain Vac body. By manually closing the Air Throttle

and opening the intake vent in the upper body, we

decrease the volume of air travelling through the

suction hose and therefore the velocity, thus allowing

separation of the grain particles from the airstream.

Although it is difficult to give an exact specification

of throttle positioning and intake vent opening for

each product because of differences in bushel weight,

the following chart can be used as a guide. In any

case, it is important to ensure that the air inlet at the

suction hose end is not choked off excessively.

In all cases, set the Air Throttle to the position shown

below and use the Vent Slide to do the fine

adjustment.

Air Throttle Position Product

A Light Oats or Barley

B Sunflowers

C Grasses

If the closing of the throttle and the intake vent

opening is still insufficient to eliminate product

discharge through the exhaust, try one or all of the

following:

A - Decrease the PTO speed.

B - Increase the length of the intake hose.

C - Allow more air at the intake end of the hose.

The manual positioning of the Air Throttle and

opening of the intake vent should only be used if

you are experiencing product discharge from the

exhaust. If the body is full, you must open the vent

fully and remove the intake hose from the grain to

allow the Grain Vac to clean itself out before

resuming normal operation.

The Air Throttle can also be pinned in the fully open

position. This position should only be used when all

the hoses are connected to the vac and you are

moving heavy product. This will give you the highest

capacity available, but will require more horsepower

from the tractor. This position must not be used

when vaccing under normal conditions. Because

of the large amount of air flow the fan can produce,

excessive strain can be put onto the slip clutch in the

PTO shaft causing it to slip and damage the clutch

pack.

FIG. 13 ADJUSTABLE VENT SLIDE

28

F. Folding Exhaust Deflector

3.8 Shutdown

To enable you to control the exhausting air from the

Grain Vac, Brandt has provided an exhaust deflector.

This deflector can pivot around 360 degrees to

ensure you are able to properly deflect the exhaust

air. This deflector also folds down for transport.

1. To rotate the exhaust deflector, open the rotation

lock handle as seen in Figure 14. Rotate to the

desired position and relock with the rotation

locking handle.

2. To fold into transport position, release folding

latch and fold the exhaust deflector down against

the silencer as seen in Figure 14.

3. Use the rubber strap on the Exhaust Stack to

hold the Exhaust Deflector in place while the

vac is being transported. See Figure 15.

Folding

Latch

1. When stopping the Grain Vac before you have

intentions to move to a new location, all you

have to do is slow down the tractor RPM and

then shut off the PTO. No special care must be

taken to empty the machine.

2. When finished a job and you will be transporting

the unit, it is best that the RPM of the tractor be

slowed to an idle and the Grain Vac be allowed

to run at slow speeds for 20 to 30 seconds to

empty the auger, vac body and hoses of grain.

3. If the Bin Snake was used during cleanup, it is

recommended that you start at the bin end and

fold each section as you let the hose down.

Once at the vac body, secure in place with strap

provided. Ensure the Bin Snake is in it’s

lowest mounting position before transport.

Failure to do this will result in damage to

the Bin Snake when the auger is folded.

Rotation

Handle

FIG. 14 FOLDING EXHAUST DEFLECTOR

Rubber

Strap

4. Reinstall all hoses and nozzles used during the

job back into the transport racks on the machine.

5. Reinstall the suction inlet plug into the suction

inlet.

6. With the tractor hydraulics, fold the auger down

into transport position. Reinstall transport safety

pins.

FIG. 15 FOLDING EXHAUST DEFLECTOR

29

Loading...

Loading...