BRAND Hydraulics SDCF User Manual

SDCF DIRECTIONAL CONTROL VALVES

INSTALLATION & USER GUIDE

SPECIFICATIONS:

• Rated for 0-18 gpm (0-68.1 lpm).

• Rated for 3000 psi (207 bar).

• Weighs 6-1/2 lbs. (2.5 kg).

MOUNTING, ADJUSTMENT & ASSEMBLY INSTRUCTIONS:

Mounting – Valve can be mounted in any orientation. Valve must be mounted on a flat surface. Special attention should

be paid to not bend or twist the casting when mounting. Doing so may cause the valve to fail.

Relief Adjustment – Relief setting is factory preset to 1500 psi, unless otherwise noted within model code. Relief valve

can be set anywhere within the range of 500 psi to 3000psi.

To adjust relief pressure: First, remove chrome the round plug above the outlet port with a 1/8” allen wrench. You

will then have access to the relief set screw. Turning this screw with a 5/32” allen wrench clockwise ¼ turn will

increase pressure approximately 700psi.

Handle Assembly – Regardless of handle style, the handle retainer will be installed on valve from factory. Unless

specified, the retainer’s placement is defaulted so the handle points up when the valve is placed on a flat surface. To

change this, prior to handle installation, the screws holding the retainer must be removed and the retainer can then be

rotated around the valve in 180º increments.

L-Style Handle: Recognized by the single hole in the end of the spool, place the ball end of the handle in the spool

and then join the handle and the retainer using the supplied pin.

J-Style Handle: Recognized by the single slot in the end of the spool, first, place a pin thru the bracket welded to

the retainer and secure with a pin clip. Next, place the C-notch of the handle over and onto the pin. Finally, align the

hole of the handle with the hole on the spool and secure both together using the second pin and clip.

FREQUENTLY ASKED QUESTIONS:

Q: Can I plumb another valve downstream from this valve, using the outlet of this valve?

A: No. The outlet of this valve should be plumbed back to tank.

Q: Can I adjust max flow from my valve? (Ex. Can I go from a 0-6 valve to a 0-18 easily?)

A: This can only be accomplished by switching out to new spool capable of larger flow.

Q: What kits are available for this valve?

A: There is a replacement seal kit (Part #: SDCF-K), and replacement relief kit (Part #: SDCF-CART) for this valve.There

are also a number of different kits available for this valve depending on the spool action, and handle option the valve is

equipped with. Please contact factory for specific kit numbers relating to different spool actions, and handle options.

Q: Can I paint the valve?

A: Painting valves is acceptable as long as the following precautions are taken:

1- All ports must be plugged

2- Spool must be masked or taped off completely.

Any paint on the spool will cause leakage when it chips off. Warranty is void if any valve is returned with paint on

the spool.

• Std. Port sizes (Consult factory for others).

3/4”NPT Inlet/outlet and 1/2” NPT work ports.

#12SAE Inlet/outlet and #10SAE work ports.

• 30 Micron filtration recommended.

04/14

GENERAL INFORMATION:

Pipe Thread Sealant - Warranty is void when Teflon tape is used to seal pipe threads. This is because Teflon tape is a

friction reducing agent which allows customers to over-torque fittings. We recommend using a sealant that does not include

friction reducing agents i.e. Lead Plate.

Spool Information - All SDCF’s are built with Iosso plated spools to help prevent the spools from locking up when they are

in a corrosive environment. For highly corrosive environments, i.e. marine applications, we recommend using a stainless

steel spool. To order a valve with a stainless steel spool simply add “SS” to the end of the model code.

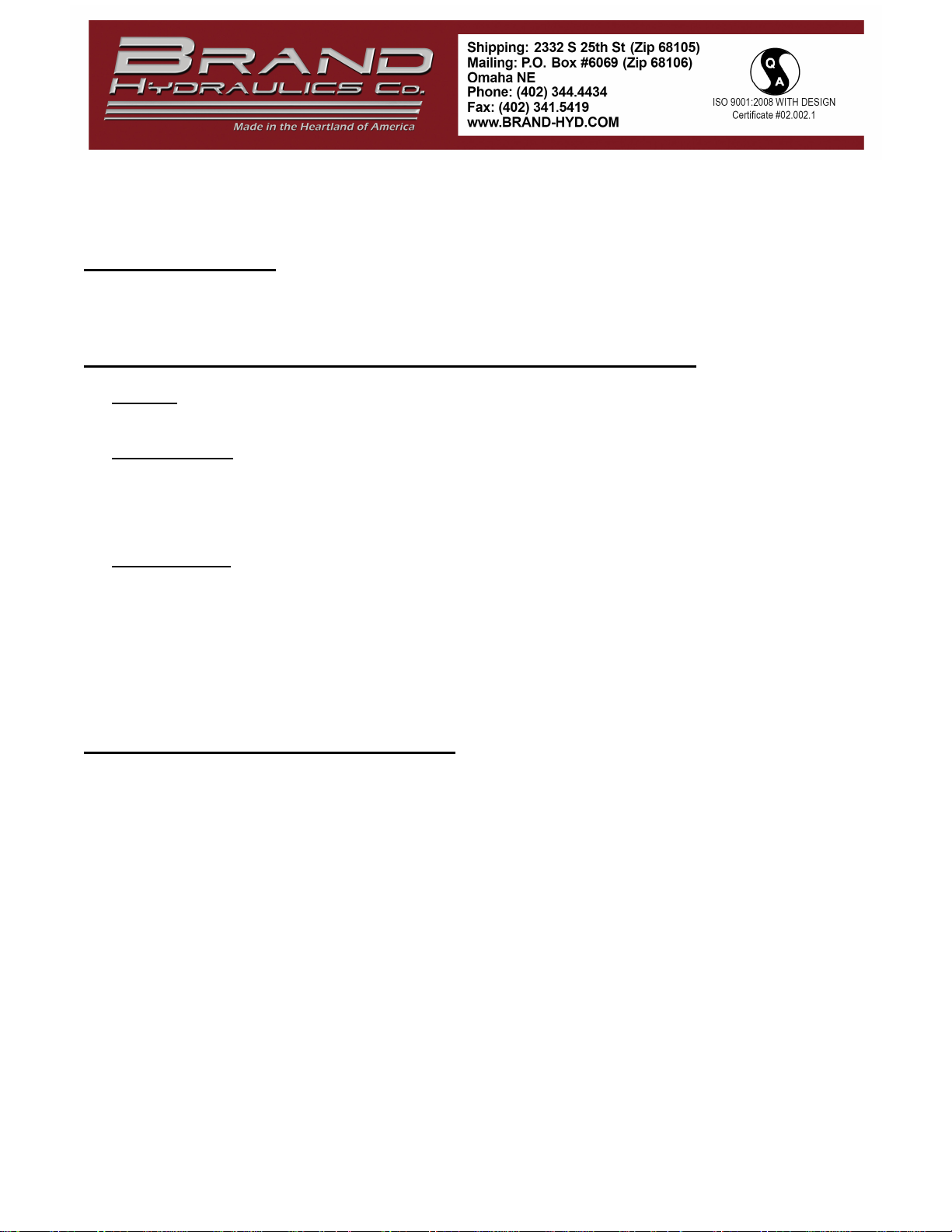

DIMENSIONAL DATA:

A PORT

RELIEF ADJUSTMENT

B PORT

0.94" [23.8]

3X Ø0.27" [Ø6.7]

8.8" [224]

3.22" [81.8]

2.24" [56.8]

11.0" [278]

2.13" [54.0]

4.32" [109.8]

2.19" [55.6]

3.94" [100.0]

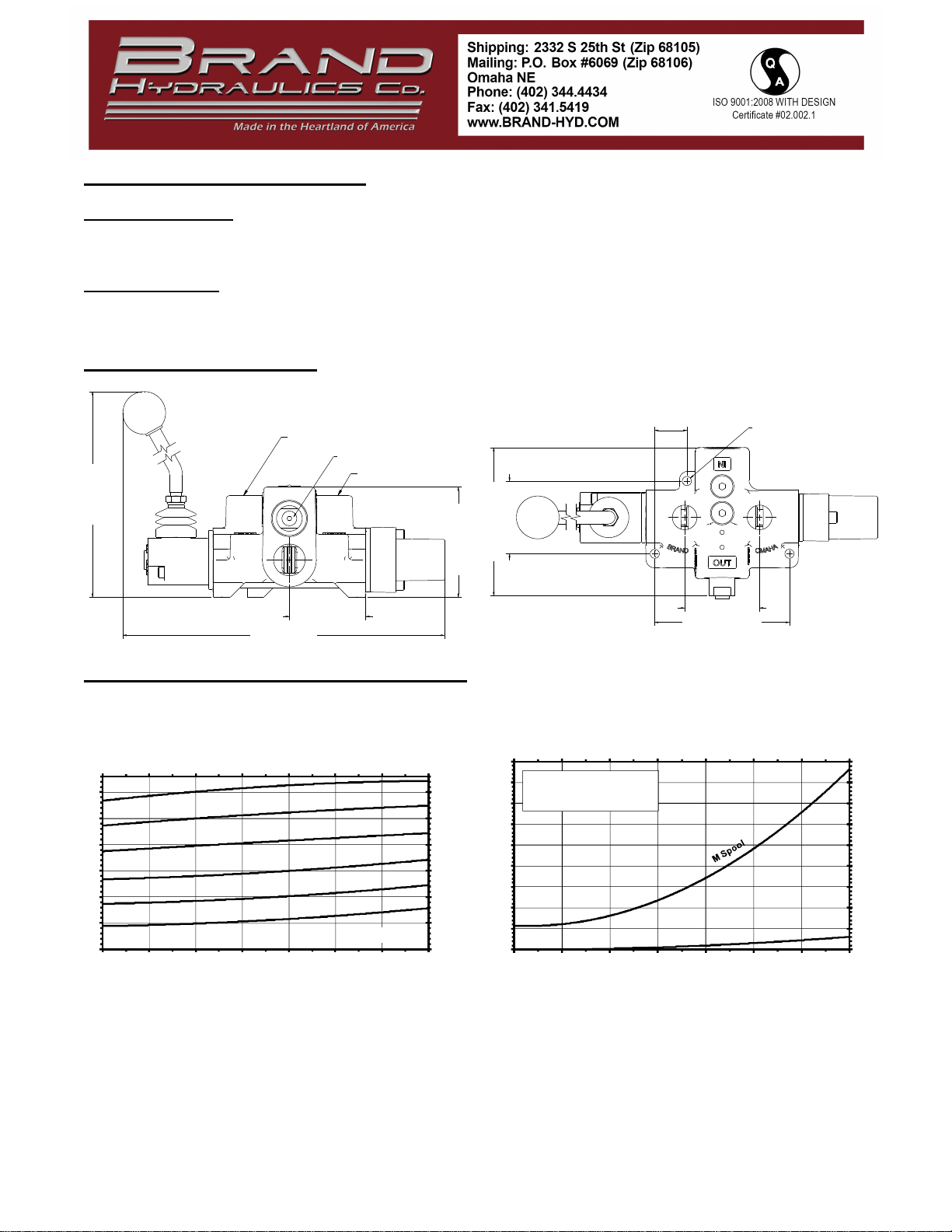

FLOW & PRESSURE INFORMATION:

3.8 11.4 22.7 34.1 45.4 56.8 68.1 75.7

3000

2500

2000

1500

Pressure (psi)

1000

Pressure vs. Flow for Pilot Relief

Relief is set at 6 gpm (22.7 lpm)

Flow (lpm)

500

0

1.0 3.0 6.0 9.0 12.0 15.0 18.0 20.0

Flow (gpm)

SF391 Spring

207

172

138

103

69

34

0

3.8 11.4 22.7 34.1 45.4 56.8 68.1 75.7

450

This curve represents the

400

pressure difference between

the inlet and the outlet.

350

300

250

200

150

Pressure (psi)

Pressure (bar)

100

50

0

1.0 3.0 6.0 9.0 12.0 15.0 18.0 20.0

Neutral Flow Pressure Drop

Flow (lpm)

TM Spool

Flow (gpm)

31

28

24

21

17

14

10

Pressure (bar)

7

3

0

04/14

Loading...

Loading...