BRAND Hydraulics MS User Manual

MS MANUAL SELECTOR VALVE

INSTALLATION & USER GUIDE

SPECIFICATIONS:

• Rated for 3000 psi (207 bar).

• Flow rating

3/4” NPT 0-30 gpm (0-113 lpm).

#16 SAE 0-45 gpm (0-170 lpm).

• 30-Micron filtration recommended.

MOUNTING INSTRUCTIONS:

Mounting – Valve can be mounted in any orientation. Valve must be mounted on a flat surface. Special attention should

be paid to not bend or twist the casting when mounting. Doing so may cause the valve to fail.

FREQUENTLY ASKED QUESTIONS:

Q: What kits are available for this valve?

A: Seal kits are available for the MS75 (Part# MS-K) and for the MS16SAE (Part #: LMS-K)

Q: Can I paint the valve?

A: Painting valves is acceptable as long as the following precautions are taken:

1- All ports must be plugged

2- Spool must be masked or taped off completely.

Any paint on the spool will cause leakage when it chips off. Warranty is void if any valve is returned with paint on

the spool.

GENERAL INFORMATION:

Pipe Thread Sealant - Warranty is void when Teflon tape is used to seal pipe threads. This is because Teflon tape is a

friction reducing agent which allows customers to over-torque fittings. We recommend using a sealant that does not include

friction reducing agents i.e. Lead Plate.

• Weight

MS75 5.5 lbs. (2.5 kg).

MS16SAE 9 lbs. (4.1 kg).

• Standard port sizes.

3/4” NPT all ports.

#16 SAE (1 5/16-12) all ports.

04/14

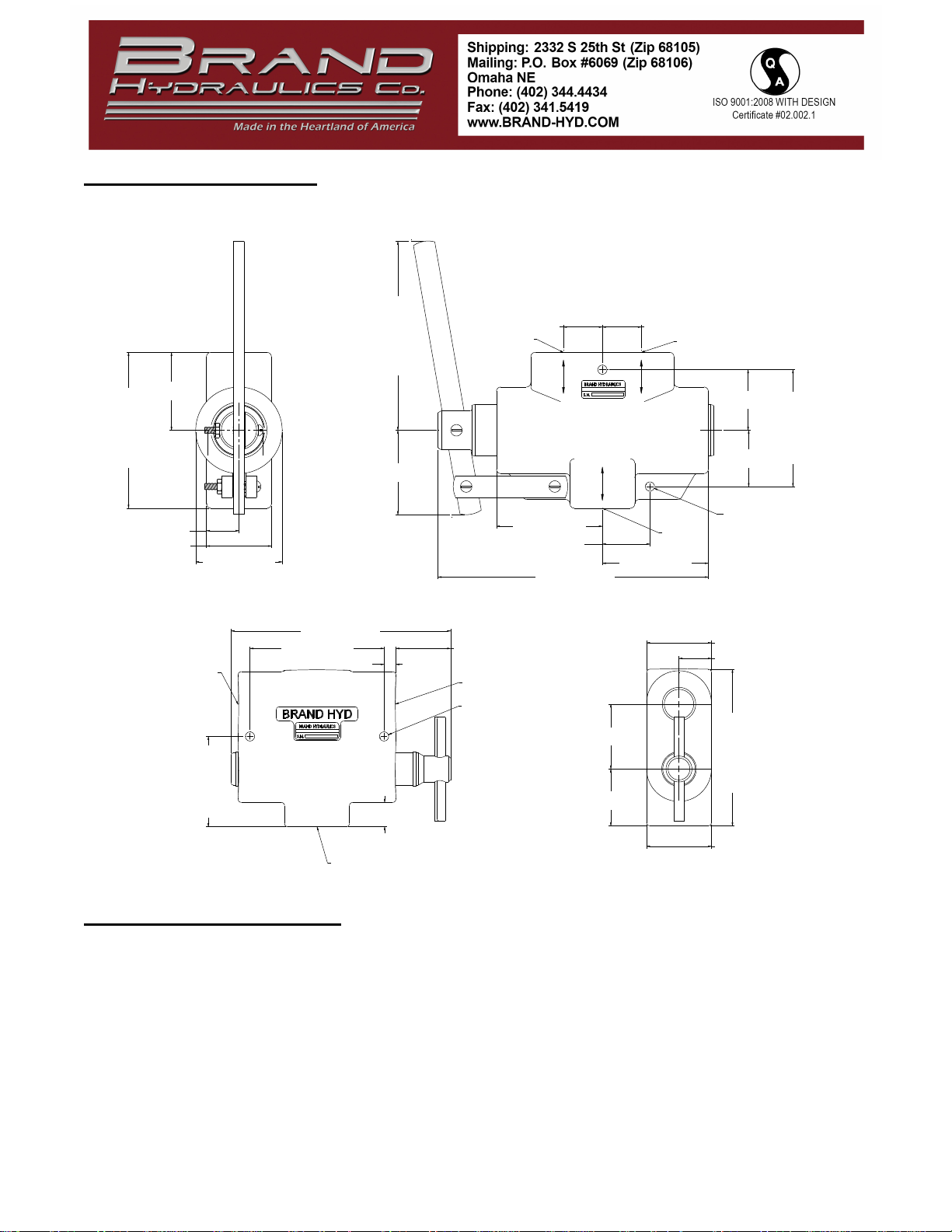

DIMENSIONAL DATA:

MS16SAE

0.63" [16.0] SPOOL

TRAVEL

2.25" [57.2]

5.46" [138.6]

4.50" [114.3]

2.44" [61.9]

1.13" [28.6] 1.13" [28.6]

PORT A

BRAND HYDRAULICS - OMAHA

PORT B

1.75" [44.5]

1.63" [41.3]

0.94" [23.8]

1.88" [47.6]

2.50" [63.5]

MS75-3/4

0.50" [12.7] SPOOL TRAVEL

PORT B

6.34" [161.1]

3.88" [98.4]

0.34" [8.7]

3.06" [77.8]

1.38" [34.9]

1.58" [40.1]

PORT A

2X Ø0.27" [Ø6.7]

INLET

3.06" [77.8]

7.81" [198.4]

3X Ø0.27" [Ø6.7]

1.88" [47.6]

0.94" [23.8]

1.88" [47.6]

2.61" [66.3]

0.70" [17.9]

1.64" [41.7]

4.52" [114.7]

INLET

1.88" [47.6]

SAFETY PRECAUTIONS:

It is the purchaser’s responsibility to determine the suitability of any Brand Hydraulics Co. product for an intended

application, and to ensure that it is installed in accordance with all federal, state, local, private safety and health

regulations, codes and standards. Due to the unlimited variety of machines, vehicles and equipment on which our

products can be used, it is impossible for Brand Hydraulics Co. to offer expert advice on the suitability of a product

for a specific application. It is our customer’s responsibility to undertake the appropriate precautions, testing and

evaluation to prevent injury to the end-user.

Overpressure may cause sudden and unexpected failure of a component in the hydraulic system, resulting in serious

personal injury or death. Always use a gauge when adjusting a relief valve.

3.38" [85.7]

04/14

Loading...

Loading...