BRAND Hydraulics MB User Manual

MB LOADER DIRECTIONAL CONTROL VALVES

INSTALLATION & USER GUIDE

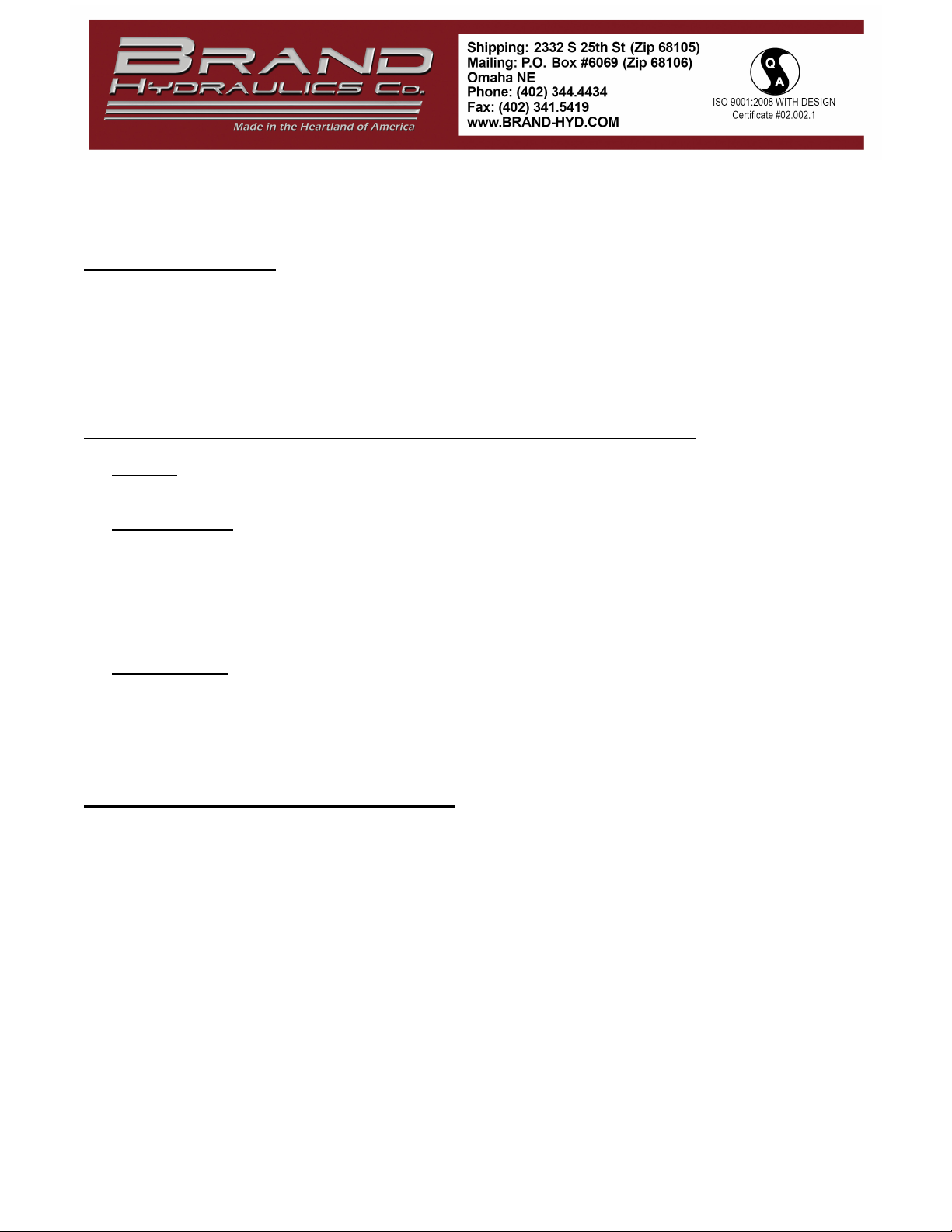

SPECIFICATIONS:

• Flow Ratings:

- MB21 & MB22 – 10 gpm (38 lpm)

- MB 23 – 8 gpm (30 lpm)

• Rated up to 4000 psi (275 bar).

• Port Sizes:

- Inlet/Outlet - #8SAE (3/4-16).

- Work Ports - #8SAE (3/4-16).

MOUNTING, ADJUSTMENT & ASSEMBLY INSTRUCTIONS:

Mounting – Valve can be mounted in any orientation. Valve must be mounted on a flat surface. Special attention should

be paid to not bend or twist the casting when mounting. Doing so may cause the valve to fail.

Relief Adjustment – Relief setting is factory preset to 2000 psi, unless otherwise noted within model code. Relief valve

can be set anywhere within the range of 500 psi to 4000 psi by switching out the relief spring to one of the following:

500-1100 psi (34-76 bar) – Use spring P/N: S065 (Silver)

1200-3000 psi (83-207 bar) – Use spring P/N: S059 (Brown, Standard Option)

3100-4000 psi (214-276 bar) – Use spring P/N: S064 (Blue)

To adjust relief pressure: First, remove the acorn nut with 1/2” wrench. Next, loosen the 1/2” hex jam nut. Using a

5/32” allen wrench on the relief adjustment screw one full turn clockwise will increase pressure by 200 psi.

Handle Assembly –

L-Style Handle: Place the threaded end of the handle in either hole of the handle adapter and lock handle into

position with the jam nut. Depending on mounting orientation of the valve this will allow the handles to positioned

either vertically or horizontally.

A, A1, A2, A3-Style Handle: Place the threaded end of the handle into the hole of the handle adapter and lock the

handle into position with the jam nut.

FREQUENTLY ASKED QUESTIONS:

Q: Can I plumb another valve downstream from this valve, using the outlet of this valve?

A: You cannot plumb direct to another valve, unless your valve is equipped with power beyond or has been converted to use

power beyond. A valve can be ordered with power beyond already installed by adding a W to the end of the model number.

Converting valve to “Power Beyond” - Order a power beyond cartridge, P/N: LV2-W. You will then install this

cartridge into the outlet of the valve. Then, remove the plug in the outlet port directly above outlet valve on the side.

Plumb this port directly back to tank for low pressure fluid.

Q: Can I convert my valve to operate in a “Closed” system?

A: Yes, order a P/N: LV2-C and install it in the outlet port on the side of the casting.

Q: What kits are available for this valve?

A: There is a replacement seal kit (Part #: LV2-SK), and replacement relief kit (Part #: LV2-B2) for this valve. There are also

a number of different kits available for this valve depending on the spool action, and handle option the valve is equipped

with. Please contact factory for specific kit numbers relating to different spool actions, and handle options.

• 25 Micron Filtration Recommended.

• Weight:

- MB21 = 8.1 lbs (3.7 kg)

- MB22 = 10.9 lbs (4.9 kg)

- MB23 = 14.2 lbs (6.4 kg)

05/14

P to B2

P to B1

FREQUENTLY ASKED QUESTIONS cont’d:

Q: Can I paint the valve?

A: Painting valves is acceptable as long as the following precautions are taken:

1- All ports must be plugged

2- Spool must be masked or taped off completely.

Any paint on the spool will cause leakage when it chips off. Warranty is void if any valve is returned with paint on

the spool

Please note you can order a valve already painted from factoring by adding a P to beginning of model number.

Q: Can I convert my joystick into a different configuration?

A: You can, but there are limitations. An A & A1 style cannot be converted to a A2 or A3 style.

To convert an A to A1 please see the instructions: Instructions for Converting the LV/MB Joystick from A to A1

To convert an A2 to A3 please see the instructions: Instructions for Converting the LV/MB Joystick from A2 to A3

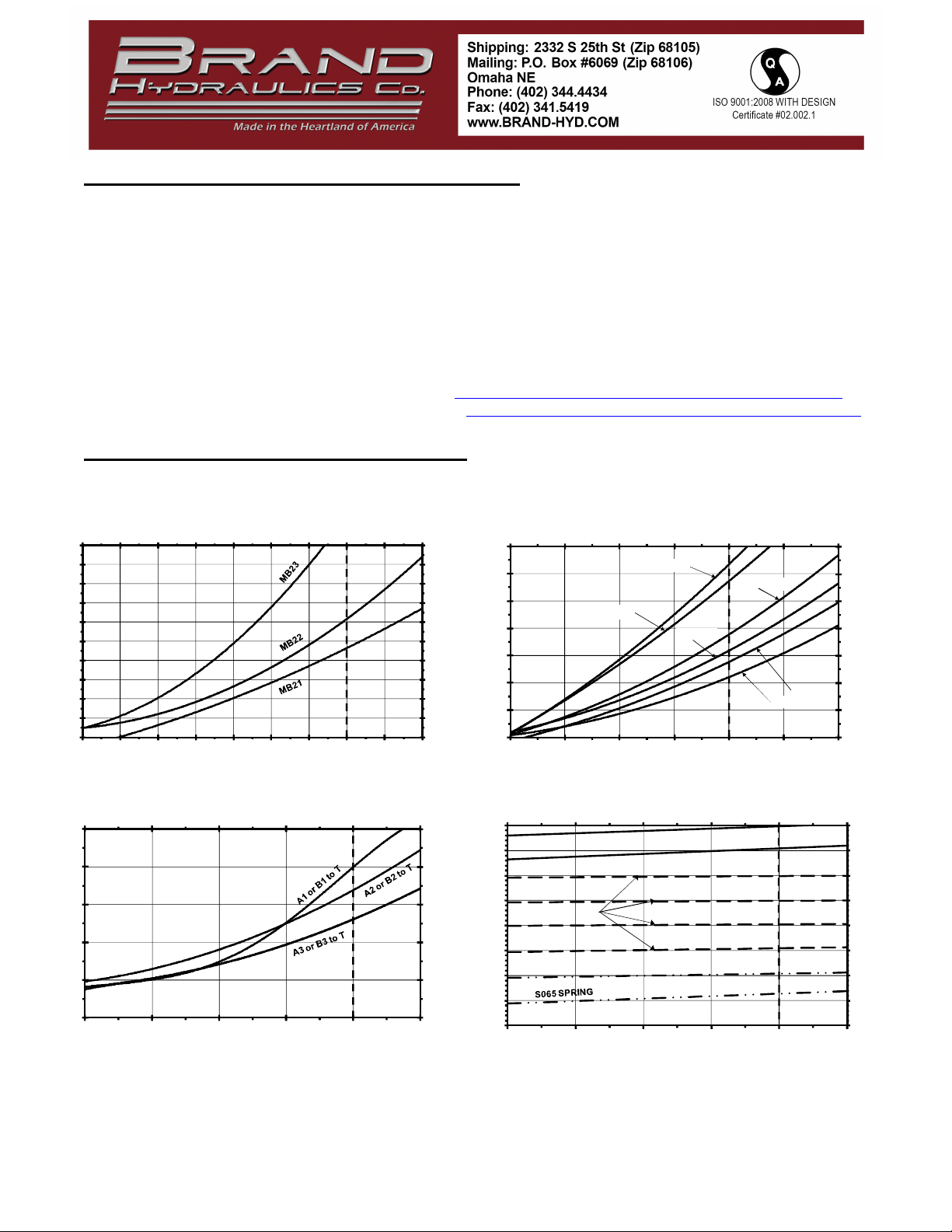

FLOW & PRESSURE INFORMATION:

3.8 7.6 11.4 15.1 18.9 22.7 26.5 30.3 34.1 37.9

100

90

80

70

60

50

40

Pressure (psi)

30

20

10

0

1 2 3 4 5 6 7 8 9 10

3.8 7.6 11.4 15.1 18.9 22.7

100

80

60

40

Pressure (psi)

20

0

1 2 4 6 8 10

Neutral Flow Pressure Drop

Flow (lpm)

MB23 Flow

Flow (gpm)

Pressure Drop vs. Flow for A or B-T

Flow (lpm)

Flow (gpm)

Pressure Drop vs. Flow for P to A or B

Flow (lpm)

6.9

6.2

5.5

4.8

4.1

3.4

2.8

2.1

1.4

Rating

0.7

0.0

3.8 7.6 15.2 22.8 30.4 34.2 38

350

300

250

200

150

Pressure (bar)

Pressure (psi)

100

50

0

1 2 4 6 8 9 10

P to B3

P to A3

Flow (gpm)

Pressure vs. Flow for MB Relief

0 8 15 23 30 38

4000

6.9

5.5

4.1

2.8

Pressure (bar)

Pressure (psi)

1.4

MB23 Flow

Rating

0.0

S064 SPRING

3500

3000

2500

2000

1500

1000

500

S059 SPRING

0

0 2 4 6 8 10

Flow (lpm)

Flow (gpm)

P to A2

MB23 Flow

Rating

P to A1

MB23 Flow Rating

24.1

20.6

17.2

13.8

10.3

6.9

3.4

0.0

276

241

207

172

138

103

69

34

0

Pressure (bar)

Pressure (bar)

05/14

Loading...

Loading...